The Gramophone Company 541, 540, 661 Service Manual

“His Master’s Voice”

SERVICE MANUAL

fo r

F IVE - V ALV E

D UA L-WAVE A. C. RECEIVER

Model 66 I

A ND

DU AL- WAVE A. C. RADIOGRAMS

Models 5 40 and 541

(3) Rotate tuning knob until pointer is over 13.9

metres on dial and adjust S.W. oscillator trim m er

until maximum output is obtained with pointer

exactly on the 13.9 metre mark. Two settings

will be found at which this trim m er w ill peak;

care must be taken that the setting finally

selected is that which gives the lower capacity,

i.e., plunger furth er out. Failure to select the

correct position of the two w ill cause serious

tracking errors and loss of sensitivity.

(4) Tune receiver and signal generator to 15 metres

(20 me.).

(5) Adjust S.W. aerial trim m er for maximum output

while “ rocking” the ganged condenser slightly

to obtain the true resonant point.

(6) Retune receiver and signal generator to 13.9

metres, and note that signal is still tuned in

correctly on dial; if not, readjust S.W. oscillator

trimmer slightly until dial reads correctly and

then repeat tests 4 to 6 inclusive.

(7) Check foregoing adjustments carefully to ensure

that correct settings have been obtained on all

trimmers. Dial should now read correctly

throughout.

Supplementary Service Information fo r Radiogram Models 541 and 5 4 0

T E CH N I CAL SP E CI F IC A T IO N

PI C K-UP A U T O B R A K E ( T yp e 324)

D.C . resistance, 7400 ohms. Standard friction type, see page II.

Impedance at 1 000 cycles, 19,000 ohms.

One of the pick-up leads, and also the screening

over the leads, is to be connected to the black pick

up socket on the chassis. For service particulars

of this pick-up, see below.

D I S MA N T LIN G

RE M OV AL OF C HAS SI S

(1) Remove knobs.

(2) Disconnect loudspeaker plug, gramophone

m otor plug, and pick-up leads.

(3) Unscrew volume control escutcheon from side of

cabinet; withdraw sufficiently to allow insertion

of a screwdriver through hole provided in side

of escutcheon, loosen and remove control knob;

the escutcheon should now be detached and the

volume control pushed to the inside of the

cabinet.

(On Model 540, unscrew volume control

bracket from inside fron t of cabinet.)

(4) Remove two nuts from chassis fixing bolts behind

wooden chassis supports; the chassis is now free.

