thermador Island hood Installation Manual

®

INSTALLATION INSTRUCTIONS

for

ISLAND HOOD

FOR RESIDENTIAL USE ONLY

IMPORTANT: Save these instructions for the Local Electrical Inspectors use.

INSTALLER: Please leave these Instructions with this unit for the owner.

OWNER: Please retain these instructions for future reference.

SAFETY WARNING:

Turn off power circuit at the service entrance

and lock out panel, before wiring this unit.

PLEASE READ ENTIRE INSTRUCTIONS BEFORE PROCEEDING.

INSTALLATION MUST COMPLY WITH ALL LOCAL CODES.

IMPORTANT SAFETY INSTRUCTIONS

WARNING

To reduce the risk of FIRE,

ELECTRIC SHOCK OR INJURY to persons, observe

the following:

A. Use this unit only in the manner

intended by the manufacturer. If

you have questions, contact the

manufacturer.

B. Before installing, servicing or clean-

ing the unit, switch power off at

service panel and lock service panel

to prevent power from being

switched on accidentally.

C Installation work and electrical wir-

ing must be done by qualified

person(s) in accordance with all

applicable codes & standards, including fire-rated construction.

D. Sufficient air is needed for proper

combustion and exhausting of gases

through the flue (chimney) of fuel

burning equipment to prevent

backdrafting. Follow the heating

equipment manufacturers guideline and safety standards such as

those published by the National

Fire Protection Association (NFPA),

and the American Society for Heat-

ing, Refrigeration and Air Conditioning Engineers (ASHRAE), and

the local code authorities.

E. Due to size and weight of this unit,

two installers are recommended.

F. When cutting or drilling into wall

or ceiling, do not damage electrical

wiring and other hidden utilities.

G. Ducted fans must always be vented

to the outdoors and upward. D o

not vent to the attic or crawl space.

H. To reduce the risk of fire, use only

metal duct work.

I. Install this hood in accordance

with all requirements specified

by the manufacturer of your

cooktop/range.

J. Flex duct is not recommended.

To reduce the risk of a

RANGE TOP GREASE

FIRE.

a) Never leave surface units unat-

tended at high settings. Boilovers cause smoking and greasy

spillovers that may ignite. Heat

oils slowly on low or medium

settings.

WARNING

b) Always turn the hood ON

when cooking at high heat or

when flambéing foods.

c) Clean ventilating fans fre-

quently. Grease should not

be allowed to accumulate on

fan or filter.

d) Use proper pan size. Always

use cookware appropriate for

the size of the surface element.

CAUTION

:

FOR VENTILATION USE

ONLY. Do not use to exhaust hazardous or explosive materials or vapor.

CAUTION:

Vent unit to the outside.

PAGE 2

WARNING

To reduce the risk of injury to persons in the

event of a range top grease fire, observe the

following:

A. SMOTHER FLAMES with a close-fitting

lid, cookie sheet, or metal tray, then turn

off the burner. BE CAREFUL TO PREVENT BURNS. If the flames do not go out

immediately, EVACUATE AND CALL THE

FIRE DEPARTMENT.

B. NEVER PICK UP A FLAMING PAN You

may be burned.

Parts included with your Island Hood:

C. DO NOT USE WATER, including wet

dishtowels or towels a violent explosion

will result.

D. Use an extinguisher ONLY if:

1) You know you have a Class ABC extinguisher, and you already know how to

operate it.

2) The fire is small and contained in the

area where it started.

3) The fire department is being called.

4) You can fight the fire with your back to

an exit.

To be purchased separately:

Hood Canopy Assembly

Rough-in Plate

Transition

Diameter 10",

Length 22-1/2"

Width 10"

Height 9-1/2"

Installation Instructions

Care & Use Manual

Registration Card

Filters:

6 pcs. for 48" hood,

8 pcs. for 60" hood

Grease Troughs (4 pieces)

Wire Nuts

Halogen Bulbs - 4 bulbs (20 Watts ea.)

