Page 1

LP GAS CONVERSION INSTRUCTIONS

For Thermador Professional® Cooktops and Dual Fuel Ranges

INSTRUCTIONS DE

CONVERSION DE GAZ LP

Pour toutes les cuisinières mixtes

Thermador Professional

®

INSTRUCCIONES DE

Model/

Modèle /

Modelo:

PLPKIT

CONVERSION DE GAS LP

Para Parillas y Estufas de Todo Tipo de Gas

Thermador Professional

®

Page 2

Table of Contents

Safety . . . . . . . . . . . . . . . . . .1

Important Safety Instructions . . . . . . . . 1

Conversion Instructions . . .2

Before You Begin . . . . . . . . . . . . . . . . . . 2

Possible Tools Needed for All Orifice

Conversions . . . . . . . . . . . . . . . . . . . . 2

Table 1: Conversion Kit Contents . . . . 2

Table 2: LP Orifice Conversion Chart—

by Model Number (older models /

newer models) . . . . . . . . . . . . . . . . . . 3

Replacing Burner Orifices in Cooktop /

Rangetop . . . . . . . . . . . . . . . . . . . . . . . . . 5

Replace the Star® Burner orifices—

all models . . . . . . . . . . . . . . . . . . . . . . 5

Replace the Gas Grill Orifice—if equipped

with Open-Grate Style Grill . . . . . . . . . 6

Replace the Gas Grill Orifice—if equipped

with Solid-Plate Style Grill . . . . . . . . . . 7

Replace the Gas Griddle Orifice—

if so equipped . . . . . . . . . . . . . . . . . . . 9

Replace the Wok Orifice in Pro Cooktop—

if so equipped . . . . . . . . . . . . . . . . . . 10

Accessing the Gas Regulator . . . . . . . 11

Converting the Regulator to

LP Operation . . . . . . . . . . . . . . . . . . . . . 12

Harper-Wyman regulator conversion 12

Maxitrol regulator conversion . . . . . . 13

Setting Manual Valve Screws for

Cooktop / Rangetop . . . . . . . . . . . . . . . 13

Screw driver for valve screw setting . 13

PRO-GRAND™ and PRO-HARMONY™

Dual-Fuel Ranges and Pro Cooktops 14

Older models of Professional® Dual-Fuel

Ranges and Cooktops . . . . . . . . . . . . 14

Check for Gas Leaks . . . . . . . . . . . . . . 15

Gas leakage checking using a liquid

solution . . . . . . . . . . . . . . . . . . . . . . . 15

Burner Testing and Adjustment . . . . . 16

Checking manifold pressure

(if necessary) . . . . . . . . . . . . . . . . . . . 16

Checking LP flame characteristics and

burner performance . . . . . . . . . . . . . . 16

Tubular and wok burner performance

and final air-shutter adjustments

(if necessary) . . . . . . . . . . . . . . . . . . . 17

Final Step—Placement of LP Conversion

Label . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Location of Rating Labels on Thermador

Professional® products . . . . . . . . . . . 19

This Thermador Appliance is made by

BSH Home Appliances Corporation

5551 McFadden Ave.

Huntington Beach, CA 92649

Questions?

1-800-735-4328

www.thermador.com

We look forward to hearing from you!

Page 3

Safety

Important Safety Instructions

PLEASE READ ENTIRE INSTRUCTIONS BEFORE PROCEEDING

Natural Gas to Propane (LP) Gas Conversion Kit for

Thermador Professional

Ranges

FOR RESIDENTIAL USE ONLY

IMPORTANT:

Only a qualified service technician or installer should make

this conversion.

INSTALLER:

Please leave these Conversion Instructions with this unit

for the owner.

OWNER:

Please retain these instructions for future reference.

®

Contains Star

conversion to Propane Gas operation for all burners in

cooktop or rangetop section of the following series models.

Save the natural gas parts for possible conversion from LP

back to the natural gas in the future.

This kit is used to convert Thermador Professional

Cooktops, PRO-GRAND™ Dual-Fuel Ranges, and PROHARMONY™ Dual-Fuel Ranges, from natural gas to

Propane (LP) Gas operation. This kit cannot be used to

convert older models of Thermador Professional cooktops

or ranges other than those identified in these instructions

(see TABLE 2). This kit cannot be used to convert

Thermador Professional

or any other brand of appliance.

Burner orifices and hood orifices for proper

®

Cooktops and Dual Fuel

®

®

All Gas Ranges, oven burners,

WARNING:

This conversion kit shall be installed

by a qualified service agency in

accordance with the manufacturer’s

instructions and all applicable codes

and requirements of the authority

having jurisdiction. If the information

in these instructions is not followed

exactly, a fire, explosion or

production of carbon monoxide may

result causing property damage,

personal injury or loss of life. The

qualified service agency is

responsible for the proper

installation of this kit. The

installation is not proper and

complete until the operation of the

converted appliance is checked as

specified in the manufacturer’s

instructions supplied with the kit.

CAUTION:

Disconnect gas and electric power before

making conversion. Before turning power ON,

be sure that all controls are in the OFF position.

To the Service Agent:

It is important that you know the following BEFORE you

begin the gas conversion of the appliance.

• Confirm that the Propane (LP) Gas supply system is

available and ready to use. This is part icu lar ly

important for new construction.

• You must plan for sufficient time and resources to

perform the LP conversion process properly and

completely before leaving the job site. Every step

described in these instructions must be performed to

safely convert the appliance for proper operation on

Propane Gas. INCOMPLETE OR INADEQUATE GAS

CONVERSION OF THE APPLIANCE CAN CREATE A

SAFETY HAZARD.

English 1

Page 4

California Safe Drinking Water and Toxic Enforcement Act (Proposition 65) Notice:

WARNING:

This product contains or, through ordinary use

for its intended purpose, facilitates emission of a

chemical or chemicals known to the State of

California to cause cancer and/or birth defects

or other reproductive harm. To mi n im iz e

exposure to these chemicals:

Conversion Instructions

Before You Begin

1. Perform the LP conversion according to the instructions in this manual.

2. The conversion and adjustment to the burners should be done by a certified installer or agency to ensure proper combustion.

3. Always operate the unit according to the instructions provided with your Range or Cooktop.

4. Ensure proper ventilation with an open window or use a ventilation fan or hood when cooking with Gas.

CAUTION:

Before proceeding with the conversion, shut off

the gas supply to the appliance prior to

disconnecting the electrical power.

Possible Tools Needed for All Orifice Conversions

• Scissors

• 7mm nut driver

• 1/2" deep-well socket and drive

• 1/4" nut driver or wrench

• Large, slotted screwdriver, .40" X .050" blade

• Extra large, slotted screwdriver, .60" X .060" blade

• 7/8" wrench or socket and drive

• Precision, slotted screwdriver, 1/8" X .020" blade

• Phillips #2 screwdriver

• Soap and water mixture or leak-check solution

Table 1: Conversion Kit Contents

Description

PLPKIT Instructions 552805 1 Foam Tape, 1” piece 418145 1 Propane Conversion

Label

Service

Number

418146 1

Quantity

Table 1: Conversion Kit Contents

Description

Plastic Bag 418148 1 Star Burner Jet

Orifice

Grill Hood Orifice

(open grate style)

Grill Hood Orifice

(solid plate style) Griddle Hood Orifice 418150 1 Wok Hood Orifice 414918 1 This Propane Conversion Kit contains the quantities of

parts indicated above; however, some parts will not be

used depending upon the type and model of appliance

being converted to LP Gas. Refer to Table 2 for a listing

of appropriate combination of orifices to be used for

each particular model.

Service

Number

424851 6

418151 1

414916 1

Quantity

CAUTION:

When connecting the unit to propane gas, make

certain the propane gas tank is equipped with its

own high pressure regulator. The maximum gas

pressure to this appliance is not to exceed 14.0

inches water column from the propane gas tank

regulator.

English 2

Page 5

When properly converted using the prescribed LP orifices,

the burners will operate at the following flow rates using

Propane (LP) Gas:

•Star

• Gas Grill (open grate style) — 17,000 BTU/hr. [4.98

• Gas Grill (solid plate style) — 12,000 BTU/hr. [3.51

• Gas Griddle — 13,000 BTU/hr. [3.81 kW], using a #57

• Gas Wok — 24,500 BTU/hr. [7.17 kW], using a #54 or

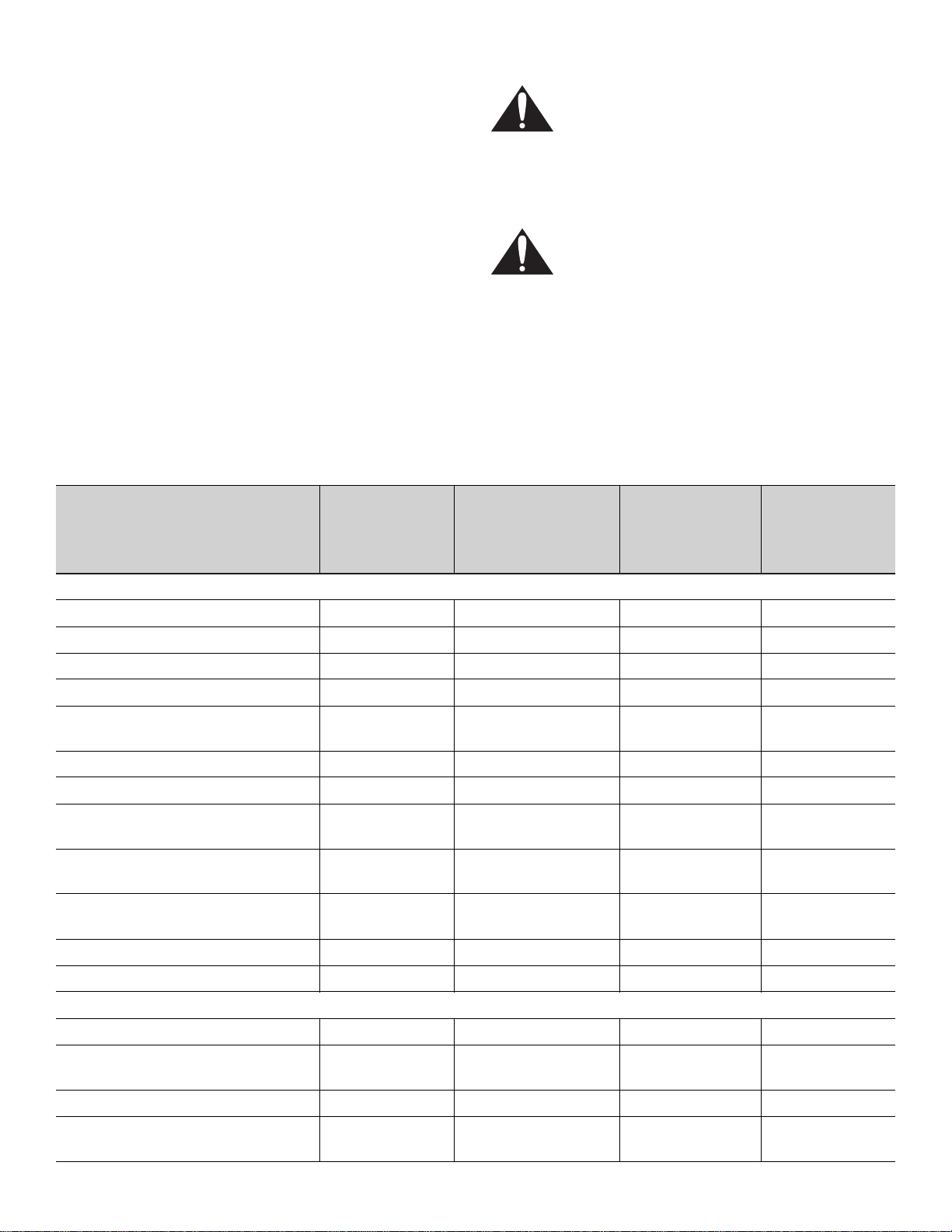

Table 2: LP Orifice Conversion Chart—by Model Number (older models / newer models)

®

Burners — 13,000 BTU/hr . [3.81 kW] each, u sing

1.07mm orifices.

kW], using a 1.20mm orifice.

kW], using a #59 orifice.

or 1.10mm orifice.

