ACQUAHOME 25 B BLU

USER MANUAL

2

ENGLISH

Dear Customer,

Thank you for preferring a T heating unit, a modern, high-quality product that is able to guarantee your maximum well-being for a long period of time, with high levels of

reliability and safety. In particular, if working together with a

Technical Assistance Centre T that is specifically

prepared and trained to perform periodic maintenance, your

unit will remain at maximum efficiency levels at minimum operating costs and if required, replacements with original spare

parts can be made.

This instruction manual contains important instructions and

precautions that must be observed to ensure the trouble-free

installation and efficient functioning of your

ACQUAHOME 25 B

BLU

boiler.

Please accept our renewed thanks for your purchase

Thermital

CONFORMITY

ACQUAHOME 25 B BLU

boilers conform to the following direc-

tives:

- Directive 92/42/EEC on efficiency requirements

- Electromagnetic Compatibility Directive 2014/30/EU

- Low Voltage Directive 2014/35/EU

- Ecodesign Directive 2009/125/CE for energy-related

products

- Energy Labelling Directive 2010/30/EU

- Delegated Regulation (EU) N. 811/2013

- Delegated Regulation (EU) N. 813/2013

- Delegated Regulation (EU) N. 814/2013

ENGLISH

This manual, Code 20129620 - Rev. 0 (07/18) comprises 20 pages.

3

ENGLISH

CONTENTS

The following symbols are used in this manual:

b

CAUTION! =

Identifies actions that require caution and

adequate preparation.

a

STOP! =

Identifies actions that you MUST NOT do.

This manual, Code

- Rev.

comprises

pages.

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . 4

General Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . 4

Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Description of the appliance . . . . . . . . . . . . . . . . . . . . . . . . 5

Safety and control devices. . . . . . . . . . . . . . . . . . . . . . . . . . 5

System layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Menu navigation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Navigation scheme. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

List of user parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

USE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Putting into service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Preliminary operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Start-up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Adjustment of heating setpoint. . . . . . . . . . . . . . . . . . . . . . 15

Enable/disable the heating function. . . . . . . . . . . . . . . . . . 15

Adjustment of domestic setpoint . . . . . . . . . . . . . . . . . . . . 15

Enable/disable the domestic function . . . . . . . . . . . . . . . . 15

Special functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Ignition failure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Temporary or short-term shut-down . . . . . . . . . . . . . . . . . . 17

Preparing for extended periods of disuse . . . . . . . . . . . . . 17

Device cleaning and maintenance. . . . . . . . . . . . . . . . . . . 17

External cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Annual cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

RECYCLING AND DISPOSAL . . . . . . . . . . . . . . . . 18

4

ENGLISH

GENERAL INFORMATION

General Safety Information

b

This product must be installed by a legally qualified heating engineer. On completion of the installation, the installer must issue the owner with a declaration of conformity

confirming that the installation has been completed to

the highest standards in compliance with the instructions

provided by

T in this instruction manual, and

that it conforms to all applicable laws and standards.

b

This product must only be used for the purpose for which

it is designed and made, as specified by T.

T declines all responsibility, contractual or

other, for damage to property or injury to persons or animals caused by improper installation, adjustment, maintenance or use.

b

The room where the boiler is installed must be properly

ventilated to ensure a sufficient supply of air for correct

combustion.

b

If you notice any water leaks, disconnect the boiler from

the mains electricity supply and shut off the water supply.

b

In case of water leaks disconnect the equipment from

the power mains, close the water supply and promptly

alert Technical Assistance Centre T or professionally qualified personnel.

b

The boiler must be serviced at least once a year. The

failure to perform annual maintenance work will void the

warranty of the equipment.

b

Periodically check that pressure in the central heating

circuit, when cold, is approximately 1.5 bar and below the maximum limit specified for the boiler. If this is

not the case, contact the Technical Assistance Centre

T or professionally qualified personnel.

b

If the boiler is not going to be used for an extended period of time, perform the operations described later in this

manual.

b

This manual is an integral part of the equipment and

therefore must be stored carefully and must ALWAYS accompany the boiler even if it is sold to another Owner or

User or transferred to another plant. If it is damaged or

lost, request another copy from your local Technical Assistance Centre T.

