Thermaco Trapzilla TZ-1826 Installation & Maintenance Instructions Manual

A THERMACO® Technology

1

2

3

Installation & Maintenance Instructions

For Trapzilla® TZ-1826

For additional information on Trapzilla or other Thermaco products,

please visit www.trapzilla.com or call at 1-800-633-4204.

AEF

®

Conforms to ASME Standard

ASME A112.14.3-2000

Please consult Thermaco, Inc. for specic models tested,

certied and/or listed by these organizations.

®

*Please consult Thermaco, Inc. for specic models tested,

certied and/or listed by these organizations.

Copyright ©2018 Trapzilla® Thermaco, Inc. • P.O.Box 2548 • Asheboro, NC 27204

Toll Free: (800) 633-4204 • Phone: (336) 629-4651 • Fax: (336) 626-5739

info@thermaco.com • www.trapzilla.com

Part# MNL-TZ-1826

Trapzilla® Grease Interceptor

Installation and Operations Manual

A THERMACO® Technology

Contents

1. System Overview.................................................................................................................................... 3

2. Models and Options................................................................................................................................ 4

2.1 Models ........................................................................................................................................... 4

2.2 Options .......................................................................................................................................... 5

3. Plumbing Installation .............................................................................................................................. 6

3.1 Plumbing Considerations Prior to Installation ................................................................................ 6

3.1.1 Locating the Unit ................................................................................................................... 6

3.1.2 Inlet/Outlet Piping ................................................................................................................. 6

3.1.3 Flow Controls ........................................................................................................................ 6

3.1.4 Venting the Outlet ................................................................................................................. 6

3.1.5 High Head Height Applications Over Six (6) Feet (1.95 m) .................................................. 6

3.2 Vessel Vent Connection .................................................................................................................. 7

3.3 Plumbing Congurations ................................................................................................................ 8

TZ-1826 Models

1. System Overview

The Thermaco, Inc. Trapzilla® Supercapacity

Grease Interceptor collects free-floating

grease & oils contained in kitchen drain water

ows. As most food service facility managers

already know, grease buildup inside a

building’s grease containment system is a

major cause of problems due to exterior drain

line blockages. These problems jeopardize

normal operations as well as create health

and safety hazards within the facility itself.

The proper installation of a Trapzilla®

Supercapacity Grease Interceptor can

reduce or eliminate grease problems and

costly sewer surcharges and nes through

efcient separation and retention of freeoating grease & oils.

3.3.1 One TZ-1826 ......................................................................................................................... 8

3.3.2 Installing Multiple Trapzilla Units in Parallel ........................................................................... 9

3.3.3 Installing Multiple Trapzilla Units in Series ............................................................................. 10

4. Above-Ground Installation ...................................................................................................................... 11

4.1 Components for Above-Ground Installations .................................................................................. 11

4.2 Instructions for Assembling and Attaching External Brace ............................................................. 12

4.3 Instructions for Installing Multiple Trapzilla Units Above-Ground .................................................... 12

4.3.1 Installing TZ-1826-SSA with TSS-95-SSA in Series .............................................................. 12

4.3.2 Construction of Riser for TSS-95-SSA installation in series with TZ-1826-SSA .................... 13

4.3.3 Installing Multiple TZ-1826-SSA in Series ............................................................................. 13

4.3.4 Installation of Pipe Hangers with Above-Ground Units .......................................................... 14

5. In-Ground Installation Instructions .......................................................................................................... 15

5.1 Single TZ-1826 Installed In-Ground ............................................................................................... 15

5.2 TZ-1826 with Optional ECA-TZ-29 Extension Collars .................................................................... 16

5.3 Concrete Specications for In-Ground Installation ......................................................................... 17

5.4 Concrete Calculations for TZ-1826 Models/Components* ............................................................. 17

5.5 Trimming and Setting the ECA-TZ-18 Single-Piece Extension Collar ............................................ 18

The Trapzilla offers patented at separation

curve technology. This means that the unit does not lose grease separation efciency as it lls with

retained grease. Thus, the Trapzilla stores large quantities of grease without losing efciency. The

unique compact design of the Trapzilla allows for installation into most facilities. Options are available

that enable a Trapzilla unit to be installed on the oor, suspended from the ceiling or in-ground outside

the facility.

