Thermal Engineering 4054M Installation Manual

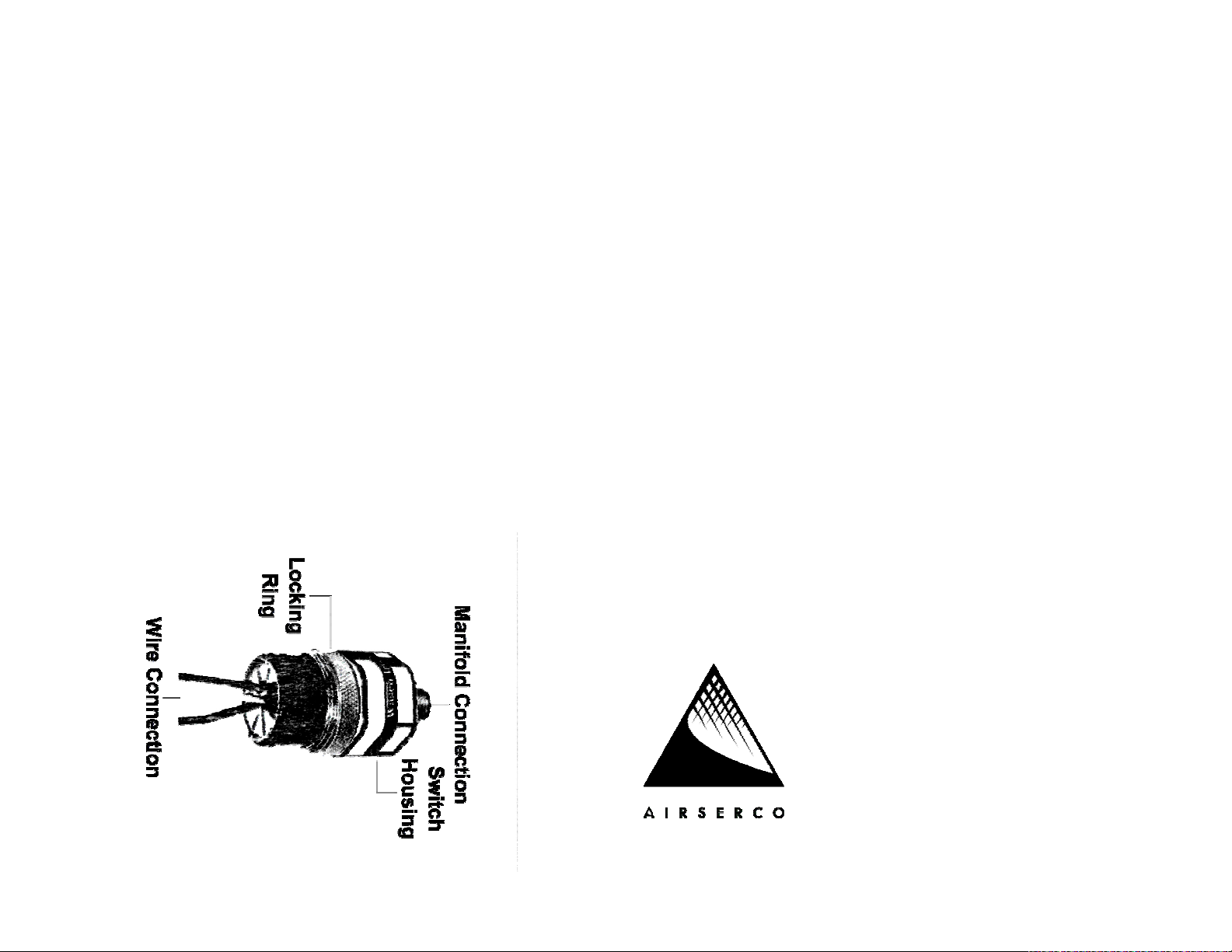

These instructions are based on viewing the pressure

switch with the manifold connection at the top and the

wire connection at that bottom. IMPORTANT: The

pressure switch is very sensitive and all adjustments

should be made in small increments. Loosen the outer

lock ring slightly. To decrease the pressure setting, turn

the switch housing clockwise (to your right.) To increase

the pressure, turn the switch housing counterclockwise

(to your left). Again, the switch is extremely sensitive,

each one (1) degree of rotation equals approximately one

(1) pound change in pressure and turning the switch as

little as 1/4 turn (90 degrees) can take the switch out of

it's range of 450 PSI. It is best to make small changes of

3-4 degrees to reach the desired setting. With the switch

powered, pressurize the switch to the desired pressure

and adjust the switch housing in small steps. By

watching for the pilot light to go out, you can adjust the

setting to very exacting pressures. Be sure to tighten the

lock ring immediately after setting the switch.

4054M

Adjusting the Pressure Switch

125 lb.

Refrigerant

Cylinder

Heater

INSTRUCTIONS

Revised 11/15/04

Airserco Manufacturing Company

7555 Tyler Boulevard

Mentor, OH 44060 U.S.A.

(440) 946-2700 FAX (440) 946-8188

www.airserco.com

4054M Cylinder Heater

The 4054M Cylinder Heater is designed for use on 125

lb. refrigerant cylinders (approx. 10-11 inches in

diameter and 54 inches tall) and consists of three basic

components:

1.) CP4054 Manifold. Manifold with pressure

control, power cords, valve and hose.

2.) CP4054-3A Element. 12" X 28" silicone

rubber heating element with cord and molded

thermostat.

3.) CP4054-5A Cover. Insulated wrap with Velcro

closure.

INSTALLATION AND USE

1.) Attach the manifold to the liquid valve of the

cylinder using the 3/4 inch nut on the manifold. After the

nut has been tightened, loop the safety chain on the

manifold's electrical box over the neck of the containers

liquid valve. Hook the 'S'- hook on the chain back