Precautions

The operation of any appliance that uses fuel, electrical power

and water demands that a number of fundamental safety precautions be respected:

a

Do not allow children or infirm persons to operate the

system unsupervised.

a

It is forbidden to use electrical devices or equipment,

such as switches, appliances, etc. if there is a smell of

gas or un-burnt products. If so:

- Ventilate the room, opening doors and windows

- Close the fuel shut-off cock

- Ask for the prompt intervention of the Technical Assistance Centre

a

Do not touch the boiler while barefoot or wet.

a

Never pull, disconnect, or twist the electrical cables coming from the appliance even if it is disconnected from the

mains electricity supply.

a

Do not obstruct or restrict the vents in the room where

the boiler is installed. Adequate ventilation is essential for

correct combustion.

a

Do not expose the boiler to the elements. It is not designed for use outdoors.

a

It is prohibited to leave inflammable substances and containers in the room where the boiler is installed.

a

Do not dispose of packaging material into the environment, or leave it within the reach of children, since it can

become a potential hazard. Dispose of packaging material in compliance with applicable legislation.

a

It is forbidden to operate the boiler without water.

a

The equipment casing must not be removed by people

without specific qualification and expertise.

5

ENGLISH

Description of the appliance

The thermal unit

ACQUAHOME 25 B BLU

is a hot water generator for the heating of environments and production of domestic

hot water (DHW) by means of a vitrified heater. It can function

at low temperature and is oil fuelled. The low NOx burner features a single-stage operation and a vertical steel combustion

chamber. The boiler unit is effectively and accurately insulated

with a high-density glass wool mat. The control panel includes

a user interface with display and an electronic board for the

thermal unit adjustment and control, which allows to manage

the control and safety devices in compliance with the regulations in force.

Safety and control devices

The control panel, apart from managing the functions of the

thermal unit

ACQUAHOME 25 B BLU

, allows to highlight any

anomaly which may affect its correct operation, ensuring the

thermal unit safety by stopping it and automatically closing the

burner light oil valve.

The burner control and adjustment board is also used to ensure the burner safety by managing its correct operation.

Any anomaly which may affect the generator operation forces

it to stop (lock-out) and is promptly signalled with a numerical

error code on the regulator display.

The following are installed on the water circuit:

-

Safety thermostat

: fitted on the generator body, it intervenes by stopping (permanent error) the thermal unit

if the boiler temperature exceeds the limit threshold of

110°C;

-

Safety valve

: intervenes if the boiler pressure exceeds

the limit threshold of 3 bar;

-

Pressure transducer

: sends a signal to the electronic regulator which views and continually checks the

primary circuit pressure to switch on the generator or

cause it to stop in case of low pressure;

-

Boiler temperature probes (delivery and return)

: immersion probe on the delivery line of the generator is used

by the regulator to view and check the delivery water

temperature and check the correct switching on and off

of the burner based on the programmed setpoint. The

regulator uses the same probe to switch off the generator in case of overtemperature, before the triggering of

the safety thermostat. The contact probe placed on the

return line of the boiler is used by the regulator to view

the return water temperature with which it calculates,

together with the delivery temperature, the temperature

difference between delivery and return (∆t), which allows regulating the modulation of the circulator in heating mode.

-

Domestic circuit temperature probe (heater)

: the immersion probe in the heater is used by the regulator to view

and check the domestic hot water temperature and to

manage the relevant operating parameters (DHW Setpoint, DHW request, etc.).

b

The intervention of a safety device indicates a potentially

dangerous malfunction in the system. Contact the manufacturer’s Technical Assistance Centre immediately.

b

Safety devices must only be replaced by the manufacturer's Technical Assistance Centre using original spare

parts. Refer to the spare parts catalogue supplied with

the boiler. After making the repair, check that the appliance is working properly.

a

The appliance must not be put in service, even temporarily, when tampered safety devices are not in operation or

have been tampered with.

