Therma-Stor Products Group PHOENIX 300 User Manual

PHOENIX 300 Operation & Service Instructions

Therma-Stor Products

A Division of DEC International

Box 8050 Madison, WI 53708

Toll Free 1-800-533-7533

Local 1-608-222-5301

Table of Contents

Specifications

1.

Operation

2.

2.1 Transporting the Phoenix 300 ......................1

2.2 Location ........................................................ 1

2.3 Electrical Requirements ............................... 2

2.4 Condensate Removal ................................... 2

2.5 Ducting .........................................................2

2.6 Power Switch................................................ 2

2.7 Pump Purge Switch ...................................... 2

2.8 Pump Fail Light............................................. 2

2.9 Hour Meter.................................................... 2

2.10 Defrost Control Adjustment ......................... 2

2.11 Low Pressure Control .................................. 3

Maintenance

3.

3.1 Air Filter ........................................................ 3

3.2 Blower Oiling ................................................ 3

3.3 Storage ......................................................... 3

Service

4.

4.1 Warranty ....................................................... 4

4.2 Technical description.................................... 4

4.3 Troubleshooting............................................ 4

4.4 Refrigerant Charging .................................... 5

4.5 Blower Replacement ....................................5

4.6 Compressor/Capacitor Replacement ........... 5

4.6A Checking Compressor Motor Circuits .....5

4.6B Replacing a Burned Out Compressor .....6

4.6C

4.7 Defrost Thermostat & Timer ......................... 7

4.8 Condensate Pump........................................ 7

4.9 Relay.............................................................7

4.10 Time Delay ..................................................7

Wiring Diagram

5.

Service Parts List

6.

.............................................................. 4

Replacing a Compressor- Non-Burn Out

................................................... 1

.......................................................... 1

..................................................... 3

................................................. 8

............................................. 9

... 7

Read the operation and maintenance instructions

carefully

these instructions is essential to obtain maximum

benefit from your Phoenix 300 dehumidifier.

before

using this unit. Proper adherence to

1 Specifications

Model: PHOENIX 300 Dehumidifier

Electrical: 110-120 Vac, 12 Amps, grounded

Capacity: 176 pints per day @ 80°F, 60% RH

Operating Temp. Range: 33°F min., 105°F max.

Air Flow: 540 CFM without external ducting

Refrigerant Charge: 2 lbs., 5 oz. R-22

Optional Duct connection: 10" round outlet

Size: 45" high x 24" wide x 20" deep cabinet

46" high x 29" wide x 25" deep overall

Weight: 175 lbs.

2 Operation

2.1 Transporting the Phoenix

The Phoenix 300 must always be upright when

transported by vehicle. It may be tipped on to its handle

and back for loading and moving by hand.

2.2 Location

Note the following precautions when locating the

Phoenix 300:

•

It is designed to be used

•

If used in a wet area, plug it into a

INTERRUPTER.

DO NOT

••••

•

It must always be used in the upright position.

•

The air inlet on top & the side outlet must be at least

1 foot from walls and other obstructions to air flow.

•

If the humid area is very large, dehumidification can

be improved by adding an outlet duct to circulate air

to stagnant areas (see Sec. 2.5).

use the Phoenix 300 as a bench or table.

INDOORS ONLY

GROUND FAULT

.

Serial No. ________________________________

Purchase Date ____________________________

Dealer's Name ____________________________

Lit. No. TS-218B-0499

2.3 Electrical Requirements

2.8 Pump Fail Light

The Phoenix 300 can be plugged into a grounded 15

Amp circuit. At 80°F, 60% RH, it draws 11.4 Amps. Due

to the high percentage of a 15 Amp circuit’s capacity

that the unit uses, the circuit should be dedicated to

running it only. Amp draw decreases at lower loads and

increases at higher loads. At extremely high loads, a 20

Amp circuit may be required.

The unit briefly draws more amps to start if it has been

stored in a cold area. This may cause a 15 Amp circuit

breaker to trip. A 20 Amp circuit is recommended in

such situations. Some models have a time delay to

delay the compressor start about 2 minutes after the

power switch is turned on. This reduces the unit’s

starting amp draw by starting the blower and

compressor at different times.

If an extension cord is required, it must have a

minimum of 12 gauge conductors if 25 feet long or less

and 10 gauge conductors if greater than 25 feet long.

2.4 Condensate Removal

The Phoenix 300 is equipped with an internal

condensate pump to remove the water that is

condensed during dehumidification. This allows the

condensate to be pumped 30' with the attached hose. If

the condensate must be pumped more than 20 feet

above the unit, a second pump must be added to relay

the condensate.

2.5 Ducting

If the condensate pump fails, water draining into the

pump reservoir will fill above its normal level. A safety

float switch will then turn on the pump fail light (located

next to the pump purge switch) and stop the

compressor. This prevents water from overflowing and

wetting the floor. The safety switch will not allow the

compressor to restart until water has been removed

from the pump reservoir.

2.9 Hour Meter

The digital hour meter measures the cumulative time

that the unit is turned on to tenths of an hour. It stores

its total when the unit is unplugged; the previous total

will be displayed when the unit is next turned on. It

resets to zero after 99,999.9 hours of operation.

2.10 Defrost Control Adjustment

When the Phoenix 300 is used in a cool area, frost will

form on the cooling coil as it dehumidifies. When

enough frost forms, the defrost thermostat will initiate

the timed defrost cycle. The cycle periodically turns off

the compressor while allowing the blower to run. The

frost is melted by the air that the blower draws through

the cooling coil.

The defrost cycle is automatic and designed for

optimum performance above 50°F. If the unit is used in

an area that is below 50°F for more than 2 hours,

adjustment of the defrost timer is recommended to

improve performance (see Sec. 2.10).

A detachable 10" round exhaust collar is supplied that

will allow a 10” round flexible duct to be attached to the

Phoenix 300 outlet. The duct and collar may be quickly

attached to the Phoenix 300 by sliding the 4 collar tabs

into the slots around the blower outlet and rotating the

collar clockwise. It may be quickly removed to transport

the unit more easily.

2.6 Power Switch

The power switch (on left side of hour meter) lights up

when the unit is turned on. The unit will continue to run

in all conditions until the switch is turned off; there is no

dehumidistat.

2.7 Pump Purge Switch

This switch (on right side of hour meter) minimizes the

water left in the condensate pump reservoir for moving

or storage. Pressing and holding the pump purge

switch will cause the condensate pump to run. Hold the

switch in until the flow from the condensate hose stops.

DRYING TIP: Air’s ability to absorb moisture from wet

surroundings and the Phoenix 300’s ability to remove

moisture from that air is greatly improved at higher

temperatures. We recommend that the area to be dried

be heated to over 70°F if possible. Less drying time will

be required and efficiency will improve.

