Therma-Tru Doors Repair and Replacement

SITE 5 Repair and Replacement

Repairing Therma-Tru Door Slabs ...................5.3

Sidelite Slab Replacement ................................ 5.6

Mull Post Replacement ................................... 5.13

Weatherstrip Replacement ............................. 5.21

Adjustable Sill Threshold Replacement ........ 5.23

Basic Fixed Sill

Vinyl Threshold Replacement ........................ 5.25

Doorlite Glass and Frame Replacement ........ 5.29

Storm Door Strip Application

(Continuous Sill) .............................................. 5.31

SITE 5 2014 5.1

Replacement

Repair and

Repair and

Replacement

5.2 2014 SITE 5

Repairing Therma-Tru Door Slabs

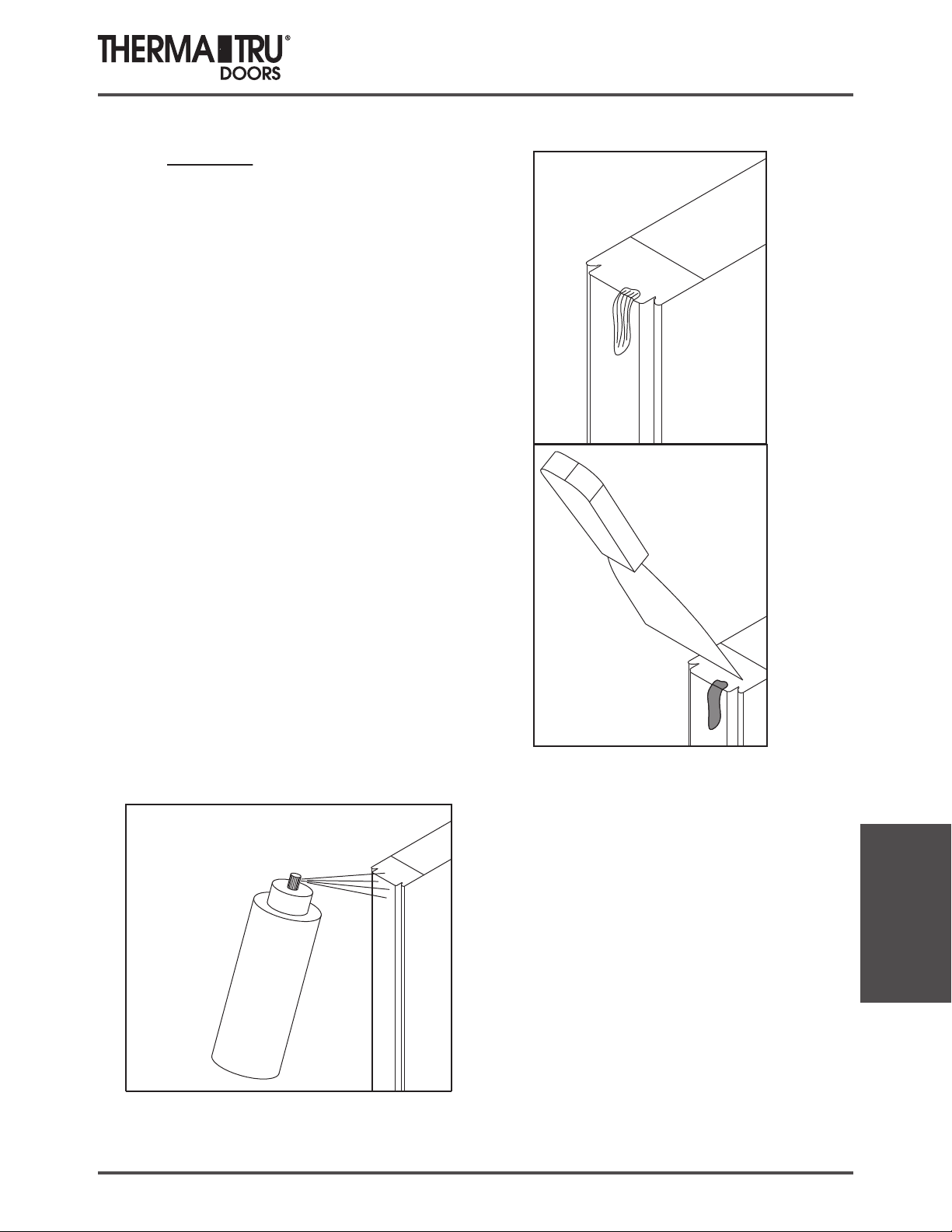

Stile Chips

Fill Chips and Sand Smooth

Fill minor cosmetic damage to wood

stiles with a hardening type wood putty.

File and sand smooth.

