BEFORE THE FIRST USING YOUR ELECTRIC STORAGE WATER

Water heater

- 1 pcs.

Safety valve of GP type

- 1 pcs.

Operation manual

- 1 pcs.

HEATER, CAREFULLY READ THIS OPERATION MANUAL

DEAR CUSTOMER!

Congratulations on your purchase of an electric water heater THERMEX.

Water heaters THERMEX are designed and manufactured in strict accordance

with domestic and international standards guaranteeing operation reliability and safety.

Present manual applies to THERMEX models of IF/IF (pro). The full name of the

model of your heater is specified in "Manufaturer’s warranty" section (sub-section

"Note of sale") and in the marking plate on the heater casing.

1. APPLICATION

Electric water heater (hereinafter referred to as the EWH) is designed to provide

with hot water for domestic and industrial facilities having a cold water supply line

pressure of not less than 0.05 MPa and not more than 0.7 MPa..

EWH shall be operated indoors in heated spaces and it is not designed for operation in continuous flow mode.

2. SCOPE OF SUPPLY

EN

Anchors for fastening (option) - 1 set

Packaging - 1 pcs.

EN

EWH power supply shall be within the range of 230 V ± 10%. Supply network

frequency 50 Hz ± 1%. Volume of the inner tank and heating element power are specified in the marking plate on the casing. Thread diameter in water inlet and outlet

pipes - G1/2 ".

The manufacturer reserves the right to make changes to the design, complete set and

specifications of the heater without prior notice.

3. MAIN TECHNICAL CHARACTERISTICS

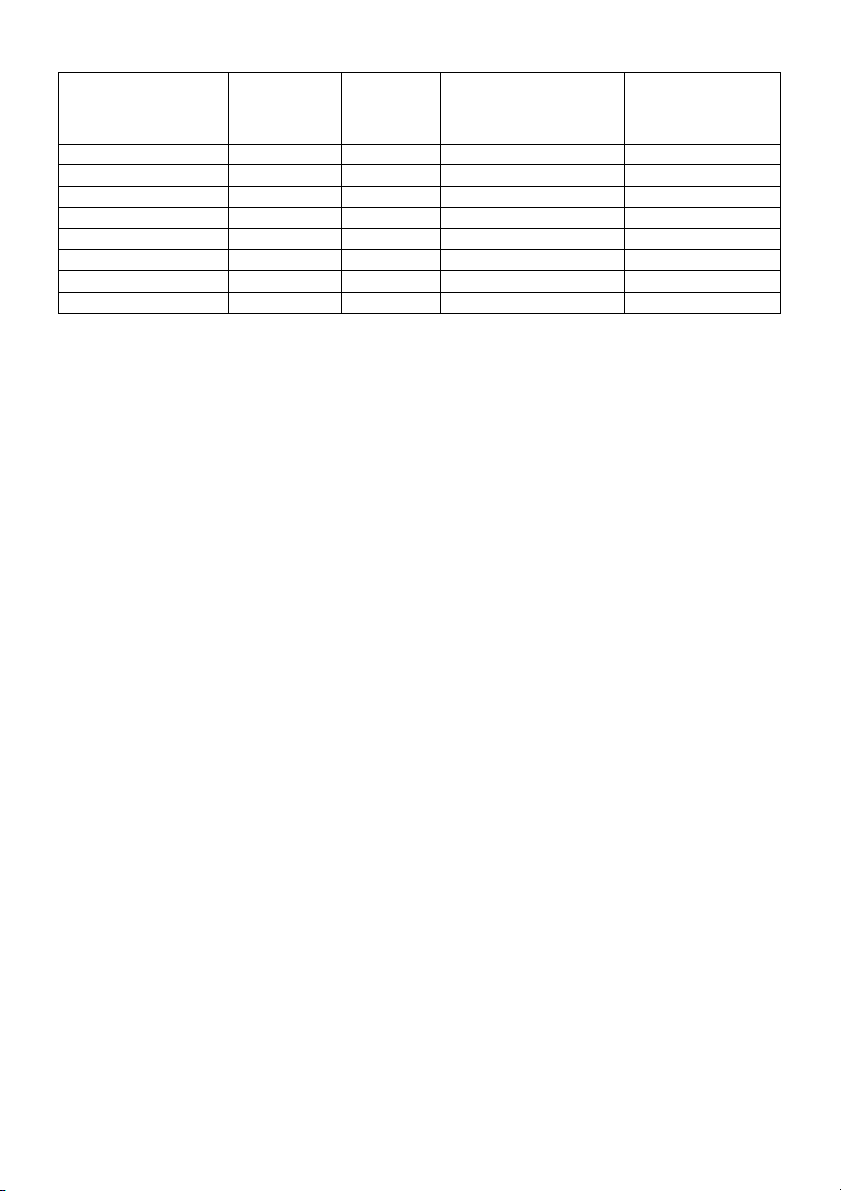

Table 1

1

Model Range EWH useful

volume, l

Average heating time T =

45° C at 2 kW

Installation

IF 30 V/ IF 30 V (pro)

IF 50 V/ IF 50 V (pro)

IF 80 V/ IF 80 V (pro)

IF 100 V/ IF 100 V (pro)

IF 30 H/ IF 30 H (pro)

IF 50 H/ IF 50 H (pro)

IF 80 H/ IF 80 H (pro)

IF 100 H/ IF 100 H (pro)

30

50

80

100

30

50

80

100

26

43

70

85

26

43

70

85

0 h 40 min.

1 h 07 min.

1 h 47 min.

2 h 14 min.

0 h 40 min.

1 h 07 min.

1 h 47 min.

