Installation

Pre-Hung Unit Installation ................................ 1.3

Pre-Hung Venting Unit Installation ............... 1.11

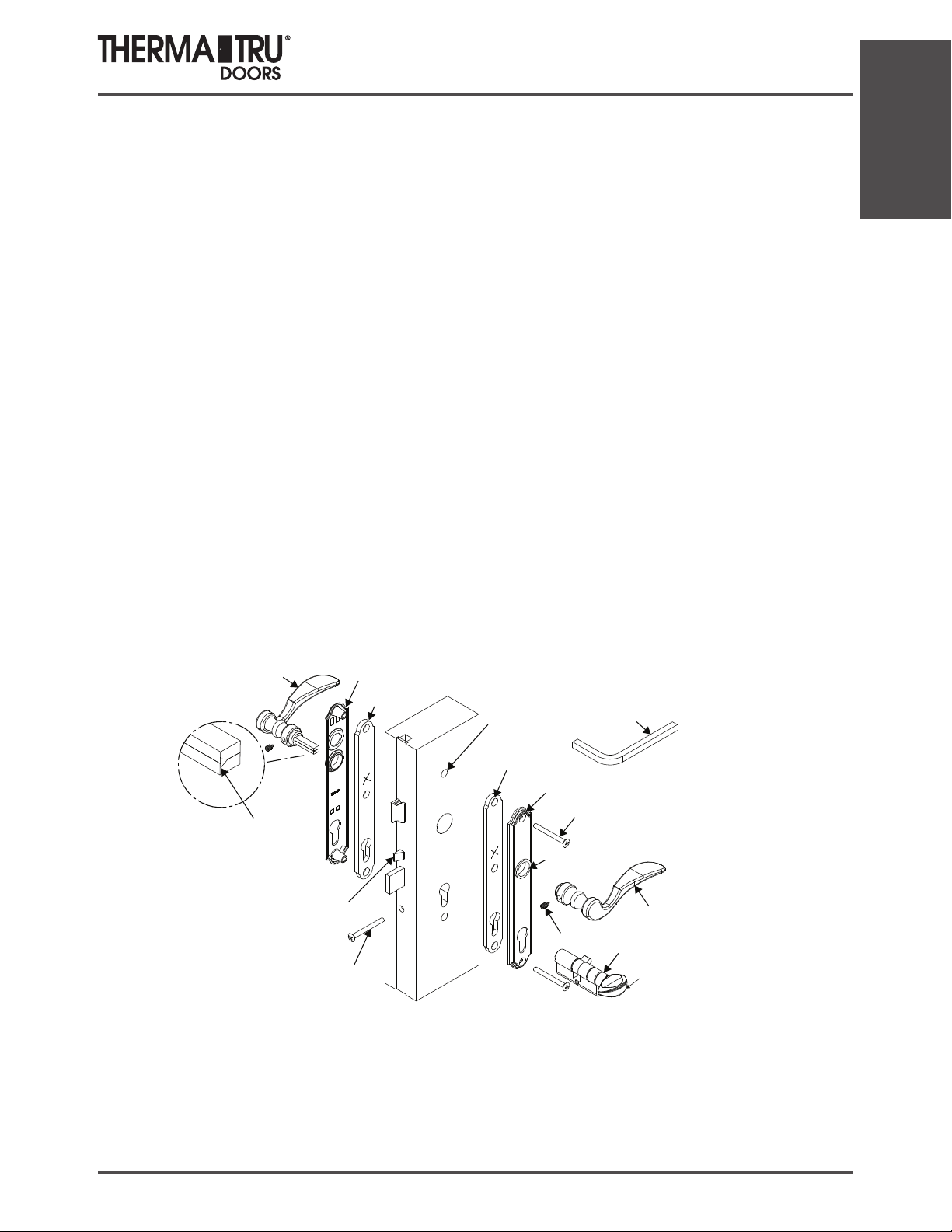

Pre-Hung Arch/Radius Unit Installation ........1.19

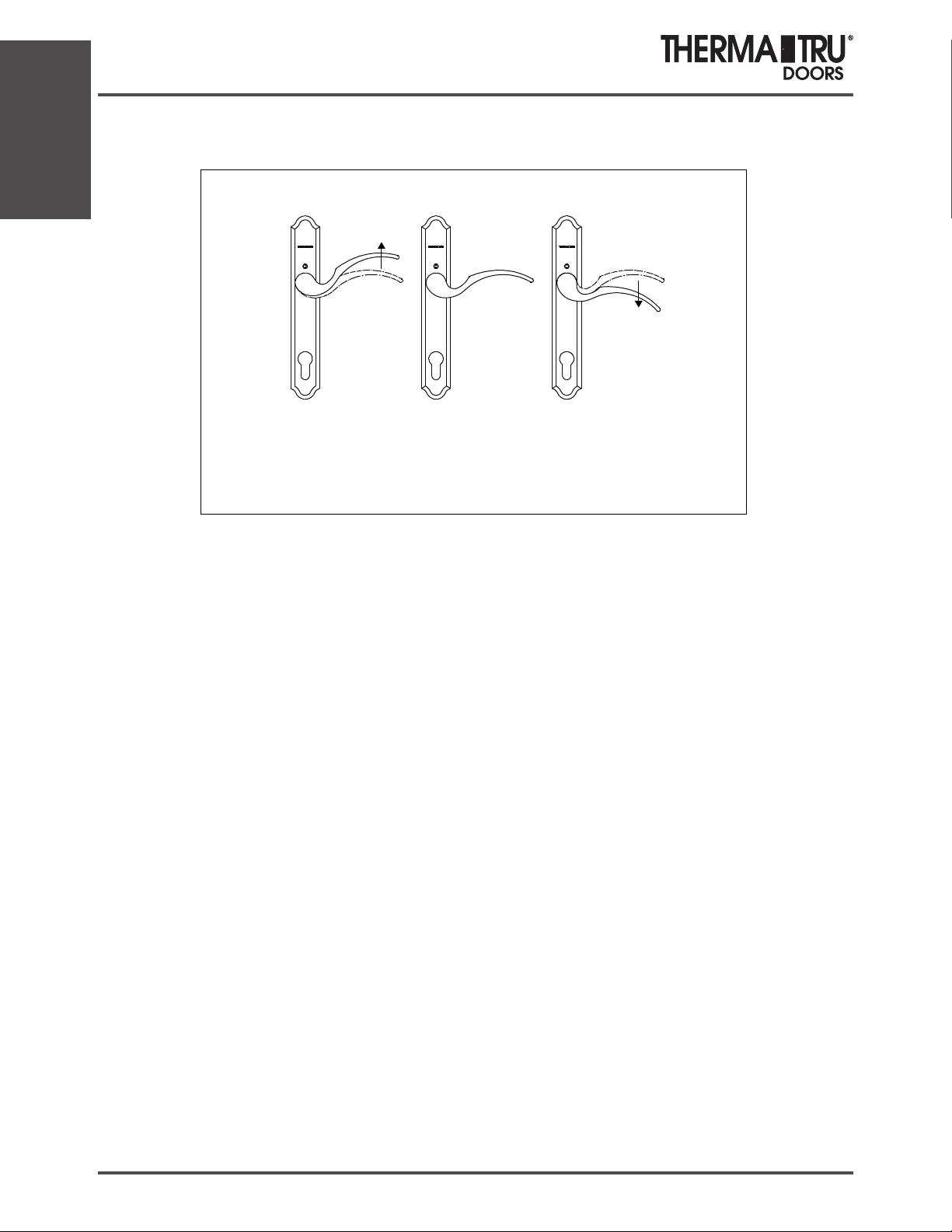

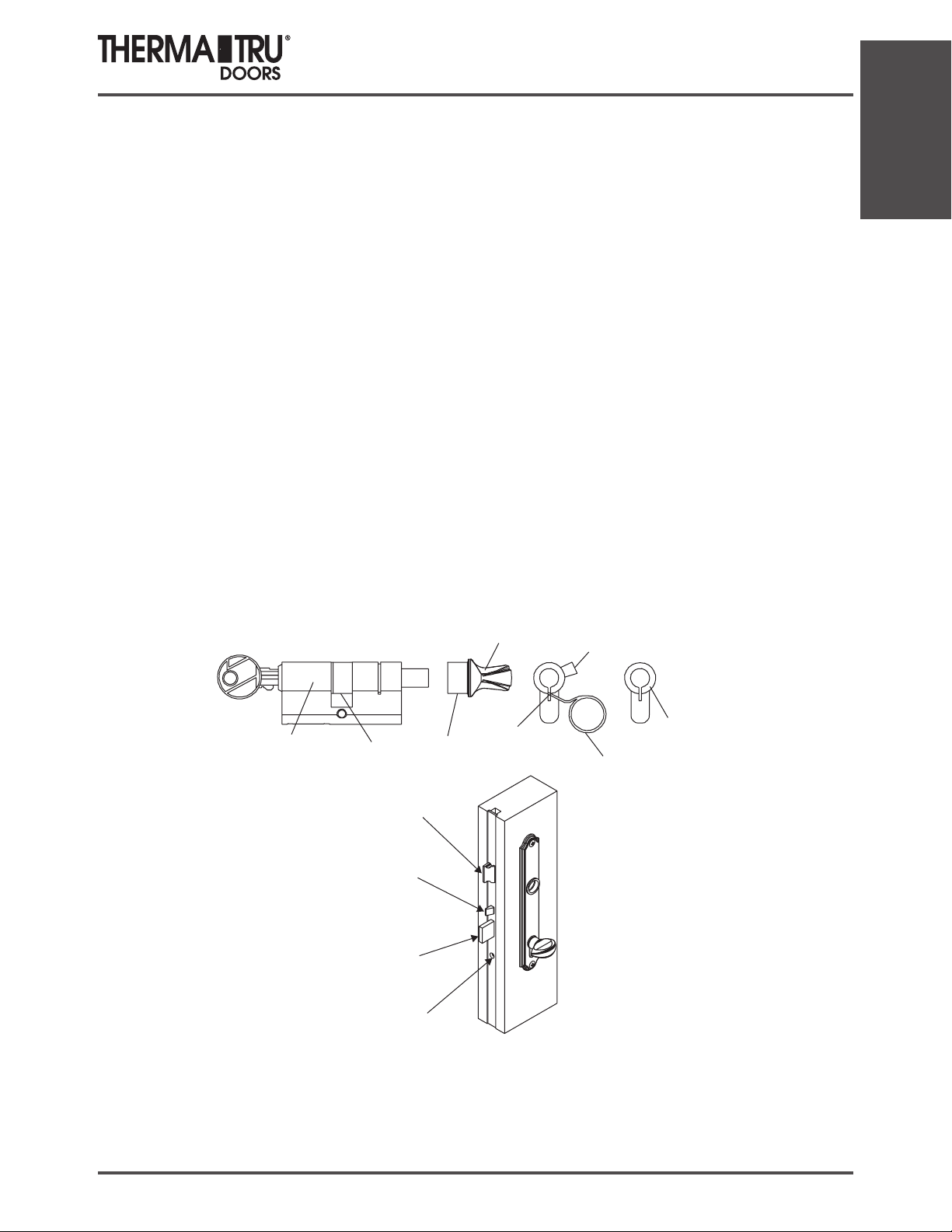

Multi-Point Lock

Quick Tip Sheet & Instructions ...................... 1.21

Sill Pan Installation Instructions .................... 1.29

Paintable & Stainable Aluminum Astragal

Site Installation Instructions .......................... 1.30

Multi-Point Shootbolt Paintable & Stainable

Astragal Installation Instructions ................... 1.33

Coastal Astragal 2 Installation Instructions .. 1.36

Multi-Point Shootbolt

Coastal Astragal 2 Installation Instructions .. 1.39

French Door System Outswing Astragal

Security Cover Installation ............................. 1.42

Transom Installation Instructions .................. 1.43

Elliptical Transom Casing Instructions .........1.55

Installation

Adjusta-Fit 2 Prehanging Instructions .......... 1.56

Sill Corner Seal Instructions .......................... 1.60

Adjustable Sill Cover Instructions ................. 1.61

Grille Installation Instructions ........................ 1.63

SDL Bar Installation Instructions ................... 1.65

Spring Hinge Instructions ............................... 1.70

Screen installation .......................................... 1.71

SITE 1 2014 1.1

Installation

1.2 2014 SITE 1

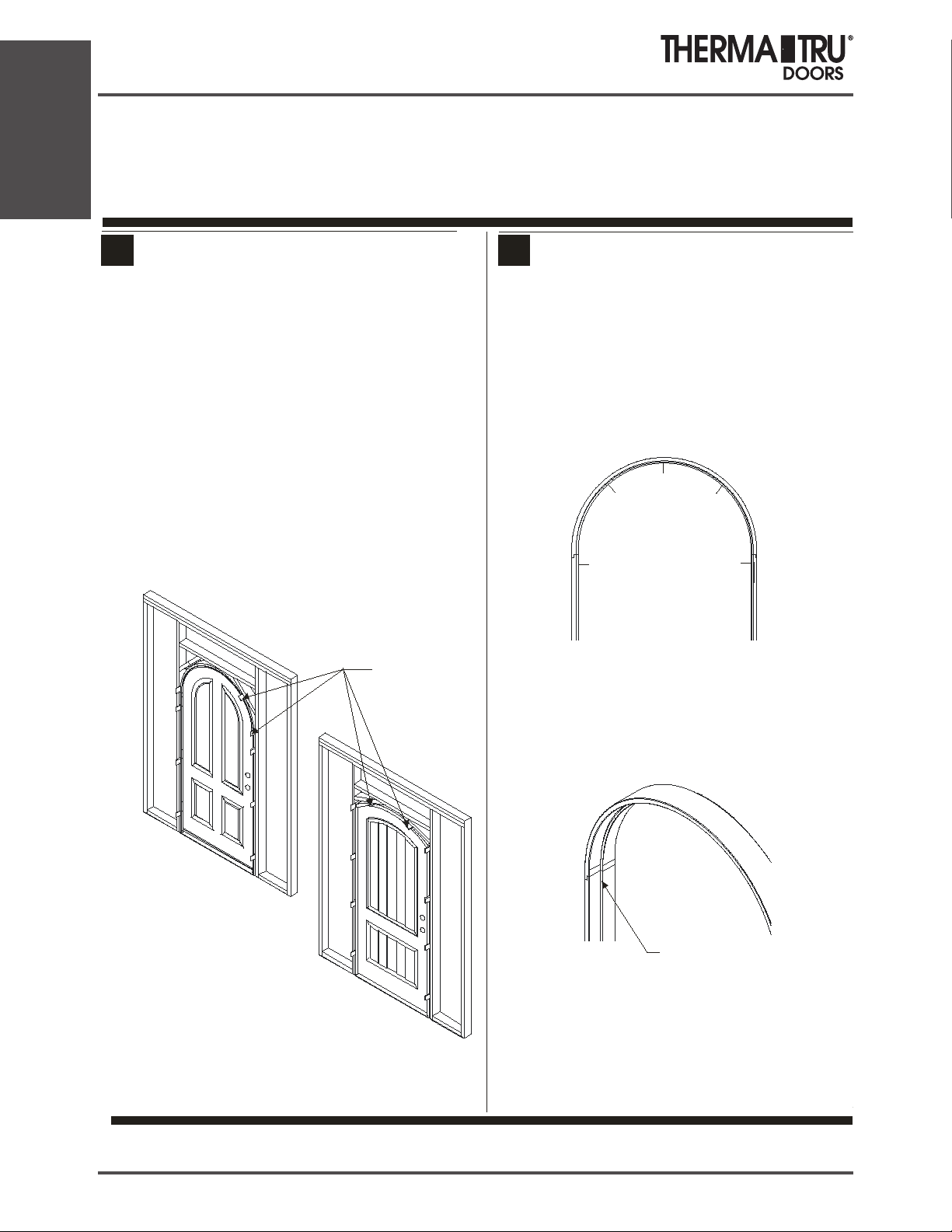

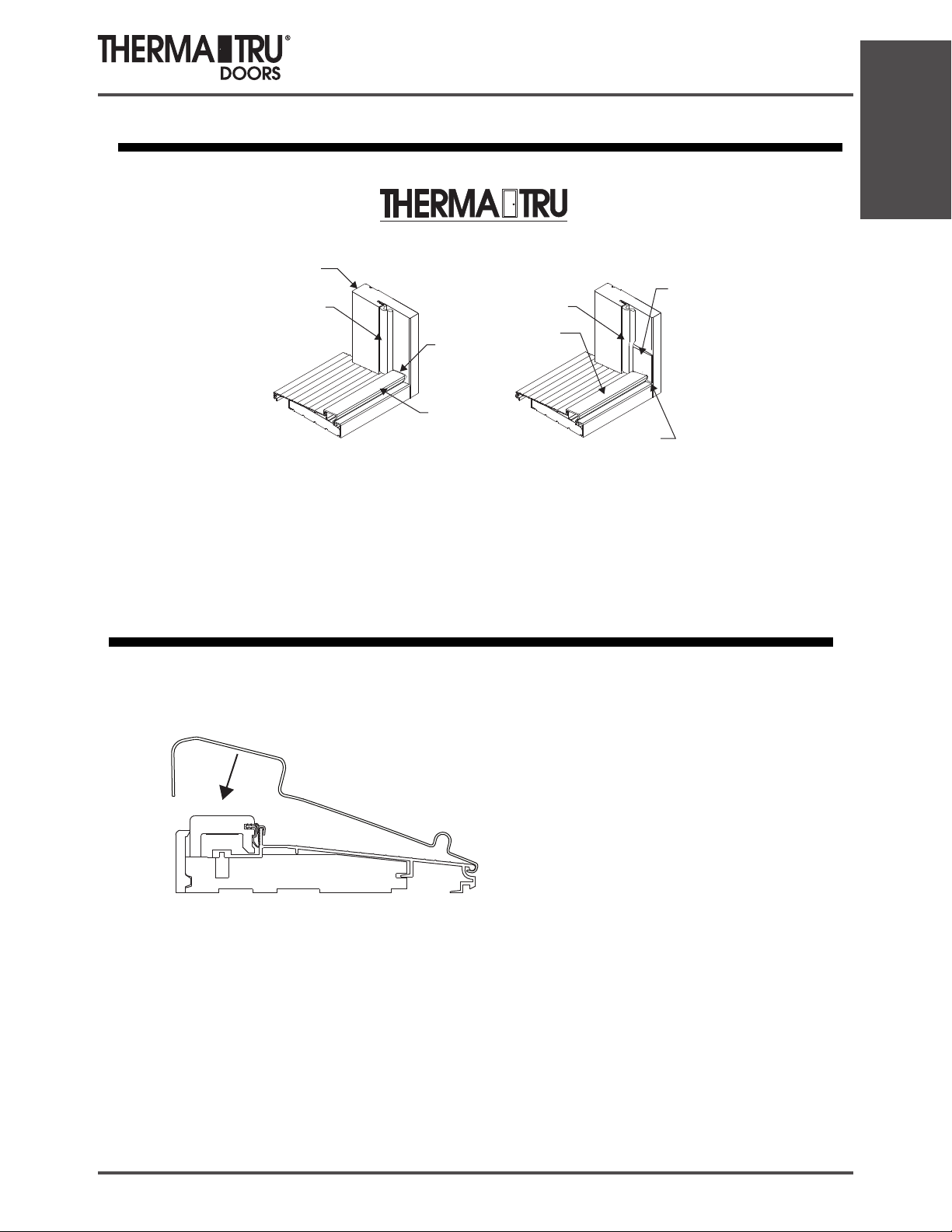

Pre-Hung Unit Installation

Builder, Subcontractor or Supplier:

Please forward these instructions to the homeowner.