6

ENGLISH

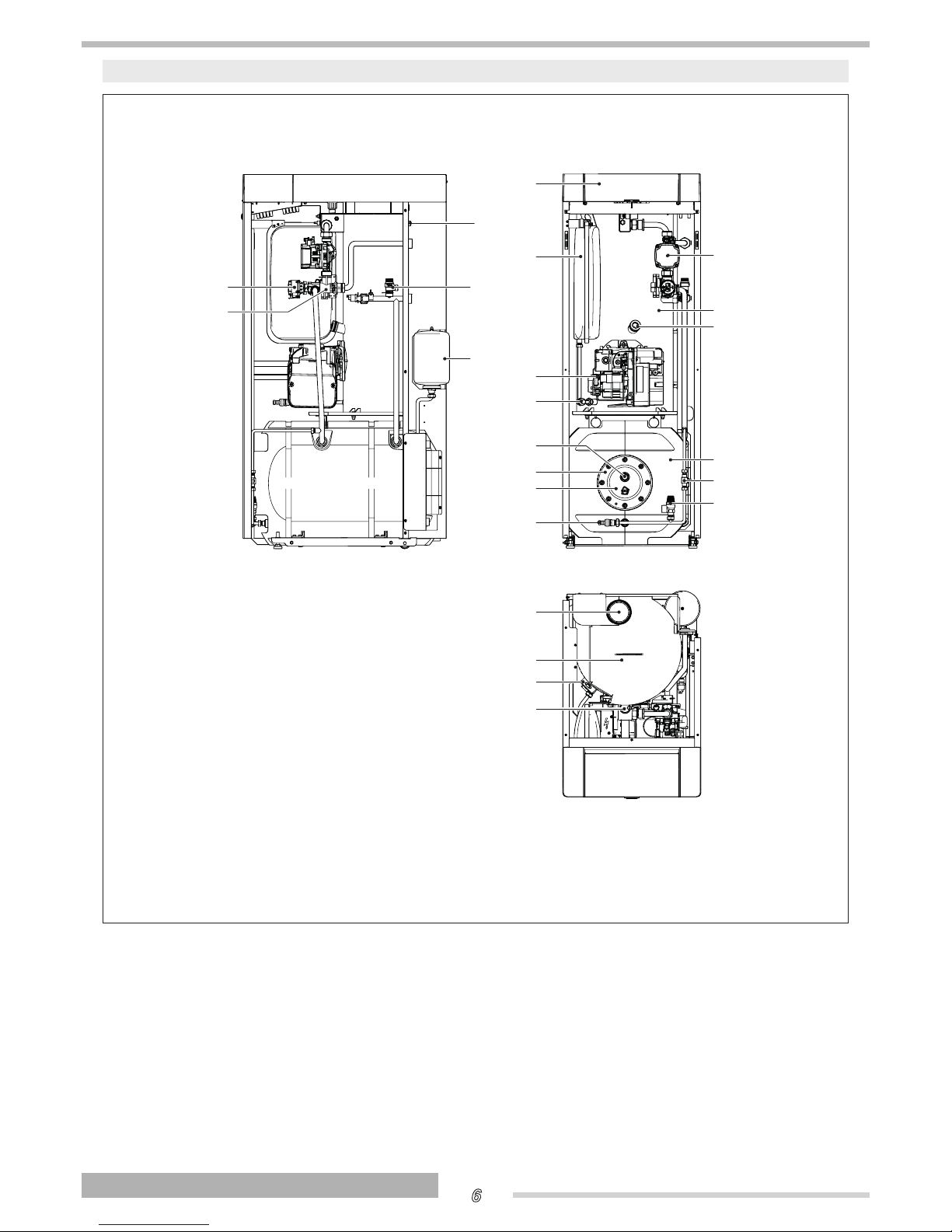

System layout

ACQUAHOME 25 B BLU

7

1

2

8

9

11

10

13

12

20

21

22

23

6

14

16

17

18

19

5

4

3

15

1

Electric actuator

2

3-way diverting valve

3

Main switch

4

Heating safety valve

5

Storage cylinder expansion vessel

6

Control panel

7

Heating expansion reservoir

8

Burner

9

Boiler drain cock

10

Magnesium anode

11

Storage cylinder inspection flange

12

Storage cylinder flange insulation

13

Storage cylinder drain cock

14

Storage cylinder safety valve

15

Storage cylinder fill cock

16

Storage cylinder with insulation

17

Flame inspection window

18

Boiler body

19

Pump

20

Flue gas exhaust fitting

21

Flue gas box cover

22

Lifting bracket

23

Automatic bleed valve

7

ENGLISH

Control panel

Controls interface

5

5

1

2

3

4

6

1

Door

2

Light guide

3

Rear light display

4

ENTER/RESET key: it allows accessing the main menu and restoring the operation after a stop

due to an anomaly

5

Navigation keys

6

Main switch (located on the equipment rear wall)

Light Guide displaying

STAT U S DESCRIPTION

Green blinking

Thermal unit drain cycle and initialization in progress after the power

supply reset.

