ACQUAHOME 25 B - 25 BS

USER MANUAL

2

ENGLISH

Dear Customer,

Thank you for preferring a T heating unit, a modern,

high-quality product that is able to guarantee your maximum

well-being for a long period of time, with high levels of reliability

and safety. In particular, if working together with a Technical

Assistance Centre T that is specifically prepared

and trained to perform periodic maintenance, your unit will

remain at maximum efficiency levels at minimum operating

costs and if required, replacements with original spare parts

can be made.

This instruction manual contains important instructions and

precautions that must be observed to ensure the trouble-free

installation and efficient functioning of your

ACQUAHOME 25

B - 25 BS

boiler.

Please accept our renewed thanks for your purchase.

Thermital

CONFORMITY

ACQUAHOME 25 B - 25 BS

boilers conform to the following di-

rectives:

- Directive 92/42/EEC on efficiency requirements

- Electromagnetic Compatibility Directive 2014/30/UE

- Low Voltage Directive 2014/35/UE

- Ecodesign Directive 2009/125/CE for energy-related

products

- Energy Labelling Directive 2010/30/EU

- Delegated Regulation (EU) N. 811/2013

- Delegated Regulation (EU) N. 813/2013

- Delegated Regulation (EU) N. 814/2013

ENGLISH

This manual, Code 20112806 - Rev. 2 (05/17) comprises 20 pages.

3

ENGLISH

CONTENTS

The following symbols are used in this manual:

b

CAUTION! =

Identifies actions that require caution and

adequate preparation.

a

STOP! =

Identifies actions that you MUST NOT do.

This manual, Code

- Rev.

comprises

pages.

GENERAL INFORMATION .................... 4

General Safety Information.......................... 4

Precautions...................................... 4

Description of the appliance ........................ 5

Safety devices ................................... 5

System layout .................................... 6

Control panel ....................................8

Electronic control unit.............................. 9

Navigation scheme............................... 10

USE ..................................... 11

Putting into service...............................11

Preliminary operations ............................ 11

Start-up........................................ 11

Ignition failure...................................12

Resetting the burner and safety thermostat............12

Menu settings...................................13

Temporary shutdown ............................. 15

Preparing for extended periods of disuse .............15

Cleaning and servicing the boiler ................... 16

External cleaning ................................ 16

Annual cleaning ................................. 16

Troubleshooting .................................18

RECYCLING AND DISPOSAL ................ 18

4

ENGLISH

GENERAL INFORMATION

General Safety Information

b

Check that the product is complete, undamaged

and as ordered as soon as you receive it. Report any

discrepancies or damage to the

T dealer

who sold it.

b

This product must be installed by a legally qualified

heating engineer. On completion of the installation,

the installer must issue the owner with a declaration

of conformity confirming that the installation has been

completed to the highest standards in compliance

with the instructions provided by T in this

instruction manual, and that it conforms to all applicable

laws and standards.

b

This product must only be used for the purpose for which

it is designed and made, as specified by T.

T declines all responsibility, contractual or

other, for damage to property or injury to persons or

animals caused by improper installation, adjustment,

maintenance or use.

b

The room where the boiler is installed must be properly

ventilated to ensure a sufficient supply of air for correct

combustion.

b

If you notice any water leaks, disconnect the boiler from

the mains electricity supply and shut off the water supply.

b

The boiler must be serviced at least once a year.

b

Periodically check that pressure in the central heating

circuit, when cold, is approximately 1.5 bar and below

the maximum limit specified for the boiler.

b

If the boiler is not going to be used for an extended

period of time, perform the operations described later in

this manual.

b

This manual is an integral part of the equipment and

therefore must be stored carefully and must ALWAYS

accompany the boiler even if it is sold to another Owner

or User or transferred to another plant. If it is damaged

or lost, request another copy from your local Technical

Assistance Centre

T.