Reprime Area Using Touch-up Paint

SITE 5 2014 5.3

Replacement

Repair and

Repairing Therma-Tru Door Slabs

Steel Door Dent Repair

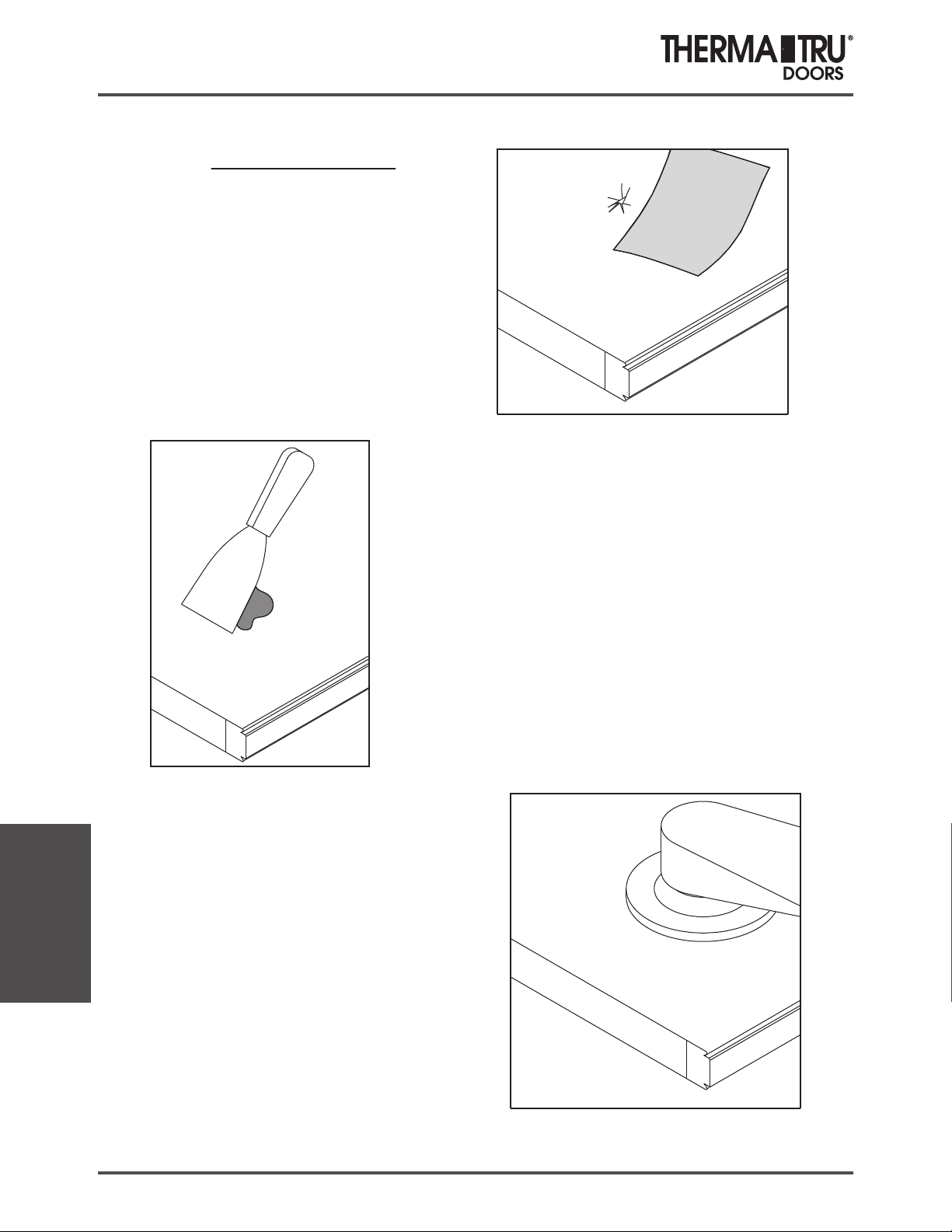

Clean and Roughen Surface

Clean surface surrounding dent.

Roughen using 100 grit sandpaper.

If possible, do not sand through

the existing factory-applied primer.

Fill Dent

Fill dent using Therma-Tru Dent Repair

Kit (Part # MS00DRK) or an automotive

body-filler compound.

Repair and

Replacement

Smooth using a wide-blade putty knife.

Overfill to account for shrinkage and

sanding.

Sand Dent Repair

Sand repair using a large sanding block

or orbital power sander with 220 grit

sandpaper.

