Thermador PRD304EG/08, PRD304EG/10, PRD304EG/11, PRD304EG/12, PRD304EG/05 Installation Guide

...Page 1

INSTALLATION MANUAL

For Thermador Professional ®PRO-GRAND TM

Dual Fuel Ranges

MANUEL D'INSTALLATION

Pour cuisiniere & combustion jumelee

Professional ® PRO-GRANDTM de

Thermador

MANUAL DE INSTALACION

Para Estufas de Todo Tipo de Gas

Professional ® PRO-GRANDTM de

Models/

Modeles /

Modelos:

PRD30

PRD36

PRD48

Thermador

Page 2

Table of Contents

Safety Instructions .............................. 1

Important Installation Information ................. 2

Step 1: Ventilation Requirements ...................................... 3

Step 2: Cabinet Preparation ........................................... 4

Step 3: Unpacking and Moving the Range ............................... 8

Step 4: Installing Anti-Tip Device ...................................... 9

Step 5: Gas Requirements and Hookup ................................ 11

Step 6: Electrical Requirements, Connection & Grounding ................ 13

Step 7: Backguard Installation ........................................ 16

Step 8: Door Removal and Reinstallation ............................... 18

Step 9: Placing and Leveling the Range ................................ 19

Step 10: Burner Test and Adjustment .................................. 21

Installer Checklist .................................................. 22

To Clean and Protect Exterior Surfaces ........... 22

This Thermador Appliance is made by

BSH Home Appliances Corporation

5551 McFadden Ave.

Huntington Beach, CA 92649

Questions?

1-800-735-4328

www.thermador.com

We look forward to hearing from you!

Page 3

Safety Instructions

Important Safety Instructions

-- READ AND SAVE THESE INSTRUCTIONS

APPROVED FOR ALL RESIDENTIAL APPLIANCES

FOR RESIDENTIAL USE ONLY

IMPORTANT: Save these Instructions for the Local Gas

Inspector's use.

INSTALLER: Please leave these Installation Instructions

with this unit for the owner.

OWNER: Please retain these instructions for future

reference.

WARNING:

Disconnect power before installing. Before

turning power ON, be sure that all controls are in

the OFF position.

Important:

Local codes vary. Installation, gas connections and

grounding must comply with all applicable codes.

WARNING:

• All Ranges can tip.

• Injury to Persons could

result.

• Install Anti-Tip Device

packaged with range.

• See Installation

Instructions.

WARNING:

If the information in this manual is

not followed exactly, a fire or

explosion may result causing

property damage, personal injury or

death.

Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

-- WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do nottouch any electrical switch.

• Do not use any phone in your

building.

• Immediately call your gas supplier

from a neighbor's phone. Follow

the gas supplier's instructions.

• If you cannot reach your gas

supplier, call the fire department.

Installation and service must be

performed by a qualified installer,

service agency or the gas supplier.

TO REDUCE THE RISK OF TIPPING

OF THE APPLIANCE, IT MUST BE

SECURED BY A PROPERLY

INSTALLED ANTI-TIP DEVICE.

VERIFY THAT THE ANTI-TIP DEVICE

IS ENGAGED PER INSTALLATION

INSTRUCTIONS. (.NOTE: ANTI-TIP

DEVICE IS REQUIRED ON ALL 30"

AND 36" RANGES; 48" RANGES DO

NOT REQUIRE AN ANTI-TIP DEVICE).

For Massachusetts Installations:

1. Installation must be performed by a qualified or

licensed contractor, plumber or gas fitter qualified or

licensed by the state, province or region where this

appliance is being installed.

2. Shut-off valve must be a "T" handle gas cock.

3. Flexible gas connector must not be longer than 36

inches.

Note:

This Range is NOT designed for installation in

manufactured (mobile) homes or for installation in

Recreational Park Trailers.

DO NOT install this range outdoors.

English 1

Page 4

_j[__; _ii_11__ ...................................................................................................................................................................................................................................................................................................................................................................................................,_

Important Installation Information

GAS Type Verification

Verify the type of gas supplied to the location. Ensure that

the appliance is connected to the type of gas for which it is

certified. All models are certified for use with natural gas.

Field conversion of the appliance for use with propane gas

supply will require a conversion kit.

WARNING:

To avoid possible burn or fire hazard, a

backguard designed specifically for this range

must be installed whenever the range is used.

Refer to "Chart C: Backguard Kit Model Numbers" on

page 18, for the correct backguard models that are

designed for this range. After selecting the correct

backguard, the range must be installed properly, using the

minimum clearances to combustible surfaces specified in

"Step 2: Cabinet Preparation" on page 4.

Important:

• A backguard must be utilized when there is less than a

12" horizontal clearance between combustible

materials and the back edge of the range. A

Thermador backguard must be ordered separately and

installed at the rear of the range. (A Low Back is

supplied with the 30" model.) For island installations

and other installations with more than 12" clearance,

an optional stainless steel Island Trim is available to

cover the backguard mounting flanges.

• Verify that the appliance is correct for the type of gas

being provided. Refer to "Step 5: Gas Requirements

and Hookup" on page 11 before proceeding with the

installation.

Gas Supply:

Natural Gas - 6 inch water column. (14.9 mb) min., 14 inch

(34.9 mb) maximum

Electric Power Supply:

See page 13 for specifications.

This appliance has been tested in accordance with ANSI

Z21.1, Standard for Household Cooking Appliances (USA)

and in accordance with CAN 1.1-M81 Domestic Gas

Ranges (Canadian).

It is stronqlv recommended that this appliance be installed

in conjunction with a suitable overhead vent hood. (See

"Step 1: Ventilation Requirements" on page 3.) Due to the

high heat capability of this unit, particular attention should

be paid to the hood and duct work installation to assure it

meets local building codes.

Check local building codes for the proper method of

appliance installation. Local codes vary. Installation,

electrical connections and grounding must comply with all

applicable codes. In the absence of local codes the

appliance should be installed in accordance with the

National Fuel Gas Code ANSI Z223. I/NFPA 54 current

issue and National Electrical Code ANSI/NFPA 70-current

issue. In Canada, installation must be in accordance with

the CAN 1-B149.1 and .2 - Installation Codes for Gas

Burning Appliances and/or local codes.

This appliance complies with one or more of the following

standards:

• UL 858, Standard for the Safety of Household Electric

Ranges

• UL 923, Standard for the Safety of Microwave Cooking

Appliances

• UL 507, Standard for the Safety of Electric Fans

• ANSI Z21.1, American National Standard for

Household Cooking Gas Appliances

• CAN/CSA-C22.2 No. 113-08 Fans and Ventilators

• CAN/CSA-C22.2 No. 61-08 Household Cooking

Ranges

Propane Gas - 11 inch water column. (27.4 mb) min.,

14 inch (34.9 mb) maximum

English 2

It is the responsibility of the owner and the installer to

determine if additional requirements and/or standards

apply to specific installations.

Due to the high heat of the cooktop burners, installing a

microwave oven with a ventilation system over the cooktop

is not recommended.

Page 5

CAUTION:

To eliminate risk of burns or fire caused by

reaching over heated surface units, cabinet

storage located above the surface units should

be avoided.

CAUTION:

When connecting the unit to propane gas, make

certain the propane gas tank is equipped with its

own high-pressure regulator in addition to the

pressure regulator supplied with the range. The

maximum gas pressure to this appliance

must not exceed 14.0 inches water column

(34.9 mb) from the propane gas tank to the

pressure regulator.

CAUTION:

This unit is designed as a cooking appliance.

Based on safety considerations, never use it for

warming or heating a room.

Step 1: Ventilation

Requirements

It is stronqly recommended that a suitable exhaust hood be

installed above the range. Downdraft ventilation should not

be used. The table on page 4 indicates the ventilation hood

options and blower capacity guidelines that are

recommended for use with all Thermador ranges.

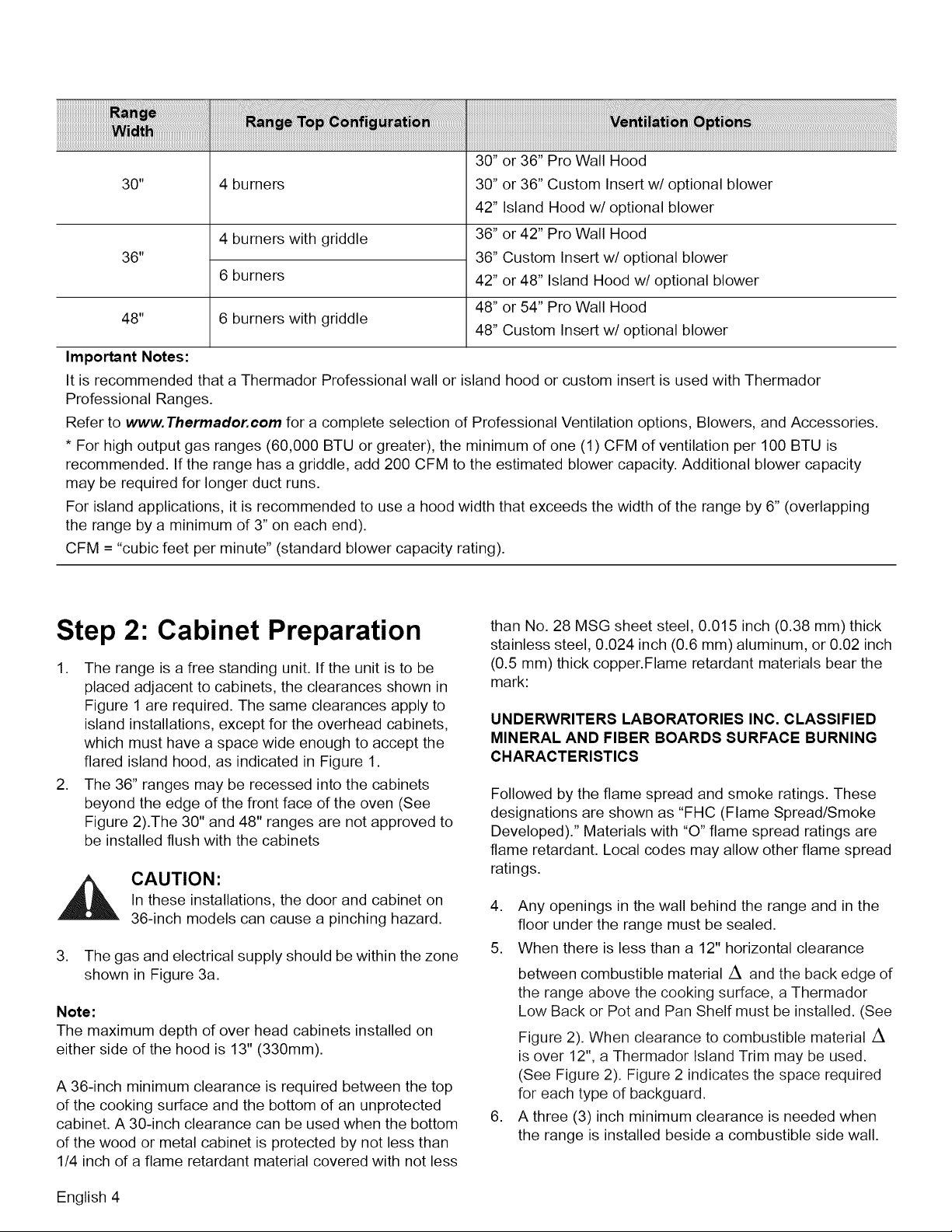

1. Select Hood and Blower Models:

• For wall installations, the hood width must, at a

minimum, equal the width of the range. Where space

permits, a hood larger in width than the range may be

desirable for improved ventilation performance.

For island installations, the hood width should, at a

minimum, overhang the range by 3" on each side.

Important:

Ventilation hoods and blowers are designed for use with

single wall ducting. However, some local building codes or

inspectors may require double wall ducting. Consult local

building codes and/or local agencies, before starting, to

assure that hood and duct installation will meet local

requirements.

Do not install a microwave oven/ventilator combination

above the range, as these type of units do not provide the

proper ventilation and are not suitable for use with the

range.

2. Hood Placement:

For best smoke elimination, the lower edge of the hood

should be installed 30" above the range cooking

surface. (See Figure 1).

If the hood contains any combustible materials (i.e. a

wood covering), it must be a minimum of 36" above the

cooking surface.

NOTICE:

Most range hoods contain combustible components which

must be considered when planning the installation.

.

Consider Make-Up Air:

Due to the high volume of ventilation air, a source of

outside replacement air is recommended. This is

particularly important for tightly sealed and insulated

homes.

A qualified heating and ventilating contractor should be

consulted.

English 3

Page 6

30" or 36" Pro Wall Hood

30"

36"

48" 6 burners with griddle

Important Notes:

It is recommended that a Thermador Professional wall or island hood or custom insert is used with Thermador

Professional Ranges.

Refer to www.Thermador.com for a complete selection of Professional Ventilation options, Blowers, and Accessories.

* For high output gas ranges (60,000 BTU or greater), the minimum of one (1) CFM of ventilation per 100 BTU is

recommended. If the range has a griddle, add 200 CFM to the estimated blower capacity. Additional blower capacity

may be required for longer duct runs.

For island applications, it is recommended to use a hood width that exceeds the width of the range by 6" (overlapping

the range by a minimum of 3" on each end).

CFM = "cubic feet per minute" (standard blower capacity rating).

4 burners

4 burners with griddle

6 burners

30" or 36" Custom Insert w/optional blower

42" Island Hood w/optional blower

36" or 42" Pro Wall Hood

36" Custom Insert w/optional blower

42" or 48" Island Hood w/optional blower

48" or 54" Pro Wall Hood

48" Custom Insert w/optional blower

Step 2: Cabinet Preparation

1. The range is a free standing unit. If the unit is to be

placed adjacent to cabinets, the clearances shown in

Figure 1 are required. The same clearances apply to

island installations, except for the overhead cabinets,

which must have a space wide enough to accept the

flared island hood, as indicated in Figure 1.

2. The 36" ranges may be recessed into the cabinets

beyond the edge of the front face of the oven (See

Figure 2).The 30" and 48" ranges are not approved to

be installed flush with the cabinets

,_ CAUTION:

3. The gas and electrical supply should be within the zone

Note:

The maximum depth of over head cabinets installed on

either side of the hood is 13" (330mm).

A 36-inch minimum clearance is required between the top

of the cooking surface and the bottom of an unprotected

cabinet. A 30-inch clearance can be used when the bottom

of the wood or metal cabinet is protected by not less than

1/4 inch of a flame retardant material covered with not less

In these installations, the door and cabinet on

36-inch models can cause a pinching hazard.

shown in Figure 3a.

than No. 28 MSG sheet steel, 0.015 inch (0.38 mm) thick

stainless steel, 0.024 inch (0.6 mm) aluminum, or 0.02 inch

(0.5 mm) thick copper.Flame retardant materials bear the

mark:

UNDERWRITERS LABORATORIES INC. CLASSIFIED

MINERAL AND FIBER BOARDS SURFACE BURNING

CHARACTERISTICS

Followed by the flame spread and smoke ratings. These

designations are shown as "FHC (Flame Spread/Smoke

Developed)." Materials with "0" flame spread ratings are

flame retardant. Local codes may allow other flame spread

ratings.

4. Any openings in the wall behind the range and in the

floor under the range must be sealed.

