User & Technical Manual

NE020, NE030, & NE040 Series

Rev 2.2

Rev

Date

Owner

Description of Changes

1.0

09-22-10

G. Gonzalez

New Format Initial Release

1.2

12-01-10

G. Gonzalez

Update Unit Specification Section for SCCR, Update Preliminary

Test Section and Controller Section for Heater Set point Defaults

1.3

12-05-11

G. Gonzalez

Update Schematic Section & specs for max ambient

1.4

03-05-12

B. Slotnick

Update filter media part number

1.5

01-14-13

B. Slotnick

Revise mounting procedure

1.6

02-22-13

B. Slotnick

Added power connector

1.7

08-17-13

B. Slotnick

Added Appendix A

1.8

01-15-14

B. Slotnick

Update Adjustable Temperature Probe length

1.9

04-03-14

B. Slotnick

Update email address

2.0

08-04-14

B. Slotnick

Delete Celsius programming flash drive key

2.1

01-22-15

B. Slotnick

Update system schematic

2.2

03-23-15

B. Slotnick

Parts list: Added high pressure switch; updated filter information

Title: NE020, NE030, & NE040 Air Conditioner Technical Manual

Department: Engineering

Objective: To provide important information for maintenance, diagnostics and advance operations of the

Thermal Edge NE020, NE030 & NE040 Series Air Conditioners.

Revision History:

Statement of Confidentiality

The Manual and other materials contain proprietary information, comprising Thermal Edge Inc.'s trade secrets.

Please maintain the confidentiality of all proprietary information during and after the term of the use agreement.

Also, please refrain from using this proprietary information in any other manner, including in any other

business, without Thermal Edge Inc.’s written approval.

Thermal Edge Inc. reserves the right to revise and otherwise modify the Manual to reflect changes in the

requirements, standards, and operating recommendations. The Manual is the sole property of Thermal Edge

Inc. It must be returned upon the expiration or the termination of the term of use agreement.

By accepting the Manual you have read and understand the Statement of Confidentiality and will abide by its

terms and conditions.

1751 Hurd Dr ive ● Irving, Texas 75038 ● (972) 580-0200 ● ( 888) 580-0202 ● Fax (972) 580-0277

URL: www.thermal-edge.com ● Email: support@thermal-edge.com

SP-E NG -210- 00 0- 06 R ev 2.2 2 | P a g e

TABLE OF CONTENTS

Overview 4

Inspecting the Equipment 4

Unpacking the Air Conditioner 4

Moving the Air Conditioner 5

Unit Label 5

Operation 6

Preliminary Testing 6

Mounting the Air Conditioner 7

Unit Specifications 8

Options 10

System Faults 13

Digital Temperature Controller Programming 13

Preventative Maintenance 16

Field Serviceable Parts 17

Safety Information 17

Troubleshooting Guide 18

Physical Dimensions 21

Electrical Schematic 23

Warranty Information 24

Return Material Authorization (RMA) Procedure 25

Appendix A – Power Connector 26

1751 Hurd Dr ive ● Irving, Texas 75038 ● (972) 580-0200 ● ( 888) 580-0202 ● Fax (972) 580-0277

URL: www.thermal-edge.com ● Email: support@thermal-edge.com

SP-E NG -210- 00 0- 06 R ev 2.2 3 | P a g e

Overview

Thank you for your purchase of the Thermal Edge Special Purpose Air Conditioner. Our air

conditioning equipment is carefully designed to cool and dehumidify the air in electronic component

enclosures. Thermal Edge has designed air conditioners for all types of electronic equipment

enclosures providing capacity from 1,000 to 20,000 BTUH.

This manual will guide you through the installation, maintenance, diagnostics and advance operations

of the NE020, NE030 & NE040 Series Air Conditioners. This manual contains important information

for the end-user who installs, maintains and/or operates the NE020, NE030 & NE040 Air Conditioner.

Technical Support

By Phone: 972-580-0200 / 888-580-0202

(Monday – Friday, 7:30 am – 5:00 pm Central Time)

By Email: support@thermal-edge.com

Our goal is to have continuous improvement for both our equipment and our documentation. We rely

and appreciate your feedback to help us achieve our goal. Our technical support team is glad to work

with you if you require additional technical information not provided in this manual.

Inspecting the Equipment

Thermal Edge air conditioning equipment is designed, manufactured and packed to prevent damage

from normal handling, shock and vibration during shipment. It is necessary to inspect your equipment

upon receipt to ensure that there is no visual or hidden damage.

Upon receipt of the equipment, ensure that it is always top side up as indicated by “THIS SIDE UP”

labels. This ensures that the compressor oil is not displaced.

Note: If the equipment has been on its side it must be put upright for at least 24 hours before installing

or running to ensure the compressor oil has returned to the compressor.

All physical damage to packing or signs of damage to the equipment must be noted on the freight bill

of lading. Packages must be opened after receipt and inspected for any internal or concealed damage

to the equipment and to verify proper count and order fulfillment. Delivery of without the pallet, not top

side up, other freight on top, damaged or wet should be refused.

Unpacking the Air Conditioner

Always keep air conditioner top up as shown by the packaging label and arrows. If the unit is to be

transported after initial unpacking, place air conditioner back in original packing to prevent damage.

For shipment by UPS or freight carrier, repack as received and re-band to the pallet.

Note: Shipping without being strapped to the pallet may result in tipping and damage, this will void the

warranty.

1751 Hurd Dr ive ● Irving, Texas 75038 ● (972) 580-0200 ● ( 888) 580-0202 ● Fax (972) 580-0277

URL: www.thermal-edge.com ● Email: support@thermal-edge.com

SP-E NG -210- 00 0- 06 R ev 2.2 4 | P a g e

Moving the Air Conditioners

Read this section completely before running or installing your Thermal Edge air conditioning

equipment.

Note: You will need to perform a Preliminary Test before mounting the air conditioner. Refer to the

Preliminary Test section in this manual for instructions on how to run this test. You will also need to

prepare the enclosure that is to be cooled for mounting in accordance with this manual and the

template supplied.

Note: Thermal Edge air conditioning equipment must be mounted vertically with a minimum of 3” air

space for condenser air return and supply. If necessary, equipment may be mounted at up to a 5

degree angle (rotary compressors) without damaging the compressor.

If air conditioner is to be shipped or transported at any time; pack in original packaging and strap to

pallet to prevent damage. Air conditioner must be kept upright at all times. Air conditioners are not

designed to be shipped attached to an equipment enclosure. Air conditioners shipped which have

internal damage due to shipping while attached to enclosures are warranty voided.