Adjustable chimney mounting structures may be purchased separately in the following sizes:

Pro Island Chimney Assembly 9 to 15" PHICHIM15

Pro Island Chimney Assembly 15 to 27" PHICHIM27

Pro Island Chimney Assembly 27 to 51" PHICHIM51

Remote Ventilator Models:

choose one of these units

VTR1000Q - 1000 CFM,

3 speed, remote

ventilator

VTR1400Q - 1400 CFM,

3 speed, remote

ventilator

Duct Tape 2" wide

Lug Screws - 1/4" Diameter x 5" Long (qty.8)

Lug Bolts - 1/4" Dia. x 1-1/2" (qty. 8) & taps (qty.8)

Angle Brackets - 2" x 2" x 1-1/2" (qty. 4)

2" Dry Wall Screws (qty.24)

Bolts - 1/2" Diameter x 5" (qty. 16)

PAGE 3

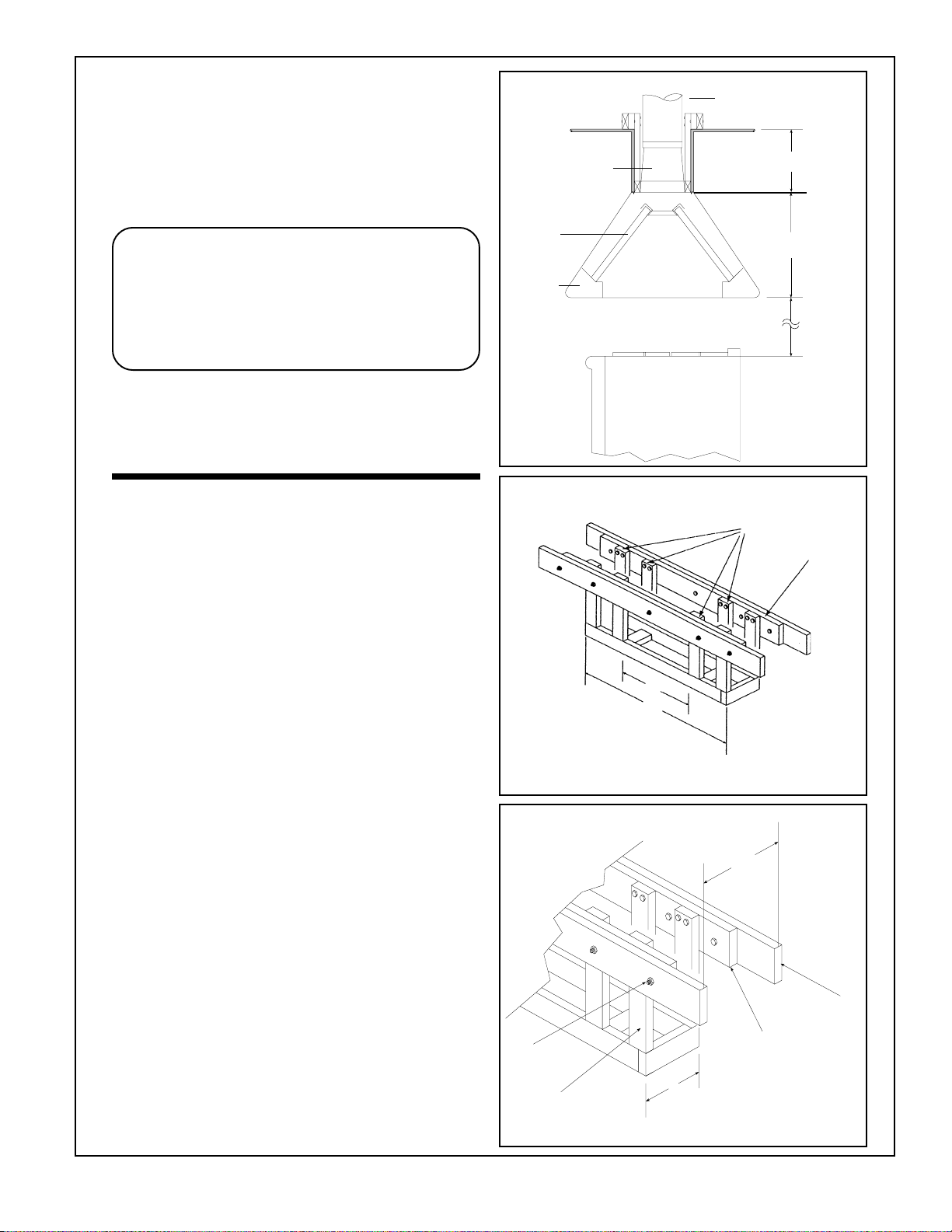

TYPICAL INSTALLATION

The Professional Island hood is designed to be installed on a rigid structural framing. Follow these

installation steps for proper hood performance. Typical installation of the Island Hood is shown in Figure 1.

10" Transition

To Be Connected to

Remote Ventilator

12" min.

NOTE: BECAUSE OF THE SIZE AND

WEIGHT OF THE ISLAND HOOD, IT IS

NECESSARY TO MAKE A 12" WIDE BY

HOOD LENGTH SOFFIT WITH RIGID

STRUCTURAL FRAMING IN AN 8-FOOT

HIGH KITCHEN CEILING.