Precautions

The operation of any appliance that uses fuel, electrical power

and water demands that a number of fundamental safety

precautions be respected:

a

Do not allow children or infirm persons to operate the

system unsupervised.

a

It is forbidden to use electrical devices or equipment,

such as switches, appliances, etc. if there is a smell of

gas or un-burnt products. If so:

- Ventilate the room, opening doors and windows

- Close the fuel shut-off cock.

a

Do not touch the boiler while barefoot or wet.

a

Never clean or service the boiler without first disconnecting

it from the mains electricity supply by turning the mains

power switch and the control panel switch OFF.

a

Do not tamper with or adjust the safety or control devices

without prior authorisation and instructions from the

manufacturer.

a

Never pull, disconnect, or twist the electrical cables

coming from the appliance even if it is disconnected

from the mains electricity supply.

a

Do not obstruct or restrict the vents in the room where

the boiler is installed. Adequate ventilation is essential for

correct combustion.

a

Do not expose the boiler to the elements. It is not

designed for use outdoors.

a

It is prohibited to leave inflammable substances and

containers in the room where the boiler is installed.

a

Do not dispose of packaging material into the

environment, or leave it within the reach of children, since

it can become a potential hazard. Dispose of packaging

material in compliance with applicable legislation.

a

It is forbidden to operate the boiler without water.

5

ENGLISH

Description of the appliance

The

ACQUAHOME 25 B - 25 BS

boiler produces hot water for

central heating and also produces domestic hot water in an

integrated 60 litre storage cylinder.

It can function at low temperature and is oil fuelled.

The single stage oil burner has a vertical steel combustion

chamber.

Model

ACQUAHOME 25 BS

(unlike model

ACQUAHOME 25 B

)

has a sealed chamber.

The boiler body is thoroughly and effectively insulated with a

layer of high density glass wool.

The

ACQUAHOME 25 B - 25 BS

boiler's control logic incorporates

a total shutdown function to minimise energy consumption:

- In "Summer" mode ("Summer/Winter" selector turned to

Summer position), the burner only starts up to restore

the setpoint temperature of the water in the storage

cylinder. In "Winter" mode ("Summer/Winter" selector

turned to Winter position), the burner starts up either in

response to a request for heat from the heating system

(i.e. when the room thermostat switches the heating on)

or to restore the setpoint temperature of the water in

the storage cylinder (DHW heat requests are prioritised

over central heating requests).

Safety devices

ACQUAHOME 25 B - 25 BS

boilers incorporate the following

safety and control devices:

-

A manual reset safety thermostat

that forces a safety shutdown if boiler temperature exceeds the safety

threshold (100°C). The sensor used to monitor this temperature is located on the body of the heat exchanger;

-

Sensors

that measure the temperature of the boiler and

storage cylinder;

-

An electronic burner controller

that monitors the correct

functioning of the selected burner program and sends

a lockout signal to the control panel in the event of an

error.

b

The intervention of a safety device indicates a potentially

dangerous malfunction in the system. Contact the

manufacturer’s Technical Assistance Centre immediately.

b

Safety devices must only be replaced by the

manufacturer's Technical Assistance Centre using

original spare parts. Refer to the spare parts catalogue

supplied with the boiler.

a

Do not use the boiler if any of its safety devices are faulty.

Always check that the boiler is functioning correctly after

repairs have been made.

