The Eltron Company P600, P500 User Manual

User’s Guide

P500 and P600

User’s Manual No. 980179-001 Rev. A

1997 Eltron International Inc.

FOREWORD

This manualcontains installation and operation information for the Privilege Series card printers

manufactured by EltronInternational Incorporated, Simi Valley, California.

RETURN MATERIALS AUTHORIZATION

Before returning any equipment to Eltronfor in-warranty or out-of-warranty repair, contact RepairAdministrationfora Return MaterialsAuthorization(RMA)number.Repacktheequipment in

the originalpacking material and mark the RMA number clearly on theoutside. Ship theequipment, freight prepaid,to the address listed below:

Eltron Repair Administration, USA

41 Moreland Road

Simi Valley, CA. 93065

Phone: +1 (805) 579-1800

FAX: +1 (805) 579-1808

Label Printers: Card Printers:

Eltron International, Europe Eltron International, Europe

Eltron House Zone Indutrielle, Rue d'Amsterdam

Molly Millars Lane 44370 Varades, France

Wokingham RG41 2QZ England Phone: +33 (0) 240 097 070

Phone: +44 (0) 1189 770 300 FAX: +33 (0) 240 834 745

FAX: +44 (0) 1189 895 762

COPYRIGHT NOTICE

This document containsinformation proprietaryto EltronInternational Incorporated.This document and the information contained within is copyrighted by Eltron International Incorporated

and maynot be duplicated in fullor in partby any person without written approval from Eltron.

While every effort has beenmade tokeep theinformation containedwithin currentand accurate

as ofthe date of publication, no guarantee isgiven or impliedthat the document is error-free or

thatitisaccurate with regard toanyspecification.Eltronreservestherightto make changes,forthe

purpose of productimprovement, at any time.

TRADEMARKS

Privilege, Privilege P500 and Privilege P600 are service marks. PrivilegeCard is a trademarkof

PrivilegeCard,S. A., asubsidiaryofEltronInternationalIncorporatedand Eltron isatrademarkof

Eltron International Incorporated.Windows andMS-DOS areregistered trademarksof Microsoft

Corp. All othermarks are trademarks or registered trademarks of their respective holders.

980179-001 Rev. A iii

WARRANTY INFORMATION

We Need To Hear From You!

To Establish Your Warranty Period And Provide Access To Technical Support,

Send Us Your Product Registration Card Today!

Eltronwarrantsthemechanism, control electronicsandpowersupply,undernormaluse and service, to be free from defects inmaterial andworkmanship fora periodof twelve(12) monthsfrom

the dateof purchaseby theend user.Eltron warrants the print headand Laminatorhead, under

normal useand service,to befree from defects in materialand workmanshipfor a period of one

yearor 40,000passes(whichever occursfirst)from thedateof purchasebythe enduser.Proof of

purchaseor productregistrationisrequired. Ifproofof purchase orproductregistration cannot be

established,shipment datetothe originalbuyer(dealer ordistributor)will beusedto establishthe

warranty period.

Failureto exercise cautiontoprotect the equipmentfromelectrostatic dischargedamage,adverse

temperatureandhumidityconditions or physicalabusemayvoidthewarranty.Failure to useonly

Eltron approved media may void the warranty. Eltron will, at it’s option, repair or replace the

equipment or any parts which are determined to be defective within this warranty period, and

which are returnedto Eltron F.O.B. factory of origin.

The warranty set forth above is exclusive and no other warranty, whether written or oral, is expressed or implied. Eltron specifically disclaims the implied warranties of merchantability and fitness for aparticular purpose.

FCC NOTICE:

This equipment hasbeen tested and foundto comply with the limits of a Class B digital device,

pursuant to Part15 ofthe FCC Rules.These limitsare designedtoprovide reasonableprotection

against harmful interferencewhen theequipment isoperated in acommercial environment.This

equipment generates, uses and can radiateradio frequencyenergy and,if notinstalled andused

in accordance with the instructions, may cause harmful interference to radio communications.

However, there isno guaranteethat interference willnot occurin aparticularinstallation. Operationof thisequipmentin aresidentialarea islikelyto causeharmfulinterference inwhichcase the

user will berequired to correct the interference at his own expense.

INDUSTRY CANADA NOTICE:

This device complieswith Industry Canada ICS-003 class B requirements.

Cet equipement estconforme a l’ICS-003 classe B de la norm Industrielle Canadian

iv 980179-001 Rev. A

Icon Descriptions

Indicatesamechanicalhazard,suchas one associated with moving parts, capable of resulting in equipment damage or personal injury.

Indicates an electrical hazard, such as an exposedvoltagepoint, capableofcausing electrical shock and personal injury if touched.

Indicates information of particular interest that

requires consideration in the associated context.

Indicatesapartthatcan operate at anelevated

temperature capable of causing pain or a burn

if touched.

Indicates an area where an electrostatic discharge (ESD) can cause component damage.

Use a grounding wrist band.

Indicatesthatfiberdeposits from fibrouscleaning materials (e.g., cotton swabs) can reduce

print quality.

Indicates that exposure to dust and other airborne particles can contaminate the printer

and reduce print quality.

Indicates that except for card and ribbon loading and maintenance, the cover must remain

closed.

980179-001 Rev. A v

ELTRON INTERNATIONAL, INC.

declaresthat the

déclareque le

bescheinigt,daß dasGerät

declaraque el

dichiarache

P500 Card Printer

P600 Card Printer

isin conformancewiththe requirements oftheEuropean CouncilDirectiveslistedbelow:

estconforme auxspécificationsdes directives del'UnionEuropéenne ci-dessous:

dernachstehend angeführtenDirektivendes EuropäischenRats:

cumple

conlos requisitosdelas Directivas delConsejoEuropeo, segúnlalista siguiente:

èconforme allespecifichedelle sequenti direttivedell’UnioneEuropea:

89/336/EEC EMC Directive

92/31/EE EMC Directive

73/23/EEC Low Voltage Directive

Onthe approximationofthe lawsof MemberStatesrelating toElectromagneticCompatibility andProductSafety.

Baséessur lalégislation desEtatsmembres relativeà lacompatibilitéélectromagnétique età lasécurité desproduits.

Ü

berdie AnnäherungderGesetze der Mitgliedsstaateninbezug aufelektromagnetischeVerträglichkeit und

Basadoen

laaproximación delas leyesdelos PaísesMiembros respectoala Compatibilidadelectromagnética

Basatesulla legislazionedeglistati membrirelativa allacompatibilitáelettromagnetica ealla securezza deiprodotti.

Thisdeclaration isbasedupon compliance oftheproduct tothefollowingstandards:

Cettedéclaration reposesurla conformité duproduitaux normessuivantes:

DieseErklärung basiertdarauf,daß das Produktdenfolgenden Normen entspricht:

Estadeclaración sebasaen el cumplimientodelproducto conlassiguientes normas:

Questadichiarazione sibasasulla conformitá delprodottoalle normesequenti:

Produktsicherheitentspricht.

ylas Medidasdeseguridad relativasal producto.

EN 55022-A, CISPR 22RF Emissions Control

EN 500082-1 IEC 801Immunity to Electromagnetic Dicturbances

EN 60950 IEC 950 Product Safety

HughGagnier, President

ELTRONINTERNATIONAL, Inc.

41Moreland Road

SimiValley, CA93065-1692 U.S.A.

vi 980179-001 Rev. A

Table of Contents

Getting Started .......................1

Introduction ..........................1

Unpacking Privilege Card Printers ...............4

Check List ...........................5

Installation ...........................7

Upgrading to Expanded Memory ...............13

Expanded Memory Board Installation .............15

Operation ..........................17

Major Components ......................17

Controls & Indicators .....................18

Ribbon Preparation ......................20

Ribbon Loading ........................21

Handling the Media ......................25

Card Gate Adjustment .....................26

Printer Access and Usage ...................30

Printing ............................31

Adjustments ..........................32

Physical Processes .......................33

Cleaning The Printer......................37

Cleaning Stationary Card Path Items .............40

Cleaning the Card-Feed Roller.................41

Cleaning the Upper and Lower Cleaning Rollers........42

Print Head Cleaning ......................44

Cleaning the Transport and Platen Rollers ...........45

Cleaning Laminator Rollers ..................49

Magnetic Card Stripe Encoder ................51

Introduction ..........................51

Media Loading Orientation ..................52

Ensuring Data Reliability....................52

Encoding ...........................53

When to Clean the Encoder ..................55

Cleaning the Encoder .....................55

Adjustments ..........................55

Smart Card Contact Station .................57

Introduction ..........................57

Media Loading Orientation ..................58

Adjustments ..........................58

Smart Card Chip Interface ...................59

Media Jams ..........................60

980179-001 Rev. A vii

Appendix A

Trouble Shooting ......................61

Other Support Resources ...................64

Parallel Interface Cable Wiring.................65

Supported Card Media and Ribbon ..............65

Printer Features and Options .................68

Appendix B

Supplies and Accessories ..................71

Accessories ..........................71

Print Ribbons .........................72

Special Ribbons ........................72

Card Media ..........................73

Miscellaneous Supplies ....................73

Installable Options .......................73

Appendix C

Windows Card Printer Driver ................75

Installation of Printer Drivers..................75

Using the Windows 95 Driver .................83

Using The Windows 3.1 Driver ................92

Glossary ...........................101

viii 980179-001 Rev. A

Getting Started

Eltron

Privilege Multiple-

Station Card Printers

Thissectioncontainsinformation ontheinstallation of Eltron’s P500 and P600 Privilege

Multiple-Station card printers.

Introduction Eltron’s Privilege Series card printers offer a

low cost, high quality solution to those requiring computer-controlled printing and encoding of credit card style plastic cards. Card

applications include personalized identification, access control, visitor, membership, promotion and luggage card, badges and tags.

1

980179-001 Rev. A 1

Getting Started

Features

• 300 dots-per-inch print resolution for crisp,

clear printing.

• High resolution color dye sublimation technology supporting 32.7K colors for photo

quality imaging, along with:

Monochrome thermal transfer technology

for solid imaging of Bar Codes, Text and

Graphic Objects, each producable from

command parameters, making related bit

map downloads unnecessary.

• A Bar Code command thatcanproduceencodedcardprinting inanyof 10 residentbar

codeformats,and aTextcommand thatcan

produce text using 2 resident fonts.

• A 3-Track Magnetic Stripe Encoder option

that writes and then read-verifies data,

supporting cards with high- or lowcoercivity magnetic stripes. P500s can have

either up- or down-facing stripe encoders.

• P500s have Windows™ design and print

user software and a Windows™ printer control driver that supports True Type fonts.

• Efficiently designed to fit in minimum footprint,with asee-through coverthat offersusers a view of the process while offering

protection from exposure to environmental

contaminants.

• Produces duplex (two-sided) Prints on either plain or preprinted plastic card materials.

2

980179-001 Rev. A

Getting Started

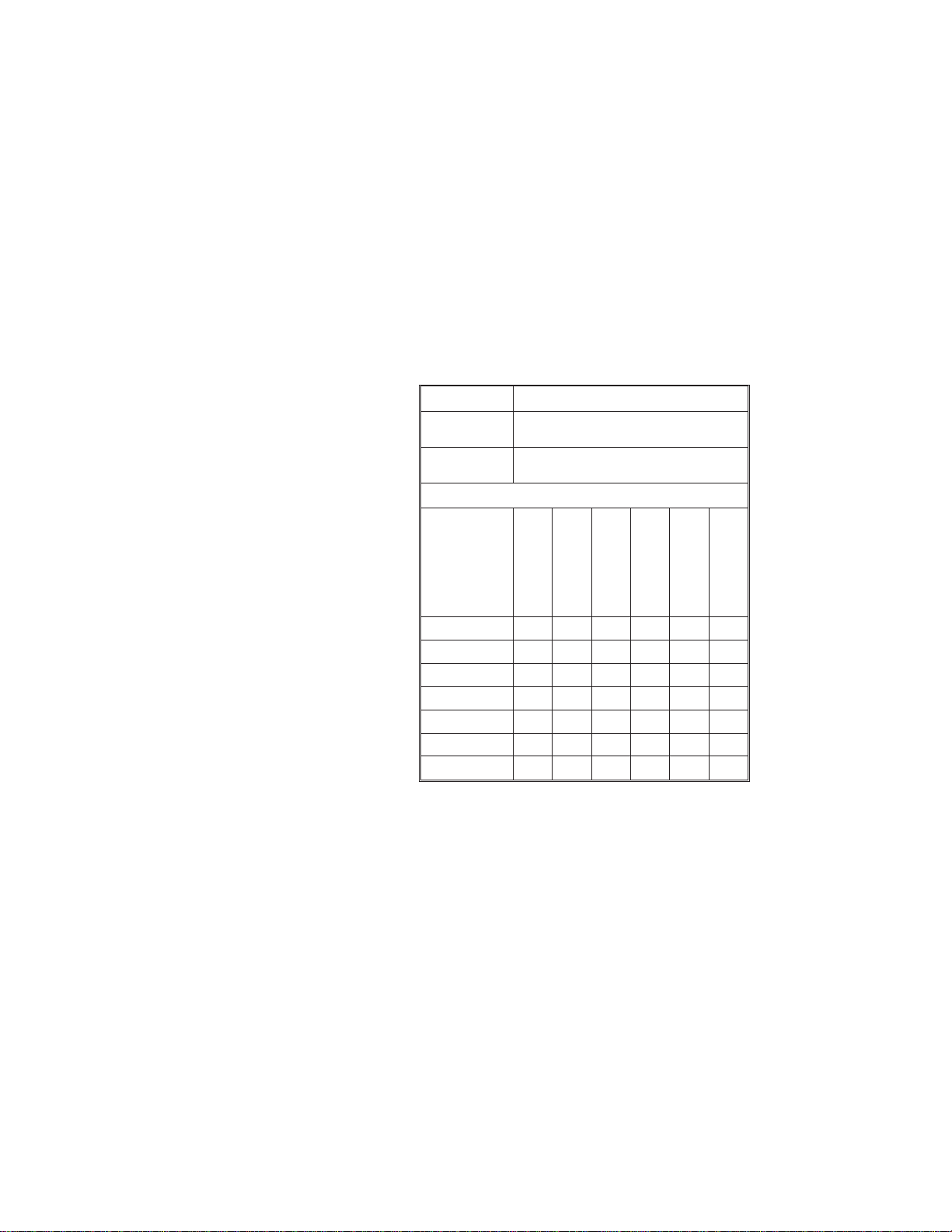

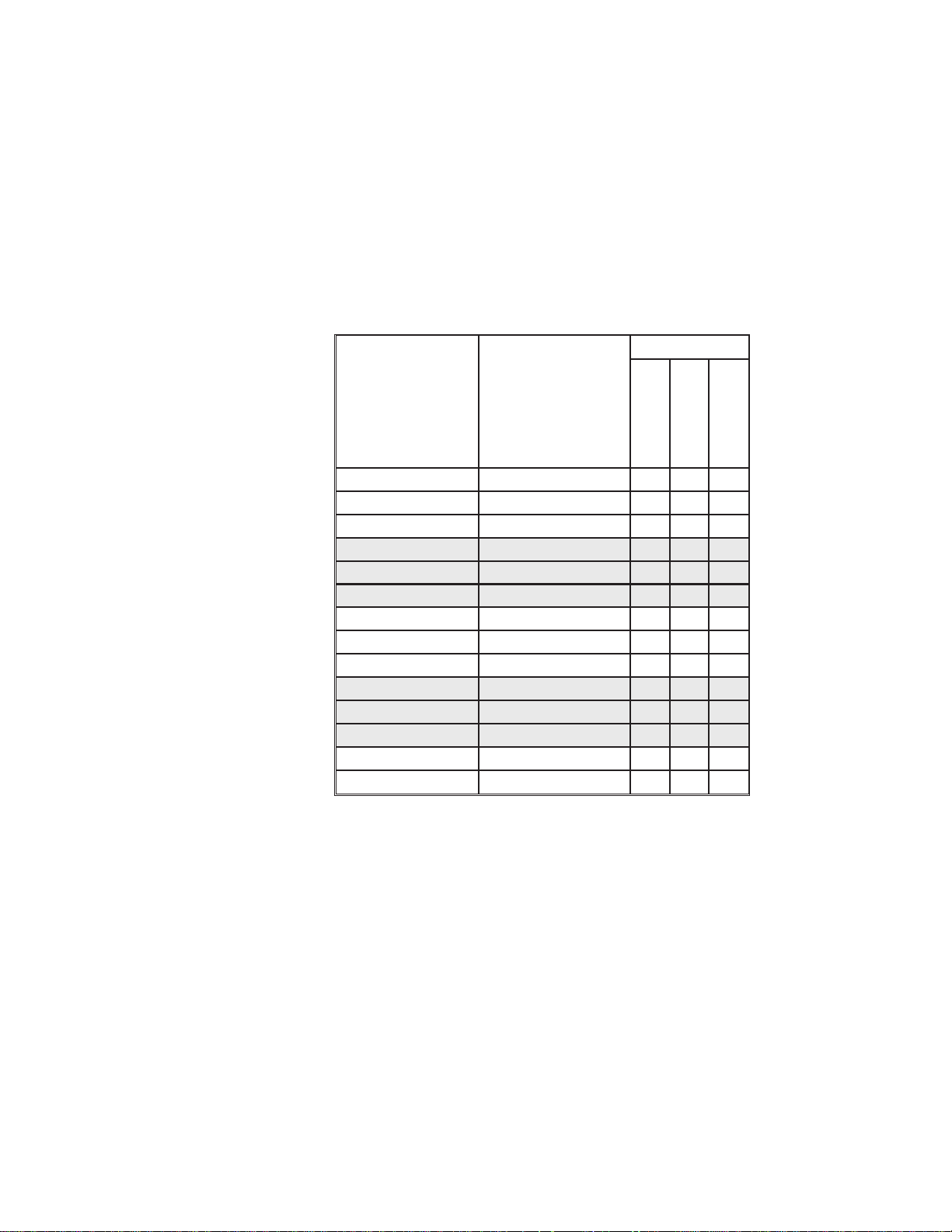

Models All printers have parallel printer ports. P500s

Include WindCard™ Classic Software. Printers

may be ordered in any of the following standard configurations:

Model No. Description

P500CF

120385-001

P600

120284-001

Option

No.’s

104525-001 •

104674-001 • •

104674-002 • •

104674-003 • •

104674-004 • •

300020-001 120V

300020-002 230V

Color Printer withLaminator

Multiple Station ColorPrinter

Options

Expanded Mem-

ory (P500)

Low Coercivity

Encoder

High Coercivity

Encoder

Encodes Down-

facing Stripe

Encodes Up-

facing Stripe

Power Cord

980179-001 Rev. A 3

Getting Started

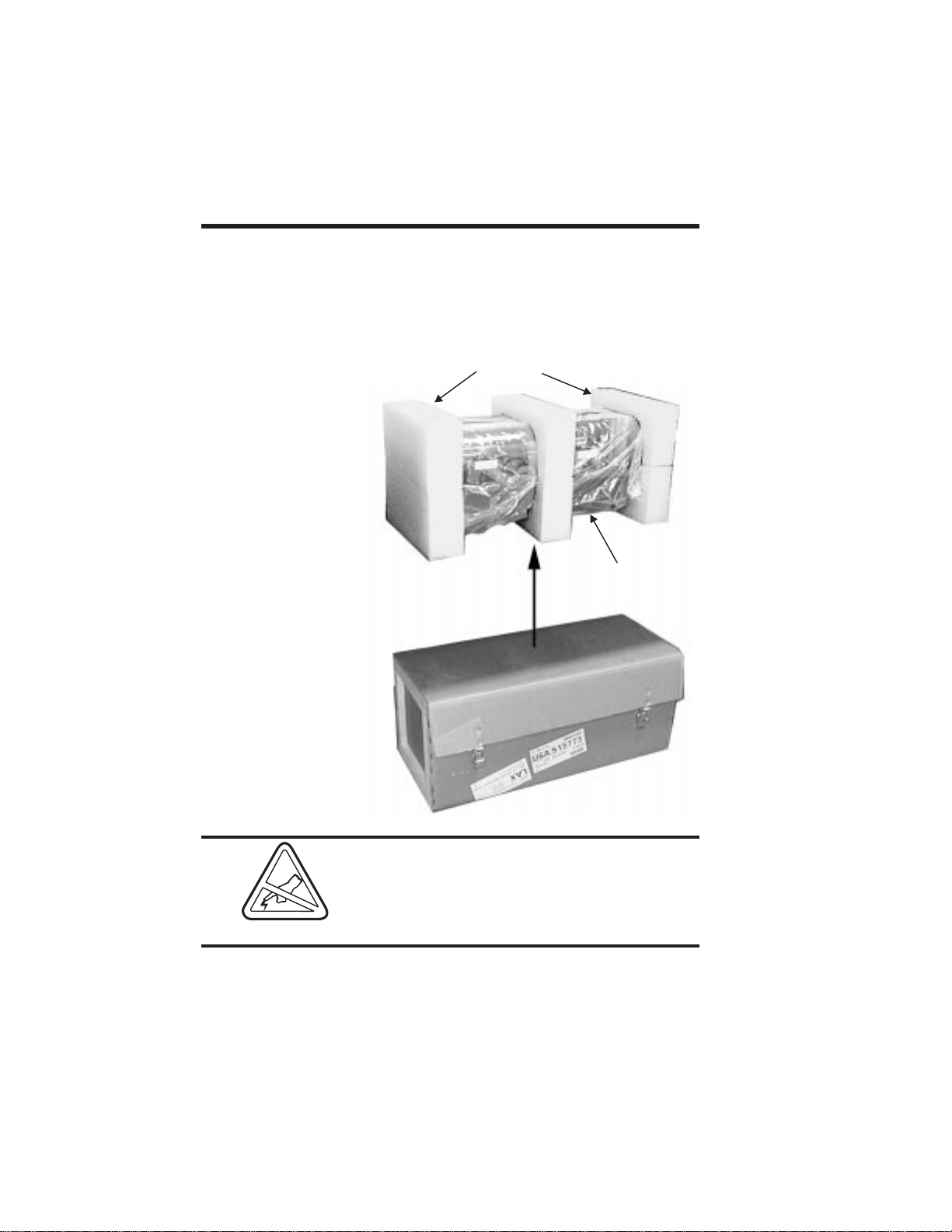

Unpacking

Privilege Card

Printers

Packing Materials

Supply Kit:

Supply Kit:

• Printer Cable

• Printer Cable

• Power Cord

• Power Cord

• Manuals

• Manuals

• Card Weight

• Card Weight

• Card Catcher

• Card Catcher

• Software (P500)

• Software (P500)

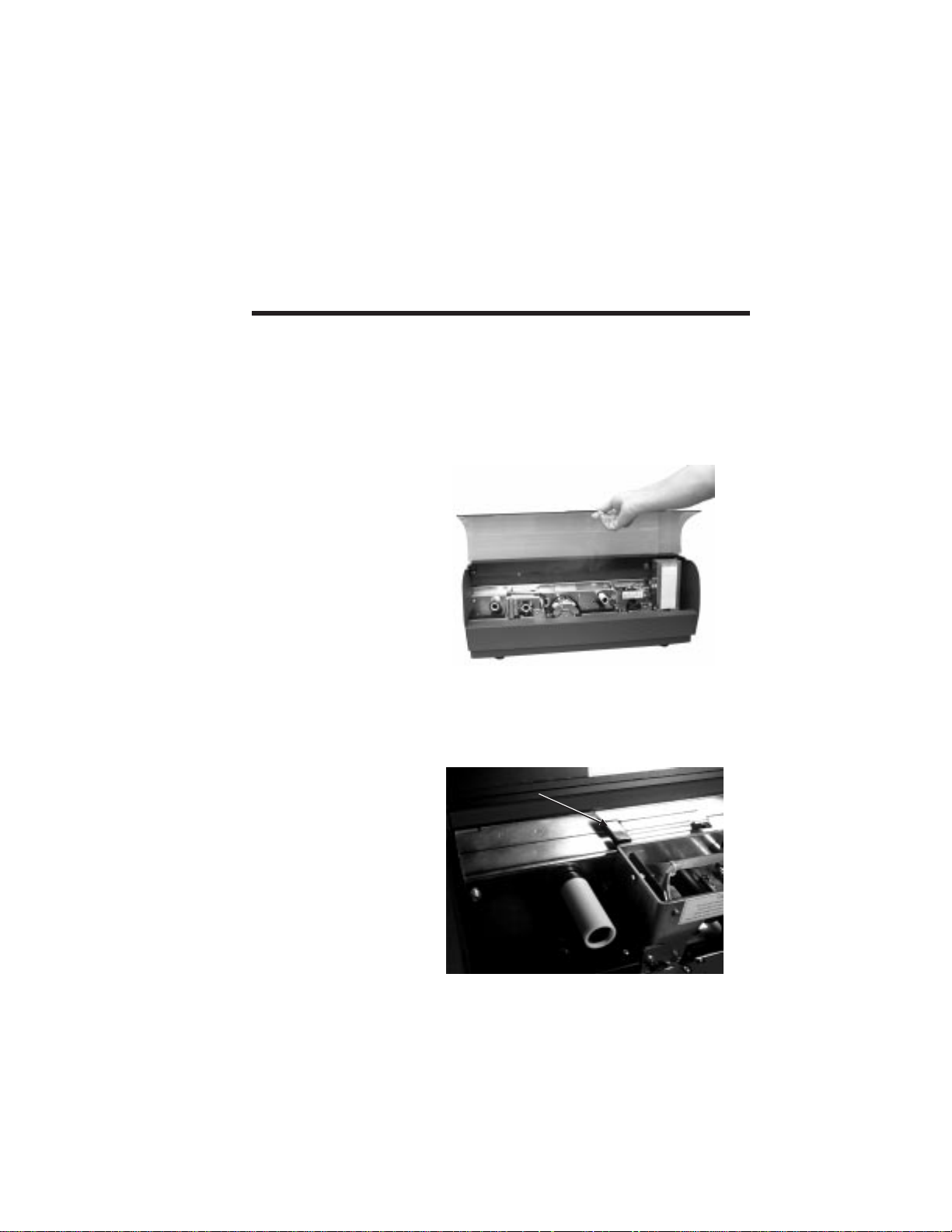

Printers ship in a carton and protective bag.

Keep all packing material in case the need to

move or reship the printer arises.Avoidtouchingtheelectricalconnectorstoprevent electrostatic discharge damage while setting up the

printer.

Foam End

Foam End

Cushons

Cushons

Printer in

Printer in

Shipping Bag

Shipping Bag

Thedischargeof electrostaticenergythat accumulates on the surface of the human body or

other surfaces can damage or destroy the

print head or other electronic components

used in this device.

4

980179-001 Rev. A

Getting Started

When unpacking the Privilege card printer

(and card media), be aware that a clean and

nearly dust free environment is required for

properoperation andstorage.Theprintquality

can be effected by dust, body oils and acids

(i.e., finger prints) and exposure to other foreignmaterialsduringunpacking orhandlingof

the printer and media.

Check List Your PrivilegeCard Printershipswiththeitems

listed below:

• Printer (Check for proper Model):

• Interface Cable

• Power Cord

980179-001 Rev. A 5

Getting Started

• Card Feeder Weight

• Card Catcher

• Manuals:

- Printer User’s Guide

• Software

• CD-ROM

- WindCard Software

- Windows Driver(s)

Ifanyitems aremissing,contact yourdealerfor

replacement parts.

6

980179-001 Rev. A

Getting Started

Cardmedia,ribbon, andsuppliesare available

from yourEltrondistributororcallELTRONat

(800) 344-4003 for the distributor nearest

you.Refer toAppendixBforcompletesupplies

ordering information.

Installation The following sections serve as a guide to

printer,WindCard™software,andWindows™

card printer driver installations.

Step Ê

Unpacking

Step Ë

Attach Power

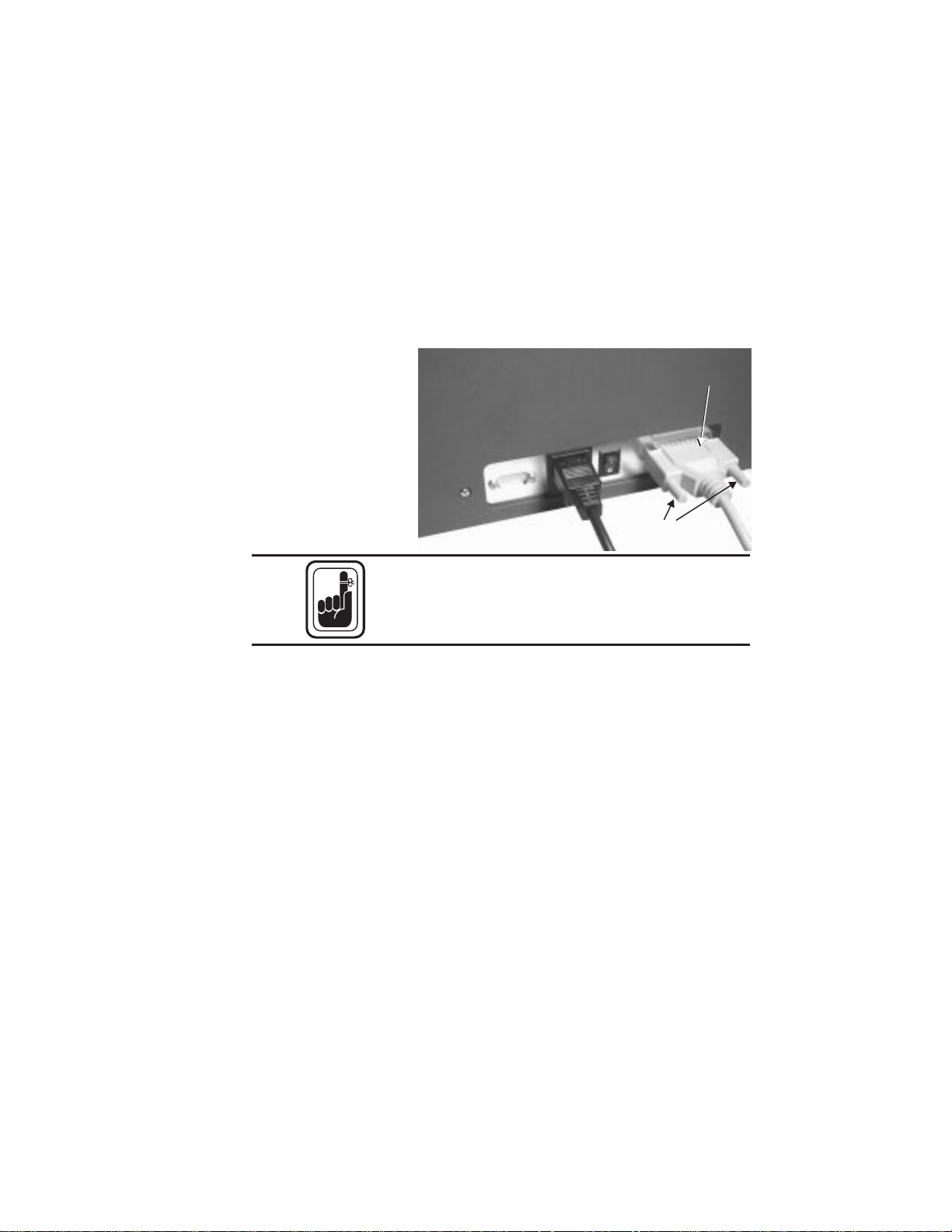

Figure 1-1

Printer

Rear Panel

With help from another person, remove the

printer from the carton and protective plastic

bag.

AC power supplied to Privilege card printers

must be current limited to 16-amps or less using an associated circuit breaker or other such

electrical device.

Place the printer in a clean, dust free loca-

tion that allows easy access to all sides of the

printer. Never operate the printer while it rests

on a side or upside down.

Set the AC power switch to the OFF (0) position.

AC Power Switch:

AC Power Switch:

1 = ON

1 = ON

O = OFF

O = OFF

980179-001 Rev. A 7

Getting Started

Power Switch

Connection

Figure 1-2

Positions

Switch OFF Switch ON

Never operate the printer in a location where

the operator, computer, or printer can get wet.

Personal injury could result.

Attach the AC power cord to the AC power receptacle in the rear of the printer.

Figure 1-3

Power

Attach the AC power cord to a grounded electricaloutlet ofthe propervoltageandplugtype.

Figure 1-4

AC Outlet

Connection

8

980179-001 Rev. A

Getting Started

Step Ì

Attach Interface

Cable

Figure 1-5

Interface

Cable

Attachandsecurethesupplied DB-25 (female)

to DB-25 (male) parallel printer cable between

the parallel port of the host computer and the

parallel interface connector on the back of the

printer.

Interface

Interface

Cable

Cable

Secure

Secure

Connector

Connector

Intermittent or unpredictable operationmay

occur from unsecured connectors.

See Appendixes A and B for cable specifications and ordering information.

Step Í

Applying Power

Setthepowerswitchto ON (1). Notethatmessagesappearon the LCDscreensasthe printer

cycles through the power-on sequence. Also

note that READY appears at the end of the sequence. If theseeventseitherfailtooccuror an

ERROR message appears instead of READY,

refer to Appendix A - Trouble Shooting.

980179-001 Rev. A 9

Getting Started

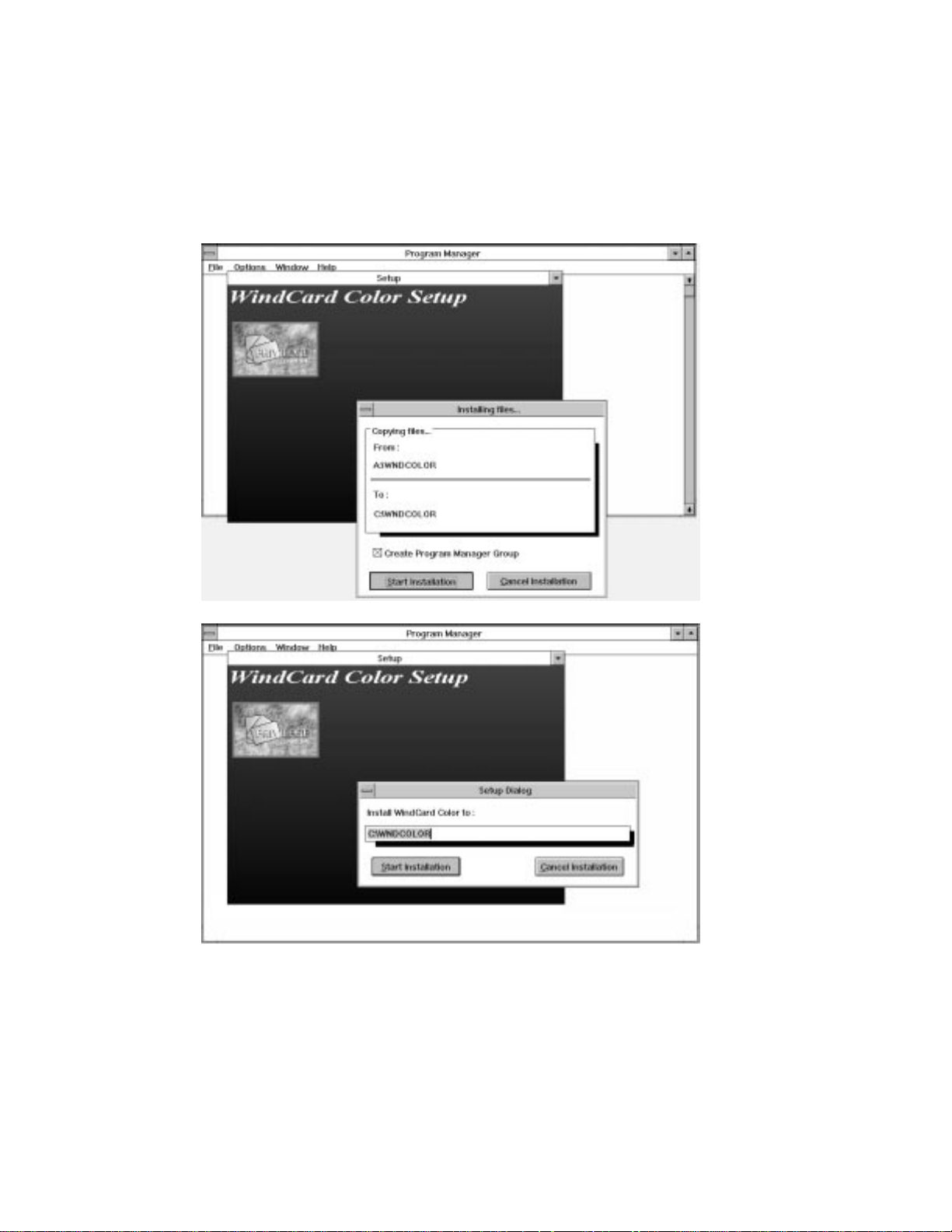

Step Î

Windows™ 3.1

Software

Installation

Startthehostcomputer.AfterDOShasloaded,

start Windows™. Insert the WindCard™ diskette into a floppy disk drive. From the Windows™ Program Manager‘s File pull-down

menu, select R

un....

Enter A:SETUP (or B:SETUP if you placed

the diskette in drive B). Press the Enter key.

10

Follow the installation instructions on the

screen to install the software.

Refer to Section 2, Operation, for information

on loading cards and ribbons and for initializing the printer for operation.

980179-001 Rev. A

Getting Started

See Appendix C for loading WindCard™ software into other operating platforms and the

Windows™ Printer Driver file.

980179-001 Rev. A 11

Getting Started

12 980179-001 Rev. A

Getting Started

Upgrading to

Expanded Memory

Users can field upgrade P500 printers to include ExpandedMemory.P600salreadyhave

thismemory.Onlythe CPUboardofModule 1

(the Print Station board) exhibits improved

performance with the Expanded Memory installed. The Memory Extension Board plugs

intotheCPU boardof Module 1. Accesstothis

board requires removal of the rearprintercase

assembly.

Avoid unnecessary risks! Removal of the

RearCase ofthe printerexposes CircuitBoards

thatcontainalithium batteries. These batteries

operate for long periods of time and, replacements may never become necessary. Anyone

replacing these batteries subjects his or herself

to the following risk:

WARNING:

• A Danger of Explosion exists if a

battery is incorrectly replaced.

• Replace only with the same or

equivalent type recommended by the

manufacturer.

• Dispose of used batteries according

to the manufacturer’s instructions.

Case removal exposes circuit points that, if

touched with power on, can present a hazard.

Therefore, never remove any case

component without first unplugging the

Power Cord.

980179-001 Rev. A 13

Getting Started

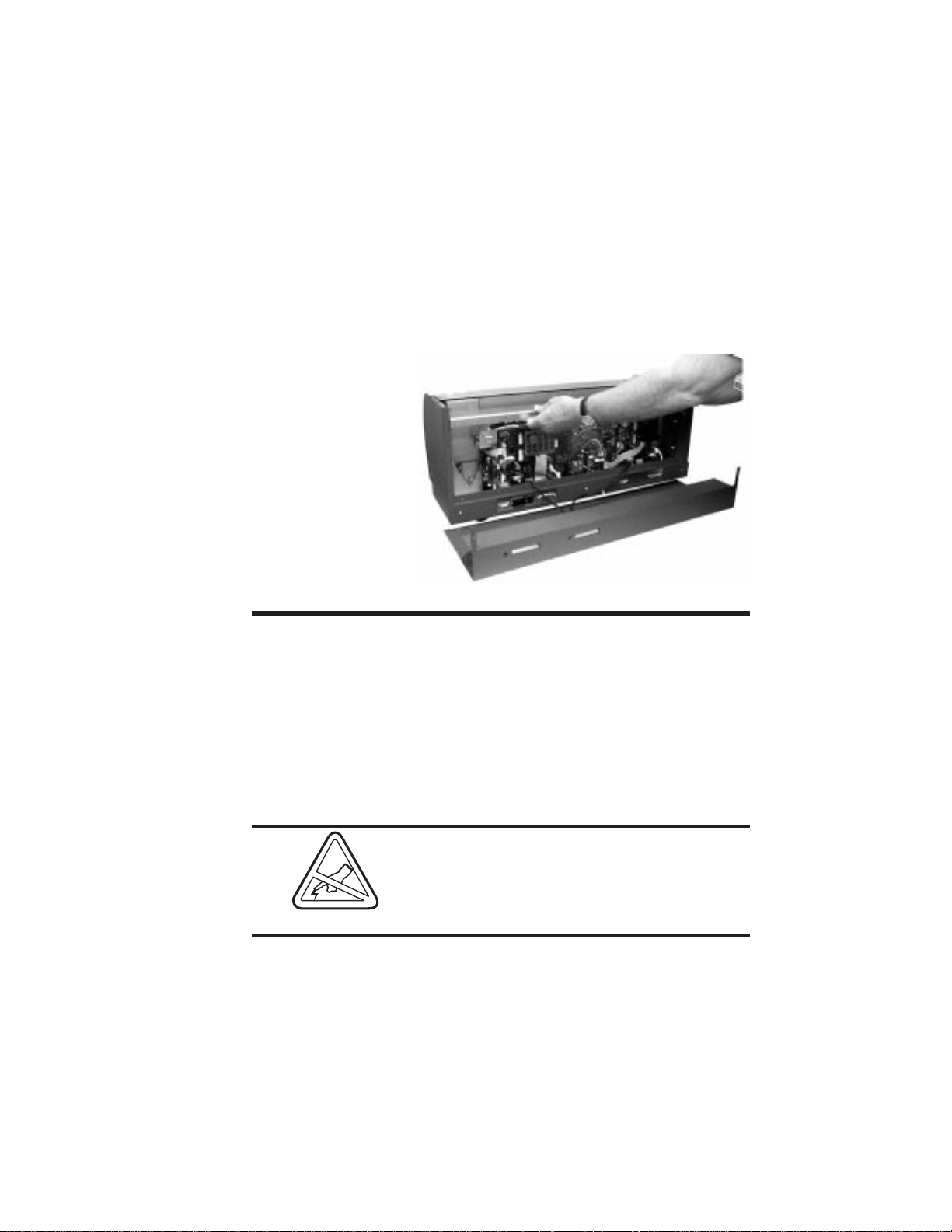

Case Removal

Step ¶

Figure 1-6

Screws Holding Rear

Case

Case Removal

Step ·

Using a one-millimeter Allen wrench, remove

the two screws holding the top of the case.

Then, using amediumPhillipsscrewdriver,remove the eight screws that secure the back of

the case.

Remove Allen

Remove Allen

Screws

Screws

Remove

Remove

Philips

Philips

Screws

Screws

Without letting the rear case move backward

fromitspositionwhilesecured, lifttherear case

straight up. Wires attached to the switches and

LCDs restrict how far the rear case can separate from the printer. Therefore, after freeing

therearcasefrom the printer,resttherear case

at a position that does not stress the wires.

Figure 1-7

Rear Case Removed

14

980179-001 Rev. A

Getting Started

Case Removal

Step 3

Figure 1-8

Bracket Removal

Expanded Memory

Board Installation

Removal of the upper Phillips screws frees a

bracket. First note the proper position of this

bracket, and then remove the bracket. If

replaced improperly, the rear case screws cannot be refastened.

The addition of an Expanded Memory board

in Module 1 of a P500 allows the host computer to download all image data in a continuous stream, instead of the single color

downloadsfollowed byassociated printingthat

occur without this addition. Multiple-card

printing occurs much faster with this option installed. Rear case removal gives access for this

upgrade.

Before touching any of the circuit components

on either the printer or the Expanded Memory

board,be sureto dischargeany staticchargeby

touching the metal chassis. Better yet, wear a

grounding wrist band.

980179-001 Rev. A 15

Getting Started

Installing the

Memory Board

Step ¶

Figure 1-9

Expanded Memory

Installation

Plug the Expanded Memory Board into the

two connectors on the upper right section of

theCPU boardof Module1. Matchtheconnectorssuchthat the ExpandedMemoryboardremains confined within the boundaries of the

CPU board, not oriented to extend over the

edge.

Installing the

Memory Board

16

Replacethebracketand printer casebyreversing the steps performed during their removal.

Step ·

980179-001 Rev. A

2

Operation

This section contains information on the operation of the Privilege card printer.

Major

Components

Figure 2-1 shows a P600 Card Printer. Note

that both models have similar

appearances—except,the P500hasaLaminatorwhere theP600 hasasecondPrintStation.

Card-Feed

Figure 2-1

Card-Flip

Major Components

Card

Card

Catcher

Catcher

Print or

Print or

Lamination

Lamination

Station

Station

980179-001 Rev. A 17

Card-Feed

Hopper

Hopper

Print

Print

Station

Station

Operation

Controls &

Indicators

The Power

Switch

Figure 2-2

Printer Controls

and Indicators

All the card printer controls and indicators, except for the power switch, reside on the top of

the printer.

The POWER SWITCH is located on back

panel of the printer. Placing the switch in the

ON (1) position applies power to the printer.

Placingtheswitchin the OFF(0)positionturns

off the printer. See Figures 1-1 and 1-2 in Section 1.

The POWER SWITCH also works in conjunction with the Panel Button. See the

Panel Button on the following pages.

Module-2 LCD

Module-2 LCD

and Button

and Button

Module-1 LCD

Module-1 LCD

and Button

and Button

The following LCD messages can appear:

18 980179-001 Rev. A

Operation

REPORTING LCD

LCD MESSAGES DESCRIPTIONS

Module 1 Print

Station

Module 2 Print

Station (P600)

INITIALIZING Printer Initializing • • •

WARMING UP P500 Laminator Wait •

READY Ready to Print • • •

PRINTING Printing in Progress • •

LAMINATING Lamination in Progress •

OUT OF RIBBON New Ribbon Required • • •

OUT OF CARD More Cards Required • • •

COMMAND ERROR Command/Parameter Error • • •

MECHANICAL ERROR Mechanical Problem • • •

ENCODING ERROR Read Verify Error • •

READING ERROR Error Reading Mag.Stripe • •

ROTATION ERROR Card-Flip Error •

TEMPERATURE ERROR Laminator Temp. Wait •

COVER OPEN To Proceed, Close Cover • • •

Module 2 Lami-

nation Station

See Appendix A for troubleshooting tips.

980179-001 Rev. A 19

Operation

Ribbon

Preparation

Figure 2-3

Ribbon and

Empty Core

Ribbon

Preparation

Step 1

Ribbon

Preparation

Step 2

Both the Print Stations and the P500 Lamination Station require the same pre-installation

ribbon preparations. To prepare a ribbon, the

taped end must be refastened to an empty

core. Eltron recommends the following:

Lamination

Place both the ribbon and an empty core on

end, next to one another, and touching. For

Lamination ribbons, the notched end of the

empty core must face up.

Untape the end that fastens the ribbon end to

the roll while leaving the tape attached on the

supply side.

Print

20

Ribbon

Preparation

Step 3

Figure 2-4

Ribbon

Preparation

Unwind enough ribbon to reach the empty

coreandtapetheend down. If boththeribbon

rollandthe emptycoreare kept touchingwhile

the tape is refastened, ribbon should be centered on thecore.Animproperlypreparedribboncanresultin wrinkling in theprinterduring

ribbon advances.

980179-001 Rev. A

Operation

Ribbon

Preparation

Wind one or two turns of ribbon onto the ribbon core.

Step 4

Ribbon Loading Ribbon loading involves the placement of the

prepared ribbon onto the Supply and Take-up

spindles.Similarprocedures applytoPrint Stations and Laminators, as follows:

Ribbon Loading

Lift open the cover.

Step 1

Figure 2-5

Raising the Cover

Ribbon Loading

Step 2

Press down on the Print/Lamination Head Release Latch to raise the Print Head. The Print

Head springs upward when released.

Press Here

Figure 2-6

Raising the Print

Press Here

to Raise

to Raise

Print Head

Print Head

Head

980179-001 Rev. A 21

Operation

DO NOT TOUCH the Print Head or nearby

electronic components. Discharged electrostatic energy from a person’s body or from

equipment can damage or destroy print heads

and other printer components.

Atthis pointconsider interruptingribbon installation to perform a cleaning, as described further on in this section. At the very least, wash

off any buildup on the Cleaning Rollers.

Ribbon Loading

Step 3

Using a prepared ribbon, unroll a comfortable

amount from the supply side to span the distance between the Supply and Take Up spindles. Then, at the same time, slide the Supply

and Take Up Cores onto their respective spindles.

Make suretopushbothfullyontothespindles.

Also make very sure that the ribbon comes off

ofthetop oftheSupply Spindleandfeeds onto

the top of the Take Up Spindle.

Note that for proper seating the take-up

cores of Lamination Ribbons have a slot

that must align with a screw on the takeup spindle.

Take extra care when installing a Print Station

ribbon. Printing with a reversed ribbon can

damage the Print Head or make an extensive

cleaning necessary.

22

980179-001 Rev. A

Loading...

Loading...