Thermaflow TSL9/140U, TSL9/170U, TSL12/140U, TSL12/170U Instructions For Use Installation And Servicing

ELECTRIC SLIMLINE COMBINATION BOILER

(Patent Pending, Design Right Protected.)

TSL9/140U & TSL9/170U

TSL12/140U & TSL12/170U

SOLAR COMPATIBLE

This product is suitable for connection to ~230-240V, 50Hz

INSTRUCTIONS FOR USE, INSTALLATION AND

SERVICING

TO BE LEFT WITH THE USER

The instructions consist of three parts; User, Installation and Servicing instructions, which include the guarantee

registration card.

The instructions are an integral part of the appliance and must, to comply with the current issue of the building, electrical

regulations and water by-laws, be handed to the user on completion of the installation.

GUARANTEE REGISTRATION

Thank you for installing a new Thermal Innovations product in your home.

Thermal innovations appliances, are manufactured to the very highest standards so we are pleased to offer our

customers, a comprehensive first year parts & Labour guarantee and a second year parts guarantee.

In the instruction envelope is to be found your guarantee registration card, which must be completed and returned to

Thermal Innovations (UK) Ltd or register your Thermal Innovations (UK) Ltd appliance for 1st year guarantee protection by

calling the below number.

Our guarantee gives you peace of mind valuable protection against breakdown by covering the cost of-

• All replacement parts

• All labour charges

• All call-out charges

THERMAL INNOVATIONS (UK) LTD

31-39 Napier Court, Cumbernauld, Glasgow, G68 0LG

Customer services

Tel +44 (0) 870 850 5207

Fax +44 (0) 870 850 5208

Web www.thermaflowheating.co.uk

Issue Number: 1a Issue date: July 2008

Copyright Notice

This document contains proprietary information protected by copyright, and this Manual and documentation are copyrighted. All rights are reserved. No part

of this document may be photocopied or reproduced by mechanical, electronic, or other means in any form without permission from Thermal Innovations

(UK) Ltd.

© Copyright Thermal Innovations (UK) Ltd 2006-09 -All rights reserved.

THERMAL INNOVATIONS (UK) LTD | THERMAFLOW® ELECTRIC COMBINATION BOILER | Tel: 0870 850 5207

Contents

0.1

..................................................................................4 Instructions general

......................................................................................5 Draining & Filling

0.2

0.3

......................................................................5 Manual Handling Guidance

0.4

....................................................................5 TESTING & CERTIFICATION

0.5

................................................................................5 THE UNIT LOCATION

Part1 - INSTRUCTIONS FOR USE............................................................................7

1.1 .........................................................................................7 INTRODUCTION

.............................................................7 Domestic hot water temperature

1.2

.................................................................................7 To turn the boiler off

1.3

1.4

......................................................................7 Maintenance and servicing

1.5

.................................................................................................7 Clearances

1.6

....................................................................................8 Draining and filling

....................................................................................8 Replacement parts

1.7

1.8

........................................................................................9 GENERAL DATA

Part 2 - INSTALLATION ..........................................................................................11

2.1.1 Sheet metal parts .......................................................................................11

2.1.2 Statutory requirements..............................................................................11

2.1.3 DATA 11

2.1.4 ELECTRICAL SUPPLY...............................................................................11

2.1.5 Electrical supply ........................................................................................11

2.1.6 Heating system controls ...........................................................................12

2.2.1 Boiler Position............................................................................................12

2.2.2 Boilers in a compartment..........................................................................12

2.2.3 Clearances..................................................................................................14

2.3.1 General notes .............................................................................................14

2.3.2 Safety valve ................................................................................................14

2.3.3 Pressure Gauge .........................................................................................14

2.3.4 Pump 14

2.3.5 Expansion vessel.......................................................................................14

2.3.6 By- pass ......................................................................................................14

2.3.7 Filling sealed systems...............................................................................14

2.3.8 Corrosion inhibitor.....................................................................................14

2.3.9 Draining ......................................................................................................14

2.4. Domestic hot water system.........................................................................15

2.4.1 General 15

2.4.2 Water pressure...........................................................................................15

2.4.3 HOT WATER FLOW RATE .........................................................................15

2.4.4 Hard water areas ........................................................................................15

2.5. Installation, PREPARATION [water connections] .....................................15

2.5.1 Water connections..................................................................................15

2.5.2 Safety valve discharge ...........................................................................15

2.6 Electrical Installation Requirements ...........................................................16

2.6.1 SUPPLY .................................................................................................16

2.6.2 18

2.6.3 External Controls....................................................................................19

Electrical Connections.....................................................................................20

2.6.4 Supply cable connection [24 HR Supply] ...............................................20

2.6.5 Heating system controls.........................................................................20

2.6.6 Electrical Test.........................................................................................20

2.6.7 Supply cable connection [Interrupted off peak supply]...........................21

2.6.8 Electrical Test.........................................................................................21

Electricity tariffs ...............................................................................................21

2.7 Commissioning .............................................................................................21

2.7.1 Filling domestic water circuit...................................................................21

2.7.2 Filling the heating system.......................................................................21

2.7.3 Domestic hot water flow rate..................................................................22

2.7.4 Temperature settings..............................................................................22

2

THERMAL INNOVATIONS (UK) LTD | THERMAFLOW® ELECTRIC COMBINATION BOILER | Tel: 0870 850 5207

2.7.5 Heating system commissioning..............................................................22

2.7.6 Completion .............................................................................................23

Instruct the user...............................................................................................23

Part 3 - SERVICING .................................................................................................24

3.1. Fault Finding.................................................................................................24

Fault: No domestic hot water or central heating..............................................25

Fault: No central heating, but hot water at taps...............................................26

Fault: CENTRAL HEATING BUT No hot water at taps ...................................27

3.2 ISOLATION ...............................................................................................28

Checking the pressure in the expansion vessel..............................................28

Checking the inline strainer............................................................................. 28

Checking the hot water blending valve............................................................28

Checking the concentration of corrosion inhibitor............................................29

Preventing pump seizure in summer...............................................................29

Checking correct operation of electrical components......................................29

Low pressure switch........................................................................................29

Control and high limit thermostats...................................................................29

Checking the elements....................................................................................29

Checking circuit breakers................................................................................30

Checking the contactor....................................................................................30

Check the operation of the AQUA STAT.........................................................30

Appendix I – Solar Connection..............................................................................31

A1.1 Solar Pipe work Schematic.....................................................................31

A1.2 Solar Wiring Schematic...........................................................................32

IMPORTANT PRE-INSTALLATION NOTES

• Power supply and wiring

The power supply to the premises must meet the minimum requirements of the unit being installed, with

special attention given to the supply current, cable size and MCB recommendation. The supply voltage to the

appliance must never drop below 207 Volts.

Important

The electrical supply requirements:-

The 9 KW and 12 KW boilers meet the requirements of EN 61000-3.3

The 9 KW and 12 KW boilers must be installed in premises having a service supply of ≥ 100A

per phase.

The 12 KW boiler must be installed in premises having a system impedance of not more than 0.1939 + J

0.1939Ω

3

THERMAL INNOVATIONS (UK) LTD | THERMAFLOW® ELECTRIC COMBINATION BOILER | Tel: 0870 850 5207

0.1 Instructions general

A pressure reducing valve must be fitted to the cold water inlet if the incoming water pressure

exceeds 400 KPA (4.0 Bar).

The primary operating pressure initial charge is 120 KPA (1.2Bar) this will increase to around 200

KPA (2.0Bar) when the system has reached maximum temperature and will depend on system

volume.

