Page 1

Helm Instrument Company, Inc.

361 West Dussel Drive

Maumee, Ohio 43537 USA

419/ 893-4356

Fax: 419/ 893-1371

www.helminstrument.com

1769 Weigh Scale

Module

Model HM1525

Instruction Manual

FEBRUARY 2004

Page 2

Solid state equipment has operational characteristics differing from those

Important User

Information

of electromechanical equipment. “Safety Guidelines for the Application,

Installation and Maintenance of Solid State Controls” (Allen-Bradley

Publication SGI-1.1) describes some important differences between solid

state equipment and hard-wired electromechanical devices. Because of

this difference, and also because of the wide variety of uses for solid

state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment

is acceptable.

In no event will the Allen-Bradley Company or Helm Instrument

Company be responsible or liable for indirect or consequential damages

resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for

illustrative purposes. Because of the many variables and requirements

associated with any particular installation, the Allen-Bradley Company or

Helm Instrument Company cannot assume responsibility or liability for

actual use based on the examples and diagrams.

No patent liability is assumed by Allen-Bradley Company or Helm

Instrument Company with respect to use of information, circuits,

equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without

written permission of the Allen-Bradley Company and Helm Instrument

Company is prohibited.

Throughout this manual we use note to make you aware of safety

considerations.

ATTENTION: Identifies information about practices or

circumstances that can lead to property damage.

Identifies information that is especially important for

successful application and understanding of the product.

Attentions help you:

• identify a hazard

• avoid the hazard

• recognize the consequences

ATTENTION: Please check power supply ratings

before proceeding! Each tonnage module

consumes (+24, 50mA +5, 66mA). Be sure to not

overload the power supply.

PLC, PLC2, PLC3, and PLC5 are registered trademarks of the Allen-Bradley Company, Inc.

SLC, SLC500, PanelView, RediPANEL, Dataliner are trademarks of Allen-Bradley Company, Inc.

IBM is a registered trademark of International Business Machines, Incorporated.

Weigh Scale is a registered trademark of the Helm Instrument Company, Inc.

Page 3

Table of

Contents

Strain Gage

Table of Contents

Weigh Scale Load Module

User Manual

Preface...................................................................... P-1

Who Should Use this Manual................................P-1

Purpose of this Manual.........................................P-1

Contents of this Manual........................................P-2

Related Documentation ........................................P-3

Terms and Abbreviations......................................P-4

Common Techniques Used in this Manual...........P-5

Product Support....................................................P-5

Your Questions or Comments on this Manual......P-5

Overview

Getting

Started

Channel

Configuration,

Data and

Status

Chapter 1..................................................................1-1

Components..........................................................1-1

Strain Gain Transducer Operation........................1-1

Hardware Overview ..............................................1-2

Chapter 2..................................................................2-1

Getting Started......................................................2-1

Required Tools and Equipment ............................2-1

System Operation.................................................2-2

Sensor Wiring .......................................................2-2

Chapter 3..................................................................3-1

Channel Configuration, Data and Status ..............3-1

Module Addressing...............................................3-1

Module Configuration.........................................3-1

Data Table Memory Map ......................................3-1

Output Image........................................................3-1

Input Image...........................................................3-3

Integer File............................................................3-5

Page 4

Initial

Setup

Procedures

System

TroubleShooting

Guide

Table of Contents

Weigh Scale Load Module

User Manual

Chapter 4..................................................................4-1

Initial Setup Procedures........................................4-1

Step 1. Balance Sensor Input...............................4-1

Step 2. Set Calibration Numbers ..........................4-2

Chapter 5..................................................................5-1

HT-400 Sensor Ohm Reading ..............................5-1

Block Diagrams.....................................................5-2

Trim Jumper Setting..............................................5-2

PLC Ladder Logic.................................................5-3

Page 5

Preface

Preface

Read this preface to familiarize yourself with the rest of this manual. This

preface covers the following topics:

• who should use this manual

• the purpose of this manual

• terms and abbreviations

• conventions used in this manual

• Allen-Bradley support

Who Should

Use this

Manual

Purpose of

This Manual

Use this manual if you are responsible for the design, installation, programming,

or maintenance of an automation control system that used Allen-Bradley small

logic controllers.

You should have a basic understanding of SLC 500 products. You should

understand electronic process control and be able to interpret the ladder logic

instructions required to generate the electronic signals that control your

application. If you do not, contact your local Allen-Bradley representative for the

proper training before using this product.

This manual is a learning and reference guide for the Helm Weigh Scale Module.

It contains the information you need to install, wire, and use the module.

