TGB EST 1000 Service Manual

EST 1000

SERVICE MANUAL

TAIWAN GOLDEN BEE CO.,LTD.

This service manual contains the technical data of each component

inspection and repairs for the Blade 1000. The manual is

shown with illustrations and focused on “Service Procedures”,

“Operation Key Points”, and “Inspection Adjustment” so that provides

technician with service guidelines.

If the style and construction of the Blade 1000 are different

from that of the photos, pictures shown in this manual, the actual

vehicle shall prevail. Specifications are subject to change without

notice.

This service manual describes basic information of different system

parts and system inspection & service for Blade 1000. In

addition, please refer to the manual contents in detailed for the

model you serviced in inspection and adjustment.

Please see the content for quick having the special parts and system

information.

1 GENERAL INFORMATION

2 SERVICE MAINTENANCE INFORMATION

5-4 TRANSMISSION BEAR BOX

5-5 CONTINUOUSLY VARIABLE TRANSMISSION

1. GENERAL INFORMATION

PAGE

3 LUBRICATION SYSTEM

4-1 FUEL SYSTEM

4-2 FUEL INJECTION SYSTEM

5-1 ENGINE ASSEMBLY

5-2 ENGINE TOP END

CONTENT

5-3 ENGINE BOTTOM END

6 DRIVE SYSTEM

7-1 STEERING SYSTEM & SUSPENSION

7-2 ELECTRIC POWER STEERING

7-3 BRAKE SYSTEM & BODY COVER

8-1 ELECTRIC SYSTEM

8-2 ELECTRIC DIAGRAM

1-2

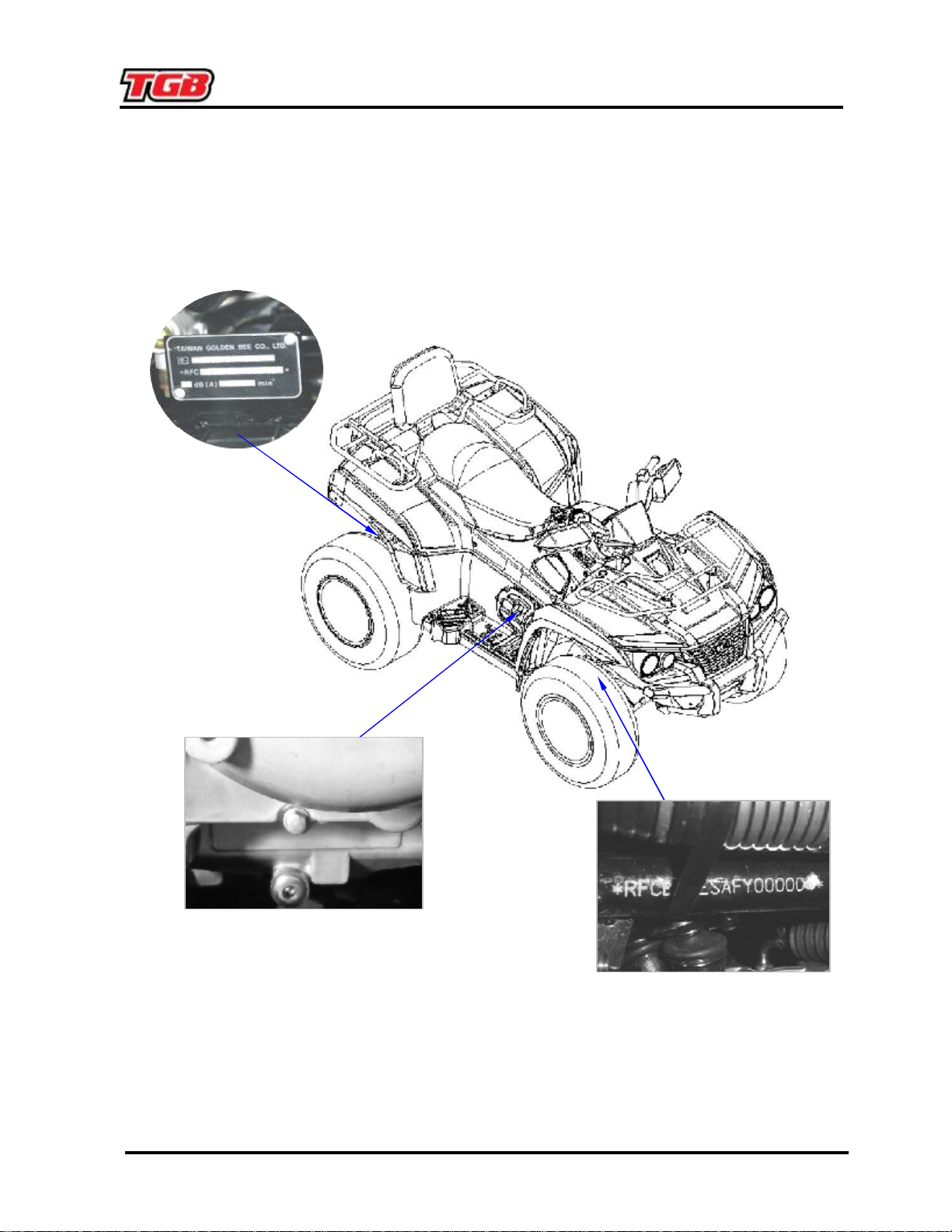

SERIAL NUMBER

Frame Number and Engine Number

TST*000001*

1. GENERAL INFORMATION

1-3

2. MAINTENANCE INFORMATION

Precautions in Operation ······················ 2-1

Periodical Maintenance Schedule ·········2-2

Fuel Lines ············································· 2-3

Acceleration Operation ························· 2-3

Air Cleaner············································ 2-3

Spark Plug ············································ 2-3

Valve Clearance ··································· 2-4

Carburetor Idle Speed Adjustment········ 2-5

Ignition System ······································2-6

Cylinder Compression Pressure ·········· 2-6

Drive Belt ············································· 2-7

Specification

Fuel Tank Capacity

Oil & Filter Change

Engine Oil

Oil change

New Engine

Brake System (Disk Brake) ················· 2-8

Brake Light Switch/Starting Inhibitor

Switch ·················································· 2-9

Headlight Beam Distance ···················· 2-10

Clutch Disc Wear ································· 2-10

Cushion················································· 2-10

Steering Handle···································· 2-11

Wheel/Tire············································· 2-11

Nuts, Bolts Tightness ··························· 2-11

Special Tools List ································· 2-12

2300 c.c.

2000 c.c.

1800 c.c.

2300 c.c.

Transmission Gear oil

Capacity of coolant

Clearance of throttle valve

Spark Plug

Idling speed

Cylinder compression pressure

Valve clearance

Tire dimension

Tire pressure

Bear Box Capacity

Front Capacity

Rear Capacity

Engine + Radiator

Reservoir upper

Type

Gap

Front

Rear

900 cc

350 c.c.

500 c.c.

2600 c.c.

IN:0.10 ± 0.02 mm EX:0.15 ± 0.02

AT25x8-12 AT26x8-14

AT25x10-12 AT26x10-14

1100 c.c.