Unit Label

Each air conditioner has a unit label, be sure to record the data from the label to the template below

and keep this information in a safe place for warranty and ordering parts. To prevent damage to

equipment, electrical panel and wiring, and to prevent personal injury, assure that the power source is

compatible with the equipment before operating. When recharging, refrigeration type and amount

must be the same as shown on the unit label or air conditioner will not operate properly or may be

damaged and may result in the warranty voided and UL listing voided.

1751 Hurd Dr ive ● Irving, Texas 75038 ● (972) 580-0200 ● ( 888) 580-0202 ● Fax (972) 580-0277

URL: www.thermal-edge.com ● Email: support@thermal-edge.com

SP-E NG -210- 00 0- 06 R ev 2.2 5 | P a g e

Operation

Thermal Edge air conditioners will lower (or increase as necessary) the temperature inside an

enclosure to ensure its proper operational temperature. Our air conditioners, when sized properly, will

provide cooling or heating automatically controlled by the temperature digital controller.

Thermal Edge air conditioners operate as a “closed loop” system with no exposure or introduction of

outside air. This ensures that the enclosure is separated from and is not contaminated with ambient

air, dirt, chemicals, dust, moisture or foreign matter so that sensitive enclosure components are

protected and are kept at your required operational temperature.

An air conditioner is designed to dehumidify and extract heat from an area, or provide heat to an area.

The cooling is done using a simple refrigeration cycle. A product of this simple refrigeration cycle is

excess humidity that condenses to a liquid.

Thermal Edge air conditioners are designed using an advanced refrigeration cycle and are equipped

with a Condensate Removal System that changes the excess humidity liquid into a vapor which is then

vented to the atmosphere. In the event of excess water vapor where the enclosure door has been left

open there is an overflow hole on the bottom of every unit. Please contact Thermal Edge Inc. if you

encounter excess water coming from your air conditioner.

Preliminary Testing

Before mounting the air conditioner to the enclosure, test for proper operation. Follow the steps below

prior to installation.

WARNINGS

The air conditioner must sit upright for 24 hours to assure the compressor oil has drained down to the

compressor. Check the unit label to assure the electric power available to the air conditioner is the

proper voltage and phase. Check the electric power source for proper ground wire and neutral wire

installation per 2008 NEC. Assure that the electric power is protected by a circuit protection device;

refer to the Unit Specification section in this manual for proper circuit protection sizing.

Connect a power source to the air conditioner to start the evaporator fan and, if desired,

change the set point. Refer to Digital Temperature Controller Programming section on this

manual for details on changing the set point. Factory default settings should be satisfactory;

however you may want to adjust heat, cooling and alarm set points for your specific

application.

1751 Hurd Dr ive ● Irving, Texas 75038 ● (972) 580-0200 ● ( 888) 580-0202 ● Fax (972) 580-0277

URL: www.thermal-edge.com ● Email: support@thermal-edge.com

SP-E NG -210- 00 0- 06 R ev 2.2 6 | P a g e

The condenser fan is controlled by the refrigerant high heat pressure and will turn on later

when the operating pressure builds up. This feature allows low ambient operation and

reduces current inrush at initial power on.

Run the air conditioner for 15 minutes; during this time the condenser fan will turn on after the

condenser coil warms up. Note: Ambient Temperature must be at least 75°F.

Turn the unit off if the equipment makes any unexpected or hard mechanical noises or

vibrations and refer to the troubleshooting guide in this manual.

The supply cold air should be at least 10°F colder than the return air entering the unit. If it is

not, refer to the troubleshooting guide in this manual;

When you are satisfied that the unit is operating properly, turn unit off, disconnect the power

and mount the unit on the enclosure in accordance with the Mounting the Air Conditioner

section in this manual.

Mounting the Air Conditioner

Using the template supplied, determine where the air conditioner is to be mounted and assure that all

required cuts and holes will not interfere with or damage the enclosure or its contents. Assure that

there is a 3” clearance between walls / obstructions and the air conditioner for the condenser supply

air and return air flow so that it is not restricted. Restricted condenser air flow will affect the air

conditioner’s performance. Mount the air conditioner high on the enclosure in order to cool the hot air

in the top of the enclosure. Position the unit where the cold air can circulate across the width of the

enclosure to cool it all the way across.

Once proper mounting placement is determined, turn the enclosure equipment off, if possible, to

prevent damage. Drill and cut the holes as indicated on the mounting template. Install insulation

gasket as required to ensure an air tight closed loop seal. Be cautious not to let any cutting debris fall

into the enclosure.

Hang the air conditioner on the Easy Hang Tabs and from inside the enclosure use the fasteners

supplied to attach the air conditioner to the enclosure. Ensure that these fasteners are tight in order to

prevent the unit from falling off the enclosure. These fasteners should be checked periodically to

ensure that they have not become loose due to vibration.

The air conditioner is provided with a power cord or a power terminal block. Ensure that the power

supplied is compatible with the air conditioner’s power requirements. Properly connect the unit to a

power circuit that meets the equipment requirements and provide a circuit protection device based on

the Unit Specifications section of this manual. See Appendix A for Phoenix Contact power connector

instructions.

After mounting the air conditioner, replace/close the enclosure door and start air conditioner; test for

air leaks to assure a proper closed air loop seal and run test the unit to assure proper operation after

mounting. If any cold air leaks are found, check for proper mounting and apply silicone-free Lexel seal

if leaks persist. Assure that the air conditioner’s condenser inlet air filter is installed properly and

cleaned regularly.

1751 Hurd Dr ive ● Irving, Texas 75038 ● (972) 580-0200 ● ( 888) 580-0202 ● Fax (972) 580-0277

URL: www.thermal-edge.com ● Email: support@thermal-edge.com

SP-E NG -210- 00 0- 06 R ev 2.2 7 | P a g e

Mo de l

Oper ating

Vo ltage

Ra ng e

(V ol ts )

In ru sh

Curr en t

(Start

Up

Cu rr ent)

(A mp s)

Loading

Curr en t

(Running

Cu rr ent)

(A mp s)

SC CR

(Sho rt

Ci rc ui t

Cu rr ent

Rating)

(A mp s)

Re co mm en de d

Fu se S el ec ti on

(A mp s)

KV A Ra ti ng

(K-W at ts )

Re fr ig er an t

Ty pe

Re fr ig er an t

Am ou nt

(o un ce s)

Low/ High

Un it

Pr es su re s

(p si )

NE 02 01 26

110-120

16 .4 2

3. 76

*2

8 Am p Cl ass

CC , CC MR

Ti me Delay *

0. 5

R4 22d

10 .2 5

18 8 / 30 0

NE 02 02 36

220-240

13 .4 1

3. 07

*2

6 Am p Cl ass

CC , CC MR

Ti me Delay *

0. 7

R4 22d

9. 75

18 8 / 30 0

NE 02 04 86

440-480

4. 11

0. 93

160K

2 Am p Cl ass

CC , CC MR

Ti me Delay *

0. 5

R4 22d

10 .2 5

18 8 / 30 0

% of Amp ere Ra ti ng

Opening Time

110 %

15min Mi nimum

125 %

1hr Maximum

200 %

12sec Mi nimu m

4min Maximum

CAUTION

If mounting the air conditioner to the enclosure door, confirm with the enclosure manufacturer that the

door’s hinges will support the air conditioner’s added weight (see equipment specifications). Ensure

that when the door is fully open that the enclosure will not topple over due to the off-center load.

