thermital MODEX ACS 40 E Instruction Manual

1

ENGLISH

THERMITAL MODEX ACS 40 E

The ACS 40 E is an instant domestic hot water mixer. It uses a brazed, stainless steel plate heat exchanger and is desi-

gned for use in combination with DHW storage cylinders.

The product is equipped with two filling/drain cocks. When the shut-off valves are closed, these can also be used to flush

out the heat exchanger.

A domestic hot water recirculation kit is available for further convenience.

The ACS 40 E instant hot water mixer comes complete with an insulated frame.

Description Qty.

1 DHW mixer in packing 1

2 Instruction manual 1

DESCRIPTION

CONTENTS OF KIT

GENERAL SAFETY INFORMATION AND PRECAUTIONS

READ THIS MANUAL THOROUGHLY BEFORE PERFORMING ANY WORK ON THE PRODUCT.

The manufacturer reserves the right to modify the product without notice for the purpose of introducing technical improvements or to facilitate production, installation and positioning. The illustrations in this manual may therefore differ

slightly from the actual product. The safety of the product and the accuracy of the instructions provided are nevertheless

guaranteed.

This manual forms an integral part of the product itself and must be kept in a safe place in order to avoid damage and to

permit rapid consultation throughout the working life of the product.

Ideally, this manual should be kept with the product where it can be consulted whenever needed. The manual should

always accompany the product if sold or transferred to a new owner, or stay with it if the owner moves house and leaves

it behind, so that the next user can consult it.

cod. Doc-0072219 - Rev. 4 (05/17)

2

GENERAL SAFETY INFORMATION

INSTALLATION

Disconnect the product from the mains power supply before commencing any work on it.

The product must be installed in conformity to the laws and standards applicable in the country of installation.

The manufacturer’s responsibility ends with the supply of the product. The product must be installed using best professional practices, in conformity to applicable standards, by suitably qualified persons employed by a company that assumes

full responsibility for the completed installation.

The manufacturer cannot be held responsible for consequences deriving from the unauthorised modification of the product or from the use of non-original spare parts.

b

Do not expose the product to the elements. It is not designed for use outdoors

ELECTRICAL CONNECTIONS

The product must be installed and all electrical connections made by suitably qualified personnel in conformity to applicable standards.

The product’s mains power cable must be connected to a fused, two-pole switch (power supply 230 VAC, 50 Hz). The

product must be correctly connected to ground.

b

The product must be connected to the mains power supply via an earth leakage breaker in accordance with applicable standards. Correct functioning is only guaranteed provided the product is used with the pump for which it is

designed. The manufacturer cannot be held responsible for the consequences of improper uses.

WATER CONNECTIONS

On completion of all transport or handling operations, always check the tightness of the water fitting ring nuts.

Take particular care when connecting the product to the water supply. When tightening a fitting, always hold the opposite

fitting steady with a second tool to avoid twisting the copper pipes.

b

The product must be installed, connected and tested by suitably qualified persons, in conformity to applicable

standards and in accordance with the instructions provided in the documentation supplied with it. N.B. All pipes

must be insulated in conformity to applicable standards.

It is essential to respect the following precautions when using the product:

- Do not touch hot parts of the product such as the water inlet and outlet pipes. Contact with hot parts can cause painful

burns.

- Do not splash water or any other liquid over the product.

- Do not rest any objects on top of the product.

- Do not expose the product to steam from a cooking hob.

- Do not allow children or inexperienced persons to operate the product.

- Do not touch the product when barefoot or wet.

- Do not pull on the electrical cables.

