Page 1

Thermador A. America.tco.,_

S!ii!!i_,_,i_,_,_,,¸.........,,,,,,,,,,,,,,,I_ji_i_,,,_l.............................

Page 2

SAFETY INSTRUCTIONS

Read All Instructions Before Using the Appliance.

READ AND SAVE THESE INSTRUCTIONS

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC

SHOCK, OR INJURY TO PERSONS, OBSERVE

THE FOLLOWING:

A. Installation work and electrical wiring must be done

by qualified person(s)in accordance with all appli-

cable codes and standards, including fire-related

construction.

B. Sufficient air is needed for proper combustion and

exhausting of gases through the flue (chimney) of

fuel burning equipment to prevent backdrafting.

Follow the heating equipment manufacturer's

guideline and safety standards such as those

published by the National Fire Protection Associa-

tion (NFPA), and the American Society for Heating,

Refrigeration and Air Conditioning Engineers

(ASHRAE), and the local code authorities.

C When cutting or drilling into wall or ceiling, do not

damage electrical wiring and other hidden utilities.

D. Ducted fans must always be vented to the outdoors.

E. Always unplug or disconnect the downdraft from the

power supply before servicing.

F. This unit is designed for indoor use only. Use this

unit only in the manner intended by the manufac-

turer.

This unit is manufactured for indoor use only. Do not use

this unit outdoors.

WARNING

CAUTION: Forgeneral ventilating use only. Do

not use to exhaust hazardous or explosive materi-

als and vapors.

To reduce risk of fire and to properly exhaust air,

be sure to duct air outside. Do not vent exhaust

air into spaces within walls, ceilings, attics, crawl

spaces or garages.

TO REDUCE THE RISK OF FIRE, USE ONLY

METAL DUCT WORK.

To reduce the risk of fire, electric shock and injury

to persons, ventilator assemblies. All CVS2

models must be installed with integral blower,

Model VTN600CV2C or remote blowers model

VTR600R or VTR1000Q. Other ventilator blowers

cannot be substituted.

To reduce the risk of fire or electric shock, do not

use the fan with any solid-state speed control

device.

This appliance has been found to be in compli-

ance with UL507 Standard for Electric Fans and

CAN/CSA-22.2 No. 113 Canadian Standard for

Fans and Ventilators. It is the responsibility of the

owner and the installer to determine if additional

requirements or standards apply in specific

installations.

Parts Needed

Blower (Remote or Integral)

Tape Measure

Phillips Head Screwdriver

Duct Tape

Ductwork (confguration varies depending on location;

See pages 4-7 for further information)

Additional Sheetmetal screws (as necessary for

ductwork installation)

Transition(s) (style varies depending on ductwork)

Transition box for remote blower installations is available

as an accessory.

Saw (or equivalent for cutting countertop)

#8 x 1 1/4" Wood Screws (4)

Parts Supplied

• Downdraft assembly (1)

#8 Sheetmetal Screws (8)

Blower Cord Strain Relief (1)

Hardware for brackets on vent (2)

Remote Blower Pigtail

Page 1

Page 3

:igure 1

Top Cap

Internal Blower

(Not Included)

Strain Relief

INTRODUCTION

GENERAL DESCRIPTION

The complete downdraft system consists of the ventilator,

the intake and the blower (See Fig. 1), The blower can be

either integral (mounted on the vent intake in the cabinet

under the cooktop) or a remote (mounted on the roof or

outside wall. When a remote blower is used, a duct transi-

tion is mounted on the ventilator intake in place of the

integral blower to connect the intake to the ductwork, The

duct transition must be purchased separately.

The integral blower or duct transition can be mounted in

different positions on the intake to route ductwork to avoid

cabinet, building framing, utilities, etc,

The downdraft system is available in 30-inch, 36-inch and

45-inch models. Black or white top cap accessories are

available to change the color from the basic stainless

steel. It is intended for use with all brands and models of

residential 30-inch, 36-inch or 45-inch gas or electric

cooktops except professional style cooktops.