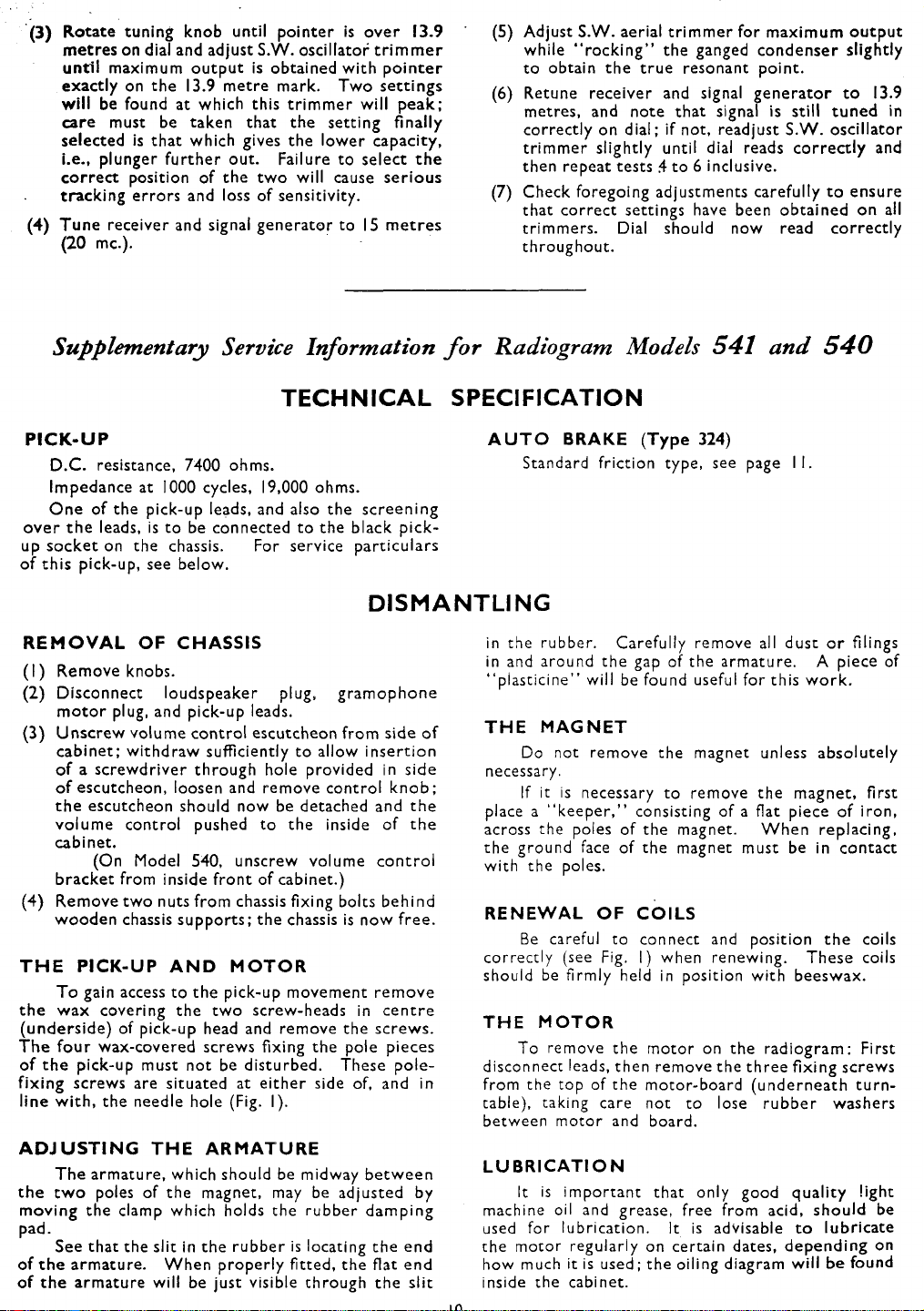

T H E P I CK- UP A N D M O TO R

To gain ac cess to the pick-up movement remove

the wax covering the tw o screw-heads in centre

(underside) of pick-up head and remove the screws.

The fo ur wax-covered screws fixing the pole pieces

of the pick-up must not be disturbed. These pole-

fixing screws are situated at either side of, and in

line with, the needle hole (Fig. I).

ADJUS TIN G T HE ARM ATU R E

The armature, which should be midway between

the tw o poles of the magnet, may be adjusted by

moving the clamp which holds the rubber damping

pad.

See that the slit in the rubber is locating the end

of the armature. When properly fitted, the flat end

of the armature w ill be just visible through the slit

in the rub b e r . Carefully remove all dust o r filings

in and arou n d the gap of the armature. A piece of

“ plasticine” will be found useful fo r this work.

TH E MAGNE T

Do not remove the magnet unless absolutely

necessary.

If it is necessary to remove the magnet, first

place a “ keeper,” consisting of a flat piece of iron,

across the poles of the magnet. When replacing,

the ground fac e of the magnet must be in contact

with th e poles.

RENEWAL OF C OILS

Be careful to connect and position the coils

correctly (se e Fig. I) when renewing. These coils

should be firm ly held in position w ith beeswax.

TH E M O T O R

To remove the motor on the radiogram: First

disconnect leads, then remove the three fixing screws

from the top of the motor-board (underneath tu rn

table), taking care not to lose rubber washers

between motor and board.

LU BR I C AT IO N

It is important that only good quality light

machine oil and grease, free from acid, should be

used for lubrication. It is advisable to lubricate

the motor regularly on certain dates, depending on

how much it is used; the oiling diagram w ill be found

inside the cabinet.

