Therma-Tru Smooth-Star, Fiber-Classic User Manual

PATIO

DOOR

SYSTEMS

Therma-Tru

Fiber-Classic

and

Smooth-Star

Sliding Patio

®

®

®

Door System

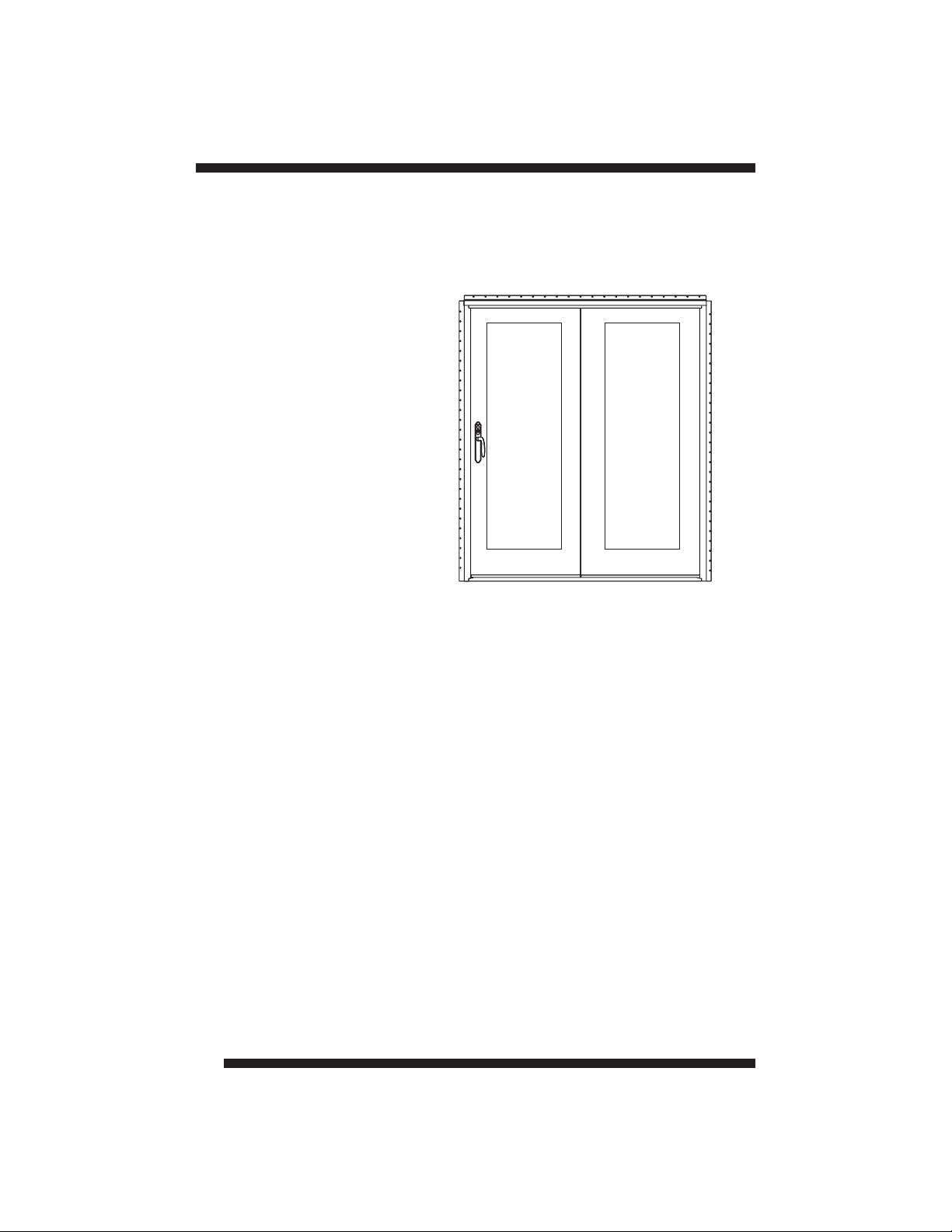

Double Unit

Assembly & Installation

Read all instructions before starting.

The applicable standards for these products are governed by

the International Residential Code.