3

ENGLISH

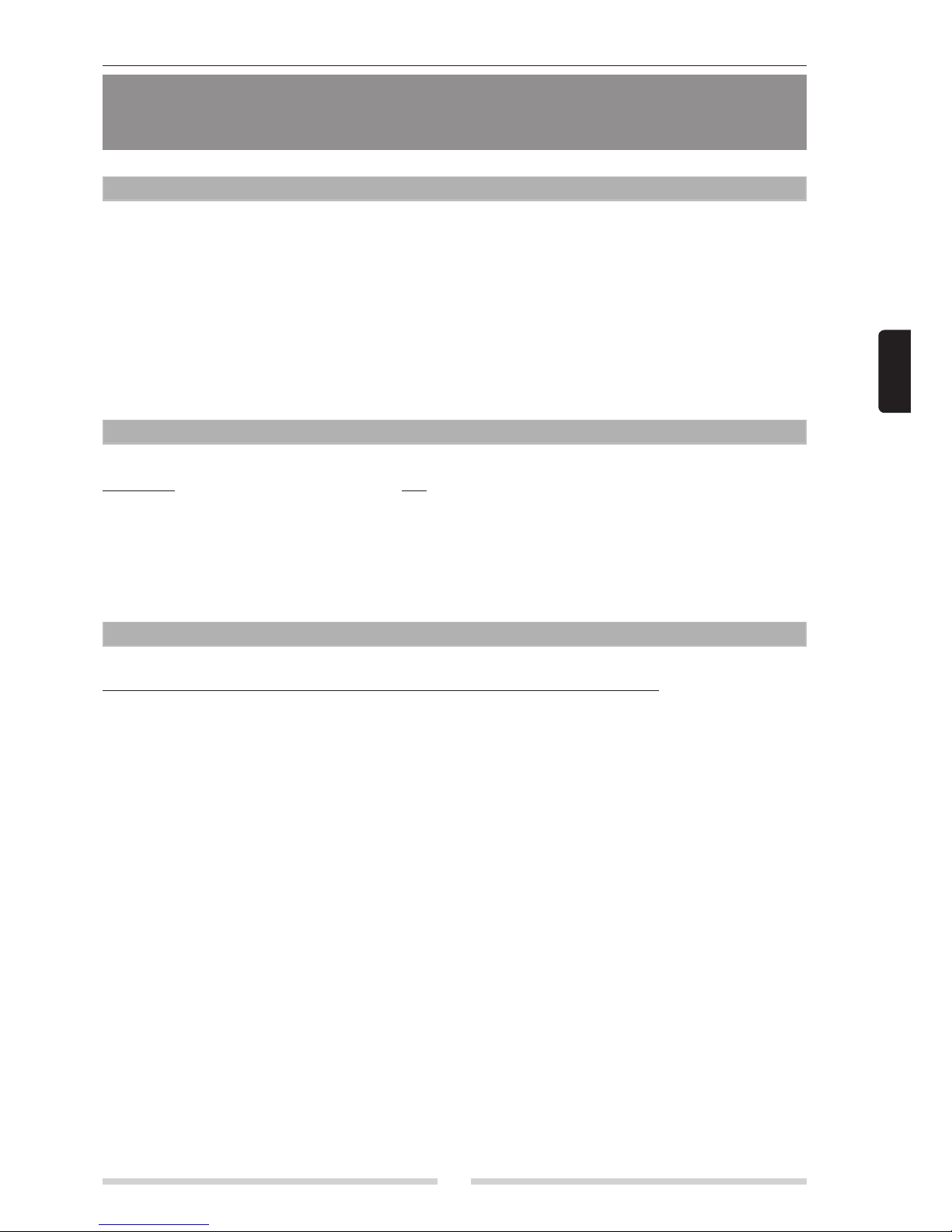

1

15

11

12

7

8

13

14

3

11

2

5

10

2

4

9

6

MAIN COMPONENTS

1 Galvanised and internally insulated backplate

2 Ball valve, DN 20 3/4” F – 1” M (primary outlet)

3 Red knob for ball valve with temperature sensor (primary inlet)

4 Blue knob for ball valve with temperature sensor (primary outlet)

5 Pump (primary circuit)

6 Ball valves, DN 20 3/4” F - 1" M (secondary circuit)

7 Red knob for ball valve (DHW outlet)

8 Blue knob for ball valve (cold water inlet)

9 Non-return valve (primary and secondary circuits)

10 Safety valve, 6 bar (secondary circuit)

11 Filling/drain cock, 1/2”

12 Flow meter and temperature sensor (secondary circuit)

13 Brazed, stainless steel, plate heat exchanger

14 Electronic control unit

15 Piping

4

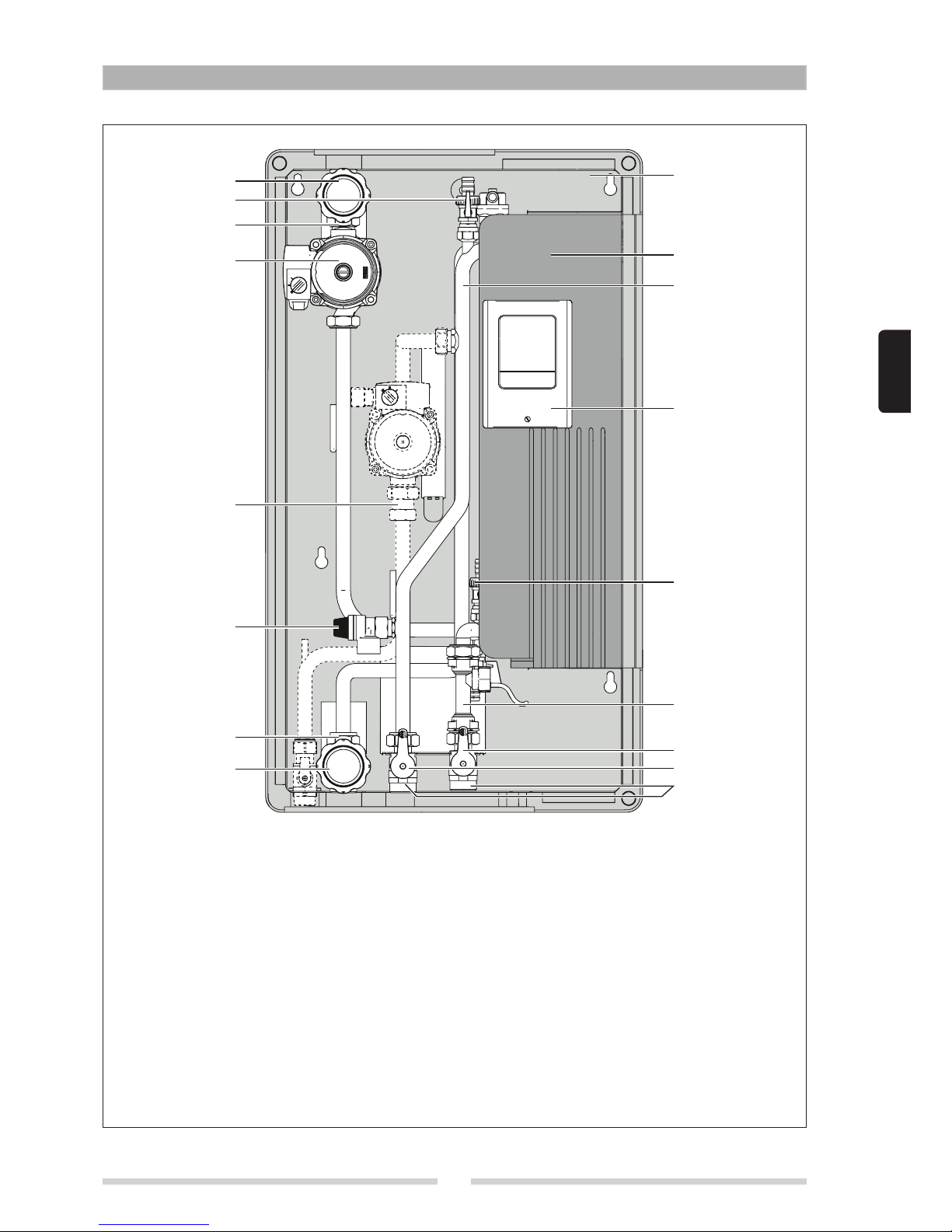

WATER CIRCUIT

TECHNICAL SPECIFICATIONS

EAF

5

9

4

6

6

3

2

1

1

10

1

8

7

8

1 Valve with temperature sensor

2 Modulating pump

3 Heat exchanger

4 Flow meter

5 Valve with temperature sensor

6 Non-return valve

7 Manual bleed valve

8 Manual drain valve

9 Recirculation pump (accessory kit)

10 Safety valve

DESCRIPTION ACS 40 E

Thermal power absorbed with storage cylinder at 50°C and DHW water delivery at 10-45°C 72 kW

Water draw at 10-45°C with storage cylinder at 50°C 29,5 l/min