T H E AU T OMAT I C B RA K E

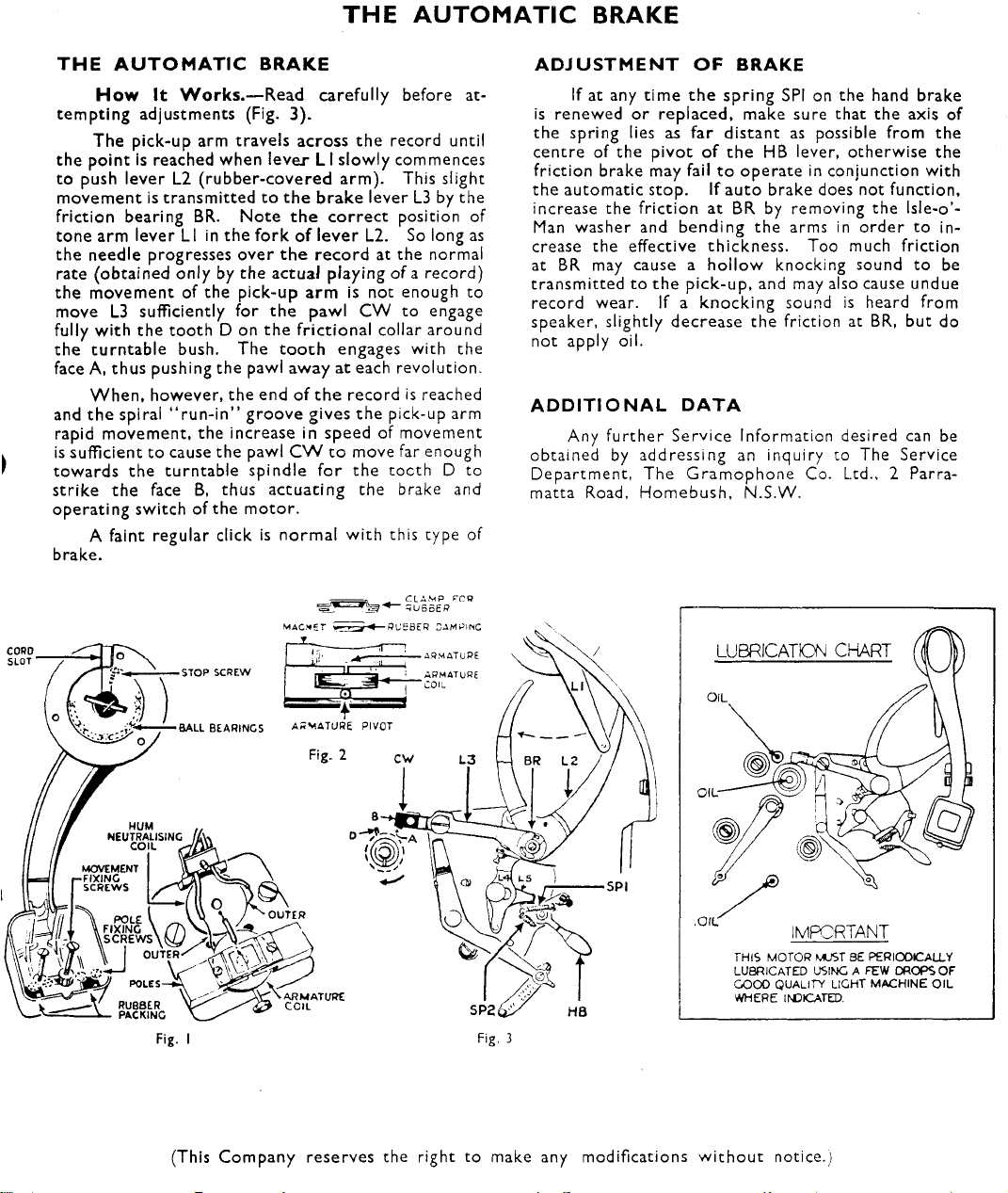

TH E A U T O M A T I C BRAKE

H ow It Wor k s. — Read carefully before at

tem pting adjustments (Fig. 3).

The pick-up arm travels across the record until

the point is reached when lever LI slowly commences

to push lever L2 (rubber-covered arm). This slight

movement is transmitted to the brake lever L3 by the

friction bearing BR. Note the corre ct position of

tone arm lever LI in the fork of lever L2. So long as

the needle progresses over the record at the normal

rate (obtained only by the actual playing of a reco rd)

the movement of the pick-up arm is not enough to

move L3 sufficiently for the pawl CW to engage

fully with the tooth D on the frictional collar around

the turntable bush. The too th engages with the

face A, thus pushing the pawl away at each revolution.

