Page 1

C-35C

®

CUTSKILL

PLASMA CUTTING

SYSTEM

Service Manual

Art # A-09400

Rev. AB Date: November 17, 2009 Manual 0-4745

Operating Features:

PLASMA

Page 2

Page 3

WARNINGS

Read and understand this entire Manual and your employer’s safety practices before installing,

operating, or servicing the equipment.

While the information contained in this Manual represents the Manufacturer's best judgement,

the Manufacturer assumes no liability for its use.

Plasma Cutting Power Supply

CutSkill

®

PCH-42

Service Manual Number 0-4745

Covered under U.S. Patents.

Published by:

Thermadyne Corporation

82 Benning Street

West Lebanon, New Hampshire, USA 03784

(603) 298-5711

www.thermal-dynamics.com

©Copyright 2006, 2007, 2008, 2009 by

Thermal Dynamics Corporation

All rights reserved.

Reproduction of this work, in whole or in part, without written permission of the publisher is prohibited.

The publisher does not assume and hereby disclaims any liability to any party for any loss or damage

caused by any error or omission in this Manual, whether such error results from negligence, accident, or

any other cause.

Printed in the United States of America

Publication Date: November

17, 2009

Record the following information for Warranty purposes:

Where Purchased:____________________________________

Purchase Date:_______________________________________

Power Supply Serial #:________________________________

Torch Serial #:________________________________________

Page 4

Page 5

TABLE OF CONTENTS

SECTION 1:

GENERAL INFORMATION ................................................................................................ 1-1

1.01 Notes, Cautions and Warnings ...................................................................... 1-1

1.02 Important Safety Precautions ....................................................................... 1-1

1.03 Publications .................................................................................................. 1-2

1.04 Declaration of Conformity ............................................................................. 1-4

1.05 Statement of Warranty .................................................................................. 1-5

SECTION 2.0

INTRODUCTION .............................................................................................................. 2-1

2.01 INTRODUCTION .......................................................................................... 2-1

2.02 GENERAL SPECIFICATION ......................................................................... 2-1

2.03 Features ....................................................................................................... 2-1

2.04 Torch Specifications ..................................................................................... 2-2

2.05 System Contents .......................................................................................... 2-2

2.06 Transporting Methods ................................................................................... 2-2

SECTION 3.0

INSTALLATION ................................................................................................................. 3-1

3.01 Site Selection ............................................................................................... 3-1

3.02 Electrical Input Connections ......................................................................... 3-1

3.03 Torch ............................................................................................................ 3-1

SECTION 4.0

OPERATION ...................................................................................................................... 4-1

4.01 Front Control Panel ....................................................................................... 4-1

4.02 Preparations For Operating ........................................................................... 4-2

SECTION 5: MAINTENANCE .................................................................................................... 5-1

5.01 General Maintenance .................................................................................... 5-1

SECTION 6:

TROUBLESHOOTING ....................................................................................................... 6-1

6.01 Normal Setup and Operation ........................................................................ 6-1

6.02 Basic Trouble Shooting Guide ....................................................................... 6-2

6.03 Control PCB Indicators ................................................................................. 6-3

6.04 Open Circuit Voltage Check .......................................................................... 6-4

6.05 Detailed Fault Finding / Error Indicators ........................................................ 6-5

6.06 Torch Tests ................................................................................................... 6-9

SECTION 7:

PARTS LIST ...................................................................................................................... 7-1

7.01 Parts List Power Supply ................................................................................ 7-2

7.02 Replacement Hand Torch Parts With Ergonomic Handle ................................ 7-6

Page 6

TABLE OF CONTENTS (Con't)

Appendix 1: Operating Sequence, Block Diagram ..................................................................... A-1

Appendix 2: Torch Connection ................................................................................................... A-2

Appendix 3: Microchip Pin-Out .................................................................................................. A-3

Appendix 4: System Schematic 230V CE ................................................................................. A-4

Appendix 5: System Schematic 230V ....................................................................................... A-6

GLOBAL CUSTOMER SERVICE CONTACT INFORMATION .............................. Inside Rear Cover

Page 7

SECTION 1:

!

GENERAL INFORMATION

1.01 Notes, Cautions and Warnings

Throughout this manual, notes, cautions, and warnings are used to

highlight important information. These highlights are categorized as

follows:

NOTE

An operation, procedure, or background information

which requires additional emphasis or is helpful in efficient operation of the system.

CAUTION

A procedure which, if not properly followed, may cause

damage to the equipment.

WARNING

A procedure which, if not properly followed, may cause

injury to the operator or others in the operating area.

1.02 Important Safety Precautions

• Use an air-supplied respirator if ventilation is not adequate to

remove all fumes and gases.

• The kinds of fumes and gases from the plasma arc depend on the

kind of metal being used, coatings on the metal, and the different

processes. You must be very careful when cutting or welding

any metals which may contain one or more of the following:

Antimony Chromium Mercury

Arsenic Cobalt Nickel

Barium Copper Selenium

Beryllium Lead Silver

Cadmium Manganese Vanadium

• Always read the Material Safety Data Sheets (MSDS) that should

be supplied with the material you are using. These MSDSs will

give you the information regarding the kind and amount of fumes

and gases that may be danger

•For information on how to test for fumes and gases in your

workplace, refer to item 1 in Subsection 1.03, Publications in

this manual.

• Use special equipment, such as water or down draft cutting

tables, to capture fumes and gases.

• Do not use the plasma torch in an area where combustible or

explosive gases or materials are located.

• Phosgene, a toxic gas, is generated from the vapors of chlorinated solvents and cleansers. Remove all sources of these vapors.

• This product, when used for welding or cutting, produces fumes

or gases which contain chemicals known to the State of California to cause birth defects and, in some cases, cancer. (California

Health & Safety Code Sec. 25249.5 et seq.)

ous to your health.

WARNINGS

OPERATION AND MAINTENANCE OF PLASMA ARC

EQUIPMENT CAN BE DANGEROUS AND HAZARDOUS

TO YOUR HEALTH.

Plasma arc cutting produces intense electric and magnetic emissions that may interfere with the proper function of cardiac pacemakers, hearing aids, or other electronic health equipment. Persons who work near plasma

arc cutting applications should consult their medical health

professional and the manufacturer of the health equipment to determine whether a hazard exists.

To prevent possible injury, read, understand and follow

all warnings, safety precautions and instructions before

using the equipment. Call 1-603-298-5711 or your local

distributor if you have any questions.

GASES AND FUMES

Gases and fumes produced during the plasma cutting process can be

dangerous and hazardous to your health.

• Keep all fumes and gases from the breathing area. Keep your

head out of the welding fume plume.

ELECTRIC SHOCK

Electric Shock can injure or kill. The plasma arc process uses and

produces high voltage electrical energy. This electric energy can cause

severe or fatal shock to the operator or others in the workplace.

• Never touch any parts that are electrically “live” or “hot.”

• Wear dry gloves and clothing. Insulate yourself from the work

piece or other parts of the welding circuit.

• Repair or replace all worn or damaged parts.

• Extra care must be taken when the workplace is moist or damp.

• Install and maintain equipment according to NEC code, refer to

item 9 in Subsection 1.03, Publications.

• Disconnect power

pairs.

• Read and follow all the instructions in the Operating Manual.

FIRE AND EXPLOSION

Fire and explosion can be caused by hot slag, sparks, or the plasma arc.

• Be sure there is no combustible or flammable material in the

workplace. Any material that cannot be removed must be protected.

• Ventilate all flammable or explosive vapors from the workplace.

• Do not cut or weld on containers that may have held combustibles.

source before performing any service or re-

Manual 0-4745 1-1 GENERAL INFORMATION

Page 8

•Provide a fire watch when working in an area where fire hazards

may exist.

• Hydrogen gas may be formed and trapped under aluminum

workpieces when they are cut underwater or while using a water

table. DO NOT cut aluminum alloys underwater or on a water

table unless the hydrogen gas can be eliminated or dissipated.

Trapped hydrogen gas that is ignited will cause an explosion.