Steady green Thermal unit on

Steady red Thermal unit in alarm mode

Red blinking Thermal unit in lock-out mode

8

ENGLISH

Display visualisation

HEAT

Bar

Bar

°C

°F

Psi

Psi

OUTSIDE

1 2 3 4 5

6

78

9

10

11

1

Icon displayed when heating mode is enabled. Blinking when there is a heat demand

2

Icon displayed when DHW mode is enabled. Blinking when there is an DHW Demand

3

Icon displayed when entering the "Installer" or "Manufacturer" menu

4

Icon displayed when the burner of the equipment is on. The icon will be marked with a cross in

case of Permanent or Temporary error.

5

Icon displayed when the climatic mode operation is active (Par. 2001= 1 or 2)

6

Celsius/Fahrenheit temperature

7

Displays current value

8

Displaying of system pressure or parameter number or external temperature

9

Icon displayed when the circulator is operating

10

Pressure in Bar/Psi

11

Icon displayed when the outdoor probe is connected

9

ENGLISH

Menu navigation

At start-up or when no key is pressed for more than 4 minutes, the display is in “basic display” mode and provides general information on the equipment operation.

5

3

4

2

1

In this mode, keys have the following functions:

Nr. Button Function

1

"+"

It increases the heating setpoint (when active/available)

2

"-"

It decreases the heating setpoint (when active/available)

3

"▲"

Raise the DHW set point (when available)

4

"▼"

Decrease the DHW set point (when available)

5 "ENTER/RESET"

Enters into "MENU" mode

If pressed for more than 5 seconds, it resets a permanent error (Loc)

Additional functions:

Button Function

"+" with "-" It accesses enable/disable heating function mode

"▲" + "▼"

It accesses enable/disable DHW production function mode

b

For more information, see paragraph "Enable/disable the heating function" on page 15.

"Basic display" mode

Adjustment of heating setpoint

°C

Adjustment of domestic setpoint

°C

or

or or

°C

or

10

ENGLISH

MENU selection

Enters into "MENU" mode when "MENU/RESET" key is pushed. The figures of the small display indicate "0000" which is the first

accessible menu.

5

3

4

2

1

In this mode, keys have the following functions:

Nr. Button Function

1 "+" Exits from the menu and cancels a parameter change

2 "-" Exits from the menu and cancels a parameter change

3

"▲"

Selects the following menu or increases a certain parameter value

4

"▼"

Selects the previous menu or decreases a certain parameter value

5 "ENTER/RESET" Enters into the selected menu/parameter or confirms the parameter change

11

ENGLISH

Navigation scheme

"Basic display" mode

"End user" mode

Bar

°C

or

Example of parameter setting

change

conrmed

change

canceled

or

or or

12

ENGLISH

List of user parameters

Menu

Par.

No.

Description Range

Default set-

ting

UM

Main menu

0000

013

Quick adjustment of direct Zone/Zone 1 heating setpoint in 0 and

3 heating modes.

By connecting the zone control accessory, this parameter can be

used to quickly change direct Zone/Zone 1 setpoint. This parameter simultaneously modifies the value of Par. 2103.

See Par. 2103 See Par. 2103 °C

0000

023

Quick adjustment of Zone 2 heating setpoint in 0 and 3 heating

modes.

By connecting the zone control accessory, this parameter can be

used to quickly change Zone 2 setpoint. This parameter simultaneously modifies the value of Par. 2203.

See Par. 2203 See Par. 2203 °C

0000

033

Quick adjustment of Zone 3 heating setpoint in 0 and 3 heating

modes.

By connecting the zone control accessory, this parameter can be

used to quickly change Zone 3 setpoint. This parameter simultaneously modifies the value of Par. 2303.

