2010 PRODUCT CATALOG

CatCh the ‘cool’ alternative

HVAC/R Accessories, Vacuum Gauges, Compressor Tools,

Oil Pumps, Vacuum Pumps, Vacuum Accessories, Charging Scales,

Charging Cylinders, Hoses, Vocational Training Units

www.thermalengineeringcompany.com | 800 473-1754

INTRODUCTION

THERMAL ENGINEERING COMPANY

Founded over 40 years ago on the principles of innovation, quality, and service,

Thermal Engineering has developed a line of HVAC/R service tools that

continue to satisfy the needs of the HVAC/R professional. As a division of the

Airserco Manufacturing Company, we continue to adhere to the original founder’s

principals by developing quality products that meet the needs of the global HVAC/R

service market, and backing those products with a high level of customer service.

The full spectrum of Thermal Engineering’s product offering is presented in this

catalog. For your convenience, items have been indexed by product category along

with a handy product reference. We also encourage you to visit our web site at

www.thermalengineeringcompany.com for our most current product offerings, new

product introductions, technical information, and buying locations.

For 2010 we are pleased to introduce the following:

• TS-500 2-Valve Manifold, page 30

• TS-1000 The Sherman 4-Valve Test and Charging Manifold, page 30

• 4775 Handheld Digital Micron Gauge, page 16

• 4975 Scale / Vacuum Combo Unit, page 16

• DRSA-1600 Digital Refrigerant System Analyzer, page 28

• HLD-1201 Refrigerant Leak Detector, page 12

• GL-1000 Compressor Jumper, page 19

Thank you for your interest in our products and your continued support!

Sincerely,

Timothy Winings, President

1

800 473-1754 | www.thermalengineeringcompany.com

TABLE OF CONTENTS

Thermal Engineering Introduction ...............................................................................1

HVAC/R Accessories

Leak Detection

.............................................................................................11 - 14

Vacuum Gauges

Thermometers

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Compressor Tools

Oil Pumps & Accessories

Vacuum Pumps

Vacuum Pump Accessories

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 - 19

..................................................................................20 - 21

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22 - 23

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Charging Cylinders & Accessories

Charging Scales

Manifolds & Gauges

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27 - 29

.............................................................................25

Hoses

Fittings

Vocational Training Units

Index

Warranty

Notes

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30 - 32

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33 - 36

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

.......................................................................................................38 - 43

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

www.thermalengineeringcompany.com | 800 473-1754

2

HVAC/R ACCESSORIES

CAP-CHECK

The Cap-Check is a Thermal Engineering innovation that has made cap tube cleaning possible and practical,

it is designed to pump a high rate of oil into the cap tube to build up pressures needed to open any plugged

cap tube, and will clean partially plugged cap tubes when used with the Thermal Chaser Kit.

CAP-CHECK MODEL 1003

Cap-Check is a portable, self contained hydraulic power unit with auxiliary equipment

especially adapted to cleaning refrigeration capillary tubes. A 0-5000 PSI gauge shows

pressure build-up if cap tube is restricted and also shows when chaser has passed

through the tube. A trigger operated gauge shutoff is provided so the gauge will not be

damaged if pressures greater than 5000 PSI are desired. A 30-inch high pressure hydraulic

hose with a 1/4-inch SAE male flare outlet connects the cap tube to the Cap-Check for

simple handling. An adapter is supplied to connect the cap tube directly to the hose outlet

without a flared fitting.

CAP-CHECK CHASER KIT MODEL 1101

Chaser Kit is the only means available to clean partially plugged cap tubes, it must be

used with the Thermal Cap-Check since no other cap tube cleaning tool provides a rate

of oil flow large enough to remove partial restrictions even from the smallest cap tubes.

The Chaser Kit consists of 10 spools of lead alloy wire which can be used as a chaser for

the 10 most popular sizes of cap tubes (.028, .031, .036, .039, .042, .046, .050, .055, .064,

.070). In addition to the wire, a cap tube gauge, a set of sizing tools, and a combination

file/reamer are all included in a durable metal case.

CAP-CHECK OUTFIT MODEL 5101

Cap-Check Outfit provides both the Cap-Check and Chaser Kit in one compact case along

with an extended base that holds the Cap-Check. The Cap-Check can be operated with

one hand, allowing high pressures to be easily pumped. Carrying case has clips to hold

Cap-Check, Chaser Kit, hose, handle, and extended base.

3

800 473-1754 | www.thermalengineeringcompany.com

HVAC/R ACCESSORIES

CAP-CHECK ACCESSORIES

A capillary tube is the most likely place a blockage in a system can occur and can cause a system to operate

very inefficiently. Therefore it is essential to have the proper tools on hand to fix this very common problem.

Below are accessories that we recommend for the Cap-Check and your service arsenal.

CAP-CHECK REPAIR KIT MODEL 1003RK

Complete Set of gaskets, “O” rings, springs, and balls for Model 1003 Cap-Check,

with instructions.

0-5000PSI GAUGE MODEL 1011

High pressure gauge for Model 1003 Cap-Check with a pressure range from 0-5000psi.

30-INCH HYDRAULIC HOSE (REPLACEMENT) MODEL 1012

30-inch high pressure hydraulic hose with a 1/4-inch SAE male flare outlet.

CAP-GAUGE MODEL 1102

Cap-Gage is a pocket knife type cap tube gauge with 10 stainless steel gauges to measure

the most popular sizes of cap tubes (.028, .031, .036, .039, .042, .046, .050, .055, .064, .070).

CARRYING CASE MODEL 1201

Store your Cap-Check in this heavy duty case that provides maximum protection from

wear and tear when not in use.

EXTENDED BASE MODEL 1301

This extension for the base of the Cap-Check provides better accessibility in certain situations.

CAPILLARY TUBING

Thermal Engineering’s quality capillary tubing available in 100ft. coils.

CAP TUBING SIZES

PART NO SIZE

CT-31-100 .031 ID X 100 FT

CT-36-100 .036 ID X 100 FT

CT-42-100 .042 ID X 100 FT

CT-49-100 .049 ID X 100 FT

CT-54-100 .054 ID X 100 FT

CT-59-100 .059 ID X 100 FT

CT-64-100 .064 ID X 100 FT

CT-70-100 .070 ID X 100 FT

www.thermalengineeringcompany.com | 800 473-1754

4

HVAC/R ACCESSORIES

SYSTEM TESTER

Make on-the-spot readings with our easy-to-use HandyStat. Very useful for troubleshooting a system!

HANDYSTAT MODEL HS-1

Save the steps, time and money to make system tests with a single tool.

FEATURES

Check out thermostat and control wiring output•

Operate individual system components for test purposes:•

Compressor, Fan, Heaters, Reversing Valves

Convenient momentary switch for quick ON-OFF activation

•

Connects to the control wiring at the point of service•

Great on Roof Top Units and Light Commercial Applications•

WARR ANTY: 12 MONTHS FROM DATE OF PURCHASE

WIRING CONNECTIONS FOR USE ON RESIDENTIAL HEAT PUMP SYSTEMS

WIRING CONNECTIONS FOR USE ON LIGHT COMMERCIAL HEAT PUMP SYSTEMS

WIRING CONNECTIONS FOR USE ON OIL OR GAS FURNACES WITH AIR CONDITIONING SYSTEMS

5

800 473-1754 | www.thermalengineeringcompany.com

HVAC/R ACCESSORIES

VIZI-VAPR

Many problems can arise from improper charging of any type of refrigeration system. Vizi-Vapr makes

it possible to correctly charge a system every time. Liquid refrigerant being charged is transformed into

a saturated vapor through a small orifice which thereafter can be viewed to ensure the system gets

charged properly.

VIZI-VAPR CHARGER MODEL 7701

The Vizi-Vapr eliminates the problem of slow vapor charging by removing the refrigerant

from the cylinder as a liquid and injecting it into the system as a saturated vapor.

Since the liquid refrigerant is removed from the cylinder by its own pressure, no heat is

removed from it and the cylinder does not get cold. Refrigerant blends must be removed

from their containers as liquid. Using the Vizi-Vapr, the blend can be charged into the

system as a saturated vapor without any composition change. Vizi-Vapr is adjustable

from 1/8hp up to 50hp. The operation is completely visible so there is little danger of

liquid entering the system.

VIZI-VAPR REPAIR KIT MODEL 7701RK

Complete set of gaskets, “O” rings, and back-up rings required for repairing the 7701 Vizi-Vapr.

www.thermalengineeringcompany.com | 800 473-1754

6

HVAC/R ACCESSORIES

HEATERS

Quick and easy process of pressurizing a refrigerant supply cylinder to move any refrigerant to another

vessel.

CYLINDER HEATER MODEL 3054

A quick, convenient, easy-to-use means to pressurize refrigerant supply cylinders to

move any refrigerant to another vessel or charging dispenser, the 3054 Cylinder Heater is

designed to fit 30Ib. and 50Ib. containers. It also can be used on 125Ib. cylinders and fits

the refrigerant cylinders in many recovery units. The device consists of a 6 x 28 flexible

silicone rubber heating element with extra-Iong Velcro straps, built-in molded thermostat,

and power cord. The heater draws 200 watts at 120 VAC and has a 135° preset thermostat.

Model 3054-230V

230 Volt model available for European market.

CYLINDER HEATER MODEL 4054M

The 4054M Refrigerant Cylinder Heater is designed to automatically maintain any desired pressure within a range of 80 to 250

PSIG. Pre-set at 160 PSIG, the unit can be easily adjusted in the field. The heating element also incorporates a 135° pre-set

thermostat as a safety backup to the pressure control.