Copies of performance ratings and testing are available on our website

www.thermatru.com and our product manual.

The following packages are needed to complete the installation of your

Sliding Patio Door System.

Check all components for correct size and color.

Frame Kit

1-Head Jamb

2-Side Jambs

1-Sill

1-Active Interlock

1-Inactive Interlock

1-Panel Bumper

12-#10 x 3" Flat Head Screws

12-#8 x 3" Pan Head Screws

1- This Instruction Booklet

2- Anchor Blocks

2- #10 x 1 Pan Head Screws

2- #10 x 2 Pan Head Screws

½"

½"

Active

Panel

Inactive

Panel

1-Sill Cap Base

1-Sill Cap Top

1-Drip Cap

1-Head Sealing Fin

2-Corner Pads

1-Foot Bolt

1-Foot Bolt Keeper

1-#8 x 1 S.S. Pan Head Screw

½"

2-#8 x 1" S.S. Pan Head Screws

2-Active Panel Hole Plug

3-#8 x 9/16" Pan Head Screw

1-Jamb Cover

Touch Up Paint

Additional Parts

Strike Plate

Handle Set Kit

7 - #8 Flat Head Screws

2-Handles

1-Exterior Backplate

1-Interior Backplate

2-Keys

2-Handle Screws

3-Phillips Head Machine Screws

1-Allen Wrench

2-Backplate Gaskets

Tools and materials needed for

assembly and installation:

• 100% Silicone Sealant and Caulk Gun

• 6' Level

• Measuring Tape

• Electric Drill

• #2 Phillips Drive Bit

• Staple Gun or Brad Nails

• 1/8 Drill Bit

1-Screen (sold separately)

1-Active Panel

"

• Screwdriver

Phillips Head

• Gloves

• Safety Glasses

1-Inactive Panel

• Partial roll of nsulation

I

• Shims

•

Rubber Mallet

Therma-Tru

®

Note: Due to ongoing product development, Therma-Tru Corp. reserves the right to make changes in

1

design, materials, and specifications without notice.

SCREW CHART

#8 x 9/16" S.S. Pan Head Screw

#8 x 1" S.S. Pan Head Screw

#8 x 1 3/8 Flat Head Screw"

#8 x 1 S.S. Pan Head Screw½"

#10 x 1 Pan Head Screw½"