See Par. 2303 See Par. 2303 °C

0000

047 Quick adjustment of DHW setpoint with heater See Par. 2047 °C

0000

048 Quick adjustment of DHW setpoint with instant production See Par. 2048 °C

0000

201

Stops the venting function

0 = No action

1 = Stop venting

0…1 0

0000

901

Unit of measurement for temperature

0 = °C

1 = °F

0...1 0

0000

902

Pressure unit of measurement

0 = BAR

1 = PSI

0...1 0

Info menu

1000

1101 Direct Zone/Zone 1 delivery temperature °C

1000

1102 Direct Zone/Zone 1 ambient temperature °C

1000

1201 Zone 2 delivery temperature °C

1000

1202 Zone 2 ambient temperature °C

1000

1301 Zone 3 delivery temperature °C

1000

1302 Zone 3 ambient temperature °C

1000

1001 CH flow temperature °C

1000

1002 Domestic hot water temperature °C

1000

1003 Domestic cold water temperature °C

1000

1004 Outdoor temperature °C

1000

1007 Return temperature °C

1000

1033 System pressure

bar

13

ENGLISH

Menu

Par.

No.

Description Range

Default set-

ting

UM

1000

1032 Error code

1000

1112 Zone 1 heating setpoint °C

1000

1113 Zone 2 heating setpoint °C

1000

1114 Zone 3 heating setpoint °C

1000

1053 Flame failure number

1000

1054 Number of ignitions

1000

1055 Number of failed ignitions

1000

1056 Total hours of operation in heating mode

h

x

10

1000

1057 Total hours of operation in domestic mode

h

x

10

1000

1058 Total hours of operation

h

x

10

1000

1063 Input signal 0-10V V

Direct Zone / Zone 1 Heating Settings

2000

2103

Direct Zone/Zone 1 setpoint in heating mode Par. 2001= 0 and 3

The thermal unit adjustment determines the boiler setpoint in

heating mode, using the highest value among the requests of all

the active zones (Par. 1101, 1201, 1301)

If Zone 1 is configured as mixed, the value set in parameter 1112

will be used as setpoint

If Zone 1 is not

enabled:

(Par. 2121, Par.

2024)

If Zone 1 is ena-

bled:

BT: (Par. 2121, 45)

AT: (Par. 2121,Par.

2024)

70 (AT)

45 (BT)

°C

2000

2130 Parallel shift of direct Zone/Zone 1 climatic curve -10…10 0 °C

Zone 2 Heating Settings

2000

2203

Zone 2 heating setpoint in 0 and 3 heating modes

The thermal unit adjustment determines the boiler setpoint in

heating mode, using the highest value among the requests of all

the active zones (Par. 1101, 1201, 1301)

If Zone 2 is configured as mixed, the value set in parameter 1113

will be used as setpoint.

BT: (Par. 2221, 45)

AT: (Par. 2221,Par.

2024)

70 (AT)

45 (BT)

°C

2000

2230 Parallel shift of direct Zone/Zone 1 climatic curve -10…10 0 °C

Zone 3 Heating Settings

2000

2303

Zone 3 heating setpoint in 0 and 3 heating modes

The thermal unit adjustment determines the boiler setpoint in

heating mode, using the highest value among the requests of all

the active zones (Par. 1101, 1201, 1301)

If Zone 3 is configured as mixed, the value set in parameter 1114

will be used as setpoint.

BT: (Par. 2321, 45)

AT: (Par. 2321,Par.

2024)

70 (AT)

45 (BT)

°C

2000

2330 Parallel shift of direct Zone/Zone 1 climatic curve -10…10 0 °C

DHW settings and system conguration

2000

2047 DHW setpoint with heater 40...65 57 °C

2000

2048 DHW setpoint with instant production 40…70 45 °C

14

ENGLISH

USE

Putting into service

Have the T Technical Assistance Service start up

your

ACQUAHOME 25 B BLU

boiler for the first time. Once this

has been done, the boiler can be left to function automatically.

Under certain circumstances, such as after long periods of

disuse, the user may need to re-start it without involving the

Technical Assistance Centre.

Preliminary operations

Perform the following checks before starting up the boiler:

- Check that the fuel shut-off cock and heating system

shut-off cock are open

- the pressure of the hydraulic circuit, with cold water, is

1.5 bar

(value indicated on the first screen of the control

panel display) and the circuit is not vented

- The thermal unit

ACQUAHOME 25 B BLU

is equipped

with a system load valve located inside the thermal unit

Bar

°C

- close the system load valve.