1.03 Publications

Refer to the following standards or their latest revisions for more infor-

mation:

1. OSHA, SAFETY AND HEALTH STANDARDS, 29CFR 1910,

obtainable from the Superintendent of Documents, U.S.

Government Printing Office, Washington, D.C. 20402

NOISE

Noise can cause permanent hearing loss. Plasma arc processes can

cause noise levels to exceed safe limits. You must protect your ears

from loud noise to prevent permanent loss of hearing.

•To protect your hearing from loud noise, wear protective ear

plugs and/or ear muffs. Protect others in the workplace.

• Noise levels should be measured to be sure the decibels (sound)

do not exceed safe levels.

•For information on how to test for noise, see item 1 in Subsec-

tion 1.03, Publications, in this manual.

PLASMA ARC RAYS

Plasma Arc Rays can injure your eyes and burn your skin. The plasma

arc process produces very bright ultra violet and infra red light. These

arc rays will damage your eyes and burn your skin if you are not

properly protected.

•To protect your eyes, always wear a welding helmet or shield.

Also always wear safety glasses with side shields, goggles or

other protective eye wear.

• Wear welding gloves and suitable clothing to protect your skin

from the arc rays and sparks.

• Keep helmet and safety glasses in good condition. Replace

lenses when cracked, chipped or dirty.

•Protect others in the work ar

booths, screens or shields.

• Use the shade of lens as suggested in the following per ANSI/

ASC Z49.1:

Arc Current Shade No. Shade No.

Less Than 300* 8 9

300 - 400* 9 12

400 - 800* 10 14

* These values apply where the actual arc is clearly seen.

Experience has shown that lighter filters may be used

when the arc is hidden by the workpiece.

LEAD WARNING

This product contains chemicals, including lead, or otherwise produces chemicals known to the State of California to cause cancer, birth

defects and other reproductive harm. Wash hands after handling.

(California Health & Safety Code § 25249.5 et seq.)

ea from the arc rays. Use protective

Minimum Protective Suggested

2. ANSI Standard Z49.1, SAFETY IN WELDING AND CUTTING,

obtainable from the American Welding Society, 550 N.W.

LeJeune Rd, Miami, FL 33126

3. NIOSH, SAFETY AND HEALTH IN ARC WELDING AND GAS

WELDING AND CUTTING, obtainable from the Superintendent of Documents, U.S. Government Printing Office, Washington, D.C. 20402

4. ANSI Standard Z87.1, SAFE PRACTICES FOR OCCUPATION

AND EDUCATIONAL EYE AND FACE PROTECTION, obtainable from American National Standards Institute, 1430

Broadway, New York, NY 10018

5. ANSI Standard Z41.1, STANDARD FOR MEN’S SAFETY-TOE

FOOTWEAR, obtainable from the American National Standards Institute, 1430 Broadway, New York, NY 10018

6. ANSI Standard Z49.2, FIRE PREVENTION IN THE USE OF

CUTTING AND WELDING PROCESSES, obtainable from

American National Standards Institute, 1430 Broadway,

New York, NY 10018

7. AWS Standard A6.0, WELDING AND CUTTING CONTAINERS WHICH HAVE HELD COMBUSTIBLES, obtainable from

American Welding Society, 550 N.W. LeJeune Rd, Miami,

FL 33126

8. NFPA Standard 51, OXYGEN-FUEL GAS SYSTEMS FOR

WELDING, CUTTING AND ALLIED PROCESSES, obtainable

from the National Fire Protection Association, Batterymarch

Park, Quincy, MA 02269

9. NFPA Standard 70, NATIONAL ELECTRICAL CODE, obtainable from the National Fir e Pr otection Association,

Batterymarch Park, Quincy, MA 02269

10. NFPA Standard 51B, CUTTING AND WELDING PROCESSES,

obtainable from the National Fire Protection Association,

Batterymarch Park, Quincy, MA 02269

11. CGA Pamphlet P-1, SAFE HANDLING OF COMPRESSED

GASES IN CYLINDERS, obtainable from the Compressed

Gas Association, 1235 Jefferson Davis Highway, Suite 501,

Arlington, VA 22202

12. CSA Standard W117.2, CODE FOR SAFETY IN WELDING

AND CUTTING, obtainable from the Canadian Standards

Association, Standards Sales, 178 Rexdale Boulevard,

Rexdale, Ontario, Canada M9W 1R3

13. NWSA booklet, WELDING SAFETY BIBLIOGRAPHY obtainable from the National Welding Supply Association, 1900

Arch Street, Philadelphia, PA 19103

14. American Welding Society Standard AWSF4.1, RECOMMENDED SAFE PRACTICES FOR THE PREPARATION FOR

WELDING AND CUTTING OF CONTAINERS AND PIPING

GENERAL INFORMATION 1-2 Manual 0-4745

Page 9

THAT HAVE HELD HAZARDOUS SUBSTANCES, obtainable

from the American Welding Society, 550 N.W. LeJeune Rd,

Miami, FL 33126

15. ANSI Standard Z88.2, PRACTICE FOR RESPIRATORY PROTECTION, obtainable from American National Standards

Institute, 1430 Broadway, New York, NY 10018

• Montez et maintenez le matériel conformément au Code électrique

national des Etats-Unis. (Voir la page

• Débranchez l’alimentation électrique avant tout travail d’entretien

ou de réparation.

• Lisez et respectez toutes les consignes du Manuel de consignes.

5,

article 9.)

Manual 0-4745 1-3 GENERAL INFORMATION

Page 10

1.04 Declaration of Conformity

Manufacturer : Ther mal Dynamics Cor poration

Address: 82 Benning Str eet

West Lebanon, New Hampshire 03784

USA

The equipment described in this manual confor ms to all applicable aspects and r egulations of the ‘Low Voltage Directive’

(European Council Dir ective 73/23/EEC as amended by Council Dir ective 93/68/EEC) and to the National legislation for the

enforcement of this Dir ective.

The equipment described in this manual confor ms to all applicable aspects and r egulations of the "EMC Directive" (European

Council Directive 89/336/EEC) and to the National legislation for the enforcement of this Directive.

Serial numbers are unique with each individual piece of equipment and details descr iption, parts used to manufactur e a unit and

date of manufacture.

National Standard and Technical Specifications

The product is designed and manufactur ed to a number of standards and technical r equirements. Among them ar e:

* CSA (Canadian Standards Association) standar d C22.2 numbe

* UL (Underwriter s Laboratory) rating 94VO flammability testing for all pr inted-circuit boar ds used.

* CENELEC EN50199 EMC Product Standar d for Arc Welding Equipment.

* ISO/IEC 60974-1 (BS 638-PT10) (EN 60 974-1) (EN50192) (EN50078) applicable to plasma cutting equipment and associated

accessories.

* For envir onments with increased hazard of electr ical shock, Power Supplies bearing the 'S' mark confor m to EN50192 when

used in conjunction with hand torches with exposed cutting tips, if equipped with pr operly installed standoff guides.

* Extensive product design ver ification is conducted at the manufacturing facility as par t of the routine design and manufactur-

ing process. This is to ensur e the product is safe, when used according to instr uctions in this manual and related industry

standards, and perfo

tured pr oduct meets or exceeds all design specifications.

Thermal Dynamics has been manufacturing products for more than 30 year s, and will continue to achieve excellence in our ar ea

of manufacture.

Manufacture r s responsible repr esentative: Steve Ward

rms as specified. Rigorous testing is incorpor ated into the manufacturing pr ocess to ensure the manufac-

Operations Director

Thermadyne Eur ope

Europa Building

Chorley N Industr ial Park

Chorley, Lancashire,

England PR6 7BX

r 60 for Arc welding equipment.

GENERAL INFORMATION 1-4 Manual 0-4745

Page 11

1.05 Statement of Warranty

LIMITED WARRANTY: Subject to the terms and conditions established below, Thermadyne® Corporation warrants to the original retail purchaser that

new Thermadyne CutSkill Series plasma cutting systems sold after the effective date of this warranty are free of defects in material and workmanship.