The primary expansion vessel pre-charge pressure is 150 KPA (1.5 Bar) and has volume of 25 and

35 litres depending on the model of boiler.

The secondary expansion vessel pre-charge pressure is 350 KPA (1.0 Bar) and has a volume of

1litre.

The primary pressure relief valve is set to 300 KPA (3.0 Bar).

Primary storage

TSL9/140U & TSL12/140U TSL9/170U & TSL12/170U

140 litres 170 Litres

Thermaflow Model Number

capacity

Weight when

50KG 56KG

Empty

Weight when Full 190KG 226KG

WARNING: BEFORE OBTAINING ACCESS TO TERMINALS, ALL SUPPLY CIRCUITS

MUST BE DISCONNECTED.

The TSL9/14OU, TSL9/170U all have 3 heating elements fitted. Size 8” in length and are

manufactured of incaloy EN60335.2.73.

The rated power input of the appliance is ~230- 240V, 50Hz, 8,250-9,000w

The TSL12/140U, TSL12/170U all have 4 heating elements fitted. Size 8” in length and are

manufactured of Incaloy EN60335.2.73.

The rated power input of the appliance is ~230-240V, 50Hz, 11,000-12,000w

The elements fitted to the Thermaflow should NOT be replaced with elements which have no

thermal cut outs

It is recommended that the Thermaflow has a safety and maintenance check on an annual

basis.

A pressure reducing valve must be fitted to the cold water inlet of the appliance if the

incoming pressure exceeds 400kPA (4 Bar).

The position of the Tundish (IF REQUIRED) shall be visible to the occupants and shall be

positioned away from any electrical devices.

The position of discharge pipes, (Tundish), drain valves and motorised valves etc, must be

positioned away from electrical components.

The water may drip from the discharge pipe of the pressure-relief device and must be left

open to the atmosphere.

The pressure relief device must be operated regularly to remove lime deposits and to verify

that it is not blocked.

The discharge pipe connected to the pressure-relief device must be installed in a

continuously downward direction and in a frost free environment.

(Additional Information given in G3 of the building regulations for discharge pipes)

.

4

THERMAL INNOVATIONS (UK) LTD | THERMAFLOW® ELECTRIC COMBINATION BOILER | Tel: 0870 850 5207

0.2 Draining & Filling

CAUTION: THE THERMAFLOW BOILER WORKS IN A PRESSURISED SYSTEM WHICH

MUST ONLY BE DRAINED, REFILLED AND PRESSURISED BY A COMPETENT PERSON.

There is one drain tap fitted to the Thermaflow boiler to drain the primary circuit within the boiler the

drain tap is located at the bottom of the appliance. Further drain taps should be fitted into the pipework at the lowest point of the potable water circuit and the heating circuit and should terminate

outside the dwelling in a suitable position.

0.3 Manual Handling Guidance

During the appliance installation it will be necessary to employ caution and assistance whilst

lifting as the appliance exceeds the recommended weight for a one man lift.

DO NOT LIFT THE APPLIANCE BY ATTACHED PIPE-WORK OR COMPONENTS

In certain situations it may be required to use a mechanical handling aid.

Take care to avoid trip hazards, slippery or wet surfaces.

IMPORTANT INFORMATION

0.4 TESTING & CERTIFICATION

The boiler is tested and certified for safety and performance. It is therefore important that no

alteration is made to the boiler, without permission, in writing, from Thermal Innovations (UK) Ltd.

Any alteration not approved by Thermal Innovations (UK) Ltd, could invalidate the certification,

boiler warranty and may also infringe the current issue of the statutory requirements, see section

2.1.2

The unit should be stored in a dry environment and should be handled with care to prevent attached

components being damaged or connections becoming loose.

leaks after installation

.

All connections should be checked for

0.5 THE UNIT LOCATION

The unit should be preferably located in a cupboard with a minimum dimension of;

L 650 mm x B 550 mm H 2.1m for the

L 650 mm x B 550 mm X H2.4M for

TSL9/14OU & TSL12/140U.

TSL9/170U & TSL12/170U

The floor to which the unit is placed upon should be capable of withstanding a load of:

190KG for the

TSL9/14OU & TSL12/140U

226KG for the TSL9/170U & TSL12/170U

The unit should be positioned in a manner that allows access to all components for future

maintenance. If located in a cupboard the unit should be positioned with all components

facing the entrance to allow elements to be replaced if required or any of the other

components.

5

THERMAL INNOVATIONS (UK) LTD | THERMAFLOW® ELECTRIC COMBINATION BOILER | Tel: 0870 850 5207

There are five water connections to be made when installing the Thermaflow, they are as follows:

1) Flow and return connections to the heating system are 22mm compression.

2) Cold water inlet-22mm compression.

3) Hot water outlet -22mm compression.

4) Pressure relief valve- 15mm compression.

5) The pressure relief valve connection should be used for no other purpose.

6

THERMAL INNOVATIONS (UK) LTD | THERMAFLOW® ELECTRIC COMBINATION BOILER | Tel: 0870 850 5207

PART1 - INSTRUCTIONS FOR USE

1.1 INTRODUCTION

This appliance is not intended for use by persons (including children) with reduced physical,

sensory or mental capabilities, or lack of experience and knowledge, unless they have been

given supervision or instruction concerning use of the appliance by a person responsible for

their safety.

Children should be supervised to ensure they do not play with the appliance.

Please read these Instructions and follow them carefully for the safe and economical use of your

combination boiler.

This boiler must have been installed by a competent person in accordance with the current rules in

force in the countries of destination at the time of installation.

The boiler is automatic in operation once the external controls are set e.g. time clock or

programmable room thermostat.

IMPORTANT NOTICE

1.2 Domestic hot water temperature

Hot water is user adjustable by turning the control knob on the thermostatic mixing valve fitted on

the hot water outlet at the top left of the boiler. It has a maximum anti-scald cut off at 63oC.

The combination boiler is able to provide room heating as part of an under-floor or central heating

system and domestic hot water direct from the cold water supply, without the need for secondary

storage.

1.3 To turn the boiler off

To turn the boiler off, isolate the boiler from both the electrical supplies i.e. the 24hr supply and the

interrupted supply, both isolating switches should be positioned next to the boiler.

1.4 Maintenance and servicing

To ensure the continued efficient and safe operation of the appliance it is recommended that it is

checked and serviced as necessary at regular intervals. The frequency of servicing will depend

upon the particular installation conditions and usage, but in general once a year should be enough.

Servicing & maintenance should be carried out by a competent person in accordance with the rules

in force in the countries of destination.

To obtain service please call your installer or Thermal Innovations (UK) Ltd, using the telephone

number on the appliance or at the front of this manual.

Please be advised that the Thermal Innovations (UK) Ltd log book should be completed by the

installation engineer on completion of commission and servicing.

1.5 Clearances

The boiler requires a clearance in front and at the sides for safety, servicing and maintenance

access, see diagram 2.2.3 for the requirements.

7

THERMAL INNOVATIONS (UK) LTD | THERMAFLOW® ELECTRIC COMBINATION BOILER | Tel: 0870 850 5207

1.6 Draining and filling

Caution this boiler works in a pressurised system which must only be drained, refilled and

pressurised by a

person competent to do so.

Note: if the pressure gauge indicates a loss of pressure that is less than 60 KPA (0.6 Bar)

YOU MUST CONTACT YOUR

unless you have been instructed by your installer on how to re-pressurise the system correctly.

INSTALLER,

1.7 Replacement parts

If replacements parts are required, contact your Installer, Service Company or Thermal Innovations

(UK) Ltd. Please quote the name and model of your appliance. (Ref. Spare Parts List - section

1.8.1).

