Page 1

INSTALLATION, OPERATING AND

SERVICE INSTRUCTIONS FOR

SOLARIS

Gas-Fired Boiler

For service or repairs to boiler, call your heating contractor. When seeking information on boiler,

provide Boiler Model Number and Serial Number as show on Rating Label.

Boiler Model Number

SOL __ __ __ __ - __ __ __

Heating Contractor Phone Number

Address

814SOL0010-8/09

Boiler Serial Number

6 __ __ __ __ __ __ __

Installation Date

Price - $5.00

1

Page 2

IMPORTANT INFORMATION - READ CAREFULLY

NOTE: The equipment shall be installed in accordance with those installation regulations enforced in the area where the

installation is to be made. These regulations shall be carefully followed in all cases. Authorities having jurisdiction

shall be consulted before installations are made.

All wiring on boilers installed in the USA shall be made in accordance with the National Electrical Code and/or local regulations.

All wiring on boilers installed in Canada shall be made in accordance with the Canadian Electrical Code and/or local regulations.

The Commonwealth of Massachusetts requires this product to be installed by a licensed Plumber or Gas Fitter.

The following terms are used throughout this manual to bring attention to the presence of hazards of various risk levels,

or to important information concerning product life.

DANGER

Indicates an imminently hazardous situation

which, if not avoided, will result in death,

serious injury or substantial property dam-

Indicates a potentially hazardous situation

which, if not avoided, may result in moderate or minor injury or property damage.

CAUTION

age.

WARNING

Indicates a potentially hazardous situation

which, if not avoided, could result in death,

serious injury or substantial property damage.

Indicates specic instructions on installation, operation, or maintenance which are

important but not related to personal injury

hazards.

NOTICE

DANGER

DO NOT store or use gasoline or other ammable vapors or liquids in the vicinity of this or any

other appliance.

If you smell gas vapors, DO NOT try to operate any appliance - DO NOT touch any electrical

switch or use any phone in the building. Immediately, call the gas supplier from a remotely located phone, Follow the gas supplier’s instructions or if the supplier is unavailable, contact the

re department.

Manufacturer’s Contact Information:

Thermal Solutions

1175 Manheim Pike

Lancaster, PA 17601

717-239-7642

www.thermalsolutions.com

2

Page 3

WARNING

This boiler requires regular maintenance and service to operate safely. Follow the instructions

contained in this manual.

Improper installation, adjustment, alteration, service or maintenance can cause property dam-

age, personal injury or loss of life. Read and understand the entire manual before attempting

installation, start-up operation, or service. Installation and service must be performed only by an

experienced, skilled, and knowledgeable installer or service agency.

This boiler must be properly vented.

This boiler needs fresh air for safe operation and must be installed so there are provisions for

adequate combustion and ventilation air.

The interior of the venting system must be inspected and cleaned before the start of the heating

season and should be inspected periodically throughout the heating season for any obstructions.

A clean and unobstructed venting system is necessary to allow noxious fumes that could cause

injury or loss of life to vent safely and will contribute toward maintaining the boiler’s efciency.

Installation is not complete unless a pressure relief valve is installed into the tapping located on

top of appliance. - See the Water Piping and Trim Section of this manual for details.

This boiler is supplied with safety devices which may cause the boiler to shut down and not restart without service. If damage due to frozen pipes is a possibility, the heating system should

not be left unattended in cold weather; or appropriate safeguards and alarms should be installed

on the heating system to prevent damage if the boiler is inoperative.

This boiler contains very hot water under high pressure. Do not unscrew any pipe ttings nor

attempt to disconnect any components of this boiler without positively assuring the water is cool

and has no pressure. Always wear protective clothing and equipment when installing, starting

up or servicing this boiler to prevent scald injuries. Do not rely on the pressure and temperature

gauges to determine the temperature and pressure of the boiler. This boiler contains components which become very hot when the boiler is operating. Do not touch any components unless

they are cool.

Boiler materials of construction, products of combustion and the fuel contain alumina, silica,

heavy metals, carbon monoxide, nitrogen oxides, aldehydes and/or other toxic or harmful substances which can cause death or serious injury and which are known to the state of California

to cause cancer, birth defects and other reproductive harm. Always use proper safety clothing,

respirators and equipment when servicing or working nearby the appliance.

Failure to follow all instructions in the proper order can cause personal injury or death. Read all

instructions, including all those contained in component manufacturers manuals which are provided with the boiler before installing, starting up, operating, maintaining or servicing.

Keep boiler area clear and free from combustible materials, gasoline and other ammable vapors or liquids.

All cover plates, enclosures and guards must be in place at all times.

This product must be installed by a licensed plumber or gas tter when installed within the Com-

monwealth of Massachusetts.

This boiler has a limited warranty, a copy of which is printed on the back of this manual. It is the

responsibility of the installing contractor to see that all controls are correctly installed and are

operating properly when the installation is complete.

NOTICE

3

Page 4

Table of Contents

I. Pre-Installation ................................................. 6

II. Unpack Boiler ...................................................7

III. Venting/Air Intake Piping ................................ 8

A. Vent Guidelines Due to Removal of an

Existing Boiler .............................................8

B. General Guidelines ..................................... 9

C. Supplemental Vent Terminal Location

Instructions ................................................10

D. Separate Horizontal Venting

System ........................................................ 11

E. Optional Horizontal Vent Terminal

Mounting .................................................... 14

F. Conventional Venting........ ........................15

G. Air Intake Piping ......................................15

H. Separate Vertical Venting System ...........17

IV. Water Piping and Trim .................................. 20

V. Gas Piping .......................................................24

VI. Electrical .........................................................26

VII. Modular Installations ....................................29

VIII. System Start-up ...........................................39

IX. Service and Maintenance ............................... 46

A. Periodic Maintenance ..............................46

B. Safety & Operating Controls .................... 49

C. Trouble Shooting ........................................50

X. Sage Boiler ControlTM (SBCTM)......................52

A. Introduction ............................................... 52

B. Front Panel Display ...................................53

C. Setup Menu ................................................54

D.BoilerCongurationMenu ......................56

E. SystemCongurationMenu ....................57

F. Setpoints Menu ..........................................58

G. Communication Menu ..............................59

H. Manual Mode Menu .................................. 59

I. Security Menu............................................60

XI. Repair Parts ....................................................61

XII. Service Record .............................................. 71

XIII. Refractory Ceramic Fiber ..........................74

XIV. Warranty .......................................................75

Minimum Clearance to Combustible Materials

Left Side Right Side Front Rear Top Flue Connector

1” 1” 24” 3” 1” 6”

Recommended Clearance for Service

Model Left Side or Right

Front Rear Top

Side

SOL-300 24” 24” 24” 16”

SOL-750 24” 24” 24” 16”

SOL-1000 24” 24” 24” 19”

SOL-1250 24” 24” 24” 31”

SOL-1500 24”

Note: Verify clearance with jurisdiction having authority and local codes.

4

Page 5

(Amps)

REAR VIEW

TOP VIEW

SIDE VIEW

L

(TYP.)

L

(TYP.)

C

2.71

E

D

B

K

A

13.00

H

M VENT

OUTLET

F OULET

WATER

F INLET

WATER

G INLET GAS

J

M VENT

INLET

Amp Draw

Rated Blower

(HP)

Rated Motor

Horse Power

Electrical Supply

(Voltz/Hertz/Phase)

Wet

(lbs.)

Weight

Dry

(lbs.)

Weight

Water

Volume

(Gallons)

BTU

(MBH)

Output

General Ratings and Capacities

(MBH)

BTU Input

Boiler

Model

SOL-300 300 252 1.1 288.5 297.7 3/4 8.5

SOL-500 500 420 1.3 316.0 326.8 3/4 8.5

SOL-750 750 637.5 2.4 508.5 528.5 120/60/1 3/4 8.0

SOL-1000 1000 850 2.6 548.5 570.2 3/4 8.0

SOL-1250 1250 1062.5 2.9 620.0 644.2 1-1/8 12

SOL-1500 1500 1275 3.3 713.0 740.5 1-1/8 12

Dimensions

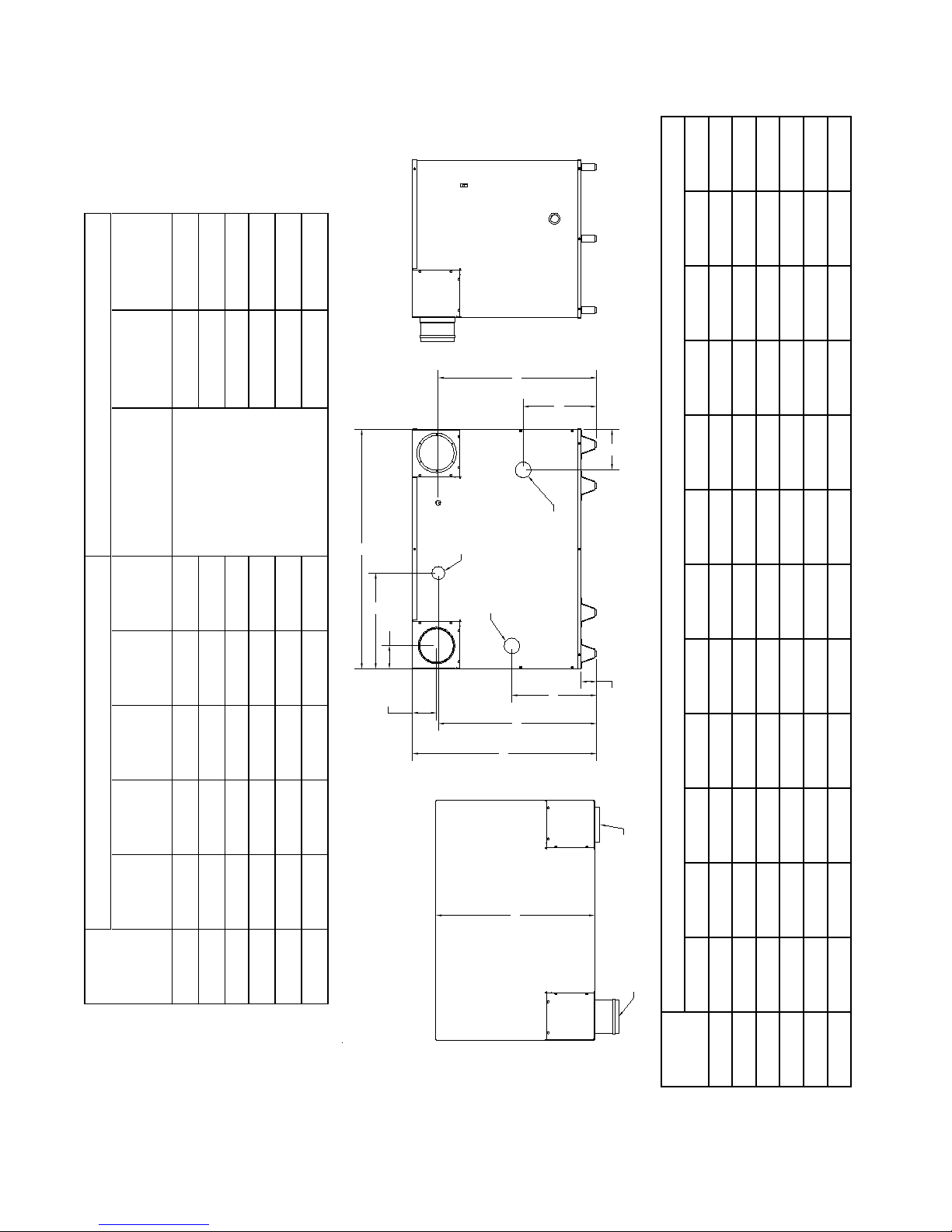

‘A’ ‘B’ ‘C’ ‘D’ ‘E’ ‘F’ ‘G’ ‘H’ ‘J’ ‘K’ ‘L’ ‘M’