P-1

Page 6

Preface

Contents of this

Manual

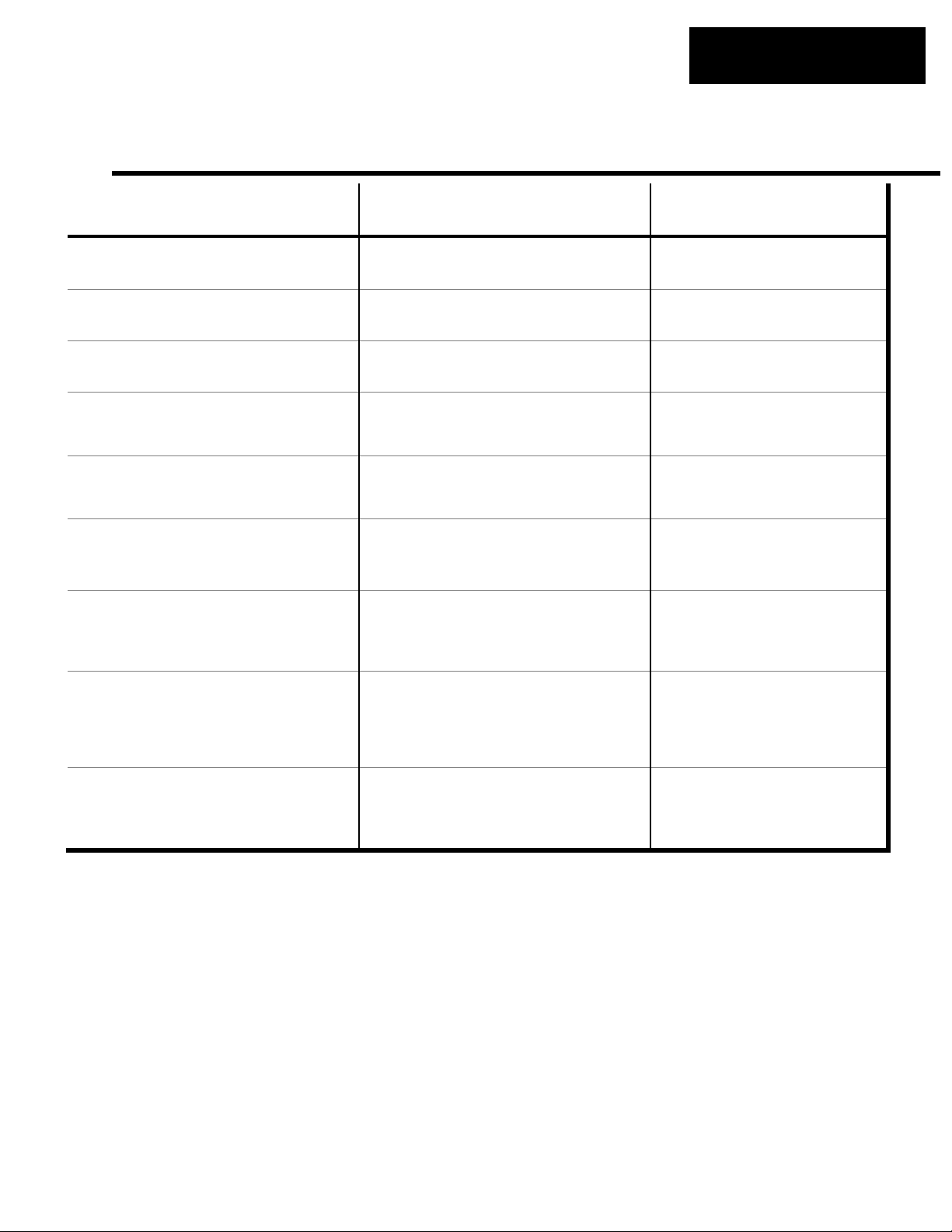

Chapter Title Content

Preface

1 Overview

2 Installation and Wiring

3 Channel Configuration, Data

and

Status

4 Ladder Programming Examples

5 Troubleshooting

Describes the purpose, background,

and scope of this manual. Also

specifies the audience for whom this

manual is intended and defines key

terms and abbreviations used

throughout this book.

Provides a hardware and system

overview. Explains and illustrates the

components of the system.

Provides installation information and

wiring guidelines.

Examines the channel configuration

and the channel status word, and

explains how the module uses

configuration data and generates

status during operation.

Gives an example of the ladder logic

required to define the channel for

operation. Also includes

representative examples for unique

requirements such as sample count,

trend calculation, etc.

Explains how to interpret and correct

problems that occur while using the

load module.

A Specifications

B Ladder Program

P-2

Provides physical, electrical,

Environmental, and functional

Specifications for the module.