8

THERMAL INNOVATIONS (UK) LTD | THERMAFLOW® ELECTRIC COMBINATION BOILER | Tel: 0870 850 5207

1.8 GENERAL DATA

Diagram 1.8.1

1 Enclosure for Low Pressure

cut-out switch & Master nonreset-able over-temperature

thermostat

2 Safety Relief Valve 300kPA

(3bar)

3 Enclosure for Contactor and

Circuit Breakers

4 22mm Compression bends

DZR

5 Pipe work

6 Filling Loop Assembly

6a Pressure gauge

7 Circulating Pump Complete

with Isolating Valves.

Central Heating Pump

8 Heating Elements

9 Aqua Thermostat

10 10-1 Enclosure for incoming

live supply, central heating

pump & Aqua stat

11 Heat Resistant Flex

12 0.5 Litre Potable expansion

vessel

13 Thermostatic Blending Valve

13b HW outlet

15 Automatic Air Eliminator

15b- connection for primary

expansion vessel ( Blank off if

connecting to CH Return

16 Stainless Steel Primary Store

17 17-1 Single check valve –

cold water inlet

17-2 Single check valve – CH

flow

17-3 Y-pattern strainer (cold

water inlet)

18 18-1 Drain point (Primary )

20 Primary Expansion vessel –

connect into CH return at

boiler or at 15B

Unit Design (Protected by Design Rights)

9

THERMAL INNOVATIONS (UK) LTD | THERMAFLOW® ELECTRIC COMBINATION BOILER | Tel: 0870 850 5207

TABLE 1.8.1 [DATA]

Lift Weight 50KG 56KG Total Weight 60KG 66KG Weight Full 190KG 226KG Heating Flow Return 22mm Compression Domestic Cold Inlet 22mm Compression Domestic Hot Outlet 22mm Compression Safety Valve PRESET 300 KPA (3.0 Bar) Safety Valve Discharge 15mm Compression Water Content Primary 140 Litres 170 Litres Water Content Domestic 4.5 Litres / 1.0 Gallons Primary Expansion Vessel 25 Litres / 5.5 Gallons Heating Cold Fill Pressure Min/Max 90 KPA (0.9 Bar) minimum / 120 KPA (1.2 Bar) maximum D.H.W Working Pressure 20 – 400 KPA (0.2-4.0 Bar)

TSL9/12/140 TSL9/12/170

Max. Heating system Content (Excluding unit

140Litres 160Litres

volume)

Electrical Mains Supply ~230-240V, 50Hz

Electrical Rating (Interrupted) & Supply Current TH9/ 8,250-9,000w- 40amp

TH12/ 11, 000-12,000w – 52 amp

MCB Rating (amp) 9Kw (40amp) 12Kw (52amp)

Electrical Rating (24Hr 95w, Fused 3amp

10

THERMAL INNOVATIONS (UK) LTD | THERMAFLOW® ELECTRIC COMBINATION BOILER | Tel: 0870 850 5207

PART 2 - INSTALLATION

2.1.1 Sheet metal parts

Warning: when installing or servicing this boiler care should be taken when handling the edges of

metal parts to avoid any possibility of personal injury.

2.1.2 Statutory requirements

The installation of this boiler must be carried out by a competent person in accordance with the

current rules in force in the countries of destination at the time of installation, and in accordance with

the relevant requirements of the current issue of:

The Building Regulations

The Local Water Company bye-laws

The Building Standards Regulations (Scotland)

The Health and Safety at Work Act

Manufacturers instructions, supplied

Manufacturer’s instructions must not be taken as overriding statutory requirements.

2.1.3 DATA

The data label is on the front case of the boiler.

2.1.4 ELECTRICAL SUPPLY

Power supply and wiring

•

The power supply to the premises must meet the minimum requirements of the unit being installed, with

special attention given to the supply current, cable size and MCB recommendation. The supply voltage to the

appliance must never drop below 207 Volts.

Important

The electrical supply requirements:The 9 KW and 12 KW boilers meet the requirements of EN 61000-3.3

The 9 KW and 12 KW boilers must be installed in premises having a service supply of ≥ 100A

per phase.

The 12 KW boiler must be installed in premises having a system impedance of not more than 0.1939 + J

0.1939Ω

WARNING: This boiler must be earthed

WARNING: Means for disconnection must be incorporated in the fixed wiring in

accordance with the wiring rules

WARNING: Electrical work must be carried out by a person competent to do so

All system components shall be of an approved type.

The electrical installation shall be in accordance with the current rules in force in the countries of

destination at the time of installation.

2.1.5 Electrical supply

Means of disconnection of the electrical supply to the boiler must be incorporated in the

fixed wiring in accordance with the wiring rules.

11

THERMAL INNOVATIONS (UK) LTD | THERMAFLOW® ELECTRIC COMBINATION BOILER | Tel: 0870 850 5207

Two isolators are required, one for the 24hr supply, and the other for the interrupted supply

(off peak if available)

Means of disconnection of the 24hr supply should be by a double pole switched fused spur box

(fuse rating 3 amp), having a minimum contact separation of 3mm in each pole. The fused spur box

should be readily accessible and adjacent to the appliance. It should be identified as to its use.

Means of disconnection should not be fitted in a room containing a fixed bath or shower. The 24hr

mains supply cable and other cables for external controls must be heat resistant and flexible PVC

type of at least 0.75mm2 (24/ 0.20mm)

Means of disconnection of the interrupted supply (off peak) should be by a double pole switched

(60amp isolator with a 40 amp MCB Type C for the TH9/ model) and a switched (100 amp isolator

with a 50 or 63 amp MCB Type C for the TH12/ model), having a minimum contact separation of

3mm in each pole. The switched isolator should be readily accessible and adjacent to the appliance.

It should be identified as to its use.

Means of disconnection should be readily accessible and adjacent to the appliance. It should

be identified as to its use.

The interrupted mains supply cable must have a cross sectional area of at least (10mm² for

the TSL9/ model) and (16mm² for the TSL12/ model). The mains supply cable from the

isolator to the boiler should be preferably encased by flexible conduit.

2.1.6 Heating system controls

The heating system should have installed: A timer and room thermostat or a programmable room

thermostat controlling the central heating system.

Thermostatic radiator valves should be installed in addition to the room thermostat for better

economy and energy saving.

2.2.1 Boiler Position

The boiler must be installed in accordance with the rules in force in the countries of destination. This

boiler is not suitable for fitting outside.

Any electrical switch must be positioned so that it cannot be touched by a person using the bath or

shower.

The boiler must be positioned on a level base or floor which is sufficiently robust to take its weight,

(Refer to table 1, “Data”)

If the location of the boiler or any part of the system is subject to severe cold weather conditions, it

is recommended that a frost thermostat is fitted. Any part of the system that may be vulnerable to

freezing must be protected.

2.2.2 Boilers in a compartment

Where the installation of the boiler will be in an unusual position, the current issue of BS 6798 gives

detailed guidance on these requirements.

An existing cupboard or compartment modified for the purpose may be used, providing minimum

clearances are maintained. Details of essential requirements for cupboards or compartment design

are given in the current issue of BS6798.

12

THERMAL INNOVATIONS (UK) LTD | THERMAFLOW® ELECTRIC COMBINATION BOILER | Tel: 0870 850 5207

The doorway opening should be of sufficient size to allow for easy removal of the boiler.

Where the boiler is fitted in a cupboard or compartment permanent ventilation is not required.

Compartment ventilation is required to dissipate heat from any external heating circuit pipe-work, to

prevent overheating of the electrical components and wiring.

Any existing compartment air vents must not be removed or blocked off.