1~3 mm

NGK DCPR8E

0.7~0.8

1250±100 rpm

9 ±1 kgf/cm²

mm

7 psi

mm

Battery

PDF created with pdfFactory Pro trial version www.pdffactory.com

12V18Ah (type : MF battery)

2. MAINTENANCE INFORMATION

Periodical Maintenance Schedule

INTERVAL

ITEM

Muffler Bolts and Exhaust Pipe Nuts

Valve Clearance I - I I

Air Cleaner - C C R

Air Cleaner Vent Tube I I I

Engine Idle RPM I I I I

Spark Plus

Engine Oil R - R R

Oil Filter R - R R

Front Differential Set Oil

Final Gear Oil

C.V.T Belt - - I I

Fuel Tube

Throttle Cable Play I I I I

Brakes I I I I

Brake Hose

Brake Fluid

Tires - I I I

Suspensions - - I I

Steering System I I I I

Chassis Bolts and Nuts T T T T

General Lubrications - L L L

Grease nipple - - L L

MONTHS 1 3 6 12

Kms INITIAL 200 EVERY 1000 EVERY 2000 EVERY 4000

MILES INITIAL 120 EVERY 600 EVERY 1200 EVERY 2400

T T T T

- - I I

Replace Every 6000KM (4000 MILES)

R - R R

Replace Every 6000KM or Every 6 Months

R - R R

Replace Every 6000KM or Every 6 Months

- I I I

Replace Every 4 Years

- - I I

Replace Every 4 Years

- I I I

Replace Every 2 Years

Code: C ~ Cleaning (replaced if necessary) I ~ Inspection, cleaning, and adjustment

L ~ Lubrication R ~ Replacement T ~ Tighten

Have your ATV checked, adjusted, and recorded maintenance data periodically by your TGB

Authorized Dealer to maintain the ATV at the optimum condition.

The above maintenance schedule is established by taking the monthly 1000 kilometers as a

reference which ever comes first.

Remarks:

1. Clean or replace the air cleaner element more often when the ATV is operated on dusty

roads or in the Heavily- polluted environment.

2. Maintenance should be performed more often if the ATV is frequently operated in high

speed and after the ATV has accumulated a higher mileage.

3. Preventive maintenance

a. Ignition system-Perform maintenance and check when continuous abnormal ignition,

misfire, after-burn, overheating occur.

b. Carbon deposit removal-Remove carbon deposits in cylinder head, piston heads,

exhaust system when power is obviously lower than normal.

PDF created with pdfFactory Pro trial version www.pdffactory.com

2. MAINTENANCE INFORMATION

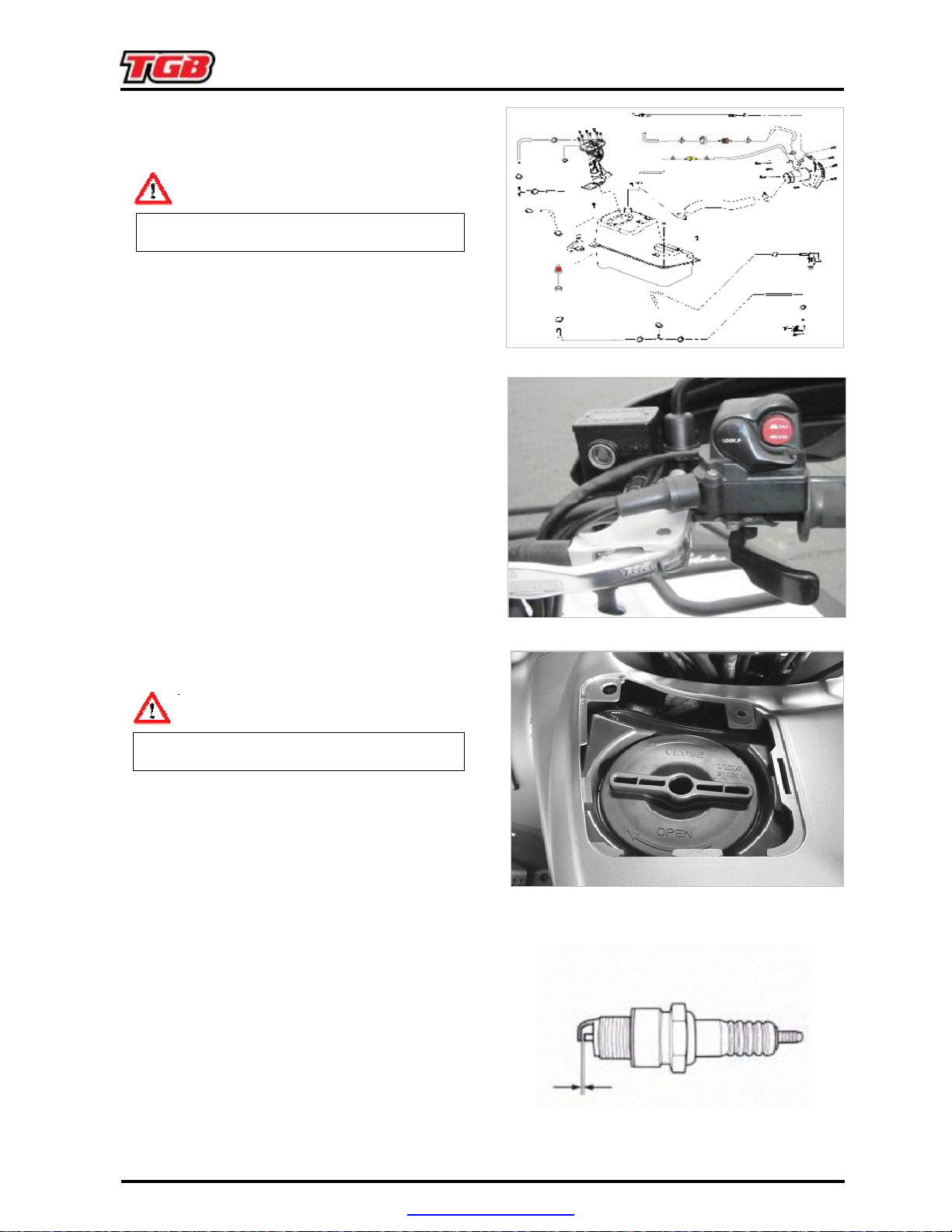

Fuel Lines

Check all lines, and replace it when they are

deterioration, damage or leaking.

For removal, refer to chapter 4 Fuel Pump.

Warning

Gasoline is a low ignition material so any kind

of fire is strictly prohibited as dealing it.