Thermal power absorbed with storage cylinder at 55°C and DHW water delivery at 10-45°C 94,0 kW

Water draw at 10-45°C with storage cylinder at 55°C 38.5 l/min

Thermal power absorbed with storage cylinder at 60°C and DHW water delivery at 10-40°C 92 kW

Water draw at 10-40°C with storage cylinder at 60°C 44 l/min

Maximum flow-rate primary 1850 l/h

Minimum permissible temperature, DHW circuit 2 °C

Maximum operating temperature 90 °C

Maximum operating pressure, primary circuit 10 bar

Opening pressure, primary circuit non-return valves 28 mbar

Opening pressure, DHW circuit non-return valves 28 mbar

Consumption 47 W

Power supply voltage 230 V

Power supply frequency 50-60 Hz

Index of protection 40 IP

Net weight 19,2 kg

Water capacity 6,6 l

5

ENGLISH

Domestic hot water production graph

NB: Correct functioning of the product is only guaranteed if the primary circuit inlet temperature is at least 5°C higher

than the DHW setpoint.

CHARACTERISTIC CURVES FOR PRIMARY CIRCUIT PUMPS

00,5 1,01,5 2,02,5 3,0

00,2 0,40,6 0,8

0246810

0

1

2

3

4

5

6

7

0

10

20

30

40

50

60

70

00,5 1,01,5 2,02,5 3,0

0

20

40

3695/ 25

PWM1

4178/ 15

PWM1

4660/ ≤5

PWM1

3213/ 35

PWM1

2730/ 45

PWM1

2248/ 55

PWM1

1765/ 65

PWM1

1283/ 75

PWM1

800/ 85

PWM1

p/kPa

H/m

P

1

/W

Q/m³/ h

Q/l/s

Q/Igpm

Q/m³/ h

max.

max.