13

THERMAL INNOVATIONS (UK) LTD | THERMAFLOW® ELECTRIC COMBINATION BOILER | Tel: 0870 850 5207

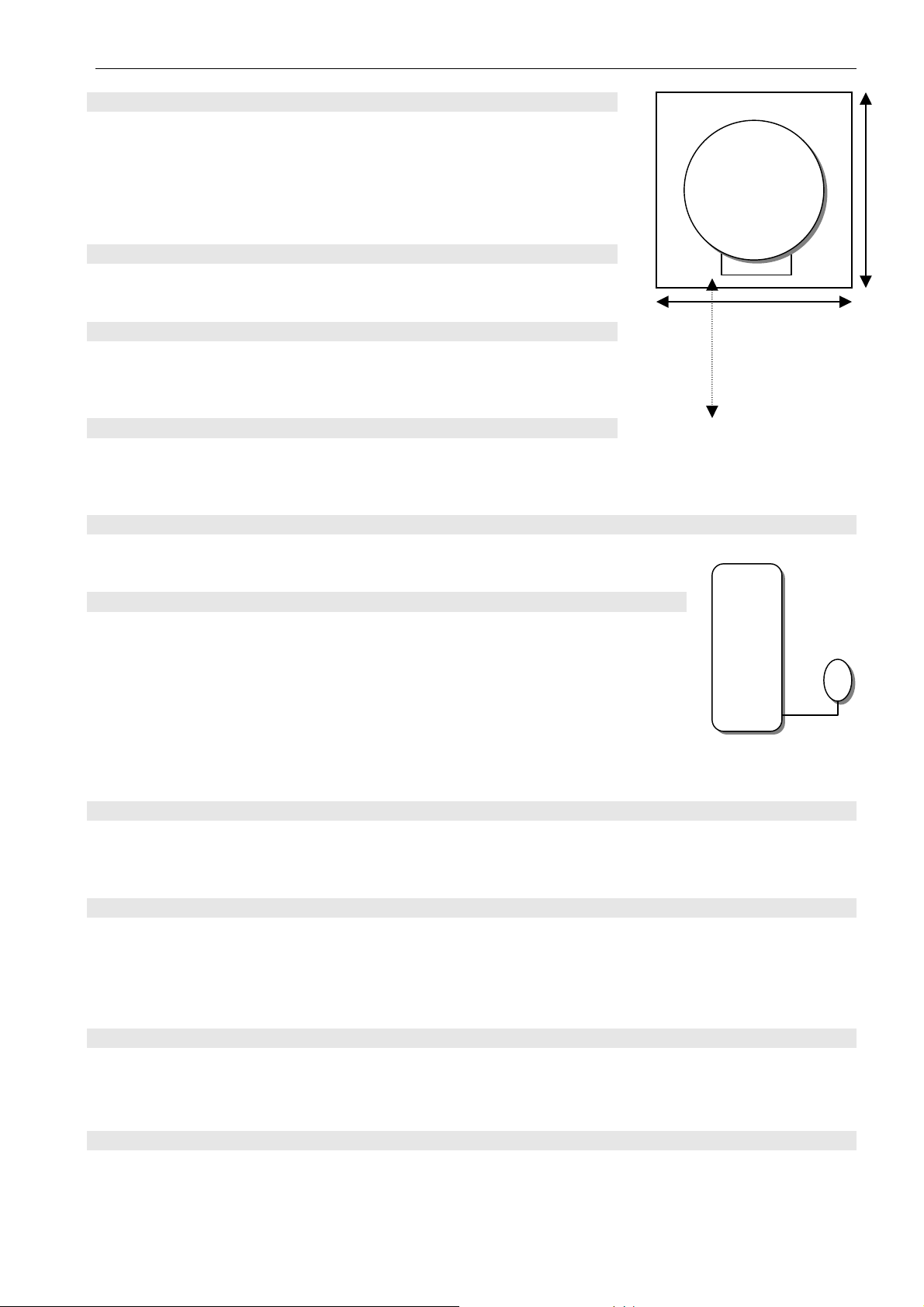

Diagram 2.2.3 - Clearances

2.2.3 Clearances

The boiler should be positioned so that at least the minimum

operational and servicing clearances are provided, see diagram

2.2.3 additional clearances may be required around the boiler for

installation. A clearance of 600mm is required at the front of the

boiler for maintenance and installation.

2.3.1 General notes

The boiler is intended for use in a sealed system only.

2.3.2 Safety valve

The safety relief valve is an integral part of the boiler. It cannot

be adjusted but has a manual test device.

2.3.3 Pressure Gauge

A pressure gauge is incorporated into the boiler to indicate the system pressure.

The gauge has a cold fill set pointer.

Thermaflow

Unit

front

500mm

600mm

600mm

2.3.4 Pump

The circulation pump is integral with the boiler.

Diagram 2.3.5

2.3.5 Expansion vessel

The TSL9/140U & TSL12/140U, TSL12/170 & TSL12/170U are all supplied

with an expansion vessel with a capacity of 25 litres. If the system water

content exceeds the maximum quoted in

table 1, [Data] an additional vessel

Expansion

Vessel

should be connected into the system as close as possible to the central

heating return connection of the boiler. Ref. Di

The charge pressure shall not be less than the static head at the point of

agram 2.3.5

Thermaflow ®

connection, which is the height of the top point of the system above the expansion vessel.

2.3.6 By- pass

An automatic by- pass valve should be incorporated in the system for maximum system

efficiency. (A By-Pass MUST be fitted on all models).

2.3.7 Filling sealed systems

The boiler has a filling loop incorporated within it, and pressure gauge to register the fill pressure.

There must be no permanent connection to the mains water supply; even though a non return valve

is supplied.

Disconnect filling loop and seal both valves with suitable caps.

2.3.8 Corrosion inhibitor

The maintenance of sufficient concentration of corrosion inhibitor in your Thermaflow system is vital

to prevent corrosion. We would recommend Sentinel X100, or equivalent. Dose appropriately

according to the size of the Thermaflow and central heating system volume combined.

2.3.9 Draining

A draining tap must be provided at the lowest points of the system, which will allow the

entire system to be drained. The boiler has one drain tap fitted to it for the primary circuit.

14

THERMAL INNOVATIONS (UK) LTD | THERMAFLOW® ELECTRIC COMBINATION BOILER | Tel: 0870 850 5207

2.4. Domestic hot water system

2.4.1 General

The domestic hot water service must be in accordance with the rules in force in the countries of

destination.

2.4.2 Water pressure

For the minimum and maximum, working pressures of the domestic hot water circuit of the boiler

refer to

(“data” table 1).

If the cold water inlet pressure exceeds 400 KPA (4 Bar) a pressure reducing valve must be

fitted to the inlet to the boiler.

2.4.3 HOT WATER FLOW RATE

The boiler is capable of flow rates of 15-20 litres per/min @ 40ºC ∆t (depending on model). Hot

water flow rate and pressure will be determined by the volume and pressure of the incoming cold

water supply.

2.4.4 Hard water areas

In areas where the water is “Hard” more than 200 mg / Litre, it is recommended that a proprietary

scale reducer or water softner is fitted in the cold water supply to the boiler. Consult the local water

authority for additional advice.

A double check valve assembly must be fitted upstream of the scale reducer/water softner, for the

relative position of the scale reducer/water softner and pressure reducing valve, if required, refer to

the manufacturers instructions.

2.5. Installation, PREPARATION [water connections]

2.5.1 Water connections

See General Data Diagram 1.8.1 & table 1.8.1 for pipe work connections

It is recommended to flush out the domestic water and heating system before connecting to the boiler.