Step 1 PLAN THE INSTALLATION

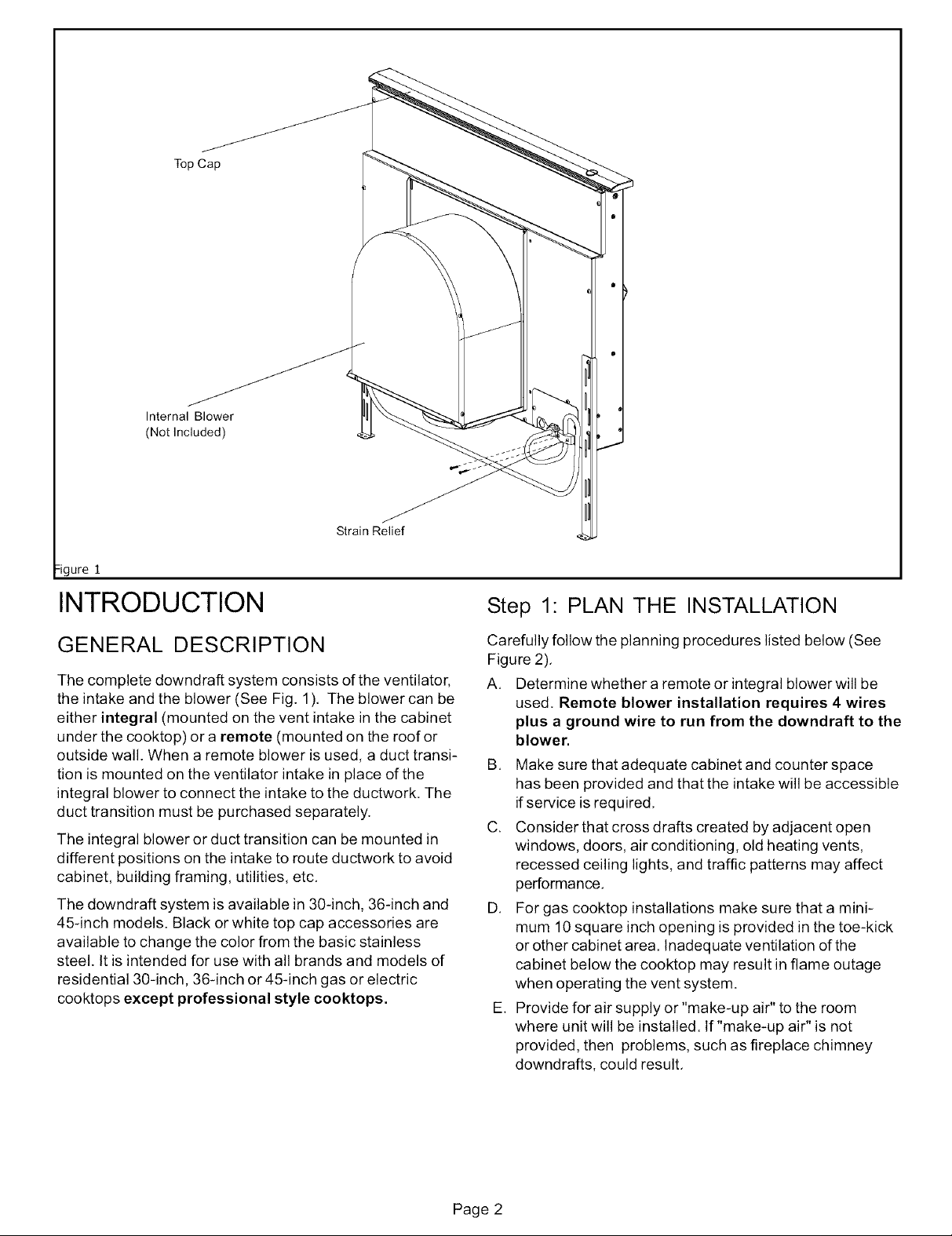

Carefully follow the planning procedures listed below (See

Figure 2),

A, Determine whether a remote or integral blower will be

used. Remote blower installation requires 4 wires

plus a ground wire to run from the downdraft to the

blower.

B, Make sure that adequate cabinet and counter space

has been provided and that the intake will be accessible

if service is required,

C. Consider that cross drafts created by adjacent open

windows, doors, air conditioning, old heating vents,

recessed ceiling lights, and traffic patterns may affect

performance,

D, For gas cooktop installations make sure that a mini-

mum 10 square inch opening is provided in the toe-kick

or other cabinet area. Inadequate ventilation of the

cabinet below the cooktop may result in flame outage

when operating the vent system.

E. Provide for air supply or"make-up air" to the room

where unit will be installed. If "make-up air" is not

provided, then problems, such as fireplace chimney

downdrafts, could result,

Page 2

Page 4

1/4"

Cooktop

" Be certain to avoid interference with gas and

electric supply to cooktop.

o

Shelving and drawer depths are dependent

upon cooktop depth and setback.