Adjustable chimney structures are available.

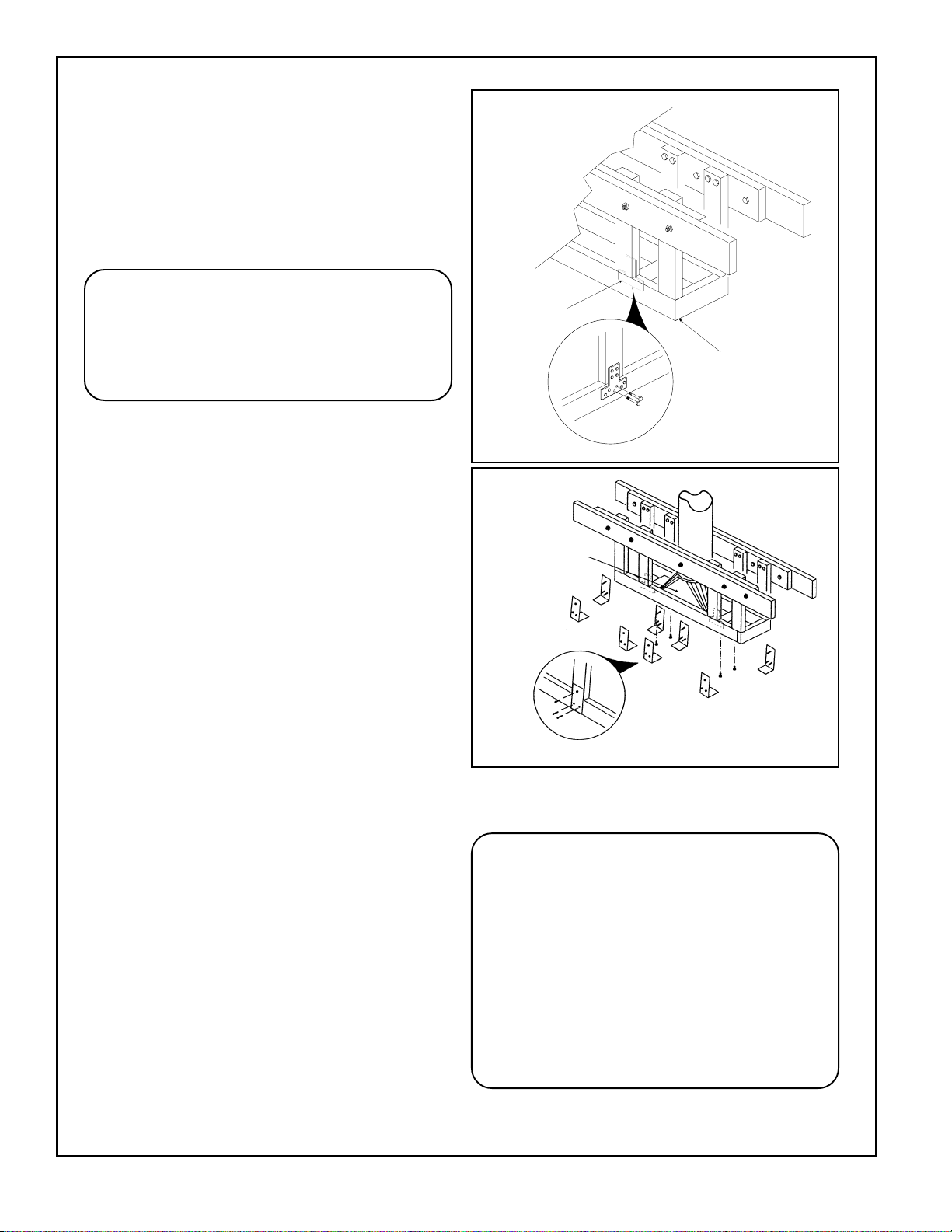

STEP 1 SOFFIT FRAMING

a) Locate and mark the center line of the hood location.

b) Use 2 pieces of 2" x 6" x 6 feet wood spacers and

bolt these pieces onto the ceiling joist as shown in

Fig. 2.

Filters

Lights

Fig. 1

15"

30" to

36"

Vertical Studs

Spacer

If the ceiling joists are spaced more than 16" apart

center to center, it is necessary to install additional

spacers so that when installing the vertical studs,

they will be 11" apart. See Fig. 3.

c) Using 1/4" diameter x 5" long lug screws, attach 2"

x 6" vertical studs onto the spacers so that their

inner edges are 23" apart. See Fig. 2

The length of these studs depends on the ceiling

height and the desired height of the hood from the

top of the cooktop. The bottom of the hood is

recommended to be within 30" to 36" over the range

cooking surface.