6

ENGLISH

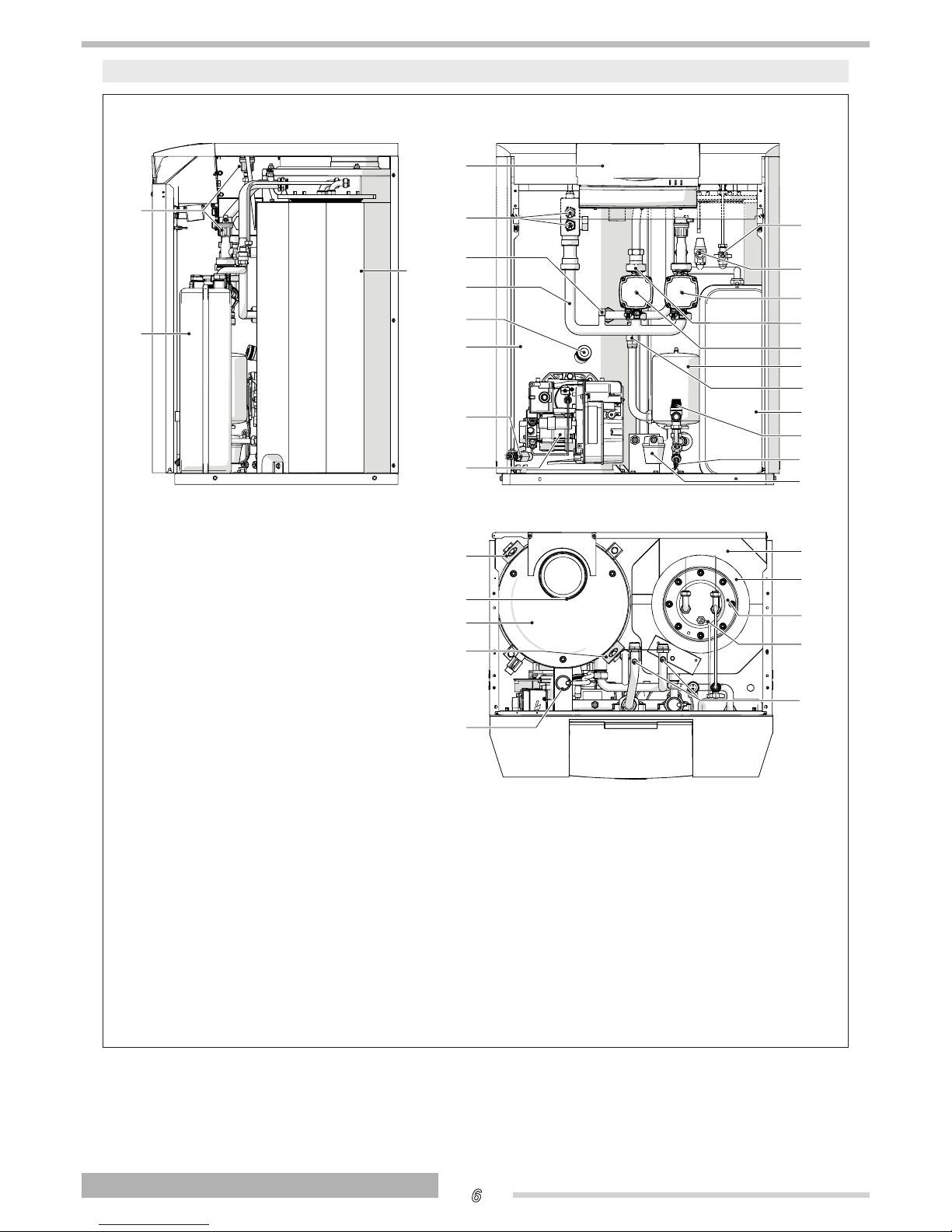

System layout

ACQUAHOME 25 B

6

8

7

5

4

1

2

9

11

10

23

21

22

23

1

17

18

15

19

20

14

2

16

3

27

3

26

25

12

13

24

15

1

Automatic bleed valve

2

Central heating circuit expansion

vessel

3

Storage cylinder with insulation

4

Control panel

5

Sensor sockets

6

Capillary pressure gauge fitting

7

Distribution manifold

8

Flame inspection window

9

Boiler body

10

Boiler drain cock

11

Burner

12

Fuel oil filter

13

Storage cylinder drain cock

14

Storage cylinder safety valve

15

Non-return valve

16

Storage cylinder expansion vessel

17

Central heating circuit pump

18

Boiler circulator

19

Central heating circuit safety valve

20

Storage cylinder fill cock

21

Flue gas exhaust fitting

22

Flue gas box cover

23

Lifting bracket

24

Manual air vent valve

25

Storage cylinder sensor socket

26

Storage cylinder inspection flange

27

Storage cylinder flange insulation

7

ENGLISH

ACQUAHOME 25 BS

6

8

7

5

4

1

2

9

10

12

11

18

19

16

20

21

15

2

17

3

29

30

3

13

14

27

16

28

22

23

24

25

26

1

1

Automatic bleed valve

2

Central heating circuit expansion vessel

3

Storage cylinder with insulation

4

Control panel

5

Sensor sockets

6

Capillary pressure gauge fitting

7

Distribution manifold

8

Flame inspection window

9

Boiler body

10

Air intake obstructed

11

Boiler drain cock

12

Burner

13

Fuel oil filter

14

Storage cylinder drain cock

15

Storage cylinder safety valve

16

Non-return valve

17

Storage cylinder expansion vessel

18

Central heating circuit pump

19

Boiler circulator

20

Central heating circuit safety valve

21

Storage cylinder fill cock

22

Air intake fitting

23

Flue gas exhaust fitting

24

Flue gas box cover

25

Air box

26

Lifting bracket

27

Manual air vent valve

28

Storage cylinder sensor socket

29

Storage cylinder inspection flange

30

Storage cylinder flange insulation

8

ENGLISH

Control panel

ACQUAHOME 25 B - 25 BS

2 31

8

7 56 4

1 Function selector

Off

On

Burner reset

2 Electronic control unit

3 Boiler pressure gauge

Displays the pressure in the central heating circuit

4 Fuse holder

Holds the protective fuse 6.3 A-T

5 Indicator showing a burner lockout for a tripped safety thermostat (red)

Lights to show that the safety thermostat has tripped

6 Burner lockout indicator (red)

Lights to show that the burner locked out

7 Electrical power indicator (green)

Lights to show that the boiler is receiving electrical power

8 Manual reset for safety thermostat

Allows you to reset the boiler if the safety thermostat trips. Unscrew the protective cover to

access the reset button

9

ENGLISH

Electronic control unit

The electronic controller provides the interface by means of which the installer and user can set and change functioning

parameters and view boiler status.

The electronic controller lets you:

- Change the functioning mode;

- View the temperature of the boiler and storage cylinder;