#10 x 2 Pan Head Screw½

#8 x 3" Pan Head Screw

#10 x 3" Flat Head Screw

2

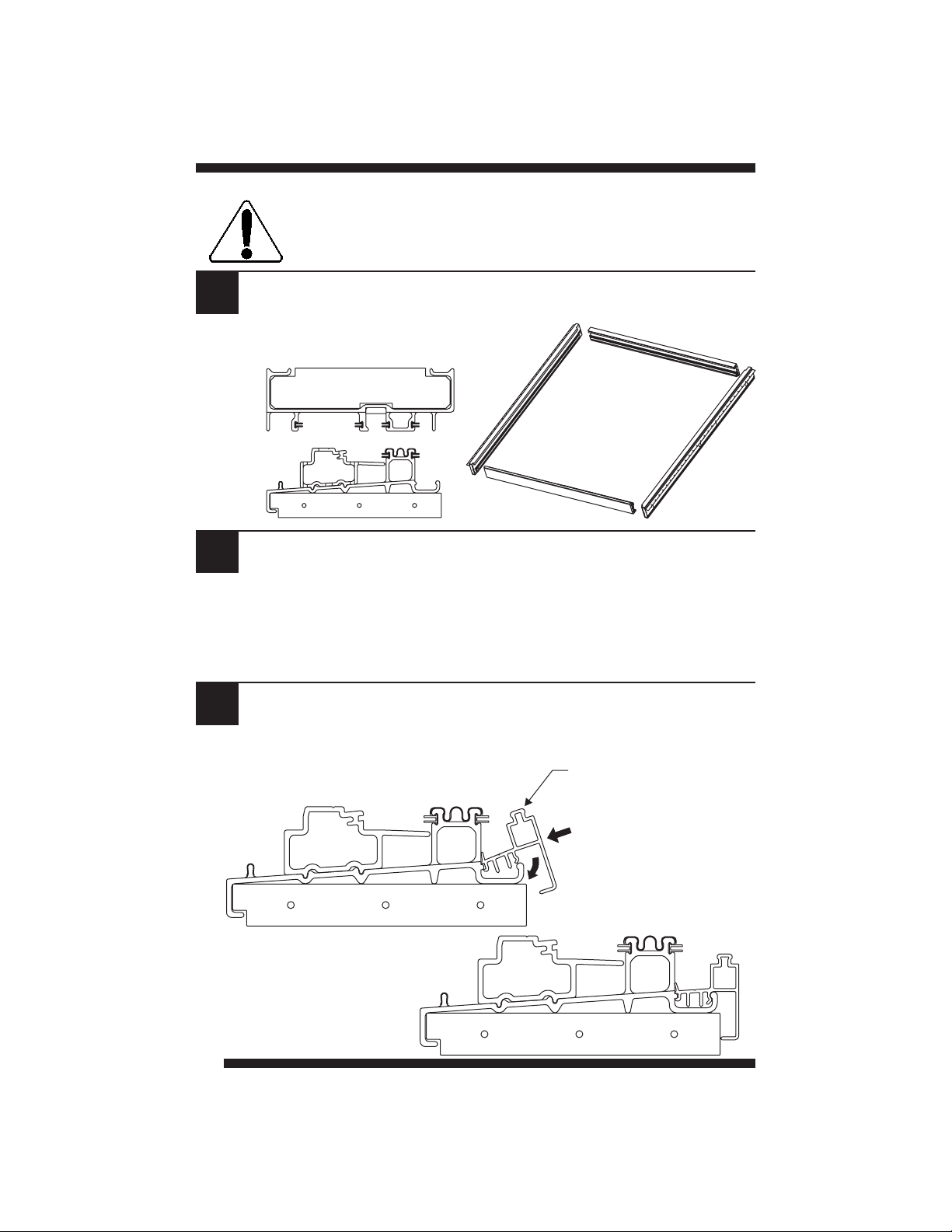

NOTE:

A large work area is needed to assemble the frame kit. Cover area with

cardboard from one or more door panel cartons to protect frame parts

and floor.

LAY FRAME COMPONENTS ONTO WORK AREA

1

Frame Assembly

Lay parts on floor and position sill, head,

and side jambs with exterior side up.

Exterior

IF APPLICABLE, INSTALL TOP-HUNG SCREEN

2

Side Jamb

Sill

Head Jamb

Side Jamb

TRACK

For units using the wide profile top-hung screens, install top-hung screen track and

adapter into head jamb prior to assembly.

Reference steps 1 thru 4 of the “Wide Profile” Screen Installation - Sliding Patio

instructions, included with the top-hung screen, for complete details.

