Pilot Operating Handbook

The Airplane Factory SLING

THE AIRPLANE FACTORY (Pty) Ltd.

HANGAR 8 TEDDERFIELD AIR PARK, JHB SOUTH, EIKENHOF, 1872, SOUTH AFRICA

PO BOX 308, EIKENHOF, 1872, SOUTH AFRICA

Phone: +27 11 948 9898

Information: info@airplanefactory.co.za

The Airplane Factory, Inc

3401 Airport Drive, Torrance, CA, 90505

Phone: 424-241-0341

info@airplanefactory.com

Date of Issue: 07 July 2014 Revision Number: 1. 3

This airplane must be operated in

compliance with information and

limitations contained herein. This

pilot operating handbook must be

available on board of the airplane at

all times.

Airplane model : Airplane Factory Sling LSA

Manufacturer : The Airplane Factory (Pty) Ltd

Airplane Serial Number : ……………………………….

Date of Construction : ………………………………..

Registration : ……………………………………….

Airworthiness Category : Light Sport Aircraft (LSA)

Issue Date of POH : 07 July 2014

PLEASE ADVISE THE AIRPLANE FACTORY ON CHANGE

OF OWNERSHIP OF THE AIRCRAFT

Date of Issue: 07 July 2014 Revision : 1.3

Page | ii

NOTICE

WITH RESPECT TO ELECTRICAL WIRING, AIRCRAFT MANUFACTURED BEFORE

AUGUST 2014 MAY NOT BE FULLY COMPLIANT WITH THIS MANUAL.

THIS MANUAL IS WRITTEN FOR THE STANDARD 912 ULS POWERED SLING LSA,

AS MANUFACTURED ON PREMISES BY THE AIRPLANE FACTORY (PTY) LTD).

DIFFERENCES APPLICABLE TO THE STANDARD 912 iS POWERED SLING LSA

AIRCRAFT, AS MANUFACTURED ON PREMISES BY THE AIRPLANE FACTORY

(PTY) LTD, ARE INCLUDED IN A SUPPLEMENT IN SECTION 9 OF THIS

HANDBOOK.

AIRCRAFT WHICH DIFFER FROM THE PRODUCTION STANDARD, IN WHATEVER

WAY, ARE NOT ADDRESSED IN THIS MANUAL, EXCEPT TO THE EXTENT SAID

AIRCRAFT CORRESPOND WITH THE PRODUCTION STANDARD.

NOTICE

THIS EDITION OF THIS MANUAL IS APPLICABLE TO AIRCRAFT REGISTERED IN

THE USA. DEFINITIONS ARE ACCORDINGLY CONSISTENT WITH US

REGULATIONS ONLY.

Date of Issue: 07 July 2014 Revision : 1.3

Page | iii

POH Compliance Notice

ASTM Standards used for the design, construction, and continued

airworthiness:

ASTM F2279.

ASTM F2295.

ASTM F2245.

Quality assurance records are stored both with the original

manufacturer in South Africa and with its US distributor at the

addresses below.

The Airplane Factory (Pty) Ltd

Hangar 8 Tedderfield Air Park, Johannesburg South, Eikenhof, 1872,

South Africa

PO Box 308, Eikenhof, 1872, South Africa

Phone: +27 11 948 9898

info@airplanefactory.co.za

The Airplane Factory USA

3401 Airport Drive, Torrance, CA, 90505

Phone: 424-241-0341

info@airplanefactory.com

Page | iv

Date of Issue: 07 July 2014 Revision : 1.3

Airplane Factory SLING LSA

Pilot Operating Handbook

Continued Operational Safety Monitoring

Manufacturer Responsibilities

The Airplane Factory has a procedure in place to monitor the safety of

the fleet and to alert pilots of any potential safety issues. The owner of a

Light Sport Aircraft is responsible for making sure they receive pertinent

safety information and complying with bulletins. The owner of a Light

Sport Aircraft is also responsible for alerting the manufacturer of any

potential safety of flight issues.

Report a Safety of Flight Issue

Please contact our US Distribution Center to report any maintenance,

service or safety issues.

Service/Maintenance/Safety issues: safety@airplanefactory.com

or

fill out a safety/service form on our website: www.airplanefactory.com.

Sign up to receive safety notices

Method for Owner/Operator to obtain the latest Safety of Flight

Information:

Please sign up on our website for continued safety/service updates:

www.airplanefactory.com, or call 424-241-0341, and we’ll sign you up. In

addition, all updates will be posted to our website.

Page | v

Date of Issue: 07 July 2014 Revision : 1.3

Airplane Factory SLING LSA

Pilot Operating Handbook

Detailed Owner/Operator Responsibilities

Each owner/operator of a LSA shall read and comply with the

maintenance and continued airworthiness information and instructions

provided by the manufacturer.

Each owner/operator of a LSA shall be responsible for providing the

manufacturer with current contact information, where the

manufacturer may send the owner/operator supplemental notification

bulletins.

The owner/operator or a LSA shall be responsible for notifying the

manufacturer of any safety of flight issue or significant service difficulty,

upon discovery.

The owner/operator of a LSA shall be responsible for complying with all

manufacturer issued notices of corrective action and for complying with

all applicable aviation authority regulations in regard to maintaining the

airworthiness of the LSA.

An owner of a LSA shall ensure that any needed corrective action be

completed as specified in a notice, or by the next scheduled annual

inspection.

Should an owner/operator not comply with any mandatory service

requirements, the LSA shall be considered not in compliance with

applicable ASTM standards and may be subject to regulatory action by

the presiding aviation authority (FAA).

Page | vi

Date of Issue: 07 July 2014 Revision : 1.3

Airplane Factory SLING LSA

Rev

No.

Affected

Section

Affected

Pages

Date of

Issue

Approve

d by

Date of

approval

Date

inserted

Sign.

1.1

All

All

04/20/2011

1.2

All

All

03/12/2012

1.3

All

All

07/07/2014

Pilot Operating Handbook

RECORD OF REVISIONS

Any revisions to this Pilots Operating Handbook must be recorded in the

following table, and, where applicable, be endorsed by the responsible

airworthiness authority

Revision numbers and dates appear at the foot of each page.