Page 7

Preface

Related

Documentation

The following documents contain information that may be helpful to you as you use Allen-Bradley SLC

products. To obtain a copy of any of the Allen-Bradley documents listed, contact your local Allen-Bradley

office or distributor.

For Read this Document Document

Number

An overview for the MicroLogixTM

Programmable Controllers

A description on how to install and use your

MicroLogix Programmable Controller

A description on how to install the processor

into the MicroLogix 1500 Base unit.

Selecting Discrete Input/Output Modules Compact Discrete Input/Output Modules

View power usage of expansion modules to

determine power supply requirements

End Cap Installation Compact I/O End Caps/Terminators

A complete listing of current Automation

Group documentation, including ordering

instructions. Also indicates whether the

documents are available on CD-ROM or in

multi-languages

A glossary of industrial automation terms

and abbreviations

MicroLogix 1500 Programmable Controllers 1764-UM001A-US-P

MicroLogix 1500 Programmable Controller

Base Units Installation Instructions and

Wiring Diagrams

MicroLogix 1500 Processor Installation

Instructions

Technical Data

Expansion Modules System Qualifier RA Website Download

Installation Instructions

Automation Group Publication Index SD499

Allen-Bradley Industrial Automation

Glossary

1764-IN001A-ML-P

1764-IN002A-ML-P

1769-2.1

1769-5.16

ICCG-7.1

An article on wire sizes and types for

grounding electrical equipment

P-3

National Electrical Code Published by the

National Fire

Protection

Association of

Boston, MA.

Page 8

Preface

Terms and

Abbreviations

The following terms and abbreviations are used throughout this manual. For definitions of terms

not listed here refer to Allen-Bradley’s Industrial Automation Glossary, Publication ICCG-7.1.

Calibration - Procedure, performed by trained personnel, where machine or press is

dynamically loaded to impact on load cells. A process of linearity measuring to determine the

loading capacity of the machine.

Calibration Number - Amplification values established during machine calibration or preassigned on force load cells.

Channel - Refers to one of two, strain gage inputs available on the modules terminal block.

Chassis - A hardware assembly that houses devices such as I/O modules, adapter modules,

processor modules, and power supplies.

Configuration Word - Contains the channel configuration information needed by the module to

configure and operate each channel. Information is written to the configuration word through

the logic supplied in your ladder program.

Data Word - A 16-bit integer that represent the value of the analog input channel. The channel

data word is valid only when the channel is enabled.

Gain - Amplification of an input signal.

Load/Force - Measurement of impact during a machine cycle. Sensors provide the input for

this measurement.

LSB - (Least Significant Bit) Refers to a data increment defined as the full scale range divided

by the resolution. The bit that represents the smallest value within a string of bits.

Remote Configuration - A control system where the chassis can be located several thousand

feet from the processor chassis.

Resolution - The smallest detectable change in a measurement, typically expressed in

engineering units (e.g. 0.15C) or as a number of bits. For example a 12-bit system has 4,096

possible output states. It can therefore measure 1 part in 4096.

Sample - Load/force values established from a series of machine cycles. Also defined as

benchmark.

Sampling time - The time required by the A/D converter to sample an input channel.

Scale - Value used to describe the press/machine overall tonnage. Set for maximum value of

one channel. For example, settings for a 150 ton press = 75.

Status Word - Contains status information about the channel’s current configuration and

operational state. You can use this information in your ladder program to determine whether

the channel data word is valid.

Update Time - The time required for the module to sample and convert the input signals of all

enables input channels and make the resulting data values available to the SLC processor.

P-4

Page 9

Common

Techniques

Used in this

Manual

Product

Support

The following conventions are used throughout this manual:

• Bulleted lists such as this one provide information, not procedural steps.

• Numbered lists provide sequential steps or hierarchical information.

Contact your Helm representative or call Helm direct at 419-893-4356:

• sales and order support

• product technical training

• warranty support

• support service agreements

Preface

Your Questions or Comments on this Manual

If you have any suggestions for how this manual could be made more useful to you, please send

us your ideas.

P-5

Page 10

Overview

Components

Strain Gain

Transducer

Operation

Chapter 1

You have just purchased the most advanced load monitoring solution

available. HELM INSTRUMENT COMPANY, INC. manufactures a

complete line of load monitoring control solutions for use on metal

stamping, forging, compaction and assembly presses; cold forming, cold

heating, injection molding and die cast machines.

Standard or custom transducers and load cells are available for in-die

monitoring of transfer or progressive tooling.

At HELM, quality is inherent not only in the design of our products but in

the attitudes of our employees as well. We’re working together to give

you the best. After all, that’s what our business is all about - providing

innovative instrumentation to help make your manufacturing process

more productive and your operation more effective.

