- 1 - A Division of:

Theratherm

Swimming Pool/Spa Heat Pump

User and Service manual

- 2 - A Division of:

INDEX

1. Specifications

2. Dimension

3. Installation and connection

4. Accessories

5. Electrical Wiring

6. Display Controller Operation

7. Troubleshooting

8. Exploded Diagram

9. Maintenance

10. Warranty

Thank you for purchasing a Theratherm Heat Pump for your pool or spa heating. Heat Pumps use the

ambient air temperature to heat your pool or spa water efficiently. Heat Pumps perform better with warmer

ambient temperatures & it will heat your water and maintain constant temperature whilst the ambient air

temperature is between -7 to 40℃. The use of a heat pump will extend your swimming season & provide

extra enjoyment for you and your family.

ATTENTION: This manual includes all the necessary information regarding the use and the

installation of your heat pump.

The installer must read the manual and attentively follow the instructions in implementation and

maintenance.

The installer is responsible for the installation of the product and should follow all the instructions of the

manufacturer and the regulations in application. Incorrect installation against the manual implies the

exclusion of the entire guarantee and warranty.

The manufacturer declines any responsibility for the damage caused to people, objects and errors due to

incorrect installation. It is the owners responsibility to ensure that the pool or spa water maintains correct

water chemistry balance as bad water chemistry can damage the heat pump internal components which

will not be covered under this warranty. Any usage outside of what is stated within this manual or its

designed purpose of manufacturing will be regarded as dangerous and is not recommended.

WARNING: Please always shut off the power supply if you need to open the heat pump cabinet to work

inside the heat pump. As this is an electrical product there is high voltage electricity inside. Any electrical

connections and/or repairs should be conducted by a licensed electrician.

WARNING: When using the 10mtr external control panel extension please ensure the display controller is

located in a dry area. Also keep the insulation cover closed to protect the display on the controller from

being damaged by humidity and possible rain.

- 3 - A Division of:

1. Specifications

Horizontal design, R410A, Heating only

Model

Theratherm

9.5

Theratherm

13.5

Theratherm

18.5

Theratherm 25

Heating Capacity at Air 27℃, Water 27℃, Humidity 80%

Heat Output (kW)

9.5

13.5

18.5

25

Power consumption (kW)

1.53

2.14

2.94

4.10

COP

6.2

6.3

6.3

6.1

Heating Capacity at Air 15℃, Water 26℃, Humidity 70%

Heat Output (kW)

6.8

9.5

13.5

17

Power consumption (kW)

1.51

2.11

2.93

3.78

COP

4.5

4.5

4.6

4.5

Refrigerant

R410A

Fuse/RCD size

15

20

35

35

Amps

6.7

9.3

12.8

17.8

Voltage

220-240V / 50Hz / 1 phase

Heat Exchanger

Titanium in PVC

Water flow

2.8~5.6m³/h

4~7.9m³/h

5.6~11.2m³/h

7.1~14m³/h

Water connection

40mm

Water Pressure (kPa)

12

15

16

18

Sound level at 1mtr

49dB(A)

52dB(A)

53dB(A)

56dB(A)

Machine Dimensions (mm)

(LxWxH)

1030*335*560

1065*360*775

1113*410*920

Packing Dimensions (mm)

(LxWxH)

1080*360*610

1160*387*820

1180*440*960

Net Weight (kg)

37

63

90

130

Gross Weight (kg)

42

70

100

133

* Above data are subjects to modification without notice.

- 4 - A Division of:

2. Dimensions

Unit : mm

Model

Theratherm

9.5

Theratherm

13.5

Theratherm

18.5

Theratherm

25

A

302

340

340

380

B

622

750

750

725

C

288

325

325

374

D

332

360

360

410

E

988

1065

1065

1081

F

230

480

480

515

G

103

112

112

112

H

557

774

774

915

I

98

103

103

136

3. Installation and connection

3.1 Notes

Upon purchase you will receive your complete Heat Pump. All other components, including a bypass, must

be provided by the user or the installer. (Bypass Recommended on all Theratherm heat pumps)

Attention:

Please observe the following rules when installing the heat pump:

1. Always install a bypass on all Theratherm heat pumps and use reference page 7.

- 5 - A Division of:

2. Any addition of automated chemicals must take place in the piping located downstream from the

heat pump.