Should any failure to conform to this warranty appear within the applicable period stated below, Thermadyne Corporation shall, upon notification thereof

and substantiation that the product has been stored operated and maintained in accordance with Thermadyne’s specifications, instructions,

recommendations and recognized industry practice, correct such defects by suitable repair or replacement.

This warranty is exclusive and in lieu of any warranty of merchantability or fitness for a particular purpose.

Thermadyne will repair or replace, at its discretion, any warranted parts o

periods set out below. Thermadyne Corporation must be notified within 30 days of any failure, at which time Thermadyne Corporation will provide

instructions on the warranty procedures to be implemented.

Thermadyne Corporation will honor warranty claims submitted within the warranty periods listed below. All warranty periods begin on the date of sale

of the product to the original retail customer or 1 year after sale to an authorized Thermadyne Distributor.

LIMITED WARRANTY PERIOD

Product

Power Supply Componants

(Parts and Labor)

r components that fail due to defects in material or workmanship within the time

Torch and Leads

(Parts and Labor)

C-20A 1 Year 1 Year

C-35A 1 Year 1 Year

C-70A 1 Year 1 Year

C-100A 1 Year 1 Year

This warranty does not apply to:

1. Consumable Parts, such as tips, electrodes, shield cups, o - rings, starter cartridges, gas distributors, fuses, filters.

2. Equipment that has been modified by an unauthorized par ty, improperly installed, improper ly operated or misused

based upon industry standards.

In the event of a claim under this warranty, the remedies shall be, at the discretion of Thermadyne Corporation:

1. Repair of the defective product.

2. Replacement of the defective product.

3. Reimbursement of reasonable costs of repair when authorized in advance by Thermadyne.

4. Payment of credit up to the purchase price less reasonable depreciation based on actual use.

These remedies may be authorized by Thermadyne and ar

service is at the owner’s expense and no reimbursement of travel or transportation is authorized.

LIMITATION OF LIABILITY: Thermadyne Corporation shall not under any circumstances be liable for special or consequential damages such as, but not

limited to, damage or loss of purchased or replacement goods or claims of customer of distributors (hereinafter “Purchaser”) for service interruption.

The remedies of the Purchaser set forth herein are exclusive and the liability of Thermadyne with respect to any contract, o

therewith such as the performance or breach thereof, or from the manufacture, sale, delivery, resale, or use of the goods covered by or furnished by

Thermadyne whether arising out of contract, negligence, strict tort, or under any warranty, or otherwise, shall not, except as expressly provided herein,

exceed the price of the goods upon which liability is based.

This warranty becomes invalid if replacement parts or accessories are used which may impair the safety or performance of any Thermadyne

product.

This warranty is invalid if the Thermadyne product is sold by non - authorized persons.

e FOB West Lebanon, NH or an authorized Thermadyne service station. Product returned for

r anything done in connection

Effective August 28, 2005

Manual 0-4745 1-5 GENERAL INFORMATION

Page 12

GENERAL INFORMATION 1-6 Manual 0-4745

Page 13

SECTION 2.0

2.03 Features

INTRODUCTION

2.01 INTRODUCTION

Plasma is a gas which has been heated to an extremely

high temperature and ionized so that it becomes electrically conductive. The plasma arc cutting process uses

this plasma to transfer an electrical arc to the workpiece. The metal to be cut is melted by the heat of the

arc and then blown away.

2.02 GENERAL SPECIFICATION

Model Desc ription 35C

Maximum output 35 Amps

Input Voltage & Phas e

Frequency 50/60Hz

Input power 8.3 kVA

Current Input fuse

No Load Voltage 330V

Load Voltage 94V

Output Current 10 - 35 Amps

Post flow time 15 Seconds

Duty cycle @ 104°F /

40° C Ambient

Genuine Cutting

Capacity

Maximum Cutting

Capacity

Dimension (W * D * H)

Gross Weight 57 lbs. (26 kg )

230V,

Single Phase

U.S. / Canada 40

Amps

All others 16A Slow

Blow Fuse

35% @ 35A @

94vdc

60% @ 27A @

91vdc

100% @ 20A @

88 vdc

3/8"

(10 m m )

5/8"

(15 m m )

10.5"x15.5"x11"

(267 mm x 394 mm

x 279 mm )

• COMPACT and LIGHT - Designed for easy transportation.

• ENERGY EFFICIENCY - Advanced technology

reduces power consumption.

• HIGH SPEED GENUINE CUTTING - The constricted plasma arc provides high speed cutting

as well as a good quality genuine, narrow cut.

• LOW COST WITH COMPRESSED AIR - The 35C

operates on compressed air.

• ALL KINDS OF METALS - Useful for most metals such as stainless steel, aluminum, mild steel,

copper and their alloys.

• PILOT ARC IGNITION FROM TORCH - The Pilot Arc ignites the cutting arc.

• POWERFUL CUTTING PERFORMANCE Genuine cutting capacity is 3/8” (10 mm) and

5/8” (15 mm) for maximum cut.

• ABLE TO CUT PAINTED MATERIALS - Pilot Arc

ignition allows the 35C to cut painted materials.

• EXTENDED PARTS LIFE - Consumable parts life

is longer.

NOTE:

Refer to Local and National Codes or local authority having jurisdiction for proper wiring requirements.

Manual 0-4745 2-1 Introduction

Page 14

2.04 Torch Specifications

g

g

y

p

g

y

10.5 in (266.7 mm)

PCH-42 Torch Ratin

Torch Configuration

Torch Leads Len

Duty Cycle

Ambient

Temperature

Maximum Current

Voltage (V

Arc Striking Voltage 12kV

Type of Cooling

Parts -in-Plac e

Gas Requirement

Gas Pressure

Minimum Gas Flow

Direct Contact Hazard

Plasma Power

Supply Used With

eak

Input

Torch Head at 70° to

th 20 feet / 6.1 m

100% @ 40 Amps

)500V

Ambient air and gas

st ream through torc h

Compressed Air Only

For operation with

recommended standoff

1/8 - 3/8" (3-9 mm).

s

Torch Handle

@ 200 scfh

104° F

40° C

40 Amps, DC,

Strai

ht Polarit

Built-in Switch

in Torch Head

Single Gas,

65 psi (4.5 bar)

(.45MPa)-

125 psi (8.6 bar)

(.86MPa)

130 scfh (61 lpm)

exposed tip the

height is

35C

3 in

(76.2 mm)

Art # A-04653

2.05 System Contents

Description ITEMS Q't

Power source Model Drag-Gun Plus 1

PCH-42, with 20'

Torch Set

Accessories &

Consumables

Input Power

Cable U.S. /

CAN.

Input Power

Cable Outside

of U. S. / CA N.

(6.1 m) leads 1

Work Cable

Manual

Torch Electrodes

Torch Tips

3 Meter NEMA 10 AWG /

2

4.8 mm

with 6 - 50 P

molded plug

3 Meter 3x2.5 sq mm

rubber wire

1

1

2

3

1

1

2.06 Transporting Methods

Lift unit with handle on top of case. Use handcart or

similar device of adequate capacity for transporting.

WARNINGS

ELECTRIC SHOCK can kill. DO NOT

TOUCH live electrical parts. Disconnect input

power from supply before moving the power

source.

FALLING EQUIPMENT can cause serious personal injury and equipment damage.

Introduction 2-2 Manual 0-4745

Page 15

SECTION 3.0

3.03 Torch

INSTALLATION

3.01 Site Selection

• Place in a clean and dry area.

• Provide adequate ventilation and fresh air supply.

• Ideal ambient temperature should not exceed

40°C / 104°F. Temperatures exceeding that may

diminish cutting capacity or quality.

• The cutting machine must be placed on an even,

flat surface so that it stands firmly.

WARNING

This equipment must be electrically connected

by a qualified electrician.

3.02 Electrical Input Connections

• Input voltage is 230V ± 10%, 50/60 Hz single

phase.

CAUTION

• Make sure that the torch cable and torch switch

terminals are connected to front panel.

• Make sure the Work Cable is connected properly

to front panel.

• Before activating, turn torch away from yourself

and others.

DANGER

Do not cut in humid or wet surroundings.

• Before you maintain or replace torch parts, wait

for the post flow air cycle to stop (approximately

15 seconds), then turn the machine off.

• Always use original manufacturers parts. The use

of aftermarket parts could result in lower parts

life and in unsatisfactory cutting results. Any warranty claims would be waived.

• Recycle worn parts according to local requirements.

NOTE

Repairs must be done by skilled and qualified

personnel only.

Check your power source for correct voltage before plugging in or connecting the unit. The

primary power source, fuse, and any extension

cords used must conform to local electrical code

and the recommended circuit protection and wiring requirements as specified in Section 2.

Manual 0-4745 3-1 Installation

Page 16

This Page Left Blank

Installation 3-2 Manual 0-4745

Page 17

SECTION 4.0

!

OPERATION

B. BUTTONS

• Torch Switch Latch Button - For

4.01 Front Control Panel

Overheating

Indicator

I

"On / Off"

35C

O

Switch

AC Power

Indicator

Air Vents

Work Lead

Connection

Art # A-04715

A. INDICATOR LAMP

• Power Indicator - Lights when primary

power switch is turned on.

• TEMPERATURE Indicator - Indicator is nor-

mally OFF. Indicator is ON when internal temperature exceeds normal limits. Shut unit OFF;

let the unit cool before continuing operation.

Air Error Indicator

Torch Switch

20

2

1

22

1

8

23

2

20

4

2

5

A

Latch Indicator

Torch Switch

18

7

1

1

9

16

14

15

1

6

12

14

13

0

1

12

8

11

115VAC

10

230VAC

Latch Button

Air Set

Button

Current

Control Knob

Torch

Connection

continuous cutting performance. Depress this

button ( turn “On” ) while cutting with the torch.

Release the torch trigger and the torch will continue to cut without depressing the torch trigger.

• Air Set Button - To check for proper air

setting and to cool down heated torch.

C. MAIN CURRENT CONTROL KNOB

To adjust cutting current. Turning clockwise increases the cutting current and counter clockwise decreases the cutting current.

20

15

10

25

30

35

A

Art # A-04387

D. PRIMARY POWER SWITCH, ON / OFF

• Air Error Indicator - This indicator lights

and is accompanied by an intermittent audible

tone when there is not enough air pressure to

operate the power supply.

NOTE

It is possible to have enough air pressure to operate the power supply but not enough air flow

to operate the torch.

• Torch Switch Latch Indicator -

This indicator lights when the Torch Switch

Latch Button has been pressed for continuous

cutting.

The power switch is located on the front panel.

Placing the primary power switch to the “ON”

position energizes the power source.

WARNING

When the power source is overloaded, the switch

turns to the OFF position automatically. DO

NOT TURN ON BY FORCE.

Manual 0-4745 4-1 Operation

Page 18

4.02 Preparations For Operating

D. Torch Operation

At the start of each operating session:

WARNING

Disconnect primary power at the source before

assembling or disassembling power supply, torch

parts, or torch and leads assemblies.

A. Torch Parts Selection

Check the torch for proper assembly and appropriate torch parts. The torch parts must correspond

with the type of operation, and with the amperage

output of this Power Supply (35 amps maximum).

Use only genuine manufacturer’s parts with this

torch.

Electrode, No. 9-6542

Gas Distributor,

No. 9-6507

• Wear gloves and protective goggles.

• Do not place bare hand on work piece.

1. For drag cutting, keep the torch in contact with

the workpiece.

2. For standoff cutting, hold the torch 1/8 - 3/8

in (3-9 mm) from the workpiece as shown below.

Torch

Shield Cup

Standoff Distance

1/8" - 3/8" (3 - 9mm)

Torch Head Assembly

Tip, No. 9-6501

Art # A-04655

Shield Cup, No. 9-6003

B. Torch Connection

Check that the torch is properly connected.

C. Connect Work Cable

Make a clean work cable

connection to the workpiece or cutting table

Work Cable

And Clamp

Art # A-04389

A-00024_AB

3. With the torch in starting position, press and

hold the Torch Trigger. After an initial two second pre-flow, the pilot arc will come on and

remain on until the cutting arc starts.

4. Once on, the cutting arc remains on as long as

the Torch Trigger is held down, unless the torch

is withdrawn from the work or torch motion is

too slow.

5. To shut off the torch simply release the Torch

Trigger. When the trigger is released a gas postflow will occur. If the Torch Trigger is pushed

during the post-flow, the cutting arc will restart

immediately when the torch is brought within

range of the workpiece.

Operation 4-2 Manual 0-4745

Page 19

E. Typical Cutting Speeds

Cutting speeds vary according to torch output, the type of material being cut, and operator skill. Speeds

shown are typical for this cutting system using air plasma to cut mild steel, with output current at the

highest setting and torch held at the indicated standoff height.

Unit Standoff

35C Drag (10 ga) 0.135" - (3mm) 94.7 2367 75.7 1893

35C Drag (7 ga) 0.179" - (4.5mm) 57.0 1425 45.6 1140

35C 1/8" - (3mm) 1/4" - (6mm) 36.3 908 29.1 727

35C 1/8" - (3mm) 3/8" - (9.5mm) 15.3 383 12.3 307

35C 1/8" - (3mm) 1/2" - (12mm) 9.7 242 7.7 193

Material

Thi c knes s

Recommended Travel SpeedMaximum Travel Speed

ipm mm/m ipm mm/m

NOTE:

Drag or Drag mode refers to the torch tip being in contact with the work piece at all times.

Manual 0-4745 4-3 Operation

Page 20

This Page Left Blank

Operation 4-4 Manual 0-4745

Page 21

SECTION 5: MAINTENANCE

5.01 General Maintenance

Warning!

Disconnect input power before maintaining.

Visually inspect the torch body

tip, electrode and shield cup

Maintain more often

if used under severe

conditions

Each Use

Visual check of

torch tip and electrode

Weekly

Visually inspect the

cables and leads.

Replace as needed

Replace all

broken parts

3 Months

Clean

exterior

of power supply

6 Months

Visually check and

Carefully clean the

interior

Art # A-06884

Manual 0-4745 5-1 Maintenance

Page 22

This Page Left Blank

Maintenance 5-2 Manual 0-4745

Page 23

SECTION 6:

TROUBLESHOOTING

6.01 Normal Setup and Operation

1. Connect the unit to power.

2. Connect the work lead clamp to cleaned area of work surface.

3. Turn the switch located on the front panel, to the "On" position. The A/C indicator on the front panel

lights and the cooling fan comes on.

4. Select the correct current setting for the material being cut.

5. Squeeze the torch trigger. The pilot arc and compressor start.

6. Transfer arc to work surface within 3-5 seconds before the pilot arc turns off. If arc was lost before transfer to

work surface, release the torch trigger and squeeze the trigger again to establish the pilot arc.

7. When the torch trigger is released, the compressor will continue to run for post flow, approximately 15 seconds.

WARNING

There are extremely dangerous voltage and power levels present inside this unit. Do not attempt to diagnose or repair

unless you have had training in power electronics measurement and troubleshooting techniques. Disconnect primary

power at the source before disassembling the power supply, torch, or torch leads.

NOTE:

All procedures are done with the cover removed.

Manual 0-4745 6-1 TROUBLE SHOOTING

Page 24

6.02 Basic Trouble Shooting Guide

Problem - SymptomPossible Cause Recommended Action

Power Swit ch is on

but the A/C Indicator

does not light

1. Improper electrical connection.

2. System was overloaded.

3. Switch may be faulty

1. Check input power source and fuse. Check input cable and

connections.

2. Turn Primary Power Switch Off and then On again.

3. Return to authorized service center for repair or replacement

Primary power

switch is on, but the

cooling fan does not

work.

No air flow at torch

when air check

switch is turned on.

Torch will not pilot

when torch switch is

activated.

Pilot / transfer arc

goes out and

doesn’t reactivate

Cut performance is

diminished.

Air flows

continuously and

torch switch latch

button doesn't work

properly.

1. No power or incorrect power to

fan.

2. Faulty fan.

1. Internal connection is loose or

disconnected.

2. Internal air supply / compressor

not working.

3. Control PCB faulty

1. Air pressure too high or too

low.

2. Torch consumables missing.

3. Worn or faulty torch parts

4. Thermal Switch activated

1. Torch removed from work piece

or moved away from metal being

cut

1. Worn torch parts.

2. Poor Work Lead connection.

3. Current sensor o

r PWM PCB

faulty.

1. Torch Switch Latch button on

front panel faulty.

2. Control PCB faulty.

1. Check electrical connections to fan.

2. Return to authorized service center for repair or replacement

1. Check all air line connections and fittings.

2. Return to an authorized service center for repair.

3. Return to an authorized service center for repair.

1. There is no adjustment, return to an authorized service

center for repair..

2. Turn off power supply. Remove shield cup. Install missing

parts.

3. Inspect torch consumable parts. Replace if necessary.

4. Allow the cooling fan to run for 2 minutes or longer until it

will resume operation.

1. Release torch trigger and re-establish the pilot arc. See

block diagram Appendix 1

1. Check current setting. Check the Electrode and Tip for

excess wear.

2. Check the connection of the Work Lead to the work piece.

3. Return to an authorized service center for repair or

replacement.

1. Return to an authorized service center for repair or

replacement.

2. Return to an authorized service center for repair or

replacement.

TROUBLE SHOOTING 6-2 Manual 0-4745

Page 25

6.03 Control PCB Indicators

WARNING

There are extremely dangerous voltage and power levels present inside this unit. Do not attempt to diagnose or repair

unless you have had training in power electronics measurement and troubleshooting techniques.

NOTE:

All procedures are done with the cover removed.

1. Turn the switch located on the front panel, to the "On" position. The A/C indicator on the front panel

lights and the cooling fan comes on.

2. Locate the Control PCB behind the front panel. LD2 (EN) LED should be "ON".

3. Press the Air Set Button . The the air compressor should come on causing air to flow through the torch

and LD1 (SOL) LED should light. Press the Air Set Button again and the air compressor stops and the LED goes

out.

4. Squeeze the torch trigger. The pilot arc and compressor start. LD2 (EN) should brighten and LD1 (SOL) LED

and LD4 (H/V) should be on.

5. Transfer the arc to the work surface within 3-5 seconds. LD4 goes off and LD3 comes on so that three LEDs are

on.

If no transfer of arc occurs, check the work lead connection.

Manual 0-4745 6-3 TROUBLE SHOOTING

Illustration 6-1, Control PCB

NOTE:

Page 26

6.04 Open Circuit Voltage Check

1. Unplug the CN1 connector on the H/V (spark gap) PCB.

2. Turn unit power on.

3. Measure terminal TB2, Pins 1 and 3. It should be 230VAC.

4. Measure output voltage on Input diode (+ and -). It should be 325VDC.

5. Depress and hold the torch trigger for each of the following checks /steps, numbers 6 - 9. Each check has to be

done within the 3-5 second pilot arc time. If not, then the trigger will have to be releaed and then depressed

again.

6. Check for illumination of the "SOL" LED and that the "EN" (Enable) LED brightens on the Logic PCB.

5

1

3

4

6

2

Art # A-06991

Illustration 6-2

7. Measure output to Main Transformer Input between points 5 and 6 in Illustration 6-2 above. It should be

220VAC.

8. Measure Main Transformer secondary voltage between points 3 and 4 in Illustration 6-2 above. It should be

190VAC.

9. Measure output OCV between points 1 and 2 in Illustration 6-2 above. It should be 325VDC.

10. Turn off the unit power and plug the connector back in to CN1, removed in step 1 above.

TROUBLE SHOOTING 6-4 Manual 0-4745

Page 27

6.05 Detailed Fault Finding / Error Indicators

Problem Check / Test Recommended Action

Air Indicator is on

and or audible

intermitant tone

Torch doesn't Pilot and

the LD1 LED light on

the Control PCB

Torch doesn't Pilot and

the LD1 LED on the

Control PCB is

"CO" LED on Control

PCB comes on when

not transferring.

is

not

1 - Check air and electrical connections

to the internal air compressor

2 - Control PCB faulty

3 - Check the compressor relay

1 - Check torch consumables.

2 - Check all air supply related issues

on

before proceding.

3 - Check LD2 (EN) LED it should get

brighter with the torch trigger

depressed .

4 - Check OCV Voltage. If OCV Voltage

is OK check C/T 1 connection

Check all air supply related issues

before proceding.

on

Check Cable Connection on PCB

(CN10) and Current Sensor.

1 - If connections are good, return

to an authorized service center for

repair.

2 - Replace the Control PCB

3 - Replace the relay if bad.

1 - Replace tor

needed.

2 - Change air related items as

needed.

3 - If OCV is not OK, follow OCV

check procedures in section 6.04

4 - If CN9 connection is OK, replace

the Control PCB

If there are no air related issues,

replace the Control PCB

If connection and Current Sensor

are OK, replace the Control PCB

ch consumables as

A. Diode Testing Basics

WARNING

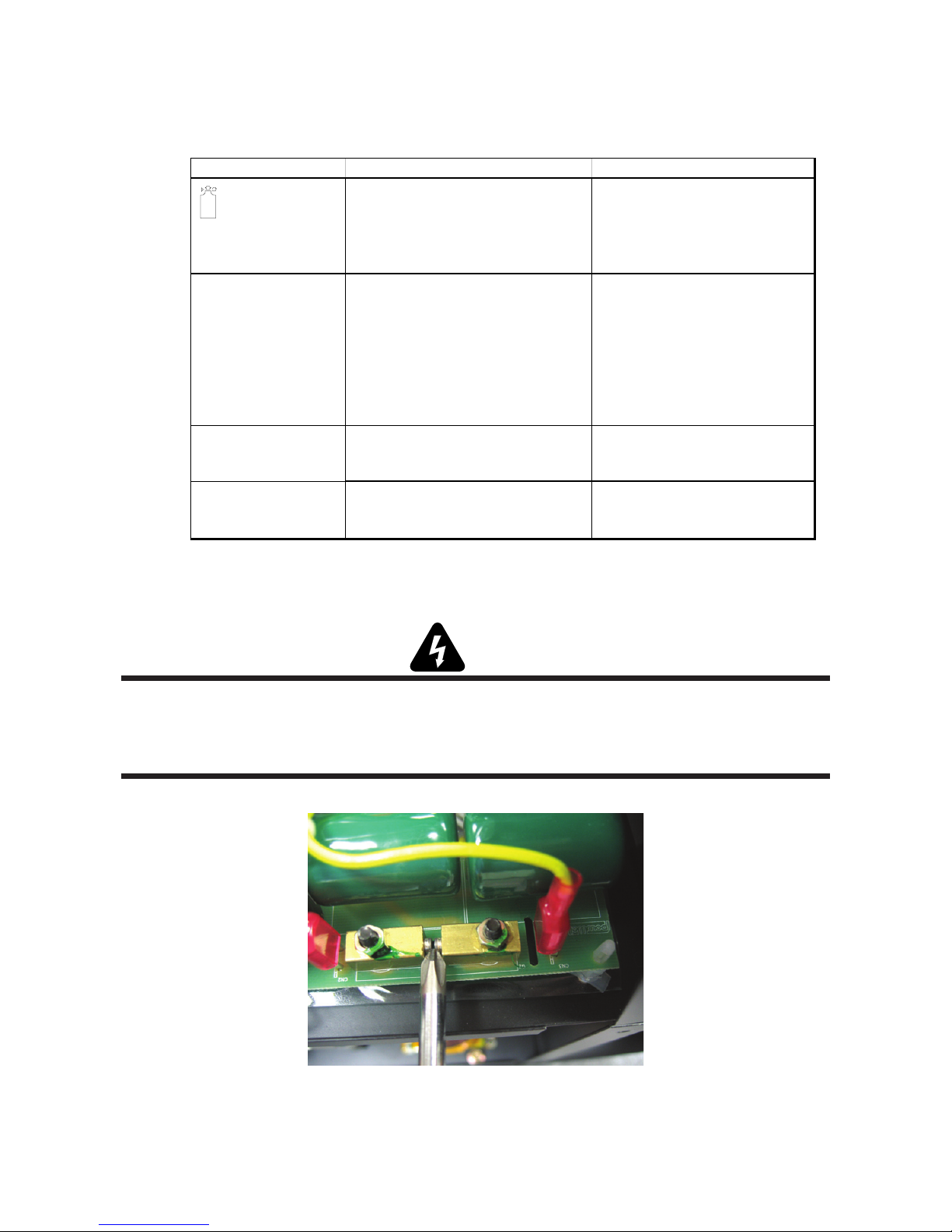

There are extremely dangerous voltage and power levels present inside this unit. Do not attempt to diagnose or repair

unless you have had training in power electronics measurement and troubleshooting techniques. Disconnect primary

power at the source before disassembling the power supply, torch, or torch leads. Discharge power at the H/V spark gap

using a metal tipped screw driver as shown:

Art # A-07116

Manual 0-4745 6-5 TROUBLE SHOOTING

Page 28

Testing of diode modules requires a digital volt/ohmmeter that has a diode test scale. Remember that even if the

diode module checks good, it may still be bad. If in doubt, replace the diode module.

1. Remove AC power. Refer to Appendix 3 Wiring diagram.

2. Locate the IGBT diode module to be tested.

3. Remove P5 from IGBT module.

4. Set digital volt/ohmmeter to diode test scale.

5. Connect the volt/ohmmeter positive lead to the anode (+) of the diode and the negative lead to the cathode (-) of

the diode for forward bias testing (refer to following figure). A properly functioning diode will conduct in the

forward bias direction and indicate between 0.3 to 0.9 volts.

Art # A-00307

0.75

Forward Bias

Diode Conducting

Diode Test Symbol

Anode

VR

+

COM

_

A

Cathode

Testing Diode Forward Bias

TROUBLE SHOOTING 6-6 Manual 0-4745

Page 29

6. Reverse the meter leads across the diode for reverse bias testing (refer to following figure). A properly functioning diode will block in the reverse bias direction and depending on the meter function will indicate an open or

“OL”.

Art # A-00306

OL

Reverse Bias

Diode Not Conducting

Cathode

Anode

+

VR

COM

_

A

Testing Diode Reverse Bias

7 Using the Figures for each test, check each diode in the module. Each diode must be checked in forward bias

(plus to negative) and reverse bias (negative to plus) direction.

Manual 0-4745 6-7 TROUBLE SHOOTING

Page 30

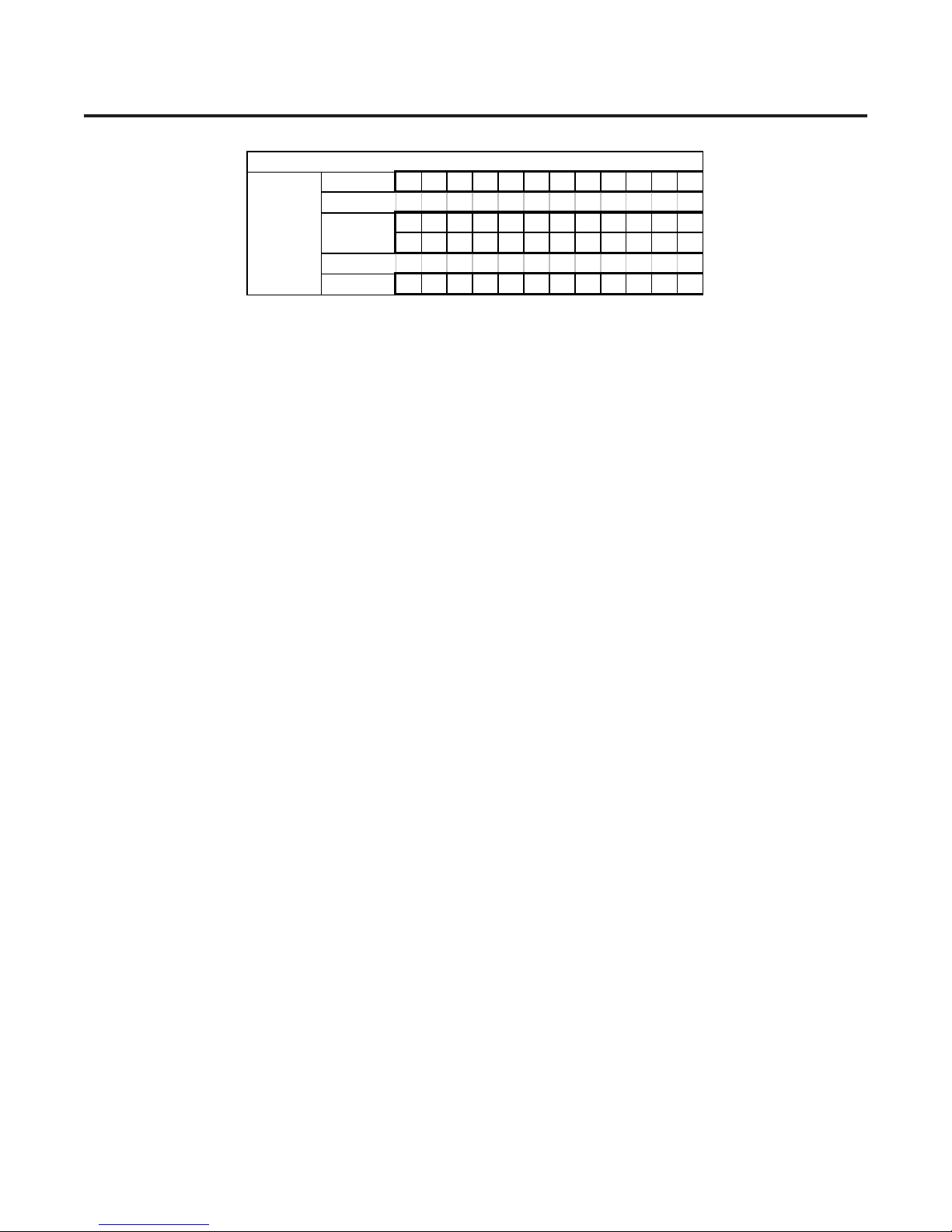

B. Component Tests

WARNING

Disconnect primary power at the source before taking any resistance checks.

1. Input Diode Module Board Circuit Test

a. Check Input Diode for short per schematic located in Appendix 4.

2. IGBT Module Test

a. With an ohmmeter set on the diode range remove P5 from the IGBT and make the following IGBT checks:

Gate PCB J5 IGBT Check

+-

E1 White + DD (1.020)

White + E1 Open After Charging

E1 Black - Open After Charging

Black - E1 DD (1.270)

E1 G1 DD (.770)

G1 E1 DD (.770)

E2 G2 DD (.770)

G2 E2 DD (.770)

E3 White + DD (1.270)

White + E3 Open After Charging

E3 Black - DD (.770)

Black - E3 DD (.770)

G3 E3 DD (.770)

E3 G3 DD (.770)

G4 E4 DD (.770)

E4 G4 DD (.770)

P5 Gate Connector

1 G1 Black 1 Black

2 E1 White 2 White

3G2 Green 3 Green

4 E2 Red 4 Red

5 G3 Black 1 Black

6 E3 White 2 White

7G4 Green 3 Green

8 E4 Red 4 Red

b. If reading is not as shown, replace both IGBT modules and Gate PCB.

c. Reconnect P5 connector.

TROUBLE SHOOTING 6-8 Manual 0-4745

Diode Test

Control Connector

TW

CN8

TW

TW

CN6

TW

Pin-out diagram

Page 31

6.06 Torch Tests

2

1

WARNING

Disconnect primary power at the source before disassembling the power supply, torch, or torch leads.

1. PIP and Torch Switch Adapter Check

a. Disconnect input power from power supply.

b. Confirm that the torch parts are in place and that they match the parts consumables label on the power

supply cover.

c. Refer to Appendix 2 for torch connection and access. With the power supply on it's side and the panel

removed, disconnect the Power Supply Adapter from the power supply.

d. While the torch trigger is depressed, complete an Ohm check on the two pins in the Power Supply Adapter

. The reading should show a short (less than 1 Ohm). Refer to diagram.

Negative / Plasma Lead

PIP

Switch

Torch

Switch

Torch Head

Black

Orange

Green

White

Pilot

Torch Leads

To Power

Supply Adapter

Continuity

Check

Pilot

Art # A-05557

2. Shorted Torch Check

a. Disconnect input power from power supply.

b. Disconnect the pilot lead (see previous diagram).

c. Perform an Ohm check of the pilot lead to the negative lead. This should show "Open". If it does not show

"Open", check that the correct consumables were installed per the consumables label on the unit cover.

d. Replace Torch as needed.

NOTE

Every effort has been made to provide complete and accurate information in this manual. However, the

publisher does not assume and hereby disclaims any liability to any party for any loss or damage caused by

errors or omissions in this Manual, whether such errors result from negligence, accident, or any other cause.

Manual 0-4745 6-9 TROUBLE SHOOTING

Page 32

This Page Left Blank

TROUBLE SHOOTING 6-10 Manual 0-4745

Page 33

SECTION 7:

PARTS LIST

General Information

This parts list covers the CutSkill

not use these instructions or parts on any other equipment.

Provide the power supply model number and serial number when ordering parts.

If a product must be returned for service, contact your distributor. Materials returned without proper authoriza-

tion will not be accepted.

Contact Information

Thermal Dynamics Technical Service Dept.

Tel: 1-800-752-7622 (1-800-PLASMA2)

Fax: 1-800-221-4401

e-mail address: tdc-tech@thermadyne.com

Replacement parts are shown on the following pages. Catalog numbers are shown below each part.

®

Model C-35C Plasma Cutting Power Supply with Internal Air Compressor. Do

Manual 0-4745 7-1 PARTS LIST

Page 34

7.01 Parts List Power Supply

Item Number Quantity Description Catalog Number

1 1 Cable Ground PG29 9-0382

2 1 Case, Front 9-0309

3 1 PCB-Front 9-7117

4 1 Circuit Breaker 9-7143

5 1 Cover Ass embly 35C 9-0310

6 1 Cooling Fan 9-7163

7 1 Power Cord Strain Relief 9-0296

8 1 Case, Back 9-0311

9 1 Case, Top 9-0312

10 1 PCB-Control 9-7181

11 1 H/V PCB 9-7147

12 1 Relay 9-0319

13 1 Resistor 9-0300

14 1 Control Transformer 9-7144

15 1 Bracket, Capacitor 9-0302

16 1 Electrolytic Capacitor As sembly 9-0303

17 1 Bracket, Upper 9-0313

18 1 Compress or Part 9-0320

19 1 Current Sensor 9-7153

20 1 PCB-Input Filter (shown) 9-7128

20 1 PCB-Input Filter (CE) 9-7133

21 1 Heat Sink Assembly 9-0306

22 1 Case, Torch Cover 9-0314

23 1 Connector 9-0305

24 1 Pilot Relay Assembly 9-0304

25 1 Main Trans and Reactor As sy 9-0315

26 1 Compress or Assembly 9-0316

27 1 Rubber Bushing 9-0318

28 1 PCB-Torch Filter 9-7121

29 1 Case, Bottom 9-0317

PARTS LIST 7-2 Manual 0-4745

Page 35

5

2

1

4

3

6

8

7

Art # A-07768

11

20

10

9

19

12

13

14

15

16

18

Art # A-07769

17

Manual 0-4745 7-3 PARTS LIST

Page 36

22

21

23

24

25

Art

28

# A-07770

26

27

29

PARTS LIST 7-4 Manual 0-4745

Page 37

This Page Left Blank

Manual 0-4745 7-5 PARTS LIST

Page 38

7.02 Replacement Hand Torch Parts With Ergonomic Handle

Item # Qty Description Catalog #

1 1 Assembly, Basic Head

70° Head 9-8442

2 2 PIP (Parts - In - Place) Pins 9-5723

3 1 #6-32 x 3/16" Phillips Pan Head Screw See Note

4 1 #6 Internal Star Washer See Note

1 Ergonomic Handle, Split, with Trigger (includes items #5 - 12) 9-8076

5 1 Trigger, Lexan, Orange 9-8059

6 1 Handle 9-8060

7 1 Spring, 0.390 O.D. x 0.750 9-8061

8 1 Torch Handle Socket Head Cap Screw Kit (5 pcs 6-32 x 1/2" ) 9-8062

9 1 Assembly, Torch Switch 9-8063

10 1 Negative / Plasma Lead Insulation Sleeving 9-8056

11 3 Pin Housing (Used with item #12) 9-8111

12 3 Pin 9-8101

13 3 Socket Housing (Used with item #14) 9-8112

14 3 Socket 9-8102

15 1 Lead Assembly, including items No. 6, 8, and 9

20 ft (7.6 m) Length 4-2989

NOTE: Item can be purchased locally.

PARTS LIST 7-6 Manual 0-4745

Page 39

10

6

13 & 14

4

3

9

11 & 12

7

1

5

6

8

2

15

Art # A-07061

Manual 0-4745 7-7 PARTS LIST

Page 40

This Page Left Blank

PARTS LIST 7-8 Manual 0-4745

Page 41

Appendix 1: Operating Sequence, Block Diagram

Primary Input Power "On" or Plugged in

Power Supply On/Off Switch "On"

Red Air Indicator

Release Torch Switch

Pilot Arc Ignition (3-5 seconds)

Pilot Arc goes out

Green Power Indicator "On" and Fan is Running

Air Set Switch "On"

Compressor Starts and Air Flows at Torch. Turn Air Set Switch "Off"

Check Torch parts

Air Flow at Torch Stops

Torch Switch "On"

Torch Tip to Work within 3-5 seconds of Pilot Arc start

Start Cutting Operation

alignment. PIP switches

need to be repaired by a

Qualified Technician

Release Torch Switch

More air flow is required

for Torch to Pilot than to

run the power supply.

Compressor not functioning

properly need to be repaired

by a Qualified Technician

No Pilot Arc

YES

Post Flow of Air, Approximately 15 Seconds Then Stops

Note: The Torch will be very hot! Do not set on or near flammable materials!

Art # A-04694

Manual 0-4745 A-1 APPENDIX

Cutting Done ?

Torch Switch "Off"

Power Supply On/Off Switch "Off"

Green Power Indicator "Off" and Fan Stops

Primary Input Power Switch "Off" or Unplugged

NO

Page 42

Appendix 2: Torch Connection

Art # A-04695

Disconnect power and air. Lay unit

on its side. Remove two screws and

access plate.

DETAIL

Power Supply

Adapter Connections

Negative / Plasma Lead

To Power

Supply Adapter

Pilot

APPENDIX A-2 Manual 0-4745

Pilot

Black

Orange

Green

White

Negative / Plasma Lead

Pilot

Torch Leads

PIP

Switch

Torch

Switch

Torch Head

Page 43

Appendix 3: Microchip Pin-Out

40 Pin Microchip

123456789101112

24222018161412108642

2321191715131197531

CPU

Socket on

Control

PCB

P2

P1

P3 123456789101112

Manual 0-4745 A-3 APPENDIX

Page 44

Appendix 4: System Schematic 230V CE

L

INPUT

AC230V

N

1 PH

G

NOTE:

Do Not

attempt to

adjust the

PCB POTs!