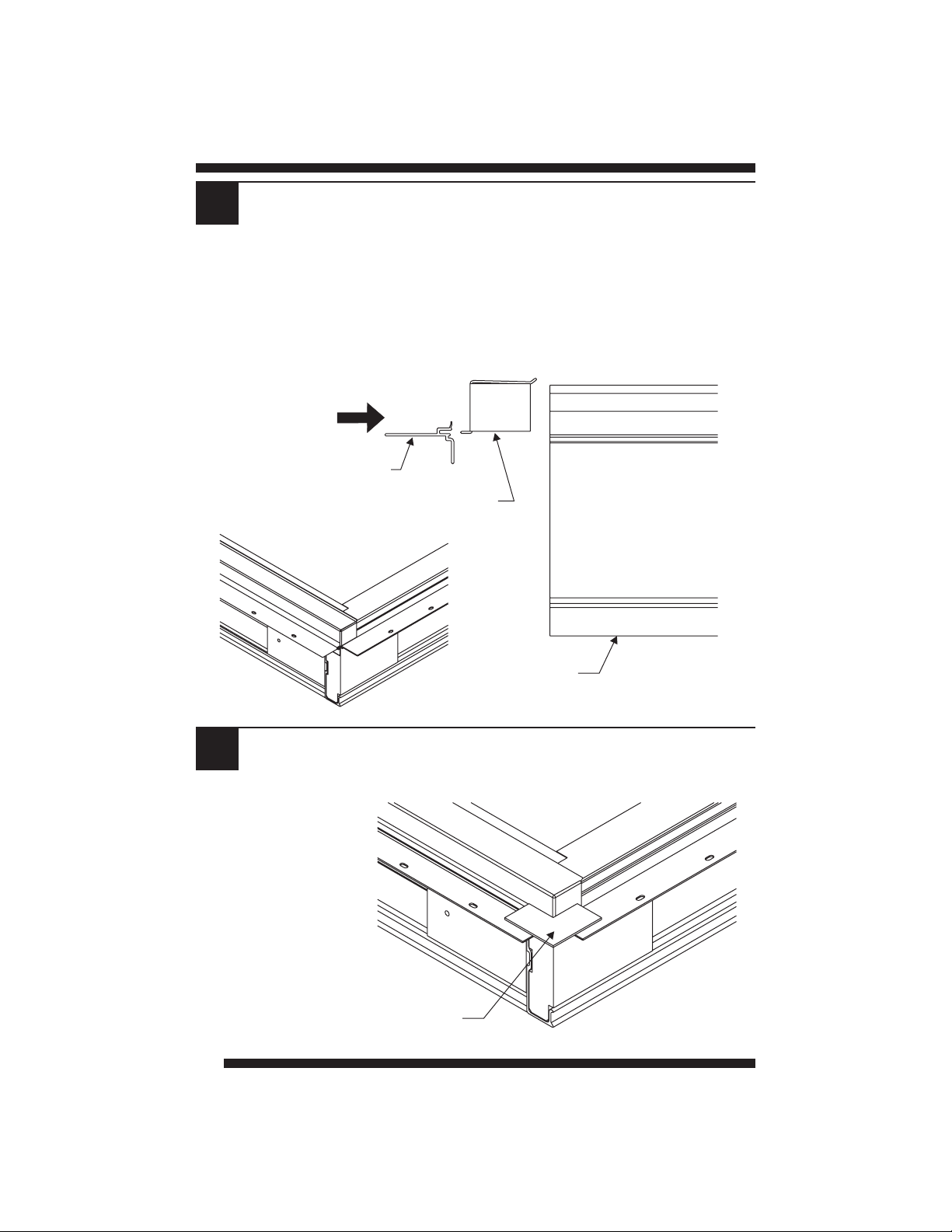

INSTALL SILL CAP BASE

3

Engage groove in sill cap base with sill.

Rotate sill cap base down to snap into place.

Use a rubber mallet if necessary.