When, however, the end o f the record is reached

and the spiral “ run-in” groove gives the pick-up arm

rapid movement, the increase in speed of movement

is sufficient to cause the pawl C W to move far enough

towards the turntable spindle fo r the tocth D to

strike the face B, thus actuating the brake and

operating switch of the m otor.

A faint regular click is norm al w ith this type of

brake.

^ ^ U Bo E P

AD JU STM EN T O F B R AKE

If at any time the spring SPI on the hand brake

is renewed or replaced, make sure that the axis of

the spring lies as far distant as possible from the

centre of the pivot o f the HB lever, otherwise the

friction brake may fail to operate in conjunction with

the automatic stop. If auto brake does not function,

increase the friction at BR by removing the lsle-o’-

Man washer and bending the arms in order to in

crease the effective thickness. Too much friction

at BR may cause a hollow knocking sound to be

transmitted to the pick-up, and may also cause undue

record wear. If a knocking sound is heard from

speaker, slightly decrease the friction at BR, but do

not apply oil.

A D D IT IO N A L D A T A

Any further Service Information desired c an be

obtained by addressing an inquiry to The Service

Department, The Gramophone Co. Ltd., 2 Parra

matta Road, Homebush, N.S.W.

THIS MOTOR MUS T BE PERIODICALLY

LUBRICATED USING A FEW DROPS OF

GOOD QUALITY LIGHT MACHINE OIL

WHERE INDIC ATED.

(This Company reserves the right to make any modifications w ithout notice.)