48" Hood - 46 3/4"

60" Hood - 58 3/4"

Fig. 2

Bolts

Vertical

Studs

Fig. 3

23"

11"

16"

2" x 6"

Spacers

Existing

Ceiling

Joists

PAGE 4

d) Construct the bottom wood framing with 2" x 4"s as

shown in Fig. 4. The center of the frame must have

an opening of 10" x 23" for the transition duct.

e) The overall length of the structural framing will

depend on the size of the island hood. Attach 2"

x 4" wood frame onto the ends of 2" x 6" so that

their outer edges are 47" apart for 48" hood, or 59"

apart for a 60" hood. See Figure 2.

NOTE: Because of the weight of the

hood, we are recommending that you

use metal joint straps to connect the

ends of wood framing per example of

Figure 4.

See Detail "A"

2" x 4" Frame

f) Using 2" x 6" wood, construct the bottom framing

for duct opening at the center bottom of the soffit. The

duct opening must be 8" x 23" as shown in Fig. 7.

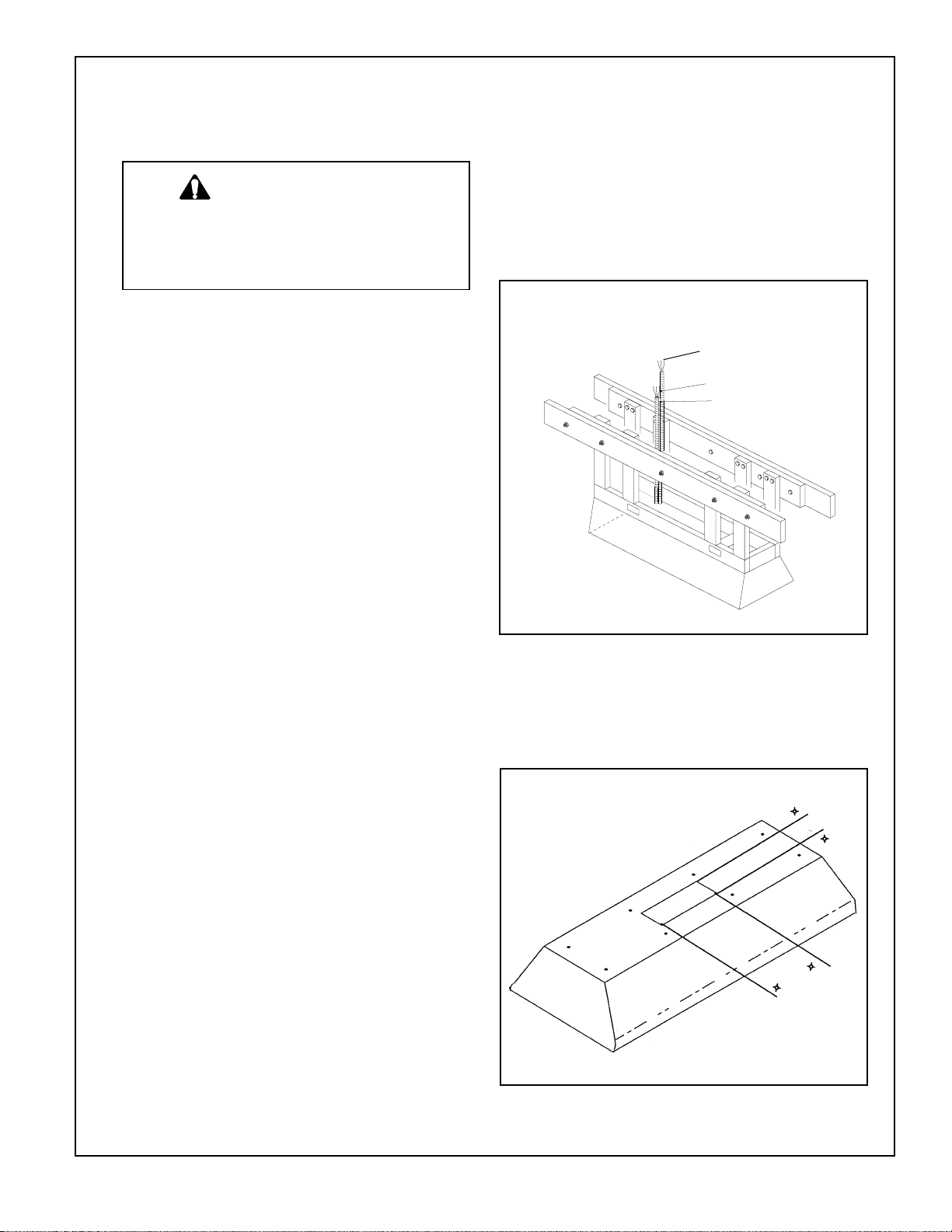

STEP 2

INSTALL HOOD ASSEMBLY

a) Install the transition (provided) to the top of the

hood using #8 x 1/2" Philips head screws. Tape all

joints, with duct tape.