Fits 125/145 Ib. refrigerant supply cylinders.

Accurate and adjustable pressure control

•

Safe and easy-to-use•

Complete, including valve and charge hose•

Energy-efficient•

The 4054M includes three basic components:

1. The control manifold, which adapts directly to the cylinder’s liquid valve and includes a visual refrigerant indicator,

pressure gauge, quarter-turn ball valve, heavy-duty 6ft. charging hose, adjustable pressure switch with power

supply cord and female connector for accepting the heating element.

2. A 350 watt, 120 VAC heating element with built-in safety thermostat and power cord that plugs into the

control manifold. The 12 x 28 heating element is secured with Velcro straps.

3. A special insulating cover that includes a Velcro seam and fits over the entire cylinder to improve efficiency.

7

800 473-1754 | www.thermalengineeringcompany.com

HVAC/R ACCESSORIES

CALCULATORS

Reference points on a variety of topics and scales to make even the most technically demanding jobs

a breeze.

ROOM AIR CONDITIONER CALCULATOR MODEL 5100

Used to determine size of air conditioner unit with allowances for:

Exposed and unexposed walls

•

Exposed and unexposed windows•

Roof and ceiling insulation•

Heat gain from number of people•

Location•

This calculator selects amount of capacity needed in a cooling load of 5000-24000 BTUs

per hour, and indicates the size of unit required in BTU ratings. The calculator not only

simplifies the job of specifying window air conditioners, but also eliminates misapplication

and paper work. An ideal service and sales tool for the estimator and service engineer, the

calculator is imprinted with full directions.

AIR DUCT CALCULATOR MODEL 5125

This ingenious, pocket-size Air Duct Calculator uses only three slides to give all of the

information needed when figuring the sizes of air ducts. Convenient tables printed on

the back of the calculator supply additional data in a handy, easy-to-use form. The few

words of instruction needed to understand and use the different slides are printed on the

calculator face, where they cannot be lost or mislaid.

Used to determine:

Size of air ducts by the equal pressure loss method

•

Size of round ducts vs. rectangular ducts•

Weight per foot of round ducts by U.S.S. gauge•

Weight per foot of rectangular ducts by U.S.S. gauge•

Recommended duct velocities•

Friction loss of 1-1/2 radius elbows•

Gauge of metal for size of ducts•

HUMIDITY CALCULATOR MODEL 5150

Designed for determining the percent of relative humidity when using any standard sling

psychrometer, this calculator eliminates the use of psychrometric charts from 60° to 100°F.

The reverse side of the calculator has a chart of recommended humidities according to

industry application and temperature.

www.thermalengineeringcompany.com | 800 473-1754

8

HVAC/R ACCESSORIES

CALCULATORS

On-the-fly calculations can be made very easily to help troubleshoot a system, saving you valuable time!

TROUBLESHOOTING CALCULATOR MODEL 5175

This calculator simplifies the job of diagnosing cooling system troubles. Ideally suited to the needs of

the expert as well as of the needs of the trainee, it provides immediate reference, from COMPLAINT to

POSSIBLE CAUSE to REPAIR.

FEATURES

19 major ‘Complaint’ sections•

32-part ‘Trouble Shooting’ Index•

127 ‘Possible Cause’ items•

All items keyed to ‘Repair’ window•

CAPILLARY TUBE AND TROUBLESHOOTING CALCULATOR MODEL 5180

TWO SLIDE CHARTS IN ONE

This is a dual-purpose slide chart. One side is a new, scientific approach for selecting

readily available standard capillary tubing sizes to replace the hard-to-get sizes that original

manufacturers often recommend. The other side is a trouble shooting calculator that

simplifies the job of diagnosing cooling system trouble where the capillary tube is suspect.

REFRIGERATION CALCULATOR MODEL 5300

A time-saving and easy-to-use calculator to supply technical refrigeration data:

Hermetic terminal colors

•

Thermostatic control settings•

Pressure control settings•

Head and back pressures•

Hermetic motor diagrams•

Temperature pressure chart•

The calculator graphically shows vital refrigeration data and provides service information not available in

any other form.

9

800 473-1754 | www.thermalengineeringcompany.com

HVAC/R ACCESSORIES

BOOKS

REVIEW OF VACUUM FOR SERVICE ENGINEERS MODEL 5225

The story of how vacuum is used as a tool to dehydrate and degas a refrigeration

system. This text is the only publication that clearly and non-technically explains vacuum

fundamentals for the service man or engineer.

Illustrated with charts, photographs, and diagrams, this authoritative handbook describes

and explores vacuum terms, properties, uses, activities, advantages, limitations, and

techniques.

FEATURES

Covers key service-related topics•

Vital for processing engineer, serviceman•

What vacuum means•

How a pump works•

Sizing high vacuum pumps and lines•

Vacuum gauges procedure for dehydration, degassing, leak detection•

“TheHardWay”

...tolearnaboutvacuums.

“TheEasyWay”

Take“TheEasyWay”with

“ReviewofVacuumforServiceEngineers”

by

Saunders&Williams

www.thermalengineeringcompany.com | 800 473-1754

10

LEAK DETECTION PRODUCTS

LEAK DETECTION

Often finding a leak is the hardest task for a technician. This tools will help make the process as easy

as possible.

REFRIGERANT LEAK DETECTOR MODEL HLD-1101

The Thermal Engineering HLD-1101 refrigerant leak detector is the perfect tool for the

service technician requiring a fast, easy to use, and economical tool for the maintenance

and repair of HVAC and refrigeration Systems.

The HLD-1101 utilizes a newly developed semi-conductor sensor which is extremely

sensitive to a variety of generally used refrigerants and the microprocessor control

provides advanced digital signal processing.

FEATURES

Heated Semiconductor•

High-Low Leak Sensitivity Selector•

7 LED Tricolored Visual Leak Level Indicator•

Audible Alarm•

Ambient Concentration Reset•

15-1/2-inch (40cm) Flexible Stainless Probe•

Detection of R-134A, R-404A, R-410A, R-407C, R-22, R-502, and R-600A Refrigerant Gas•

Sensitivity as Small 6g/year•

In accordance with SAE J1627, CE Design•

Low Battery Indication•

Reference Leak Source included•

Carrying case included•

Operating Temperature: 0˚ to 40˚C (32˚ to 104˚F)•

Size: 216mm x 66mm x 56mm•

8.5-inches x 2.6-inches x 2.2-inches

Weight: Approximately 1lb. (with battery)

•

Power Source: (4) AA Size Alkaline Batteries (included)•

Battery Life: Approximately 40 hours•

11

LEAK DETECTION SENSITIVITY

SENSITIVITY HI LO

R-22, R-134A 0.21 OZ (6G) /YEAR 1.05 OZ (30G) /YEAR

R-404A, R-407C, R-410A 0.28 OZ (8G) /YEAR 1.41 OZ (40G) /YEAR

800 473-1754 | www.thermalengineeringcompany.com

LEAK DETECTION PRODUCTS

LEAK DETECTION

REFRIGERANT LEAK DETECTOR MODEL HLD-1201

Building on their successful line of leak detection products, Thermal Engineering introduces the

HLD-1201 refrigerant leak detector. This durable hand held detector has increased sensitivity

of up to 3 grams/0.105 ounces per year and a pump for faster response time. Utilizing newly

developed semi-conductor gas sensing technology, the HLD-1201 is ideal for diagnosing leaks

on air-conditioning and cooling systems utilizing a wide variety of common refrigerants.

FEATURES

•

Heated semiconductor gas sensor

• High low leak sensitivity selector, 3 levels of sensitivity

• Bright LED display

• Ambient concentration reset

• Includes durable carrying case and reference source

• Optional DC adapter 3.3V 0.5A

SPECIFICATIONS

•

Alarm method: Buzzer, Tri-color LED Bar Indicator

• Power usage: (4) AAA size (6V DC) Alkaline batteries

• Snake tube length: 15.5 inches (40cm)

• Dimensions / Weight: 173mm x 66mm x 56mm (400 grams)

6.8-inches x 2.6-inches x 2.2-inches (14.1 oz)

• Accessories: Aklaline batteries (4 pieces), user manual, leak check bottle, carrying case