Trapzilla units are designed to treat high ows of kitchen drainwater with large grease storage capacity

within a small footprint unit. These units are easy to maneuver into position and just as easy to plumb.

Hydromechanical grease interceptors, automatic recovery units, grease removal devices and other

similar plumbing devices receiving kitchen ows from sinks, oor drains, woks and other food bearing

sources may generate odors. There are many factors inuencing odor evolution and dissemination.

These include room ventilation, kitchen menu, ambient temperatures, ware washing practices, grease/oil

input, daily input uid volume, sanitizers, installation plumbing design and product maintenance/upkeep.

Odors are usually prevented by good area ventilation, frequent uid inputs, good product maintenance

practices and proper product installation. Additional steps, including aeration, chlorination, pH control,

improved area ventilation and additional maintenance may be needed at some sites.

*Devices formerly referred to as grease traps are now called hydromechanical grease interceptors.

6. Unit Maintenance.................................................................................................................................... 20

6.1 Measuring Grease/Solids Levels .................................................................................................... 20

6.2 Pumping/Servicing Unit .................................................................................................................. 21

7. Limited Warranty and Remedy ............................................................................................................... 22

MNL-TZ-1826 2

©2018 Thermaco, Inc. All rights reserved • Patented/Patents Pending • Specications subject to change without notice

Thermaco, Inc. • 646 Greensboro St. • Asheboro, N. C. 27204-2548 • (336) 629-4651