While making the connections, do not subject any of the connections to heat as you may

damage the seals.

2.5.2 Safety valve discharge

It must not discharge above an entrance or window or any type of public access.

The position of the tundish shall be visible to the occupants and shall be positioned away

from any electrical devices.

The position of discharge pipes, tundish, drain valves and motorised valves etc. must be

positioned away from electrical components.

The water may drip from the discharge pipe of the pressure-relief device and must be left

open to the atmosphere.

The pressure relief device must be operated regularly to remove lime deposits and to verify

that it is not blocked.

15

THERMAL INNOVATIONS (UK) LTD | THERMAFLOW® ELECTRIC COMBINATION BOILER | Tel: 0870 850 5207

The discharge pipe connected to the pressure-relief device must be installed in a

continuously downward direction and in a frost free environment.

The connection for the discharge is made at the bottom side of the safety relief valve. A

tundish should be fitted by the installer in accordance with G3 of the current building

regulations.

This must be extended, using not less than 15mm O.D. metal pipe, to discharge, in a visible position,

outside the building, facing downwards, preferably over a drain. The pipe must have a continuous fall

and be routed to a position so that discharge water, possibly boiling or steam, cannot create any

danger to persons, damage to property or external electrical components and wiring.

2.6 Electrical Installation Requirements

• Power supply and wiring

The power supply to the premises must meet the minimum requirements of the unit being installed, with

special attention given to the supply current, cable size and MCB recommendation. The supply voltage to the

appliance must never drop below 207 Volts.

Important

The electrical supply requirements:The 9 KW and 12 KW boilers meet the requirements of EN 61000-3.3

The 9 KW and 12 KW boilers must be installed in premises having a service supply of ≥ 100A

per phase.

The 12 KW boiler must be installed in premises having a system impedance of not more than 0.1939 + J

0.1939Ω

2.6.1 SUPPLY

The boiler requires two separate ~230-240V power supplies. A (24HR) supply for controls and an

interruptible supply for the boiler. (Off Peak power supply if it is

The off peak or interruptible mains supply is wired according to the following

available).

diagram 2.6.1, from the

63 amp double pole isolator by way of flexible 16mm² cable into the main terminals in enclosure

marked

No. 3 on the boiler schematic diagram 1.8.1, see diagram 2.6.1 below.

16

THERMAL INNOVATIONS (UK) LTD | THERMAFLOW® ELECTRIC COMBINATION BOILER | Tel: 0870 850 5207

Diagram 2.6.1

Cable Sizing

Boiler Rating Minimum Cable Size ~

Supply

*

CONNECT TO METER / TELE-SWITCH

100A Double Pole

Isolating switch

with 63A or 50A

Type C MCB

located at meter or

consumer unit

*

L

*

N

*

E

25mm2 COLOUR CODED METER TAILS

100A Double Pole

Isolating switch

located adjacent to

Thermaflow

THERMAFLOW

TERMINALS

L

N

E

230-240V-50Hz, (8,250-9,000w - 10mm²) and (11,000-12,000w

– 16mm²). MCB MUST BE RATED ACCORDINGLY AND BE TYPE C

17

THERMAL INNOVATIONS (UK) LTD | THERMAFLOW® ELECTRIC COMBINATION BOILER | Tel: 0870 850 5207

Diagram 2.6.2a

2.6.2

The mains supply into the enclosure marked

No 10.1 on the boiler diagram should be wired to the

24HR supply via 3 Amp fused isolating switch located at the boiler,

ref. diagram 2.6.2a.

18

THERMAL INNOVATIONS (UK) LTD | THERMAFLOW® ELECTRIC COMBINATION BOILER | Tel: 0870 850 5207

Diagram 2.6.2b

2.6.3 External Controls

External heating controls should be connected to the terminals marked R1 & R2 shown in

. All external controls should be connected to terminals marked R1 & R2 in the enclosure

2.6.2b

marked

No 22 in the boiler schematic diagram 1.8.1.

diagram

WARNING: ALL EXTERNAL CONTROLS MUST NOT BE TAKEN FROM ANY OTHER

POWER SUPPLY OTHER THAN VIA THE

3 AMP FUSED ISOLATING SWITCH MENTIONED ABOVE.

19

THERMAL INNOVATIONS (UK) LTD | THERMAFLOW® ELECTRIC COMBINATION BOILER | Tel: 0870 850 5207

Electrical Connections

2.6.4 Supply cable connection [24 HR Supply]

Caution: To prevent an induced current from switching the central heating on when not required it is

important that the heating system control cables are separated from the other mains cables.

There is provided 2 heat resistant cables extending from the enclosure situated between both

circulating pumps. One cable has 3 cores. Live, Neutral and earth to be connected to a 3 amp double

pole fused isolator. The other cable has 2 cores coloured brown and (blue core covered with brown

sleeve) these are both common live and switched live wires to be connected to external heating

controls.

The boiler requires a permanent mains supply through an external isolator (rated to 3amp) which

must isolate any heating system controls see

diagram 2.6.2b

Any heating system controls must not interrupt the permanent mains supply to the boiler.

Standard colours are Brown- Live, Blue- Neutral and Green and yellow- Earth. Make the earth cable

of a greater length so that if the cable becomes strained the earth would be the last to become

disconnected.

CAUTION: IT IS ESSENTIAL TO MAKE SURE THAT THE POLARITY IS CORRECT.

2.6.5 Heating system controls

All external controls and wiring are required to provide a minimum of reinforced insulation at 250

vrms between the parts of those devices operating at mains hazardous voltage and the user

accessible parts of those devices.

Note: for further information, see the building regulations 1991- conservation of fuel and power,

1995 edition- appendix G, table 4B.

When any kind of external heating system controls are being used to regulate the heating system

connect a single pole type, to the appropriate terminals of the connector shown in

(to the 2 core cable provided).

diagram 2.6.2b, or

If the installation requires protection by a “Frost Thermostat” connect a single pole type, to the

appropriate terminals of the connector shown in

diagram 2.6.2b.

2.6.6 Electrical Test

Carry out preliminary electrical system checks as below.

1) Test insulation resistance to earth of mains cables.

2) Test earth continuity and short circuit of all cables.

3 Test the polarity of the mains.

4 Refit the enclosure cover.

20

THERMAL INNOVATIONS (UK) LTD | THERMAFLOW® ELECTRIC COMBINATION BOILER | Tel: 0870 850 5207

2.6.7 Supply cable connection [Interrupted off peak supply]

Open the lower of the two enclosures situated at the top of the boiler.

Using 16mm² twin and earth cable of a suitable length route the mains interrupted supply cable

through a piece of suitably sized flexible conduit from the 60amp isolator into the terminals shown in

diagram 5.

Standard colours are Brown- Live, Blue- Neutral and the earth should be sleeved with a suitably

sized green and yellow earth sleeve.

Make the earth cable of a greater length so that if the cable is strained the earth would be the last to

become disconnected.

CAUTION: IT IS ESSENTIAL TO MAKE SURE THE POLARITY IS CORRECT.

2.6.8 Electrical Test

Carry out preliminary electrical system check as below:

1) Test insulation resistance to earth, of mains cables.

2 Test earth continuity and short circuit of all cables

3 Test the polarity of the mains.

4 Refit the enclosure cover.

Electricity tariffs

The Thermaflow will operate on any ~230-240V, 50Hz supply. The most economical option is a

peak avoidance tariff as described previously.

Scottish Power, Eastern Energy, Guernsey Electric North Eastern Electricity all has an 18 hour tariff.

Other areas offer their own tariffs, which may be viable for economic operation.

2.7 Commissioning

2.7.1 Filling domestic water circuit

Check that the boiler is isolated from the electrical supply, at both external isolators.

