THERMADOR.COM

Installation

INSTRUCTIONS

Pro Harmony® and Pro Grand® High Altitude Conversion Kit

THERMADOR.COM

Installation

INSTRUCTIONS

Table of contents (English) ................................................................ 3

Table de matières (Français) ............................................................ 18

Índice de materias (Español)............................................................ 34

Models |

Modèles |

Modelos:

PAALTKITGW

PAALTKITHW

12025444

Pro Harmony® and Pro Grand® High Altitude Conversion Kit

Table of

Safety

CONTENTS

Safety ...................................................................................... 4

Important safety instructions ..........................................4

High altitude instructions........................................................ 6

Before you begin ............................................................ 6

Natural gas units above 5,400 ft. and up to 10,200 ft.... 6

PAALTKITHW checklist............................................. 6

PAALTKITGW checklist............................................. 6

Propane gas units from 10,000 ft. to 10,200 ft............... 7

12025444 checklist................................................... 7

Installation procedure.............................................................8

Changing the STAR® burner orifices ............................. 8

Disassembling the rangetop........................................... 8

Changing the broil orifice...............................................9

Changing the bake orifice ..............................................10

Checking for gas leaks.................................................... 13

DEFINITIONS

9 WARNING

This indicates that death or serious injuries may occur as a

result of non-observance of this warning.

9 CAUTION

This indicates that minor or moderate injuries may occur as a

result of non-observance of this warning.

NOTICE: This indicates that damage to the appliance or

property may occur as a result of non-compliance with this

advisory.

Note: This alerts you to important information and/or tips.

Checking the flame and burner performance................. 15

®

Setting the STAR

Support, accessories, and parts..................................back page

burner valve screws.......................... 16

This THERMADOR® appliance is made by

BSH Home Appliances Corporation

1901 Main Street, Suite 600

Irvine, CA 92614

Questions?

1-800-735-4328

www.thermador.com

We look forward to hearing from you!

Page. 3

Safety

9 IMPORTANT SAFETY INSTRUCTIONS

READ AND SAVE THESE INSTRUCTIONS

Please read carefully

Save the original gas parts for possible conversion back in

the future.

Important: Only a qualified service technician or installer

should make this conversion.

Installer: Please leave these instructions with this unit for

the owner.

Owner: Please retain these instructions for future

reference.

WARNING

If the information in this manual is

not followed exactly, a fire or

explosion may result causing

property damage, personal injury or

death.

-- DO NOT store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

-- WHAT TO DO IF YOU SMELL GAS

• DO NOT try to light any appliance.

• DO NOT touch any electrical switch.

• DO NOT use any phone in your

building.

• Immediately call your gas supplier

from a neighbor’s phone. Follow the

gas supplier’s instructions.

• If you cannot reach your gas supplier,

call the fire department.

-- Installation and service must be

performed by a qualified installer, service

agency or the gas supplier.

These instructions advise you at what elevations and which

models you will need to convert your appliance for proper

operation at high altitude regions. It further instructs you

which parts of the appliance will need to convert to high

altitudes.

This kit is for converting Thermador appliances. This kit

cannot be used to convert older models of ranges. This kit

cannot be used to convert any other brand of appliance.

WARNING

This conversion kit shall be installed by a

qualified service agency in accordance with the

manufacturer’s instructions and all applicable

codes and requirements of the authority having

jurisdiction. In any case, the installation of this

conversion kit must conform with local codes

or, in the absence of local codes, with the

National Fuel Gas Code, ANSI Z223.1/NFPA 54

or, in Canada, the Natural Gas and Propane

Installation Code, CSA B149, latest edition. If

the information in these instructions is not

followed exactly, a fire, explosion or

production of carbon monoxide may result

causing property damage, personal injury, or

loss of life. The qualified service agency is

responsible for the proper installation of this

kit. The installation is not proper and complete

until the operation of the converted appliance

is checked as specified in the manufacturer’s

instructions supplied with the kit.

WARNING

Never Operate the Top Surface Cooking Section of this

Appliance Unattended

• Failure to follow this warning statement could result

in fire, explosion, or burn hazard that could cause

property damage, personal injury, or death.

• If a fire should occur, keep away from the appliance

and immediately call your fire department. DO NOT

ATTEMPT TO EXTINGUISH AN OIL/GREASE FIRE

WITH WATER.

Page. 4

9 IMPORTANT SAFETY INSTRUCTIONS

READ AND SAVE THESE INSTRUCTIONS

For Massachusetts installations

1. Installation must be performed by a qualified or

licensed contractor, plumber, or gas fitter qualified or

licensed by the state, province or region.

2. Shut-off valve must be a “T” handle gas cock.

3. Flexible gas connector must not be longer than 36

inches.

The following must be met when testing supply piping

system:

• The appliance and its individual shut-off valve must be

disconnected from the gas supply piping system at

test pressures in excess of 1/2 psig

(3.5 kPa).

• The appliance must be isolated from the gas supply

piping system by closing its individual manual shut-off

valve during any pressure testing of the gas supply

piping system at test pressures equal to or less than 1/

2 psig (3.5 kPa).

Proposition 65 Warning

This product may contain a chemical known to the State of

California, which can cause cancer or reproductive harm.

Therefore, the packaging of your product may bear the

following label as required by California:

State of California Proposition 65 Warning:

: WARNING

Cancer and Reproductive Harm -

www.P65Warnings.ca.gov

To the service agent

It is important that you know the following BEFORE you

begin the conversion of the appliance.

• Confirm that the gas supply system is available and

ready to use. This is particularly important for new

construction.

• Verify the type of gas supplied to the location. Ensure

that the appliance is connected to the type of gas for

which it is certified.

• You must plan for sufficient time and resources to

perform the conversion process properly and

completely before leaving the job site. Every step

described in these instructions must be performed to

safely convert the appliance for proper operation at

high altitudes. INCOMPLETE OR INADEQUATE

CONVERSION OF THE APPLIANCE CAN CREATE A

SAFETY HAZARD.

Gas and dual fuel ranges converted for propane (LP)

gas and high altitude

The appliance must first be converted for use with

propane (LP) gas before it can be converted for use at

high altitude. It is required that a a qualified service

technician install the propane (LP) conversion kit and the

high altitude kit.

WARNING

NEVER leave the gas conversion partially completed. If

the appliance is operated while the gas conversion is

incomplete, high levels of carbon monoxide may be

emitted, or a fire or explosion may occur.

Page. 5

High altitude instructions

Before you begin

9 CAUTION

Before proceeding with the conversion, shut off the

gas supply to the appliance prior to disconnecting the

electrical power.

Disconnect the appliance from electrical power by

unplugging the electrical cord from its receptacle or

by disconnecting power at the circuit breaker box.

Tools needed

• T-20 torx driver

• 7/16'' box end wrench

• 13/16'' box end wrench

• 7 mm or a 9/32'' socket

• 1/4'' nut driver

• 16 mm hex bit or 5/8'' hex bit or 16 mm Allen wrench

• T-30 torx driver

• 1/2'' offset box end wrench

• 9/32'' open end wrench

• 7/8'' socket or 7/8'' open end wrench

• Adjustable wrench

• Soap and water mixture or leak-check solution

Converting natural gas units

Change only the following oven bake burner. All other

burners’ orifices shall remain the same.

Checklist for 36'' and 48'' PRO HARMONY

Ù Step 1

Ù Step 2

Ù Step 3

Ù Step 4

Ù Step 5

Ù Step 6

Ù Step 7

Remove the oven door (page 11).

Remove the kick and front panels (page 12).

Change the main oven bake burner orifice to

the 2.06 mm (206) orifice (page 12).

Reassemble the door (page 11).

Check the main oven bake burner for gas

leaks (page 14).

Check flame and burner performance of the

main oven bake burner (page 17).

Reassemble the kick and front panels

(page 12).

PAALTKITGW Pro Grand checklist

For altitudes above 5,400 ft. and up to 10,200 ft. on

48'' PRO GRAND natural gas ranges only

Parts included Qty.

Screwdriver, 1/8'' x 0.20'' 1

Orifice, 1.85 mm (185), 48'' Pro Grand, auxiliary

oven bake burner only

1

above 5,400 ft. and up to

10,200 ft.

Each of the following steps must be completed correctly

for the appliance to function properly. Check off each step

as it is finished.

PAALTKITHW Pro Harmony checklist

For altitudes above 5,400 ft. and up to 10,200 ft. on

36'' and 48'' PRO HARMONY natural gas ranges only

Parts included Qty.

Screwdriver, 1/8'' x 0.20'' 1

Orifice, 2.06 mm (206), 36'' and 48'' Pro

Harmony, main oven bake burner only

1

Change only the following oven bake burner. All other

burners’ orifices shall remain the same.

Checklist for 48'' PRO GRAND

Ù Step 1

Ù Step 2

Ù Step 3

Ù Step 4

Ù Step 5

Ù Step 6

Ù Step 7

Remove the oven door (page 11).

Remove the kick and front panels (page 12).

Change the auxiliary oven bake burner orifice

to the 1.85 mm (185) orifice (page 13).

Reassemble the door (page 11).

Check the auxiliary oven bake burner for gas

leaks (page 14).

Check flame and burner performance of the

auxiliary oven bake burner (page 17).

Reassemble the kick and front panels

(page 12).

Page. 6

Converting propane gas units

Checklist for 48'' PRO HARMONY

from 10,000 ft. to 10,200 ft.

Each of the following steps must be completed correctly

for the appliance to function properly. Check off each step

as it is finished.

12025444 Pro Harmony and Pro Grand

propane gas checklist

For altitudes from 10,000 ft. to 10,200 ft. on 36'' PRO

HARMONY LP converted ranges

®

Change only the following STAR

burners shall remain the same.

Parts included Qty.

Screwdriver, 1/8'' x 0.20'' 1

Orifice, 1.26 mm (126), front STAR burner 3

Checklist for 36'' PRO HARMONY

Ù Step 1

Ù Step 2

Ù Step 3

Ù Step 4

Ù Step 5

For altitudes from 10,000 ft. to 10,200 ft. on 48'' PRO

HARMONY LP converted ranges

Disassemble the rangetop (page 8).

Change only the front burner orifices to the

1.26 mm (126) orifices (page 8).

Check the rangetop for gas leaks (page 13).

Reassemble the rangetop and check STAR

burner flame performance (page 15).

Set the valve screws for the front STAR

burners only (page 16).

burner orifices. All other

Ù Step 1

Ù Step 2

Ù Step 3

Ù Step 4

Ù Step 5

Ù Step 6

Ù Step 7

Ù Step 8

Ù Step 9

For altitudes from 10,000 ft. to 10,200 ft. on 36'' PRO

GRAND LP gas converted ranges

Change only the following oven orifice. All other burners

shall remain the same.

Screwdriver, 1/8'' x 0.20'' 1

Orifice, 1.20 mm (120), main oven broil burner 1

Checklist for 36'' PRO GRAND

Ù Step 1

Ù Step 2

Ù Step 3

Disassemble the rangetop (page 9).

Change only the front burner orifices to the

1.26 mm (126) orifices (page 8).

Remove the backguard (page 9).

Change the main oven broil burner orifice to

the 1.20 mm (120) orifice (page 9).

Check the oven and rangetop for gas leaks

(page 14).

Reassemble the rangetop and check STAR

burner flame performance (page 15).

Set the valve screws for the front STAR

burners only (page 16).

Check the broil flame performance (page 17).

Reassemble the backguard (page 9).

Parts included Qty.

Remove the backguard (page 9).

Change the main oven broil burner orifice to

the 1.20 mm (120) orifice (page 9).

Check the oven for gas leaks (page 14).

Change only the following STAR burner and oven orifices.

All other burners shall remain the same.

Parts included Qty.

Screwdriver, 1/8'' x 0.20'' 1

Orifice, 1.20 mm (120), main oven broil burner 1

Orifice, 1.26 mm (126), front STAR burner 3

Ù Step 4

Ù Step 5

Check the broil flame performance (page 17).

Reassemble the backguard (page 9).