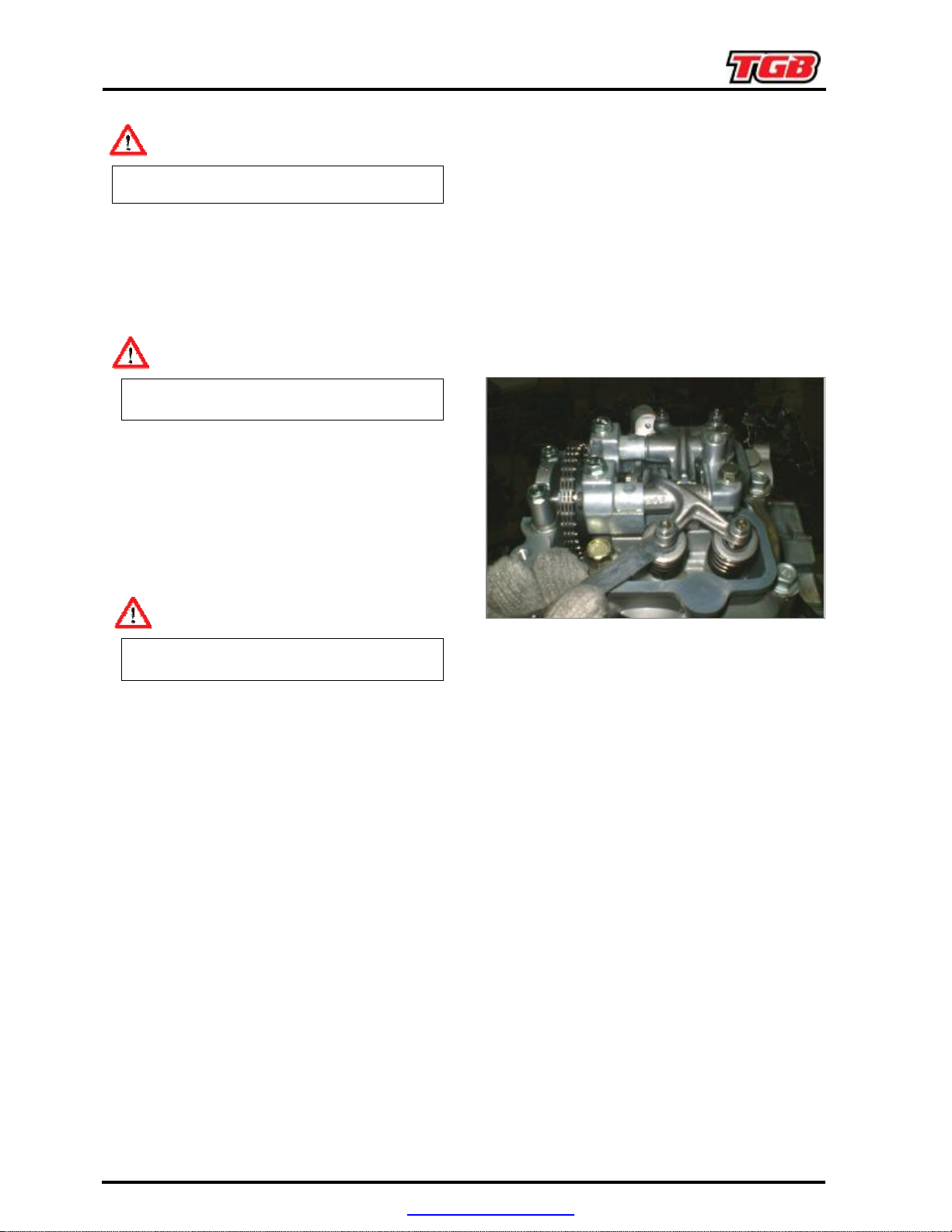

Acceleration Operation

Have a wide open of throttle valve as handle in

any position and release it to let back original

(full closed) position.

Check handle if its operation is smooth.

Check acceleration cable and replace it if

deteriorated, twisted or damaged.

Lubricate the cable if operation is not smooth.

Measure the throttle lever free play in its flange

part.

Remove rubber boot, loosen fixing nut, and

then adjust it by turning the adjustment screw.

Tighten the fixing nut, and check acceleration

operation condition.

Free play: 1~3 mm.

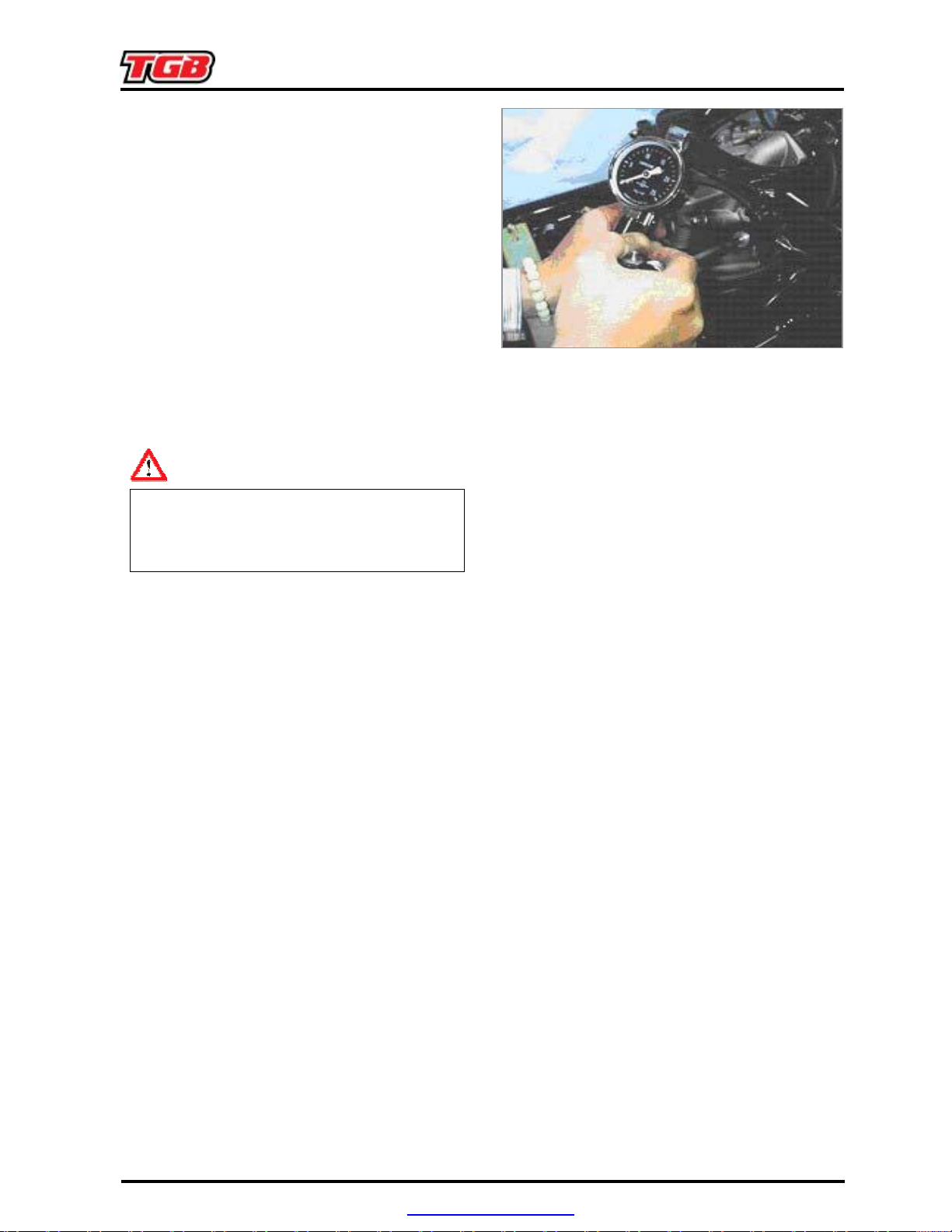

Air Cleaner

Open access cover.

Counterclockwise turn the lid and pull out

the element

Loosen the screw and separate the element.

Clean the sponge with non-flammable or

high-flash point solvent and then squeeze it for

dry.

Caution

Never use gasoline or acid organized solvent

to clean the element.

For installation, reverse the removal procedure.

