TGB Hornet 50, Hornet 90 Service Manual

CONTENT

1. REGULAR INSPECTION -----------------------------------------2

1-1 Delivery Introduction ---------------------------------------------------2

1-2 Inspection Before Running -------------------------------------------4

1-3 Regular Inspection ------------------------------------------------------5

1-4 General Inspection ------------------------------------------------------6

2. MAINTENANCE INFORMATION------------------- ------------7

2-1 Specification Sheet -----------------------------------------------------7

2-2 Maintenance Data ---------------------------- ---------------------------8

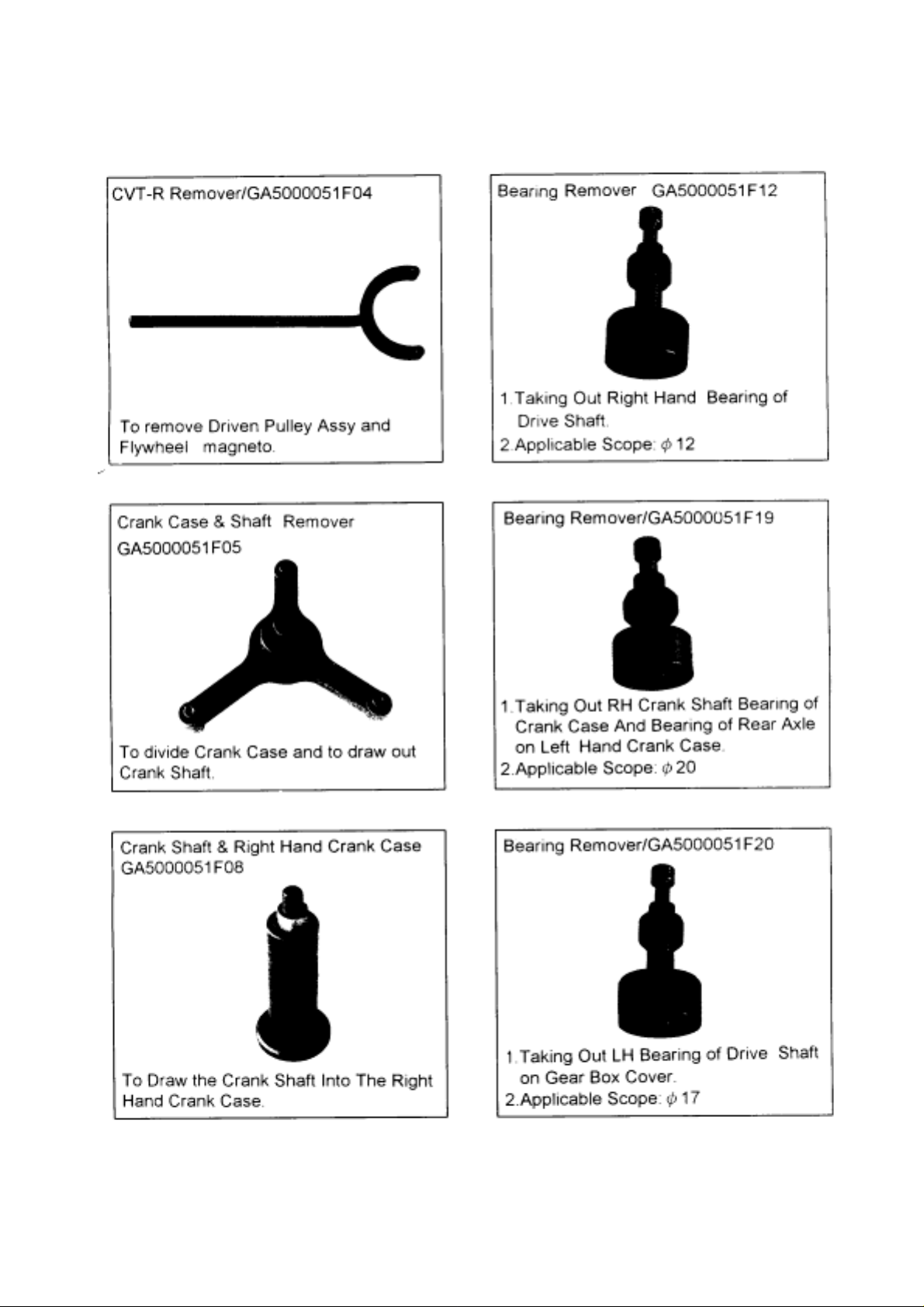

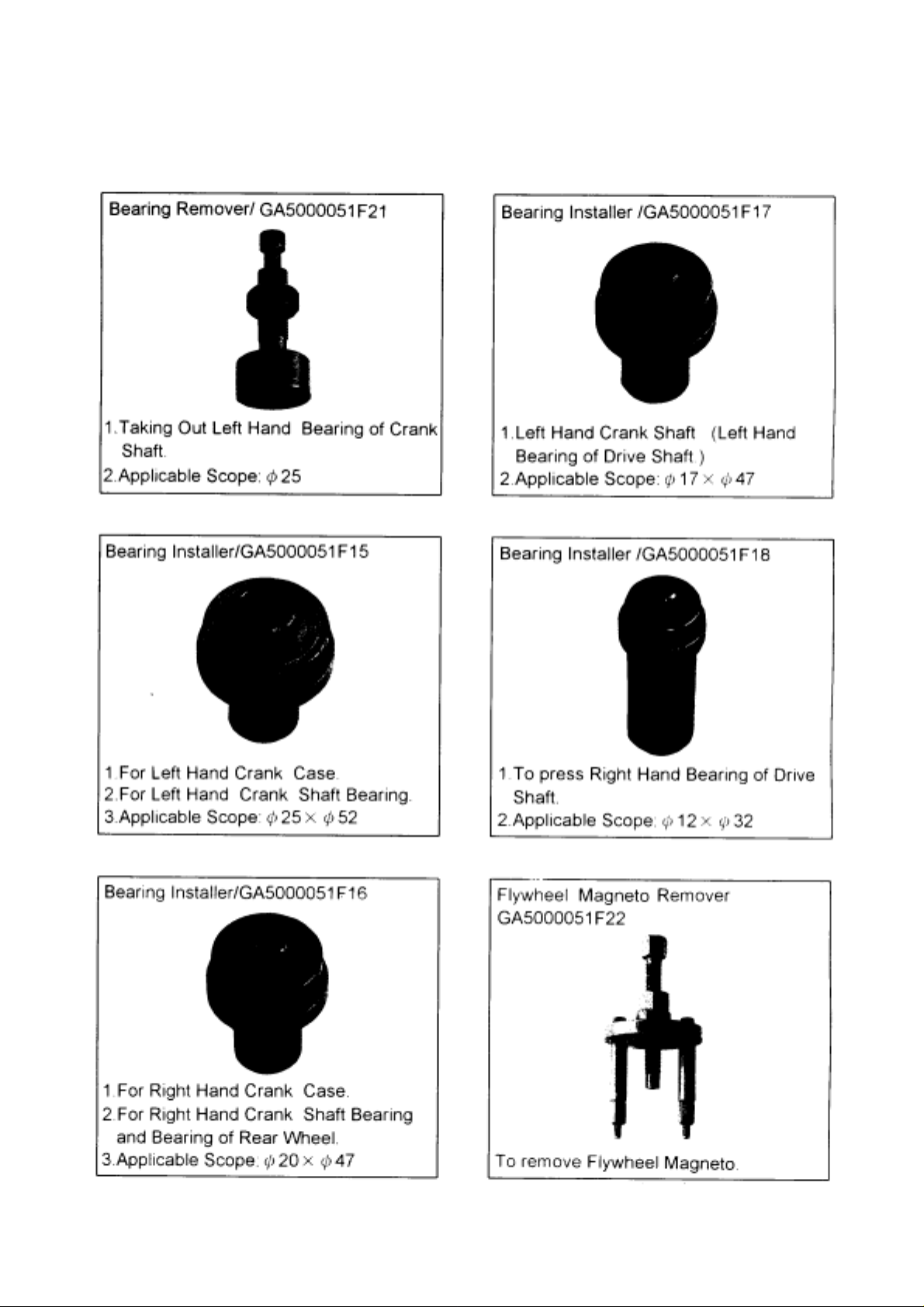

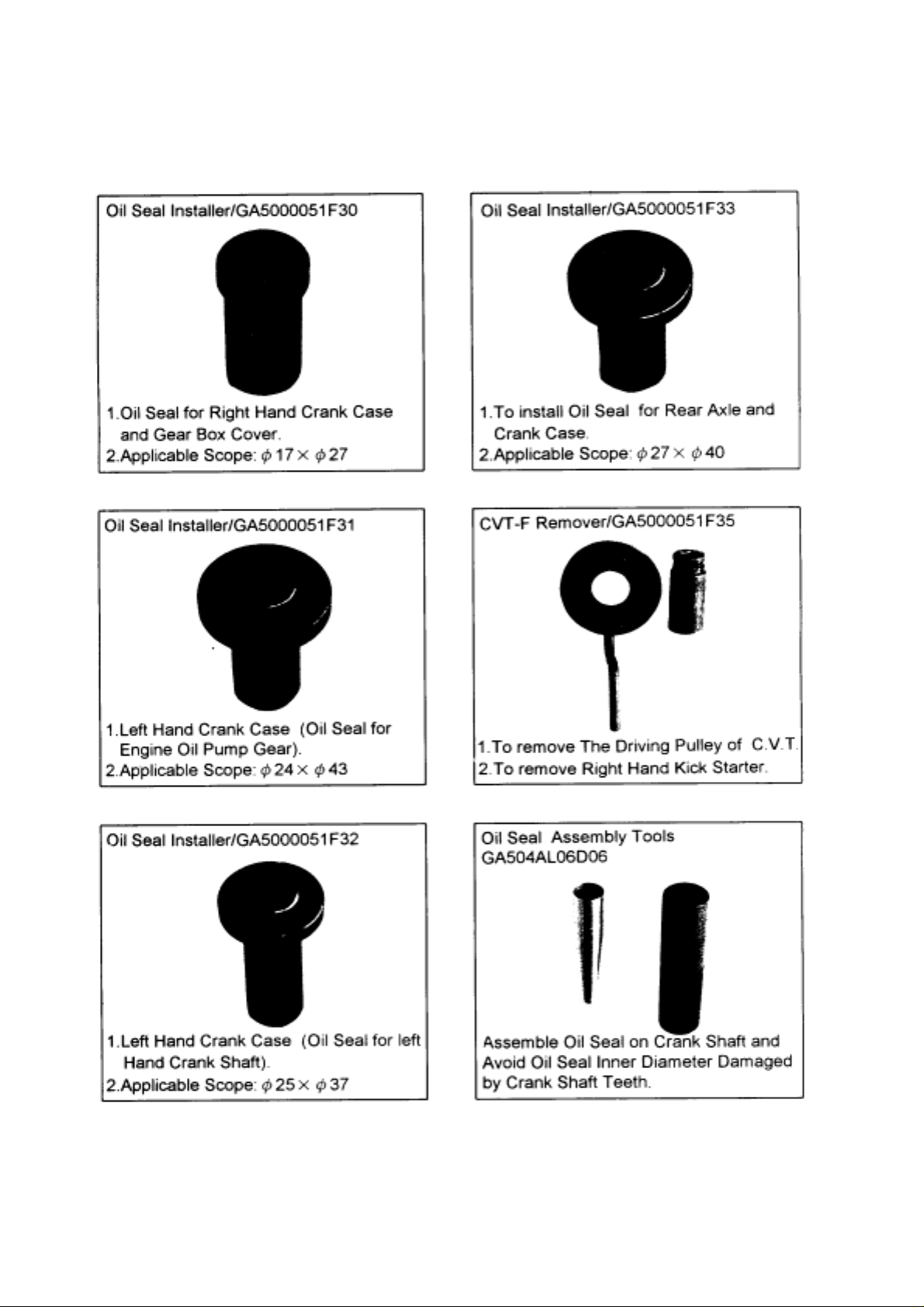

2-3 Special Tools --------------------------------------------------------------9