W

Br

NFB

230 VAC

Bl

Bl

R

Bk

R

R

Bl

TB2

Bk

1

W

N/C

3

W

R

W,2

Located on IGBT

Heatsink

N/C

Or

Or

C3

Capacitor

W

W

Bk

11

230 VAC

TB1

2

Wh

3

Inrush Filter PCB

CN2

13 3 3 31

W

W

230 VAC

580

Ω

FAN

AC230

230 VAC

Lt

W

Bl

Br

N/C

3

1

Comp

Relay

4

N/C

Compressor Relay

R

75

Jumper

826

Bl

230 VAC

No.40276005

CN1 CN4THCN3

1

WW

Bk Bk

R1

Ω

50

T1

AC12

AC18

AC18

672Ω

MF 103K

630V

Pressure

Sensor

DIODE

DC

325

R2

C2

+

N/C

N/C

(-)

+12VDC

2

1

2

1

2

1

Red

C2

Bk

Bk,2

CN5

CN1

+25VDC

CN4

+12VDC

CN7

IGBT

C3

R2

E1 G2

G1

E2 G4

G3 E4E3

TW TW TW TW

B W G R B W G R

E4 G3 G2G4 E3 E1E2 G1

CN6

LD1

SOL

Control Board

No.40271005

LD3

CO

CN2

IGBT

CN8

Compressor

Art # A-06978

APPENDIX A-4 Manual 0-4745

CN1

Bl

C1

Bl

MAIN

POWER

Panel Board

No.40270601

TEMP

AIR

ERROR

ERROR

HOLD

Page 45

No H.F.

On

220

VAC

Bk

LD2

Enable

Bk

C/T 1

CN9

Main Tra nsformer

W

Twi sted

+12VDC

-12VDC

CN10

190VAC

1

2

3

4

5

VC_1

VD_1

OU_1

OU_2

GN_1

C4

R3

Current Sensor

+

C5

R4

R5

C6

C7

R6

BR

Red

O

Y

(-)

VC_1

VD_1

OU_1

GN_1

REACTOR

1

3

CN1

R7

36VAC

10k Ω

O

F/G

G

Br

OU_2

Conduit Coil

C8

Spark Gap

H/V Board

No.40273003

R

Y

G

Pilot

Relay

WW

80

Ω

WORK

O.C.V. 325

Pilot 130

Cutting 80-100

(See Sec. 6 OCV

in Service Manual)

PILOT

TORCH

WW

PCR

H/V Contactor

+12VDC

to engage

Pilot Relay

LD4

H/V

HOLD

AIR

CHECK

CN11

CN12

+12VDC

CN3

2

1

1

2

2

1

W

W

NOTE:

Do Not attempt to

adjust the PCB

POTs!

Torc h

Filter

No. 40276002

Bk (1 only)

Y

Y

Air Plasma 35C (230V CE)

No. 66001012

oct. 19. 2005

S/W

S/W

Y

**PCB not removable from relay

Y

AA

Art # A-06978

Manual 0-4745 A-5 APPENDIX

Page 46

Appendix 5: System Schematic 230V

INPUT

AC230V

1 PH

NOTE:

Do Not

attempt to

adjust the

PCB POTs!

230 VAC

NFB

L

N

G

Br

W

Bk

11

230 VAC

TB1

2

Wh

3

CN2

13 3 3 31

W

W

Filter Board

230 VAC

580

Ω

FAN

AC230

230 VAC

Lt

W

Bl

Br

N/C

3

1

Comp

Relay

4

N/C

Compressor Relay

R

75

Jumper

826

Bl

230 VAC

No.40276003

CN1 CN4THCN3

1

WW

Bk Bk

R1

Ω

50

T1

AC12

AC18

AC18

672Ω

MF 103K

630V

Pressure

Sensor

TB2

3

1

Bk

R

Bl

Bl

R

Bk

R

R

Bl

DIODE

W

N/C

W

C3

W,2

+

Capacitor

Located on IGBT

Heatsink

N/C

W

W

N/C

N/C

Or

Or

Compressor

DC

325

R2

C2

(-)

2

1

2

1

2

1

Red

C2

Bk

Bk,2

+12VDC

CN5

CN1

+25VDC

CN4

+12VDC

CN7

IGBT

C3

R2

E1 G2

G1

G3 E4E3

E2 G4

TW TW TW TW

B W G R B W G R

E4 G3 G2G4 E3 E1E2 G1

CN6

LD1

SOL

Control Board

LD3

CO

CN2

CN1

IGBT

CN8

No.40271005

Panel Board

No.40270601

Art # A-07024

APPENDIX A-6 Manual 0-4745

Bl

C1

Bl

MAIN

POWER

TEMP

ERROR

AIR

ERROR

HOLD

Page 47

No H.F.

On

220

VAC

Bk

LD2

Enable

Bk

C/T 1

CN9

Main Tra nsformer

W

Twi sted

+12VDC

-12VDC

CN10

190VAC

1

2

3

4

5

VC_1

VD_1

OU_1

OU_2

GN_1

C4

R3

Current Sensor

+

C5

R4

R5

C6

C7

R6

BR

Red

O

Y

(-)

REACTOR

1

3

CN1

VC_1

VD_1

OU_1

GN_1

36VAC

10k Ω

O

R7

F/G

G

Br

OU_2

Conduit Coil

C8

Spark Gap

H/V Board

No.40273003

R

Y

G

Pilot

Relay

WW

80

Ω

WORK

O.C.V. 325

Pilot 130

Cutting 80-100

(See Sec. 6 OCV

in Service Manual)

PILOT

TORCH

WW

PCR

H/V Contactor

+12VDC

to engage

Pilot Relay

LD4

H/V

HOLD

AIR

CHECK

CN11

CN12

+12VDC

CN3

2

1

1

2

2

1

W

W

Torc h

Filter

No. 40276002

Bk (1 only)

Y

Y

S/W

S/W

**PCB not removable from relay

Y

Y

NOTE:

Do Not attempt to

adjust the PCB

POTs!

Air Plasma 35C (230V )

No. 66001008

oct. 19. 2005

AB

Art # A-07024

Manual 0-4745 A-7 APPENDIX

Page 48

This Page Left Blank

APPENDIX A-8 Manual 0-4745

Page 49

GLOBAL CUSTOMER SERVICE CONTACT INFORMATION

Thermadyne USA

2800 Airport Road

Denton, Tx 76207 USA

Telephone: (940) 566-2000

800-426-1888

Fax: 800-535-0557

Email: sales@thermalarc.com

Thermadyne Canada

2070 Wyecroft Road

Oakville, Ontario

Canada, L6L5V6

Telephone: (905)-827-1111

Fax: 905-827-3648

Thermadyne Europe

Europe Building

Chorley North Industrial Park

Chorley, Lancashire

England, PR6 7Bx

Telephone: 44-1257-261755

Fax: 44-1257-224800

Thermadyne Asia Sdn Bhd

Lot 151, Jalan Industri 3/5A

Rawang Integrated Industrial Park - Jln Batu Arang

48000 Rawang Selangor Darul Ehsan

West Malaysia

Telephone: 603+ 6092 2988

Fax : 603+ 6092 1085

Cigweld, Australia

71 Gower Street

Preston, Victoria

Australia, 3072

Telephone: 61-3-9474-7400

Fax: 61-3-9474-7510

Thermadyne Italy

OCIM, S.r.L.

Via Benaco, 3

20098 S. Giuliano

Milan, Italy

Tel: (39) 02-98 80320

Fax: (39) 02-98 281773

Thermadyne, China

RM 102A

685 Ding Xi Rd

Chang Ning District

Shanghai, PR, 200052

Telephone: 86-21-69171135

Fax: 86-21-69171139

Thermadyne International

2070 Wyecroft Road

Oakville, Ontario

Canada, L6L5V6

Telephone: (905)-827-9777

Fax: 905-827-9797

Page 50

Corporate Headquarters

16052 Swingley Ridge Road

Suite 300

St. Louis, MO 63017

Telephone: 636-728-3000

Email: TDCSales@Thermadyne.com

www.thermadyne.com

Loading...

Loading...