AEF

MNL-TZ-1826 3

Trapzilla® Grease Interceptor

1

2

3

1

2

3

1

2

3

1

2

3

4

1

2

3

Installation and Operations Manual

A THERMACO® Technology

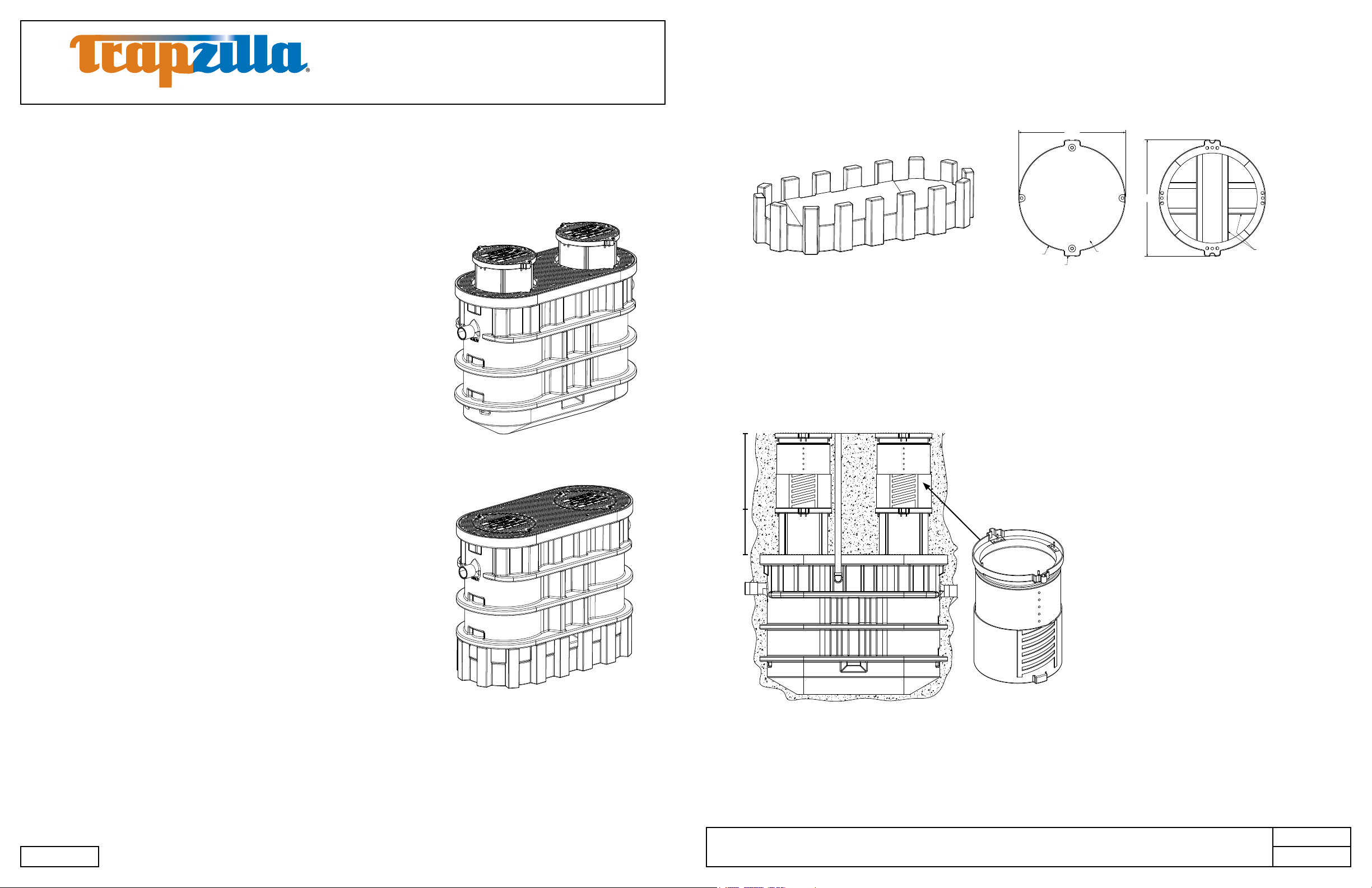

2. Models and Options

Thermaco offers different models and options specically designed to assist the owner/installer meet

site conditions while complying with local pretreatment and plumbing code.

2.1 Models

TZ-1826

1,826 pounds of grease storage, PDI and ASME rated

at 100 gpm. Equipped with 4” inlet/outlet, 2” vessel vent

connection, and 4” Low-Head Flow Control Accessory to

limit ow to 100 gpm.

Comes with: Extension Collar Adapter Lid Assembly with

two 18” tall extension collars and two 22” diameter lids.

TZ-1826 Models

2.2 Options (Some options must be purchased separately)

Top View

21.13 in

[53.7 cm]

R10.56 in

[26.8 cm]

R11.56 in

[29.4 cm]

SSA-1826

Support Stand for TZ-1826 for Above-Ground

Installations. Must be fully supported, not to

be installed over grates.

*Included with TZ-1826-SSA Models

Optional 22” diameter cover available for

In-Ground installations. Provides a non-slip,

diamond patterned aluminum replacement for

the standard STC-22 cover. Each TZ-1826

would require two (2) FTCA-22 covers.

DIAMOND PLATE SURFACE

FTCA-22

23.10 in

[58.7 cm]

Bottom View

ANGLE STIFFENERS

ECA-TZ-29

(purchase separately)

ECA-TZ-29

TZ-1826-SSA

1,826 pounds of grease storage, PDI and ASME rated

at 100 gpm. Equipped with 4” inlet/outlet, 2” vessel vent

connection, and 4” Low-Head Flow Control Accessory to

limit ow to 100 gpm.

Comes with: Extension Collar Adapter Lid Assembly with

two 18” tall extension collars, two 22” diameter lids,external

brace (not pictured) and SSA-1826 Support Stand.

*Models available with 6” Inlet/Outlet, add sufx -6 to model.