Page. 7

Installation procedure

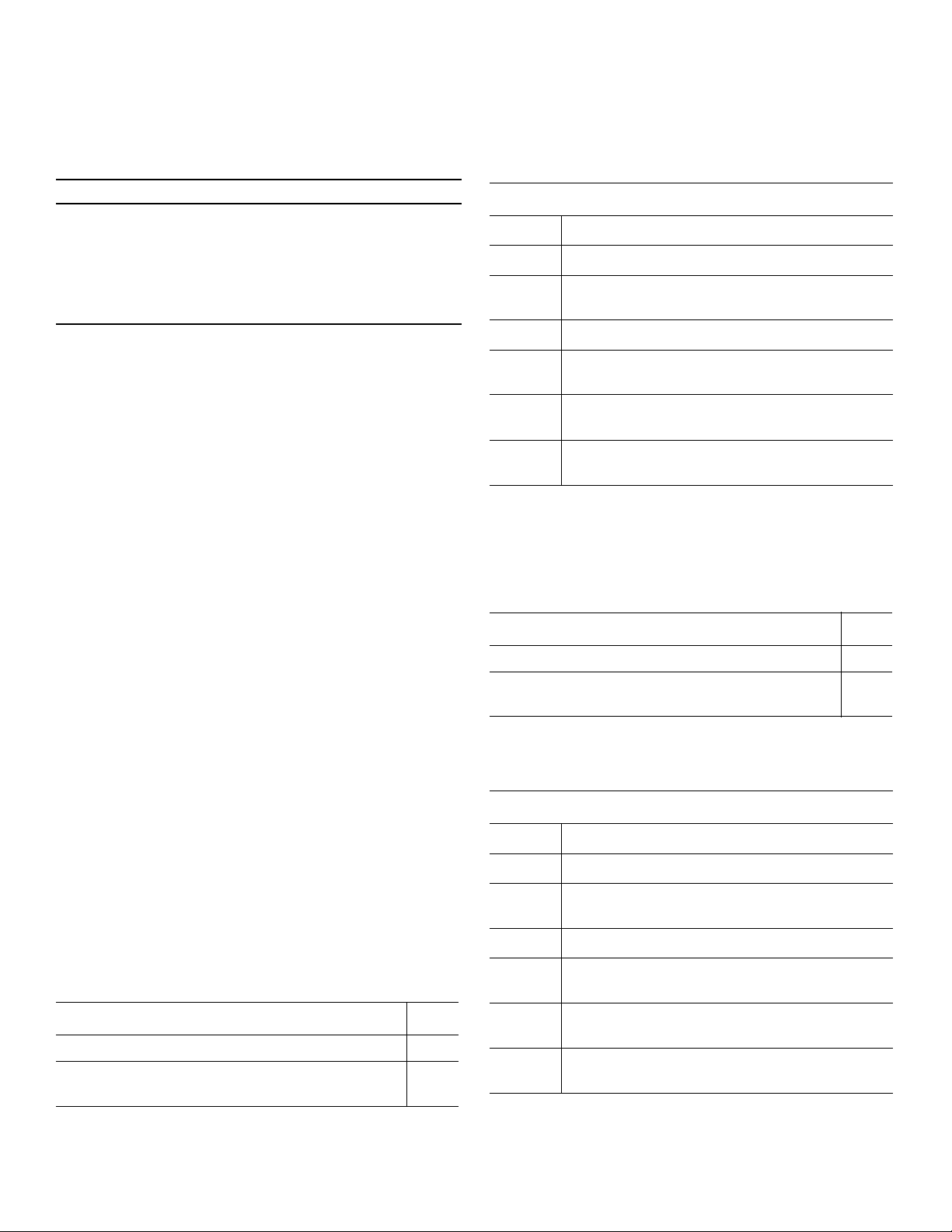

d

b

a

e

f

g

h

c

i

j

1

2

a

b

Changing the STAR® burner

orifices for converting propane

gas units from 10,000 ft. to

10,200 ft. (12025444 kits)

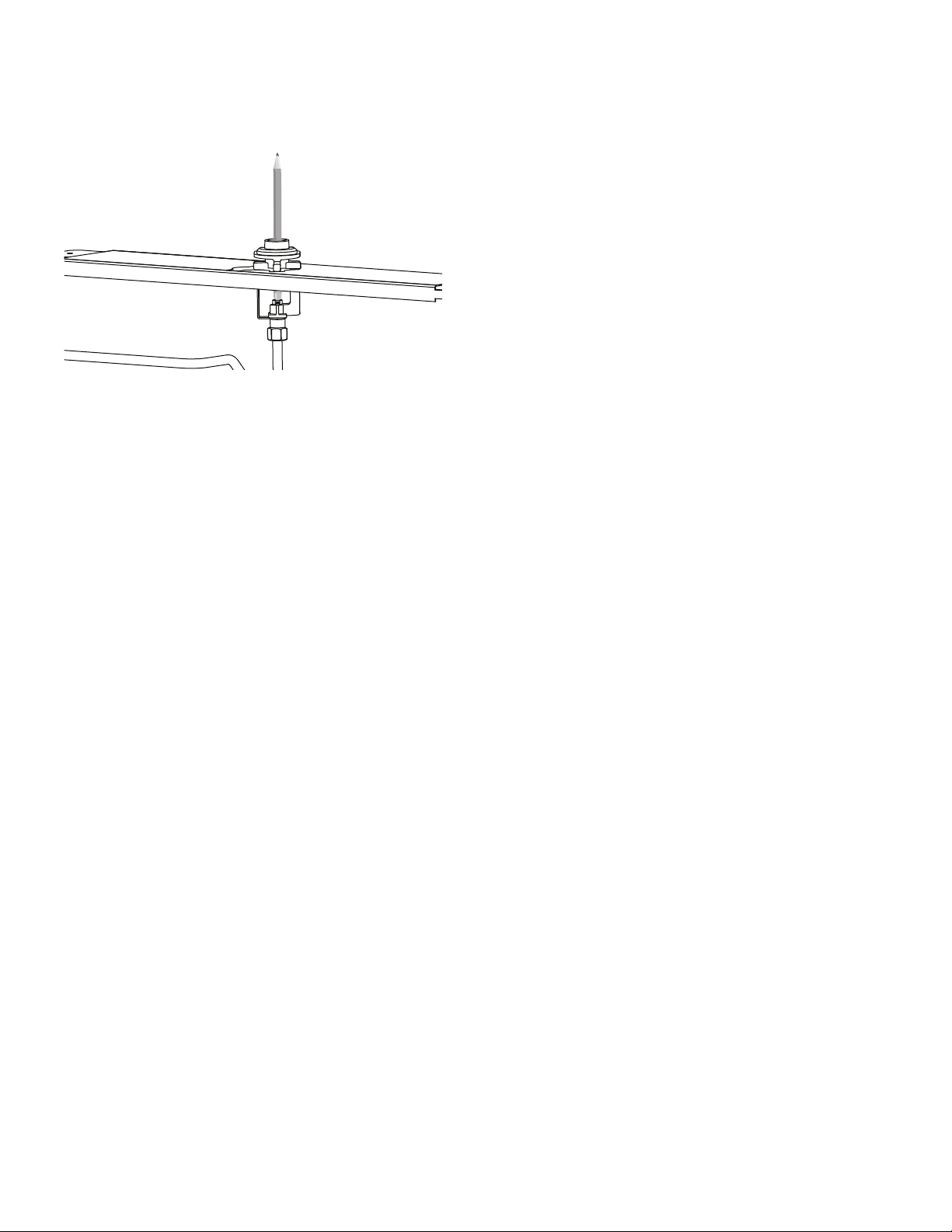

Disassembling the rangetop

9 CAUTION

Before proceeding, shut off the gas supply to the

appliance prior to disconnecting the electrical power.

Disconnect the appliance from electrical power by

unplugging the electrical cord from its receptacle or

by disconnecting power at the circuit breaker box.

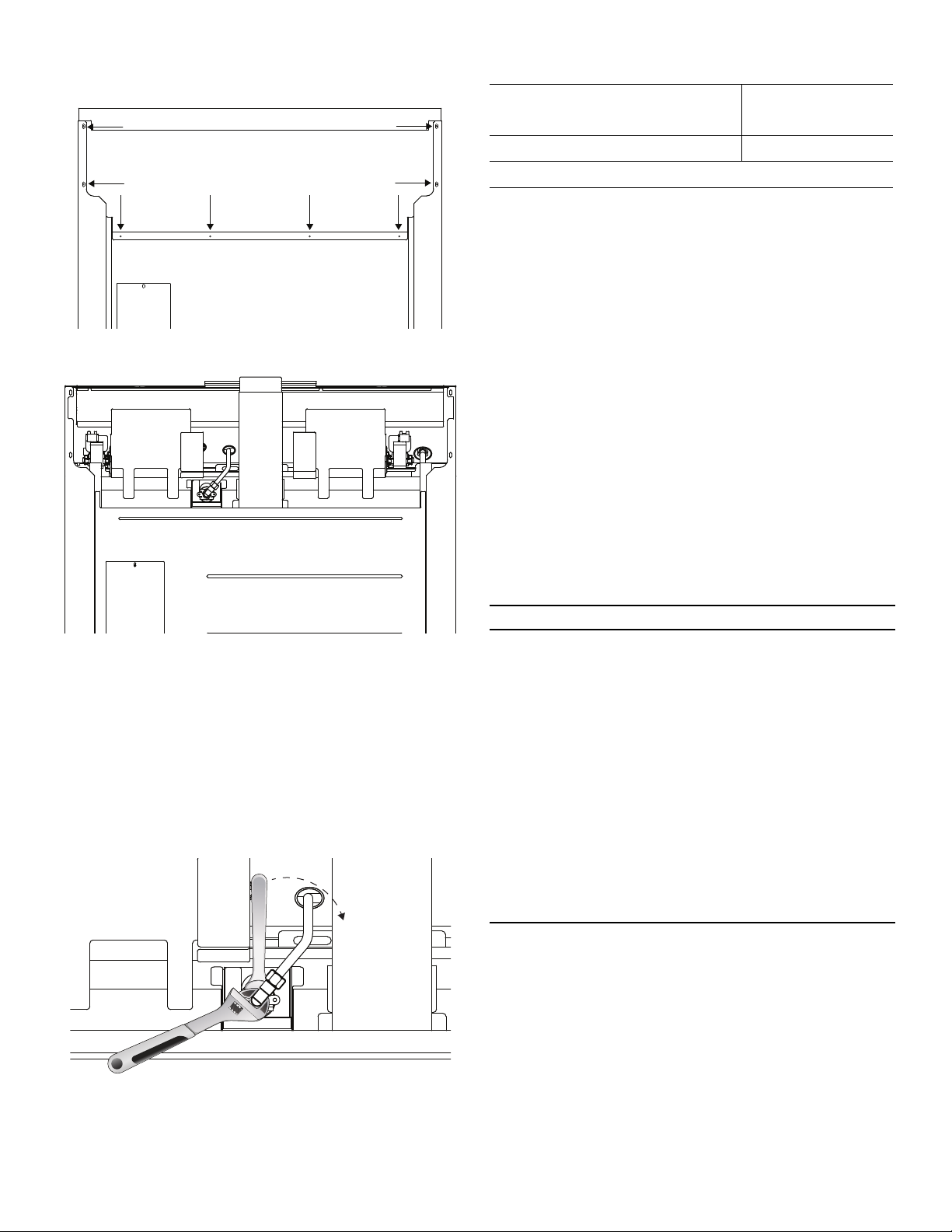

To disassemble the rangetop

1. Remove the rangetop grates and the burner caps.

2. To facilitate the removal of the spill tray, remove the T20 torx screws in the front face of the island trim or

backguard.

3. Use a 16 mm hex head bit or Allen wrench to remove

the burner venturi from each burner base.

a. Grate

b. Burner cap

c. Venturi

d. Burner base

e. Electrode

f. Burner pedestal

g. Spill tray

h. Heat shield

i. Igniter housing

j. Igniter wire

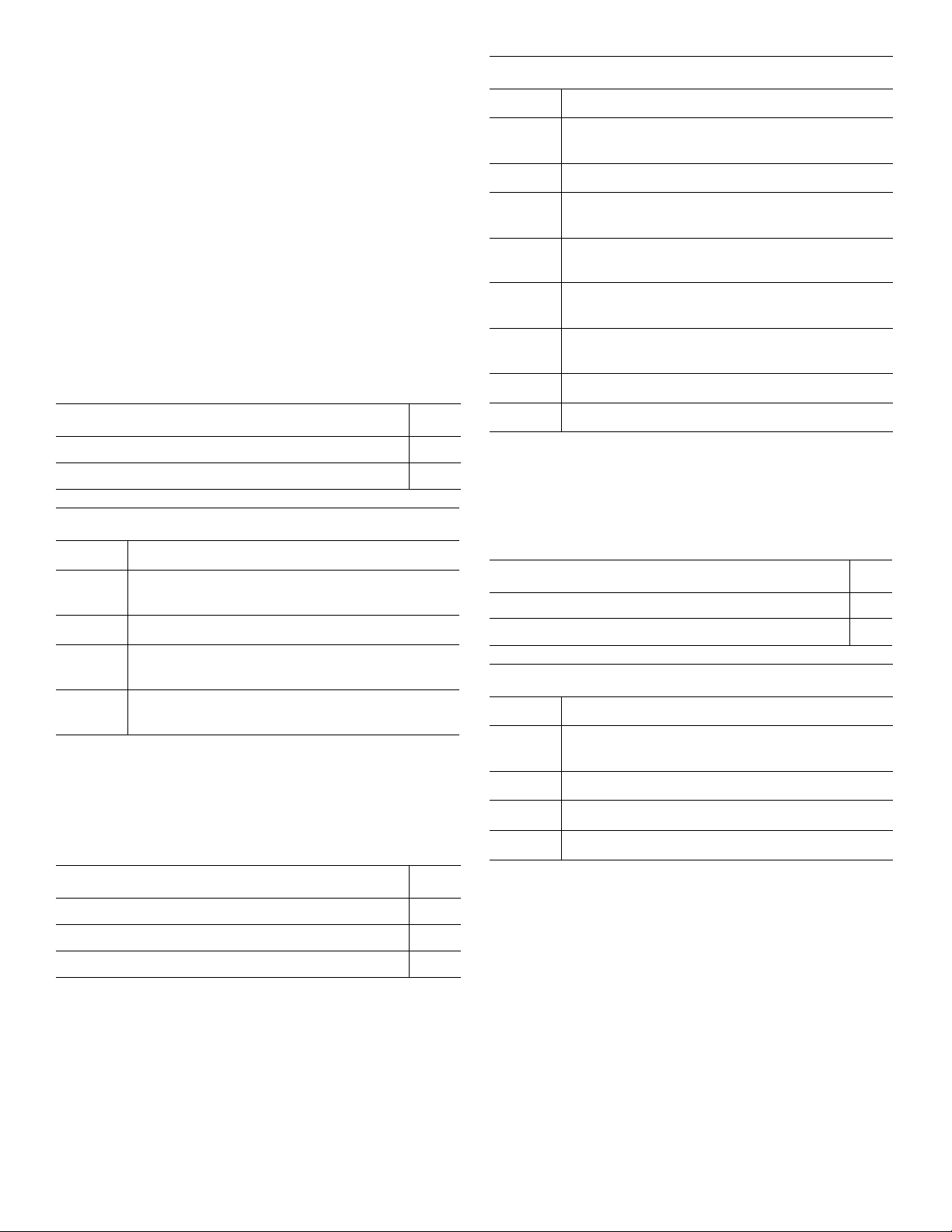

a. Hex head bit or Allen wrench b. Burner venturi

TIP: If a 16 mm hex head bit is not readily available, a

5/8'' hex bit can be selected. Alternatively, a bolt with

5/8'' head either “double-nutted” or tightened into

the chuck of a power driver can be used.