• Battery Life: 7 hours normal usage

• Auto Power off: 10 minutes

• Disable Auto Power off: Press and hold (HI) button then power on the meter

LEAK DETECTION SENSITIVITY

SENSITIVITY HI MEDIUM LO

R-22, R-134A 0.105 OZ (3G) /YEAR 0.529 OZ (15G) /YEAR 1.05 OZ (30G) /YEAR

R-404A, R-407C, R-410A 0.141 OZ (4G) /YEAR 0.705 OZ (20G) /YEAR 1.41 OZ (40G) /YEAR

www.thermalengineeringcompany.com | 800 473-1754

12

LEAK DETECTION PRODUCTS

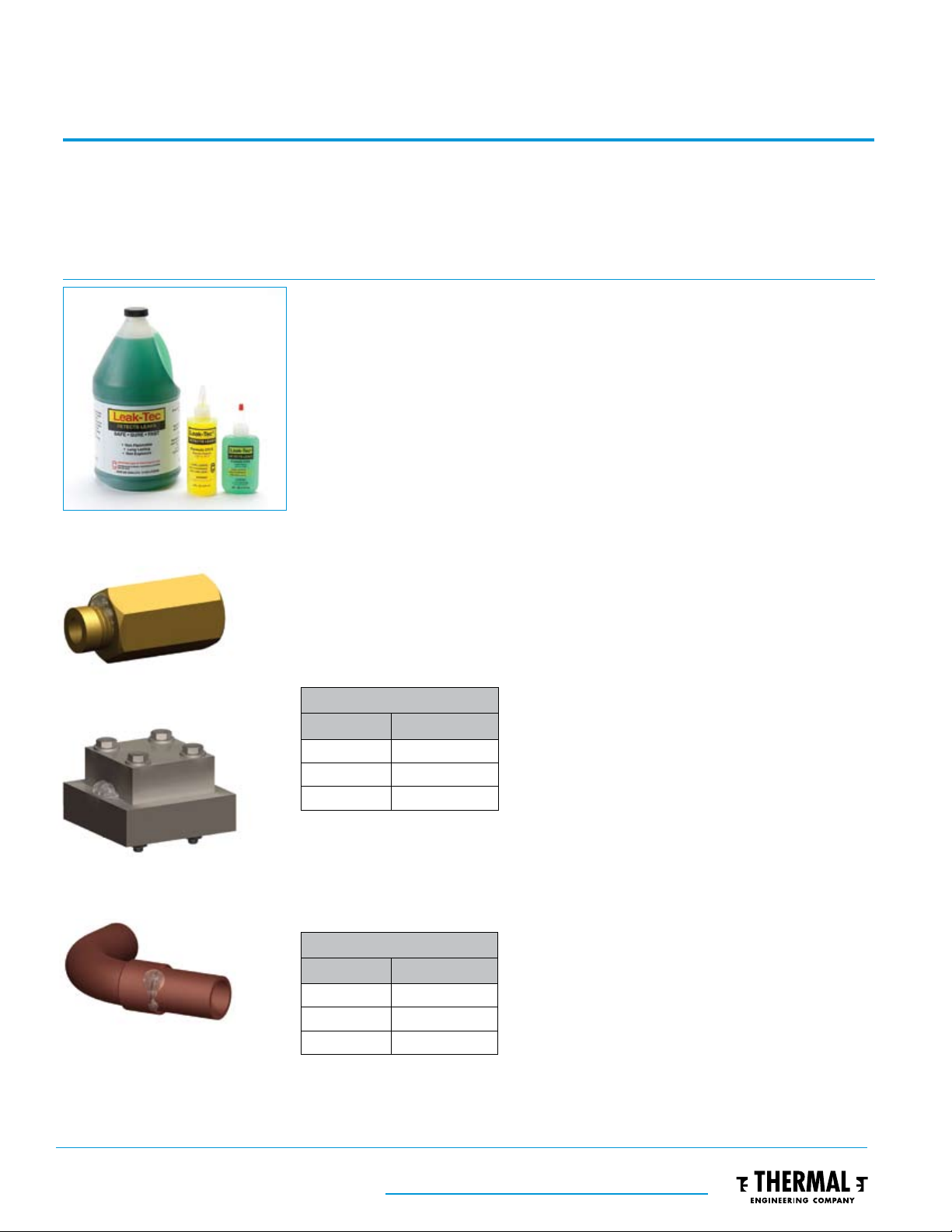

LEAK-TEC MODEL 4014

FEATURES

Fast, quickly finds and pinpoints the smallest of leaks•

Safe, does not affect metal or rubber and is nonflammable•

Economical, a few drops do the job•

Convenient, unbreakable dispenser bottle•

Stocked in 4oz. and 8oz. squeeze bottles, and 1 gallon jugs•

Leak-Tec is a non-toxic, nonflammable liquid that produces a white foam of live bubbles at

the point of leakage. The high viscosity enables the liquid to cling to surfaces long enough

to pinpoint leaks as small as .05oz. per year. The liquid spreads quickly and penetrates oil

and grease films common on metal surfaces. Used in small amounts, the mass of bubbles

will continue to foam as long as pressure is maintained on the equipment being tested.

Leak-Tec is stocked in 4oz., 8oz. and 1 gallon containers in two different formulas to fit most

applications. Additional formulas and container sizes are also available as special order.

THREAD CONNECTIONS

MACHINE SURFACE CONNECTIONS

SOLD ERE D O R WELDE D

CONNECTIONS

SPECIFICATIONS

No.4014 Formula 372E

Application: compressed air and stable gases

Sensitivity: 1 x 10

-5

std. cc of air per sec.

Temperature Range: +35°F to +160°F

AVAILABLE SIZES

PART NO CONTAINER

4014 4 OZ

4014-8OZ 8 OZ

4014-G GALLON

SPECIFICATIONS

No.4015 Formula 372G

Application: Refrigerants, low temp,

Sensitivity: 1 x 10

-4

std. cc of air per sec.

Temperature Range: -35°F to +180°F

AVAILABLE SIZES

PART NO CONTAINER

4015 4 OZ

4015-8OZ 8 OZ

4015-G GALLON

13

OTHER SIZES AVAILABLE AND SPECIAL FORMULAS AVAIL ABLE.

800 473-1754 | www.thermalengineeringcompany.com

LEAK DETECTION PRODUCTS

ULTRASONIC LEAK DETECTOR TYPE VPE MODEL 9997

FEATURES

Detects any type of refrigerant gas•

Battery-powered for cordless operation•

Does not require tracer gases•

Detects vacuum and pressure leaks•

Headset and padded carrying case included•

Adjustable sensitivity•

The VPE Leak Detector represents state-of-the-art technology for pin-pointing leaks in air

conditioning/refrigeration systems. Able to detect both vacuum and pressure leaks, the

VPE overcomes the disadvantages inherent in other types of leak detectors. No ultraviolet

dyes or tracer gases are necessary, and the VPE can detect any gas, even in a gassaturated environment. The VPE offers both visual and sound identification via the LED

display and the included headset. Lightweight and easy to use, the VPE is a tool every

technician should have.

SPECIFICATIONS

Nominal sensitivity: -80db / V / uBar

Frequency response: 38 to 42 kHz

Display: 10-bar element graph audio output

Power: 9V cell

Battery life: 15 hrs. continuous

Headset: dynamic 32 ohm

Size: 4.56 x 2.40 x .866

Weight: 1/2Ib.

Housing: durable PVC/aluminum

PART NO CONTAINER

9997 PVC

www.thermalengineeringcompany.com | 800 473-1754

14

VACUUM GAUGES

VAK-CHECK

For proper evacuation and dehydration of refrigeration and air conditioning systems, an electronic vacuum

gauge is an indispensable companion to a vacuum pump. Significant dehydration does not occur until a

vacuum of 1000 microns or greater has been achieved. Use of electronic vacuum gauges is the only way

to determine when dehydration is occurring and when it is complete.

Thermal Engineering Vak-Checks are precision thermistor vacuum gauges designed especially for

refrigeration and air conditioning service. They automatically compensate for changes in ambient temperature

and permit continuous monitoring during evacuation. These instruments are compact, lightweight, easy to

use, and read directly in microns on a large easy-to-read meter.

VAK-CHECK MODEL 4501

FEATURES

Atmosphere to 10 microns•

Ambient temperature compensated•

Accuracy: 200-1000 microns: ±5%•

Comes complete with Model 4510 Sensor•

Battery powered, No searching for outlets (2 “D” cell batteries not included)•

SUPER VAK-CHECK II MODEL 14571

This analog thermistor vacuum gauge allows you to choose between 110AC and

battery as your power source with the same features as the Model 4501.

FEATURES

AC/battery operated•

Range: Atmosphere to 10 microns•

Ambient temperature compensated•

Complete with Model 4510 Sensor•

Accuracy: 200-1000 microns ±5%•

Power: 110AC or 2 “D” cell batteries (Batteries not included)•

REPLACEMENT VACUUM SENSORS MODEL 4510

FEATURES

Vacuum Sensor for Vak-Check, Super Vak-Check, and Super Vak-Check II•

Models 4501, 4575 and 14571 with 0 to 50 calibration scale•

15

800 473-1754 | www.thermalengineeringcompany.com

VACUUM GAUGES

VAC-SCALE

Saving the service technician time and money, Thermal Engineering provides the ability to combine digital

hand held vacuum gauge technology with strain gauge technology for refrigerant charging. The 4775 and

4975 are the first components of Thermal Engineering’s new Adaptable™ Tool Series.

HANDHELD DIGITAL MICRON GAUGE MODEL 4775

Thermal Engineering is pleased to introduce the 4775 handheld digital micron gauge.

Backed by Thermal’s 45 years of vacuum technology the 4775 borrows from the old while

incorporating advanced new features including (7) units of measure, an LCD backlight, LCD

contrast control, and a vacuum minimum/maximum function that stores the last vacuum

reading in memory. Lightweight and easy to use, the 4775 will provide the discriminating

service technician with a dependable instrument for accurately measuring vacuum in an airconditioning or refrigeration system.

FEATURES

E• rgonomic durable case

A

• uto shutoff

L

• CD backlight and contrast

M

• ultiple units of measure

SCALE / VACUUM COMBO UNIT MODEL 4975

Building on its reputation for delivering innovative products to the HVAC/R industry, Thermal

Engineering is proud to introduce the 4975, a combination charging scale and digital vacuum

gauge. As the first launch of its new Adaptable™ Tool Series, the 4975 scale/vacuum

combo tool fits nicely in one compact carrying case and eliminates the need for the service

technician to carry multiple tools, saving time and money.

The scale provides 220 lb. (100kg) weight capacity with a resolution up to a 1/4 oz. and the

ergonomically designed digital vacuum gauge features an internal thermistor gauge, a high

resolution back lit LCD, high and low vacuum memory option, and (7) vacuum readings.

Warranty, 1 year.

