TGB Xmotion 125, Xmotion 250 Owner's Manual

Xmotion 125/250

OWNER-MANUAl

MAINTENANCE HANDBOOK

TAIWAN GOLDEN BEE CO.,LTD.

PDF created with pdfFactory Pro trial version www.pdffactory.com

TABLE OF CONTENT

1. REGULAR INSPECTION

1-1 Delivery Introduction -----------------------------------------------------2

1-2 Inspection Before Running ---------------------------------------------4

1-3 Regular Maintenance Schedule -------------------------------------- 5

1-4 General Inspection -------------------------------------------------------6

1-5 Notes for Inspection ----------------------------------------------------- 7

2. MAINTENANCE INFORMATION

2-1 Specification Sheet -----------------------------------------------------8

2-2 Safety Precautions--------------------------------------------------------10

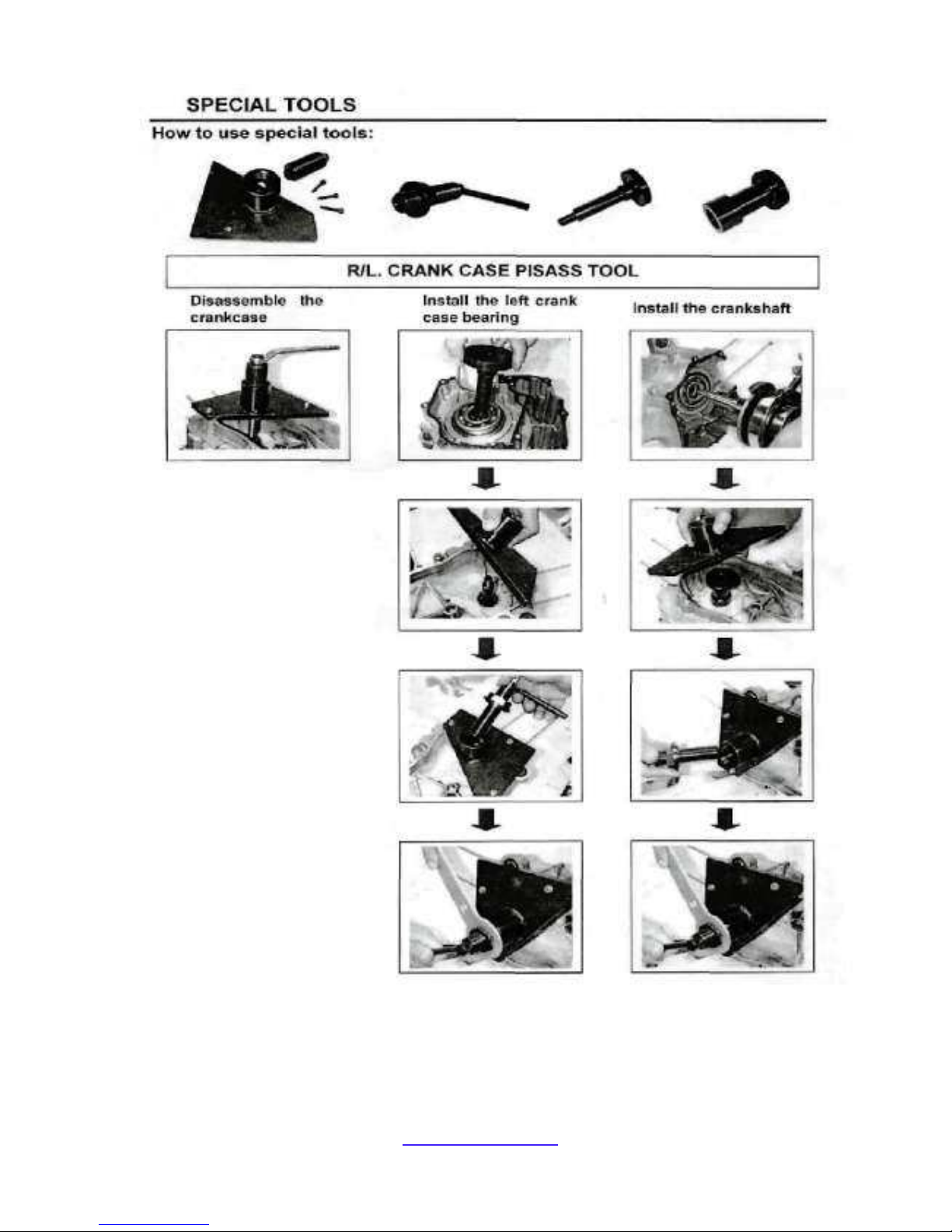

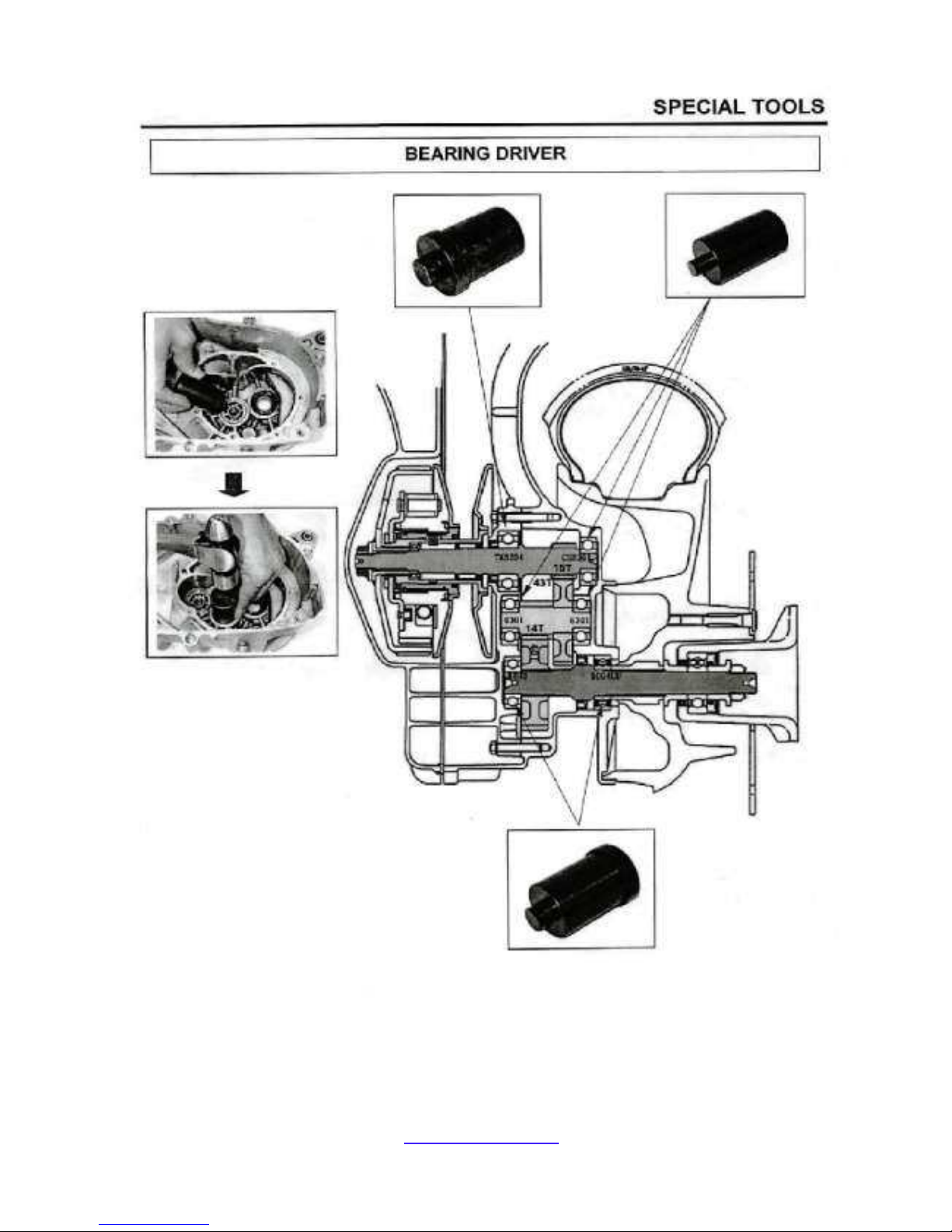

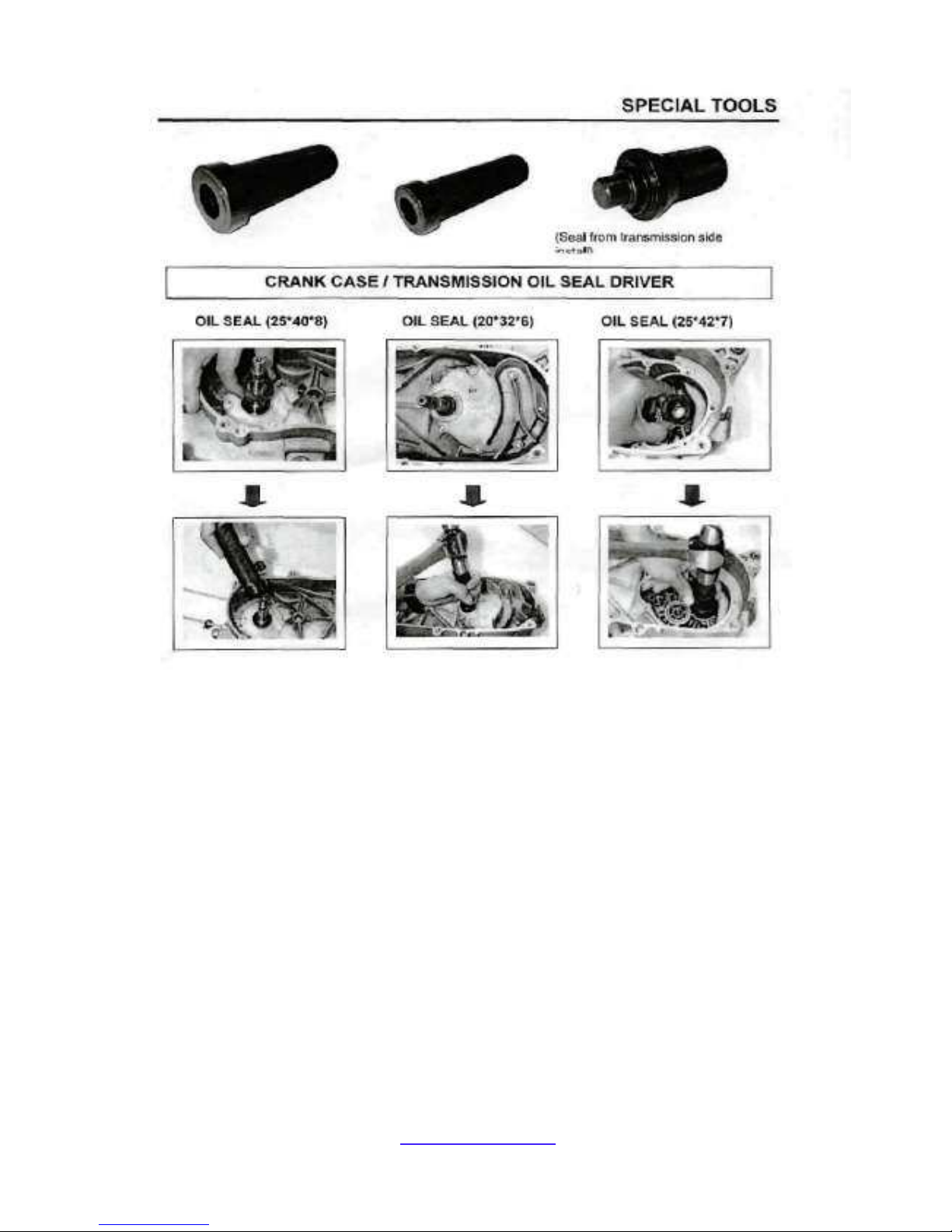

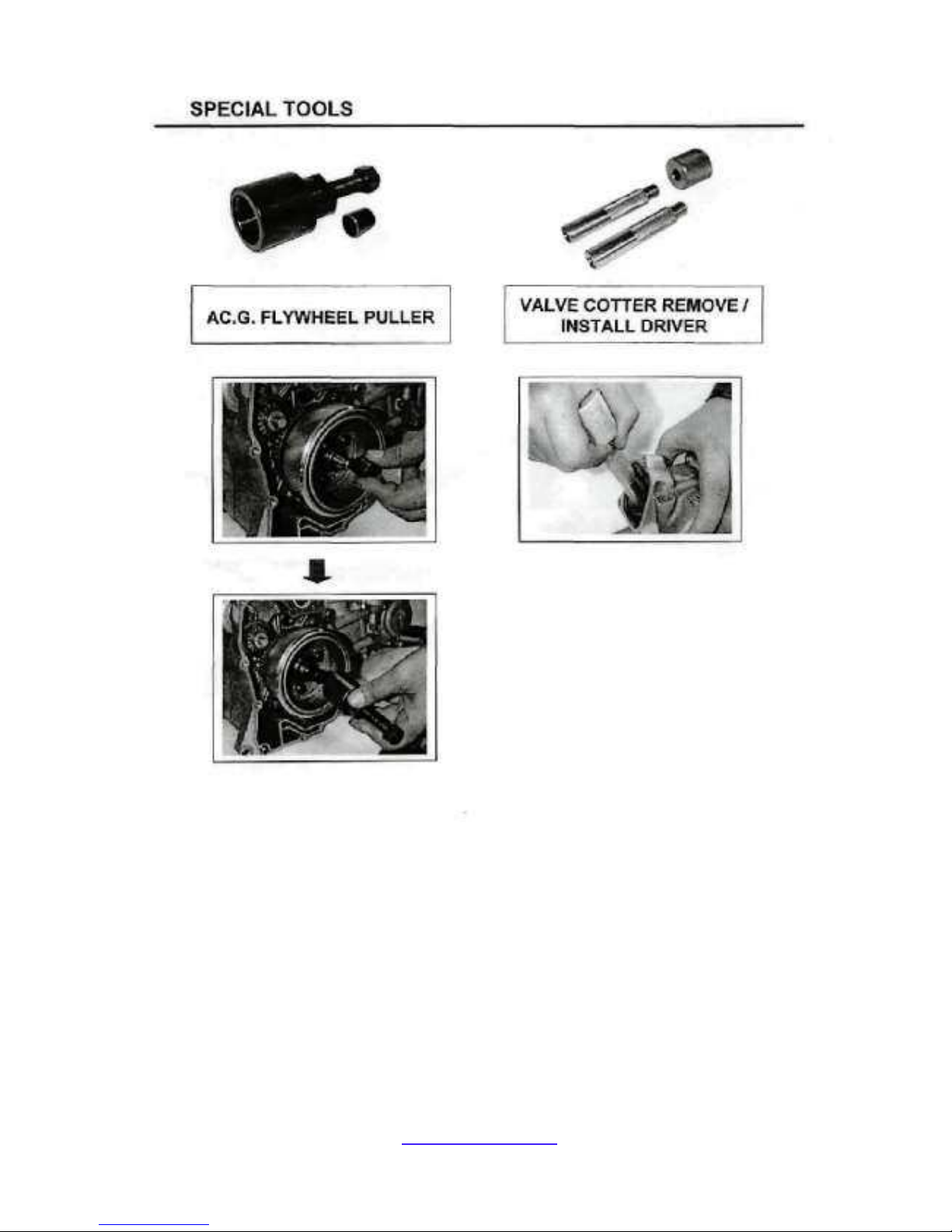

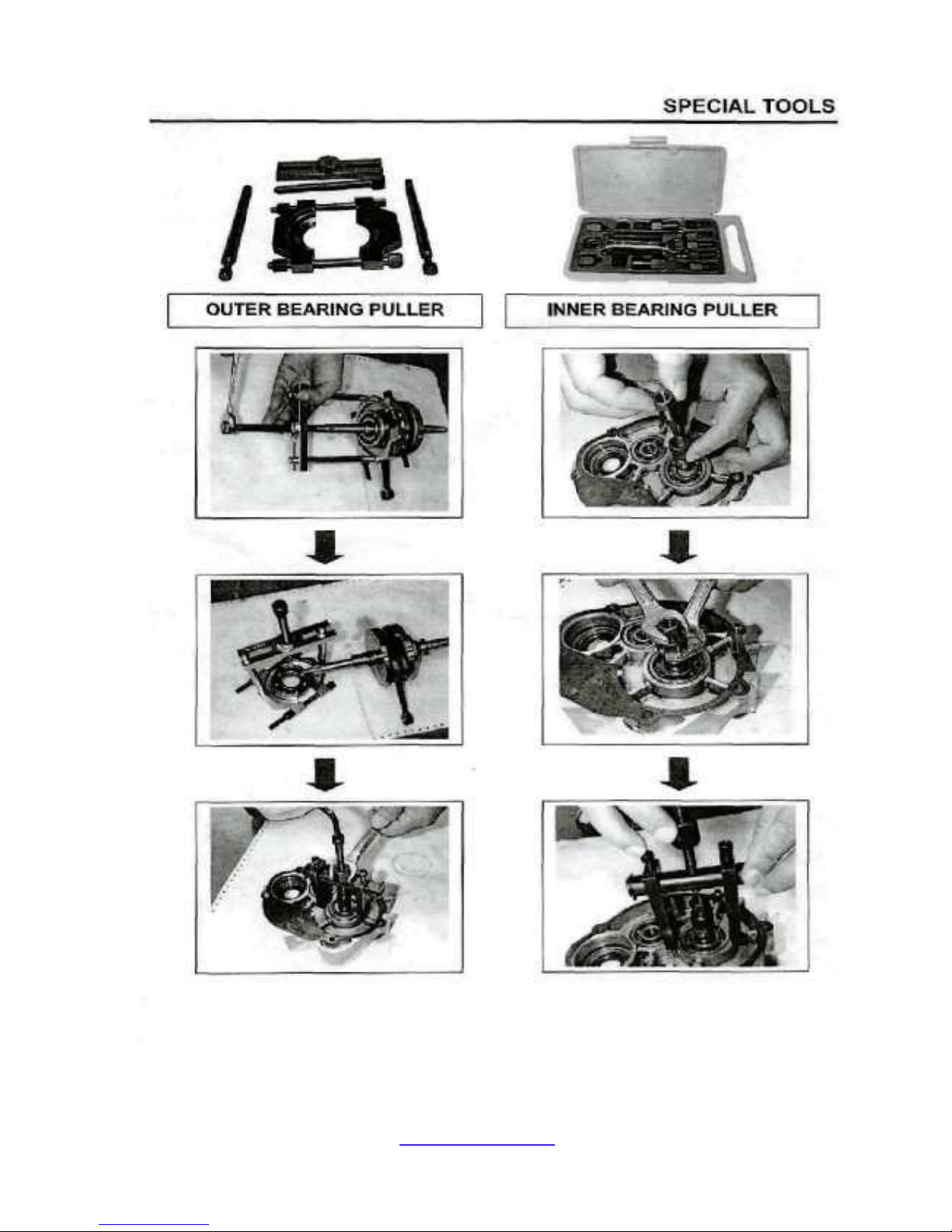

2-3 Special Tools --------------------------------------------------------------11

2-4 List of Grease & Oil Adopted ----------------------------------------- 24

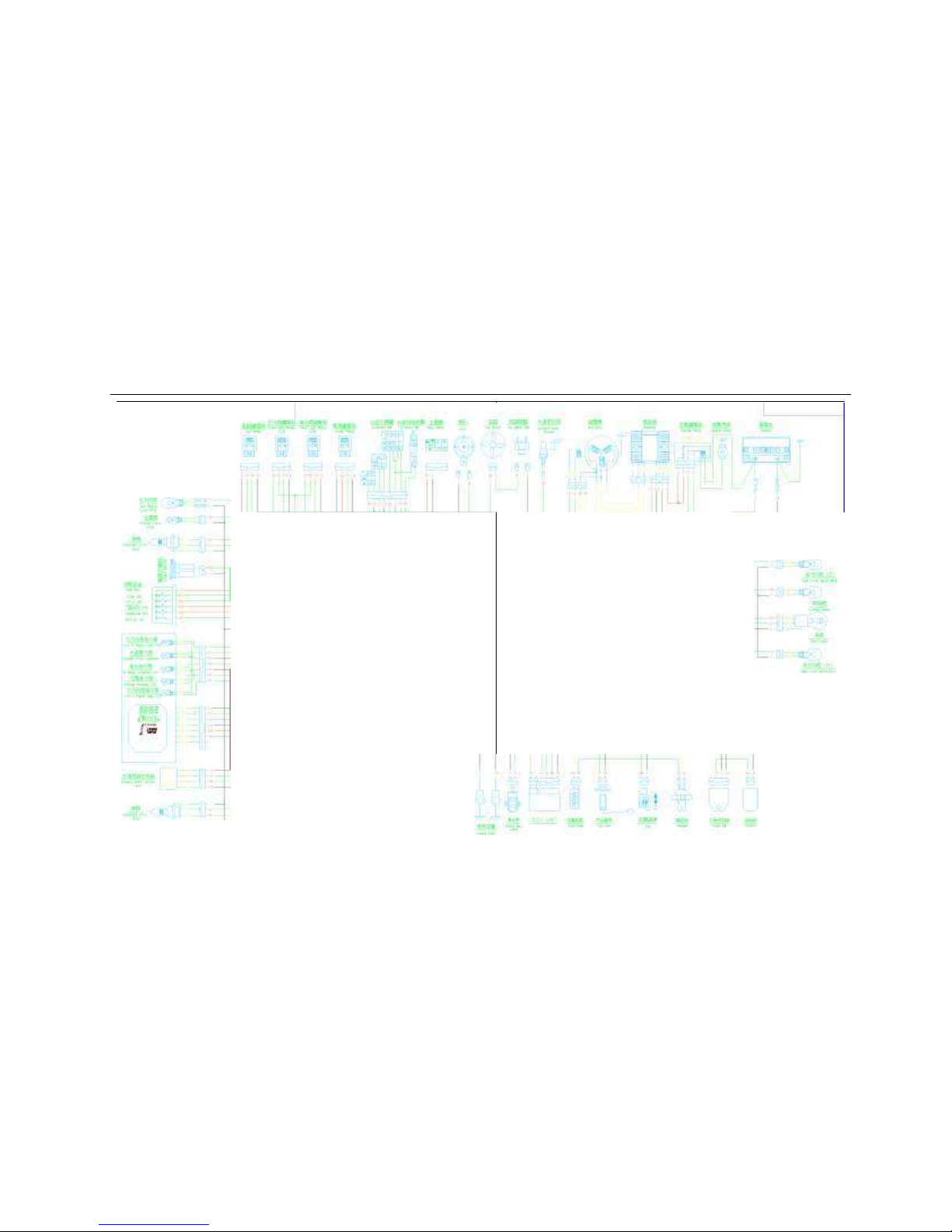

2-5 Circuit Drawings --------------------------------------------------------- 25

2-6 Troubleshooting ----------------------------------------------------------27

2-7 Tighting Torque of Screws --------------------------------------------27

2-8 Troubleshooting ----------------------------------------------------------30

3. DESCRIPTION OF PARTS AND COMPONENTS

3-1 Engine ---------------------------------------------------------------------39

3-2 Electric System ---------------------------------------------------------- 126

Q Q

Rnrlv 1^1

\J \J UUUjf

I \J I

4. DISASSEMBLY REPAIRMENT

4-1 Notice for Disassembly Repairment ----------------------------- 137

4-2 Removal and lnstallation of Engine -------------------------------138

4-3 Removal and Inspection of Electric Items -----------------------199

4-4 Removal and Inspection of Body Parts ----------------------------206

4-5 Brake System ----------------------------------------------------------- 214

î

PDF created with pdfFactory Pro trial version www.pdffactory.com

CHAPTER I

REGULAR INSPECTION

1-1 Delivery Introduction 1-4 General Inspection

1-2 Inspection Before Running 1-5 Notes for Inspection

1-3 Regular Maintenance Schedule _______________________

1-1 Delivery Introduction

To inform customers of correct methods to use: To practically and correctly

ride a scooter according to the Instruction of Manual and Maintenance

Handbook. Customers should also try in person according to this manual.

1. Starting:

A. Turn the power switch to "ON."

B. Hold the front or rear brake and press the "START" button.

C. If the scooter is not started, release the "START" button and try again after a few

minutes. Each start should be less than five seconds to avoid battery consumption.

Note: This is an AUTO-CHOKE scooter, thus there is no choke lever.

The fuel is controlled only by throttle grip.

The accelerator has to return to its original place when the scooter is not in use.

D. If the scooter can not be started by the "START" button, try the kick starter.

2. Fuel:

Inform customers to refill the fuel to no more than 80% of the tank capacity only.

PDF created with pdfFactory Pro trial version www.pdffactory.com

2

1-1 Delivery Introduction 3

. Lubricant Adopted:

A. WARNING : The engine oil must be refilled when the oil warning lamp lights, otherwise the

engine will be burned-out due to insufficient lubrication. Recommended oil : TGB Genuine

EXTRA 4X OIL.

B. Genuine TGB HYPOID GEAR OIL(or SAE85W-140) will be adopted as gear oil to be

changed on a periodical basis. Gear oil and engine oil are different in their nature.

Attention should be paid to avoid mistake when used.

4. Regular Inspection and Maintenance:

Inform customers of the importance of inspection before running and regular inspection.

A. Inspection Before Running: Riders should perform nspection by themselves before

running.

B. Regular Inspection: Regular inspection should be performed after the first month and

the sixth month and every six months afterwards.

5. Description of Warranty System:

Clearly identify the content of warranty in accordance with the warranty paper.

A. Content and term of warranty.

B. Maintenance items not guaranteed.

C. Items should be followed by customers.

Instruct customers to carry the OWNER'S Manual with them when they come for regular

inspection and maintenance. It is because such inspection should be recorded onto the

Manual.

PDF created with pdfFactory Pro trial version www.pdffactory.com

3

1-2 Inspection Before Running

Items to be Inspected Before Running by Customers:

ITEM

CONTENT

GUIDELINE

1. Starter

Is the oil volume

proper?

1 .Check Oil Warning Lamp to see if the oil

volume is proper?

2 .Fuel

Is the fuel volume

sufficient?

1 .Check fuel volume to see if it is enough

to the destination.

3. Lamp &

Direction

Indicator

Is the lamp condition

well? Is there any

dirt?

1 .Check if the lighting condition of head

lamp, tail lamp, licence lamp, brake lamp,

direction indicator and other lamp is well.

2. Lamps should be kept clean and

undamaged.

4. Back Mirror

Is the reflecting

image well?

1. Look at the back mirror from the

seat to check if the rear view is clear.

5. License Plate &

Reflector

No dirt and damage

should appear.

1. License plate should be installed, letters

and numbers should be kept clear and

clean. 2. Dirt and damage should not

appear on the reflector.

6 . Brake

Check the distance of

brake handle lever

and the brake effect.

1 .Operate the handle lever slowly to the

brake begin to effect in order to inspect the

moving distance. 2.Test the brake with low

speed running to see the brake effect of

front and rear brakes.

1.Is the air pressure

proper?

1 .Check if the air pressure of tire is

sufficient with a gauge or by sight.

2.Groove should be

deep enough.

1 .Check if the groove of tires is enough.

3.Unusual wear is not

desired.

1 .Check landing flat of tire to see if

any unusual wear appears.

4.Breaking and damage

are not desired.

1 .Check landing flat and side to see if

any breaking or damage appear.

7. Tire

5.Metal, stone and

other articles are

not desired.

1 .Cneck if any cracking, stone or any

other article sticks into the tire.

4

PDF created with pdfFactory Pro trial version www.pdffactory.com

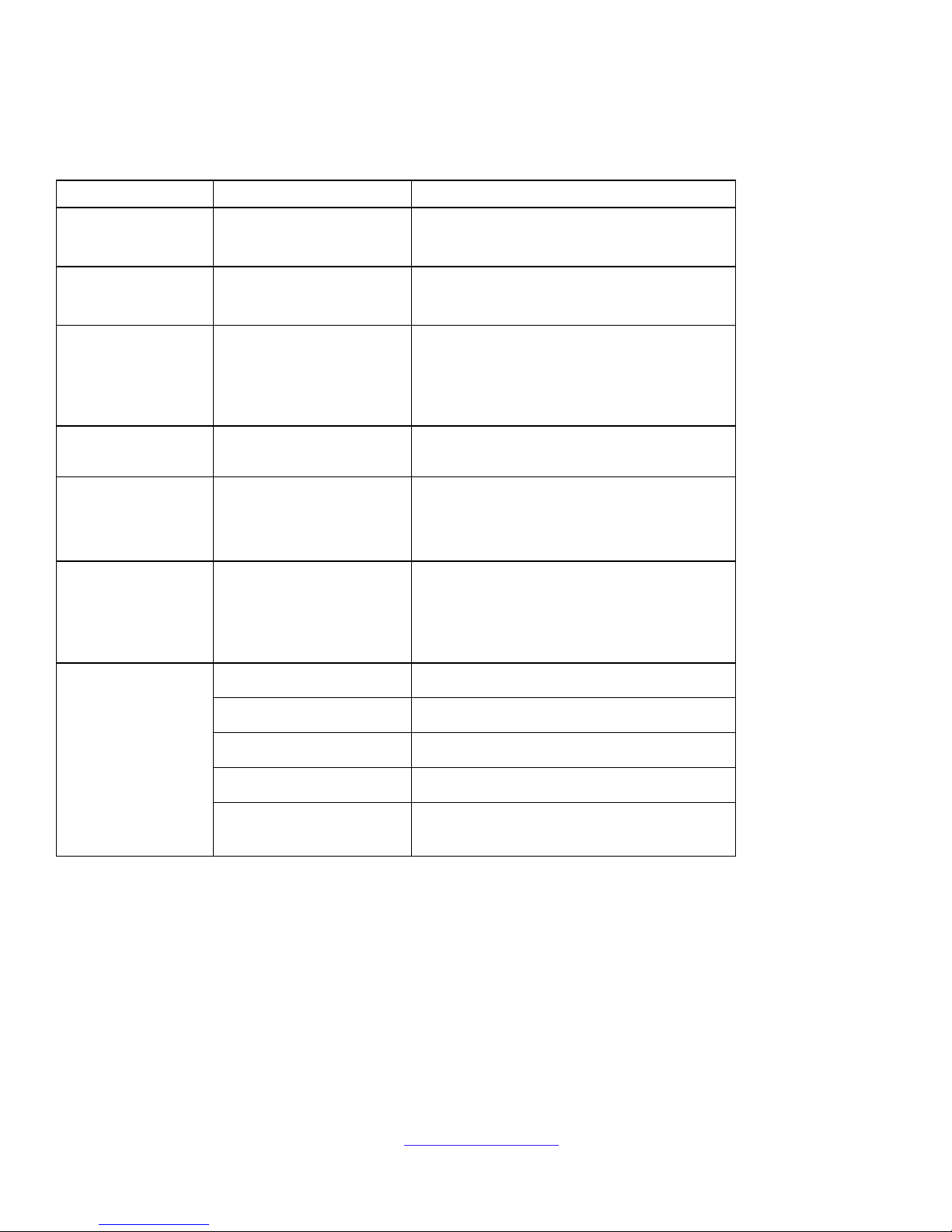

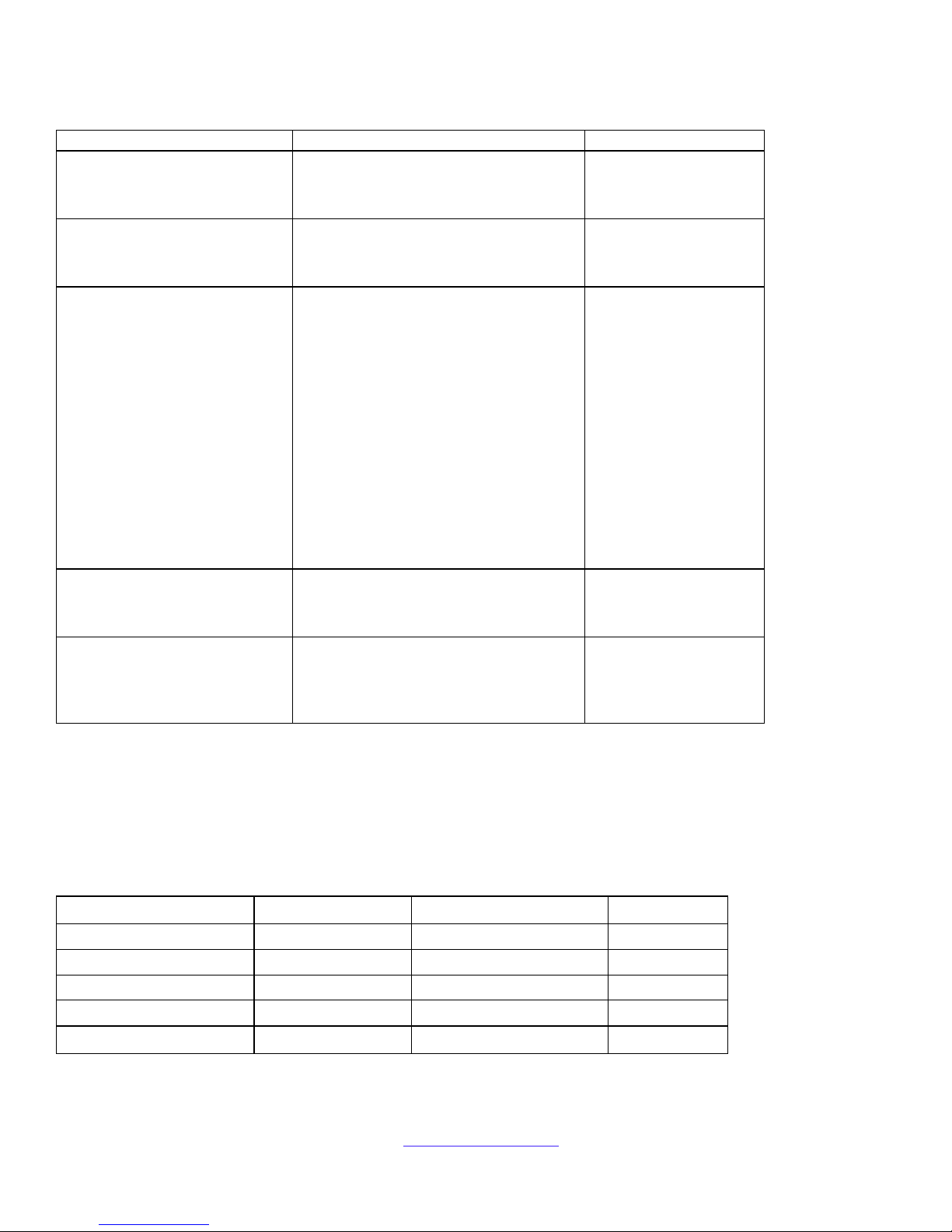

1-3 Regular Maintenance Schedule

The chart below lists the recommended intervals for all the returned periodic service work

necessarily to keep the motorcycle operating at peak performance and utmost efficiency.

Mileages are expressed in terms of kilometers and months. These intervals judged by

odometer reading or month whichever comes first.

\~^^^^ Maintenance

N, ^^\ kilometer

300KM

Every

1000KM

Every

3000KM

Every

6000KM

Every

12000KM

Item

^^ Maintenance Interval

Check Items \

NEW

1 Month 2 Month 3 Month 4 Month

Remarks

01 Air cleaner element(Remark)

I

C

C

02 Oil filter(Screen)

C

R

03 Engine oil

R

I

Replacement for every 3000KM

04 Tire, pressure

I

I

05 Battery

I

I

06 Spark plug

I

I

R

07 Carburetor(idle speed)

I

I

08 Steering bearing and handles

I

I

09 Check Transmission for leakage

I

I

10 Check crankcase for leakage

I

I

11 Transmission oil

R

Replacement for every 5000KM

(5 Month)

12 Drive Belt/roller

I

R

13 Fuel tank switch and lines

I

I

14 Throttle valve operation and cable

I

I

15 Engine bolts and nuts

I

I

16 Cylinder head, cylinder, and piston

I

17 Exhaust system/cleaning carbon

I

18 Cam chain/ignition time

I

I

19 Valve clearance

I

I

20 Shock absorbers

I

I

21 Front/rear suspension

I

I

22 Main/side stands

I

I/L

23 Crankcase Blow - by system(PCV)

I

I

24 Coolant

I

I

R

25 Cooling fan, lines

I

I

26 Clutch disk

I

27 Brake mechanism/brake lining(pad)

I

I

28 Bolts/nuts for each components

I

I

PDF created with pdfFactory Pro trial version www.pdffactory.com

5

*The above maintenance schedule is established by taking the monthy 1000 kilometers as

areference which ever comes first.

Code : I ~ Inspection, cleaning, and adjustment R ~ Replacement

C ~ Cleaning(replaced if necessary) L ~ Lubrication

Remark : 1. Clean or replace the air cleanr element more often whe the scooter is operated on

dusty roads or in the Heavily - polluted environment.

2. Maintenance should be performed more often if the scooter is frequently operated

in high speed and after the scooter has accumulated a higher mileage.

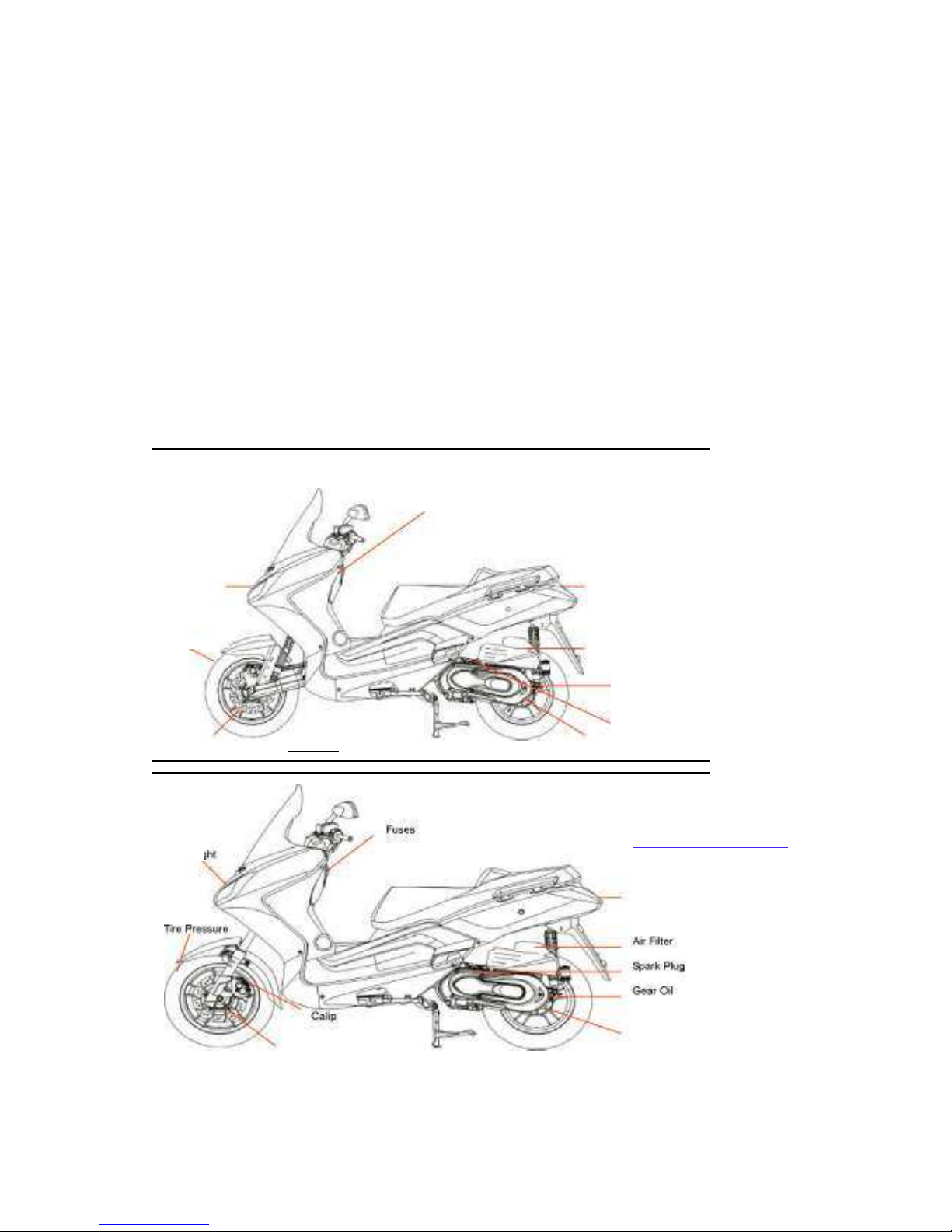

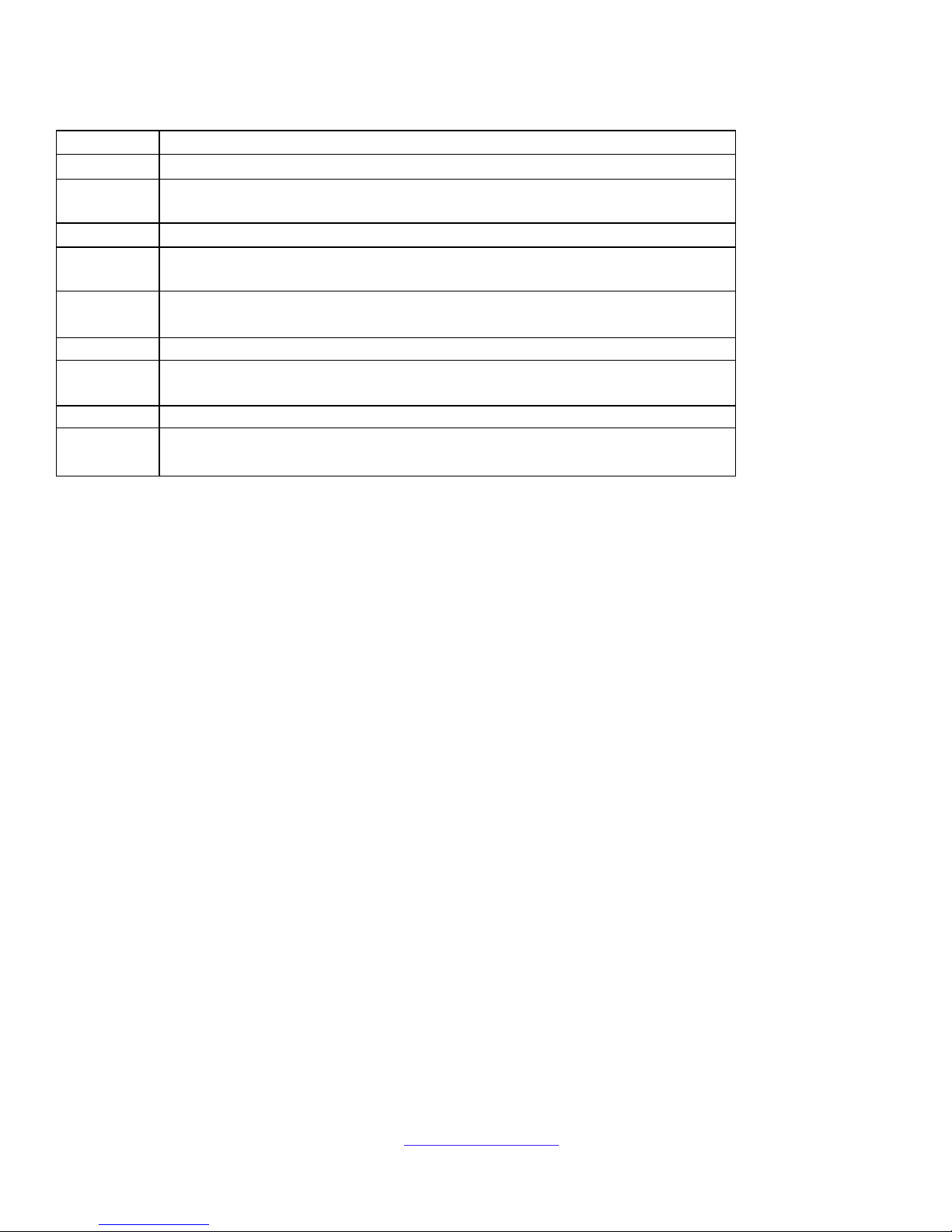

1-4 General Inspection General Inspection and Adjustment

* means adjustable.

Note: The ignition of this scooter by the use of crank-shaft which is 4 ignitions/revolution.

Special attention should be paid while setting the turning speed of Engine by Tachometer.

Brake

Disc

Tail Light/Turn

Signal Light

Gear Oil

Spark Plug

Raer Brake

Brake Disc

PDF created with pdfFactory Pro trial

version www.pdffactory.com

Fuses

Head Light

Tire

Air Filter

Head Lig

Tail Light/Turn

Signal Light

Raer

6

1-5 Notes for Inspection

ITEM

INSPECTION DETAILS

1

Be aware of smoke and fire while performing maintenance.

2

New Packing, Gasket, O Ring, locking pin should be used while

assembling.

3

Only designated TGB oils should be used on spare parts.

4

Clean the vehicle before maintenance to avoid dirt or mud on

disconnected parts.

5

The locking sequence of Bolt and Nut should be from inside to

outside, or in diagonal step. Reverse the sequence to loose.

6

Special tools should be used when necessary.

7

Attention should be paid to avoid damage or loss of disconnected parts. Clean

and grease properly before the assembly. No grease on Bolt's Thread.

8

Reconfirm each function after the assembly.

9

Special attention should be paid to the battery's electrolyte

and brake oil which will stam clothes.

7

PDF created with pdfFactory Pro trial version www.pdffactory.com

CHAPTER 2

MAINTENANCE INFORMATION

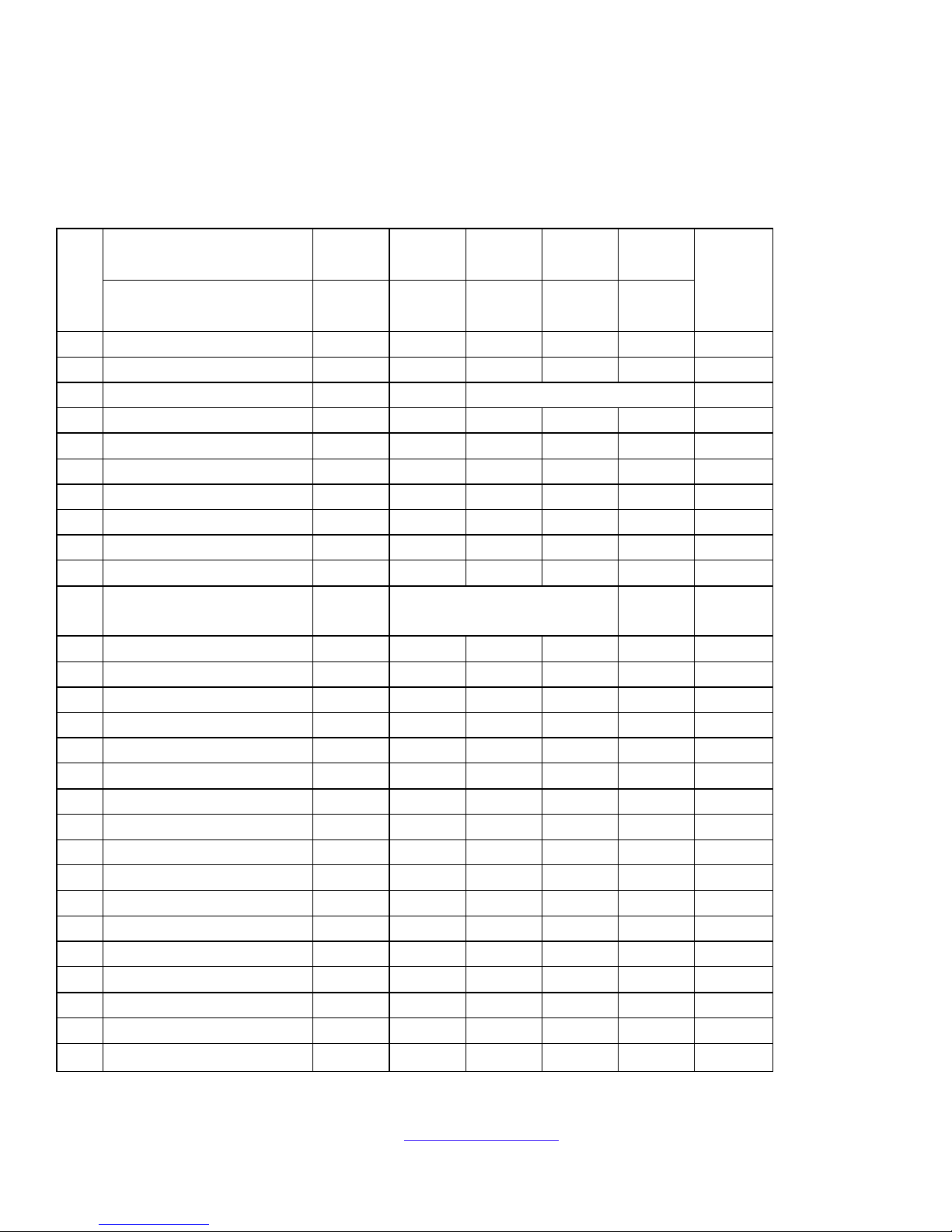

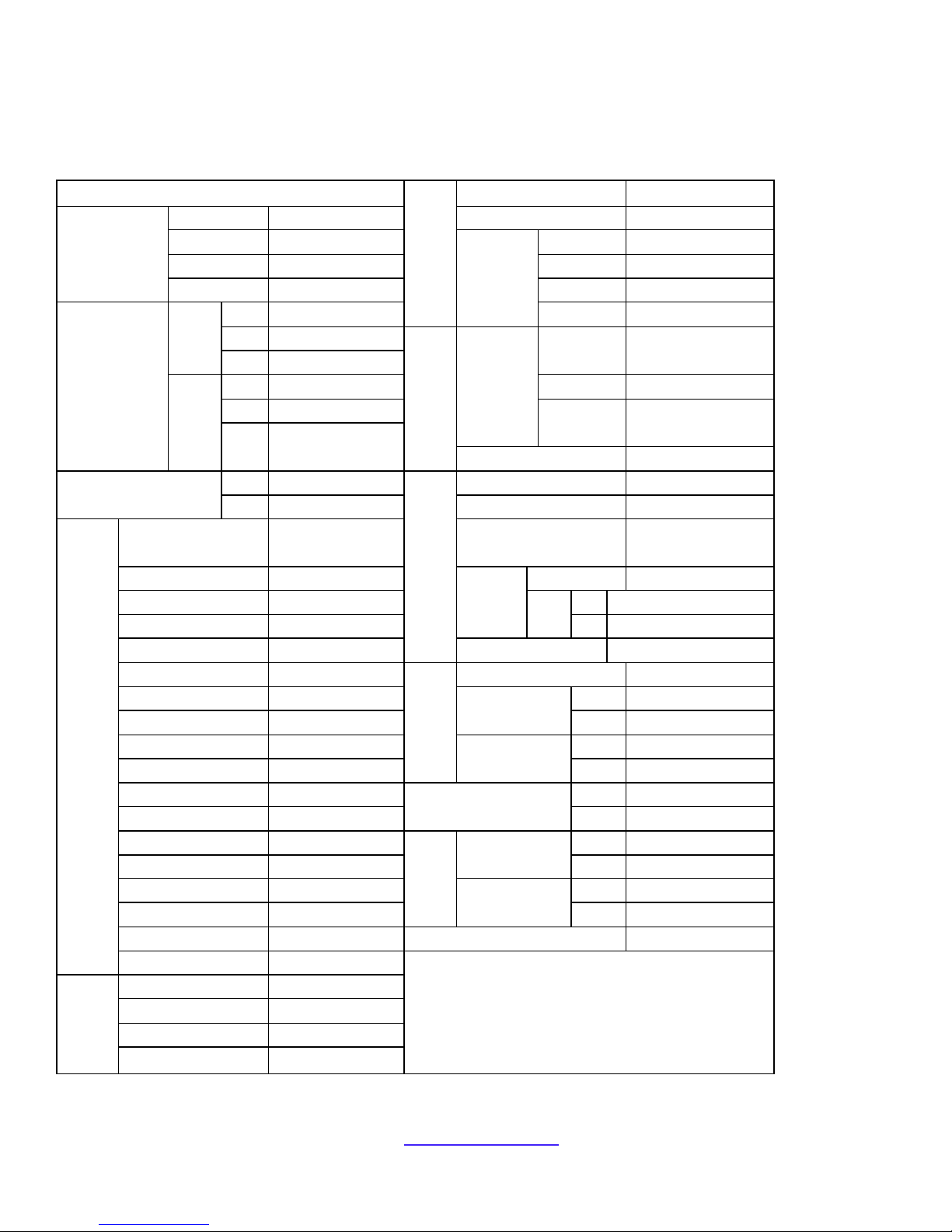

2-1 Specification Sheet

CU8 (X-Motion 125)

Air Filter

Paper Type

Length (mm)

2130

Fuel Capacity

11 L

Wi dth (mm)

840

Type

CVK164

Dimen

Height (mm)

1380

Venturi (mm)

25

sion

Wheelbase (mm)

1500

Front

55

Fuel

System

Carburetion

Rear

95

Unload

mass

Total

150

Type

C.D.I.

Ma

s

Front

102

Spark

CR8E

Rear

198

Ignition

Pointgap (mm) 0.8+0.1

s

Total mass

2 person/

150 kg

Total

300

Electric

system

Battery Type

GTX14-BS

Front

120/70-14

type

Automatic

Tire

Rear

140/60-13

Clutch type

Centrifugal type

Engine Type

4 Stroke 4V electroplated

ceramic cylinders engine

Transmission type

CVT

Fuel Type

Petrol

Type

Automatic

Number of Cylinder

Single cylinder

R1

0.79~2.72

Bore X Stroke (mm )

57 X 48.8

Gear Box

Gear

Ratio

R2

9.67

Cylinder Capacity

124.5 c.c.

Transmis -

sion

Starter

Electric &Kick

raked angle ( ° )

Cooling System

Liquid

Front

28

Lubrication system

Forced circulation & splashing

Tire Pressure (psi)

Rear

32

Reference and setting range(IN )

0.12±0.02 mm

Left

Reference and setting range(EX)

0.12±0.02 mm

Motion

system

Turn angel ( ° )

Right

...

MaxSpeed (km/hr)

105 km/h

Front

Disk

Idle speed (rpm )

1800+100 rpm

Braking system

Rear

Disk

Max Power ( Kw/rpm )

9 kw/8750 rpm

Front

Hydraulic-pressed Spring type

Max Torque (Nm/rpm)

10.5Nm/8250rpm

Suspension

Rear

Hydraulic-pressed Spring type

Compression Ratio

10.5

Front

Hydraulic-pressed Spring

Oil Spec.

SAE 10W-30

Buffer

Buffer

Rear

Hydraulic-pressed Spring

Oil Capacity ( L)

1 L

Frame Type

Welding Tube

Engine

Gear Oil Spec., Capacity

SAE 90, 0.11L

Front Lamp

35W/35W-12V

Rear Lamp

5W-12V

Brake Lamp

21W-12V

Lamp

Direction Lamp

21W-12V

8

PDF created with pdfFactory Pro trial version www.pdffactory.com

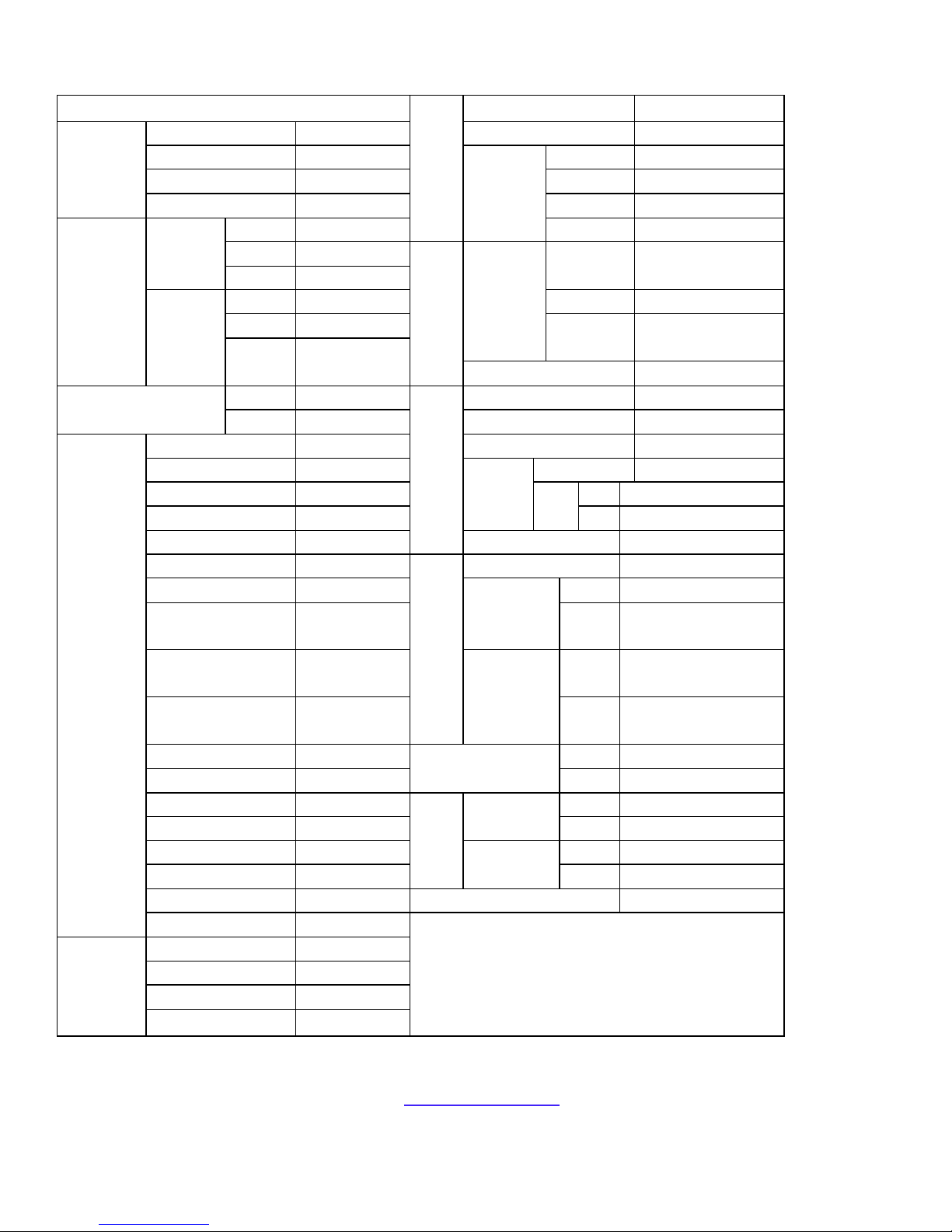

CUB (X-Motion 250)

Air Filter

Paper Type

Length (mm)

2130

Fuel Capacity

11 L

Width (mm)

840

Type

...

Height (mm)

1380

Venturi (mm)

...

Dimension

Wheelbase (mm)

1500

Front

60

Fuel

System

Carburetion

Rear

100

Unload mass

Total

160

Type

E.C.U.

Front

107

Spark

CR8E

Rear

203

Ignition

Point ga (mm) 0.8±0.1

Mass

Total mass 2

person/ 150

kg

Total

310

Electric

system

Battery Type

GTX14-BS

Front

120/70-14

type

Automatic

Tire

Rear

140/60-13

Clutch type

Centrifugal type

Engine Type

4 Stroke

Transmission type

CVT

Fuel Type

Petrol

Type

Automatic

Number of Cylinder

Single cylinder

R1

0.8~2.30

Bore X Stroke (mm )

71 X 63.3

Gear Box

Gear

Ratio

R2

7.42

Cylinder Capacity

249.4 c.c.

Transm -

ission

Starter

Electric

raked angle ( ° )

—

Cooling System

Liquid

Front

28

Lubrication system

Forced circulation &

splashing

Tire Pressure

(psi)

Rear

32

Reference and setting

range(IN)

0.1 ±0.02 mm

Left

—

Reference and setting

range(EX)

0.15±0.02 mm

Motion

system

Turn angel ( ° )

Right

—

Max Speed (km/hr)

128 km/h

Front

Disk

Idle speed (rpm )

1650±100 rpm

Braking system

Rear

Disk

Max Power ( Kw/rpm )

17.2kw/8750 rpm

Front

Hydraulic-pressed Spring type

Max Torque (Nm/rpm)

22.7Nm/8250rpm

Suspension

Rear

Hydraulic-pressed Spring type

Compression Ratio

10.8

Front

Hydraulic-pressed Spring

Oil Spec.

SAE 10W-30

Buffer

Buffer

Rear

Hydraulic-pressed Spring

Oil Capacity (L)

1.4 L

Frame Type

Welding Tube

Engine

Gear Oil Spec.,Capacity

SAE 90, 0.18L

Front Lamp

35W/35W-12V

Rear Lamp

5W-12V

Brake Lamp

21W-12V

Lamp

Direction Lamp

21W-12V

PDF created with pdfFactory Pro trial version www.pdffactory.com

9

2-2 Safety Precautions

Warning: Engine Exhaust

Please keep good ventilation during engine operation. Do not operate engine in closed-room.

The toxic carbon-oxygen (CO) in exhaust may lead human to loss conscious and even death.

Warning: Gasoline

The gasoline is very easy to burn or explode. Forbid any fire during inspection of gasoline

tank or gasoline leak.

Warning: Battery H2 and Battery Liquid

1. The battery liquid is toxic sodium liquid. Please do not contact the liquid with skin or eye. If

any contact happens, please wash with massive clean water and contact with doctor.

2. The released H2 from battery is explosive. Please keep good ventilation during charging

battery and forbid any fire.

Watch: Brake Fluid

The brake fluid can damage the painting on plastic. Please cover the plastic parts with towel

or cloth during maintenance of brake disk. If the brake fluid is split on plastic component,

please remove the fluid and wash the surface with water right away.

Watch: High Temperature of Engine

The engine cover, cylinder, and exhaust pipe have high temperature after starting of engine.

Please wear glove in maintenance of parts during engine operation, or maintenance should

be waited until engine is cooled.

10

PDF created with pdfFactory Pro trial version www.pdffactory.com

2-3 Special Tools

125 ce:

11

PDF created with pdfFactory Pro trial version www.pdffactory.com

12

PDF created with pdfFactory Pro trial version www.pdffactory.com

LUOO'

U0JSJ9A

\BU}

U(\\M

P91B9J0

£1

14

PDF created with pdfFactory Pro trial version www.pdffactory.com

PDF created with pdfFactory Pro trial version www.pdffactory.com

16

PDF created with pdfFactory Pro trial version www.pdffactory.com

17

PDF created with pdfFactory Pro trial version www.pdffactory.com

18

PDF created with pdfFactory Pro trial version www.pdffactory.com

19

PDF created with pdfFactory Pro trial version www.pdffactory.com

woo■

UOJSJGA

\e\j\ ojd

Âjopejpd

LUOO

■ Ajojoewpa Nwm

UOJSJGA \BU}

OJd Âjojoejpd I^

M

22

PDF created with pdfFactory Pro trial version www.pdffactory.com

23

PDF created with pdfFactory Pro trial version www.pdffactory.com

2-4 List of Grease & Oil Adopted:

TGB Supper Grease

No.0

Apply in Oil Seal.

Supper Grease No.3

Apply in Axle Shaft,

inside of Oil Seal.

1104 Sealing ThreeBond Apply on Right

Hand Crank Surface.

TGB Gear Oil 85w-140

Transmission Gear Oil

for Scooters.

TGB Genuine EXTRA 4X OIL

Engine Oil Apply in oil tank

Three-Bond 1322 Under

M10 Screw (For

medium fixing) for

Flywheel Magneto.

TGB Supper Grease

No. I

Apply in Oil Seal.

DOT-3 Brake Oil For

Brake.

TGB Supper Grease

No.2

Apply in Kick Starter.

TGB Supper Grease No.4

For Movable Drive Face Comp.

Cemedine 575 Apply

in Handle Grip

24

PDF created with pdfFactory Pro trial version www.pdffactory.com

"0

D

T|

O

3

3

0)

Ui

*~t Wfmmk CRITICAL CHARACTERISTIC ►

Ifffitt SIGNIFICANT CHARACTERISTEC

—\

O

I

D

3

5

(A

o

o

■

L

"i

k

r

d

!

2

COLOR

COLOR

COLO R

1

BLACK

r?

CHOCOLATE

28

WHITE/RED

1

-

BLACK

13

BROWN/WHITE

29

GREEN/BLUE

1

-

BLACK

14 M/

Ë

BLUE/WHITE Jti

*

PURPLE

2

RED

1

.

GREEN/YELLOW

37

BLACK/GREEN

2

-

RED

16

GREEN/BLACK

3S

BLACK /YELLOW

t->

,81

RED

1 / w/

É

YELLOW/WHITE 3U Ë/i.

WHITE/BLUE

2

-

RED

ia

PINK

4U

Ë/w WHITE/YELLOW

2

-

RED

19

BLUE/RED

42

^/K YELLOW/BLUE

J RED

2

SKY BLUE

4H

SS BLUE

4

BROW

2

1

RED/YELLOW

49

#" ORANGE

S) S/

Ê

GREEN/WHITE

'>■>

YELLOW

bi

BLACK/RED

6 K/w

BLUE/YELLOW

2J

GREEN

b4

YELLOW

lu Ë

/S

WHITE/BLACK

2b

BROWN/BLUE

bb

* YELLOW

11

DEEP GREEN

26 81 /

RED/WHITE

"0

D

T|

O

3

3

0)

CT

N

O

o

o

C0L0R

W

COLQR ^^ COLQR

COLQR

1

BLACK

11 3Sg

DEEP GREEN 2/

É

/i

WHITE/GREE N 4J WHITE/B ROW

1

-

BLACK

12 #

î§

CHOCOLATE 2S WHITE/RE D

44

YELLOW

I-J BLACK

13

BROWN/ WHITE 2y

^/

M

GREEN/Y ELLOW

4b

YELLO W/BLACK

RED

14 M/B

BLUE/ WHITE .1(1 ORAN GE/BL UE

4ti

GREEN /BROW

2-1 RED

1fi

GREEN/YELL OVJ

31

BLUE /ORANG E

4/ ^/*

BLA CK/PU RPLE

2

-

RED

1

GREE N/BLA CK

32

RED/O RANGE

4

BLUE

2

-

RED

17 #/R

YELLOW/WH ITE

,1,1

BLUE/ GREEN

49 ^g

ORANGE

2

-

RED

1

PINK

M

ORANGE/ WHITE

b(

w/^

YELLOW/GR EEN

RED

1

M/,1

BLUE /RED 3b RED /GRAY

b1

BLA CK/RE D

4

BROW

2

SKY BLUE

PURPLE

b2

SKYBLUE/ORANGE

b iift/

É

GREEN/W HITE

'A

E/w

RED/Y ELLOW 3/

^/

»

BLACK /GREEN

BROW/YE LLOW

6 &/w

BLUE/ YELLOW

22

M YELLOW

3H ^/w

BLAC K/YELL OW

7

BLUE /BLA CK 23 GREEN

jy

Ê

/M

WHI TE/BLUE

H

BLAC K/YELL OW

24

PINK/WHITE

4U &/

M

WHI TE/YELLOW

9

BROW N/BLA CK V.

^/M

BROW N/BLUE

41 ilS/fl

GREEN /RED

1U Ê/£

WHI TE/BLA CK 2fci

SI/B

RED /WHI TE

42 f/M

YELLQ W/BLUE

—ï

2-6 Troubleshooting

Complaint

Possible Reason

Remedy

No action for starter motor

1. Fuse breaks. 2. No power in

battery. 3. Defective action of brake

switch. 4 Short circuit of starter

relay.

Replace

Charging

Replace

Replace

No sparking or poor sparking

1. Defective spark plug. 2. Defective

CDI & ignition coil unit. 3. Defective

magneto stator coil. 4. Loose

connection of lead wire.

Replace

Replace

Replace

Connect

Unable or

Difficult to start

Plug not sparking

1. Damaged spark plug or spark plug cap. 2.

Dirty or wet spark plug. 3. Defective CDI

&ignition coil unit or stator coil. 4.Open or

short in high-tension cord. 5. Defective

ignition switch. No fuel reaching the

carburetor 1. No gasoline in fuel tank.

2.Clogged hole in the fuel tank cap.

3.Clogged or defective fuel cock. 4.Clogged

fuel hose or defective vacuum hose.

Compression too low 1. Excessively worn

cylinder or piston rings. 2.Spark plug too

loose. 3. Broken,cracked or otherwise failed

piston.

Replace Clean &

dry Replace

Replace Replace

Replace Clean

Clean or replace

Clean or replace

Replace Tighten

Replace

Noisy engine

1 . Piston or cylinder worn down. 2.

Combustion chamber fouled with carbon. 3.

Piston pin,bearing or piston pin worn. 4.

Worn or burnt crankshaft bearings.

Replace

Clean

Replace

Replace

Engine idles poorly

1. Stiff piston ring in place. 2. Excessively

worn cylinder or piston rings. 3. Gas leaks

from crankshaft oil seal. 4. Defective CDI &

ignition coil unit. 5. Clogged jets in

carburetor.

Replace Replace

Replace Replace

Clean or adjust

2-7 Tighting Torque of Screws

*Standard Torque Values of Bolts and Nuts *

Specification

Torque (kg-cm)

Specification

Torque (kg-cm)

5 mm Bolt and Nut

40

8 mm Bolt and Nut

220

5 mm Flange Bolt and Nut

50

8 mm Flange Bolt and Nut

270

6 mm Bolt and Nut

100

10 mm Bolt and Nut

350

6 mm Flange Bolt and Nut

120

10 mm Flange Bolt and Nut

400

6 mm SH Bolt and Nut

90

12 mm Bolt and Nut

550

27

PDF created with pdfFactory Pro trial version www.pdffactory.com

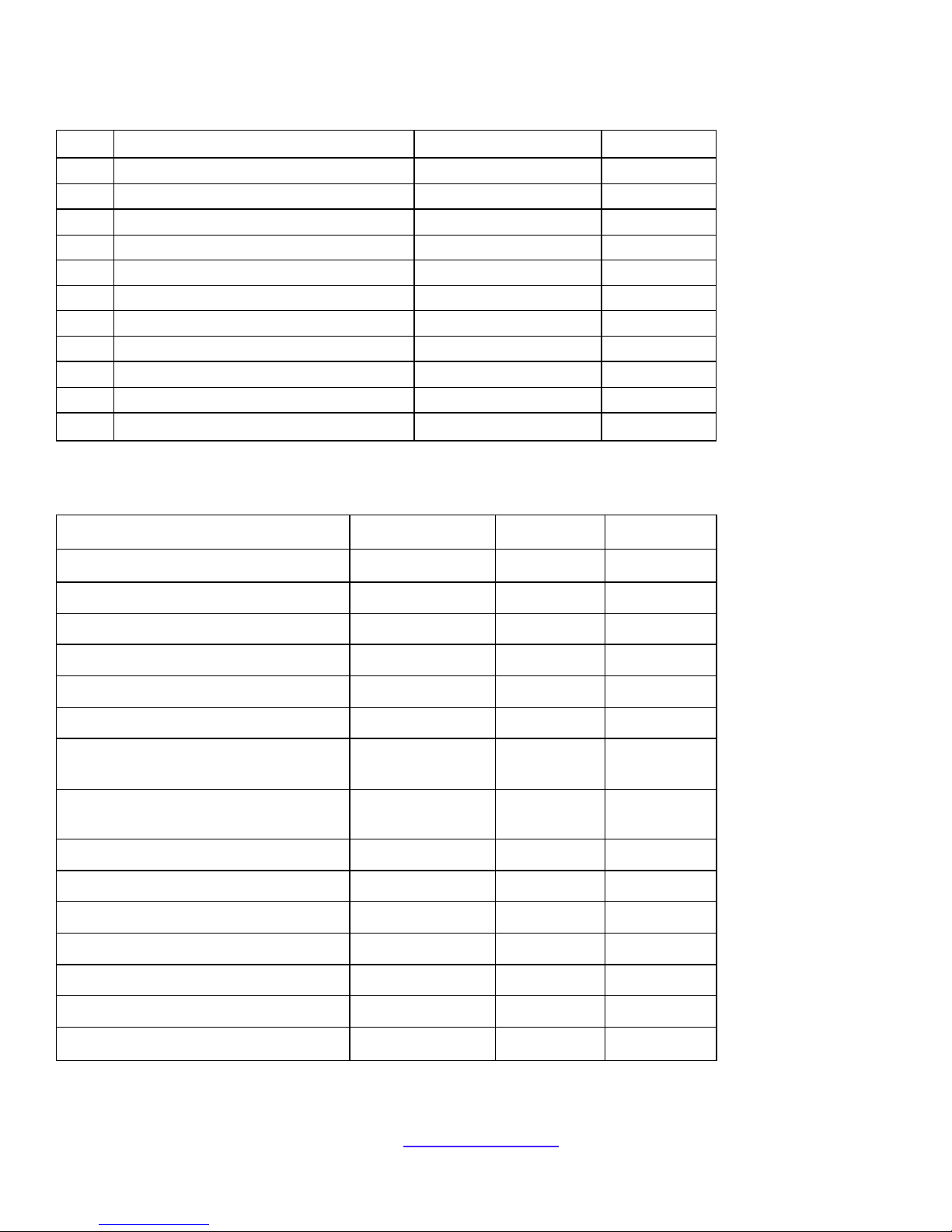

* Torque Values of Chassis Components *

No. Tightening Location

Specification

Torque

(kg-cm)

1

Front Wheel Axle Self-lock Nut

M12

500~600

2

Brake Disk Hex Bolt

M5

180~280

3

Brake Clipper Tightening Bolt

M 8x35

210~250

4

Speed Meter Cable Nut

X

60

5

Front Fork Bearing Tightening Nut

M25x1.0

600~650

6

Rear Wheel Axle Self-lock Nut

M16x10

600~900

7

Rear Brake Connecting Rod Bolt

M16x32

50~80

8

Rear Brake Pin Self-lock Nut

M8

250~270

9

Rear Upper Cushion Tightening Bolt

M10*46

200~300

10

Rear Lower Cushion Tightening Bolt

M8*35

200~300

* Torque Values of Engine components *

Tightening Location

Specification

Torque

Quantities

(kg-cm)

Cylinder Head Bolt

M6

80~100

4

Cylinder Stud Bolt

M8x182.5

500~800

2

M8x195.5

2

Cylinder Intake Pipe Stud Bolt

M6x50

500~800

2

Muffler and Exhaust Pipe Tightening Screw

M6

100~120

2

Muffler & Right Crankcase Upper Tightening

Screw

M 8x42

300~400

1

Muffler & Right Crankcase Lower Tightening

Screw

M 8x38

300~400

1

Spark Plug

M10

100~120

1

Valve Gap Adjust Lock Bolt

M5

50~90

2

Fuel Filter Nut Cap

M30

150~200

1

Cooler Fan Lock CR

M6x18

500~800

4

Wire Assembly Lock Screw

M6x20

800~1000

2

Start Clutch Gear ightening Nut

M22 (R.T.)

800~1000

1

Driven Belt Pully Assembly

M12

400~600

1

28

PDF created with pdfFactory Pro trial version www.pdffactory.com

Loading...

Loading...