The Galley IBT-D-RSS-AU Installation Guide

Galley BarTap® Installation Guide

THEGALLEY®TA P

Before You Begin Installation

INSTALLATION WARNING: NEVER USE TEFLON TAPE FOR OUT-OF-THE-WALL THREADED CONNECTIONS. USE

PROVIDED RUBBER GASKETS ONLY. NOT COMPLYING WITH THIS INSTRUCTION COULD DAMAGE THE PRODUCT

AND GENERATE LEAKAGE.

1. Observe all local plumbing codes.

2. Turn o water supply.

3. Inspect water supplies for signs of damage. Replace if necessary.

4. DO NOT use petroleum-based products on this faucet.

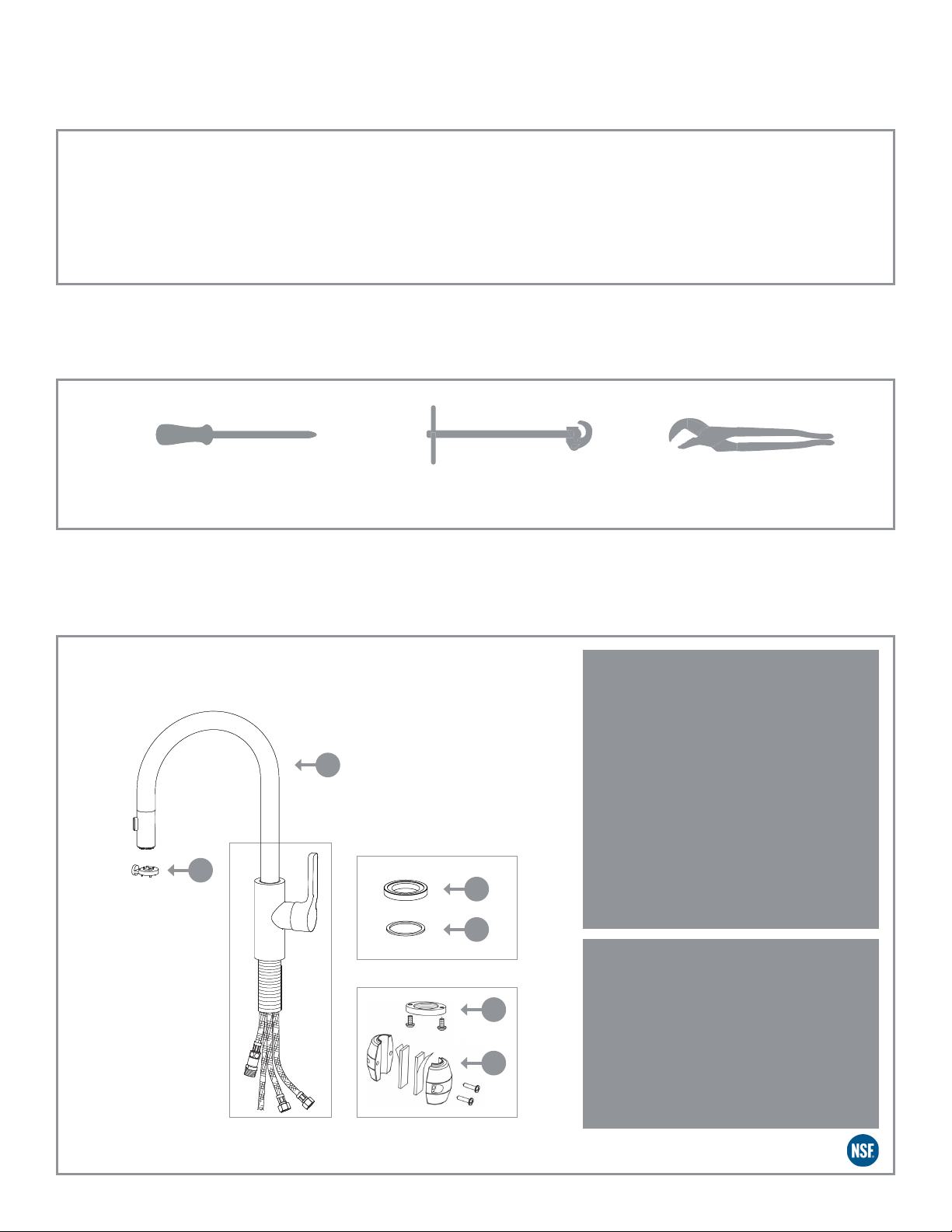

Tools

#2 & #3 PHILLIPS SCREWDRIVERS ADJUSTABLE WRENCH ADJUSTABLE PLIERS

Package Contents

1

Remove all contents from the package and

identify before installation.

1 - Aerator Key

2 - Faucet

2

1

3

4

5

6

3 - Optional Base Ring

4 - Stainless Steel Mounting Washer

5- Stainless Steel Mounting Nut with Two

Crosshead Screws

6- Counterweight with two rubber strips

Note: All Hoses come pre-installed into Faucet and

are water tested at the factory.

TECHNICAL INFORMATION

Recommended Pressure Range: 20PSI 75PSI

Maximum Flow Rate: l.8GPM / 6.8L /min

Maximum Temperature: 150° F

Product is Certified to NSF/ ANSI 372 and conforms with

the lead content requirements for “lead free” plumbing as

e defined by California, Vermont, Maryland, and Louisiana

state laws and the U.S. Safe Drinking Water Act. This

faucet complies with ASME 112.18.1-2018/CSA B125.1-2018

requirements.