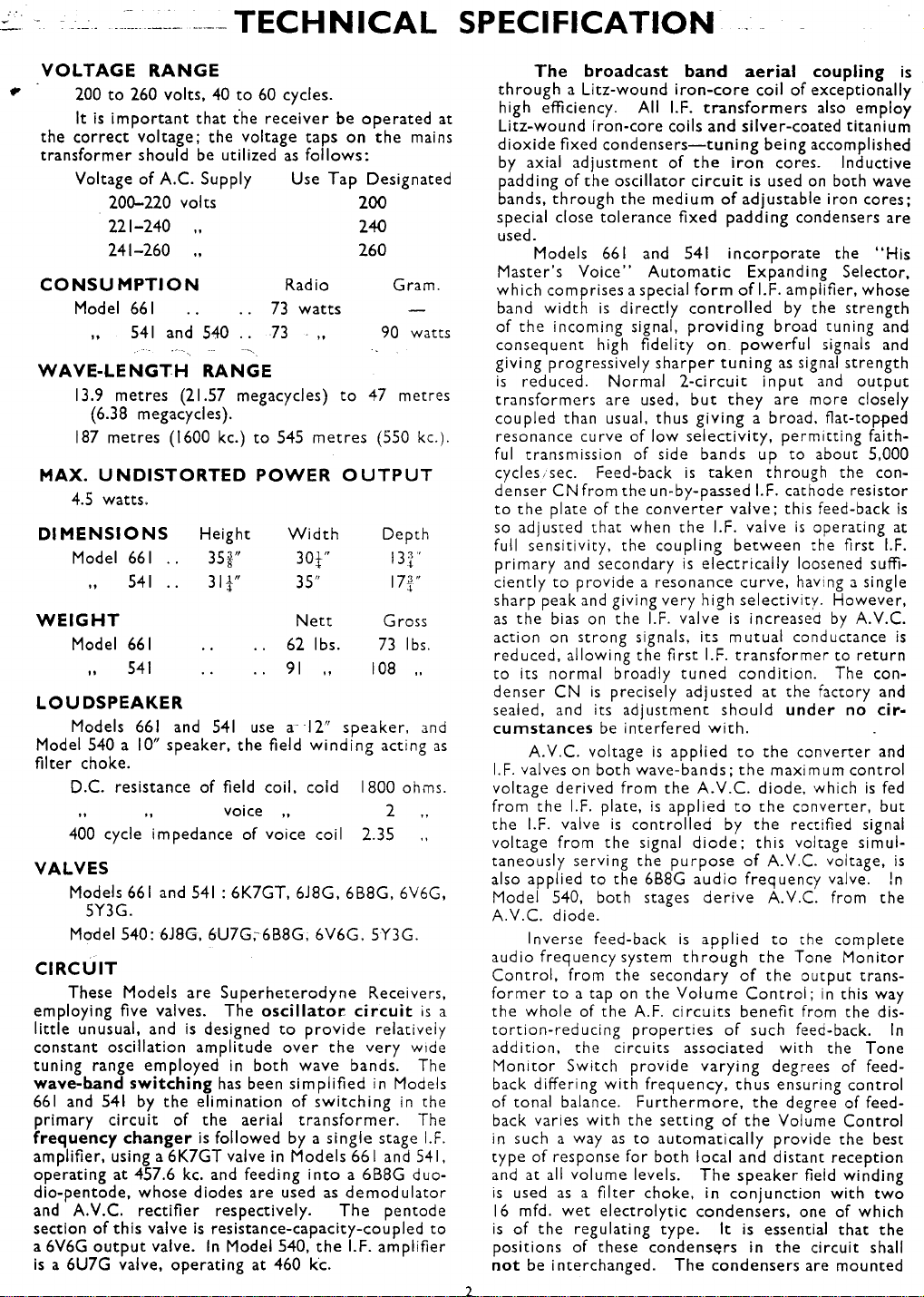

TECHNICAL SP E CIF I CATIO N

V O L TA G E RANG E

20 0 to 2 60 v olts, 40 to 60 cycl es .

It is i m portant t hat the r ece i ver be ope ra te d at

th e c or re ct vo l tage ; t he voltag e ta ps on the mains

tr ansfo rme r s h ould be util i zed as foll ows;

Voltage of A .C. S u p ply Use Tap Designa t ed

2 0 0 - 2 2 0 volt s 2 0 0

2 21- 240 „ 240

2 41- 260 „ 260

C O N S U M P TIO N Rad io G r am.

Mo d el 661 . . ..73 w at ts —

„ 541 and 540 .. 7 3 „ 90 watt s

W AV E-LE NGTH RANGE

13.9 me tre s ( 21.57 m e g a c ycles ) to 4 7 metr e s

(6 . 38 m e g a c y c le s ).

187 met res (160 0 k c.) t o 54 5 metre s (5 50 kc.).

MA X. U ND I S TO RT E D POWE R O U T P U T

4.5 w atts.

DIM EN SIO NS Height W i d th D ep t h

Mo d el 661 . .

„ 541 ..

3 5f"

3 I f '

W E IG H T N e tt

Model 661

541

30J "

35"

62 lbs. 73 lbs.

91 „

Ι 3 Γ

I7§”

Gros s

108 „

L OU DSPEAKER

Mo d e l s 661 and 541 use a 12" sp ea ke r, and

Model 540 a 10" spe ake r , the f i e l d windi ng a c t i n g as

fi lter chok e .

D.C. res istance of field c oil, cold 18 00 ohms.

voice ,, 2

400 cycle i mpe dan ce of vo i ce coil 2. 35

VAL VE S

Mod els 661 and 541 : 6 K7GT, 6 J8 G, 6 B8 G, 6 V 6 G ,

5Y3G .

Mo d el 54 0: 6 J8 G, 6U7G,~ 6B 8G , 6 V 6 G . 5Y3G.

CI R CUIT

The se Mo d els ar e S uperheterody ne R e c eiver s,

empl oyi ng fi ve va lv e s . The o sc i ll a t or cir cuit is a

littl e unusual, and is desig ne d to prov ide r ela tively

con s t a nt oscillatio n a mpli t ud e ove r the very wide

tu n i ng range emplo yed in both wave ba n d s . T h e

wave -ba nd s w it ch i ng has been s im plified in Mod els

661 and 541 by the e limina t ion of switchi ng in the

primary cir cuit of the a e r i a l transf o rm er. T h e

freq ue nc y c h an g er is f oll owed by a si ngl e stage I.F.

amplifi er, using a 6K 7G T va lv e in Models 6 6 1 and 541,

operat i ng a t 457.6 kc. and f eed i ng i nto a 6 B8 G d uo-

dio-pen tode, who se diode s a r e used as demodulator

and A.V. C . rec tif ie r r espectiv ely . The p ent o de

sectio n of t his va l v e is resi sta nce -ca pacity-c ouple d to

a 6 V6 G out put valve. In M ode l 5 40, t h e I.F. amp l i fie r

is a 6U7G valve, operating a t 460 kc.