The application performance standards for these products may be governed by

the International Residential Code, International Building Code and other state

and jurisdictional requirements. Copies of performance ratings are available

on our website at www.thermatru.com

.

Installation Instructions for

Pre-hung Door Systems

These installation instructions are designed to assist door installers who have

an understanding of carpentry principles, and know how to properly and

safely use power tools. The purpose of these instructions is to illustrate how

to install a Therma-Tru door system using methods and materials that help

eliminate water related leaks. If the

directions are closely followed, the door

system will have a long useful life with good resistance to rain related water

intrusion problems.

These methods are “tried and true” They are used widely by builders and

remodelers who are serious about managing and keeping water outside the

home. Rather than eliminate any steps that may be unclear to you, please call

1-800-THERMATRU and ask for clarific

ation. If you remain unclear, please

seek more professional assistance with the installation.

Different parts of the country have different code requirements, which may

not be covered in these instructions. The installer is responsible for insuring

the installation complies with local codes. If you have unique code

requirements that do not appear please contact 1-800-THERMATRU.

Required Tools

& Materials: 2 & 6 foot Levels, Hammer, Putty Knives

(firm & flexible), Framing Square, Caulking Gun, Sturdy Ladder, Shims,

Tape Measure, High Quality Elastomeric or Polyurethane Sealant, Screw

Gun/Drill -1/8 inch Drill Bit, Razor Knife, #2 & #3 Philips Bit, Stapler,

Insulating Material, Eye Protection, Water Resistive Barrier, Flashing

Material, #8 x 2-1/2 inch Exterior Grade Screws, & Optional

Sill Pan.

Read all instructions before starting.

Therma-Tru Recommended Best Practices

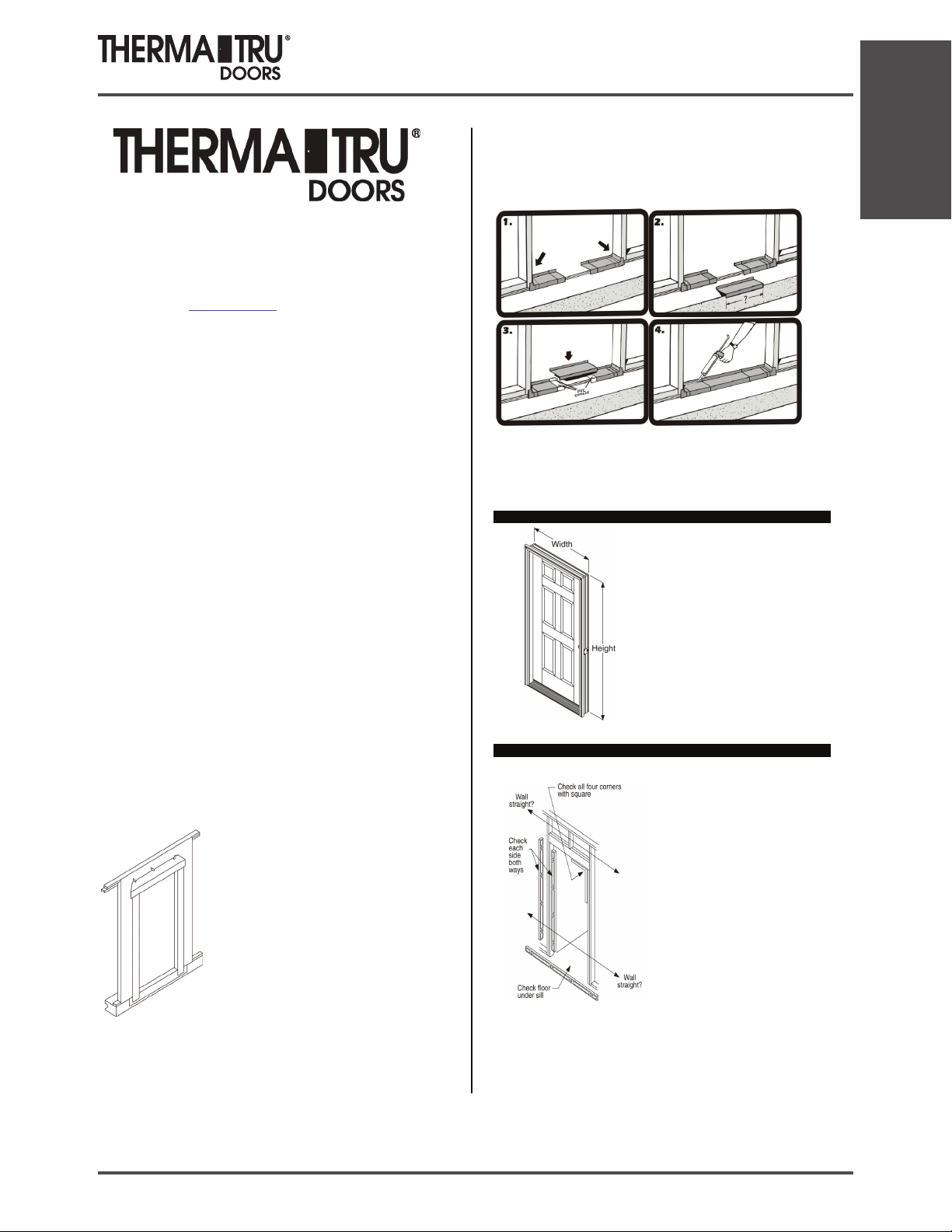

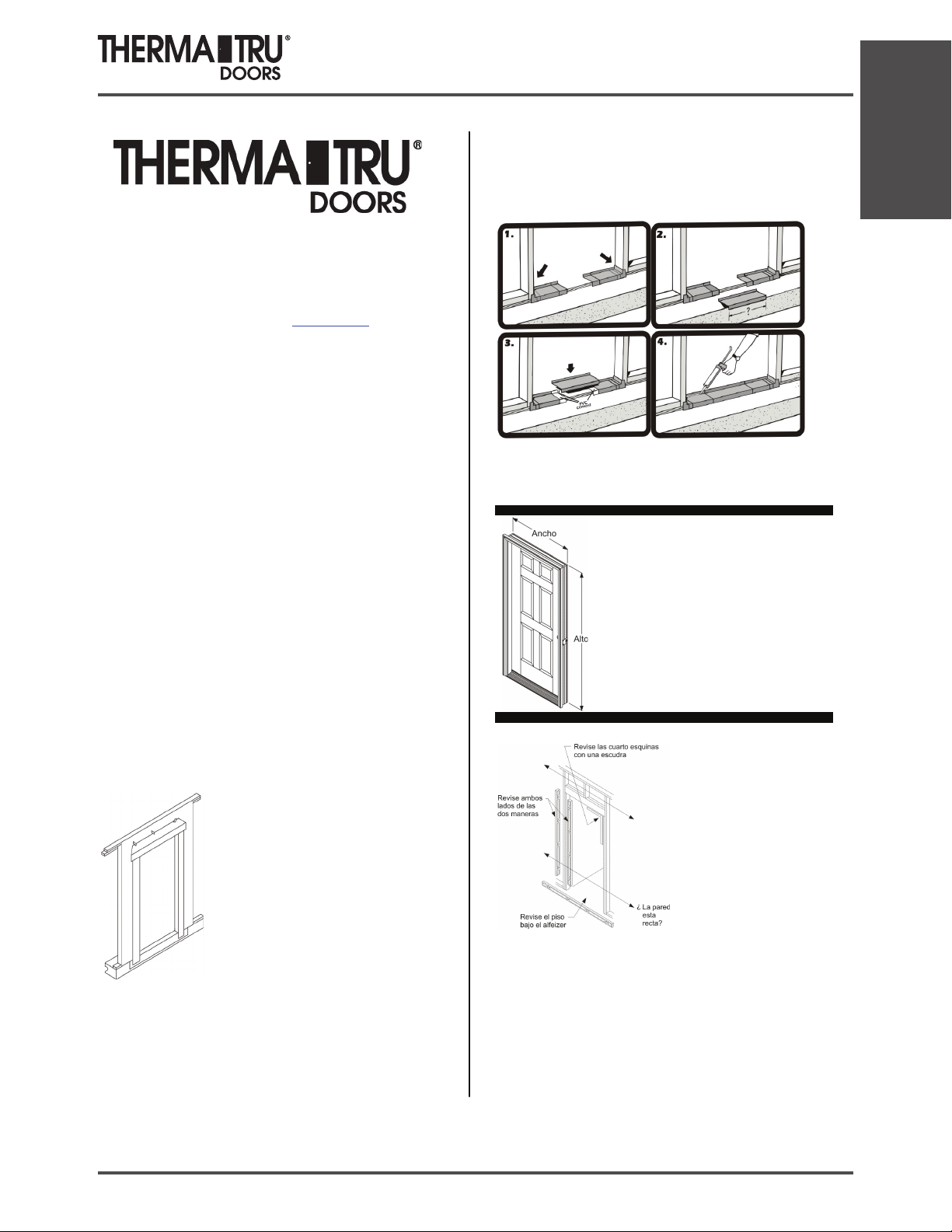

Use Water Resistive Barrier and Flexible Flashing:

We recommend the use of a Water Resistive Barrier

(WRB) applied to the exterior sheathing (OSB or

other) and the use of an adhesive or flexible flashing

product to seal around the opening. The WRB should

be cut in the opening (follow manufacturer’s

guidelin

es) with the head of the flap taped up, to be

sealed later in Step 11. The flashing should be applied

in an overlapping manner as shown, always working

from the bottom up (follow manufacturer’s

guidelines).

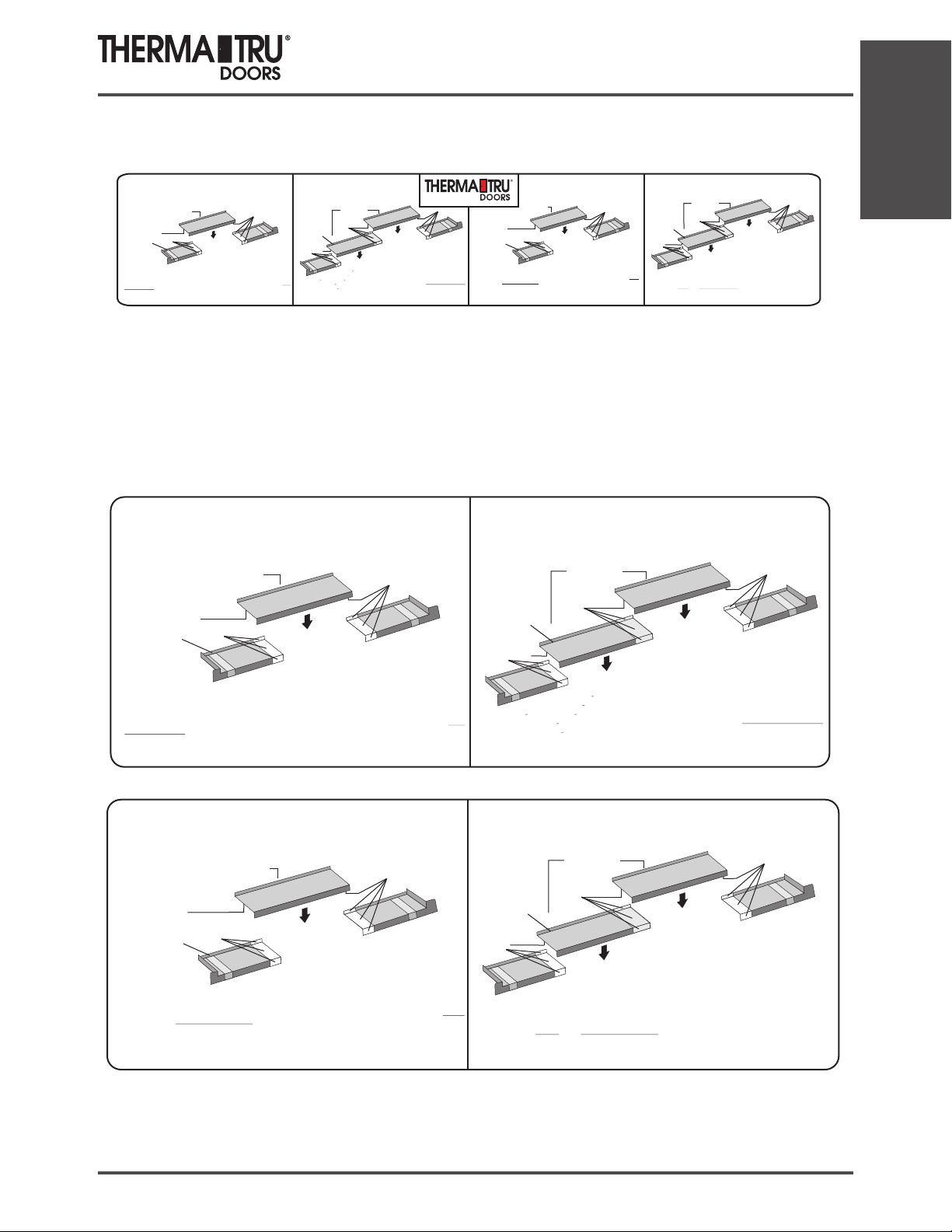

Use a Sill Pan:

We recommend you first “dry fit” the sill pan in the opening,

following the instructions furnished with the sill pan. Place the right and left

sill pan ends tight against the sides of the opening. Check the center section

for proper length and if necessary, cut with a hack saw or tin snips. Be sure to

allow 2 inches of overlap at the joints.

Note: Use only the PVC cement provided in the sill pan kit to glue the pieces

together. The sill pan must be sealed to the sub-floor using an Elastomeric or

Polyurethane sealant, but do not apply sealant to the bottom of the sill when

using a sill pan.