2-4 List of Grease & Oil Adopted ----------------------------------------12

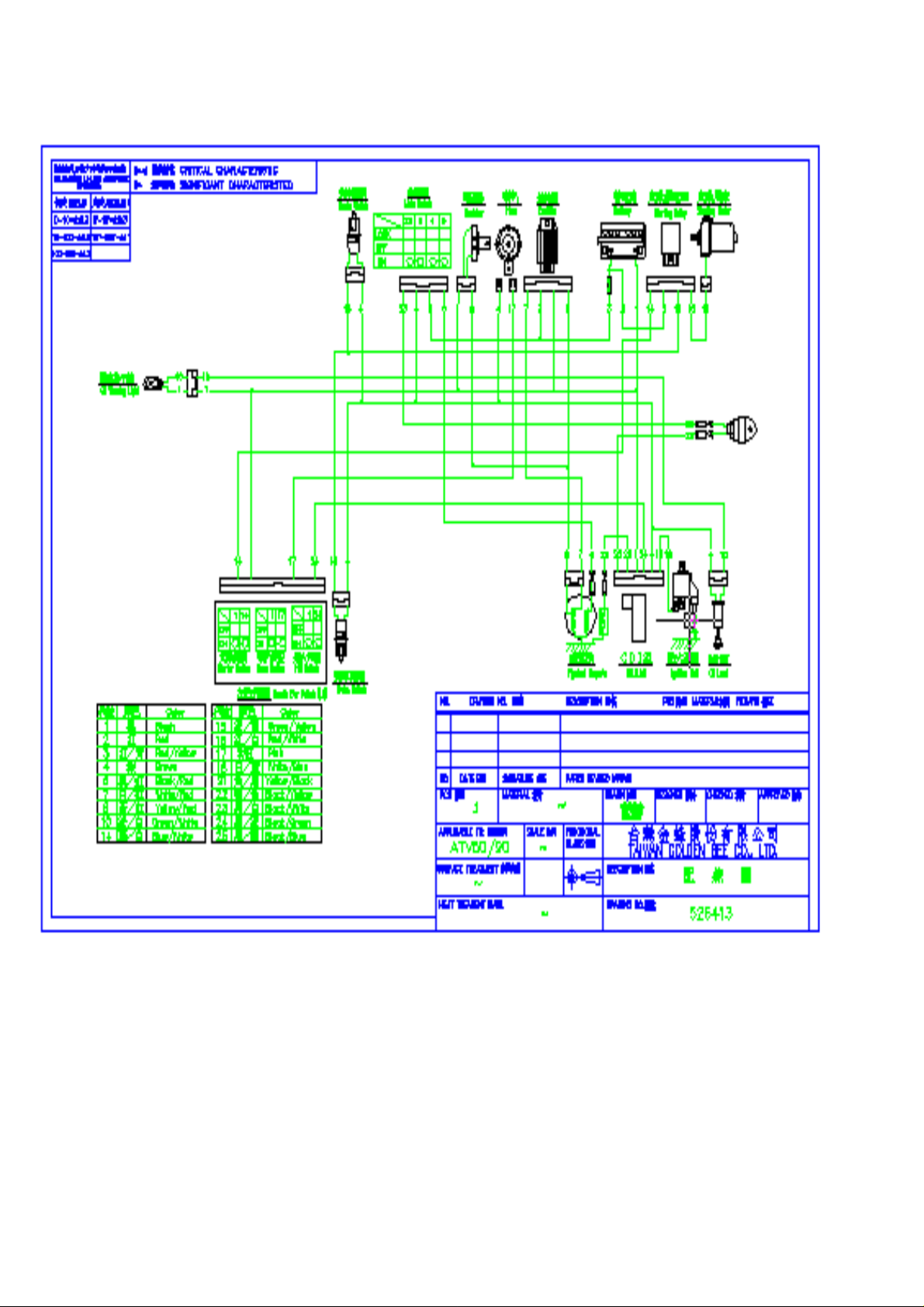

2-5 Circuit Drawings ---------------------------------------------------------13

2-6 Tighting Torque of Screws---------------------------------------------14

2-7 Simplified Troubleshooting -------------------------------------------16

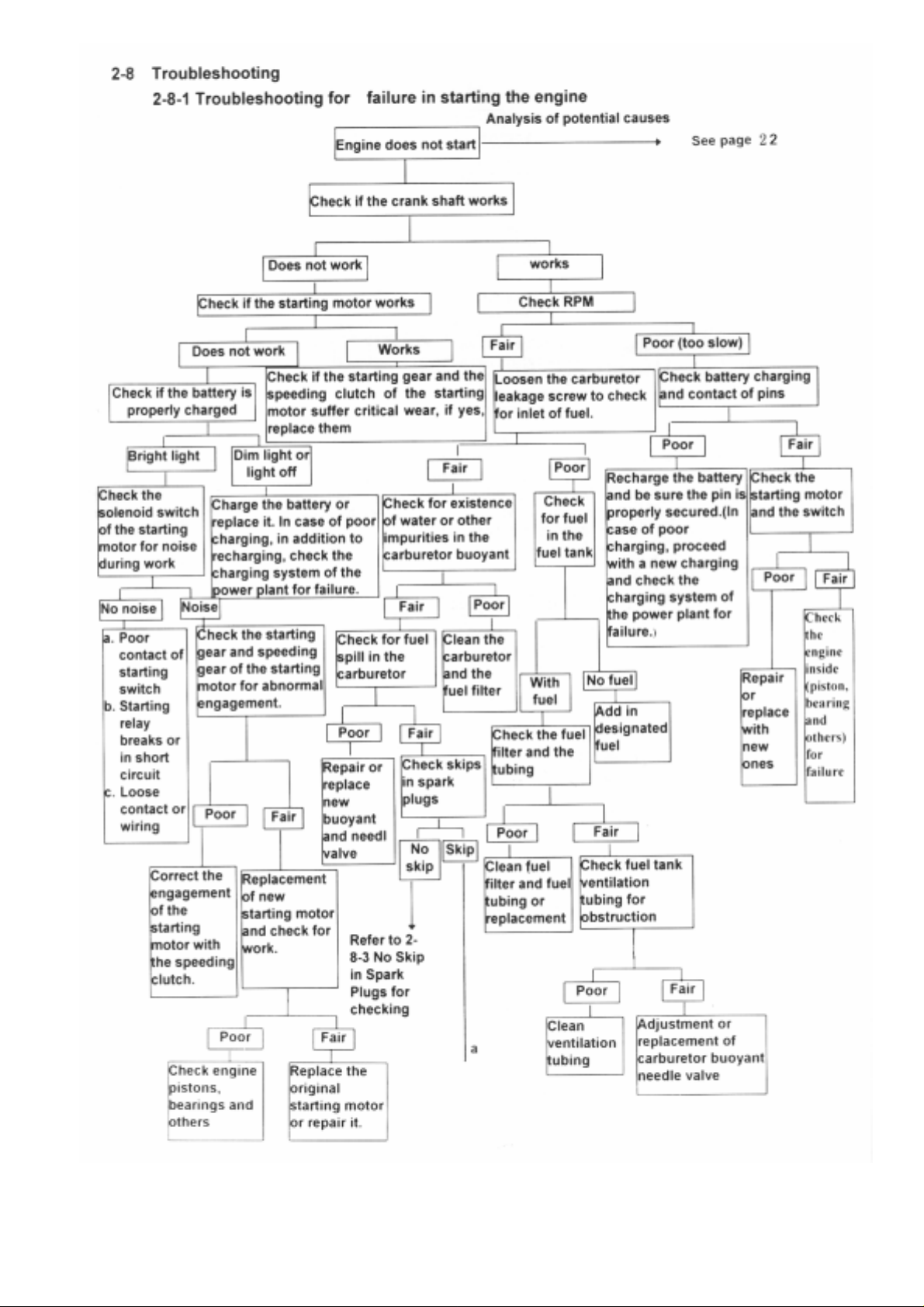

2-8 Troubleshooting ----------------------------------------------------------17

3. DESCRIPTION OF COMPONENTS AND ASSEMBLY ---25

3-1 Cover and Seat -----------------------------------------------------------26

3-2 Engine ----------------------------------------------------------------------27

3-3 Transmission Mechanism --------------------------------------------30

3-4 Electric System -----------------------------------------------------------35

3-5 Body --------------------------------------------------------------------------37

4. DISASSEMBLY REPAIRMENT

4-1 Notice for Disassembly Repairment ------------------------------40

4-2 Removal and lnstallation of Engine -------------------------------41

4-3 Disassembly and Assembly of Engine ---------------------------43

4-4 Removal and Assembly of Carburetor ---------------------------73

4-5 Removal and Inspection and Assembly of Electric Parts --75

4-6 Removal and Inspection and Assembly of Body Parts -----80

------------ ------------------------39

1

CHAPTER I

:

REGULAR INSPECTION

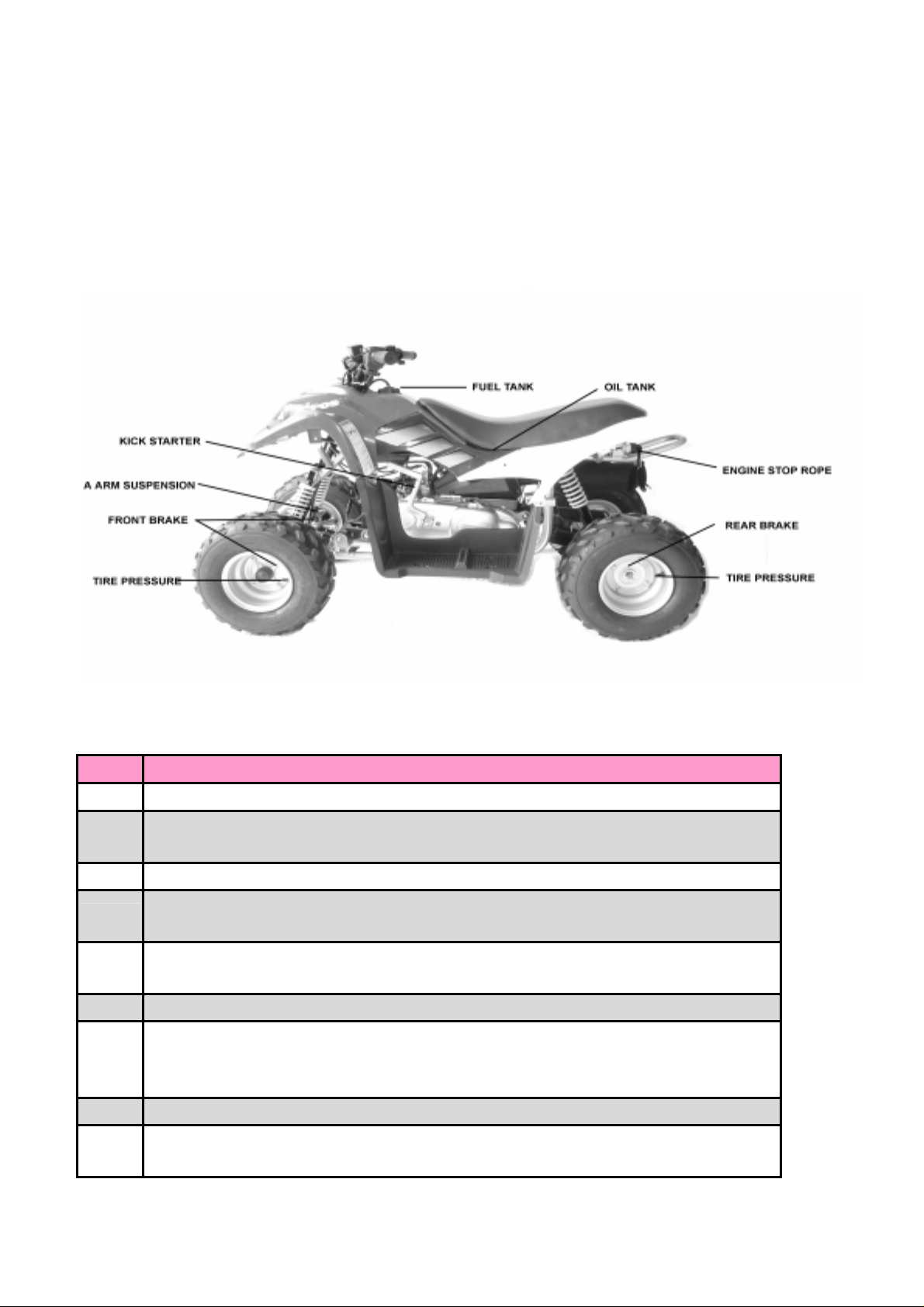

1-1 Delivery Introduction

To inform customers of correct methods to use:

To practically and correctly ride ATV according to the Instruction of

Manual and Maintenance Handbook. Customers should also try in person

according to this manual.

1. Starting:

A. Turn the power switch to "ON."

B. Hold the front or rear brake and press the "START" button.

C. If ATV is not started, release the "START" button

and try again after a few minutes. Each start should be

less than five seconds to avoid battery consumption.

Note: This is Manual CHOKE ATV and the choke lever is in the left handle

bar.

The fuel is controlled only by throttle grip.

The accelerator has to return to its original place when ATV

is not in use.

D. If ATV can not be started by pressing the "START" button, try the kick starter.

2. Fuel:

Inform customers to refill the fuel to no more than 90% of the tank capacity only.

2

1-1 Delivery Introduction

3 . Lubricant Adopted:

A. WARNING : TGB Supper Oil GA50400002 ( OR 2 STROKE OIL in accordance

with JASO FC ) will be adopted as two-stroke engine oil. The engine oil must be

refilled when the oil warning lamp lights, otherwise the engine will be

burned-out due to insufficient lubrication.

B. TGB Gear Oil GA50400004 ( OR SAE 85W-90 )

changed on a periodical basis. Gear oil and engine oil are different in their nature.

Attention should be paid to avoid mistake when used.

4. Regular Inspection and Maintenance:

Inform customers of the importance of inspection before running and regular inspection.

A. Inspection Before Running: Riders should perform inspection by themselves before

running.

B. Regular Inspection: Regular inspection should be performed after the first month and

the three month and every three months afterwards.

5. Description of Warranty System:

Clearly identify the content of warranty in accordance with the warranty paper.

A. Content and term of warranty.

B. Maintenance items not guaranteed.

will be adopted as gear oil to be

C. Items should be followed by customers.

Instruct customers to carry the OWNER'S Manual with them when they come for regular

inspection and maintenance. It is because such inspection should be recorded onto the

Manual.

3

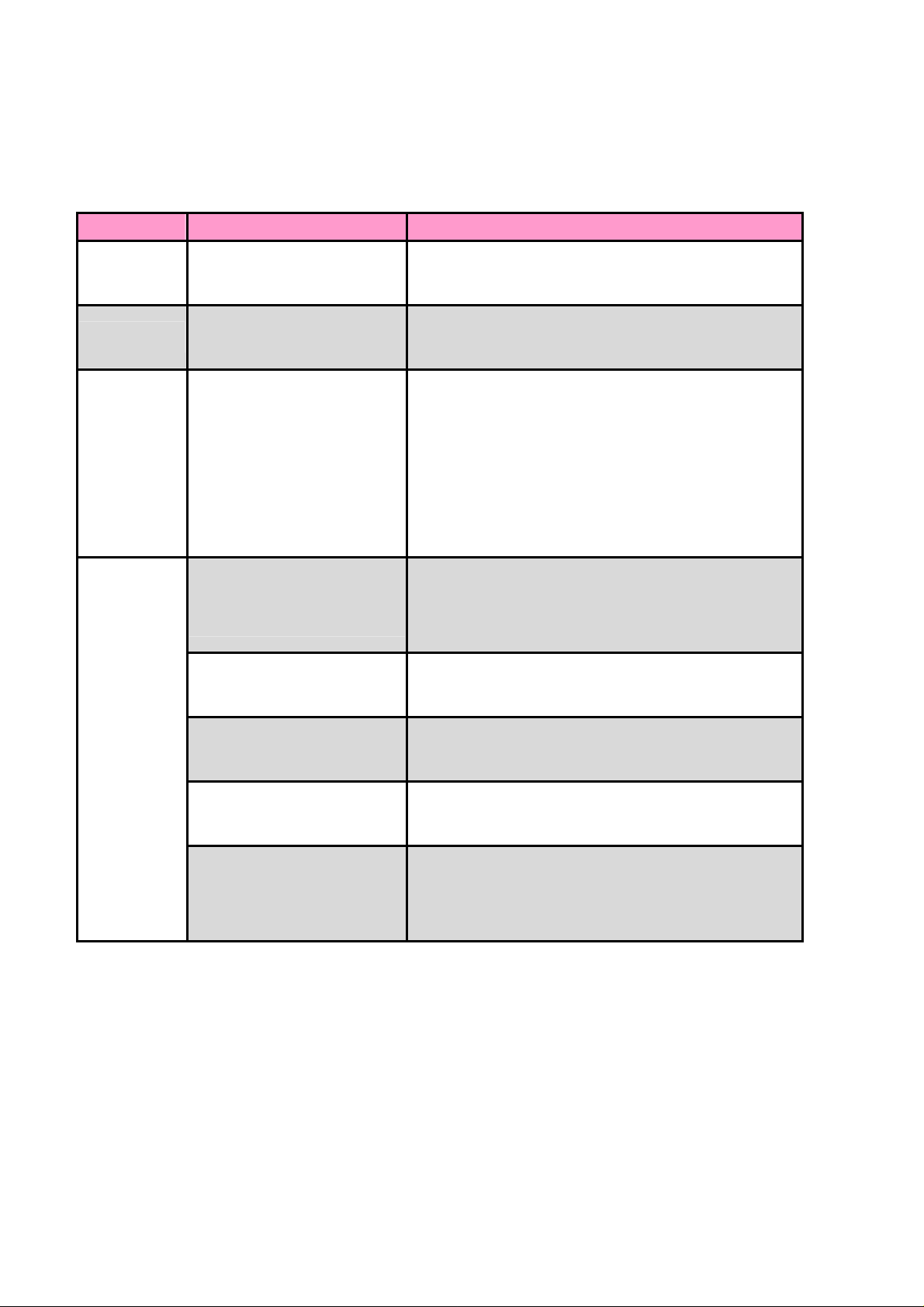

1-2 Inspection Before Running

Items to be Inspected Before Running by Customers:

ITEM CONTENT

Is the oil volume

1. Starter

2 .Fuel

3 . Brake

proper?

Is the fuel volume

sufficient?

Check the distance

of brake handle lever

and the brake effect.

1.Is the air pressure

proper?

2.Groove should be

1.Check Oil Warning Lamp to see if

the oil volume is proper?

1.Check fuel volume to see if it is

enough to the destination.

1.Operate the handle lever slowly to

the brake begin to effect in order to

inspect the moving distance.

2.Test the brake with low speed

running to see the brake effect of

front and rear brakes.

1.Check if the air pressure of tire is

sufficient with a gauge or by sight. The

recommended pressure of tire is 4 p.s.i.

1.Check if the groove of tires is

GUIDELINE

deep enough.

4. Tire

Note: Customers should be informed to perform inspection by themselves before

running in according to this table.

3.Unusual wear is not

desired.

4.Breaking and damage

are not desired.

5.Metal, stone and

other articles are

not desired.

enough.

1.Check landing flat of tire to see if

any unusual wear appears.

1.Check landing flat and side to see

if any breaking or damage appear.

1.Cneck if any cracking, stone or any

other article sticks into the tire.

