Installation and

User Manual

TABLE OF CONTENTS

INTRODUCTION............................................................................................

..........................

.. 2 1-WARNINGS AND WARRANTY TERMS............................................

...

....................

........

.

........

3 2-

INSTALLATION INSTRUCTIONS.................................................................

.......................

....... 7 3-DRAWINGS AND TECHNICAL SPECIFICATIONS.........................................

......

................

........

16 4-

INSTALLATION AND ASSEMBLY....................................................

......................

...................

18 5-

PLUMBING CONNECTION............................................................

....................

....

.................

20 6-

ELECTRICAL CONNECTIONS................................................................

.........................

..........

24 7-

INITIAL START

-

UP..........................................................................

..........

................

..............

25 8-

OPERATION...........................................................................................

..........................

..... 29 9-SAFETY DEVICES ……………………..................................................

........

.................

...................

34 10-

CLEANING AND MAINTENANCE...............................................

........................

....................

35 11-

TROUBLESHOOTING..............................................................

............

.............

.....................

40 12-

WIRING DIAGRAM.......................................................................

..........................

.............

42

INTRODUCTION

Dear Customer,

Thank you for having chosen our product.

To allow for optimal operation and for you to enjoy the warmth and sense of

wellbeing that the fire can convey in your home, we advise you to read this manual

carefully before starting up the product for the first time.

CARE OF THE MANUAL AND HOW TO CONSULT IT

Take care of this manual and keep it in an easily accessible place.

Should the manual be misplaced or ruined, request a copy from your retailer or

directly from the authorised Technical Assistance Department.

SYMBOLS USED IN THE MANUAL

ATTEN

TION:

carefully read and understand the relative message because failure to

comply with what is written can cause serious damage to the product

and put the user’s safety at risk.

INFORMATION:

failure to comply with these provisions will compromise the use of the

product.

OPERATING SEQUENCES:

sequence of buttons to be pressed to access the menus or make

adjustments.

MANUAL

carefully read this manual or the relative instructions.

SAFETY PRECAUTIONS

• Installation, electrical connection, functional verification and maintenance must only be

performed by qualified or authorised personnel.

• Install the product in accordance with all the local and national laws and Standards applicable

in the relative place, region or country.

• This product is not intended for use by persons (including children) with reduced physical,

sensory or mental capabilities, or lack of experience and knowledge, unless they are

supervised or trained on how to use the product by a person responsible for their safety.

• Only use fuel recommended by the company. The product must not be used as an incinerator. It

is strictly forbidden to use liquid fuel.

• The instructions provided in this manual must always be complied with to ensure the product

and any electronic appliances connected to it are used correctly and accidents are prevented.

• The user, or whoever is operating the product, must read and fully understand the contents of

this installation and use guide before performing any operation. Errors or incorrect settings can

cause hazardous conditions and/or poor operation.

• Do not use the product as a ladder or supporting structure.

• Do not place laundry on the product to dry. Any clothes horses or similar objects must be kept at

a safe distance from the product. Fire hazard.

• All liability for improper use of the product is entirely borne by the user and relieves the

Manufacturer from any civil and criminal liability.

• Any type of tampering or unauthorised replacement with non-original spare parts could be

hazardous for the operator's safety and relieve the company from any civil and criminal liability.

• Most of the surfaces of the product are very hot (door, handle, glass, smoke outlet pipes, etc.).

Avoid contact with these parts unless adequate protective clothing is worn or appropriate means

are used, such as heat protective gloves or cold handle type operating systems.

• It is forbidden to operate the product with the door open or the glass broken.

• The product must be powered by a system that is equipped with an effective earth system.

• Switch the product off in the event of a fault or malfunctioning.

• Accumulated unburned pellets in the burner after each "failed start-up" must be removed before

starting up again.

• Do not wash the product with water. The water could get inside the unit and damage the

electrical insulation and cause electric shocks.

• Do not stand in front of the product for a long time. Do not overheat the room where the

product is installed. This could cause injuries and health problems.

• Do not put any fuel other than wood pellets in the hopper.

• Install the product in rooms that are adequately protected against fire and equipped with all the

utilities such as supplies (air and electricity) and smoke outlets.

• If a fire breaks out inside the chimney, switch the appliance off, disconnect it from the mains and

do not open the door. Then contact the competent authorities.

• The product and the ceramic/serpentine cladding must be stored in a place where there is no

humidity and must not be exposed to the elements.

• It is recommended not to remove the feet that support the product in order to guarantee

adequate insulation, especially if the flooring is made of flammable material.

• If the ignition system is faulty, do not force ignition with flammable materials.

• Special maintenance must only be performed by authorised and qualified personnel.

• Assess the static conditions of the surface on which the weight of the product will rest and

provide suitable insulation if it is made of flammable material (e.g. wood, fitted carpet or plastic).

1

WARNINGS AND WARRANTY TERMS

INFORMATION:

Please contact the retailer or qualified personnel authorised by the company to resolve a problem.

• Only fuel stipulated by the company must be used.

• Check and clean the smoke outlet pipes regularly (connection with the product).

• The product is not a cooking appliance.

• Always keep the cover of the fuel hopper closed.

• Keep this instruction manual in a safe place as it must accompany the product throughout its

working life. If it is sold or transferred

• to another user, always make sure that the manual accompanies the product.

INTENDED USE

The product only works with wood pellets and must be installed indoors.

WARRANTY CONDITIONS

The company provides a product warranty, excluding the parts subject to normal wear stipulated

below, for a period of two years from the date of purchase, which is proven by a supporting

document that contains the name of the seller and the date when the sale took place. Warranty

cover is valid if the completed warranty is returned within 8 days and the product is installed and

tested by a qualified installer, according to the detailed instructions provided in the instruction

manual supplied with the product.

The term ‘warranty’ refers to the (free-of-charge) replacement or repairs of parts acknowledged to

be faulty due to manufacturing defects.

RESTRICTIONS

The above-mentioned warranty does not cover parts of electrical and electronic components and

fans, which are covered for two years from when the product is purchased, proof of which is

provided as specified above. The warranty does not cover parts subject to normal wear, such as:

gaskets, glass and all parts that can be removed from the firebox. Replaced parts will be covered by

the warranty for the remaining period of the warranty in force as from the date of purchase of the

product.

EXCLUSIONS

Variations in colour of the painted do not constitute grounds for a claim as they are natural

characteristics of the material and product use.

The warranty does not cover any part that may be faulty as a result of negligence or careless use,

incorrect maintenance or installation that does not comply with the company's instructions (see the

relative chapters in this user manual).

The company declines all liability for any damage which may be caused, directly or indirectly, to

persons, animals or objects as a consequence of non compliance with all the prescriptions specified

in the manual, especially warnings regarding installation, use and maintenance of the appliance.

If the product does not work correctly, contact your local retailer and/or importer. Damage caused

during transport and/or when handled is excluded from the warranty.The supplied installation guide

is the only reference for installation and product use.

The warranty will be rendered null and void in the event of damage caused by tampering,

atmospheric agents, natural disasters, electrical discharges, fire, defects in the electrical system, and

maintenance not being performed at all or as indicated by the manufacturer.

INTERVENTION REQUEST

The company declines all liability if the product and any other accessory is used

incorrectly or altered without authorisation.

All parts must be replaced with original spare parts.

The request must be sent to the retailer who will forward it to the Technical Assistance

Service.

SPARE PARTS

Only use original spare parts. The retailer or service centre can provide all the useful information

regarding spare parts.

It is recommended not to wait for the parts to be worn before having them replaced. It is important

to perform regular maintenance.

PRECAUTIONS FOR CORRECT DISPOSAL OF THE PRODUCT IN ACCORDANCE WITH THE EUROPEAN

DIRECTIVE 2002/96/EC AND ITS SUBSEQUENT AMENDMENT 2003/108 EC.

At the end of its working life, the product must not be disposed of as urban waste.

It must be taken to a special differentiated waste collection centre set up by the local authorities or

to a retailer that provides this service.

Disposing of the product separately prevents possible negative consequences for the environment

and health deriving from inappropriate disposal and allows to recycle its materials in order to obtain

significant savings in energy and resources.

As a reminder of the need to dispose of appliances separately, the product is marked with a crossedout wheeled dustbin.

The product is a stove designed for operation with wood pellets. It must be installed in compliance

with the regulations listed below:

• EN 10683 (2012) heat generators fed with wood and other solid fuels: installation.