1.40mm orifice.

WARNING:

NEVER leave the gas conversion partially

completed. If the appliance is operated while the

gas conversion is incomplete, high levels of

carbon monoxide may be emitted, or a fire or

explosion may occur.

WARNING:

If the Natural Gas orifices are left in place while

attempting to operate the appliance using

Propane (LP) Gas, at the higher pressure

setting for LP Gas, the burners will produce

large flames which may emit high levels of

carbon monoxide into the room, or a fire or

explosion may occur.

Appliance Model Numbers

(older/newer)

Pro Cooktops:

PC304 / PCG304E 4 each - 1.07mm

PC366 / PCG366E 6 each - 1.07mm

PC364GD / (no newer model) 4 each - 1.07mm #57 or 1.10mm

PC364GE / PCG364ED 4 each - 1.07mm

PC364GL / PCG364EL 4 each - 1.07mm 1.20mm (grate) or

PC486GD / (no newer model) 6 each - 1.07mm #57 or 1.10mm

PC486GE / PCG486ED 6 each - 1.07mm

PC486GL / PCG486EL 6 each - 1.07mm 1.20mm (grate) or

PC484GG / (no newer model) 4 each - 1.07mm 1.20mm (open grate

PC484GGE / PCG484EC 4 each - 1.07mm 1.20mm (grate) or

PC484WK / PCG484EW 4 each - 1.07mm #54 or 1.40mm

PC484GE / PCD484EE 4 each - 1.07mm

Star Burners

#424851

Jet Orifice

Gas Grill*

(Grate/Plate Styles)

#418151 or #414916

Hood Orifice

#59 (plate)

#59 (plate)

grill only)

#59 (plate)

Gas Griddle**

#418150

Hood Orifice

#57 or 1.10mm

Gas Wok

#414918

Hood Orifice

PRO-GRAND™ Dual-Fuel Ranges (27" depth):

PD304 / PRD304EG 4 each - 1.07mm

PD366 / PRD366EG and

PRD366EPG

PD364GD / (no newer model) 4 each - 1.07mm #57 or 1.10mm

PD364GE / PRD364EDG and

PRD364EDPG

6 each - 1.07mm

4 each - 1.07mm

English 3

Page 6

Table 2: LP Orifice Conversion Chart—by Model Number (older models / newer models)

Appliance Model Numbers

(older/newer)

PD364GL / PRD364ELG 4 each - 1.07mm 1.20mm (grate) or

PD486GD / (no newer model) 6 each - 1.07mm #57 or 1.10mm

PD486GE / PRD486EDG and

PRD486EDPG

PD486GL / PRD486ELG 6 each - 1.07mm 1.20mm (grate) or

PD484GG / (no newer model) 4 each - 1.07mm 1.20mm (open grate

PD484GGE / PRD484ECG 4 each - 1.07mm 1.20mm (grate) or

PD484GE / PRD484EEG 4 each - 1.07mm

PRO-HARMONY™ Dual-Fuel Ranges (24" depth):

DP304 / PRD304EH 4 each - 1.07mm

DP366 / PRD366EH 6 each - 1.07mm

DP364GE / PRD364EDH 4 each - 1.07mm

DP364GL / PRD364ELH 4 each - 1.07mm #59 (solid plate grill

Star Burners

#424851

Jet Orifice

6 each - 1.07mm

Gas Grill*

(Grate/Plate Styles)

#418151 or #414916

Hood Orifice

#59 (plate)

#59 (plate)

grill only)

#59 (plate)

only)

Gas Griddle**

#418150

Hood Orifice

#57 or 1.10mm

Gas Wok

#414918

Hood Orifice

(no older model) / PRD486EDH 6 each - 1.07mm

(no older model) / PRD486ELH 6 each - 1.07mm #59 (solid plate grill

only)

(no older model) / PRD484ECH 4 each - 1.07mm #59 (solid plate grill

only)

(no older model) / PRD484EEH 4 each - 1.07mm

NOTES:

* Some newer-model Pro Cooktops and Pro-Grand DF Ranges have the open grate style Gas Grill.

** Older model numbers with letters "GE" and newer "E" model numbers that have letters "ED", "EC", or "EE" are for

models with Electric Griddle -- which do not require conversion.

Examples

High Altitude:

Many of the Thermador appliances that are serviced by this

Propane (LP) conversion kit are CSA-certified for safe

operation on LP Gas up to an elevation of 10,200 ft.

[3,109m] above sea level without additional alterations. For

: "PC484GGE", "DP364GE", "PRD364EDG", "PRD484ECH", or "PCD484EE".

safe LP conversion of an appliance for use at higher

elevations, consult the local gas company for their

recommendations for correct orifice sizes an d an y oth er

necessary adjustments that will provide proper gas

combustion at high altitudes.

English 4

Page 7

Replacing Burner Orifices in Cooktop / Rangetop

NOTICE:

After the replacement of each orifice, and before

reassembly of the burner, perform a brief gas leakage

check of the orifice and associated fittings, per the "Check

for Gas Leaks" section of these instructions.

Replace the Star® Burner orifices— all models

• Cut a 3/8" long piece of the adhesive foam strip

supplied in the kit and place over the edge of the nut

®

driver used to replace the Star

shown.

Burner orifices, as

• Use a 7mm nut driver to reach down through the

venturi and remove the orifice from the burner's jet

holder.

• Replace each star burner jet orifice with one of the

1.07mm, LP jets supplied in the kit. These are sized for

the Star

flow rate using Propane (LP) Gas.

®

Burners to produce 13,000 BTU/hr . [3.81 kW]

Foam Strip

The foam piece helps to retain the orifice in the end of

the nut driver, so it will not fall inside the appliance

during orifice removal or installation.

• Perform a brief gas leakage test of each orifice and

associated supply tube fittings, per the "Check for Gas

Leaks" section of these instructions. Proper access to

the burner's jet holder can be accomplished after spill

tray removal—see "Accessing the Gas Regulator"

section for instructions on how to remove the spill tray.

English 5

Page 8

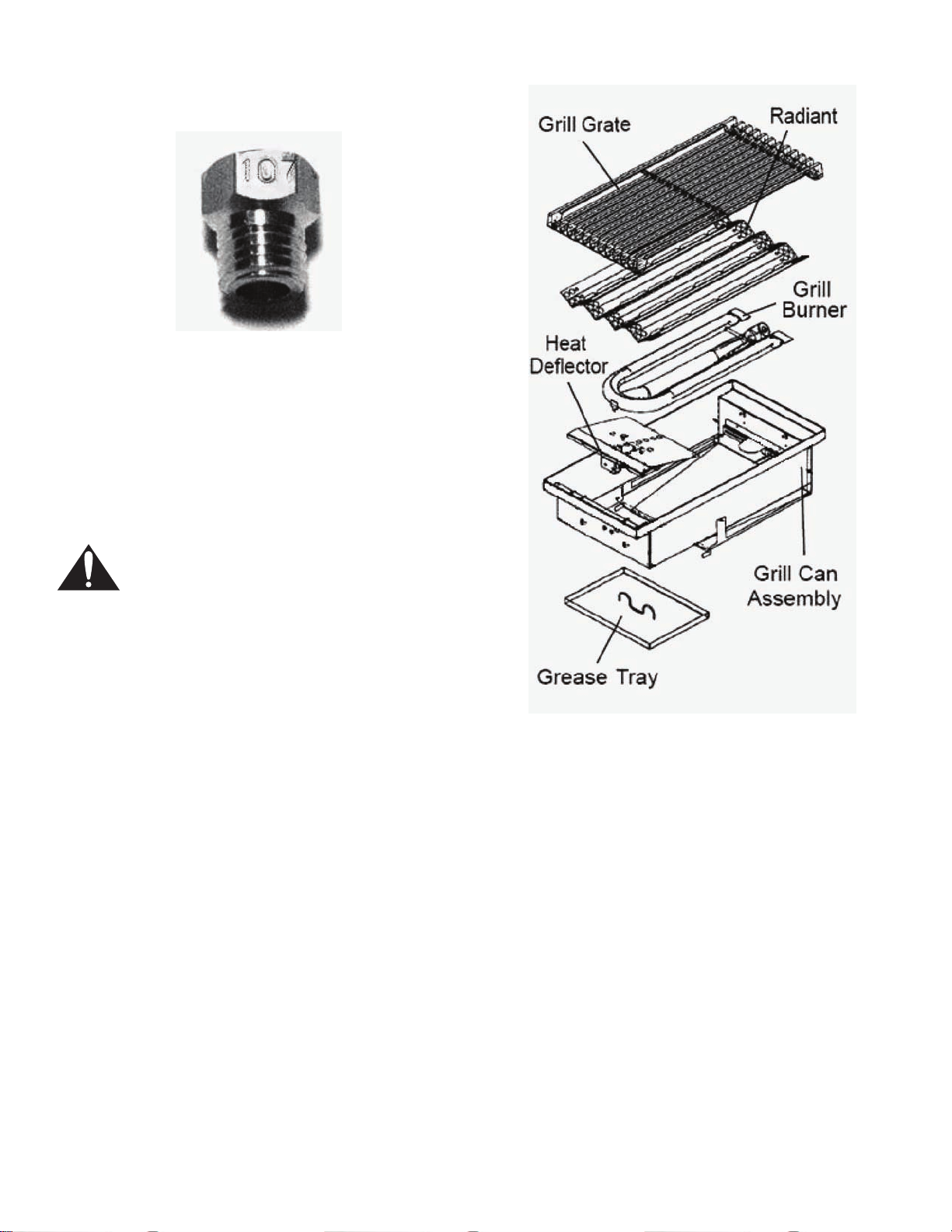

• Each orifice is stamped "107" (for 1.07mm orifice

diameter) as shown.

Replace the Gas Grill Orifice—if equipped with Open-Grate Style Grill

This style grill is an open-top design that can be identified

by its "U" shaped burner tube and corrugated stainlesssteel radiant, as shown in the exploded view.

WARNING

The grill must be assembled as shown. The drip

tray heat shields must be in place, and the

burner must be properly positioned relative to

the gas supply. Incorrect assembly of the grill

may result in unsafe or hazardous conditions

during operation.

• Remove the Grill Grate, Radiant, and Grill Burner from

the Grill Can Assembly.

• Pull back the metal lever at the front of the Grill Burner

to release it, and then remove the Grill Burner.

• Use a 1/2" deep-well socket to remove the Grill hood

orifice and replace with the 1.20mm LP hoo d orifice

supplied in this kit.

• Pre-adjust the burner's air shutter to approximately

75% closed (approximately 0.20" opening) position and

re-tighten screw(s) using a 1/4" nut driver or wrench.

• Re-insert the venturi end of the Grill Burner into the two

slots at the back of the Grill Can Assembly. Then rotate

the other end of the burner into position and lock the

tab on the front of the burner into the slot in the Heat

Deflector.

• Re-install the stainless steel Radiant onto the two studs

on each end of the Grill Can Assembly.

English 6

Page 9

• Replace the Grill Grate such that the raised food

containment rail is oriented toward the back of the Grill.

• The "1.20MM"-stamped hood orifice is sized to

produce 17,000 BTU/hr . [4.98 kW], using Propane (L P)

Gas.

Replace the Gas Grill Orifice—if equipped with Solid-Plate Style Grill

This style grill design can be identified by its ribbed grill

plate and its "T" shaped burner, as shown in the exploded

view.

• After the orifice conversion, gas leak check, and reinstallation of the grill burner, check that the electrode

and bracket spacing to the burner is within the distance

range shown here.

• Verify that the grill burner's air shutter is properly readjusted, per the “Burner Testing and Adjustment"

section of these instructions, as air-shutter position can

also influence ignition performance.