Wilo-Yonos Para RS

15/7.0, 20/7.0, 25/6, 30/7.0

1-230 V - Rp1/2, Rp3/4, Rp1, Rp1 1/4

n=1/min/ % PWM 1

45

40

40 45 50 55 60 65 70 75 80 85

35

30

25

20

Produzione ACS (l/min

)

Mandata primario (°C)

10÷42 °C

10÷45 °C

10÷48 °C

10÷50 °C

10÷55 °C

10÷60 °C

10÷65 °C

Primary inlet (°C)

DHW ow rate (l/min)

00,5 1,01,5 2,02,5 3,0

00,2 0,40,6 0,8

0246810

0

1

2

3

4

5

6

7

0

10

20

30

40

50

60

70

00,5 1,01,5 2,02,5 3,0

0

20

40

800 1/min

2390 1/min

3400 1/min

4660 1/min

max.

p/kPa

H/m

P

1

/W

Q/m³/ h

Q/l/s

Q/Igpm

Q/m³/ h

max.

Wilo-Yonos Para RS

15/7.0, 25/7.0, 30/7.0

1-230 V - Rp1/2, Rp1, Rp1 1/4

6

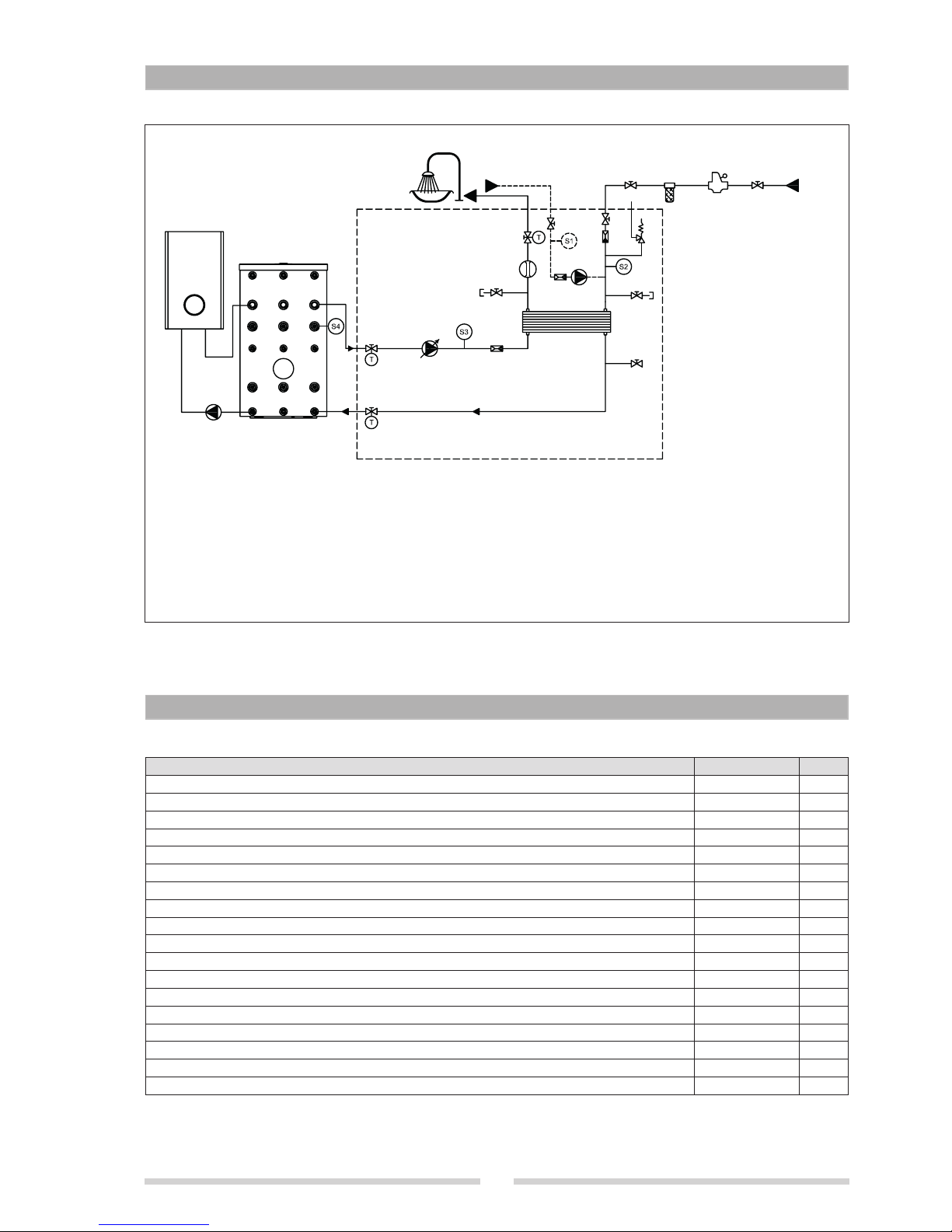

DIMENSIONS AND FITTINGS

MP

RS

RP EAFS UACS

480

100

807555 45 225

840

ACS 40 E

MP - Primary inlet 1 M - 3/4" F

RP - Primary outlet (return) 1 M - 3/4" F

EAFS - Domestic cold water

inlet

1 M - 3/4" F

UACS - DHW outlet 1 M - 3/4" F

RS - Recirculation union 3/4” M

1” M

3/4” F

7

ENGLISH

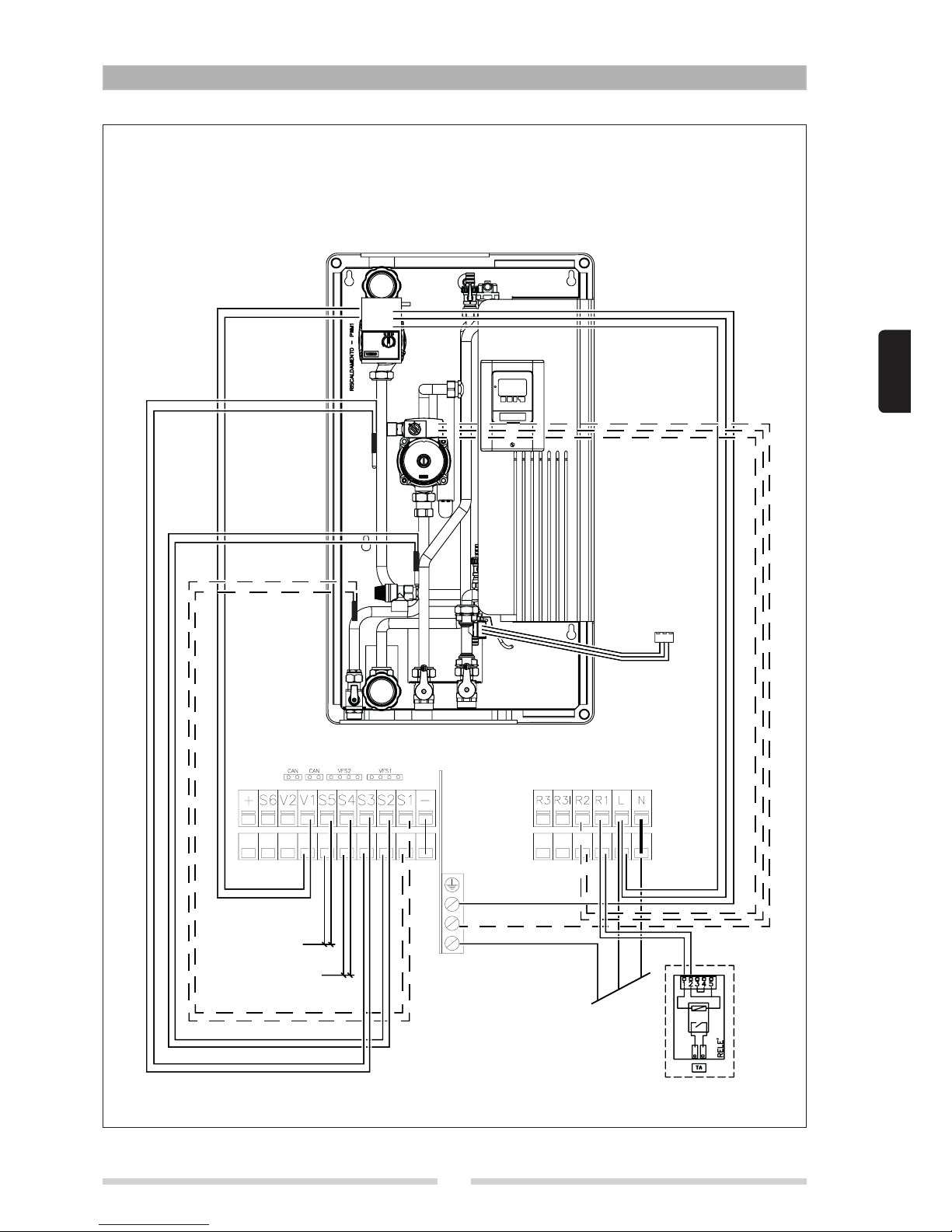

WIRING DIAGRAM

S5

S4

(*)