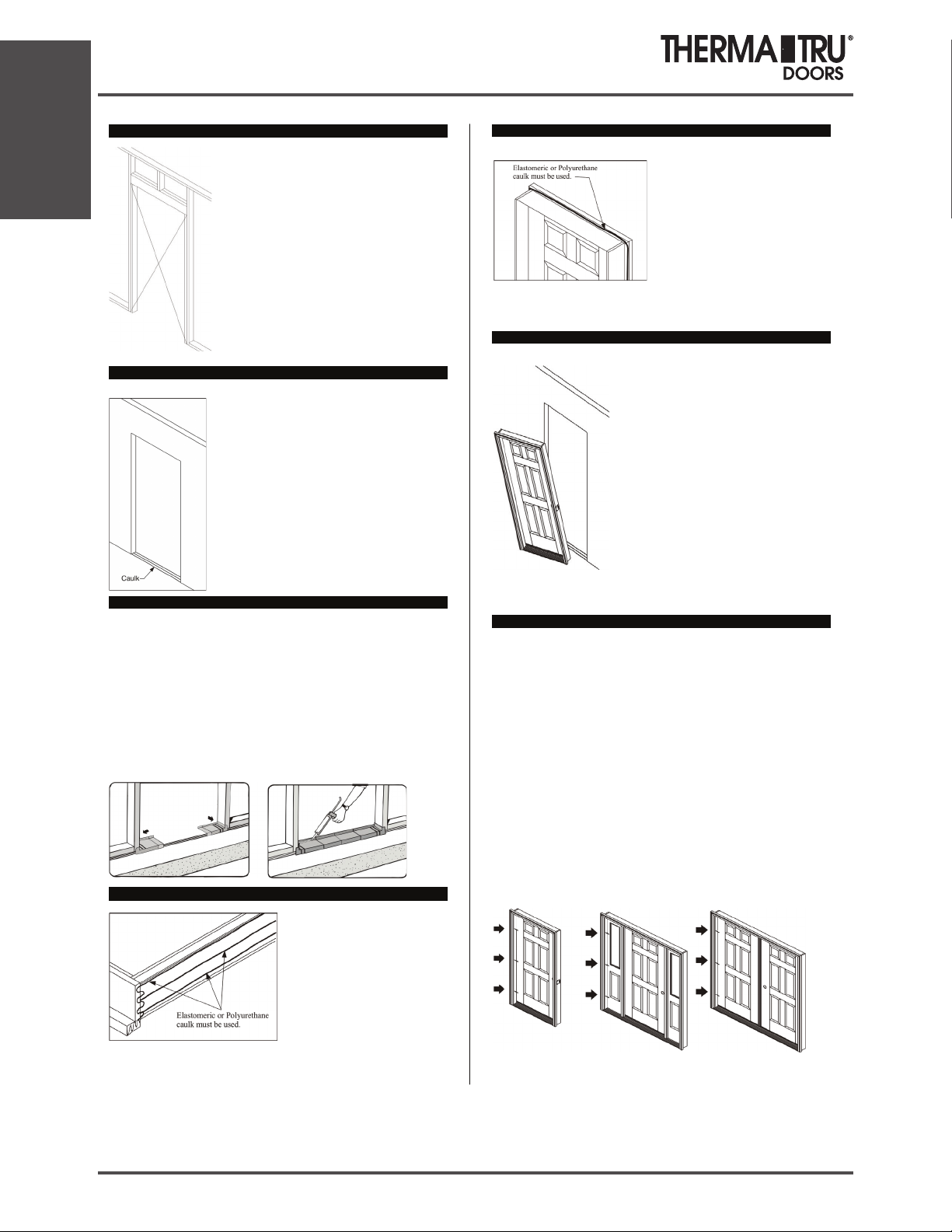

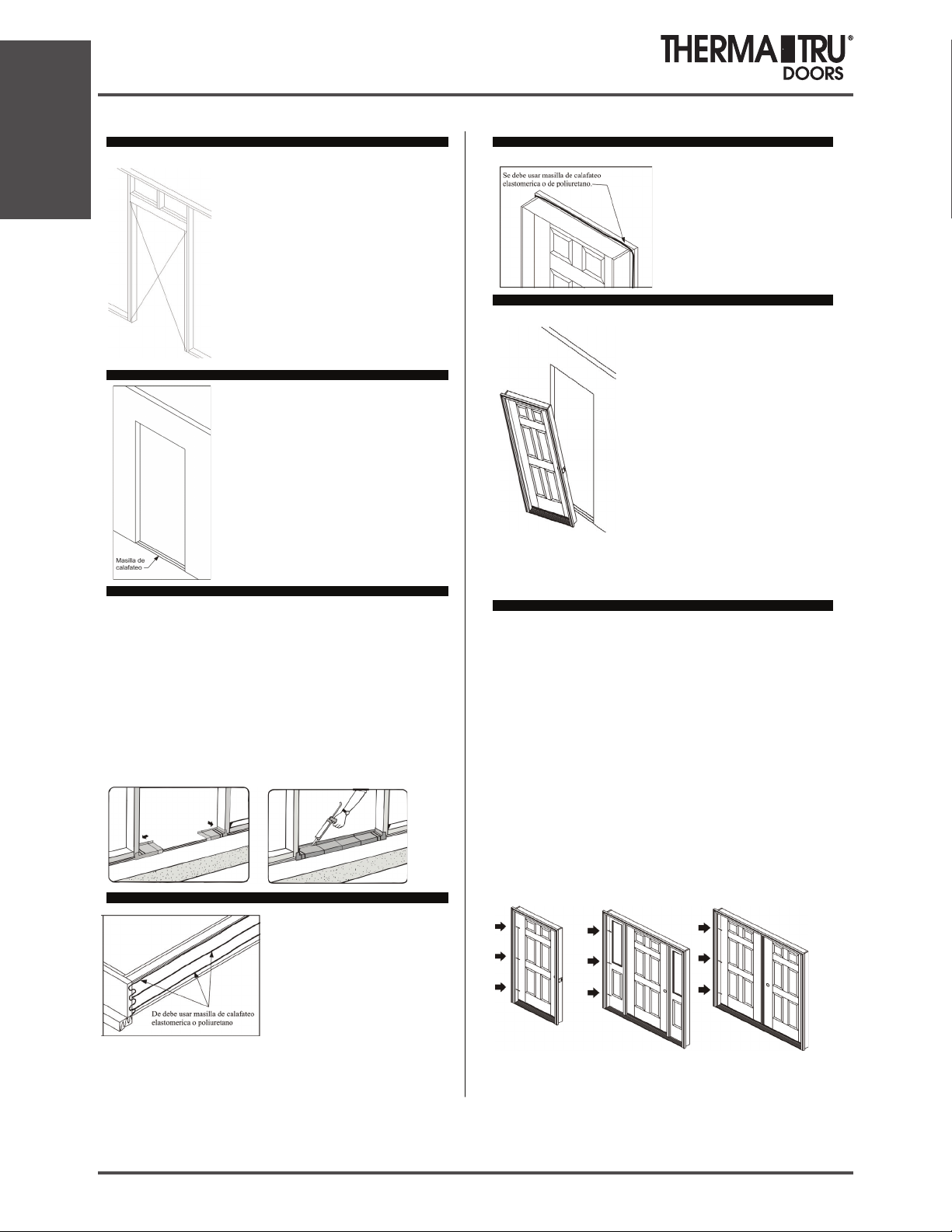

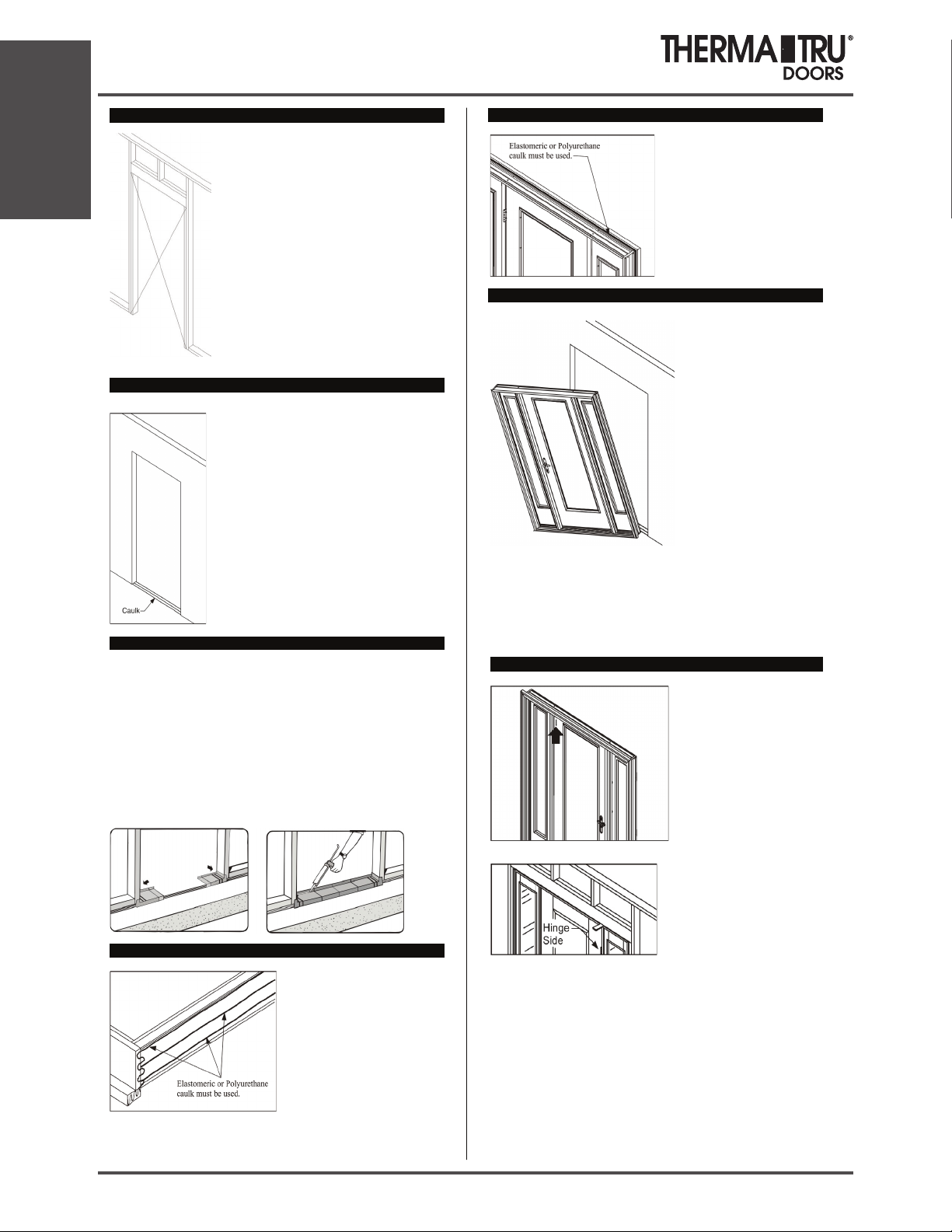

Step 1: Check Door Unit.

Check width and height.

Measure size of frame (width and height), not

brickmould.

Remove cleats and packaging, but keep door

fastened closed with transport clip. Do Not

remove the transport clip until instructed to d

o

so later in Step 7.

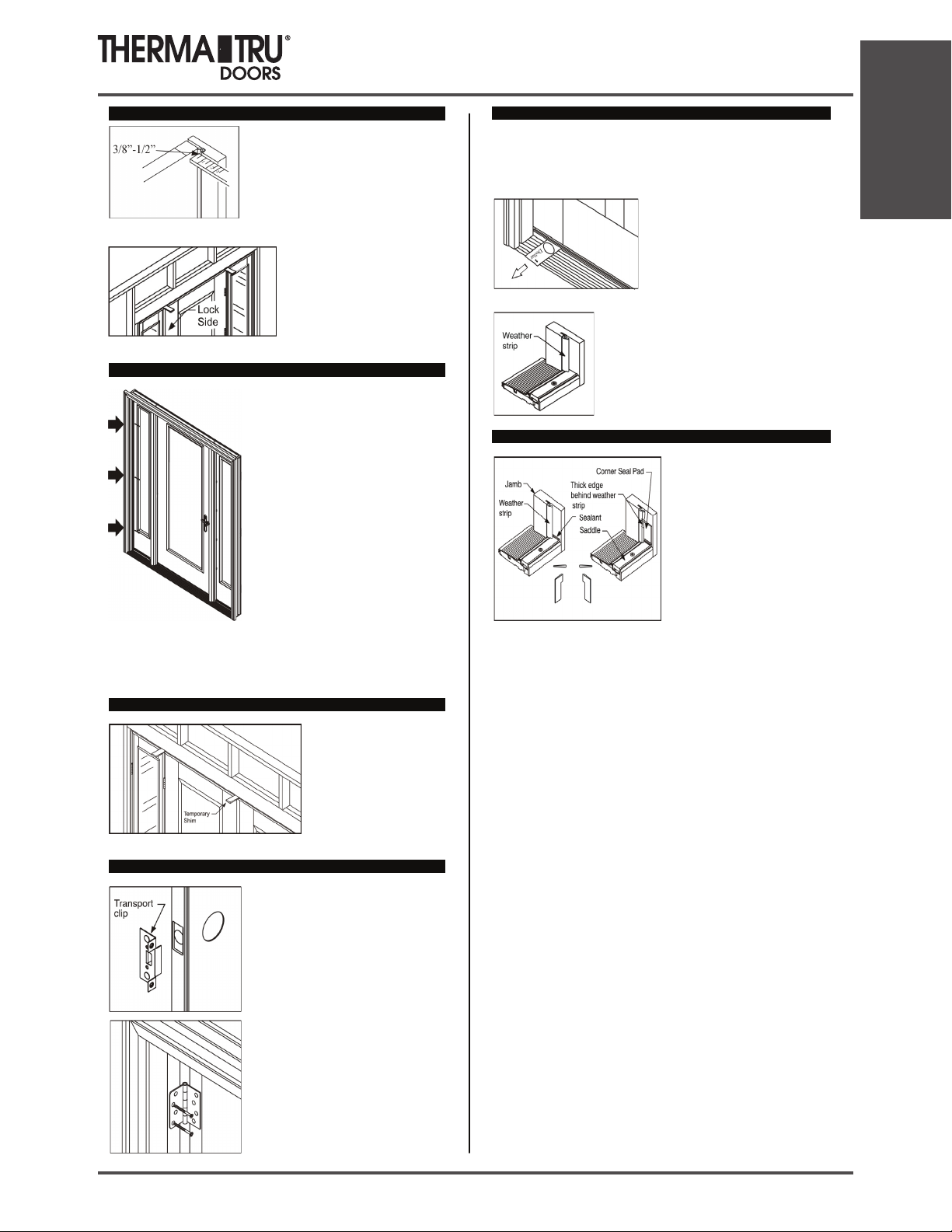

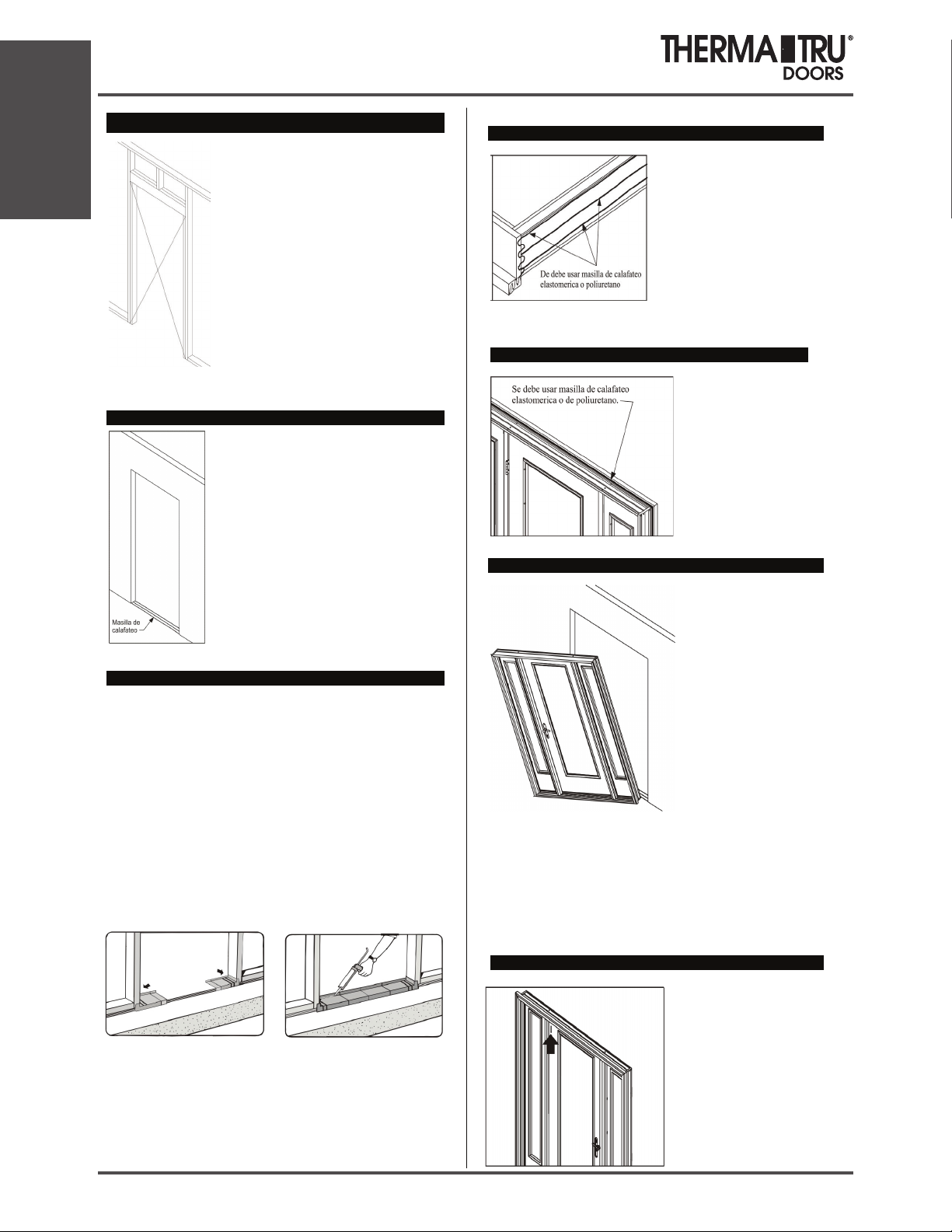

Step 2: Check and Prepare Opening.

Is the opening the correct size for th

e

door unit? Check it against the door

frame size now, before installation. The

opening should be frame height plus 1/2

inch, and frame width plus 1/2 inch t

o

3/4 inch. Fix any problems now.

Are the framing and walls PLUMB? Use

a 6 foot level and check both sides of th

e

opening, both ways (front to back and

right to left). Fix any problems now.

Is the sub floor level and solid? Provid

e

a flat, level, clean weight bearing

surface so the sill pan or sill can be

properly caulked and sealed to the

opening. Scrape sand or fill as required.

Note: If additional floor covering clearance is required, attach the shim board

to the sub floor. Be sure to caulk well under the shim board.

Is the opening square? Check all corners with a framing square. Double check

by comparing diagonal measurements. Fix any problems now.

Installation

SITE 1 2014 1.3

Installation

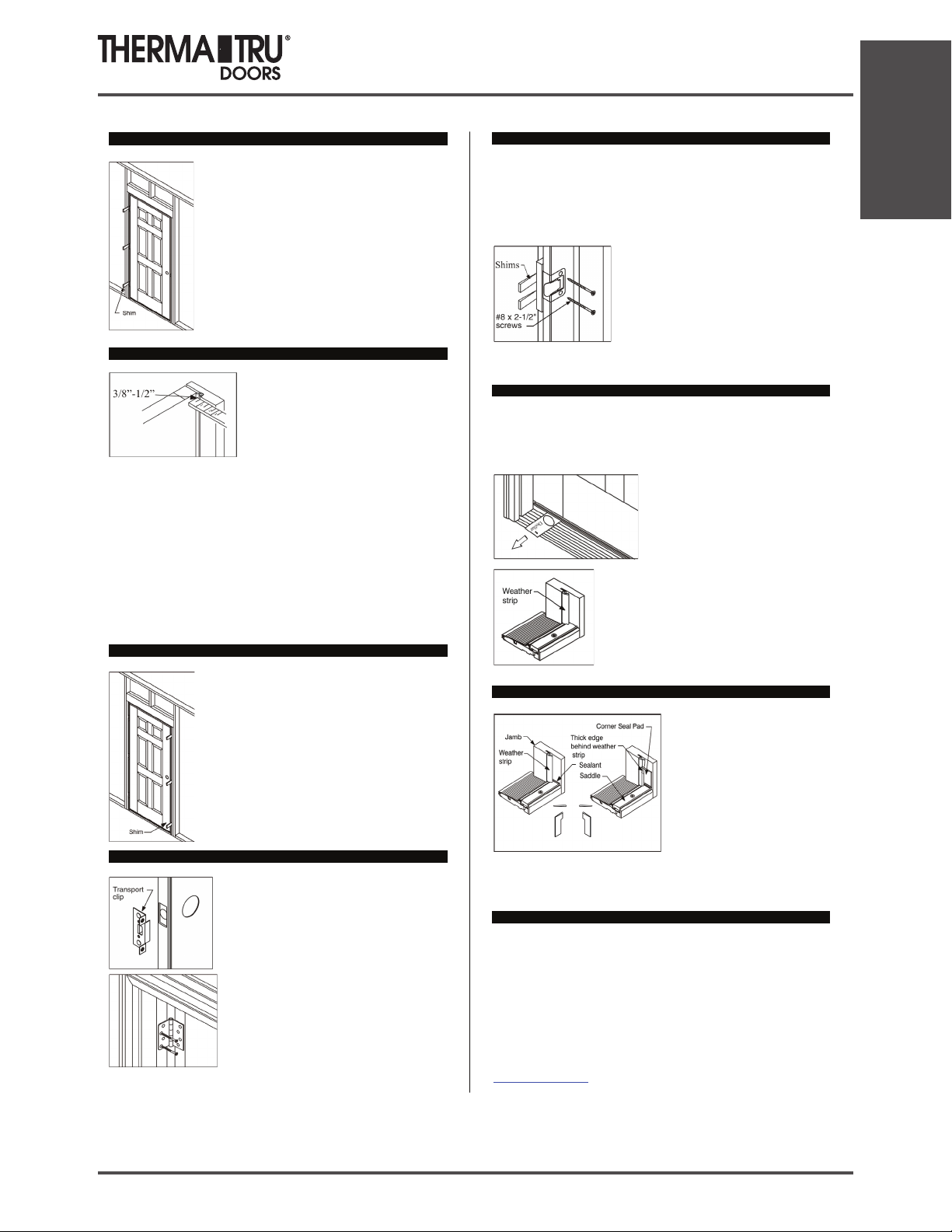

Step 2 cont.: Check and Prepare Opening.

Check to be sure the framing walls around the

opening are in the same plane. Do this by

performing a “string test” for plumb.