Fully open the domestic water supply stop cock or valve in the supply to the boiler.

Open all hot water draw-off taps and close them when water flows. Check for water soundness of

the whole domestic hot water installation and boiler.

2.7.2 Filling the heating system

Flush, fill and vent the system refer to section 3.7 “Filling sealed systems”.

The boiler and central heating system should be completely filled and purged of air before switching on the

power to the appliance. The cold fill pressure should register no more than 120 KPA (1.2 Bar). See Table

1.8.1 (DATA), for minimum and maximum pressures.

Make sure the automatic air vent at the top of the boiler is operating correctly.

21

THERMAL INNOVATIONS (UK) LTD | THERMAFLOW® ELECTRIC COMBINATION BOILER | Tel: 0870 850 5207

IMPORTANT

MAKE SURE THE BOILER AND SYSTEM IS COMPLETELY FULL OF WATER AND ALL

AIR IS ELIMINATED BEFORE TURNING ON ANY OF THE POWER SUPPLIES TO THE

BOILER.

Take care not to splash any of the electrical components.

Pressurise the system until the pressure is 150 KPA (1.5 Bar).

boiler for

water soundness.

Check the operation of the safety valve by turning the safety valve knob in the direction of the arrow.

Lower the pressure to the initial cold fill design pressure of 120 KPA (1.2 Bar),

Position the set pointer on the boiler pressure gauge at this pressure also.

NOTE: When the boiler reaches its maximum temperature, the pressure will increase to around 200

KPA (2.0 Bar)

2.7.3 Domestic hot water flow rate

The domestic hot water flow rate can be set by adjusting the stop cock on the cold water inlet to the

boiler.

Check the heating system and

refer to table 1.8.1.

2.7.4 Temperature settings

The maximum temperature setting for the domestic hot water is 50oC but is user adjustable by

altering the setting on the hot water mixing valve on the boiler.

The maximum flow temperature setting for central heating is 82oC this is the preset and is not

adjustable.

2.7.5 Heating system commissioning

Make sure the boiler and heating system is completely full of water. (SEE ABOVE SECTION 7.2)

Turn on both 24Hr & Interrupted power supplies. Allow approximately 90 - 160 minutes to bring the

boiler up to temperature (depending on model). Check that all external controls, are calling for heat.

Fully open all thermostatic and lock shield valves on each radiator.

Set the aqua stat, positioned at the centre of the boiler to 30ºC (It must remain at this setting)

Allow this system to reach maximum temperature then switch off both electrical supplies at the

isolators. Drain the system rapidly while still hot.

Fill and vent the system as described in section 7.2 “Filling the central heating circuit” Add inhibitor

as required refer to section 3.8 “Corrosion Inhibitor”

Set to the initial cold fill design pressure, using the external draining tap. Refer to table 1, and

section 3.9

NOTE: The system fill pressure may require to be recharged once or twice in the first two to

three weeks after the initial commissioning of the boiler due to oxygen in the system being

expelled through the automatic air eliminator. There should be no further need to repressurise the system after this period. If the system requires continuous re-pressurisation,

there may be a leak in the installation.

22

THERMAL INNOVATIONS (UK) LTD | THERMAFLOW® ELECTRIC COMBINATION BOILER | Tel: 0870 850 5207

2.7.6 Completion

Set any external heating control to the desired settings.

Instruct the user

Instruct and demonstrate the isolating switches then advise the user of the efficient and safe

operation of the boiler.

Instruct and demonstrate the operation of any heating system controls.

Advise the user on the use and maintenance of any scale reducer and pass on any relevant

instructional documents.

Advise the user that to ensure continued efficient and safe operation of the appliance, it is

recommended that it is checked and serviced at regular intervals. The frequency of servicing will

depend on the particular installation and usage, but in general once a year should be enough.

Any servicing should be carried out by a person competent to do so.

Advise the user of the precautions necessary to prevent damage to the system and building in the

event of the heating system being out of use during frost and freezing conditions.

Reminder- leave these instructions with the user.

Advise the user that the logbook should be completed by the engineer on completion of

commissioning. Failure to do so will invalidate the warranty. The user must sign the log book

and retain it for future reference.

23

THERMAL INNOVATIONS (UK) LTD | THERMAFLOW® ELECTRIC COMBINATION BOILER | Tel: 0870 850 5207

PART 3 - SERVICING

3.1. Fault Finding

MUST BE CARRIED OUT BY A PERSON COMPETENT TO DO SO

Before trying to operate the boiler make sure that:

The heating system pressure is at 120 KPA (1.2 Bar) when the system is cold and 200 KPA (2.0

Bar) when the system is at maximum temperature.

There is a permanent mains power, (24hr supply) to the terminals marked in the controls enclosure

at the bottom of the boiler (Marked No 10-1 on the boiler schematic diagram 1.8.1).

There is power at the off peak (Interrupted) supply main switch in the lower enclosure at the top of

the boiler (Marked No 3 on the boiler schematic diagram 1.8.1).

WARNING: BEFORE OBTAINING ACCESS TO TERMINALS, ALL SUPPLY CIRCUITS

MUST BE DISCONNECTED.

IMPORTANT:

ON COMPLETION OF THE FAULT FINDING TASK WHICH HAS REQUIRED

THE BREAKING OR REMAKING OF THE ELECTRICAL CONNECTIONS, THE

CONTINUITY, POLARITY, SHORT CIRCUIT AND RESISTANCE TO EARTH CHECKS

MUST BE REPEATED USING A SUITABLE MULTI- METER.

Type of fault

Check

No domestic hot water or central heating ~230-240V Supply (24HR)

~230-240V Supply (Off Peak)

System water pressure

Master high limit thermostat

Contactor

Reset-able Over Heat Thermostats

No central heating but hot water at

taps

Heating elements

~230-240V Supply (24HR)

~230-240V Supply (Off Peak)

External controls

Heating elements

Reset-able Over Heat Thermostats

Temperature at centre of store

setting of 30ºC

Central heating but no hot water at

taps or temperature diminishes after a

short period

Central heating pump

Auto air eliminator in closed position

Hot water mixing valve set too low or is faulty

must be above aqua stat

24

THERMAL INNOVATIONS (UK) LTD | THERMAFLOW® ELECTRIC COMBINATION BOILER | Tel: 0870 850 5207

Fault: No domestic hot water or central heating

Is there ~230-240V at the 24HR supply?

No

Is there ~230-240V at the off peak supply?

Yes

No

Is system pressure above 60 KPA (0.6 Bar)?

Yes

No

Is there continuity through master high limit stat?

Yes

No

Is there continuity through contactor?

Yes

No

Yes

Is there ~230-240V at each heating element and

continuity through thermostats within?

No

Check Fuse, MCB or Meter for correct

operation

Check Fuse or MCB

Increase Pressure

Replace Thermostat

Replace Contactor

Replace or re-set as necessary

25

THERMAL INNOVATIONS (UK) LTD | THERMAFLOW® ELECTRIC COMBINATION BOILER | Tel: 0870 850 5207

Fault: No central heating, but hot water at taps

Is there continuity through master high limit stat?

No

Yes

Replace Thermostat

Is there continuity through contactor?

Yes

Is there ~230-240V at each heating element and

continuity through thermostats within?

Yes

Are external controls calling for heat?

Yes

Is temperature above setting on aqua stat?

(Should be set to 30

o

C)

Yes

Is there ~230-240V and continuity at terminals of the

aqua stat?

Yes

No

No

No

No

No

Replace Contactor

Replace or re-set as necessary

Adjust the setting

Re-check when temperature increases

Check ~230V Supply

Is there ~230-240V supply at central Heating pump?