5.4 2014 SITE 5

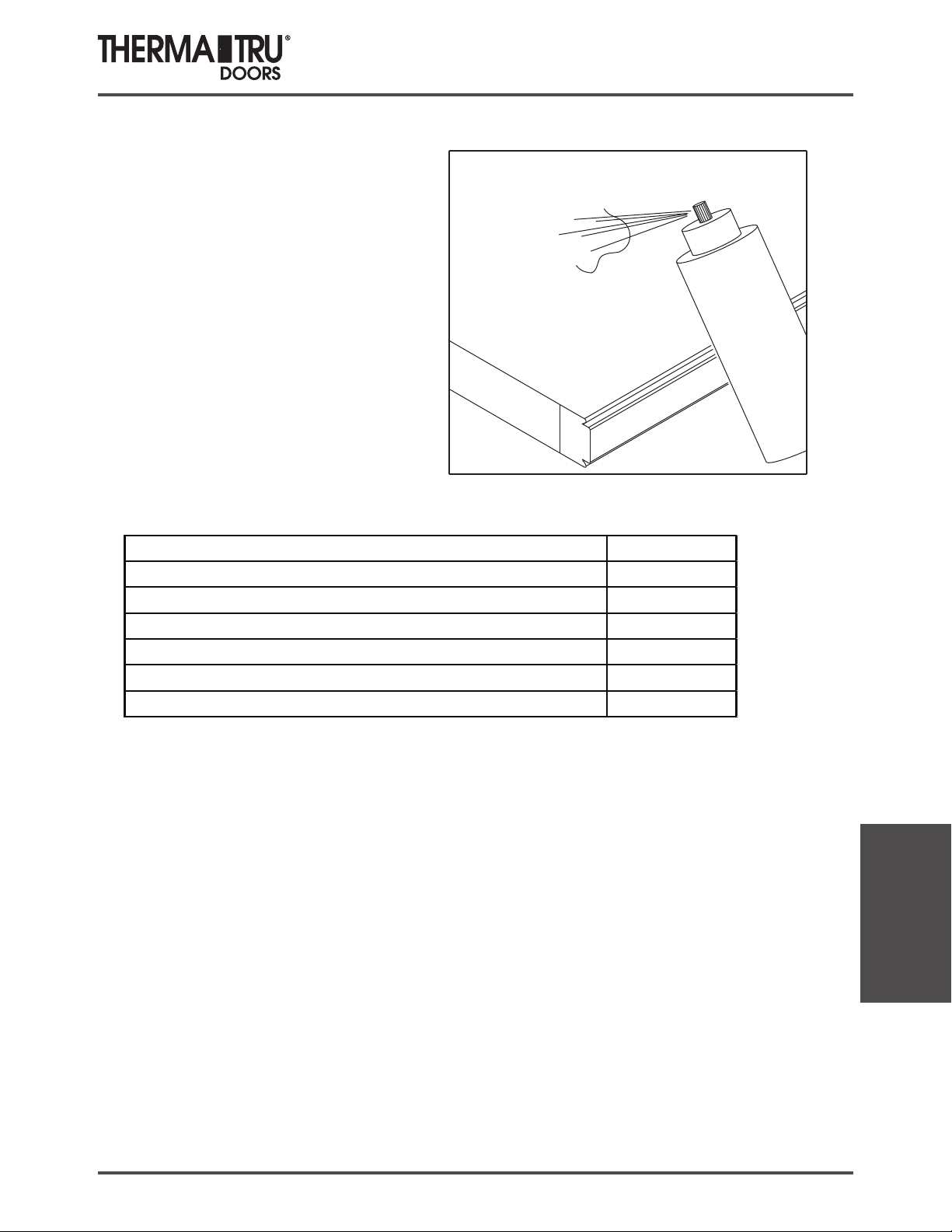

Re-prime Repair Area(s)

If bare metal was exposed, paint

entire repair area with a primer

containing rust inhibitors.

Re-prime repaired area using

Therma-Tru touch-up primer. If a

rust inhibiting primer was used, let

dry thoroughly before applying

Therma-Tru touch-up primer.

THERMA-TRU TOUCH-UP PRIMERS

Repairing Therma-Tru Door Slabs

Descripon Part Number

Steel White Primer MSWHABP-01

Classic-Cra Canvas, Oak, Rusc, and Fiber-Classic Primer MSCCAB-01

Classic-Cra Mahogany Primer MSCCMAB-01

Smooth-Star Primer MSWHSABP-03

Steel Edge Door Primer MSWHSED

Steel Frame Primer MSWHAF2

Classic-Craft, Fiber-Classic and Smooth-Star Skin Repair

For minor scratches in Classic-Craft Canvas, Oak, Rustic or Fiber-Classic doors, use Classic-Craft &

Fiber-Classic Primer (Part # MSCCAB-01) to touch up.

For minor scratches in Classic-Craft Mahogany doors, use Primer (Part # MSCCMAB) to touch up.

For minor scratches in Smooth-Star doors, use Smooth-Star White Primer (Part # MSWHSABP-03)

to touch up.

Replacement

Repair and

For deep scratches, fill with crayon or patch pencil.

Therma-Tru does not recommend any other repair procedures for composite doors.