CHARGING SCALE FEATURES

H• eavy duty portable carrying case

L

• arge anti-slip weighing platform

M

• easures imperial or metric

M

• odern strain gauge technology

VACUUM SCALE FEATURES

E• rgonomic durable case

A

• uto shutoff

L

• CD backlight and contrast

M

• ultiple units of measure

www.thermalengineeringcompany.com | 800 473-1754

16

THERMOMETERS

TEMP-CHECK

Perhaps the most influential measurement you can take on a refrigeration system, temperature.

DIGITAL THERMOMETER MODEL D4101

Model D4101 combines the best features of the other Thermal electronic thermometers

and improves on them. This instrument measures up to four separate temperatures

simultaneously and will measure temperature differential directly. Push button probe

selector allows quick switching between probes. Amplified digital circuit gives fast

response from -40 to 1400°F (760°C). The durable case provides ample storage space for

a variety of probes. Special probe configurations can be used with Model D4101. Standard

subminiature Type J thermocouple probes are compatible. Large 1/2-inch liquid crystal

display makes it easy to read in sunlight. Unit comes complete with (2) Model D4109 low

range PVC thermocouple probes and (2) Model 14116 Velcro straps. Probes are field

repairable, designed for many years of service.

RANGE ACCURACY BATTERY LIFE POWER SOURCE

-40° TO 1400°F, -40° TO 760°C ±1% OF READING

±1 DIGIT

OPTIONAL PROBES, FOR USE WITH D4101

PART NO DESCRIPTION

D4109 GENERAL PURPOSE LOW RANGE FLEXIBLE PVC THERMOCOUPLE PROBE (-40° TO 220°F) 15 FT

D4111 GENERAL PURPOSE BRAIDED FIBERGLASS PROBE (-40° TO 1400°F) 15 FT

D4113 25 FT EXTENSION FOR THERMOCOUPLE PROBES

D4115 MODEL D4111 PROBE WITH 10-INCH STAINLESS STEEL PROTECTION TUBE

®

D14116 VELCRO

FLEXIBLE PROBE CLAMP CONTAINS (2) 6-INCH STRIPS

200 HOURS CONTINUOUS (1) 9V ALKALINE BATTERY

(NOT INCLUDED)

17

800 473-1754 | www.thermalengineeringcompany.com

COMPRESSOR TOOLS

HERMETI-CHECK

Hermetic compressors are permanently sealed which means there is little you can do to fix one that is

broken on the inside, however with the following tools brought to you by Thermal Engineering, you can test

the compressor for any electrical problems it may have which can help determine the appropriate actions

to take.

HERMETI-CHECK MODEL 2001

Hermeti-Check tests all single phase compressors up to 5 HP, 110, 220 or 277 volts.

FEATURES

Tied-up compressors may be freed by reversing motor rotations•

Tests windings for opens, continuity, and grounds•

Tests start and run capacitors and system relays by substitution•

Measures running amps, 0-10, 50A range•

Measures start and run volts, 0-150, 600V AC ranges•

Compressors are tested in the manner in which they were designed to operate: •

Split-phase, capacitor start, or PSC

Has provisions for connecting external run capacitor. (1) 30A breaker protected to allow

•

high starting current with adequate overload protection

Complete with 220V adapter cord and capacitor leads

•

PROFESSIONAL SERIES DIGITAL HERMETIC ANALYZER MODEL 12501A

FEATURES

Easy to read digital LCD display•

Tests and runs 110, 220 or 277 volt 50/60 Hz single phase compressors up to 5 HP•

Tied-up compressors may be freed by reversing motor rotation•

Tests windings for opens, continuity, and grounds•

Checks capacitors for leaks, opens, and shorts•

Measures capacitor values, 0-200, 0-2000 MFD ranges•

Automatic capacitor discharge•

Measures compressor amps, 0-30A•

Measures start and run volts, 0-600VAC•

Measures winding resistance, 0-2000 ohm•

500V megger for testing compressor windings for grounds•

Compressors are tested in the manner in which they were designed to operate:•

Split-phase, capacitor start, or PSC•

Multiple internal starting capacitors: 100, 200 and 400 MFD values•

Has provisions for connecting external run capacitor•

30A breaker protected•

Complete with 220V adapter leads and capacitor leads•

UPGRADED FEATURES

Combined run and start information onto single screen•

Each screen describes what it is measuring•

New safety features prevent switching from high voltage to low voltage measurement •

until charge has dissipated

Compressor cannot be started unless selector switch is in a run mode

•

WEIGHT POWER DIMENSIONS

5.5 LBS 110, 220, OR 277 VAC 50/60 HZ 13 1/2 X 10 X 4

www.thermalengineeringcompany.com | 800 473-1754

18

COMPRESSOR TOOLS

ACCESSORIES

A compressor may just have a bad electrical part. These accessories will help determine exactly what is

going on.

QUIK-START MODEL 2601

Quick-Start starts all single phase compressors up to 5 HP 110, 200, 277V AC. A troubleshooting aid for determining whether fault lies with compressor or component parts.

Fusetron protects against shorts and overloads, but allows high starting load. Capacitor

leads provide means of starting split phase, capacitor start, or permanent split capacitor

compressors.

TEST LEAD KIT MODEL 2605

Test Lead Kit consists of 4 leads 30-inch long with insulated test clips in each end for

temporarily connecting relays, capacitors, etc., into a system for test purposes and has

a 6ft. heavy duty power cord with a male pIug on one end and insulated test clips on

the other. Also has a 12-inch power cord with a female socket on one end and Insulated

clips on the other.

QUICK-START + TEST LEAD KIT COMBO MODEL 2602

Combination of Model 2601 Quick-Start and Model 2605 Test Lead Kit.

ADAPTER CORD MODEL 2136

Provides a 12-inch 3-wire grounded power cord with standard female plug on one end and insulated clips on the other end. This

cord is supplied as standard equipment with Models 2001, 2605, and 12501A.

COMPRESSOR TERMINAL REPAIR KIT MODEL GL-1000

The GL-1000 Gator-Lok is designed to repair burnt terminals on compressors up to 5 tons.

Gator-Lok’s unique design makes installation a snap and requires no special tools.

19

Gator-Lok is made from high quality materials. Once installed properly, it provides multiple

points of contact on the burnt terminal.

Gator-Lok can be easily installed in minutes, therefore giving the technician the ability to

restore power to the unit, and eliminates the need to replace the compressor.

Each Gator-Lok Kit includes a set of three Gator-Loks (1 red, 1blue and 1 black 10 gauge

wire with 30-inch leads).

800 473-1754 | www.thermalengineeringcompany.com

OIL PUMPS & ACCESSORIES

OIL PUMPS

Precisely and exactly the right amount of oil in the cleanest and most efficient manner.

CHARGE-OIL PUMP MODEL 1700

It charges without pumping the compressor down thus reducing charging time

by over 70%. Also avoids the embarrassment of spilling oil on the customer’s

premises. Provides the professional touch since oil can be accurately measured into

the compressor without having to pour it from the can. Fits all popular brands of

refrigeration oil.

Complete Adapter Kit supplied to accommodate most containers. The Charge-Oil

Pump cap seals the can so pump need not be removed until can is empty. Thermal

Charge-Oil Pump is a piston type high pressure pump designed to operate at

pressures to 250 PSI. It pumps one quart in 20 full strokes of the piston. Pump is

connected to compressor by refrigerant charging line or copper tubing from 1/4-inch

male fitting.

Suitable for use with alkybenzene and POE oils.

1702, 1703, 1751

PART NO DESCRIPTION

1702 THERMAL CHARGE-OIL PUMP

1703 THERMAL CHARGE-OIL PUMP FOR 5 GALLON CAN

REPAIR KIT FOR MODEL 1702 & 1703 MODEL 1705

Complete set of gaskets, bearings, rings, springs and washers for the repair of thermal oil pumps.

CHANGE-OIL PUMP MODEL 1751

Change-Oil Pump is a companion to the famous Thermal Charge-Oil Pump. It has been designed for use in pumping oil from

refrigeration compressors, marine engines, and other equipment where it is impossible to drain oil in the conventional manner.

Removing oil from refrigeration compressors before dehydrating with vacuum is a necessity. Suction tube is 5/16-inch OD

semirigid plastic, 15-inches long. Suction tubes up to 60-inch long can be used if necessary. Will not pump under pressure.

Pumping capacity about 10 strokes per quart.

REPAIR KIT FOR MODEL 1751 MODEL 1751RK

Complete set of gaskets, bearings, rings, springs and washers for the repair of thermal oil pumps.

www.thermalengineeringcompany.com | 800 473-1754

20

OIL PUMPS & ACCESSORIES

ADAPTER KITS

Allow for all popular sizes of oil cans and bottles to fit with our oil pumps.

ADAPTER KIT MODEL 1768

Adapter Kit for all popular cans and bottles of refrigerant oil. Kit contains 5 rings and one spacer to accommodate

most oil containers.

ADAPTER KIT MODEL 1770

Suction Adapter for aluminum Charge-Oil Pump. Converts Model 1702 Charge-Oil Pump into suction pump for refrigeration,

marine and other similar applications where it is impossible to draw oil in the normal manner.

21

800 473-1754 | www.thermalengineeringcompany.com

VACUUM PUMP ACCESSORIES

VACUUM PUMP ACCESSORIES

These vacuum accessories will help you make easy vacuum connections many types of systems.

MINI-VAC MODEL 1833

Mini-Vac is a compact High Vacuum Manifold which provides a 3/8 flare yoke and

an electronic vacuum gauge sensor port (sensor not included). Features a 3/8 packless

diaphragm valve to isolate the vacuum pump from the system. The Mini-Vac mounts

on the pump with a 3/8 quick coupler.

MANIFOLD GASKET SET MODEL 1843

Gasket set for Model 1833 Mini-Vac.