• Remove the Grill Plate. Some Grills have a Grill Plate

and Frame as two separate pieces, similar to the Gas

Griddle on the next pages.

English 7

Page 10

• Remove the screws at each end of the Flame

Spreader, tilt to ward you, and pull the spreader out of

the front slot in the Grill Box.

• Use a 1/2" deep-well socket to remove the Grill hood

orifice.

• The LP orifice is a #59 drill (stamped "59"), which is

sized to produce 12,000 BTU/hr. [3.51 kW], using

Propane Gas.

• Pre-adjust the burner's air shutter to approximately

75% closed (approximately 0.20" opening) position and

re-tighten screw(s) using a 1/4" nut driver or wrench.

• After the orifice conversion, gas leak check, and resetting of the grill burner, check that the Hot-Surface

Ignitor (HSI) spacing to the burner is within the

distance ranges shown, for the following two types of

ignitors used with Grill models.

English 8

Page 11

Replace the Gas Griddle Orifice— if so equipped

• The LP orifice is a #57 drill (stamped "57"), which is

sized to produce 13,000 BTU/hr. [3.81 kW], using

Propane (LP) Gas. The orifice diameter could also be

1.10mm; in which case, the hood orifice could have a

"110" or "1.10MM" stamp.

• Pre-adjust the burner's air shutter to approximately

75% closed (approximately 0.20" opening) position and

re-tighten screw(s) using a 1/4" nut driver or wrench.

• Remove the Griddle's Grease Tray, Griddle Plate and

Griddle Frame. These items are not held with

fasteners, so they should lift up and out easily.

• Remove the screws on each end of the Flame

Spreader, while paying attention not to drop the

spacers inside the cooktop / rangetop area.

• Remove the Cover Plate with four (4) screws, which

covers the Griddle Burner's venturi at the bottom of the

Griddle Box.

• Lift out the Griddle Burner.

• Use a 1/2" deep-well socket to remove the Grill hood

orifice. When installing the LP orifice, take extra care

not to bend the sheet metal orifice bracket.

• After the orifice conversion, gas leak check, and reinstallation of the griddle burner, check that the ignitor

electrode tip spacing to the surface of the burner

(tangent point) is approximately 0.105". There is some

movement available in the burner mounting, on each

end, to adjust this spacing if needed.

English 9

Page 12

Replace the Wok Orifice in Pro Cooktop— if so equipped

• Remove the two screws that attach the pilot burner to

the bracket on the Wok Top Support Assembly.

• Lift the Top Assembly straight up, away from the Wok

Chassis a few inches, and then remove the Wok

Burner.

• Lift out the Wok Top Support Assembly. This will

expose the Safety Valve.

Wok Safety Valve with Hood Orifice

• The LP orifice for the Wok is a #54 drill (stamped "54"),

which is sized to produce 24,500 BTU/hr. [7.17 kW],

when using Propane (LP) Gas. The orifice diameter

could also be 1.40mm; in which case, the hood orifice

could have a "140" or "1.40MM" stamp.

• Use a 1/2" deep-well socket to remove the hood orifice

from the safety valve.

NOTE:

The pilot burner does not require orifice conversion for

operation on Propane Gas.

• Pre-adjust the air shutter on the Wok Burner to fully

open position.

• Replace the Wok Top Assembly.

• Re-install the wok burner. Make sure that the burner's

venturi is properly positioned on the hood orifice, and

that the bottom of the burner head is positioned

between the pins on the cross member at the base of

the top support.

• Re-attach the pilot burner to the bracket on the Wok

Top Support.

English 10

Page 13

Accessing the Gas Regulator

All dual-fuel range models and some cooktop models have

the gas regulator located inside the cooktop/rangetop,

under the left spill tray .

• Gas regulator is located inside cooktop, left side

• Remove the cooking grates

• Remove Star

both burners using a 13/16" socket or wrench.

• Disconnect the spark wire from the tab on the spark

electrode for each burner.

®

Burner caps, then remove venturi from

• Remove aluminum trim from sides of left spill tray

• Remove the shield on some models. Some models

have a double-width shield that extends under ad jacent

spill tray.

English 11

Page 14

• The gas regulator is located near the left rear corner

inside the cooktop area of appliance.

NOTE:

Fallen star-burner orifices inside cooktop area, from the

replacement process, can usually be retrieved during this

step.

Converting the Regulator to LP Operation

WARNING:

If the Natural Gas orifices are left in place while attempting to operate the appliance using Prop ane (LP) Gas, at

the higher pressure setting for LP Gas, the burners will produce large flames which may emit high levels of

carbon monoxide into the room, or a fire or explosion may occur. All orifice replacements for LP operation

should be performed prior to regulator conversion.

Harper-Wyman and Maxitrol are the two brands of gas regulators that are used on Thermador Professional

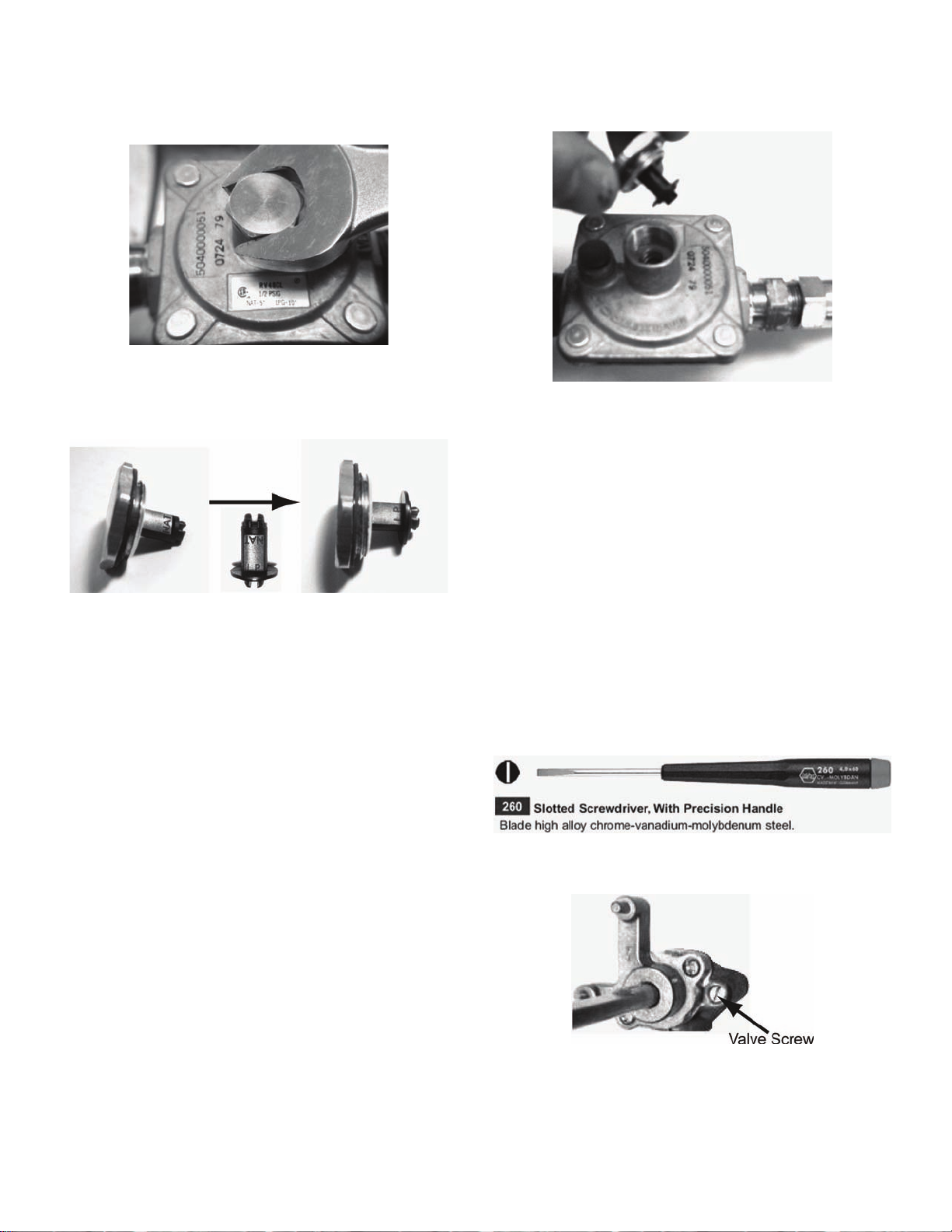

Harper-Wyman regulator conversion

• Use a large, slotted screwdriver, with .40" X .050"

blade, to remove conversion cap.

• Using a large screwdriver, press down on conversion

cap and rotate counter-clockwise to release bayonet

mount.

• Flip the conversion cap over to show the recessed

side. "LP" will show at the bottom of the recess.

• Use an extra large, slotted screwdriver, with .60" X

.060" blade, to re-install LP cap.

• Re-insert cap in top of the regulator with rece ss up ,

"LP" visible. Press down and rotate clockwise to lock

cap position.

®

products.

English 12

Page 15

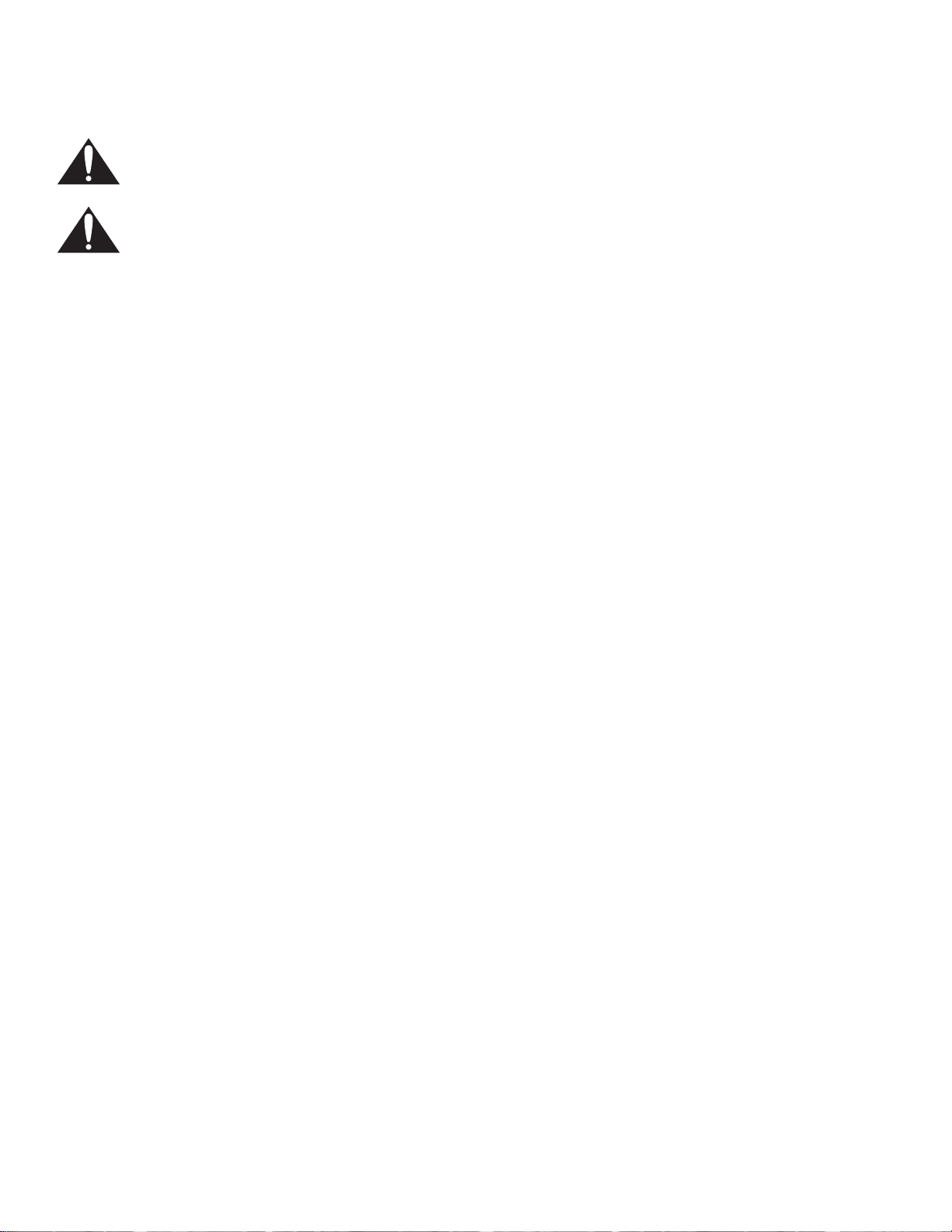

Maxitrol regulator conversion

• Remove conversion cap with a 7/8" socket or wrench.