-: 25"

/

/

t Dimensions are dependent on

discharge direction.

Cutout

Depth

SB (see

Fig. 7,8)

L

/

/

f

36"

22" t

Drawer

Max.

Shelving must

be removable

|

14" Max,

Integral/Remote

A 9-13/16"

B 13"

Figure 2

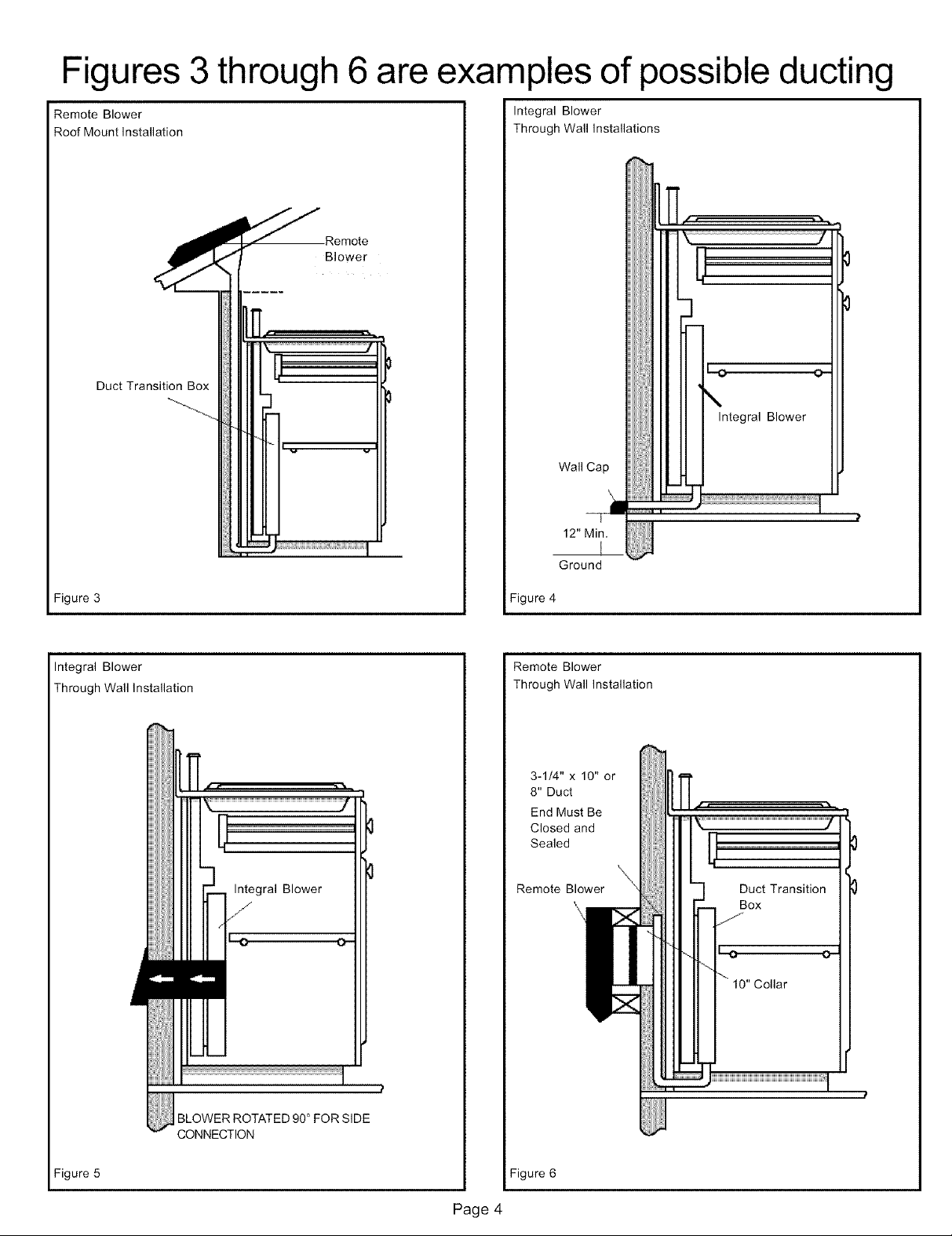

Investigate potential ductwork routes and choose the G.

shortest possible route from the unit to an outside wall

or to the roof via an inside wall and attic. For guidance,

typical ducting installations are shown in figures 3

through 6. Installation in island locations will require

under floor ducting. Peninsula locations usually require

ducting laterally through cabinets or under cabinet toe-

spaces. Consider potential interferences to ductwork

from building framing (floor joists, wall studs, etc.) and

utilities (electrical wiring, water, gas, or sewer lines, H.

etc.).