The chimneys must be in compliance with:

• EN 13063-1 and EN 13063-2, EN 1457, EN 1806 in the event of non-metallic chimneys:

• EN 13384-1 (13384) chimneys. Thermal and fluid dynamic calculation methods.

• EN 1443 (2005) chimneys: general requirements.

• EN 1457 (2012) chimneys: clay/ceramic flue liners.

The installation procedure requires the heating system diagram, prepared in compliance with the

standard and local recommendations in force as follows:

• For the heating system - EN 303-5/2000 - “Heating boilers. Part 5: Heating boilers for solid

fuels, hand and automatically stoked, with a nominal heat output of up to 300 kW.

Terminology, requirements, testing and marking”.

• Local requirements for the connection to the chimney.

• Local requirements for fire regulations.

• For the power circuit - EN 60335-1/2008- “Safety of household and similar electrical

appliances, Part 1 - General Requirements”.

One must also bear in mind all laws and national, regional, provincial and town council Standards

present in the country in which the appliance has been installed.

PELLETS

Wood pellets are manufactured by hot-extruding compressed sawdust which is produced during the

processing of natural dried wood (without paints). The compactness of the material is guaranteed by

the lignin contained in the wood itself and allows pellets to be produced without glue or binders.

The market offers different types of pellets with characteristics that vary according to the wood

mixtures used. The diameter varies between 6 and 8 mm, with a standard length ranging from 5 to

30 mm. Good quality pellets have a density that varies between 600 and over 750 kg/m3, with a

moisture content that ranges from 5% to 8% of its weight.

Pellets have technical advantages besides being an ecological fuel, as the wood residue is used

completely, thereby achieving cleaner combustion than that of fossil fuels.

Good-quality wood has a calorific value of 4.4 kW/kg (15% moisture, after about 18 months of

seasoning), whereas that of pellets is 4.9 kW/kg. To ensure good combustion, the pellets must be

stored in a dry place and protected from dirt. Pellets are usually supplied in 15 kg bags, therefore,

storing them is very convenient.

Good quality pellets guarantee good combustion, thereby decreasing harmful emissions into the

atmosphere.

2

INSTALLATION INSTRUCTIONS

The poorer the quality of the fuel, the more often the internal parts of the brazier and

combustion chamber must be cleaned.

The pellet used must comply with the features described by Standards:

EN PLUS - UNI EN 16961 - 2 class A1 or A2

Ö-NORM M 7135

DIN PLUS 51731

We recommend using pellets with a diameter of 6mm with its products.

Pellet storage

To guarantee combustion without problems, the pellets must be kept in a dry place.

Poor quality pellets or others that do not comply with that specified previously

compromises the operation of your product and can therefore render the warranty and

product liability null and void.

PRECAUTIONS REGARDING INSTALLATION

The product must be installed in a suitable place for it to be regularly opened and routine

maintenance to be performed. The site must be:

• Compliant for proper operation.

• Equipped with an adequate smoke expulsion system.

• Equipped with ventilation intake from outside.

• Equipped with 230V 50 Hz power supply with an EC compliant earth system.

The product must be connected to a chimney or an internal or external vertical duct that complies

with the regulations in force. The product must be positioned in such a way that the electrical

socket is accessible.

IMPORTANT!

The product must be connected to a chimney or a vertical duct that can expel the smoke at

the highest point of the building. In any case smoke derives from combustion of types of

wood and if it comes in contact with or close to walls, these can become dirty. Moreover,

utmost attention is required as they are almost invisible but very hot and can cause burns.

The holes of the external air inlet and the smoke outlet pipe must be drilled before positioning the

product.

THE OPERATING ENVIRONMENT

For correct operation and even distribution of heat, the product must be placed where the air

required for combustion can flow.

The volume of the room should be no less than 15 m3.

Air must enter through permanent openings made in the walls (near the product) that reach

outwards with a minimum section of 100 cm2 without the protective grille. These openings (air

inlets) must be made in such a way that it is impossible for them to be obstructed in any way.

Air can also be drawn from adjacent rooms to the one that is to be ventilated, provided they have an

external air inlet and are not used as a bedroom or bathroom or where there is a fire hazard, such as:

garages, timber storerooms, warehouses of flammable materials, observing under all circumstances

the provisions of all the applicable standards in force.

If the product is placed too close to the wall it could cause overheating and damage the

plaster (yellowing, cracking, etc.).

POSITIONING AND RESTRICTIONS

In the case of simultaneous installation with other heating appliances, provide appropriate air inlets

for each one (according to the instructions of each product).

The product cannot be installed (except for sealed or closed operation appliances with

external ducted combustion air intake):

in bedrooms or bathrooms;

in rooms where there are liquid fuel appliances with continuous or intermittent operation

that draw the combustion air from the room they are installed in;

in rooms where there are B-type gas heating appliances, with or without domestic hot

water production and interconnecting rooms;

where another heating appliance is installed without an independent air flow.

It is forbidden to place the product in an explosive atmosphere.

BOILER ROOM

Check that the room meets the requirements and characteristics in compliance with the standards in

force. The room must also have suitable ventilation required for proper combustion. One must

therefore make openings in the room walls that meet the following requirements:

• They must have a section of at least 6 cm2 per each 1 kW (859.64 kcal/h). The minimum opening

section must in any case not be below 100 cm2. The section may also be calculated using the

following relation:

S = K * Q . 100 cm2

Where “S” is expressed in cm2, “Q” in kW, “K” = 6 cm2/kW

• The opening must be positioned in the lower part of an outer wall, preferably opposite to that in

which the smoke evacuation duct is located.

MINIMUM DISTANCES

Room ventilation can only be set towards the rear wall if there is adequate insulated

ducting of the hot air flow.

If particularly delicate objects are present, such as furniture, curtains or sofas the distance of the

product must be significantly increased.

If the floor is made of wood, it is recommended to place a floor protection in accordance

with the Standards in force in the country of installation.

Heat-sensitive or flammable objects cannot be placed near the product. Keep such

objects at a minimum distance of 80 cm from the outermost point of the product.

CONNECTION OF THE SMOKE EXHAUST DUCT

When making the hole for the passage of the smoke

discharge pipe, one must take into account the

possible presence of flammable materials. If the hole

must be made through a wooden wall or

thermolabile material, the INSTALLER MUST first of

all use the appropriate wall fitting (minimum

diameter 13 cm) and suitably insulate the pipe of the

product that passes through it using adequate

insulating materials (1.3 - 5 cm thick with minimum

thermal conductivity 0.07 W/m°K).

The same minimum distance must be applied if the

pipe of the product must pass through vertical or

horizontal sections near the thermolabile wall. It is

recommended to use an insulated double-wall pipe in

external sections in order to prevent condensation

from forming.

The combustion chamber works in negative pressure.

REAR VIEW OF A PELLET STOVE

1) SMOKE OUTLET

2) COMBUSTION AIR INLET

Always use pipes and fittings with appropriate seals that guarantee tightness.

REFERENCES

FLAMMAB

LE OBJECTS

NON

-

FLAMMABLE

A 200 mm 100 mm

B 200 mm 100 mm

It must be possible to inspect all sections of the flue duct and they must be removable for periodic

internal cleaning (T-fitting with inspection hole).

Position the product considering all the above requirements and instructions.

IMPORTANT!

The following conditions must be complied with when connecting the appliance to the

chimney:

The smoke duct must be at least category T200 (or higher if required by the smoke

temperature of the appliance) and P1-type (airtight).

All 90° angles (max. 3) in the smoke exhaust duct must be preferably fitted with the

relative T-fittings with inspection hole. (See pellet product accessories).

It is strictly forbidden to fit a mesh at the end of the exhaust pipe as it could cause the

product to malfunction (due to clogging).

It is forbidden to use counter-sloping pipes.

The horizontal section of the smoke duct must not be longer than 2-3 m.

It is also recommended not to exceed 6 metres in length with the pipe Ø 80 mm.

The smoke duct must not cross rooms in which it is forbidden to install combustion

appliances.

FRESH AIR INTAKE

To ensure trouble

-

free operation the stove/fireplace

must have the necessary air available for combustion

and this is provided through the fresh air intake.

The fresh air intake must:

have a total free cross section at least equal to the

size given in the paragraph “TECHNICAL DATA”;

be protected by a grille or suitable guard provided

it does not reduce the minimum recommended

section;

be in a position whereby it cannot be obstructed.