• Snap-out stem from bottom of the cap, flip stem over to

show "LP" end, and snap stem back into the cap, as

shown.

Flip Stem

• Re-install conversion cap -configured for LP gas- back

into top of the Maxitrol regulator.

Setting Manual Valve Screws for Cooktop / Rangetop

Screw driver for valve screw setting

A precision screwdriver with high-strength blade, similar to

the *Wiha no. 26033, with 1/8" [3.0mm] wide, .020"

[0.50mm] thickness tip, shown below, should be used to reposition the bypass screws for minimum flow settings on

manual valves.

*Used by permission from Wiha Quality Tools division of Willi

Hahn Corporation USA.

English 13

Page 16

PRO-GRAND™ and PRO-HARMONY™ Dual-Fuel Ranges and Pro Cooktops

• Remove knob from the valve stem by slowly pulling

knob straight out, away from control panel.

• For newer models, remove the bezel-mounting screw

located to the right of the valve stem.

• Turn the valve screw clockwise just until "bottom out"

position is reached. DO NOT over-tighten the valve

screw.

• For open-grate style Grill or Wok valves — After turning

valve screw to bottom position, turn screw counterclockwise one-half (1/2) turn.

NOTE:

• It is necessary that the two valves for XLO operation

(farthest left on control panel) are in the OFF position

for proper access to the valve screws through

clearance holes in the XLO potentiometers.

• Solid-plate style Gas Grill and Gas Griddle are

controlled by thermostats and do not have valves that

require adjustments.

Older models of Professional® Dual-Fuel Ranges and Cooktops

• Remove knob from the valve stem by slowly pulling

knob straight out, away from control panel.

• To engage the valve screw, insert precision

screwdriver into hole in bezel created by removal of

mounting screw.

English 14

• Valve screws on older models can be accessed directly

through the control panel, without removing bezel

screws.

Page 17

Check for Gas Leaks

WARNING:

DO NOT use a flame of any kind to check for gas leaks.

WARNING:

Hot Surface Ignitor (HSI) for Grill gets very hot and can cause severe burns.

Gas leakage checking using a liquid solution

All of the replacement orifices in the PLPKIT, LP conversion

kit, have straight threads (not pipe threads) and do not

require thread sealing compound.

Leak-checking should occur after the orifice conversion is

complete, and before the burner is reassembled and

tested.

• Make sure that all of the LP orifices have been

tightened and that all valves and controls are in the

OFF position.

• Turn on electrical and gas supplies.

• Briefly evaluate the threaded connection of each

replaced orifice individually - that is, one orifice at a

time.

• Spray a generous amount of soap and water mixture—

or other solution designed for checking gas leaks—on

the threaded junction at the base of the orifice. Avoid

spraying electrical devices. (A 25% dishwashing liquid

to water mixture is effective for this.)

• Briefly turn on the valve or control while blocking the

orifice hole with a soft pencil eraser, your finger, or

something similar. It is normal to hear spark ignition

noise during this process. —Avoid extreme heat from

the Grill HSI on models so equipped. See warning

above.—

• Monitor the base of the orifice junction to see if bubbles

are forming anywhere around the threaded co nnection.

• Bubbles forming are indications of gas leaks. The

amount and sizes of the bubbles are indications of the

severity of the leakage.

• Repair all gas leaks immediately after their discovery;

this can often be accomplished by re-tightening the

orifice.

• Since considerable torque is sometimes used during

orifice replacement, leak-check other fitting junctions

leading up to the orifice as well.

• Turn off the gas and electrical supplies.

• Reassemble the appliance in preparation for testing

the newly-converted burner systems.

English 15

Page 18

Burner Testing and Adjustment

Checking manifold pressure (if necessary)

Checking the appliance manifold pressure is NOT

REQUIRED for the Propane Gas conversion; however, if

the outlet pressure of the gas regulator or the inlet pressure

to the appliance is suspect, the following procedure can be

used to check the manifold pressure.

• A manifold pressure measurement can be acquired at

one of the star burner orifices, as shown.

Checking LP flame characteristics and burner performance

To observe the burner flames, loosen or remove the

minimum number of components necessary for an unobstructed view. It may be necessary to turn off lights or

close window blinds to darken the room for easier viewing

of the flame.

• Test Burner Ignition. Push in the burner control knob

and turn counter-clockwise (CCW) to "HI". The ignitor

electrode and spark module will produce a clicking

sound. Once the air has been purged from the supply

lines, the burner should light within four (4) seconds.

• Attach a portable or hand-held manometer, that reads

pressure in inches water column ("WC), using a piece

of PVC or vinyl tubing.

• Turn on the electrical and gas supplies to the cooktop

or range.

• Turn on one of the top burners to HI position. This is

important to acquire a true pressure reading under g as

flow conditions.

• Turn the manual valve for the burner being monitored

to HI position. (Spark ignition noise will be heard

coming from this burner.)

• The manifold pressure reading on the manometer

should be between 9.50 and 10.50"WC for an

appliance regulator converted to LP gas.

• If the manifold pressure reading is below this range,

verify that the regulator has been properly converted

for use with LP gas, and that the inlet pressure to the

appliance is between 11.0 and 14.0"WC.

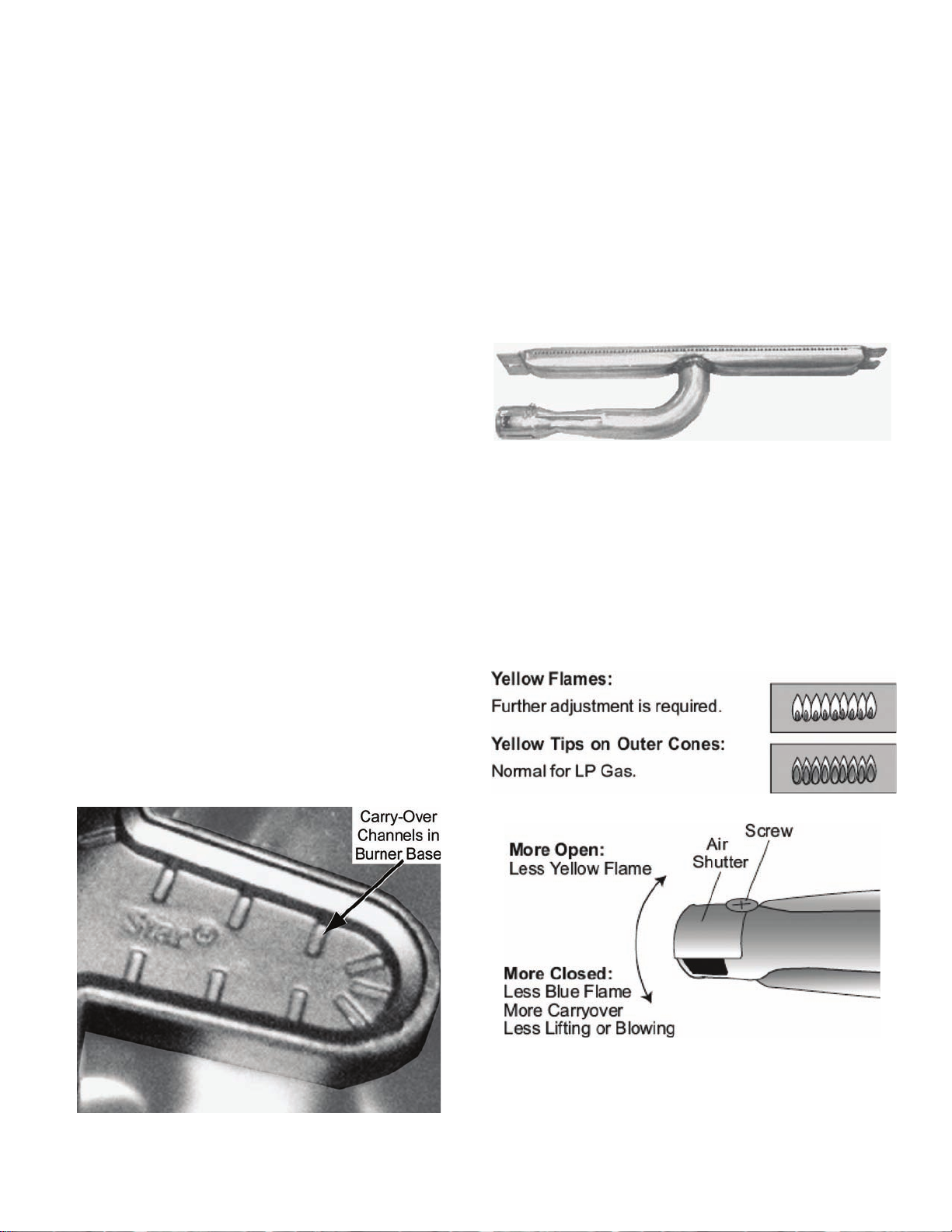

• The LP flames should be stable, with no excessive

noise. The inner cones of the individual flames should

be well defined and distinctly separate from each other .

• Portions of the flame, along the burner, should not

exhibit excessive or continuous indications of "lifting" or

"lazy flame".

• It is normal for slight yellow tipping of the flames to

appear after a few minutes of operation using Propane

English 16

Page 19

(LP) Gas. Orange-colored streaks in the flame are

produced from burning airborne debris; this is normal

during initial start up and should dissipate within a few

minutes of operation.

• Adjust the burner's control valve or thermostat to "LO"

or "SIM" to see that the flame continues to wrap around

the burner. Blow out the flame, or use a quick fan

motion from a writing tablet or piece of cardboard to

extinguish the flame, and then observe the burner's

ability to re-ignite and wrap around ("carry-over") the

burner within several seconds. The flame "carry-over"

is essential for proper burner ignition and re-ignition.

• Test re-ignition of the two Star

of the appliance by turning the control knobs to "XLO"

and observe the carry-over of the small simmer flames

as the XLO system cycles the two burners on and off.

• If the flame performance is not acceptable, verify that

the burner has the correct size LP orifice installed, and

that the regulator has been properly converted for LP

Gas.

• For un-acceptable performance of a Star

verify that the burner cap is seated properly in its

burner base. The cap should fit reasonably flat when

correctly-positioned in the base and not rock

significantly.

• If the burner flame is uneven, flutters, makes excessive

noise, or lifts, some of the ports in the burner cap may

be blocked with food spillage or other debris. Clogged

ports can be cleared using a straightened paper clip,

needle, or similar object. This is also applicable for

blocked ports in Grill or Griddle Burners.

• Additionally , hardened food spillage or other debris can

block some of the small carry-over channels in the

®

Star

Burner base, which can inhibit the flame from

wrapping around the burner. The channels can be

cleared using a wire brush.

®

Burners on the left side

®

Burner,

Tubular and wok burner performance and final air-shutter adjustments (if necessary)

Propane (LP) Gas is heavier, with greater density than

Natural Gas, and is distributed within the appliance at

higher pressure. The differences in properties an d

application cause LP Gas to entrain different amounts of

primary air which usually requires different air-sh utter

openings, as compared to Natural Gas applications for the

same or similar BTU ratings.

Burner for "solid plate" style Grill or Griddle

• A "too open" air shutter position creates noticeable

"lifting" (also called "blowing") of the flame - which can

degrade carry-over performance of the burner. This

condition can also create excessive noise.