b) Locate and mark the centerlines of the hood soffit

framing and hood assembly. Align both center

lines and secure the hood assembly with 8 pieces

- 1/4" diameter x 1-1/2" long lug bolts with taps

and 2" x 2" x 1 1/2" angle brackets.

STEP 3

DUCTING INSTALLATION

a) Run 10" round duct work from the remote ventilator

Model #VTR1000Q or Model #VTR1400Q (purchase separately) to the transition (provided with

the hood). See Figure 1.

b) Seal all joints with duct tape. Use straight duct if

possible or, if necessary, the fewest elbows for

best performance.

Detail "A"

Fig. 4

Transition

Provided

Fig. 5

NOTE: COLD WEATHER installations

should have an additional backdraft damper

installed to minimize backward cold air flow.

A nonmetallic thermal break can be installed

to minimize conduction of outside temperature as part of the ductwork. The damper

should be on the cold air side of the thermal

break. The break should be as close as

possible to where the ducting enters the

heated portion of the house.

PAGE 5

STEP 4 ELECTRICAL CONNECTION:

STEP 5 INSTALL GREASE TROUGHS

AND FILTERS

SAFETY WARNING:

Turn off power circuit at the service

entrance and lock out panel before

wiring this unit.

I WIRING TO THE REMOTE VENTILA-

TOR:

a) Run five wires #12 AWG MIN. (black white, blue, red,

and green) in 1/2" conduit from the remote ventilator

to the J-Box located in the hood assembly. See Fig,

6.

b) Strip approximately 3/8" at the end of the above

wires. Use spring type wire nuts supplied to connect

blue, red, black, white and green wires to corresponding color wires located inside the J-box. (Note:

Follow the wiring diagram supplied with ventilator.)

(Lost or missing wire nuts should only be replaced

with: Spring type wire nuts, rated for a minimum of

(2) # 18ga wires and maximum of (4) #14ga wires,

UL & CSA rated to 600V and 302 deg. F./150 deg. C).

See Care and Use Manual for instructions.

To Remote Ventilator

Power Supply Wires

Conduit

Fig. 6

II WIRING TO THE POWER SUPPLY:

a) Power supply required for this model is 120V., 19

Amps., 60 Hz. Using flex conduit , run three (3) #12

AWG. maximum (black, white, and green) from the

service panel to the J-Box located in the hood. See

Fig. 6.

b)

Strip approximately 3/8" at the end of these three

wires. Use the provided wire nuts to connect the

black, white, and green wires to the corresponding

color wires located inside the J-box. (Note: follow

the wiring diagram.)

c) When using the power supply in a damp location or

outdoors, always install it in a GFCI protected branch

circuit.

8"

23"

Fig.7

PAGE 6

STEP 6 -

OFF

S

D

SHUT OFF

T

3

TURN THE POWER ON AND

CHECK HOOD OPERATION

®

STEP 7 INSTALL DRYWALL ON THE

SOFFIT

ADJUSTABLE CHIMNEY MOUNTING

STRUCTURES MAY BE PURCHASED

SEPARATELY IN THE FOLLOWING

SIZES:

Pro Island Chimney Assembly 9 to 15" PHICHIM15

Pro Island Chimney Assembly 15 to 27" PHICHIM27

Pro Island Chimney Assembly 27 to 51" PHICHIM51

Fig. 8

PEE

Y

TER

LIGH

Chimney

Fig. 9

PAGE 7

We reserve the right to change specifications or design without notice. These models are certified for use in the

United States and Canada. Thermador is not responsible for products that are transported from the United States for

use in other countries. Check with your local distributor or dealer.

For the most up to date critical dimensions by fax, use your fax handset and call 775-833-3600. Use code

# 8030.

®

5551 McFadden Avenue, Huntington Beach, CA 92649 800/735-4328

5060009137 Rev. A BSH Home Appliances Corp. Litho U. S. A. 01/03

PAGE 8

Loading...

Loading...