The Helm Weigh Scale combines machine and tooling monitoring with

programmable limit switch function. User programmable high and low

limits protect the machine and tooling to ensure part quality.

Critical setup information can be stored and uploaded as part of a die

recipe program. An optional resolver input module is used to compare

machine/press tonnage to crank angle for real time signature analy sis.

The Helm Weigh Scale module is attached to the controller or to an

adjacent I/O module on the din rail. The system is comprised of two

parts; the input module and two Helm Strain gage based sensors.

The primary part of the load monitoring system centers around the

measurement. The basic function of the Helm Strain Gain sensor is to

detect the amount of deflection imposed on the press or die as parts are

being formed. All Strain Gain sensors are matched to within 1% and

therefore can be replaced without recalibration of the machine.

The Helm Strain Gain sensors can be mounted to strategic high stress

areas of the machine frame or strategically located in tooling or applied

to stop blocks. Signals from these sensors are routed to the Weigh

Scale module for processing. The Helm Strain Gage is capable of

measuring either a tension or compression

signal.

Page 1-1

Page 11

Hardware

Overview

Chapter 1

The Weigh Scale module can be attached to the controller or to an

adjacent I/O module before or after din rail mounting. It is a Class 1

module (uses eight input words and eight output words). It interfaces to

strain gage based transducers (350ohm or 700ohm).

The module can accept input from two sensors. The module has no

output channels. Module configuration requires manual and user

programmable setup.

The Weigh Scale module receives and stores digitally converted analog

data into its image table for retrieval by processor. The module supports

connections from any combination of up to two strain gage sensors.

Any combination of Helm Strain Gage sensors can be used. Contact

Helm for additional information on the type and application of different

sensor options.

Page 1-2

Page 12

Getting

Started

This chapter can help you to get started using the Helm Weigh Scale

module. The procedures included here assume that you have a basic

understanding of PLC products. You should understand electronic

process control and be able to interpret the ladder logic instructions

required to generate the electronic signals that control your application.

Because it is a start-up guide, this chapter does not contain detailed

explanations about the procedures listed. It does, however, reference

other chapters in this book where you can get more information about

applying the procedures described in each step. It also references other

SLC documentation that may be helpful if you are unfamiliar with

programming techniques or system installation requirements.

If you have any questions or are unfamiliar with the terms used or

concepts presented in the procedural steps, always read the referenced

chapters and other recommended documentation before trying to apply

the information.

This chapter will:

• Tell you what equipment you need

Chapter 2

• Explain how to install and wire the module

• Show you how to set channels for the sensor input

Required Tools and Equipment

Have the following tools and equipment ready:

• Small blade screwdriver

• Appropriate strain gage cable

• Programming equipment (All programming examples shown in this

manual demonstrate the use of Allen-Bradley’s RS Logix 500.

Page 2-1

Page 13

System

Operation

Sensor

Wiring

Chapter 2

The Weigh Scale module communicates to the processor through the parallel

backplane interface and receives +5Vdc and +24Vdc power from the power

supply through the backplane. No external power supply is required. The

MicroLogix and CompactLogix platforms can support up to 8 I/O modules. You

may install up to 3 Weigh Scale modules using the base power supply. An

additional power supply can be added to support more than 3 modules. Refer to

publication 17864-UM100A-US-P for information on expansion power supply

systems.

Each individual channel on the module can receive input signals from strain gage

based sensors. The module converts the analog values directly into digital

values.

The sensors are wired to the modules using the rightmost bank of inputs.

The pin-out is shown below.

To ensure proper operation

and high immunity to

electrical noise, always use

Helm strain gage cable.

To limit noise, keep strain gage cable as

far away as possible from power and load

lines.

The module can support up to

two sensor inputs DO NOT

attempt to parallel additional

gages as you will cause

damage to the module and void

product warranty.

Page 2-2

Page 14

Chapter

3

Channel

Configuration

Data and

Status

This chapter explains how the Weigh Scale module and the processor com m unicate

through the module's input and output image.

For CompactLogix / RSLogix™ 5000 setup, please refer to Appendix A

With RS Logix500 software, verify the module ID code.

Expansion General Configuration

Weigh

Scale

Module ID

Code = 1

Series/Major Rev/Minor Rev = D

Vendor ID = 3

Product Type = 9

Product Code = 1

No special I/O configuration (SPIO CONFIG) information is required. The module ID code

automatically assigns the correct number of input and output words. The following memory map

shows how the output and input image tables are defined.

The 8 word output image (output from the CPU to the module) contains

Output Image

Information that you configure to define the way a specific channel will work.