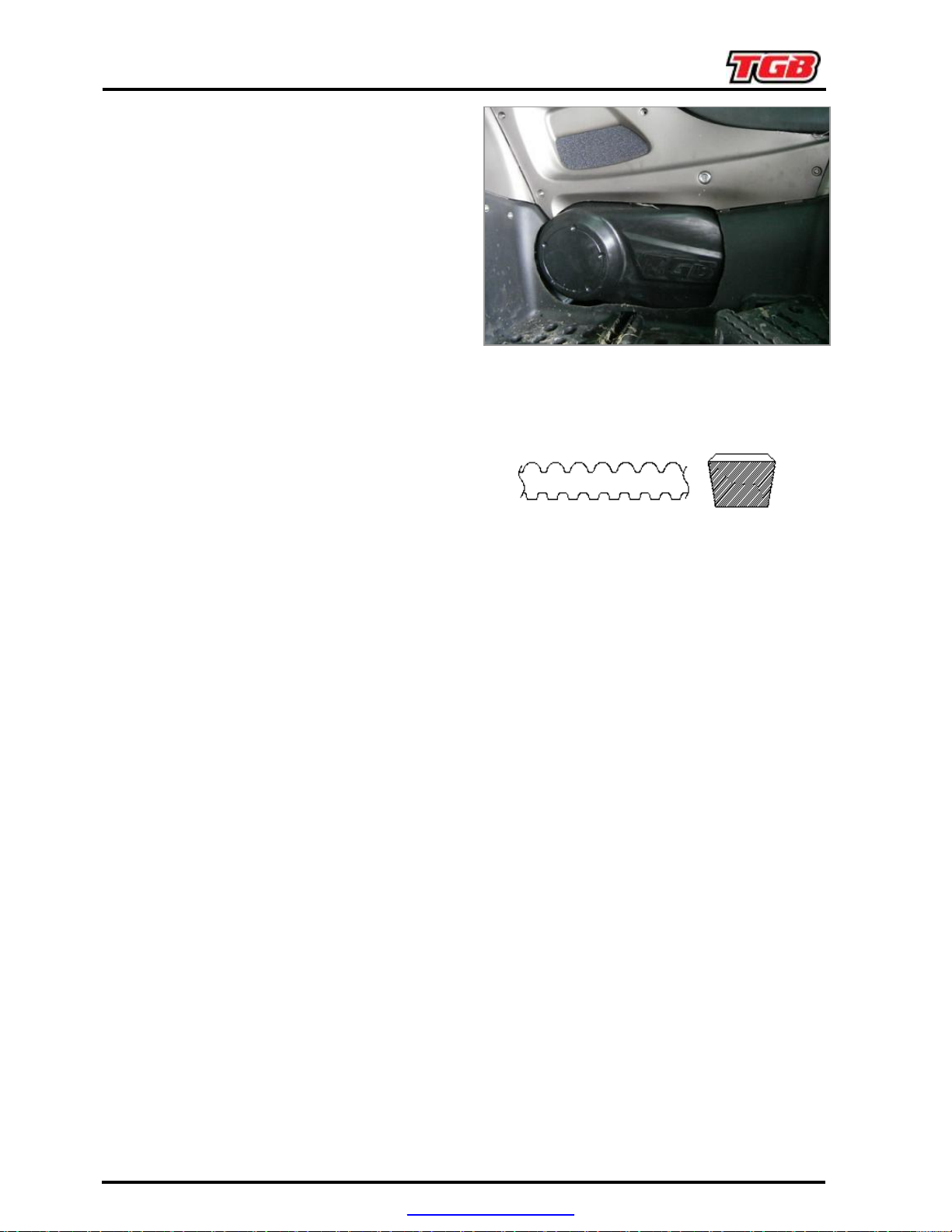

Spark Plug

Recommended spark plug:

NGK

/ DCPR8E

Remove spark plug cap.

Clean dirt around the spark plug hole. Remove

spark plug.

Measure spark plug gap.

Spark plug gap:0.7~0.8 mm

Carefully bend ground electrode of the plug to

adjust the gap if necessary.

Hold spark plug washer and install the spark

plug by screwing it.

Tighten the plug by turning 1/2 turn more with

plug socket after installed.