4

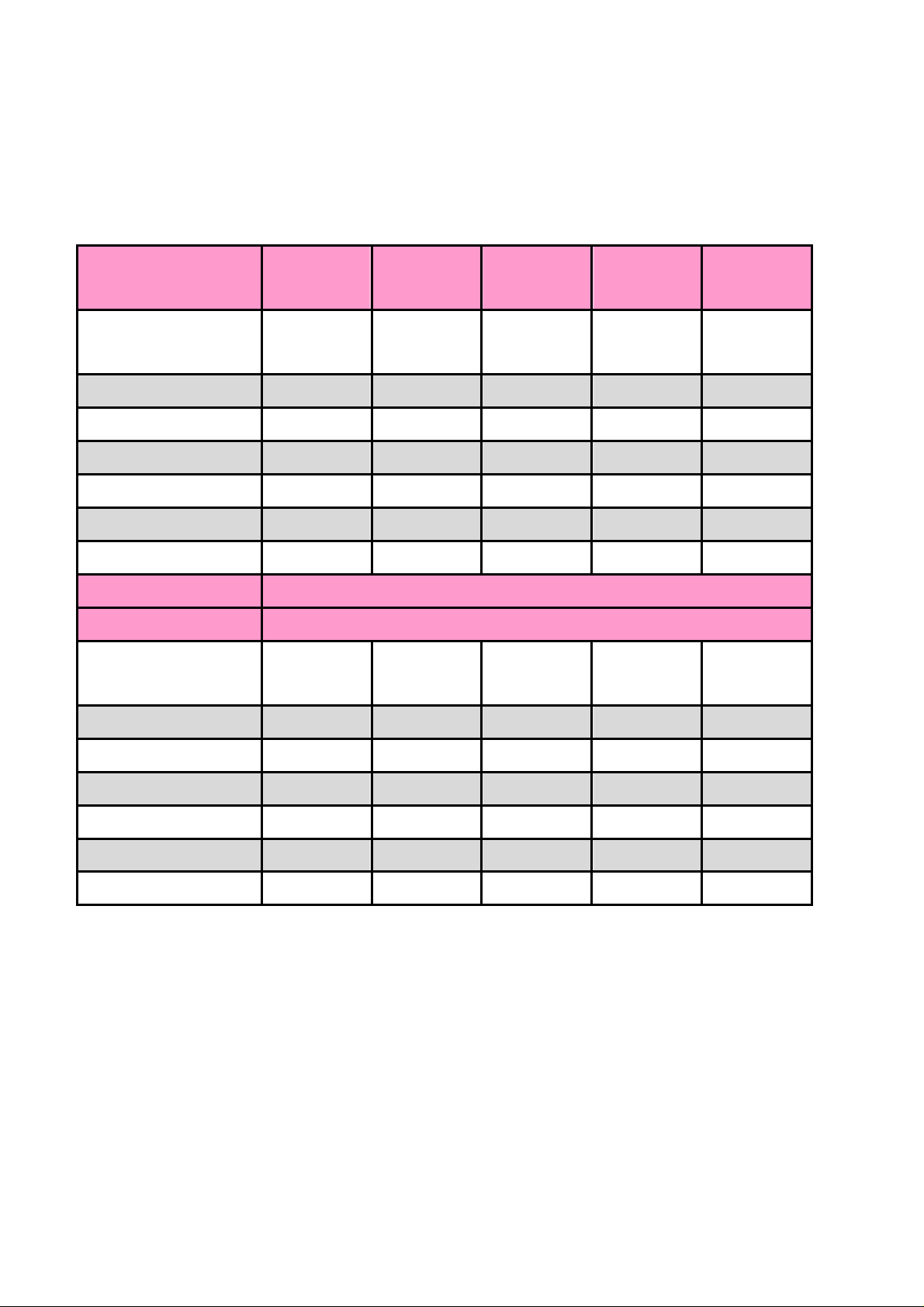

1-3 Regular Inspection

The chart below lists the recommended intervals for all the returned periodic

service work necessarily to keep the motorcycle operating at peak performance

and utmost efficiency. Mileages are expressed in terms of months.

These intervals judged by recorded run-hours or month whichever comes first.

Km

MONTHS

ITEM

Battery

Tire

Brake

Brake fluid

Bolts and nuts

Spark plug

Air cleaner

Final gear oil

Cylinder head nut

exhaust pipe bolts

0

km

0

months

I

I

I

I

I

-

-

1000

km

2

months

I

I

I

I

T

Clean every 3000 km

Replace every 5000 km

T

6000

km

12

months

I

I

I

I

T

R

T

12000

km

24

months

I

I

I

R

T

R

T

18000

km

36

months

I

I

I

I

T

R

T

Steering system

Suspension system

Engine idle rpm

Muffler

Oil pump

Fuel Filter R R R

I

I

I

I

I

I

I

I

I

-

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

NOTE : I=Inspect and clean, adjust, lubricate or replace, if necessary.

R=Replace

T=Tighten

5

1-4 General Inspection General Inspection and Adjustment

means adjustable.

*

Note:

Special attention should be paid while setting the turning speed of Engine by

Tachometer.

The ignition of ATV by the use of crank-shaft which is 2 ignitions/revolution.

1-5 Notes for Inspection

ITEM

Be aware of smoke and fire while performing maintenance.

1

New Packing, Gasket, O Ring, locking pin should be used while

2

assembling.

Only designated TGB oils should be used on spare parts.

3

Clean the vehicle before maintenance to avoid dirt or mud on

4

disconnected parts.

The locking sequence of Bolt and Nut should be from inside to

5

outside, or in diagonal step. Reverse the sequence to loose.

Special tools should be used when necessary.

6

Attention should be paid to avoid damage or loss of

disconnected parts. Clean and grease properly before the

7

assembly. No grease on Bolt's Thread.

Reconfirm each function after the assembly.

8

Special attention should be paid to the battery's electrolyte

9

and brake oil which will stam clothes.

INSPECTION DETAILS

6

2-1 Specification Sheet

ITEM NO. Hornet 50 Hornet 90

Exhaust Volume 49.3c.c 82.4c.c

Stroke 2T 2T

Overall Length mm 1420 1490

Overall Width mm 870 880

Overall Height mm 905 940

ATV

Weight (Empty)

Maximum Load 95kg 95kg

Tire(tubeless)

Cylinder Type Horizontally Placed

Max Horsepower 3.3ps/5500rpm 5.4ps/5000rpm

Gasoline 92/ 95 Unleaded Gasoline

Lubrication Method Oil Supplied Separately by Oil Pump

Cooling Type for

Engine

Ignition Method C.D.I Ignition device w/o point.

Rim comp Size

Spark Plug

Clearance: 0.6- 0.7mm

112kg 120kg

Front:16 x 8 – 7

Rear: 16 x 8 – 7

Air Cooled by Cooling Fan

Front:7 x 5.2

Rear: 7 x 5.2

BPR7HS (NGK)

BPR7HS –10(NGK)

Clearance :0.9-1.0mm

Front:19 x 7 – 8

Rear: 19 x 8 – 8

Front:8 x 5.5

Rear: 8 x 7.0

Battery 12V/7Ah 12V/7Ah

flywheel magneto Alternating Output:12V-50W Alternating Output:12V-50W

Transmission V-belt Continuous Variable Transmission

Brake

Front: Drum

Rear:Disc

Frame Made of High Resistance Steel Pipes

Oil warning Lamp 3.4W

Fuel Tank 5.6 liters 5.6 liters

Front: Drum

Rear:Disc

7

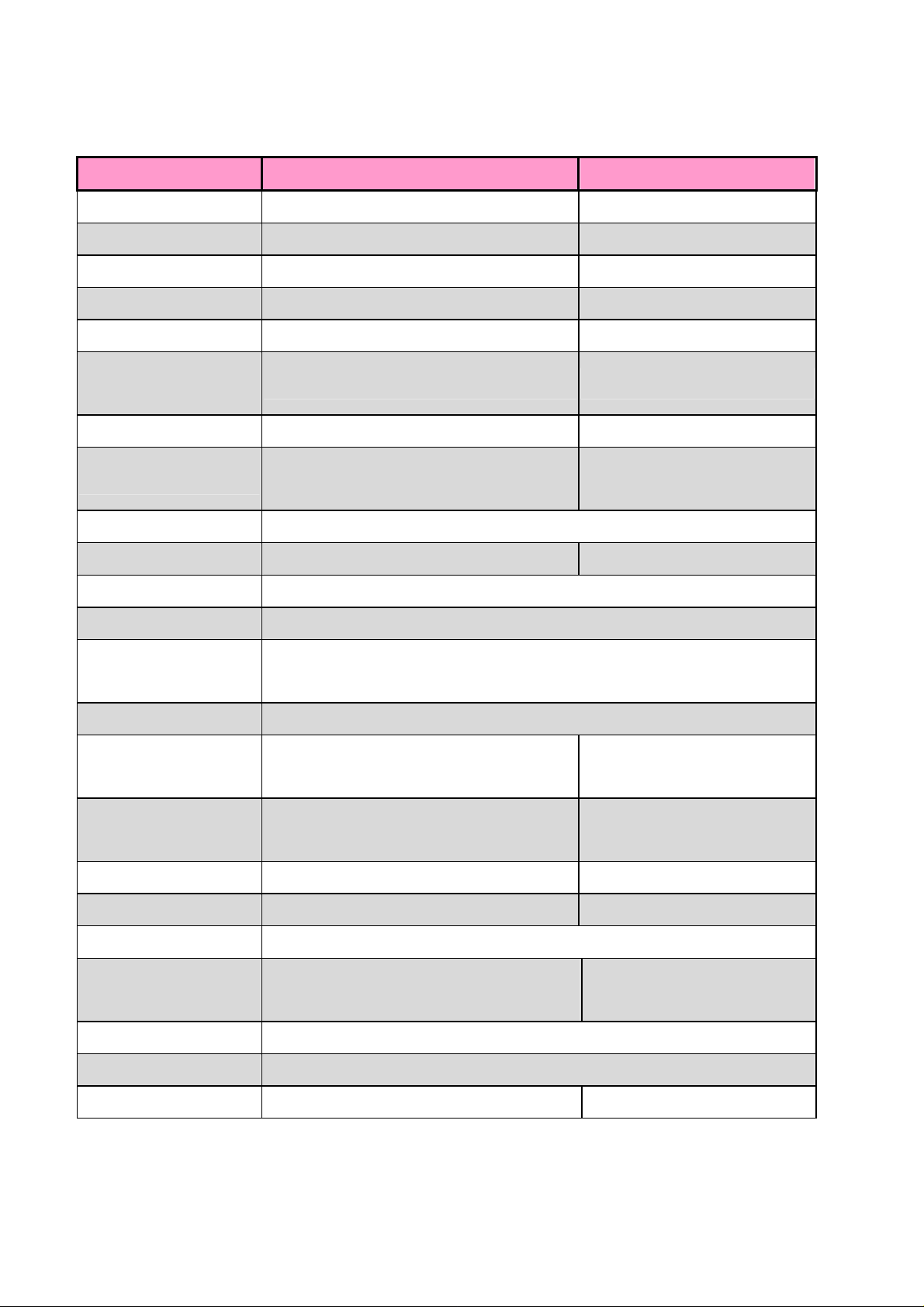

2.2 Maintenance Data

Cylinder +piston+Crank Shaft

ITEM 50 C.C. 90 C.C.