3. Install the heat pump above the water level of the swimming pool.

4. Always place the heat pump on a solid foundation and use the included rubber mounts to avoid

vibration and noise.

5. Always fit plug and drain hose to underneath of base plate of heat pump.

6. Always hold the heat pump upright. If the unit has been held at an angle, wait at least 24 hours

before starting the heat pump.

3.2 Heat pump location

The unit will work properly in any desired location as long as the following three items are present:

1. Fresh air – 2. Electricity – 3. Swimming pool filtration

The unit may be installed in virtually any outdoor location as long as the specified minimum distances to

other objects are maintained (see drawing below). Please consult your installer for installation with an indoor

pool. Installation in a windy location does not present any problem at all, unlike the situation with a gas

heater (including pilot flame problems).

ATTENTION: Never install the unit in a closed room with limited air volume in which the air expelled from

the unit will be reused, or close to shrubbery/plant life that could block the air inlet. Such locations impair

the continuous supply of fresh air, resulting in reduced efficiency and possibly preventing sufficient heat

output. Heat Pumps require fresh air & maximum ventilation to be more productive. See the drawing below

for minimum dimensions.

3.3 Distance from your swimming pool

The heat pump is normally installed within a perimeter area extending 7.5 m from the swimming pool. The

greater the distance from the pool, the greater the heat loss in the pipes. As the pipes are mostly

underground, the heat loss is low for distances up to 30 m (15 m from and to the pump; 30 m in total) unless

the ground is wet or the groundwater level is high. A rough estimate of the heat loss per 30 m is 0.6 kWh

(2,000 BTU) for every 5 ºC difference between the water temperature in the pool and the temperature of the

soil surrounding the pipe. This increases the operating time by 3% to 5%.

- 6 - A Division of:

3.4 Check-valve installation

Note: If automatic dosing equipment for chlorine and acid (pH) is used, it is essential to protect the heat

pump against excessively high chemical concentrations which may corrode the heat exchanger. For this

reason, equipment of this sort must always be fitted in the piping on the downstream side of the heat pump,

and it is recommended to install a check-valve to prevent reverse flow in the absence of water circulation.

Damage to the heat pump caused by failure to observe this instruction is not covered by the warranty.

3.5 Typical arrangement

- 7 - A Division of:

Note: This arrangement is only an illustrative example. 3.6

Adjusting the bypass assembly

Use the following procedure to adjust the

bypass:

• On start-up fully open all two

valves

• slowly close valve 1 into the heat

pump until water pressure is

increased by approximately 100

to 200 g (refer to pressure gauge)

• Slowly Close valve 2

approximately half-way to adjust

the gas pressure in the cooling

system .

• If the display shows "ON" or

error code EE3, close step by

step the valve 2, to increase

water flow and stop when the

code disappear.

Optimal operation of the heat pump occurs when the cooling gas pressure is 22 2 bar.

This pressure can be read on the pressure gauge next to the control panel. Under these conditions the water

flow through the unit is also optimal.

Note: Operation without a bypass or with improper bypass adjustment may result in sub-optimal

heat pump operation and possibly damage to the heat pump, which renders the warranty null and

void.

3.7 Electrical connection

Note: Although the heat pump is electrically isolated from the rest of the swimming pool system,

this only prevents the flow of electrical current to or from the water in the pool. Earthing is still

required for protection against short-circuits inside the unit. Always provide a good earth

connection.

We also recommend that electrical installation is conducted by a licensed electrician.

Before connecting the unit, verify that the supply voltage matches the operating voltage of the heat pump.

It is recommended to connect the heat pump to a circuit with its own fuse or circuit breaker and adequate

wiring.

Connection: Open the terminal box on the side panel.

Connect the electrical wires to the terminal block marked ‘POWER SUPPLY’

- 8 - A Division of:

A second terminal block marked ‘WATER PUMP ’ is located next to the first one. If you are using a secondary

pump to circulate water from the pool to the heat pump this pump can be connected to the second terminal

block here. This allows the filter pump operation to be controlled by the heat pump.