4. Disconnect the igniter. Carefully pull up on the burner

base.

5. Remove the screw securing the burner pedestal with a

T-30 torx driver. Carefully remove each burner

pedestal.

6. Remove the spill trays by pivoting the trays up and out

the back.

7. Remove the heat shield on some models. Some

models have a double-width shield that extends under

adjacent spill tray.

Page. 8

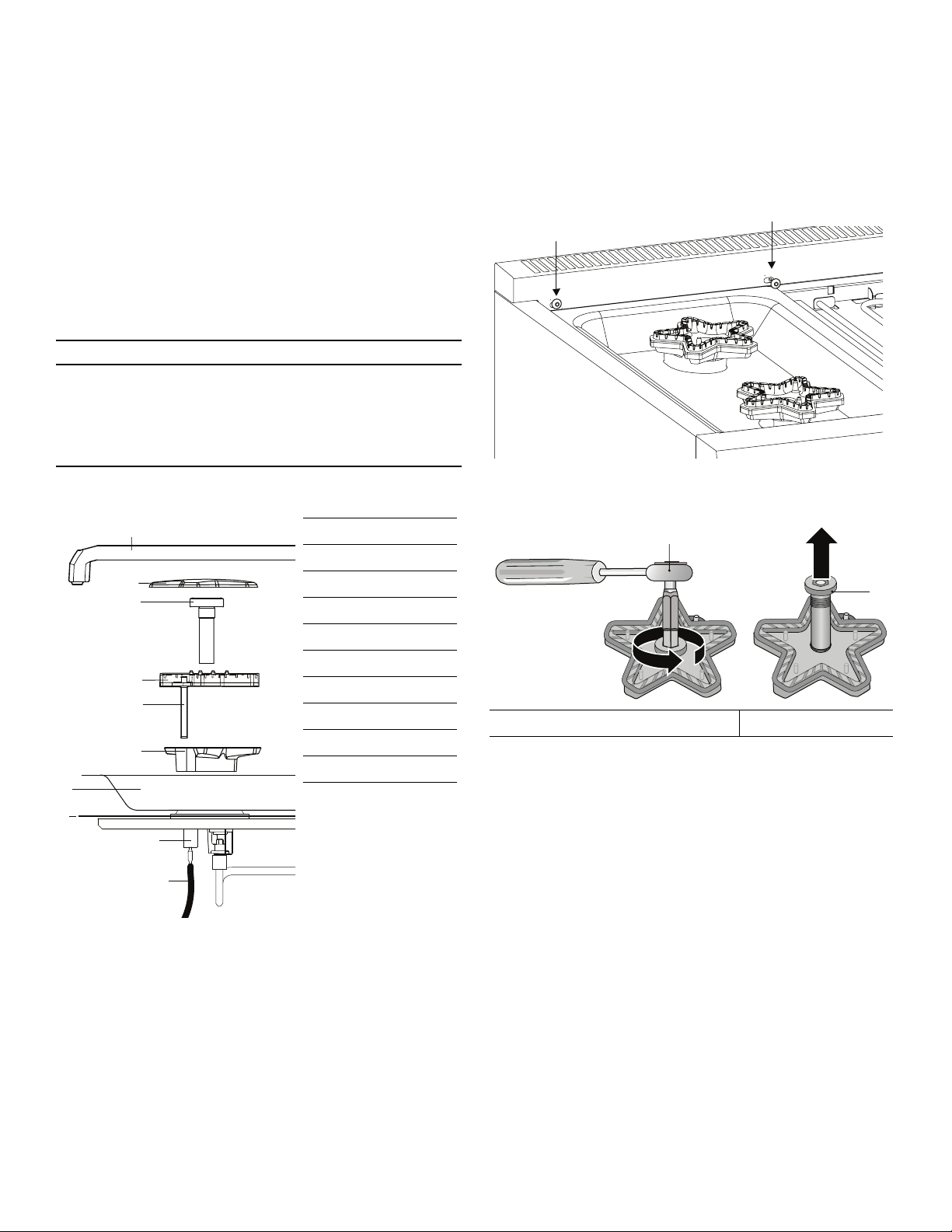

Preparing for STAR® burner orifice

1

2

conversion

To prepare the 7 mm, 9/32'' socket, or ¼'' nut driver for

STAR burner orifice replacement

1. Trim a small piece of the foam tape provided with this

kit to about 1/4 – 1/2'' (6 – 12 mm).

2. Place foam tape over the edge of a 7 mm or a 9/32''

socket, or with 1/4'' nut driver used to replace the

burner orifices, as shown below.

• The foam tape helps to retain the orifice in the

end of the nut driver so it will not fall inside the

appliance during orifice removal or installation.

3. Locate the proper STAR burner

orifices included with the kit.

Orifices are stamped with the

orifice diameter size on the side.

4. Replace orifices as indicated in the table below.

Ensure the orifice is completely seated and tight to

the jet holder to avoid possible gas leaks.

36'' and 48'' Pro Harmony, LP units Orifice no.

®

All front STAR

All rear STAR burners remain unchanged

NOTE: All of the replacement orifices in the conversion kit

have straight threads (not pipe threads) and do not

require thread sealing compound.

burners only

1.26 mm (126)

Changing the broil orifice, for

converting propane (LP) gas

units from 10,000 ft to 10,200

To replace the front STAR burner orifices

1. With the foam tape wrapped nut driver, reach down

through the jet holders and remove the gas orifice

from the STAR burner’s jet holder.

2. Label each of the removed orifices, noting from which

burner they were removed, in the event the appliance

is converted back.

For your convenience, note the orifice sizes and

locations in the following table.

ft. only (12025444 kits)

9 CAUTION

After the replacement of the broiler orifice, and

before reassembly of the back panel and backguard to

the range, perform a brief gas leakage check of the

orifice and associated fittings, per the “Checking for

gas leaks” section of these instructions.

Removing the backguard assembly

1. Move the range out of its installed position to gain full

access to the rear panel of the backguard assembly

and to the broil burners' orifices.

2. Use a T-20 torx screwdriver to remove the screws from

the front of the backguard assembly.

Burner location Orifice size

Left front

Center front

Right front

All rear burners remain unchanged

Page. 9

3. Use a T-20 torx screwdriver to remove the screws from

the back rear panel of the backguard assembly.

4. Carefully lift the backguard assembly from the range.

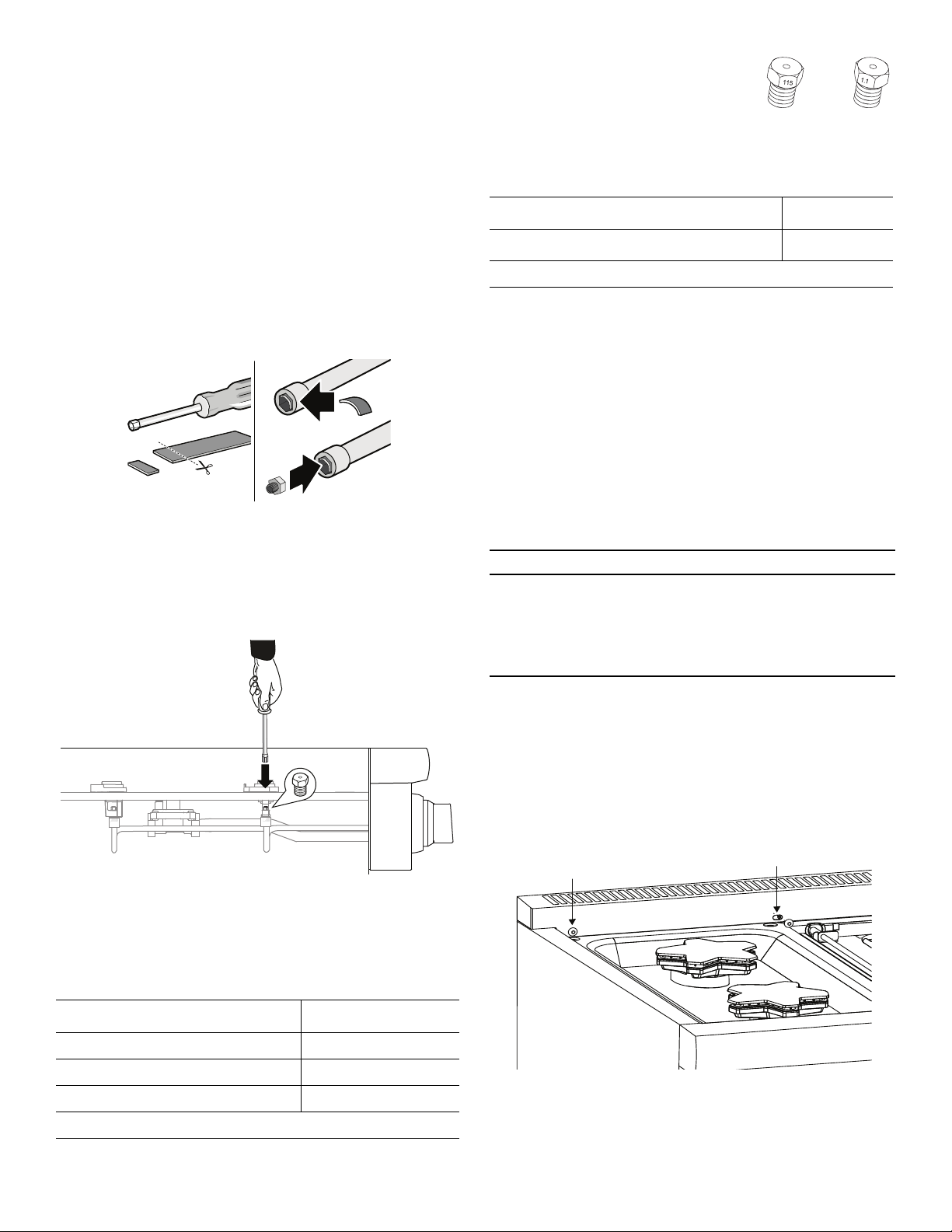

2. Replace the orifices as indicated in the table.

48'' Pro Harmony and 36'' Pro

Grand, LP units

Main oven broil 1.20 mm (120)

Auxiliary oven broil remain unchanged

NOTE: The replacement broil orifices have straight

threads (not tapered threads) and DO NOT require thread

sealing compound.

3. Perform a gas leakage check of the orifice and

associated supply tube fittings, per “Gas leak

checking the broil orifice” on page 14.

Orifice no.

Changing the bake orifice, for

converting natural gas units

above 5,400 ft. and up to

10,200 ft. only (PAALTKITHW

Changing the broil burner orifice

1. Remove broil orifice using a 7/16'' box end wrench,

while restraining the elbow fitting from rotation using

a small adjustable wrench.

IMPORTANT: DO NOT bend the broil burner orifice

bracket. Ensure that the broiler orifice is aligned to the

center of the burner tube inlet.

and PAALTKITGW kits)

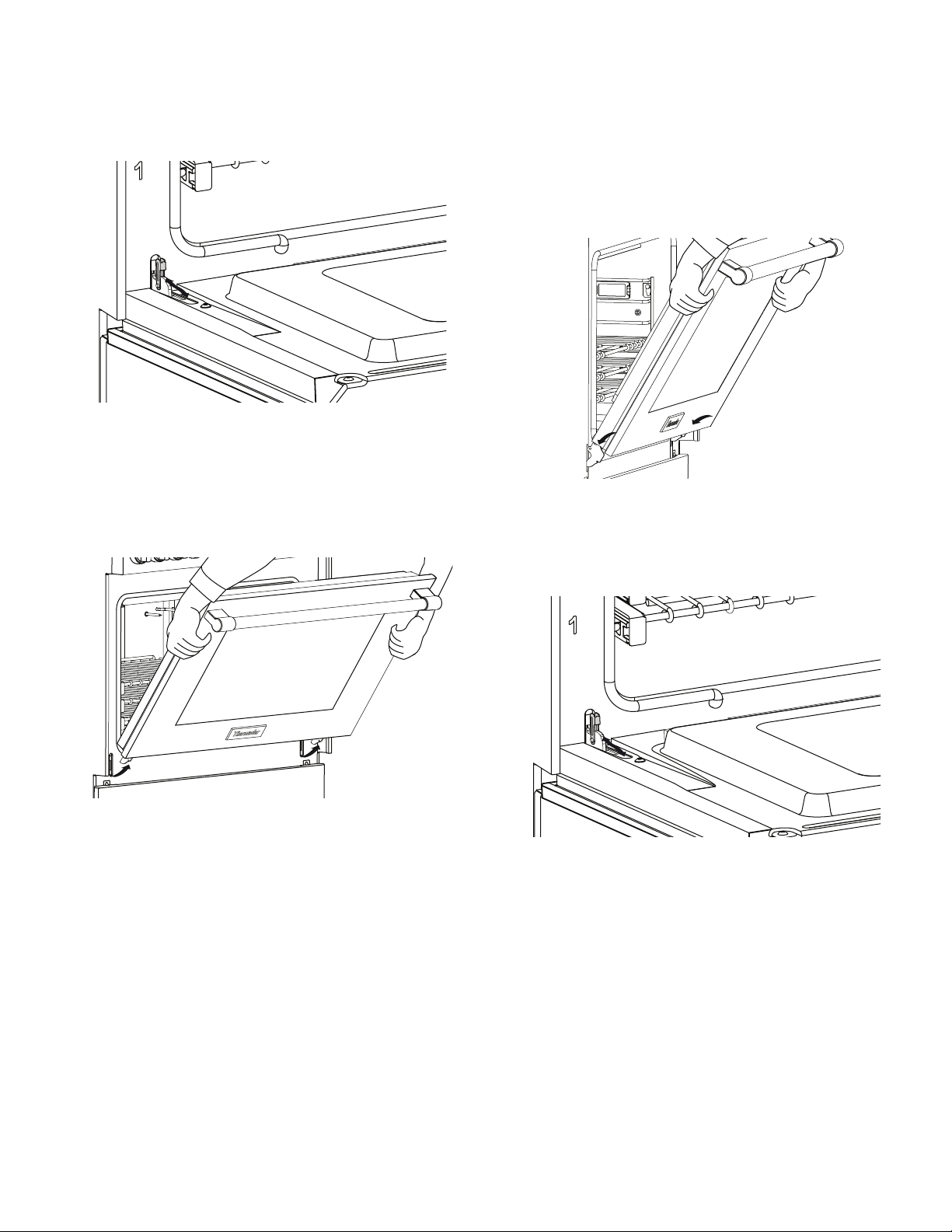

Removing the oven door

9 CAUTION

• USE CAUTION WHEN REMOVING THE DOOR.