STANDARD LIMIT STANDARD LIMIT

Cylinder Cover Flatness 0∼0.02 0.1 0~0.02 0.1

Piston Outside Diameter

(15mm above skirt)

Clearance BetweenCylinder and Piston 0.065~0.075 0.12 0.065~0.075 0.12

Bore of Piston Pin 10.002~10.01 10.04 12.004~12.015 12.05

Outside Diameter of Piston Pin 9.995~10.00 9.98 11.995~12.00 11.98

Bore of Small End of Con-Rod 14.003~14.011 14.05 14.996~15.007 15.05

Inside Diameter of Cylinder 41.005~41.020 41.07 5.005~50.020 50.07

Clearance at terminal of piston ring when

assembled in Cylinder.

Radial Clearance of Big-End at Con-Rod 0.1~0.55 1.0 0.1~0.55 1.0

Runout of Crank Shaft 0~0.05 0.1 0~0.05 0.1

CVT

Free Length of Clutch Spring 23.8 25.0 23.8 25.0

Thickness of Clutch Lining 3.0 2.0 3.0 2.0

Bore of Clutch Housing 110~110.15 110.40 110~110.15 110.40

BRAKE

Engine Oil

Ignition

Battery

Brake

Tire Pressure

Bore of Brake Drum 85 85.6 85 85.6

Brake Lining O.D. 84.3 82.3 84.3 82.3

Thickness of Disc Brake Lining 4.7 3.7 4.7 3.7

Capacity 0.9L 0.9L

Residual Capacity when Light on 0.23L 0.23L

Oil Used TGB Super Engine Oil (JASO FC ) TGB Super Engine Oil (JASO FC )

Oil Capacity of Gear Box 90c.c 90c.c

Lead 15°±3°BTDC /4000rpm 15°±3°BTDC /4000rpm

Spark Distance 6-8mm 5mm 6-8mm 5mm

Inner Electric Resistance at Spark Plug Cap 5~7.6kΩ 3kΩ 5~7.6kΩ 3kΩ

Battery 12V/7AH 12V/7AH

Fuse 7A 7A

Clearance of Front Brake Lever 20-30mm 20-30mm

Clearance of Rear Brake Lever 15-35mm 15-35mm

Front (psi) 4 4

Rear (psi) 4 4

40.935~40.95 40.89 49.94~49.955 49.90

0.10~0.25

0.75

(1st&2nd Rings)

0.15~0.35 0.85

8

2-3 Special Tools

9

2-3 Special Tools

10

2-3 Special Tools

11

2-4 List of Grease & Oil Adopted:

GA55100001

TGB Supper Grease

No.0

Apply in Oil Seal.

GA50400001

1104 Sealing ThreeBond Apply on Right

Hand Crank Surface.

GA50400002

TGB Supper Oil

GA50400003

Supper Grease No.3

Apply in Axle Shaft,

inside of Oil Seal.

GA50400004

TGB Gear Oil 85w/90

Transmission Gear Oil

for Scooters.

GA55100002

Three-Bond 1322

Under M10 Screw

(JASO FC)

Apply in oil tank

GA50400005

TGB Supper Grease

No. I

Apply in Oil Seal.

GA5040006

TGB Supper Grease

No.2

Apply in Kick Starter.

(For medium fixing) for

Flywheel Magneto.

GA55100003

DOT-3 Brake Oil For

Brake.

GA50400008

TGB Supper Grease

No.4

For Movable Drive Face Comp.

GA50400017

Cemedine 575

Apply in Handle Grip

12

2-5 Circuit Drawing

13

2-6 Tighting Torque of Screws

Screw Torque of Body

tem

I

Locking Location

1 Rear Fork Nut 14 1

2 Crank Case Bracket Nut 10 2 550-600

3 Rear Swing Assy. Nut 8 2 250

4 Rear Swing Assy. Bolt 8 1 250

5 Fixed Nut for Rim 14 4 500~550

6 Self-lock Nut for Rim 10 16 400~450

7 Brake Hose pipe Bolt 10 2 250~300

8 A Arm control linkage Nut 10 4 450~550

9 Front Shock Absorber Nut 10 4 450~550

10 Rear Shock Absorber Bolt 10 2 450~550

11 Steering shaft Assy. Nut 10 2 400~450

12 Steering Linkage Nut 10 4 250

13 Steering Joint Nut 10 4 250~350

14 Steering Shaft Housing Nut 8 2 140~160

15 Steering Stem Lock Nut 14 1 700~750

16 Chain Adjustment Bolt 12 4 500~600

17 Rear Axle Nut 27 1 800

18 Raer Axle Nut 27 1 950

19 Master Cylinder Bolt 6 2 80~120

20 Brake Disc Bolt 10 3 200~250

21 Caliper Bolt 8 2

22 Right handle Lever Bolt 6 100-200

23 Handle-bar Bolt 6 4 100-200

24 Lower Bumper Bolt 8 4 200-300

25 Muffler fixed with frame Bolt 8 1 300-400

26 Chain gear Bolt 8 3 200-250

Thread pcs Torque(kg-cm

600-800

200-250

)

14

2-6 Tighting Torque of Screws

Screw Torque of Engine

Locking Location

Spark Plug

Flywheel Magneto 10 350-450

Nut of Kick Starter, RH 12 400-600

Bolt of Kick Starter 6 80-120

Nut of Driven Pulley Assy. 28 400-600

Nut of Clutch Housing 10 400-600

Bolt of Fuel Inlet 8 90-150

Screw of Fuel Outlet 6 40-70

Bolt of Left engine case 10 550-600

Bolt of Lower left engine case 12 550-600

General Torque

Thread General Bolt kg-cm Heavy Duty Bolt kg-cm

4 10~20 15~30

5 20~40 30~60

8 100~160 80~120

10 220~350 300~400

12 350~550 500~600

)

Thread Torque(kg.cm

250-300

15

2.7 Simplified Troubleshooting

Complaint

No action for

starter motor

No sparking or

poor sparking

Unable or

Difficult to start

I. Fuse breaks.

Possible Reason

2. No power in battery.

3. Defective action of brake switch.

4 Short circuit of starter relay.

I . Defective spark plug.

2. Defective CDI & ignition coil unit.

3. Defective magneto stator coil.

4. Loose connection of lead wire.

Plug not sparking

I. Damaged spark plug or spark plug cap.

2. Dirty or wet spark plug.

3. Defective CDI &ignition coil unit or stator coil.

4.Open or short in high-tension cord.

5. Defective ignition switch.

Remedy

Replace

Charging

Replace

Replace

Replace

Replace

Replace

Connect

Replace

Clean & dry

Replace

Replace

Replace

Noisy engine

Engine idles

No fuel reaching the carburetor

I. No gasoline in fuel tank.

2.Clogged hole in the fuel tank cap.

3.Clogged or defective fuel cock.

4.Clogged fuel hose or defective vacuum hose.

Compression too low

I. Excessively worn cylinder or piston rings.

2.Spark plug too loose.

3. Broken,cracked or otherwise failed piston.

I . Piston or cylinder worn down.

2. Combustion chamber fouled with carbon.

3. Piston pin,bearing or piston pin worn.

4. Worn or burnt crankshaft bearings.

I. Stiff piston ring in place.

Replace

Clean

Clean or replace

Clean or replace

Replace

Tighten

Replace

Replace

Clean

Replace

Replace

Replace

poorly

2. Excessively worn cylinder or piston rings.

3. Gas leaks from crankshaft oil seal.

4. Defective CDI & ignition coil unit.

5. Clogged jets in carburetor.

16

Replace

Replace

Replace

Clean or adjust

17

18

Check item:

○

No fuel

○

Dirty fuel filter

○

Obstructed ventilation tubing of th efuel tank

○

Poor carburector buoyant needle valve

○

Carburetor buoyant with impurities

○

Poor carburetor buoyant

○

No skip in spark plugs

○

Poor skip in spark plugs

○

Dirty spark plugs

○

Incorrect spark plugs gap

○

Dirty and wet spark plugs

○

Loose adjustment screws in the carburetor

○

Carburetor choke

○

Obstructed carburetor slow nozzle

○

Ailing carburetor threshold

○

Obstructed air filter grill

○

Leakage in cylinder washer

○

Seriously damaged cylinder, piston

○

Dead battery

○

Poor contact of battery pin and conductors

○

Starting switch with poor or failure

○

Starting relay with broken wire or short circuit

○

Loose contact and wiring

○

Starting gear and speeding clutch gear seriously worn

○

Starting gear and speeding clutch gear in poor engagement

○

Poor starting motor

19

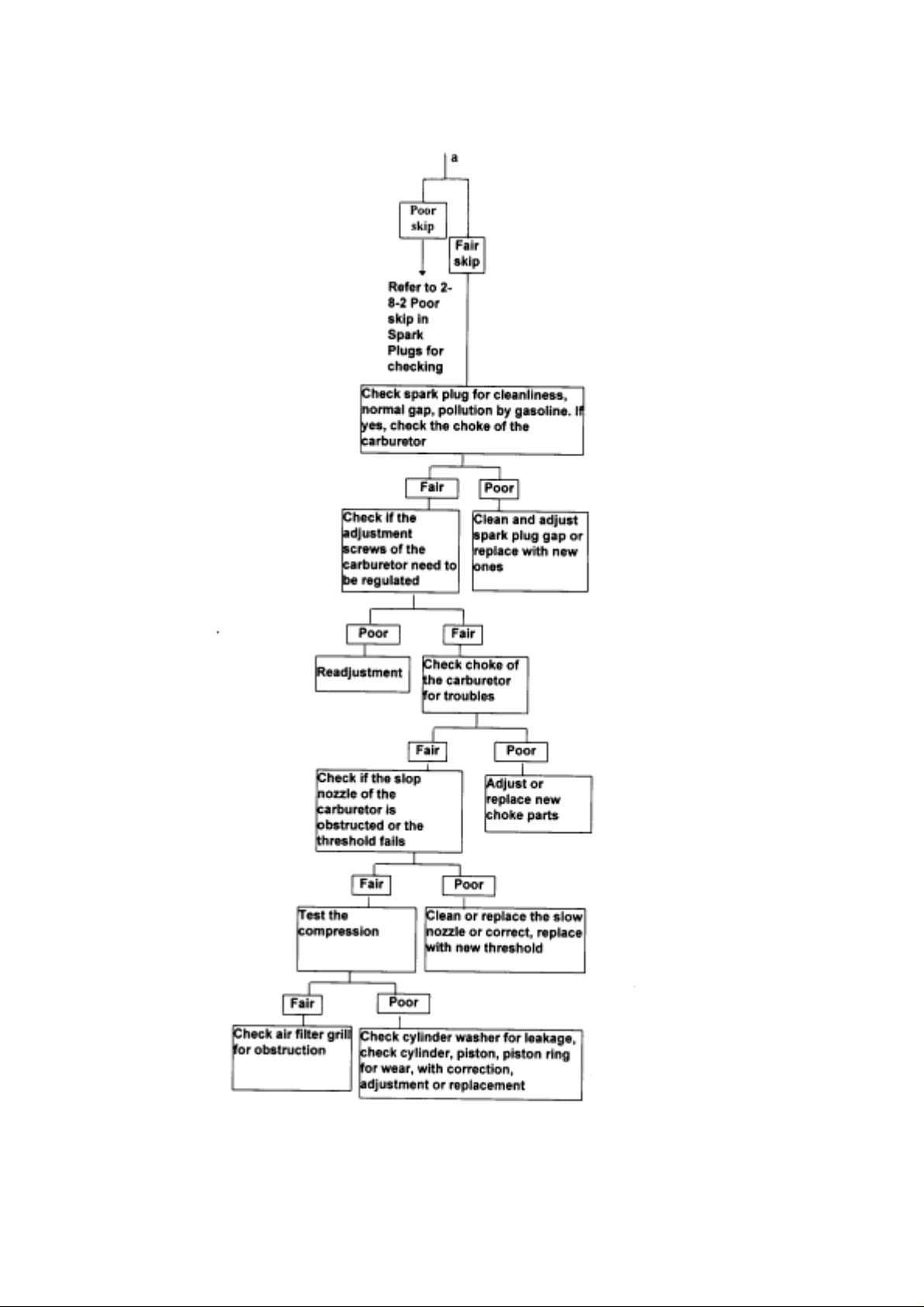

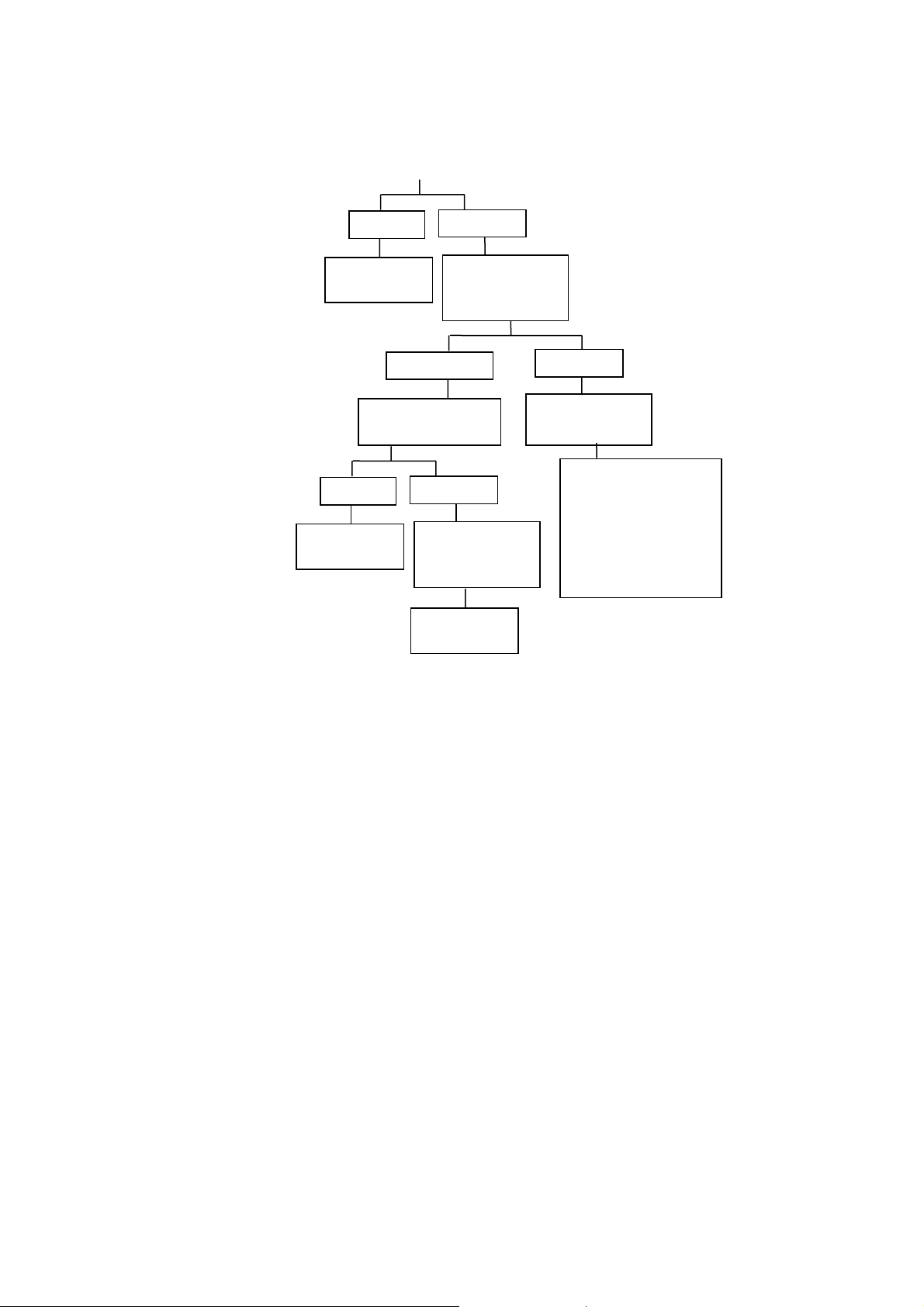

2-8-2 Troubleshooting for poor skip of spark plugs

20

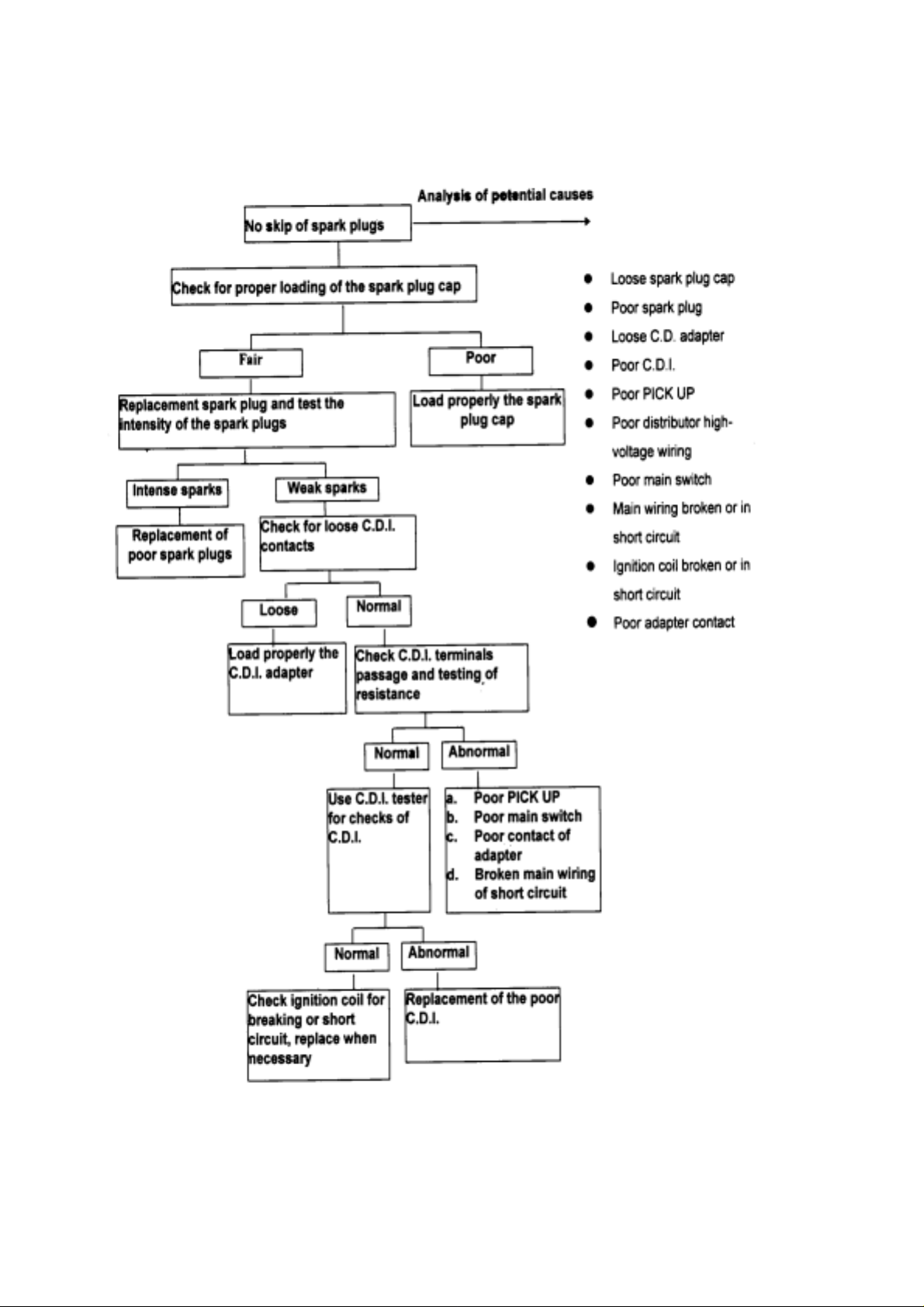

2-8-3 Troubleshooting for no-skip of spark plugs

Replacement spark plug and test the

intensity of the spark plugs

Intense sparks

Replacement of

poor spark plugs

Check for proper loading of the spark plug cap

No skip of spark plugs

Fair

Check for loose C.D.I.

contacts

Loose

Load properly the

C.D.I. adapter

Check ignition coil for

breaking or short

circuit, replace when

necessary

Weak sparks

Normal

Check C.D.I. terminals

passage and testing of

resistance

Use C.D.I. tester

for checks of

C.D.I.

Normal

Normal

Analysis of potential causes

Load properly the spark

Abnormal

Replacement of the

poor C.D.I.

z Loose spark plug cap

z Poor spark plug

z Loose C.D. adapter

z Poor C.D.I.