3.8 Initial operation

Note: In order to heat the water in the pool (or spa), the filtration pump must be running to cause the

water to circulate through the heat pump. The heat pump will not start up if the water is not

circulating through it.

After all connections have been made and checked, carry out the following procedure:

1. Switch on the filtration pump. Check for leaks and verify that water is flowing from and to the swimming

pool.

2. Connect power to the heat pump and press the On/Off button on the electronic control panel. The

unit will start up after the time delay expires (see below).

3. After a few minutes, check whether the air blowing out of the unit is cooler.

4. When turning off the filtration pump , the unit should also turn off automatically , if not, then adjust the

flow switch.

5. Allow the heat pump and the filtration pump to run 24 hours a day until the desired water temperature

is reached. The heat pump will stop running at this point. After this, it will restart automatically (as long

as the filter pump is running) whenever the swimming pool water temperature drops 2 degrees below

the set temperature.

Depending on the initial temperature of the water in the swimming pool and the air temperature, it may take

several days to heat the water to the desired temperature. A good swimming pool cover can dramatically

reduce the required length of heating time & is highly recommended as standard.

Water Flow Switch:

The heat pump is fitted with an automatic flow switch to protect the heat pump from inadequate water flow.

If the pool water level is

higher than 1m above or below the heat pump’s automatic adjustment knob, your dealer may need to adjust

its initial startup.

Time delay:

The heat pump has a built-in 3-minute start-up delay to protect the circuitry and avoid excessive contact

wear. The unit will restart automatically after this time delay expires. Even a brief power interruption will

trigger this time delay and prevent the unit from restarting immediately. Additional power interruptions during

this delay period do not affect the 3-minute duration of the delay.

3.9 Condensation

The air drawn into the heat pump is strongly cooled by the operation of the heat pump for heating the pool

water, this may cause condensation on the fins of the evaporator. The amount of condensation may be as

much as several litres per hour at high relative humidity. This is sometimes mistakenly regarded as a water

leak. If there is excessive water coming from your heat pump please see your installer.

- 9 - A Division of:

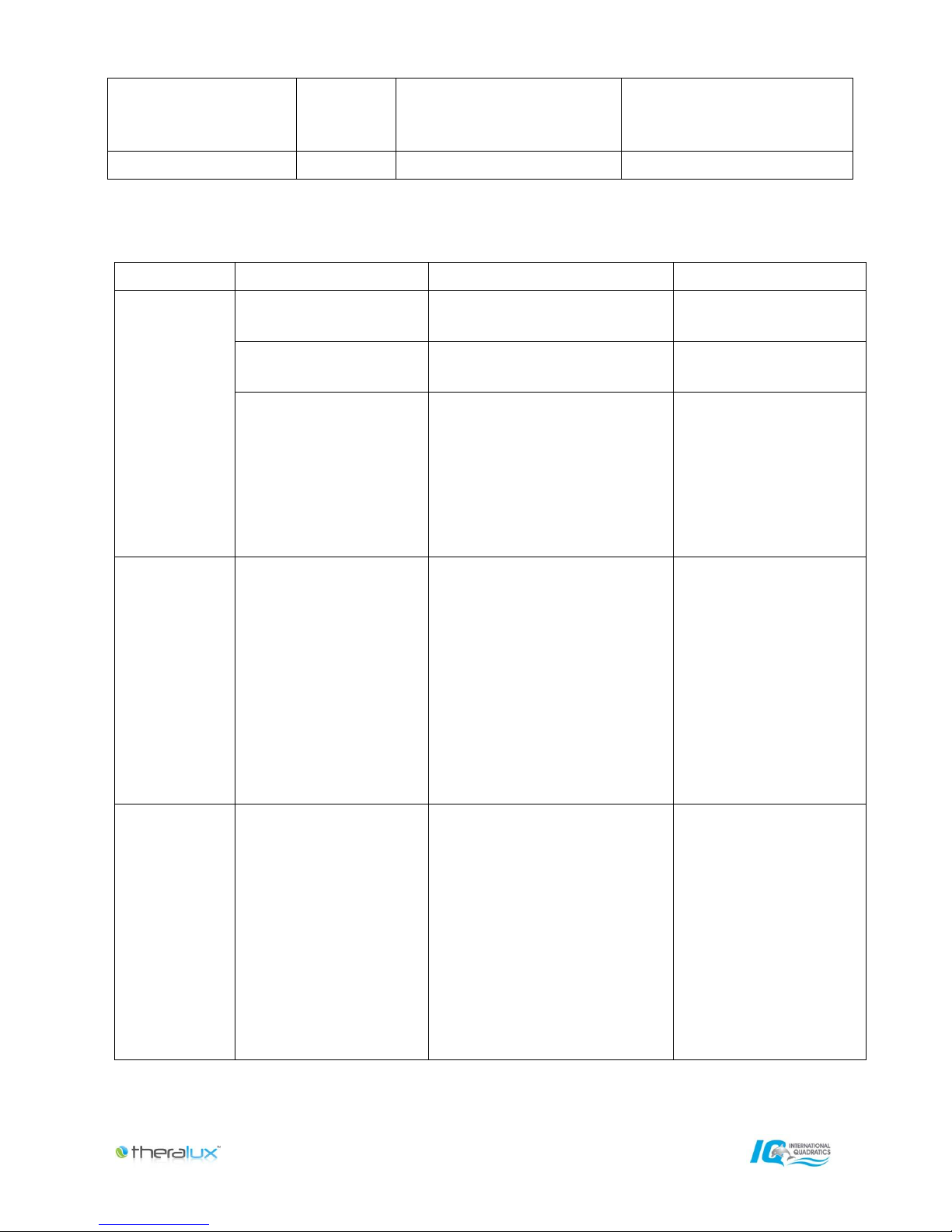

3.10 Pressure gauge display (R410A)

Examine the pressure gauge which indicates the refrigerant gas pressure of the unit, the below table

shows the normal value of the gas pressure (R410A) when the machine is powered off or in running

mode.

Unit Condition

Power Off

Running

Ambient (℃)

-5~5

5~15

15~25

25~35

/

/

/

/

/

Water temp (℃)

/

/

/

/

10~15

15~20

20~25

25~30

30~35

Pressure gauge (Mpa)

0.68~0.93

0.93~1.25

1.25~1.64

1.64~1.82

1.3~1.8

1.5~1.9

1.6~2.3

2.2~2.8

2.3~2.9

4. Accessories

4.1 Accessories list

- 10 - A Division of:

Anti-vibration base, 4 pcs

Draining jet, 2 pcs

Waterproof box, 1 pc

10M Signal wire, 1 pc

Water connection assembly, 2 sets

4.2 Accessories Installation

Anti-vibration bases

1. Take out 4 Anti-vibration

bases

2. Put them one by one on

the bottom of machine feet like

the picture.

Draining jet

1. Install the draining jet

under the bottom panel

2. Connect with a water pipe

to drain the water.

Note: Lift the heat pump to install

the jet. Never overturn the heat

pump as it could damage the

compressor.

- 11 - A Division of:

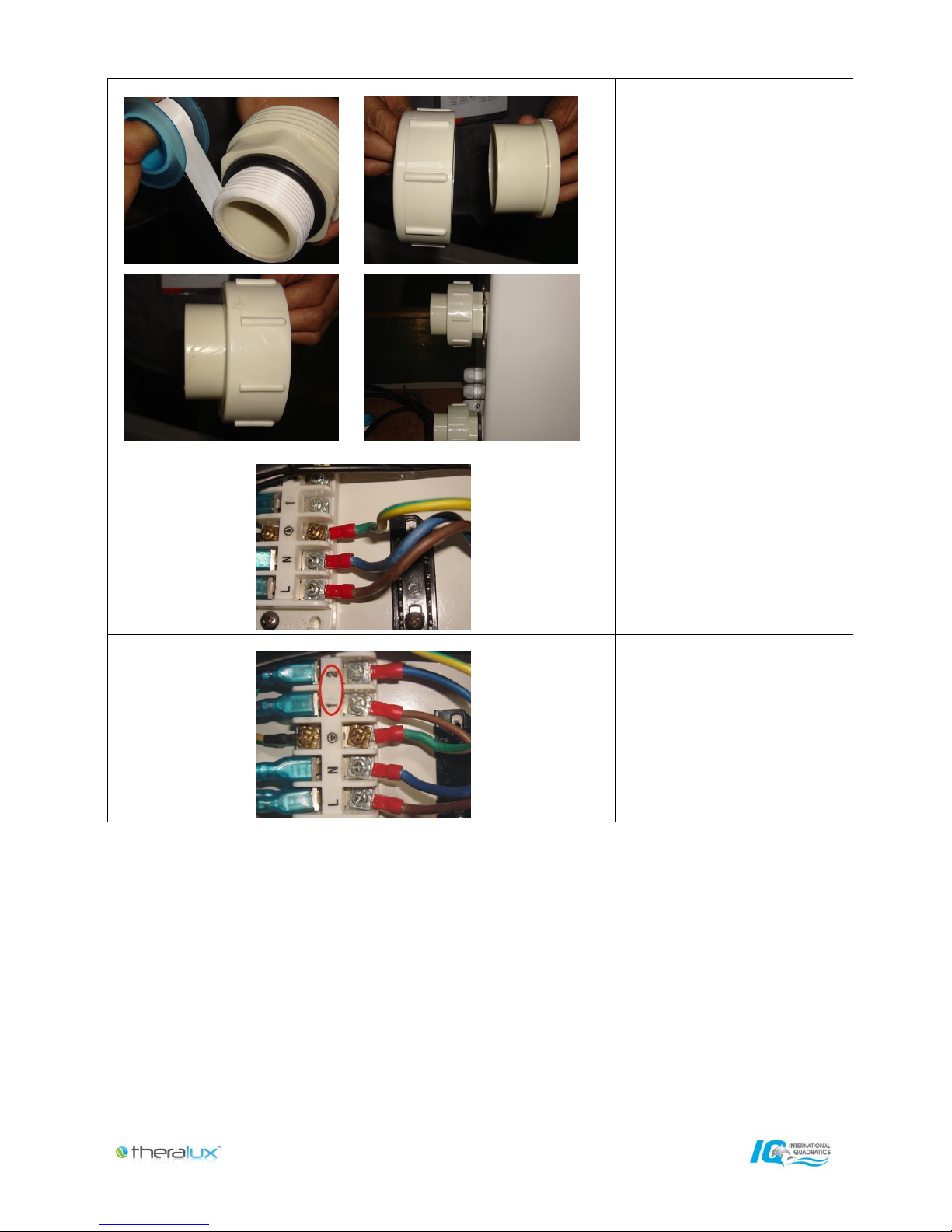

Water Inlet & outlet junction 1.

Use the pipe tape to connect the

water Inlet & outlet junction onto

the heat pump

2. Install the two joints like

the picture shows

3. Screw them onto the

water

Inlet & outlet junction

Extension cable wiring

Please refer to the photo

Secondary pump connection

wiring

Please refer to the photo

- 12 - A Division of:

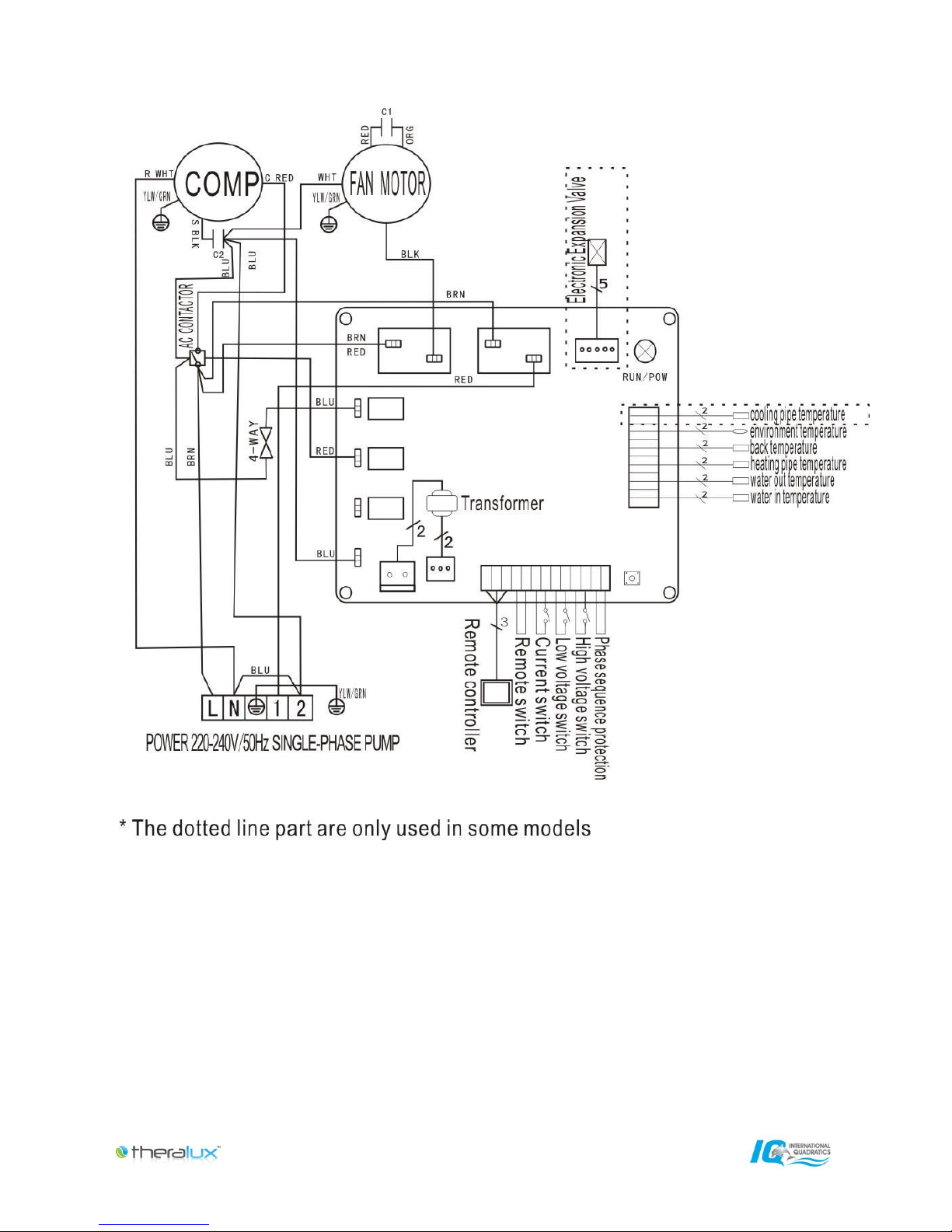

5. Electrical Wiring

5.1 Electrical wiring diagram for Theratherm 9.5

- 13 - A Division of:

5.2 Electrical wiring diagram for Theratherm 13.5

- 14 - A Division of:

5.3 Electrical wiring diagram for Theratherm 18.5 & Theratherm 25

NOTE:

(1)Above electrical wiring diagram is only for your reference, please consult the manufacturer for repair advice.

(2)The swimming pool heat pump must be connected to earth, although the units heat exchanger is

electrically isolated from the rest of the unit .Grounding the unit is still required to protect you against short

circuits inside the unit .Bonding is also required.

Disconnect: A disconnect means (circuit breaker, fused or un-fused switch) should be located within sight

of and readily accessible from the unit .This is common practice on commercial and residential heat pumps.

It prevents remotely-energizing unattended equipment and permits turning off power at the unit while the

unit is being serviced.

- 15 - A Division of:

5.2 Installation of the control panel & external cable extension (to be completed prior to

electrical connection).

Photo (1) Photo (2) Photo (3)

- Control panel can be removed & disconnected from the heat pump (photo1).

- Control panel wiring can be disconnected from the heat pump by the quick release connector (photo 2). -

The control panel can be connected to the 10mtr extension cable for external mounting of the control panel

(photo 3).

6. Display Controller Operation

6.1 The buttons of LED controller

When the heat pump is running, the LED display shows the inlet water temperature. When

the heat pump is standby, the LED display shows the real time.

6.2 Start or stop the heat pump.

- 16 - A Division of:

and

Press to start the heat pump unit, the LED display shows the desired water temperature for 5 seconds, then

shows the inlet water temperature.