Date of Issue: 07 July 2014 Revision : 1.3

Page | vii

Airplane Factory SLING LSA

Page

Page

Status

Latest

Revision

Page

Page

Status

Latest

revision

i

Revised

1.3

1-10

Revised

1.3

ii

Revised

1.3

1-11

Revised

1.3

iii

Revised

1.3

1-12

Revised

1.3

iv

Revised

1.3

1-13

Revised

1.3

v

Revised

1.3

1-14

Revised

1.3

vi

Revised

1.3

1-15

Revised

1.3

vii

Revised

1.3

1-16

Revised

1.3

viii

Revised

1.3

1-17

Revised

1.3

ix

Revised

1.3

1-18

Revised

1.3

x

Revised

1.3

2-1/2-

2

Revised

1.3

xi

Revised

1.3

2-3

Revised

1.3

xii

Revised

1.3

2-4

Revised

1.3

1-1/1-

2

Revised

1.3

2-5

Revised

1.3

1-3

Revised

1.3

2-6

Revised

1.3

1-4

Revised

1.3

2-7

Revised

1.3

1-5

Revised

1.3

2-8

Revised

1.3

1-6

Revised

1.3

2-9

Revised

1.3

Pilot Operating Handbook

LIST OF EFFECTIVE PAGES

Date of Issue: 07 July 2014 Revision : 1.3

Page | viii

Airplane Factory SLING LSA

1-7

Revised

1.3

2-10

Revised

1.3

1-8

Revised

1.3

2-11

Revised

1.3

1-9

Revised

1.3

2-12

Revised

1.3

2-13

Revised

1.3

3-14

Revised

1.3

2-14

Revised

1.3

3-15

Revised

1.3

2-15

Revised

1.3

3-16

Revised

1.3

2-16

Revised

1.3

3-17

Revised

1.3

2-17

Revised

1.3

3-18

Revised

1.3

2-18

Revised

1.3

3-19

Revised

1.3

2-19

Revised

1.3

4-1/4-

2

Revised

1.3

2-20

Revised

1.3

4-3

Revised

1.3

2-21

Revised

1.3

4-4

Revised

1.3

2-22

Revised

1.3

4-5

Revised

1.3

3-1/3-

2

Revised

1.3

4-6

Revised

1.3

3-3

Revised

1.3

4-7

Revised

1.3

3-4

Revised

1.3

4-8

Revised

1.3

3-5

Revised

1.3

4-9

Revised

1.3

3-6

Revised

1.3

4-10

Revised

1.3

3-7

Revised

1.3

4-11

Revised

1.3

3-8

Revised

1.3

4-12

Revised

1.3

Pilot Operating Handbook

Date of Issue: 07 July 2014 Revision : 1.3

Page | ix

Airplane Factory SLING LSA

3-9

Revised

1.3

4-13

Revised

1.3

3-10

Revised

1.3

4-14

Revised

1.3

3-11

Revised

1.3

4-15

Revised

1.3

3-12

Revised

1.3

4-16

Revised

1.3

3-13

Revised

1.3

4-17

Revised

1.3

Pilot Operating Handbook

Date of Issue: 07 July 2014 Revision : 1.3

Page | x

Airplane Factory SLING LSA

Page

Page Status

Latest Revision

Page

Page Status

Latest Revision

4-18

Revised

1.3

7-6

Revised

1.3

4-19

Revised

1.3

7-7

Revised

1.3

4-20

Revised

1.3

7-8

Revised

1.3

5-1/5-2

Revised

1.3

7-9

Revised

1.3

5-3

Revised

1.3

7-10

Revised

1.3

5-4

Revised

1.3

7-11

Revised

1.3

5-5

Revised

1.3

7-12

Revised

1.3

5-6

Revised

1.3

7-13

Revised

1.3

5-7

Revised

1.3

7-14

Revised

1.3

6-1/6-2

Revised

1.3

7-15

Revised

1.3

6-3

Revised

1.3

7-16

Revised

1.3

6-4

Revised

1.3

7-17

Revised

1.3

6-5

Revised

1.3

7-18

Revised

1.3

6-6

Revised

1.3

7-19

Revised

1.3

6-7

Revised

1.3

7-20

Revised

1.3

6-8

Revised

1.3

7-21

Revised

1.3

6-9

Revised

1.3

7-22

Revised

1.3

7-1/7-2

Revised

1.3

7-23

Revised

1.3

7-3

Revised

1.3

7-24

Revised

1.3

7-4

Revised

1.3

7-25

Revised

1.3

7-5

Revised

1.3

7-26

Revised

1.3

Pilot Operating Handbook

Date of Issue: 07 July 2014 Revision : 1.3

Page | xi

Airplane Factory SLING LSA

Page

Page Status

Latest

Revision

Page

Page

Status

Latest

Revision

7-27

Revised

1.3

9-7

Revised

1.3

7-28

Revised

1.3

9-8

Revised

1.3

7-29

Revised

1.3

9-9

Revised

1.3

7-30

Revised

1.3

9-10

Revised

1.3

7-31

Revised

1.3

9-11

Revised

1.3

7-32

Revised

1.3

9-12

Revised

1.3

8-1/8-2

Revised

1.3

9-13

Revised

1.3

8-3

Revised

1.3

9-14

Revised

1.3

8-4

Revised

1.3

9-15

Revised

1.3

8-5

Revised

1.3

9-16

Revised

1.3

8-6

Revised

1.3

9-17

Revised

1.3

8-7

Revised

1.3

9-18

Revised

1.3

8-8

Revised

1.3

9-19

Revised

1.3

8-9

Revised

1.3

9-20

Revised

1.3

9-1/9-2

Revised

1.3

9-21

Revised

1.3

9-3

Revised

1.3

9-4

Revised

1.3

9-5

Revised

1.3

9-6

Revised

1.3

Pilot Operating Handbook

Date of Issue: 07 July 2014 Revision : 1.3

Page | xii

Airplane Factory SLING LSA

Pilot Operating Handbook

TABLE OF CONTENTS

1. GENERAL INFORMATION .......................................................................... 1-1

2. LIMITATIONS ............................................................................................. 2-1

3. EMERGENCY PROCEDURES ....................................................................... 3-1

4. NORMAL PROCEDURES ............................................................................. 4-1

5. PERFORMANCE ......................................................................................... 5-1

6. WEIGHT AND BALANCE ............................................................................. 6-1

7. SYSTEMS ................................................................................................... 7-1

8. AIRPLANE GROUND HANDLING AND SERVICING ...................................... 8-1

9. SUPPLEMENTARY INFORMATION ............................................................. 9-1

Page | xiii

Date of Issue: 07 July 2014 Revision : 1.3

Airplane Factory SLING LSA

Pilot Operating Handbook

1. GENERAL INFORMATION

1.1 Introduction to airplane............................................................................ 1-3

1.2 Warnings, cautions and notes .................................................................. 1-4

1.3 Aircraft 3-view drawing ............................................................................ 1-5

1.4 Data for Sling LSA aircraft and systems ..................................................... 1-7

1.5 Terminology, symbols and conversion factors ........................................ 1-12

1.6 Supporting documents ........................................................................... 1-18

Page | 1-1/1-2

Date of Issue: 07 July 2014 Revision : 1.3

Airplane Factory SLING LSA

Pilot Operating Handbook

1.1 Introduction to airplane

The Airplane Factory Sling LSA is a two seat (side-by-side), single engine,

tricycle undercarriage aluminum aircraft with a conventional low wing design

and is compliant with the requirements of the FAA Light Sport Aircraft (LSA)

category according to ASTM Standards F2245, F2279 and F2295.

With only minor modifications to the aircraft and the application of a revised

Pilot’s Operating Handbook the Sling LSA may be made to comply with the

requirements of the EASA (European Aviation Safety Agency) CS-VLA

(Certification Standard Very Light Aircraft) standard, having a maximum all up

weight of 700 kg (1543.24 lb).

The Sling LSA is intended chiefly for recreational and cross-country flying. It is

not intended for aerobatic operation. It is considered to be suitable for use as

a trainer. This Pilot Operating Handbook has been prepared to provide pilots

with information for the safe and efficient operation of the Sling LSA.

Page | 1-3

Date of Issue: 07 July 2014 Revision : 1.3

Airplane Factory SLING LSA

WARNING

CAUTION

NOTE

Pilot Operating Handbook

1.2 Warnings, cautions and notes

The following definitions apply to warnings, cautions and notes in the Pilot

Operating Handbook.

Means that non-observation of the corresponding procedure leads to an

immediate or important degradation of flight safety.

Means that non-observation of the corresponding procedure leads to a

minor or possible long term degradation of flight safety.

Draws attention to any special item not directly related to safety but which

is important or unusual.

Page | 1-4

Date of Issue: 07 July 2014 Revision : 1.3

Airplane Factory SLING LSA

DIMENSIONS IN THIS DRAWING

ARE IN FEET.

Pilot Operating Handbook

1.3 Aircraft 3-view drawing

Page | 1-5

Date of Issue: 07 July 2014 Revision : 1.3

Airplane Factory SLING LSA

DIMENSIONS IN THIS DRAWING

ARE IN FEET.

Pilot Operating Handbook

Page | 1-6

Date of Issue: 07 July 2014 Revision : 1.3

Airplane Factory SLING LSA

Pilot Operating Handbook

1.4 Data for Sling LSA aircraft and systems

WING

Wing span: 9.165 m (30 ft).

Mean Aerodynamic Chord: 1.339 m (52.7 inch).

Wing surface area: 11.845 m2 (131.75 ft2).

Wing loading: 59.10 kgm

Aspect ratio: 7.04.

Taper ratio: 1.375.

Dihedral: 5o

FUSELAGE

-2

(11.7 lb /ft2).

Fuselage length: 5.77 m (19 ft).

Overall length: 6.675 m (21ft 11 inches).

Overall width: 1.15 m (45 inches).

Overall height: 2. 5m (98 inches).

EMPENNAGE

Horizontal stabilizer span: 2.825 m (9 ft 3 inch).

Horizontal stabilizer surface area: 0.96 m2 (10 ft2).

Elevator surface area: 1.02 m

2

(11 ft2).

Horizontal stabilizer angle of incidence -4o

Vertical stabilizer span: 1.47 m (16 ft).

Vertical stabilizer surface area: 0.53 m2 (6 ft2).

Rudder surface area: 0.59 m2 (6 ft2).

LANDING GEAR

Wheel track: 1.95 m (6ft 5 inches).

Wheel base: 1.41m (4ft 6 inches).

Brakes: Hydraulic.

Main gear tires: 15x6.00-6, 6-ply (2.2 bar /

30 psi) pressure).

Page | 1-7

Date of Issue: 07 July 2014 Revision : 1.3

Airplane Factory SLING LSA

Pilot Operating Handbook

Nose gear tires: 5.00-5, 6-ply (1.8 bar / 26 psi

CONTROL SURFACE TRAVEL LIMITS

Ailerons: 24o up and down (±2°).

Elevator: 30o up and 20o down (±2°).

Trim tab: 5o up and 32o down (±5°).

Rudder: 25o left and right (±2°).

Flaps: 0o to 30o down(±3°).

ENGINE

pressure).

Manufacturer: Bombardier-Rotax GmbH.

Model: 912 ULS.

Type: 4 Cylinder horizontally opposed with overall

displacement 1 352 cc, mixed cooling (water-cooled

heads and air-cooled cylinders), twin carburetors,

integrated reduction gearbox with torque damper

Maximum power: 73.5 kW (98.5hp) at 5 800 rpm (maximum 5 minutes).

69 kW (92.5hp) at 5 500 rpm (continuous).

For Sling LSA aircraft fitted with the 912 iS engine refer to the applicable

supplement at the end of this manual.

PROPELLER

Manufacturer: Warp drive.

No of blades: 3.

Diameter: 1.83 m (72 inches).

Type: Composite.

Page | 1-8

Date of Issue: 07 July 2014 Revision : 1.3

Airplane Factory SLING LSA

Pilot Operating Handbook

FUEL

Fuel grade: Minimum RON 95 / minimum AKI 91.

MOGAS: EN 228 Super, EN 228 Super plus,

ASTMD4814.

Leaded AVGAS: AVGAS 100LL (ASTM D910).

Unleaded AVGAS: UL91 (ASTM D7547).

(Refer to latest revision of engine operator /

maintenance manual and latest revision of

service instruction SI-912-016. For aircraft fitted

with the 912 iS engines refer to the applicable

supplement at the end of this manual).

Fuel tanks: Two. One fuel tank integrated within each wing

Capacity of tank: 75 liters (19.8 US gallons), 73 liters (19.3 US

Total capacity: 150 liters (39.6 US gallons).

Total usable fuel: 146 liters (38.6 US gallons).

leading edge. Each tank is equipped with finger

strainers (in pick up line) and drain fittings.

gallons useable).

Page | 1-9

Date of Issue: 07 July 2014 Revision : 1.3

Airplane Factory SLING LSA

Pilot Operating Handbook

OIL SYSTEM

Oil system type: Forced, with external oil reservoir.