Tighten torque: 2.0~0.2kgf-m

PDF created with pdfFactory Pro trial version www.pdffactory.com

2. MAINTENANCE INFORMATION

with cylinder head mark so that piston is placed

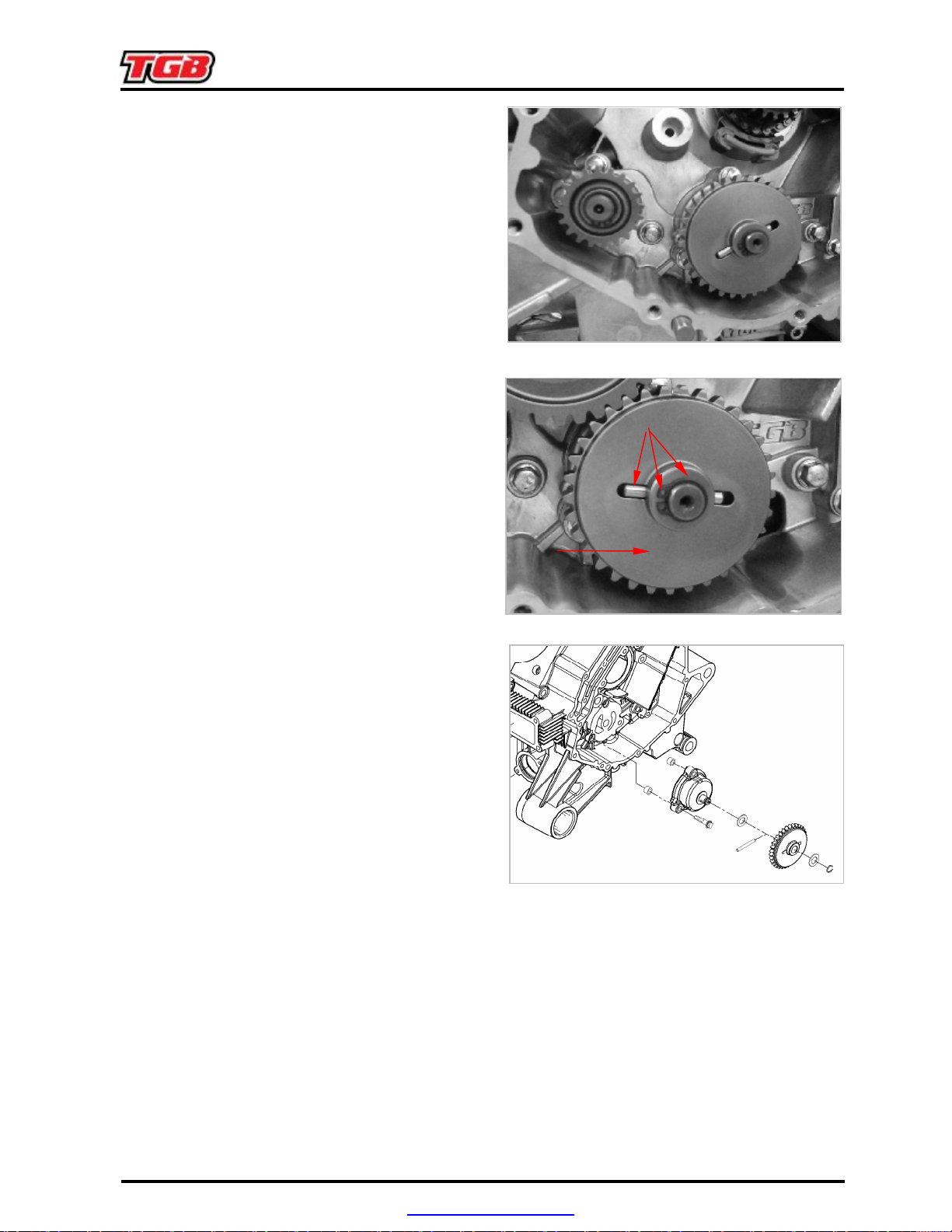

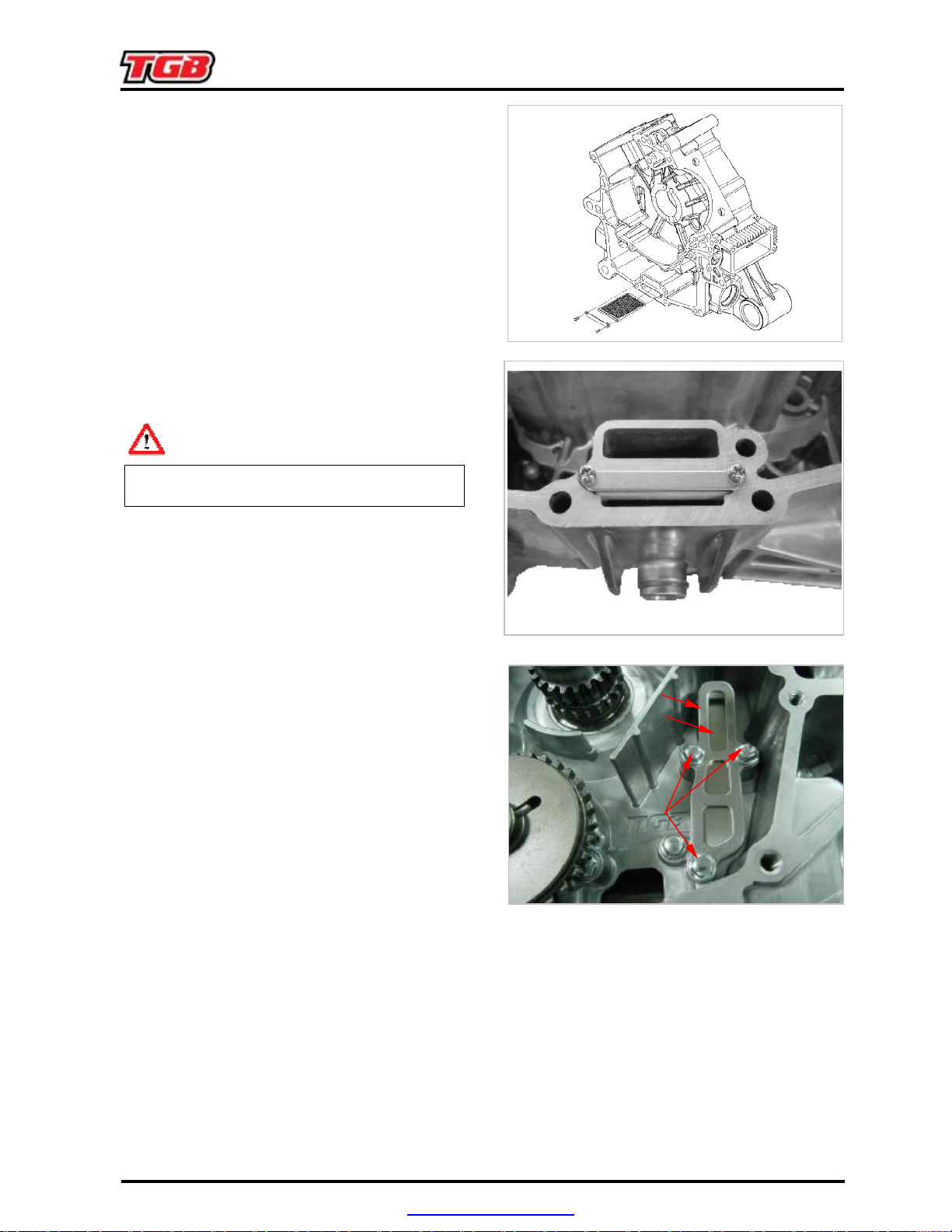

Valve Clearance

Caution

Checks and adjustment must be performed

when the engine temperature is below 35℃.

Remove front fender, top cover and air cleaner.

Remove cylinder head cover.

Turn camshaft bolt in C.W. direction and let the

Printing mark on the camshaft sprocket align

at TDC position in compression stroke.

Caution

Do not turn the bolt in C.C.W. direction to

prevent from camshaft bolt looseness.

Valve clearance inspection and adjustment.

Check & adjust valve clearance with feeler

gauge.

Loosen fixing nut and turn the adjustment nut

for adjustment.

Standard Value: IN 0.10 ± 0.02 mm

EX 0.15 ± 0.02 mm

Caution

Re-check the valve clearance after tightened

the fixing nut.

PDF created with pdfFactory Pro trial version www.pdffactory.com

2. MAINTENANCE INFORMATION

Ignition System

For ignition system, refer to chapter 5 electric

system.

Cylinder Compression Pressure

Warm up engine.

Turn off the engine.

Remove the top cover.

Remove the side cover.

Remove any one of the spark plug cap and

spark plug.

Install compression gauge.

Full open the throttle valve, and rotate the

engine by means of starter motor.

Caution

●

Rotate the engine until the reading in the

gauge no more increasing.

●

Usually, the highest pressure reading will be

obtained in 4~7 seconds.

Compression pressure: 9.0 ± 2 bar

Check following items if the pressure is too low:

●

Incorrect valve clearance.

●

Valve leaking.

●

Cylinder head leaking, piston, piston ring

and cylinder worn out.

If the pressure is too high, it means carbon

deposits in combustion chamber or piston head.

PDF created with pdfFactory Pro trial version www.pdffactory.com

2. MAINTENANCE INFORMATION

Drive Belt

Remove side cover.

Remove footrest.

Remove bolts of the clutch cover.

Check if the belt is crack or worn out.

Replace the belt if necessary or in accord with

the periodical maintenance schedule to replace

it.