Start-up

Once you have completed all the checks listed above, proceed as follows to start up the boiler for the first time:

- set the main switch of the system to ON and the main

switch of the equipment to (I).

Once the device is on, the software version number will be

displayed for a few seconds.

Once the initialization phase is complete, the display switches

to “basic display” mode.

In this mode, the main information on the equipment operation

is displayed. The meaning of the different icons displayed is

explained in paragraph Control panel.

The icon

and the heating delivery temperature are displayed, either if the boiler is in stand-by mode or if a temperature request is active (icon

blinking).

To switch off the equipment, set the main switch to “0”.

b

Never power off the appliance before switching the master switch to the "0" position.

b

Never switch off the appliance with the master switch if a

request is active. Always make sure that the appliance is

in stand-by before switching the main switch.

Example of generator stand-by display in heating only

mode (external probe not connected)

Bar

°C

- Set the room thermostat to the required temperature (~

20°C) or, if the system has a timer or timer-thermostat,

make sure that this is switched “ON” and adjusted to

the required temperature (~ 20°C).;

15

ENGLISH

Adjustment of heating setpoint

- Press the key“+” or “-” to display the current value of the

heating temperature setpoint.

°C

- Increase or decrease the setpoint according to the type

of system by using the key “+” of “-”.

- To save the modification made and go back to the initial

screen, wait for 3 seconds or press the key “ENTER/

RESET”.

- Check that the thermal unit starts the ignition phase and

that the display shows the icon

blinking (ambient

heating request) and the icon

.

- The thermal unit ignition phase will start only after the

light oil pre-heating phase will be completed and will

remain active until the set temperature will be reached.

Enable/disable the heating function

- Press the keys “+” and “-” simultaneously for a few seconds;

- The icon

and the current heating mode (ON or OFF)

will blink on the display;

- Press the keys “+” and “–” to select the required mode;

- Press the key “ENTER/RESET” or wait for 3 seconds to

save the modification made and go back to the initial

screen.

Adjustment of domestic setpoint

- Press the key "▲" o "▼" to display the current value of

domestic setpoint.

°C

- Increase or decrease the setpoint by using the key “▲"

o "▼".

- To save the modification made and go back to the initial

screen, press the key “ENTER/RESET”.

Enable/disable the domestic function

- Press the keys "▲" and "▼" simultaneously for a few

seconds;

- The icon

and the current domestic mode (ON or

OFF) will blink on the display;

- Press the keys "▲" and "▼" to select the required mode;

- To save the modification made and go back to the initial

screen, press the key “ENTER/RESET”.

16

ENGLISH

Special functions

When a special function is active, a specific message is shown

on the display of the thermal module control interface.

Frost protection

When the anti-freeze function is active, the message “AFro” is

displayed.

Venting

The function is automatically enabled at the first start-up and at

each reset of the power supply.

During the venting, the circulator is enabled, so that the air

which may be present inside the system circuit can exit through

the automatic drain valve of the thermal module.

The light guide status changes as indicated in the paragraph

Light guide Displaying.

Anti-legionella

The function is automatically enabled at first start-up, at each

reset of the power supply or daily, if necessary.

When the function is active, the message “ALE9” is displayed

beside the heater temperature and the icon

blinks.

The function increases the water temperature inside the heater

up to 65°C and keeps it for 30 minutes.

Once this time has elapsed, the control box normal operation

is restored.

Ignition failure

If an ignition or operating anomaly occurs, the thermal unit display will show a text message (small digit) and a number (large

digit), which vary according to the anomaly detected.

For a detailed description, see the error list.

There are 3 error levels:

- Permanent (Loc)

- Temporary (Err)

- Alerts (AttE)

The section with the large digit will display the error number

and , according to the error / alert, a message which will cyclically blink together with the number.

For a detailed description, see the error list.

Permanent Error

The text “Loc” is displayed together with the permanent er-

ror number. The icon

indicates that the burner is disabled.

The equipment must be manually reset by keeping the key

“ENETER/RESET” pressed.

Temporary Error

The text “Err” is displayed together with the temporary error

number.

The icon

indicates that the burner is disabled.

The lock-out error must be solved.

17

ENGLISH

Warnings

The text “AttE” is displayed together with the alert number.

The equipment is not locked out, but its functions may be limited (according to the alert).