THE DOOR IS VERY HEAVY.

• Make sure oven is cool and power to the oven has

been turned off before removing the door. Failure

to do so could result in electrical shock or burns.

• The oven door is heavy and fragile. Use both

hands to remove or replace the door.

• Failure to grasp the oven door firmly and properly

could result in personal injury and product

damage.

• With the door off, never release the levers and try

to close the hinges. Without the weight of the

door, the powerful springs will snap the hinges

closed with great force.

To gain access to the bake burner orifices, you will need to

remove the oven door, kick panel, and the bottom front

panel, if applicable.

Page. 10

To remove the oven door

Reinstalling the oven door before leak

1. Open the door fully. Flip the hinge clips down for both

sides of the door. A screwdriver may be required to

carefully pry the clip back.

2. Close the door gently until it stops against the hinge

clips. The open hinge clips will hold the door open at

a slight angle, about 30°, from the closed position.

3. Grasp the door firmly on the ends of the door. Lift the

door up and out. There will be some spring resistance

to overcome.

testing the broil or bake burners

1. Hold the door firmly in both hands.

2. Hold the door at a 30° angle from the closed position.

Insert hinges centered evenly into the hinge slots. The

hinges will securely hook into the slots when properly

installed. DO NOT force, bend or twist the door.

3. Open door fully to expose hinges, levers, and slots.

4. Flip the hinge forward until seated on the bracket. A

screwdriver may be required to carefully push the clip

back.

4. Place the door in a safe and stable location.

5. Close and open the door slowly to ensure it is

correctly and securely in place.

Page. 11

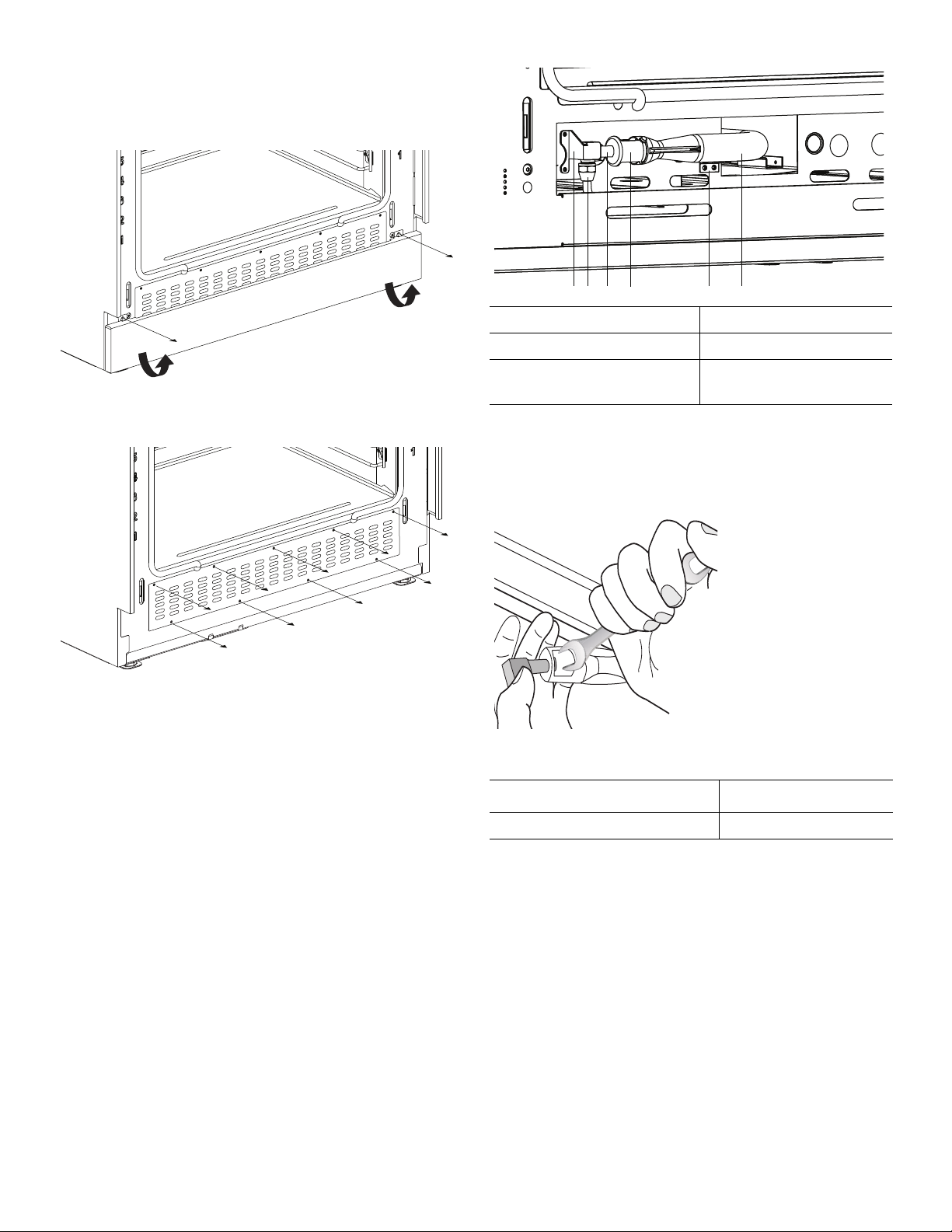

Removing the kick and front panels

a e f

cb

d

1. Remove the kick panel screws using a T-20 torx

screwdriver.

2. Remove the front panel screws using a T-20 torx

screwdriver.

a. Anti-rotation bracket b. Bake gas line

c. Elbow fitting d. Shutter

e. Bake burner tube

mounting bracket

1. Remove the bake gas line using a 13/16'' box end

wrench.

2. Remove the two screws from the bake burner tube

mounting bracket with a T-20 torx driver.

f. Bake burner tube

Changing the main oven bake burner

orifice

IMPORTANT:

• Do not bend the bake burner tube.

• Do not bend the bake burner gas tube.

• Do not modify the shutter opening. The air shutter

should remain fully open.

• Do not remove the anti-rotation bracket when

performing the orifice change. This bracket is

critical to the alignment of the bake burner tube

with the burner orifice. After the orifice

replacement, this bracket will facilitate the burner

tube’s realignment.

3. Insert a 1/2'' offset

wrench into the

shutter opening to

restrain the bake

orifice while hand

twisting the orifice

elbow

counterclockwise.

4. Replace the orifice as indicated in the table.

36'' and 48'' Pro Harmony Orifice no.

Main oven bake burner only 2.06 mm (206)

5. Ensure that the bake orifice is aligned to the center of

the burner tube inlet. Reinstall the bake burner tube

beneath the oven. If necessary, use a flashlight to aid

in seeing the locating slot where the burner tube sits

at the backside of the burner cavity.

6. Slide the elbow fitting back into the anti-rotation

bracket. Reattach the two bake burner mounting

bracket screws and tighten the gas line.

7. Perform a gas leakage check of the orifice and

associated supply tube fittings per “Checking for gas

leaks” on page 13.

Page. 12

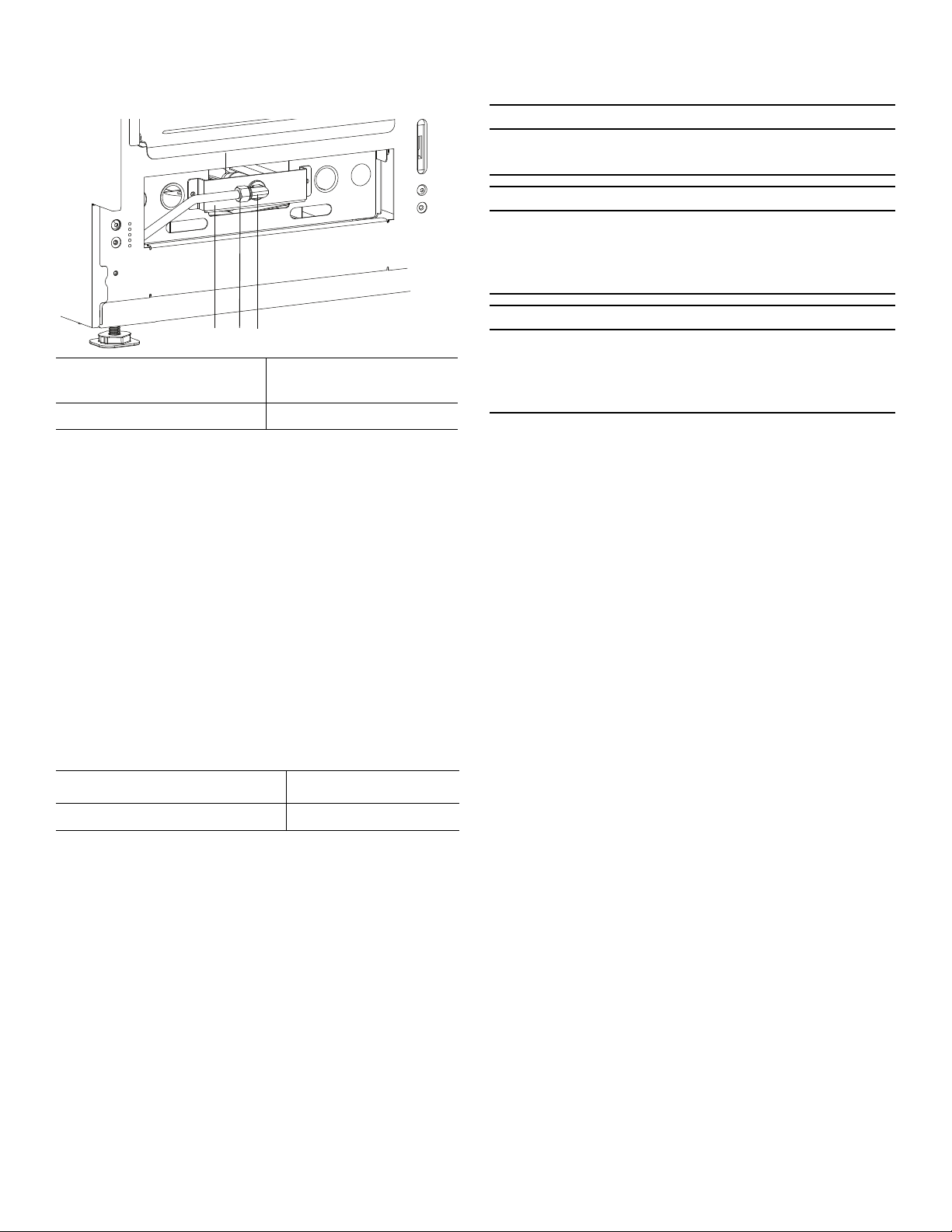

Changing the auxiliary oven bake burner

a

c

b

d

orifice

a. Auxiliary bake burner

mounting bracket

c. Elbow fitting d. Bake burner tube

IMPORTANT:

• Do not bend the bake burner tube.

• Do not bend the bake burner gas tube.

• Do not modify the shutter opening. The air shutter

should remain fully open.

b. Aux oven bake gas

line

Checking for gas leaks

9 WARNING

DO NOT use a flame of any kind to check for gas

leaks.

9 CAUTION

DO NOT spray water solution onto exposed electrical

components. If solution does drip onto electrical

components, shut the power off before wiping off the

electronics.

9 CAUTION

Ensure that the STAR burner igniter wire terminals do

not touch the chassis metal, or any metal part, to

prevent sparking. Do not touch the igniter wires while

the burner is turned on to avoid being shocked.

Leak testing should occur after the orifices are replaced

and before the appliance is fully reassembled. However,

the doors of the appliance must also be installed and

closed in order to leak check the broil and bake burners.

Leak testing of the appliance shall be conducted

according to the following instructions.

1. Remove the two screws from the auxiliary bake burner

mounting bracket with a T-20 torx driver. Pull the

bracket and gas line carefully towards you.

NOTE: It is not necessary to loosen the auxiliary oven

bake gas line.

2. With an adjustable wrench, restrain the elbow fitting.

With a 1/2'' offset wrench, unscrew the auxiliary bake

burner orifice.

3. Replace the orifice as indicated in the table.

48'' Pro Grand Orifice no.

Auxiliary oven bake burner only 1.85 mm (185)

NOTE: The replacement bake orifices have straight

threads (not tapered threads) and DO NOT require thread

sealing compound.

4. Before reattaching the auxiliary bake burner mounting

bracket, perform a gas leakage check of the orifice

and associated supply tube fittings per “Gas leak

checking the bake orifice” on page 14.