Width limit: 31.0 mm or above

PDF created with pdfFactory Pro trial version www.pdffactory.com

2. MAINTENANCE INFORMATION

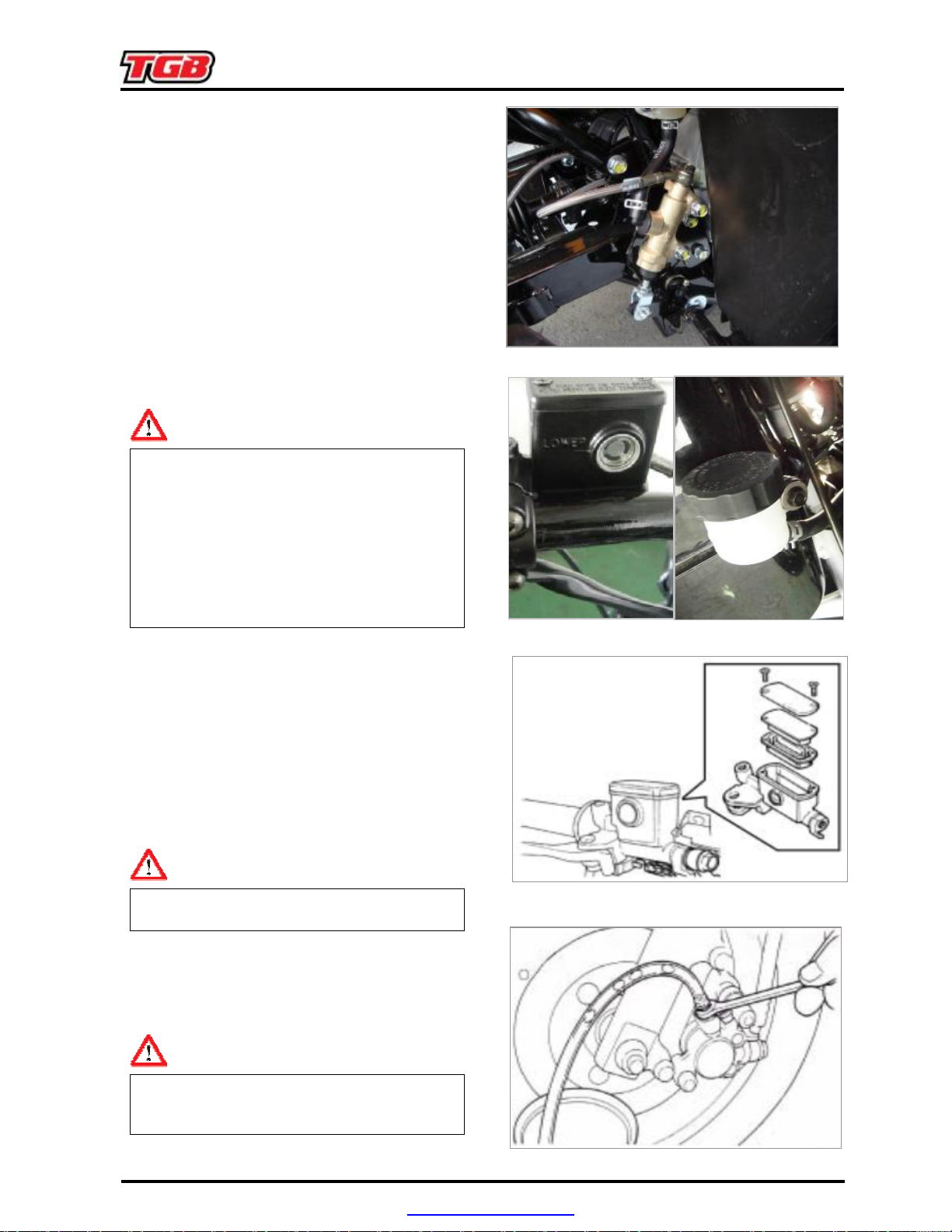

In order to maintain brake fluid in the reservoir

Hold the brake lever and open air bleeding valve.

Brake System

Brake System Hose

Make sure the brake hoses for corrosion or

leaking oil.

Brake Fluid

Check brake fluid level in the brake fluid

reservoir.

If the level is lower than the LOWER limit, add

brake fluid to UPPER limit. Also check brake

system for leaking if low brake level found.

Caution

●

in horizontal position, do not remove the cap

until handle stop.

●

Do not operate the brake lever after the

cap had been removed. Otherwise, the

brake fluid will spread out if operated the

lever.

●

Do not mix non-compatible brake fluid

together.

Filling Out Brake Fluid

Tighten the drain valve, and add brake fluid.

Operate the brake lever so that brake fluid

contents inside the brake system hoses.

Air Bleed Operation

Connect a transparent hose to draining valve.

Perform this operation alternative until there is

no air inside the brake system hoses.

Caution

Before closing the air bleed valve, do not

release the brake lever.

Added Brake Fluid

Add brake fluid to UPPER limit lever.

Recommended brake fluid: DOT3 or DOT4

WELL RUN brake fluid.

Caution

Never mix or use dirty brake fluid to prevent

from damage brake system or reducing brake

performance.

PDF created with pdfFactory Pro trial version www.pdffactory.com

2. MAINTENANCE INFORMATION

In order to maintain brake power balance, the

ght as

Make sure that electrical starter can be operated

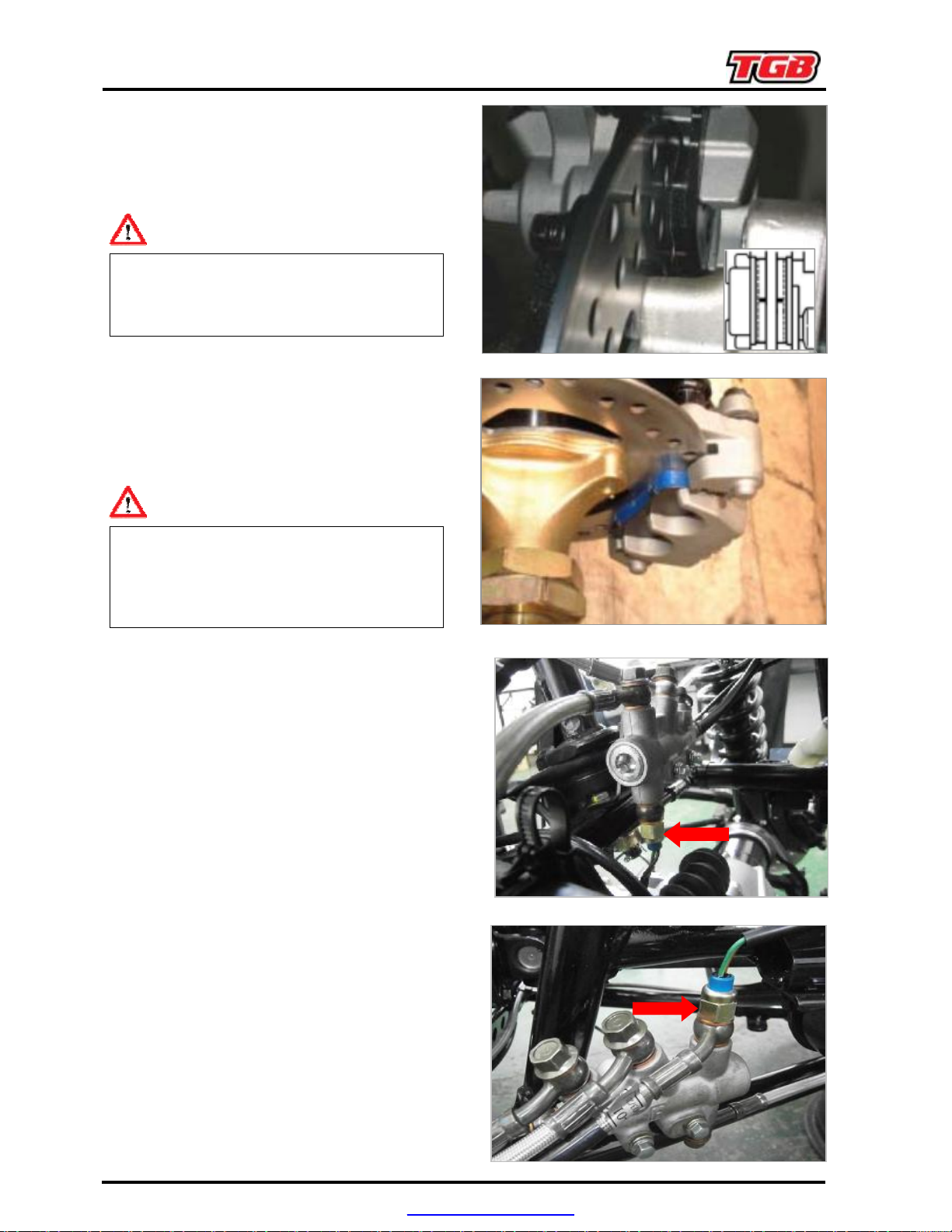

Brake

The indent mark on brake lining is the wear

limitation.