MINI-VAC MANIFOLD + 0-30-INCH VACUUM GAUGE COMBO MODEL 1834

Combination of Model 1833 Mini-Vac Manifold and 0-30-inch mechanical vacuum gauge which attaches to the sensor port.

VACUUM TEE MODEL 1832

Vacuum Tee for evacuating from two ports with one vacuum source. (2) 3/8 MFL x 3/8 quick coupler includes (2) 3/8 x 1/4 x 6ft.

high vacuum hoses.

HIGH VACUUM HOSE MODEL 1836 & 1836-38

Vacuum Hose provides faster evacuation with better capabilities. Tests prove vacuum

pump capacity is reduced by 50% over standard 1/4 refrigeration hose is used.

PART NO DESCRIPTION

1836 60-INCH HOSE, 3/8 FFL X 1/4 FFL 45º

1836-38 60-INCH HOSE, 3/8 FFL X 3/8 FFL

www.thermalengineeringcompany.com | 800 473-1754

22

VACUUM PUMP ACCESSORIES

High quality vacuum pump oil and sealants help maintain your vacuum pumps and prolong their life.

VACUUM PUMP OIL MODELS 1810 & 1813

Thermal Vacuum Pump Oil keeps any high vacuum pump at maximum performance. No

pump can deliver a lower pressure than its sealing oil’s vapor pressure. This oil must have

the viscosity to lubricate and seal clearances in the pump’s moving parts at the extreme

temperatures developed during continuous use. Thermal’s Vacuum Pump Oil is a premium

quality mineral oil formulated to tolerate exposure to vacuums of 5 microns. Thermal’s

Vacuum Pump Oil resists the formation of deposits and maintains its original lubricating

properties over a long life. Thermal’s Vacuum Pump Oil offers very high vacuums, excellent

lubrication, and long oil life. Available in 1 gallon plastic containers, 4 per case, or 1qt.

bottles, 6 per case.

PART NO CASE SIZE GRAVITY,

API

1810 (4) GALLON CONTAINERS 29.2 SUS AT 100°F, 335 450°F 5

1813 (6) QUART CONTAINERS 29.2 SUS AT 100°F, 335 450°F 5

VISCOSITY FLASH

POINT

PRESSURE,

MICRONS,

HG, MAX

LIQUI-VAC MODELS 4036 & 4036-Q

FE ATURE S

Sets up quickly•

Seals to 1 micron•

Remains flexible•

Ready to use•

A real time-saver in servicing cooling systems, Liqui-Vac is the only liquid sealant with

the capacity of sealing high vacuum connections. It will positively seal high vacuum leaks

around threads, through flared connections, face joints, wherever metal joins metal.

Airserco Liqui-Vac sets up quickly, but remains flexible for easy disconnection. Liqui-Vac is

resistant to most solvents, can seal to 1 micron, and withstands temperatures from -100°F

to +325°F. Available in 4 oz. brush-in-cap cans, 12 per case, or in 1qt. cans.

23

EASY BRUSH ON APPLICATOR FOR:

THREAD CONNECTIONS

MACHINE SURFACE CONNECTIONS

SOLDERED OR WELDED CONNECTIONS

800 473-1754 | www.thermalengineeringcompany.com

CHARGING CYLINDERS & ACCESSORIES

CHARG-CHECK

Accurately charge your refrigeration system with Charg-Check, available in a number of sizes to suit

your needs.

CHARG-CHECK

FEATURES

Comes in three sizes to suit any application, 1lb. (16oz.), 5Ib. (80oz.), and 10lb. (160oz.) •

sizes cover the field from light domestic to heavy commercial.

Allows you to measure out precise quantities of refrigerant.

•

Helps speed up the charging process by letting you charge with heat. All cylinders •

except the 16oz. model will hold a Model 7020 Heater Assembly.

Allows you to carry small quantities of refrigerant to the job, yet buy refrigerant in large

•

quantities and keep the drum back at your shop.

Is available in a steel carrying case to completely protect them from tough use. Cylinder

•

need not be removed from the case as all connections and valves are accessible from

front. Case forms a wstand to set on the floor or bench.

Are easily used in the field. They hang onto system being charged by means of a top-

•

mounted bail.

Can be calibrated for ambient temperature variations by means of temperature correction

•

chart on the side of the scale. This is required only if better than 2% accuracy is needed.

Safety relief valve for protection.

•

Plastic liquid level indicators.•

HFC-134A MODELS WITH 1/4 SAE FITTINGSR-12, R-22, R-502 MODELS

PART NO CAPACITY GRADUATION

7001 16 OZ 1/2 OZ

7002* 16 OZ 1/2 OZ

7005 80 OZ 1 OZ

7006* 80 OZ 1 OZ

7009 160 OZ 2 OZ

7010 160 OZ 2 OZ

PART NO CAPACITY GRADUATION

U7001 16 OZ (450 G) 1/8 OZ (5 G)

U7002* 16 OZ (450 G) 1/8 OZ (5 G)

U7005 80 OZ (450 G) 1 OZ (25 G)

U7006* 80 OZ (450 G) 1 OZ (25 G)

U7009 160 OZ (900 G) 2 OZ (50 G)

U7010 160 OZ (900 G) 2 OZ (50 G)

* CARRYING CASE INCLUDED

GASKET SETS AND REPAIR KITS

Charg-Check Repair kits contain a complete gasket set and replacement gauge.

PART NO DESCRIPTION

7001GS GASKET SET FOR 16 OZ CHARGE-CHECK

7001RK REPAIR KIT FOR 16 OZ CHARGE-CHECK

7003GS GASKET SET FOR 2-1/2 LB CHARGE-CHECK

7003RK REPAIR KIT FOR 2-1/2 LB CHARGE-CHECK

7005GS GASKET SET FOR 5 LB CHARGE-CHECK

7005RK REPAIR KIT FOR 5 LB CHARGE-CHECK

7009GS GASKET SET FOR 10 LB CHARGE-CHECK

7009RK REPAIR KIT FOR 10 LB CHARGE-CHECK

www.thermalengineeringcompany.com | 800 473-1754

24

CHARGING CYLINDERS & ACCESSORIES

CHARG-CHECK ACCESSORIES

Optional accessories for the Charg-Check Series charging cylinders

CARRYING CASES FOR THE CHARG-CHECK (PICTURED ON PAGE 24) MODEL 7000

An ideal way to protect the Charg-Check cylinder from various damage including a broken sight glass. The carrying cases are

constructed of 20 gauge steel and supplied with a durable powder coat finish. Optional accessories for the Charg-Check Series.

PART NO DIMENSIONS USED WITH

7007 4.25 W X 16.75 H X 3.625 D 7001 / U7001

7008 4.75 W X 23.5 H X 5 D 7005 / U7005

7013 6 W X 25 H X 7 D 7009 / U7009

CHARG-CHECK HEATER ASSEMBLIES MODELS 7020 & 7024

Model 7020

The 120 Volt heater assembly is threaded into the bottom of the cylinder to increase the

speed of the charge.

Model 7024

The 240 Volt heater assembly is threaded into the bottom of the cylinder to increase the

speed of the charge.

7024, 7020

25

800 473-1754 | www.thermalengineeringcompany.com

CHARGING SCALES

CHARGING SCALES

Convenient solution for refrigerant charging. Easy to use, even easier to carry around.

CHARGING SCALE MODEL 4900

The 4900 refrigerant charge scale is the ideal choice for field service work. With a high

resolution LCD screen that reads in both lbs. and kg., this scale comes packaged in a

convenient carrying case and is powered by (1) 9 volt battery (included).

FEATURES

Battery operated (9V) for ease of portability•

220lbs. (100kg.) capacity•

High resolution LCD screen with backlight capability•

Automatically powers off•

5g, 0.25oz. resolution•

Readout in lbs. or kg.•

Zero/Tare capable•

Weight 6.5lbs.•

Extra sturdy aluminum bound case•

CHARGING SCALE MODEL 5100B

FEATURES

Simple keypad entry for charges up to 100lbs. (50kg.)•

Extremely accurate strain gauge technology•

LCD display for easy reading•

Solenoid actuated for accurate charging down to 1/4 oz.•

Compact design includes extra outlet for auxiliary items•

Compensates for temperatures from 50°-120°•

Easily converted to Acme threads for HFC-134a•

VAC powered for consistent readings•

Completely made in America•

www.thermalengineeringcompany.com | 800 473-1754

26

MANIFOLDS & GAUGES

MANIFOLDS & GAUGES

For proper evacuation, charging, and diagnosis of refrigeration and air conditioning systems, the Thermal

Engineering TS series 2-valve and 4-valve manifolds deliver the type of quality and functionality demanded

by the discriminating service technician.

TS-500 2-VALVE MANIFOLD

The TS-500 2-Valve manifold offers great functionality combined with ‘Made in the USA’

quality. The hard coat anodized body, large bore construction, and double o-ring piston

design, provide the essential elements for quick and easy evacuation and refrigerant

charging.

FEATURES

•

Heavy-duty anodized machined body with radius edges

• Ergonomic handles with 30 degree offset

• Double o-ring piston design

• Brass SAE wye fitting with hose hanging functionality

MODEL DESCRIPTION

TS-500 2-VALVE MANIFOLD, R22, R404A, R410A

TS-500-60H 2-VALVE MANIFOLD, R22, R404A, R410A, WITH 60 INCH HOSE SET (9701 SERIES)

TS-1000 THE SHERMAN 4-VALVE TEST AND CHARGING MANIFOLD

The Sherman 4-Valve test and charging manifold is Tough as a Tank™. Designed by

service technicians, the Sherman not only feels good in your hands, it significantly reduces

evacuation time and allows for precise metering of refrigerant. In addition, the industries

only double sight glass design provides excellent refrigerant visibility. The Sherman is a

“must-have” for the discriminating service technician.