Gas leak checking the rangetop STAR®

burners

To leak check the rangetop’s STAR burners

1. Make sure that the orifices have been tightened and

that all valves and controls are in the OFF position.

2. Turn on electric and gas supplies.

3. Spray a generous amount of soap and water

mixture—or other solution designed for checking gas

leaks—on the threaded junction at the base of the

orifice, the elbow fitting, and gas tube compression

nut. (A 25% dishwashing liquid to water mixture is

effective for this.) Avoid spraying electrical

components.

Page. 13

4. Turn the corresponding STAR burner knob to HI while

firmly blocking the STAR burner's orifice hole with a

soft rubber pencil eraser, your finger, or something

similar.

5. Monitor the base of the orifice junction, elbow fitting,

and compression nut to see if bubbles are forming

anywhere around the connections.

• Bubbles forming are indications of gas leaks.

6. If appliance leaks, repair all gas leaks immediately. Do

not over-torque the junctions, orifices or nuts, or bend

the gas tubes.

7. Repeat for all STAR burners.

Gas leak checking the broil orifice

To leak check the broil burner orifice

1. Spray a generous amount of soap and water

mixture—or other solution designed for checking gas

leaks—on the threaded junction at the base of the

orifice, the elbow fitting, and gas tube compression

nut. (A 25% dishwashing liquid to water mixture is

effective for this.) Avoid spraying electrical

components.

2. Turn the mode knob and the oven temperature knob

to BROIL while blocking the broil orifice hole with a

soft pencil eraser, your finger, or something similar.

• There will be a delay of approximately 45 to 90

seconds as the safety valve coil heats to release

the valve’s actuator. A single pop noise can usually

be heard as the broiler’s safety valve opens.

3. Monitor the base of the orifice junction, elbow fitting,

and compression nut to see if bubbles are forming

anywhere around the connections.

• Bubbles forming are indications of gas leaks.

4. If appliance leaks, repair all gas leaks immediately. Do

not over-torque the junctions, orifices or nuts, or bend

the gas tubes.

5. If applicable, repeat for the auxiliary broil orifice.

Gas leak checking the bake orifice

To leak check the oven bake burner orifice

1. Spray a generous amount of soap and water

mixture—or other solution designed for checking gas

leaks—on the threaded junction at the base of the

orifice, the elbow fitting, and gas tube compression

nut. (A 25% dishwashing liquid to water mixture is

effective for this.) Avoid spraying electrical

components.

2. Turn the mode knob to BAKE and the oven

temperature knob to any setting while blocking the

bake orifice hole with your finger.

• There will be a delay of approximately 45 to 90

seconds as the safety valve coil heats to release

the valve’s actuator. A single pop noise can usually

be heard as the broiler’s safety valve opens.

3. Monitor the base of the orifice junction, elbow fitting,

and compression nut to see if bubbles are forming

anywhere around the connections.

• Bubbles forming are indications of gas leaks.

4. If appliance leaks, repair all gas leaks immediately. Do

not over-torque the junctions, orifices or nuts, or bend

the gas tubes.

5. If applicable, repeat for the auxiliary bake orifice.

6. If the appliance has been satisfactorily leak checked,

turn off the gas and electric supplies. Reinstall the

auxiliary bake burner mounting bracket, if applicable,

and continue to “Checking the flame and burner

performance”.

Page. 14

Checking the flame and burner

d

b

a

e

f

g

h

c

i

j

aaa

bb

cc

dd

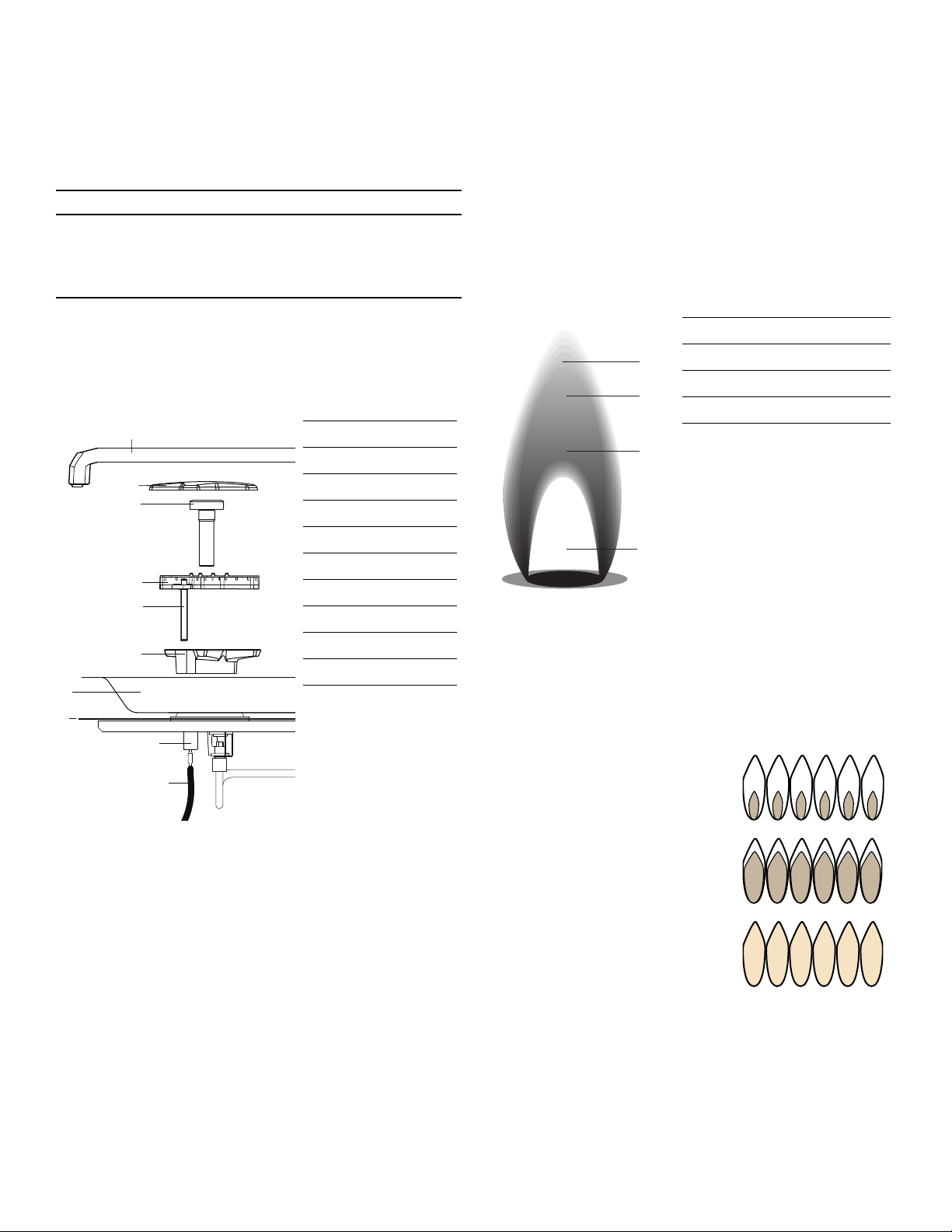

Checking the STAR burner ignition and flame

performance

Checking the STAR® burner performance

9 WARNING

When cooking with the STAR burners, the burner

flame size should be adjusted so it does not extend

beyond the edge of the cooking utensil. This

instruction is based on safety considerations.

To observe the burner flames, it may be necessary to turn

off lights or close window blinds to darken the room for

easier viewing of the flame.

Reassemble the rangetop as follows:

a. Grate

b. Burner cap

c. Venturi

d. Burner base

e. Electrode

1. Push in the burner control knob and turn it to “HI”.

• The igniter electrode and spark module will

produce a clicking sound. Once the air has been

purged from the supply lines, the burner should

light within four seconds.

• The flames should be stable, with no excessive

noise. The inner cones of the individual flames

should be defined and separate from each other.

Portions of the flame, along the burner, should not

exhibit excessive or continuous indications of

“lifting” or “lazy flame”.

a. Dark blue

b. Secondary cone

c. Light blue

d. Primary cone

f. Burner pedestal

g. Spill tray

h. Heat shield

i. Igniter housing

j. Igniter wire

TIP: Use the burner venturi as a centering guide when

remounting the burner pedestals. If the pedestals are

centered, the venturi will slide in and out easily after the T30 torx head screw has been secured. If the pedestals are

not centered properly, loosen the mounting screw and

recenter the burner until the venturi slides freely.

NOTE: It is normal for slight yellow tipping of the flames

to appear after a few minutes of operation using Propane

(LP) gas. Orange-colored streaks in the flame are

produced from burning airborne debris; this is normal

during initial start up and should dissipate within a few

minutes of operation.

Yellow flames:

Further adjustment is

required.

Yellow tips on outer cones:

Normal for LP gas

Soft blue flames:

Normal for natural gas

Page. 15

5. Adjust the burner’s control valve to LO to see that the

Star

®

Star

®

flame continues to wrap around the burner. Blow out

the flame, or use a quick fan motion from a writing

tablet or piece of cardboard to extinguish the flame,

and then observe the burner’s ability to reignite and

wrap around (also called “carry-over”) the burner

within several seconds. This flame “carry-over” is

essential for proper burner ignition and re-ignition.

6. Test re-ignition of the XLO and observe the carry-over

of the small simmer flames as the XLO system cycles

the burners on and off.

• If the low flame performance is not acceptable it

may be necessary to readjust the valve screw for a

®

STAR

burner that does not have sufficient carryover of the low flame. Turn the valve screw very

slightly counter-clockwise until carry-over of the

flame is acceptable. (See “Setting the STAR®

burner valve screws” on page 16.)

• If the burner flame is uneven, flutters, makes

excessive noise, or lifts, some of the slots in the

burner base may be blocked with food spillage or

other debris.

• Clogged slots can be cleared using a straightened

paper clip, needle, or similar object. Hard-toremove, encrusted food or debris can sometimes

be removed using a steel wool pad or fine wire

brush.

• Burner flames that are “lazy”, with excessivelylong flames, can be created by an incorrectly

fitted burner cap—from which many of the outer

mantles of the individual flames will tend to

“coalesce” or blend together. Verify that the

burner cap is seated properly on its burner base.

The cap should fit reasonably flat when correctly-

positioned on the base and not rock significantly.

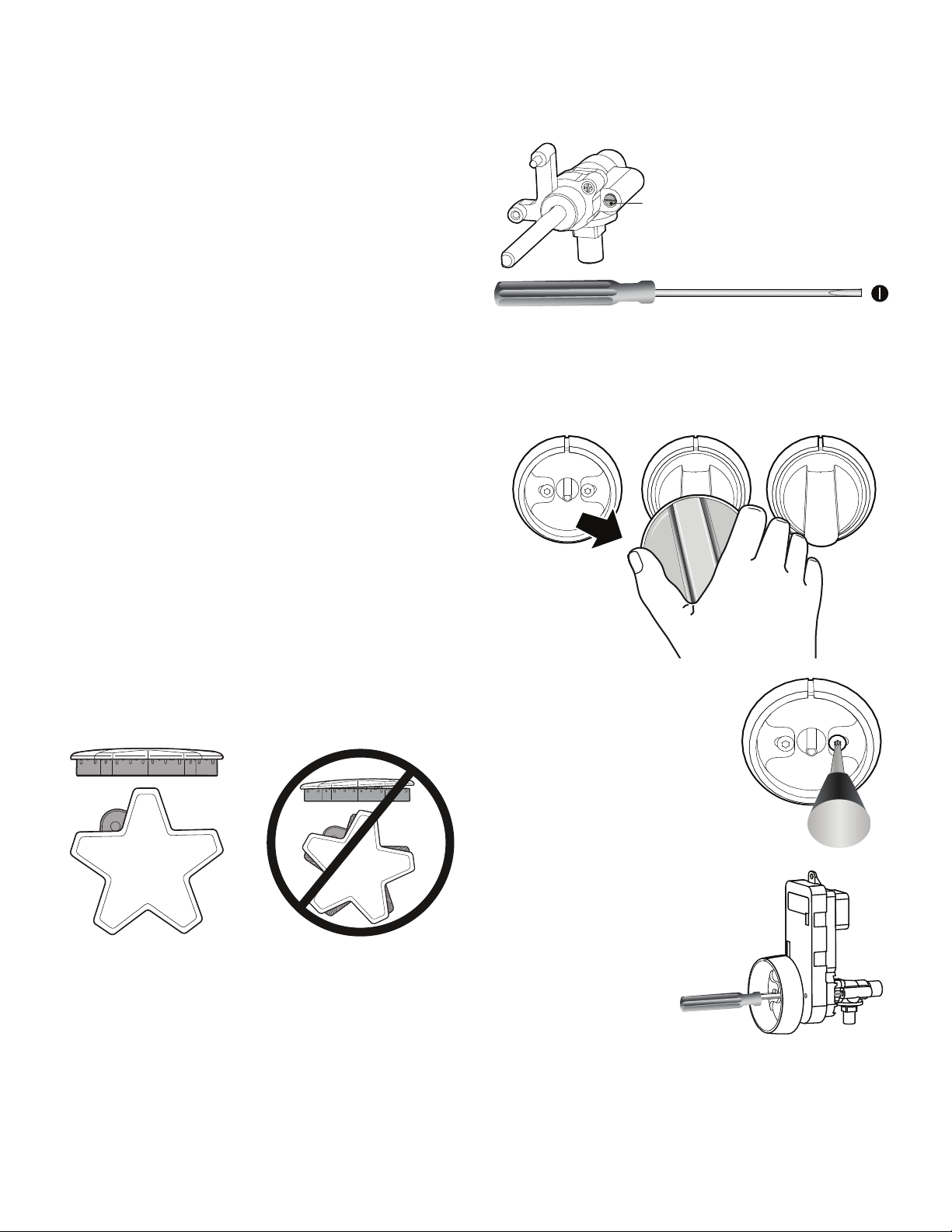

Setting the STAR® burner

valve screws

A flat-head screwdriver with an

1/8" [3.0 mm] wide, .020"

[0.50 mm] thickness tip

(included) is used to adjust the

valve screws.