Page 3

24 _'

Determine whether the chosen route of ducting will meet

vent system performance requirements. To do this,

measure the duct lengths needed and determine spe-

cific fittings required. Enter this data in the spaces

provided in addition, the duct installation guidelines in

Table 2 (See Page 6) should be followed in developing

the ductwork plan.

Purchase the necessary ductwork inaccordance with

the listing developed in G above.

Page 5

Figures 3 through 6 are examples of possible ducting

Remote Blower

Roof Mount Installation

Duct Transition Box

Integral Blower

Through Wall Installations

Remote

Blower

Wall Cap

12" Min.

I

Ground

Figure 3

Integral Blower

Through Wall Installation

Figure 4

Remote Blower

Through Wall Installation

3-1/4" x 10" or

8" Duct

End Must Be

Closed and

Sealed

",\

Remote Blower

Figure 5

BLOWER ROTATED 90° FOR SIDE

CONNECTION

Figure 6

Page 4

Page 6

TABLE I. VENTILATOR PERFORMANCE CALCULATION

DUCTPIECES

ROUND

I.-- I' .--I 10"

i STRAIGHT

I'_ I"_1 STRAIGHT

(_ 6" 12'

3-1/4" x 10"

3-1/4" x 14"

90 °

ELBOW 7" 8'

ROUND 8" 6'

4s° 7" 4'

ELBOW

EQUIVALENT:_UANTITY EQUIVALENT

SIZE LENGTH USED LENGTH

1!

7"

0.95' \\Z_ CENTER

8"

0.7' _ _ REVERSE

0.6' ELBOW LEFT

0.7' ELBOW

6" 5'

ROUND 8" 3'

_3-1/4"Xl 0" N/A

90° ELBOW

TOTAL

DUCTPIECES

J.2' _3-1/4"X 10"

3-1/4"X 10"

REVERSE

J' _ CENTER

_ 3-1/4"X 10"

1

_]._ WALL CAP '_

_r Model #WC I 0 I 0"

RIGHT

RIGHT

REVERSE

ELBOW

LEFT

REVERSE

3-1/4"X 10"

ELBOW

ROUND 6"

Model #WCE 8'm'

SIZE EQUIVALENTQUANTITY TOTAL

USED EQUIVALENT

LENGTH LENGTH

N/A 15'

N/.,_

N/_ 25'

N/._

25'

15'

1

-

6 ww

_3-1/4"X 10"

45° ELBOW

- 114"El 0"

FLAT N/A

ELBOW

ROUND TO 6"

I/4"XI0" 7"

3-1/4"XI0" 6"

ROUND 7"

ROUND TO 6"

3-1/4"Xl 0"

° ELBOW 7"

3- I/4"X I 0" 6"

TO ROUND

0° ELBOW 7"

N/A

15'

ROOF

ROUND 7"

CAP 8"

20'

-I/4"xl 0" Flex

Model #RD 1

I'

I'

,

3'

10'

8' Damper

I 0' Roof Jack

5' Model # RJ310

m_F_ 3"I14'' ,,

'C'._i_ 1 _ 3-1/4 xlO"

<- - __'_ to Round

• 6,,_/4 Model 310TRI0

_M 3- I/4"x I0"

_ 3-1/4"xl0"

Wall Cap

odel WC310

Backdraft

7" In-Line

Model # I 40

& Shutter,

1

20'

!

1

1

NOTE: Fittings with model numbers stated are available through your

Thermador dealer. All other fittings are available from most major

hardware stores.

Page 5

TOTAL (of both columns)=

Page 7

DUCTWORK INSTALLATION GUIDELINES

For safety reasons, ducting should vent directly

outdoors (not into an attic, underneath the house, into

the garage or into any enclosed space).

Keep duct runs as short and straight as possible.

Duct fittings (elbows and transitions) reduce air flow

efficiency.

Back to back elbows and "S" turns give very poor

delivery and are not recommended.

A short straight length of duct at the inlet of the

remote blower gives the best delivery.