Poor

plug cap

z Poor PICK UP

z Poor distributor high-

z Poor main switch

z Main wiring broken or in

z Ignition coil broken or in

z Poor adapter contact

Abnormal

a. Poor PICK UP

b. Poor main switch

c. Poor contact of

adapter

d. Broken main wiring

of short circuit

voltage wiring

short circuit

short circuit

21

j

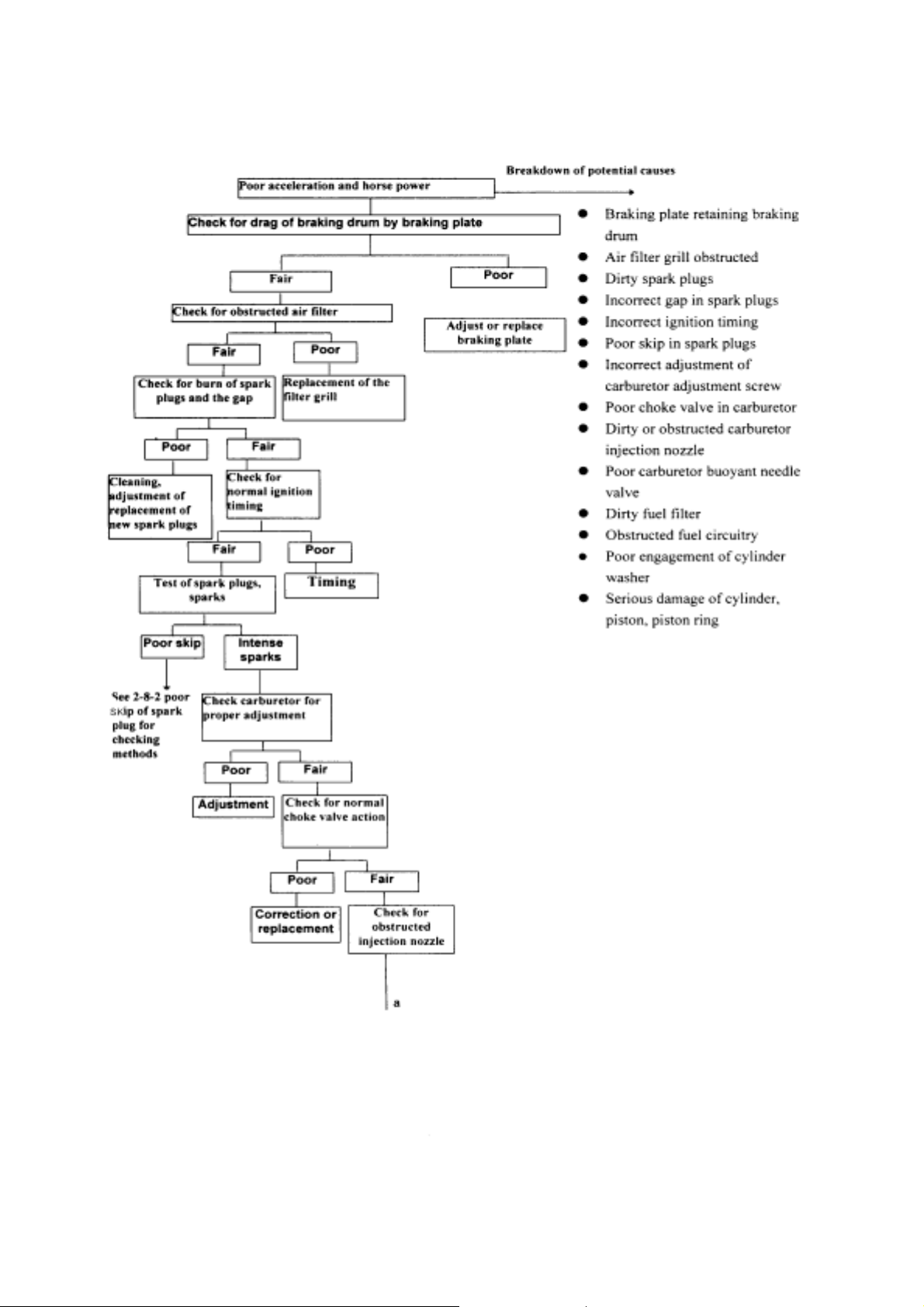

2-8-4 Troubleshooting for slow run (troubled engine)

Check for contamination in spark plugs and excessive gap

Fair

Alarming abnormality of ignition timing

Poor

adjustment

Replacement of

the filter grill

Poor slow run

Is the air filter grill

obstructed?

Poor

Check if the choke valve

fails (valve does not

open) ?

Correction

Add tightening force or

replacement of the washer

Fair

Poor

Fair

Is the carburetor buoyant

level normal ?