The broadc as t b a n d ae r i al coupling is

throug h a Litz-w ound iron-core c oil of e xcept i onally

high eff icien c y . A ll I.F. transformer s also employ

Litz-wou nd ir on-core coils and silver- coated titan ium

d i oxide fi x ed con d ense r s — tunin g bei ng acco m p lished

by axi a l a djustm ent o f the iron c o r e s . Indu ctive

pa ddin g of th e oscill a tor circu it is used on bot h w a ve

bands, thr ou gh th e me dium of adju stabl e iron core s;

special close toler ance fi xe d padd i ng con de n s er s are

used.

Model s 661 and 541 inco rpo rate the “ His

Master ’ s Voice” A utomat ic Exp anding Se l ector,

whic h comp r i s e s a special f orm o f I.F. am plif ier, w h ose

band widt h is di re ctl y cont rolle d by the s t ren gth

of the in c om i ng signal, pr ovidi ng br o ad tuning and

cons equent high f idelity o n powerfu l signals and

giv i ng p r ogr ess i v ely sha rper tun ing as signal streng t h

is r educed. Norma l 2-circuit i nput and output

tr ansformers a re used, b ut they are m ore cl os e ly

co upled than usual, t h u s giving a b road, f l at-t opped

res onan ce curv e o f low selec tivity , p ermi tti ng faith

ful transmis s i on of side b a n ds up t o a bout 5, 000

cyc l es/s e c. Feed-ba c k is t aken t hrough the co n

dens er C N fro m th e un-by-pas s ed I.F. cat h ode r esis t or

to the p l a t e of t he c o nverter valve ; this f e ed-back is

so ad juste d t hat whe n the I.F. valve is opera t i ng at

full sensiti vity, the c ou pling betwee n t he first I.F.

p rimary and secon dary is el ectrically loosened suffi

ci en t l y to provi de a res onanc e c urve , having a sin gle

sha rp peak and giv in g very h igh se l ec t i vit y. Ho wev er,

as th e bias on the I.F. v alv e is inc r e a s e d by A.V.C .

act i on on st ron g signals, its mu tu al co n ducta n c e is

re duced , all owi ng the fi r st I .F . tra nsf ormer t o ret ur n

to its nor mal br oad l y tu ned co nd ition. The con

denser C N is pr e c i s e ly adju sted a t the fa ctory and

seale d , and its ad justmen t shoul d und er no cir

cumsta nc es be i nterfere d with .

A.V .C. volt age is appli ed to the conve rte r and

I.F. valv es on b oth wave-band s; the ma ximu m contr ol

vo l tag e deriv ed from the A .V .C . dio de , wh ic h is fed

fr om the I.F. plate , is a pp l i ed to t he convert er, bu t

the I.F. val ve is cont ro l led by the r e c t i f ied signal

volta ge f rom the signal diode; this vol ta g e sim ul

taneously serving the purpose o f A. V.C. volt a ge, is

also applied to the 6 B8 G audio fre qu ency valve. In

Model 540, bo t h stages deriv e A .V.C. fr om the

A.V .C. diode.

Inv e rse feed -ba ck is a pplied to th e co mp l ete

au dio fr equency system th rough the Tone Mon itor

Control, from th e secondar y of th e o utpu t tra ns

fo rm e r to a tap on the Volum e Contr o l; in this w a y

the whole of th e A. F . circ uit s benefit fro m t he dis

tortion-red ucing prope rti es of such f e e d - b a ck. In

add i tio n, t he cir c uits a s s ociat e d w i th the Tone

Monitor Swit ch provi de var ying d e g re e s of feed

back differing wit h freq uency, thus en s u r ing con trol

of to nal balance . Furthermore, the deg r e e of f eed

back va r ie s wi th t he setting of the V olum e Co nt ro l

in such a way as to automatical l y prov ide the best

type of respon s e for b oth lo c a l and di stan t r eceptio n

and a t all v olume level s. T he sp eake r field win ding

is used as a fi lter c hoke, in conj un ction wi th t w o

16 mfd. w et elec trolyti c co nden sers, on e of which

is of the re g ula t i ng t ype. It is essentia l tha t the

positio ns of th e s e condensers in the ci r cu i t shall

no t be inte rchanged. The co ndens ers ar e mount ed

2

Loading...

Loading...