through the eye on the electrical box. This is important

to prevent any strain on the manifolds electrical

connections.

2.) Secure the heating element to the cylinder. With

the molded thermostat facing out and the molded cord

pointing downward, wrap the heating element around

the cylinder at its base. Pull the Velcro straps tight so

the element is secure with the area behind the

thermostat in contact with the surface of the cylinder.

Connect the male plug on the elements cord to the

short female connector on the manifolds electrical box.

INSTALLATION AND USE (Cont'd)

3.) Connect the charging hose to the 1/4" flare end of the

ball valve on the manifold. Make sure the valve is closed.

Connect the other end of the hose to the container or

device to receive the refrigerant from the 125 lb. cylinder.

Open the liquid valve on the cylinder. Connect the

manifold's power supply cord to a standard 115VAC

outlet (or timer switch). The heating element will begin to

heat and is now operating under the control of the

manifold's pressure switch. The pressure is preset at

160-165 PSIG, but is easily field adjusted. To adjust or

change the pressure setting, see the diagram on the back

of this page.

4.) Wrap the insulated cover around the container. The

foil side should be against the cylinder with the white

outer layer outside and the black bound edges running

vertically. Press the Velcro tab closed. It is best to align

the cover so that a part of the thermostat is visible at the

seam to provide air circulation. The thermostat is set to

trip at 133º F and acts as a safety device backing up the

primary control, the pressure switch.

5.) When you want the refrigerant to flow, open the 1/4"

ball valve on the manifold. The pressure developed by

heating the 125 lb. cylinder will force the refrigerant under

pressure to the vessel or device connected to the valve.

DO NOT OPERATE THE HEATER WITH THE TANKS

LIQUID VALVE CLOSED. THE VALVE MUST BE OPEN

TO ALLOW THE PRESSURE SWITCH TO OPERATE

PROPERLY. USE ONLY THE MANIFOLD'S BALL

VALVE TO CONTROL REFRIGERANT FLOW.

Loading...

Loading...