Oil: Automotive grade API “SF” or “SG” type oil

preferably synthetic or semi-synthetic. When

operating on unleaded fuels or MOGAS fully

synthetic oil is recommended.

(Refer to latest revision of engine operator /

maintenance manual and latest revision of

service instruction SI-912-016. For aircraft fitted

with the 912 iS engine refer to the applicable

supplement at the end of this manual).

Capacity: 3.5 liters (3.5 quarts) (approximately).

COOLING

Cooling system: Mixed: air and liquid pressurized closed circuit

system.

Coolant: 1. Water-free propylene glycol based coolant

concentrate (this is not allowed for 912 iS

engine).

2. Ethylene glycol based coolant mixed 1:1 with

distilled water.

Note: Do not mix the above types of coolant.

Capacity: 2.5 liters (2.5 quarts pints) (approximately).

Page | 1-10

Date of Issue: 07 July 2014 Revision : 1.3

Airplane Factory SLING LSA

Pilot Operating Handbook

MAXIMUM WEIGHTS

Maximum take-off weight: 600 kg (1320 lb).

Maximum landing weight: 600 kg (1320lb).

Maximum baggage weight: 15 kg (77lbs (this is what we say) lb).

Front luggage compartment maximum 15 kg (77lb).

Rear luggage compartment maximum 15 kg (55 lb).

STANDARD WEIGHTS

Standard empty weight: 370 kg (814 lb).

Maximum useful load: 230 kg (506 lb).

SPECIFIC LOADINGS

Wing loading (MAUW): 50.65 kg.m-2 (10.0 lb.ft-2).

Power loading: 6.00 kg.hp

-1

(13.2 lb.hp-1).

Page | 1-11

Date of Issue: 07 July 2014 Revision : 1.3

Airplane Factory SLING LSA

AC

Alternating Current.

ALT

Altimeter.

API

American Petroleum Institute

ASI

Airspeed Indicator.

AVGAS

Aviation gasoline.

COM

Communication (radio).

EFIS

Electronic Flight Information System.

FAA

Federal Aviation Authority.

GLS

GPS Landing System.

GmbH

Gesellschaft mit beschränkter Haftung (company with limited liability).

GPS

Global Positioning System.

IFR

Instrument Flying Rules.

LED

Light Emitting Diode.

MOGAS

Automobile (car) gasoline.

NGL

Normal Ground Line.

NRV

Non Return Valve.

POH

Pilot Operating Handbook.

PTT

Push-To-Talk (button).

VFR

Visual Flying Rules.

VMC

Visual Meteorological Conditions.

VSI

Vertical Speed Indicator.

Pilot Operating Handbook

1.5 Terminology, symbols and conversion factors

General terminology / acronyms

Page | 1-12

Date of Issue: 07 July 2014 Revision : 1.3

Airplane Factory SLING LSA

IAS

Indicated Airspeed.

KCAS

Calibrated Airspeed, being the indicated airspeed corrected for

position and instrument error, expressed in knots.

KIAS

Indicated Airspeed, being the speed shown on the airspeed

indicator, expressed in knots.

KTAS

True Airspeed, being the airspeed, expressed in knots, relative to

undisturbed air, and which is KCAS corrected for altitude and

temperature.

TAS

True Airspeed.

VA

Maneuvering speed.

VBG

Best Glide Speed, being the speed (at MAUW) which results in the

greatest gliding distance over the ground.

VFE

Maximum Flap Extended Speed, being the highest speed

permissible with wing flaps deployed.

VH

Maximum Speed in level flight at maximum continuous power.

V

LOF

Lift-off Speed, being the speed at which the aircraft generally lifts

off from the ground during take-off.

VNE

Never Exceed Speed, being the speed that may not be exceeded at

any time.

VNO

Maximum Structural Cruising Speed, being the speed that should

not be exceeded, except in smooth air, and then only with caution.

V

REF

Indicated airspeed at 15 m (50 ft) above threshold, which is not less

than 1.3Vso.

V

ROT

Rotation Speed, being the speed at which the aircraft should be

rotated about the pitch axis during take-off (i.e. the speed at which

the nose wheel is lifted off the ground).

VS

Stall Speed, maximum weight, engine idling, flaps fully retracted.

VSO

Stall Speed in landing configuration (flaps fully extended), MAUW,

engine idling.

VX

Best Angle of Climb Speed, being the speed (at MAUW, flaps fully

retracted) which results in the greatest altitude gain over a given

horizontal distance (i.e. highest climb angle).

Pilot Operating Handbook

General airspeed terminology and symbols

Page | 1-13

Date of Issue: 07 July 2014 Revision : 1.3

Airplane Factory SLING LSA

VY

Best Rate of Climb Speed, being the speed (at MAUW, flaps fully

retracted) which results in the greatest altitude gain over a given

time period.

ISA

International Standard Atmosphere.

QNH

The local pressure setting that if set on the subscale of an altimeter

will cause the altimeter to indicate local altitude above mean sea

level.

QFE

The local airfield pressure setting that if set on the subscale of an

altimeter will cause the altimeter to indicate local height above

airfield.

CHT

Cylinder Head Temperature.

EGT

Exhaust Gas Temperature.

OHV

Overhead Valve.

RPM/

rpm

Revolutions per minute, being the number of revolutions per minute

of the engine crank.

Pilot Operating Handbook

Meteorological terminology

Engine terminology

Page | 1-14

Date of Issue: 07 July 2014 Revision : 1.3

Airplane Factory SLING LSA

Crosswind

component

The velocity of the crosswind component during takeoff and

landing.

g

The acceleration / load factor.

Landing run

The distance measured during landing from actual touchdown to

the end of the landing run.

Landing

distance

The distance measured during landing from clearance of a 15 m

obstacle (in the air) to the end of the landing run.

Take-off

distance

The take-off distance measured from the actual start of the takeoff run to clearance of a 15 m (50 ft) obstacle (in the air).

Take-off

run

The take-off distance measured from actual start of the take-off

run to the wheel lift off point.

Usable fuel

The fuel available for flight planning.

Pilot Operating Handbook

Airplane performance and flight planning terminology

Page | 1-15

Date of Issue: 07 July 2014 Revision : 1.3

Airplane Factory SLING LSA

Arm

Is the horizontal distance from the reference datum to the center

of gravity of an item

CG

Center of Gravity, being the point at which the airplane, or

equipment, would balance if suspended. Its distance from the

reference datum is found by dividing the total moment by the

total weight of the airplane

Datum

Reference datum is an imaginary vertical plane from which all

horizontal distances are measured for balance purposes. (In the

Sling this plane runs through the center point of the flat front

face of the engine flange of the Rotax engine)

Empty

weight

Is the weight of the airplane with engine fluids and oil at

operating levels

MAC

Mean Aerodynamic Chord.

MAUW

Maximum All Up Weight

Maximum

Landing

Weight

Is the maximum weight approved for the landing touch down

Maximum

Take-off

Weight

Is the maximum weight approved for the start of the take-off run

Moment

Is the product of the weight (mass) of an item multiplied by its

arm

W

R

Weight read from scale under right main wheel during aircraft

weighing

W

L

Weight read from scale under left main wheel during aircraft

weighing

W

N

Weight read from scale under nose main wheel during aircraft

weighing

WE

Aircraft empty weight

WT

Aircraft total weight

W

MAUW

Aircraft maximum (allowed) all up weight

Pilot Operating Handbook

Weight and balance terminology and symbols

Date of Issue: 07 July 2014 Revision : 1.3

Page | 1-16

Airplane Factory SLING LSA

L

R

Right main wheel arm (aft of reference)

L

L

Left main wheel arm (aft of reference)

L

N

Nose wheel arm (aft of reference)

M

T

Total moment arm

Pilot Operating Handbook

Useful conversion factors

1 pound = 0.4536 kilogram

1 pound per square inch = 6.895 kilopascal

1 inch = 25.4 millimeters

1 foot = 0.3048 meter

1 statute mile = 1.609 kilometers

1 nautical mile = 1.852 kilometers

1 millibar = 1 hectopascal

1 millibar = 0.1 kilopascal

1 imperial gallon = 4.546 liters

1 US gallon = 3.785 liters

1 US quart = 0.946 liter

1 cubic foot = 28.317 liters

degrees fahrenheit = [1.8 x degrees celsius] + 32

degrees celcius = (degrees fahrenheit - 32) x (5/9)

Date of Issue: 07 July 2014 Revision : 1.3

Page | 1-17

Airplane Factory SLING LSA

Pilot Operating Handbook

1.6 Supporting documents

The following documents are regarded as supporting documents

to this Pilot Operating Handbook:

1. For aircraft fitted with 912 ULS engines: latest revision / edition

of the Operators Manual For Rotax® Engine Type 912 Series,

Ref No.: OM-912.

2. For aircraft fitted with 912 iS engines: latest revision / edition

of the Operators Manual For Rotax® Engine Type 912 i Series,

Ref No.: OM-912 i.

3. Latest revision / edition of Rotax service instruction SI-912-016

or SI-912i-001, as applicable (to type of engine fitted).

4. MGL EFIS operator manual.

5. Operator manual for COM radio and transponder (if fitted)

equipment fitted to the aircraft.

Reference should be made to these documents for operational

guidelines and instructions. These should be incorporated into

the normal and emergency procedures for the aircraft as

applicable.