Boiler

Model

SOL-300 27.8 32.6 28.1 25.9 15.0 2.0 1.00 4.1 29.3 17.0 4.1 4.0

SOL-500 42.6 32.6 28.1 28.0 15.0 2.0 1.00 7.2 27.8 17.0 4.1 6.0

SOL-750 41.4 36.9 31.8 32.4 13.0 3.0 1.00 3.5 32.1 23.6 6.2 8.0

SOL-1000 49.4 36.9 31.8 32.4 13.0 3.0 1.25 3.5 32.1 21.6 6.2 8.0

SOL-1250 61.6 36.9 31.8 32.4 13.0 3.0 1.25 3.5 32.1 26.5 6.2 10.0

Figure 1: Dimensions

SOL-1500 73.9 36.9 31.8 32.4 13.0 3.0 1.50 3.5 32.1 25.6 6.2 10.0

5

Page 6

I. Pre-Installation

WARNING

If you do not follow these instructions ex-

actly, a re or explosion may result causing

property damage or personal injury.

DANGER

Do not install boiler where gasoline or other

ammable vapors or liquids, or sources

of hydrocarbons (i.e. bleaches, cleaners,

chemicals, sprays, paint removers, fabric

softeners, etc.) are used or stored.

NOTICE

E. Protect gas ignition system components from water

(dripping, spraying, rain, etc.) during boiler operation

and service (circulator replacement, condensate trap,

control replacement, etc.).

F. Provide combustion and ventilation air in accordance

with sections 5.3 of the National Fuel Gas code,

ANSIZ223.1/NFPA 54, or sections 7.2, 7.3, or 7.4 of

CAN/CSA B149.1, Natural Gas and Propane Installation code, or applicable provisions of the local building

codes.

WARNING

Adequate combustion and ventilation air

must be provided to assure proper combustion.

Due to the low water content of the boiler,

mis-sizing of the boiler with regard to the

heating system load will result in excessive

boiler cycling and accelerated component

failure. Thermal Solutions DOES NOT

warrant failures caused by mis-sized boiler

applications. DO NOT oversize the boiler

to the system. Modular boiler installations

greatly reduce the likelihood of boiler oversizing.

A. Installation must conform to the requirements of the

authority having jurisdiction. In the absence of such

requirements, installation must conform to the Na-

tional Fuel Gas Code, NFPA 54/ANSI Z223.1, and/or

CAN/CGA B149 Installation Codes. Where required

the installation must conform to the standard for con-

trols and safety devices for automatically red boilers,

ANSI/ASME CSD-1.

B. Appliance is design certied for installation on combus-

tible ooring. Do not install boiler on carpeting.

C. Provide clearance between boiler jacket and combus-

tible material in accordance with local re ordinance.

Refer to Figure 1 for minimum listed clearance from

combustible material. Recommended service clearance

is 24 inches from left side, right side and front. Recommended service clearance is 36” at rear of unit. Service clearances may be reduced to minimum clearances

to combustible materials.

The following guideline is based on the National Fuel Gas

Code, NFPA 54/ANSI Z223.1.

1. Determine volume of space (boiler room). Rooms

communicating directly with space (through openings not furnished with doors) are considered part of

space.

Volume [ft³] = Length [ft] x Width [ft] x Height [ft]

2. Determine Total Input of all appliances in space.

Round result to nearest 1,000 Btu per hour (Btuh).

3. Determine type of space. Divide Volume by Total

Input.

a. If result is greater than or equal to 50 ft³ per

1,000 Btuh, space is considered an unconned

space.

b. If result is less than 50 ft³ per 1,000 Btuh, space

is considered a conned space.

4. Determine building type. A building of unusually

tight construction has the following characteristics:

a. Walls and ceiling exposed to outside atmosphere

have a continuous water vapor retarder with a

rating of 1 perm or less with openings gasketed

and sealed, and;

b. Weather-stripping has been added on openable

windows and doors, and;

c. Caulking or sealants applied in joints around

window and door frames, between sill plates and

oors, between wall-ceiling joints, between wall

panels, at plumbing and electrical penetrations,

and at other openings.

D. Install on level oor. Floor must be able to support

weight of boiler, water and all additional system components.

6

Page 7

5. For boiler located in an unconned space in a

building of other than unusually tight construction, adequate combustion and ventilation air

is normally provided by fresh air inltration

through cracks around windows and doors.

6. For boiler located within unconned space in

building of

within equate conned space, provide outdoor

air through two permanent openings which

communicate directly or by duct with the

outdoors or spaces (crawl or attic) freely commu nicating with the outdoors. Locate one opening

within twelve (12) inches of top of space. Locate

remaining opening within twelve (12) inches of

bottom of space. Minimum dimension of air

opening is three (3) inches. Size each opening

per following:

a. Direct communication with outdoors. Minimum

free area of one (1) square inch per 4,000 Btu per

hour input of all equipment in space.

b. Vertical ducts. Minimum free area of one (1)

square inch per 4,000 Btu per hour input of all

equipment in space. Duct cross-sectional area

shall be same as opening free area.

c. Horizontal ducts. Minimum free area of one (1)

square inch per 2,000 Btu per hour input of all

equipment in space. Duct cross-sectional area

shall be same as opening free area.

unusually tight construction, or

Alternate method for boiler located within

conned space. Use indoor air if two permanent

openings communicate directly with additional

space(s) of sufcient volume such that combined

volume of all spaces meet criteria for unconned

space. Size each opening for minimum free area

of one (1) square inch per 1,000 Btu per hour

input of all equipment in spaces, but not less than

100 square inches.

7. Combustion Air/Ventilation Duct Louvers and

Grilles. Equip outside openings with louvers to

prevent entrance of rain and snow, and screens to

prevent entrance of insects and rodents. Louvers and

grilles must be xed in open position or interlocked

with equipment to open automatically before burner

operation. Screens must not be smaller than ¼ inch

mesh.

Consider the blocking effect of louvers, grilles and

screens when calculating the opening size to provide

the required free area. If free area of louver or grille

is not known, assume wood louvers have 20-25

percent free area and metal louvers and grilles have

60-75 percent free area.

CAUTION

Avoid operating this boiler in an environment where saw dust, loose insulation bers, dry wall

dust, etc. are present. If boiler is operated under these conditions, the burner interior and ports

must be cleaned and inspected daily to insure proper operation.

II. Unpack Boiler

CAUTION

Do not drop boiler. Do not bump boiler

jacket against the oor.

A. Move boiler to approximate installed position.

B. Remove all crate fasteners.

C. Lift and remove outside container. Save two of the

wooden slats from the container sleeve for use in Steps

E and F.

D. Remove all boiler hold-down fasteners.

Installation of this boiler should be undertaken only by trained and skilled personnel

from a qualied service agency.

E. Tilt the boiler to its front side or back side and slide a

wooden slat under the raised feet.

F. Tilt the boiler in the opposite direction and slide another

wooden slat under the raised feet.

G. Slide the boiler left or right off the skid using the two

wooden slats as runners.

H. Move boiler to its permanent location.

WARNING

7

Page 8

III. Venting / Air Intake Piping

WARNING

Do not use this boiler with galvanized, non metallic or any other venting material that is not de-

signed for condensing ue gas applications.

Do not use a drafthood with this appliance.

Do not use vent dampers with this boiler.

Moisture and ice may form on surfaces around termination. To prevent deterioration, surfaces

should be in good repair (sealed, painted, etc.).

This appliance needs fresh air for safe operation and must be installed so there are provisions

for adequate combustion and ventilation air.

Do not reduce size of air intake pipe.

Read, understand and follow combustion air instruction restrictions contained in the Pre-Installa-

tion instructions of this manual.

Do not operate appliance where gasoline or other ammable vapors or liquids, or sources of

hydrocarbons (i.e. bleaches, cleaners, chemicals, sprays, paint removers, fabric softeners, etc.)

are used, stored and/or present in the air.

When installing vent pipe through chimney, no other appliance can be vented into the chimney.

Do not exceed maximum vent/air intake lengths. Refer to Table 1.

A. Vent Guidelines Due to Removal of an Ex-

isting Boiler

For installations not involving the replacement of an

existing boiler, proceed to Step B.

When an existing boiler is removed from a common

venting system, the common venting system is likely to

be too large for proper venting of the remaining appliances. At the time of removal of an existing boiler, the

following steps shall be followed with each appliance

remaining connected to the common venting system

placed in operation, while the other appliances remaining connected to the common venting system are not in

operation:

1. Seal any unused openings in the common venting

system.

2. Visually inspect the venting system for proper size

and horizontal pitch and determine there is no

blockage or restriction, leakage, corrosion, and

other deciencies which could cause an unsafe

condition.

3. Insofar as is practical, close all building doors and

windows and all doors between the space in which

the appliances remaining connected to the common

venting system are located and other spaces of the

building. Turn on clothes dryers and any appliance

not connected to the common venting system.

Turn on any exhaust fans, such as range-hoods

and bathroom exhausts, so they will operate at

8

maximum speed. Do not operate a summer exhaust

fan. Close replace dampers.

4. Place in operation the appliance being inspected.

Follow the Lighting (or Operating) Instructions.

Adjust thermostat so appliance will operate

continuously.

5. Test for spillage at the draft hood relief opening

after ve (5) minutes of main burner operation. Use

the ame of a match or candle, or smoke from a

cigarette, cigar or pipe.

6. After it has been determined that each appliance

remaining connected to the common venting

system properly vents when tested as outlined

above, return doors, windows, exhaust fans, re

place dampers and any other gas burning appliance

to their previous conditions of use.