- Change the boiler and storage cylinder parameters (password required);

- view alarms.

T3D P1 T4T1T2 S1 S2 P

S3

S4 S5TR S6

T1 Storage cylinder parameter selection / setting key

T2 Boiler parameter selection / setting key

T3 Value increase button

T4 Value decrease button

S1 Storage cylinder temperature / setpoint indicator (yellow)

S2 Boiler temperature / setpoint indicator (yellow)

S3 Service/error indicator (red)

S4 Stand-by mode indicator (green)

S5 Summer mode indicator (green)

S6 Winter mode indicator (green)

TR Mode selection key

D Three digit display

P Parameter index point

P1 “10,000 hours/starts” indicator points

Right decimal point only: value = 10000

Central decimal point only: value = 20000

Central decimal point + right decimal point: value = 30000

≥ 900 ore

≤ 999 ore

≥ 9900 ore

≤ 9999 ore

≥ 19900 ore

≤ 19999 ore

≥ 29900 ore

≤ 29999 ore

≥ 39900 ore

≤ 39999 ore

10

ENGLISH

Navigation scheme

Displaying and changing storage cylinder settings

Displaying and changing boiler settings

+

Displaying hours remaining to the next service

11

ENGLISH

USE

Putting into service

Have the T Technical Assistance Service start up

your

ACQUAHOME 25 B - 25 BS

boiler for the first time. Once this

has been done, the boiler can be left to function automatically.

Under certain circumstances, such as after long periods of

disuse, the user may need to re-start it without involving the

Technical Assistance Centre.

Preliminary operations

Perform the following checks before starting up the boiler:

- Check that the fuel shut-off cock and heating system

shut-off cock are open

- check that the central heating circuit pressure gauge

shows a pressure over

1,5 bar

with the system cold.

Check also that the circuit is properly de-aerated

Start-up

Once you have completed all the checks listed above, proceed

as follows to start up the boiler for the first time:

- Turn the boiler’s mains power switch ON

- Set the room thermostat to the required temperature (~

20°C) or, if the system has a timer or timer-thermostat,

make sure that this is switched “ON” and adjusted to

the required temperature (~ 20°C).;

- Open the control panel access door;

- Set boiler temperature to 75°C and storage cylinder

temperature to 50°C as instructed in the relevant parts

of the "Menu settings" section;

- Turn the function selector to "ON" and make sure that

the green power indicator lights;

- Press the mode key to set the desired functioning mode

(Summer or Winter);

The burner only starts up at the end of the fuel oil pre-heating

phase.

The boiler now starts up and the burner remains lit until the

temperature setpoint is reached.

12

ENGLISH

Ignition failure

If any ignition errors or malfunctions occur, the burner enters

“LOCKOUT”. This is shown by the red button light on the

burner and by the warning light on the control panel.

b

If a “LOCKOUT SHUTDOWN” occurs, wait about 30

seconds before resetting the burner.