Unit Specifications

The following table provides electrical and refrigeration specifications for the NE020, NE030 & NE040

Series Air Conditioners.

NE020Series

Nominal Capacity Rating: 2,000 BTUH

Standard Maximum Ambient: 125°F

Unit Weight: 99lbs (120/230VAC) / 123lbs (480VAC)

* Time-delay F us es w ith the fol lo wing electrical characteristics are recommend ed. F ast -acting fus es

are not recommen de d.

*2

SCCR rating is based o n the SCCR rating for the circuit prot ec ti on device installed in the panel /

enclosure per UL50 & U L508a to protect the AC unit. Typicall y 100KA – 200KA for T im e-Delay Fuses.

1751 Hurd Dr ive ● Irving, Texas 75038 ● (972) 580-0200 ● ( 888) 580-0202 ● Fax (972) 580-0277

URL: www.thermal-edge.com ● Email: support@thermal-edge.com

SP-E NG -210- 00 0- 06 R ev 2.2 8 | P a g e

Mo de l

Oper ating

Vo ltage

Ra ng e

(V ol ts )

In ru sh

Curr en t

(Start

Up

Cu rr ent)

(A mp s)

Loading

Curr en t

(Running

Cu rr ent)

(A mp s)

SC CR

(Sho rt

Ci rc ui t

Cu rr ent

Rating)

(A mp s)

Re co mm en de d

Fu se S el ec ti on

(A mp s)

KV A Ra ti ng

(K-W at ts )

Re fr ig er an t

Ty pe

Re fr ig er an t

Am ou nt

(o un ce s)

Low/ High

Un it

Pr es su re s

(p si )

NE 03 01 26

110-120

23 .4 2

5. 15

*2

12 A mp C la ss

CC , CC MR

Ti me Delay *

0. 7

R4 22d

10 .2 5

18 8 / 30 0

NE 03 02 36

220-240

13 .6 5

3. 07

*2

7 Am p Cl ass

CC , CC MR

Ti me Delay *

0. 7

R4 22d

9. 75

18 8 / 37 5

NE 03 04 86

440-480

5. 86

1. 51

160K

3 Am p Cl ass

CC , CC MR

Ti me Delay *

0. 75

R4 22d

10 .2 5

18 8 / 30 0

Mo de l

Oper ating

Vo ltage

Ra ng e

(V ol ts )

In ru sh

Curr en t

(Start

Up

Cu rr ent)

(A mp s)

Loading

Curr en t

(Running

Cu rr ent)

(A mp s)

SC CR

(Sho rt

Ci rc ui t

Cu rr ent

Rating)

(A mp s)

Re co mm en de d

Fu se S el ec ti on

(A mp s)

KV A Ra ti ng

(K-W at ts )

Re fr ig er an t

Ty pe

Re fr ig er an t

Am ou nt

(o un ce s)

Low/ High

Un it

Pr es su re s

(p si )

NE 04 01 26

110-120

23 .4 2

5. 53

*2

12 A mp C la ss

CC , CC MR

Ti me Delay *

0. 7

R4 22d

10 .2 5

18 8 / 34 5

NE 04 02 36

220-240

13 .6 5

3. 07

*2

7 Am p Cl ass

CC , CC MR

Ti me Delay *

0. 7

R4 22d

9. 75

18 8 / 37 5

NE 04 04 86

440-480

5. 86

1. 51

160K

3 Am p Cl ass

CC , CC MR

Ti me Delay *

0. 75

R4 22d

10 .2 5

18 8 / 34 5

% of Amp ere Ra ti ng

Opening Time

110 %

15min Mi ni mu m

125 %

1hr Maximum

200 %

12sec Mi nimu m, 4 mi n Ma ximum

NE030 Series

Nominal Capacity Rating: 3,000 BTUH

Standard Maximum Ambient: 125°F

Unit Weight: 99lbs (120/230VAC) / 123lbs (480VAC)

NE040 Series

Nominal Capacity Rating: 4,000 BTUH

Standard Maximum Ambient: 125°F

Unit Weight: 99lbs (120/230VAC) / 123lbs (480VAC)

* Time-delay F us es w ith the following electrical ch aracteri st ic s are recommended. Fast -acting fus es

are not recommen de d.

*2

SCCR rating is based o n the SCCR rating for the circuit protect io n device installed in the panel /

enclosure per UL50 & U L508a to protect the AC unit. Typicall y 100KA – 200KA for T im e-Delay Fus es.

1751 Hurd Dr ive ● Irving, Texas 75038 ● (972) 580-0200 ● ( 888) 580-0202 ● Fax (972) 580-0277

URL: www.thermal-edge.com ● Email: support@thermal-edge.com

SP-E NG -210- 00 0- 06 R ev 2.2 9 | P a g e

Options

The NE020, NE030 & NE040 Series Air Conditioners may be ordered with the following options.

Review the list below for the specifications and functions of the option(s) that apply to your unit.

Built-in Heater

This unit is configurable to include a Built-in Heater to increase the temperature of your enclosure in

lower temperature conditions. The digital controller is programmed with an individual heater set point

to maintain your enclosure at your desired operating temperature.

Heater capacities are available in 500 Watt & 1000 Watt.

Default Settings:

55°F Heat Set Point

3°F Differential

At the default settings the heater turns on at 52°F and operates until temperature has reached 55°F.

Refer to Digital Temperature Controller Programming section for details on changing these

parameters.

Low Ambient

This option consists of circuitry to protect the compressor in a low ambient temperature environment.

The low ambient package is designed to provide an optimum constant low current in the compressor

motor during the non cooling state. This option provides internal heat to the compressor to protect it

from stalls and hard starts during long periods of compressor off state.

Dry Contact

This option provides an early warning capability to your enclosure to aid in the protection of your

expensive equipment. The Dry Contact is programmed with an individual dry contact set point to

monitor the enclosure temperature limit that you require. When the enclosure temperature has

exceeded the maximum limit, the Form C gold plated contact will activate to notify you that there is a

problem in achieving your cooling set point.

Default Settings:

105°F Dry Contact High Temperature Alarm Set Point

2°F Recovery Differential

3min Temperature Alarm Delay

At the default settings the Dry Contact initial conditions are normally open and/or normally closed.