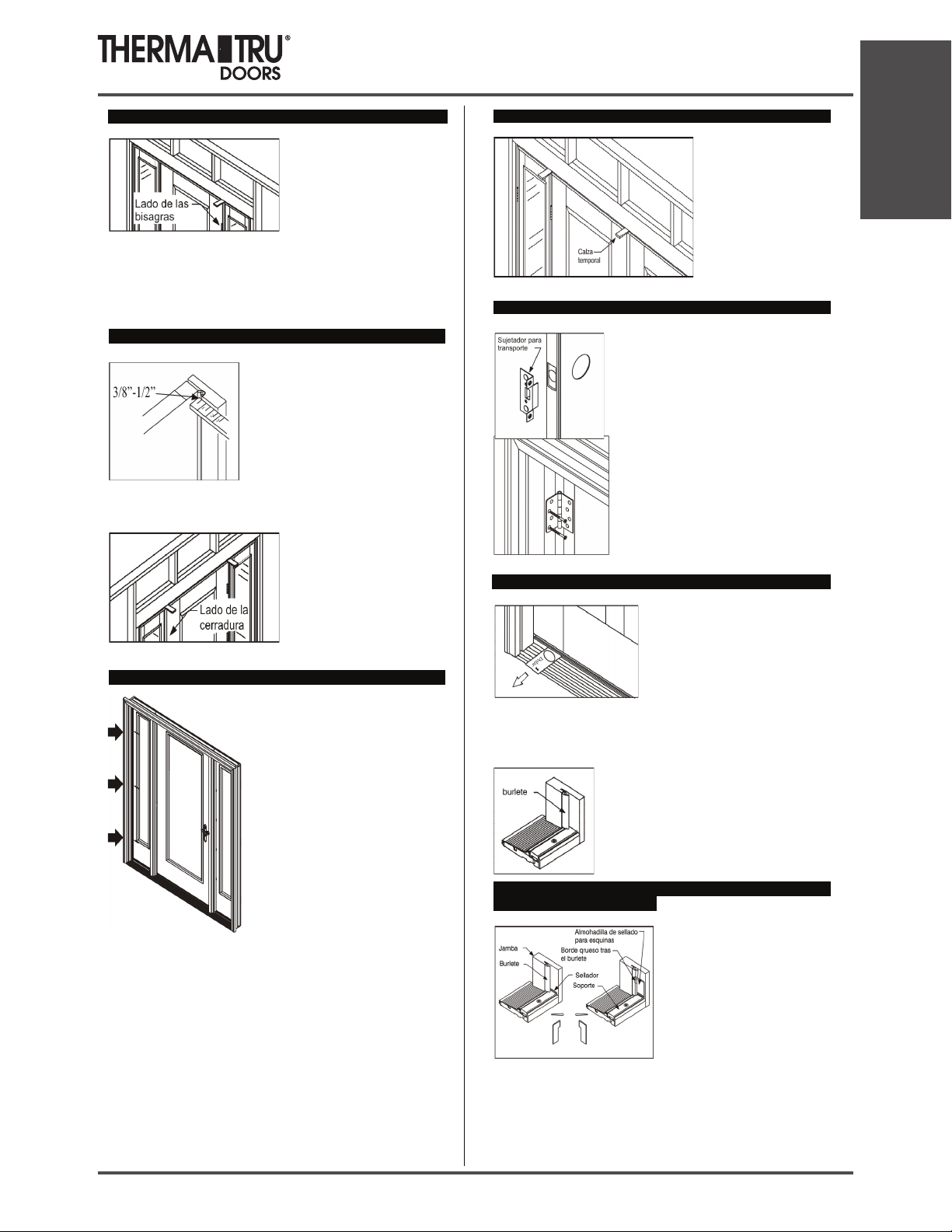

String Test for Plumb: Attach a string diagonally

across the opening from the outside, as shown. The

string(s) should gently touch in the center, if not the

opening is “out of plumb” by twice that distance

and needs to be corrected. Flip the string over

itself to check

both planes. Fix any problems now.

*An “out of plumb” condition is one of the most

common reasons door units leak air and water.

Step 3: Caulk the Sub Floor.

On the sub floor at opening, place 3 very large beads

of sealant. Run beads full width of the opening.

Use Only Elastomeric or Polyurethane sealant.

Use an Entire Tube when Caulking along the Sub

Floor.

Step 3A: Installation with a Sill Pan.

Place the right and left sill pan ends onto the caulk beads and tightly against

the side of the opening.

Then, liberally coat the overlapped areas and the recessed areas of the pieces

with the PVC cement provided. Place center section(s) in position and hold

pieces together long enough to ensure a good bond.

For added protection, spread a bead of caulk al

ong the glue joints and to

prevent air infiltration, run a bead of caulk along the lower interior edge of the

sill pan. Additional caulking could affect the performance of the sill pan.

Do Not Caulk the bottom of the Sill when using a sill Pan.

Step 3B: Installation without a Sill Pan.

Lay the door unit on edge or face so

that the bottom surface of the sill

can be caulked. Place very large

beads of caulk across the full width

of the sill. Additionally, place beads

of caulk along the junction of the

sill and the jamb and on the bottom

surface of the jambs and

brickmould.

Note: If a sill extender is used, place a large bead of caulk at the junction of

the extender and the sill approach.

Step 3 cont.: Caulking Back side of Brickmould.

Important!

Apply sealant to the back side of

brickmould around the entire perimeter

of the door unit. A 1/2 – 5/8 inch bead

of Elastomeric or Polyurethane caulk is

essential.

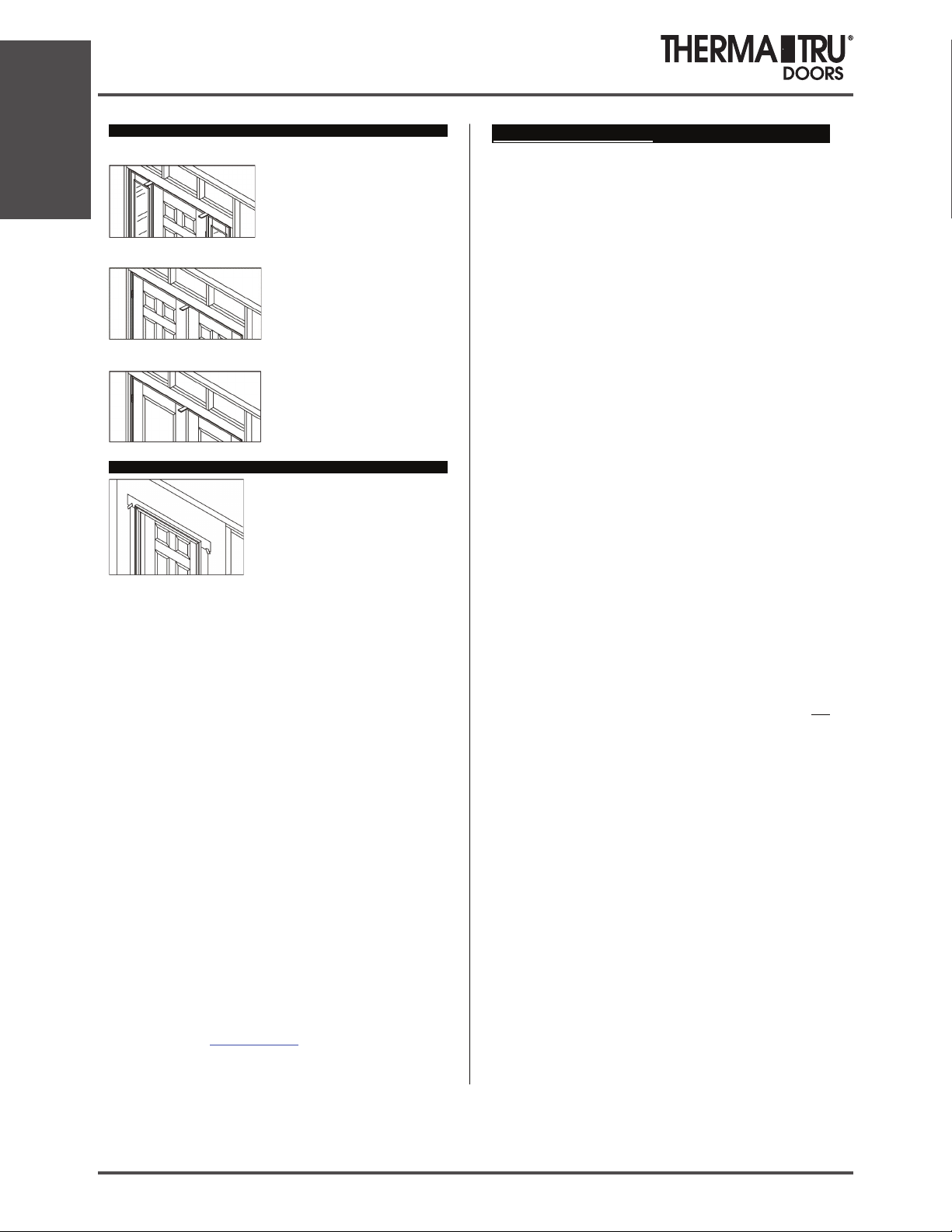

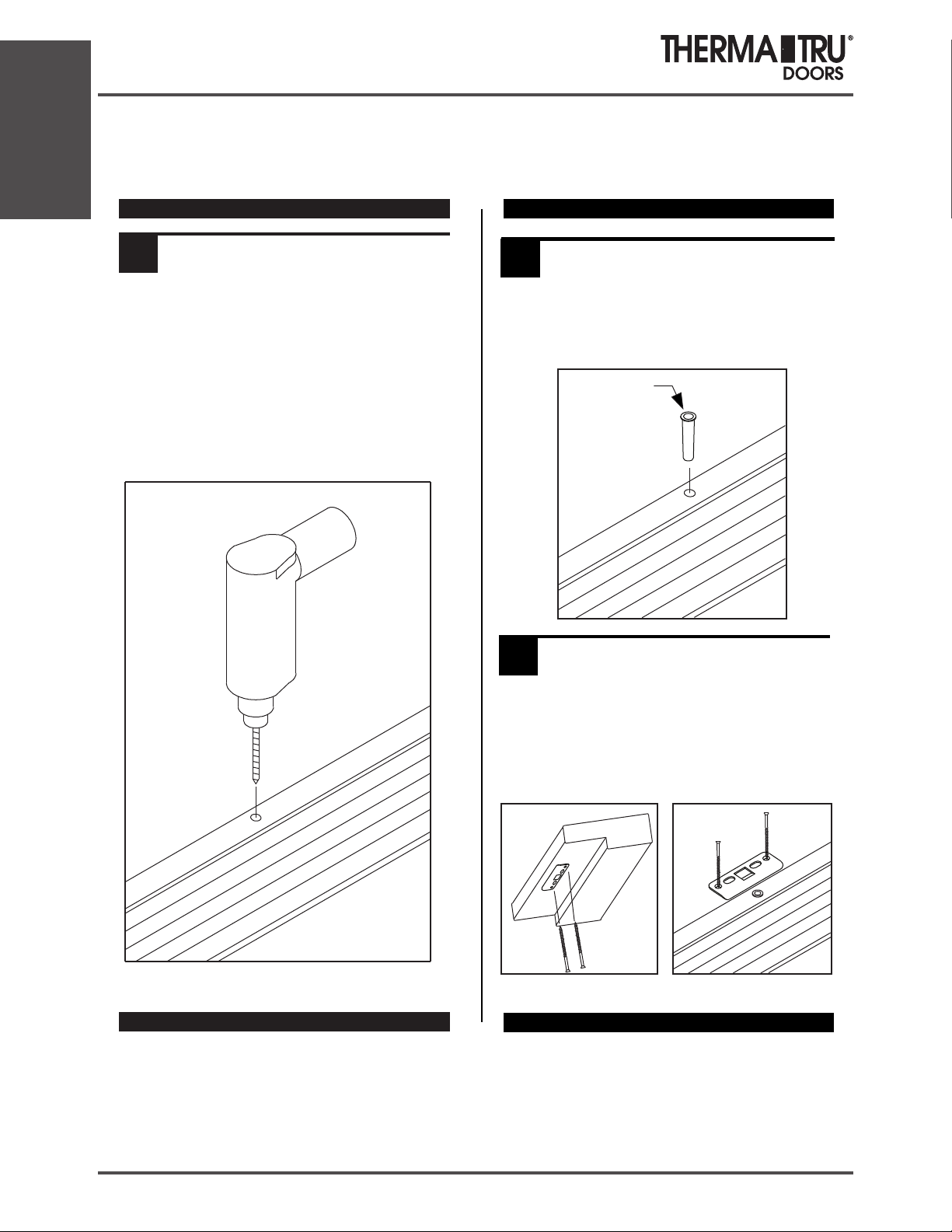

Step 4: Place Unit in Opening and Temporarily Fasten.

Lift the unit up. With top edge tilted away from

opening, center the unit and place sill down onto

sill pan or caulk beads and tilt into opening.

For all door unit configurations, note the hinge

locations and mark those locations on the jamb

faces near the door surfaces. Pre-drill 1/8 inch

diameter holes at these locations for screw

placement. A counter sink bit will help to

conceal the screw heads.

Install screws in the center pre-drilled hole

locations on both jambs to temporarily secure

the unit in the place. Do not drive screws

completely in at this time. Use #8 X 2-1/2 inch

or 3 inch exterior grade screws.

Do Not Fasten through the Brickmould.

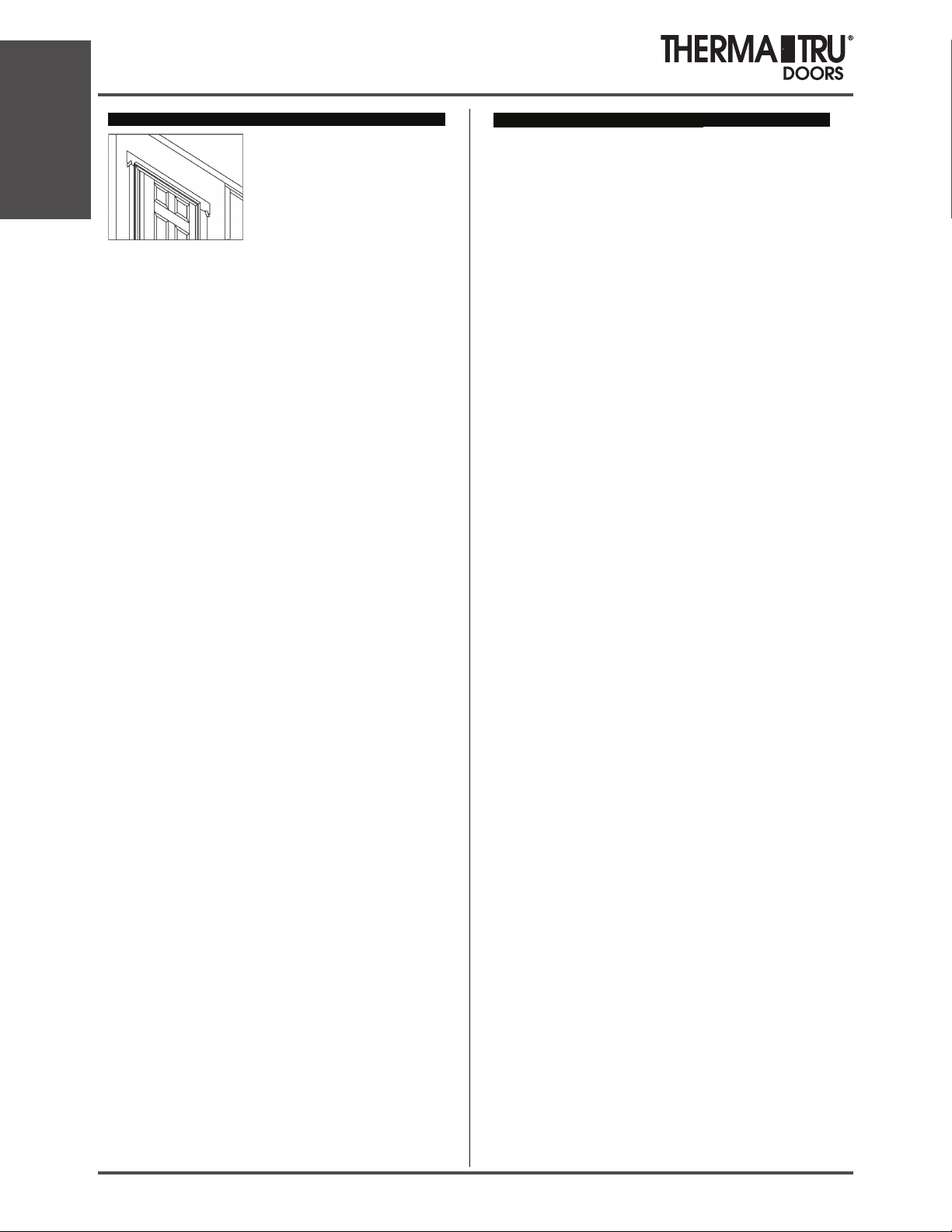

Step 4 cont.: Plumb Hinge Side Jamb.

Work from side of the door that is weather-stripped.

Use a 6 foot level and plumb the hinge side jamb both ways (right to left and

inside to outside).

Place screws through the hinge side jamb into the studs, at each remaining

hinge location, as shown in the diagrams. Use #8 X 2-1/2 inch or 3 inch

exterior grade screws.

Do Not drive the screws completely in at this time.

For Single or Double Doors, place screws at each hinge location, so shims can

be placed behind hinges above screws. The screws will keep the shims from

falling down while adjustments are being made.

For Sidelite units, fasten the jamb on the hinge side of the door.

For Double Door and Patio Units, fasten the fixed or passive side of the unit

first.

Single Unit Sidelite Unit Double Unit

Pre-Hung Unit Installation

1.4 2014 SITE 1

Pre-Hung Unit Installation

Step 5: Shim at Hinge Locations and Secure Hinge jamb.

Leave door fastened and closed with transport clip.

Shim above screws, behind each hinge location,

between the opening and the jamb.

Use a 6 foot level and re-check hinge jamb to ensure it

is plumb and straight.

Finish driving screws tight in the middle first then top

and bottom last.

Step 6: Adjust Rest of Frame and Fasten.

From the weatherstrip side of the door, check

weatherstrip margins and contact.

Make frame adjustments so the weatherstrip

contacts the door surface equally at the top,

middle and bottom, an even 3/8 inch to 1/2

inch when fully closed.

Secure the lock side jamb with #8 X 2-1/2 or 3 inch screws through the predrilled holes at the top and bottom. Do Not

drive screws tight at this time.

From the swing side of the door, shim above the screw locations and make

adjustments so the margins between the door and frame are even top to

bottom.

Note: For Double Doors, make adjustments that effect the alignment, margins

and weatherstrip contact between the doors. Also follow the Astragal Site

Package Instructions for details on properly setting the slide

bolt hole

locations.

Step 6 cont: Adjust Rest of Frame and Fasten.

Re-check everywhere for plumb and square, and an

even weatherstrip contact.

Finish driving all screws tight.