LATO SONDE E CONTROLLO LATO ALIMENTAZIONE 230 V

SENSOR AND CONTROL

TERMINALS 230 V POWER TERMINALS

S4 Storage cylinder top sensor

S5 Storage cylinder bottom sensor

(*) Connect to controller terminal VFS1

8

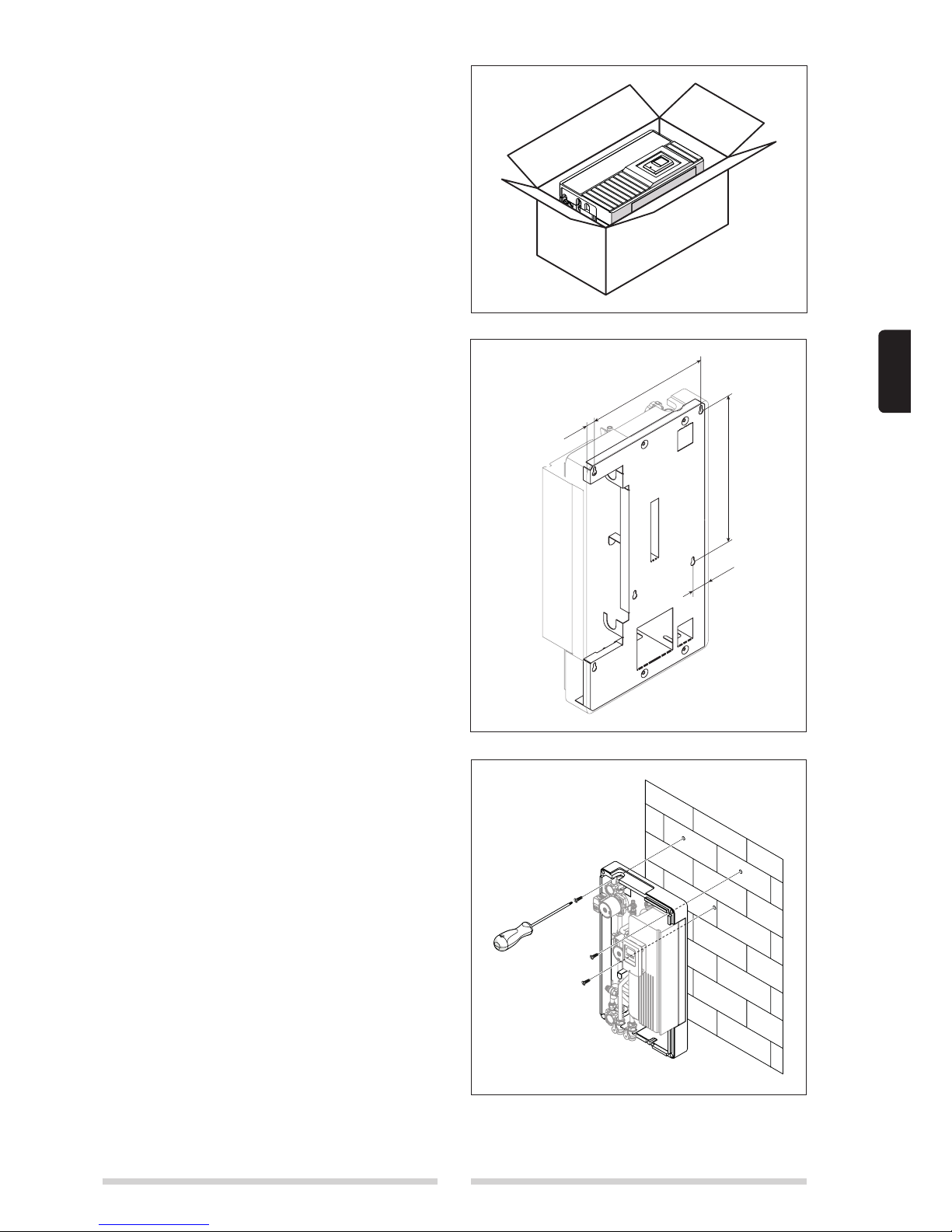

PRELIMINARY CHECKS

Carefully remove the packing and check that the product is complete and undamaged. If any defect or damage is detected, do not install or attempt to repair the product but return it to the retailer. Dispose of packaging in compliance with

applicable law.

b

Make sure that the installation position provides easy visibility of and access to the safety valves.

b

Connect the safety valves to a drain in conformity to applicable standards.

b

Install the product as near as practical to the storage cylinder. The product is designed to work with a pipe length

of 4 metres (inlet and return) between itself and the storage cylinder.

b

Disconnect the product from the mains power supply before commencing any work on it.

b

The product must be installed in conformity to the laws and standards applicable in the country of installation.

b

The manufacturer’s responsibility ends with the supply of the product. The product must be installed in conformity

to applicable standards by suitably qualified persons employed by a company that assumes full responsibility for

the completed installation.