To set the burner valve screws

1. Remove the knob from the valve stem by slowly

pulling knob straight out, away from the control panel.

2. Remove the bezel-mounting

screw located to the right of

the valve stem, using a T-20

torx screwdriver.

Correct burner cap Incorrect burner cap

7. Repeat the ignition and flame test procedures for

each rangetop STAR burner.

Page. 16

3. Insert included 1/8''

flat-blade

screwdriver into the

hole of the bezel

mounting screw.

Access to the valve

screws through the

clearance hole in the

spark module. You

should feel the

engagement of the

screwdriver and the

valve screw.

4. Adjust the valve screw by turning the valve screw

about an 1/8

reduce simmer flame size. Turn the screw counterclockwise to make the simmer flame larger. Adjust the

valve screw as little as required to reach satisfactory

simmer results. Due to normal fluctuations in gas

pressure, over-adjustment of valve screw may affect

flame stability.

th

turn. Turn the screw clockwise to

Checking the broil burner(s) performance

NOTE: The oven door(s) must be installed and closed.

To check the gas broil ignition and flame

1. Turn on the main oven mode knob and the oven

temperature knob to BROIL.

• The hot-surface igniter will attempt to light the

broiler after approximately 45 to 90 seconds, as

the safety valve coil heats to open. Once the air

has been purged from the gas supply line, the

broiler should light within four (4) seconds.

• Observe the broil flame performance through the

oven door window. The ceramic tiles of the burner

should glow red hot (infrared) after several

minutes of operation. If after several minutes with

the burner lit, the broiler only has a small amount

of red glow (and burns mostly with blue flame

floating on the burner surface), check that the

broiler orifice is aligned to the center of the

burner tube inlet.

2. If the broil burner burns satisfactorily, reassemble the

backguard onto the appliance (see page 9).

Checking the bake burner(s) performance

NOTE: The oven door(s) must be installed and closed

To check the gas bake ignition and flame

1. Install the front panel (see page 12).

2. Turn the main oven mode knob to BAKE and the oven

temperature knob to any setting.

• The hot-surface igniter will attempt to light the

burner tube after approximately 45 to 90 seconds,

as the safety valve coil heats to open. Once the air

has been purged from the gas supply line, the

burner should light within four (4) seconds.

• Observe the bake burner flame through the slots

in the bottom front panel. Look for considerable

“yellow tipping,” noting that some small amount

of yellow tipping is normal in the flame

characteristics of burners running with propane

(LP) gas, flame lifting, or lazy flames.

3. If the bake burner burners perform satisfactorily,

reinstall the kick panel (see page 12).

Page. 17

Table des

Définitions de

MATIÈRES

Sécurité...................................................................................19

Consignes de sécurité importantes ................................ 19

Directives pour conversion à haute altitude........................... 21

Avant de commencer...................................................... 21

Conversion au gaz naturel pour fonctionnement

entre 5 400 pi (1 645 m) et 10 200 pi (3 110 m). ............21

PAALTKITHW liste de vérification ............................ 21

PAALTKITGW liste de vérification ............................22

Conversion au gaz propane pour fonctionnement

entre 10 000 pi (3 048 m) et 10 200 pi (3 110 m) ...........22

12025444 liste de vérification................................... 22

Procédure d’installation.......................................................... 24

Remplacement des ports de brûleur STAR® ................. 24

Démontage de la table de cuisson.................................24

Remplacement du port du gril........................................ 25

Remplacement du port de cuisson.................................27

SÉCURITÉ

9 AVERTISSEMENT

Ceci indique que le non respect de cet avertissement peut

entraîner des blessures graves, voire la mort.

9 ATTENTION

Ceci indique que le non respect de cet avertissement peut

entraîner des blessures légères ou modérées.

NOTICE : Ceci indique que la non-conformité à cet avis de

sécurité peut entraîner des dégâts à l'appareil ou à la propriété.

Note : Ceci vous avertit que d'importantes informations et/ou

conseils sont fournis.

Inspection des fuites de gaz ........................................... 29

Vérification du rendement de la flamme et du brûleur .. 31

Réglage des vis de la soupape des brûleurs STAR......... 32

Soutien, pièces et accessoires................................page arrière

Cet appareil électroménager de THERMADORTM

est fait par BSH Home Appliances LtD

6696 Financial Drive, Unit 3

Mississauga, ON L5N 7J6

Des questions?

1-800-735-4328

www.thermador.ca

Nous attendons de vos nouvelles!

Page. 18

Sécurité

9 CONSIGNES DE SÉCURITÉ IMPORTANTES

LIRE ET CONSERVER CES DIRECTIVES

Veuillez lire attentivement

Conservez les pièces originales du modèle à gaz dans

l’éventualité d’une reconversion future.

Important : Seul un technicien ou un installateur qualifié

en réparation peut procéder à cette conversion.

Installateur : Prière de laisser les directives avec cet

appareil à l’intention du propriétaire.

Propriétaire : Prière de conserver les directives pour

pouvoir s’y référer ultérieurement.

AVERTISSEMENT

Si les directives du présent manuel

ne sont pas suivies à la lettre, il y a

un risque d’incendie ou d’explosion

pouvant entraîner des dommages

matériels, des blessures ou la mort.

-- NE PAS conserver ou utiliser de l’essence

ou d’autres liquides et vapeurs

inflammables à proximité de cet appareil

ou de tout autre appareil.

-- QUE FAIRE SI VOUS PERCEVEZ UNE

ODEUR DE GAZ

• NE PAS essayer de mettre un appareil

électroménager sous tension.

• NE PAS toucher d’interrupteur de

courant électrique.

• NE PAS utiliser de téléphone dans

l’édifice.

• Communiquer immédiatement avec le

fournisseur de gaz depuis l’appareil

téléphonique d’un voisin. Respecter

les directives du fournisseur de gaz.

• S’il s’avère impossible de joindre le

fournisseur de gaz, communiquer avec

les pompiers.

-- Utiliser les services d’un installateur ou

d’une agence de réparation qualifiés ou le

fournisseur de gaz pour procéder à

l’installation et aux réparations.

Cette trousse permet de convertir les appareils

Thermador. Cette trousse ne peut pas être utilisée pour

convertir d’anciens modèles de cuisinières. Cette trousse

ne peut pas être utilisée pour convertir toute autre

marque d’appareil.

AVERTISSEMENT

Cette trousse de conversion doit être installée

par une agence de réparation qualifiée en

conformité aux directives du fabricant et de

tous les autres codes et toutes les exigences en

vigueur de l’autorité ayant juridiction.Dans tous

les cas, l'installation de cette trousse de

conversion doit être conforme aux

réglementations locales ou, en l'absence de

telles réglementations, aux versions les plus

récentes du National Fuel Gas Code (Code

national du gaz combustible), ANSI Z223/NFPA

54 ou, au Canada, du Code d'installation du

gaz naturel et du propane, CSA B149, en

vigueur. Si les directives ne sont pas suivies à la

lettre, il y a un risque d’incendie, d’explosion

ou de génération de monoxyde de carbone

pouvant entraîner des dommages matériels, des blessures

ou une perte de vie. L’agence de réparation qualifiée est

responsable de la bonne installation de cette trousse.

L’installation n’est pas jugée terminée et adéquate jusqu’à

ce que l’on ait testé l’appareil converti comme précisé

dans les directives du fabricant fournies avec la trousse.

AVERTISSEMENT

Ne Jamais Faire Fonctionner La Surface De La Table De

Cuisson De Cet Appareil Sans Surveillance.

• Le non-respect de cet avertissement pourrait

entraîner un risque d'incendie, d'explosion ou de

brûlure qui pourrait provoquer des dommages

matériels, des blessures ou un décès.

• En cas d'incendie, se tenir à l'écart de l'appareil et

appeler immédiatement les pompiers. NE PAS

ESSAYER D'ÉTEINDRE UN INCENDIE DE GRAISSE

OU D'HUILE AVEC DE L'EAU.

Page. 19

9 CONSIGNES DE SÉCURITÉ IMPORTANTES

LIRE ET CONSERVER CES DIRECTIVES

Pour les installations au Massachusetts

1. L’installation doit être exécutée par un entrepreneur,

un plombier ou un ajusteur d’appareils à gaz qualifié

ou autorisé par l’État, la province ou la région.

2. Le robinet d’arrêt doit être un robinet à gaz avec une

poignée en T.

3. Le connecteur à gaz souple ne doit pas dépasser

36 pouces (914 mm).

Veuillez respecter les exigences ci-dessous lors de la

mise à l’essai de la canalisation du système

d’alimentation en gaz :

• L’appareil et son propre robinet d’arrêt doivent être

déconnectés de la canalisation du système

d’alimentation en gaz aux pressions de test qui

dépassent 1/2 psig (3,5 kPa).

• L’appareil électroménager doit être isolé de la

canalisation du système d’alimentation en gaz en

fermant son propre robinet d’arrêt manuel pour tout

test de pression de la canalisation du système

d’alimentation en gaz à des pressions égales ou

inférieures à 1/2 psig (3,5 kPa).

À l’intention de l’agent de réparation

AVANT d’amorcer la conversion de l’appareil, il est

important de connaître les éléments suivants.

• Confirmer que le système d’alimentation en gaz est

disponible et prêt à utiliser. Ceci est particulièrement

important dans le cas d’une nouvelle construction.

• Vérifier le type de gaz fourni à cet endroit. S’assurer

que l’appareil est bien raccordé au type de gaz pour

lequel il est certifié.

• Vous devez prévoir assez de temps et de ressources

pour bien exécuter le processus de conversion et le

terminer avant de quitter le chantier. Toutes les étapes

décrites dans ces directives doivent être exécutées

pour obtenir une conversion sécuritaire de l’appareil

pour un bon fonctionnement à haute altitude. UNE

CONVERSION INACHEVÉE OU INADÉQUATE DE

L’APPAREIL PEUT CRÉER UN DANGER POUR LA

SÉCURITÉ.

Cuisinières au gaz et bi-énergie converties au gaz

propane et à haute altitude

Avertissement issu de la proposition 65 :

Ce produit pourrait contenir un produit chimique reconnu

par l'État de la Californie comme cancérigène ou ayant

des effets nocifs sur la reproduction. Par conséquent,

l’emballage de votre produit pourrait porter l’étiquette

suivante, comme requis par la Californie :

AVERTISSEMENT ISSU DE LA PROPOSITION 65 DE

L’ÉTAT DE LA CALIFORNIE :

: AVERTISSEMENT

Cancér et dommages à la reproduction –

www.P65Warnings.ca.gov.

AVERTISSEMENT

NE JAMAIS laisser la conversion de gaz inachevée. Si

l’appareil est utilisée avec une conversion de gaz

inachevée, il est possible qu’il émette des niveaux élevés

de monoxyde de carbone ou provoquer un incendie ou

une explosion.

Il faut d’abord convertir l’appareil pour utilisation au gaz

propane avant de procéder avec la conversion pour

utilisation à haute altitude. Un technicien de réparation

qualifié est requis pour l’installation de la trousse de

conversion au gaz propane (LP).

Page. 20

Directives pour conversion à haute altitude

Avant de commencer

9 MISE EN GARDE

Avant d’amorcer la conversion, coupez l’alimentation

en gaz de l’appareil avant de le déconnecter de

l’alimentation électrique.

Coupez l'alimentation électrique en déconnectant le

cordon électrique à trois broches de sa prise ou en

débranchant l'alimentation du boîtier du disjoncteur.

Outils requis

• Tournevis Torx T-20

• Clé polygonale de 7/16 po

• Clé polygonale de 13/16 po

• Douille de 7 mm ou de 9/32 po

• Tournevis à douille de 1/4 po

• Tête hexagonale de 16 mm ou de 5/8 po ou 16 mm

clé Allen

• Tournevis Torx T-30

• Clé polygonale de 1/2 po

• Clé à fourche 9/32''

• Douille de 7/8 po ou clé à fourche 7/8 po

• Clé réglable

• Mélange d’eau savonneuse ou solution de détection

de fuites

Conversion d’appareils au gaz

naturel pour fonctionnement

entre 5 400 pi (1 645 m) et 10

200 pi (3 110 m)

Pour le bon fonctionnement de l’appareil électroménager,

il faut bien achever chacune des étapes suivantes. Cocher

les étapes au fur et à mesure qu’elles sont achevées.

Liste de vérification PAALTKITHW Pro

Harmony

Trousse pour fonctionnement à haute altitude four de

cuisinières PRO HARMONY de 36'' et 48'' au gaz, entre

5 400 pi et 10 200 pi

Pièces incluses Qté

Tournevis, 1/8 x 0,20 po 1

Port, 2,06 mm (206), Harmony de 36/48 po,

four principal, cuisson

Remplacer uniquement le brûleur de cuisson de four qui

suivent. Tous les autres brûleurs de cuisson demeurent

inchangés.

Liste de vérification PRO HARMONY de 36'' et 48''

1

Ù Étape 1

Ù Étape 2

Ù Étape 3

Ù Étape 4

Ù Étape 5

Ù Étape 6

Ù Étape 7

Démonter la porte du four (page 27).

Retirer les panneaux décoratif et de façade

(page 28).

Remplacer le port du brûleur de cuisson du

four principal par celui de 2,06 mm (206)

(page 28).

Remettez en place la ou les portes du four

(page 27).

Vérifier le four à la recherche de fuites de

gaz (page 30).

Vérification du rendement de la flamme et

du brûleur (page 33).