SITE 5 2014 5.5

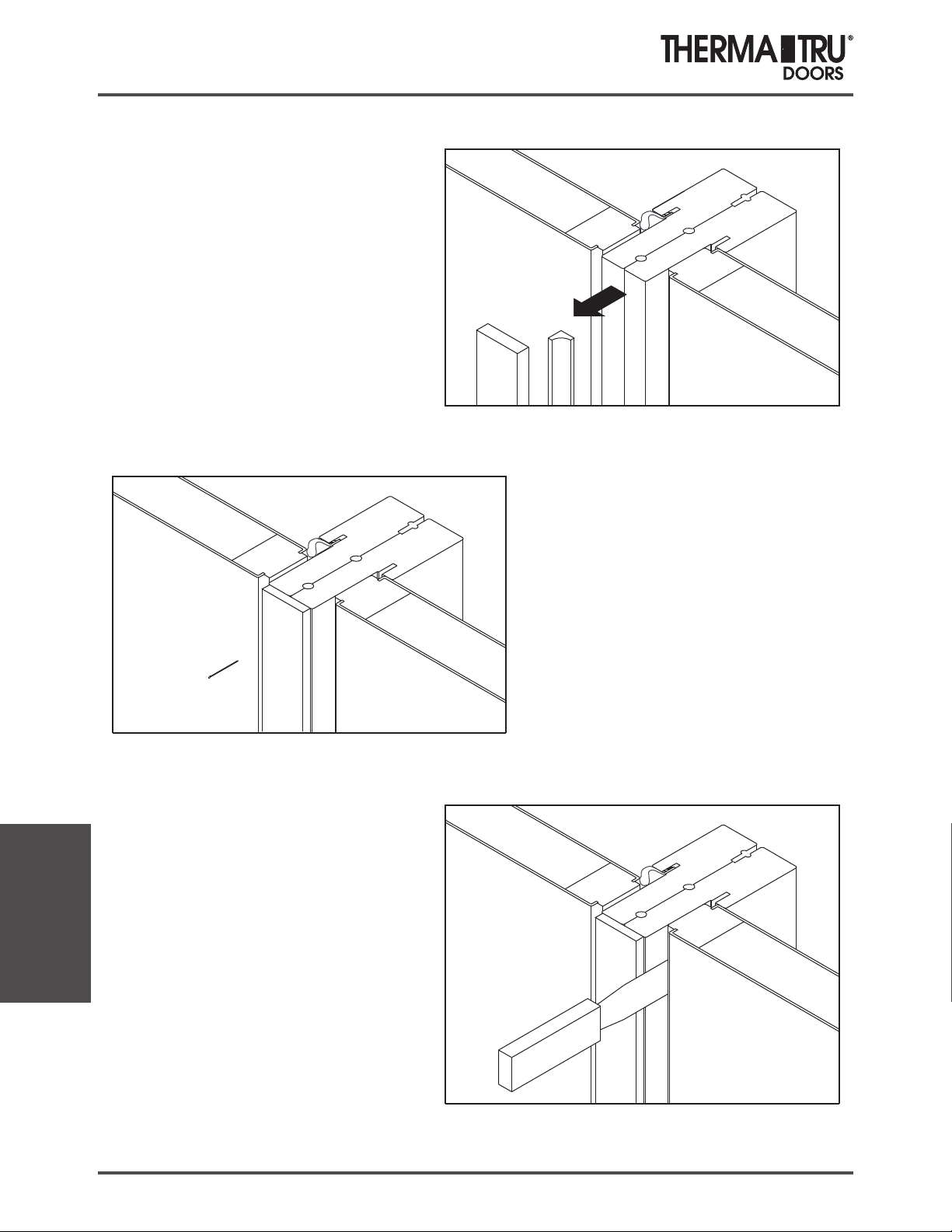

Sidelite Slab Replacement

Remove Cove Molding and

Inside Vertical Casing if applicable

Remove and set aside cove molding.

If post between sidelite and door is two

“mulled” jambs, remove casing there also.