FEATURES

•

Heavy-duty anodized machined body with radius edges

• Ergonomic handles with 30-degree offset for high and low side refrigerant

• Double sight glass design

• Large bore machine holes and 3/8 vacuum connection

• Double o-ring piston design

• Hose Hangers

• Hanging Hook

• Made in the USA

MODEL DESCRIPTION VACUUM PORT HI/LO CHARGE

Designed to fit seamlessly with the DigiCool

digital refrigerant manifold series, this manifold

can be purchased individually or coupled to the

Digi-Cool models 1250, 1200, and 1600.

TS-1000* MANIFOLD ONLY 3/8 1/4

TS-1000-60H WITH 60-INCH TRU PRO RYB

HOSE SET & 3/8 45˚

TS-1000-60HR WITH 60-INCH REFLOC

RYB HOSE SET & 3/8 45˚

TS-1000-80 WITH R22, R404A, R410A 80MM GAUGES 3/8 1/4

TS-1000-80G WIT H R22, R404A, R410A 80MM GAUGES

(GLYCERIN FILLED)

*Standard manifold is blue Custom colors and engraving available upon request

(Minimum orders apply)

3/8 1/4

3/8 1/4

3/8 1/4

27

800 473-1754 | www.thermalengineeringcompany.com

MANIFOLDS & GAUGES

DIGITAL REFRIGERANT SYSTEM ANALYZER

DRSA-1600 DIGITAL REFRIGERANT SYSTEM ANALYZER

Thermal Engineering is pleased to introduce the DRSA 1600, an advanced, robust, and

reliable A/C refrigeration manifold gauge built for professional HVAC/R technicians!

UTILIZATION OF THE DRSA 1600 HAS PROVEN TO PROVIDE THE FOLLOWING

•

Provides rapid payback on investment

• Improves productivity—Average one week of pure profit per technician per year!

• Minimizes training time

• Reduces downtime

• Increases staff’s trouble shooting capability

• Reduces costs on current maintenance contracts

• Simplifies cumbersome procedures

• Eliminates need for unnecessary or inappropriate repairs

FEATURES

•

Compact Sleek design for easier handling

• Made for maximum robustness and durability

• Temperature probe for automatic superheat and subcooling readings

• 30 refrigerants are included onboard

• Updated pressure port design

• Attaches to the TS series manifolds using swivel fittings

• Dynamic offset bar graph clearly shows modulation of control valves,

system behavior, and faults

www.thermalengineeringcompany.com | 800 473-1754

28

MANIFOLDS & GAUGES

1400 SERIES

Rugged design, top notch performance, high and low pressure gauges for all popular refrigerants in

use today.

1400 SERIES GAUGE MANIFOLDS

The Thermal Engineering 1400 series manifolds are the ideal choice for the value driven

service technician. The 1400 series body is forged brass with full size porting for maximum

flow. The gauges include a rugged metal housing and the no flutter dial ensures accuracy.

With hard to break steel knobs and 1/4-inch hose hangers, the 1400 series allows the

service engineer to “get the job done right.”

FEATURES

•

Forged brass body with hanger

• Rugged metal housing with no flutter gauge

• Easy to grip steel knobs

• 1/4-inch fittings and hose holders

• Double o-ring piston valve system

PART NO REFRIGERANTS MANI FOL D &

HOSE HO LDE R

FITTINGS

1440 R12, R22, R502 1/4, 1/4 -- BAR / PSI 2-1/2, STEEL

1440-36C R12, R22, R502 W/ 36-INCH HOSE SET 1/4, 1/4 36-RYB, 3 PACK BAR / PSI 2-1/2, STEEL

1440-60C R12, R22, R502 W/ 60-INCH HOSE SET 1/4, 1/4 60-RYB, 3 PACK BAR / PSI 2-1/2, STEEL

1441 R22, R404A, R410 1/4, 1/4 -- BAR / PSI 2-1/2, STEEL

1441-36C R22, R404A, R410 W/ 36-INCH HOSE SET 1/4, 1/4 36-RYB, 3 PACK BAR / PSI 2-1/2, STEEL

1441-60C R22, R404A, R410 W/ 60-INCH HOSE SET 1/4, 1/4 60-RYB, 3 PACK BAR / PSI 2-1/2, STEEL

1442 R22, R134A, R407C 1/4, 1/4 -- BAR / PSI 2-1/2, STEEL

1442-36C R22, R134A, R407C W/ 36-INCH HOSE SET 1/4, 1/4 36-RYB, 3 PACK BAR / PSI 2-1/2, STEEL

1442-60C R22, R134A, R407C W/ 60-INCH HOSE SET 1/4, 1/4 60-RYB, 3 PACK BAR / PSI 2-1/2, STEEL

Manifold and hose assemblies utilize V-line hoses.

REFRIGERANT GAUGES

PART NO REFRIGERANTS TYPE SCALE SIZE/TYPE

1440GB R12, R22, R502 COMPOUND BAR / PSI 2-1/2, STEEL

1440GR R12, R22, R502 PRESSURE BAR / PSI 2-1/2, STEEL

1441GB R22, R404A, R410 COMPOUND BAR / PSI 2-1/2, STEEL

1441GR R22, R404A, R410 PRESSURE BAR / PSI 2-1/2, STEEL

1442GB R22, R134A, R407C COMPOUND BAR / PSI 2-1/2, STEEL

1442GR R22, R134A, R407C PRESSURE BAR / PSI 2-1/2, STEEL

41GB 80 R22, R404A, R410A COMPOUND ºF / PSI 80MM, STEEL

41GR80 R22, R404A, R410A PRESSURE ºF / PSI 80MM, STEEL

41GBG80 R22, R404A, R410A (GLYCERIN FILLED) COMPOUND ºF / PSI 80MM, STEEL

41GRG80 R22, R404A, R410A (GLYCERIN FILLED) PRESSURE ºF / PSI 80MM, STEEL

HOSES SCALE SIZE/TYPE

29

NOTE: Special gauges available upon request, minimum order quantites may apply.

800 473-1754 | www.thermalengineeringcompany.com

HOSES

CHARGING HOSES

Premium quality, durable, long lasting hoses made in the USA with a 4,000psi minimum burst pressure.

TRU PRO CHARGING HOSE

For those interested in premium quality, the Thermal Engineering Tru Pro Series refrigerant

charge hose is the only choice. Made in the USA, these hose assemblies conform to UL

1963, SAE J-51, J-639, J-2196 and J-2197. With 4000psi minimum burst and a working

pressure of 800psi these hoses are long lasting, durable, and come in a range of options

to meet your specific requirements.

1/4 TRU PRO - 1/4 FFL X 1/4 FFL 45° AND BRASS DEPRESSOR

LENGTH (FT) YELLOW BLUE RED PACKAGE SET

(RED, YELLOW, BLUE)

3 9701-Y-3 9701-B-3 9701-R-3 9701-3-3

5 9701-Y-5 9701-B-5 9701-R-5 9701-3-5

10 9701-Y-10 9701-B-10 9701-R-10 9701-3-10

12 9701-Y-12 9701-B12 9701-R-12 9701-3-12

15 9701-Y-15 9701-B-15 9701-R-15 9701-3-15

20 9701-Y-20 9701-B-20 9701-R-20 9701-3-20

25 9

50 9701-Y-50 9701-B-50 9701-R-50 9701-3-50

100 9701-Y-100 9701-B-100 9701-R-100 9701-3-100

Suitable for R12, R22, R134A, R404A, R407C, R410A, R500, R502.

Custom lengths and end fitting options available upon request.

701-Y-25 9701-B-25 9701-R-25 9701-3-25

9701

1/4 TRU PRO - 1/4 FFL X 1/4 REFLOC ANTI-BLOW BACK FITTING

LENGTH (FT) YELLOW BLUE RED PACKAGE SET

(RED, YELLOW, BLUE)

3 9701RL-Y-3 9701RL-B-3 9701RL-R-3 9701RL-3-3

5 9701RL-Y-5 9701RL-B-5 9701RL-R-5 9701RL-3-5

10 9701RL-Y-10 9701RL-B-10 9701RL-R-10 9701RL-3-10

12 9701RL-Y-12 9701RL-B12 9701RL-R-12 9701RL-3-12

15 9701RL-Y-15 9701RL-B-15 9701RL-R-15 9701RL-3-15

20 9701RL-Y-20 9701RL-B-20 9701RL-R-20 9701RL-3-20

25 9701RL-Y-25 9701RL-B-25 9701RL-R-25 9701RL-3-25

50 9701RL-Y-50 9701RL-B-50 9701RL-R-50 9701RL-3-50

100 9701RL-Y-100 9701RL-B-100 9701RL-R-100 9701RL-3-100

Suitable for R12, R22, R134A, R404A, R407C, R410A, R500, R502.

Custom lengths and end fitting options available upon request.

www.thermalengineeringcompany.com | 800 473-1754

970 1RL

30

HOSES

CHARGING HOSES

TRU PRO CHARGING HOSE – BALL VALVE AND AUTOMOTIVE

For those interested in premium quality, the Thermal Engineering Tru Pro Series refrigerant

charge hose is the only choice. Made in the USA, these hose assemblies conform to UL

1963, SAE J-51, J-639, J-2196 and J-2197. With 4000psi minimum burst and a working

pressure 800psi these hoses are long lasting, durable, and come in a range of options to

meet your specific requirements.