Example – If you want to configure channel 2 on the module located in slot 4

in the SLC chassis, your address would be O:4.2.

(

o = file type : =element delimiter 4=slot .=word delimiter 2=word)

Bit Reserved O:e.0/0

Bit Reserved O:e.0/1

Bit Reserved O:e.0/2

Bit Zero Stabilize 0=Off 1=On O:e.0/3

Bit LSD Flicker 0=Off 1=On O:e.0/4

Bit Vibration Filter 0=Off 1=On O:e.0/5

Bit Channel 2 Trim O:e.0/6

Bit Coarse Zero Up Adjust O:e.0/7

Bit Channel 1 Trim O:e.0/8

Bit Reserved O:e.0/9

Bit Reserved O:e.0/10

Bit Reserved O:e.0/11

Bit Coarse Zero Down Adjust O:e.0/12

Bit Clear Tare O:e.0/13

Bit Tare O:e.0/14

Bit Channel Toggle 0=CH1 1=CH2 O:e.0/15

Integer Channel 1 Scale value O:e.1

Integer Channel 1 mV/V Setting O:e.2

Integer Channel 1 A/D Trim Setting O:e.3

Integer Channel 2 mV/V Setting O:e.4

Integer Channel 2 A/D Trim Setting O:e.5

Integer A/D Samples Setting O:e.6

Integer Channel 2 Scale value O:e.7

Page 3-1

Page 15

Output

Image

(cont.)

Zero Stabilize Bit (O:e/3)

Enables module feature to display “0” when Weigh scale is empty.

0 = Disable 1 = Enable

Least Significant Bit (LSD) Flicker Bit (O:e/4)

LSD of weigh value. Does not change when load is applied or if load

is constant.

Vibration Filter Bit (O:e/5)

Enables vibration filter to cancel out load variation due to vibration of

product weighed. 0 = Disable 1 = Enable

Channel 2 Trim Bit (O:e/6)

Factory set bit to load Channel 2 trim value into module (Not for end user)

Coarse Zero Up Adjust Bit (O:e/7)

Used to increase offset of amplifier to set to range of A/D.

Channel 1 Trim Bit (O:e/8)

Factory set bit to load Channel 1 trim value into module (Not for end user)

Coarse Zero Down Adjust Bit (O:e/12)

Used to decrease offset of amplifier to set to range of A/D.

Clear Tare Bit (O:e/13)

Resets or removes tare value from module. (Used to initially setup module)

Tare Bit (O:e/14)

Sets weigh value to zero.

Channel Toggle Bit (O:e/15)

Used to switch from Channel 1 to Channel 2 when setting up channels.

Channel 1 Scale Value (Integer Word O:e.1)

Value of scale from capacity of load cell for Channel 1.

Channel 1 mV/V Setting (Integer Word O:e.2)

4 digit mV/V setting from load cell mV/V specification.

Channel 1 A/D Trim Setting (Integer Word O:e.3)

Factory set trim value for Channel 1. (Not for end user)

Channel 2 mV/V Setting (Integer Word O:e.4)

4 digit mV/V setting from load cell mV/V specification.

Channel 2 A/D Trim Setting (Integer Word O:e.5)

Factory set trim value for Channel 2. (Not for end user)

A/D Samples Setting (Integer Word O:e.6)

Sets number of samples (for averaging) of weigh value. (0-1000)

Channel 2 Scale Value (Integer Word O:e.7)

Value of scale from capacity of load cell for Channel 2.

Page 3-2

Chapter

3

Page 16

Data Table

Input Image

Chapter

3

The 8-word module input image (input from the module to the CPU) represents data

words and status words. Input words (data words) hold the input data that represents

the values of the sensor inputs.

Input words (status bits) contain the various status conditions and reflect the

configuration settings you have entered into the output configuration words.

(I =file type : =element delimiter 2 =slot . =word delimiter 0 =word / 2 =bit)

Bit Trim Mode I:e.0/1

Bit Reserved I:e.0/2

Bit Reserved I:e.0/3

Bit Reserved I:e.0/4

Bit Reserved I:e.0/5

Bit Reserved I:e.0/6

Bit Channel 1 Sign Bit I:e.0/14

Integer Channel 1 Weigh Value I:e.1

Bit Reserved I:e.0/0

Bit Channel 2 Sign Bit I:e.0/15

Integer Channel 2 Weigh Value I:e.2

Integer Channel 1 A/D Trim Value I:e.3

Integer Reserved I:e.4

Integer Channel 2 A/D Trim Value I:e.5

Integer Communication Fault Counter I:e.6

Integer Reserved I:e.7

Calibrate Mode Bit (I:e/1)

If set, module is in trim mode. Bit should always be clear.