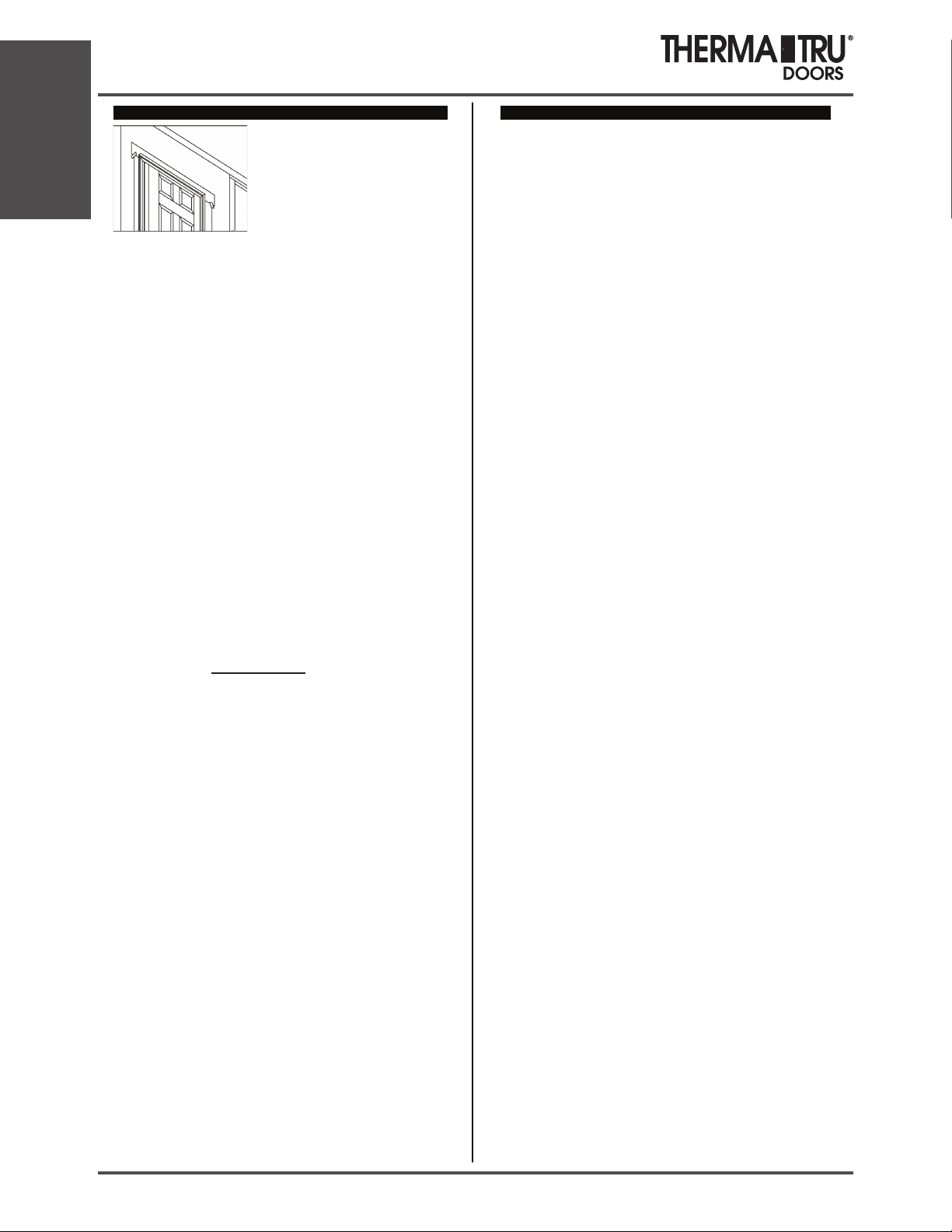

Step 7: Remove Transport Clip and Open Door.

Remove the transport clip.

Open and close door to check for smooth

operation.

With the door open, drill 1/8 inch diameter pilot

holes in the top hinge in the 2 screw hole

locations closest to the weatherstrip. Then, install

the #10 X 2-1/2 inch screws (provided) through

the hinge, into the stud, to anchor the door frame

and prevent sagging.

Step 7 cont.: Remove Transport Clip and Open Door.

For Sidelite and Patio Units: With the door open, check to determine if the 21/2 inch long hinge screws were pre-installed in the hinges. If not, drill 1/8

inch diameter pilot holes and install the long hinge screws in the hole

locations closest to the weatherstrip.

Close the door and carefully shim between the jamb and the opening behind

the adjustable strike plate area.

Then open the door and drill 1/8 inch dia. pilot

holes and install the #8 X 2-1/2 inch screws

(provided) through the strike plate holes to

secure the lock side jamb and provide security.

Adjust strike plate in or out for proper

weatherstrip contact and door operation, then

finish tightening screws.

Step 8: Adjust Sill.

Your door unit may have an adjustable threshold cap. When properly

adjusted, it should be snug and slightly difficult to pull a dollar bill out from

under the door when it is fully closed. The dollar bill should be able to be

removed without tearing.

This check should be performed at each

adjustment screw location.

After adjusting the threshold cap, ensure that the

weatherstrip is flush with the top of the threshold

cap. Trim as necessary.

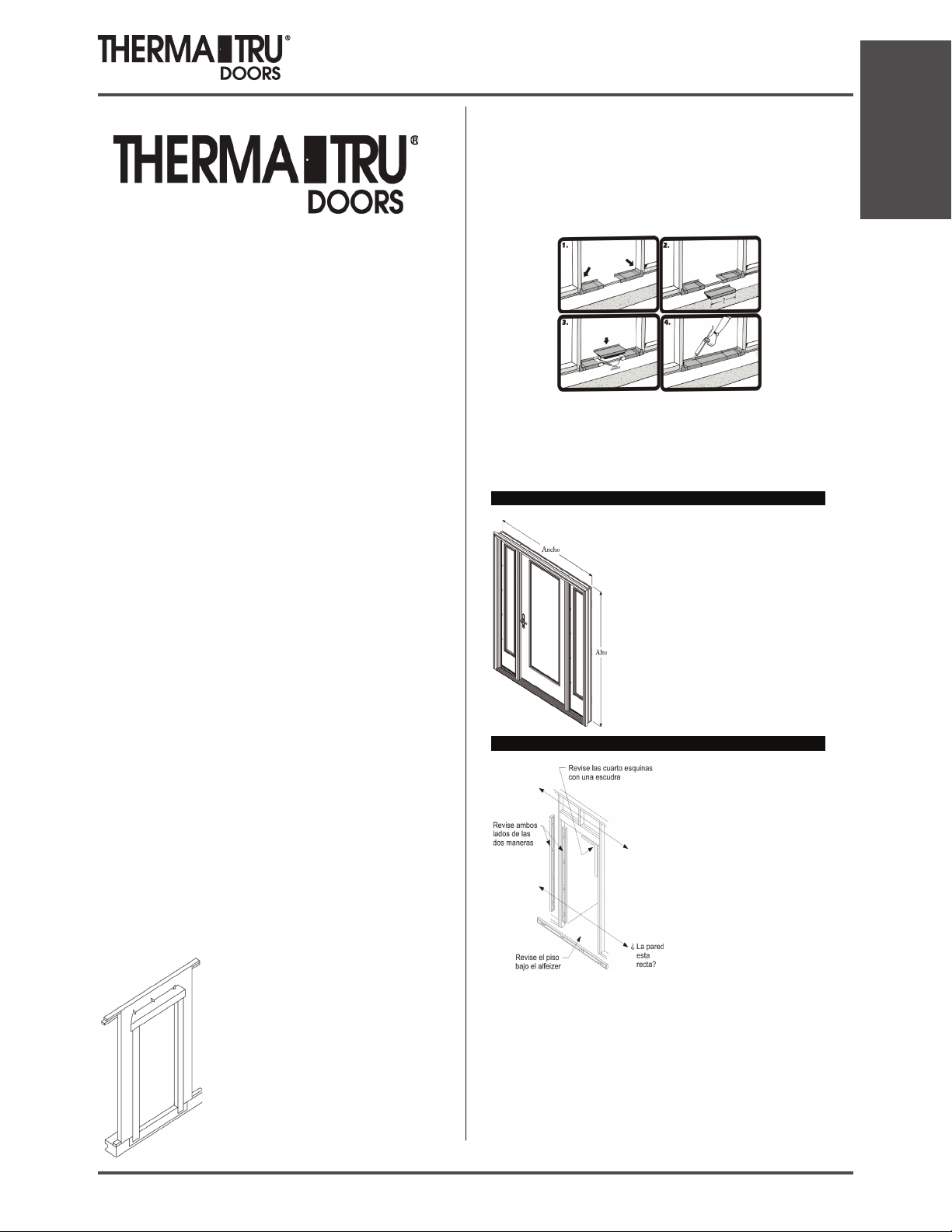

Step 9: Install Corner Seal Pads – Inswing units Only.

Apply sealant (Polyurethane or

Elastomeric) at the joint where the

threshold cap meets the door jambs.

Remove the self-stick paper from

the corner seal pads and apply to the

door jamb, with the bottom lined up

evenly with the top of the threshold

cap. When the pad is correctly

installed, the tab is on top and the

narrow part is on the bottom.

The bottom of the pad is the same width of the threshold cap to help with

alignment during installation.

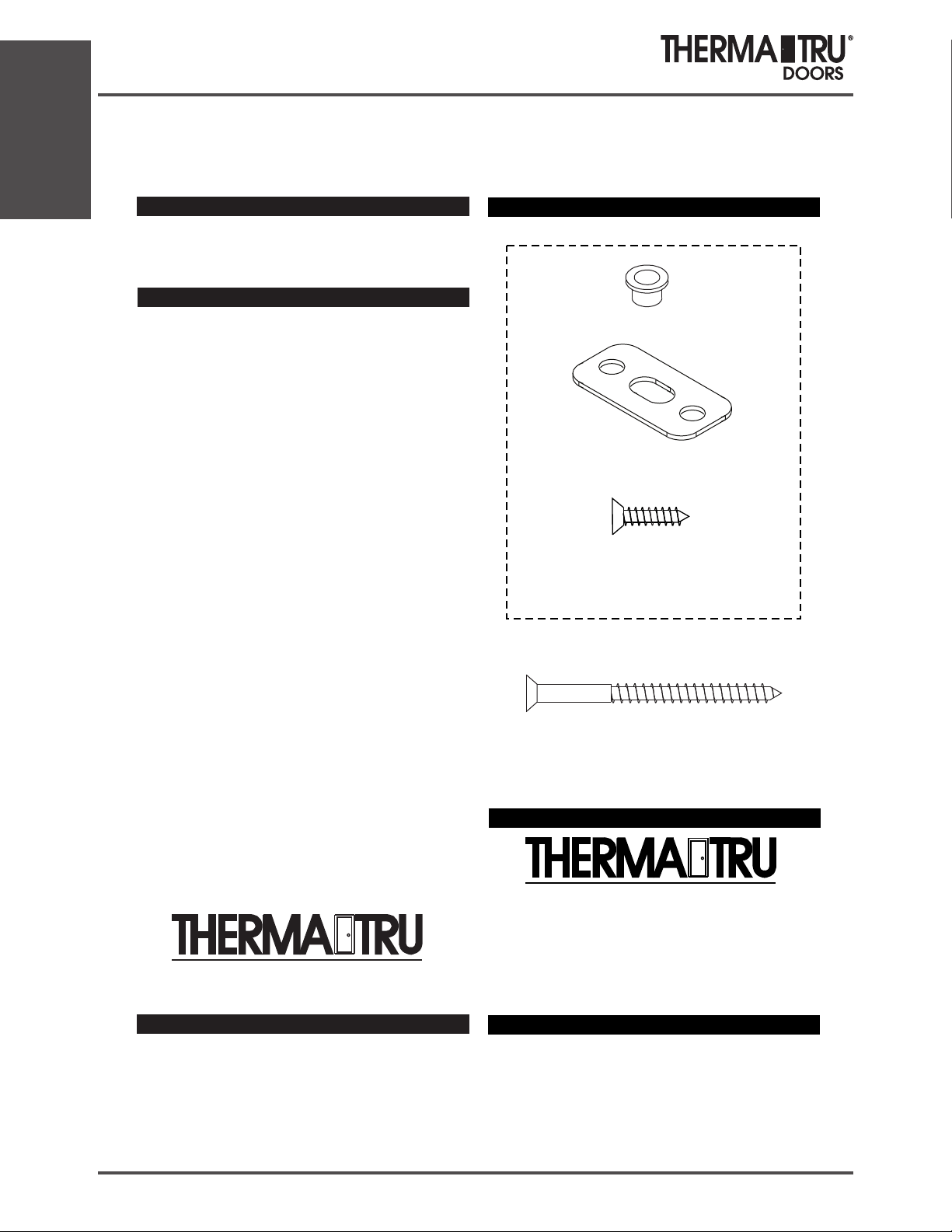

Step 10: Additional Frame Anchoring.

If sill is prepared for anchoring screws, place appropriate screws through

the sill into the sub floor where needed. (Primarily on Outswing Sills)

We recommend that you provide additional frame anchoring as shown

here. Certain states or jurisdictions, notably Florida and the coast of

Texas, have specific installation requirements and may require

installation in strict accordance with the product approval for a specific

product. You should always check with the local authority having

jurisdiction for any specific installation requirements that may apply.

Specific product approval installation instructions, including those

required for the High Velocity Zone (HVHZ), are also available at

www.thermatru.com

Installation

SITE 1 2014 1.5

Installation

Step 10 cont.: Additional Frame Anchoring.

Doors with Sidelites:

Shim above mull post or jambs

separating doors and sidelites. Screw

through the frame into the header,

adjacent to the shims.

Double doors:

Place temporary shims above the center

of the head frame, where doors meet.

Pre-drill and insert a screw through

frame into header, then remove the

temporary shims.

Patio Doors:

Shim above the mull post(s), Pre-drill

and insert a scre

w through the frame

into the header, at either side of the

post.

Step 11: Weatherproof, Finish and Maintain.

Provide and maintain a properly installed

cap or head flashing to protect top of

surfaces from Water intrusion and

damage. Tape and properly seal the top

flap of the Water Resistive Barrier (WRB)

over the head flashing.

Caulk around entire “weather” side of unit,

sealing along the brickmould to the flashing material or siding and seal all

joints betwee

n the jambs and moldings.

Seal the joints between the exterior hardware trim and the door face to

prevent air and water infiltration.

Place and set galvanized finish nails through the brickmould around the

perimeter. Use exterior grade screws if you are installing a storm door to the

brickmould. Countersink all fasteners and cover with exterior grade putty.

Add insulation material to the cavi

ty between the opening and the unit to

reduce air infiltration and heat transfer.

All Therma-Tru Steel doors must be finished within several days of the

installation date for continued warranty coverage. For Fiberglass doors the

finishing requirement is within 6 months of installation.

Paint or stain according to Therma Tru Finishing instructions. Do Not paint

or stain the weatherstrip, it is “

friction-fit” and easily removed for painting or

staining.

All 6 sides of the doors must be finished. For out-swing doors the sides, top

and bottom must be inspected and maintained as regularly as all other

surfaces.

All bare wood surfaces such as the door frame exposed to weather should be

primed and painted or stained and top coated within two weeks of exposure

for best performance.

Maintain

or replace sealants and finishes as soon as any deterioration is

evident. For semi-gloss or glossy paint or clear coats, do this when the surface

becomes dull or rough. More severe climates and exposures will require more

frequent maintenance.

Access our website www.thermatru.com

for printable versions of the

installation and Same Day Stain finishing instructions and to view our

Troubleshooting video for minor installation issues and adjustments.

Finishing Instructions.

Work only when temperatures are between 50°and 90°F and with

humidity less than 85%. Do not finish in direct sunlight.

Steel and Smooth-Star® Doors:

To paint Doors: Clean first with mild detergent and water or use a TSP (tri-

sodium phosphate) solution. Rinse well and allow to dry completely. Mask

off hardware, glass and remove weatherstripping before painting. Use highquality acrylic latex house paint, following manufacturer’s directions for

application. Use exterior grade finishes for outside surfaces. Paint edges and

exposed ends of door.

To Paint Doorlite Frames: Remove any excess glass glazing sealant by first

spraying with a window cleaner or water. Use a single edge razor blade to

score the glazing along the edge of the frame. Holding the razor blade at a 45

degree angle, scrape glazing from glass. Wipe remaining residue off with

window cleaner or mineral spirits. Clean frame with a mild detergent and

water, or use a TSP solution. Rinse well and allow to dry completely. Mask

off glass. Prime door lite frames with an alkyd- or acrylic-based primer.

Allow primer to dry before applying finish paint coats. Use high-quality

acrylic latex house paint, following manufacturer’s application instructions.

Use exterior grade finishes for outside surfaces.

Classic-Craft® and Fiber-Classic® Doors:

To Finish Doorlite Frames and Panel Inserts:

Remove any excess glazing sealant by first spraying with a window cleaner or

water. Use a single edge razor blade to score the glazing along the edge of the

frame. Holding the razor blade at a 45° angle, scrape glazing from glass.

Wipe remaining residue off with window cleaner or mineral spirits. Mask off

glass. Paint or stain using same materials as for the door. (See below).

To Paint Doors:

Clean first with mild detergent and water or use a TSP (tri-sodium phosphate)

solution. Rinse well and allow to dry completely. Prime with an alkyd- or

acrylic-based primer. Allow primer to dry completely, then paint with acrylic

latex house paint, following paint manufacturer’s application instructions.

Use a primer and paint that are compatible. Use exterior grade finishes for

outside surfaces. Paint edges and exposed ends of door.

To Stain Doors:

Clean first with a clean cloth and mineral spirits and allow to air dry or wash

door with mild detergent and water, or a TSP (tri-sodium phosphate) solution.

Rinse well and allow to dry completely. For stained surfaces, we only

recommend the use of the stain and clear coat products found in the Therma-

Tru Same-Day Stain™ Finishing Kit. Apply stain with a rag. The longer

the stain is left to “setup” before wiping off, the darker the color will be.

Using a clean rag, wipe off the stain to the color shade you desire. Remove

any excess stain from the panel grooves with the foam brush provided; allow

the stain to dry for at least 6 hours before applying topcoat. See Therma-Tru

Same-Day Stain™ Finishing Kit instructions for complete details.

Warning:

Modification or machining of this product can release wood dust, a

substance known to the State of California to cause cancer.

Pre-Hung Unit Installation

1.6 2014 SITE 1

Pre-Hung Unit Installation

Constructor, subcontratista o proveedor:

Entregue estas instrucciones al propietario.

Los estándares de rendimiento de aplicación para estos productos están regidos por el

Código Residencial Internacional, el Código de C onstrucción Internacional y por otras

normas estatales o jurisdiccionales. Las copias de las c lasificaciones de rendimiento se

encuentran disponibles en nuestro sitio Web en ww

w.thermatru.com.