When the unit is powered on and the temperature exceeds 105°F for a period longer than 3 minutes

the Dry Contact will activate. At this time the normally open contact will close and the normally closed

contact will open. This state will remain until the temperature has decreased to 103°F.

Note: The dry contact is not a power status indicator, rather a high temperature alarm alerting you that

the unit is unable to meet the cooling set point.

1751 Hurd Dr ive ● Irving, Texas 75038 ● (972) 580-0200 ● ( 888) 580-0202 ● Fax (972) 580-0277

URL: www.thermal-edge.com ● Email: support@thermal-edge.com

SP-E NG -210- 00 0- 06 R ev 2.2 10 | P a g e

Refer to Advanced Digital Temperature Controller Programming section on page 8 for details on

changing these parameters.

Celsius Programming

Celsius Programming option allows the user to control the Thermal Edge Air Conditioner in SI units.

This feature can be programmed into the digital temperature controller at time of manufacturing.

External Heat Output

This option allows you to add an external heater to be located anywhere in your enclosure. These

external heaters are ideal for focusing on individual sections of the enclosure without having a large

capacity Built-in Heater.

External Heater capacities available are 100 Watt, 150 Watt, 200 Watt, 250 Watt, 300 Watt,

400 Watt, 550 Watt, 650 Watt & 950 Watt

Default Settings:

At the default settings the heater output turns on at 52°F and operates until the temperature has

reached 55°F. Refer to Advanced Digital Temperature Controller Programming section on this manual

for details on changing these parameters.

Special Programming

All Thermal Edge Air Conditioners have a Special Programming option for selecting unique pre in

programmed settings for special requirements. Although most parameters are accessible in our digital

controller, this option allows you to receive a unit preset to your requirements without the need to

manually configure the unit. Refer to Advanced Digital Temperature Controller Programming section

for details on all default settings.

High Ambient

Most of our air conditioners have capabilities for high ambient application upgrades from our Standard

Maximum Ambient temperature of 125°F. With this option we can optimize the Air Conditioner during

manufacturing to achieve improved performance at high ambient conditions.

55°F Heat Set Point

3°F Differential

1751 Hurd Dr ive ● Irving, Texas 75038 ● (972) 580-0200 ● ( 888) 580-0202 ● Fax (972) 580-0277

URL: www.thermal-edge.com ● Email: support@thermal-edge.com

SP-E NG -210- 00 0- 06 R ev 2.2 11 | P a g e

Open Door Kill Switch

This option provides you with an adjustable and mountable safety switch for your electronics

enclosure. This switch will disable power to the air conditioner when your electronics enclosure door is

open allowing you to work on your enclosure without the risk of unintentionally powering the unit.

Adjustable Temperature Probe

The adjustable temperature probe provides you with a 12’ temperature probe that can be installed

anywhere in your enclosure. This allows you to have the flexibility to monitor and maintain the

temperature at any specific location of your enclosure.

Ethernet/IP Controller Output

This option provides the ability to communicate with the Thermal Edge Air Conditioner controller via

the Ethernet/IP protocol. You can monitor and control all settings from a remote location with a PLC.

Full specifications will be provided with this option. For full details refer to the Ethernet/IP Option

Specifications included with the Air Conditioner.

Outdoor Option

When having our Programmable Digital Controller on the face of our Air Conditioner does not fit your

application, Thermal Edge offers the OD Package (i.e. Outdoor Option). This option moves the

controller into your enclosure using a 10’ cable along with a universal, 16 gauge powder coated steel

mounting bracket. The Air Conditioner will have no openings on the face of the unit. Below is partial

schematic showing the OD option wiring connections to the digital controller.

1751 Hurd Dr ive ● Irving, Texas 75038 ● (972) 580-0200 ● ( 888) 580-0202 ● Fax (972) 580-0277

URL: www.thermal-edge.com ● Email: support@thermal-edge.com

SP-E NG -210- 00 0- 06 R ev 2.2 12 | P a g e

System Faults

If any of the critical control parameters exceed limits, the compressor is turned off and an alarm

condition is indicated on the front panel.

There are three main conditions that can shut the AC compressor down:

The condenser high temperature alarm

The evaporator coil alarm

The compressor thermal overload

In the event that the condenser coil overheats, a condenser high temperature alarm, HA2, will flash on

the display of the digital temperature controller and the compressor will turn off after a 3 minute time

delay.

In the case that the evaporator coil ices up or there is a leak, an evaporator coil alarm, CA, will flash

on the display of the digital temperature controller and the compressor will turn off after a 2 minute

time delay.

A thermal overload protects the compressor against faults. In the event that the snowflake status LED

is not flashing on the display and the compressor is not running, an internal fault may have occurred

on the unit. Refer to the Troubleshooting Guide in this manual.

Digital Temperature Controller Programming

For the end user this section will provide all the necessary information to view and change all functions

and parameters available to you.

HOW TO SEE THE SETPOINT……..

1. Press and immediately release the SET key. The display will show the setpoint value.

2. Press and immediately release the SET key or wait for 15 seconds to display the enclosure temperature

again.

HOW TO CHANGE THE SETPOINT……..

1. Press the SET key for more than 2 seconds to change the setpoint value.

2. The value of the setpoint will be displayed and the “F” LED starts blinking.

3. To change the SET value, press the UP or DOWN arrow key within 15 seconds.

4. To store the new setpoint value, press the SET key again or wait 15 seconds.

Note: The set value is stored even when the procedure is exited by waiting for the time-out to expire.

1751 Hurd Dr ive ● Irving, Texas 75038 ● (972) 580-0200 ● ( 888) 580-0202 ● Fax (972) 580-0277

URL: www.thermal-edge.com ● Email: support@thermal-edge.com

SP-E NG -210- 00 0- 06 R ev 2.2 13 | P a g e

Fu nc tion

Oper ation

Pa ra me te r

Me nu

Location

Fa ct or y

De fault

Oper ating

Ra ng e

Un it

Co oling Setpoint

Se t De si red Co ol ing

Te mp erature

SET

Main

90

70 - 95

°F

Co oling

Differential

Co ntrol Hysteresis

Hy

Hi dden

Menu 1

5

1 - 45

°F

Co mp ressor

Pr otection

An ti s hort -c yc le d el ay

AC

Hi dden

Menu 2

5

0 - 50

mi n

Pr obed Displayed

Se lect D isplay Probe

P1 – E nclo sure Temperature

P2 – C ondenser Temperature

Lod

Hi dden

Menu 2

P1

P1 / P 2

N/ A

Au xiliary

Se tpoint

Se tpoint for D ry C on tact *1

/ Heater

SAA

Hi dden

Menu 2

105 / 55

-67 - 302

°F

HOW TO ACCESS HIDDEN MENU 1……..

1. Enter the Programming mode by pressing the SET + DOWN arrow keys simultaneously for 3 seconds.

The “F” LED starts blinking.