Press to stop the heat pump unit.

6.3 Setting the real time

On standby or running mode, hold the button for 10 seconds, then press to adjust

hour/minute.

Then press the button again to store the new data.

When setting the time, cannot work.

6.4 Water temperature setting:

On standby or running mode, press to adjust the desired water temperature

6.5 Automatic start/stop the heat pump

To set the time to start the unit (this option is only if you are running a secondary pump

exclusively for the heat pump).

Press to set the time to start the unit, then press to adjust the time (set the time for start 5

minutes after the water pump).

Press again to store the new data.

To set the time to stop the unit

Press to set the time to stop running, then press to adjust the time (set the time for stop 5

minutes before the water pump).

Press again to store the new data.

6.6 Cancel the automatic start/stop

To cancel the automatic starter

Press , then press light off and the automatic setting is now off.

To cancel the automatic stop

Press , then press light off and the automatic stop is now off.

or

and

or

or

,

,

- 17 - A Division of:

7. Troubleshooting

7.1 Error code display on LED wire controller

Malfunction

Error code

Reason

Solution

Inlet water temperature

sensor failure

PP1

The sensor in open or short

circuit

Check or change the sensor

Outlet water temperature

sensor failure

PP2

The sensor in open or short

circuit

Check or change the sensor

Heating condenser sensor

failure

PP3

The sensor in open or short

circuit

Check or change the sensor

Gas return sensor failure

PP4

The sensor in open or short

circuit

Check or change the sensor

Ambient temperature

sensor failure

PP5

The sensor in open or short

circuit

Check or change the sensor

Temperature difference

between water inlet and

outlet is too much

PP6

Water flow volume not

enough ,water pressure

difference is too low

Check the water flow volume,

backwash filter & check baskets

Cooling outlet water

temperature is too low

PP7

Water flow volume is

not enough

Check the water flow, backwash

filter & check baskets

First grade antifreeze

protection in Winter

PP7

Ambient temperature or water

inlet temperature is too low

Water pump will run automatically

for first grade antifreeze

Second grade antifreeze

protection in Winter

PP7

Ambient temperature or water

inlet temperature is too low

Heat pump will start heating for

second grade antifreeze

Cooling condenser sensor

failure

PP8

The sensor in open or short

circuit

Ch

High pressure protection

EE1

1.

2.

Refrigerant is too high

Air flow is not enough

1.

Discharge redundant

refrigerant from HP gas

system

2.

Clean the air exchanger

Low pressure protection

EE2

1.

2.

3.

Refrigerant is low

Water flow is not enough

Filter jammed or pump

jammed

1.

2.

3.

Check if there is any gas

leakage ,re-fill the refrigerant

Clean the air exchanger

Check filter & pump

Flow switch closed

EE3 or ‘ON’

Low water flow, wrong flow

direction, or flow switch failure.

Check if the water flow is enough

and flow in right direction, or

check flow switch itself.

Power supply connections

wrong (for 3 phase unit)

EE4

Wrong connection

Check the connection of power

cable

- 18 - A Division of:

Inlet and outlet water

temperature difference

malfunction

EE5

Water flow volume is not

enough ,water pressure

difference is too low

Check the water flow rate,

backwash filter & empty baskets

Communication failure

EE8

Wire connection is not good

Check the wire connection

7.2 Other Malfunctions and Solutions (No display on LED controller)

Malfunctions

Observing

Reasons

Solution

Heat pump is

not running/

compressor is

on but fan is off

LED controller shows no

display.

No power supply

Check cable and circuit

breaker if it is connected

LED wire controller.

displays the actual time.

Heat pump under standby

status

Startup heat pump to run.

LED wire controller

displays the actual

water temperature.

1. Water temperature is

reaching to setting value, HP under

constant temperature status.

2. Heat pump just starts to

run.

3. Under defrosting.

1. Verify water

temperature setting.

2. Startup heat pump

after a few minutes.

3. LED wire controller

should display "Defrosting".

Water

temperature is

cooling when

HP runs under

heating mode

LED wire controller

displays actual water

temperature and no error

code displays.

