Thermaco W-350-IS-230-SS User Manual

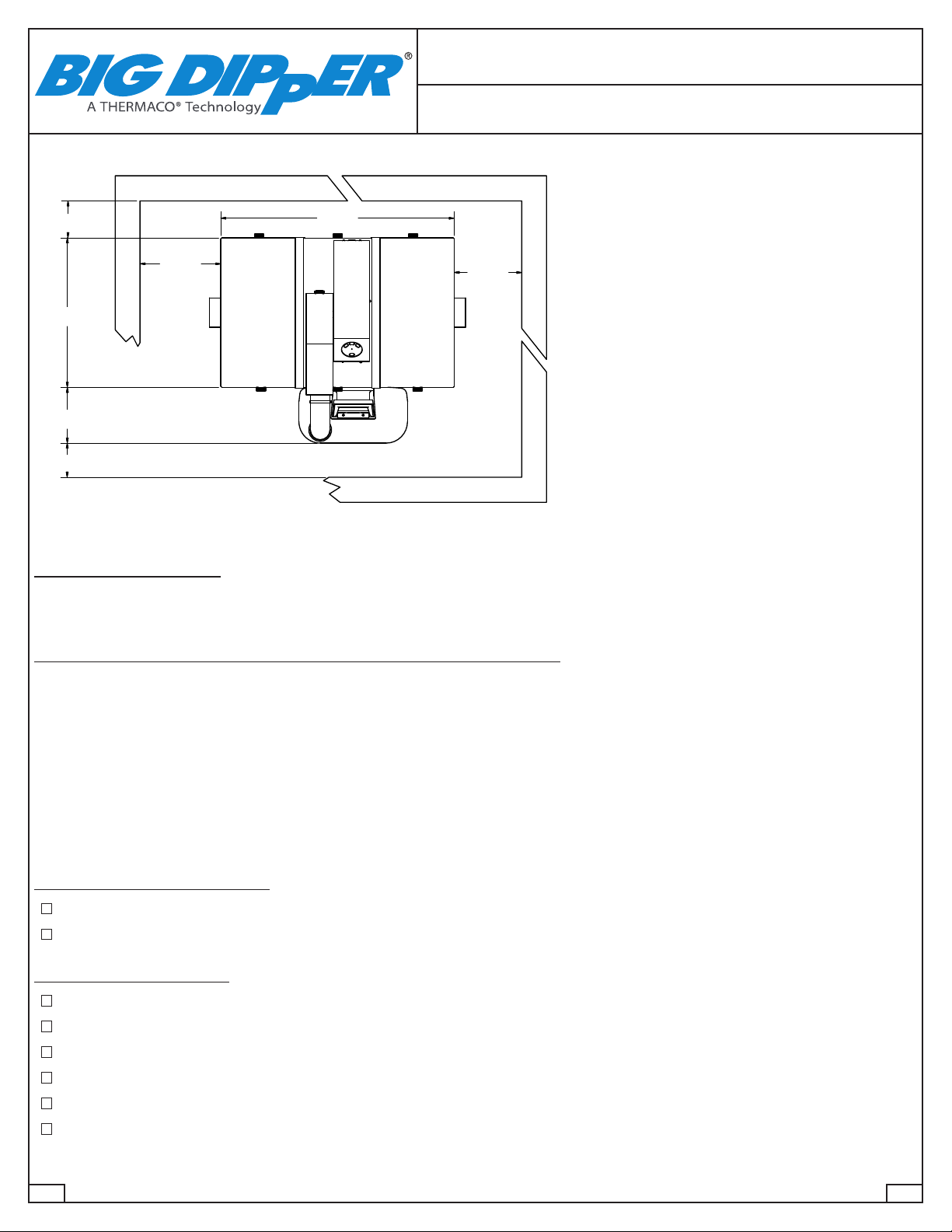

Big Dipper® IS Point Source Automatic

1

2

27.75

704.9 mm

3.50

88.9 mm

22.03

559.4 mm

12.50

317.5 mm

31.00

787.4 mm

17.85

453.4 mm

24.52

622.7 mm

INLET

31.75" (806 mm) CLEARANCE

FROM BOTTOM OF TANK

REQUIRED FOR STRAINER

BASKET & LID REMOVAL

GC-50000

GREASE COLLECTOR

7 QUART (6.6 L)

CAPACITY

OUTLET

INLET

OUTLET

1

2

3

4

27.75

704.9 mm

3.50

88.9 mm

22.03

559.4 mm

12.50

317.5 mm

31.00

787.4 mm

17.85

453.4 mm

24.52

622.7 mm

INLET

31.75" (806 mm) CLEARANCE

FROM BOTTOM OF TANK

REQUIRED FOR STRAINER

BASKET & LID REMOVAL

GC-50000

GREASE COLLECTOR

7 QUART (6.6 L)

CAPACITY

OUTLET

INLET

OUTLET

1

2

Grease Removal Systems

W-350-IS-SS Specications

PRODUCT FEATURES

Fully automatic self cleaning cycle. Removes

collected grease & oils from tank without any

operator assistance. Comes complete with Digital

Control and Grease Collector.

Constructed of corrosion resistant materials suitable

for installation in virtually any location. Attractive

sanitary Stainless Steel exterior.

Integrated Motor/Grease Outlet/Heater/Lid enables

a fast, do-it-yourself unit operation reversal.

Compact footprint.

Two (2) No-Hub Connectors provided.