Transition to duct from the integral blower or remote

duct transition as close to the downdraft as is pos-

sible. In order of preference, use

1st. 10" round duct

2nd. 8" round duct

3rd. 3-1/4" x 14" duct

4th. 7" round duct

5th. 3-1/4" x 10"duct

6th. 6" round duct

The use of flexible metal round duct should only be

used when no other duct fitting exists. Limit use to

short lengths and do not crush when making corners.

Where local codes permit, plastic pipe (PVC-schedule

40 pipe orABS pipe 7" or 8" diameter) can be used in

areas of high ground moisture and in slab floors to

eliminate future rusting.

Use only duct work constructed of materials that are

acceptable by the applicable codes. All duct should

be 26 gauge or heavier to minimize flex due to airflow.

The remote blowers requires a 10" or 8" diameter

round duct (depending on model) to match the inlet

ring. A transition is necessary from other duct sizes.

Use sheet metal screws as required to support the

duct weight, and seal all joints with duct tape.

Be certain that the duct work does not interfere with

floor joists or wall studs.

Do not exhaust more than one vent into a single duct

run.

Thermal breaks, such as a short section of nonmetal-

lic duct, should be used in areas of extreme cold.

Always use an appropriate roof or wall-cap with

damper. Laundry type wall caps should never be used.

Step 2: Prepare Countertop Cutout

For installation with a Thermador cooktop, refer to Part A(at

left) and Figure 7 (Page 7)). For installation with another

brand of cooktop, refer to Part B (Page 8).

For all installations verify that all cutouts will clear the inside

of the front countertop support rail, and that the cooktop and

vent will be centered left to right within the cutout. Also,

make certain that the front and rear cutouts are straight and

parallel to the front edge of countertop and the rear backs-

plash and/or wall. Assure that the side cutouts are square

to the front and rear cutouts. All illustrations and dimen-

sions are based on standard 24" deep by 36" high American

style base cabinets with 25" countertops.

When installing laminated or solid surface countertops such

as Surell TM and Corian ®, be sure to follow the countertop

manufacturer's instructions regarding minimum corner radii,

reinforcement of corners, etc.

For overhead cabinet and cooktop side clearances

consult cooktop Installation Instructions.

A, FOR INSTALLATION WITH A

THERMADOR COOK TOP (FIGURE 7

AND TABLE 3)

Provide an opening in the countertop as specified in

Table 3 (Page 8). Make sure that the distance from the

front of the countertop to the front of the cutout is not

less than dimension "SB". Verify that the available flat

countertop is greater than dimensions "OW" by "OD".

Make certain that the backsplash thickness does not

exceed dimension "BT".

Page 6

Page 8

TABLE 2: INSTALLATION

COOKTOP

Cooktop CW

Model No, Cutout

Width

DIMENSIONS FOR CVS2 WITH THERMADOR

Cutout Overall Overall

I CD OW OD

Depth Width Depth

Minimum

I SB

Set Back

Backsplash

I T, Max++

Thickness

I

I 30" Cooktops:

SGS304"

SGSX304*

CET304

CEP304

CEM304

Installed with CVS230 / UCV230

28-15/16

28-15/16

28-3/4

28-3/4

28-3/4

22-1/4

22-1/4

22-1/8

22-1/8

22-1/8

31

31

31

31

31

23-3/4

23-3/4

23-7/8

23-7/8

23-7/8

1-1/2

1-1/2

2-1/2

2-1/2

2-1/2

[ 36"Cooktops: Installed with CVS236 / UCV236

SGS365"*

SGSX365**

CET365

CEP365

CEM365

45" Cooktops:

I

SGS456

SGSX456

CET456

CEP456

CEM456

Table 2 Notes

* Dimension "SB" is the minimum distance from the leading

edge of the counter to the leading edge of the cutout,

++Dimension "BT" is the thickness of backsplash that

provides 1/4" clearance between vent and backsplash,

Any backsplash with a curved radius where it meets the

counter will require additional clearance. Thicker

backsplashes may be used by increasing the counter

and cabinet depths,

34-15/16

34-15/16

34-3/4

34-3/4

34-3/4

22-1/4

22-1/4

22-1/8

22-1/8

22-1/8

37

37

37

37

37

23-3/4

23-3/4

23-7/8

23-7/8

23-7/8

Installed with CVS245 / UCV245

43-15/16 22-1/4

43-15/16 22-1/4

43-3/4 22-1/8

43-3/4 122-1/8

43-3/4 [22-1/8

46

46

46

46

46

All dimensions are in inches and are based upon a

23-3/4

23-3/4

23-7/8

23-7/8

23-7/8

standard 24" deep base cabinet with 25" countertop.

* * SGS and SGSX: width in table is at the widest point

(center).

Refer to cooktop Installation Instructions for complete

information prior to making any cutouts,

Clearance is provided to allow raising of the hinged main

top,

1-1/2

1-1/2

2-1/2

2-1/2

2-1/2

1-1/2

1-1/2

2-1/2

2-1/2

2-1/2

INSTALLATION WITH THERMADOR COOKTOPS WHEN SPECIFIED

1

3/4

3/4

0

0

0

1

3/4

3/4

0

0

0

I

3/4

3/4

0

0

0

Figure 7

2 1/4"

Page 7

Page 9

INSTALLATION WITH OTHER COOKTOPS WHERE SPECIFIED (SEE PART B)

21/4"

Figure 8

B. FOR INSTALLATION WITH ANOTHER BRAND OF COOKTOP (Figure 8)

Have the following cooktop measurements available before

proceeding All cooktop dimensions should be verified

through measurement prior to cutting the countertop:

CCW = Cooktop Cutout Width

CCD = Cooktop Cutout Depth

COW = Cooktop Overall Width

COD = Cooktop Overall Depth

with the above dimensions confirmed, determine the cutout

size as follows:

1. Find the cutout width, (CW):

If CCW is smaller than the CVS2 / UCV2 cutout width

then:

Installation CW

CVS230 / UCV230 283/8

CVS236 / UCV236 343/8

CVS245 / UCV245 433/8

If CCW is larger than the CVS2 / UCV2 cutout width

then:

CW = CCW

See Figure 8 for CVS2 / UCV2 cutout widths and

dimension definitions,

2. Calculate the cutout depth, CD:

Determine the cooktop overhang (CO)

CO = (COD-CCD)/2 (Assumes front and rear cooktop

overhangs are equal) Calculate the cutout depth, (CD):

CD = COD-CO+1-7/8"

3. Determine setback (SB) distance from front of

countertop to front of cutout. SB is specified in the

installation instructions shipped with the cooktop,

4. Backsplash thickness must not exceed BT as

calculated below:

BT = 24 7/8"- OD-SB+CO

(Provides 1/8"clearance between vent and backsplash.)

A negative value for BT means countertop is too small

for the installation,

5, Verify that the available flat countertop has a width

greater than OW and a depth greater than OD,

OW depends on the installation:

CVS230 / UCV230: OW equals the greater of

COW or 30",

CVS236 / UCV236: OW equals the greater of

COW or 36",

CVS245 / UCV245: OW equals the greater of

COW or45".

OD is determined by: OD=COD+21/8 ",

6. Cut countertop using dims: CD, CW and SB as

defined in Figure 8,

Page 8

Page 10

/

Countertop

Surface

J

Left Side

.rl nes .,f _._ "N I

ular Duct Shown _ WE Cabinet Bottom Shelf NJ

Figure 9: Cabinet Cutout for Ductwork

Cabinet Cutout Dimensions for Blower:

_,/- Point "P" (Center of Rear Cut-line)

./

Cabinet Back

F

Plumb line to

intersection A-A

& B-B

A C! B A

Right Side

4

Receptacle

Location

6 3/8" 14 1/2" 1 7/8" 15 1/2" 9 3/4"

Table 4: Cabinet Cutout Dimensions

STEP 3: Prepare Duct Cutouts in Cabinet

A. Refer to Figure 9. Drop a plumb-line from Point "P" at

the rear center of the countertop cutout. Mark this point

on the bottom of the cabinet below, Construct two

reference lines through this point: one should be parallel

to the cabinet front and directly below the rear counter-

top cutout (Line A-A), and the other (Line B-B) should

be at right angles to A-A.

B,

Using these reference lines as a base for the measure-

ments shown in Table 4, layout the necessary cabinet

cutouts needed to implement the planned ductwork

route, Where a range of measurements is noted,

choose a measurement that allows best clearance from

wall studs, floor joists, utilities, or other obstructions,

C,

Temporarily set intake and cooktop in place and attach

integral blower (or duct transition fitting if a remote

blower is installed), Refer to steps 6 and 7, Verify that

the duct cutouts as marked will match the hardware

installation. Adjust the duct cutout as necessary to

match hardware installation.

D. Remove temporarily placed hardware and make cutouts

in cabinet to accommodate ductwork installation.

E. Make all other cabinet modifications needed to provide

proper clearances for drawers or removable shelving,

Page 9

Page 11

Step 4: Install Ductwork (Remote Blower,

If Used)

A. Install the ductwork and remote blower (if used) in

accordance with the ductwork routing plan developed in

Step 1.

B. Make sure that the installation complies with all installa-

tion guidelines in Table 2. Also check that the opening

where duct passes through outside wall or roof has

been properly flashed and sealed to prevent leakage.

C. If using Integral Blower, Model VTN600CV2C, proceed to

Step 5.

D. If using Remote Blower Model VTR600R or VTR1000Q,

refer to Installation Instructions with that model.

Step 5: Install Electrical Service

Check your local building codes for proper method of instal-

lation. In the U.S., if there are no applicable local codes,

this unit should be installed in accordance with the National

Electric CodeANSI/NFPA No. 70, Current Issue. (In

Canada, installation must be in accordance with the CAN 1-

B149.1 and .2 - Installation Codes for Gas Burning Appli-

ances and/or local codes).

Step 6: Mount Vent and Cooktop

A. Remove grease filters and any packing materials from

inside the intake.

B. Set the vent intake into rear of countertop opening.

Carefully lower it into position so that the flanges on the

rear sides and edges fully support the unit hanging from

the countertop.

C Hold the unit against the rear of the countertop opening,

and slide the leg brackets down to meet the bottom of

cabinet. Check and adjust for plumb, then fasten leg

brackets to cabinet with hardware provided.

D. Place the cooktop in countertop opening with the rear

edge of cooktop overlapping the front edge of the vent.

Make sure rear edge of cooktop does not bind

against front of snorkel. Follow the manufacturer's

installation instructions for installing gasket strips,

protective heat tape (if required), securing the cooktop

to the countertop and making the cooktop electrical

and/or gas connections.

The appliance must be grounded. In the event of an electri-

cal short circuit, grounding reduces the risk of electric

shock by providing an escape wire for the electric current.

This appliance is equipped with a cord having a grounding

wire with a grounding plug. The plug must be plugged into

an outlet that is properly installed and grounded.

WARNING -Improper grounding can result in a risk of

electric shock.

Consult a qualified electrician if the grounding instructions

are not completely understood, or if doubt exists as to

whether the appliance is properly grounded.

Do not use an extension cord. If the power supply cord is

too short, have a qualified electrician install an outlet near

the appliance.

The receptacle should be located under the countertop so

that the 30 inch long power cord from the vent will reach it.

See Figure 9. The cord should be routed beneath the

appliance and away from heat generated by the cooktop.

Access should not be obstructed by blower, cabinet work,

ductwork or electrical/gas utilities for the cooktop. All power

for the vent system (including the remote blower, if used) is

supplied via the cord to the intake unit. The outlet can

usually be extended from another kitchen outlet or have its

own circuit from the main service panel.

Do not plug vent cord into receptacle until Step 8.

Page 10

Page 12

Step 7: Mount Integral Blower or

Outlet Duct Transition for

Remote Blower

Integral Blower VTN600CV2C (See

Figures 10 and 12for further detail):

A. Attach blower in front of round exhaust

outlet with 4-6 (depending on configura-

tion) #8 sheetmetal screws

B. Feed cord from blower through strain

relief.

C. Secure strain relief with screws.

D. Attach strain relief to downdraft near

junction box.

E. Connect cord to downdraft at 6 pin con-

nector

F. Connect blower to ductwork.

Figure 10 - Internal Blower

6 Pin

Connector

/

Remote Blower VTR600R or VTR1000Q

(See Figures 11and 12for furtherdetail):

A. Remove junction boxcoverand connect

conduit with 5 wires from remote blower.

Hook up wires per Wiring Diagram,

Fig. 10. Replace junction box cover.

B. Attach duct transition Model CV2T6 at

mounting holes with sheetmetal screws.

C. Feed remote blower pigtail through strain

relief.

D. Attach strain relief to downdraft near

junction box.

E. Connect pigtail to downdraft at 6 pin

connector.

F. Run pigtail wires to junction box.

G. Inside junction box, connect conduit with

five wires from remote blower. Use a

conduit connector to secure.

Note: Blower and duct transition box may be

installed with duct outlet left, down or

right. Install blower or duct transition in

such a way that access panels can be

removed for service.