1

Installation

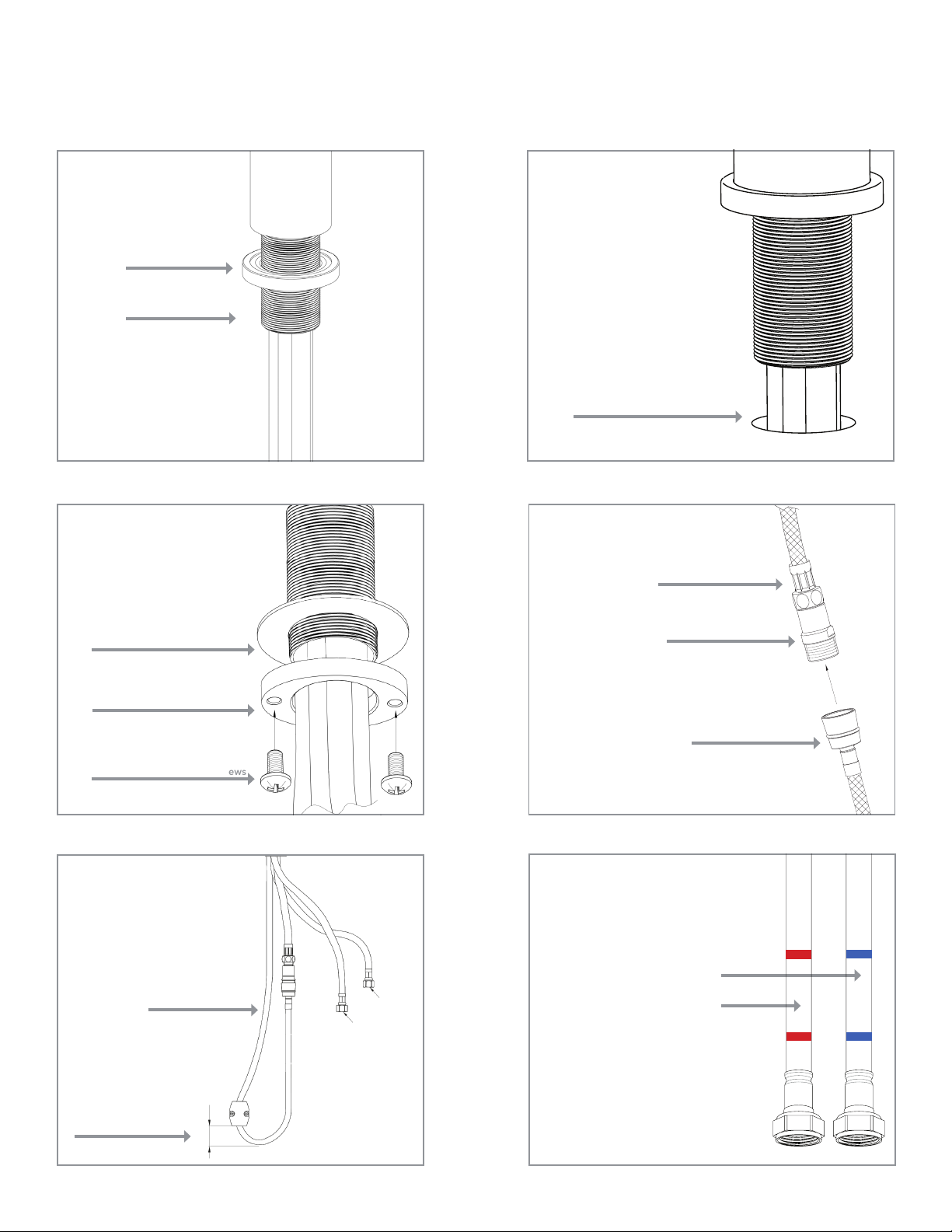

Step 1

The Galley BarTap® comes with

an Optional Base Ring. It can be

installed with the Base Ring or

without it.

Optional Base Ring

Mounting Shank

Step 3

On the underside of the counter

top, install the stainless steel

Washer and Mounting Nut by

slipping them over the hoses

and threading the nut onto the

Mounting Shank. Tighten the

Mounting Nut against the counter

top and tighten the two screws so

the faucet is secure.

Stainless Steel Washer

Step 2

Insert all hoses and Mounting

Shank through the hole in counter

top.

Ø 1-3/8” drill hole in counter top

Ø 1- 1/2” fast water jet hole in

counter top

Step 4

Connect the Hand Spray Hose to the

Hand Spray Supply Hose on which

the Check Valve housing is fitted.

Hand Spray Supply Hose

Check Valve Housing

Stainless Steel Mounting Nut

Stainless Steel Crosshead Screws

Step 5

Install the Counterweight onto the

Hand Spray Hose as shown.

Proper placement of the

Counterweights is critical for the

proper retraction of the spray hose.

Hand Spray Hose

VERY IMPORTANT!

1”

Hand Spray Hose

Note: make sure the Hand Spray Hose and

Counterweight are free to extend or retract and

are not in conflict with any plumbing components

or items under the sink or Workstation.

Step 6

Before connecting the hot and cold

Supply Hoses, flush water supply

stops to clear any debris. Place

a bucket underneath the stops

and run water for 5 to 10 seconds.

Carefully turn on the water.

Carefully position hot and cold

supplies so they will not interfere

with other hoses.

C

H

Connect the 3/8” Compression

Connections (Hot and Cold Supply

Hoses) to your hot and cold inlets.

Hoses are marked hot and cold.

Cold Supply

Hot Supply

2

Loading...

Loading...