Fair

Check of for air between the

carburetor and the air inlet

Analysis of potential causes

Poor

Cleaning and

adjustment

Poor

Adjustment or replacement of

the buoyant needle valve

Fair

Poor

Check for obstruction in

the carburetor slow

Cleaning Test the compression

z Dirty spark plugs

z Incorrect spark

plug gaps

z Incorrect ignition

timing

z Obstructed air

filter grill

z Poor carburetor

buoyant needle

valve

z Poor carburetor

choke valve

z Poor engagement of

carburetor and

inlet tube

z Obstructed

carburetor slow

injection

z Poor engagement of

cylinder head

washer

z Severe wear of

cylinder, piston,

piston ring

Fair

Poor

Check for air leakage in the cylinder washer,

check wear of cylinder, piston, piston ring

Fair

and other elements with correction,

ad

ustment or replacement

22

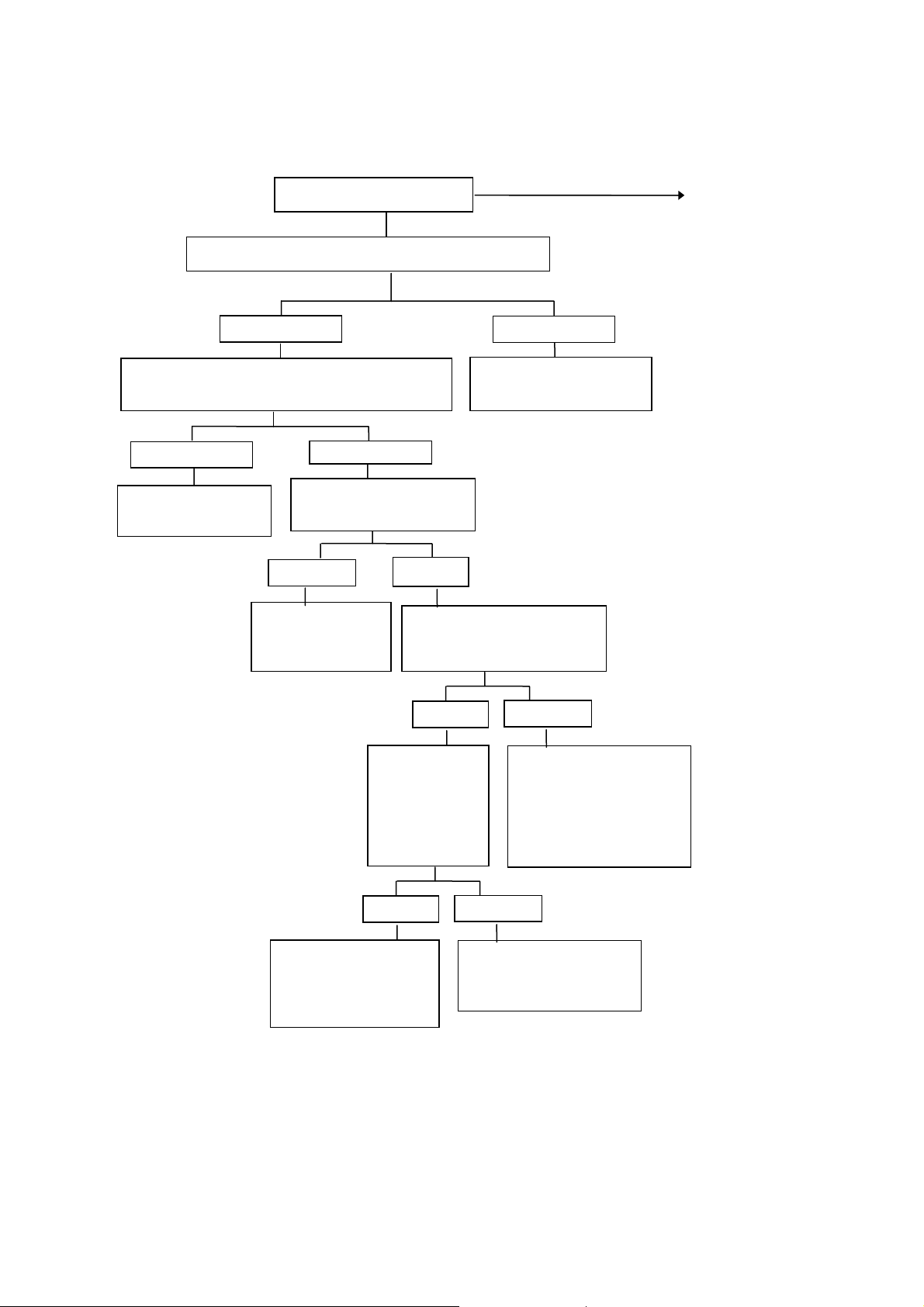

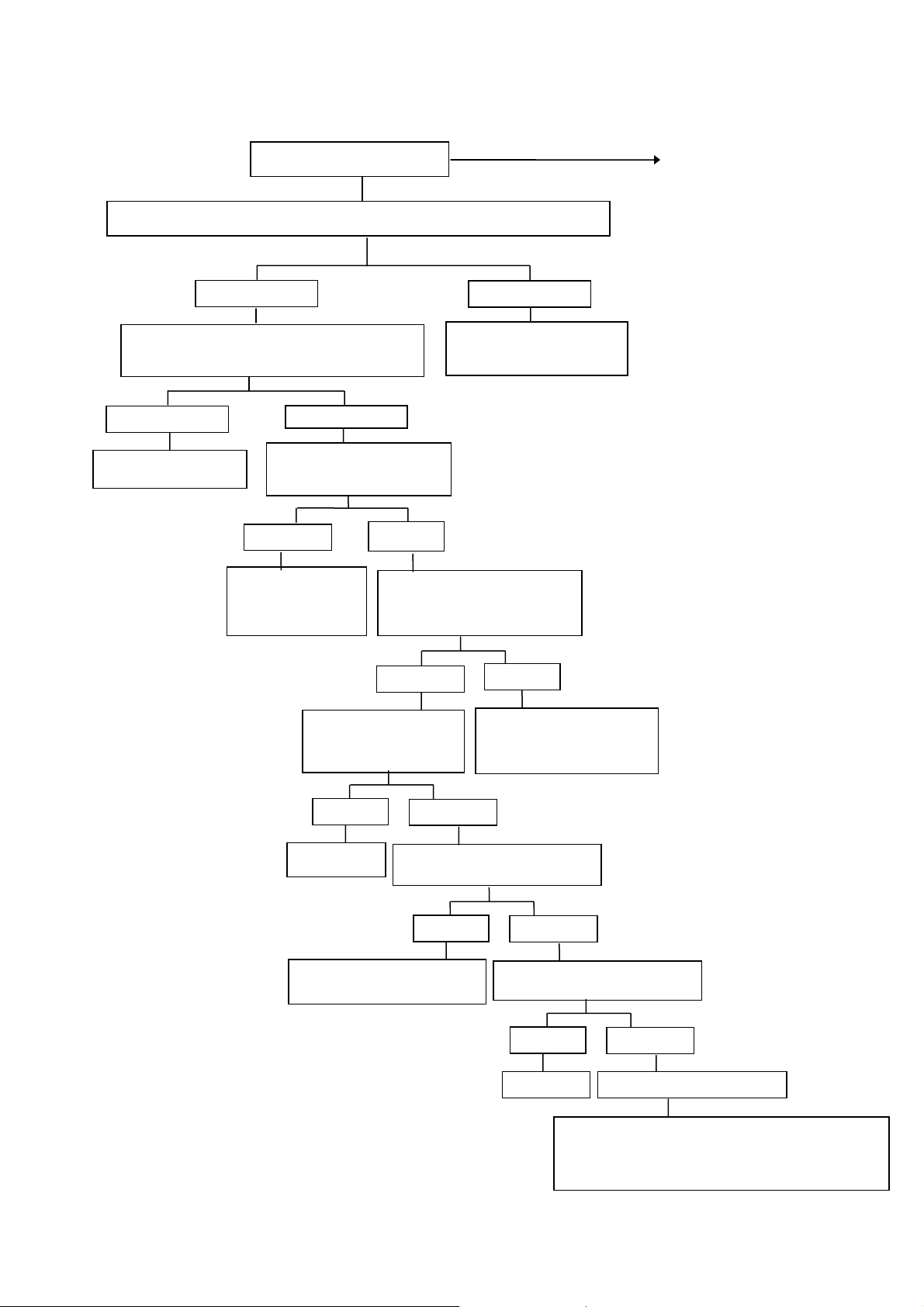

2-8-5 Poor acceleration and horse power

23

a

Poor

Cleaning or

Poor (low

Check of needle

Poor

Adjustment

Check fuel pipe

for obstruction

Cleaning or

Fair

Check for

normal fluid

level in the

Check the

Fair

and carburetor

Fair

Check for leakage in

cylinder washer;

check cylinder,

piston, piston ring

for wear. Correct,

adjustment or

replacement when

24

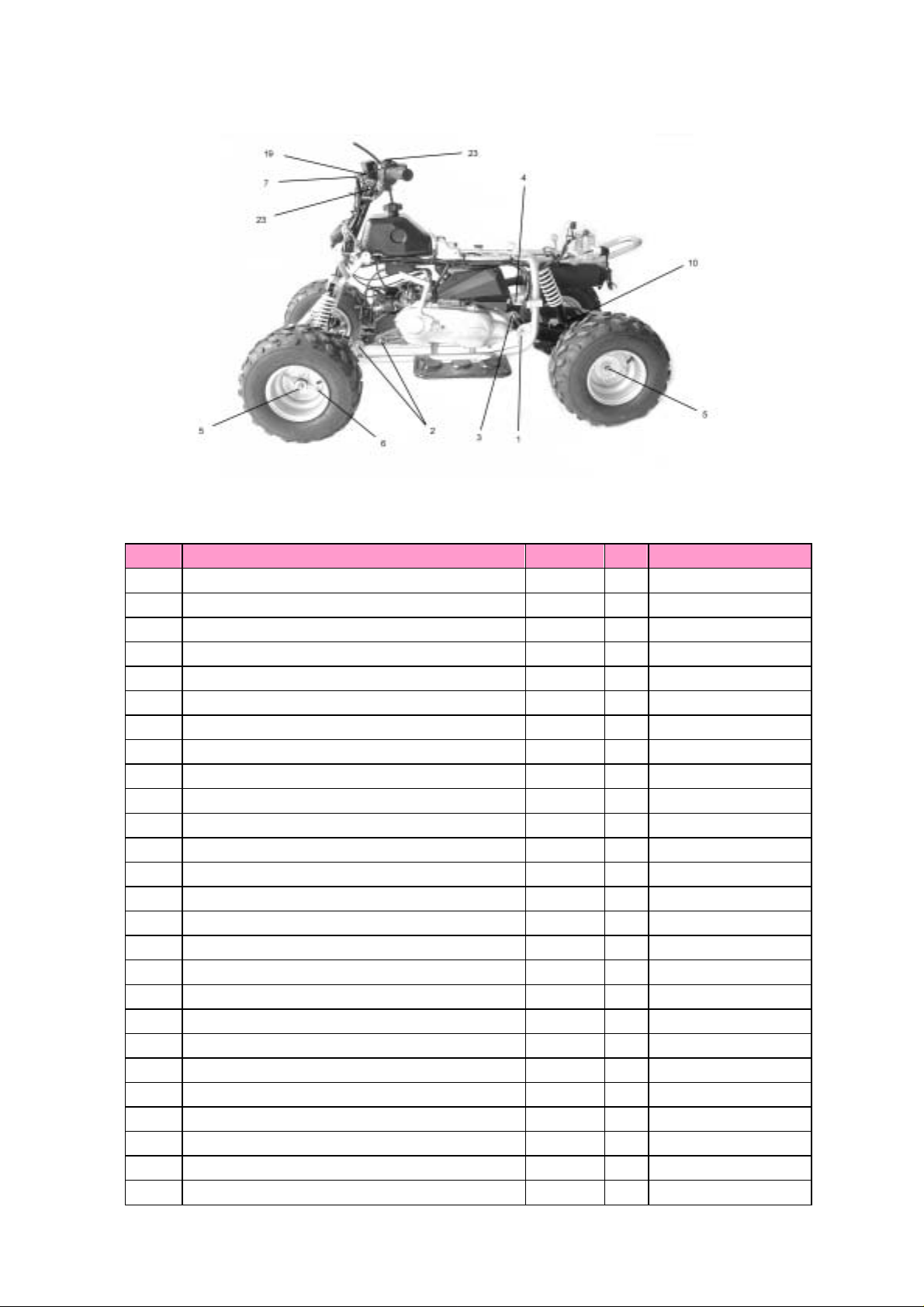

CHAPTER 3. DESCRIPTION OF COMPONENTS AND ASSEMBLY

3-1 COVER AND SEAT

3-1-1 Cover

3-1-2 Seat

3-2 ENGINE

3-2-1 Combustion & Air In-Take & Exhaust System

3-2-2 Carburetor

3-2-3 Lubrication & Cooling System

3-3 TRANSMISSION MECHANISM

3-3-1 Power Transmission

3-3-2 Continuous Variable Transmission

3-3-3 Reducing Gear

3-3-4 Kick Starter

3-4 ELECTRIC SYSTEM

3-4-1 Ignition & Battery Device

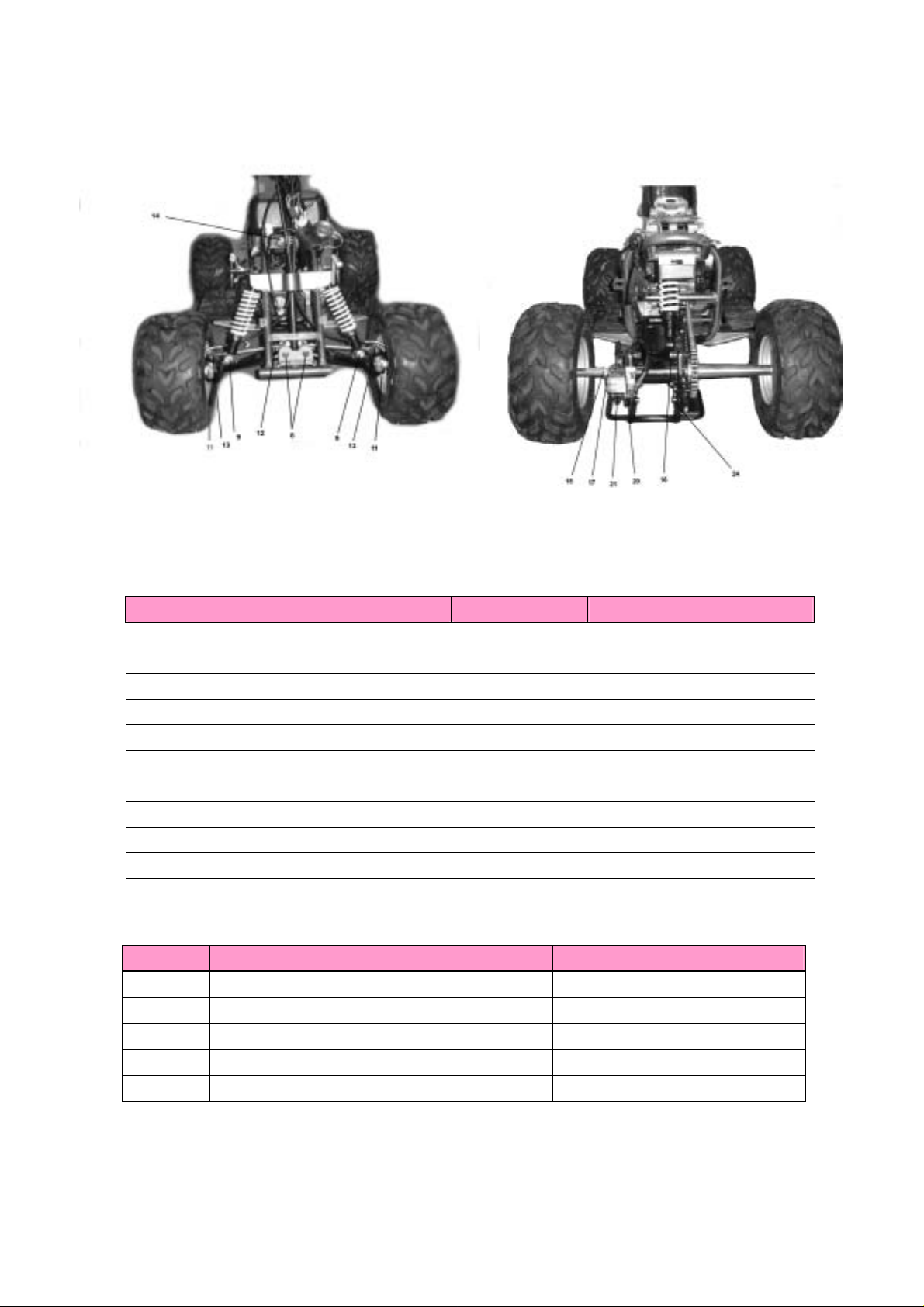

3-5 BODY

3-5-1 Frame, Fuel and Oil System

3-5-2 Front & Rear Suspension System

3-5-3 Brake System

25

3-1 COVER AND SEAT

3-1-1 COVER

A. The cover of the ATV can be cleaned with vacuum cleaner. It can also

be washed and put back after dried. (please do not wash with volatile

fluid, such as gasoline)

If thecovers were damaged, please replace the new covers. Otherwise,

B.

the covers will cause the injury.

3-1-2 SEAT

A. The seat has to be locked. If theseat is not locked during riding, it will

be affect tehsafety and even cause injury.

B. The seat is controlled by the seat lock on the rear.

26

Loading...

Loading...