Sill cap base

3

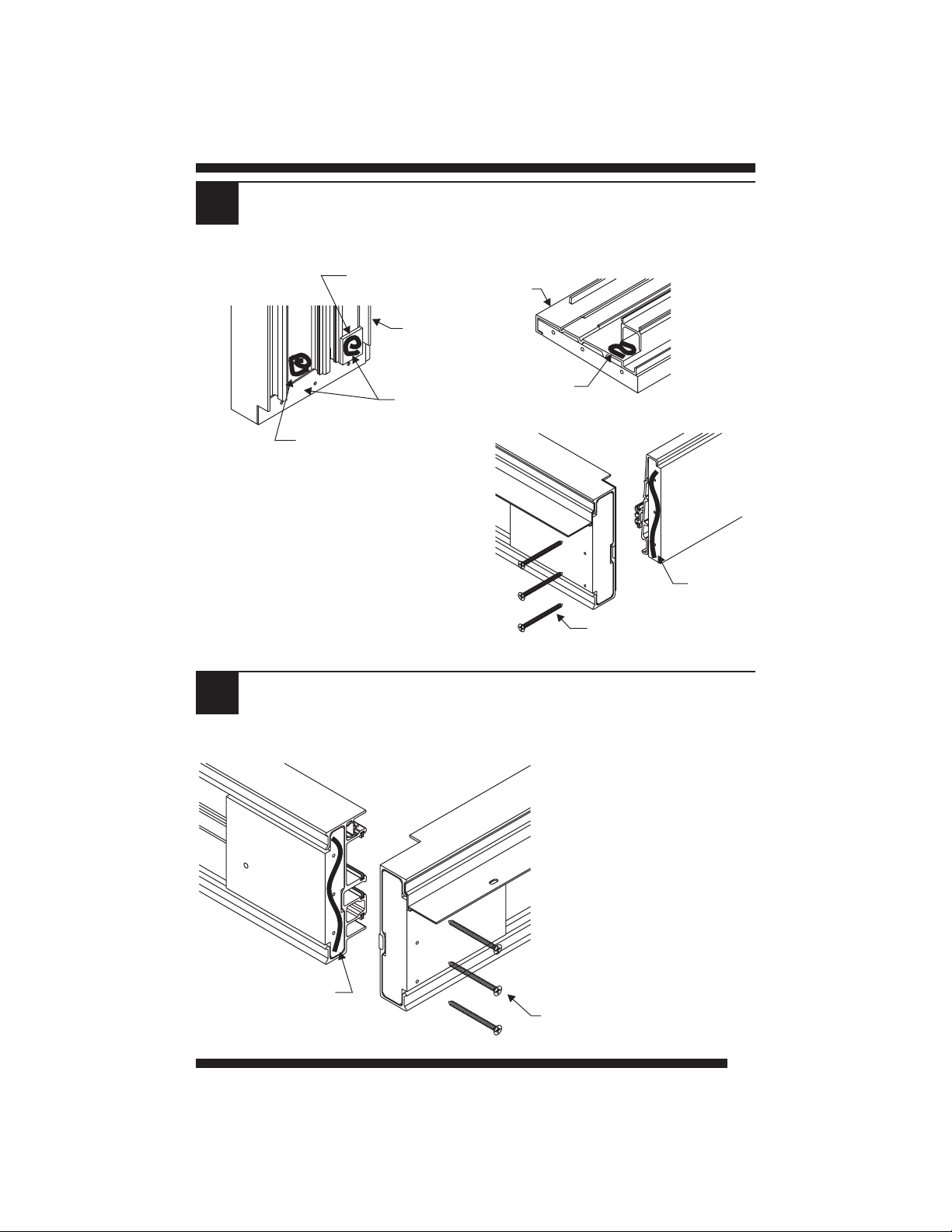

ATTACH SILL TO JAMBS

4

NOTE: Be sure that foam pads are in place before assembling frame.

Sealant

Jamb

Sill

Pads

Apply sealant here

INACTIVE side ONLY

Apply sealant to sill and side

jambs as shown.

Fasten side jambs to sill through

pre-drilled holes using (3) #10 x 3

flat head screws. (Starting with

center screw is recommended.)

Repeat of opposite side.

ATTACH HEAD TO JAMBS

5

Head Jamb

"

Side Jamb

Sealant

Jamb

Sill

Sealant

#10 x 3” flat head screw

Apply sealant to end of head

jamb.

Fasten side jambs to head jamb

through pre-drilled holes using

(3) #10 x 3 flat head screws.

"

(Starting with center screw is

recommended.)

Sealant

Repeat for opposite side.

#10 x 3” flat head screw

4

DRIP CAP INSTALLATION

6

Place drip cap on top of head jamb.

Place head sealing fin on top of drip cap, engaging slot in

sealing fin with flange on drip cap.

Staple head sealing fin to each of the anchor blocks in

head jamb using 1/2" staples, nails or screws (not provided).