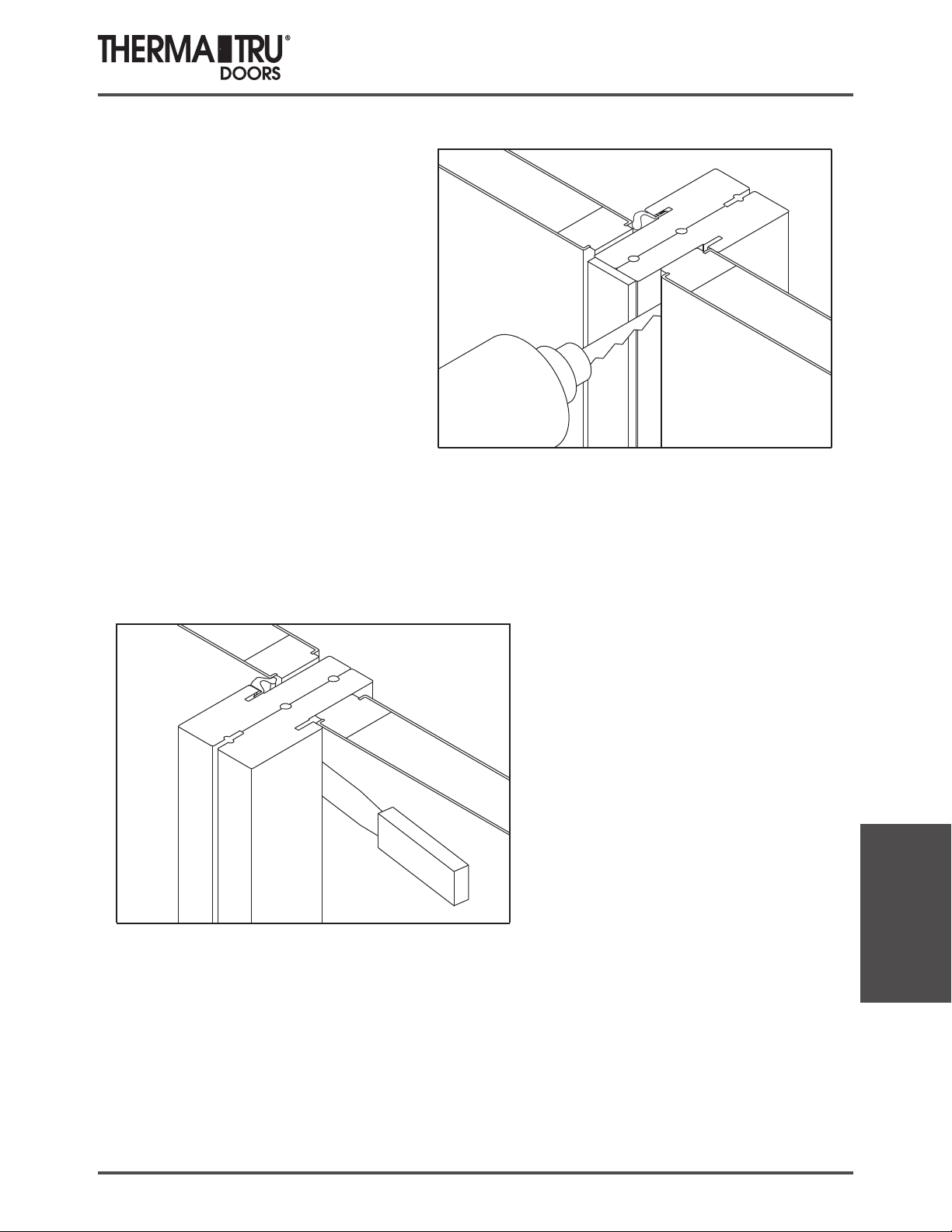

Tack on Protective Strips

Tack on softwood strips to protect jamb

and mullion faces adjacent to sidelite

slab.

Repair and

Replacement

Locate Fasteners

Find fasteners by running a putty

knife blade in the margins and

marking the locations.

5.6 2014 SITE 5

Cut Through Fasteners

Use a reciprocating saw with a metal

cutting blade to cut through fasteners.

Run sawblade in margin.

Remove softwood strip.

Sidelite Slab Replacement

Cut Sealant Joints

On outside face of unit, use putty knife

and cut through sealant joints along head

and at sides.

Replacement

Repair and

SITE 5 2014 5.7

Sidelite Slab Replacement

Remove Slab

Push slab through from outside.

Repair and

Replacement

Prepare Opening for New Slab

Cut away and clean off all old caulking.

Cut away all old fasteners flush with

Frame.