Replace the brake lining if the wear limit mark

closed to the edge of brake disc.

Lining Wear

Caution

●

To check front brake lining must be remove

front wheel first.

●

It is not necessary to remove brake hose

when replacing the brake lining.

Brake

Lining

Replacement (refer chapter

7-3)

Make sure the brake lining condition. Replace

the lining if the brake lining wear limitation

groove close to the brake disc.

Caution

●

Do not operate the brake lever after the

clipper removed to avoid clipping the brake

lining.

●

brake lining must be replaced with one set.

Brake Light Switch/Starting

Inhibitor Switch

The brake light switch is to light up brake li

brake applied.

only under brake applying.

PDF created with pdfFactory Pro trial version www.pdffactory.com

2. MAINTENANCE INFORMATION

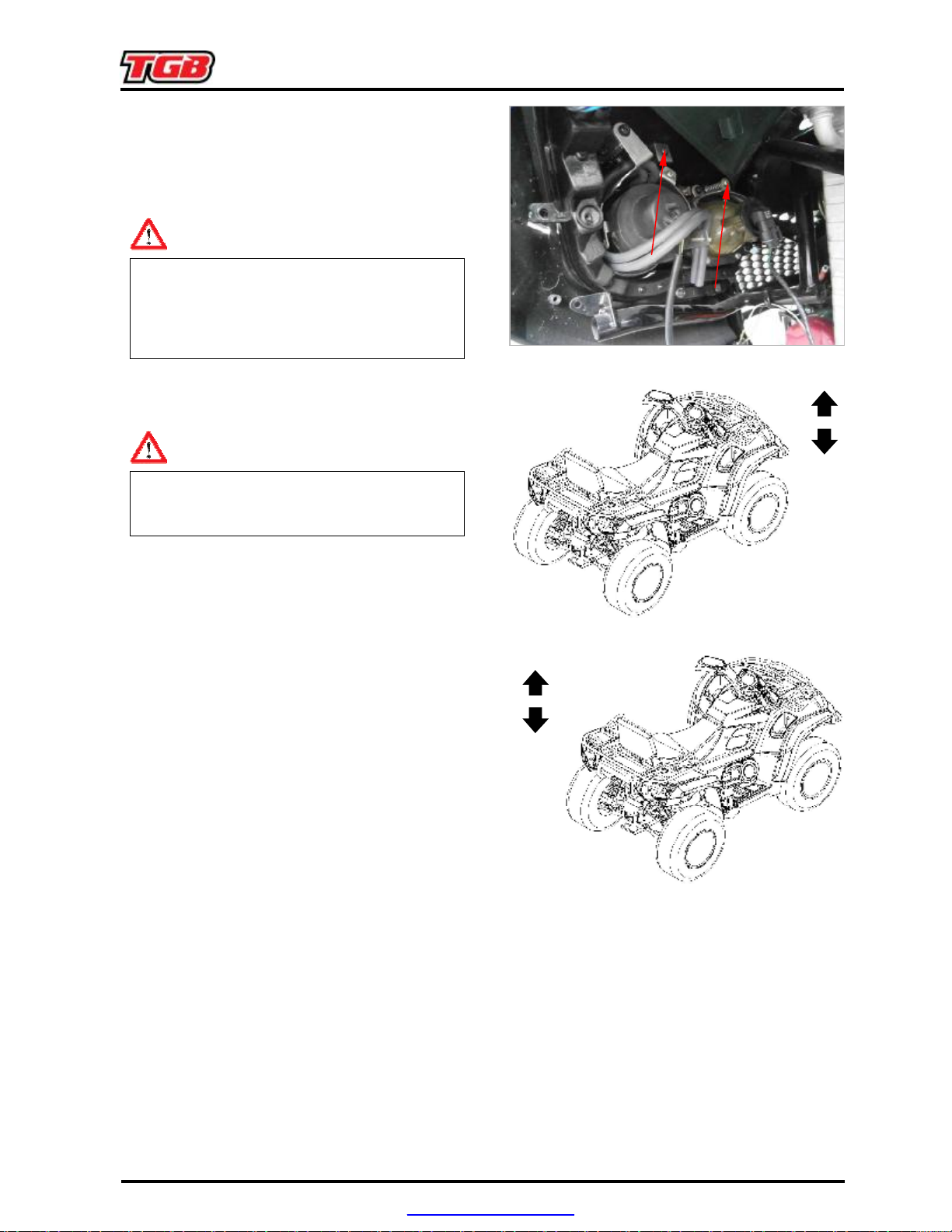

Press down the front cushion for several times to

Headlight Beam Distance

Turn on main switch.

Headlight beam adjustment.

Turn the headlight adjustment screw to adjust

headlight beam high.

Caution

●

To adjust the headlight beam follows related

regulations.

●

Improper headlight beam adjustment will

make in coming driver dazzled or insufficient

lighting.

Cushion

●

Do not ride the ATV with poor cushion.

●

Looseness, wear or damage cushion will

make poor stability and drive-ability.

Warning

Front cushion

check it operation.

Check if it is damage

Replace relative parts if damage found.

Tighten all nuts and bolts.

Rear Cushion

Press down the rear cushion for several times to

check it operation.

Check if it is damage

Replace relative parts if damage found.