The airflow

necessary for the fire may be obtained in

different ways:

through a fresh air intake direct into the room of

installation;

with ducting through pipes direct to the room of

installation, increasing the recommended minimum

free cross section by at least 15%;

from an adjacent room to the place of installation

provided this air flows freely through permanent

apertures communicating with the outside.

The adjacent room from which air is taken

must not have a low pressure compared to

the exterior due to a counter draught

caused by the presence in that room of another

appliance in use or of a suction device.

The permanent apertures in the adjacent room must

comply with the requirements given above.

Combustion air must not be taken from adjacent

rooms used as a garage or a combustible materials

store or for activities posing a fire hazard.

CONNECTION TO THE EXTERNAL AIR INLET

It is essential for the room where the product is installed to be adequately ventilated in order to

guarantee sufficient air for proper combustion in the appliance. This is possible by means of suitable

ventilation openings in the room itself or in an interconnected room through a permanent opening

between the rooms (room ventilation is excluded in the case of installation with Oyster technology,

where combustion air is ducted directly from outside)

For this purpose, drill a hole on the outer wall close to the product with a minimum section of 80 cm²

(11 cm in diameter or 10x10 cm if rectangular, considering the protective grilles), protected by a

grille on the outside.

The air inlet must also:

• be protected with a grid, metal mesh, etc. without reducing the net section.

• Be positioned in such a way so as not to be obstructed.

• Allow maintenance to be performed.

• Be directly interconnected with the room where the product is installed.

• In the case of ducting, up to 3.5 linear metres, increase the cross-section by about 5%,

whereas for longer ducts, increase it by 15%.

Remember that the ventilation grilles always show the useful section in cm2 on one

side. When choosing the grille and size of the hole, check that the useful section of the

grille is larger or equal to the section required by the company for product operation.

IMPORTANT!

The air flow can also be drawn from an adjacent room to that of the room where the

product is installed, provided the air can flow freely through permanent openings

interconnected with the outside; air inlets connected to thermal units, garages, kitchens

or bathrooms must be avoided.

CONNECTION TO THE CHIMNEY

The chimney is the fundamental element for smoke expulsion and must therefore comply with the

following requirements:

• be waterproof and thermally insulated.

• Be made of suitable materials that resist mechanical stress over time, heat, the effects of the

combustion products and any possible condensation.

• Have a vertical set-up with deviations from the axis of no more than 45° and free of bottlenecks.

• Must be suitable for the specific operating conditions of the product and have the CE marking

(EN1856-1, EN1443).

• Must be adequately sized for the draught/smoke expulsion requirements that are necessary for the

product to operate correctly (EN13384-1).

• The internal section is preferably circular.

• In the case of a pre-existing product that has been used, it must be cleaned.

• The chimney must not be shared with other appliances.

The chimney is fundamental for correct operation and safety of your product.

1) WINDPROOF CHIMNEY POT 2) CHIMNEY 3) INSPECTION HOLE

Use adequate instruments to verify that there is a minimum draught of 5 Pa.

Set-up an inspection hole at the bottom of the chimney to perform periodic checks

and cleaning, which must be done annually.

The connection to the chimney must be sealed and the fittings and pipes

recommended by us must be used (CE marked, EN1856-2 with the minimum requisites: T200

and P1).

You must ensure that a windproof chimneypot is installed in accordance with the regulations in

force.This type of connection guarantees smoke expulsion even in the event of a temporary

power cut.

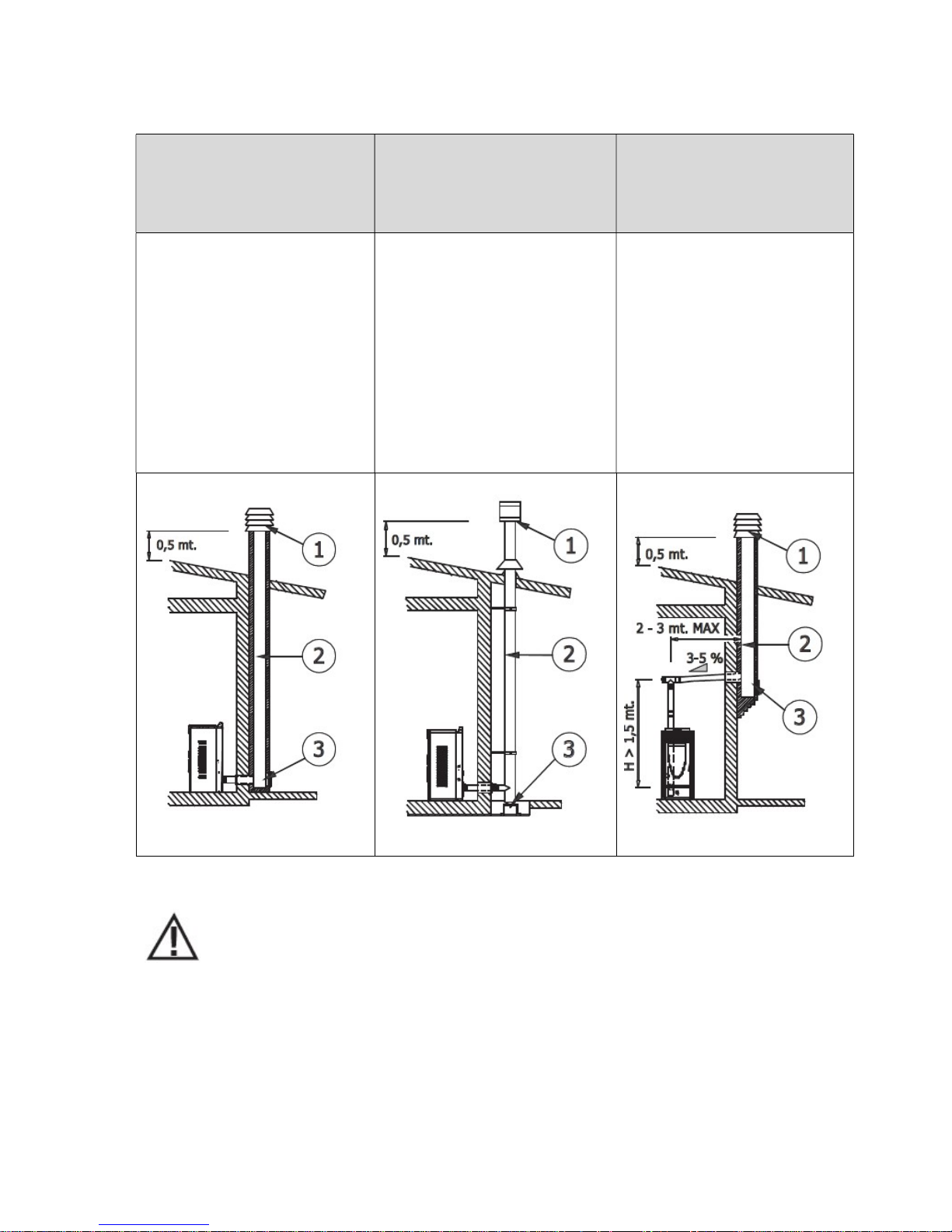

CONNECTION TO THE CHIMNEY

CONNECTION TO AN

EXTERNAL DUCT WITH AN

INSULATED OR DOUBLE-WALL

PIPE

CONNECTION TO THE CHIMNEY

The chimney's internal

dimensions must not exceed

20x20 cm or 20 cm diameter; in

the event of bigger sizes or bad

chimney conditions (e.g. cracks,

poor insulation, etc.), it is

advisable to fit a stainless steel

pipe of suitable diameter

throughout the length of the

chimney right to the top.

The minimum internal dimensions

of the external duct must be

10x10 cm or 10 cm

in diameter and must not exceed

20x20 cm or 20 cm in diameter.

Only stainless steel insulated

(double-wall) pipes must be used,

which are smooth on the inside

and fixed to the wall. Flexible

stainless steel pipes must not be

used.

The connection between the

product and the chimney or the

smoke duct must not have an

inclination that is less than 3% in

the horizontal sections, which

must have a maximum overall

length of 2/3 m. The vertical

section between one T-fitting and

another (angle) must not be less

than 1.5 m.

CHIMNEY STACK

The chimney stack is a device fitted on the top of

the chimney that is designed to

aid dispersion of the products of combustion in the

atmosphere.