1/4 TRU PRO - 1/4 FFL X 1/4 FFL 45° AND BRASS DEPRESSOR WITH BALL VALVE

970 1BV

LENGTH (FT) YELLOW BLUE RED PACKAGE SET

(RED, YELLOW, BLUE)

3 9701B V-Y-3 9701BV-B-3 9701BV-R-3 9701BV-3-3

5 9701BV-Y-5 9701BV-B-5 9701BV-R-5 9701BV-3-5

10 9701BV-Y-10 9701BV-B-10 9701BV-R-10 9701BV-3-10

12 9701BV-Y-12 9701BV-B12 9701BV-R-12 9701BV-3-12

Suitable for R12, R22, R134A, R404A, R407C, R410A, R500, R502.

Custom lengths and end fitting options available upon request.

9701R134

1/4 TRU PRO - 1/2 FE ACME X 14 MM MALE (RED AND BLUE)

1/4 TRU PRO - 1/2 FE ACME X 1/2 REFLOC FITTING (YELLOW)

LENG TH

(FT)

5 9701R134-Y-5 9701R134-B-5 9701R134-R-5 9701R134-3-5

6 9701R134-Y-6 9701R134-B-6 9701R134-R-6 9701R134-3-6

8 9701R134-Y-8 9701R134-B-8 9701R134-R-8 9701R134-3-8

10 9701R134-Y-10 9701R134-B-10 9701R134-R-10 9701R134-3-10

Suitable for R134A.

Custom lengths and end fitting options available upon request.

BALL VALVE HOSE ADAPTER

Utilizing Thermal Engineering Tru Pro adapters, the service technician can connect to

any 1⁄4-inch hose and control refrigerant flow by simply opening and closing the in-line

ball valve. Easy to use and available in red, yellow, blue or as a complete set to meet your

specific requirements. For 6-inch adapter orders remove suffix (5).

PART NODESCRIPTION

99901 1⁄4 MFL X 1⁄4 FFL X 6-INCH LENGTH RED TRU PRO ADAPTERS

99902 1⁄4 MFL X 1⁄4 FFL X 6-INCH LENGTH YELLOW TRU PRO ADAPTERS

99903 1⁄4 MFL X 1⁄4 FFL X 6-INCH LENGTH BLUE TRU PRO ADAPTERS

99904 1⁄4 MFL X 1⁄4 FFL X 6-INCH LENGTH (RED, YELLOW AND BLUE SET) TRU PRO ADAPTERS

YELLOW BLUE RED PACKAGE SET

(RED, YELLOW, BLUE)

31

800 473-1754 | www.thermalengineeringcompany.com

HOSES

Custom hose adapter, coupling and fitting solutions tailored to your exact needs and specifications.

V-LINE

Economy line of refrigerant charging hose sets with 800 PSI working pressure and 4000

PSI minimum burst. These hoses are UR Rated and conform to SAE J2196. Sets are

available in both 3ft. and 5ft. lengths.

1⁄4 V-Line

PART NO DESCRIPTION

9601-3-3 36-INCH HOSE SET, RED, YELLOW & BLUE - 1/4 FFL X 1/4 FFL 45°

9601-3-5 60-INCH HOSE SET, RED, YELLOW & BLUE - 1/4 FFL X 1/4 FFL 45°

BALL VALVE HOSE ADAPTER

Utilizing Thermal Engineering V-Line adapters, the service technician can connect to any

1⁄4-inch hose and control refrigerant flow by simply opening and closing the in-line ball

valve. Easy to use and available in red, yellow, blue or as a complete set to meet your

specific requirements. For 6-inch adapter orders remove suffix (5).

PART NO DESCRIPTION

9701BVC-R-5 1⁄4 MFL X 1⁄4 FFL X 5FT LENGTH RED V-LINE ADAPTERS

9701BVC-Y-5 1⁄4 MFL X 1⁄4 FFL X 5FT LENGTH YELLOW V-LINE ADAPTERS

9701BVC-B-5 1⁄4 MFL X 1⁄4 FFL X 5FT LENGTH BLUE V-LINE ADAPTERS

9701BVC-3-5 1⁄4 MFL X 1⁄4 FFL X 5FT LENGTH (RED, YELLOW & BLUE SET) V-LINE ADAPTERS

CONVERSION ADAPTERS

The Thermal Engineering conversion adapter consists of a compact ball valve that is ideal

for retrofitting standard refrigerant hoses, providing instant refrigerant shut off capabilities.

Available in standard 1/4 and 5/16 sizes for refrigerant 410A.

PART NO DESCRIPTION

TE-BV01R 1⁄4 SAE X 1/4 F SAE

TE-BV01Y 1⁄4 SAE X 1/4 F SAE

TE-BV01B 1⁄4 SAE X 1/4 F SAE

TE-BV01-3 1⁄4 SAE X 1/4 F SAE, SET OF 3

TE-BV02R 1⁄4 SAE X 5/16 F SAE

TE-BV02Y 1⁄4 SAE X 5/16 F SAE

TE-BV02B 1⁄4 SAE X 5/16 F SAE

TE-BV02-3 1⁄4 SAE X 5/16 F SAE, SET OF 3

www.thermalengineeringcompany.com | 800 473-1754

32

FITTINGS

ADAPTERS & FITTINGS

Custom hose adapter, coupling and fitting solutions tailored to your exact needs and specifications.

ANTI-BLOWBACK BRASS HOSE ADAPTER

Convert standard 1/4 hose to anti-blowback functionality.

PART NO MALE FEMALE OTHER PKG

TE-BARL14 1/4 SAE 1/4 SAE W/ CORE AND DEPRESSOR 1

R-410A BRASS ADAPTER

Convert new R-410A system ports with 5/16 SAE connections to 1/4 SAE.

PART NO MALE FEMALE OTHER APPLICATION PKG

TE-BA01 1/4 SAE 5/16 SAE W/ CORE AND DEPRESSOR R-410A INTERNATIONAL 1

ADDITIONAL END FITTING OPTIONS

Thermal Engineering understands that no two jobs are alike. In keeping with our commitment to serve the HVAC/R professional

we offer a multitude of end fitting options custom tailored for your application. Listed below is a sample of the end fittings

available in any combination. Please call us for your inquiries, 800 473-1754.

1⁄4 Anti-blow back

1⁄2 Acme Anti-blow back

1⁄2 Acme FFL

1⁄2 Acme FFL 45°

1⁄2 Acme FFL 90°

1⁄2 Acme 14mm

1⁄4 FFL

1⁄4 FFL 45°

1⁄4 FFL 90°

1⁄2 Acme Hex Nut

1⁄2 Acme Hex Nut 45°

1⁄2 Acme Hex Nut 90°

1⁄4 Hex Nut

1⁄4 Hex Nut 45°

1⁄4 Hex Nut 90°

In-line filter element

(10 microns)

AUTOMOTIVE A/C COUPLERS

PART NO DESCRIPTION

134ACR HIGH SIDE X 14 MM R-134A COUPLER

134ACB LOW SIDE X 14 MM R-134A COUPLER

33

800 473-1754 | www.thermalengineeringcompany.com

High quality brass refrigeration fittings.

SWIVEL FLARE CONNECTIONS

TEE WITH DEPRESSOR

PART NO DESCRIPTION PKG

TE-SF01D 1/4 FE SAE SWIVEL NUT ON RUN 3

TE-SF02D 1/4 FE SAE SWIVEL NUT ON BRANCH 3

TEE WITHOUT DEPRESSOR

PART NO DESCRIPTION PKG

TE-SF01 1/4 FE SAE SWIVEL NUT ON RUN 3

TE-SF02 1/4 FE SAE SWIVEL NUT ON BRANCH 3

FITTINGS

BRASS FITTINGS

3/8-INCH SAE TEE

PART NO DESCRIPTION PKG

TE-SF03 3/8 SAE X 3/8 FE SAE

SWIVEL NUT X ACCESS

TE-SF04 3/8 SAE X ACCESS X 3/8 FE SAE

SWIVEL NUT

COPPER BRAZE TEES

PART NO SLIP FIT CONNECTING

LINE SIZE

TE-BT01 1/4 OD 2-1/8 3

TE-BT02 5/16 OD 2-1/8 3

TE-BT03 3/8 OD 2-1/8 3

TE-BT04 1/2 OD 2-1/8 3

TE-BT05 5/8 OD 2-1/2 1

TE-BT06 3/4 OD 3 1

TE-BT07 7/8 OD 3-1/2 1

TE-BT08 1-1/8 OD 3-13/16 1

TE-BT09 3/16 OD 4 2

TE-BT10 1/4 OD 4 2

TE-BT11 5/16 OD 4 2

OVERALL

LENGTH

PKG

1

1

www.thermalengineeringcompany.com | 800 473-1754

34

FITTINGS

BRASS BODIES

TE-CRT01

STRAIGHT

PART NO DESCRIPTION PKG

TE-BB01 1/8 OD 3

TE-BB02 3/16 OD 3

TE-BB03 1/4 OD 3

TE-BB04 5/16 OD 3

TE-BB05 3/8 OD 3

TE-BB06 1/2 OD 3

CORE REMOVAL TOOL

TE-CRT01

MULTISTEP

PART NO DESCRIPTION PKG

TE-BB07 3/16 X 1/4 OR 3/8 STEPS 5

TE-BB08 3/16, 1/4, 5/16 1/2 STEPS 3

TE-BB09 1/8 X 3/16, 1/4 OR 5/16 STEPS 3

This core removal tool is about the size of a pen. Store extra cores within the body of this

handy tool.