7. Any improper operation of the common venting

system should be corrected so the installation

conforms with the National Fuel Gas Code, NFPA

54/ANSI Z223.1 and/or CAN/CSA B149.1 Natural

Gas and Propane Installation Code. When resizing

any portion of the common venting system, the

common venting system should be resized to approach the minimum size as determined using the

appropriate tables in Part 11 of the National Fuel

Gas Code, ANSI Z223.1/NFPA 54 and/or CAN/CSA

B149.1 Natural Gas and Propane Installation Code.

Page 9

B. General Guidelines

1. Vent system installation must be in accordance with

Part 7, Venting of Equipment of the National Fuel

Gas Code, ANSI Z223.1/NFPA 54, or Section 7,

Venting Systems and Air Supply for Appliances of

the CAN/CSA B149.1, Natural Gas and Propane Installation Code, or applicable provisions of the local

building codes.

2. Contact local building or re ofcials about restrictions and installation inspection in your area.

3. Refer to the appropriate drawings in this section of

this manual to determine the proper conguration of

venting system. Figures 2 thru 11. The vent system

shall be installed in accordance with the instructions

listed in this manual.

4. This appliance requires a Special Gas Vent. The

product is designed to use AL 29-4C® Stainless

Steel or other Stainless Steel material approved for

condensing ue gas applications. The boilers are

shipped with AL 29-4C® vent adapter to directly

connect to Heat Fab Saf-T-Vent. The use of alternate manufacturer’s venting systems will require

adapters and vent terminal. These adapters are not

supplied with this unit and should be obtained from

the supplier of alternate venting system.

5. The venting system must be installed so as to

prevent accumulation of condensate. Horizontal

vent pipe must maintain a minimum ¼ inch per foot

slope down towards boiler.

a. Do not manifold condensate drains.

b. A common condensate pump/sump may be used.

Run separate condensate piping from each vent

drain to the sump. A common drain may be used

to discharge condensate from the sump.

Consult pump/sump manufacturer for compat-

ibility of materials of construction with ue gas

condensate. If a common pump/sump is used,

individual vent drain lines must be connected

such that one drain pipe cannot back feed into

another vent drain.

c. Consult local authorities regarding disposal of

ue gas condensate into public waste water system. Some jurisdictions require that the condensate be buffered before discharge. this buffering

is commonly achieved by draining the condensate through a limestone bed. Consult chemical

treatment company for buffering systems.

6. Use noncombustible ¾ inch pipe strap to support

horizontal runs and maintain vent location and

slope while preventing sags in pipe. Do not restrict

thermal expansion or movement of vent system.

Maximum support spacing is ve (5) feet. Do not

penetrate any part of the vent system with fasteners.

7. Vent length restrictions are based on equivalent

length of vent/air pipe (total length of straight

pipe plus equivalent length of ttings). Maximum

vent/air lengths are listed in Table 1. Do not exceed

Table 1: Vent & Air Intake Length

Vent/Air Intake

Pipe Dia.Min Max

Boiler Model

SOL-300 5 50 4

SOL-500 5 78 6

SOL-750 5 50 8

SOL-1000 5 50 8

SOL-1250 5 50 10

SOL-1500 5 50 10

maximum vent/air intake lengths. Refer to vent

manufacturer’s recommendations for the equivalent

length of ttings.

8. Provide and maintain vent pipe minimum clearances

to combustible materials. Vent pipe minimum clearance to combustible material is four (4) inches when

vent is installed in a fully enclosed (chase) application or three (3) inches when vent is installed with

at least one side open, similar to a joist bay application. Use double wall thimble when penetrating a

combustible wall. Some examples of Wall thimble

manufactures are American Metal Products, Hart &

Cooley, and Metal Fab.

9. Do not install venting system components on the ex-

terior of the building except as specically required

by these instructions. The vent termination location

is restricted as follows:

a. The minimum distance from adjacent public

walkways, adjacent buildings, openable win

dows and building openings shall not be less

than those values specied in the National Fuel

Gas Code, ANSI Z223.1/NFPA 54 and/or CAN/

CSA B149.1, Natural Gas and Propane Installa

tion Code.

b. Minimum twelve (12) inches above grade plus

normally expected snow accumulation level, or

seven (7) feet above grade if located adjacent to

public walkway. Do not install over public walkway where local experience indicates appliance

ue gas vapor or condensate creates a nuisance

or hazard.

c. Minimum three (3) feet above any forced air

inlet located within ten (10) feet.

d. Power Vent - Minimum four (4) feet below, four

(4) feet horizontally from, or four (4) feet above

any door, window, or gravity air inlet.

ft. ft. In.

9

Page 10

e. Minimum of four (4) feet horizontally from, and

in no case above or below, unless a 4 foot horizontal distance is maintained from electric meters, gas meters, regulators and relief equipment.

This distance may be reduced if equipment is

protected from damage due to condensation or

vapor by enclosure, overhangs, etc.

f. Minimum twelve (12) inches from overhang or

corner of building.

g. The vent termination shall be located such that

no damage to building materials will occur from

Figure 2: Vent Therminal Location

NOTICE

Cut must be square with pipe and led or

sanded smooth before joining. Carefully

ensure roundness of cut pipe by hand with

gloves before installing. Seal joint with RTV

specied in this manual.

ue gasses degradation.

10. Enclose vent passing through occupied or unoccu

pied spaces above the boiler with material having a

re resistance rating of at least equal to the rating

of the adjoining oor or ceiling. Maintain minimum

clearances to combustible materials. See page 4.

11. Plan venting system to avoid possible contact with

plumbing or electrical wires. Start at vent connector

on top of boiler and work towards vent terminal.

12. Once a vent pipe manufacturer and system is chosen never mix and match vent systems.

13. Field Supplied Vent Terminations (One per boiler)

a. Horizontal - Use Saf-T Vent mitered termination

with screen or equivalent

b. Vertical - Use Saf-T Vent rain cap or equivalent

C. Supplemental Vent Terminal Location In-

structions (Massachusetts Code Only)

The Commonwealth of Massachusetts requires compli-

ance with regulation 248 CMR 4.00 and 5.00 for installation of side-wall vented gas appliances as follows:

(a) For all side wall horizontally vented gas fueled equip-

ment installed in every dwelling, building or structure

used in whole or in part for residential purposes, including those owned or operated by the Commonwealth and

where the side wall exhaust vent termination is less than

seven (7) feet above nished grade in the area of the

venting, including but not limited to decks and porches,

the following requirements shall be satised:

1. INSTALLATION OF CARBON MONOXIDE DETECTORS. At the time of installation of the side wall

horizontal vented gas fueled equipment, the installing

plumber or gastter shall observe that a hard wired

carbon monoxide detector with an alarm and battery

back-up is installed on the oor level where the gas

equipment is to be installed. In addition, the install-

ing plumber or gastter shall observe that a battery

operated or hard wired carbon monoxide detector with

an alarm is installed on each additional level of the

dwelling, building, or structure served by the side wall

horizontal vented gas fueled equipment. It shall be the

responsibility of the property owner to secure the services of qualied licensed professionals for the installation of hard wired carbon monoxide detectors.

a. In the even that the side wall horizontally vented

gas fueled equipment is installed in a crawl space or

an attic, the hard wired carbon monoxide detector with

alarm and battery back-up may be installed on the next

adjacent oor level.

b. In the event that the requirements of this subdivision

can not be met at the time of completion of installation, the owner shall have a period of thirty (30) days

to comply with the above requirements; provided, however, that during said thirty (30) day period, a battery

operated carbon monoxide detector with an alarm shall

be installed.

2. APPROVED CARBON MONOXIDE DETECTORS.

Each carbon monoxide detector as required in accordance with the above provisions shall comply with

NFPA 720 and be ANSI/UL 2034 listed and IAS certi-

ed.

3. SIGNAGE. A metal or plastic identication plate shall be

permanently mounted to the exterior of the building at

a minimum height of eight (8) feet above grade directly

in line with the exhaust vent terminal for the horizontally vented gas fueled heating appliance or equipment.

The sign shall read, in print size no less than one-half

(1/2) inch in size, “GAS VENT DIRECTLY BELOW,

KEEP CLEAR OF ALL OBSTRUCTIONS”.

4. INSPECTION. The state or local gas inspector of the side

wall horizontally vented gas fueled equipment shall

not approve the installation unless, upon inspection,

10

Page 11

the inspector observes carbon monoxide detectors and

signage installed in accordance with the provisions of

248 CMR 5.08(2)(a)1 through 4.

(b) EXEMPTIONS: The following equipment is exempt

from 248 CMR 5.08(2)(a)1 through 4:

1. The equipment listed in Chapter 10 entitled “Equipment Not Required To Be Vented” in the most current

edition of NFPA 54 as adopted by the board; and

2. Product Approved side wall horizontally vented

gas fueled equipment installed in a room or structure

separate from the dwelling, building or structure used in

whole or in part for residential purposes.

(c) MANUFACTURER REQUIREMENTS - GAS

EQUIPMENT VENTING SYSTEM PROVIDED.

When the manufacturer of Product Approved side wall

horizontally vented gas equipment provides a venting

system design or venting system components with the

equipment, the instructions provided by the manufacturer for installation of the equipment and the venting

system shall include:

1. Detailed instructions for the installation of the venting system design or the venting system components;

and

2. A complete parts list for the venting system design or

venting system.

(d) MANUFACTURER REQUIREMENTS - GAS

EQUIPMENT VENTING SYSTEM NOT PROVIDED.

When the manufacturer of a Product Approved side

wall horizontally vented gas fueled equipment does not

provide the parts for venting the ue gasses, but identies “special venting systems”, the following requirements shall be satised by the manufacturer:

1. The referenced “special venting system” instructions shall be included with the appliance or equipment

installation instructions; and

2. The “special venting systems” shall be Product

Approved by the Board, and the instructions for that

system shall include a parts list and detailed installation

instructions.

(e) A copy of all installation instructions for all Product

Approved side wall horizontally vented gas fueled

equipment, all venting instructions, all parts lists for

venting instructions, and/or all venting design instructions shall remain with the appliance or equipment at

the completion of the installation.

D. Separate Horizontal Venting System. See

Figures 3, 4 and 5.

1. Vent Piping –

a. Do not exceed maximum vent/air intake

lengths. Refer to Table 1.

b. Recommended horizontal installation consists

of vent being sloped down ¼ inch per foot

toward boiler.

c. Use appropriate designed thimbles when

passing through combustible walls (thimble

use optional for noncombustible walls). Insert

thimble through wall from outside. Secure

outside ange to wall with nails or screws, and

seal ID, OD and vent holes with sealant

material. Install inside ange to inside wall,

secure with nails or screws, and seal with

sealant material.

d. For noncombustible wall application when

thimble is not used, size opening such that bell

with locking band attached cannot pass

through.

e. Join vent terminal to vent pipe. Locate vent

pipe such that vent terminal is between six (6)

inches and twenty-four (24) inches from wall

when joined to inside vent piping. See Figure

3 or 4.

f. Insert vent pipe through thimble/opening from

outside and join to vent system. Apply seal ant between vent pipe and opening/thimble to

provide weathertight seal.

2. Side Vent Installation. See gure 5.

a. Horizontal vent/air intake runs with no

vertical rise in piping allowed.

b. Do not exceed maximum vent/air intake

lengths. Refer to Table 1.

c. Recommended Horizontal Installation only

consists of vent/air intake sloped down 1/4

inch per foot toward termination.

d. Thimbles, same as “C” above in section D.1

e. same as “D” above in section D.1

f. same as “E” above in section D.1

g. same as “F” above in section D.1

Figure 3: Side Top Vent

11

Page 12

12

Figure 4: Recommended Separate Horizontal - Vent/Air Intake Installation

Page 13

Figure 5: Side Vent

13

Page 14

E. Optional Separate Horizontal Vent Terminal Mounting – See Figure 6

1. Do not exceed maximum vent/air intake lengths.

Refer to Table 1.

2. This installation will allow a maximum of ve (5)

feet vertical exterior run of the vent/air intake piping

to be installed on separate horizontal venting and

indoor air horizontal venting.

Note: Exterior run to be included in equivalent vent/

air intake lengths.

3. Install vent piping.

a. Install vent piping for desired venting system.

Refer to specic section for details for vent pipe

installation.

b. After penetrating wall/thimble, install a 90°

elbow so that elbow leg is in the up direction.

c. Install maximum of ve (5) feet of vent pipe.

Refer to Sections C through E for proper proce-

dures for joining vent pipe and ttings.

d. At top of vent pipe length install a 90° elbow so

that elbow leg is opposite the building’s exterior

surface.

e. Install 45° elbow to upper 90° elbow so that leg

of 45° is in down direction (see Figure 6). If not

using indoor air, proceed to Step f.

f. Install horizontal vent terminal.

g. Brace piping if required.

4. Air Intake Piping (not required for indoor air).

a. Install air intake piping for desired venting sys-

tem. Refer to specic section for details for air

intake installation.

b. After penetrating wall, install a corrosion re-

sistant 90o elbow so that elbow leg is in the up

direction.

c. Install maximum of ve (5) feet of corrosion

resistant air intake pipe.

d. At top of air intake pipe install air intake termi

nal (provided with boiler).

e. Brace piping if required.

-

14

Figure 6: Optional Indoor Air – Vent Terminal Installation

Page 15

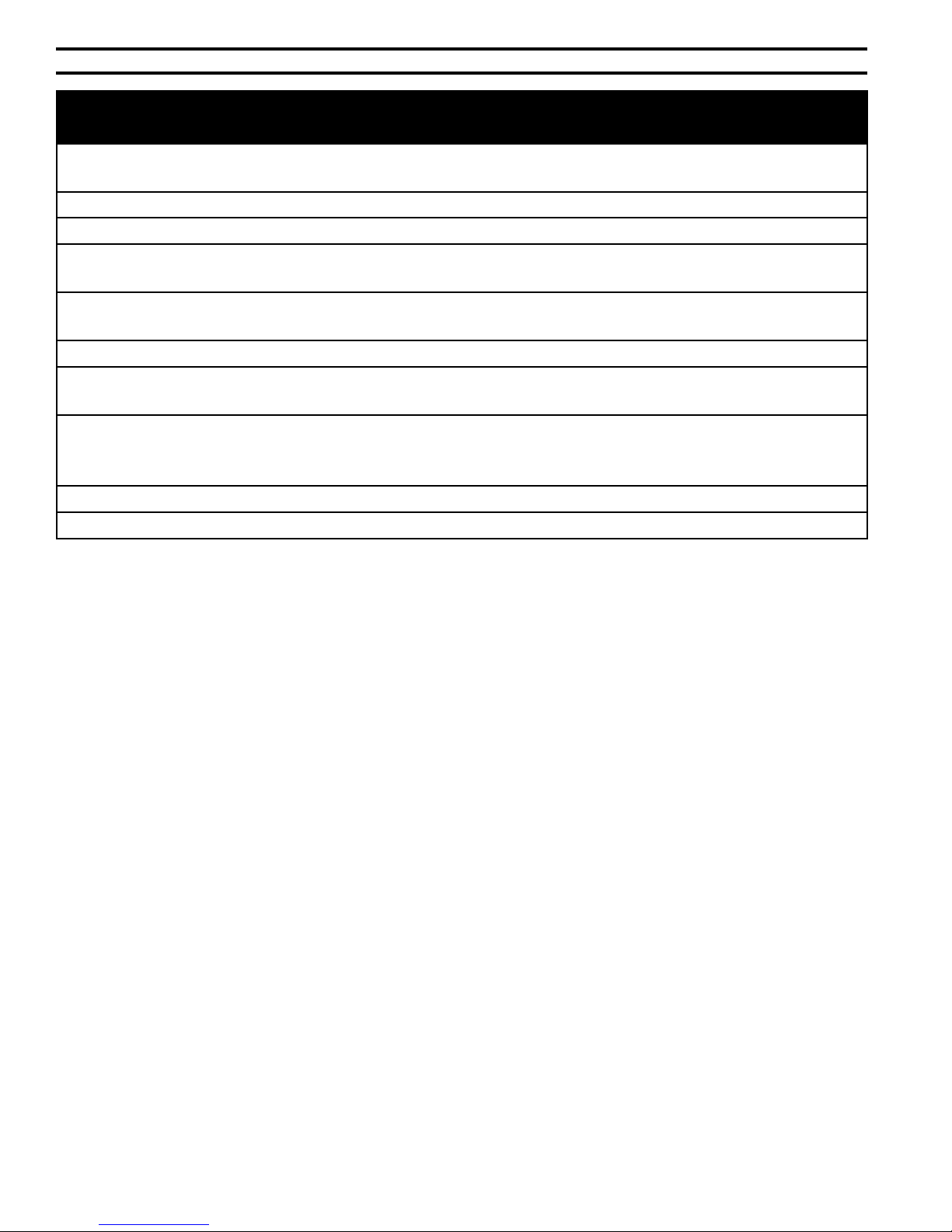

F. Conventional Venting (Negative Draft) – See Figure 7

a. The minimum chimney height is 15 feet.

b. The chimney must be protected from down

drafts, rain and debris by using a chimney cap or

star.

c. Start installing vent at vent cap and continue

installation toward the boiler.

d. The ue connector and chimney ue diameter

may need to be increased or decreased depend

ing on the dimensions of the boiler. Consult the

National Fuel Gas Code or Local Codes for siz-

ing. Boiler input, ue connector lateral distance

and chimney height affect the ue connector or

chimney ue diameters.

e. A double acting barometric damper with integral

ue spillage interlock switch must be used when

the boiler is vented conventionally.

f. The chimney and ue connector must be sized

and congured to provide a minimum - 0.04 inch

w.c. draft at the vent outlet of the boiler.

g. Maintain a minimum vertical pitch of one (1)

inch in four (4) feet of vent connector run.

G. Air Intake Piping - See Figure 4 & 8

1. Locate air intake termination on the same wall as the

vent termination if possible, to prevent nuisance boiler

shutdowns. However, boiler may be installed with vertical venting and sidewall combustion air inlet or vice

versa, if installation conditions do not allow alternate

arrangement.

2. Do not exceed maximum air intake length. See Table 1.

3. Use single wall metal pipe and ttings or thin wall PVC

available at most heating distributors.

4. Air intake termination must be located: Horizontal - At

least twelve (12) inches above grade plus the expected

snow accumulation.

5. Start at collar on burner enclosure (inside boiler jacket)

and work towards the air intake terminal.

6. Maintain minimum of 1/4 inch per foot slope on

horizontal runs. Slope towards air inlet terminal when

possible. If not, slope towards boiler.

7. The air intake pipe must be adequately supported with

straps or supports no less than ve (5) feet apart on

horizontal runs. The complete air intake piping system

must be rigid and able to withstand minor impacts without collapse.

8. Inlet air pipe penetration: Horizontal - Size wall penetration to allow easy insertion of air inlet piping. Seal

around pipe with sealant to form weathertight exterior

joint.

9. Seal all joints airtight, using silicone caulk or self-adhesive aluminum tape.

10. Install Air Intake Terminal.

Figure 7: Conventional Venting (Negative Draft)

15

Page 16

16

SEE TABLE 1.

Figure 8: Separate Horizontal – Vent/Air Intake Terminal Conguration

Page 17

H. Separate Vertical Venting System - See Figures 9, 10, and 11.

Vertical Venting –

1. Do not exceed maximum vent lengths. Refer to

Table 1.

2. Slope horizontal runs minimum ¼ inch per foot

down towards boiler.

3. Install re stops where vent passes through oors,

ceilings or framed walls. The re stop must close

the opening between the vent pipe and the structure.

Fire stop manufacturers are Air-Jet, American Metal

Products, Metal-Fab, and Simpson Dura-Vent.

4. Whenever possible, install vent straight through the

roof. Refer to Figure 9 if offset is necessary. Maintain minimum clearance to combustible

materials.

5. Install Vent Terminal.

a. Size roof opening to maintain minimum clear-

ance from combustible materials.

b. Extend vent pipe to maintain minimum vertical

and horizontal distance of twelve (12) inches

from roof surface. Allow additional vertical distance for expected snow accumulation. Provide

brace as required. Refer to Figure 11.

c. Vertical venting requires use of the roof ashing

and storm collar to prevent moisture from entering the structure.

d. Install storm collar on vent pipe immediately

above ashing. Apply Dow Corning Silastic 732

RTV Sealant between vent pipe and storm collar

to provide weathertight seal.

e. Attach vent terminal.

Vertical Air Intake Piping –

1. Do not exceed maximum air intake length. Refer to

Table 1.

2. Locate air intake termination on the same roof loca

tion as the vent termination if possible, to prevent

nuisance boiler shutdowns. However, boiler may be

installed with vertical venting and sidewall combustion air inlet or vica versa, if installation conditions

do not allow alternate arrangement.

-

8. Inlet air pipe penetration:

9. Seal all joints airtight, using silicone caulk or self -

adhesive aluminum tape.

10. Install Air Intake Terminal:

Vertical - Insert intake piping into intake terminal

collar. Secure terminal to intake piping and seal

joint with silicone caulk.

with straps or supports no less than ve (5) feet

apart on horizontal runs. The complete air intake

piping system must be rigid and able to withstand

minor impacts without collapse.

Vertical - Size roof opening to allow easy insertion

of inlet piping and allow proper installation of ashing and storm collar.

a. Use appropriately designed vent ashing when

passing through roofs. Follow ashing manufac-

turers’ instructions for installation procedures.