The chimney stack must comply with the following

requirements:

it must have an internal section and shape

the same as the flue (A);

it must have a useful outlet section (B) of

not less than twice that of the flue (A);

the part of the chimney that emerges from

the roof or remains in contact with the

outside (e.g. in the case of a flat roof), must

be covered with brick or tile elements and

in any case well insulated;

it must be built in such a way as to prevent

the penetration of rain, snow and foreign

matter into the flue and to ensure that in

the event of winds from all directions and

angle, discharge of the combustion

products is assured (chimney stack with

down-draught cowl).

No Description

1

Top cover

2

Smoke hood cover

3 Turbulators

4

Cast iron top plate

5

Glass

6

Cast iron door

7

Grate

8

Ash pan

9

Smoke chamber plate

10

Display

11

Air valve

12

Sensor pocket

13

Safety Thermostat

14

Air pressure switch

15

Electronic board

16

Water pressure switch

17

Pump

18

Expansion tank

No

Description

19

Tube cleaning

rod 20 Vermiculite board (back panel)

21

Auger motor

22

Igniter

23

Extraction Fan

2

DRAWINGS AND TECHNICAL SPECIFICATIONS

12 16 24

Thermal power (min/max) kW 5 / 12 6,7 / 16 10 / 24

Thermal power of fluid (water) (min/max) kW 4,1 / 9,7 5,4 / 12,9 8,1 / 19,4

Hourly fuel co nsumption (min/max) kg/h 1,1 / 2,6 1,5 / 3,6 2,3 / 5,4

Efficiency % 89 90 90

CO content (with 13% O2) min/max % 0,02 / 0,0025 0,02 / 0,0025 0,02 / 0,003

Flue temp erature (min/max) °C 125 / 180 110 / 170 85 / 140

Minimum draught Pa

Maximum power rating W

Power rating at work W

Supp ly voltage and frequency V/Hz

Fuel tank capacity kg 27 32 36

Expansion tank ca pacity lt

Maximum working pressure bar

Flow / Re turn (F / R ) R

Safety valve (SV) R

External dimensio ns

H mm 1050 1120 1180

H1 mm

H2 mm

H3 mm

W mm 600

W1 mm 110

L mm 610

D mm

Fresh air intake dia meter mm

230/50

6

3/4"

Ø 50

Mo del HYDRA

Types

320

10

400

160

3

3/4"

Ø 80

560

540

80

250

50

PREPARATION AND UNPACKING

The stove is supplied complete with all its electrical and mechanical components and factory-tested.

Open the package and cut the strip that fasten the stove to the pallet.

Set the stove in the pre-selected place, making sure this complies with the requirements. The stove

body or unit must always be kept in a vertical position when handled and moved by using carts only.

Pay particular attention that its door and its glass are protected from knocks that might compromise

their integrity.

Always handle the product with care. If possible, unpack the stove near the chosen place of

installation. The materials that make up the packaging are neither toxic nor harmful, and so require

no particular disposal measures.

After removing the packaging make sure that the stove is complete and not damaged. if in doubt

contact the dealer.

The product packaging contains the following documents and accessories:

• user manual

• warranty

• allen wrench

• tube cleaning tool

REQUIREMENTS FOR SYSTEM INSTALLATION

the minimum distance in front of the product to allow for cleaning, maintenance, etc. must be

at least 1000 mm;

the minimum admitted distance between the rear of the product and the wall must be 400 mm;

4

INSTALLATION AND ASSEMBLY

the minimum distance between the upper part of the product and a wall (ceiling) must be of 400

mm to ensure easy access for heat exchanger cleaning and maintenance (for example to remove

ashes);

the minimum distance between the product and wall must be 300 mm.

It is essential to make ventilation holes connecting to the exterior and in compliance with Standard

UNI 10683, with the following characteristics:

1. They must have a section of at least 100 cm2;

2. They must be made at a height close to that of the floor;

3. They must be adequately protected by wire mesh or grille, provided it does not reduce the

minimum passage section;

4. They must be positioned in such a way as not to be clogged.

Proper air flow can also be guaranteed by openings to an adjacent room, as long as it

has direct ventilation and is not an environment with danger of fire, such as storage

rooms, garages or warehouses as regulated by Standard UNI 10683.

It is good practice to install the boiler in rooms in which there are no leaking devices with respect to

the room or appliances which may cause depression in the room itself with respect to the external

environment thus causing poor draught problems of the smoke evacuation system (UNI 10683).

IMPORTANT!

If installation of the product involves interaction with another, pre-existing system

complete with heating equipment (gas boiler, methane boiler, diesel boiler, etc.),

contact qualified personnel, who subsequently will be responsible for conformity of the

system in compliance with the applicable law in force.

The Company declines all responsibility for damage to persons or things in the event of failed or

incorrect operation, if the aforementioned warnings are not complied with.

Make the connections to the corresponding fittings shown in the diagram above. Make sure the

pipes are not placed under tension or undersized.

IMPORTANT!!!

5

PLUMBING CONNECTION

FLUSH THE ENTIRE SYSTEM BEFORE CONNECTING THE BOILER IN ORDER TO REMOVE

RESIDUES AND DEPOSITS.

Always install gate valves upstream from the boiler so as to disconnect it from the plumbing

system should it be necessary to move it, or when it requires routine and/or special maintenance.

Connect the boiler using hoses so that the boiler is not too strictly connected to the system, and to

allow slight movements.

SYSTEM FILLING

Filling must be carried out slowly so that air bubbles can get out via the purposely placed outlets on

the heating system. In closed circuit heating systems the loading pressure of the system when cold

and the expansion tank preloading pressure must be the same.

In open tank heating systems, there is direct contact between the circulating liquid and air.

During the heating season the end user must regularly check the level of water circulating in

the expansion tank. The content of water in the recycling system must be kept constant.

Practical experience demonstrates that the water level must be inspected regularly every 14

days to maintain the water content almost constant. In the event one needs to add water

one must carry out the filling process when the boiler has cooled down to room

temperature. These precautions aim to prevent the onset of a thermal stress of the steel

body of the boiler.

In systems equipped with an open tank the water pressure in the boiler - when the system is

cold - must not fall below 0.3 bar;

The water used for filling the heating system must be decontaminated and without air.

Attention!

Do not mix the heating water with antifreeze or anticorrosion substances in the wrong

concentrations! It can damage the seals and cause the onset of noise during operation.

The manufacturer declines all responsibility if the damage caused to persons, animals or

things is a result of failure to comply with the above.

Once all plumbing connections have been carried out, proceed with the inspection of the seals

under pressure, by filling the boiler.

This operation must be done carefully observing the following steps:

open the radiator, boiler and system air valves;

gradually open the system filling tap making sure that any automatic air valves installed on

the system work properly;

close the radiator air valves as soon as water starts to come out;

on the system pressure gauge check that the pressure reaches a value of approximately 1 bar

(applicable only for systems equipped with a closed tank - refer to any standards or local

regulations that allow it); for open tank systems refilling takes place automatically via the

same tank;

close the system loading tap and then bleed air again via the radiator air valves;

check tightness of all connections;

after having started the boiler for the first time and heated up the system, stop the pumps

and repeat the air bleeding operations;

let the system cool down and if needed take the water pressure back to 1 bar (applicable

only for systems equipped with a closed tank - refer to any standards or local regulations that

allow it); for open tank systems refilling takes place automatically via the same tank.

NOTE

In systems equipped with a closed tank, where possible, the water pressure in the

heating system - when the system is cold - must be no less than 1 bar; if under this value,

act on the system filling tap. The operation must be carried out when the system is cold.

The system pressure gauge enables to monitor the pressure in the circuit.

To fill the system, the boiler is fitted with a tap (4), with a check valve, to load the heating system

manually. During this operation, any air in the system is released via the air valve located in the

upper part of the boiler.

To ensure the valve vents, it is advisable to loosen the top cap (see figure).

The filling pressure of the system WHEN COLD must be 1 bar.

Upon completion of this filling operation, always close the tap.

Air valve

HYDRAULIC SYSTEM

6

ELECTRICAL CONNECTIONS

Electrical safety of the system is ensured only when it is properly connected to an efficient earthing

system made in compliance with the safety standards in force: gas, water or heating systems pipes

are not suitable as earth connections.