Extension

0-18” Built-In

Optional, eld-modiable extension

collars available to provide

additional depth for existing kitchen

drainage piping.

• TZ-1826-ECA Models ship with

two (2) built-in 0-18” extension

collars.

• ECA-TZ-29 adds 0-29” depth

to -ECA model.

• Contact Thermaco before

installing any Trapzilla more

than 60” below grade from

center of outlet pipe or in

location where water table will

ever rise above bottom of unit.

MNL-TZ-1826 4

©2018 Thermaco, Inc. All rights reserved • Patented/Patents Pending • Specications subject to change without notice

Thermaco, Inc. • 646 Greensboro St. • Asheboro, N. C. 27204-2548 • (336) 629-4651

AEF

MNL-TZ-1826 5

Trapzilla® Grease Interceptor

1

2

3

Installation and Operations Manual

A THERMACO® Technology

3. Plumbing Installation

3.1 Plumbing Considerations Prior to Installation

3.1.1 Locating the Unit

The system should be visible and easily accessible for maintenance and inspection. Options are available

to install the Trapzilla in a basement, suspended from a ceiling or in-ground in an exterior location. Make

sure adequate room is provided around the unit to allow easy access for a pump truck operator. Make

sure the height above the Trapzilla access cover is enough to properly service the system.

3.1.2 Inlet/Outlet Piping

The inlet and outlet piping connections require exible sleeve pipe couplings. Keep outlet piping as

straight as possible. Thermaco, Inc. recommends installation of Two-Way Cleanouts on both the Inlet and

Outlet of Trapzilla Interceptors and Solids Separators in accordance with all applicable laws, regulations

and codes. These cleanouts should match the size of the Inlet and Outlet Piping (i.e. for 4” Inlet/

Outlet piping, a 4” cleanout should be used). Use only “sweep” connections. Do not reduce the pipe

sizing on the outlet piping. Do not install “P” trap on outlet connection of system. (Note: The system

already has a internal gas trap)