Remonter la porte et les panneaux décoratif

et de façade (page 28).

Page. 21

Liste de vérification PAALTKITGW Pro

Grand

Trousse pour fonctionnement à haute altitude four de

cuisinières Pro Grand de 48'' au gaz, entre 5 400 pi et

10 200 pi

Conversion d’appareils au gaz

propane (PL) pour

fonctionnement entre

10 000 pi et 10 200 pi

Pièces incluses Qté

Tournevis, 1/8 x 0,20 po 1

Port, 1,85mm (185), Grand de 48 po, four

auxiliaire, cuisson

Remplacer uniquement le brûleur de cuisson de four qui

suivent. Tous les autres brûleurs de cuisson demeurent

inchangés.

Liste de vérification PRO GRAND 48''

Ù Étape 1

Ù Étape 2

Ù Étape 3

Ù Étape 4

Ù Étape 5

Ù Étape 6

Ù Étape 7

Démonter la porte du four (page 27).

Retirer les panneaux décoratif et de façade

(page 28).

Remplacer le port du brûleur de cuisson du

four auxiliaire par celui de 1,85 mm (185)

(page 29).

Remettez en place la ou les portes du four

(page 27).

Vérifier le four à la recherche de fuites de

gaz (page 30).

Vérification du rendement de la flamme et

du brûleur de cuisson du four auxiliaire

(page 33).

Remonter la porte et les panneaux décoratif

et de façade (page 28).

1

Pour le bon fonctionnement de l’appareil électroménager,

il faut bien achever chacune des étapes suivantes. Cocher

les étapes au fur et à mesure qu’elles sont achevées.

Liste de vérification 12025444 Pro

Harmony de 36'' et Pro Grand de 48'' au

gaz propane (PL)

Trousse pour fonctionnement à haute altitude four de

cuisinières PRO HARMONY de 36'' au gaz propane,

entre 10 000 pi et 10 200 pi

®

Remplacer uniquement le brûleur STAR

four qui suivent. Tous les autres brûleurs demeurent

inchangés.

Pièces incluses Qté

Tournevis, 1/8 x 0,20 po 1

Port, 1,26 mm (126), brûleur STAR 3

Liste de vérification PRO HARMONY de 36''

Ù Étape 1

Ù Étape 2

Ù Étape 3

Ù Étape 4

Démonter la table de cuisson (page 24).

Remplacer uniquement les ports du brûleur

avant avec des ports de 1,26 mm (126)

(page 24).

Vérifier la table de cuisson à la recherche de

fuites de gaz (page 30).

Remonter la table de cuisson et vérification

du rendement de la flamme et du brûleur

(page 31).

et les ports de

Page. 22

Ù Étape 5

Régler les vis de soupape uniquement pour

les brûleurs STAR avant (page 32).

Trousse pour fonctionnement à haute altitude de

cuisinières PRO HARMONY de 48''

10 000 pi et 10 200 pi

gaz propane, entre

Trousse pour fonctionnement à haute altitude de

cuisinières PRO GRAND de 36'' gaz propane, entre

10 000 pi et 10 200 pi

Pièces incluses Qté

Tournevis, 1/8 x 0,20 po 1

Port, 1,20 mm (120), gril du four principal 1

Port, 1,26 mm (126), brûleur STAR 3

Liste de vérification PRO HARMONY de 48''

Ù Étape 1

Ù Étape 2

Ù Étape 3

Ù Étape 4

Ù Étape 5

Ù Étape 6

Démonter la table de cuisson (page 24).

Remplacer uniquement les ports du brûleur

avant avec des ports de 1,26 mm (126)

(page 24).

Retirer le dosseret (page 26).

Remplacer le port du brûleur de cuisson du

four principal par celui de 1,20 mm (120)

(page 26).

Vérifier la table de cuisson et le four à la

recherche de fuites de gaz (page 29).

Remonter la table de cuisson et vérification

du rendement de la flamme et du brûleur

(page 31).

Pièces incluses Qté

Tournevis, 1/8 x 0,20 po 1

Port, 1,20 mm (120), gril du four principal 1

Liste de vérification PRO GRAND de 36''

Ù Étape 1

Ù Étape 2

Ù Étape 3

Ù Étape 4

Ù Étape 5

Retirer le dosseret (page 26).

Remplacer le port du brûleur de cuisson par

celui de 1,20 mm (120) (page 26).

Vérifier le four à la recherche de fuites de gaz

(page 30).

Vérifiez le rendement du brûleur de gril

(page 33).

Remonter le dosseret (page 26).

Ù Étape 7

Ù Étape 8

Ù Étape 9

Régler les vis de soupape uniquement pour

les brûleurs STAR avant (page 32).

Vérifiez le rendement du brûleur de gril

(page 33).

Remonter le dosseret (page 26).

Page. 23

Procédure d’installation

d

b

a

e

f

g

h

c

i

j

1

2

a

b

Remplacement des ports de

brûleur STAR® uniquement

nécessaire pour la conversion

d’appareils au gaz propane

pour fonctionnement entre

10 000 pi et 10 200 pi

(12025444 trousse)

Démontage de la table de cuisson

9 MISE EN GARDE

Avant d’amorcer la conversion, coupez l’alimentation

en gaz de l’appareil avant de le déconnecter de

l’alimentation électrique.

Coupez l'alimentation électrique en déconnectant le

cordon électrique à trois broches de sa prise ou en

débranchant l'alimentation du boîtier du disjoncteur.

1. Retirer les grilles et les chapeaux de brûleur de la

table de cuisson.

2. Pour faciliter le retrait du plateau de déversement,

retirer les vis torx T-20 de la façade de la garniture de

l’îlot ou du dosseret.

3. Utiliser l’embout à tête hexagonale de 16 mm ou clé

Allen pour les brûleurs.

Démontage de la table de cuisson

a. Grille

b. Chapeau du

brûleur

c. Venturi du

brûleur

d. Base du brûleur

e. Électrode

f. Piédestal du

brûleur

g. Plateaux de

déversement

h. Tôle

réfléchissante

i. Boîtier de

l’allumeur

j. Fil de l’allumeur

a. Tête hexagonale ou clé Allen b. Venturi du brûleur

CONSEIL : Si un embout à tête hexagonale de 16 mm

n’est pas facilement accessible, sélectionnez un embout

de 5/8 po. Autrement, il est possible d’utiliser un boulon

avec un embout de 5/8 po mis en double ou inséré sur le

mandrin d’une perceuse électrique.

4. Déconnecter l’allumeur. Dégager délicatement la base

du brûleur.

5. Retirez la vis de fixation de la base du brûleur à l'aide

d'un tournevis torx T-30. Retirer délicatement l’étrier

de chaque brûleur.

6. Retirer les plateaux de déversement en les faisant

pivoter vers le haut et en les sortant par l’arrière.

7. Sur certains modèles, retirer la tôle réfléchissante.

Certains modèles disposent de tôles de largeur

double qui s’insèrent sous le plateau de déversement

adjacent.

Page. 24

Remplacement des brûleurs STAR®

1

2

Pour préparer la douille de 7 mm, de 9/32 po ou le

tournevis à douille de ¼ po pour la conversion de l'orifice

du brûleur STAR

Pour votre commodité, notez la taille et

l'emplacement des ports dans le tableau suivant.

Emplacement Port

Avant gauche

1. Couper un petit morceau du ruban de mousse (fourni)

de cette trousse (environ 1/4 – 1/2'' (6 – 12 mm)).

2. Déposer le morceau de ruban de mousse sur le bord

de la douille de 7 mm ou de 9/32 po, ou le tournevis à

douille de 1/4 po utilisé pour remplacer les ports de

brûleur comme illustré ci-dessous.

• Le ruban de mousse vous aidera à maintenir le

port sur l’extrémité du tournevis à douille pour qui

ne tombe pas dans l’appareil au cours du retrait

ou de l’insertion d’un port.

Pour remplacer les ports des brûleurs STAR avant

1. Avec le morceau de ruban de mousse enroulé autour

du tournevis à douille, aller vers le bas par les porteinjecteurs et retirer le port de gaz des porte-injecteurs

des brûleurs STAR.

Avant centre

Avant droite

Tous les brûleurs arrière demeurent inchangés

3. Localiser les bons ports de

brûleurs STAR compris dans la

trousse. Les ports sont

estampillés avec le diamètre de

l’orifice sur le côté.

4. Remplacer uniquement les ports de four qui suivent.

Tous les autres brûleurs STAR demeurent inchangés.

Pro Harmony de 36'' et de 48'' au PL Port

®

Tous les brûleurs STAR

Tous les brûleurs STAR arrière demeurent inchangés

REMARQUE : Tous les ports de remplacement de la

trousse de conversion ont un filetage cylindrique (et non

un filetage conique) et ne requièrent pas de produit

d'étanchéité.

avant seulement

1,26 mm (126)

Remplacement du port du gril,

2. Étiquetez chacun des ports enlevés, en notant de quel

brûleur ils ont été retirés, dans l'éventualité où

l'appareil serait ultérieurement converti.

uniquement pour la conversion

d’appareils au gaz propane

pour fonctionnement entre

10 000 pi et 10 200 pi

(12025444 trousse)

9 MISE EN GARDE

Après le remplacement du port du gril, et avant de

réassembler le panneau arrière et le dosseret de la

cuisinière, effectuer un bref essai d’étanchéité sur le

port et les raccords connexes, conformément à la

section « Inspection des fuites de gaz » des présentes

directives.

Page. 25

Retrait du module du dosseret

Remplacement du port du brûleur du gril

1. Sortir la cuisinière de l'endroit où elle est installée

pour librement accéder au panneau arrière du module

du dosseret et aux ports de gril.

2. Utiliser un tournevis Torx T-20 pour dévisser les vis de

la façade du module du dosseret.

3. Utiliser un tournevis Torx T-20 pour dévisser les vis du

panneau arrière du module du dosseret.

REMARQUE : Cette procédure s'applique à la fois au

brûleur de gril du four principal et, le cas échéant, au

brûleur de gril du four auxiliaire.

1. Retirer le port du gril avec la clé polygonale de 7/

16 po tout en empêchant le raccord en coude de

tourner en le tenant avec une petite clé réglable.

IMPORTANT : NE PAS plier l’équerre du port du

brûleur du gril. S’assurer que le port du gril est aligné

au centre de la conduite d’admission du brûleur.

4. Soulever délicatement le module du dosseret pour le

retirer de la cuisinière.

2. Remplacez les ports comme indiqué dans le tableau.

Pro Harmony de 48'' et de 36''

Pro Grand, au PL

Gril du four principal 1,20 mm (120)

Gril du four auxiliaire demeurent inchangés

REMARQUE : Les ports de rechange du gril comportent

un filetage droit (et non conique) et NE requièrent PAS de

produit d’étanchéité.

3. Effectuer un essai d’étanchéité sur le port et les

raccords d’alimentation de conduites connexes,

conformément à la section “Inspection des fuites de

gaz”.

Port

Page. 26

Remplacement du port de

cuisson pour la conversion

d’appareils au gaz naturel pour

fonctionnement entre 5 400 pi

et 10 200 pi (PAALTKITHW et

PAALTKITGW)

Remplacer uniquement les ports de brûleur de cuisson de

four qui suivent. Tous les autres ports demeurent

inchangés.

Retrait de la porte du four

9 MISE EN GARDE

• FAIRE PREUVE DE PRUDENCE AU RETRAIT DE

LA PORTE. ELLE EST TRÈS LOURDE.

• Avant de démonter la porte, s’assurer que le four

soit froid et que le courant qui l’alimente a été

coupé. Le non-respect de cette précaution

pourrait entraîner un choc électrique ou des

brûlures.

• La porte du four est lourde et fragile. L’enlever à

deux mains ou remplacer la porte.

• Si la porte du four n’est pas saisie fermement et

correctement, il y a un risque de blessure et de

dommage à l’appareil.

• Sans la porte, ne jamais relâcher les leviers ni

essayer de fermer les charnières. Sans la poids de

la porte, les puissants ressorts fermeront les

charnières avec une poussée importante.

2. Fermer délicatement la porte jusqu’à ce qu’elle soit

appuyée sur les crochets. Les crochets de la charnière

maintiendront la porte ouverte à un angle de près de

30 degrés par rapport à sa position fermée.

3. Saisir fermement la porte par les extrémités. Soulever

la porte et la sortir. Il y aura une certaine résistance

provenant des ressorts.

4. Placer la porte dans un endroit sécuritaire et stable.

Réinsertion de la porte du four

1. Maintenir fermement la porte des deux mains.

2. Tenir la porte à près de 30 degrés par rapport à la

position fermée. Insérer les charnières au centre dans

les fentes à cet effet. Lorsque bien installées, les

charnières s’accrochent solidement dans les fentes.

NE PAS exercer de force sur la porte, ni la plier ou la

tordre.

1. Ouvrir la porte au maximum. Abaisser les crochets de

la charnière des deux côtés de la porte. Par la suite, il

est possible que vous ayez besoin d’un tournevis pour

dégager délicatement les crochets.

3. Ouvrir la porte au maximum pour exposer les

charnières, les leviers et les fentes.

Page. 27

4. Faire basculer la charnière vers l’avant jusqu’à ce

a e f

cb

d

qu’elle soit bien appuyée sur l’équerre de fixation. Il

est possible que vous ayez besoin d’un tournevis pour

ramener délicatement le crochet.

5. Fermer et ouvrir la porte lentement pour s’assurer

qu’elle est correctement et solidement installée.

Retrait des panneaux décoratif et de

Changement du port de cuisson du four

principal

IMPORTANT :

• Ne pliez pas le raccord du brûleur de cuisson.

• Ne pliez pas la conduite d'admission du brûleur

de cuisson.