2. Select the required parameter by pressing the UP or DOWN arrow key. Press the SET key to display

its value.

3. Use the UP or DOWN arrow key to change its value.

4. Press SET to store the new value and move to the following parameter.

Note: The set value is stored even when the procedure is exited by waiting for the time-out to expire.

To exit: Press SET + UP arrow keys or wait 15 seconds without pressing a key.

HOW TO ACCESS HIDDEN MENU 2……..

Note: The set value is stored even when the procedure is exited by waiting for the time-out to expire.

1. Enter the Programming mode by pressing the SET + DOWN arrow keys simultaneously for 3 seconds.

The “F” LED starts blinking.

2. Release the keys, then push the SET + DOWN arrows keys simultaneously, again for more than 7

seconds.

The Pr2 label will be displayed immediately followed by the HY parameter.

3. Select the required parameter by pressing the UP or DOWN arrow key. Press the SET key to display

its value.

4. Use the UP or DOWN arrow key to change its value.

5. Press SET to store the new value and move to the following parameter.

To exit: Press SET + UP arrow keys or wait 15 seconds without pressing a key.

HOW TO LOCK THE KEYPAD……..

1. Press and hold the UP and DOWN arrow keys simultaneously for more than 3 seconds.

2. The POF message will be displayed and the keyboard will be locked.

At this point, it will be possible only to see the setpoint or the MAX or MIN temperature stored.

3. If a key is pressed for more than 3 seconds the POF message will be displayed.

HOW TO UNLOCK THE KEYPAD……..

1. Press and hold the UP + DOWN arrow keys simultaneously for more than 3 seconds until the Pon

Functions and Parameters

message is displayed.

1751 Hurd Dr ive ● Irving, Texas 75038 ● (972) 580-0200 ● ( 888) 580-0202 ● Fax (972) 580-0277

URL: www.thermal-edge.com ● Email: support@thermal-edge.com

SP-E NG -210- 00 0- 06 R ev 2.2 14 | P a g e

Fu nc tion

Oper ation

Pa ra me te r

Me nu

Location

Fa ct or y

De fault

Oper ating

Ra ng e

Un it

Au xiliary

Differ ential

He ater or Dry Contact

Hy steresis *1

Sh y

Hi dden

Menu 2

3

1 - 45

°F

Maximum

Te mp erature

Al arm

Al erts with “HA” when

ma xi mu m temperature has

been exceeded

AL U

Hi dden

Menu 2

105

45 - 302

°F

Minimum

Te mp erature

Al arm

Al erts with “LA” when

mi nimum temp erature has

been exceeded

AL L

Hi dden

Menu 2

45

-67 - 105

°F

Me ss ag e

Cause

Outputs

“P 1”

En clos ure Probe Failure

St art and stop o f the compressor after 15 minute

intervals *2

“P 2”

Co ndenser Probe Failure

No Output *2

“H A”

Maximum Temperature Alarm: P1 > 1 05 °F for 3

minutes (after initial 30 min. start up delay)

No Output *2

“L A”

Minimum Te mp erature Alarm: P 1 < 45 °F for 3

minutes (after initial 30 min. start up delay)

No Output *2

“H A2 ”

Co ndenser High Temperature Alarm: P2 > 145 °F for

3 minutes

Co mp ressor Off *2

“L A2 ”

Co ndenser Low Temperature Alarm: P2 < 50 °F for 3

minutes

No Output *2

“C A”

Ev aporator Coil Alarm: Low Pressure for 2 m inutes

Co mp ressor Off *2

“n oP ”

In valid Probe Selected: Low Evaporator Coil

No Output, Display Only

*1No te: Wh en b oth He at er a nd D ry C on ta ct o ptions are included , thes e pa rameters o nl y co nt rol He at er

Alarms Signals

Se tt ings. D ry Contact is controlled by ALU.

*2No te: Wh en b oth He at er a nd D ry C on ta ct o pt io ns a re inc lu ded, D ry Con tact (Alarm Contact) Relay is

acti vated.

ALARM RECOVERY……..

If the compressor is turned off due to an alarm, it will be able to restart after the AC anti short-cycle time delay.

(Parameter AC = 5minutes)

Probe alarm P1 is cleared with no time delay after the fault is cleared.

Probe alarm P2 starts and stops with no time delay.

Temperature alarm HA automatically clears as soon as the temperature returns to below 105°F (the ALU setpoint) -2°F = 103°F.

Temperature alarm LA automatically clears as soon as the temperature returns to above 55°F (the ALL setpoint) +2°F = 47°F.

Temperature alarm HA2 automatically clears as soon as the condenser coils temperature returns to below 135°F.

Temperature alarm LA2 automatically clears as soon as the condenser coils temperature returns to above 60°F.

Temperature alarm CA automatically clears as soon as the pressure returns to normal.

1751 Hurd Dr ive ● Irving, Texas 75038 ● (972) 580-0200 ● ( 888) 580-0202 ● Fax (972) 580-0277

URL: www.thermal-edge.com ● Email: support@thermal-edge.com

SP-E NG -210- 00 0- 06 R ev 2.2 15 | P a g e

Preventative Maintenance

Air conditioners require regular cleaning of the condenser air inlet filter. Wash filter often if washable

using proper cleaning compound and back flushing the dirt out, or replace if not washable whenever it

appears physically dirty. Restriction to the flow of air over the condenser coil will degrade the

performance of the equipment, cause it to overheat, reduce cooling and can damage the compressor.

The overload switch in the compressor may cause the compressor to cycle if the condensing coil

pressure becomes too high due to air restriction. A further safety feature is the refrigerant high

pressure cut off switch which will stop the compressor if the condensing pressure becomes too high

due restricted condenser air flow or some other cause.

Restricted air flow due to neglecting a dirty filter will cause unit to repeatedly turn off and then turn

back on after it cools off. An operation in this safety cycling mode will eventually damage the equipment and

void the warranty.

Refer to Field Serviceable Parts section in this manual for details on parts that can be changed to help

increase the uninterruptable life of the Air Conditioner.

Air Filter Service

Remove the air conditioner filter and wash if washable or replace if not washable. Dry thoroughly

before replacing. THERMAL EDGE Air Filter Treatment Spray in aerosol cans or spray bottle is

recommended to enhance air filter efficiency. Replacement filters are readily available from THERMAL

EDGE Customer Service. DO NOT operate the air conditioner without the air filter. Such operation will

allow the condenser coil to become dirty and loose efficiency, causing overheating and diminished

cooling capacity. Dirty condensing coils must be back-flush cleaned using proper commercial coil

cleaning compounds and thorough back-flush rinsing. Refer to directions on the cleaning compounds

selected. Acid wash is not recommended as it reduces the life of the coil.

Note: Do not use solvents to clean the programmable thermostat. Wipe with mild soap and water.