Page | 1-18

Date of Issue: 07 July 2014 Revision : 1.3

Airplane Factory SLING LSA

Pilot Operating Handbook

2. LIMITATIONS

2.1 Introduction .............................................................................................. 2-3

2.2 Airspeed limitations .................................................................................. 2-3

2.3 Airspeed indicator markings ..................................................................... 2-4

2.4 Stall speed adjustment for turning flight or load factor ............................ 2-5

2.5 Crosswind and wind limitation (demonstrated) ....................................... 2-6

2.6 Service ceiling ........................................................................................... 2-6

2.7 Load factors .............................................................................................. 2-6

2.8 Weights..................................................................................................... 2-6

2.9 Center of gravity range ............................................................................. 2-7

2.10 Prohibited maneuvers ............................................................................ 2-8

2.11 Flight crew ............................................................................................. 2-9

2.12 Passengers ............................................................................................. 2-9

2.13 Kinds of operation ................................................................................ 2-10

2.14 Engine limitations ................................................................................ 2-11

2.15 Other limitations .................................................................................. 2-14

2.16 Flight in rain ......................................................................................... 2-14

2.17 Limitation, warning, information and identification placards .............. 2-15

Page | 2-1/2-2

Date of Issue: 07 July 2014 Revision : 1.3

Airplane Factory SLING LSA

SPEED

KIAS

REMARKS

VNE

Never exceed

speed

135

Never exceed this speed in any

operation.

VNO

Maximum

structural

cruising speed

110

Never exceed this speed unless in

smooth air, and then only with

caution.

VA

Maneuvering

speed

91

Do not make full or abrupt control

movements above this speed as this

may cause stress in excess of limit

load factor.

VFE

Maximum flap

extended

speed

85

Never exceed this speed unless the

flaps are fully retracted.

VH

Maximum

speed in level

flight

118

The aircraft will not exceed this speed

at MAUW in level flight.

VS

Stall speed at

MAUW

45

At maximum all up weight in the most

forward CG configuration, with flaps

fully retracted, engine idling, the

aircraft will stall if flown slower than

this speed.

VS0

Stall speed

with flaps

40

With full flap, maximum all up weight,

engine idling, the aircraft will stall if

flown slower than this speed.

Pilot Operating Handbook

2.1 Introduction

This section includes operating limitations, instrument markings and basic

placards necessary for the safe operation of the Airplane Factory Sling LSA, its

engine, systems and equipment.

2.2 Airspeed limitations

Date of Issue: 07 July 2014 Revision : 1.3

Page | 2-3

Airplane Factory SLING LSA

MARKING

KIAS

SIGNIFICANCE

White arc

40-85

Flap Operating Range (lower limit is

VS0 at maximum weight, and upper

limit is the maximum speed (Vfe)

permissible with flaps deployed)

Green arc

45-110

Normal Operating Range (lower limit

is VS at maximum weight and most

forward CG with flaps retracted and

upper limit is maximum structural

speed VNO)

Yellow arc

110-135

Maneuvers must be conducted with

caution and only in smooth air

Red line

135

Maximum speed for all operations

Pilot Operating Handbook

2.3 Airspeed indicator markings

Date of Issue: 07 July 2014 Revision : 1.3

Page | 2-4

Airplane Factory SLING LSA

MULTIPLICATION FACTOR

0 10 20 30 40 50 60 70 80 90

This graph is only valid for level (i.e.

non-descending) turning flight.

VT = V + ( V x MULTIPLICATION FACTOR )

V is straight and level stall speed

(at load factor = 1 g).

V

T

is stall speed in turn (non-

descending).

VST = V

√

N

V is straight and level stall

speed (at load factor = 1 g).

V

ST

is stall speed due to

increased load factor.

N is (positive) load factor.

Pilot Operating Handbook

2.4 Stall speed adjustment for turning flight or load factor

Stall speeds listed in Section 2 (this section) are listed for straight and level

(non-turning) flight at load factor = 1 g and should be adjusted for turning

flight or increased load factor:

0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8

BANK ANGLE (DEGREES)

Date of Issue: 07 July 2014 Revision : 1.3

Page | 2-5

Airplane Factory SLING LSA

Pilot Operating Handbook

2.5 Crosswind and wind limitation (demonstrated)

Maximum demonstrated cross wind component

for take-off and landing 15 kts.

2.6 Service ceiling

Service ceiling 12 000 ft.

2.7 Load factors

Maximum positive limit load factor +4 g.

Maximum negative limit load factor -2 g.

Maximum positive load factor with flaps +2 g.

Maximum negative load factor with flaps -1 g.

2.8 Weights

Maximum take-off weight 600 kg (1320 lb).

Maximum landing weight 600 kg (1320 lb).

Maximum total baggage weight 15 kg (77 lb).

Front luggage compartment maximum 15 kg (77lb).

Rear luggage compartment maximum 15 kg (55lb).

Page | 2-6

Date of Issue: 07 July 2014 Revision : 1.3

Airplane Factory SLING LSA

WARNING

It is the pilot’s responsibility to ensure that the

airplane is properly loaded. Refer to section 6

for information on weight and balance

Pilot Operating Handbook

2.9 Center of gravity range

Datum Center of front face of engine propeller

flange (without propeller extension).

Reference (longitudinal leveling) Upper surface of canopy sliders on

cockpit side skins, with canopy open.

Reference (transverse leveling) Upper surface of center spar cap under

pilot and passenger seats.

Forward limit 1.635 m / 5.364 ft (20% MAC) aft of

datum.

Rear limit 1.772 m / 5.814 ft (30.3% MAC) aft of

datum.

Date of Issue: 07 July 2014 Revision : 1.3

Page | 2-7

Airplane Factory SLING LSA

WARNING

Aerobatics and intentional spins are

prohibited

WARNING

Limit load factor would be exceeded by

moving flight controls abruptly to their limits

at a speed above VA (91 KIAS – maneuvering

speed)

Pilot Operating Handbook

2.10 Prohibited maneuvers

The Sling is approved for normal maneuvers including the following:

Steep turns not exceeding 60° bank.

Lazy eights.

Chandelles.

Stalls (not including whip stalls).

Date of Issue: 07 July 2014 Revision : 1.3

Page | 2-8

Airplane Factory SLING LSA

Pilot Operating Handbook

2.11 Flight crew

Minimum crew for flight is one pilot seated on the left side.

2.12 Passengers

Only one passenger is allowed on board the aircraft (in addition to the pilot).

Page | 2-9

Date of Issue: 07 July 2014 Revision : 1.3

Airplane Factory SLING LSA

NOTE

Additional equipment may be required to fulfill

national or specific requirements and may be fitted.

WARNING

Notwithstanding that installed equipment may include GPS and

other advanced flight and navigational aids, such equipment

may not be used as the sole information source for purposes of

navigation or flight, save where specifically permitted by law.

The airplane instrumentation is not certified and applicable

regulations should be complied with at all times.

Pilot Operating Handbook

2.13 Kinds of operation

The Sling LSA, in standard configuration, is approved only for day VFR operation

with visual contact with terrain. When equipped for night flight, the Sling LSA

may be operated in night VFR conditions.

Minimum equipment required is as follows-

Altimeter.

Airspeed indicator.

Compass.

Fuel level indicators.

Oil pressure indicator.

Oil temperature indicator.

Cylinder head temperature indicator.

Outside air temperature indicator.

Tachometer.

Chronometer.

First aid kit (compliant with national legislation).

Fire extinguisher.

Date of Issue: 07 July 2014 Revision : 1.3

Page | 2-10

Airplane Factory SLING LSA

ENGINE START AND OPERATION TEMPERATURE LIMITS (912 ULS)

Maximum

50 °C ( 122 °F) (ambient temperature)

Minimum

-25 °C ( -13 °F) (oil temperature)

ENGINE LOAD FACTOR (ACCELERATION) LIMITS

Maximum

5 seconds at maximum -0.5 g.

Pilot Operating Handbook

2.14 Engine limitations

Instruments reflecting engine parameters should in each case be marked / set

to reflect the minimum and maximum figures.

For airplanes with the Rotax 912iS engine installed, refer to the supplement at

the end of this manual.

Always refer to latest edition / revision of the engine Operators Manual for

latest information regarding operating limitations.

Date of Issue: 07 July 2014 Revision : 1.3

Page | 2-11

Airplane Factory SLING LSA

ENGINE OPERATING AND SPEEDS LIMITS (912 ULS)

Engine Model:

ROTAX 912 ULS

Engine Manufacturer:

Bombardier-Rotax GMBH

Power

Maximum

take-off

73.5 kW (98.6 hp) at 5800 rpm, max. 5 min.

Maximum

continuous

69 kW (92.5 hp)at 5500 rpm

RPM

Maximum take-

off

5800 rpm, maximum 5 minutes

Maximum

continuous

5500 rpm

Idle

1 600 rpm (minimum)

Cylinder head

temperature

Minimum

N/A

Maximum

135 °C (275 °F)

Normal

75 to 110 °C (167 to 230 °F)

Oil

temperature

Minimum

50 °C (122 °F)

Maximum

130 °C (266 °F)

Normal

90 to 110 °C (194 to 230 °F)

EGT

Maximum

880 °C (1616 °F)

Coolant

temperature

Maximum

120 °C (248 °F)

Oil pressure

Minimum

0.8 bar (12 psi) – below 3500 rpm

Maximum

7 bar (102 psi) – permissible for short period during cold

engine start

Normal

2 to 5 bar (29 to 73 psi) – above 3500 rpm

Pilot Operating Handbook

Date of Issue: 07 July 2014 Revision : 1.3

Page | 2-12

Airplane Factory SLING LSA

Fuel pressure

Minimum

0.15 bar (2.2 psi)

WARNING

Exceeding maximum

allowed fuel pressure will

override the float valves of

the carburetors and lead to

engine failure.