Temporary or short-term shut-down

In the event of temporary or short-term shut-down (e.g. due to

holidays), proceed as follows:

- Remove the power supply by setting the main switch

of the equipment and the main switch of the system to

"OFF".

- If there is a danger of frost, keep the system on. To reduce fuel consumption, set the heating set point to the

minimum allowed value.

Preparing for extended periods of disuse

If the appliance is not going to be used for a long period of

time, the following operations should be carried out:

set the main switch of the system to OFF and the main switch

of the equipment to (0);

- close the fuel cock and heating circuit water cock.

b

Drain the central heating circuit if there is any risk of

freezing.

Device cleaning and maintenance

Please remember that THE PERSON RESPONSIBLE FOR

SYSTEM MANAGEMENT MUST ENSURE THAT PROFESSIONALLY QUALIFIED HEATING ENGINEERS UNDERTAKE

PERIODIC MAINTENANCE AND COMBUSTION EFFICIENCY

MEASUREMENTS.

T’s Technical Assistance Centre is qualified to

satisfy these legal requirements and can also provide useful

information on MAINTENANCE PROGRAMMES designed to

guarantee:

- Greater safety

- Compliance with applicable legislation

- Freedom from the risk of fines in the event of spot

checks.

Regular maintenance is essential for the safety, efficiency and

durability of the boiler.

Servicing is a legal requirement and must be performed at

least once a year by a professionally qualified heating engineer.

External cleaning

Clean the boiler’s casing panels and control panel with a soft

cloth damped in soapy water.

To remove marks from the boiler casing, use a cloth damped in

a 50% mix of water and denatured alcohol or a suitable cleaning product.

Wipe the boiler dry after cleaning it.

a

Do not use abrasive products, petrol or triethylene.

Annual cleaning

At least once a year, the user must have the boiler served by

T's Technical Assistance Service or by a qualified

heating engineer.

18

ENGLISH

Troubleshooting

FAU LT CAUSE SOLUTION

There is a smell of fumes Fumes escaping into the air

- Contact your local Technical Assistance Centre

The generator is at temperature but

the heating system is cold

Air in the circuit

- Contact your local Technical Assistance Centre

Pump malfunctioning

- Contact your local Technical Assistance Centre

The boiler does not reach its tempera-

ture setpoint

Boiler temperature setpoint

- Check the temperature setting

- Contact your local Technical Assistance Centre

The generator triggers a thermal safe-

ty block

Safety thermostat / delivery overtemper-

ature

- Contact your local Technical Assistance Centre

No water

- Contact your local Technical Assistance Centre

The safety valve keeps opening

Incorrect central heating circuit pressure

- Contact your local Technical Assistance Centre

CH expansion vessel

- Contact your local Technical Assistance Centre

The circulator does not work

Pump seized

Electrical connections

- Contact your local Technical Assistance Centre

The request from the ambient thermostat

is missing

- Check the temperature set on the ambient thermostat

- Contact your local Technical Assistance Centre

Insufcient domestic hot water or

water not hot enough

Diverter valve or pump faulty

- Contact your local Technical Assistance Centre

Domestic setpoint

- Check the temperature setting

- Contact your local Technical Assistance Centre

RECYCLING AND DISPOSAL

The device is primarily composed of:

Material Component

Metal materials Pipes, circulator, boiler body

ABS (acrylonitrile-butadi-

ene-styrene)

Control panel enclosure

Glass wool felt Boiler body insulation

Electrical and electronic

components

Cables and wirings, regulator, circulator

At the end of the life cycle, safely remove the components and

dispose of them in a responsible manner, in compliance with

the installation country's applicable environmental legislation.

b

Adequate sorted waste collection, processing and environmentally-friendly disposal contribute to preventing

possible negative impacts on the environment and health

and promote the reuse and/or recycling of the materials

of which the appliance consists.

b

Illegal disposal of the product by the owner shall be subject to administrative fines provided for by applicable

laws.

19

ENGLISH

20129620 - Rev. 0 (07/18)

RIELLO S.p.A.

Via Ing. Pilade Riello, 7

37045 - Legnago (VR)

www.thermital.it

The manufacturer strives to continuously improve all products. Appearance, dimensions, technical

specications, standard equipment and accessories are therefore liable to modication without

notice.

Loading...

Loading...