Condenser and Evaporator Fans

Thermal Edge air conditioners use high efficiency, long life, sealed ball bearing fans engineered for

optimum performance that require no maintenance. Keep fan blades clean for optimal performance.

Fans are removable and attached by plug in connections.

Compressor

Thermal Edge uses hermetically factory sealed compressors that are quiet, low vibration and are

maintenance free. Thermal overload devices are installed to protect the compressor from damage

due to overheat and short cycle faults. If the compressor thermal overload fails, it is recommended to

return the unit to Thermal Edge customer service for proper replacement. Note that the rotary

compressor runs with compressed refrigerant gas on the outer case and therefore is hot to the touch.

Loss of Refrigerant

Thermal Edge air conditioners are meticulously leak and run tested after assembly. If a leak in the

system should develop due to shipping damage or mechanical vibration, the leak must be detected,

repaired and the refrigerant charge restored to the system by a qualified refrigeration professional.

1751 Hurd Dr ive ● Irving, Texas 75038 ● (972) 580-0200 ● ( 888) 580-0202 ● Fax (972) 580-0277

URL: www.thermal-edge.com ● Email: support@thermal-edge.com

SP-E NG -210- 00 0- 06 R ev 2.2 16 | P a g e

Pa rt Des cr ip tion

Th er ma l Ed ge P ar t #

Digita l Controller

52110-1 f or 120VAC/ 48 0V AC

52112-1 f or 230VAC

52111-1 f or 120VAC/ 48 0V AC w / bo th D ry C a nd Hea te r

52111-2 f or 230VAC w/ both Dry C and Heater

Low Pressure S witch

38151-1

Hi gh P ressure Switch

38176-1

Co ndenser Fan Cut- In P re ss ur e Sw it ch

38001-1

Te mp erature Probe

52126-1

Co ndenser Fan Relay

55761-1 f or 120VAC/ 48 0V AC

55762-1 f or 230VAC

Th ermal Expansion Value TXV

NE 02 0 12 0V AC O nly = 32006- 1, N E0 20 2 30 VA C/ NE 03 0/ NE 04 0 = 32 00 2-1

Co mp ressor

NE 02 0 = 31520-1 f or 1 20 VA C/ 48 0V AC , 31570-1 for 2 30 VA C

NE 03 0/ NE 04 0 = 31525-1 f or 120 VA C/480V AC, 31570-1 for 2 30 VA C

Co mp ressor Thermal Overload

NE 02 0 = 31520- 2 for 12 0V AC /4 80 VA C, 3 15 70 -2 for 2 30 VA C

NE 03 0/ NE 04 0 = 31525- 2 fo r 120V AC /4 80 VA C, 3 15 70 -2 for 2 30 VA C

Ga sket Installation Kit

71401-N 23 4

Ev aporator Fan

41005-1 -1 f or 120VAC/ 48 0V AC

41005-2 -1 f or 230VAC

Co ndenser Fan

41025-1 -1 f or 120VAC/ 48 0V AC

41025-2 -1 f or 230VAC

Fi lt er Media

44 20 2 (12 pack)

Ca pa citor

54001-1

Field Serviceable Parts

Thermal Edge carefully designs and selects components with the maximum life expectancy. Due to

OEM manufacturing tolerances, poor unit maintenance or extreme operating conditions, components

may fail before their maximum life expectancy. The table below lists parts that are serviceable in the

field by an Air Conditioner Technician.

Safety Information

Unit is carefully designed to restrict access to movable parts to minimize any potential injury. This Air

Conditioner has been tested by UL to meet the safety requirements of the UL484 specification. When

working with the Thermal Edge Air Conditioner always makes sure shroud is installed. Verify proper

voltage is applied to unit as specified in the UL label of the Air Conditioner. In the event of a field

service repair, power down unit using the power on/off switch and disconnect power from unit. It is

always recommended to use a licensed Air Conditioner Technician for internal diagnostics and repairs

issues.

Contact Thermal Edge technical support for further details on opening the unit and troubleshooting

tips.

1751 Hurd Dr ive ● Irving, Texas 75038 ● (972) 580-0200 ● ( 888) 580-0202 ● Fax (972) 580-0277

URL: www.thermal-edge.com ● Email: support@thermal-edge.com

SP-E NG -210- 00 0- 06 R ev 2.2 17 | P a g e

Un it Will Not Run

Is Uni t

Co nnec ted?

YES

NO

Pl ease Con nect

Po wer

Ve ri fy Power O n/ Of f

Sw itch is on p osition

ON

OFF

To gg le S witch

then Retry

Ve ri fy input power

me ets voltage

requ irements as

sh own in the UL label

YES

If probl em is still pr esent contac t

technical support

Un it Overheats /

In su ff icient C oo li ng

Is F il ter

Cl ean?

NO

Cl ean / Replace

Fi lt er

YES

Ar e Condenser &

Ev aporator Fans ON?

NO

Ch eck fo r Faulty

Fa n & replace

YES

Is C ondenser

Co il d ir ty?

YES

Cl ean Co il

NO

NO

Is E vaporator Coil

Fr ozen / Iced?

YES

Po tentia l Bad

Ev aporator Fan,

chec k for faulty

fan.

NO

Co ntac t Qualified Refrigeration Service

Te chni cian to ch eck Refrigerant Pressure. Un it

ma y have a refrigeration leak. If problem is not

resolved contact technical s up po rt.

Troubleshooting Guide

The following guide provides a flow chart to identify a problem, determine the root cause and identify

the action needed to correct an issue.

1751 Hurd Dr ive ● Irving, Texas 75038 ● (972) 580-0200 ● ( 888) 580-0202 ● Fax (972) 580-0277

URL: www.thermal-edge.com ● Email: support@thermal-edge.com

SP-E NG -210- 00 0- 06 R ev 2.2 18 | P a g e

Un it Not Cooling

Is C om pressor

On?

YES

NO

Ch eck

Se tpoint. Is

Se tpoint

below

am bi ent?

YES

NO

Is snowfla ke

LE D li t on

contro ller?

Se t Se tpoint between

70 to 95 deg F

YES

NO

Is evaporator

Fa n on?

YES

NO

Is there voltage to

compressor? Use

3

Ch eck fo r faul ty

3

Measure Temperature at Evap orator

& Ve ri fy Heat Load Requirements. Is

un it capacity adequate for internal

head load? Possible low refrigeran t.

Is compr essor

thermal overload

open? Use ohm

me ter.3

Ch eck fo r error code

C A, LA ,H A, LA 2, HA 2,

P1 , or P 2

YES

NO

Ch eck contactor

circui t. D oes it have

power?3

NO

YES

Refer to Alarm Signals

in D ig ital Temperature

Co ntroller

Pr og ramm ing Section

Co ntac t Customer

Su ppor t

NO

YES

Ve ri fy con tact coi l is

being ac ti vated. Che ck

connectivity3, if i ss ue

pers ists c om ponent

replacement may be

needed.