• A flame that is "lazy", with excessively-long flames that

are reaching for air, is created by a "too closed" air

shutter. Many of the outer mantle s of the individual

flames tend to "coalesce" or blend together. Excessive

yellow color in the flame can also occur with an

excessively-closed shutter.

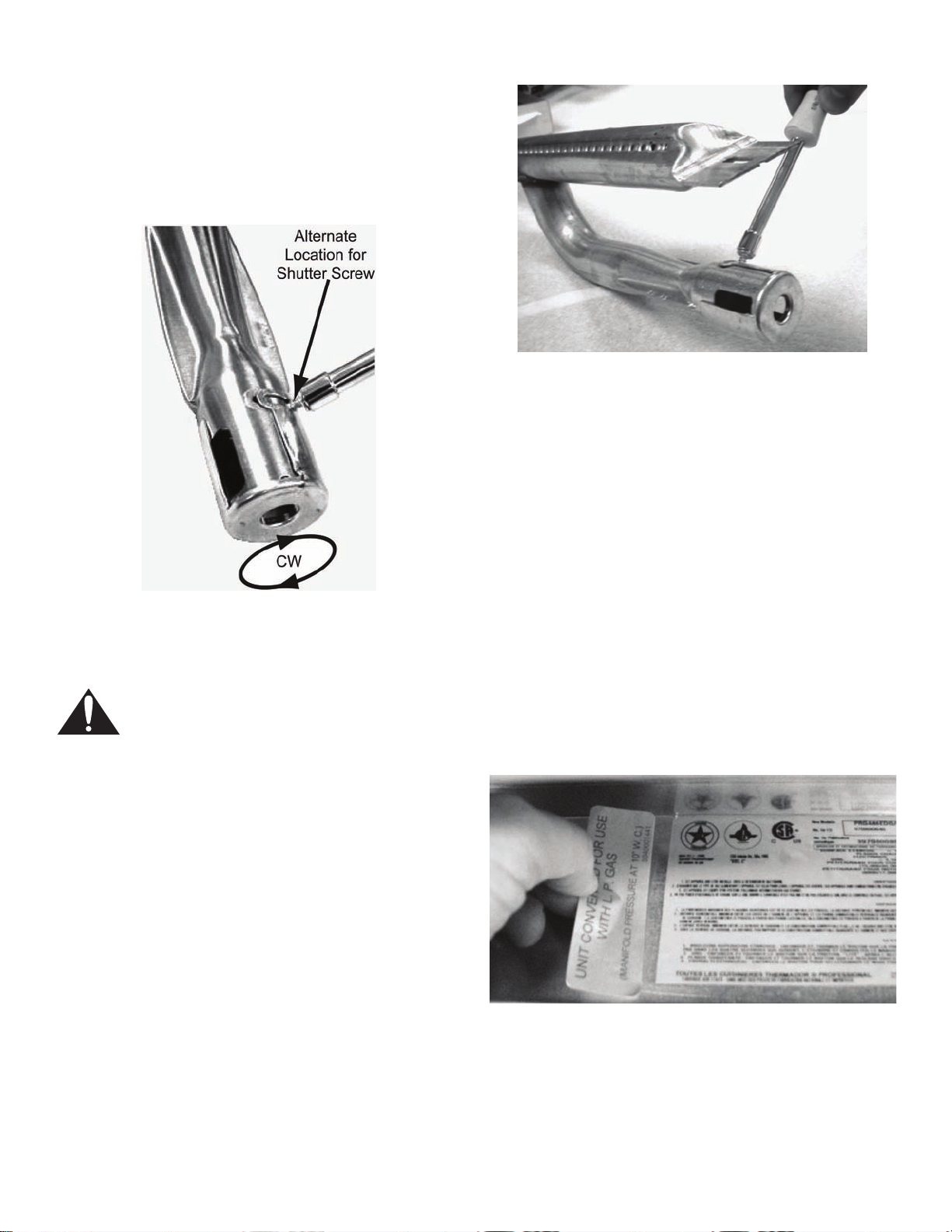

If air-shutter adjustment is needed, remove the burner from

the appliance. Loosen the shutter's retaining screw using a

1/4-inch nut driver or wrench and rotate the shutter to its

new position. If less than 50% opening is desired, move the

retaining screw to the alternate location shown on the next

page and rotate the shutter to its new position. Re-install

English 17

Page 20

the burner and re-evaluate flame performance

characteristics. Repeat this process as necessary to

produce acceptable flame performance.

• For less than 50% air-shutter opening, move the

retaining screw to the alternate location and rotate the

air shutter in the clockwise (CW) direction as needed.

Final Step—Placement of LP Conversion Label

WARNING:

NEVER leave the gas conversion partially completed. If the appliance is operated while the gas conversion is

incomplete, high levels of carbon monoxide may be emitted, or a fire or explosion may occur.

IMPORTANT:

For proper identification and evidence of the appliance's

conversion to Propane (LP) Gas, affix the provided

Conversion Label in a location next to the Rating Labels on

the appliance. This is particularly important if the converted

appliance is re-installed in a different home.

English 18

Page 21

Location of Rating Labels on Thermador

®

Professional

Rating labels are found at various locations on the

appliances, depending upon the model series:

products

the range's lower front-frame, behind the kick-panel.

(See illustration below.)

• Pro Cooktops

the underside, chassis bottom of the cooktop, and can

be accessed inside the cabinet area, underneath the

unit.

• Pro-Grand Dual-Fuel Ranges

typically located behind the kick-panel, on the lower

cross member of the frame of the range.

• Pro-Harmony Dual-Fuel Ranges

typically located either under the front edge of rangetop

section or on a metal plate, attached with a lanyard to

— Rating labels are typically located on

— Rating labels are

— Rating labels are

English 19

Page 22

Table des matières

Sécurité . . . . . . . . . . . . . . . .1

Instructions de sécurité importantes . . 1

Instruction pour conversion 2

Avant de commencer . . . . . . . . . . . . . . . 2

Outils nécessaires pour conversion

des orifices : . . . . . . . . . . . . . . . . . . . . 2

Table 1: PLPKIT - nécessaire . . . . . . . 2

Table 2: tableau de conversion des orifices

LP --par numéro de modèle (anciens

modèles/nouveaux modèles) . . . . . . . 3

Remplacement des orifices de brûleurs sur

surfaces de cuisson et cuisinières . . . . 5

Remplacer les orifices de brûleur Star®–

tous les modèles . . . . . . . . . . . . . . . . . 5

Remplacer l’orifice de gril de gaz — si

équipé avec gril style grille ouverte . . . 6

Remplacer l’orifice de gril à gaz – si doté

du style plaque unie . . . . . . . . . . . . . . 7

Remplacer l’orifice de grille de gril –

si doté . . . . . . . . . . . . . . . . . . . . . . . . . 9

Remplacer l’orifice du wok — si équipé 10

Accès au régulateur de gaz . . . . . . . . . 11

Conversion du régulateur pour le

fonctionnement LP . . . . . . . . . . . . . . . . 12

Conversion du régulateur

Harper-Wyman . . . . . . . . . . . . . . . . . 12

Conversion du régulateur Maxitrol . . 13

Réglage des vis de soupape manuelle

pour brûleurs de surface de cuisson

et cuisinière . . . . . . . . . . . . . . . . . . . . . . 13

Tournevis pour régler la vis de

soupape . . . . . . . . . . . . . . . . . . . . . . 13

Cuisinière à combustion jumelé

PRO-GRAND™ et PRO-HARMONY™ et

surface de cuisson- Pro . . . . . . . . . . 14

Anciens modèles de cuisinière à

combustion jumelée et surface de

cuisson Professional® . . . . . . . . . . . . 14

Vérifier les fuites de gaz . . . . . . . . . . . 15

Vérifier les fuites de gaz avec une solution

liquide . . . . . . . . . . . . . . . . . . . . . . . . 15

Test et réglage des brûleurs . . . . . . . . 16

Vérifier la pression du distributeur

(au besoin) . . . . . . . . . . . . . . . . . . . . 16

Vérifier les caractéristiques de flamme

LP et rendement des brûleurs . . . . . . 16

Rendement du brûleur de wok et tubulure

et réglage final de l’obturateur d’air

(au besoin) . . . . . . . . . . . . . . . . . . . . 17

Étape finale – Pose de l’étiquette de

conversion LP . . . . . . . . . . . . . . . . . . . . 18

Emplacement de l’étiquette

signalétique sur les produits

Professional®Thermador . . . . . . . . . . 19

Cet appareil électroménager de Thermador est fait par

BSH Home Appliances Corporation

5551 McFadden Ave.

Huntington Beach, CA 92649

Questions ?

1-800-735-4328

www.thermador.com

Nous attendons de vos nouvelles !

Page 23

Sécurité

Instructions de sécurité importantes

LIRE LES INSTRUCTIONS AVANT DE COMMENCER

Nécessaire de conversion de gaz naturel à gaz

propane (LP) pour surfaces de cuisson et cuisinières à

®

combustion jumelée Thermador Professional

POUR L'USAGE RÉSIDENTIEL SEULEMENT

IMPORTANT :

Seul un technicien qualifié peut effectuer la conversion.

INSTALLATEUR :

Laisser les instructions de conversion avec l’appareil pour

le propriétaire.

PROPRIÉTAIRE :

Conserver ces instructions à des fins de références.

Comprend des orifices de brûleur Star

protecteurs pour une conversion appropriée en vue du

fonctionnement au gaz propane pour tous les brûleurs de

la surface de cuisson ou de la cuisinière des modèles de la

gamme suivante.

Conservez les pièces servant au gaz naturel pour une

future conversion de gaz LP au gaz naturel.

Ce nécessaire est utilisé pour convertir les surfaces de

cuisson Professional

PRO-GRAND™ et PRO-HARMONY™ Thermador pour un

fonctionnement du gaz naturel au gaz propane (LP). Ce

nécessaire ne peut pas être

anciens modèles de cuisinières ou surface de cuisson

Professional Thermador autres que ceux spécifiés dans

ces instructions (voir le TABLEAU 2). Ce nécessaire ne

peut pas être utilisé pour convertir les cuisinières, brûleurs

de four à gaz Professional

marque d’appareils.

®

, cuisinières à combustion jumelée

utilisé pour convertir les

®

Thermador ou tout autre

®

et orifices

AVERTISSEMENT :

Ce nécessaire de conversion doit

être effectué par un technicien

qualifié conformément aux

instructions du fabricant et à tous

les codes et exigences applicables

ayant juridiction. Si l’information

n’est pas observée à la lettre, il peut

en résulter un incendie, explosion

ou une production de monoxyde de

carbone causant ainsi des

dommages à la propriété, des

blessures ou même la mort.

L’agence de service est responsable

pour une installation appropriée de

ce nécessaire. L’installation n’est

pas appropriée ni complétée tant

que le fonctionnement de l’appareil

converti n’est pas vérifié tel qu’il est

indiqué dans les instructions

fournies avec le nécessaire.

ATTENTION :

Débrancher l’alimentation en gaz et électrique

avant d’effectuer la conversion. Avant de

remettre en circuit, s’assurer que tous les

contrôles sont en position arrêt (OFF).

À l’agence de service :

Il est important de savoir ce qui suit AVANT de commencer

la conversion de l’appareil.

• S’assurer qu’un système d’alimentation en gaz

propane (LP) est disponible et prêt à l’utilisation. Ceci

est particulièrement important avec les nouvelles

constructions.

• Il faut planifier suffisamment de temps et de ressources

afin d’effectuer adéquatement la conversion LP et la

compléter avant de quitter les lieux. Toutes les étapes

décrites dans ces instructions doivent être faites pour

convertir de façon sécuritaire l’appareil poru un

fonctionnement approprié au gaz propane. UNE

CONVERSION INCOMPLÈTE OU INADÉQUA TE DE

L’APPAREIL PEUT CRÉER UN RISQUE.