Instrucciones de instalación para

sistemas de puertas preafabricadas

Estas instrucciones de instalación están diseñadas para a yudar a los instaladores de

puertas que t ienen nociones principios de carpintería y saben cómo usar herramientas

eléctricas de manera adecuada y segura. El propós ito de estas instrucciones es demostrar

la manera de instalar un sistema de puertas Therma-Tru mediante el u

so de métodos y

materiales que ayudan a eliminar las filtraciones relacionadas con el agua. Si se siguen

cuidadosamente las instrucciones, el sistema de puertas tendrá una vida útil prolongada

con una buena resistencia a los problemas relacionados con el agua de lluvia.

Estos métodos estan “comprobados”. So n usados frecuentemente por los constructores y

remodeladores preocupados por mantener el

agua fuera de las casa. En caso de que estas

instrucciones no aclaren sus dudas, no se salten ninguno de los, y llame al 1-800-

THERMATRU y pida aclaraciones. S i todavía tiene dudas, busque más ayuda

profesional para la instalación.

Las diferentes regiones del país cuentan con difere ntes requisitos de códigos, que pueden

no estar cubiertos por estas instrucciones. El instalador es el responsable d

e asegurar que

la instalación cumpla con los códigos lo cales. Si se aplican códigos únicos que no

aparecen, póngase en contacto con el 1-800-THERMATRU.

Herramientas y materiales necesarios: niveles de 2’ y 6’, martillo, espátulas

(rígidas y flexibles), escuadra de e nmarcar, pistola para calafateo, escalera resistente,

calzas, cinta métrica, sellador elastomérico o de poliuretano de alta calidad,

pistola

atornilladora o taladro: taladro con broca para taladro de 1/8”, navaja, puntas Philips #2 y

#3, engrapadora, material de aislamiento, gafas de protección, barrera resistente a l agua,

material tapajuntas, tornillos para exteriores #8 x 2-1/2” y revestimiento para alféi zar

opcional.

Lea todas las instrucciones antes de comenzar.

Mejores prácticas recomendadas por Therma-Tr u

Use barreras re

sistentes al aqua y tapajuntas flexibles:

Recomendamos el uso de barreras res istentes al a gua (WRB,

por sus siglas en inglés) ap licadas al revestimiento exterior

(OSB u otras) y el uso de productos adhesivos o de tapajuntas

flexibles para sellar el perímetro de la abertura. Se debe cortar

la WRB en la abertura (siga las pa utas de l fabricante) co n e l

cabezal de la lengüeta cubierta con cinta adhesi

va, para

sellarla después en el paso 11. Se debe aplicar el tapajuntas de

manera superpuesta, como se muestra, siempre co menzando

desde la parte inferior hacia arriba (siga las pautas del

fabricante).

1994-2009 Therma Tru Corp. All rights reserved.

Therma-Tru Doors is an operating company of Fortune Brands, Inc.

Issued 4/11 Rev.G Part# MSDRIST65

Use un revestimiento para alféizar: recomendamos que primero compruebe que el

revestimiento para alféizar cabe en la abertura siguiendo las instrucciones incluidas con

éste. Coloque los extremos derecho e izquierdo del revestimiento para alféizar contra los

costados de la abertura. Compruebe que la sección central tenga el largo adecuado y, de

ser necesario, córtela con una sierra de mano o tijeras para hojalata. Asegúrese de dejar

5,08 centímetros de superposición para las uniones.

Nota: Use sólo el cemento PVC incluido en el kit de revestimiento para alféizar para unir

las piezas. El alféizar se debe sellar al subsuelo con un sellador elastomérico o de

poliuretano, pero no aplique se llador a la parte inferior del alféizar usando un

revestimiento para alféizar

Paso 1: revise la puerta.

Revise el ancho y alto.

Mida el tamaño del marco (ancho y alto), no de la moldura.

Retire las tablitas y e l empaque, pero mantenga la puerta

fijamente cerrada con e l sujetador para transporte. No retire el

sujetador para transporte hasta que se le indique hacerlo más

adelante en el paso 7.

Paso 2: revise y prepare la abertura.

¿La abertura es del tamaňo correcto para

la puerta? Compárela con el tamaňo del

marco de la puerta ahora, antes de la

instalación. La abertura debe tener el

alto del marco más 1.27 cm y el ancho

del macro más 1,27 a 1,91 c m. Resuelva

cualquier problema en este momento.

¿Los marcos y las paredes están A

PLOMO? Use un nivel de 6 pies y

revise ambos lados de la abertura, de las

dos maneras (del frente hacia atrás y de

derecha a izquierda). Resuelva

cualquier problema en este momento.

¿El subsuelo está nivelado y sólido? Proporcione u na superficie plana, nivelada y

limpia que soporte el peso, de m anera que se pueda aplicar masilla de calafateo y sellar

de forma adecuada el revestimiento para alféizar o el alféizar a la abertura. Raspe, lije

o rellene según se necesite.

Nota: si se necesita una separación adicional de la cobertura del piso, fije la tabla de

calza al subsuelo. Asegúrese de calafatear bien bajo la tabla de calza.

¿La aber tura está a escuadra? Revise todas las esquinas con una escuadra de enmarcar.

Revise dos veces comparando las medidas diagonales. R esuelva cualquier problema en

este momento.

Installation

SITE 1 2014 1.7

Installation

Paso 2, cont.: revise y prepare la abertura.

Aseqúrese de que las paredes que enmarcan el perímetro

de la abertura están en el mismo plano. Hágalo realizando

una prueba con un cordel para verificar que está a plomo.

Prueba con cordel para verificar que está a plo mo: Coloque

un cordel que cruce diagonalmente la abertura desde el

exterior, como se muestra. Los cordeles se deben tocar

suavemente en

el centro, de lo contrario, la abertura está

“fuera de plomo” por el doble de dicha distancia y se debe

corregir. Voltee el cordel sobre sí mismo para verificar

ambos planos. Resuelva cualquier problema en este

momento.

*

El estado “fuera de plomo” es una de las razones más

comunes por las que las puertas sufren fugas de aire y agua

Paso 3: Aplique masilla de calafateo en el subsuelo.

Coloque 3 cordones de sellador muy grandes en el

subsuelo de la abertura. E xtienda los cordones hasta

alcanzar el ancho total de la abertura.

Use sólo sellador elastomérico o de poliuretano.

Use un tubo completo para calafatear a lo largo del

subsuelo.

Paso 3A: instalación con un revestimiento para alféizar.

Coloque los extremos derecho e izquierdo del revestimiento para alféizar en los cordones

de masilla de calafateo y firmemente contra el costado de la abertura.

Luego, cubra generosamente las áreas superpuestas de las piezas con el cemento PVC

incluido. Coloque las secciones centrales en posición y mantenga juntas las pieza s el

tiempo sufic

iente para asegurar la formación de una buena adhesión.

Para obtener protección adicio nal, esparza un cordón de masilla de calafateo a lo largo de

las uniones de adhesivo y, para evitar la fil tración de aire, extienda un cordón de masilla

de calafateo a lo largo del borde interior inferior de l revestimiento para alféizar. Colocar

masilla de calafateo adicional puede afectar el rendimiento del rev

estimiento para

alféizar.

No calafatee l a parte inferior del alféizar cuando use un revestimiento para alféizar

Paso 3B: instalación sin un revestimiento para alféizar.

Coloque la puerta sobre su borde o frente, de

manera que se pueda calafatear la superficie

inferior del alféizar. Coloque co rdones de

masilla de ca lafateo muy grandes a lo largo

de todo el ancho de l alféizar. Además,

coloque cordones de masilla de calafateo a lo

largo de la unión del alféizar y la jamba y en

la s uperficie inferior de las ja

mbas y las

molduras.

Nota: si usa una extensión para alféizar, coloque un cordón de masilla de calafateo

grande en la unión de la extensión y la entrada de l alféizar.

Paso 3, cont.: calafateo de la parte posterior de la moldura.

¡Importante!

Aplique sellador a la parte posterior de la

moldura, en todo el perímetro de la puerta.

Es fundamental colocar un cordón de

masilla de calafateo elastomérica o de

poliuretano de 1,27 a 1,59 cm.

Paso 4: coloque la unidad en la abertura y fije temporalmente.

Levante la unidad. Incline e l borde superior

alejándolo de la abertura y centre la unidad; coloque

el alféizar en el revestimiento para alféizar o los

cordones de masilla de calafateo e inclínelo hacia la

abertura.

Tenga presente la ubicación de las bisagras para todas

las configuraciones de las puertas y márquelas en el

frente de las jambas, cerca de las superficies de la

puerta. Pretaladre orificios de 0,32 cm de diámetro en

estas ubicaciones para colocar los tornillos. Puede

ocultar las cabezas de los tornillos s i usa una broca

para avellanar.

Instale los tornillos en la ubicación del orificio

pretaladrado central de ambas jambas para asegurar la

unidad temporalmente en el lugar. No coloque los tornillos completa mente en este

momento. Use tornillos para exteriores de #8 X 2 -1/2 ó 3 pulgadas.

No los apriete a través de la moldura.

Paso 4, cont.: coloque a plomo el lado de las bisagras de la jamba.

Comience a trabajar desde el lado con burletes de la puerta.

Use un nivel de 6 pies y coloque a plo mo el lado de las bisagras de las ja mbas de las dos

maneras (de derecha a izquierda y del interior al exterior).

Haga pasar los t ornillos a través del lado d e las bisagras de la jamba hasta los montantes,

en cada una de las ubicaciones de las bisagras restantes como se muestra en los

diagramas. Use tornillos para exteriores de #8 X 2-1/2 ó 3 pulgadas.

No coloque los tornillos completamente en este momento.

En el caso de las puertas simples y d obles, coloque los tornillos e n cada una de las

ubicaciones de las bisagras, de manera que se pueda colocar las calzas tras las bisagras y

sobre los tornillos. Los tornillos evitarán que las calzas se caigan mientras se realizan

ajustes.

En el ca so de las unidades con vidrieras laterales, apriete la ja mba en el lado de las

bisagras de la puerta.

En el caso de las unidades de puerta doble y para patio, apriete primero el lado fijo o

pasivo de la unidad.

Unidad simple Unidad con vidriera lateral Unidad doble

Pre-Hung Unit Installation

1.8 2014 SITE 1

Pre-Hung Unit Installation

Paso 5: coloque calzas en las ubicaciones de las bisagras y asegure la

jamba con bisagras.

Deje la puerta fija y cerrada con el sujetador para transporte.

Coloque calzas sobre los tornillos, detrás de cada ubicación de

las bisagras, entre la abertura y la jamba.

Use un nivel de 6 pies y vuelva a verificar la jamba con

bisagras para asegurarse de que está a plomo y recta.

Termine de apretar primero los tornillos del medio, luego los

de la parte superior y finalmen

te los de la parte inferior.

Paso 6: ajuste el resto del marco y apriete.

Verifique los márgenes y contactos de los burletes

desde el lado de la puerta que los tiene.

Ajuste el marco de mane ra que los burletes hagan

contacto con la s uperficie de la puerta de la misma

manera en la parte superior, la parte del medio y la

parte inferior, una distancia pareja de 0,95 a 1,27

centímetros cuando está completamente cerrada.

Asegure la jamba del lado del seguro con tornillos de #8 X 2-1/2 ó 3 pulgadas a través de

los orificios pretaladrados en la parte superior e inferior. No apriete los tornillos en este

momento.

Coloque calzas sobre las ubicaciones de tornillos desde el lado de apertura de la puerta y

realice ajustes de manera que los márgenes entre la puerta y el marco queden parejos

desde la parte superior a la inferio

r.

Nota: en e l caso de las puertas dobles, realice aj ustes que tengan efecto sobre la

alineación, los márgenes y el contacto de los burletes entre las puertas. Además, siga las

instrucciones del paquete del sitio de Astragal para obtener detalles sobre la

configuración adecuada de la ubicación de los orificios para el cerrojo.

Paso 6, cont.: ajuste el resto del marco y apriete.

Vuelva a verificar que todos los lugares estén a plomo y a

escuadra y que los burletes estén en contacto de manera pareja

Termine de apretar todos los tornillos.

Paso 7: retire el sujetador para transporte y abra la puerta.

Retire el sujetador para transporte.

Abra y cierre la puerta para verificar que funciona

correctamente

Con la puerta abierta, taladre orificios guía de 0,32 cm

de diámetro e n la bisagra superior, en las 2 ubicaciones

de los orificios para tornillos más cercanas al burlete.

Luego, instale los tornillos de #10 X 2-1/2 pulgadas

(incluido

s) a través de la bisagra, pasando por el

montante, para anclar el marco de la puerta y evitar que

quede suelta.

Paso 7, cont.: retire el sujetador para transporte y abra la puerta.

Para unidades con vidriera lateral y para patio: con la puerta abierta, verifique y

determine s i se instalaron pre viamente los tornillos para bisagra largos de 2-1/2” en las

bisagras. De no ser así, taladre orificios guía de 0,32 cm de diámetro e instale los tornillos

largos para bisagra en las ubicaciones de orificio más cercanas al burlete.

Cierre la puerta y coloque calzas cuidadosamente e ntre la jamba y la abertura tras el área

de la cerradura de seguridad ajustable.

Luego, abra la puerta y taladre orificios guía de 0,32

cm de diámetro e instale los tornillos de #8 X 2-1/2

pulgadas (incluidos) a través de los orificios de la

cerradura para asegurar la jamba del lado del seguro y

proporcionar seguridad

Ajuste la cerradura hacia adentro o afuera para que

entre en contacto co n el burlete y la puerta funcione de

manera adecuada, luego, termine de apretar los tornillos.

Paso 8: ajuste el alféizar.

Es pos ible q ue s u pue rta te nga una c ubierta para umbral a justable. Cuando se ajusta de

manera adec uada, la puerta debe quedar apretada y de be ser ligera mente d ifícil jalar un

billete de un dólar por debajo de ella c uando está bien cerrada. Se debe poder retirar el

billete de un dólar sin rasgarlo.

Esta verificación se debe rea lizar en cada

ubicación de tornillo de ajuste.

Después de ajustar la cubierta para umbral, asegúrese de

que el burlete está al ras co n la parte superior de la cubierta

para umbral. Recorte si es necesario.

Paso 9: instale las almohadillas de sellado para esquinas: sólo para

unidades de apertura hacia adentro.

Aplique se llador (e lastomérico o de

poliuretano) en la unión entre la cubierta

para umbral y las jambas de la puerta.

Retire e l papel autoadhesivo de las

almohadillas de sellado para esquinas y

aplíquelas a la jamba de la puerta, alinea ndo

de forma pareja la parte inferior con la

parte superior de la cubierta para umbral.

Cuando la almohadilla se instala correctamente, la lengüeta se encontrará encima y la

parte estrecha abajo.

La parte inferior de la almohadilla tiene el mismo ancho que la cubierta para umbral, para

ayudar a alinearlas durante la instalación.

Paso 10: anclaje adicional del marco.

Si el alféizar cuenta con preparación para tornillos de anclaje, coloque los tornillos

adecuados a través de l alféizar y hasta el subsuelo de ser necesario. (Principalmente en

alféizares para apertura hacia afuera).

Le recomendamos proporcionar anclaje adicional a l marco, como lo mostramos aquí.

Algunos estados o jurisdicciones, como es el caso de Florida y la costa de Texas, cuentan

con normativa de instalación específica y pueden req uerir que la instalación se haga de

estricto acuerdo con la aprobación del producto pa ra un producto específico. Usted debe

siempre ver

ificar con la autoridad local que tenga jurisdicción s i existe normativa de

instalación específica que pueda aplicarse. Disponemos de instrucciones específicas de

instalación para aprobación de productos, lo que incluye aquellos requeridos para la zona

de huracanes de alta velocidad, en www.ther matru.com

Installation

SITE 1 2014 1.9

Installation

Paso 10, cont.: anclaje adicional del marco.

Puertas con vidrieras laterales:

Coloque calzas sobre los listones verticales o

las jambas de puerta que separan las puertas

de las vidrieras laterales. Atornille a través del

marco hasta el dintel, junto a las calzas.

Puertas dobles:

Coloque calzas temporales sobre e l centro del

marco del dintel, donde se unen las puertas.

Pretaladre e inserte un tor

nillo, a través del

marco, en el dintel y luego retire las calzas

temporales.

Puertas para patio:

Coloque calzas sobre los listones verticales,

pretaladre e inserte un tornillo, a través del

marco, en el d intel, a cada lado de los

listones.

Paso 11: deje a prueba de intemperie, aplique un acabado y dé mantenimiento.

Proporcione y mantenga una cubierta o un

tapajuntas del d intel adecuadamente instalados

para proteger la parte superior de las superficies

del ingreso de agua y del daño. Coloque cinta

adhesiva y selle de manera adecuada la parte

superior de la lengüeta de la barrera resistente al

agua (WRB) sobre el tapajuntas del dinte

l.

Calafatee alrededor de todo el lado expuesto al c lima de la unidad, sellando a lo largo de

la moldura hasta el material de tapajuntas o los revestimientos y selle todas las uniones

entre las jambas y las molduras.

Selle las uniones e ntre el reborde de los accesorios exteriores y el frente de la puerta para

evitar la filtración de aire y agua.

Coloque y a juste clavos galvanizados para acabado a través de la moldura, alrededo r del

perímetro. Use tornillos para exteriores si está instalando una contrapuerta en la moldura.

Avellane todos los sujetadores y cúbralos con mas illa para exteriores.

Añada material de aislamiento a la cavidad entre la abertura y la unidad, a fin de red ucir

la filtración de aire y la transferencia de calor.

Todas las puertas de acero T herma Tru deben finalizarse dentro de los días siguientes a la

fecha de la instalación para una adecuada cobertura de la garantía. Para puertas de fibra

de vidrio, el acabado debe darse dentro de los 6 meses después de la instalación.

Pinte o tiña de acuerdo con las instrucciones de acabado de Therma Tru. No pinte ni tiña

el burlete, está ajustado para la fricción y se retira fácilmente para pintar o teñir.

Las puertas de apertura hacia fuera deben tener acabados en todos los bordes, los

costados, la parte superior y la parte inferior. Inspeccione y dé mantenimiento a estos

bordes con la misma regularidad que con todas las demás superficies.

Se debe dar acabado a los 6 lados de las puertas. Para las puertas que se abren para

afuera, los lados, la parte superior y la parte inferior deben inspeccionarse y conserva

rse

con la misma regularidad que las otras superficies.

Dé mantenimiento o reemplace los selladores y acabados tan pronto el deterioro sea

evidente. En el caso de la pintura brillante o semibrillante y de las capas transparentes,

hágalo cuando la superficie se vuelva opaca o áspera. Los climas y las exposiciones más

rigurosos necesitarán de mantenimiento más frecuente.

Ingrese a nuestro s itio Web www.thermatru.com para obtener versiones imprimibles

de la instalación e instrucciones para el acabado el mismo día y para consultar nuestro

vídeo de solución de problemas sobre problemas y ajustes menores de la instalación.

Instrucciones para el acabado:

Trabaje sólo cuando las temperaturas s e encuentren entre 10 y 32,2º C y la humedad sea

menor a un 85%. No aplique acabados bajo la luz s olar directa.