Channel 1 Sign Bit (I:e/14)

If Channel 1 signal is positive value, Bit = 0 and negative value Bit = 1.

Channel 2 Sign Bit (I:e/15)

If Channel 2 signal is positive value, Bit = 0 and negative value Bit = 1.

Page 3-3

Page 17

Input

Image

(cont.)

Channel 1 Weigh Value (I:e.1)

Weigh value for Channel 1

Channel 2 Weigh Value (I:e.2)

Weigh value for Channel 2.

Channel 1 A/D Trim Value (I:e.3)

Value stored in module for Channel 1. Value should match value on sticker.

Channel 2 A/D Trim Value (I:e.5)

Value stored in module for Channel 2. Value should match value on sticker.

Communication Fault Counter (I:e.6)

Used to troubleshoot noise or ground loops. Associated with module faults to PLC.

Counter value should always be zero.

Page 3-4

Chapter

3

Page 18

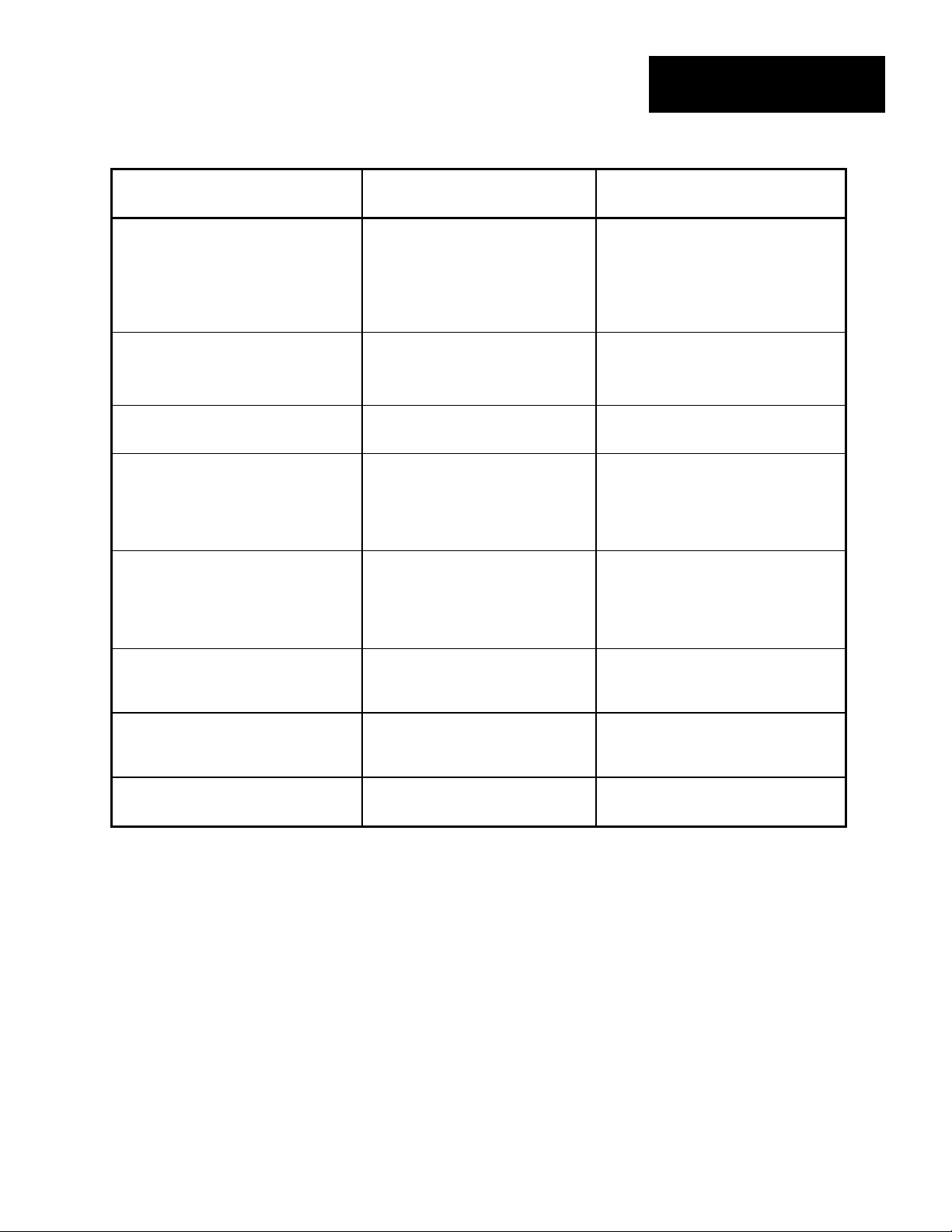

Integer File

Using RS Logix500 software, reserve an integer file for Weigh Module monitoring.