Flashing manufacturers are Air-Jet, American

Metal Products, Metal Fab, and Simpson DuraVent.

b. Extend air intake pipe to maintain minimum

vertical and horizontal distance of twelve (12)

inches from roof surface. Allow additional vertical distance for expected snow accumulation.

Provide brace as required. Refer to Figure 11.

c. Vertical air intake requires ashing and a storm

collar to prevent moisture from entering the

structure.

d. Install storm collar on air intake pipe immediate-

ly above ashing. Apply Dow Corning Silastic

732 RTV Sealant between air intake pipe and

storm collar to provide weathertight seal.

3 Use single wall metal pipe and ttings or thin wall

PVC available at most heating distributors.

4. Air intake termination must be located:

Vertical - At least twelve (12) inches above the roof

surface plus the expected snow accumulation.

5. Start at collar on burner enclosure (inside boiler

jacket) and work towards the air intake terminal.

6. Maintain minimum of 1/4 inch per foot slope on

horizontal runs. Slope down towards boiler.

7. The air intake pipe must be adequately supported

17

Page 18

18

Figure 9: Vertical Vent Installation

Page 19

Figure 10: Attic Offset

Figure 11: Indoor Air - Horizontal / Vertical Vent Terminal Installation

Extend Vent/Air Intake Piping to maintain minimum vertical (“X”) and minimum horizontal (“Y”) distance of twelve

(12) inches from roof surface. Allow additional vertical (“X”) distance for expected snow accumulation.

19

Page 20

IV. Water Piping and Trim

CAUTION

iii. Oxygen permeable materials in the distribu-

tion system.

Failure to properly pipe boiler may result in

improper operation and damage to boiler or

structure.

1. Design and install boiler and system piping to

prevent oxygen contamination of boiler water and

frequent water additions.

CAUTION

Oxygen contamination of boiler water will

cause corrosion of iron and steel boiler

components, and can lead to boiler failure. Thermal Solutions Standard Warranty

does not cover problems caused by oxygen contamination of boiler water or scale

(lime) build-up cause by frequent addition of

water.

CAUTION

All piping either new or existing must be

cleaned with a tri sodium phosphate (TSP)

solution to remove mill scale and oils from

the system. Failure to do so could result in

premature failure of the heat exchanger (not

covered by Thermal Solutions warranty.)

CAUTION

On an existing or retrot system, a lter or

strainer must be installed on the system

return prior to the boilers.

b. In order to insure long product life, oxygen

sources must be eliminated. This can be accomplished by taking the following measures:

i. Repairing system leaks to eliminate the need

for addition of make-up water.

ii. Eliminating and/or repairing ttings which

allow oxygen absorption.

iii. Using non-permeable materials in the distri-

bution system.

iv. Isolating the boiler from the system water by

installing a heat exchanger.

vi. Using properly designed and operating air

elimination devices in water piping.

2. Design and install system piping to prevent return

water temperatures below 130°F. Refer to Table 2

for boiler ow and pressure drop requirements.

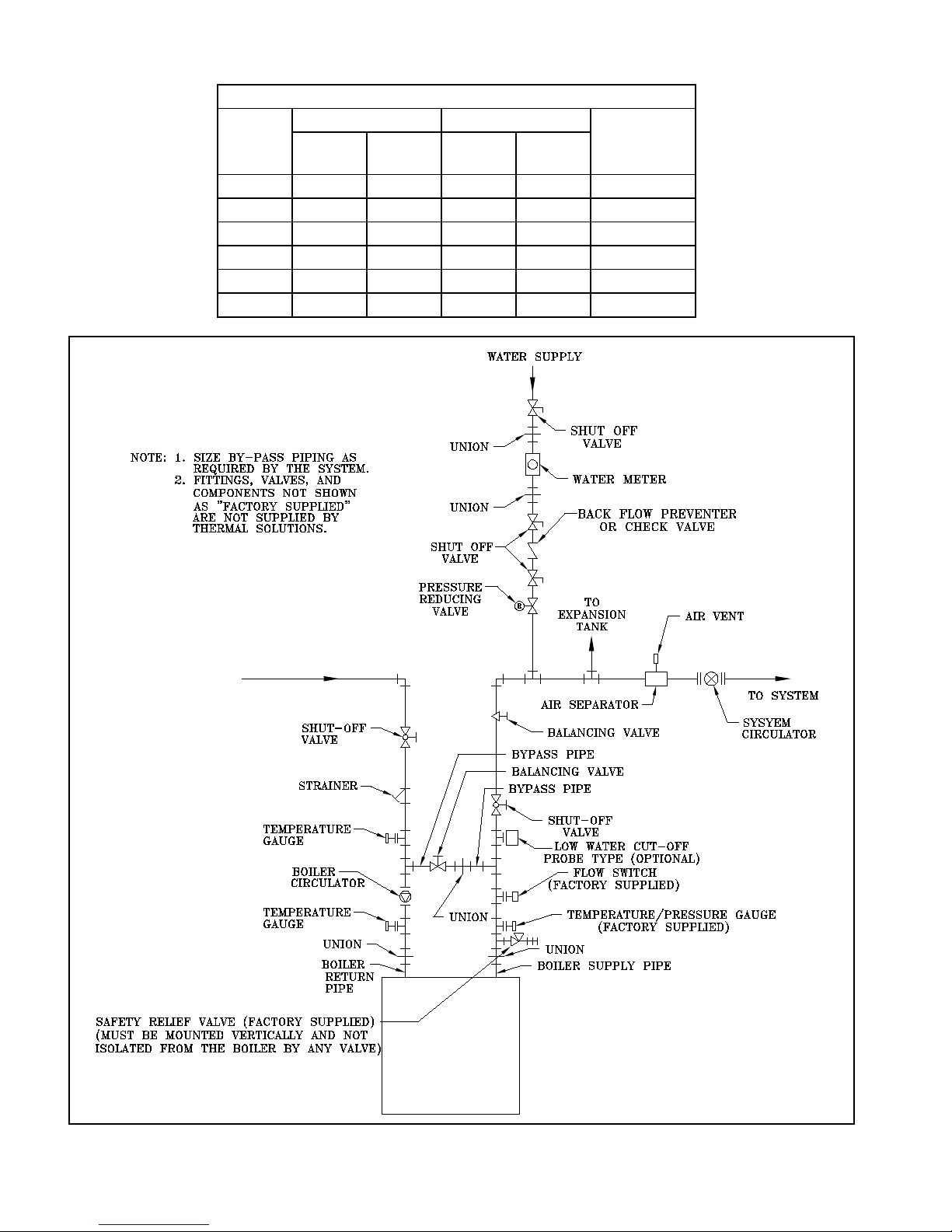

3. Connect system supply and return piping to boiler.

Refer to Figure 12. Also consult I=B=R Installation

CAUTION

Return water temperature below 130°F

will cause ue gas condensation inside the

boiler. Flue gas condensate can lead to

boiler failure. Thermal Solutions Standard

Warranty does not cover problems caused

by ue gas condensation.

WARNING

CAUTION

When using Glycol products, all Glycol

manufacturers’ requirements, including

rust inhibitors, must be adhered. Max 50%

Glycol.

a. There are many possible causes of oxygen con-

tamination such as:

i. Addition of excessive make-up water as a

result of system leaks.

ii. Absorption through open tanks and ttings.

20

Supply and return water temperature differences greater than 40°F can lead to boiler

failure. Thermal Solutions Standard Warranty does not cover problems caused by

temperature difference greater than 40°F.

and Piping Guides. Maintain ½” minimum distance

between water piping and combustible material.

Consult Thermal Solutions for unusual system

requirements.

4. A pressure relief valve is supplied with each appliance. No valve is to be placed between the relief

valve and appliance. No reducing coupling or other

restriction shall be installed in the discharge line.

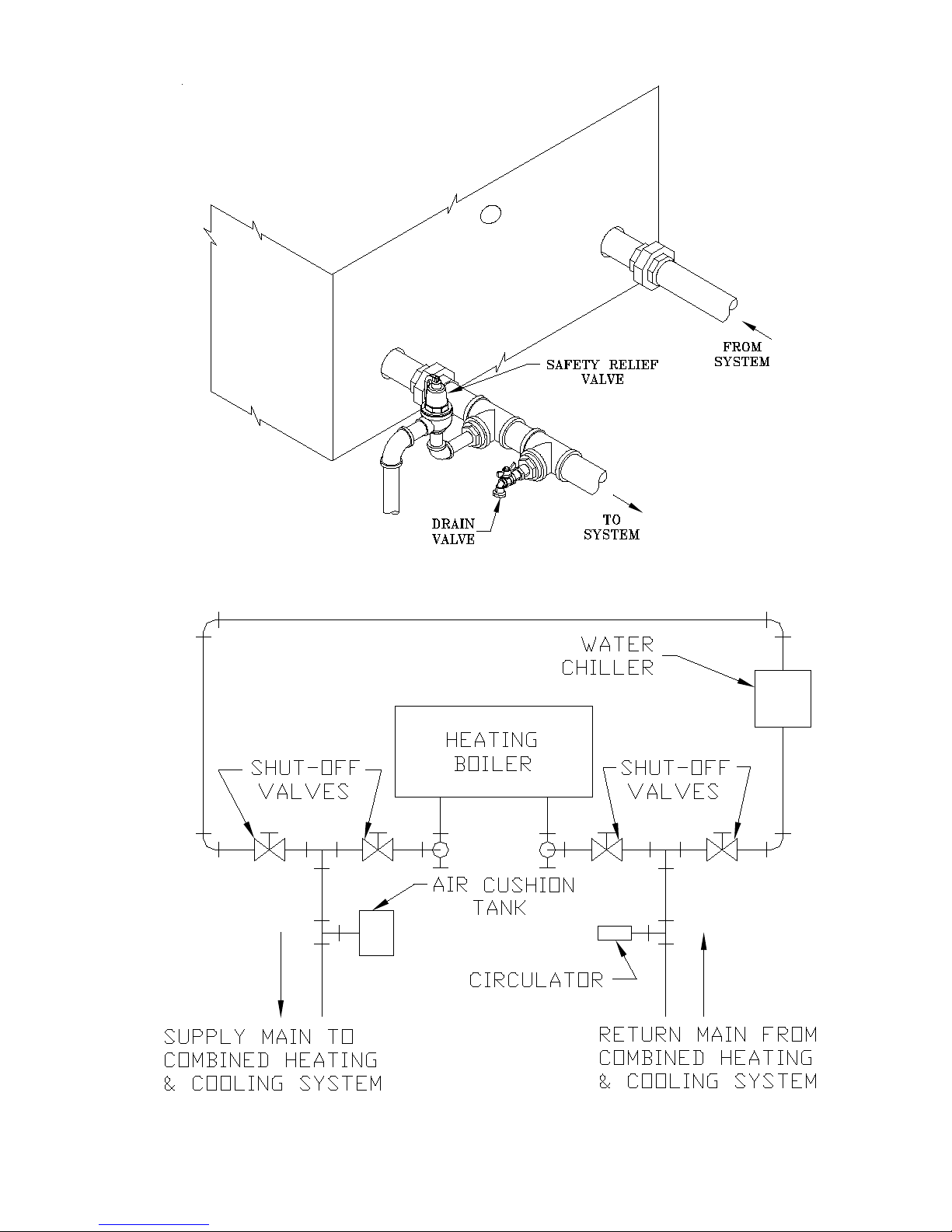

Page 21

See Figure 13.

compatible with local environmental regulations.

a. Pipe the safety relief discharge to a suitable place

for disposal when relief occurs.

b. Do not install reducing couplings for other

restrictive devices in the safety relief discharge

line.

c. The safety relief discharge line must allow for

complete drainage of both the valve and line.