PART NO DESCRIPTION

TE-CRT01 FOR 1/4 VALVE CORE TOOL

TE-CRT02 VALVE CORE REMOVAL TOOL

TE-CRT02

35

800 473-1754 | www.thermalengineeringcompany.com

COPPER TUBE EXTENSION

PART NO DESCRIPTION PKG

TE-CTX01 1/8 OD 5

TE-CTX02 3/16 OD 5

TE-CTX03 1/4 OD 5

TE-CTX04 5/16 OD 5

TE-CTX05 3/8 OD 5

TE-CTX06 1/2 OD 3

PART NO DESCRIPTION PKG

TE-CTX07 1/8 EXT.;

3/16, 1/4 AND 5/16 BODY STEPS

TE-CTX08 3/16 EXT.;

1/4 AND 3/8 BODY STEPS

FITTINGS

5

5

VALVE CORE DEPRESSOR

PART NO DESCRIPTION PKG

7025 FOR 1/4 MALE FLARES 1

www.thermalengineeringcompany.com | 800 473-1754

36

VOCATIONAL TRAINING UNITS

Ask for our Vocational Training Units Catalog!

Providing dedicated and high quality educational tools for tomorrow’s HVAC/R industry.

37

800 473-1754 | www.thermalengineeringcompany.com

INDEX

By Part Number

NUMBER DESCRIPTION PAGE

134ACB Low Side x 14mm R134a coupler .................................................................................................................... 33

134ACR Hi side x 14mm R-134a coupler ....................................................................................................................... 33

1003 Cap-Check Capillary Tube Cleaner ................................................................................................................... 3

1003RK Cap-Check Repair Kit ........................................................................................................................................ 4

1011 0-5000 PSI Gauge .............................................................................................................................................4

1012 30-inch Hydraulic Hose ..................................................................................................................................... 4

1101 Cap Check Chaser Kit ....................................................................................................................................... 3

1102 Cap-Gauge ........................................................................................................................................................ 4

1201 Carrying Case for Cap-Check ........................................................................................................................... 4

1301 Extended Base for Cap-Check.......................................................................................................................... 4

1440 2 Valve Hi/Low Brass Manifold - R12, R22, R502 ........................................................................................... 29

1440-36C 36 2 Valve Hi/Low Brass Manifold - R12. R22, R502 w/ 36-inch Hose Set .................................................... 29

1440-60C 2 Valve Hi/Low Brass Manifold - R12. R22, R502 w/ 60-inch Hose Set ......................................................... 29

1440GB Refrigerant Gauge, Compound - R12, R22, R502 ........................................................................................... 29

1440GR Refrigerant Gauge, Pressure - R12, R22, R502 ............................................................................................... 29

1441 2 Valve Hi/Low Brass Manifold - R22, R404A, R410 ....................................................................................... 29

1441-36 2 Valve Hi/Low Brass Manifold - R22, R404A, R410 w/ 36-inch Hose Set ..................................................... 29

1441-60 2 Valve Hi/Low Brass Manifold - R22, R404A, R410 w/ 60-inch Hose Set ..................................................... 29

1441GB Refrigerant Gauge, Compound - R22, R404A, R410 ...................................................................................... 29

1441GR Refrigerant Gauge, Pressure - R22, R404A, R410 .......................................................................................... 29

1442 2 Valve Hi/Low Brass Manifold - R22, R134A, R407C ....................................................................................29

1442-36 2 Valve Hi/Low Brass Manifold - R22, R134A, R407C w/ 36-inch Hose Set .................................................. 29

1442-60 2 Valve Hi/Low Brass Manifold - R22, R134A, R407C w/ 60-inch Hose Set .................................................. 29

1442GB Refrigerant Gauge, Compound - R22, R134A, R407C .................................................................................... 29

1442GR Refrigerant Gauge, Pressure - R22, R134A, R407C ........................................................................................ 29

1702 Charge-Oil Pump .............................................................................................................................................20

1703 Charge-Oil Pump for 5 gallon can ................................................................................................................... 20

1705 Repair Kit for 1702 and 1703............................................................................................................................ 20

1751 Change-Oil Pump ............................................................................................................................................ 20

1751RK Repair Kit for 1751 ............................................................................................................................................ 20

1768 Special Adapter Kit for Suniso Cans and Calgon Bottles ............................................................................... 21

1770 Suction Adapter for Aluminum Pumps ............................................................................................................ 21

1810 Vacuum Pump Oil, Gallon, 4 per case ............................................................................................................. 23

1813 Vacuum Pump Oil, Quart, 6 per case .............................................................................................................. 23

1832 Vacuum Yoke with 2 High Vacuum Hoses ....................................................................................................... 22

1833 Mini-Vac Manifold ............................................................................................................................................ 22

1834 Mini-Vac Manifold with 0-30-inch Mechanical Vacuum Gauge ...................................................................... 22

1836 High Vacuum Hose for use with 1833 and 1834 Mini-Vac Manifold ...............................................................22

1836-38 High Vacuum Hose for use with 1833 and 1834 Mini-Vac Manifold ............................................................... 22

1843 Repair Kit for Model 1833 and 1834 Mini-Vac Manifold .................................................................................. 22

2001 Hermeti-Check ................................................................................................................................................. 18

2136 Adapter Cord .................................................................................................................................................... 19

2601 Quik-Start ......................................................................................................................................................... 19

2602 Quik-Start with 2605 Test Leads ..................................................................................................................... 19

2605 Test Lead Kit .................................................................................................................................................... 19

3054 Refrigerant Cylinder Heater 30lb., 50lb., 120V .................................................................................................. 7

3054-230V Refrigerant Cylinder Heater 30lb., 50lb., 230V .................................................................................................. 7

4014 Leak-Tec Formula 372E, 4oz. .......................................................................................................................... 13

4014-8OZ Leak-Tec Formula 372E, 8oz. .......................................................................................................................... 13

4014-G Leak-Tec Formula 372E, Gallon ....................................................................................................................... 13

4015 Leak-Tec Formula 372G, 4oz. ......................................................................................................................... 13

www.thermalengineeringcompany.com | 800 473-1754

38

INDEX

4015-8OZ Leak-Tec Formula 372G, 8oz. ......................................................................................................................... 13

4015-G Leak-Tec Formula 372G, Gallon....................................................................................................................... 13

4036 4 oz. Liqui-Vac Sealant, 12 per case ............................................................................................................... 23

4036-Q Quart Liqui-Vac Sealant ................................................................................................................................... 23

4054M Refrigerant Cylinder Heater, 125lb. with automatic control .............................................................................. 7

41GB80 R22, R404A, R410A - Compond Gauge, º F / PSI, 80MM, Steel .................................................................... 29

41GR80 R22, R404A, R410A - PSI Gauge, º F / PSI, 80MM, Steel .............................................................................. 29

41GBG80 R22, R404A, R410A - Compond Gauge, º F / PSI, 80MM, Steel .................................................................... 29

41GRG80 R22, R404A, R410A - PSI Gauge, º F / PSI, 80MM, Steel ............................................................................... 29

D4101 Digital Thermometer ........................................................................................................................................ 17

D4109 Flexible PVC Covered Thermocouple Probe for D4101 .................................................................................. 17

D4111 General Purpose Thermocouple Probe for D41 01 ......................................................................................... 17

D4113 25ft. Thermocouple Extension Probe for D4101 ............................................................................................. 17

D4115 D4111 Probe with 10-inch Stainless Steel Protection Tube for D41 01 ........................................................... 17

4501 Vak-Check ........................................................................................................................................................ 15

4510 Sensor for All Models with 0 to 50 Calibration Scale ...................................................................................... 15

4775 Handheld Digital Micron Gauge ...................................................................................................................... 16

4900 Refrigerant Charging Scale, non-programmable ............................................................................................ 26

4975 Scale / Vacuum Combo Unit ........................................................................................................................... 16

5100 Room Air Conditioning Calculator ..................................................................................................................... 8

5100B Refrigerant Charging Scale, programmable .................................................................................................... 26

5101 Complete Cap-Check Outfit .............................................................................................................................. 3

5125 Air Duct Calculator ............................................................................................................................................. 8

5150 Humidity Calculator ........................................................................................................................................... 8

5175 Trouble Shooting Calculator .............................................................................................................................. 9

5180 Capillary Tube Calculator ................................................................................................................................... 9

5225 Review of Vacuum Textbook............................................................................................................................ 10

5300 Refrigeration Calculator ..................................................................................................................................... 9

7001 16 oz. Charg-Check Charging Cylinder ........................................................................................................... 24

U7001 HFC-134a 16oz. Charg-Check Charging Cylinder .......................................................................................... 24

7001GS Gasket Set for 7001 and 7002 Charg-Check .................................................................................................. 24

7001RK Repair Kit for 16oz. Charg-Check.................................................................................................................... 24

7002 7001 with Carrying Case .................................................................................................................................. 24

U7002 HFC-134a 7001 with Carrying Case ................................................................................................................ 24

7003GS Gasket Set for 2-1/2lb. Charg-Check .............................................................................................................. 24

7003RK Repair Set for 2-1/2lb. Charg-Check ............................................................................................................... 24

7005 80oz. Charg-Check Charging Cylinder ........................................................................................................... 24

U7005 HFC-134a 80oz. Charg-Check Charging Cylinder .......................................................................................... 24

7005GS Gasket Set for 7005 and 7006 Charg-Check .................................................................................................. 24

7005RK Repair Kit for 5Ib. Charg-Check ...................................................................................................................... 24

7006 80oz. Charg-Check Charging Cylinder with Carrying Case ........................................................................... 24

U7006 HFC-134a 80oz. Charg-Check Charging Cylinder with Carrying Case .......................................................... 24