Yes

Is pump impeller turning?

Yes

Check thermostat and lock shield Valves on radiators are

open & calling for heat

No

No

Check for faulty external controls

Replace central heating pump

26

THERMAL INNOVATIONS (UK) LTD | THERMAFLOW® ELECTRIC COMBINATION BOILER | Tel: 0870 850 5207

Fault: CENTRAL HEATING BUT No hot water at taps

Is the automatic air eliminator on top of the boiler in the

open position causing an air trap in the top of the boiler?

Is the hot water mixing valve set correctly?

Replace hot water mixing valve

Yes

Yes

No

No

Open the small screw cap on top of the

auto air eliminator

Set to desired temperature

27

THERMAL INNOVATIONS (UK) LTD | THERMAFLOW® ELECTRIC COMBINATION BOILER | Tel: 0870 850 5207

WARNING: FOR YOUR OWN SAFETY

SERVICING AND MAINTENANCE SHOULD BE CARRIED OUT BY A PERSON WHO IS

COMPETENT TO DO SO.

3.2 ISOLATION

• Before commencing, refer to section 1. Installation

Checking the pressure in the expansion vessel

The primary expansion vessel (volume 25 litres) is the red or vessel connected to the central

heating return pipe or to the branch of the tee where the auto air vent is connected to on top of the

boiler. Its purpose is to take up expansion in the boiler and central heating system.

The pressure can be accurately checked with the pressure relieved on the other side of the

diaphragm. To do this drain some water from the central heating system until the pressure gauge

registers zero. Connect a pressure gauge to the car tyre type valve on the vessel. The pressure

should register 150 KPA (1.5 Bar). Refill heating system as described in section 2.7.2

The secondary expansion vessel (volume 1 or 2 litres) is the white or silver vessel connected to the

hot outlet of the pre-heat coil at the top of the boiler.

Its function is to take up expansion in the hot water pipe work and so protect the blender from

damage.

The pressure can be accurately checked with the pressure relieved on the other side of the

diaphragm. To do this, isolate the water supply to the Thermaflow and open a hot tap. Water will run

for a few seconds then stop.

Connect a pressure gauge to the car tyre type valve on the vessel. The pressure should register

100KPA (1.0 Bar) on the 1 litre vessel or 350 KPA (3.5 Bar) on the 2 litre vessel. Close the hot taps

and turn the water supply back on.

Checking the inline strainer

Whilst the water is off, remove and clean the gauze in the brass strainer assembly. To remove the

gauze for cleaning un-screw the brass plug.

Checking the hot water blending valve

With the store temperature fully recovered, run a hot tap and check the flow rate and temperature.

If the hot water has deteriorated suddenly (over less than a month) then this points to a problem

with the blender.

A broken blender is usually linked to a loss of pressure in the secondary expansion vessel. The

expansion vessel protects the blender from damage when the water in the secondary system

expands as the water re-heats after water is drawn off.

Check the pressure in the secondary expansion vessel as detailed previously in section 2. If it does

not hold pressure it will need to be changed along with the blender.

Strip off the blender and check hot and cold mesh filters for blockage. (Clean if necessary).

28

THERMAL INNOVATIONS (UK) LTD | THERMAFLOW® ELECTRIC COMBINATION BOILER | Tel: 0870 850 5207

Checking the concentration of corrosion inhibitor

We would recommend Sentinel X100, or equivalent. Dose appropriately according to the size of the

Thermaflow and central heating system volume combined and in accordance with the inhibitor

manufacturer’s guidelines.

Preventing pump seizure in summer

To prevent seizure of the central heating pump we recommend you turn the central heating on for

30 seconds or so every few weeks throughout the summer.

Seized pumps can usually be freed. The air release on the pump can be completely removed. A

small flat blade screwdriver can be inserted into the slot in the centre and rotated to free the pump.

Checking correct operation of electrical components

WARNING: BEFORE OBTAINING ACCESS TO TERMINALS, ALL SUPPLY CIRCUITS

MUST BE DISCONNECTED.

Low pressure switch

To check correct operation of the low pressure switch, drain some water from the central heating

system until the pressure falls below 0.5 bar, then check continuity between terminals 1 and 2 there

should be no continuity between these terminals. Re pressurise the boiler and re check there is

continuity between the same terminals.

Control and high limit thermostats

Check operation of the control and over temperature thermostats by checking for continuity between

both terminals. (YOU MAY HAVE TO REMOVE THESE THERMOSTATS IF THE BOILER IS STILL

HOLDING HOT WATER. YOU CAN PLACE THE THERMOSTATS IN A BEAKER OF COLD

WATER AND THEN CHECK FOR CONTINUITY ACROSS THE THERMOSTAT).

CONTROL THERMOSTATS; there are three or four of these thermostats in total, one in each

element. The control thermostats are individually preset and sealed; they should not be tampered

with. If a failure on one of the thermostats has occurred, take note of which element it was removed

from and contact Thermal Innovations (UK) Ltd for spares and advice.

OVER TEMPERATURE THERMOSTATS (Manual reset); there is also three or four of these, one in

each element. The over temperature thermostats are individually preset and sealed they should not

be tampered with. If a failure on one of the thermostats has occurred, reset the thermostat by

pressing the small reset button on the thermostat. If the thermostat continues to fail in an overheat

condition, take note of which element it was removed from and contact Thermal Innovations (UK)

Ltd for spares and advice.

There is also a non reset-able over temperature thermostat in the top enclosure this is the master

over temperature thermostat, this will break the circuit on over temperature it is preset and sealed

and should not be tampered with. This thermostat is not reset-able and will have to be replaced if it

has incurred an overheat situation). This will indicate a fault has occurred elsewhere and will

have to be investigated and rectified before the appliance is turned back on for use. If a

failure has occurred, contact Thermal Innovations (UK) Ltd for spares and advice.

Checking the elements

Check the continuity between live and neutral terminals on the element. Replace the element if

there is no continuity.

29

THERMAL INNOVATIONS (UK) LTD | THERMAFLOW® ELECTRIC COMBINATION BOILER | Tel: 0870 850 5207

Checking circuit breakers

Switch each circuit breaker off in turn and check that continuity is broken to each element.

Checking the contactor

Turn the main isolator off (this should be situated adjacent to the boiler) you should hear a dull

thump from the enclosure marked number 3 on the boiler schematic diagram 1.8.1. This indicates

that the contactor has disconnected the circuit to the MCB’s and in turn the heating elements. Turn

the main isolator on and off a few times and listen for this noise. This will indicate correct operation

of the contactor.

Check the operation of the AQUA STAT

The Aqua Stat is positioned at the entrance to the pre-heat coil on the cold water supply above the

top heating element on the boiler.