5. If the relief valve discharges periodically, this may

be due to thermal expansion in a closed water

supply system. Contact the water supplier or local

plumbing inspector on how to correct this situation.

DO NOT PLUG THE RELIEF VALVE.

6. Install the drain valve provided with the appliance at

the lowest elevation. See Figure 13.

7. If this boiler is used in connection with refrigeration systems, the boiler must be installed so that the

chilled medium is piped in parallel with the boiler

using appropriate valves to prevent the chilled

medium from entering the boiler, see gure 13A.

Also consult I=B=R Installation and Piping Guides.

If this boiler is connected to heating coils located

in air handling units where they may be exposed to

refrigerated air circulation, the boiler piping must be

equipped with ow control valves or other automatic means to prevent gravity circulation of boiler

water during operation of the cooling system.

8. Install water ow switch. Water ow switch must

be located such that water ow disruptions do not

affect switch operation. Maintain maximum practi-

cal straight piping before and after ow switch to

minimize water disruptions. Refer to manufactures’

instructions for proper paddle length.

9. A low water cutoff is required to protect a hot water

boiler when any connected heat distributor (radiation) is installed below the top of the hot water

boiler (i.e. baseboard on the same oor level as the

boiler). In addition, some jurisdictions require the

use of a LWCO with a hot water boiler. If a low

water cutoff is required, it must be mounted in the

system piping above the boiler. The minimum safe

water level of a hot water boiler is just above the

highest water containing cavity of the boiler; that is,

a hot water boiler must be full of water to operate

safely.

10. Oil, grease, and other foreign materials which

accumulate in new hot water boilers and a new or

reworked system should be boiled out, and then

thoroughly ushed. A local qualied water

treatment chemical specialist is a suggested source

for recommendations regarding appropriate

chemical compounds and concentrations which are

11. After the boiler and system have been cleaned and

ushed, and before relling the entire system add

appropriate water treatment chemicals, if necessary,

to bring the pH between 8.8 and 9.2.

12. If it is required to perform a long term pressure

test of the hydronic system, the boiler should rst

be isolated to avoid a pressure loss due to the

escape of air trapped in the boiler.

To perform a long term pressure test including the

boiler, ALL trapped air must rst be removed from

the boiler.

A loss of pressure during such a test, with no

visible water leakage, is an indication that the

boiler contained trapped air.

WARNING

Failure to operate the unit with the proper

water ow rate can lead to appliance failure.

Always install water ow switch so that the

unit stops operating if improper water ow

is present.

Safety relief valve discharge piping must

be piped such that the potential of severe

burns is eliminated. DO NOT pipe in any

area where freezing could occur. DO NOT

install any shut-off valves, plugs or caps.

Consult Local Codes for proper discharge

piping arrangement.

Do not operate boiler with ow rates in

excess of the maximum ow rates listed in

Table 2. Boiler tube erosion and pitting will

occur. Thermal Solutions Standard Warranty does not cover problems caused by

excessive water ow rates.

If a high head system pump is installed, assure that the boiler relief valve and system

piping are capable of operating properly

at the combined pressure of the system ll

pressure plus the pump static head pressure.

21

Page 22

Table 2 - Solaris Boiler Flow and Pressure Drop

20° ΔT (max) 40° ΔT (min)

Boiler

Model

SOL-300 0.8 24 0.5 12 2

SOL-500 6.9 41 1.4 20 2

SOL-750 6.5 64 1.5 32 3

SOL-1000 16.1 85 3.7 43 3

SOL-1250 23.5 106 6.9 53 3

SOL-1500 29.1 128 10.6 64 3

Flow

(GPM) Δ P (ft)

Flow

(GPM)

Supply/Return

Pipe (in. dia.)Δ P (ft)

Figure 12: Water Piping (Single Boiler)

22

Page 23

Figure 13: Safety & Drain Valve Installation

Figure 13 A: Recommended Piping for Combination

Heating & Cooling (Refrigeration) System

23

Page 24

V. Gas Piping

WARNING

Failure to properly pipe gas supply to boiler

may result in improper operation and damage to the boiler or structure. Always assure

gas piping is absolutely leak free and of the

proper size and type for the connected load.

An additional gas pressure regulator may

be needed. Consult gas supplier.

A. Size gas piping. Design system to provide adequate gas

supply to boiler. Consider these factors:

1. Allowable pressure drop from point of delivery to

boiler. Maximum allowable system pressure is ½

psig. Actual point of delivery pressure may be less;

contact gas supplier for additional information. The

minimum and maximum gas valve inlet pressure is

stamped on the rating label and can be found in table

3.

2. Maximum gas demand. Refer to the boiler’s input

found in Figure 1 or as printed on it’s rating label.

Also consider existing and expected future gas

utilization equipment (i.e. water heater, cooking

equipment).

3. Length of piping and number of ttings. Refer to

Table 5 for maximum capacity of Schedule 40 pipe.

Table 6 lists equivalent pipe length for standard ttings.

Table 3: Gas Ratings

Maximum

Boiler

Model

SOL-300 14 4.5 3.5

SOL-500 14 4.5 1.3

SOL-750 14 4.5 2.3

SOL-1000 14 4.5 1.9

SOL-1250 14 4.5 1.5

SOL-1500 14 4.5 1.3

Gas Pressure

(in. w.c.)

Minimum

Gas Pressure

(in. w.c.)

Manifold

Pressure

(in. w.c.)

4. Specic gravity of gas. Gas piping systems for

gas with a specic gravity of 0.70 or less can be

sized directly from Table 5, unless authority having

jurisdiction species a gravity factor be applied.

For specic gravity greater than 0.70, apply gravity

factor from Table 4. If exact specic gravity is not

shown choose next higher value.

Table 4: Specic Gravity Correction Factors

Specic

Gravity

0.50 1.10 1.10 0.74

0.55 1.04 1.20 0.71

0.60 1.00 1.30 0.68

0.65 0.96 1.40 0.66

0.70 0.93 1.50 0.63

0.75 0.90 1.60 0.61

0.80 0.87 1.70 0.59

0.85 0.84 1.80 0.58

0.90 0.82 1.90 0.56

1.00 0.78 2.00 0.55

For materials or conditions other than those listed above, re-

fer to National Fuel Gas Code, NFPA54/ANSI Z223.1,

or size system using standard engineering methods

acceptable to authority having jurisdiction.

Correction

Factor

Specic

Gravity

Correction

Factor

B. Connect boiler gas valve to gas supply system.

1. Use methods and materials in accordance with local

plumbing codes and requirements of gas supplier. In

absence of such requirements, follow National Fuel

Gas Code, NFPA 54/ANSI Z223.1.

2. Use thread (joint) compounds (pipe dope) resistant

to action of liqueed petroleum gas.

3. Install sediment trap, ground-joint union and manual

shut-off valve upstream of boiler gas control valve

and outside jacket. See Figure 14.

4. All above ground gas piping upstream from manual

shut-off valve must be electrically continuous and

bonded to a grounding electrode. Do not use gas

piping as grounding electrode. Refer to National

Electrical Code, NFPA 70.

USA boilers built for installation at altitudes greater than 2,000 feet above sea level have been

specically oriced to reduce gas input rate 4 percent per 1,000 feet above sea level per the

National Fuel Gas Code, NFPA 54/ANSI Z223.1.

24

C. Pressure test. The boiler and its gas connection must be

NOTICE

Page 25

Table 5: Maximum Capacity of Schedule 40 Pipe in CFH* for Gas Pressures of 0.5 psig or Less

MANUAL

SHUT-OFF

VALVE

GROUND-JOINT

UNION

TEE

CAP

3" MIN.

0.3 inch w.c. Pressure Drop 0.5 inch w.c. Pressure Drop

Length (Feet)

3/4 1 1-1/4 1-1/2 3/4 1 1-1/4 1-1/2

10 273 514 1060 1580 360 678 1390 2090

20 188 353 726 1090 247 466 957 1430

30 151 284 583 873 199 374 768 1150

40 129 243 499 747 170 320 657 985

50 114 215 442 662 151 284 583 873

60 104 195 400 600 137 257 528 791

70 95 179 368 552 126 237 486 728

80 89 167 343 514 117 220 452 677

90 83 157 322 482 110 207 424 635

100 79 148 304 455 104 195 400 600

* 1 CFH of Natural Gas is approximately equal to 1 MBH.

leak tested before placing boiler in operation.

1. Protect boiler gas control valve. For all testing over

DANGER

½ psig, boiler and its individual shutoff valve must

be disconnected from gas supply piping. For testing at ½ psig or less, isolate boiler from gas supply

Do not use matches, candles, open ames

or other ignition source to check for leaks.

piping by closing boiler’s individual manual shutoff

valve.

2. Locate leaks using approved combustible gas detector, soap and water, or similar nonammable solution.

WARNING

Failure to use proper thread compounds

on all gas connectors may result in leaks of

ammable gas.

WARNING

Gas supply to boiler and system must be

absolutely shut off prior to installing or servicing boiler gas piping.

Table 6: Equivalent Lengths of Standard Pipe Fittings & Valves

VALVES FULLY OPEN

Figure 14: Recommended Gas Piping

Pipe Size I.D. Gate Globe Angle Swing 90° Elbow 45° Elbow 90° Tee, Flow 90° Tee, Flow

1/2” 0.622 0.35 18.6 9.3 4.3 1.6 0.78 1.0 3.1

3/4” 0.824 0.44 23.1 11.5 5.3 2.1 0.97 1.4 4.1

1” 1.049 0.56 29.4 14.7 6.8 2.6 1.23 1.8 5.3

1-1/4” 1.380 0.74 38.6 19.3 8.9 3.5 1.60 2.3 6.9

25

Page 26

VI. Electrical

DANGER

Positively assure all electrical connections are unpowered before attempting installation or service of electrical components or connections of the boiler or building. Lock out all electrical boxes

with padlock once power is turned off.

WARNING

Failure to properly wire electrical connections to the boiler may result in serious physical harm.