Head sealing fin

Drip cap

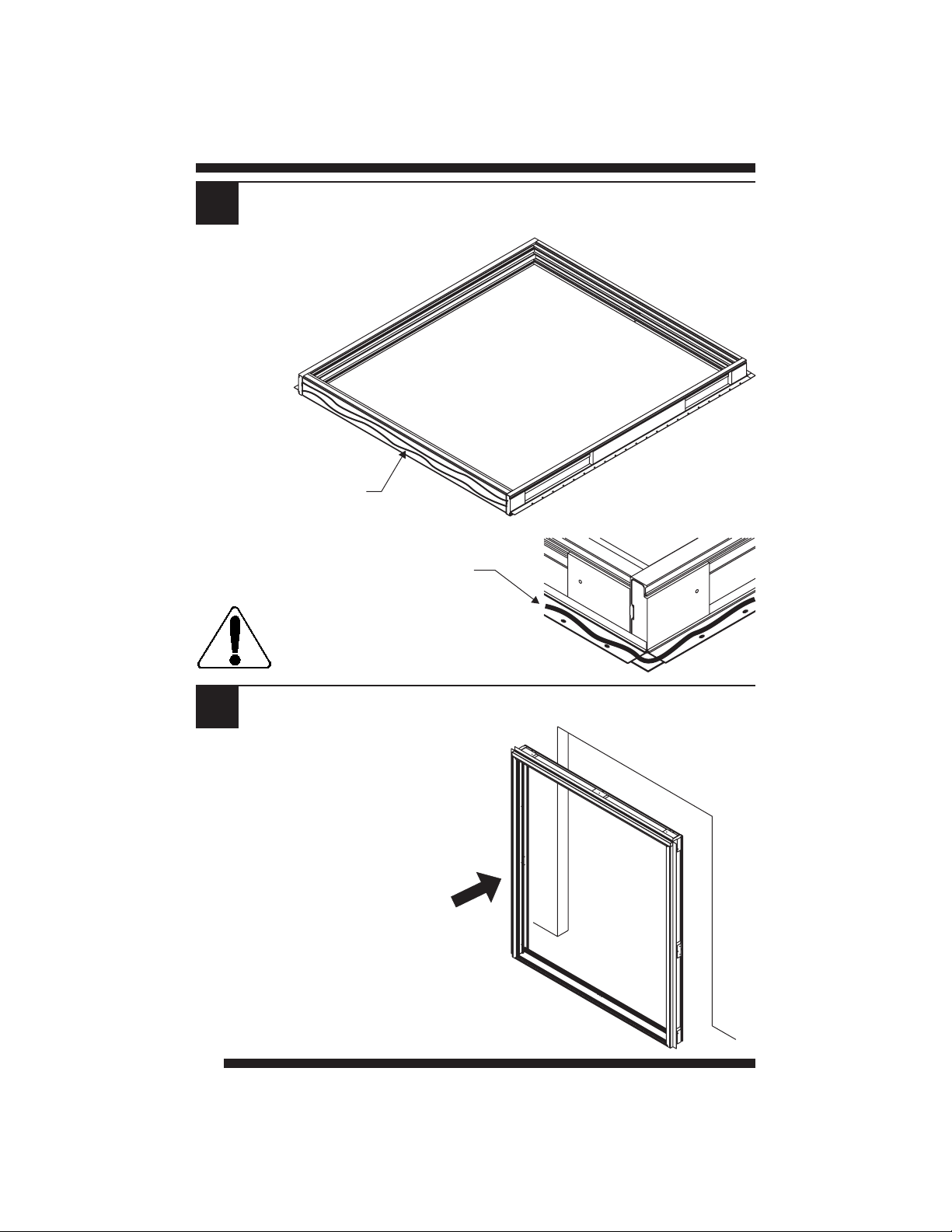

APPLY CORNER PADS TO SEALING FIN

7

Apply corner pads to

sealing fins at top corners.

5

Side jamb

Exterior

Corner pad

Wall

straight?

Check each

side both

ways.

Frame Installation

Check rough opening as follows and correct if necessary:

• Sub-floor to be flat, level, and clean. Sill must be supported throughout

its entire length.

• All four corners to be square. Check with a framing square.

• Framing and walls to be plumb. Use a 6-foot level to check both sides

of opening.

• All wall surfaces to be straight and sides parallel.

• Opening to be correct size. Allow 3/8 on sides and at head."½"

Check floor

under sill.

Wall

straight?

Check all four

corners with

square.

6

APPLY SILICONE SEALANT TO SILL AND FINS

8

Run continuous beads of sealant

across entire length of sill bottom

and around entire perimeter of

backside of sealing fin to

provide a weather-tight seal.

Sealant

Sealant

NOTE:

CONTINUOUS BEADS OF

SEALANT ARE REQUIRED.

SET UNIT INTO ROUGH OPENING

9

From outside of house, set system

into rough opening. Apply pressure

on sill to set sealant.

7

Exterior

Loading...

Loading...