Make sure the external controls are calling for heat. Turn the dial

on the thermostat up and down and listen for a small click. As you turn the thermostat dial up and

down check if the central heating pump, (positioned on the right side of the unit) is switching

and

off. If this is the case, this indicates correct operation of the thermostat.

on

30

THERMAL INNOVATIONS (UK) LTD | THERMAFLOW® ELECTRIC COMBINATION BOILER | Tel: 0870 850 5207

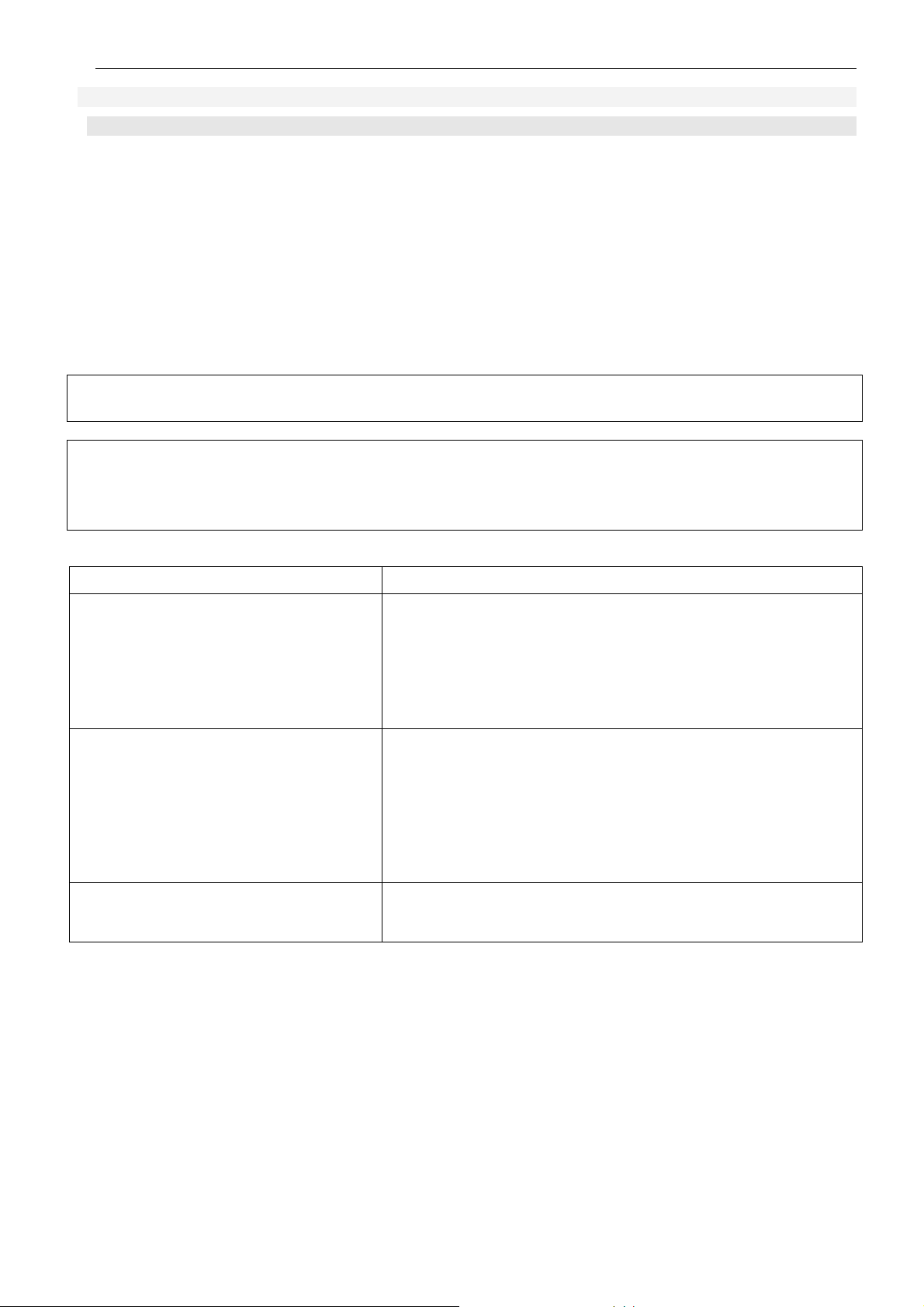

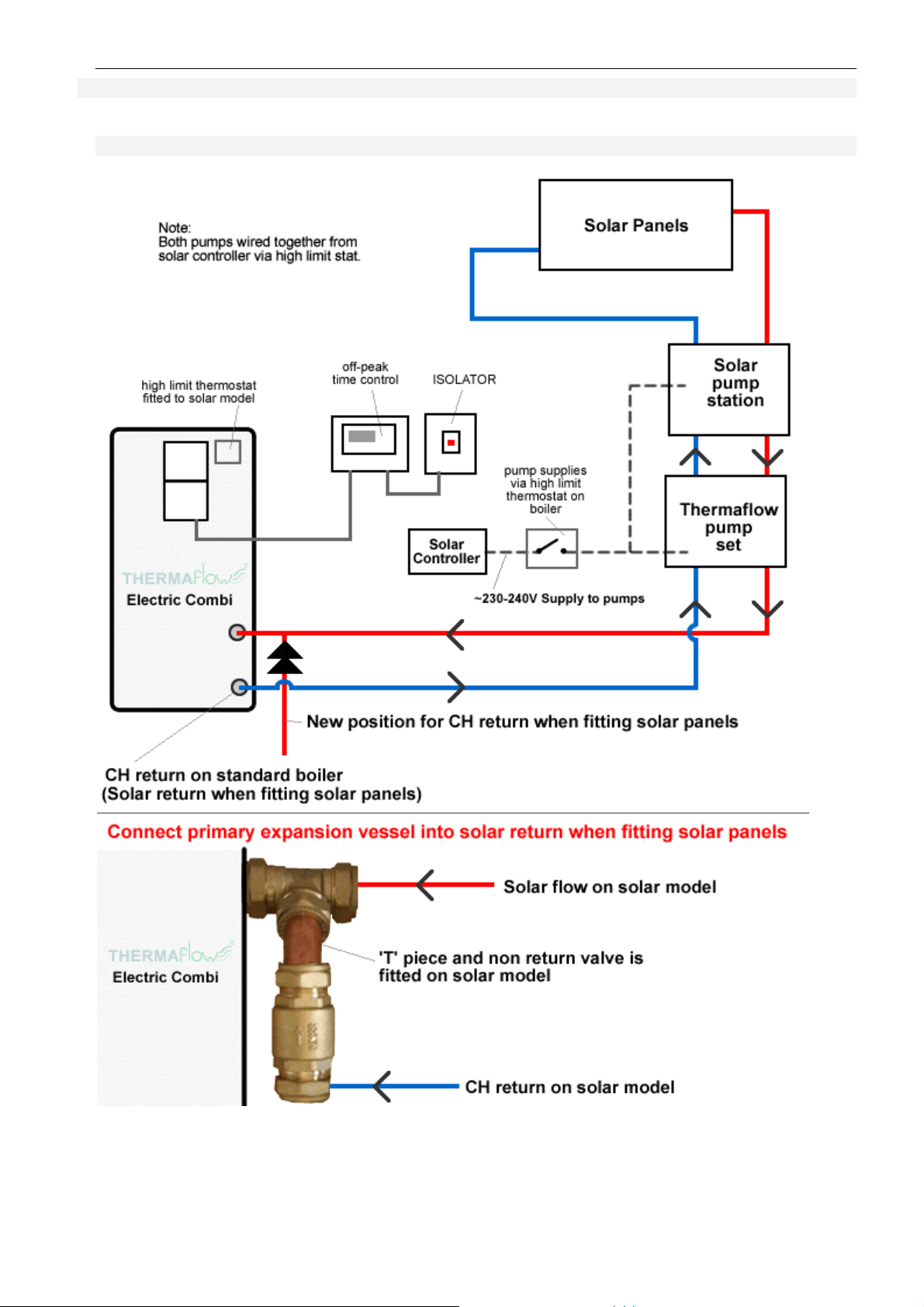

APPENDIX I – SOLAR CONNECTION

A1.1 Solar Pipe work Schematic

31

THERMAL INNOVATIONS (UK) LTD | THERMAFLOW® ELECTRIC COMBINATION BOILER | Tel: 0870 850 5207

A1.2 Solar/Off Peak Wiring Schematic

32

Loading...

Loading...