Electrical power may be from more than one source. Make sure all power is off before attempt-

ing any electrical work.

Each boiler must be protected with a properly sized over-current device.

Never jump out or make inoperative any safety or operating controls.

The wiring diagrams contained in this manual are for reference purposes only. Each boiler is

shipped with a wiring diagram attached to the front door. Refer to this diagram and the wiring

diagram of any controls used with the boiler. Read, understand and follow all wiring instructions

supplied with the controls.

A. General. Install wiring and electrically ground boiler

in accordance with authority having jurisdiction or, in

the absence of such requirements, follow the National

Electrical Code, NFPA 70, and/or CSA C22.1 Electrical

Code.

B. A separate electrical circuit must be run from the main

electrical service with an over-current device/disconnect in the circuit. A service switch is recommended

and may be required by some local jurisdictions. Install

the service switch in the line voltage “Hot” leg of the

power supply. Locate the service switch such that the

boiler can be shut-off without exposing personnel to

danger in the event of an emergency. Connect the main

power supply and ground to the three (3) boiler wires

(black, white and green) located in the junction box at

the back of the boiler jacket.

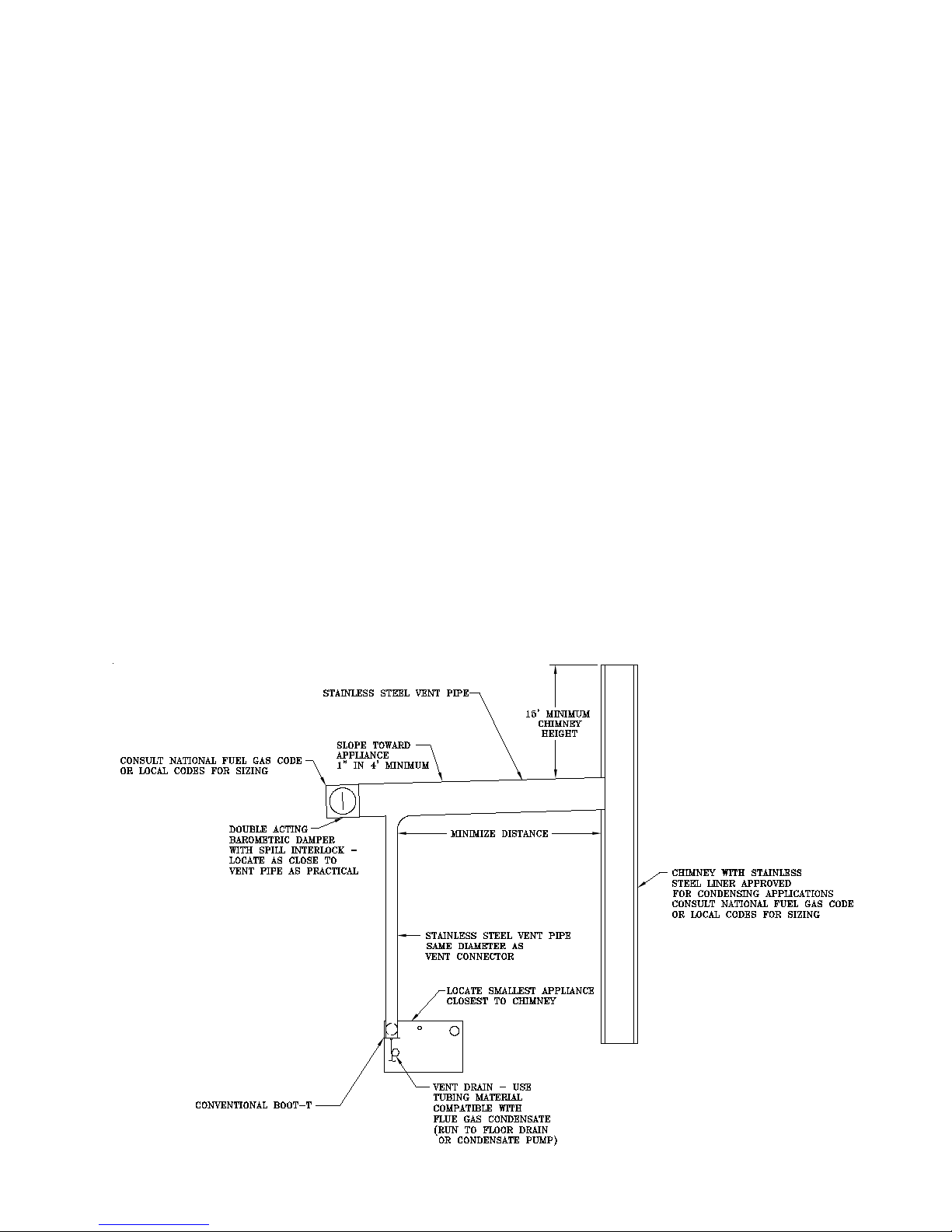

C. Refer to Figures 15 and 16 for details on the internal

boiler wiring.

D. When installed, the boiler must be electrically bonded

to ground in accordance with the requirements of the

authority having jurisdiction or, in the absence of such

requirements, with the National Electric Code, ANSI/

NFPA70 and/or the Canadian Electrical Code Part 1,

CSA C22.1, Electrical Code.

NOTICE

This boiler is equipped with a high water temperature limit located inside the internal wiring of the

boiler. This limit provides boiler shutdown in the event the boiler water temperature exceeds the

set point of the limit control. Certain Local Codes require an additional water temperature limit. In

addition, certain types of systems may operate at temperatures below the minimum set point of

the limit contained in the boiler.

If this occurs, install an additional water temperature limit (Honeywell L4006 Aquastat) located in

the system piping as shown in the Water Piping and Trim Section of this manual. Wire as indicated in the Electrical Section of this manual.

26

Page 27

SAGE

CONTROLLER

Solaris

Ladder Diagram

LOW WATER

CUTOFF

OPTION

(SEE NOTE 1)

WATER FLOW SWITCH

BURNER ON/OFF SWITCH

HIGH LIMIT AND OPERATING

TEMPERATURE SWITCHES

HIGH AND LOW GAS

PRESSURE SWITCHES

CNO

CNC

CC

CNO

MM 750-

MT-120

IGNITION PILOT

IGNITION XFMR

IGN

.

LEAD

2

1

P

GR

INTERMITTENT

PILOT

GAS VALVE

3

5

COMBUSTION AIR FLOW

SWITCH

CNO

BLOCKED VENT

GN

RD

10

18

17

20

19

22

21

237

K1 K1

26

27

FUSE

G

2

10 28

8

9

11

12

13

14

16

15

7

8

9

11

10

3

2

5

SENSE

MAIN FUEL VALVE

6

SENSE

COMBUSTION AIR

FLOW

SENSE

HIGH LIMIT

SENSE

GAS PRESS SWITCHES

SENSE

WATER FLOW SWITCH

SENSE

BURNER ON/OFF

SWITCH

SENSE

LOW WATER CUTOFF

6

2

2

2

L1

L2

G

TO DISCONNECT (BY

OTHERS). GROUND

UNIT TO TECHNICAL

EARTH GROUND

120V-1PH-60HZ

43

31

32

34

35

33

36

K5

K5

29

37

38

K3

2

40

39

K4

41

4

4

5

3

K3

K5

K2

K3

SENSE

ALARM RELAY K2

K4

K6

51

52

1

2

1

4

1

5

0-10 VDC

TO

135 OHM

(+)

(-)

HONEYWELL Q7800H

FLAME SAFEGUARD SUBBASE

AND

PROGRAMMER CONTROL

RM7897A-1002

CALL FOR

HEAT

LC

CA

42

47

48

49

K2

2

3

3

2

3

50

2

0

30

K6

45

46

3

2

44

Flame

Rod

F

O+

O-

R+

R-

DP

LR

RO

SI

C

OUTSIDE AIR

SENSOR

REMOTE SYSTEM

SENSOR

OUTSIDE AIR

RESET OPTION

SYSTEM

TEMPERATURE

CONTROL OPTION

OUTLET

SENSOR

INLET

SENSOR

RJ45

MULTIPLE BOILER OUTSIDE AIR AND

REMOTE SYSTEM TEMPERATURE

SENSOR SHARING

C

SP

BP

VI

LO

SO

SYSTEM PUMP

COLD AIR DAMPER,

SYSTEM PUMP BACKUP

OR ALARM

BOILER PUMP

SPARE

LOCKOUT INDICATOR

CONTROL RELAY OPTIONS

MIXING VALVE

ACTUATOR

C-

C+

MR

MS

OR

1-9 VDC

24VAC +

24VAC -

2

12

7

5

4

6

8

9

1

11

10

3

K1

CS

AL

PR

C

LC

CH

FUSE

24VAC +

24VAC -

2

3

7

5

4

6

8

9

1

10

OO V

- V+

P-P

+

CA HL GP WF

Pin 6

Pin 1

Pin 7

Pin 1

BC

BO

BI

V+

V-

COMBUSTION BLOWER

SPEED CONTROL

CIRCUIT (0-10VDC)

COMBUSTION BLOWER

120 VAC CIRCUIT

GND TO

CHASSIS

GND TO

CHASSIS

2

1

3

GND TO

CHASSIS

2

1

3

GND TO

CHASSIS

MAIN

GAS VALVE

115V TO 24V

TRANSFORMER

L2

L1

C

C

C

O+

O-

R+

R-

RJ11

SAGE CONTROLLER PEER-TO-PEER

COMMUNICATION

GND TO

CHASSIS

CNC

NC NC

LINE VOLTAGE ALARM

BLOWER MOTOR

AUXILIARY RELAY

AUXILIARY RELAY

MAIN FUEL VALVE(S)

20

HIGH LIMIT OPERATING LIMIT

HIGH LOW

GND TO

CHASSIS

FACTORY WIRING, LINE VOLTAGE

LINE TYPES:

FIELD WIRING, LINE VOLTAGE

FACTORY WIRING, LOW VOLTAGE(SEE NOTE 3)

FACTORY WIRING, SPECIAL IGNITER

FIELD WIRING, LOW VOLTAGE

25

24

CS AL CH C PR

OO WF GP HL

THERMAL FUSE

(SEE NOTE 2)

BOILER

STATUS

12 VDC

0.5A MAX TOTAL

FOR SO, SP, BP,

V1, & LO

REMOTE ON/OFF

(ENABLE/DISABLE)

SPARE INPUT

DOMESTIC HOT

WATER PRIORITY

LOCAL/REMOTE

(REMOVE JUMPER IF USED)

12 VDC

REMOTE CONTROL

REMOTE SETPOINT

OPTIONAL WIRING

CRA1

CRA2

CRA3

CRA4

CRA5

NOTES:

1. IF LOW WATER CUTOFF (LWCO) IS NOT USED, WIRE #P2 10/THERMAL

FUSE MUST BE WIRED FROM TERMINAL TO THE THERMAL FUSE.