One must check this essential safety requirement; if in doubt, request an accurate inspection of the

electrical system to be carried out by qualified personnel, because the boiler manufacturer is not

responsible for any damage caused by failure to earth the system.

Have professionally qualified personnel check the electrical system is suitable for the maximum

power absorbed by the heating system, ensuring in particular that the diameter of cables is

appropriate for the power absorbed by the loads.

The use of any component that is powered by electricity entails compliance with some basic rules

such as:

• do not touch the appliance with wet and/or damp body parts and/or bare feet;

• do not pull the electric cables;

• do not leave the appliance exposed to weathering (rain, sun, etc.);

• do not allow the appliance to be used by children or inexperienced persons.

230V electrical power supply connection

Installation of the boiler accessory electrical components requires electrical connection to a 230 V –

50 Hz mains.

Hazard!

Electrical installation must be carried out by a qualified technician only.

Before performing connections or any operation on the electrical parts, always

disconnect the power supply and make sure it cannot be accidentally reconnected.

Please note that the boiler electrical power line must be fitted with a bipolar switch

with a contact gap greater than 3 mm, easy to access, in order to make any maintenance

operations quick and safe.

The power cable must be replaced by authorised technical personnel.

If the supply cord is damaged, it must be replaced by a special cord or assembly available from

the manufacturer or its service agent.

ELECTRICAL CONNECTION

First connect the power cable to the side of the stove and then to a wall socket. The main switch at

the side must only be activated to switch the stove on; otherwise, it is advisable to keep it off.

It is recommended to disconnect the power cable when the stove is not used.

Electrical connection of the stove

BEFORE START-UP

GENERAL PRECAUTIONS

Remove all components that could burn from the brazier and glass (manual, various adhesive labels

and any polystyrene).

Check that the brazier is positioned correctly and rests properly on the base.

After a long period of inactivity, remove any pellets left in the hopper (using a vacuum

cleaner with a long pipe ), as they could have absorbed moisture, thereby altering their

original characteristics and no longer being suitable for combustion.

The first start-up may not be successful as the feed screw is empty and does not always

manage to load the required amount of pellets in the brazier in time for the fire to be

regularly ignited.

CANCEL THE FAILED START-UP ALARM STATUS BY PRESSING AND HOLDING KEY 1 (ESC).

REMOVE THE PELLETS FROM THE BRAZIER AND REPEAT START-UP.

If a flame does not ignite after a number of failed start-ups, even though the pellet supply is correct,

make sure the brazier is set in place correctly, which must be interlocked in its seat and free from any

ash deposits. If no anomaly is found during this inspection, there may be a problem with the product

components or installation may not be correct.

REMOVE THE PELLETS FROM THE BRAZIER AND CONTACT AN AUTHORISED TECHNICIAN.

Avoid touching the stove during the initial start-up, as the paint in this stage hardens; by touching

the paint, the steel surface may be exposed.

It is good practice to guarantee effective ventilation in the room during the initial startup, as the stove will emit some smoke and smell of paint.

Do not stand close to the product and air the room. The smoke and smell of paint will disappear after

about an hour of operation, however, remember they are not harmful in any case.

The stove will be subject to expansion and contraction during the start-up and cooling phases,

therefore light creaking noises may be heard. This is absolutely normal as the structure is made of

laminated steel and must not be considered a defect.

7

INITIAL START

-

UP

It is extremely important to make sure the product is not immediately overheated and the

temperature is increased gradually, initially using low power. This will prevent damaging the ceramic

or serpentine tiles, the welds and the steel structure.

DO NOT EXPECT HEATING EFFICIENCY IMMEDIATELY!!!

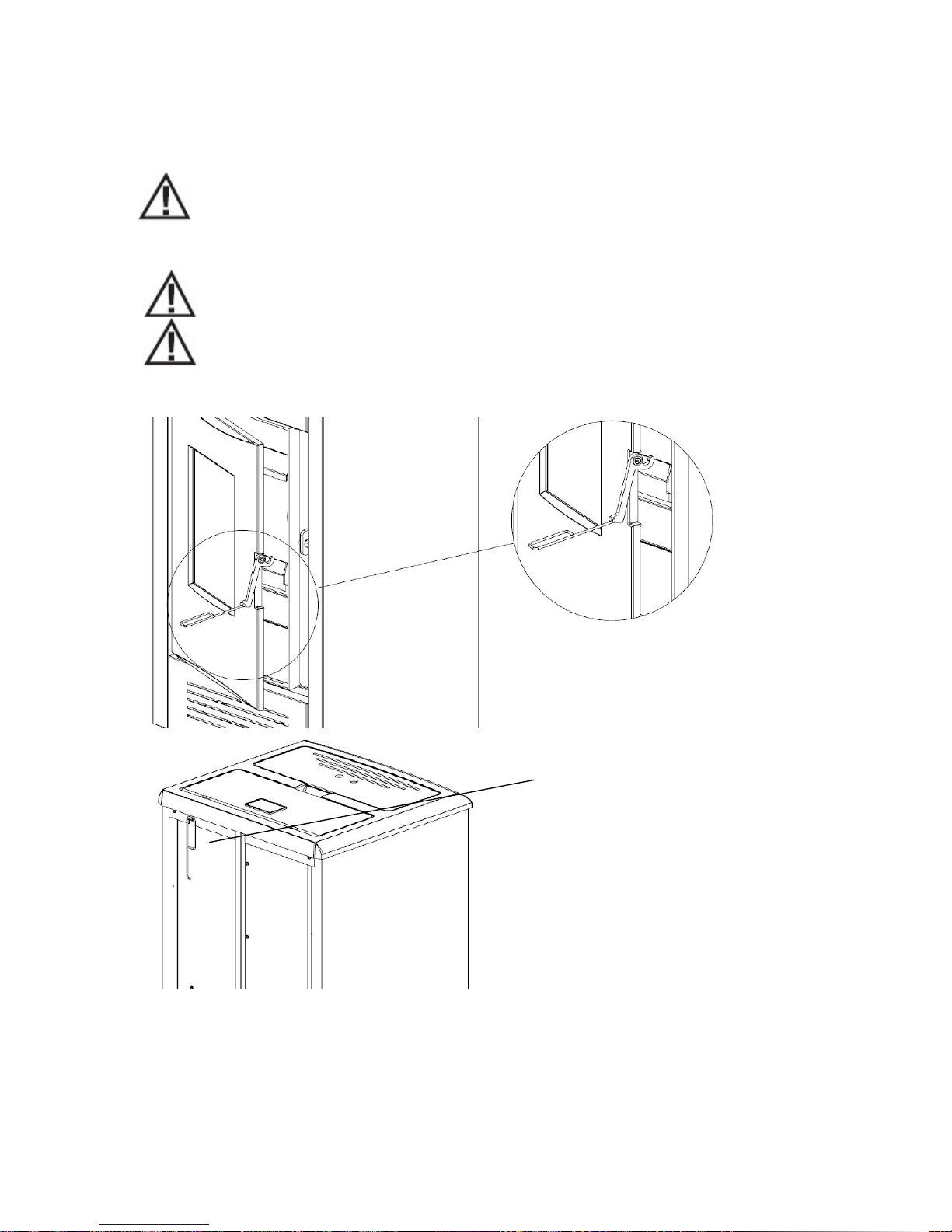

OPENING/CLOSING THE DOOR

ATTENTION!

The door must be closed properly for the stove to work correctly.

"Use suitable Personal Protective Equipment (e.g. gloves) to open the stove door.

To open the door, lift the hook, as shown in the figure"

SETTINGS TO BE CARRIED OUT BEFORE THE INITIAL START-UP

Once the power cable is connected in the rear part of the stove, turn the switch, also placed at the

rear, to position (I). To switch the stove on or off press key 1 on the control panel.

Door hook is hanged at the back of

the stove

LOADING THE PELLETS

Fuel is loaded by lifting the cover on the upper

part of the product.

Slowly pour the pellets into the

hopper.

Be careful as the cover could

become very hot.

No other type of fuel other then

pellets, in compliance with abovementioned specifications, is to be

inserted into the hopper.

EXTERNAL THERMOSTAT

The external thermostat can be used to turn the combustion system on and off. In this case

the controller ignores all internal temperature thresholds and is operating exclusively with the

thermostat input.

To configure this option; Connect the external thermostat to IN5, S5AND and GND.