INSTALLATION AND PUTTING INTO SERVICE

Bear in mind the following before installing the product:

- The product is designed to mix domestic hot water from a storage cylinder. Any other use, or any use incompatible with

the product’s technical specifications, is considered improper. Do not connect the product directly to a boiler.

- The product is not designed to be operated by children or persons with limited physical, psychological, sensorial or

mental capacities.

- If the piping needed to connect the product to the water system is damaged, it must be replaced by a suitably qualified

person.

- The installation must comply with all applicable laws and standards.

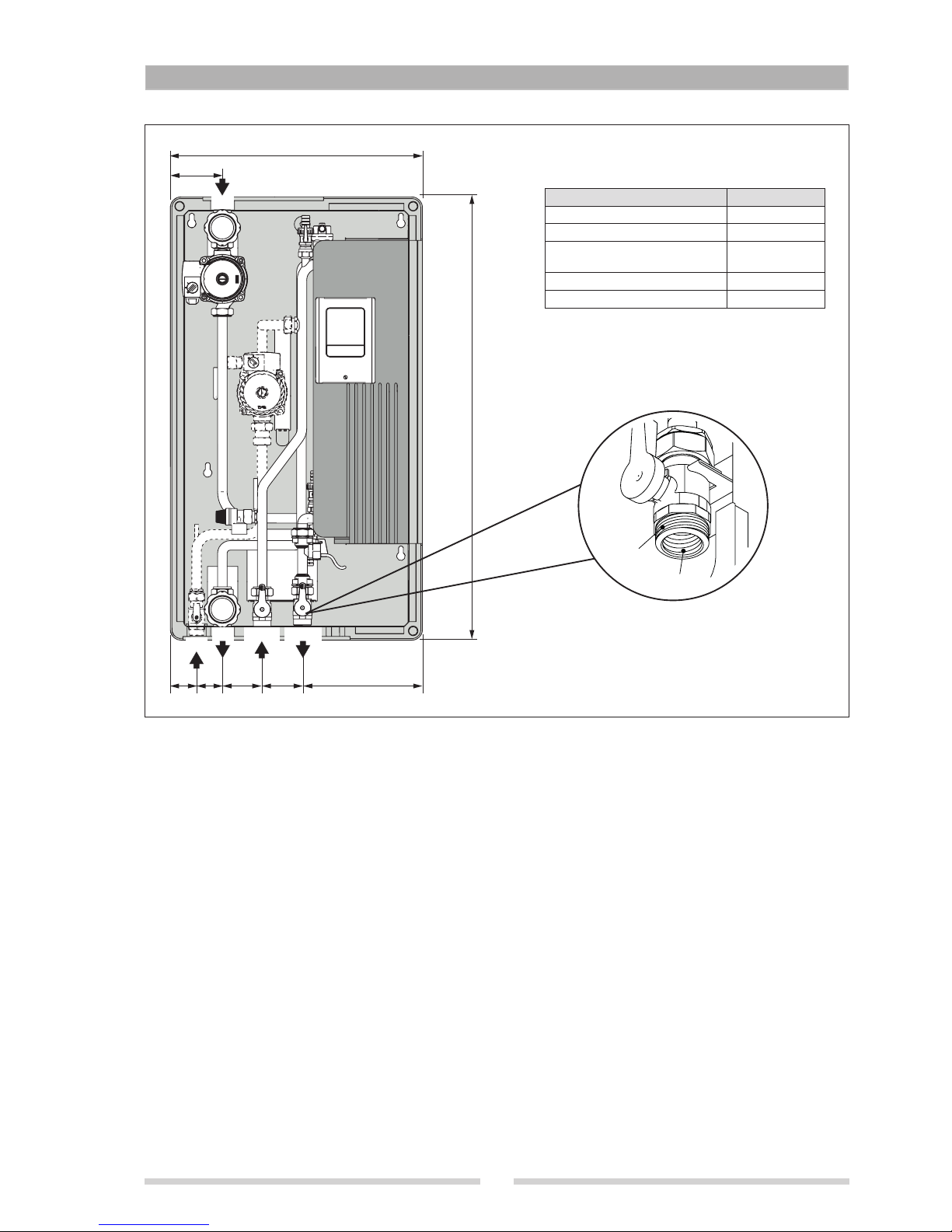

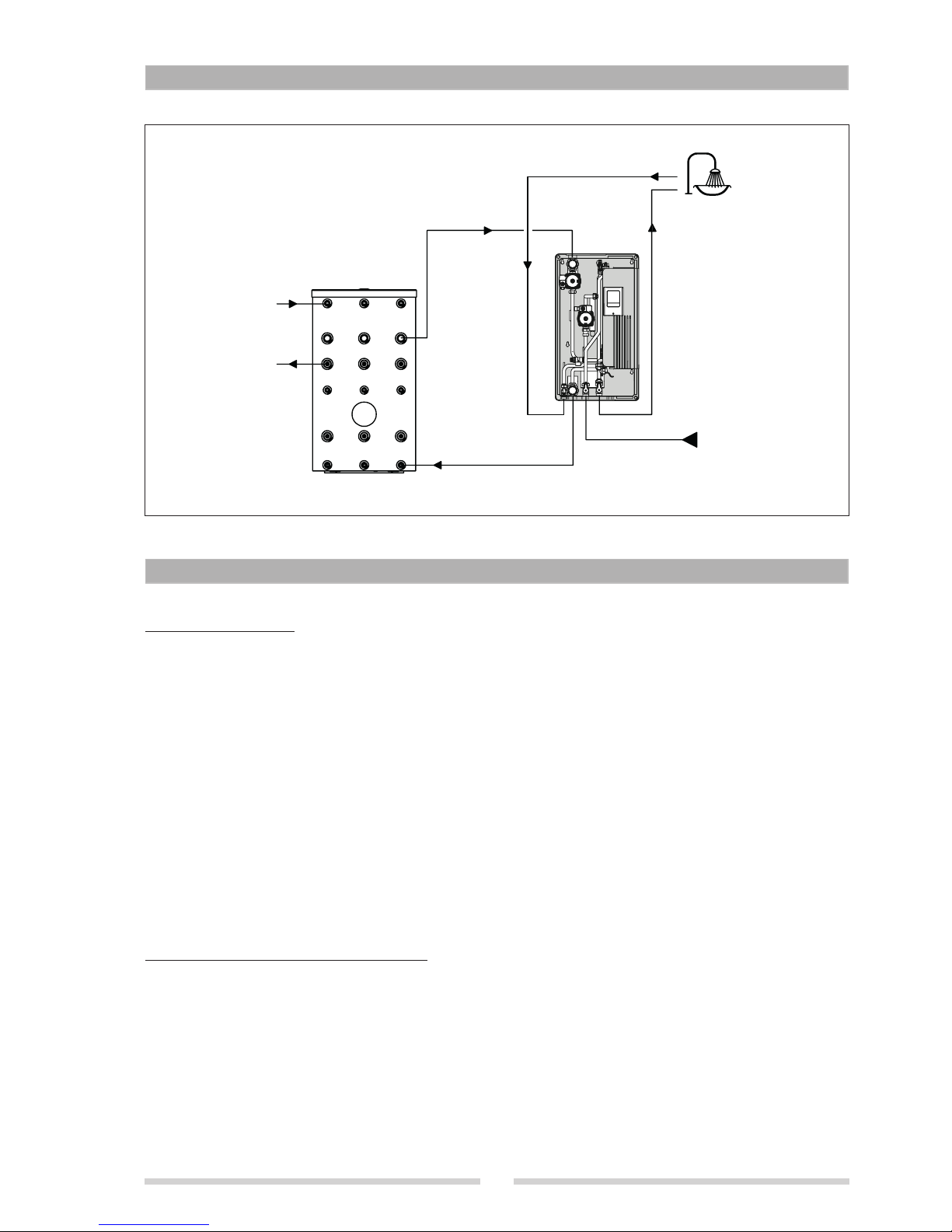

SYSTEM SCHEMATIC

INSTALLATION

Example of wall mounted installation

Boiler

DHW outlet

Recirculation

Cold water inlet

Primary outlet (return)

Primary inlet

9

ENGLISH

394

15

45

495

b

Installation and connection of the product must be

performed by an authorised, specialist company.

The company installing the product assumes all

responsibility for ensuring that the installation and

functioning of the product conform to applicable

standards.

b

The product must be stored in a dry place where it

is not subject to frost. The product must be installed

where it is protected against splashes of water. Ambient temperature in the place of installation must

not exceed 40°C during functioning of the product.

b

It is advisable to install the product as near as practically possible to the storage cylinder, in order to

avoid unnecessary heat loss from the connecting

pipes.

b

Handle with care!

- Remove the product from its packaging and remove the

polypropylene cover.

- Drill the wall at the positions shown in the figure and fit

three 12 mm wall plugs. Mount the product on the wall,

inserting the wall plugs through the slots in the rear. Slide the product down until the screws lie at the top of

the slots.

- Tighten the screws on the metal backplate through the

holes in the front of the product as shown in the figure.

- Connect the water pipes according to the schematic in

“System schematic”.

- Check that all connections have been made correctly.

Make sure that the entire system is water tight before

putting the mixer into service. To ensure maximum efficiency, also make sure that all air has been bled from

the system.

- Fit the cover.

Loading...

Loading...