TZ-1826 Models

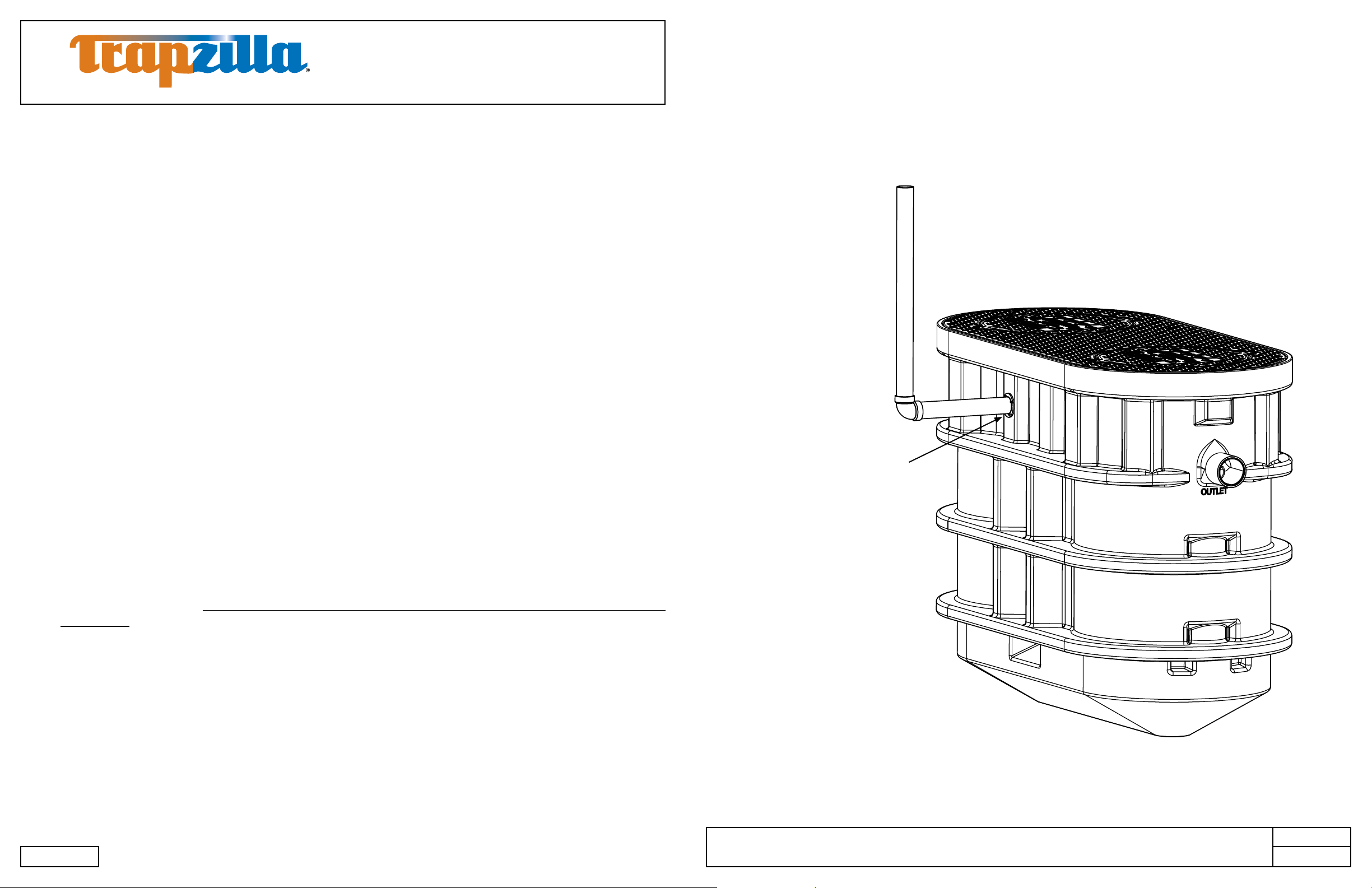

3.2 Vessel Vent Connection

Venting of the Trapzilla tank is recommended by the manufacturer and required for in-door installations.

• Vent the tank through the provided 2” NPT threaded connector on the side of the tank (This vent may

be located above the outlet or on the side of the tank depending on model).

• Remove and discard the plug and connect appropriate vent lines as indicated below (for 2” vent

connection, use 2” pipe).

3.1.3 Flow Controls

Trapzilla systems are supplied with a Low-Head Flow Control module (LHFC). This should be connected

to the inlet of the Trapzilla unit in situations where ow rate needs to be restricted to the ASME rated

ow or when vented ow control is required by local code.

3.1.4 Venting the Outlet

An outlet vent or approved air admittance valve of at least 1/2 the diameter of the system’s outlet

connection must be present as close as possible to the Trapzilla outlet to prevent possible siphonage

problems. The Vent on the Outlet piping is to be installed in accordance with all applicable laws,

regulations and codes. Failure to provide a vent for the system voids Thermaco’s Limited Warranty for

the system.

3.1.5 High Head Height Applications Over Six (6) Feet (1.95 m)

For installations where there is head height of greater than 6 feet (1.95 meters), Thermaco, Inc.

recommends installation of a code-approved Vented Flow Control Assembly (Thermaco VFCA not

included with Trapzilla).

Vessel Vent Connection

Can be connected to the outlet vent,

facility vent, or independently vented to

atmosphere

Note: Drawing for reference only. Equipment must be installed in compliance with all applicable laws, regulations

and codes, including plumbing codes. Installation should be performed by a qualied plumber.

MNL-TZ-1826 6

©2018 Thermaco, Inc. All rights reserved • Patented/Patents Pending • Specications subject to change without notice

Thermaco, Inc. • 646 Greensboro St. • Asheboro, N. C. 27204-2548 • (336) 629-4651

AEF

MNL-TZ-1826 7

Loading...

Loading...