For illustration purposes in this manual, we have reserved Integer file N10:0 - N10:16.

Data Description Address

Bit Channel 2 Sign Bit N10:0/3

Integer Channel 1 A/D Trim N10:5

Integer Channel 1 Weigh Value N10:8

Bit Up Button N10:16/1

Bit Channel 2 A/D Trim Set Bit N10:16/2

Bit Down Button N10:16/3

Bit Reset Zero N10:16/9

Bit Tare/Zero Button N10:16/12

Bit Channel Toggle Bit 0=CH1 1=CH2 N10:16/13

Bit Channel 1 Sign Bit N10:0/2

Integer Faults N10:2

Integer Channel 2 A/D Trim N10:6

Integer Channel 2 Weigh Value N10:9

Bit Channel 1 A/D Trim Set Bit N10:16/4

Page 3-5

Chapter 3

Page 19

Setup

Procedure

A complete listing of a sample ladder logic program is included at the back of this manual.

Examples shown here are for reference.

All values are 0 (default) on initial start-up. This means that all alarms are

disabled. You must make the following adjustments for proper operation:

•

Balance sensor input(s)

•

Set Calibration numbers

Step 1. Balance Sensor Input.

1. Set mV/V to 2000.

2. Set Scale to 10000.

Chapter

4

3. Press Clear Tare pushbutton.

4. Use Up and Down buttons to set amplifier to low range of A/D (20,000 counts)

5. Press Zero/Tare pushbutton.

Step 2. Set Calibration Numbers

1. Set Scale to capacity of load cell.

2. Set mV/V to load cell specification.

3. Example:

100 ton load cell, 2.025 mV/V

For scale set, enter 100

For mV/V set, enter 2025

Page 4-1

Page 20

System

Troubleshooting

Guide

HT-400 Sensor Ohm Readings

Green-Black 350 ohms

Red-White 350 ohms

All other color combinations 266 ohms

All colors to Ground open

Shield to Ground open

Electrical Specifications:

Type of input Strain Gage (350 ohm, 700 ohm)

Input Impedance 10k

Display Resolution Up to .0025% of full scale

Overall Module Accuracy .01% of full scale

Module Update Time 10 µsec

Number of Channels 2 (isolated)

A/D Conversion Method Successive Approximation - 16 bit

Normal Mode Rejection:

(between +/- input) 116DB CMRR

Amplifier Bandwidth 200 kHz

Calibration Software Selectable

Isolation: 500 VDC continuous between inputs

and chassis ground, and between input

and backplane

LED indicators 2 LED's for Power and Alarm

Recommended Cable Strain Gage Cable (Helm part number 6117)

Terminal Strip 16-pin removable

Operating Temperatures 0°C to 60°C (32°F to 140°F)

Hazardous Environment

Classification Class 1 Division 2 Hazardous Environment

Trim Jumper

Located at Bottom

Left Corner of Module

Black Jumper

Factory Jumper. Removing this

Jumper will cause module to

Become unstable.

Page 5-1

Chapter

5

Page 21

Page 22

Page 23

Page 24

APPENDIX A – Module Properties RSLogix™5000

Page 25

WEIGH_MODULE - Ladder Diagram Page 1

WEIGH_1525:MainTask:MainProgram 2/27/2008 3:01:17 PM

Total number of rungs in routine: 7 C:\Jobs\Helm\Module_Logic\COMPACTLOGIX_HM1525.ACD

MOVE SAMPLE SETPOINT FROM MMI SCREEN TO MODULE

MOVE SAMPLE SETPOINT FROM MMI SCREEN TO MODULE

0

MOVE SCALE SETPOINTS FROM MMI SCREEN TO MODULE

MOVE SCALE SETPOINTS FROM MMI SCREEN TO MODULE

1

WEIGH MODULE A/D

SAMPLES SETTING

MOV

Move

Source

Dest

WEIGH MODULE CHANNEL

Move

Source

Dest

WEIGH MODULE CHANNEL

Move

Source

Dest

HM1525_CONTROL[1]

Local:1:O.Data[6]

1 SCALE

MOV

HM1525_CONTROL[2]

10000

Local:1:O.Data[1]

10000

2 SCALE

MOV

HM1525_CONTROL[3]

10000

Local:1:O.Data[7]