ALARMS

Safety Thermostat (stove) HV1: always signalled

Block

Safety Thermostat (pellet) HV2: always signalled

Extinguishing

for Lack of Flame

Extinguishing for Water over Temperature

Extinguishing for Exhaust gas over Temperature

Encoder Error: No Encoder Signal

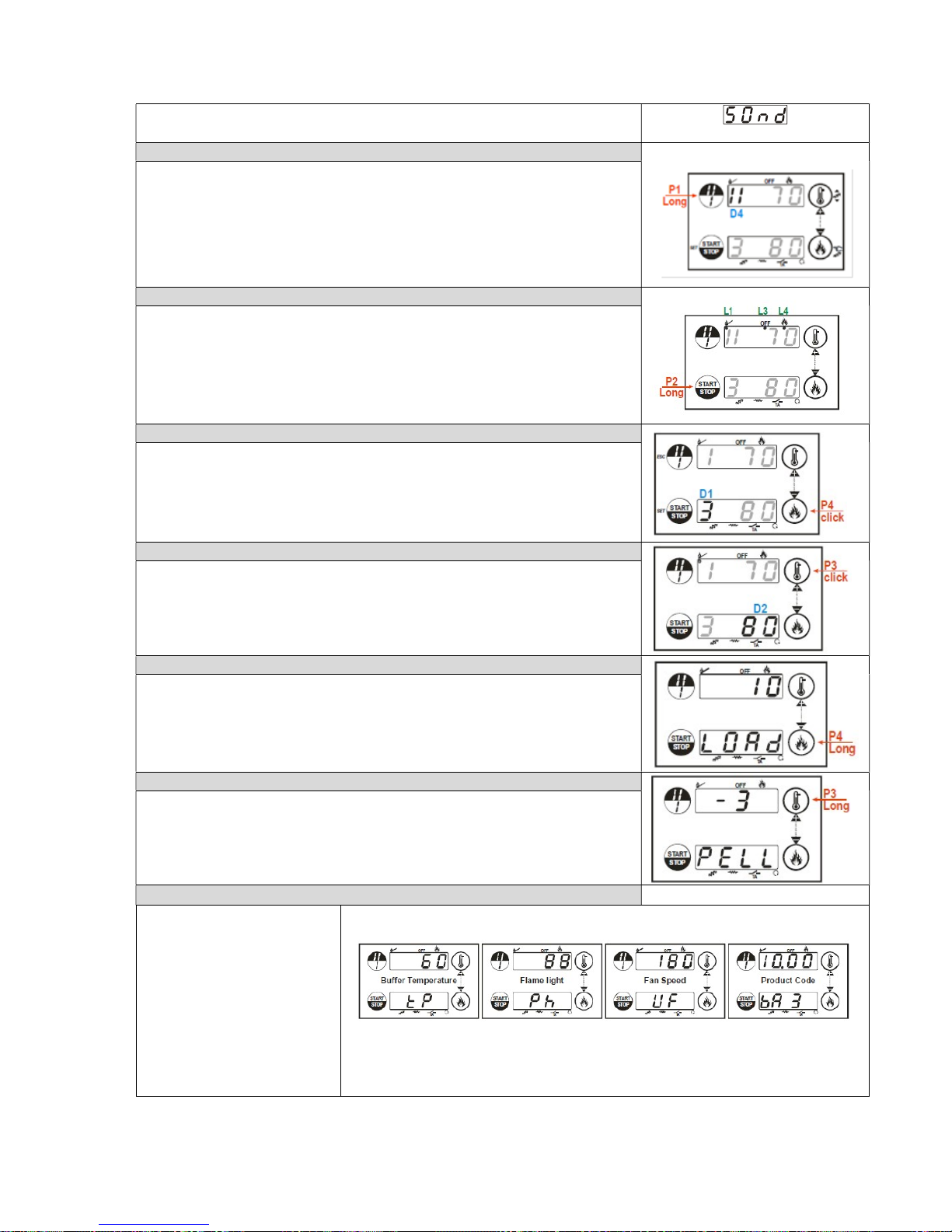

Encoder Error: Combustion Fan regulation failed

Failed Ignition

Lack of fuel

Led Fix Blinking

L1 Stabilization phase

Ignition Start phase

L3

Burner OFF

Extinguishing phase

L4

Work phase

Modulation/Standby

phase

L5 Auger ON

L6 Igniter Resistance ON

External Thermostat open

L7 L8

Pump

Display

Fix Blinking

D1

Work Combustion

Power Set

D2

Stove Thermostat Set

Combustion Power

Change

D3 Stove Temperature

Stove Thermostat Cha

nge D4 I indicates the Pellet

recipe 1

II indicates the Pellet

recipe 2

Button

Click [P click]

Long Pressure [P long]

P1

Display other data / Esc

Pellet recipe selection

P2

Set in to the Menu function

Burner Start / Stop

P3

Thermostat Setting/ In

creasing Value / Scroll

Menu

Pellet Loading Correction

P4

Combustion Power Setting/Decreasing

Value/Scroll Menu

8

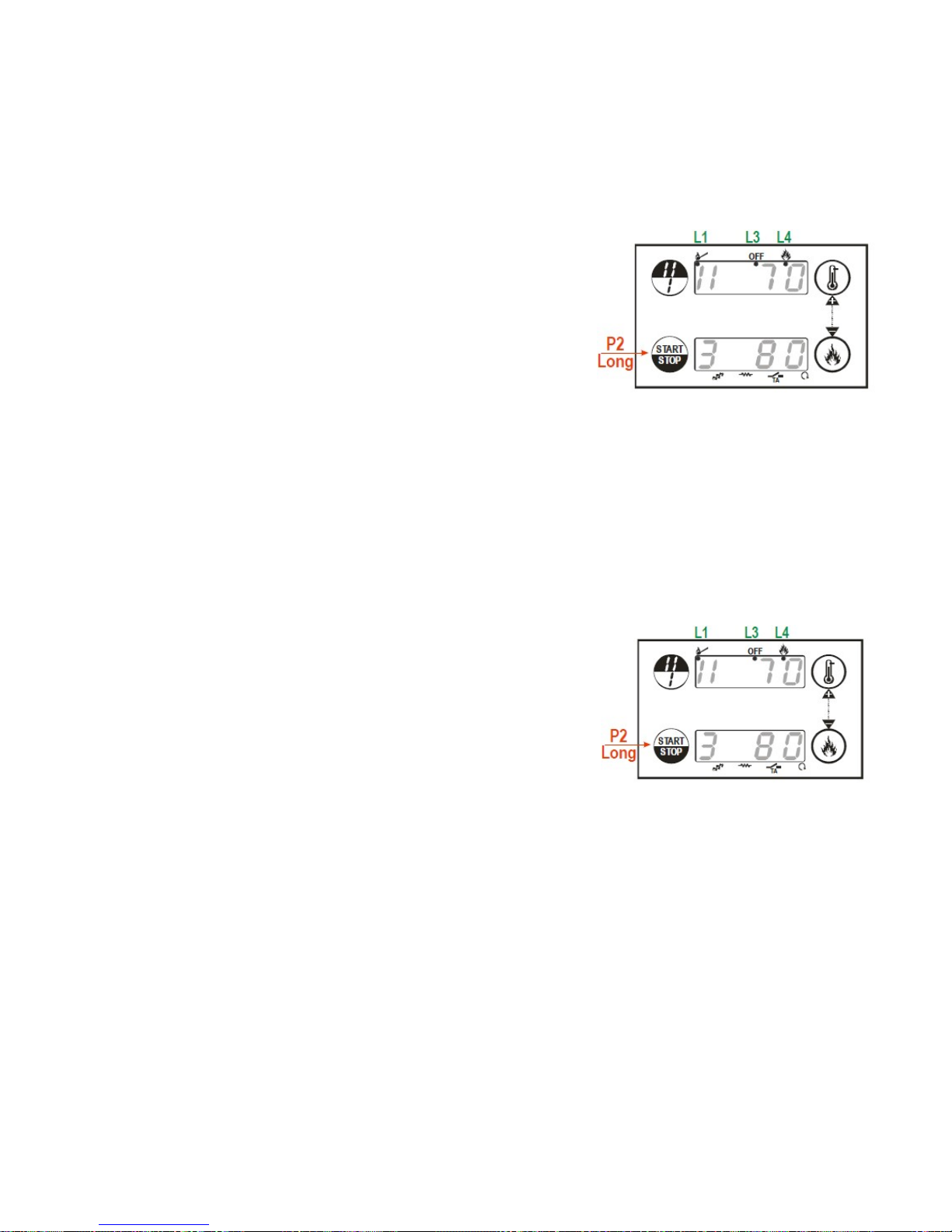

OPERATION

Anomaly in probe control during Check Up phase

Fuel or Recipe Selection

Through a long pushing of the button P1 is changed the type of receipe.