Puertas de acero y Smooth-Star®

Para pintar p uertas: primero limpie con un detergente s uave y agua o use una solución

de TSP ( fosfato trisódico). Enjuague b ien y deje secar completamente. Proteja los

accesorios, los vidrios y los burletes antes de pintar. Use pintura látex de casas de alta

calidad y siga las instrucciones del fabricante para su aplicación. Use acabados para

exteriores para las superficies exteriores. Pinte los b ordes y los extremos expuestos de la

puerta.

.

Para pintar marcos de vidrieras para puertas: Primero retire cualquier exceso de

sellador de esmalte para vidrios rociando con un limpiador de ventanas o agua. Use una

navaja de un solo filo para hacer cortes en e l esmalte a lo largo del borde del marco.

Raspe el esmalte del vidr io sosteniendo la cuchilla de la navaja e n un ángulo de 45

grados. Retire el residuo restante con un limpiador de ventanas o aguarrás mineral.

Limpie e l marco con un dete rgente suave y agua o use una solución de TSP. Enjuague

bien y deje secar completamente. Proteja el vidrio. Aplique una pintura base de resina

alquídica o acrílica a los marcos de vidrieras. Deje secar la pintura base antes de aplicar

las capas de pintura de acabado. Use pintura látex de casas de alta calidad y siga las

instrucciones del fabricante para s u aplicación. Use acabados para exteriores para las

superficies exteriores.

Puertas Classic-Craft® y Fiber-Classic®:

Para dar acabado a marcos de vidrieras para puertas y a accesorios para paneles:

primero retire cualquier exceso de se llador de esmalte rociando c on un limpiador de

ventanas o agua. Use una navaja de un solo filo para hacer cortes en el es malte a lo largo

del borde del marco. Raspe el esmalte del vidrio sosteniendo la cuchilla de la navaja en

un ángulo de 45°. Retire el residuo restante con un limpiador de ventanas o aguarrás

mineral. Proteja el vidrio. Pinte o tiña usando los mismos materiales de la puerta.

(Consulte abajo.)

Para pintar puertas:

primero limpie con un detergente suave y agua o use una solución de TSP (fosfato

trisódico). Enjuague bien y deje secar completa mente. Aplique una p intura base de resina

alquídica o acrílica. Deje que la pintura base se seque completamente, luego, pinte con

pintura láte x de casas siguiendo las instrucciones del fabricante para su aplicación. Use

una pintura base y una pintura que s ean compatibles. Use acabados para exteriores para

las superficies exteriores. Pinte los bordes y los extre mos expuestos de la puerta.

Para teñir puertas:

primero limpie con un paño limpio y aguarrás mineral y deje secar a l aire o lave la pu erta

con un detergente suave y agua o una solución de TSP (fosfato trisódico). Enjuague bien

y deje s ecar completamente. En e l caso de las superficies teñidas, sólo recomendamos el

uso de tintes y productos de capas transparentes que se encuentran en el kit para

acabado Therma -Tru Sa me-Day Stain™. Aplique el tinte co n un paño. Mientras más

tiempo se deje el tinte para “asentarse” antes de limpiarlo, más oscuro será el color. Use

un paño limpio para limpiar el tinte hasta lograr el tono del color q ue desea. Retire

cualquier exceso de t inte de las gr ietas del panel con la brocha de espuma que se incluye.

Deje secar e l tinte durante al menos 6 horas antes de aplicar una capa s uperior. Consulte

las instrucciones del kit para acabado Therma-Tru Same-Day Sta in™ para obtener

información detallada.

Advertencia:

La modificación o el mecanizado de este prod ucto puede liberar polvo de madera,

una sustancia que el Estado de California reconoce co mo causante de cáncer

.

Pre-Hung Unit Installation

1.10 2014 SITE 1

Builder, Subcontractor or Supplier:

Please forward these instructions to the homeowner.

Therma-Tru® certified door systems and Therma-Tru® door systems that

require product approval (typically for coastal applications) may require

special assembly, components and installation. Always refer to the certified

system requirements and product approval assembly and installation drawings

on our websit

e for these applications.

Building codes can vary by Jurisdiction, County and/or State. Always check

for any specific assembly or installation that may be required by Code in your

area.

Installation Instructions for Vented Sidelite Door

Systems

These installation instructions are designed to assist door installers who have

an understanding of carpentry principles, and know how to properly and

safely use power tools. The purpose of these instructions is to illustrate how to

install a Therma-Tru® door system using methods and materials that help

eliminate air infiltration and water related leaks. If the directions are closely

followed, the door system will have a long useful life with good resistance to

air and water intrusion problems.

These methods are “tried and true” They are used w

idely by builders and

remodelers who are serious about managing and keeping water outside the

home. Rather than eliminate any steps that may be unclear to you, please call

1-800-THERMATRU and ask for clarification. If you remain unclear, please

seek more professional assistance with the installation.

Required Tools & Materials: 2 & 6 foot Levels, Hammer, Putty Knives

(firm & flexible), Framing Sq

uare, Caulking Gun, Sturdy Ladder, Shims,

Tape Measure, High Quality Elastomeric or Polyurethane Sealant, Screw

Gun/Drill -1/8 inch Drill Bit, Razor Knife, #2 & #3 Philips Bit, Stapler,

Insulating Material, Eye Protection, Water Resistive Barrier, Flashing

Material, #8 x 2-1/2 inch Exterior Grade Screws, & Optional Sill Pan.

The door unit is large, heavy and can be cumbersome to lift, move and

po

sition. Use safe lifting techniques and a helper(s) to assist you with

installation, in order to prevent personal injury and damage to the unit,

and to help facilitate proper installation.

Read all instructions before starting.

Therma-Tru

®

Recommended Best Practices

Use Water Resistive Barrier and Flexible Flashing:

We recommend the use of a Water Resistive Barrier

(WRB) applied to the exterio

r sheathing (OSB or

other) and the use of an adhesive or flexible flashing

product to seal around the opening. The WRB should

be cut in the opening (follow manufacturer’s

guidelines) with the head of the flap taped up, to be

sealed later in Step 13. The flashing should be applied

in an overlapping manner as shown, always working

from the bottom up (follow manufacturer’s

guidelines).

Use a Sill Pan: We recommend you first “dry fit” the sill pan in the opening,

following the instructions furnished with the sill pan. Place the right and left

sill pan ends tight against the sides of the opening. Check the center section

for proper length and if necessary, cut with a hack saw or tin snips. Be sure to

allow 2 inches of overlap at the joints.

Note: Use only the PVC cement provided in the sill pan kit to glue the pieces

together. The sill pan must be sealed to the sub-floor using an Elastomeric or

Polyurethane sealant, but do not apply sealant to the bottom of the sill when

using a sill pan.

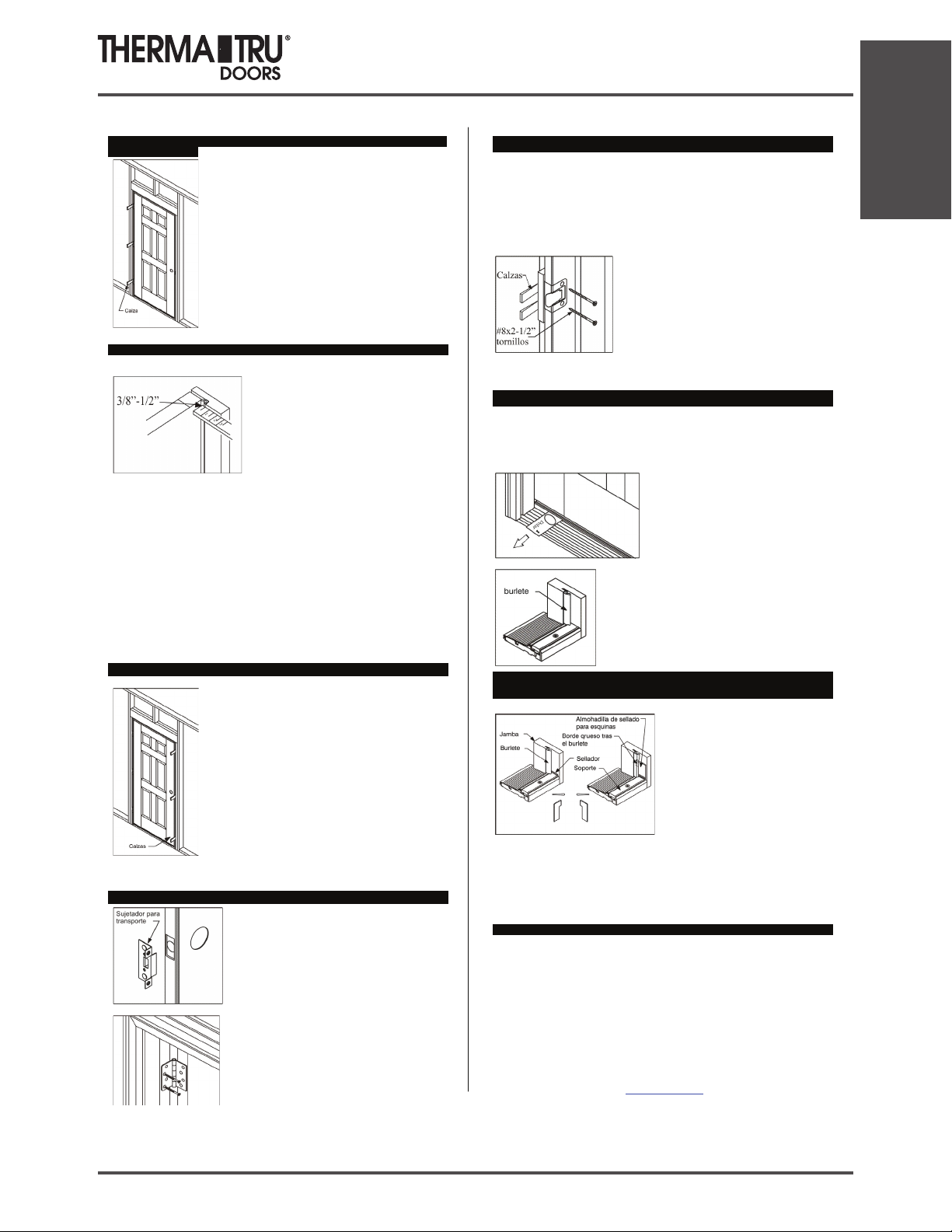

Step 1: Check Door Unit.

Check width and height.

Measure size of frame (width and height), not

brickmould.

Remove cleats and packaging, but keep door

fastened closed with transport clip. Do not

remove the transport clip until instructed to do s

o

later in Step 9.

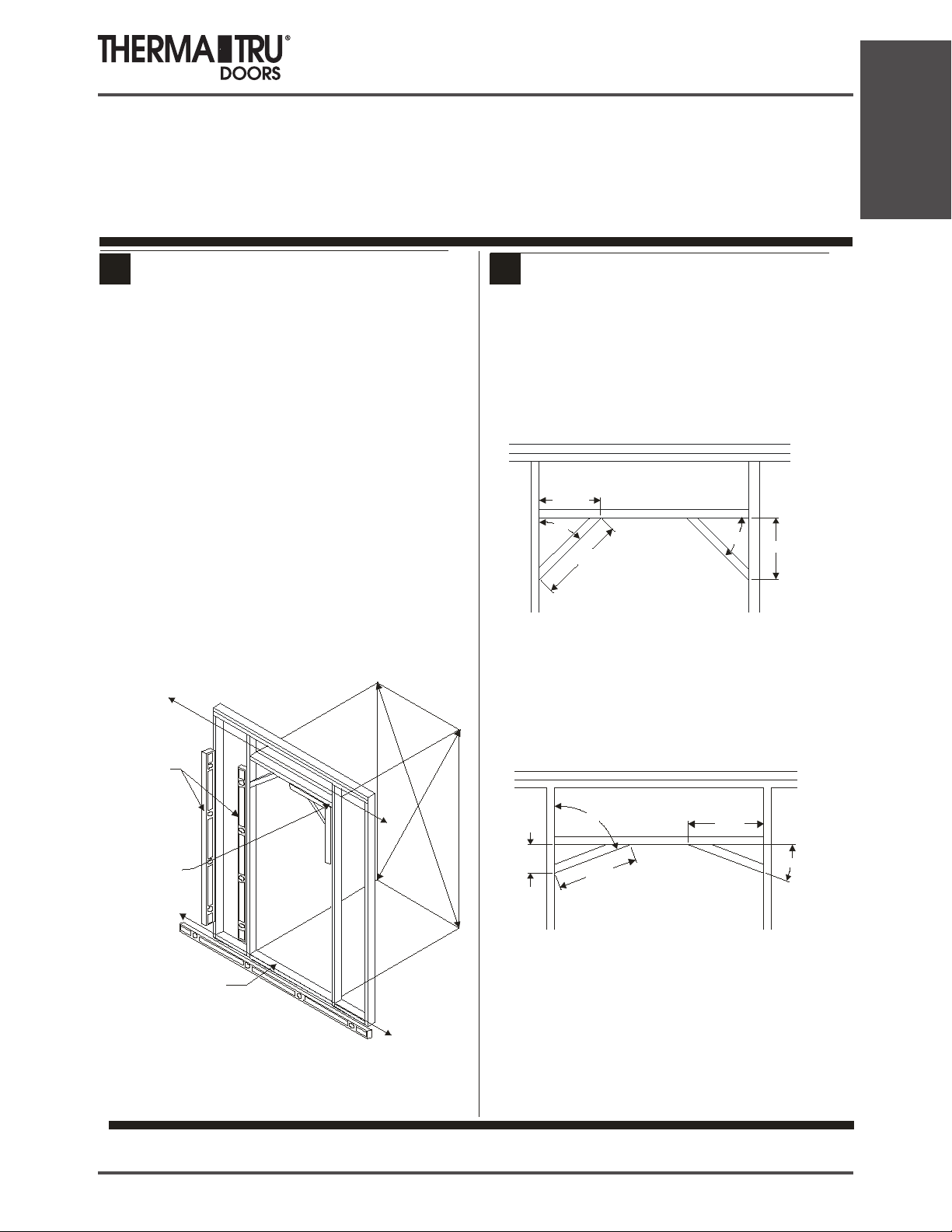

Step 2: Check and Prepare Opening.

Is the opening the correct size for th

e

door unit? Check it against the door

frame size now, before installation. The

opening should be frame height plus

½

inch, and frame width plus ½ inch to ¾

inch. Fix any problems now.

Are the framing and walls PLUMB? Use

a 6 foot level and check both sides of th

e

opening, both ways (front to back and

right to left). Fix any problems now.

Is the sub floor level and solid? Provid

e

a flat, level, clean weight bearing

surface so the sill pan or sill can be

properly caulked and sealed to the

opening. Scrape sand or fill as required.

Note: If additional floor covering clearance is required, attach the shim board

to the sub floor. Be sure to caulk well under the shim board.

Is the opening square? Check all corners with a framing square. Double check

by comparing diagonal measurements. Fix any problems now.

SITE 1 2014 1.11

Pre-Hung Venting Unit Installation

Installation

Installation

Step 2 cont.: Check and Prepare Opening.

Check to be sure the framing walls around the

opening are in the same plane. Do this by

performing a “string test” for plumb.

String Test for Plumb: Attach a string diagonally

across the opening from the outside, as shown. The

string(s) should gently touch in the center, if not the

opening is “out of plumb” by twice that distance

and needs to be corrected

. Flip the string over itself

to check both planes. Fix any problems now.

*An “out of plumb” condition is one of the most

common reasons door units leak air and water.

Step 3: Caulk the Sub Floor.

On the sub floor at opening, place 3 very large beads

of sealant. Run beads full width of the opening.

Use Only Elastomeric or Polyurethane sealant.

Use an Entire Tube when Caulking along the Sub

Floor.

Step 3A: Installation with a Sill Pan.

Place the right and left sill pan ends onto the caulk beads and tightly against

the side of the opening.

Then, liberally coat the overlapped areas and the recessed areas of the pieces

with the PVC cement provided. Place center section(s) in position and hold

pieces together long enough to ensure a good bond.

For added protection, spread a bead of caulk alo

ng the glue joints and to help

prevent air infiltration, run a bead of caulk along the lower interior edge of the

sill pan. Additional caulking could affect the performance of the sill pan.

Do Not Caulk the bottom of the Sill when using a sill Pan.

Step 3B: Installation without a Sill Pan.

Lay the door unit on edge or face so

that the bottom surface of the sill

can be caulked. Place very large

beads of caulk across the full width

of the sill. Additionally, place beads

of caulk along the junction of the

sill and the jamb and on the bottom

surface of the jambs and

brickmould.

Note: If a sill extender is used, place a large bead of caulk at the junction of

the extender and the sill approach.

Step 3 cont.: Caulking Back side of Brickmould.

Important!

Apply sealant to the back side of

brickmould around the entire

perimeter of the door unit. A 1/2 –

5/8 inch bead of Elastomeric or

Polyurethane caulk is essential.

Step 4: Place Unit in Opening and Temporarily Fasten.

Lift the unit up. With top edge

tilted away from opening,

center the unit and place sill

down onto sill pan or caulk

beads and tilt into opening. For

all door unit configurations,

note the hinge locations and

mark those locations on the

jamb faces near the door

surfaces. Pre-drill 1/8 inch

diameter holes at these

locations and through the head

jamb adjacent to the mullions,

over the active sidelites. A

counter sink bit will help to

conceal the screw heads.

Install screws in the center predrilled hole locations on both jambs to temporarily secure the unit in the

place. Do not drive screws completely in at this time. Use #8 X 2-1/2 inch or 3

inch exterior grade screws.

Do Not Fasten through the Brickmould.

Step 5: Plumb and Fasten Side Head Mull Post .

Use a 6 foot level and plumb the

hinge side mullion both ways

(right to left and inside to

outside).

Place a screw through the predrilled hole in the head jamb at

the hinge side mullion.

Do not drive the screw

completely in at this time.

Shim directly over hinge side mull

post. Using a 6 foot level, recheck

hinge mull post to ensure it is

plumb and straight. Finish driving

screw tight.

Note: When installing a French door with active sidelites, first set the hinge

mullion for the passive door. For details on properly setting the astragal slide

bolt hole locations, follow the instructions in the astragal site pack.

Pre-Hung Venting Unit Installation

1.12 2014 SITE 1

Step 6: Adjust and Fasten Lock Side Mull Post.

Adjust lock side mull post so that the

weatherstrip contacts the door surface

equally at the top, middle, and bottom, an

even 3/8” – 1/2” when fully closed. Place a

screw through the pre-drilled hole in the

head jamb at the lock side mullion.

Do Not drive the screw completely in at this time.

Shim directly over lock side mull

post. Recheck

lock mull post to

ensure weatherstrip contact is even

top to bottom. Finish driving screw

tight.

Step 7: Adjust and Secure Side Jambs.

Adjust the sidelite hinge jamb on the hinge

mull side of the unit to obtain even

weatherstrip contact top to bottom at the

lock side of the sidelite. Place a screw

through the hinge side jamb, into the stud, at

each remaining hinge location.