2. IF THE HIGH AND LOW GAS PRESSURE SWITCHES ARE NOT USED, A

WIRE MUST BE INSTALLED BETWEEN TERMINAL AND .

3. FACTORY WIRING, LOW VOLTAGE IS 24VAC UNLESS OTHERWISE INDICATED.

10

16

17

GND TO

CHASSIS

Figure 15: Internal Boiler Wiring Ladder Diagram

27

Page 28

E. System Controls and Wiring

E1

W7W6W5W4W3W2W1

250V T5A

SIZE 3AG

W15

W14 W11

W10 W12

W13

W8

W9

K2

K6

K4K3

K5

K1

24V

COIL

CAUTION

HAZARD OF ELECTRIC SHOCK.

MORE THAN ONE DISCONNECT

SWITCH MAY BE REQUIRED TO

DE-ENERGIZE THE DEVICE

FOR SERVICING.

GND

L2 L1

120VAC POWER

SUPPLY

2

3 10

11 12

13

14

15 16

17

18 19 20

21 2

28

2272

2625

24

23

22

2923031323334353637383940414243444546

32323

3

4748492505152

P8

176

12

RJ11

RJ45

BC

BO

BI

CCC

SO

SP

BPVILO

MR

MS

C-

C+

LC

CH

O+

O+

O-

O-

R+

R+

R-

R-

DP

LR

RO

SI

C

C

CPRALCS

WF

P+P-V+V-OO

CA HL GP

HLPR

C

CHWF

GP

AL

CS

CA

LC

OO

G

L2

3456789

10

F

1213141516171819202122

3 5

SWITCH

ON/OFF

BURNER

NO

NC

C

CNO CNC

GAS PRESSURE SWITCH

LOW HIGH

MANUAL

SWITCH

AIR FLOW

COMBUSTION

TRANSFORMER

IGNITION

PILOT

INGITION

FLAME ROD

OR ALARM

SYSTEM PUMP BACKUP

COLD AIR DAMPER,

SYSTEM PUMP

BOILER PUMP

SPARE

LOCKOUT INDICATOR

AUXILIARY EQUIPMENT

AIR SENSOR

OUTSIDE

SYSTEM TEMPERATURE CONTROL OPTION

OUTSIDE AIR RESET OPTION

WATER PRIORITY

DOMESTIC HOT

(ENABLE/DISABLE)

REMOTE ON/OFF

SPARE INPUT

^WE

^WE

^BK

^BK

WE

BNBNBNBNBN

YW

BN

^BK

^WE

WE

BK

GN

WE

BK

WE

BK

YW

OE

OE

BN

WE

BN

WE

BN

WE

BE

YWYWYWYWYWYWYWYWYW

YW

NC C

NC C

RESET HIGH LIMIT

AUTO

TRANSFORMER

NEC

LOAD

R

C

YW

YW

YW

YW

YW

YW

YW

YW

YW

YW

YW

BE

YW

BE

YW

YW

BE

BE

YW

YW

YW

^WE

^BK

YW

YW

YW

YW

IGN LEAD

SWITCH OPTION

LOCAL REMOTE

(SEE NOTE 3)

BLOCKED

VENT

SWITCH

P1 P2

P3

P5

P4

P6

P7

104 GN

YW

OE

SWITCH

FLOW

WATER

LOW

F1

F2

125V T5A

SIZE 5MM X 20MM

CHASSIS

GND TO

GROUND

L2

L1

TO DISCONECT,

(BY OTHERS)

GROUND UNIT TO

TECHINCAL EARTH GND.

208/230/460V-3PH-60HZ

GN

WE

BK

CHASSIS

GND TO

OE

2

1

3

CHASSIS

GND TO

2

1

3

CHASSIS

GND TO

GAS VALVE

IGNITION PILOT

GAS VALVE

MAIN

WIRE COLORS:

BE = BLUE

BK = BLACK

BN = BROWN

GN = GREEN

OE = ORANGE

PK = PINK

RD = RED

VT = VIOLET

WT = WHITE

YW = YELLOW

RELAY/SWITCH TERMINALS:

C = COMMON

NC = NORM. CLOSED

NO = NORM. OPEN

WIRE TYPES:

(BLACK COLOR SHOWN, TYPICAL FOR ALL COLORS)

FACTORY WIRING, LINE VOLTAGE, 12 AWG, 105°C

FACTORY WIRING, LINE VOLTAGE, 18 AWG, 105°C

FACTORY WIRING, LOW VOLTAGE, 18 AWG, 105°C

FACTORY WIRING, LOW VOLTAGE, 18 AWG, SHIELDED

FACTORY WIRING, SPECIAL IGNITER, NOT IN HARNESS

OPTIONAL WIRING, LINE VOLTAGE, NOT IN HARNESS, 18AWG, 105°C

OPTIONAL WIRING, LOW VOLTAGE, NOT IN HARNESS

^BK

BK

BK

*BK

WE

BK

CHASSIS

GND TO

BLOWER

VARIABLE SPEED

PIN 6

PIN 1

PIN 7

PIN 1

BK

WE

(SEE NOTE 2)

(CRA1)

(CRA2)

(CRA3)

(CRA4)

(CRA5)

STANDARD FACTORY WIRING, LINE VOLTAGE, NOT IN HARNESS, 18AWG, 105°C

STANDARD FACTORY WIRING, LOW VOLTAGE, NOT IN HARNESS

STANDARD FACTORY WIRING, NOT IN HARNESS, 16AWG, 200°C

FUSE

^BK

^WE

NO

C

C

NC

THERMAL FUSE

(SEE NOTE 1)

(INSTALL IGNITION TERMINAL,

RAJAH MODEL AEBF)

(REMOVE)

(REMOVE)

(REMOVE)

(REMOVE)

(REMOVE)

(REMOVE JUMPERS 11, 12, & 15)

NOTES:

1. IF THE LOW WATER CUTOF F(LWCO) IS USED, DISCONNECT WIRE LABELED

P2 10/THERMAL FUSE FROM THE THERMAL FUSE AND CONNECT IT TO

LWCO TERMINAL 3. ALSO, CONNECT LWCO TERMINAL 5 TO THE THERMAL FUSE.

2. IF GAS PRESSURE SWITCHS ARE USED, INSTALL WIRING BETWEEN P16 AND

P17 TO INCLUDE THE PRESSURE SWITCH(S) AS SHOWN. IF NO GAS PRESSURE

SWITCH IS REQUIRED, INSTALL A JUMPER BETWEEN TERMINALS P16 AND

P17 AS SHOWN.

3. IF THE REMOTE ON/OFF FUNCTION IS DESIRED, REMOVE JUMPER WIRE BETWEEN

TERMINALS RO & C AND WIRE AS SHOWN. NOT TO BE DONE AT FACTORY.

THERMAL SOLUTIONS SAGE CONTROLLER™ (SBC™)

PART NO. 801SOL0001

(BACK VIEW)

P12

LOW WATER

CUTOFF (LWCO)

OPTION

WE

GN

HONEYWELL

PROGRAMMER CONTROL

RM789A-1002

HONEYWELL Q7800H

PART NO. 101182-01

CHASSIS

GND TO

1. Refer to National Electric Code or Local Electric Codes for proper size and type of wire required. Follow Code.

2. Use anti-short bushings on all wiring passing through boiler jacket, junction boxes and/or control boxes.

3. Use armored cable (BX) over all exposed line voltage wiring.

28

Figure 16: Schematic Diagram

Page 29

VII. Modular Installation

A. General Guidelines

1. Read and follow all venting, combustion air, water

piping, gas piping and electrical instructions contained in this manual unless otherwise instructed in

this section.

2. Consult Local Building Codes or National Fuel Gas

Code, NFPA 54/ANSI Z222.3 for restrictions and

instructions on modular boiler installations.

3. Modular systems are complex. Design and installation of modular systems should only be undertaken

by skilled and knowledgable engineers and contractors.

4. Use stainless steel vent material approved for con-

densing ue gass applications.

B. Module Sizing

Thermal Solutions recommends sizing each boiler in a

modular system to provide 20 % of the combined heating load where ever possible. If the combined load ex-

ceeds the output of ve (5) boilers, install the minimum

number of boilers to meet the load requirements.

C. Venting

1. Horizontal/Vertical Venting

a. Use Stainless Steel vent material approved for

condensing ue gas applications.

WARNING

CAUTION

Installing multiple vent terminations close

together promotes frost buildup on buildings. To minimize this possibility, extend the

distance from the building to the end of the

vent termination and increase the horizontal

distance between terminations.

f. Refer to the cautions, notices, and warnings in

Section III.

2. Conventional Venting (Negative Draft)

a. Refer to Figure 17 for conventional venting

guideline for modular boilers.

b. Refer to National Fuel Gas Code to determine

required chimney diameter and common venting diameter. Note that combined input, lateral

length and chimney height affect vent diameter.

c. A single double acting barometric damper can

be utilized on the common venting when venting

according to Figure 17.

d. Slope common venting a minimum of one (1)

inch in four feet of run towards boilers.

e. Locate boiler(s) with lowest input closest to

chimney.

f. Refer to cautions, notices, and warnding in Sec-

tion III.

Do not manifold vent components of a

boiler without correcting to negative draft.

b. See Table 1 for the maximum vent length of each

size boiler.

c. Refer to Section III of this manual for guidelines

on venting of modular boilers individually. Each

boiler requires an individual vent pipe.

d. The minimum horizontal distance between vent

terminations is one (1) foot. Additional horizontal distance is desirable to avoid frost damage to

the building. Vent terminations must be at least

twelve (12) inches above the ground plus the

expected snow accumulation.

e. Multiple vertical vent pipes may be piped

through a common conduit or chase so that one

roof penetration may be made. Each vent termination must be one (1) foot from other terminations. A minimum of at least six (6) inches from

the common conduit to combustible material

must be maintained unless otherwise instructed

by the conduit manufacturer.

D. Air Intake Piping

1. Locate air intake termination on the same wall as

the vent termination if possible, to prevent nuisance

boiler shutdowns. However, boiler may be installed

with vertical venting and sidewall combustion air

inlet (or visa versa) if installation conditions do not

allow alternate arrangement.

2. Refer to Figures 18 and 19 for common air intake

guidelines for modular water heaters.

3. Individual air intake pipes may be used in lieu of

common air intake piping. If so desired, refer to

Figures 4 and 8.

4. Refer to Table 1 for the maximum air intake length.

Common air intake straight lengths and ttings

should be assumed to have the equivalent length

the same as an individual air intake pipe used for a

given boiler intake pipe diameter.

5. Position horizontal air intake termination center line

below horizontal vent termination’s center line.

6. Vertical air intake pipe must terminate at least two

(2) feet above teh closest portion of the roof.