The Audio Circuit Mylar Brochure

®

Mylar

polyester film

Electrical Properties

Product Information

Mylar® offers unique design capabilities to the

electrical industry due to the excellent balance of

its electrical properties with its chemical, thermal,

and physical properties. Detailed descriptions of

these latter properties are included in other available bulletins. Table 1 is a summary of some

typical electrical properties; further details on these

and other electrical properties are included in the

remaining pages of the bulletin.

Dielectric Strength

The short-term dielectric strength test (ASTM

D149) is primarily used to measure the quality of a

film. This test method allows considerable freedom

in the choice of electrode size, environmental

conditions, etc. The following discussion of these

variables is based on tests run with brass electrodes

of the dimensions prescribed in ASTM D2305. In

limited testing, stainless steel electrodes gave

results similar to those obtained with the standard

brass electrodes. The data were obtained at a

frequency of 60 Hz, using a 500 V/sec rate of rise,

unless otherwise noted.

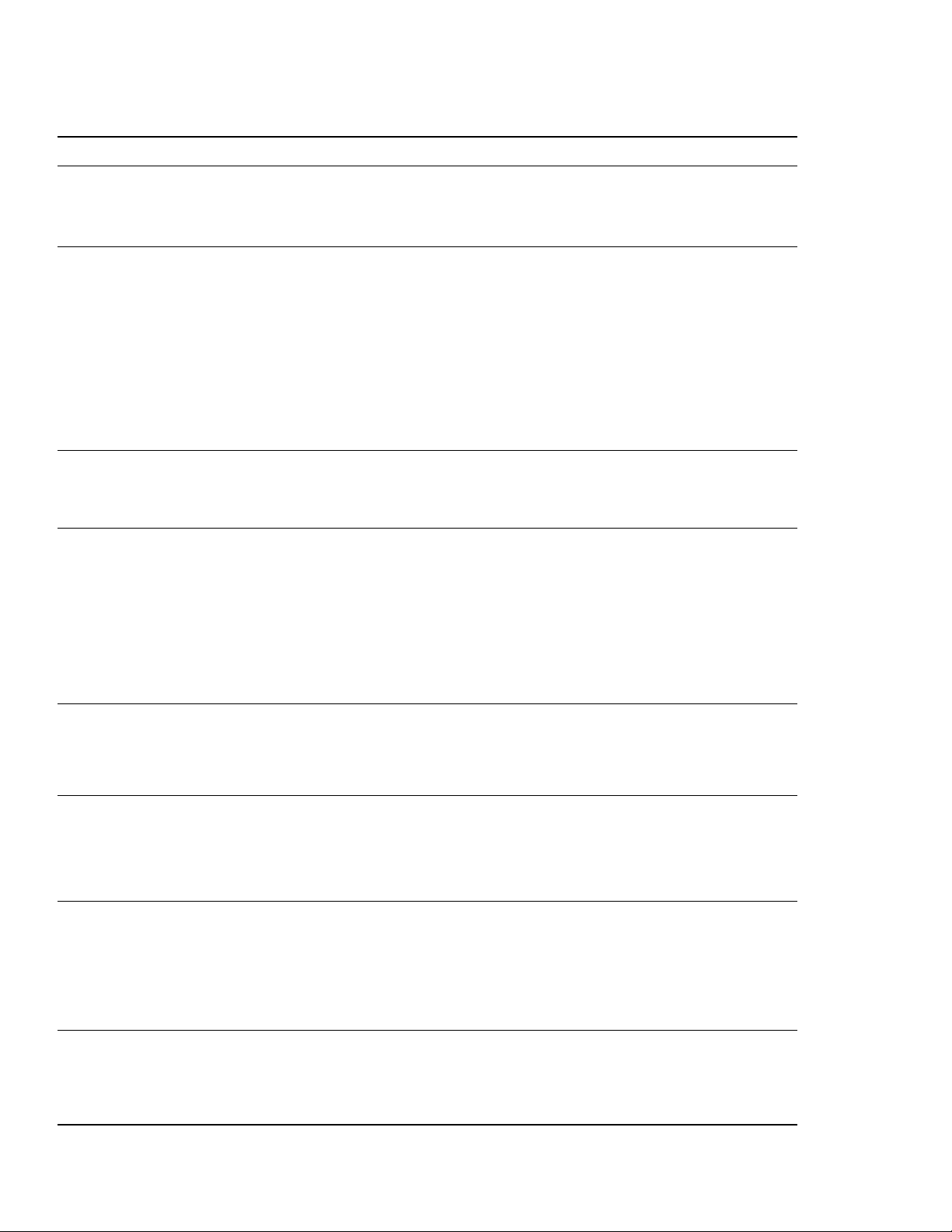

Film Thickness

As with most materials, the AC Dielectric Strength

of Mylar

thickness increases (see Figure 1). At 500 V/sec

rate of rise, corona occurs within a few seconds,

and the film begins to melt before the actual

breakdown occurs. The greater the film thickness,

the more the failure is due to melting and, thus, the

lower the V/mil as thickness increases.

®

polyester film in V/mil decreases as film

Electrode Size

Differences in dielectric strength values may result

when comparing

electrodes. Because of the larger film area between

the electrodes, the potential for lower dielectric

strength values is greater with 2-in electrodes.

Figure 1. Dielectric Strength vs. Thickness

Dielectric Strength, V/mil

(2 in Electrode in air at 25°C [77°F])

40,000

30,000

20,000

10,000

8,000

6,000

4,000

3,000

2,000

1,000

1

4 /12

1

/4 in and 2 in diameter brass

1 2 4 6 8 10 14 20/

Thickness, mil

Table 1

Typical Electrical Properties of Mylar Polyester Film

Property Value Test Method

DC Dielectric Strength Typical Value for Mylar 92 EL/C*

25°C (77°F) 11.0 kV/mil

Gauge and Type at 25°C (77°F) Minimum Values for Mylar C Film

6C 0.225 kV Minimum average

7C 0.300 kV voltage of 20 film-foil

8C 0.320 kV capacitors, 0.5 µF each

10C 0.490 kV

12C 0.650 kV

14C 0.825 kV

20C 1.500 kV

24C 2.000 kV

32C 3.100 kV 100 V/sec rate of rise

40C 4.100 kV

48C 4.900 kV

75C 5.500 kV

92C 6.000 kV

AC Dielectric Strength Typical Value for Mylar 92 EL/C*

25°C (77°F) 7.0 kV/mil ASTM D149 and

Gauge and Type at 25°C (77°F) Minimum Values for Mylar EL Film

48EL 2.8 kV ASTM D149 and D2305,

75EL 3.5 kV Minimum average

92EL 4.0 kV voltage of 10 sheet

142EL 5.5 kV samples

200EL 7.7 kV

300EL 10.0 kV 60 Hz

500EL 13.5 kV 500 V/sec rate of rise

750EL 17.5 kV

900EL 18.4 kV

1000EL 19.0 kV

1400EL 20.0 kV

Dielectric Constant Typical Value for Mylar 92 EL/C*

25°C (77°F)—60 Hz 3.3 ASTM D150

25°C (77°F)—1 kHz 3.25

25°C (77°F)—1 MHz 3.0

25°C (77°F)—1 GHz 2.8

150°C (302°F)—60 Hz 3.7

Dissipation Factor Typical Value for Mylar 92 EL/C

25°C (77°F)—60 Hz 0.0025 ASTM D150

25°C (77°F)—1 kHz 0.0050

25°C (77°F)—1 MHz 0.016

25°C (77°F)—1 GHz 0.008

150°C (302°F)—60 Hz 0.004

–269°C (–452°F)—1 kHz (in Helium) 0.0002

Volume Resistivity Typical Value for Mylar 92 EL/C

25°C (77°F) 1018 ohm⋅cm ASTM D257 and D2305

150°C (302°F) (Type C Film) 1013 ohm⋅cm

Surface Resistivity

23°C (73°F)—30% RH 1016 ohm/sq

23°C (73°F)—80% RH 1012 ohm/sq

Insulation Resistance

35°C (95°F)—90% RH 1012 ohm

Capacitor Insulation Typical Value for Mylar 92 C

Resistance

100°C (212°F) 30,000 MΩ-µF Based on 0.5 µF film125°C (257°F) 1,000 MΩ-µF foil capacitor sections,

150°C (302°F) 100 MΩ-µF using single layer, 92

*Data relevant for other types of Mylar

1

/4 in upper electrode

and flat plate lower

electrode. 500 V/sec

rate of rise

ASTM D2305

60 Hz

500 V/sec rate of rise

Mylar C

2

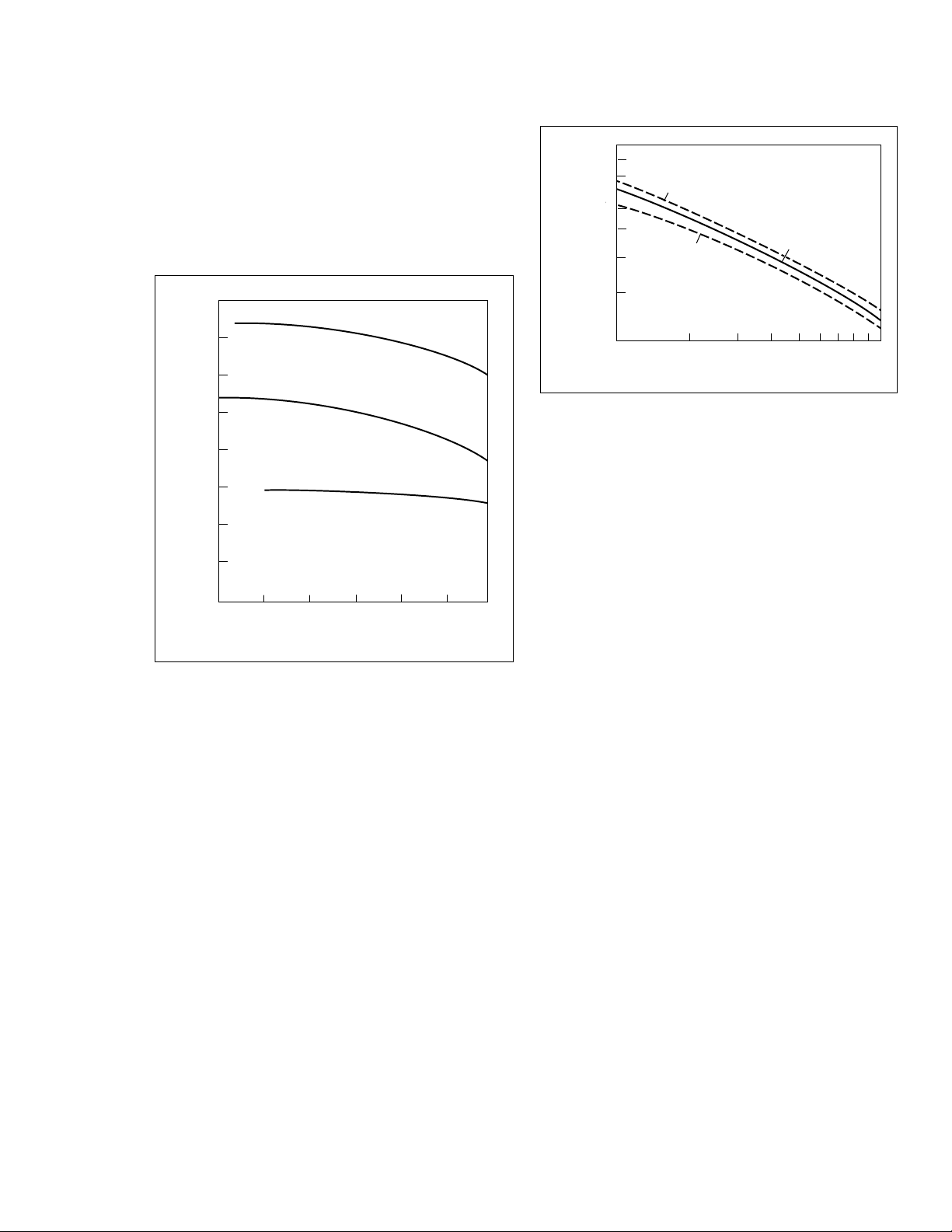

Temperature

The effect of film temperature on the dielectric

strength of Mylar

Figure 2; there is a slight decrease in dielectric

strength from room temperature up to 150°C

(302°F).

®

polyester film is shown in

Figure 3. Dielectric Strength at Various Humidities

10,000

8,000

6,000

20% RH

Figure 2. Dielectric Strength vs. Temperature

8,000

7,000

6,000

5,000

4,000

3,000

Dielectric Strength, V/mil

2,000

1,000

0

0

25

(32)

(77)

50

(122)

Temperature,

0.92 mil

75

(167)

2 mil

7.5 mil

100

(212)

°C (°F)

125

(257)

150

(302)

Humidity

While the dielectric strength of Mylar® is much less

sensitive to the humidity of the surrounding air than

cellulosic materials, there is a slight effect as shown

in Figure 3. For films above 2 mil thick, the effect

of varying the relative humidity from 20 to 80%

causes a maximum change in the dielectric strength

of less than ±10% from the value obtained at 35%

RH. The absolute differences in dielectric strength

as a result of humidity changes appear to be independent of electrode size.

4,000

Dielectric Strength, V/mil

2,000

12345678910

80% RH

Thickness, mil

35% RH

Frequency and Wave Form

The DC dielectric strength of Mylar® 92 EL varied

from 14,000 V at 25°C (77°F) to 12,000 V at 90°C

(194°F), 8,000 V at 150°C (302°F), and 5,500 V

at 200°C (392°F). These data were obtained with a

1

/4 in upper electrode and a flat plate lower elec-

trode using a 500 V/sec rise.

Deviations from a sinusoidal wave form can have

marked effects on the measured dielectric strength

at power frequencies. To simulate the effect of

transients, impulse strength tests were run using

1.5 × 40 µsec square wave forms and subjecting

specimens to five pulses at each voltage. (The

voltage was increased by several hundred volts

between each set of pulses.) The average impulse

strengths were 22 kV for Mylar

film and 26 kV for Mylar

samples were tested in air.

®

®

300 EL polyester

1000 EL when the

3

Loading...

Loading...