Français 1

Page 24

Avis de la Loi sur la toxicité et la potabilité de la Californie (proposition 65) :

AVERTISSEMENT :

Ce produit contient ou facilite l’émission, lors

d’une utilisation ordinaire pour laquelle il est

prévu, d’un ou de plusieurs produits chimiques

qui, selon les connaissances de l’État de la

Californie, peuvent causer le cancer et/o u des

anomalies congénitales ou d’autres problèmes

congénitaux. Pour minimiser toute exposition à

ces produits chimiques :

1. Effectuez la conversion au LP conformément aux instructions contenues dans le présent manuel.

2. Pour assurer une combustion adéquate, la conversion et l’ajustement des brûleurs devraient être réalisés par une agence ou un installateur accrédités.

3. Faites toujours fonctionner l’appareil conformément aux instructions fournies avec votre cuisinière ou votre surface de cuisson.

4. Lorsque vous cuisinez au gaz, assurez-vous de bien faire aérer la pièce en ouvrant une fenêtre ou en utilisant un ventilateur ou une hotte.

Instruction pour conversion

Avant de commencer

ATTENTION :

Avant de commencer la conversion, fermer

l’alimentation en gaz à l’appareil avant de

débrancher l’alimentation électrique.

Outils nécessaires pour conversion des orifices :

• Ciseaux.

• Tourne-écrou 7 mm.

• Douille profonde 1/2 po.

• Tourne-écrou 1/4 po ou clé.

• Tournevis à lame plate large 0,40 X 0,050 po.

• Tournevis à lame plate très large 0,60 X 0,060 po.

• Clé ou douille 7/8 po.

• Tournevis de précision à lame plate 1/8 X 0,020 po.

• Tournevis Phillips n° 2.

• Solution d’eau et savon ou conçue pour les fuites.

Tableau 1: PLPKIT - nécessaire

Description

Instructions PLPKIT 552805 1 Ruban mousse, 1 po 418145 1 Étiquette conversion au

propane Sac de plastique 418148 1 Orifice jet de brûleur

étoile

Orifice de gril (style grille

ouverte)

Orifice de gril (style

plaque unie) Orifice protecteur de grille 418150 1 Orfice protecteur de wok 414918 1 Ce nécessaire de conversion au propane comprend les

quantités de piéces indiquées ci-dessus. Toutefois,

certaines piéces ne seront pas utilisées selon le type et

le modéle de l’appareil à convertir. Consulter le

TABLEAU 2 pour une liste de combinaison d’orifices

appropriée à utiliser pour un modéle particulier.

Numéro

Service

418146 1

424851 6

418151 1

414916 1

Quantité

Français 2

Page 25

ATTENTION :

Au moment de brancher l’appareil sur le gaz,

s’assurer que le réservoir de gaz propane est

doté de son propre régulateur de pression

élevée. La pression maximale de gaz à cet

appareil ne doit pas excéder 14,0 po, C.E. du

régulateur du réservoir de gaz propane.

Lorsque converti adéquatement en utilisant les orifices LP

indiqués, les brûleurs fonctionneront au débit suivant avec

le gaz propane (LP) :

• Brûleurs Star

avec orifices 1,07 mm.

• Gril à gaz (style grille ouverte) — 17 000 BTu/h [4.98

kW], avec orifice 1,20 mm.

• Gril à gaz (style plaque unie) — 12 000 BTu/h [3.51

kW], avec orifice n° 59.

• Grille à gaz — 13 000 BTu/h [3.81 kW], avec orifice n°

57 – ou – 1,10 mm.

Tableau 2: tableau de conversion des orifices LP --par numéro de modèle (anciens modèles/nouveaux modèles)

®

— 13 000 BTu/h [3.81 kW] chacun,

• Wok à gaz — 24 500 BTu/h [7.17 kW], avec orifice n°

54 – ou – 1,40 mm.

AVERTISSEMENT :

NE JAMAIS laisser la conversion incomplète. Si

l’appareil est actionné lorsque la conversion est

incomplète, il y a risque d’émission élevée de

monoxyde de carbone, d’incendie ou

d’explosion.

AVERTISSEMENT :

Si les orifices pour gaz naturel sont laissés en

place pendant que l’on tente de faire foncti onner

l’appareil avec le gaz propane, à un réglage de

pression élevé pour gaz LP, les brûleurs

produiront une flamme plus grosse ce qui peut

émettre des niveaux élevés de monoxyde de

carbone dans la pièce, causer un incendie ou

une explosion.

Appareil

Numèro de modèle

(ancien/nouveau)

Surfaces de cuisson Pro :

PC304 / PCG304E 4 chac - 1.07mm

PC366 / PCG366E 6 chac - 1.07mm

PC364GD / (aucun nouveau) 4 chac - 1.07mm #57 -ou- 1.10mm

PC364GE / PCG364ED 4 chac - 1.07mm

PC364GL / PCG364EL 4 chac - 1.07mm 1.20mm (grille) ou 59

PC486GD / (aucun nouveau) 6 chac - 1.07mm #57 -ou- 1.10mm

PC486GE / PCG486ED 6 chac - 1.07mm

PC486GL / PCG486EL 6 chac - 1.07mm 1.20mm (grille) ou 59

PC484GG / (aucun nouveau) 4 chac - 1.07mm 1.20mm (grille

PC484GGE / PCG484EC 4 chac - 1.07mm 1.20mm (grille) ou 59

PC484WK / PCG484EW 4 chac - 1.07mm 54 -ou- 1.40mm PC484GE / PCD484EE 4 chac - 1.07mm

Cuisinières à combustion jumelèe PRO-GRAND

Brûleur Star

424851

Orifice

MC

(27 po de profondeur) :

Gril à gaz*

(style grille/plaque)

418151 -ou- 414916

Orifice protecteur

(plaque)

(plaque)

ouverte seul.)

(plaque)

Gril à gaz**

418150

Orifice

protecteur

#57 -ou- 1.10mm

Wok à gaz

414918

Orifice

protecteur

PD304 / PRD304EG 4 chac - 1.07mm

PD366 / PRD366EG et

PRD366EPG

6 chac - 1.07mm

Français 3

Page 26

Tableau 2: tableau de conversion des orifices LP --par numéro de modèle (anciens modèles/nouveaux modèles)

Appareil

Numèro de modèle

(ancien/nouveau)

Brûleur Star

424851

Orifice

Gril à gaz*

(style grille/plaque)

418151 -ou- 414916

Orifice protecteur

Gril à gaz**

418150

Orifice

protecteur

PD364GD / (aucun nouveau) 4 chac - 1.07mm 57 -ou- 1.10mm PD364GE / PRD364EDG et

4 chac - 1.07mm

PRD364EDPG

PD364GL / PRD364ELG 4 chac - 1.07mm 1.20mm (grille) ou 59

(plaque) PD486GD / (aucun nouveau) 6 chac - 1.07mm 57 -ou- 1.10mm PD486GE / PRD486EDG et

6 chac - 1.07mm

PRD486EDPG

PD486GL / PRD486ELG 6 chac - 1.07mm 1.20mm (grille) ou 59

(plaque)

PD484GG / (aucun nouveau) 4 chac - 1.07mm 1.20mm (grille

57 -ou- 1.10mm

ouverte seul)

PD484GGE / PRD484ECG 4 chac - 1.07mm 1.20mm (grille) ou 59

(plaque) PD484GE / PRD484EEG 4 chac - 1.07mm

Cuisinières à combustion jumelèe PRO-HARMONY

MC

(24 po de profondeur) :

Wok à gaz

414918

Orifice

protecteur

DP304 / PRD304EH 4 chac - 1.07mm

DP366 / PRD366EH 6 chac - 1.07mm

DP364GE / PRD364EDH 4 chac - 1.07mm

DP364GL / PRD364ELH 4 chac - 1.07mm 59 (plaque unie

seul.)

(aucun ancien) / PRD486EDH 6 chac - 1.07mm

(aucun ancien) / PRD486ELH 6 chac - 1.07mm 59 (plaque unie

seul.)

(aucun ancien) / PRD484ECH 4 chac - 1.07mm 59 (plaque unie

seul.)

(aucun ancien) / PRD484EEH 4 chac - 1.07mm

REMARQUES :

* Certains nouveaux modéles de surfaces de cuisson Pro et cuisiniéres à combustion jumelée Pro-Grand ont le style

gril à gaz ouvert..

** Les modéles plus anciens avec les lettres <<GE>> et les nouveaux modéles <<E>> dotés des lettres <<ED>>,

<<EC>> ou <<EE>> sont pour les modéles avec grille électrique - aucune conversion nécessaire

Exemples

Haute altitude:

Plusieurs appareils Thermador doté du nécessaire de

conversion au gaz propane (LP) sont certifiés ACNOR pour

un fonctionnement sécuritaire jusqu’à une élévation de 10

200 pi (3 109 m) au-dessus du niveau de la mer, sans autre

: "PC484GGE", "DP364GE", "PRD364EDG", "PRD484ECH", or "PCD484EE".

appareil utilisé à une altitude plus élevée, consulter la

compagnie de gaz locale relativement à leurs

recommandations pour la dimension appropriée de l’orifice

et tout autre réglage nécessaire afin d’obtenir une

combustion appropriée du gaz à une altitude élevée.

modification. Pour une conversion LP sécuritaire d’un

Français 4

Page 27

Remplacement des orifices de brûleurs sur surfaces de cuisson et cuisinières

Important :

Après le remplacement de chaque orifice et avant de

réassembler le brûleur , effectuer une vérification de fu ite de

gaz de l’orifice et des raccords associés, selon Vérification

des fuites de gaz donnée dans ces instructions.

Remplacer les orifices de brûleur Star®– tous les modèles

• Couper une pièce d’adhésif mousse de 3/8 po de long

fournie dans le nécessaire et placer sur le bord du

tourne-écrou utilisé pour remplacer les orifices de

brûleur Star, comme montré.

• Utiliser un écrou 7 mm pour se passer par le venturi et

enlever l’orifice du porte-jet du brûleur.

• Remplacer chaque orifice de brûleur avec un jet LP

1,07 mm fourni avec le nécessaire. C’est la dimension

pour les brûleurs Star pour produire un dé bit de 13 000

BTu/h [3,81 kW] avec le gaz propane LP.

Bande mousse

La mousse aide à maintenir l’orifice dans l’extrémité du

tourne-écrou pour ne pas qu’il tombe dans l’appareil

pendant l’installation ou le retrait.

• Effectuer un bref test de fuite pour chaque orifice et

raccords associés, selon Vérification des fuites donnée

dans les instructions. Un accès approprié au porte-jet

de brûleur peut être fait après le retra it du plateau

égouttoir – voir Accès au régulateur de gaz pour le

retrait du plateau égouttoir.

Français 5

Page 28

• Chaque orifice porte la marque «107» (pour le

diamètre de 1,07 mm diamètre), comme montré.

Remplacer l’orifice de gril de gaz — si équipé avec gril style grille ouverte

Ce modèle est de style grille ouverte pouvant être identifié

par un brûleur tubulaire en U et déflecteur de chaleur

ondulé, comme montré.

AVERTISSEMENT

Le gril doit être assemblé comme montré.

L’écran d e ch aleur du platea u ég outtoir doit ê tre

en place et le brûleur doit être bien positionné

relativement à l’alimentation en gaz. Un

assemblage incorrect peut causer un risque

pendant le fonctionnement.

• Retirer la grille, le radiant et le brûleur de l’assemblage

du réservoir de gril

• Tirer le levier en métal sur le devant du brûleur de gril

pour le dégager, puis retirer le brûleur de gril.

• Utiliser une douille 1/2 po de profondeur pour enlever

l’orifice protecteur du gril et remplacer avec un orifice

LP 1,20 mm fourni avec le nécessaire.

• Prérégler le volet d’air du brûleur à approximativement

75 % fermé (ouverture approximative de 0,20 po) et

serrer la vis avec un tourne-écrou ou une clé1/4 po.