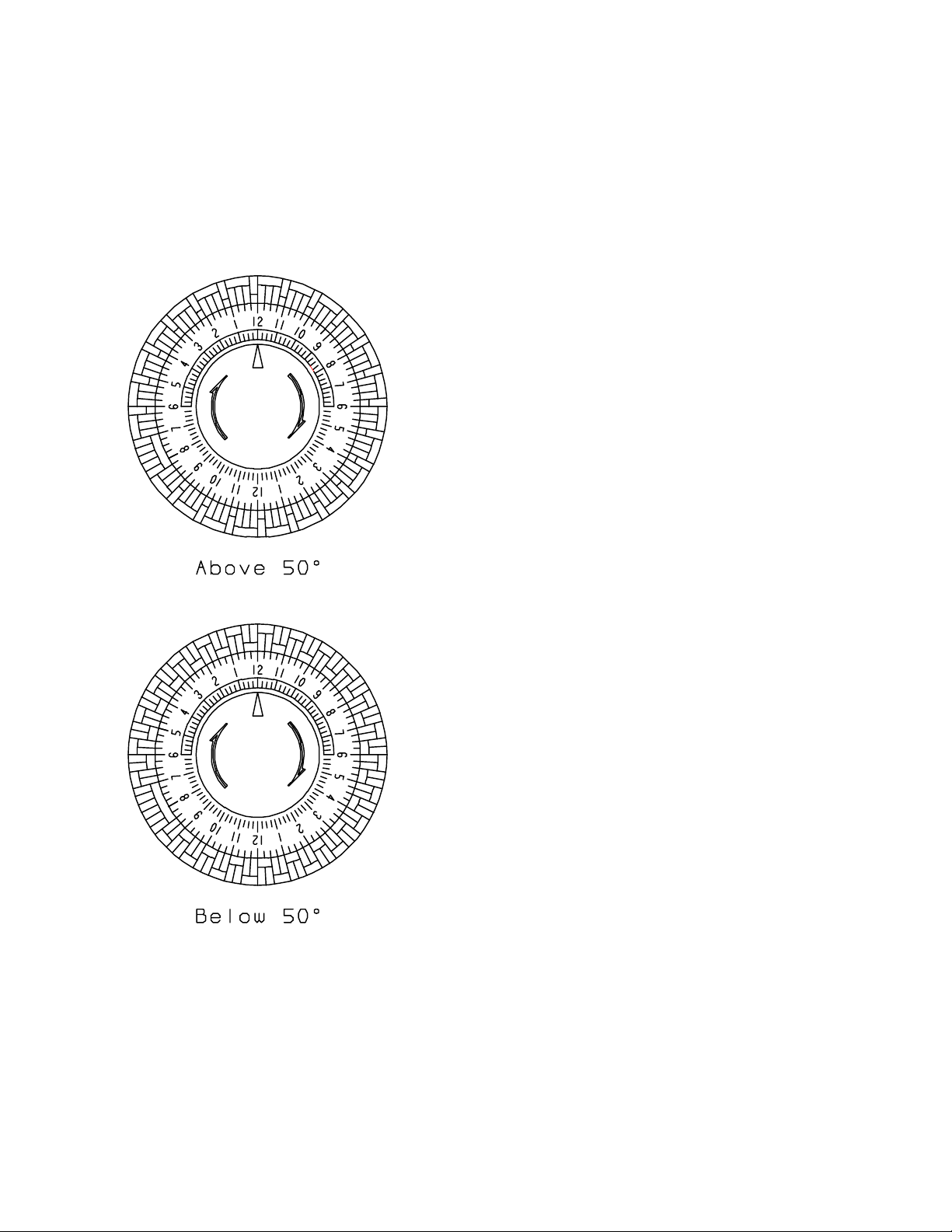

To adjust the defrost timer:

1. Unplug the unit.

2. Remove the front cover (6 screws).

3. The timer is fastened to the right inside panel.

Every fourth peg around the dial is pushed out

from the dial center except one section with 5

pegs out in a row. See figure 1. Each fourth “out”

peg represents 15 minutes of compressor "off"

time during every hour that the unit is in the

defrost cycle.

4. To improve performance below 50°F, the

compressor "off" time must be increased to 30

minutes per hour to allow the frost to completely

melt. To do this, push the pegs out from the dial

2

center so that the pegs alternate with 2 toward the

center, then 2 out from the center, all the way

around the dial except for the section now with 6

pegs out in a row (see Fig. 1).

5. Replace the cover.

Change the timer pegs back to the original pattern for

use above 50°F.

2.10 Low Pressure Control

If the low side refrigerant pressure drops to 15 PSIG,

the low pressure control opens and shuts off the

compressor and blower. It is an automatically reset

control. Its primary function is to prevent damage to the

compressor if a leak develops in the refrigeration

system. It may also open if the unit is A) used in a cool

area (below 50°F) and the defrost timer is not adjusted

(see Sec. 2.10) or B) stored where it is below 40°F and

then started. Under these conditions, the unit will

restart within several minutes. Until the unit warms up,

it may cycle several times.

Figure 1: Defrost Control Timer

3

Loading...

Loading...