Resetting the burner and safety thermostat

To restore normal startup conditions, open the cover of the

control panel and turn the function selector to

"Reset burner"

for at least 1 second before returning it to its original position.

Wait for the burner to complete the entire ignition cycle again,

up to the ignition of the flame.

If boiler temperature becomes too high, the manual reset

safety thermostat trips.

b

If the safety thermostat trips (T>100°C), the warning light

on the control panel comes on

Proceed as follows to reset the safety thermostat.

- Wait until boiler temperature falls below 80°C.

- Remove the safety thermostat cover.

- Press the manual reset button.

- Wait for the complete ignition cycle to be repeated and

for the flame to ignite.

b

Eliminate the cause of the overheating before restarting

the boiler. Contact T’s Technical Assistance

Service.

13

ENGLISH

Menu settings

TEMPERATURE DISPLAY

Storage cylinder temperature display

Press the key to display storage cylinder temperature.

The indicator in the key itself shows steady light. Temperature

is expressed in degrees centigrade. The display can show

values between 110°C and 10°C. The mode indicators show

the current functioning mode and burner state. The display

automatically returns to showing boiler temperature after 2

seconds.

Boiler temperature display

To view boiler temperature, press the key.

The indicator in the key itself shows steady light. Temperature

is expressed in degrees centigrade. The display can show

values between 110°C and 10°C. The mode indicators show

the current functioning mode and burner state.

b

If no key is pressed for two minutes, the system enters

“low consumption” mode and the central section of the

display flashes. Pressing any key restores the boiler

temperature display.

CHANGING THE FUNCTIONING MODE

You can only change the boiler’s functioning mode when

the display is reading out either boiler or storage cylinder

temperature. Press the "mode key" repeatedly to scroll to the

required functioning mode. The default setting is "Winter".

- In stand-by mode (with the indicator lit) the boiler

remains off unless settings activate the anti-frost or antilegionella function (if enabled)

- In summer mode (with the indicator lit) the boiler

responds only to requests for domestic hot water.

The central heating system is switched off. This mode

indicator is continuously lit if the burner is running and

flashes if the burner is shut down.

- In winter mode (with the indicator lit) the boiler

responds to heat requests from the domestic hot water

and central heating systems. This mode indicator is

continuously lit if the burner is running and flashes if the

burner is shut down.

14

ENGLISH

DISPLAYING AND CHANGING BOILER

AND STORAGE CYLINDER SETPOINTS

Displaying and changing the boiler setpoint

Press the key to display boiler temperature.

If you press the or key while the boiler temperature is

displayed, the indicator starts to flash and the boiler's current

setpoint is shown on the three digit display. The default value is

75°C. Pressing the

or key once more changes the value.

Press the key to confirm the setpoint and return to the boiler

temperature display. The indicator stops flashing.

Displaying and changing the storage cylinder setpoint

Press the key to display storage cylinder temperature.

If you press the or key while the storage cylinder

temperature is displayed, the

indicator starts to flash and

the storage cylinder's current setpoint is shown on the three

digit display. The default value is 50°C. Pressing the

or

key once more changes the value.

Press the key to confirm the setpoint and return to the storage

cylinder temperature display. The indicator stops flashing.

15

ENGLISH

Temporary shutdown

To switch the boiler off for short periods with outdoor

temperature ABOVE ZERO:

- Open the control panel access door;

- Turn the function selector to

"ON";

- Press the electronic controller's "mode key" to select

STAND-BY mode ( );

b

The boiler has a FROST PROTECTION FUNCTION that

switches on the burner and the pumps if there is a risk

of freezing.

Preparing for extended periods of disuse

If the boiler is not going to be used for an extended period of

time, proceed as follows to prepare it for shut-down

- Open the control panel access door;

- Turn the main power switch to

"OFF" and make sure

that the green power indicator goes out;

- switch the boiler OFF at the mains power switch;

- Close the boiler’s fuel cock and water supply cock.

b

Drain the central heating circuit and domestic hot water

circuit if there is any risk of freezing.

16

ENGLISH

Cleaning and servicing the boiler

Please remember that THE PERSON RESPONSIBLE

FOR SYSTEM MANAGEMENT MUST ENSURE THAT

PROFESSIONALLY QUALIFIED HEATING ENGINEERS

UNDERTAKE PERIODIC MAINTENANCE AND COMBUSTION

EFFICIENCY MEASUREMENTS.