• Réinsérer l’extrémité du venturi du brûleur de gril sur

les deux fentes à l’arrière de l’assemblage de réservoir

de gril, comme montré ci-dessous. Tourner ensuite

l’autre extrémité du brûleur en position et verrouiller la

languette sur le devant du brûleur dans la fente du

déflecteur de chaleur.

• Réinstaller le radiant en acier inoxydable sur les deux

tiges de chaque côté de l’assemblage de réservoir de

gril.

Français 6

Page 29

• Remettre la grille de façon à ce que le rail pour

surélever les aliments soit orienté ver l’arrière du gril.

• L’orifice protecteur marqué 1,20 mm est conçu pour

produire 17 000 BTu/h [4.98 kW], avec gaz propane

(LP).

Remplacer l’orifice de gril à gaz – si doté du style plaque unie

Ce style peut être identifié par sa plaque de gril côtelée et

son brûleur tubulaire en T, comme montré.

• Après la conversion d’orifice, vérifier les fuites de gaz

et réinstaller le brûleur de gril, vérifier que l’espace

d’électrode et fixation au brûleur est selon la distance

montrée ici.

• Vérifier si le volet d’air du brûleur de gril est bien réglé,

selon Test et réglage du brûleur dans ces instructions,

car la position du volet d’air peut aussi modifier le

rendement de l’allumage.

• Retirer la plaque de gril. Certains modèles ont une

plaque et un cadre en deux pièces, semblable au

modèle de la page suivante.

Français 7

Page 30

• Enlever les vis à chaque extrémité de la cannelure de

flamme, incliner vers soi et tirer la cannelure hors de la

fente avant dans le réservoir de gril.

• Utiliser une douille 1/2 po de profondeur pour enlever

l’orifice protecteur de gril.

• L’orifice LP est étampé 59, format produisant 12 000

BTu/h [3,51 kW], avec le gaz propane.

• Régler le voleur d’air du brûleur à approximativement

75 % fermé (environ 0,20 po d’ouverture) et serrer la

vis avec un tourne-écrou ou une clé 1/4 po.

• Après la conversion, vérifier les fuites de gaz et régler

le brûleur de gril, vérifier si l’espace de l’allumeur de

surface chaude (HSI) est selon la distance montrée,

pour les deux types d’allumeurs suivants utilisés avec

les modèles gril.

Français 8

Page 31

Remplacer l’orifice de grille de gril – si doté

• L’orifice LP porte le n° 57 ce qui est la dimension pour

produire 13 000 BTu/h. [3,81 kW], en utilisant le gaz

propane (LP). L’orifice peut aussi être de 1,10 mm de

diamètre; dans quel cas, l’orifice protecteur doit porter

la marque «110» ou «1,10 mm».

• Prérégler le volet d’air du brûleur à approximativement

75 % fermé (environ 0,20 po ouvert) et serrer la vis à

l’aide d’un écrou ou d’une clé de 1/4 po.

• Retirer le plateau égouttoir de grille, la plaque et le

cadre. Ces pièces ne sont pas maintenues, elles

s’enlèvent facilement.

• Enlever les vis de chaque côté de la cannelure de

flamme tout en portant attention à ne pas échapper les

entretoises à l’intérieur de l’appareil.

• Enlever la plaque couvercle avec 4 vis, la quelle couvre

le venture du brûleur de grille au fond du réservoir de

grille.

• Soulever le brûleur de grille.

• Utiliser une douille 1/2 po de profondeur pour enlever

l’orifice de grille. Au moment d’installer l’orifice LP, faire

très attention à ne pas plier la fixation d’orifice en

métal.

• Après la conversion, vérifier les fuites de gaz et

réinstaller le brûleur de grille, vérifier si l’espace de la

pointe de l’électrode d’allumeur à la surface du brûleur

(point tangent) est d’environ 0,105 po. Il y a un peu de

mouvement disponible dans la fixation du brûleur, à

chaque extrémité pour régler l’espacement au besoin.

Français 9

Page 32

Remplacer l’orifice du wok — si équipé

• Enlever les 2 vis qui maintiennent la veilleuse du

brûleur de la fixation sur l’assemblage du support

supérieur du wok.

• Soulever droit l’assemblage, de quelques pouces du

châssis de wok et enlever le brûleur de wok.

• Retirer l’assemblage supérieur de wok. Ceci expose la

soupape de sécurité.

Soupape de sécurité de wok avec or if ic e

• L’orifice LP porte le n° 54 ce qui est la dimension pour

porduire 24 500 BTu/h. [7,17 kW], en utilisant le gaz

propane (LP). L’orifice peut aussi être de 1,40 mm de

diamètre; dans quel cas, l’orifice protecteur doit porter

la marque «140» ou «1,40 mm».

• Utiliser une douille 1/2 po de profondeur pour enlever

l’orifice protecteur de la soupape de sécurité.

REMARQUE :

La veilleuse de brûleur ne requiert pas une conversion pour

fonctionnement avec le gaz propane.

• Prérégler le volet d’air sur le brûleur de wok en position

complètement ouverte.

• Remettre l’assemblage supérieur de wok.

• Réinstaller le brûleur de wok. S’assurer que le venturi

du brûleur est adéquatement positionné sur l’orifice

protecteur et que le bas de la tête du brûleur est

positionné entre les tiges sur la croix à la base du

support supérieur.

• Fixer la veilleuse de brûleur sur la fixation du support

supérieur de wok.

Français 10

Page 33

Accès au régulateur de gaz

Tous les modèles à combustion jumelée et certaines

surfaces de cuisson sont dotés d’un régulateur de gaz situé

à l’intérieur de l’appareil, sous le plateau égouttoir gauche.

• Régulateur de gaz situé à l’intérieur, côté gauche.

• Retirer les grilles de cuisson.

• Retirer le capuchon de brûleur Star

leégouttoir venturi des 2 brûleurs avec une clé ou

douille 13/16 po.

• Débrancher le fil d’étincelle de la languette sur

l’électrode d’étincelle pour chaque brûleur.

®

, puis enlever

• Retirer la garniture aluminium des côtés du plateau.

• Enlever l’écran sur certains modèles. Certains modèles

ont un écran double qui va jusqu’en dessous du

plateau égouttoir.

Français 11

Page 34

• Le régulateur de gaz est situé près du coin arrière

gauche à l’intérieur de l’appareil.

REMARQUE :

Un orifice de brûleur étoile tombé lors du remplacement

peut être récupéré à cette étape.

Conversion du régulateur pour le fonctionnement LP

AVERTISSEMENT :

Si les orifices pour gaz nature l sont en pla ce pendan t le fonctionne ment de l’appareil avec du gaz propane ( LP),

à un réglage de pression élevée pour le gaz LP, les brûleurs produiront une grosse flamme ce qui peut émettre

des niveaux élevés de monoxyde de carbone dans la pièce, un incendie ou une explosion. Tous les

remplacements des orifices pour le fonctionnement au gaz LP doivent être faits avant la conversion du

régulateur.

Harper-Wyman et Maxitrol sont les deux marques de régulateurs de gaz utilisés avec les produits Professional

Thermador.

Conversion du régulateur Harper-Wyman

• Utiliser un tournevis à lame plate large 0,40 X 0,050

po, pour enlever le capuchon de conversion.

• Avec le tournevis large, presser sur le capuchon de

conversion et tourner dans le sens contre horaire pour

dégager la base baïonnette.

• Retourner le capuchon, côté creux sur le dessus. «LP»

figure au fond du capuchon.

• Utiliser un tournevis à lame plate très large 0.60 X

0,060 po, pour réinstaller le capuchon.

®

Français 12

Page 35

• Remettre le capuchon sur le régulateur avec le creux

sur le dessus, «LP» est visible. Presser vers le bas et

tourner dans le sens horaire pour verrouiller le

capuchon en place.

Conversion du régulateur Maxitrol

• Enlever le capuchon de conversion avec une douille ou

une clé 7/8 po.

• Dégager la tige du bas du capuchon, retourner la tige

pour voir l’extrémité «LP» et réenclencher la tige dans

le capuchon, comme montré.

Retourner la tige

• Réinstaller le capuchon de conversion, configuré pour

le gaz LP, dans le régulateur Maxitrol

Réglage des vis de soupape manuelle pour brûleurs de surface de cuisson et cuisinière

Tournevis pour régler la vis de soupape

Un tournevis de précision à lame robuste, semblable au

*Wiha n° 26033, avec lame 1/8 po [3,0 mm] de large, 0 ,020

po [0,50 mm] d’épaisseur, comme ci-dessous, doit être

utilisé pour repositionner les vis de dérivation pour un

réglage de débit minimal sur les soupapes manuelles.

*Utilisé avec la permission de Wiha Quality Tools, une division

de Willi Hahn Corporation, É.-U.

Français 13

Page 36

Cuisinière à combustion jumelé PROGRAND™ et PRO-HARMONY™ et

surface de cuisson- Pro

• Enlever le bouton de la tige de soupape en tirant droit

lentement, hors du panneau de contrôle.

• Tourner la vis de soupape dans le sens horaire jusqu’à

ce que la position «bas» soit atteinte. NE PAS trop

serrer la vis de soupape.

• Pour les soupapes de gril à grille ouverte ou de wok –

après avoir tourner la vis de soupape vers le bas,

tourner la vis dans le sens contre horaire un demi (1/2 )

tour.

REMARQUES :

• Il est nécessaire que les deux soupapes pour XLO (les

plus à gauche sur le panneau de contrôle) soient en

position arrêt (OFF) pour un accès approprié aux vis

de soupape par les trous de dégagement dans le

potentiomètre XLO.

• Le gril à gaz de style plaque unie et la grille à gaz sont

contrôlés par thermostat et ne requièrent pas de

réglage de soupape.

• Pour les nouveaux modèles, enlever la vis de bague

de fixation située à la droite de la tige de soupape.

• Pour la vis de soupape, insérer le tournevis de

précision dans le trou de la bague créé en enlevant la

vis de fixation.

Anciens modèles de cuisinière à

combustion jumelée et surface de cuisson

Professional

• Enlever le bouton de la tige de soupape en tirant droit

lentement, hors du panneau de contrôle.

• Les vis de soupape sur les modèles plus anciens

peuvent être accédées directement par le panneau de

contrôle, sans retirer les vis de bague.

®

Français 14

Page 37

Vérifier les fuites de gaz

AVERTISSEMENT :

NE PAS utiliser de flamme pour vérifier les fuites de gaz.

AVERTISSEMENT :

L’allumeur d e surface chaude (HSI) pour le gril devient très chaud et peut causer des brûlures graves.

Vérifier les fuites de gaz avec une solution liquide

Tous les remplacements d’orifices du nécessaire de

conversion PLPKIT pour le gaz LP sont dotés de filetage

droit (non comme un tuyau) et ne requièrent pas de

scellant à filetage.

La vérification de fuites doit être faite une fois la conversion

des orifices complétée et avant que les brûleurs ne soient

réassemblés et testés.

• S’assurer que tous les orifices LP sont bien serrés et

que toutes les soupapes et contrôles sont en position

OFF.

• Mettre en circuit les alimentations électrique et de gaz.

• Évaluer brièvement la connexion filetée de chaque

orifice remplacé, un à la fois.

• Vaporiser une généreuse quantité de solution eau et

savon ou une solution conçue pour vérifier les fuites de

gaz sur les connexions filetées à la base de l’orifice.

Éviter de vaporiser les dispositifs électriques. (Une

solution d’eau et de savon pour la vaisselle, 25 %, est

efficace pour cette marche à suivre.)

• Mettre en circuit brièvement la soupape ou le contrôle

tout en bloquant le trou d’orifice avec une efface

souple, le doigt ou un objet semblable. Il est normal

d’entendre un bruit d’allumage pendant ce processus. -

--Éviter la chaleur extrême du gril HIS sur les modèles

qui en sont dotés. Voir l’avertissement ci-dessus. ---

• Surveiller la base de l’orifice pour voir s’il y a des bulles

qui se forment autour de la connexion filetée.