1. Chosen the wrong mode.

2. Figures show defects.

3. Controller defect.

1. Adjust the mode to

proper running mode.

2. Replace the defect

LED controller, and then

check the status after

changing the running mode,

verifying the water inlet and

outlet temperature.

3. Replace or repair

the

heat pump unit

Short running

LED displays actual water

temperature, no error code

displays.

1. Fan NOT running.

2. Air ventilation is not enough.

3. Refrigerant is not enough.

1. Check the cable

connections between the

motor and fan, if

necessary, it should be

replaced.

2. Check the location

of heat pump unit, and

eliminate all obstacles to

make good air ventilation. 3

Replace or repair the heat

pump unit.

- 19 - A Division of:

water stains

Water stains on heat pump

unit.

1. Concreting.

2. Water leakage.

1. No action.

2. Check the titanium

heat exchanger carefully

for any leaks.

Too much ice on

evaporator

Too much ice on

evaporator.

1. Check the location of

heat pump unit, and

eliminate all obstacles to

make good air ventilation.

2. Replace or repair the

heat pump unit.

8. Exploded Diagram

- 20 - A Division of:

No.

Name of parts

No.

Name of parts

1

Pillar

34

Electric terminal block

2

Side grill

35

Cable fixing clamp

3

Fan motor bracket

36

Water pump terminal block

4

Pillar

37

Water pump terminal block stand

5

Fan motor

38

Terminal block box

6

Fan blade

39

Water-out temperature sensor clip

7

Front grill

40

Water flow switch

8

Front panel

41

Water-out temperature sensor

9

LED controller

42

Collection pipes

10

Waterproof wiring box

43

Pillar

11

Base tray

44

Back panel

12

high pressure protection switch

45

Pipe temperature sensor case

13

low pressure protection switch

46

Pipe temperature sensor clip

14

Exhaust pipe

47

Pipe temperature sensor

15

Suction pipe

48

Ambient temperature sensor

16

Pipe (4 way valve to separator)

49

Ambient temperature sensor clip

17

4 way valve coil

50

Top cover

18

4 way valve

51

Back grill

19

Pipe (4 way valve to titanium)

52

Evaporator

20

4 way valve to collection pipes

53

Isolation panel

21

Gas-liquid separator

54

Thermostatic expansion valve

22

Pillar

55

Filtrer assembly

23

Water-in temperature sensor clip

56

Left panel

24

Water-in temperature sensor

57

Scaleboard

25

Titanium heat exchanger

58

AC communicator

26

Suction valve

59

Compressor capacitance

27

Water inlet screw cap

60

Compressor capacitance clip

- 21 - A Division of:

28

Water inlet bolt(blue)

61

Fan motor capacitance

29

Pressure guage

62

Transformer

30

Water outlet screw cap

63

Shared terminal block

31

Water outlet bolt(red)

64

PC board

32

Switch knob

65

Electric box

33

Right panel

66

Top frame

9. Maintenance

(1) You should check the water supply system regularly to avoid any air entering the system and occurrence of

low water flow, because it would reduce the performance and reliability of HP unit.

(2) Clean your pools and filtration system regularly to avoid damage of the unit as a result of a clogged/dirty

filter causing reduction in water flow.

(3) You should discharge the water from bottom of water pump if HP unit is intended to be shut down for a long

period (during the winter season).

(4) Upon start up after a long period of having the HP switched off, you should check the unit is full of water

before the unit starts to run again.

(5) When the unit is running, there will always be a little water discharge under the unit – this is normal.

11. Warranty

Theratherm Heat Pump warranty is a structured warranty. It particularly covers manufacturing faults & is set out

as below:

7 years on Titanium Heat Exchanger

7 years on scroll compressor

2 years on all other parts

Any faults with the Heat Pump resulting from incorrect installation, incorrect sizing, incorrect usage, neglect of

water chemistry or any other misuse will void the above stated warranty.

Please validate your warranty by visiting www.theralux.com.au and register your purchase. You can also contact

our customer service department via our website should you have any concerns.

Enjoy your new Theratherm Heated Swimming Pool.

- 22 - A Division of:

From the team at,

Theralux.

Loading...

Loading...