5.8 2014 SITE 5

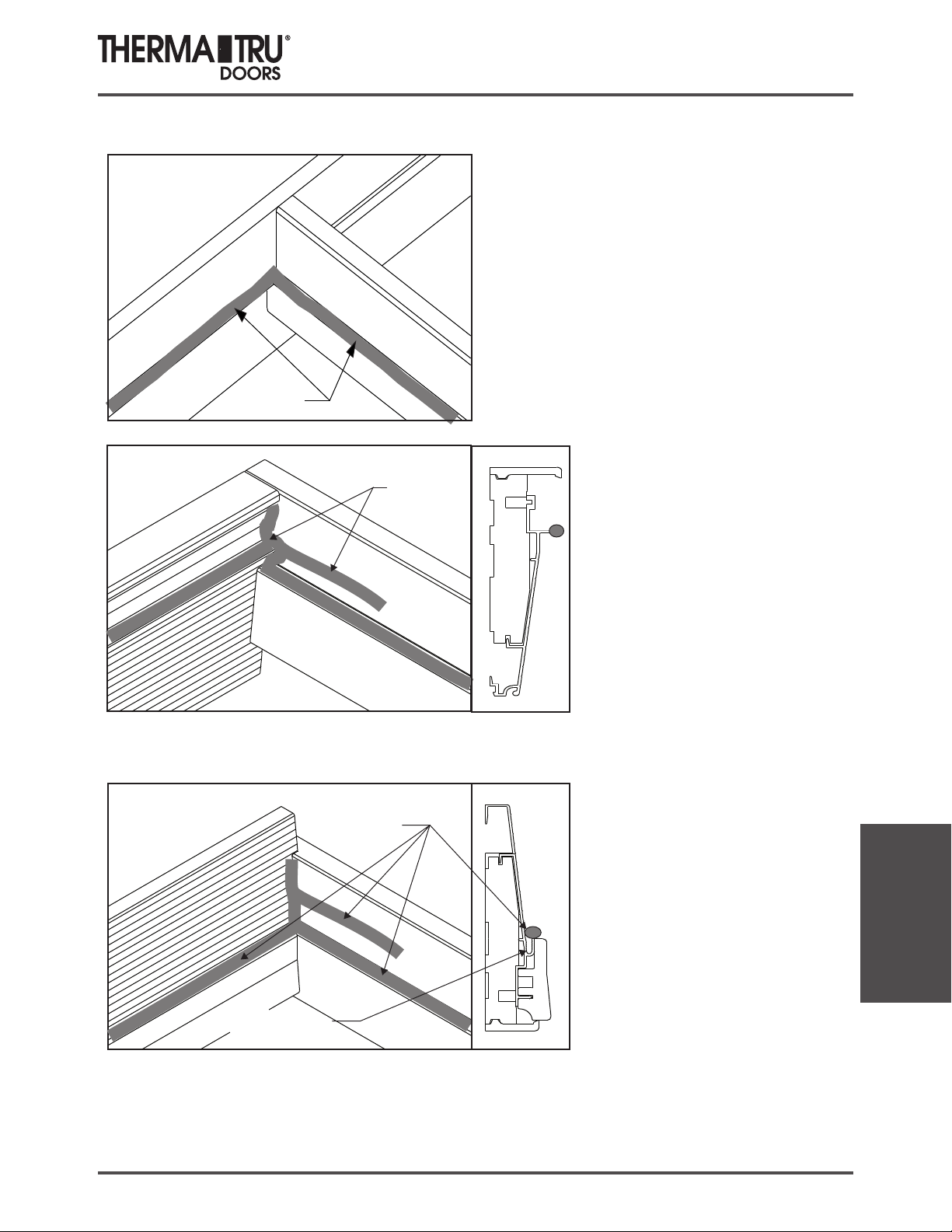

Sidelite Slab Replacement

Mullion system shown

Head

Sealant

Mullion

Sealant

Seal Perimeter

Apply 1/4” bead of (Elastomeric or

Polyurethane) sealant around entire

perimeter on jamb and/or mullion stops.

Inswing Sill

Apply a generous amount of

(Elastomeric or Polyurethane)

sealant at joints where sill and

jamb/mullion meet.

Apply a 1/4” bead of (Elastomeric

or Polyurethane) sealant

approximately 1” above

weatherstrip kerf, 6” long.

Inswing

Weatherstrip

channel

Outswing

Sealant

Outswing Sill

Apply a 1/4” bead of

(Elastomeric or Polyurethane)

sealant on saddle surface that

contacts door face.

Apply a generous amount of

sealant at joints where sill and

jamb/mullion meet.

Apply a 1/4” bead of (Elastomeric

or Polyurethane)sealant approx

1” above weatherstrip kerf, 6”

long.

Replacement

Repair and

.

SITE 5 2014 5.9

Loading...

Loading...