• Ne modifiez pas l'ouverture de l'obturateur.

L'obturateur d'air doit demeurer complètement

ouvert.

• Ne retirez pas la patte anti-rotation lors du

changement de port. Elle est essentielle à

l'alignement du raccord du brûleur de cuisson au

port du brûleur. Après le remplacement du

brûleur, cette patte permet de réaligner plus

aisément le raccord du brûleur.

façade

1. Dévisser les vis du panneau décoratif avec un

tournevis Torx T-20.

2. Dévisser les vis du panneau de façade avec un

tournevis Torx T-20.

a. Patte anti-rotation b. Conduite d'admission

de cuisson

c. Raccord coudé d. Obturateur

e. Support de fixation du

raccord de brûleur de

cuisson

1. Retirez la conduite d'admission de cuisson à l'aide

d'une clé polygonale de 13/16 po.

2. Dévissez les deux vis du support de fixation du

raccord du brûleur de cuisson avec le tournevis torx T-

20.

f. Raccord du brûleur de

cuisson

3. Insérez une clé

polygonale de 1/2

po dans

l'ouverture de

l'obturateur pour

retenir le port de

cuisson tout en

tournant

manuellement le

raccord coudé du

port dans le sens

antihoraire.

Page. 28

4. Remplacez le port comme l'indique le tableau.

a

c

b

d

Pro Harmony de 36'' et de 48'' No de port

Uniquement brûleur de cuisson du four

principal

5. Vérifiez que le port de cuisson est aligné au centre de

la conduite d'admission du brûleur. Réinstallez la

conduite d'admission du brûleur de cuisson sous le

four. Le cas échéant, utilisez une lampe de poche pour

repérer plus facilement la fente de positionnement de

la conduite d'admission du brûleur à l'arrière de la

cavité du brûleur.

6. Réinsérez le raccord coudé dans la patte anti-rotation.

Revissez les deux vis du support de fixation du brûleur

de cuisson et serrez la conduite d'admission.

7. Si la cuisinière à gaz est un four simple, vérifiez

l'étanchéité du port et de ses raccords en suivant les

directives de la section “Inspection des fuites de gaz”.

Si la cuisinière à gaz est équipée d'un four auxiliaire,

suivez les instructions suivantes.

2,06 mm (206)

1. Dévissez les deux vis du support de fixation du

raccord du brûleur de cuisson avec le tournevis torx T-

20. Tirez doucement le support et la conduite

d'admission vers vous.

REMARQUE : Il n'est pas nécessaire de desserrer la

conduite d'admission de cuisson du four auxiliaire.

2. À l'aide d'une clé à molette, retenez le raccord coudé.

Avec la clé polygonale de 1/2 po, dévissez le port du

brûleur de cuisson du four auxiliaire.

3. Remplacez le port comme l'indique le tableau.

Pro Grand de 48'' No de port

Uniquement brûleur de cuisson du four

auxiliaire

REMARQUE : Les ports de cuisson de remplacement ont

des filetages cylindriques (et non des filetages coniques)

et NE nécessitent PAS de produit d'étanchéité.

4. Avant de replacer le support de fixation du brûleur

auxiliaire, vérifiez l'étanchéité du port et les raccords

d'alimentation qui lui correspondent, selon les

directives de la section “Inspection des fuites de gaz”.

1,85 mm (185)

Changement du port de cuisson du four

auxiliaire

a. Support de fixation du

brûleur de cuisson du

four auxiliaire

c. Raccord coudé d. Raccord du brûleur de

IMPORTANT :

• Ne pliez pas le raccord du brûleur de cuisson.

• Ne pliez pas la conduite d'admission du brûleur

de cuisson.

• Ne modifiez pas l'ouverture de l'obturateur.

L'obturateur d'air doit demeurer complètement

ouvert.

b. Conduite d'admission

du brûleur de cuisson

du four auxiliaire

cuisson

Inspection des fuites de gaz

9 AVERTISSEMENT

NE PAS utiliser une flamme quelconque pour vérifier

l’étanchéité.

9 MISE EN GARDE

NE PAS vaporiser de solution d’eau sur les dispositifs

électriques exposés. Si la solution coule sur des

composants électriques, couper l’alimentation avant

d’essuyer les pièces.

9 MISE EN GARDE

Vérifiez que les bornes du fil d'allumage du brûleur

STAR ne touchent pas le métal du châssis, ou toute

pièce métallique, pour éviter les étincelles. Ne

touchez pas les fils de l'allumeur lorsque le brûleur est

allumé pour éviter de subir un choc électrique.

Un test d'étanchéité doit être effectué après le

remplacement des ports et avant le réassemblage

complet de l'appareil. Cependant, les portes de l'appareil

doivent également être installées et fermées afin de

vérifier l'étanchéité des brûleurs de gril et de cuisson.

L'essai d'étanchéité de l'appareil doit être effectué

conformément aux instructions suivantes.

Page. 29

Inspection des fuites de gaz sur les

brûleurs de cuisinière STAR

Pour les fuites, vérifiez les brûleurs de la cuisinière STAR

1. Vérifiez que les ports sont bien serrés et que toutes

les vannes et commandes sont en position OFF.

2. Branchez l'alimentation électrique et de gaz.

3. Vaporisez une quantité généreuse d'eau savonneuse,

ou d'une autre solution conçue pour vérifier s'il y a des

fuites de gaz sur la jonction filetée à la base du port, le

raccord coudé et l'écrou de compression du tuyau de

gaz. (Un mélange d'un volume de liquide à vaisselle

pour trois volumes d'eau est efficace.) Évitez de

pulvériser les composants électriques.

4. Allumez le bouton du brûleur STAR correspondant sur

HI tout en bloquant fermement le port du brûleur

STAR avec une gomme à effacer souple, votre doigt

ou tout objet similaire.

®

2. Tournez le bouton de commande de mode de cuisson

et celui de la température du four sur BROIL (GRIL)

tout en bloquant le port du gril avec une gomme à

effacer souple, votre doigt ou un objet similaire.

• Comptez un délai d'environ 45 à 90 secondes

pendant que la bobine de la soupape de sécurité

chauffe pour libérer le poussoir. Un déclic se fait

généralement entendre lorsque la soupape de

sûreté du gril s'ouvre.

3. Surveillez la base de la jonction du port, du raccord

coudé et de l'écrou de compression pour voir si des

bulles se forment autour de ces joints.

• La formation de bulles indique des fuites de gaz.

4. Si l'appareil fuit, réparez immédiatement toutes les

fuites de gaz. Ne serrez pas trop les joints, les ports ou

les écrous, et ne pliez pas les tuyaux de gaz.

5. Le cas échéant, répétéz l'opération pour le port de

gril du four auxiliaire.

Vérification d'étanchéité du ou des ports

de brûleurs de cuisson

5. Surveillez la base de la jonction du port, du raccord

coudé et de l'écrou de compression pour voir si des

bulles se forment autour de ces joints.

• La formation de bulles indique des fuites de gaz.

6. Si l'appareil fuit, réparez immédiatement toutes les

fuites de gaz. Ne serrez pas trop les joints, les ports ou

les écrous, et ne pliez pas les tuyaux de gaz.

7. Répétez l'opération pour tous les brûleurs STAR.

Vérification d'étanchéité du ou des ports

de brûleurs de gril

Pour vérifier l'étanchéité du ou des ports de brûleurs

de gril

1. Vaporisez une quantité généreuse d'eau savonneuse,

ou d'une autre solution conçue pour vérifier s'il y a des

fuites de gaz sur la jonction filetée à la base du port, le

raccord coudé et l'écrou de compression du tuyau de

gaz. (Un mélange d'un volume de liquide à vaisselle

pour trois volumes d'eau est efficace.) Évitez de

pulvériser les composants électriques.

Pour vérifier l'étanchéité du ou des ports de brûleurs

de cuisson

1. Vaporisez une quantité généreuse d'eau savonneuse,

ou d'une autre solution conçue pour vérifier s'il y a des

fuites de gaz sur la jonction filetée à la base du port, le

raccord coudé et l'écrou de compression du tuyau de

gaz. (Un mélange d'un volume de liquide à vaisselle

pour trois volumes d'eau est efficace.) Évitez de

pulvériser les composants électriques.

2. Tournez le bouton de commande du mode de cuisson

sur BAKE (CUISSON) et le bouton de commande de

température du four sur n'importe quel réglage tout

en bloquant du doigt le port de cuisson.

• Comptez un délai d'environ 45 à 90 secondes

pendant que la bobine de la soupape de sécurité

chauffe pour libérer le poussoir. Un déclic se fait

généralement entendre lorsque la soupape de

sûreté du gril s'ouvre.

3. Surveillez la base de la jonction du port, du raccord

coudé et de l'écrou de compression pour voir si des

bulles se forment autour de ces joints.

• La formation de bulles indique des fuites de gaz.

4. Si l'appareil fuit, réparez immédiatement toutes les

fuites de gaz. Ne serrez pas trop les joints, les ports ou

les écrous, et ne pliez pas les tuyaux de gaz.

5. Le cas échéant, répétéz l'opération pour le port de

cuisson du four auxiliaire.

6. Si la vérification d'étanchéité n'a révélé aucune fuite,

coupez l'alimentation en gaz et en électricité.

Réinstallez le support de fixation du brûleur de

cuisson du four auxiliaire, s'il y a lieu, et passez à la

section “Vérification du rendement de la flamme et du

brûleur”.

Page. 30

Vérification du rendement de

d

b

a

e

f

g

h

c

i

j

aaa

bb

cc

dd

Mise à l’essai de l’allumage des brûleurs STAR

la flamme et du brûleur

Vérification du rendement du brûleur

STAR

9 AVERTISSEMENT

Pour observer les flammes de brûleurs, il sera

probablement nécessaire d’éteindre les lampes ou de

fermer les stores de la fenêtre pour obscurcir la pièce pour

mieux voir la flamme.

Remonter l’appareil dans la séquence qui suit

®

Lors de la cuisson avec les brûleurs STAR, la taille de la

flamme du brûleur doit être réglée de manière à ce

qu'elle ne dépasse pas le bord de l'ustensile de

cuisson. Cette directive se fonde sur des critères de

sécurité.

:

a. Grille

b. Chapeau du

brûleur

c. Venturi

d. Base de brûleur

1. Enfoncer le bouton de commande du brûleur et le

tourner à « HI ».

• Le module de l’électrode et de la bougie de

l’allumeur produira un déclic. Une fois l’air purgée

des conduites d’alimentation, le brûleur devrait

s’allumer dans les quatre (4) secondes.

• Les flammes devraient être stables sans bruit

excessif. Les cônes intérieurs des flammes doivent

être bien définis et être distinctement séparés l’un

de l’autre. La flamme, tout autour du brûleur, ne

doit pas comporter des parties excessivement

élevées ou de flammes « paresseuses ».

a. Bleu foncé

b. Cône secondaire

c. Bleu clair

d. Cône primaire

e. Électrode

f. Chapeaux de

brûleur

g. Plateaux de

déversement

REMARQUE : Il est normal que des pointes légèrement

jaunes apparaissent à l’extrémité des flammes après

quelques minutes de fonctionnement au gaz propane (LP).

Les traits orangés dans la flamme sont produits par la

combustion de débris flottant dans l’air. Ce phénomène

h. Tôle

réfléchissante

i. Boîtier de

est normal durant les moments suivant l’allumage et

devrait se dissiper après quelques minutes de

fonctionnement.

l’allumeur

j. Fil de l’allumeur

Flammes jaunes :

Réglage supplémentaire

requis.

CONSEIL : Utilisez le Venturi du brûleur comme guide de

Extrémités des cônes externes

jaunes :

centrage lorsque vous réinstallez les bases de brûleurs. Si

les bases sont centrées, le Venturi s'insèrera et se retirera

facilement une fois la vis torx T-30 vissée. Si les bases ne

sont pas centrées correctement, desserrez la vis de

montage et recentrez le brûleur jusqu'à ce que le Venturi

s'insère naturellement.

Normales pour un gaz de

pétrole liquéfié

Flammes bleues douces :

Normales pour le gaz naturel

Page. 31

2. Ajuster la soupape de commande du brûleur à LO

Star

®

Star

®

pour vérifier si la flamme continue de brûler tout

autour du brûleur. Éteindre la flamme en soufflant

dessus ou en l’éventant à l’aide d’un bloc-notes ou

d’un morceau de carton, puis observer la capacité du

brûleur à se rallumer et à propager la flamme sur tout

le brûleur en quelques secondes (propagation de la

flamme). La propagation de la flamme est essentielle

pour l’allumage et le rallumage adéquats du brûleur.

3. Tester la capacité de rallumage des brûleurs à XLO

et observer la propagation des petites flammes de

mijotage pendant que le système XLO allume et

éteint les brûleurs.

• Si le rendement de la flamme n’est pas

convenable, il peut s’avérer nécessaire d’ajuster

de nouveau la vis de la soupape pour un brûleur

supérieur qui ne propage pas assez la flamme.

Tourner très légèrement la vis de la soupape dans

le sens antihoraire jusqu’à ce que la propagation

de la flamme soit acceptable. (Consulter “Réglage

des vis de la soupape des brûleurs STAR®” on

page 32.)

• Si la flamme d’un brûleur est inégale, scintille,

produit des bruits excessifs ou s’élève, certaines

des fentes de la base du brûleur sont

possiblement obstruées par des débordements

d’aliments ou par d’autres débris. Les fentes

bloquées peuvent être nettoyées à l’aide d’un

trombone, d’une épingle ou d’un objet

semblable. Les aliments ou les débris incrustés et

difficiles à enlever peuvent parfois être retirés en

utilisant une laine d’acier ou une brosse de soies

métalliques fines.

• Une flamme « paresseuse », avec de très longues