• Une formation de bulle indique une fuite de gaz. La

grosseur et la quantité de bulles représentent une

indication de la sévérité de la fuite.

• Réparer immédiatement toute fuite de gaz. Ceci peut

être effectué en serrant l’orifice.

• Puisqu’une force considérable est utilisée parfois

pendant le remplacement d’orifices, vérifier les fuites

de gaz aux autres raccords menant à l’orifice.

• Fermer les alimentations en électricité et en gaz.

• Réassembler l’appareil en vue d’un test des systèmes

de brûleurs nouvellement convertis.

Français 15

Page 38

Test et réglage des brûleurs

Vérifier la pression du distributeur (au besoin)

La vérification de la pression du distributeur de l’appareil

N’EST P AS nécessaire pour la conversion au gaz propane.

Toutefois, si la pression à la sortie du régulateur de ga z ou

la pression d’entrée à l’appareil semble suspecte, ef fectuer

les étapes suivantes pour vérifier la pression du

distributeur.

• La mesure de pression du distributeur peut être

obtenue à un des orifices de brûleurs étoile, comme

montré.

Vérifier les caractéristiques de flamme LP et rendement des brûleurs

Pour observer la flamme, desserrer ou enlever le nombre

minimum de pièces nécessaires pour une vue non

obstruée. Il peut être nécessaire de fermer les éclairages

ou les stores de fenêtres pour assombrir la pièce et faciliter

la vérification.

• Vérifier l’allumage du brûleur. Pousser le bouton de

contrôle du brûleur et tourner dans le sens contre

horaire à HI. L’électrode d’allumage et le module

d’étincelle produisent un clic. Une fois l’air purgé de la

canalisation, le brûleur devrait s’allumer dans un délai

de 4 secondes.

• Fixer un manomètre portatif qui lit la pression en

pouces par colonne d’eau en utilisant un tube en vinyle

ou en PVC.

• Ouvrir les alimentations électrique et de gaz à

l’appareil.

• Ouvrir un des brûleurs de surface en position HI. Ceci

est important pour obtenir une lecture de pression

véritable dans des conditions de débit de gaz.

• Ouvrir la soupape manuelle pour le brûleur en q uestion

en position HI. (Il y aura un bruit d’allumage provenant

de ce brûleur.)

• La pression du distributeur sur le manomètre doit être

entre 9,50 et 10,50 po C.E. pour le régulateur converti

au gaz LP.

• Si la pression du distributeur est inférieure à cette

gamme, vérifier si le régulateur a été adéquatement

converti pour le gaz LP et que la pression d’entrée à

l’appareil est entre 11,0 et 14,0 po C.E.

• La flamme LP devrait être stable, sans bruit excessif.

Le cône intérieur de chaque flamme doit être bien

défini et distinct des uns des autres

• La portion de la flamme le long du brûleur ne doit pas

être excessive ni soulevée ou couchée.

Français 16

Page 39

• Il est normal d’avoir une pointe jaune qui apparaît

après quelques minutes d’utilisation. Des rayures

orangées dans la flamme sont produites par les débris

dans l’air; ceci est normal pendant la mise en marche

initiale et devrait se dissiper après quelques minutes.

• Régler la soupape de contrôle du brûleur ou le

thermostat à LO ou SIM pour voir si la flamme continue

d’envelopper le brûleur. Souffler la flamme ou utiliser

un mouvement de vent avec une tablette pour éteindre

la flamme, puis observer si le brûleur est apte à

réallumer et si la flamme enveloppe le brûleur en

quelques secondes. La flamme enveloppante est

essentielle pour un allumage et un rallumage du

brûleur.

• Vérifier le rallumage des deux brûleurs étoiles sur le

côté gauche de l’appareil en tournant les boutons de

contrôle à XLO et observer si la petite flamme pour

mijoter enveloppe le brûleur pendant le cycle XLO des

deux brûleurs.

• Si le rendement de la flamme n’est pas acceptable,

vérifier si le brûleur est doté du format approprié

d’orifice LP et que le régulateur a été adéquatement

converti pour le gaz LP.

• Pour un rendement inacceptable du brûleur étoile,

s’assurer que le capuchon du brûleur est bien en

place. Le capuchon doit s’ajuster à plat lorsque bien

positionné à la base et ne pas ballotter trop.

• Si la flamme du brûleur n’est pas uniforme, qu’elle

vacille, fait du bruit ou se soulève, certains ports du

brûleur peuvent être obstrués. Les nettoyer à l’aide

d’un trombone étiré, une aiguille ou objet semblable.

Ceci s’applique également aux ports obstrués des

brûleurs de gril ou de grille.

• Également, des déversements d’aliments ou autres

peuvent obstruer certains des petits canaux à la base

du brûleur étoile, ce qui peut empêcher la flamme de

bien envelopper le brûleur. Nettoyer les canaux avec

une brosse métallique.

Rendement du brûleur de wok et tubulure et réglage final de l’obturateur d’air (au besoin)

Le gaz propane (LP) est plus lourd avec une plus grande

densité que le gaz naturel et est distribué dans l’appareil à

une pression plus élevée. Les différences dans les

propriétés et les applications font que le gaz LP entraîne

une quantité différente d’air primaire lequel requiert

habituellement différentes ouvertures d’obturateur d’air,

comparativement aux applications du gaz naturel pour la

même cote en BTu.

Brûleur pour gril de style plaque uni ou brûleur de grille

• Une position d’obturateur d’air trop ouverte peut créer

un soulèvement notable de la flamme, ce qui dégrade

le rendement enveloppant du brûleur. Cette condition

peut causer aussi du bruit excessif.

• Une flamme dite paresseuse est une flamme

excessivement longue qui recherche l’air et qui est

créée par un obturateur d’air trop fermé. Plusieurs

manteaux extérieurs de chaque flamme tendent à se

mettre ensemble. Une couleur jaune excessive de la

flamme survient lorsque l’obturateur est trop fermé.

Si un réglage de l’obturateur d’air est requis, enlever le

brûleur de l’appareil. Desserrer la vis qui maintient

l’obturateur avec une douille ou une clé 1/4 po et tourner

Français 17

Page 40

l’obturateur à sa nouvelle position. Si une ouverture de

moins de 50 % est désirée, déplacer la vis de retenue

comme montré ci-dessous et tourner l’obturateur à sa

nouvelle position. Réinstaller le brûleur et évaluer de

nouveau les caractéristiques de rendement. Répéter au

besoin pour un rendement adéquat.

• Pour une ouverture de moins de 50 %, déplacer la vis

de retenue à une autre position et tourner l’obturateur

d’air dans le sens horaire au besoin.

Étape finale – Pose de l’étiquette de conversion LP

AVERTISSEMENT :

NE JAMAIS laisser la conversion de gaz partiellement terminée. Si l’appareil est actionné pendant une

conversion incomplète, il y aura de hauts niveaux d’émission de monoxyde de carbone, un risque d’incendie ou

d’explosion.

IMPORTANT :

Pour une identification adéquate et une mise en évidence

de la conversion de l’appareil au gaz propane (LP),

apposer l’étiquette de conversion fournie à côté des

étiquettes signalétiques sur l’appareil. Ceci est

particulièrement important si l’appareil conve rti est

réinstallé dans une nouvelle maison.

Français 18

Page 41

Emplacement de l’étiquette signalétique

®

sur les produits Professional

Les étiquettes signalétiques sont situées à différents

endroits sur les appareils, selon les modèles :

Thermador

plaque en métal fixée au cadre avant inférieur de

l’appareil, derrière la plaque inférieure (voir illustration).

• Surface de cuisson Pro

sont habituellement situées sur le dessous, au bas du

boîtier de la surface de cuisson et peut être accédée

par l’intérieur, sous l’appareil.

• Cuisinière à combustion jumelée Pro- Gr an d

étiquettes signalétiques sont habituellement situées

derrière la plaque inférieure, sur la traverse inférieure

du cadre de l’appareil.

• Cuisinière à combustion jumelée Pro- Ha rm on y

étiquettes signalétiques sont habituellement situées

sous le bord avant de la section cuisinière ou sur la

– les étiquettes signalétiques

– les

– les

Français 19

Page 42

Table des matières

Seguridad . . . . . . . . . . . . . . .1

Instrucciones Importantes de Seguridad 1

Instrucciones de conversión 2

Antes de comenzar . . . . . . . . . . . . . . . . 2

Posibles Herramientas Necesarias para

Todas las Conversiones de Orificio: . . 2

Table 1: Contenido del Kit de

Conversión . . . . . . . . . . . . . . . . . . . . . 2

Table 2: Tabla de Conversión de Orificio —

por Número de Modelo (modelos anteri-

ores / modelos nuevos) . . . . . . . . . . . . 3

Reemplazando los Orificios de

Quemadores en Parrillas / Estufas . . . . 5

Reemplace los orificios del Quemador

Star® – todos los modelos . . . . . . . . . 5

Reemplace el Orificio de la Parrilla –

si está equipado con parrilla estilo

rejilla-abierta . . . . . . . . . . . . . . . . . . . . 6

Reemplace el Orificio de Gas de la

Parrilla – si está equipada con Parrilla

Estilo Placa-Sólida . . . . . . . . . . . . . . . 7

Reemplace el Orificio de la Plancha de

Gas – si así está equipada . . . . . . . . . 9

Reemplace el Orificio de Wok en la

Pro Cooktop – si así está equipada . 10

Accediendo el Regulador de Gas . . . . 11

Convirtiendo el Regulador a Operación

con LP . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Conversión de reguladores

Harper-Wyman . . . . . . . . . . . . . . . . . 13

Conversión de reguladores Maxitrol . 13

Estableciendo Tornillos de Válvula

Manualmente para Quemadores de

Parrillas/Estufas . . . . . . . . . . . . . . . . . . 14

Desarmador para establecer el tornillo

de válvula . . . . . . . . . . . . . . . . . . . . . 14

Estufas y Parrillas PRO-GRAND™ y

PRO-HARMONY™ de Combustible

Dual . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Modelos anteriores de Estufas y Parrillas

Professional® de combustible dual . . 15

Comprobación de Fugas de Gas . . . . 16

Comprobación de Fugas de Gas utilizando

una solución líquida . . . . . . . . . . . . . 16

Prueba y ajuste de Quemador . . . . . . . 17

Verificando la presión del múltiple

(si es necesario) . . . . . . . . . . . . . . . . 17

Verificando las características de flama del

LP y el desempeño de quemadores . 17

Desempeño de quemador tubular y

de wok y ajustes al abturador de aire

(si es necesario) . . . . . . . . . . . . . . . . 18

Paso Final – Colocación de la Etiqueta de

Conversión a LP . . . . . . . . . . . . . . . . . . 20

Ubicación de las Etiquetas de

Especificaciones en productos

Thermador Professional

®

. . . . . . . . . 20

Cet appareil électroménager de Thermador est fait par

BSH Home Appliances Corporation

5551 McFadden Ave.

Huntington Beach, CA 92649

Questions ?

1-800-735-4328

www.thermador.com

Nous attendons de vos nouvelles !

Page 43

Seguridad

Instrucciones Importantes de Seguridad

POR FAVOR LEA EL INSTRUCTIVO COMPLETO ANTES DE PROCEDER

Kit de Conversión de Gas Natural a Propano (LP) para

®

Parrillas Thermador Professional

Combustible Dual

PARA EL USO RESIDENCIAL SOLAMENTE

IMPORTANTE:

Solo técnicos de servicio o instaladores calificados o

deben realizar la conversión.

INSTALADOR:

Por favor deje estas Instrucciones de Conversión junto a la

unidad con el dueño.

DUEÑO:

Por favor conserve estas instrucciones para referencia

futura.

Contiene orificios de Quemador Star

campana para la propia conversión a operación con Gas

Propano para todos los quemadores en la sección de

parrilla o plancha de las series de modelos siguientes.

Conserve las piezas de gas natural para una posible

conversión de gas LP a gas natural en el futuro.

y Estufas de

®

y orificios de

ADVERTENCIA: