The Audio Circuit Hostaphan RE Brochure

®

WORLD CLASS

®

Hostaphan RE

Film for capacitors

®

Hostaphan RE is a biaxially oriented, heat set film, made of Polyethylene Terephthalate (PET) and characterised by

outstanding physical data. The film can be easily used with normal capacitor production lines. ®Hostaphan RE is

made from a very pure raw material that was specially developed for demanding dielectric applications.

In the ultra thin range, D025 was specially designed for very compact capacitor constructions. Its roughness value Ra is

about 10 nm below that of the standard film type in the corresponding thickness.

V024, which is especially strong lengthwise, is available in the 5 to 12µm range.

Characteristics:

- High mechanical strength and stiffnes for easy processing

- Particularly suited for metallizing, reliable self-healing characteristics

- Good electric values, such as high dielectric strength and favourable permittivity

- High capacity yield due to optimum surface structure

- Very good thermal characteristics, providing large range of operating temperatures for capacitors

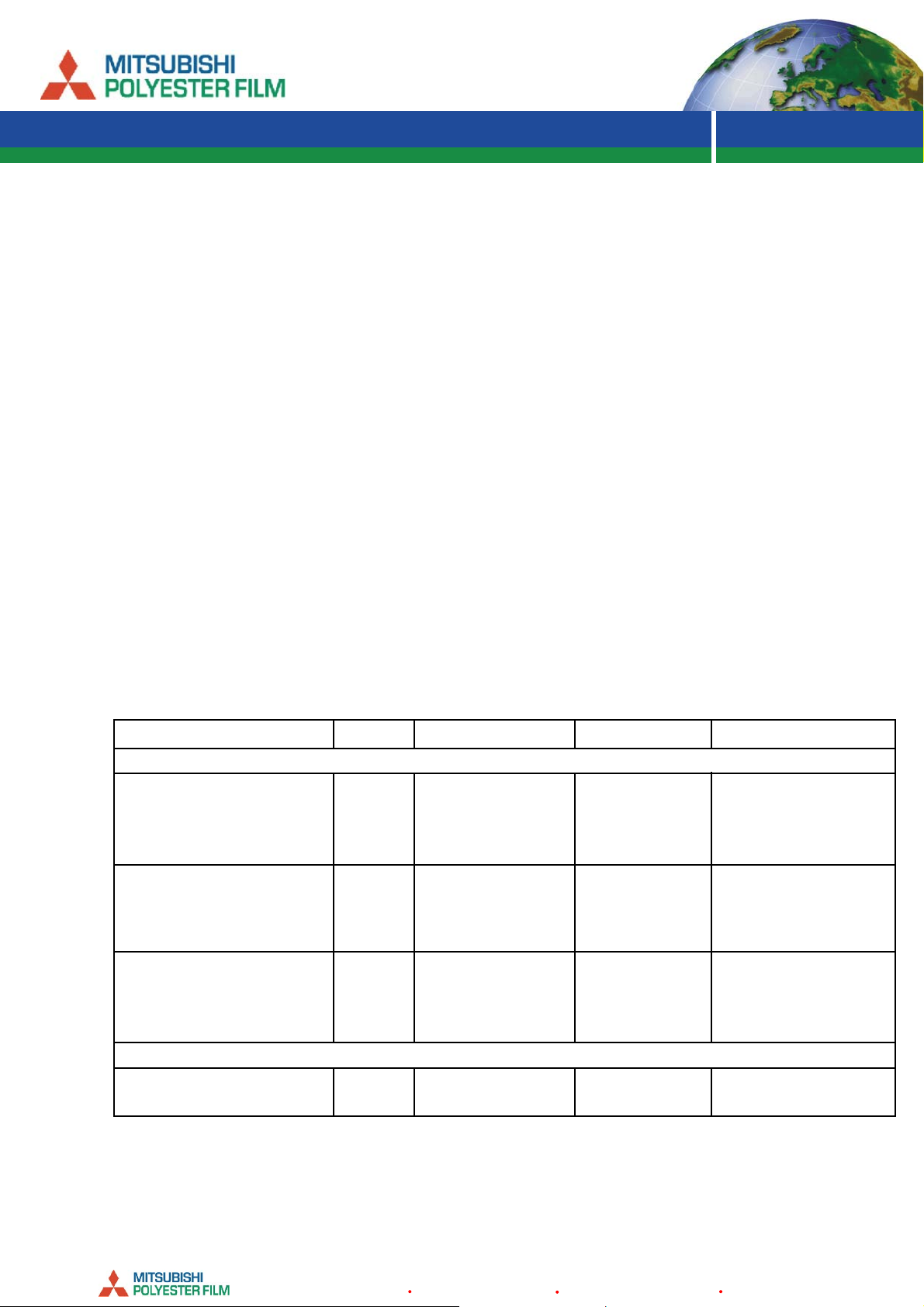

Typical Property Values

Property

MECHANICAL

Tensile strength**

_

RE < 5 µm/RE D025

RE V024 6 -12 µm

_

RE > 15 µm

Elongation at break**

_

RE < 5 µm/RE D025

RE V024 6 -12 µm

_

RE > 15 µm

Young´s modulus

_

RE < 5 µm/RE D025

RE V024 6-12 µm

_

RE > 15 µm

PHYSICAL/CHEMICAL

Density

*)

MD = machine direction, TD = transverse direction

**)

Reduced values for ultra thin films

Units

N/mm

N/mm

N/mm

%

%

%

N/mm

N/mm

N/mm

3

g/cm

Typical Values

2

MD* 200 TD* 200

2

MD* 350 TD* 200

2

MD* 200 TD* 200

MD* 100 TD* 100

MD* 50 TD* 100

MD* 100 TD* 100

2

MD* 4 500 TD* 5 000

2

MD* 6 300 TD* 4 300

2

MD* 4 500 TD* 5 000

1.395

Test Method

ISO 527-1-2

ISO 527-1-2

ISO 527-1-2

ASTM-D 1505-68

Method C

Test Conditions

Test speed 100 %/min.;

23 °C, 50 % r.h.

Test speed 100 %/min.;

23 °C, 50 % r.h.

Test speed 1 %/min.;

23 °C, 50 % r.h.

23 °C

Edition 11/03

Rheingaustraße 190-196 D-65203 Wiesbaden

Tel. ++49/611/9628817 Fax ++49/611/9629322

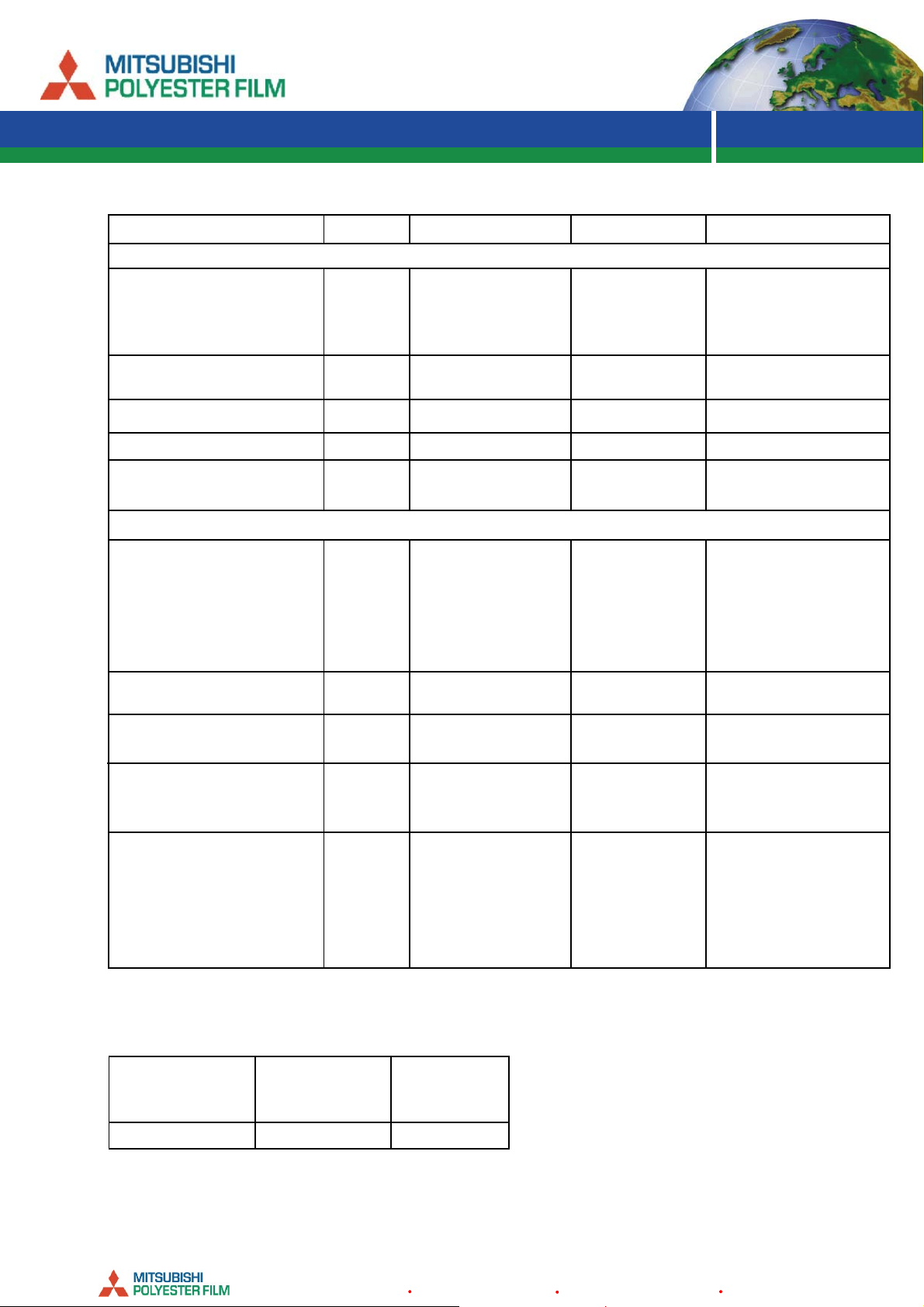

Typical Property Values

WORLD CLASS

Property

THERMAL

Shrinkage

RE < 5 µm/RE D025

_

RE V024 6 - 12 µm

_

RE > 15 µm

Melting point

Low temperature stability

Maximum working

temperature

Maximum ambient

temperature

ELECTRICAL

Dielectric constant

Units

%

%

%

°C

°C

°C

°C

-

-

-

-

-

-

Typical Values

MD* < 2.5 TD* < 2

MD* < 3 TD* < 2

MD* < 2 TD* < 1

260

- 196

up to 150

+ 125 letter code K

3.3

3.3

3.2

2.9

2.9

3.6

Test Method

DIN 40634

Differential

Scanning Calorimetry

DIN 53372

-

DIN 40040

DIN 53483

Test Conditions

150 °C, 15 min.

3 K/min.

tested as low as -196 °C***

in air

23 °C, 50 Hz

23 °C, 1 kHz

23 °C, 1 MHz

23 °C, 240 MHz

23 °C, 9 300 MHz

150 °C, 50 Hz

Dielectric strength

kV/mm

kV/mm

Volume resistivity

Ω x cm

Ω x cm

Surface resistance

Ω

Ω

Ω

Dielectric loss factor

(tan δ)

-

-

-

-

-

-

*)

MD = machine direction, TD = transverse direction

***)

The low temperature stability as per DIN 53372 can also be expected at even lower temperatures.

580

320

17

10

13

10

> 5 x 10

14

10

14

10

0.002

0.005

0.021

0.006

0.005

0.005

14

DIN 53481

DIN 53482

DIN 53482 or

VDE 0345

DIN 53483

Delivery program ®Hostaphan RE

Thickness range

µm

0.9 - 75

Core diameter: 150 mm

Standard roll

diameter

mm

210/240/270/310

Roll width

mm

315 to 900

Please contact us,

if other dimensions

are required.

23 °C, DC

23 °C, 50 Hz

23 °C, DC

150 °C

23 °C, 25 % r.h.

23 °C, 50 % r.h.

23 °C, 75 % r.h.

23 °C, 50 Hz

23 °C, 1 kHz

23 °C, 1 MHz

23 °C, 240 MHz

23 °C, 9 300 MHz

150 °C, 50 Hz

The information provided here is consistent with the state of our knowledge at the time of printing. If required please

request an up-to-date version of this publication. No representation of warranty is made for specific product properties

Edition 11/03

or the suitability of products in specific applications. Industrial property rights must be observed. We warrant full

product quality under the terms of the General Conditions of Sale of MITSUBISHI POLYESTER FILM GmbH.

Rheingaustraße 190-196 D-65203 Wiesbaden

Tel. ++49/611/9628817 Fax ++49/611/9629322

Loading...

Loading...