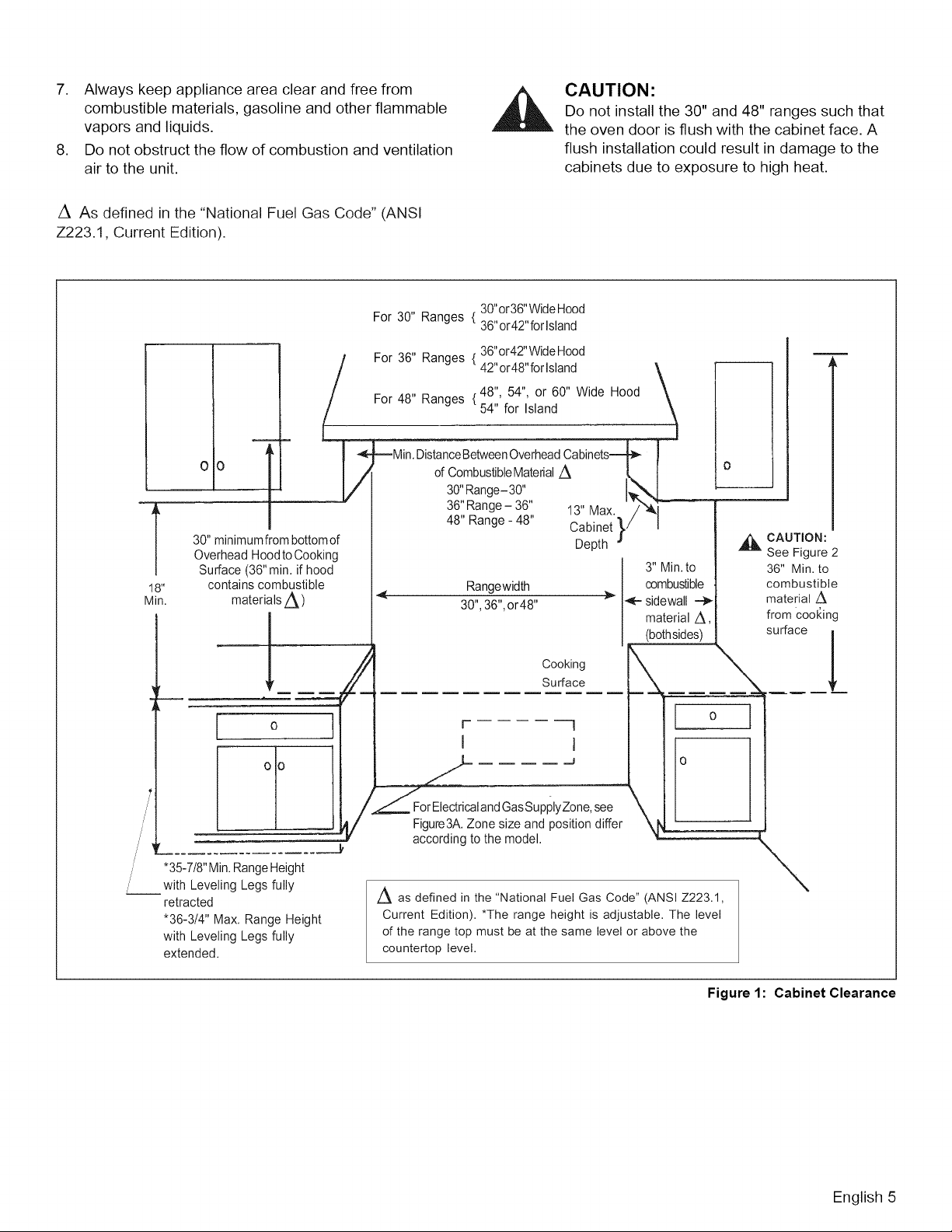

5. When there is less than a 12" horizontal clearance

between combustible material A and the back edge of

the range above the cooking surface, a Thermador

Low Back or Pot and Pan Shelf must be installed. (See

Figure 2). When clearance to combustible material A

is over 12", a Thermador Island Trim may be used.

(See Figure 2). Figure 2 indicates the space required

for each type of backguard.

6. A three (3) inch minimum clearance is needed when

the range is installed beside a combustible side wall.

English 4

Page 7

7. Alwayskeepapplianceareaclearandfreefrom

combustiblematerials,gasolineandotherflammable

vaporsandliquids.

8. Donotobstructtheflowofcombustionandventilation

airtotheunit.

/k As defined in the "National Fuel Gas Code" (ANSI

Z223.1, Current Edition).

For 30" Ranges { 36"or42"forlsland

CAUTION:

Do not install the 30" and 48" ranges such that

the oven door is flush with the cabinet face. A

flush installation could result in damage to the

cabinets due to exposure to high heat.

30"or36"WideHood

oo l

30" minimumfrombottomof

Overhead Hoodto Cooking

Surface(36" min. if hood

18"

Min.

/

/

/

contains combustible

materialsA)

"35-7/8"Min.RangeHeight

with Leveling Legs fully

retracted

"36-3/4" Max. Range Height

with Leveling Legs fully

extended.

[

t

For 36" Ranges " 36"or42"WideHood

For 48" Ranges { 48", 54", or 60" Wide Hood

u

ForElectricalandGasSupplyZone,see

Figure3A.Zone size and positiondiffer

according to the model.

A

as defined in the "National Fuel Gas Code" (ANSI Z223.1,

Current Edition). *The range height is adjustable. The level

of the range top must be at the same level or above the

countertop level.

t 42"or48"forlsland

" 54" for Island

of CombustibleMaterialA

30"Range- 30"

36"Range- 36" 13" Max. /

48" Range - 48" Cabinet _,/

Depth _

30",36",or48"

Rangewidth _* _--

Cooking

Surface

|

3" Min.to

combustible

sidewall

material z&,

(bothsides)

0

o

,_ CAUTION:

0

See Figure2

36" Min. to

combustible

material Z_

from coot_ing

surface

_L

\

Figure 1: Cabinet Clearance

English 5

Page 8

Installation with "Low Back" or "Pot and Pan Shelf"

T

36" Min. to

Combustibles A

T I

36-3/4" Max.. "

35-7/8" Min.z

s'

/

/

I

I

!

IIII IIII IIII _Combustible

I

I

l//,s

32-5/8" _-

29-1/2"

12-7/8"

Pot and _ _.

Pan She f-_E_ 'm

Low

Materials A

m3-7/8"

22"

_-12" for 36" or 48" Ranges

9" for 30" Ranges

I

I

_Wall

I

I

--Combustible

Materials A

Note: For Island

Trim installations,

counter surface

should have a

cantilever edge

meeting the back

section of the

Island Trim

accessory.

Cantilever

Note: If an inner wall is

used under the

cantilever counter top,

there should be a 1/8"

gap from the rear of the

range to the inner wall.

I !

F Kicki:

I

I

I

4

I

A as defined in the "National Fuel Gas Code" (ANSI Z223.1, Current Edition)

÷

I

i

36" Min. to

Combustibles A

I

I

I

I

I _ 27-1/8" =!

47-3/8" _"

Installation with "Island Trim"

12" Min. to

Combustibles A

with Island Trim

Island Trim---_ I

T

36-3/4" Max.

35-7/8" Min.

Front Face

English 6

Figure 2: Side View

Page 9

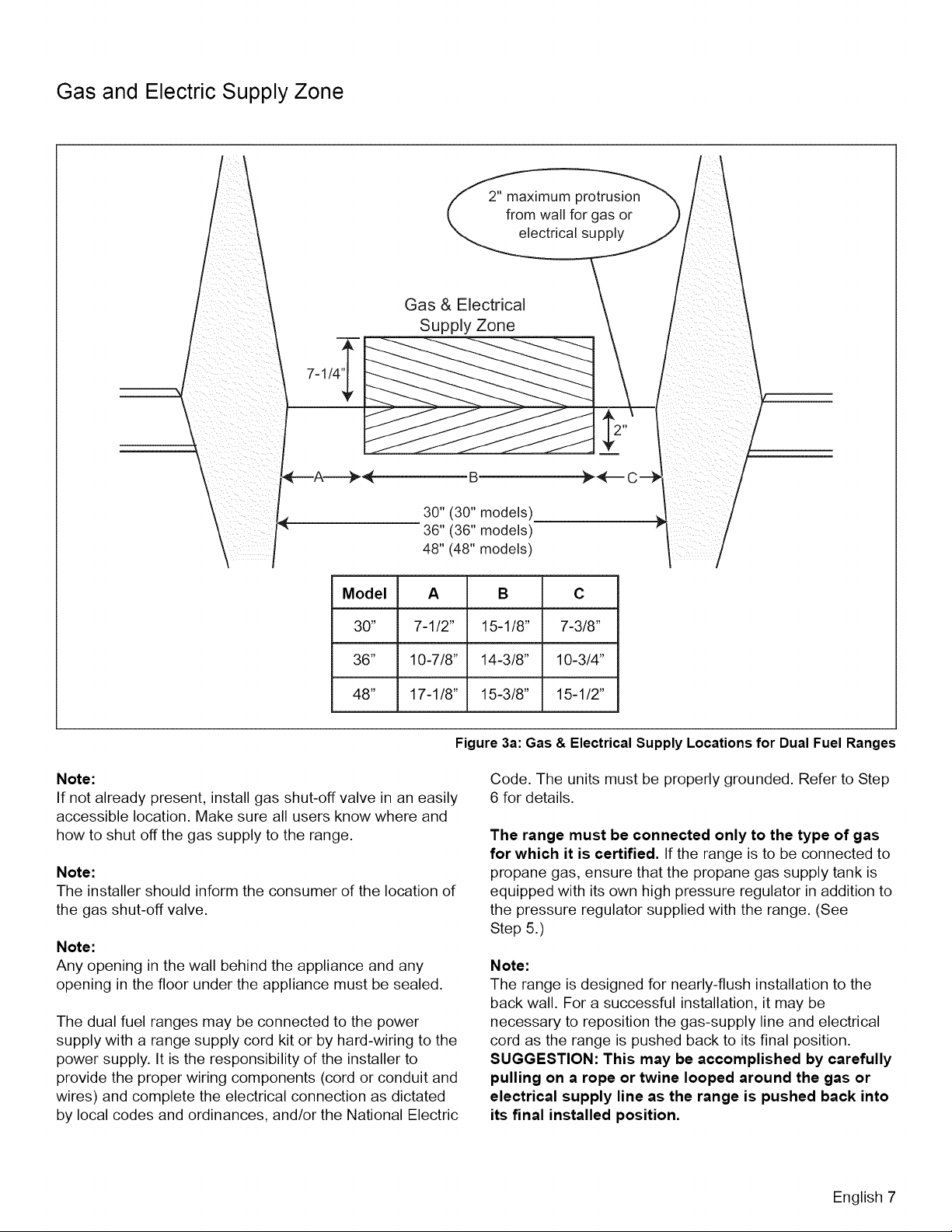

Gas and Electric Supply Zone

2" maximum protrusion

from wall for gas or

electrical supply

Gas & Electrical

Supply Zone

30" (30" models)

36" (36" models)

48" (48" models)

Model A B C

30" 7-1/2" 15-1/8" 7-3/8"

36" 10-7/8" 14-3/8" 10-3/4"

48" 17-1/8" 15-3/8" 15-1/2"

Note:

If not already present, install gas shut-off valve in an easily

accessible location. Make sure all users know where and

how to shut off the gas supply to the range.

Note:

The installer should inform the consumer of the location of

the gas shut-off valve.

Note:

Any opening in the wall behind the appliance and any

opening in the floor under the appliance must be sealed.

The dual fuel ranges may be connected to the power

supply with a range supply cord kit or by hard-wiring to the

power supply. It is the responsibility of the installer to

provide the proper wiring components (cord or conduit and

wires) and complete the electrical connection as dictated

by local codes and ordinances, and/or the National Electric

Figure 3a: Gas & Electrical Supply Locations for Dual Fuel Ranges

Code. The units must be properly grounded. Refer to Step

6 for details.

The range must be connected only to the type of gas

for which it is certified. If the range is to be connected to

propane gas, ensure that the propane gas supply tank is

equipped with its own high pressure regulator in addition to

the pressure regulator supplied with the range. (See

Step 5.)

Note:

The range is designed for nearly-flush installation to the

back wall. For a successful installation, it may be

necessary to reposition the gas-supply line and electrical

cord as the range is pushed back to its final position.

SUGGESTION: This may be accomplished by carefully

pulling on a rope or twine looped around the gas or

electrical supply line as the range is pushed back into

its final installed position.

English 7

Page 10

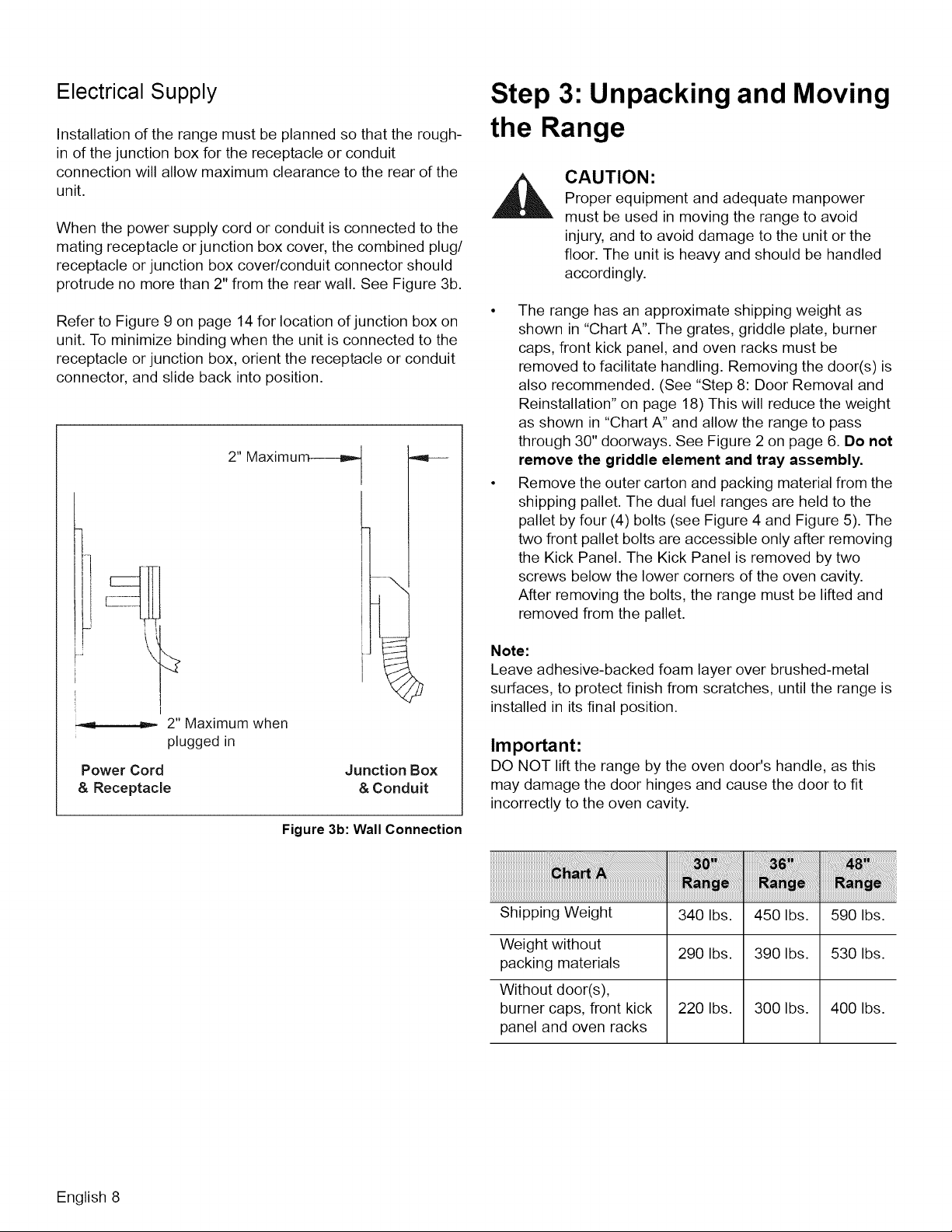

Electrical Supply

Step 3: Unpacking and Moving

Installation of the range must be planned so that the rough-

in of the junction box for the receptacle or conduit

connection will allow maximum clearance to the rear of the

unit.

When the power supply cord or conduit is connected to the

mating receptacle or junction box cover, the combined plug/

receptacle or junction box cover/conduit connector should

protrude no more than 2" from the rear wall. See Figure 3b.

Refer to Figure 9 on page 14 for location of junction box on

unit. To minimize binding when the unit is connected to the

receptacle or junction box, orient the receptacle or conduit

connector, and slide back into position.

2" Maximu_

L

\

F

2" Maximum when

plugged in

Power Cord

& Receptacle

Figure 3b: Wall Connection

Junction Box

&Conduit

the Range

CAUTION:

Proper equipment and adequate manpower

must be used in moving the range to avoid

injury, and to avoid damage to the unit or the

floor. The unit is heavy and should be handled

accordingly.

• The range has an approximate shipping weight as

shown in "Chart A". The grates, griddle plate, burner

caps, front kick panel, and oven racks must be

removed to facilitate handling. Removing the door(s) is

also recommended. (See "Step 8: Door Removal and

Reinstallation" on page 18) This will reduce the weight

as shown in "Chart A" and allow the range to pass

through 30" doorways. See Figure 2 on page 6. Do not

remove the griddle element and tray assembly.

• Remove the outer carton and packing material from the

shipping pallet. The dual fuel ranges are held to the

pallet by four (4) bolts (see Figure 4 and Figure 5). The

two front pallet bolts are accessible only after removing

the Kick Panel. The Kick Panel is removed by two

screws below the lower corners of the oven cavity.

After removing the bolts, the range must be lifted and

removed from the pallet.

Note:

Leave adhesive-backed foam layer over brushed-metal

surfaces, to protect finish from scratches, until the range is

installed in its final position.

Important:

DO NOT lift the range by the oven door's handle, as this

may damage the door hinges and cause the door to fit

incorrectly to the oven cavity.

English 8

iiiiiiiiiiiiiiiiiiiiiiiii!_i_i_i_i_i_i!i_i!i'_!ii61i_iifii_i_i_i_i_i_i_ii,!i_iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiililililiiiiiii_i!iiii';ii_ii!ililiiii!ii_i_iiii!81i;_i_i_i_ii_ii_iii_!_iiii_ii_i!_!i_i!iiiilililililililili!i_

,

Shipping Weight 340 Ibs. 450 Ibs. 590 Ibs.

Weight without 290 Ibs. 390 Ibs. 530 Ibs.

packing materials

Without door(s),

burner caps, front kick 220 Ibs. 300 Ibs. 400 Ibs.

panel and oven racks

Page 11

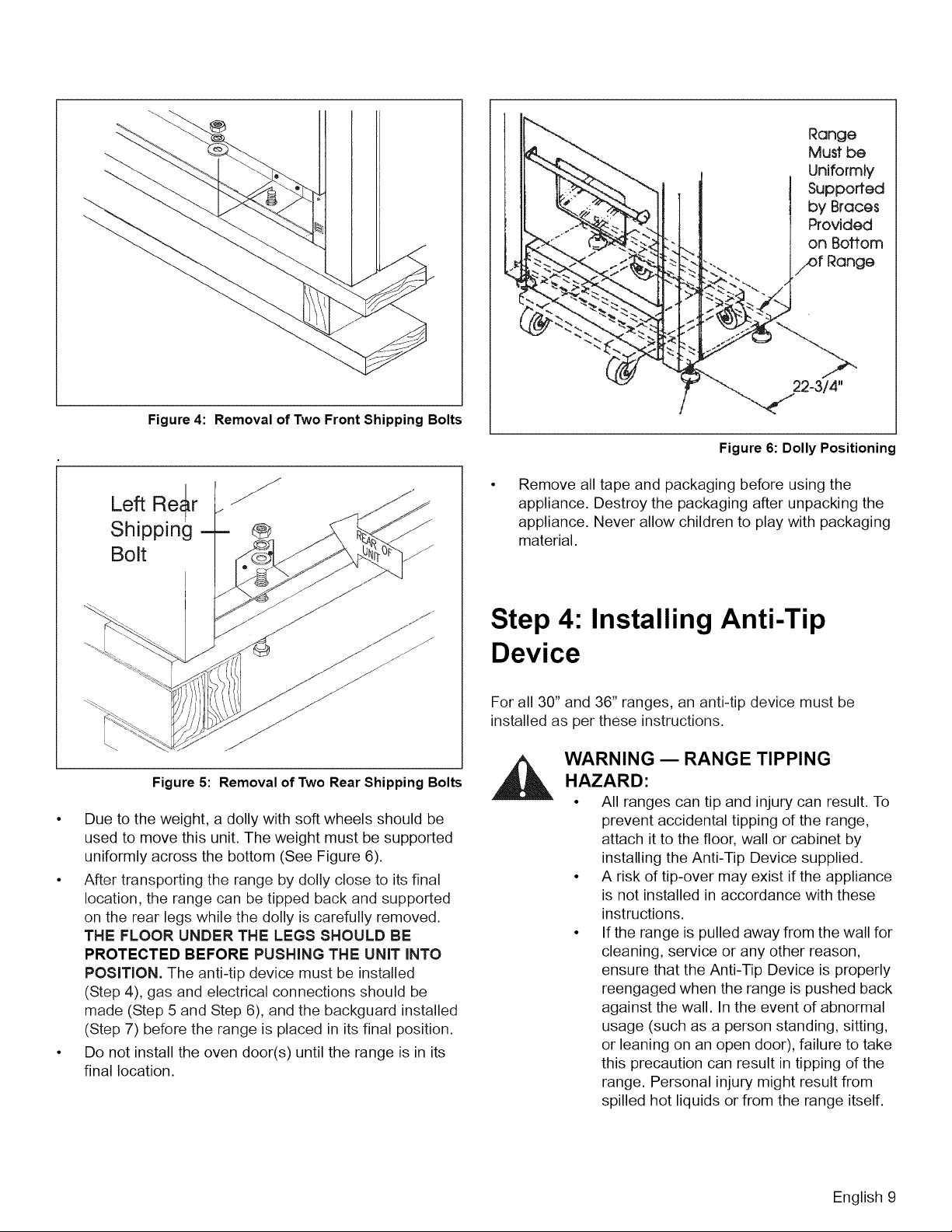

Figure 4: Removal of Two Front Shipping Bolts

Shipping ®

Bolt

Range

Must be

Uniformly

Supported

by Braces

Provided

on Bottom

/43f Range

Figure 6: Dolly Positioning

Remove all tape and packaging before using the

appliance. Destroy the packaging after unpacking the

appliance. Never allow children to play with packaging

material.

Figure 5: Removal of Two Rear Shipping Bolts

• Due to the weight, a dolly with soft wheels should be

used to move this unit. The weight must be supported

uniformly across the bottom (See Figure 6).

• After transporting the range by dolly close to its final

location, the range can be tipped back and supported

on the rear legs while the dolly is carefully removed.

THE FLOOR UNDER THE LEGS SHOULD BE

PROTECTED BEFORE PUSHING THE UNiT iNTO

POSiTiON. The anti-tip device must be installed

(Step 4), gas and electrical connections should be

made (Step 5 and Step 6), and the backguard installed

(Step 7) before the range is placed in its final position.

• Do not install the oven door(s) until the range is in its

final location.

Step 4: Installing Anti-Tip

Device

For all 30" and 36" ranges, an anti-tip device must be

installed as per these instructions.

_ ARNING m RANGE TIPPING

HAZARD:

• All ranges can tip and injury can result. To

prevent accidental tipping of the range,

attach it to the floor, wall or cabinet by

installing the Anti-Tip Device supplied.

• A risk of tip-over may exist if the appliance

is not installed in accordance with these

instructions.

• If the range is pulled away from the wall for

cleaning, service or any other reason,

ensure that the Anti-Tip Device is properly

reengaged when the range is pushed back

against the wall. In the event of abnormal

usage (such as a person standing, sitting,

or leaning on an open door), failure to take

this precaution can result in tipping of the

range. Personal injury might result from

spilled hot liquids or from the range itself.

English 9

Page 12

WARNING m ELECRICAL SHOCK

HAZARD:

• Use extreme caution when drilling holes

into the wall or floor. There may be

concealed electrical wires located behind

the wall or under the floor.

• Identify the electrical circuits that could be

affected by the installation of the Anti-Tip

Device, then turn off power to these

circuits.

• Failure to follow these instructions may

result in electrical shock or other personal

injury.

,_IL WARNING:

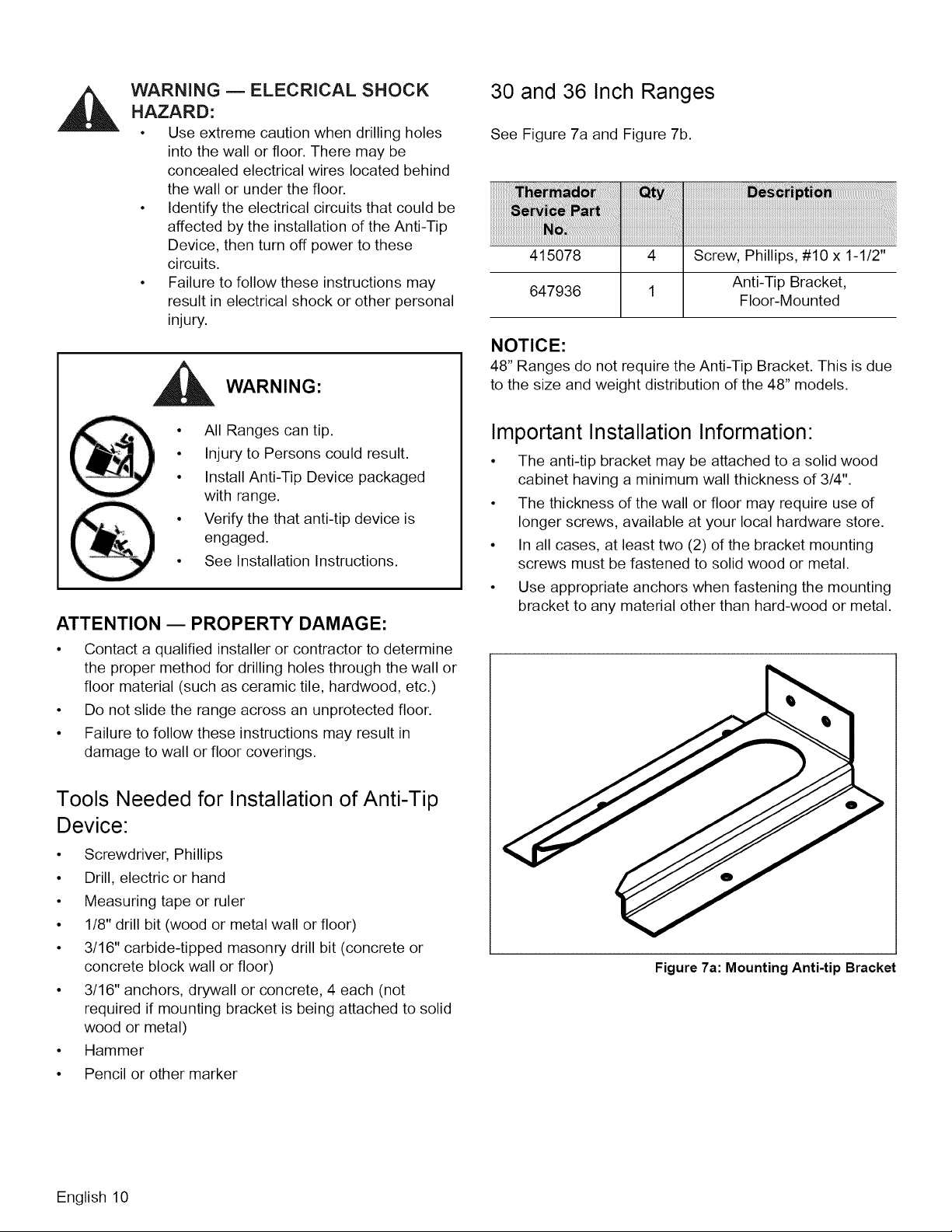

30 and 36 Inch Ranges

See Figure 7a and Figure 7b.

415078 4 Screw, Phillips, #10 x 1-1/2"

647936 1 Anti-Tip Bracket,

NOTICE:

48" Ranges do not require the Anti-Tip Bracket. This is due

to the size and weight distribution of the 48" models.

Floor-Mounted

• All Ranges can tip.

• Injury to Persons could result.

• Install Anti-Tip Device packaged

with range.

• Verify the that anti-tip device is

engaged.

• See Installation Instructions.

ATTENTION m PROPERTY DAMAGE:

• Contact a qualified installer or contractor to determine

the proper method for drilling holes through the wall or

floor material (such as ceramic tile, hardwood, etc.)

• Do not slide the range across an unprotected floor.

• Failure to follow these instructions may result in

damage to wall or floor coverings.

Tools Needed for Installation of Anti-Tip

Device:

• Screwdriver, Phillips

• Drill, electric or hand

• Measuring tape or ruler

• 1/8" drill bit (wood or metal wall or floor)

• 3/16" carbide-tipped masonry drill bit (concrete or

concrete block wall or floor)

• 3/16" anchors, drywall or concrete, 4 each (not

required if mounting bracket is being attached to solid

wood or metal)

• Hammer

• Pencil or other marker

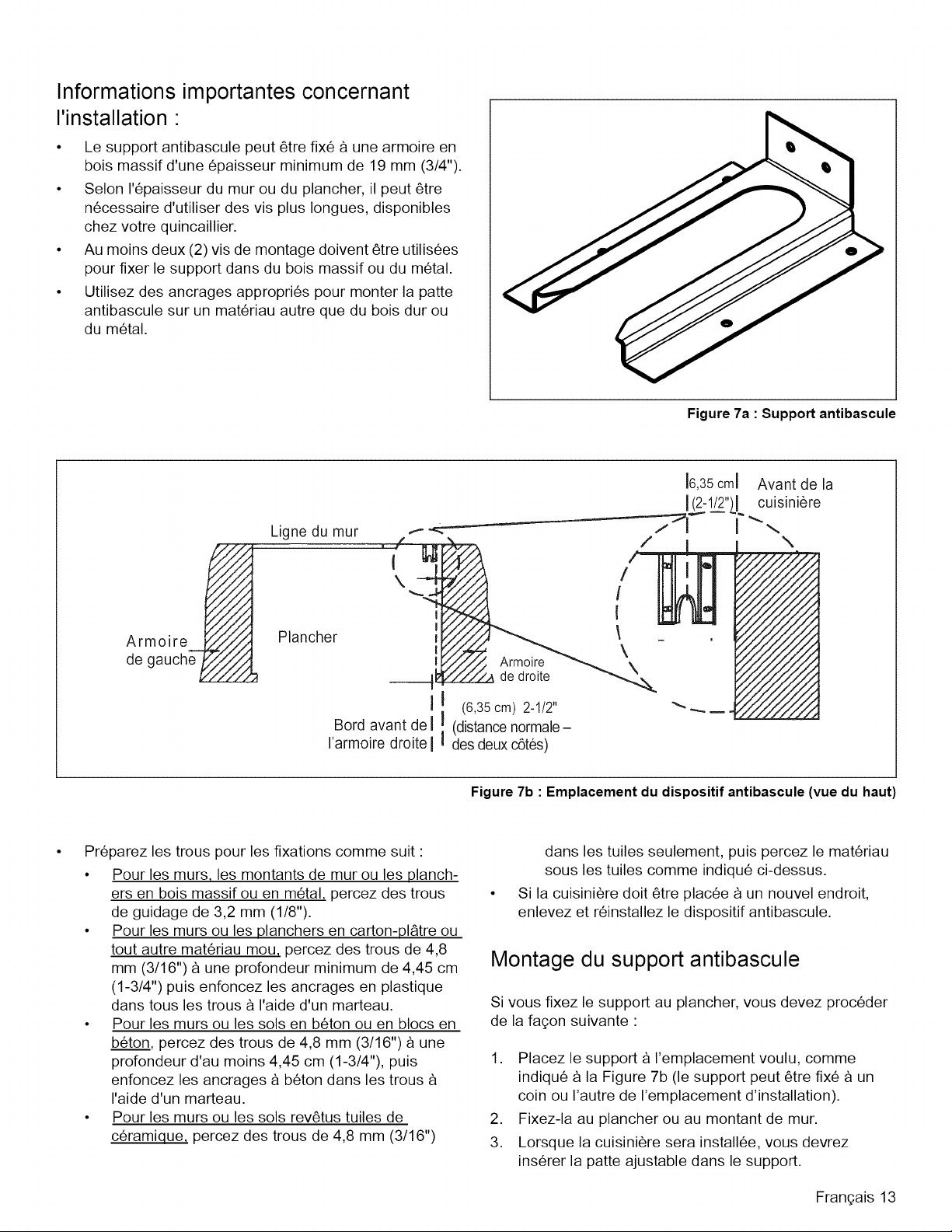

Important Installation Information:

• The anti-tip bracket may be attached to a solid wood

cabinet having a minimum wall thickness of 3/4".

• The thickness of the wall or floor may require use of

longer screws, available at your local hardware store.

• In all cases, at least two (2) of the bracket mounting

screws must be fastened to solid wood or metal.

• Use appropriate anchors when fastening the mounting

bracket to any material other than hard-wood or metal.

Figure 7a: Mounting Anti-tip Bracket

English 10

Page 13

Wall Line

Floor

--tt

Front Edge of I

Right Cabinet I

I

I

I

I

I

I

_/

/

2-t/2"

(typical -

either side)

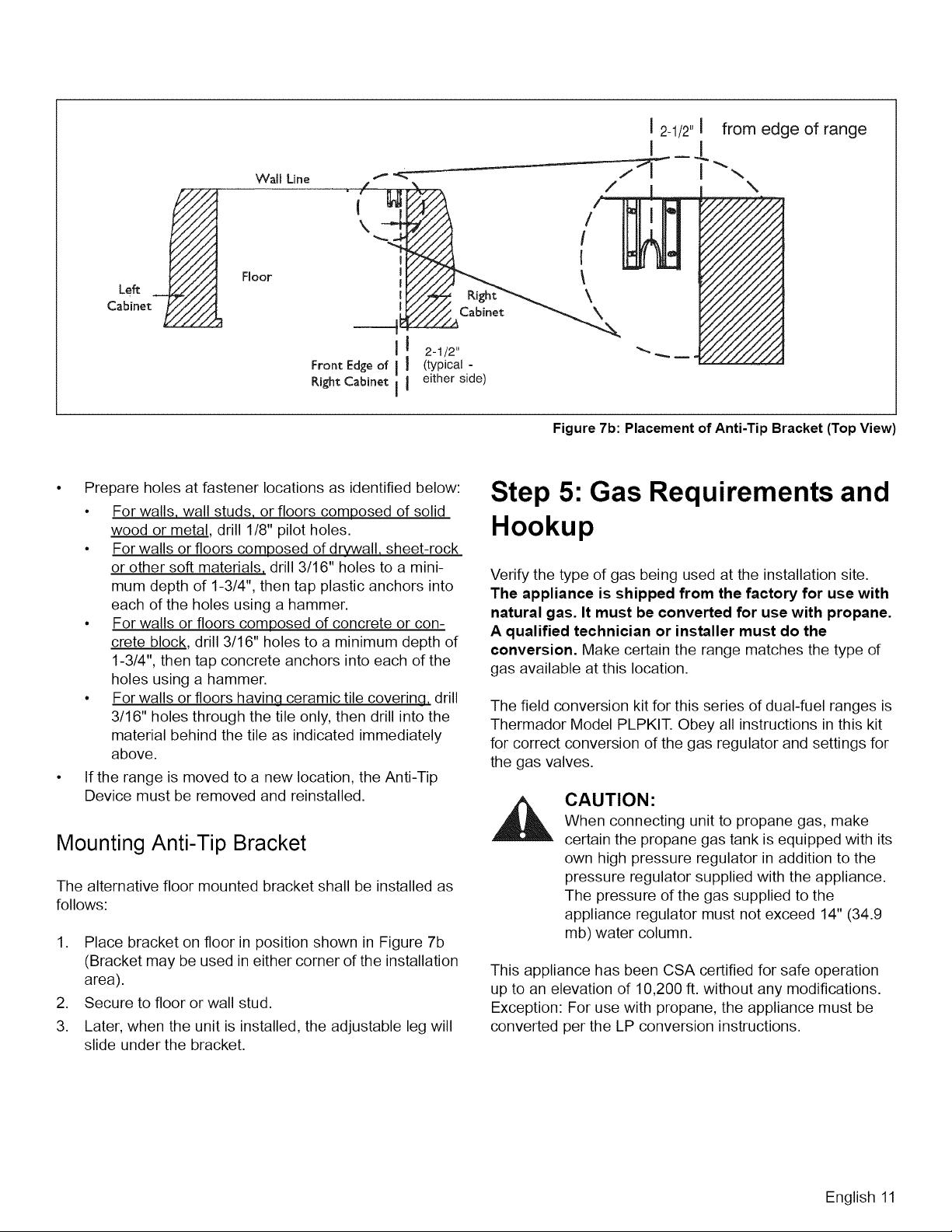

Figure 7b: Placement of Anti-Tip Bracket (Top View)

Prepare holes at fastener locations as identified below:

• For walls, wall studs, or floors composed of solid

wood or metal, drill 1/8" pilot holes.

• For walls or floors composed of drywall, sheet-rock

or other soft materials, drill 3/16" holes to a mini-

mum depth of 1-3/4", then tap plastic anchors into

each of the holes using a hammer.

• For walls or floors composed of concrete or con-

crete block, drill 3/16" holes to a minimum depth of

1-3/4", then tap concrete anchors into each of the

holes using a hammer.

• For walls or floors havinq ceramic tile coverinq, drill

3/16" holes through the tile only, then drill into the

material behind the tile as indicated immediately

above.

If the range is moved to a new location, the Anti-Tip

Device must be removed and reinstalled.

Mounting Anti-Tip Bracket

The alternative floor mounted bracket shall be installed as

follows:

,

Place bracket on floor in position shown in Figure 7b

(Bracket may be used ineither corner of the installation

area).

,

Secure to floor or wall stud.

3.

Later, when the unit is installed, the adjustable leg will

slide under the bracket.

Step 5: Gas Requirements and

Hookup

Verify the type of gas being used at the installation site.

The appliance is shipped from the factory for use with

natural gas. It must be converted for use with propane.

A qualified technician or installer must do the

conversion. Make certain the range matches the type of

gas available at this location.

The field conversion kit for this series of dual-fuel ranges is

Thermador Model PLPKIT. Obey all instructions in this kit

for correct conversion of the gas regulator and settings for

the gas valves.

CAUTION:

When connecting unit to propane gas, make

certain the propane gas tank is equipped with its

own high pressure regulator in addition to the

pressure regulator supplied with the appliance.

The pressure of the gas supplied to the

appliance regulator must not exceed 14" (34.9

mb) water column.

This appliance has been CSA certified for safe operation

up to an elevation of 10,200 ft. without any modifications.

Exception: For use with propane, the appliance must be

converted per the LP conversion instructions.

English 11

Page 14

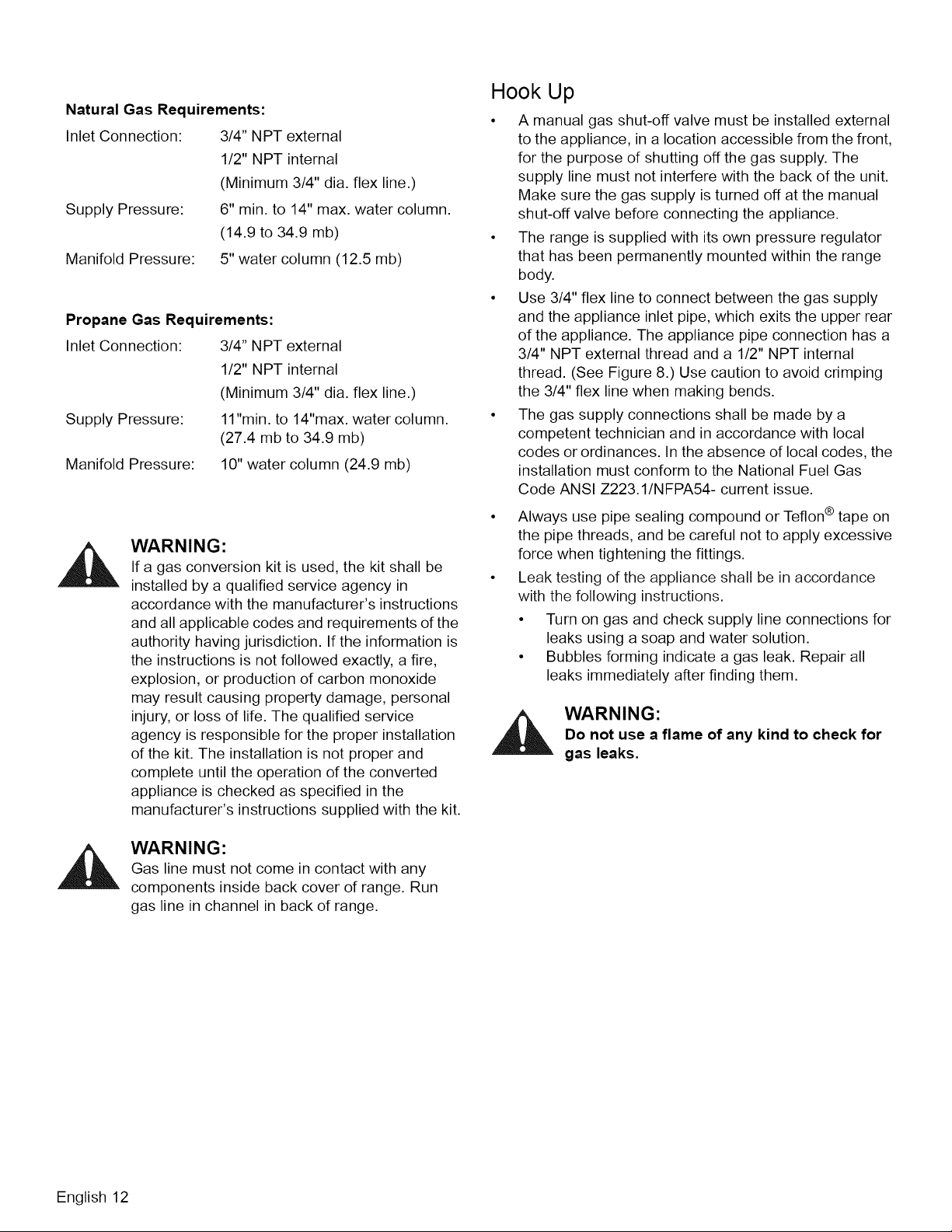

Natural Gas Requirements:

Inlet Connection: 3/4" NPT external

1/2" NPT internal

(Minimum 3/4" dia. flex line.)

Supply Pressure: 6" min. to 14" max. water column.

(14.9 to 34.9 mb)

Manifold Pressure: 5" water column (12.5 mb)

Propane Gas Requirements:

Inlet Connection: 3/4" NPT external

1/2" NPT internal

(Minimum 3/4" dia. flex line.)

Supply Pressure:

Manifold Pressure:

11"min. to 14"max. water column.

(27.4 mb to 34.9 mb)

10" water column (24.9 mb)

WARNING:

If a gas conversion kit is used, the kit shall be

installed by a qualified service agency in

accordance with the manufacturer's instructions

and all applicable codes and requirements of the

authority having jurisdiction. If the information is

the instructions is not followed exactly, a fire,

explosion, or production of carbon monoxide

may result causing property damage, personal

injury, or loss of life. The qualified service

agency is responsible for the proper installation

of the kit. The installation is not proper and

complete until the operation of the converted

appliance is checked as specified in the

manufacturer's instructions supplied with the kit.

Hook Up

• A manual gas shut-off valve must be installed external

to the appliance, in a location accessible from the front,

for the purpose of shutting off the gas supply. The

supply line must not interfere with the back of the unit.

Make sure the gas supply is turned off at the manual

shut-off valve before connecting the appliance.

• The range is supplied with its own pressure regulator

that has been permanently mounted within the range

body.

• Use 3/4" flex line to connect between the gas supply

and the appliance inlet pipe, which exits the upper rear

of the appliance. The appliance pipe connection has a

3/4" NPT external thread and a 1/2" NPT internal

thread. (See Figure 8.) Use caution to avoid crimping

the 3/4" flex line when making bends.

• The gas supply connections shall be made by a

competent technician and in accordance with local

codes or ordinances. In the absence of local codes, the

installation must conform to the National Fuel Gas

Code ANSI Z223.1/NFPA54- current issue.

Always use pipe sealing compound or Teflon ® tape on

the pipe threads, and be careful not to apply excessive

force when tightening the fittings.

Leak testing of the appliance shall be in accordance

with the following instructions.

• Turn on gas and check supply line connections for

leaks using a soap and water solution.

• Bubbles forming indicate a gas leak. Repair all

leaks immediately after finding them.

_h= WARNING:

-- gas leaks.

Do not use a flame of any kind to check for

English 12

WARNING:

Gas line must not come in contact with any

components inside back cover of range. Run

gas line in channel in back of range.

Page 15

GasInlet IConnection

Channel

Recess in I

Back Panel,I

for 3/4"Gas

Lne.

Figure 8: Appliance Manifold Pipe Connection

CAUTION:

The appliance must be isolated from the gas

supply piping system by closing its individual

manual shut-off valve during any pressure

testing of the gas supply piping system at test

pressures equal to or less than 1/2 psig

(3.5kPa.).

The appliance and its individual shut off valve

must be disconnected from the gas supply

piping system during any pressure testing of the

system at test pressures in excess of 1/2 psig

(3.5kPa.).

When checking the manifold gas pressure, the

inlet pressure to the regulator should be at least

6.0" (14.9 mb) W.C. for natural gas or 11.0"

(27.4 mb) for propane.

Do not attempt any adjustment of the pressure

regulator.

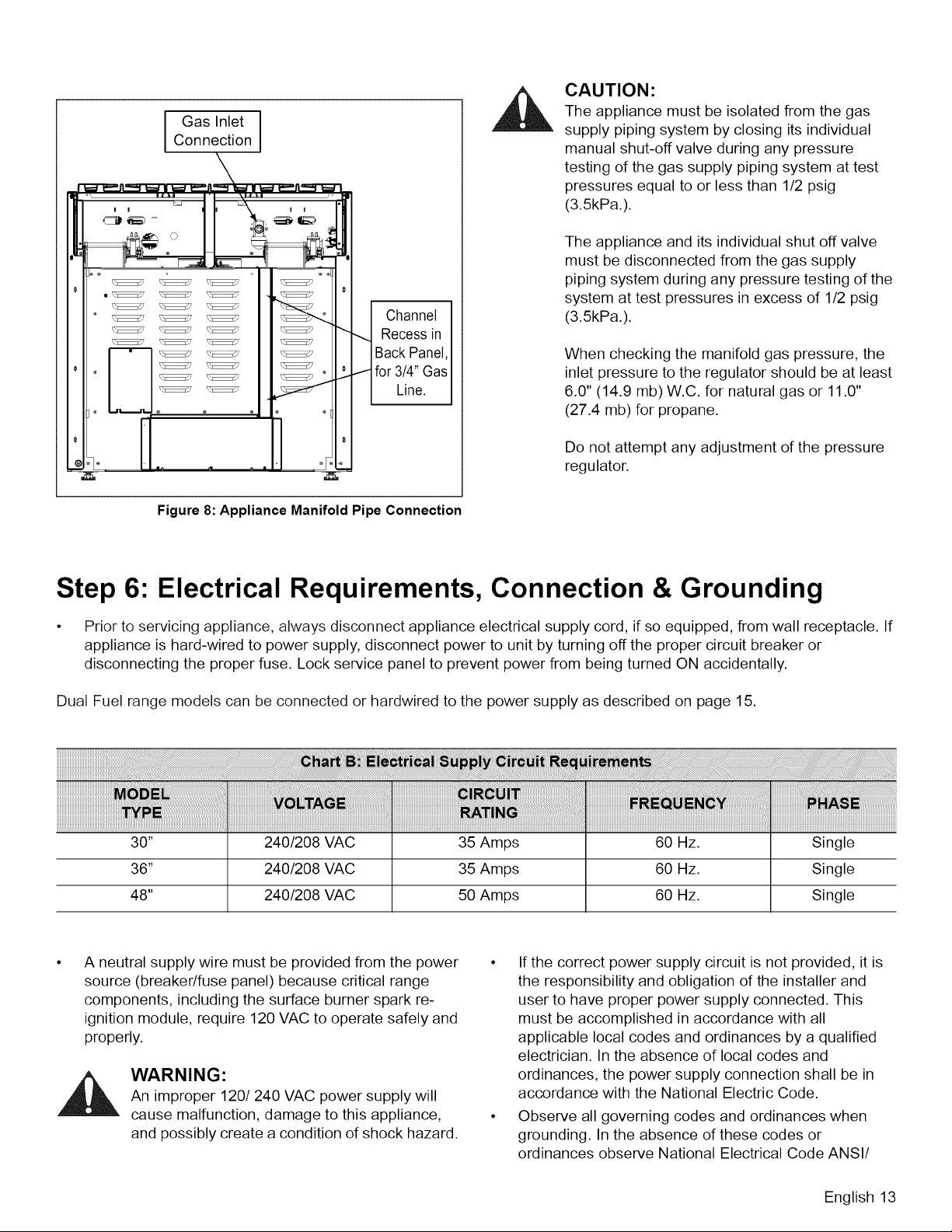

Step 6: Electrical Requirements, Connection & Grounding

• Prior to servicing appliance, always disconnect appliance electrical supply cord, if so equipped, from wall receptacle. If

appliance is hard-wired to power supply, disconnect power to unit by turning off the proper circuit breaker or

disconnecting the proper fuse. Lock service panel to prevent power from being turned ON accidentally.

Dual Fuel range models can be connected or hardwired to the power supply as described on page 15.

30" 240/208 VAC 35 Amps 60 Hz. Single

36" 240/208 VAC 35 Amps 60 Hz. Single

48" 240/208 VAC 50 Amps 60 Hz. Single

A neutral supply wire must be provided from the power

source (breaker/fuse panel) because critical range

components, including the surface burner spark re-

ignition module, require 120 VAC to operate safely and

properly.

WARNING:

An improper 120/240 VAC power supply will

cause malfunction, damage to this appliance,

and possibly create a condition of shock hazard.

If the correct power supply circuit is not provided, it is

the responsibility and obligation of the installer and

user to have proper power supply connected. This

must be accomplished in accordance with all

applicable local codes and ordinances by a qualified

electrician. In the absence of local codes and

ordinances, the power supply connection shall be in

accordance with the National Electric Code.

Observe all governing codes and ordinances when

grounding. In the absence of these codes or

ordinances observe National Electrical Code ANSI/

English 13

Page 16

NFPANo.70currentissue.Seethefollowing

informationinthissection(Step6)forgrounding

method.

• Electricalwiringdiagramsandschematicsareattached

behindthetoekickpaneloftherangeforaccessbya

qualifiedservicetechnician.

• Therangesaretobeconnectedtoa240/208VAC

powersupply.

DualFuelmodelsmustbeconnectedtothepowersupply

utilizingoneofthefollowingmethods.Forallmethodsof

connection,thelengthofthecordorconduit/wiringmust

allowtheunittobeslidcompletelyoutofthecabinet

withouthavingtounplugordisconnecttheunitfromthe

powersupply.Recommendedminimumfreelengthofcord

orconduitisfourfeet.Electricalinstallationsandgrounding

mustbeinaccordancewithalllocalcodesandordinances,

and/ortheNationalElectricCode,asapplicable.

4-CONDUCTOR CORD m NORMALLY, A UNIT

MUST BE CONNECTED TO THE POWER SUPPLY

WITH A 3-POLE, 4-CONDUCTOR CORD KIT RATED

125/250 VOLTS, 50 AMPERES, AND MARKED FOR

USE WITH RANGES. The cord kit must be attached to

the range junction box with a strain relief which will fit a

1" diameter hole. If not already equipped, the cord

must have 1/4" faston closed-loop lugs attached to the

free ends of the individual conductors, preferably

soldered in place.

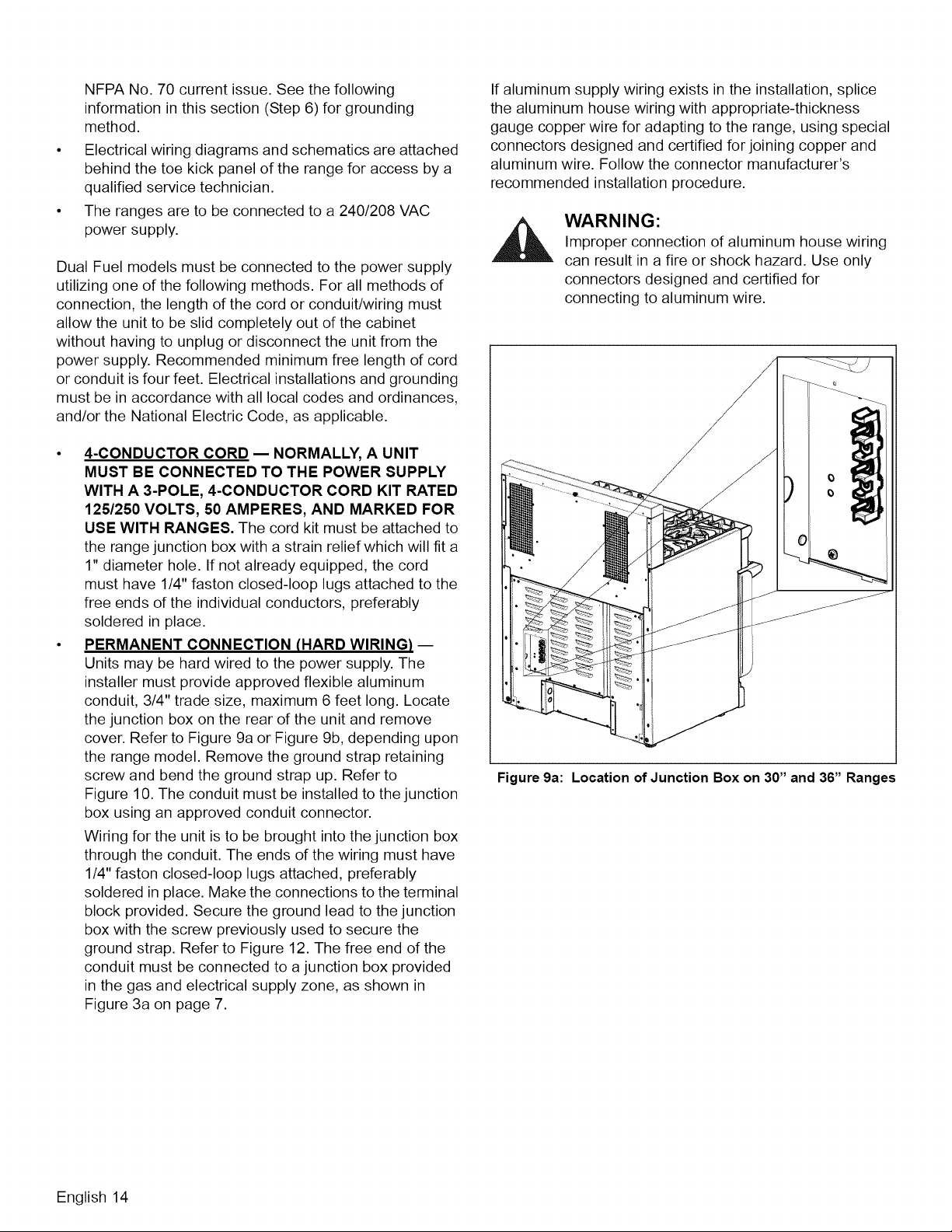

PERMANENT CONNECTION (HARD WIRING) --

Units may be hard wired to the power supply. The

installer must provide approved flexible aluminum

conduit, 3/4" trade size, maximum 6 feet long. Locate

the junction box on the rear of the unit and remove

cover. Refer to Figure 9a or Figure 9b, depending upon

the range model. Remove the ground strap retaining

screw and bend the ground strap up. Refer to

Figure 10. The conduit must be installed to the junction

box using an approved conduit connector.

Wiring for the unit is to be brought into the junction box

through the conduit. The ends of the wiring must have

1/4" faston closed-loop lugs attached, preferably

soldered in place. Make the connections to the terminal

block provided. Secure the ground lead to the junction

box with the screw previously used to secure the

ground strap. Refer to Figure 12. The free end of the

conduit must be connected to a junction box provided

in the gas and electrical supply zone, as shown in

Figure 3a on page 7.

If aluminum supply wiring exists in the installation, splice

the aluminum house wiring with appropriate-thickness

gauge copper wire for adapting to the range, using special

connectors designed and certified for joining copper and

aluminum wire. Follow the connector manufacturer's

recommended installation procedure.

WARNING:

Improper connection of aluminum house wiring

can result in a fire or shock hazard. Use only

connectors designed and certified for

connecting to aluminum wire.

Figure 9a: Location of Junction Box on 30" and 36" Ranges

English 14

Page 17

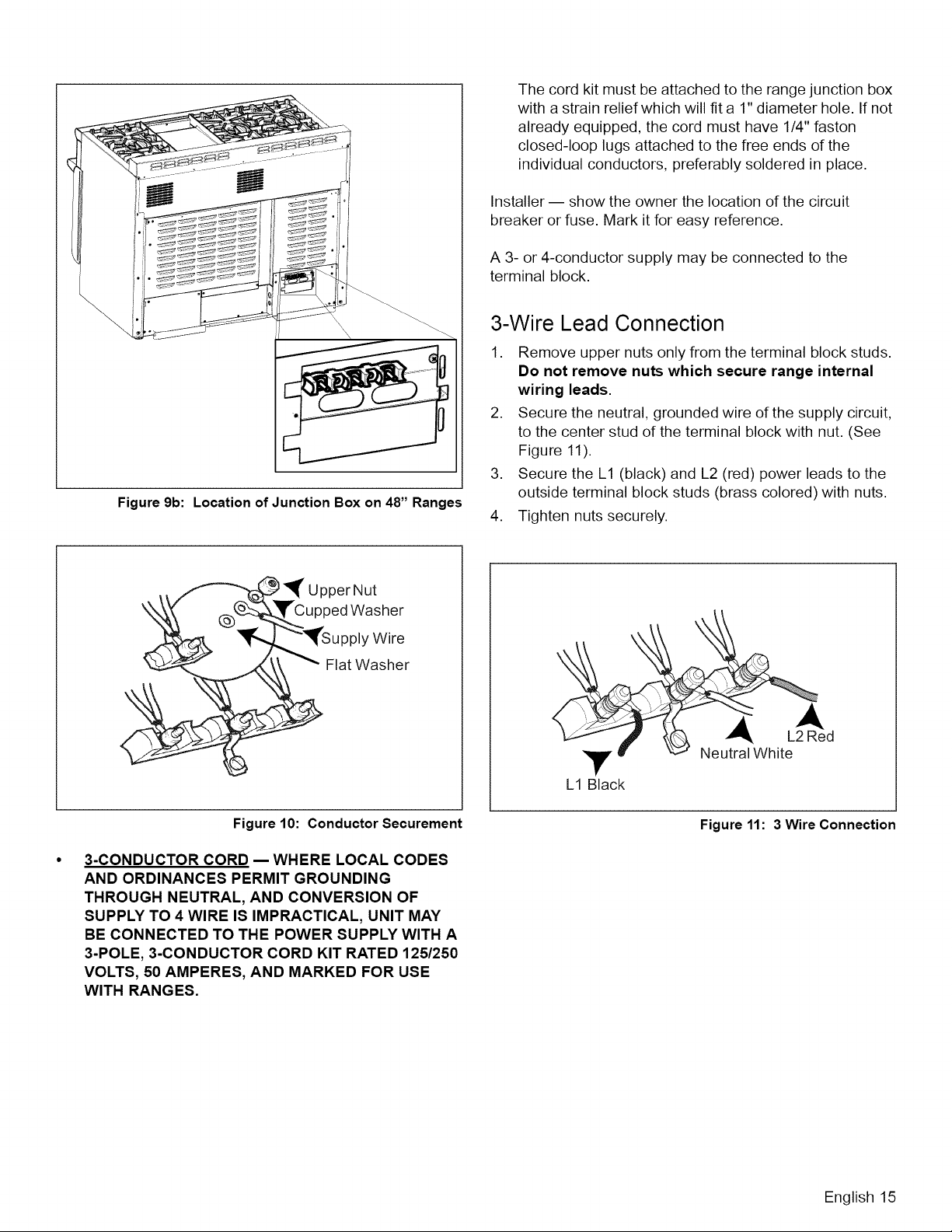

Figure 9b: Location of Junction Box on 48" Ranges

The cord kit must be attached to the range junction box

with a strain relief which will fit a 1" diameter hole. If not

already equipped, the cord must have 1/4" faston

closed-loop lugs attached to the free ends of the

individual conductors, preferably soldered in place.

Installer -- show the owner the location of the circuit

breaker or fuse. Mark it for easy reference.

A 3- or 4-conductor supply may be connected to the

terminal block.

3-Wire Lead Connection

1. Remove upper nuts only from the terminal block studs.

Do not remove nuts which secure range internal

wiring leads.

2. Secure the neutral, grounded wire of the supply circuit,

to the center stud of the terminal block with nut. (See

Figure 11).

3. Secure the L1 (black) and L2 (red) power leads to the

outside terminal block studs (brass colored) with nuts.

4. Tighten nuts securely.

UpperNut

)ed Washer

'Wire

Flat Washer

Figure 10: Conductor Securement

3-CONDUCTOR CORD m WHERE LOCAL CODES

AND ORDINANCES PERMIT GROUNDING

THROUGH NEUTRAL, AND CONVERSION OF

SUPPLY TO 4 WIRE IS IMPRACTICAL, UNIT MAY

BE CONNECTED TO THE POWER SUPPLY WITH A

3-POLE, 3-CONDUCTOR CORD KIT RATED 125/250

VOLTS, 50 AMPERES, AND MARKED FOR USE

WITH RANGES.

L2 Red

Neutral White

L1 Black

Figure 11:3 Wire Connection

English 15

Page 18

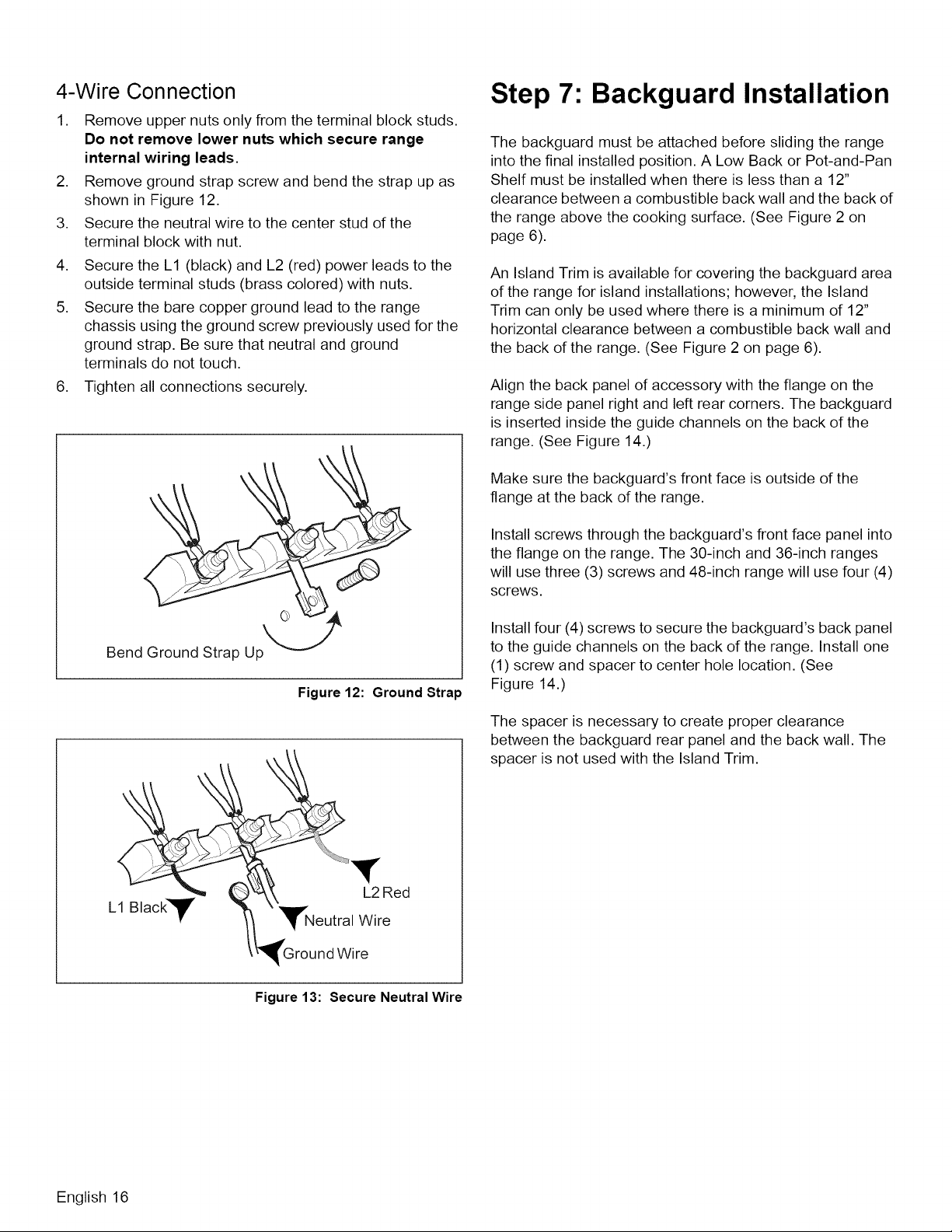

4-Wire Connection

,

Remove upper nuts only from the terminal block studs.

Do not remove lower nuts which secure range

internal wiring leads.

,

Remove ground strap screw and bend the strap up as

shown in Figure 12.

3.

Secure the neutral wire to the center stud of the

terminal block with nut.

4.

Secure the L1 (black) and L2 (red) power leads to the

outside terminal studs (brass colored) with nuts.

5.

Secure the bare copper ground lead to the range

chassis using the ground screw previously used for the

ground strap. Be sure that neutral and ground

terminals do not touch.

6. Tighten all connections securely.

O

Bend Ground Strap Up

Figure 12: Ground Strap

Step 7: Backguard Installation

The backguard must be attached before sliding the range

into the final installed position. A Low Back or Pot-and-Pan

Shelf must be installed when there is less than a 12"

clearance between a combustible back wall and the back of

the range above the cooking surface. (See Figure 2 on

page 6).

An Island Trim is available for covering the backguard area

of the range for island installations; however, the Island

Trim can only be used where there is a minimum of 12"

horizontal clearance between a combustible back wall and

the back of the range. (See Figure 2 on page 6).

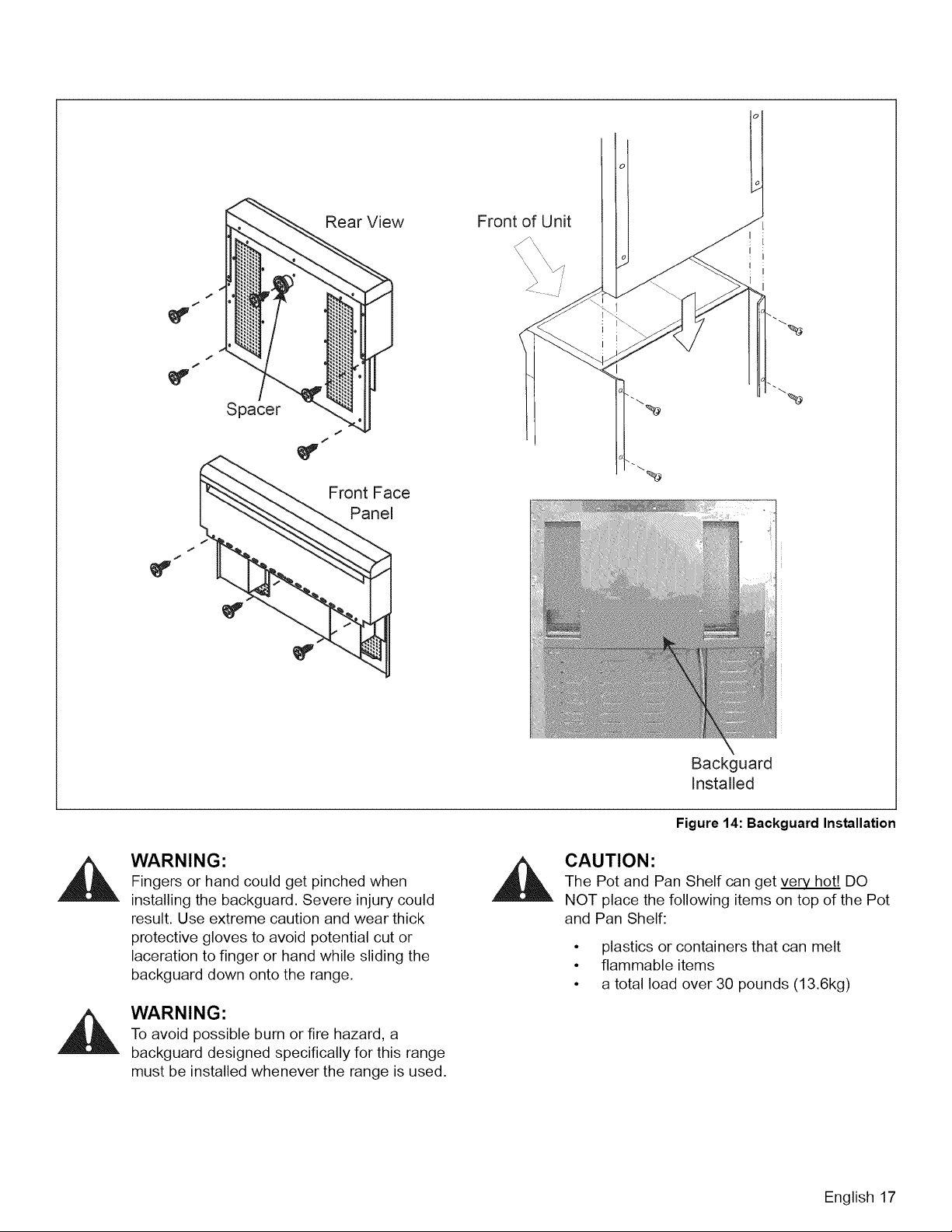

Align the back panel of accessory with the flange on the

range side panel right and left rear corners. The backguard

is inserted inside the guide channels on the back of the

range. (See Figure 14.)

Make sure the backguard's front face is outside of the

flange at the back of the range.

Install screws through the backguard's front face panel into

the flange on the range. The 30-inch and 36-inch ranges

will use three (3) screws and 48-inch range will use four (4)

screws.

Install four (4) screws to secure the backguard's back panel

to the guide channels on the back of the range. Install one

(1) screw and spacer to center hole location. (See

Figure 14.)

L1 Black_"

The spacer is necessary to create proper clearance

between the backguard rear panel and the back wall. The

spacer is not used with the Island Trim.

L2 Red

Neutral Wire

Figure 13: Secure Neutral Wire

English 16

Page 19

I

t

Spacer

__"FrontaFeaCe

Rear View

Front of Unit

I

• i\\

WARNING:

Fingers or hand could get pinched when

installing the backguard. Severe injury could

result. Use extreme caution and wear thick

protective gloves to avoid potential cut or

laceration to finger or hand while sliding the

backguard down onto the range.

WARNING:

To avoid possible burn or fire hazard, a

backguard designed specifically for this range

must be installed whenever the range is used.

Backguard

Installed

Figure 14: Backguard Installation

CAUTION"

The Pot and Pan Shelf can get very hot! DO

NOT place the following items on top of the Pot

and Pan Shelf:

• plastics or containers that can melt

• flammable items

• a total load over 30 pounds (13.6kg)

English 17

Page 20

30" Included N/A HS30R IT30R

36" N/A LB36R HS36R IT36R

48" N/A LB48R HS48R IT48R

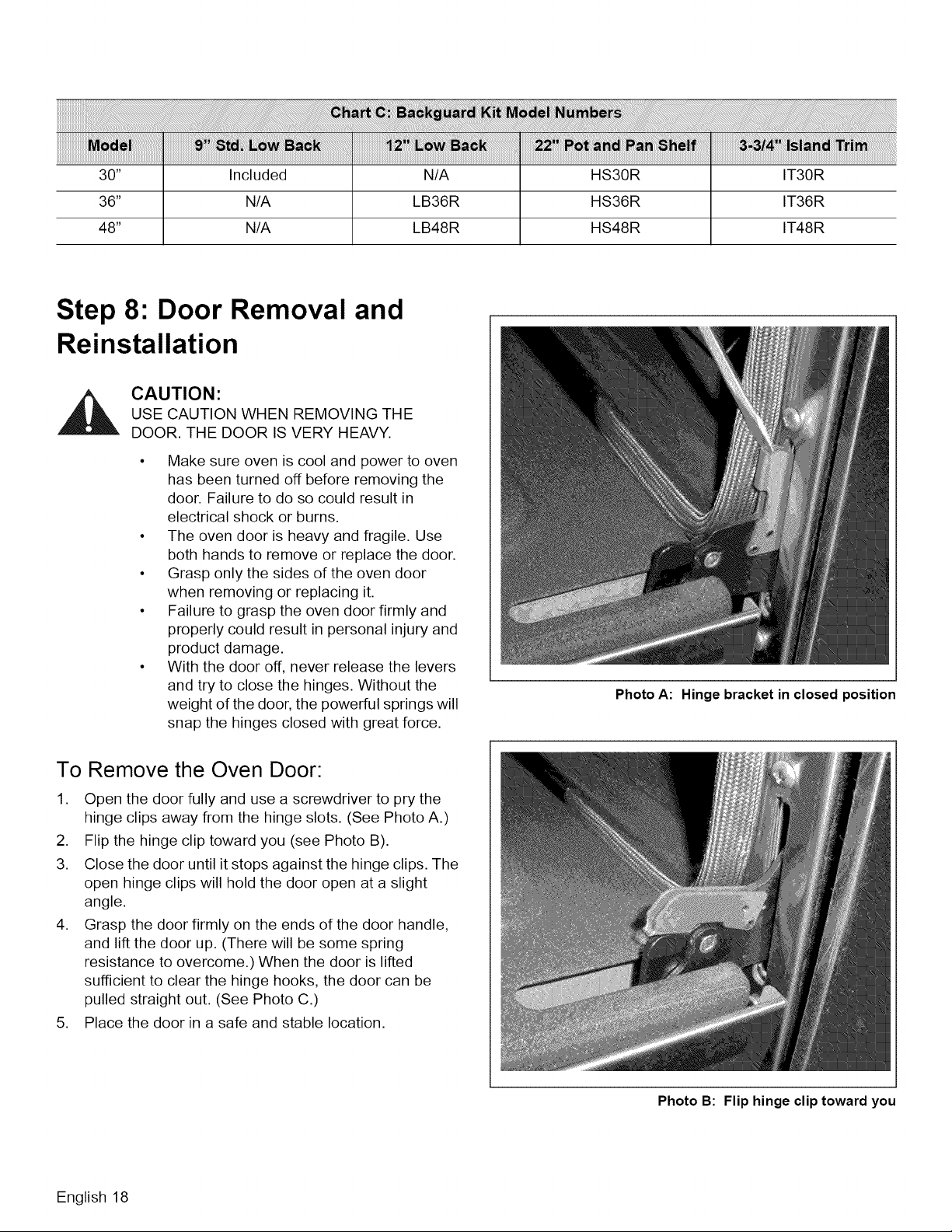

Step 8: Door Removal and

Reinstallation

CAUTION:

USE CAUTION WHEN REMOVING THE

DOOR. THE DOOR IS VERY HEAVY.

• Make sure oven is cool and power to oven

has been turned off before removing the

door. Failure to do so could result in

electrical shock or burns.

• The oven door is heavy and fragile. Use

both hands to remove or replace the door.

• Grasp only the sides of the oven door

when removing or replacing it.

• Failure to grasp the oven door firmly and

properly could result in personal injury and

product damage.

• With the door off, never release the levers

and try to close the hinges. Without the

weight of the door, the powerful springs will

snap the hinges closed with great force.

Photo A: Hinge bracket in closed position

To Remove the Oven Door:

1. Open the door fully and use a screwdriver to pry the

hinge clips away from the hinge slots. (See Photo A.)

2. Flip the hinge clip toward you (see Photo B).

3. Close the door until it stops against the hinge clips. The

open hinge clips will hold the door open at a slight

angle.

4. Grasp the door firmly on the ends of the door handle,

and lift the door up. (There will be some spring

resistance to overcome.) When the door is lifted

sufficient to clear the hinge hooks, the door can be

pulled straight out. (See Photo C.)

5. Place the door in a safe and stable location.

English 18

Photo B: Flip hinge clip toward you

Page 21

PhotoC:Hingeremovedfrom oven

To Reinstall the Oven Door:

1. Position the door at a slight angle and insert the hinges

into the hinge slots - one on each side of the range.

The hinges will securely hook into the slots when

properly installed. Do not force, bend, or twist the door.

2. Open door all the way to expose hinge clips. Push

hinge clips away from you (toward the oven) until they

meet the hinge.

Tip:

• Rest the door on your foot while using your leg for

stability.

3. Open the door fully and use a screwdriver to push the

hinge clips all the way into the hinge slots. Be careful

not to scratch the range during this process.

To Check Door Fit and Operation:

1. Open and close the door slowly to test the movement

and the fit of the door to the oven cavity. Do not force

the door to open or close. If the door is properly

installed, it should move smoothly and rest straight on

the front of the range when closed.

2. If the door does not operate correctly, verify that the

hinges are properly seated into the hinge slots, and

that the hinge clips are fully engaged into the slots.

Step 9: Placing and Leveling

the Range

For proper performance, the range must be level.

(This is very important for all products that have the

griddle feature.)

The range has four (4) leveling legs that are threaded

into the sheet metal base structure. The range is

leveled by rotating the legs using a 318" socket or a

wrench on the hex flats at the top of each leg, or using

an adjustable wrench on the flats on the sides of the

foot.

Progression of the height adjustments should be

alternated proportionally between the four legs, until

the top edges of the range's side panels are close to

matching the countertop height.

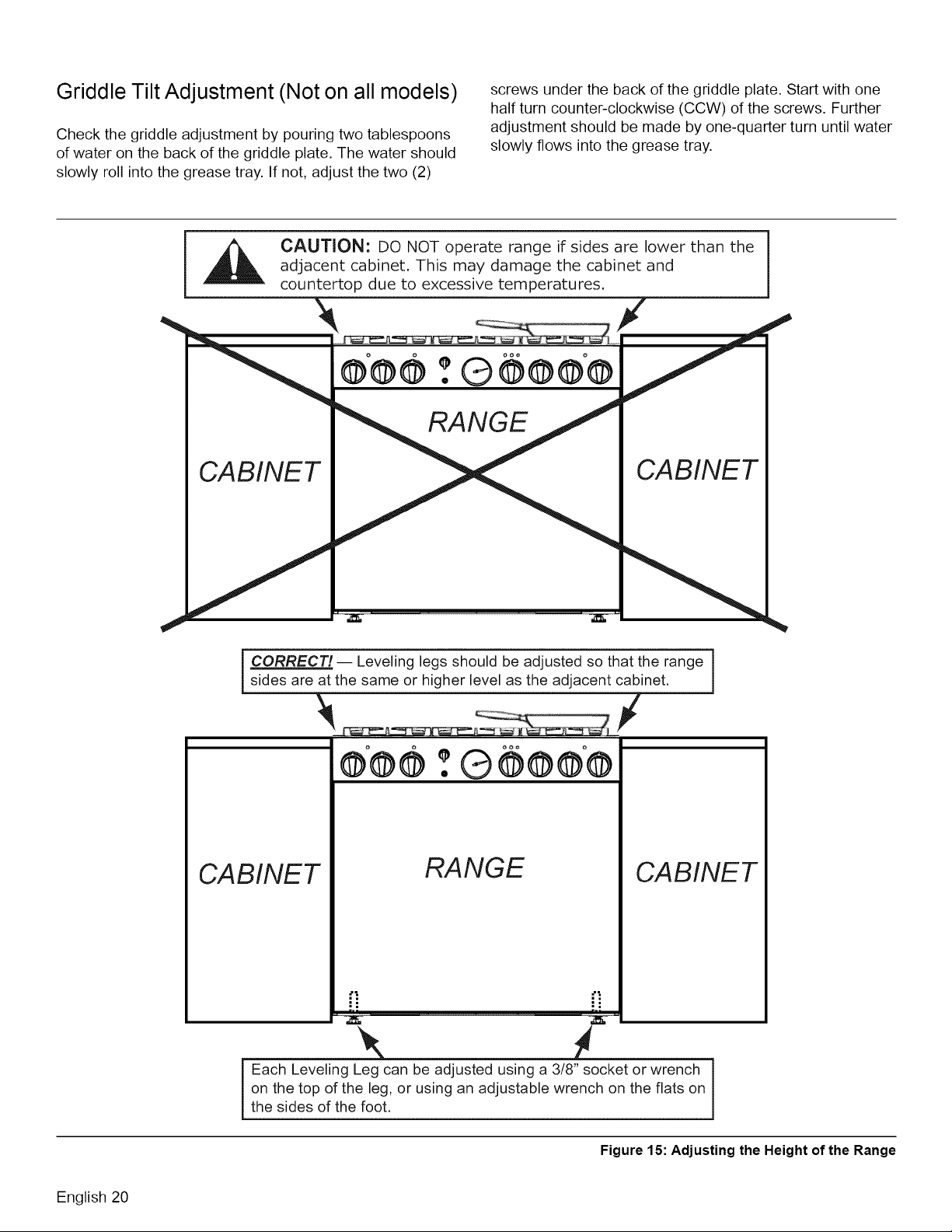

CAUTION"

The top edges of the range's side panels must

be on the same or higher level as the adjacent

countertop. If the range is operated while at a

lower height relative to the adjacent cabinet, the

cabinet could be exposed to excessive

temperatures, causing damage to the cabinet

and countertop. (See Figure 15.)

Final height adjustments of the two rear legs take place

before moving the range into its installed position in the

cabinet.

As the range is moved into its final, installed position,

verify that one of the rear feet has properly engaged

the Anti-Tip Bracket. (See Step 4.) This can be verified

by viewing through the opening near the floor with the

Kick Panel removed.

NOTICE:

Due to their size and weight distribution, the 48" ranges

do not require the use of the Anti-Tip Bracket.

• With the range in the installed position, the final height

adjustments are made to the two front legs to ensure

proper alignment to the countertop.

Note:

It is assumed that the countertop adjacent to the range

has been properly leveled.

After the range is properly leveled, replace the Kick

Panel and reinstall the Oven Door. (See Step 8 for door

installation.) It is important that the two (2) screws

retaining the kick panel are secure to prevent

accidental access to hot surfaces.

Ensure that the burner caps are correctly seated on

the burner bases of the range's cooktop.

English 19

Page 22

Griddle Tilt Adjustment (Not on all models)

Check the griddle adjustment by pouring two tablespoons

of water on the back of the griddle plate. The water should

slowly roll into the grease tray. If not, adjust the two (2)

CAUTION: DO NOT operate range if sides are lower than the

,&

-- countertop due to excessive temperatures.

adjacent cabinet. This may damage the cabinet and

screws under the back of the griddle plate. Start with one

half turn counter-clockwise (CCW) of the screws. Further

adjustment should be made by one-quarter turn until water

slowly flows into the grease tray.

CABINET

4

CABINET

CABINET

CORRECT! -- Leveling legs should be adjusted so that the range

sides are at the same or higher level as the adjacent cabinet.

®®® ®¢¢,®°®

RANGE

CABINET

English 20

•1% ."".

• . _..

on the top of the leg, or using an adjustable wrench on the flats on

Each Leveling Leg can be adjusted using a 3/8" socket or wrench

the sides of the foot,

Figure 15: Adjusting the Height of the Range

Page 23

Step 10: Burner Test and

Adjustment

The two rangetop burners on the left side feature XLO that

causes the flame to cycle on and offwhen the knob is set to

the XLO range. This is normal operation.

Install any loose components, such as burner caps and

grates, that may have been removed earlier. Be certain that

burner caps seat properly into the burner bases. Before

testing operation of the appliance, verify that the unit and

the gas supply have been carefully checked for leaks and

that the unit has been connected to the electrical power

supply. Turn the gas shut-off valve to the open position.

Test Rangetop Burners

Test Burner Ignition. Select a rangetop burner knob. Push

down and turn counterclockwise to HI. The ignitor/spark

module will produce a clicking sound. Once the air has

been purged from the supply lines, the burner should light

within four (4) seconds.

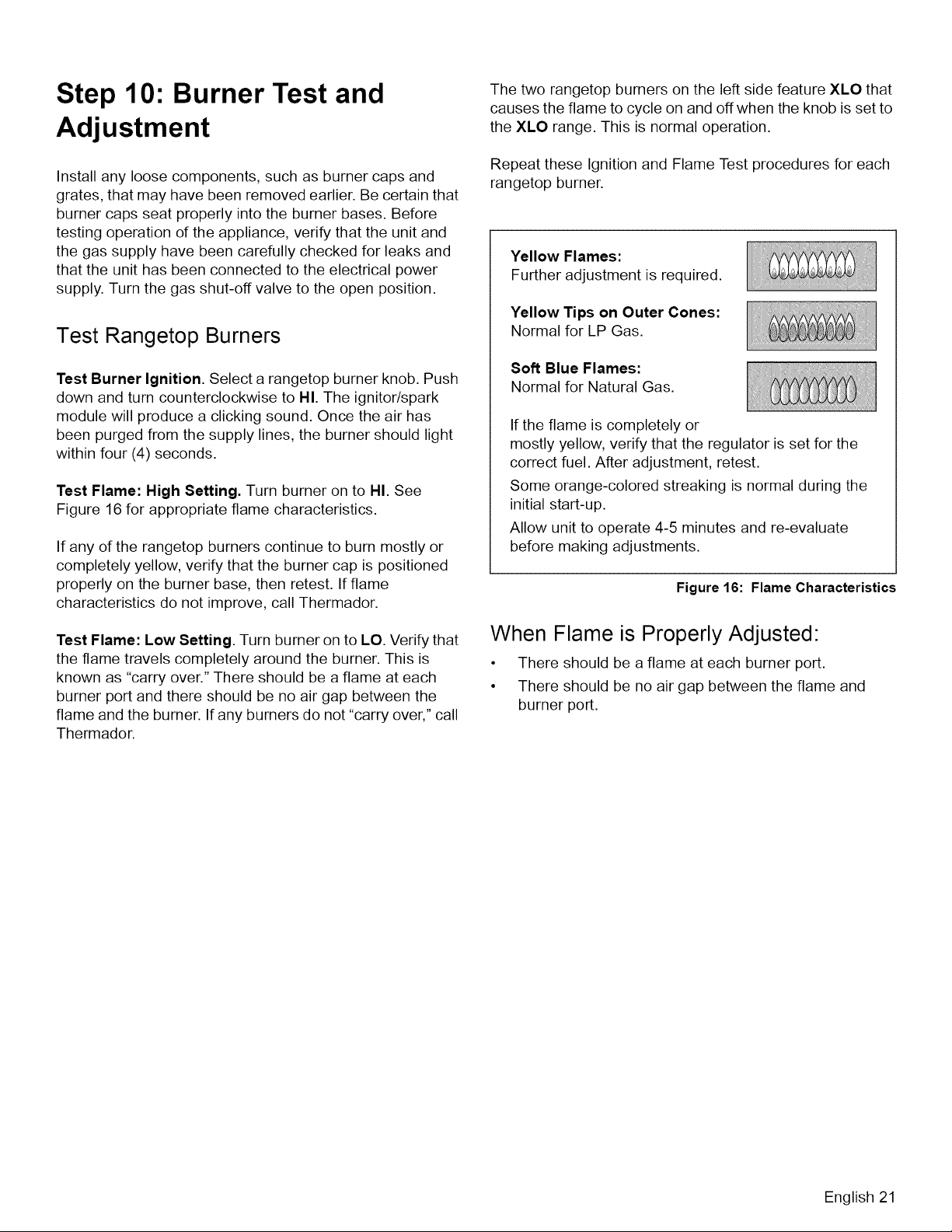

Test Flame: High Setting. Turn burner on to HI. See

Figure 16 for appropriate flame characteristics.

If any of the rangetop burners continue to burn mostly or

completely yellow, verify that the burner cap is positioned

properly on the burner base, then retest. If flame

characteristics do not improve, call Thermador.

Repeat these Ignition and Flame Test procedures for each

rangetop burner.

Yellow Flames:

Further adjustment is required.

Yellow Tips on Outer Cones:

Normal for LP Gas.

Soft Blue Flames:

Normal for Natural Gas.

If the flame is completely or

mostly yellow, verify that the regulator is set for the

correct fuel. After adjustment, retest.

Some orange-colored streaking is normal during the

initial start-up.

Allow unit to operate 4-5 minutes and re-evaluate

before making adjustments.

Figure 16: Flame Characteristics

Test Flame: Low Setting. Turn burner on to LO. Verify that

the flame travels completely around the burner. This is

known as "carry over." There should be a flame at each

burner port and there should be no air gap between the

flame and the burner. If any burners do not "carry over," call

Thermador.

When Flame is Properly Adjusted:

• There should be a flame at each burner port.

• There should be no air gap between the flame and

burner port.

English 21

Page 24

Installer Checklist

Final Check List

• Specified clearances maintained to cabinet surfaces.

• Unit Level - front to back - side to side.

• Burner caps positioned properly on burner bases.

• All packaging material removed.

• Island trim or backguard attached according to

instructions.

• Kick panel is in place and the two (2) mounting screws

are secure.

• The griddle plate is correctly positioned, tilted slightly

forward. (See page 20 for adjustment procedure.)

Gas Supply

• Gas Connection: 3/4" N.RT. with a minimum 3/4"

diameter flex line.

• The appliance is connected only to the type of gas for

which it is certified for use.

• Manual gas shut off valve installed in an accessible

location (without requiring removal of range).

• Unit tested and free of gas leaks.

• If used on propane gas, verify that the propane gas

supply is equipped with its own high pressure regulator

in addition to the pressure regulator supplied with the

appliance.

Electrical

• Receptacle with correct over-current protection is

provided for service cord connection.

• Proper ground connection.

Operation

• Bezels centered on burner knobs, and knobs turn

freely.

• Each burner lights satisfactorily, both individually and

with other burners operating.

• Oven door hinges seated and hinge locks in proper

position. Door opens and closes properly.

• Burner grates correctly positioned, level, and do not

rock.

• INSTALLER: Leave the CARE AND USE MANUAL

and INSTALLATION INSTRUCTIONS with the owner

of the appliance.

To Clean and Protect Exterior Surfaces

The stainless steel surfaces may be cleaned by wiping with

a damp soapy cloth, rinsing with clear water and drying

with a soft cloth to avoid water marks. Any mild glass

cleaner will remove fingerprints and smears.

For discolorations or deposits that persist, refer to the Care

and Use Manual.

To polish and protect the stainless steel, use a cleaner/

polish such as Stainless Steel Magic ®.

DO NOT allow deposits to remain for long periods of time.

DO NOT use ordinary steel wool or steel brushes. Small

bits of steel may adhere to the surface causing rust.

DO NOT allow salt solutions, disinfectants, bleaches or

cleaning compounds to remain in contact with stainless

steel for extended periods. Many of these compounds

contain chemicals which could prove harmful. Rinse with

water after exposure and wipe dry with a clean cloth.

English 22

Page 25

Table des mati res

CONSlGNES DE SI_CURITI_ ...................... 1

CONSIGNES D'INSTALLATION

Cha

3itre 1

Cha

3itre 2

Cha

3itre 3

Cha

3itre 4

Cha

3itre 5

Cha

3itre 6

au branchement eta la mise a la terre ................................. 16

Cha3itre 7 "Installation du dosseret ................................... 18

Cha 3itre 8 • Retrait et installation de la porte ............................ 20

Cha 3itre 9 • Mise en place et nivelage de la cuisiniere .................... 22

Cha 3itre 10 • Test et reglage des brQleurs .............................. 24

Liste de verification a I'intention de I'installateur ........................ 24

: Exigences en matiere de ventilation ......................... 4

: Preparation des armoires .................................. 5

: Deballage et manutention de la cuisiniere .................... 10

: Installation du dispositif antibascule ........................ 11

: Exigences relatives a I'alimentation en gaz et au raccordement.. 14

: Exigences relatives a I'alimentation electrique,

IMPORTANTES ...... 3

Nettoyage et protection des surfaces externes ..... 25

Cet appareil electromenager de Thermador est fait par

BSH Home Appliances Corporation

5551 McFadden Ave.

Huntington Beach, CA 92649

Questions ?

1-800-735-4328

www.thermador.com

Nous attendons de vos nouvelles !

Page 26

CONSIGNES DE SI CURITI

CONSIGNES DE SI CURITI IMPORTANTES

-- LISEZ ET CONSERVEZ CES INSTRUCTIONS

APPROUVI_ POUR TOUS LES APPAREILS

RI_SIDENTIELS

POUR UTILISATION RC:SIDENTIELLE SEULEMENT

IMPORTANT : Conservez ces instructions pour

I'inspecteur de la soci_t_ gazi_re de votre localitY.

INSTALLATEUR : Veuillez laisser ces instructions

d'installation avec I'appareil pour le propri_taire.

PROPRII_TAIRE : Veuillez conserver ces instructions pour

consultation ult_rieure.

Coupez I'_lectricit_ avant d'installer I'appareil.

AVERTISSEMENT :

-- Avant de remettre I'_lectricit_, assurez-vous que

toutes les commandes sont _ la position OFF.

Important •

Les r_glementations locales varient. L'installation, le

branchement au gaz et la mise _ la terre doivent _tre

conformes _ toutes les r_glementations en vigueur.

AVERTISSEMENT :

• Toutes les cuisini_res

peuvent basculer.

• Cela pourrait causer

des blessures.

• Installez le dispositif

anti-bascule inclus

avec la cuisini_re.

• Consultez les

instructions

d'installation.

POUR RI_DUIRE LE RISQUE QUE

L'APPAREIL BASCULE, IL DOlT I_TRE

FlXl_ AU MUR _, L'AIDE D'UN

DISPOSITIF ANTI-BASCULE

ADI_QUAT. ASSUREZ-VOUS QUE LE

DISPOSITIF ANTI-BASCULE EST

INSTALLI_ CONFORMI_MENT AUX

INSTRUCTIONS D'INSTALLATION.

(NOTE : LE DISPOSITIF ANTI-

BASCULE EST REQUIS POUR

TOUTES LES CUISINIC:RES DE 30 ET

36 POUCES. LES CUISINIC:RES DE

48 POUCES NE REQUIC:RENT PAS

L'UTILISATION D'UN DISPOSITIF

ANTI-BASCULE).

Fran9ais 1

Page 27

AVERTISSEMENT :

Si les directives contenues dans ce

manuel ne sont pas respectees,

des incendies ou des decharges

electriques pourraient 6tre &

I'origine de dommages materiels ou

de blessures corporelles.

N'entreposez pas et n'utilisez pas

d'essence ou d'autres produits

inflammables a proximite de la

cuisini@e ou de tout autre appareil.

Pour les installations au Massachusetts :

1. L'installation doit _tre r6alis6e par un entrepreneur

qualifi6 ou accr6dit6, un plombier ou un installateur

de gaz qualifi6 ou autoris6e par I'l_tat ou la r6gion

dans laquelle cet appareil est install6.

2. Le robinet d'arr6t de gaz doit 6tre pourvu d'une

poign6e en <<T >>.

3. La Iongueur maximale autoris6e du tuyau de gaz est

de 91,4 cm (36").

Note :

Cette cuisini@e N'EST PAS congue pour les maisons

mobiles ni pour les v6hicules r6cr6atifs.

SI VOUS DI_TECTEZ UNE ODEUR

DE GAZ

• N'allumez aucun appareil.

• Netouchez pas aux interrupteurs

electriques.

• N'utilisez pas lestelephones du

b_timent.

• Appelez immediatementvotre

compagnie de gaz chez un voisin.

Suivez les instructions de la

compagnie.

• Si vous n'arrivez pas a contacter

votre compagnie de gaz, appelez

le service d'incendie.

L'installation et les reparations

doivent _tre realisees par un

installateur qualifie, un centre de

reparation agree ou la societe

gazi@e.

N'installez PAS cet appareil a I'exterieur.

Frangais 2

Page 28

_j[_,_,_,_,_; ss_,__,_;,,,,,,,,,,__,_,_,_;__;_s _,_ _H_iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii_Jj_j_j_ __jj_j_,........................................................................................................__jj_j_j_,,,,,,,,,,,,,,_jj_j_j_j_j_iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii__]J_J_,,,,,,,,,,,,,,,_iJ_J_J_J_,,,,,,,,,,,,,,,_JJJ[J_!_!_!_!_!_!_!_!_!_JJJ_i__i_i!ii_iiii_iiii_iiii_____iiii_ii!ii_iiii_iiii___i__i_JJJ_____jjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjj__Jjjjj[jiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii_____x_x_x_x_x_x_x_x_x_x_x_x_x__X_x_x_x_x_x_x_x_x_x_x_x_x_x_x_x_x_x_x_x_x_x_x_x_x_x_ii]JJJJJJJJJ_J_i

CONSIGNES D'INSTALLATION IMPORTANTES

Verification du type de gaz

V@ifiez le type de gaz qui alimente I'endroit oQ vous

installez I'appareil. Assurez-vous que I'appareil est branch6

au type de gaz pour lequel il est certifi6. Toutes les

cuisini@es sont certifi6es pour une utilisation au gaz

naturel. Pour proc6der _ la conversion de I'appareil pour

une utilisation au gaz propane, procurez-vous le jeu de

conversion.

AVERTISSEMENT •

Pour 6viter tout risque de brQlure ou d'incendie,

un dosseret congu sp6cifiquement pour cette

cuisini@e doit 6tre install6.

Consultez le <<Tableau C : Num6ro de module de dosseret

>>_ la page 20 pour connaftre les modules de dosseret qui

sont appropri6s pour cet appareil. Une fois le dosseret

choisi, I'appareil doit _tre install6 ad6quatement en

respectant les espaces libres minimaux pour surfaces

combustibles mentionn6s au <<Chapitre 2 : Pr6paration des

armoires >>de la page 5.

Important :

• Un dosseret doit _tre install6 Iorsque I'espace

horizontal entre les mat@iaux combustibles et le c6t6

arri@e de la cuisini@e est de moins de 12 pc.

Commandez s6par6ment le dosseret Thermador et

installez-le _ I'arri@e de la cuisini@e (un dosseret est

inclus avec les modules de 30 pc). Pour les

installations en riot et toute autre installation avec un

espace de plus de 12 pc, une garniture en acier

inoxydable est vendue en option afin de recouvrir les

brides de montage du dosseret.

• Assurez-vous que I'appareil convient au type de gaz

fourni. Consultez le <<Chapitre 5 : Exigences relatives

I'alimentation au gaz et au raccordement >>de la

page 14, avant de proc6der _ I'installation.

Alimentation en gaz

Gaz naturel- 14,9 mb min. (6 po, C.E.), _ 34,9 mb max.

(14 po, C.E.)

Gaz propane -- 27,4 mb min. (11 po, C.E.), 34,9 mb max.

(14 po).

Alimentation electrique •

Consultez la page 16 pour obtenir les sp6cifications.

Cet appareil a 6t6 test6 conform6ment _ la norme

am6ricaine ANSIZ21.1 pour les appareils 61ectrom6nagers

de cuisson au gaz et _ la norme canadienne CAN 1.1-M81

sur les cuisini@es _ gaz m6nag_res.

II est fortement recommand6 d'installer une hotte de

ventilation adapt6e au-dessus de cet appareil (voir le

<<Chapitre 1 : Exigences en mati_re de ventilation >>_ la

page 4). Puisque cet appareil peut d_gager une forte

chaleur, une attention particuli@e doit _tre port_e aux

travaux d'installation des conduits et de la hotte, lesquels

doivent _tre conformes _ la r_glementation locale en

mati@e de construction.

V@ifiez la r_glementation locale en vigueur pour connaftre

la bonne m_thode d'installation de I'appareil. Les

r_glementations locales varient. L'installation, le

branchement _lectrique et la mise _ la terre doivent

respecter toutes les r_glementations en vigueur. S'il n'y a

pas de r_glementation, I'appareil doit _tre install_

conform_ment au Code national am_ricain actuel sur les

gaz combustibles ANSI Z223.1/NFPA 54 et au Code

am_ricain de I'_lectricit_ actuel ANSI/NFPA No. 70. Au

Canada, I'installation doit _tre conforme aux normes

canadiennes CAN 1-B149.1 et CAN 1-B149.2 du code du

b_timent pour I'installation d'appareils fonctionnant au gaz,

et/ou au code de construction local.

Cet appareil est conforme _ une ou plusieurs des normes

suivantes •

• UL 858 - norme visant la s_curit_ en mati@e de

cuisini@es _lectriques domestiques

• UL 923 - norme visant la s_curit_ en mati@e d'appareil

de cuisson par micro-ondes

• UL 507 - norme visant la s_curit_ en mati@e de

ventilateurs _lectriques

• ANSI Z21.1 - norme am_ricaine r_gissant les appareils

_lectrom_nagers _ gaz

• CAN/CSA-C22.2 No 113.08 - ventilateurs

• CAN/CSA-C22.2 No 61 - cuisini@es domestiques

II est de la responsabilit_ du propri_taire et de I'installateur

de d_terminer les exigences ou les normes

suppl6mentaires qui s'appliquent _ des installations

particuli@es.

Compte tenu de la chaleur intense des brQleurs de la

surface de cuisson, il n'est pas recommand_ d'installer un

Frangais 3

Page 29

four_ micro-ondesavecunsyst_medeventilationau-

dessusdelasurfacedecuisson.

ATTENTION •

Pour 61iminer tout risque de brQlure ou

d'incendie caus6 par la proximit6 de surfaces

surchauff6es, vous devriez 6viter d'entreposer

quoi que ce soit dans les armoires situ6es au-

dessus des appareils.

ATTENTION :

Lorsque vous branchez I'appareil _ gaz

propane, assurez-vous que le r6servoir de gaz

propane est muni de son propre m6canisme

r6gulateur _ haute pression en plus du

r6gulateur _ haute pression de I'appareil. La

pression de gaz de cet appareil ne devrait

pas exceder 14,0 pouces de colonne d'eau

(34,9 mb) entre le reservoir de gaz propane et

le regulateur a haute pression.

large que la table de cuisson pour une ventilation

accrue.

Pour les installations en riot, la largeur de la hotte

devrait d6passer la cuisini_re d'au moins 3" de chaque

c6t6.

Important •

Les hottes et les ventilateurs sont congus pour _tre utilis6s

avec un seul conduit mural. Cependant, certains

inspecteurs ou codes du b_timent municipaux exigent un

double conduit. Consultez les codes applicables ou les

organismes de votre r6gion avant d'entreprendre les

travaux pour vous assurer que I'installation de la hotte et

des conduits r6pond aux exigences locales.

N'installez pas un combin6 hotte/four _ micro-ondes au-

dessus de la cuisini_re. Ces appareils n'assurent pas une

ventilation appropri6e et ne sont pas congus pour 6tre

utilis6s avec une cuisini@e.

ATTENTION •

Cet appareil est congu pour un usage culinaire.

Pour des raisons de s6curit6, ne I'utilisez jamais

pour chauffer une piece.

Chapitre 1 : Exigences en

mati re de ventilation

II est fortement recommand6 d'installer une hotte de

ventilation appropri6e au-dessus de la cuisini@e. Une

ventilation par aspiration descendante ne devrait pas _tre

utilis6e. Le tableau de la page 5 6num@e les hottes qu'il

est conseill6 d'utiliser avec les cuisini@es Thermador ainsi

que la puissance minimale requise de ces hottes.

, Choix des modeles de hotte et de ventilateur :

Pour les installations murales, la largeur de la hotte doit

_tre au moins 6gale _ celle de la cuisini@e. Si I'espace

le permet, il est souhaitable d'installer une hotte plus

2. Emplacement de la hotte :

• • Pour une meilleure 61imination de la fum6e, le bord

inf@ieur de la hotte doit se trouver _ 30" au-dessus de

la table de cuisson (Figure 1).

• • Laissez au moins 36" d'espace libre si la hotte

contient des mat@iaux combustibles, comme du

recouvrement de bois.

AVIS :

La plupart des hottes contiennent des mat@iaux

combustibles qui doivent _tre pris en consid6ration Iors de

la planification de I'installation.

,

Air d'appoint :

Compte tenu de I'important volume d'air requis pour

assurer une bonne ventilation, il est recommand6 de

pr6voir un apport d'air de I'ext@ieur. Cet aspect rev6t

une importance particuli_re dans les maisons bien

isol6es et tr_s 6tanches.

II est 6galement recommand6 de consulter un

sp6cialiste qualifi6 en chauffage et en climatisation.

Frangais 4

Page 30

HotteProWallde30ou36po

30po

4brOleurs

Garnituresurmesurede30ou36poavecventilateur

optionnel

Hotted'flotde42poavecventilateuroptionnel

36po

48po

4brOleursavecplaquechauffante

6brOleurs

6brOleursavecplaquechauffante

HotteProWallde36ou42po

Garnituresurmesurede36poavecventilateuroptionnel

Hotted'flotde42ou48poavecventilateuroptionnel

HotteProWallde48ou54po

Garnituresurmesurede48poavecventilateuroptionnel

Remarquesimporlantes:

IIestrecommand6d'utiliserunehottemuraleouunehotteriotProfessionaldeThermadorousurmesureavecles

cuisini_resProfessionaldeThermador.

Consultezlewww.Thermador.compourlagammecompletedesoptionsdeventilation,desouffleriesetd'accessoires

ProfessionaldeThermador.

*Pourlescuisini_res_gaz_rendement61ev6(60000BTUouplus),uneventilationminimalede1pi3/minpar100BTU

estrecommand6e.Silacuisini_reestdot6ed'uneplaquechauffante,ajouter200pP/min_lacapacit6desoufflerie

estim6e.Uneplusgrandecapacit6desouffleriepeut@trerequisepourdesconduitspluslongs.

Danslecasdesriots,ilestrecommand6d'utiliserunehottedontlalargeurexc_decelledelacuisini_rede6po(3pode

chaquec6t6).

pi3/min=piedcubeparminute(cotestandardpourlacapacit6d'unesoufflerie)..

Chapitre 2 : Preparation des

armoires

1. La cuisini@re est un appareil monobloc. Les espaces

libres requis sont indiqu6s _ la Figure 1 pour les

cuisini@res install6es entre deux armoires. Les m_mes

espaces libres s'appliquent aux installations en riot,

saul pour les armoires suspendues, qui doivent laisser

un espace suffisamment grand pour poser une hotte

riot 6vas6e (Figure 1).

2. Les cuisini@res de 36 po peuvent _tre encastr6es entre

les armoires au-del_ de I'avant du four (Figure 2). Les

mod@les de 30 et 48 pouces ne sont pas congus pour

6tre align6s avec les armoires.

ATTENTION :

Dans ce type d'installation, avec les modules de

36 pouces, faites attention de ne pas vous

pincer entre la porte et I'armoire.

3. Les entr6es d'61ectricit6 et de gaz doivent se trouver

dans les zones indiqu6es _ la Figure 3a.

Note :

La profondeur maximale des armoires suspendues,

install6es d'un c6t6 ou de I'autre de la hotte, est de 330 mm

(13 po).

Un espace libre minimal de 36 po est n6cessaire entre la

surface de la cuisini@re et le dessous de route armoire non

prot6g6e. Si le dessous de I'armoire en bois ou en m6tal

est prot6g6 par un mat6riau ignifuge d'au moins 6,35 mm

(1/4 po) rev_tu d'une feuille d'acier no 28 MSG de 0,4 mm

(0.015 po) en acier inoxydable, de 0,6 mm (0.024 po) en

aluminium ou de 0,5 mm (0.02 po) en cuivre, la distance

minimale est de 91,4 cm (36 po). Les mat6riaux ignifuges

portent la marque suivante :

UNDERWRITERS LABORATORIES INC. CLASSIFIED

MINERAL AND FIBER BOARDS SURFACE BURNING

CHARACTERISTICS (Panneaux de fibres et min6raux

class6s, caract6ristiques d'inflammation des surfaces).

Cette indication est suivie des indices de propagation de la

flamme et de la fum6e. Ces d6signations sont indiqu6es

par <<FHC >>(Flame Spread/Smoke Developed -

Propagation de la flamme/Production de fum6e). Les

mat6riaux ayant un indice de propagation de la flamme de

Frangais 5

Page 31

<<O>>sontignifuges.Lar6glementationmunicipalepeut

autoriserunindicedepropagationdelaflammediff6rent.

4. Touteouverturedanslemurderrierelacuisini@eet

dansleplanchersouslacuisini@edoit_trescell6e.

5. Siladistanceentreunmat@iaucombustible/_ et le

bord arri@e de la cuisini@e au-dessus de la table de

cuisson est de moins de 30,5 cm (12 po), il est

obligatoire d'installer un dosseret bas ou une tablette

casserole Thermador (Figure 2). Lorsque I'espace libre

entre la cuisini@e et le mat@iau combustible /_ est de

plus de 12 po, la garniture d'flot Thermador peut _tre

utilis6e. La Figure 2 indique I'espace libre n6cessaire

pour chaque type de dosseret.

6. Un espace libre minimal de 3 po est n6cessaire Iorsque

la cuisini@e est install6e _ c6t6 d'un mur lat6ral

combustible.

7. L'appareil ne doit jamais se trouver _ proximit6 de

mat@iaux combustibles, d'essence et d'autres produits

inflammables (vapeurs ou liquides).

8. L'air de combustion et de ventilation arrivant

I'appareil doit pouvoir circuler librement dans les

conduits.

/_ Tel que d6fini dans le code national du gaz combustible

(ANSI Z223.1, NFPA 54, derni_re 6dition).

ATTENTION •

Lors de I'installation de cuisini@es de 30 et 48

pouces, veillez _ ce que la porte du four ne soit

pas parfaitement align6e avec le devant des

armoires, car les temp@atures 61ev6es du four

pourraient endommager les armoires.

Frangais 6

Page 32

Cuisini@ede Hottede76,2cm(30")ou de 91,4cm(36")

76,2 cm (30") { 91,4cm(36")ou 106,7cm (42")pourinstallationen1lot

Cuisiniere de {

91,4 cm (36")

?_..... Hottede 121,9 cm (48"), \!s2_ere,a,e,,,{137,1 cm (54")ou 152,3 cm (60") \

],ucmt_u ) 137.,1cm(54")pourinstallationenilot _

Hottede 91,4cm (36")ou 106,7cm(42")

106,7cm (42")ou 121,9cm (48")pourinstallationen'_lot

,&

OO

30" min. entre ledessous

]

45,8cm

(18")min.

de la hotte etla surface de

cuisson(36"min. si la hotte

contientdes mat@iaux

combustibles/_ )

!

b,

[ ° ]

/

*Hauteurmin.de la cuisini@eavec

/

pieds ajustablesenti@ement

/

_r6tract6s :91,1cm (35-7/8")

*Hauteur max. de la cuisini@e

avec pieds ajustables enti@ement

d@loy6s : 93,3 cm (36-3/4").

Distan minim_aleentreI_esarmoires_ I

suspenduescontenantdes I J

mat@iauxcombustibles/_ IX,_ J __

Cuisini@es _ I_'%_._

de30"- 76,2 cm Profondeur max. /"4_

Cuisini@es de I'armoire : _,/ J

de 36"- 91,4 cm 33cm (13"). J Min.7,6 cm (3")

Cuisinieres

de 48"- 121,9 cm

Largeurdela cuisini@e• _.

76,2 cm (30"), 91,4 cm (36")

ou 48" (121,9 cm)

Table de cuisson

r ]

si la paroi Voir figure 2. Distance

lat@ale _ min. de 91,4 cm (36")

contient entre la table de cuisson

des mat@iaux et les mat&iaux

combustiblesA combustibles /_

des deux c6t6s

O

_, MISE EN GARDE :

O

I I

J

Zoned'arriveed'electricit6-etdegaz

(voirFig.3a).Ladimensionet laposition

decettezonediff@entselon lemod61e.

ATel que defini dans le <<Code national du gaz combustible >>

(ANSIZ223.1 -derniereedition). * La hauteur delacuisiniere

est reglable. Le dessus de la cuisiniere dolt 6tre au m6me

niveau ou plus elev6 que le comptoir.

O

\

Figure 1 : Espace libre - Armoires

Frangais 7

Page 33

Installation avec dosseret bas ou etag_re _ casseroles

T

Min. 36"-

materiaux

combustibles A

T I

36-3/4" Max. ,,"

35-7/8" Min._

/

/

!

!

!

!

E-

ill Plaque de

I protection

I 1_----27-1/8" =l

I I

i 9 47-3/8" _1

32-5/8" _-

29-1/2" -_-_

Etagere a _ .._

casseroles---... L

Dosseret -"

bas

I

I

combustibles A

12-7/8"

13-7/8"

22"

-]_12" pour les cuisinieres

de 36" et 48"

pour les cuisinieres de 30"

_3/8"

A Tel que d6fini dans le code national du gaz combustible (ANSI Z223.1, derni_re 6dition.)

Installation avec _<garniture d'ilot >>

Materiaux

Min. 12" - materiaux

I combustibles A

i

Min. 36"- garniture pour riot

materiaux

combustibles A Garniture

I d'flot

I

I

Devant

Saillie

Note : Si une'paroi

interne est utilisee sous

la saillie, il devrait y

avoir un espace de 1/8"

entre I'arriere de la

cuisiniere et la paroi

interne.

combustibles A

Note : Pour les

installations avec

garniture d'flot,

une saillie entre le

comptoir et la

section arriere de

la garniture est

requise.