Maximum

0.4 bar (5.8 psi)

0.5 bar (7.26 psi) (fuel

pump S/N 11.0036

onwards)

Pilot Operating Handbook

Date of Issue: 07 July 2014 Revision : 1.3

Page | 2-13

Airplane Factory SLING LSA

WARNING

IFR flights and intentional flights under icing

conditions are prohibited!

Pilot Operating Handbook

2.15 Other limitations

No smoking is allowed on board of the airplane.

VFR flights only are permitted.

2.16 Flight in rain

When flying in the rain no additional steps are required. Airplane qualities

and performance are not substantially changed. However, VMC should be

maintained.

Page | 2-14

Date of Issue: 07 July 2014 Revision : 1.3

Airplane Factory SLING LSA

PASSENGER WARNING

THIS AIRCRAFT WAS MANUFACTURED IN ACCORDANCE

WITH LIGHT SPORT AIRCRAFT AIRWORTHINESS STANDARDS

AND DOES NOT CONFORM TO STANDARD CATEGORY

AIRWORTHINESS REQUIREMENTS

Pilot Operating Handbook

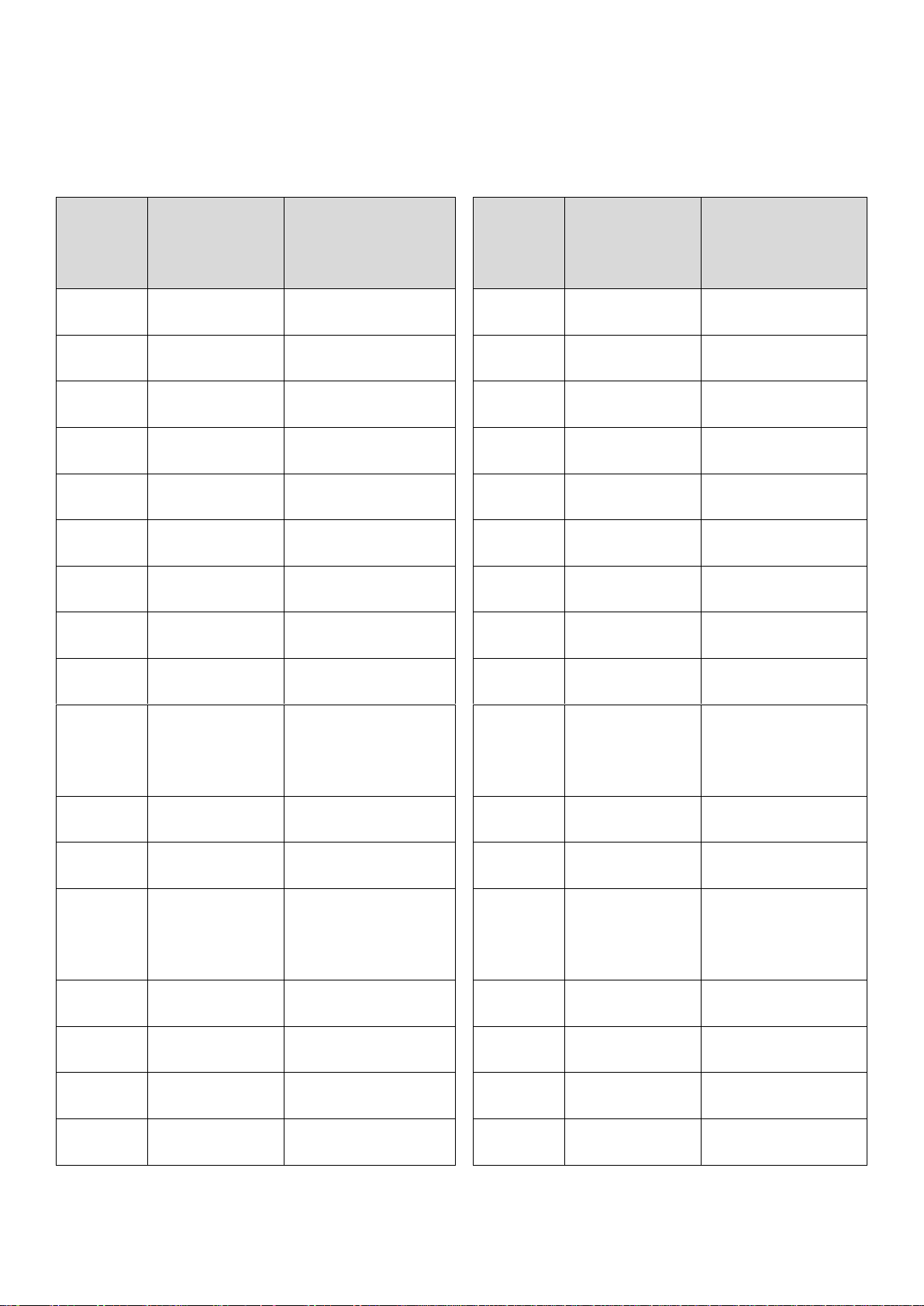

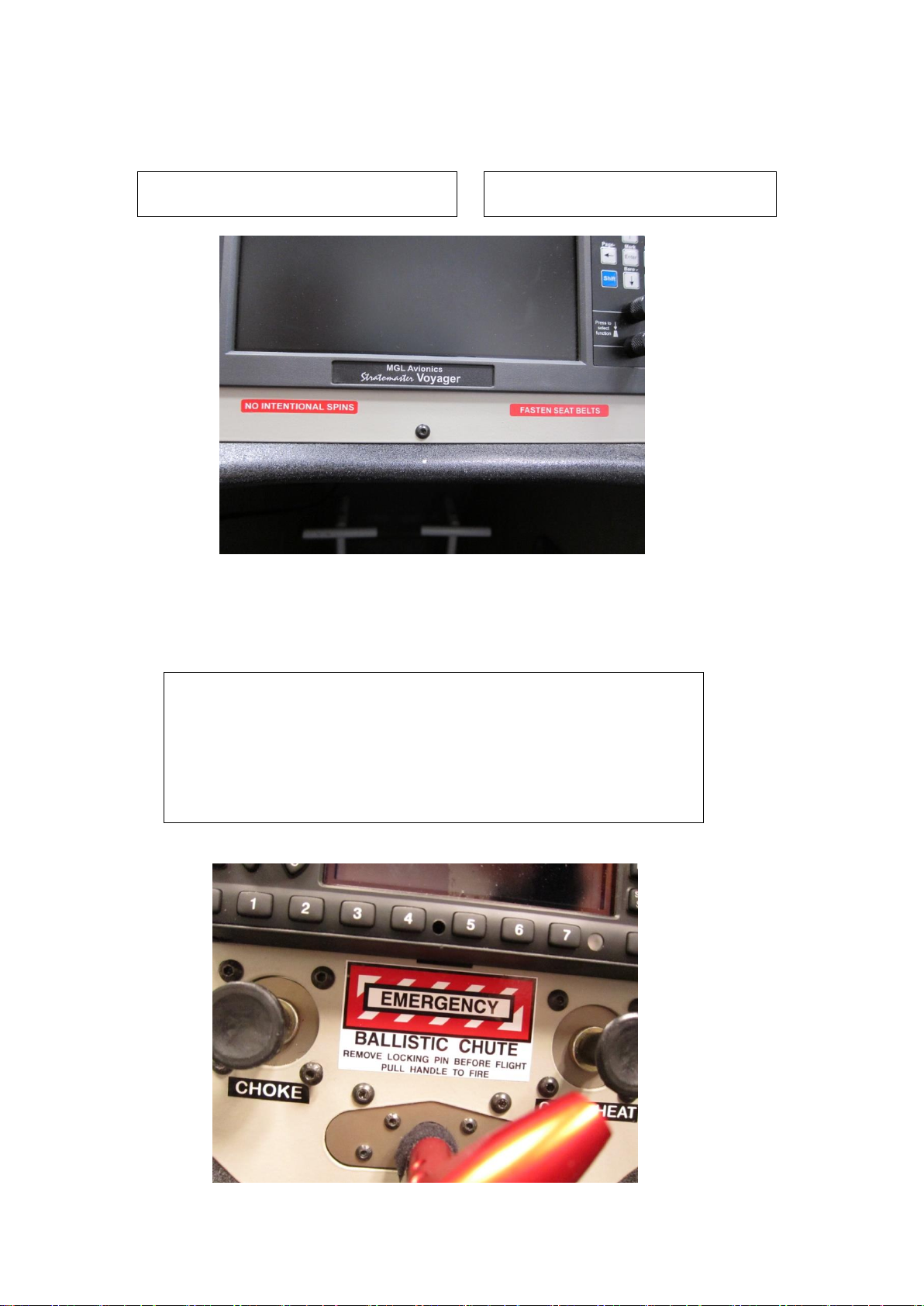

2.17 Limitation, warning, information and identification placards

The following limitation warning placards must be placed in or on the

aircraft and positioned in plain view of the pilot, passenger or third person,

as the case may be.

In a place visible to pilot and passenger:

Date of Issue: 07 July 2014 Revision : 1.3

Page | 2-15

Airplane Factory SLING LSA

FASTEN SEATBELTS

NO INTENTIONAL SPINS

EMERGENCY

BALLISTIC CHUTE

REMOVE LOCKING PIN BEFORE FLIGHT

PULL HANDLE TO FIRE

Pilot Operating Handbook

If a ballistic rescue parachute is fitted, adjacent to the ballistic

parachute activation lever:

Date of Issue: 07 July 2014 Revision : 1.3

Page | 2-16

Airplane Factory SLING LSA

19.8 U.S. GALS.

91 OCT. MOGAS

100LL AVGAS

MAX TOTAL BAGGAGE WEIGHT – 35 KG / 77 LB

MAX FRONT SECTION 35 KG / 77LB

MAX REAR SECTION 25 KG / 55 LB

Pilot Operating Handbook

On the baggage space separator channel:

Adjacent to the fuel filler caps:

Date of Issue: 07 July 2014 Revision : 1.3

Page | 2-17

Airplane Factory SLING LSA

TIRE PRESSURE

32 P.S.I

TIRE PRESSURE

26 P.S.I

Pilot Operating Handbook

Adjacent to the filler hole in the main gear wheel pants (on each wheel):

Adjacent to the filler hole in the nose gear wheel pants:

Page | 2-18

Date of Issue: 07 July 2014 Revision : 1.3

Airplane Factory SLING LSA

NO STEP

Pilot Operating Handbook

On the inboard upper wing flap surface:

Page | 2-19

Date of Issue: 07 July 2014 Revision : 1.3

Airplane Factory SLING LSA

LIGHT-SPORT

WARNING

This aircraft is equipped with a ballistically-

deployed emergency parachute system

Pilot Operating Handbook

On the exterior of the fuselage adjacent to the entrance to the cockpit:

On both pilot and passenger sides:

If a ballistic rescue parachute is installed:

Page | 2-20

Date of Issue: 07 July 2014 Revision : 1.3

Airplane Factory SLING LSA

DANGER EXPLOSIVE EGRESS

Rocket Deployed Parachute Egress Area

STAY CLEAR

DANGER EXPLOSIVE ROCKET

Pilot Operating Handbook

If a ballistic rescue parachute is installed:

On the exterior of the fuselage, adjacent to the egress point of the

rescue parachute system:

On the parachute rocket body, inside the rocket housing:

Date of Issue: 07 July 2014 Revision : 1.3

Page | 2-21

Airplane Factory SLING LSA

AIRCRAFT IDENTIFICATION

BUILDER: THE AIRPLANE FACTORY (Pty) Ltd

MODEL: SLING

SERIAL NO: ###

MADE IN SOUTH AFRICA

Pilot Operating Handbook

On a fireproof metal plate attached to the exterior of the aircraft, aft of

the cabin:

Note: ### represents the information applicable to the specific aircraft.

The airplane must be placarded to show the identity of:

All fuses/circuit breakers.

Magneto / ignition switches.

All other switches.

Choke (if fitted).

Starter.

Trim : Nose up and down.

Flaps : Up and Down.

Date of Issue: 07 July 2014 Revision : 1.3

Page | 2-22

Airplane Factory SLING LSA

Pilot Operating Handbook

3. EMERGENCY PROCEDURES

3.1 Introduction .............................................................................................. 3-3

3.2 Speeds for emergency operations ............................................................ 3-3

3.3 Engine related emergencies ..................................................................... 3-4

3.4 Smoke and fire .......................................................................................... 3-8

3.5 Emergency landings ................................................................................ 3-12

3.6 Recovery from unintentional spin .......................................................... 3-15

3.7 Other emergencies ................................................................................. 3-16

Page | 3-1/3-2

Date of Issue: 07 July 2014 Revision : 1.3

Airplane Factory SLING LSA

SPEED

KIAS

REMARKS

VBG

Best Glide

Speed

72

The speed (at MAUW, flaps fully retracted)

which results in the greatest gliding

(horizontal) distance.

Speed for inflight engine

start

> 72

Recommended speed.

Pilot Operating Handbook

3.1 Introduction

This section provides checklists and amplified procedures for coping with

various emergencies that may arise.

Emergencies caused by aircraft or engine malfunction are extremely rare if

proper pre-flight inspections and maintenance are practiced. However,

should an emergency arise, the basic guidelines described in this section

should be considered and applied as necessary to manage the problem.

In case of emergency the pilot should remember the following priorities –

1 Keep control of and continue flying the aircraft.

2 Analyze the situation.

3 Apply applicable procedures.

4 Inform air traffic control of the situation if time and conditions

permit it.

3.2 Speeds for emergency operations

Date of Issue: 07 July 2014 Revision : 1.3

Page | 3-3

Airplane Factory SLING LSA

Pilot Operating Handbook

3.3 Engine related emergencies

3.3.1 Engine failure during take-off run

1. Throttle - idle.

2. Magnetos / ignition - off.

3. Brakes - apply as needed.

4. Master switch - off.

With airplane under control –

5. Fuel selector valve - off.

6. Auxiliary (electric) fuel pump - off (912 ULS).

Electric fuel pumps (both) - off (912 iS).

3.3.2 Engine failure immediately after take-off

1. Speed - check.

2. Find a suitable place on the ground to land safely. The landing

should be planned straight ahead with only small changes in direction

not exceeding 45 degrees to either side.

3. Flaps - as needed (plan to land as slowly

as possible).

Before touch down

4. Magnetos / ignition - off.

5. Master - off.

6. Fuel selector valve - off.

7. Electric fuel pump - off (912 ULS).

Electric fuel pumps (both) - off (912 iS).

Page | 3-4

Date of Issue: 07 July 2014 Revision : 1.3

Airplane Factory SLING LSA

Pilot Operating Handbook

3.3.3 Engine irregularities in flight

3.3.3.1 Irregular engine rpm

1. Verify magneto switches - both on.

2 Verify throttle position.

3. Verify engine and fuel quantity indicators.

4. Electric fuel pump on (912 ULS).

Auxiliary electric fuel pump on (912 iS).

If engine continues to run irregularly

5. Land as soon as possible.

3.3.3.2 Low fuel pressure (refer to engine limitations, Section 2 (912 ULS)

or 912 iS engine supplement at end of manual)

1. Check fuel quantity indicator.

2. Switch electric fuel pump on (912 ULS).

Switch auxiliary electric fuel pump on (912 iS).

If fuel pressure remains low

3. Decrease throttle setting if viable to do so.

If fuel pressure remains low

4. Land as soon as possible.

Page | 3-5

Date of Issue: 07 July 2014 Revision : 1.3

Airplane Factory SLING LSA

Pilot Operating Handbook

3.3.3.3 Low oil pressure (refer to engine limitations, Section 2 (912 ULS) or

912 iS engine supplement at end of manual)

1. Check oil temperature.

If oil temperature is high or increasing

2. Set throttle to a setting which gives an aircraft speed of 72 KIAS

(most efficient speed).

If oil pressure remains low or temperature remains high or increasing

3. Land as soon as possible and remain vigilant for impending engine

failure.

Page | 3-6

Date of Issue: 07 July 2014 Revision : 1.3

Airplane Factory SLING LSA

NOTE

It is possible that the propeller may continue to rotate if the

airspeed remains above approximately 72 KIAS. In such

circumstances no application of the starter switch may be

required. If the propeller stops rotating increasing airspeed

may result in it again starting to do so.

Pilot Operating Handbook

3.3.4 In-flight engine restart

1. Electric fuel pump - on (912 ULS).

Electric fuel pumps (both) - on (912 iS).

2. Fuel selector - open (RIGHT).

3. Throttle - set to middle position.

4. Master switch - check on.

5. Magnetos / ignition - check both on.

6. Starter - engage.

7. Electric fuel pump - off (912 ULS) (after positive start).

Auxiliary fuel pump - off (912 iS) (after positive start).

If engine should fail to restart

8. Apply forced landing without engine power procedure, according

to 3.5.1.

Page | 3-7

Date of Issue: 07 July 2014 Revision : 1.3

Airplane Factory SLING LSA

Pilot Operating Handbook

3.4 Smoke and fire

3.4.1 Engine fire on ground during engine start

1. Starter - release.

2. Fuel selector - close.

3. Electric fuel pumps (both) - off (912 iS).

4. Throttle - idle.

5. Magnetos / ignition - off.

6. Master switch - off.

7. Retrieve fire extinguisher if possible.

8. Exit the airplane.

9. Extinguish fire by fire extinguisher or call for a fire-brigade if you

cannot do it.

3.4.2 Engine fire on ground with engine running

1. Cabin heat - close.

2. Fuel selector - close.

3. Electric fuel pumps (both) - off (912 iS).

4. Throttle - idle.

5. Magnetos / ignition - off.

6. Master switch - off.

7. Retrieve fire extinguisher if possible.

8. Leave the airplane.

9. Extinguish fire by fire extinguisher or call for a fire-brigade if you

cannot do it.

Page | 3-8

Date of Issue: 07 July 2014 Revision : 1.3

Airplane Factory SLING LSA

NOTE

Estimated time to empty carburetors

after fuel selector valve is closed is

30 seconds

WARNING

Do not attempt to re-start

the engine!

Pilot Operating Handbook

3.4.3 Engine fire during take-off run

1. Throttle - idle.

2. Brakes - stop the aircraft.

3. Cabin heat - close.

4. Fuel selector - close.

5. Electric fuel pump(s) - off.

6. Magnetos / ignition - off.

8. Master switch - off.

9. Retrieve fire extinguisher if possible.

10. Exit the aircraft.

11. Extinguish the fire by fire extinguisher or call for fire services if

unable to do so.

3.4.4 Engine fire in flight

1. Heating - close.

2. Fuel selector - close.

3. Throttle - full power.

4. Magnetos / ignition - switch off after the fuel in carburetors

5. Electric fuel pumps (both) - off (912 iS).

6. Choose landing area - choose emergency landing area.

7. Emergency landing - perform according to 3.5.1.

8. Retrieve fire extinguisher if possible.

9. Exit the airplane.

10. Extinguish fire by fire extinguisher / call for fire-brigade if you

cannot do it.

is consumed and engine has shut down.

Date of Issue: 07 July 2014 Revision : 1.3

Page | 3-9

Airplane Factory SLING LSA

Pilot Operating Handbook

3.4.5 Electrical fire in flight

An electrical fire is often characterized by white smoke and an acrid

smell.

1. Master switch - off (see NOTE below).

2. Cabin heat - close.

3. Use the fire extinguisher (if possible).

4. Ventilate cabin if required / applicable (open air vents on instrument

panel).

5. If fire is extinguished consider executing a precautionary landing /

land as soon as practical.

6. If fire does not extinguish land immediately.

NOTE:

If the location / source of the electrical fire can be determined

and electrical power can be removed from that system / location

by isolating / switching the system off, do so. This may alleviate

the need to switch off the master switch.

For aircraft equipped with a 912 iS engine, refer to the applicable

supplement at the end of this manual, with regard to the Master

switch.

The EFIS and associated equipment (iBox, RDAC etc.) can still be

powered (to provide engine monitoring) from the EFIS back-up battery

circuit when the master switch is off, provided that the EFIS system is

not the location / source of the electrical fire.

Page | 3-10

Date of Issue: 07 July 2014 Revision : 1.3

Airplane Factory SLING LSA

Pilot Operating Handbook

3.4.6 Cabin fire

If the fire is electrical in nature follow the procedure for electrical fires

in flight (3.4.5).

Alternatively:

1. Cabin heat - close.

2. Use the fire extinguisher (if possible).

3. Ventilate cabin if required / applicable (open air vents on instrument

panel).

4. If fire is extinguished consider executing a precautionary landing /

land as soon as practical.

5. If fire does not extinguish land immediately.

Page | 3-11

Date of Issue: 07 July 2014 Revision : 1.3

Airplane Factory SLING LSA

WARNING

Flaps and elevator trim cannot operate without power on the main bus.

Make final flap selection before turning master switch off.

Pilot Operating Handbook

3.5 Emergency landings

Emergency landings are generally carried out in the case of engine failure

during which the engine cannot be re-started. Other reasons for an

emergency landing may, however, arise.

3.5.1 Engine-off emergency landing

1. Speed - best glide speed of 72 KIAS.

2. Trim - trim for best glide speed.

3. Landing location - locate most suitable landing location,

free of obstacles and preferably into

wind.

4. Safety harness - tighten.

5. Engine restart - if time permits and if appropriate

attempt to identify reason for engine

failure and attempt restart.

6. Flaps - extend as needed.

7. Communications - report your location to third parties if

possible.

8. Passenger - brief.

Immediately before touchdown-

9. Fuel selector - shut off.

10. Electric fuel pump - off (912 ULS).

Electric fuel pumps (both) - off (912 iS).

11. Magnetos / ignition - off.

12. Master switch - off.

Page | 3-12

Date of Issue: 07 July 2014 Revision : 1.3

Airplane Factory SLING LSA

NOTE

Keep the chosen area in sight during

precautionary landing.

Pilot Operating Handbook

3.5.2 Precautionary landing

A precautionary landing is generally carried out in cases where the pilot

may be disorientated, the aircraft has no fuel reserve or possibly in bad

weather conditions.

1. Choose landing area, determine wind direction.

2. Report your intention to land and the landing location via radio.

3. Perform a low altitude pass into wind, over the right-hand side of

the selected area, with flaps extended as required and thoroughly

inspect the landing area.

4. Perform a circuit pattern.

5. Perform approach at increased idle with flaps fully extended.

6. Reduce power to idle when flying over the runway threshold and

touch-down at the very beginning of the selected area.

7. After stopping the aircraft switch off all switches, shut off the fuel

selector, lock the aircraft and seek assistance.

Page | 3-13

Date of Issue: 07 July 2014 Revision : 1.3

Airplane Factory SLING LSA

Pilot Operating Handbook

3.5.3 Landing with a flat tire / damaged wheel

1. If a main landing gear tire is flat or a wheel is damaged, perform

touch-down at the lowest practical speed with the aircraft slightly

banked towards the serviceable tire / wheel. Maintain directional

control during the landing run and keep the flat tire / damaged

wheel off the ground, just above or very lightly on the ground, until

the lowest speed possible.

2. If the nose wheel is damaged / flat perform touch-down at the

lowest practical speed and hold the nose wheel off the ground as

long as possible, via elevator control.

Page | 3-14

Date of Issue: 07 July 2014 Revision : 1.3

Airplane Factory SLING LSA

WARNING

Intentional spins are prohibited!

NOTE

Notwithstanding that installed equipment may

include GPS navigational aids, such equipment may

not be used as the sole information source for

purposes of navigation unless permitted by law.

Pilot Operating Handbook

3.6 Recovery from unintentional spin

The aircraft is unlikely to enter an unintentional spin unless extreme

control are applied.

Unintentional spin recovery technique:

1. Throttle - idle.

2. Lateral control - ailerons neutral.

3. Rudder pedals - full rudder in direction opposite to spin

4. Rudder pedals - neutralize rudder immediately when

rotation stops.

5. Longitudinal control - neutralize control column or push

forward if necessary to lower nose, then

recover from dive ensuring VNE and load

factor limitations are not exceeded.

In the unlikely event that applied control inputs result in the aircraft

entering a flat spin and the steps listed above do not result in recovery

(following their application for a sustained period), the following

technique may be implemented:

1. Throttle - set to full power.

2. Lateral control - ailerons neutral.

3. Rudder pedals - full rudder in direction opposite to spin.

4. Rudder pedals - neutralize rudder immediately when

rotation stops.

5. Throttle - reduce to idle.

6. Longitudinal control - as per step 5 (longitudinal control) above.

Date of Issue: 07 July 2014 Revision : 1.3

Page | 3-15

Airplane Factory SLING LSA

Pilot Operating Handbook

3.7 Other emergencies

3.7.1 Vibration

If any abnormal aircraft vibration occurs:

1. Set engine speed to a setting where the vibration is least, if viable.

2. Land on the nearest airfield or perform a precautionary landing

according to 3.5.2.

3.7.2 EFIS System Failure

If the EFIS system freezes, otherwise fails or reacts incorrectly in flight:

1. Maintain straight and level flight utilizing other instruments and

ground references.

2. Switch the EFIS back-up battery and the EFIS main switch off (i.e.

remove power from the EFIS).

3. Following a 3 second delay, apply power to the EFIS, maintaining

straight and level flight at all times.

4. Maintain straight and level for at least another 15 seconds while the

system boots up (when the system reboots, the navigation system(s)

should remain active and any active routes (preceding the failure)

should continue to be shown).

In case the system fails to re-boot properly:

5. Execute a precautionary landing at the first safe opportunity and

have the instrument repaired.

Page | 3-16

Date of Issue: 07 July 2014 Revision : 1.3

Airplane Factory SLING LSA

Pilot Operating Handbook

3.7.3 Carburetor icing

Carburetor icing is evidenced through a decrease in engine power and

an increase of engine temperatures.

To recover the engine power, the following procedure is

recommended:

1. Speed - 75 KIAS

2. Throttle - 1/3 power.

3. If possible leave the (icing) area.

4. Increase the engine power gradually up to cruise conditions after

1 to 2 minutes.

If you fail to recover engine power, land on the nearest airfield (if

possible) or, depending on the circumstances, perform a precautionary

landing according to 3.5.2.

Page | 3-17

Date of Issue: 07 July 2014 Revision : 1.3

Airplane Factory SLING LSA

NOTE

The 912 ULS engine operation is independent from the aircraft

main battery (except for start motor operation) / alternator. The

engine will continue running after an alternator / charge system

failure and / or with a depleted battery.

Pilot Operating Handbook

3.7.4 Alternator / charge system failure

For aircraft fitted with the 912 iS engine please refer to the supplement

at the end of this manual.

Alternator failure (912 ULS) is evidenced by the illumination of the (red)

alternator / charge warning light.

1. EFIS switch - off.

2. All non-critical electrical equipment - off.

(navigation, strobe, taxi, landing lights etc.).

3. Auxiliary fuel pump - off.

4. Autopilot - off.

5. Set EFIS brightness to minimum.

6. Restrict / avoid the use of the elevator trim control. Restrict radio

transmission to minimum / only that which is absolutely necessary.

7. Land as soon as possible.

Date of Issue: 07 July 2014 Revision : 1.3

Page | 3-18

Airplane Factory SLING LSA

Pilot Operating Handbook

3.7.5 Main bus power failure

Refer to paragraph 7.17, under Main bus, for a list of equipment

affected by a loss of power to the main bus.

1. The EFIS should automatically switch over to the EFIS back-up battery

supply , provided that the EFIS battery back-up switch is on (if not,

switch on the EFIS battery back-up switch) and the back-up battery

contains adequate charge.

2. Land as soon as possible.

Page | 3-19

Date of Issue: 07 July 2014 Revision : 1.3

Airplane Factory SLING LSA

Pilot Operating Handbook

4. NORMAL PROCEDURES

4.1 Introduction .............................................................................................. 4-3

4.2 Speeds for normal operation .................................................................... 4-3

4.3 Use of taxi, landing, strobe and navigation lights ..................................... 4-4

4.4 Pre-flight check ......................................................................................... 4-5

4.5 Engine start ............................................................................................. 4-10

4.6 Taxi ......................................................................................................... 4-11

4.7 Normal take-off ...................................................................................... 4-12

4.8 Climb....................................................................................................... 4-14

4.9 Cruise ...................................................................................................... 4-15

4.10 Descend ............................................................................................... 4-15

4.11 Approach ............................................................................................. 4-16

4.12 Normal landing .................................................................................... 4-17

4.13 Baulked landing procedures ................................................................. 4-18

4.14 Short field take-off and landing procedures ........................................ 4-18

4.15 Engine shutdown ................................................................................. 4-19

4.16 Aircraft parking and tie-down .............................................................. 4-20

Page | 4-1/4-2

Date of Issue: 07 July 2014 Revision : 1.3

Airplane Factory SLING LSA

SPEED

KIAS

REMARKS

Vx

Best Angle of

Climb Speed

65

The speed (at MAUW, flaps fully retracted)

which results in the greatest altitude gain

over a given horizontal distance (i.e.

largest climb angle).

VY

Best Rate of

Climb Speed

72

The speed (at MAUW, flaps fully retracted)

which results in the greatest altitude gain

over a given time period.

V

ROT

Rotation

Speed

40

The speed at which the aircraft should be

rotated about the pitch axis during takeoff (i.e. the speed at which the nose wheel

is lifted off the ground).

V

LOF

Lift-off

Speed

48

The speed at which the aircraft generally

lifts off from the ground during take-off.

Cruise Climb

75 to 90

Approach

speed - long

finals

65 to 75

V

REF

Threshold

crossing

speed

≥ 52

Indicated airspeed at 15 m (50 ft) above

threshold, which is not less than 1.3VSO.

Pilot Operating Handbook

4.1 Introduction

This section provides checklists and recommended procedures for normal

operation of the airplane.

4.2 Speeds for normal operation

Unless otherwise noted, the following speeds are based on a maximum

weight of 600 kg (1320 lb).

Date of Issue: 07 July 2014 Revision : 1.3

Page | 4-3

Airplane Factory SLING LSA

Pilot Operating Handbook

4.3 Use of taxi, landing, strobe and navigation lights

Taxi lights should be used as appropriate and their use should be

incorporated in the applicable (taxi and before take-off) procedures as

required. Give consideration to taxi lights as an aid to enhancing the

aircraft’s visibility to other traffic / pedestrians / wildlife.

Landing lights should be used as appropriate and their use should be

incorporated in the applicable (before take-off, take-off, climb, approach

and landing) procedures as required. Give consideration to landing lights

as an aid to enhancing the aircraft’s visibility to other traffic / pedestrians /

wildlife.

Strobe and navigation lights should be used as appropriate and their use

should be incorporated in the following (normal) procedures as required.

Give consideration to using the strobe light as an indicator / warning of

imminent engine start (i.e. switch on the strobe before starting the

engine).

Page | 4-4

Date of Issue: 07 July 2014 Revision : 1.3

Airplane Factory SLING LSA

NOTE

The word “condition” in the instructions means a visual

inspection of surface for damage deformations,

scratching, chafing, corrosion or other damages, which

may lead to flight safety degradation.

Pilot Operating Handbook

4.4 Pre-flight check

Carry out the pre-flight inspection every day prior to the first fight. Preflight inspections must also be performed after any accident, incident,

maintenance activity, assembly of any aircraft component or suchlike.

Incomplete or careless inspection can result in an accident. Carry out the

inspection following the instructions in the Inspection Check List.

Inspection check List

1. Cabin

- Magnetos / ignition - off.

- Master switch - on

- Fuel level indicator - verify fuel quantity.

- Flaps - move to full down position.

- Master switch - off.

- Avionics - verify condition.

- Control System - visual inspection, free movement up to

stops, verify function.

- Canopy - attachment condition, clean.

- Cockpit - check for loose objects.

- Fire extinguisher - verify present and valid.

- Documentation - verify present and valid.

Page | 4-5

Date of Issue: 07 July 2014 Revision : 1.3

Airplane Factory SLING LSA

CAUTION

In case of long-term parking it is recommended to turn the engine

over several times (Ignition OFF!) by turning the propeller in order

to prime the lubrication system. Always handle the propeller blade

area with the palm of your hand i.e. do not grasp only the blade

edge with your fingers.

Pilot Operating Handbook

2. Nose Section and Nose Gear

- Engine cowling condition - check.

- Propeller and spinner condition - check.

- Air intakes - check.

- Radiators - check.

- Engine mount and exhaust manifold condition- check.

- Oil and coolant quantity check - check.

- Visual inspection of fuel and electrical system- check.

- Engine checks as per Rotax manual - complete.

- Other actions according to the engine manual

- Parachute cover - if fitted check sealed

- Tire - condition, inflation,

- Wheels - security, general

- Chocks and tie-down ropes - remove.

- Suspension and undercarriage - check and test.

and secure.

wear.

condition.

Date of Issue: 07 July 2014 Revision : 1.3

Page | 4-6

Airplane Factory SLING LSA

WARNING

Physically verify the fuel level before each take-off

to make sure you have sufficient fuel for the

planned flight.

Pilot Operating Handbook

3. Right Fuselage

- Surface condition - check.

- Cowling attachment - check.

- Wing/fuselage fairings - check.

- Empennage fairings - check.

- Antenna/e - check condition and security.

4. Right Wing and Main Gear

- Wheel fairing - security, cracks.

- Wheel and brakes - fluid leaks, security, general

condition, tire condition, inflation

and wear.

- Wheel strut - condition, cracks.

- Leading edge condition - check.

- Taxi / landing lights and lens - check for cracks and condition.

- Fuel vent (underside of wing) - unobstructed.

- Wing trailing edge - check condition.

- Aileron - freedom of movement,

attachment, surface condition.

- Aileron hinges, control horn, bolts, pushrod - secure, condition.

- Flap hinges, control horn, bolts, pushrod - secure, condition.

- Wing tip - check condition.

- Strobe/Nav light and lens - check for cracks and condition.

Date of Issue: 07 July 2014 Revision : 1.3

Page | 4-7

Airplane Factory SLING LSA

Pilot Operating Handbook

5. Empennage

- Tie-down rope - removed.

- Horizontal and vertical stabilizers - check condition.

- Elevator and tab - condition and movement.

- Rudder - condition and movement.

- Hinges, control horns, bolts, pushrod - condition and secure.

6. Left Fuselage

- Surface condition - check.

- Cowling attachment - check.

- Wing/fuselage fairings - check.

- Empennage fairings - check.

- Antenna/e - check condition and security.

Page | 4-8

Date of Issue: 07 July 2014 Revision : 1.3

Airplane Factory SLING LSA

Pilot Operating Handbook

7. Left Wing

- Wheel fairing - security, cracks.

- Wheel and brakes - fluid leaks, security, general

condition, tire condition, inflation

and wear.

- Wheel strut - condition, cracks.

- Leading edge condition - check.

- Taxi / landing lights and lens - check for cracks and condition.

- Fuel vent (underside of wing) - unobstructed

- Wing trailing edge - check condition.

- Aileron - freedom of movement,

attachment, surface condition.

- Aileron hinges, control horn, bolts, pushrod - secure, condition.

- Flap hinges, control horn, bolts, pushrod - secure, condition.

- Wing tip - check condition.

- Strobe/Nav light and lens - check for cracks and condition.

- Pitot tube - security, unobstructed, remove

cover.

Page | 4-9

Date of Issue: 07 July 2014 Revision : 1.3

Airplane Factory SLING LSA

CAUTION

In case of long-term parking it is recommended to turn the engine

over several times (Ignition / magnetos OFF!) by turning the

propeller in order to prime the lubrication system. Always handle

the propeller blade area with the palm of your hand i.e. do not

grasp only the blade edge with your fingers.

CAUTION

Observe the temperature limits for engine start as specified in

paragraph 2.14.

Pilot Operating Handbook

4.5 Engine start

Reference should be made to the operator’s manual for the Rotax

912 iS or 912 ULS engine, as the case may be, for operational guidelines

and instructions. These should be incorporated into the normal or

emergency procedures as applicable.

4.5.1 Before starting engine

1. Pre-flight inspection - completed.

2. Emergency equipment - on board.

3. Passenger - briefed.

4. Seats, seatbelt and harnesses - adjust and secure.

5. Brakes - on.

Date of Issue: 07 July 2014 Revision : 1.3

Page | 4-10

Airplane Factory SLING LSA

Pilot Operating Handbook

4.5.2 Engine start

If a Rotax 912 iS engine is installed rather than a Rotax 912 ULS engine,

please refer to the supplement at the end of this manual.

1. Master switch - on.

2. EFIS back-up battery - on, verify EFIS on and back-up

battery voltage.

3. Magneto / ignition switches - on.

4. Fuel selector - open (RIGHT).

5. Electric fuel pumps (both) -on (912 iS).

6. Choke (cold engine) - pull to open and gradually release

7. Throttle - closed if choke used, cracked just

8. Propeller area - clear of people and obstructions.

9. Starter - engage (maximum 10 seconds).

Immediately after start-up:

10. Throttle - adjust for smooth running

11. Oil pressure - increase within 10 seconds.

12. EFIS switch - on and verify battery charging.

after engine start (912 ULS).

open if not.

(approximately 2000 rpm).

Page | 4-8

Date of Issue: 07 July 2014 Revision : 1.3

Airplane Factory SLING LSA

CAUTION

The starter should be activated for a maximum of 10 seconds, followed by 2 minute pause

to allow the starter to cool.

Verify the oil pressure, which should increase within 10 seconds. Increase the engine

speed only if oil pressure is steady above 2 bar (29 psi).

At an engine start with low oil temperature continue to watch the oil pressure as it could