Vessel Vent Connection with 1” NPT Connection for

easy installation.

VESSEL VENT WITH

1" NPT CONNECTION

15.59

396.0 mm

.38

36.7 mm

2.00

50.8 mm

1.75

44.5 mm

3" (75mm) PIPE

INLET/OUTLET

17.35

440.7 mm

END VIEW

SPECIFICATIONS

Construction: Exterior: 304 Stainless Steel, Bright Finish

Interior: Rotationally Molded Polyethylene

Electrical: 115 VAC, 50/60 Hz, 520 Watts (4.5 Amps)*

Flow Rating: 35 GPM (2.21 l/s)

No. of Skimming Wheels: 1

Skimning Rate: 20 Pounds (9.08 Kg) Per Hour

Grease Capacity: 85.2 Pounds (38.6 Kg)

Solids Strainer Capacity: 1.85 Gallons (7 Liters)

Inlet/Outlet: 3” (75 mm)

*For Additional Electrical Congurations, see Electrical Variations section on page 2.

INLET

31.00

787.4 mm

27.75

704.9 mm

OUTLET

17.85

453.4 mm

24.52

622.7 mm

TOP VIEW

31.75” (806 mm) CLEARANCE

FROM BOTTOM OF TANK

REQUIRED FOR STRAINER

BASKET & LID REMOVAL

©2016 Thermaco, Inc. • All rights reserved • Patented/Patents Pending • Specications subject to change without notice

3/16

Thermaco, Inc. • PO Box 2548 • Asheboro, NC 27204-2548 • (336) 629-4651 • www.big-dipper.com

SIDE VIEW

Conforms to ASME Standard

ASME A112.14.3 and A112.14.4

®

®

1

Big Dipper® IS Point Source Automatic

1

2

3

6.00 in

152.4 mm

6.00 in

152.4 mm

28.25 in

717.6 mm

4.00 in

101.6 mm

6.67 in

169.3 mm

17.85 in

453.4 mm

4.00 in

101.6 mm

INLET

OUTLET

GC-50000

GREASE COLLECTOR

Grease Removal Systems

W-350-IS-SS Specications

INSTALLATION NOTES

1. READ instruction manual included with system before

installing/operating.

2. Install unit allowing for the minimum clearances

shown. Make sure there is sufcient space above Internal

Strainer access cover to remove the strainer [minimum

of 14” (356mm)]

3. Make piping connections with rubber “No Hub” connectors.

4. Keep outlet piping as straight as possible. Use only

“sweep” connections.

5. Install vent on outlet piping.

6. Fill the tank with water before energizing the power

to the motor and heater.

7. Do not install “P” Trap on outlet connection of tank

(unit already has internal gas trap).

8. Do not reduce pipe size on outlet piping

9. Do not pressure test unit.

Equipment must be installed in compliance with all applicable laws, regulations and codes, including plumbing

codes. Installation should be performed by a qualied

plumbing contractor.

JOB SPECIFICATION

Grease and oils separator(s) shall be Thermaco Big Dipper automatic grease/oil recovery system(s) as manufactured by Thermaco, Inc., Asheboro, North Carolina as noted on plans.

AUTOMATIC GREASE REMOVAL DEVICE SPECIFICATIONS

Furnish and install ___ Thermaco Big Dipper Model No. W-350-IS-SS, bright nish type 304 stainless steel exterior, rotationally

molded polyethylene interior automatic self-cleaning grease and oil recovery separator(s) for oor mounted or partially recessed

installation, rated at 35 gallons per minute (2.21 l/s) peak ow, 85.2 Pounds (38.6 Kg) of grease capacity and including as an integral part of the unit, 1 rotating gear hydrophobic wheel assembly for automatic grease/oil removal, an integral ow control device,

self-regulating enclosed electric immersion heater, a vessel vent, an integral gas trap, a digital control for programmable operation,

a eld reversible motor location, a eld reversible grease/oil sump outlet, quick release stainless steel lid clamps, a gasketted and

fully removable 304 stainless steel lid, a lift-out strainer basket access, an internal stainless steel strainer basket for collection

of coarse solids, and a separate grease and oils collection container. Electric assembly shall be tested to comply with pertinent

sections of the Standards for Safety ANSI/UL 73 and/or ANSI/UL 1004. Electric motor equipped with overload protection. Two (2)

no-hub connectors for plumbing connection provided.

ELECTRICAL VARIATIONS

W-350-IS-SS: 115V 50/60Hz, 520 Watts (4.5 Amps)

W-350-IS-230-SS: 230V 50/60Hz, 520 Watts (2.3 Amps)

SUBMITTAL OPTIONS

FS-1 Point Source Flat Strainer

ESU-1 External Strainer (1.16 Gallons of additional solids storage capacity)

AP-6000-1-TK Alarm Probe for excessive grease accumulation

AP-6000-1-TKDC Alarm Probe with dry contact for remote warning light notication

HAG-3 Horizontal Air Gap Assembly with 2” connection

HAG-BA-1 Solids Strainer Baskets for use with HAG-2 Assembly (Specify Quantity based on Number of Sinks: ___)

3/16

©2016 Thermaco, Inc. • All rights reserved • Patented/Patents Pending • Specications subject to change without notice

Thermaco, Inc. • PO Box 2548 • Asheboro, NC 27204-2548 • (336) 629-4651 • www.big-dippper.com

2

Loading...

Loading...