Internal Blower

/

Strain Relief

Figure 11 - Remote Blower

6 Pin Connector

Junction Box

Transition

CV2T6

Page 11

Strain Relief

Remote Blower

Pigtail

Conduit To

Remote Blower

Page 13

CVS2

Figure 12- Wiring Diagram

SW POSITION

SHOWN WITH

DOWNDRAFT IN "=

LOWERED POSITION

ABBREVIATIONS:

C= COMMON

NO = NORMALLY OPEN

NC = NORMALLY CLOSED

WARNING: POWER MUST BE DISCONNECTED BEFORE SERVICING THIS APPLICANCE

L0

I ed

L

!

brown

blue

red

" Control pc bQord

!.

!.

!.

!.

I"

!.

!.

I

%

POWER

3 WIRE SINGLE PHASE 60 Hz

LI: 120 V

N: GROUNDED WHITE WIRE

SPEED 1 RED WIRE

SPEED 2 BLUE WIRE

SPEED 3 BROWN WIRE

GND: GROUNDED GREEN WIRE

RATING: 120V-10A

UCV2

Figure 12 - Wiring Diagram

SW POSITION

SHOWN WITH

DOWNDRAFT IN LOWERED

POSITION

ABBREVIATIONS: "o

C= COMMON

NO = NORMALLY OPEN

NC = NORMALLY CLOSED

P[o

WARNING: POWER MUST BE DISCONNECTED BEFORE SERVICING THIS APPLICANCE

conbro I

pc boord

I

d)

POWER

3 WIRE SINGLE PHASE 60 Hz

LI: 120V

N: GROUNDED WHITE WIRE

SPEED 1 RED WIRE

SPEED 2 BLUE WIRE

SPEED 3 BROWN WIRE

GND: GROUNDED GREEN WIRE

RATING: 120V-10A

Page 12

Page 14

Step 8: Install Coordinating Topcap

(if applicable) only for CVS2

Step 9 Verify Installation, Operation and

Cooktop Alignment

The downdraft is shipped from the factory with a stainless

steel topcap. Color coordinating topcaps in white and black

are available as accessory parts.

A. Remove filters and set aside. Remove 4 screws from

below topcap and two screws (one on each side) from

endcaps. Discard topcap and endcaps. Set screws

aside.

B. Install new endcaps and topcap as seen in Figure 13

(insert endcaps first). Replace screws.

Topcap

Endcaps

Figure 13 - Topcap installation

Before performing this procedure, verify that all packing

materials were removed from inside the snorkel and that the

grease filters and front panel have been properly installed.

Refer to the Care and Use Manual for instructions regarding

filter and front panel installation.

Plug the vent power cord into a proper electrical receptacle

and ensure that the circuit is energized.

A. Raise the snorkel to its fully extended position by

pressing the UP/DOWN push-button once (Figure 12).

Do not hold the push-button. The elevating motor will

stop when the snorkel reaches its full height. (Note: the

blower will not operate unless the snorkel is fully

raised).

B. Remove protective tape from top cap.

C. Turn the blower ON by selecting in turn each of the 3

speeds. Let the blower run several minutes at each

speed to evaluate its operation.

D. With the blower running, lower the snorkel to its fully

retracted position by pressing the UP/DOWN push-

button once. The blower will immediately turn off.

E. With the blower on HIGH, close the windows and doors

to the area to ensure that fan does not cause back

drafting in any outlet vent for another appliance.

F. Raise and lower the vent again, and check to make sure

that the top cap on the snorkel does not catch on the

back edge of the cooktop when it is lowered. If

interference occurs, adjust the position of the cooktop

by moving it against the front edge of the countertop

cutout, then re-secure the cooktop to the countertop.

Failure to eliminate interference may result in

permanent damage to the vent. Also, ensure that the

vent support legs have been properly secured to the

cabinet base using the screws provided.

If the vent system does not operate satisfactorily during any

of the above procedures, review all steps in these

Installation Instructions to ensure that nothing has been

omitted or overlooked. Also, refer to the Care & Use Manual

for additional information or call Thermador Customer

Support 1-800-735-4328.

Page 13

Page 15

Thermador AoA,oo_..,,_9co,.,_

5551 McFadden Avenue, Huntington Beach CA, 92649 • 800-735-4328 • www.thermador com

9000036121 • 10013 RevB • 07/06 © BSH Home Appliances Corporation • Litho in U.S.A.

Loading...

Loading...