2 h 14 min.

vertical

vertical

vertical

vertical

horizontal

horizontal

horizontal

horizontal

4. DESCRIPTION AND PRINCIPLE OF OPERATION

The outside casing of the EWH is made of impact-resistant plastic. The inner tank is

made of high-quality austenitic stainless steel, which provides high corrosion resistance and long operating life. The space between the outside casing and the inner

tank is filled with polyurethane foam - a modern, ecologically clean thermal insulation, which has the best heat-saving characteristics. IF/IF (pro) models have two

screwed nozzles: for inlet of cold water (Figure 1, p. 3) with a blue ring and for outlet

of hot water (Figure 1, p. 2) — with a red ring, and equipped with an additional drain

connection (closed with metal plug button) for draining the water and flushing the

inner tank (Figure 1, p. 17). The control panel, in all models, is on the front side of the

EWH. (Figure 1, p. 16).

Tubular heating element (THE), thermostat and thermal switch sensors are mounted

on the removable flange. THE is used to heat water and thermostat provides with possibility of heating temperature regulation up to +65°С. All models have electronic

control with sensor adjustment. Electronics maintain automatically water temperature

at the level set by the user. The thermostat is used for protecting against EWH overheating, which disconnects THE from power supply when water temperature exceeds

95°С. (Fig. 3).

Safety valve (Fig. 1, p. 5) operates as the check valve, ensuring protection of the water

ingress from the water heater into the sewage system in case of pressure drop in the

sewage system and in case of pressure rise in the tank at high water heating, as well as

the functions of the safety valve, releasing overpressure in the tank at high water heating. During water heater operation water may leak out of the exhaust outlet pipe of the

safety valve to relieve excessive pressure, which is made for the purpose of water

heater safety. This outlet pipe shall remain open to the atmosphere and be installed

constantly down.

Drainage of water from the safety valve exhaust pipe into the drain shall be pro-

vided with installation of the corresponding EWH drainage.

2

It is required regularly (at least once a month) to discharge a small amount of water through the exhaust pipe of the safety valve into the drain to remove lime deposits

and to test the operating functionality of the valve. Handle (Fig. 1, p. 15) is intended to

open the valve. It is necessary to control when operating water heater this handle to be

in position closing water draining from the tank.

5. SPECIFYING SECURITY MEASURES

Electrical safety and corrosion protection of EWH are guaranteed only if there is

an effective grounding in accordance with applicable electric installation rules and

regulations.

Plumbing pipes and fittings shall conform to parameters of water main and have

the required certificates of quality.

When installing and operating EWH the following is not allowed:

• To power EWH if EWH is not filled with water.

• To remove the protective cover when the power is on.

• Use EWH without grounding or use water pipes as grounding.

• To connect EWH to water supply with pressure exceeding 0.7 MPa.

• To connect EWH to the water supply without safety valve.

• To drain water from EWH with power switched on.

• To use spare parts not recommended by the manufacturer.

• To use water from the EWH for cooking.

• To use water containing impurities (sand, small stones), which might lead to

EWH and safety valve breakdown.

• To modify design and installation dimensions of EWH brackets.

Ambient temperature shall be within the range of 3ºС to 40ºС. Water in freezing

EWH at negative temperatures results in malfunction, which is not a warranty case.

Attention should be paid to children so that they do not play with EWH.

EWH is not intended for use by persons (including children) with limited

physical, sensory or mental capabilities, or by persons who do not know

how to use the EWH, except for cases when this happens under the

supervision or instructions by persons responsible for safety of the EWH.

During EWH operation, it shall be inspected regularly for proper health (absence

of dripping, burning smell, wiring sparks, etc.). In the case of long interruptions in

water heater operation, water supply failures, EWH shall be disabled and cold water

inlet valve shall be shut off.

3

6. ARRANGEMENT AND INSTALLATION

All installation, plumbing and electrical works shall be performed by qualified

personnel.

EWH installation shall be performed in accordance with marking on the housing.

It is recommended to install EWH as close as possible to the place of hot water

using to reduce heat loss in the pipes.

When choosing the place of installation it should be taken into account the total

weight of EWH filled with water. Walls and floor with low carrying capacity should

be strengthened accordingly. When drilling (making) holes in the wall consider cables,

ducts and pipes in the wall.

EWH is suspended by brackets on hook anchors fixed in the wall. Hooks mounting on the wall shall exclude spontaneous movement of EWH brackets along them.

The manufacturer bears no liability for EWH falling associated with improper installation of anchors and their selection.

For EWH maintenance the distance from the protective cover to the nearest surface in the direction of the removable flange axis shall be at least 30 cm for all models.

In order to avoid damage of the user’s and/or third parties’ property in

the event of a faulty hot water system, it is required to install EWH in

spaces with waterproofing and drainage to the sewers, and in no case to

place under items exposed to the water under EWH. When placed in unprotected areas a protective plate (not supplied) with drainage into sewers shall be installed under the EWH.

In case of placing EWH in hard-to-reach places in order to perform maintenance

and warranty service (mezzanine floors, niches, ceiling voids, etc.), installation and

dismantling of EWH is carried out by the user on his own or for his own account.

Note: safety tray is not included into the scope of EWH supply.

7. CONNECTION TO WATER MAINS

Cold water shall be supplied to EWH using pre-filter with water treatment level

not less than 200 µm.

Install pressure relief valve (fig. 1, p.5) at the cold water inlet (fig. 1, p. 3) tube

with the blue ring, by 3.5-4 turnings, ensuring junction tightness with any sealing material (flax, FUM tape, etc.).

During EWH operation you can observe water leak out of the outlet pipe of the

safety valve for excessive pressure release to ensure safety of the water heater. It is

4

EN

Loading...

Loading...