The display D4 shows the selected recipe (I=Recipe 1; II= Recipe 2)

Ignition/Exstinguishing

The Ignition and Extinguishing are activated with a long pushing of the button P2

The Ignition is signalled by the first blinking than fix led L1

The Work state is signalled by the fix led L4

The Modulation state is signalled by the blinking L4

The Extinguishing is signalled by the blinking led L3

The Extinguishing finished = OFF state is signalled by the fix led L3

Combustion Power Setting

Click button P4: the display D1 blinks

Trough the click of the buttons P4 (increasing)or P3 (decreasing) the power is

changed according to the values available

Ex.: 1 – 2 – 3 – 4 – 5 – A (A= Automatic Combustion)

After 5 seconds the new value is memorised and the display shows as normal

Work Thermostat Setting

Click button P3: the display D2 blinks

Trough the click of the buttons P4 (increasing)or P3 (decreasing) the value of the

thermostat is changed.

After 5 seconds the new value is memorised and the display shows as normal

Manual Pellet Loading

Not applicable.

Pellet Loading Correction

The activation is with a long pushing of the button P3

The bottom display shows PELL, the upper display shows the blinking value

With buttons P3 / P4 the blinking value increases or decreases

The values are between the range– 7 ÷ 7.The default value is ‘0’

After 5 seconds the new value is memorised and the display shows as normal

Display

With a click sequence of P1

tP= Buffer Probe Temperature

(if present)

UF= Combustion Fan Speed

[RPM/Volt]

tF= Exhaust temperature [°C]

+ Product Code

START-UP

At the first loading the feed screw may be empty. So start the stove and wait until the first pellet

starts falling into the burning pot. Then stop the stove by pressing long to the P2 button. Now you

can restart the stove again.

Switch ON the stove

Check the stove to be in “OFF” position (fixed led L3).

Switch ON the stove with a long pushing of the button P2.

Led status when the stove is ON:

1. The Ignition is signalled by the first blinking than fix led L1

2. The Work state is signalled by the fix led L4

3. The Modulation state is signalled by the blinking L4

If the ignition is not succeed during the predefined time (time out) the controller will turned OFF and

the error message “Err12” will be displayed.

An odour of the paint can be felt while the stove fired up for the first time.

Do not open the combustion chamber door during operation.

Never fill the burner pot with pellets by hand. Excessive combustion material in the burner

pot means that the pellets will not be ignited optimally.

Switch OFF the stove

Switch OFF the stove with a long pushing of the button P2.

Led status when the stove is switched OFF:

1. The Extinguishing is signalled by the blinking led L3

2. The Extinguishing finished = OFF state is signalled by the fix

led L3

When the stove is switched OFF the fan continues running until the flue gas temperature falls below

the set trash hold and then the fan is turned off.

OPERATION PHASES

Check Up

This stage allows for the cleaning of the stove and burner before the ignition phase.

-The exhaust fan on the burner run at full power to eliminate any dust or smoke (in the event of a

hot restart) from the stove.

-All the system sensors are checked for correct connections.

Pre-Heating

This stage brings the ignition element to the correct temperature before loading the burner with

pellets.

Pre-Load

A pre-defined starting dose of pellets is given into the burner by the auger.

Variable Ignition

This stage starts the ignition process.

-The heat from the ignition element is directed at the pellets by the fan which runs at a relatively

slow speed.

-At intervals the auger introduces more pellets once the flame has begun to establish.

-The flue gas temperature probe measures the temperature in the flue.

-At the end of this stage if the flue gas temperature is over a pre-defined temperature the process

continues to the next stage (Stabilisation)

-If this variable are not satisfied then this stage continues for another minutes (second ignition

attempt) and if the variable has not reached its value by the end of the second attempt,

EXTINGUISHING will occur and an Er12 (Failed Ignition) will be displayed on the screen.

Stabilisation

This stage develops the flame even further before allowing the system to enter RUN mode.

-The auger introduces pellets more frequently into the burner.

-The combustion fan and exhaust fan increase in speed to speed up the combustion process.

-The ignition element remains on in this stage.

-At the end of this stage if the flue gas temperature is over a pre-defined temperature the process

continues to the next stage. (Run mode)

-If this variable are not satisfied then this stage continues for another minutes (second ignition

attempt) and if the variable has not reached its value by the end of the second attempt,

EXTINGUISHING will occur and an Er12 (Failed Ignition) will be displayed on the screen.

Run Mode

During run mode the combustion rates are pre-set for the 5 different power levels.

-On entering this phase the system starts at Power Level 1 and after defined time intervals increases

a Power Level each time until Power 5 is reached.

-The stove will continue to run at Power 5 until the water temperature reaches within 8°C of the set

point.

-The ignition element is off during this phase.

-The auger ON/OFF values are pre-set for each of the power levels.

-The circulation pump is activated by the controller once the water in the stove reaches 40°C. The

pump will turn off once the temperature drops to 38°C.

-If the unlikely event that the flue gas temperature decrease below pre-set low value for a period of

time then Er13 will appear to indicate that the light has gone out. This may be due to a lack of pellets

entering the combustion tube due to dust or poor quality pellets.

Modulation Mode

The modulation range has been pre-set so that the system starts reducing to a lower power level

when the water temperature comes within 8°C of the set point.

Standby / Extinguishing / OFF

The system goes into STANDBY when the water in the buffer reaches its set temperature or the

water in the stove reaches its set temperature (whichever is sooner) and the system goes into an

extinguishing mode.

-The auger stops feeding pellets to the burner.

-The exhaust fan will run at full power until all light in the burner has extinguished and the

temperature in the flue has decreased to a safe temperature.

-Once the flame has been extinguished the system enters its Final Cleaning stage where the burner

cleaning takes place (the fan runs in its maximum to eliminate the dust in the fire pote).

The system will sit in standby until the water temperature decreases to a pre-determined amount

when it will restart again with the CHECK UP phase.

The system will go into the OFF state when the system gets a signal from a room thermostat or if the

system is turned off manually on the controller. The shutdown procedure is the same as STANDBY.

Once the extinguishing phase has been completed the stove will remain in the OFF state until a signal

is given to the stove to start.

Shutting the stove down (end of season)

At the end of season, before shutting down the stove, we recommend completely removing pellets

from the hopper with the use of a vacuum cleaner with an extension.

During periods of disuse, the stove must be unplugged and placed in a dry place

protected from the elements. For greater safety, especially if there are children around,

we recommend removing the supply cable from the rear of the stove.

The product is supplied with the following safety devices

PRESSURE SWITCH

Monitors pressure in the smoke duct. It is designed to shut down the pellets feed screw in the event

of an obstructed flue or significant back-pressure. (wind)

SMOKE TEMPERATURE PROBE

Detects the temperature of the smoke, thereby enabling start-up or stopping the product when the

temperature drops below the preset value.

CONTACT THERMOSTAT IN THE BOILER

If the temperature exceeds the preset safety level, it immediately shuts down stove operation.

WATER TEMPERATURE PROBE

If the water temperature approaches the shutdown temperature (85°C) the probe makes the boiler

perform the “OFF Stand-by” automatic shutdown.

ELECTRICAL SAFETY

The product is protected against sudden current surges by a main fuse in the power supply panel on

the rear part of the product. Other fuses that protect the electronic boards are found on the latter.

SMOKE FAN

If the fan stops, the electronic board promptly shuts off the pellets supply and an alarm message is

displayed.

GEAR MOTOR

If the gear motor stops, the boiler will continue to run until the flame goes out due to lack of fuel and

until a minimum level of cooling is reached.

TEMPORARY POWER CUT

If the power cut lasts less than 10" the stove returns to its previous operating status; if it lasts more it

carries out a cooling/restart cycle.

FAILED START-UP

If during ignition no flame develops, the boiler will go into alarm condition.

ANTIFREEZE FUNCTION

If the probe in the boiler detects a water temperature of less than 5°C, the circulation pump is

automatically activated to prevent the system from freezing.