Do not drive the screws completely in at this

time.

Shim above the screws behind each hinge

location between t

he opening and the jamb

and make adjustment so the margin between

the sidelite and mullion are even top to

bottom. This margin will be slightly larger

than the margin at the door. Recheck

sidelite hinge jamb to ensure weatherstrip

contact is even top to bottom. Finish driving

screws tight.

Repeat the previous step on the sidelite hinge jamb on the lock mull side of

the unit.

Step 8: (French Door) Temporary Shim at Head Jamb.

When installing a French door

with active sidelites, place

temporary shims above the

center of the head frame,

where doors meet. Pre-drill

and insert a screw through

frame into header, then

remove the temporary shims.

Step 9: Remove Transport Clip and Open Door.

Remove transport clips. Confirm door and

sidelites operate properly.

Make adjustments as needed.

With sidelites open, drill 1/8” diameter pilot

holes and install the long hinge screws in the

hinge locations closest to the weatherstrip.

Do this for all hinges.

Step 10: Adjust Sill.

Your door unit has adjustable threshold caps. When properly adjusted, it

should be snug and slightly difficult to pull a dollar bill out from under the

door and sidelites when fully closed. The dollar bill should be able to be

removed without tearing.

This check should be performed at each

adjustment screw location on each active

threshold cap.

After adjusting the threshold cap, ensure that the

weatherstrip is flush with the top of the threshold

cap. Trim as necessary.

Step 11: Install Corner Seal Pads – Inswing units Only.

Apply sealant (Polyurethane or

Elastomeric) at the joint where the

threshold cap meets the jambs and

mull posts.

Remove the self-stick paper from

the corner seal pads and apply to the

jamb or mull post, with the bottom

lined up evenly with the top of the

threshold cap. When the pad is

correctly installed, the tab is on top

and the narrow part is on the

bottom.

The bottom of the pad is the same width of the threshold cap to help with

alignment during installation. Corner pads must be installed on both sides of

each active opening.

Pre-Hung Venting Unit Installation

Installation

SITE 1 2014 1.13

Step 12: Weatherproof, Finish and Maintain.

Provide and maintain a properly installed

drip cap or head flashing to protect top of

surfaces from Water intrusion and

damage. Tape and properly seal the top flap

of the Water Resistive Barrier (WRB) over

the head flashing.

Caulk around entire “weather” side of unit,

sealing along the brickmould to the flashing

material or siding and seal all joints between the jambs and moldings.

Seal the join

ts between the exterior hardware trim and the door face to

prevent air and water infiltration.

Place and set galvanized finish nails through the brickmould around the

perimeter. Use exterior grade screws if you are installing a storm door to the

brickmould. Countersink all fasteners and cover with exterior grade putty.

Add insulation material to the cavity between the opening and the unit to

red

uce air infiltration and heat transfer.

All Therma-Tru® Fiberglass doors must be finished within 6 months of the

installation date for continued warranty coverage.

Paint or stain according to Therma-Tru® Finishing instructions. Do Not paint

or stain the weatherstrip, it is “friction-fit” and easily removed for painting or

staining.

All 6 sides of the doors must be finished. All door edges must

be inspected

and maintained as regularly as all other surfaces.

All bare wood surfaces such as the door frame exposed to weather should be

primed and painted or stained and top coated within two weeks of exposure

for best performance.

Maintain or replace sealants and finishes as soon as any deterioration is

evident. For semi-gloss or glossy paint or clear coats, do this when the surface

becomes

dull or rough. More severe climates and exposures will require more

frequent maintenance.

Access our website www.thermatru.com

for printable versions of the

installation and Same-Day® Stain finishing instructions and to view our

Troubleshooting video for minor installation issues and adjustments.

P/N MSDRIST-VS

Finishing Instructions

.

Work only when temperatures are between 50°and 90°F and with

humidity less than 85%. Do not finish in direct sunlight. Work only in

well-ventilated areas.

Smooth-Star® Doors:

To Paint Doors: Clean first with mild detergent and water or use a TSP

(trisodium phosphate) solution. Rinse well and allow to dry completely. Mask

off hardware, glass and remove weatherstripping before painting. Use high

quality acrylic latex house paint, following manufacturer’s directions for

application. Use exterior grade finishes for outside surfaces. Paint edges and

exposed ends of door.

To Paint Doorlite Frames: Remove any excess glass sealant by first spraying

with a window cleaner or water. Use a single edge razor blade to score the

sealant along the edge of the frame. Holding the razor blade at a 45 degree

angle, scrape the sealant from glass. Wipe remaining residue off with window

cleaner or mineral spirits. Clean glass frame with a mild detergent and water,

or use a TSP solution. Rinse well and allow to dry completely. Mask off glass.

Prime glass frames with an alkyd- or acrylic-based primer. Allow primer to

dry before applying finish paint coats. Use high-quality acrylic latex house

paint, following manufacturer’s application instructions. Use exterior grade

finishes for outside surfaces.

Fiber-Classic® Doors:

To Finish Doorlite Frames and Panel Inserts:

Remove any excess glass sealant by first spraying with a window cleaner or

water. Use a single edge razor blade to score the sealant along the edge of the

frame. Holding the razor blade at a 45° angle, scrape the sealant from glass.

Wipe remaining residue off with window cleaner or mineral spirits. Clean

glass frame with a mild detergent and water, or use a TSP solution. Rinse well

and allow to dry completely. Mask off glass. Prime glass frames with an

alkyd- or acrylic-based primer. Allow primer to dry before applying finish

paint coats. Use high-quality acrylic latex house paint, following

manufacturer’s directions for application and dry time. Use exterior grade

finishes for outside surfaces.

To Paint Doors:

Clean first with mild detergent and water or use a TSP (tri-sodium phosphate)

solution. Rinse well and allow to dry completely. Prime with an alkyd- or

acrylic-based primer. Allow primer to dry completely, then paint with acrylic

latex house paint, following paint manufacturer’s application instructions.

Use a primer and paint that are compatible. Use exterior grade finishes for

outside surfaces. Paint edges and exposed ends of door.

To Stain Doors:

Clean first with a clean cloth and mineral spirits and allow to air dry or wash

door with mild detergent and water, or a TSP (tri-sodium phosphate) solution.

Rinse well and allow to dry completely. For stained surfaces, we only

recommend the use of the stain and clear coat products found in the Therma-

Tru® Same-Day® Stain Fin

ishing Kit. Apply stain with a rag. The longer

the stain is left to “setup” before wiping off, the darker the color will be.

Using a clean rag, wipe off the stain to the color shade you desire. Remove

any excess stain from the panel grooves with the foam brush provided; allow

the stain to dry for at least 6 hours before applying topcoat. See Therma-

Tru® Same-Day® Stain Finishing Kit instructions

for complete details

Pre-Hung Venting Unit Installation

Installation

1.14 2014 SITE 1

Constructor, subcontratista o proveedor:

Entregue estas instrucciones al propietario.

Los sistemas de puertas Therma-Tru® certificados y los sistemas de puertas

Therma-Tru® que requieren aprobación (especialmente para aplicaciones en

zonas costeras) posiblemente necesiten ensamblajes, componentes e

instalaciones especiales. Siempre consulte los requisitos del sistema

certificado y los dibujos d

e instrucción de ensamblaje e instalación para la

aprobación de productos en nuestro sitio Web para dichas aplicaciones.

Los códigos de construcción pueden variar según la jurisdicción, el condado

y/o el estado. Siempre verifique si es necesario algún ensamblaje o instalación

especial según el código de su área.

Instrucciones de instalación para sistemas de

puertas con vidrieras laterales con ve

ntilación

Estas instrucciones de instalación están diseñadas para ayudar a los

instaladores de puertas que comprenden algunos principios de carpintería y

saben cómo usar herramientas eléctricas de manera adecuada y segura. El

propósito de estas instrucciones es ilustrar la instalación de un sistema de

puertas Therma-Tru® mediante el uso de métodos y materiales que ayudan a

eliminar la infiltració

n de aire y las fugas de agua. Si se siguen

cuidadosamente las instrucciones, el sistema de puertas tendrá una vida útil

prolongada con una buena resistencia a los problemas relacionados con el aire

y el agua.

Estos métodos han sido probados y son verdaderos. Son usados

frecuentemente por constructores y remodeladores preocupados de manejar y

mantener el agua fuera de las casas. En lugar de omiti

r cualquier paso que no

comprenda, llame al 1-800-THERMATRU y solicite aclaraciones. Si todavía

tiene dudas, busque ayuda profesional para la instalación.

Herramientas y materiales necesarios: Niveles de 2 y 6 pies, martillo,

espátulas (rígidas y flexibles), escuadra de enmarcar, pistola para calafateo,

escalera firme, calzas, cinta métrica, sellador elastomérico o de poliuretano de

alta calidad,

pistola atornilladora o taladro con broca para taladro de 1/8”,

navaja, puntas Philips #2 y #3, engrapadora, material aislante, lentes de

protección, barrera resistente al agua, material tapajuntas, tornillos para

exteriores #8 x 2-1/2” y revestimiento para alféizar opcional.

El módulo para puerta es grande, pesado y puede ser incómodo

para levantar, mover y colocar. Use técnicas de levantamient

o seguras y

pida a un asistente que le ayude con la instalación para evitar lesiones

personales y daños al módulo, y para facilitar una instalación correcta.

Lea todas las instrucciones antes de comenzar.

Mejores prácticas recomendadas por Therma-Tru®

Use barreras resistentes al agua y

tapajuntas flexibles:

Recomendamos el uso de barreras resistentes al agua

(WRB, por sus siglas en inglés) ap

licadas al

revestimiento exterior (OSB u otras) y el uso de

productos adhesivos o de tapajuntas flexibles para

sellar el perímetro de la abertura. Se debe cortar la

WRB en la abertura (siga las pautas del fabricante)

con el cabezal de la lengüeta cubierta con cinta

adhesiva, para sellarla después en el paso 13. Se debe

aplicar el tapajuntas de manera superpuesta, como se

muestra, siempre comenzand

o desde la parte inferior

hacia la superior (siga las pautas del fabricante).

Use un revestimiento para alféizar: Recomendamos que primero compruebe

que el revestimiento para alféizar cabe en la abertura siguiendo las

instrucciones incluidas con éste. Coloque los extremos derecho e izquierdo del

revestimiento para alféizar contra los lados de la abertura. Verifique que la

sección central tenga el largo adecuado y, de ser necesario, córtela con una

sierra de mano o tijeras para hojalata. Asegúrese de dejar 5,08 cm d

e

superposición en las uniones.

Nota: Use sólo el cemento PVC incluido en el kit de revestimiento para

alféizar para unir las piezas. El revestimiento para alféizar se debe sellar al

subsuelo usando un sellador elastomérico o de poliuretano, pero no apliqu

e

sellador a la parte inferior del alféizar cuando use un revestimiento para

alféizar.

Paso 1: Revise el módulo para puerta.

Revise el ancho y alto.

Mida el tamaño del marco (ancho y alto), no d

e

la moldura de ladrillo.

Retire las tablitas y el empaque, pero mantenga

la puerta fijamente cerrada con el sujetador para

transporte. No retire el sujetador para transport

e

hasta que se le indique hacerlo en el paso 9.

Paso 2: Revise y prepare la abertura.

¿La abertura es del tamañ

o

correcto para el módulo para

puerta? Compárela con el tamañ

o

del marco para puerta ahora, antes

de la instalación. La abertura debe

tener el alto del marco más 1,27

cm y el ancho del marco más 1,27

a 1,91 cm. Resuelva cualquie

r

problema en este momento.

¿Los marcos y las paredes están

A

PLOMO? Use un nivel de 6 pies y

revise ambos lados de la abertura,

de dos maneras (del frente hacia

atrás y de derecha a izquierda).

Resuelva cualquier problema e

n

este momento.

¿El subsuelo está nivelado y es sólido? Proporcione una superficie plana,

nivelada y limpia que soporte el peso, de manera que se pueda aplicar

masilla de calafateo y sellar de forma adecuada el revestimiento para

alféizar o el alféizar a la abertura. Raspe, lije o rellene según sea necesario.

Nota: Si se necesita una separación adicional del cubrepiso, fije la tabla de

calza al subsuelo. Asegúrese de calafatear bien bajo la tabla de calza.

¿La abertura está a escuadra? Revise todas las esquinas con una escuadra d

e

enmarcar. Revise dos veces comparando las medidas diagonales. Resuelva

cualquier problema en este momento.

Pre-Hung Venting Unit Installation

Installation

SITE 1 2014 1.15

Paso 2, cont.: Revise y prepare la abertura.

Asegúrese de que las paredes que enmarcan el

perímetro de la abertura están en el mismo plano.

Hágalo realizando una prueba con un cordel para

verificar que están a plomo.

Prueba con cordel para verificar que están a plomo:

Coloque un cordel que cruce diagonalmente la

abertura desde el exterior, como se muestra. Los

cordeles se deben tocar suavemen

te en el centro, de

lo contrario, la abertura está “fuera de plomo” por

el doble de dicha distancia y se debe corregir.

Voltee el cordel sobre sí mismo para verificar

ambos planos. Resuelva cualquier problema en

este momento.

*

El estado “fuera de plomo” es una de las razones

más comunes por las que los módulos para puerta

sufren fugas de aire y agua.

Paso 3: Aplique masilla de calafateo en el subsuelo.

Coloque 3 cordones muy grandes de sellador en el

subsuelo de la abertura. Extienda los cordones hasta

alcanzar el ancho total de la abertura.

Use sólo sellador elastomérico o de poliuretano.

Use un tubo completo para calafatear a lo largo

del subsuelo.

Paso 3A: Instalación con un revestimiento para alféizar.

Coloque los extremos derecho e izquierdo del revestimiento para alféizar

sobre los cordones de masilla de calafateo y firmemente contra el lado de la

abertura.

Luego, cubra generosamente las áreas superpuestas y empotradas de las piezas

con el cemento PVC incluido. Coloque las secciones centrales en posición y

mantenga las piezas juntas e

l tiempo suficiente para asegurar una buena

adhesión.

Para una mayor protección, esparza un cordón de masilla de calafateo a lo

largo de las uniones de adhesivo y, para ayudar a evitar la infiltración de aire,

extienda un cordón de masilla de calafateo a lo largo del borde interior

inferior del revestimiento para alféizar. Colocar masilla de calafateo adicional

puede afectar el rendimiento del re

vestimiento para alféizar.

No calafatee la parte inferior del alféizar cuando use un revestimiento

para alféizar

Paso 3B: Instalación sin un revestimiento para alféizar.

Coloque el módulo para puerta sobre

su borde o frente, de manera que se

pueda calafatear la superficie inferior

del alféizar. Coloque cordones muy

grandes de masilla de calafateo a lo

largo de todo el ancho del alféizar.

Además, coloque cordones de masilla

de calafateo a lo largo de la unión del

alféizar y la jamba y en la superficie

inferior de las jambas y las molduras

de ladrillo.

Nota: Si usa una extensión para alféizar, coloque un cordón grande de masilla

de calafateo en la unión de la extensión y la entrada del alféizar.

Paso 3, cont.: Calafateo de la parte posterior de la moldura de ladrillo.

¡Importante!

Aplique sellador a la parte

posterior de la moldura de

ladrillo, en todo el perímetro del

módulo para puerta. Es

fundamental colocar un cordón

de masilla de calafateo

elastomérica o de poliuretano de

1,27 a 1,59 cm.

Paso 4: Coloque el módulo en la abertura y fije temporalmente .

Levante el módulo. Incline el

borde superior alejándolo de la

abertura y centre el módulo;

coloque el alféizar en el

revestimiento para alféizar o

sobre los cordones de masilla

de calafateo e inclínelo hacia la

abertura. Tenga presente la

ubicación de las bisagras para

todas las configuraciones de los

módulos para puerta y

márquelas en el frente de las

jambas, cerca de las superficies

de la puerta. Taladre

previamente orificios de 0,32

cm de diámetro en dichas

ubicaciones a través de la jamba

del dintel adyacente a los entrepaños, sobre las vidrieras laterales activas.

Puede ocultar las cabezas de los tornillos con una broca para avellanar.

Instale los tornillos en la ubicación del orificio central taladrado previamente

en ambas jambas para asegurar el módulo temporalmente en el lugar. No

apriete completamente los tornillos en este momento. Use tornillos para

exteriores #8 X 2-1/2" ó 3".

No los apriete a través de la moldura de ladrillo.

Paso 5: Coloque a plomo y fije el listón vertical del cabezal lateral.

Use un nivel de 6 pies y coloque a

plomo el entrepaño del lado con

bisagras de dos maneras (de

derecha a izquierda y del interior

al exterior).

Coloque un tornillo en el orificio

taladrado previamente en la jamba

del cabezal, en el entrepaño del

lado con bisagras.

No atornille el tornillo

completamente en este momento

Pre-Hung Venting Unit Installation

Installation

1.16 2014 SITE 1

Paso 5, cont.: Coloque a plomo y fije el listón vercal del cabezal lateral.

Coloque calzas directamente en el

listón vertical del lado con bisagras.

Con un nivel de 6 pies, vuelva a

revisar el listón vertical con

bisagras para asegurarse de que está

a plomo y recto. Termine de apretar

el tornillo.

Nota: Cuando instale una puerta estilo francés con vidrieras laterales activas,

primero coloque el

entrepaño con bisagras para la puerta pasiva. Siga las

instrucciones del paquete del astrágalo para obtener detalles sobre la

configuración adecuada de la ubicación de los orificios para el perno

deslizante.

Paso 6: Ajuste y fije el listón vertical del lado de la cerradura.

Ajuste el listón vertical del lado de la

cerradura de manera que los burletes hagan

contacto con la superficie de la puerta de

forma pareja en la parte superior, la parte del

medio y la parte inferior a unos 0,95 a 1,27

cm cuando la puerta esté completamente

cerrada. Coloque un tornillo en el orificio

taladrado previamente en l

a jamba del

cabezal, en el entrepaño del lado de la

cerradura.

No apriete completamente el tornillo en este momento.

Coloque calzas directamente en el

listón vertical del lado de la

cerradura. Vuelva a revisar el listón

vertical del lado de la cerradura

para asegurarse de que los burletes

estén en contacto de forma pareja

desde la parte superior a la parte

inferior. Termine de apretar el

tornill

o.

Paso 7: Ajuste y asegure las jambas laterales.

Ajuste la jamba de la bisagra de la vidriera

lateral en el lado del listón con bisagras del

módulo para que los burletes hagan contacto

de forma pareja desde la parte superior a la

parte inferior del lado de la cerradura de la

vidriera lateral. Pase un tornillo a través de

la jamba del lado con bisagras hasta el

montante, en cada ubicación de las

bisagras

restantes.

No apriete completamente los tornillos en

este momento.

Coloque calzas sobre los tornillos detrás de

cada ubicación de las bisagras entre la

abertura y la jamba, y realice ajustes de

manera que el margen entre la vidriera