10000

1

1

MOVE MV/V SETPOINTS FROM MMI SCREEN TO MODULE

MOVE MV/V SETPOINTS FROM MMI SCREEN TO MODULE

WEIGH MODULE CHANNEL

1 MV/V SETTING

MOV

2

Move

Source

Dest

WEIGH MODULE CHANNEL

Move

Source

Dest

HM1525_CONTROL[4]

Local:1:O.Data[2]

2 MV/V SETTING

MOV

HM1525_CONTROL[5]

Local:1:O.Data[4]

2000

2000

2000

2000

RSLogix 5000

Page 26

WEIGH_MODULE - Ladder Diagram Page 2

WEIGH_1525:MainTask:MainProgram 2/27/2008 3:01:17 PM

Total number of rungs in routine: 7 C:\Jobs\Helm\Module_Logic\COMPACTLOGIX_HM1525.ACD

TOGGLE VIBRATION FILTER, ZERO STABILIZE, FLICKER OFF/ON CONTROL FROM MMI SCREEN TO MODULE

TOGGLE VIBRATION FILTER, ZERO STABILIZE, FLICKER OFF/ON CONTROL FROM MMI SCREEN TO MODULE

3

VIBRATION FILTER

OFF/ON TOGGLE

HM1525_CONTROL[0].0

ZERO STABLE OFF/ON

TOGGLE

HM1525_CONTROL[0].1

WEIGH MODULE

VIBRATION FILTER

OFF/ON

Local:1:O.Data[0].5

WEIGH MODULE ZERO

STABLE OFF/ON

Local:1:O.Data[0].3

LSD FLICKER OFF/ON

TOGGLE

HM1525_CONTROL[0].2

COURSE ZERO UP, COURSE ZERO DOWN, CLEAR TARE, TARE, CHANNELS 1/2 PUSHBUTTONS FROM MMI

COURSE ZERO UP, COURSE ZERO DOWN, CLEAR TARE, TARE, CHANNELS 1/2 PUSHBUTTONS FROM MMI

SCREEN TO MODULE

SCREEN TO MODULE

COURSE ZERO UP

PUSHBUTTON

HM1525_CONTROL[0].3

4

COURSE ZERO DOWN

PUSHBUTTON

HM1525_CONTROL[0].4

CLEAR TARE

PUSHBUTTON

HM1525_CONTROL[0].5

TARE PUSHBUTTON

HM1525_CONTROL[0].6

CHANNELS 1/2 TOGGLE

BIT

HM1525_CONTROL[0].7

ONE_SHOTS.0

ONS

ONE_SHOTS.1

ONS

WEIGH MODULE LSD

FLICKER OFF/ON

Local:1:O.Data[0].4

WEIGH MODULE COURSE

ZERO UP ADJUST

Local:1:O.Data[0].7

WEIGH MODULE COURSE

ZERO DOWN ADJUST

Local:1:O.Data[0].12

WEIGH MODULE CLEAR

TARE

Local:1:O.Data[0].13

WEIGH MODULE TARE

Local:1:O.Data[0].14

WEIGH MODULE

CHANNELS 1/2 TOGGLE

0=CH1 1=CH2

Local:1:O.Data[0].15

CHANNELS 1 AND 2 DATA SIGN BITS FROM MODULE TO MMI SCREEN

CHANNELS 1 AND 2 DATA SIGN BITS FROM MODULE TO MMI SCREEN

WEIGH MODULE CHANNEL

1 SIGN BIT

Local:1:I.Data[0].14

5

WEIGH MODULE CHANNEL

2 SIGN BIT

Local:1:I.Data[0].15

MMI CHANNEL 1 SIGN

BIT STATUS

HM1525_STATUS[0].0

MMI CHANNEL 2 SIGN

BIT STATUS

HM1525_STATUS[0].1

RSLogix 5000

Page 27

WEIGH_MODULE - Ladder Diagram Page 3

WEIGH_1525:MainTask:MainProgram 2/27/2008 3:01:17 PM

Total number of rungs in routine: 7 C:\Jobs\Helm\Module_Logic\COMPACTLOGIX_HM1525.ACD

CHANNELS 1 AND 2 WEIGH VALUES FROM MODULE TO MMI SCREEN

CHANNELS 1 AND 2 WEIGH VALUES FROM MODULE TO MMI SCREEN

6

MMI WEIGH MODULE

CHANNEL 1 WEIGH

VALUE

MOV

Move

Source

Dest

MMI WEIGH MODULE

CHANNEL 2 WEIGH

Move

Source

Dest

Local:1:I.Data[1]

HM1525_STATUS[1]

VALUE

MOV

Local:1:I.Data[2]

HM1525_STATUS[2]

207

207

207

206

(End)

RSLogix 5000

Loading...

Loading...