Co ntac t

Cu stomer

Su ppor t

YES

NO

YES

Co ntac t Customer

Su ppor t

Replace Thermal

Overload.

*3N ot e: R ef er t o El ec tr ic al S ch em at ic s fo r fu rt her diagno st ics.

URL: www.thermal-edge.com ● Email: support@thermal-edge.com

1751 Hurd Dr ive ● Irving, Texas 75038 ● (972) 580-0200 ● ( 888) 580-0202 ● Fax (972) 580-0277

SP-E NG -210- 00 0- 06 R ev 2.2 19 | P a g e

Fl as hing Err or

Codes

Si ng le or

Multiple

Co des?

2 +

1

Refer to Alarm Signals

in D ig ital Temperature

Co ntroller

Pr og ramm ing Section

P1 / P 2

combination

flas hing?

YES

NO

Po tentia l bad

connection. Check

gr een connecto r

behind c ontroller.

CA

YES

NO

Ch eck Low Pressure

Sw itch Connections

an d Verify Pressure

sw itch i s clos ed. Use

me ter.

3

P1 o r

P2

NO

YES

Ch eck probe

connections, potential

faul ty probe.

LA , LA 2, H A,

HA2

YES

Refer to Alarm Signals

in D ig ital Temperature

Co ntroller

Pr og ramm in g Se ction

Fu se / C ircuit

Pr ot ec tion

Nu isance Trip

Is fus e open ing as

soon as un it turns

on?

NO

YES

Ch eck incoming power

su pply and connections

for po tentia l sh or t circui t

Does fus e open

wh en compressor

star ts?

YES

NO

Ch eck electrical specification.

Ve ri fy proper recommended fuse

ha s been selected.

Ch eck compressor, if excess heat present compressor may

be faulty. Contact Technical Support.

*3N ot e: R ef er t o El ec tr ic al S ch em at ic s fo r fu rt her diagnostics.

1751 Hurd Dr ive ● Irving, Texas 75038 ● (972) 580-0200 ● ( 888) 580-0202 ● Fax (972) 580-0277

URL: www.thermal-edge.com ● Email: support@thermal-edge.com

SP-E NG -210- 00 0- 06 R ev 2.2 20 | P a g e

Wa te r ov er fl ow /

ex ce ss iv e

Ch eck drain, is it

plugged?

YES

NO

Cl ean condensate pan and

drain; add 1 tbsp bleach to

up per pan monthly to kill

Is A ir Condi ti oner sealed

ag ai nst enclosure

properly, tightly sealed

an d do or closed?

YES

Co ntac t Customer Service

NO

En sure air t ig ht

seal between air

cond it ioner and

enclosure. Make

su re door is

clos ed.

Physical Dimensions

1751 Hurd Dr ive ● Irving, Texas 75038 ● (972) 580-0200 ● ( 888) 580-0202 ● Fax (972) 580-0277

URL: www.thermal-edge.com ● Email: support@thermal-edge.com

SP-E NG -210- 00 0- 06 R ev 2.2 21 | P a g e

THIS PAGE IS INTENTIONALLY LEFT BLANK

1751 Hurd Dr ive ● Irving, Texas 75038 ● (972) 580-0200 ● ( 888) 580-0202 ● Fax (972) 580-0277

URL: www.thermal-edge.com ● Email: support@thermal-edge.com

SP-E NG -210- 00 0- 06 R ev 2.2 22 | P a g e

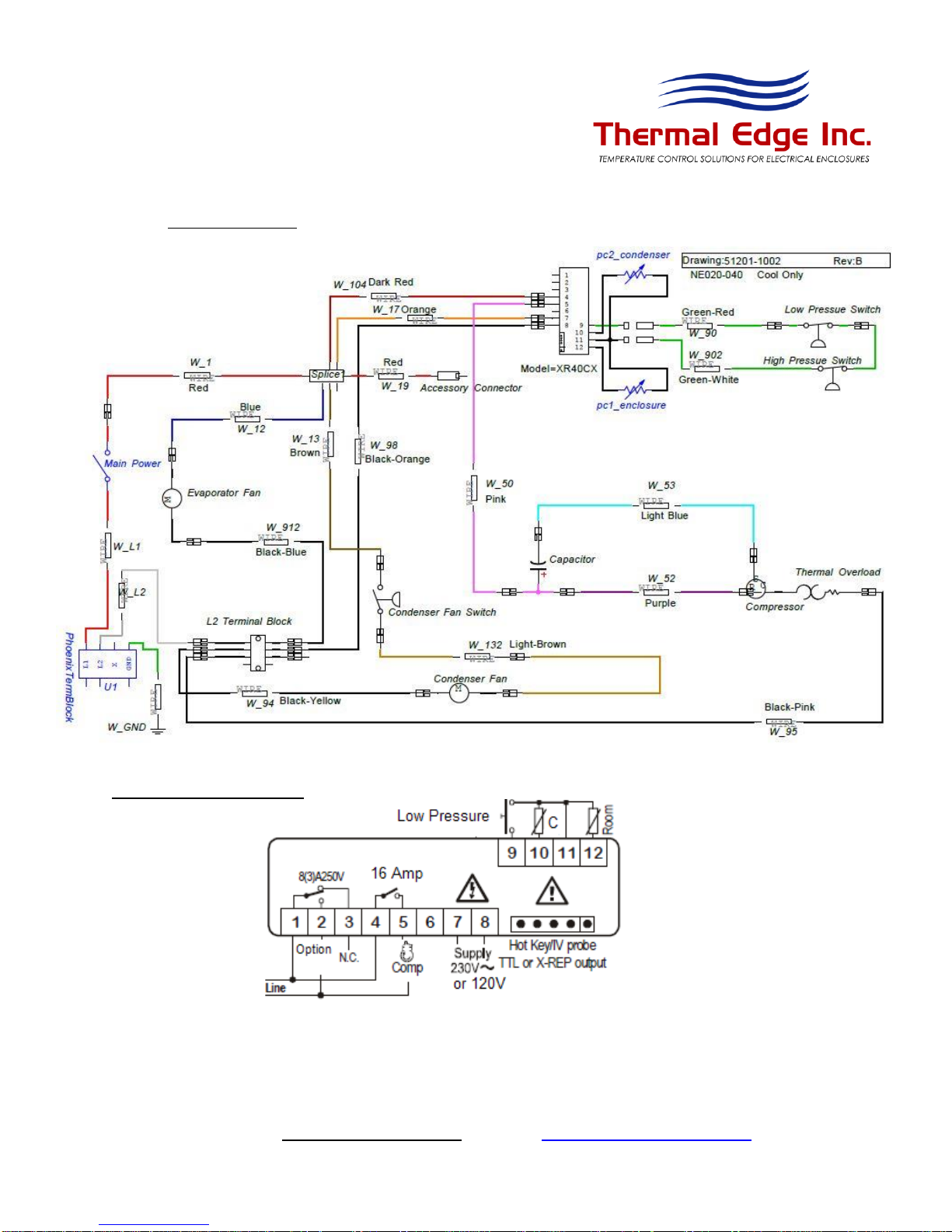

Electrical Schematics

System Schematic

Digital Controller Schematic

Note: Schematics apply to all voltages; optional accessories wiring not provided in this document. If you

require electrical schematic with options contact our technical support and provide your model number.