PUMP ANTI-SEIZURE FUNCTION

If the pump is not used for prolonged periods, it is activated periodically for a few seconds to prevent

it from seizing up.

9

SAFETY DEVICES

DAILY CLEANING PERFORMED BY THE USER

Burn Pot

Remove the burn pot from the relevant compartment and free the holes using the appropriate fire

irons supplied, remove the ash from the burn pot using a suction device.If the pellets in the hopper

finish, unburned pellets may accumulate in the burn pot. Always empty the residue in the burn pot

before starting-up.

REMEMBER THAT ONLY A CORRECTLY POSITIONED AND CLEAN BRAZIER CAN

GUARANTEE START-UP AND OPTIMAL OPERATION OF YOUR PELLET BOILER.

Heat Exchanger

Cleaning of the heat exchangers allows to guarantee constant heat output through time. This type of

maintenance must be performed at least once a day. To do this, just use the relevant scrapers

positioned in the upper part of the stove, moving them up and down several times.

10

CLEANING AND MAINTENANCE

CHECKS TO BE PERFORMED EVERY 2/3 DAYS

Ash Pan and Combustion Chamber

Remove the ash pan and clean the compartment around the brazier from ash paying attention to hot

ashes.

Only if the ash is completely cold can a vacuum cleaner be used to remove it. Use a drum-type

vacuum cleaner that is suitable for picking up particles of a certain size. Experience and the quality of

the pellets will determine the cleaning frequency required.

However, it is recommended not to exceed 2 or 3 days.

Disposal of ashes

The ashes should be placed in a metal container with a sealed cover. The sealed

container should be placed on a noncombustible surface at a safe distance from

combustible materials until the cinders have been completely extinguished.

Only when they have been fully extinguished can the ashes be thrown away with organic

waste, assuming that nails or other nonorganic material are not present.

Make sure that the ash is completely cold before emptying it into a suitable container.

Cleaning the Glass

Clean the glass with a damp cloth or damp paper rubbed in ashes. Rub the glass until it comes clean.

Although it is likely that tar will build up on the glass during the lighting stage, it will burn off with the

stove in full operation. If, however, the tar is left to build up over a long period it will require more

effort to remove. We therefore recommend that the glass be cleaned daily before lighting the stove.

Do not clean the glass while the stove is working and the glass is HOT; do not use abrasive

sponge and corrosive substance such as solvents.

MONTHLY CLEANING

Smoke Chamber

Proceed with cleaning the smoke chamber.

Remove the ash pan.

Using the Allen wrench provided in the kit, loosen the screws fastening the smoke chamber

bottom plate (the screw need not be fully removed).

Grasp the smoke chamber bottom plate, slide it towards the front of the appliance, lift it and

remove it.

Now clean the actual smoke chamber: remove the deposited ash and combustion products

also from under the flue gas ducts at the sides of the smoke chamber.

PERIODIC MAINTENANCE

The scheduled maintenance work listed below must be carried out ONCE A YEAR and

prior to starting up the appliance or after a long period of inactivity. This work is

necessary to ensure that the appliance remains efficient and safe.

Thorough cleaning of the smoke

chamber.

Check and clean the smoke outlet and

flue system.

Clean away dust and cobwebs from

the area inside the cladding.

Clean moving parts and mechanisms

(motors and circulation pump).

Check the electrical part as well as the

connected electronic and water circuit

components.

Check the water level and pressure of

the water system, resetting the

values, and if necessary bleed the

valves and radiators.

Check that the circulation pump

impeller is in proper working order. If

it is locked, unscrew the plug from the

circulation pump and release the

impeller with a screwdriver.

Check the tightness and state of the

gaskets/seals of the glass door, the

water system and all the elements

subject to wear and if necessary

replace.

Check the seal and tightness of the

joints and connecting pipes.

Check the state of the

temperature/pressure relief and

safety valves and if they have been

activated. Check that they are in

proper working order and if necessary

replace.

Carry out all maintenance and checks

required for correct operation and

adaptation to safety regulations.

Light the stove in accordance with

instructions given in the paragraph.

All cleaning and maintenance must

be carried out with the power cable

disconnected from the power supply.

Cleaning the Flue System

Until you have got reasonably used to the operating conditions of the stove, we recommend that this

maintenance be carried out on a monthly basis. Remove the plug from the Tee and clean the pipes. If

necessary, particularly on the first few occasions, we recommend calling in a qualified

technician.

CLEANING THE SMOKE DUCT AND GENERAL CHECKS:

Clean the smoke exhaust, especially around the T-fittings, curves and any horizontal sections. For

information on cleaning the flue, contact a chimney sweeper. Check the tightness of the ceramic

fibre gaskets on the boiler door. If necessary, order new replacement gaskets from the retailer or

contact an authorized service centre to carry out this task.

ATTENTION:

The frequency with which the smoke exhaust must be cleaned depends on the use of the

boiler and the type of installation.

We recommend contacting an authorised service centre for end-of-season maintenance

and cleaning as the above-mentioned operations will be performed together with a

general inspection of the components.

END-OF-SEASON SHUTDOWN

At the end of season, before shutting down the boiler, we recommend completely removing pellets

from the hopper with the use of a vacuum cleaner with an extension.

Error Code

Cause Remedy

ER 01 Safety Thermostat Tripped

The stove safety thermostats

have tripped due to high water

temperature in the stove

Check the stove and heating system is full of water.

Check the stove pump is working

Check that there are no valves in the stove primary

circuit that may have been closed inadvertently.

Reset high limit thermostats. (remove black caps and

press red button with the tip of a ballpoint pen or

similar until it clicks)

Reset the stove by pressing on-off button (P2) for 3

seconds for the error to clear.

If error does not clear call your installer

ER 02 Pellet thermostat tripped

The pellet thermostat has

detected heat travelling back up

the drop tube into the burner

Check that the exhaust fan is running

Check for blockages in the flue, clear if found.

Turn off power to the stove

Ensure the pellet drop tube is cool to the touch.

Press the button on the pellet thermostat to reset

the thermostat.

Ensure that the connectors have connected with the

pins on the thermostat.

Turn power back on.

Reset the stove by pressing on-off button (P2) for 3

seconds for the error to clear.

If error does not clear turn power off and re-check

pin connectors

If error does not clear call your installer

ER 03 Accidental extinguishing due to

low flame

The stove has gone out

unexpectedly!!

It may have run out of fuel

The pellets may be poor quality.

The fire pot may be blocked

Ensure the stove is cool

Open the fire door; remove the fire pot and clear with

the brush. Note what you find: (typically unburned

pellets but may be char or clinkers as well).

Reset the stove by pressing on-off button (P2) for 3

seconds for the error to clear.

Restart the stove.

If the stove does not relight:

Refer to ER 12 and:

Check there are enough pellets in the hopper

Check that the pellets are not dusty.

IF the pellets are dusty the hopper and auger will need

to be cleared. call your installer

11

TROUBLESHOOTING

Error Code

Cause Remedy

ER 04

Water Over Temperature

The water in the stove has

reached a temperature of

95°C

Check that the stove is full of water by:

Checking that the system is at the correct operating

pressure (sealed systems only)

Check the pump is working.

Reset the stove by pressing in the manual high limit

thermostat. Reset the stove by pressing on-off button

(P2) for 3 seconds for the error to clear.

If error does not clear call your installer

ER 05

Exhaust Over Temperature

Flue gas temperature has

exceeded pre-defined value.

IF the flue temperature has reached this high level it is

likely that the heat exchanger is damaged or not

working.

Check when the stove was last serviced.

If the stove was serviced less than 1200 hours ago

check the target board for damage.

In either case call your installer

ER 07

No encoder signal

The sensor is broken. Call your installer.

ER 08 Fan regulation failed

The fan is damaged.

The fan is blocked.

Call your installer.

ER 12 Ignition Failed

During the ignition cycle the

stove has not detected a flame

The ignitor has failed

OR the pellets have not lit for

another reason

Ensure the stove is cool

Open the fire door; remove the fire pot and clear with

the brush. Note what you find: (typically unburned

pellets but may be char or clinkers as well).

Check there are enough pellets in the hopper

Check that the pellets are not dusty.

IF the pellets are dusty the hopper and auger will need

to be cleared.

Check that the ignitor is functioning.

If not call your installer.

12

ELECTRICAL WIRING DIAGRAM

Loading...

Loading...