T’s Technical Assistance Centre is qualified to

satisfy these legal requirements and can also provide useful

information on MAINTENANCE PROGRAMMES designed to

guarantee:

- greater safety

- compliance with applicable legislation

- freedom from the risk of fines in the event of spot

checks.

Regular maintenance is essential for the safety, efficiency and

durability of the boiler.

Servicing is a legal requirement and must be performed at least

once a year by a professionally qualified heating engineer.

External cleaning

Clean the boiler’s casing panels and control panel with a soft

cloth damped in soapy water.

To remove marks from the boiler casing, use a cloth damped

in a 50% mix of water and denatured alcohol or a suitable

cleaning product.

Wipe the boiler dry after cleaning it.

a

Do not use abrasive products, petrol or triethylene.

Annual cleaning

At least once a year, the user must have the boiler served by

T's Technical Assistance Service or by a qualified

heating engineer.

17

ENGLISH

SYSTEM ERRORS AND ALARMS

Alarm Description

AL1

This message on the three digit display indicates an active burner lockout alarm. The

indicator shows steady

light.

AL2

This message on the three digit display indicates an active safety temperature alarm (safety thermostat

tripped). The

indicator shows steady light.

AL6

This message on the three digit display indicates a malfunction (short circuit) of the storage cylinder sensor.

The

indicator shows steady light.If no storage cylinder sensor is detected, the storage cylinder is assumed

to be disabled; for this reason not alarm is generated. If you try to view the value on the display, only “- - -”

appears.

AL7

This alarm on the three digit display indicates a boiler sensor malfunction (sensor failure or short circuit).The

indicator shows steady light.

SEr

Service threshold near warning

When the burner reaches 90% of the operating hours set in boiler parameter P7 (see Programming

Parameters), the three figure display reads out the message “SEr” for about three seconds every time the

burner starts (unless the display is in low consumption mode).

Service threshold passed warning

If the burner’s operating hours reach or exceed the value set in boiler parameter P7 (see Programming

Parameters), the

indicator flashes to show that the burner requires service. The three figure display reads

out the message “SEr” for about three seconds every time the burner starts (unless the display is in low

consumption mode).

Displaying the hours left before service is needed

Press the and keys simultaneously to read out on the 3 figure display how many hours of operation are left

before the service threshold is reached (max 999).

18

ENGLISH

Troubleshooting

FAULT CAUSE SOLUTION

There is a smell of fumes Fumes escaping into the air

- Contact your local Technical

Assistance Centre

The generator is at temperature but

the heating system is cold

Air in the circuit

- Contact your local Technical

Assistance Centre

Pump malfunctioning

- Contact your local Technical

Assistance Centre

The boiler does not reach its

temperature setpoint

Boiler dirty

- Contact your local Technical

Assistance Centre

Burner capacity insufficient

- Contact your local Technical

Assistance Centre

Problem with boiler control card

- Contact your local Technical

Assistance Centre

The generator triggers a thermal

safety block

Problem with boiler control thermostat

- Contact your local Technical

Assistance Centre

No water

- Contact your local Technical

Assistance Centre

The safety valve keeps opening

Incorrect central heating circuit pressure

- Contact your local Technical

Assistance Centre

CH expansion vessel

- Contact your local Technical

Assistance Centre

The central heating pump is not

working

Pump seized

Electrical connections

- Contact your local Technical

Assistance Centre

No heat request from

- Contact your local Technical

Assistance Centre

RECYCLING AND DISPOSAL

Packaging materials from T

ACQUAHOME 25 B - 25

BS

boilers must be disposed of through appropriate channels

in order to permit recovery and recycling. At the end of its

useful life, dispose of the boiler in compliance with applicable

legislation.

19

ENGLISH

20112806 - Rev. 2 (05/17)

RIELLO S.p.A.

Via Ing. Pilade Riello, 7

37045 - Legnago (VR)

www.thermital.it

The manufacturer strives to continuously improve all products. Appearance, dimensions, technical

specications, standard equipment and accessories are therefore liable to modication without

notice.

Loading...

Loading...