1751 Hurd Dr ive ● Irving, Texas 75038 ● (972) 580-0200 ● ( 888) 580-0202 ● Fax (972) 580-0277

URL: www.thermal-edge.com ● Email: support@thermal-edge.com

SP-E NG -210- 00 0- 06 R ev 2.2 23 | P a g e

Warranty Information

Thermal Edge products are warranted to be free of defects in workmanship, materials and components.

The warranty period applies from date of shipment for one year.

The above warranty applies when the equipment is operated under the following conditions:

Ambient temperature not in excess of performance rating in normal atmosphere or as stated on

product nameplate

Voltage variation no greater than ± 10% from nameplate rating

Frequency variation no greater than ± 3Hz from nameplate rating

Maximum cooling load no higher than air conditioner nameplate rating

Waiting five minutes before restarting air conditioner after intentional or accidental shutoff

Compliance to all other installation, maintenance and operating instructions, as supplied

Thermal Edge cannot assume responsibility for misapplication of its products or the erroneous selection of

an inappropriate product by a non-authorized Thermal Edge representative. Our applications engineers

will gladly assist in the selection of the proper product provided all required details of the application are

furnished.

Thermal Edge assumes no liability beyond the repair or replacement of its own product. This Warranty

does not cover:

Labor or reimbursement of labor for evaluation, removal, installation, repair, or cost of any

warranted part, except at the Thermal Edge factory in Dallas, Texas

Use of equipment for other than its designed purpose or operating conditions

Operation in harsh, oily, corrosive or other abnormal environmental conditions, without the proper

filtration, sealing, protective coatings and/or weather protection

Damage to hermetic system resulting from continuous operation with dirty or clogged air filters or

improper or negligent maintenance

Use of refrigerant other than designated

Customer modification or abuse

Shipping damage or other accident

Repair or service by unauthorized personnel.

Cracked or broken hermetic tubing or brazed joints caused by shipping damage or mishandling are not

covered under the Warranty. Claims for shipping damage are the responsibility of the Consignee. Timely

claims must be filed with the freight carrier.

The purchaser assumes the responsibility of grounding the unit and installing it in accordance with local

electrical and safety codes, as well as the 2008 National Electric Code (NEC) and OSHA.

THIS WARRANTY CONSTITUTES THE ENTIRE WARRANTY WITH RESPECT TO THE PRODUCT AND

IS IN LIEU OF ALL OTHERS, EXPRESSED OR IMPLIED, INCLUDING ANY WARRANTY OF

MERCHANTABILITY AND WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE AND IN NO

EVENT IS THERMAL EDGE RESPONSIBLE FOR ANY CONSEQUENTIAL DAMAGES OF ANY NATURE

WHATSOEVER.

1751 Hurd Dr ive ● Irving, Texas 75038 ● (972) 580-0200 ● ( 888) 580-0202 ● Fax (972) 580-0277

URL: www.thermal-edge.com ● Email: support@thermal-edge.com

SP-E NG -210- 00 0- 06 R ev 2.2 24 | P a g e

Return Material Authorization (RMA) Procedure

All returns require a Return Material Authorization (RMA) number for warranty or non-warranty repair, rotation

of stock, damage or any other reason.

IMPORTANT

Returns without an RMA number will be refused and returned. Improper packaging may void

warranty. Air Conditioners shipped laying down will void the warranty. Collect shipments will be

refused. Returns received after 60days will be refused and RMA will be canceled.

Please be ready to provide:

Purchase Order Number & Date

Product Description & Reason for Request

Model Number & Serial Number

Customer name and contact info (email, phone number and address)

Shipping method

Pack unit in a suitable packing for shipment, preferably the original packaging if available.

If suitable packing is not available, arrange for packaging to be shipped to you.

Air Conditioners must be returned in an upright position properly secured to a pallet.

Tip unit to empty water from the evaporator and boil off pans.

Clearly mark the RMA number on the box.

Customer will pay all freight charges.

Out of Warranty Repair

If your Thermal Edge air conditioner is out of warranty and requires repair, simply call Thermal Edge Customer

Service at (888)-580-0202 for an RMA number. Customer Service will help you determine what repairs or

parts are needed and, if possible, an estimate of the cost.

After the unit is received and diagnosed, you will receive a ship estimate on the work and parts needed. The

repairs and test process may uncover other issues for which you will be informed and given quotes for the

work needed.

1751 Hurd Dr ive ● Irving, Texas 75038 ● (972) 580-0200 ● ( 888) 580-0202 ● Fax (972) 580-0277

URL: www.thermal-edge.com ● Email: support@thermal-edge.com

SP-E NG -210- 00 0- 06 R ev 2.2 25 | P a g e

Assembly channels

1. Line1

2. Line2

3. Empty

4. Ground

TOP

FRONT

Connecting Sequence: LEFT TO RIGHT

1

2

4

Appendix A

Phoenix Contact Power Connector Instructions

Scope: Instructions for connecting power wires to air conditioners equipped with a “Phoenix Contact” power

connector.

1 - Remove cover from chassis using T25 Torx bit.

2 - Push both orange tabs in to release male

connector and pull out for wire connection.

3 - The top of the male connector is shown with the

formed assembly channels facing UP.

4 - Starting from the left, connect the wires by

inserting them into the lower receptacles located

on the front of connector in the following order.

NOTE: If using stranded wires, it may be difficult to

insert into the receptacles without releasing the

spring tension as described below in the removal

instructions. The wires can be tinned or pin

terminals (as shown above) or pin ferrules may be

attached to stranded wires to ease insertion into

the receptacles.

5 – Firmly insert the male connector into chassis

receptacle. A light click should sound when

secured.

6 – If wires need to be removed from the male

connector, insert a small screwdriver or pick into

the hole directly above each wire and push to

release it.

1751 Hurd Dr ive ● Irving, Texas 75038 ● (972) 580-0200 ● ( 888) 580-0202 ● Fax (972) 580-0277

URL: www.thermal-edge.com ● Email: support@thermal-edge.com

SP-E NG -210- 00 0- 06 R ev 2.2 26 | P a g e

Loading...

Loading...