PDF created with pdfFactory Pro trial version www.pdffactory.com

2. MAINTENANCE INFORMATION

Check all wires and cables if they are interfered

handle can be operated in vertical direction, then

Check if tire surface is ticked with nails, stones or

central surface. Replace the tire if the depth is not

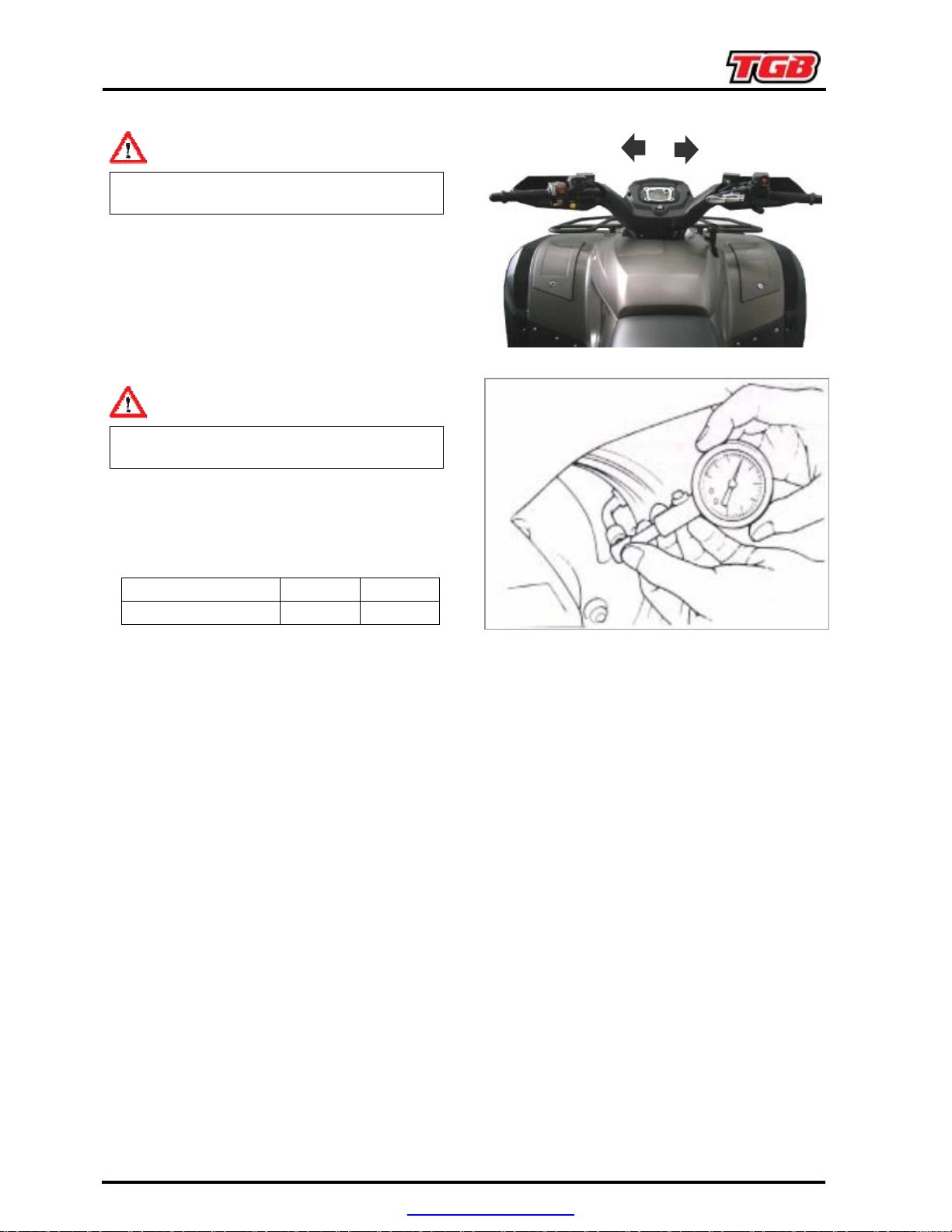

Steering Handle

Caution

with the rotation of steering handle bar.

Lift the front wheel out of ground.

Turn handle from right to left alternative and

check if turning is smoothly.

If handle turning is uneven and bending, or the

check the handle top bearing.

Wheel/Tire

Caution

Tire pressure check should be done as cold

engine.

other materials.

Appointed tire pressure

Tire size Front Tire Rear Tire

Tire pressure as cold 7

psi

7

psi

Check if front and rear tires’ pressure is in

normal. Measure tire thread depth from tire

come with following specification:

Front tire: 1.5 mm

Rear tire: 2.0 mm

Nuts, Bolts Tightness

Perform periodical maintenance in accord with

the Periodical Maintenance Schedule

Check if all bolts and nuts on the frame are

tightened securely.

Check all fixing pins, snap rings, hose clamp,

and wire holders for security.

PDF created with pdfFactory Pro trial version www.pdffactory.com

2. MAINTENANCE INFORMATION

Special Tools List

PARTS NO. : 440649

PARTS NAME : EXTENSION PULLER / REMOVER

PARTS NO. : 440651

PARTS NAME : BEARING(924384) REMOVER φ15

PARTS NO. : 440650

PARTS NAME : BUSHING(924739) REMOVER

PARTS NO. : 440652

PARTS NAME : BEARING(924384) REMOVER

φ20

PARTS NO. : 440653

PARTS NAME : BEARING(924384) REMOVER φ45

PARTS NO. : 552303

PARTS NAME : PISTON & ROD CONNECTING

HOLDER

PARTS NO. : 440656

PARTS NAME : L CRANK CASE OIL SEAL

REMOVER

PARTS NO. : 440662

PARTS NAME : CYLINDER HEAD VALVE GAP

ADJUSTER

PDF created with pdfFactory Pro trial version www.pdffactory.com

2. MAINTENANCE INFORMATION

PARTS NO. : 440667

PARTS NAME : CYLINDER HEAD VALVE AND

SPRING INSTALLER/REMOVER

PARTS NO. : 560001

PARTS NAME : FLYWHEELREMOVER

PARTS NO. : 560003

PARTS NAME : RIGHT CRANKCASE MECHNICAL

SEAL INSTALLER/REMOVER

PARTS NO. : 560005

PARTS NAME : DRIVEN PULLEY FIXING TOOL

PARTS NO. : 440671

PARTS NAME : WET CLUTCH SCREW NUT

FIXER

PARTS NO. : 560002

PARTS NAME : FLYWHEEL INSTALLER

PARTS NO. : 560004

PARTS NAME : DRIVE PULLEY FIXING ROD

PARTS NO. : 560006

PARTS NAME : DRIVE PULLEY REMOVER

PDF created with pdfFactory Pro trial version www.pdffactory.com

PARTS NO. : 560007

PARTS NAME : DRIVEN PULLEY EXTEND TOOL

FOR REMOVE BELT

PARTS NO. : 560009

PARTS NAME : DEAR DIFF. NEEDLE BEARING

REMOVER (W/ 440649 Ø20 mm)

PARTS NO. : 552312

PARTS NAME : EPS STEERING BEARING SEAT

SOCKET

PARTS NO. : 560011

PARTS NAME : PLAIN BEARING INSTALLER

(LEFT CRANKCASE)

2. MAINTENANCE INFORMATION

PARTS NO. : 560008

PARTS NAME : BEARING REMOVER (W/

440649 Ø20 mm)

PARTS NO. : 560010

PARTS NAME : REAR DIFF. BEARING SPACER

INSTALLER

PARTS NO. : 560012

PARTS NAME : PLAIN BEARING REMOVER

(LEFT CRANKCASE

PDF created with pdfFactory Pro trial version www.pdffactory.com

2. MAINTENANCE INFORMATION

PARTS NO. : 560013

PARTS NAME : PLAIN BEARING INSTALLER

(RIGHT CRANKCASE)

PARTS NO. : 560015

PARTS NAME : CRANKCASE COVER LH

PLAIN BEARING INSTALLER

(LEFT CRANKCASE)

PARTS NO. : 560017

PARTS NAME : GOVERNOR CUP

INSTALLER/REMOVER KIT

(DRIVE PULLEY)

PARTS NO. : 560019

PARTS NAME : HAFT SHEAVE PRESSING TOOL

PARTS NO. : 560014

PARTS NAME : PLAIN BEARING REMOVER

(RIGHT CRANKCASE

PARTS NO. : 560016

PARTS NAME : CRANKCASE COVER LH

PLAIN BEARING REMOVER

(LEFT CRANKCASE

PARTS NO. : 560018

PARTS NAME : DRIVE PULLEY FIXING SEAT

FOR INSTALL AND REMOVE

PARTS NO. : 560020

PARTS NAME : DRIVEN PULLEY FIXING SEAT

FOR INSTALL AND REMOVE

PDF created with pdfFactory Pro trial version www.pdffactory.com

Precautions in Operation

General Information

This chapter contains maintenance operation

for the engine oil pump and gear oil replacement.

Specifications

Engine oil quantity

Overhaul: 2300 c.c.

Filter change: 1800 c.c.

3.LUBRICATION SYSTEM

Change: 2000 c.c.

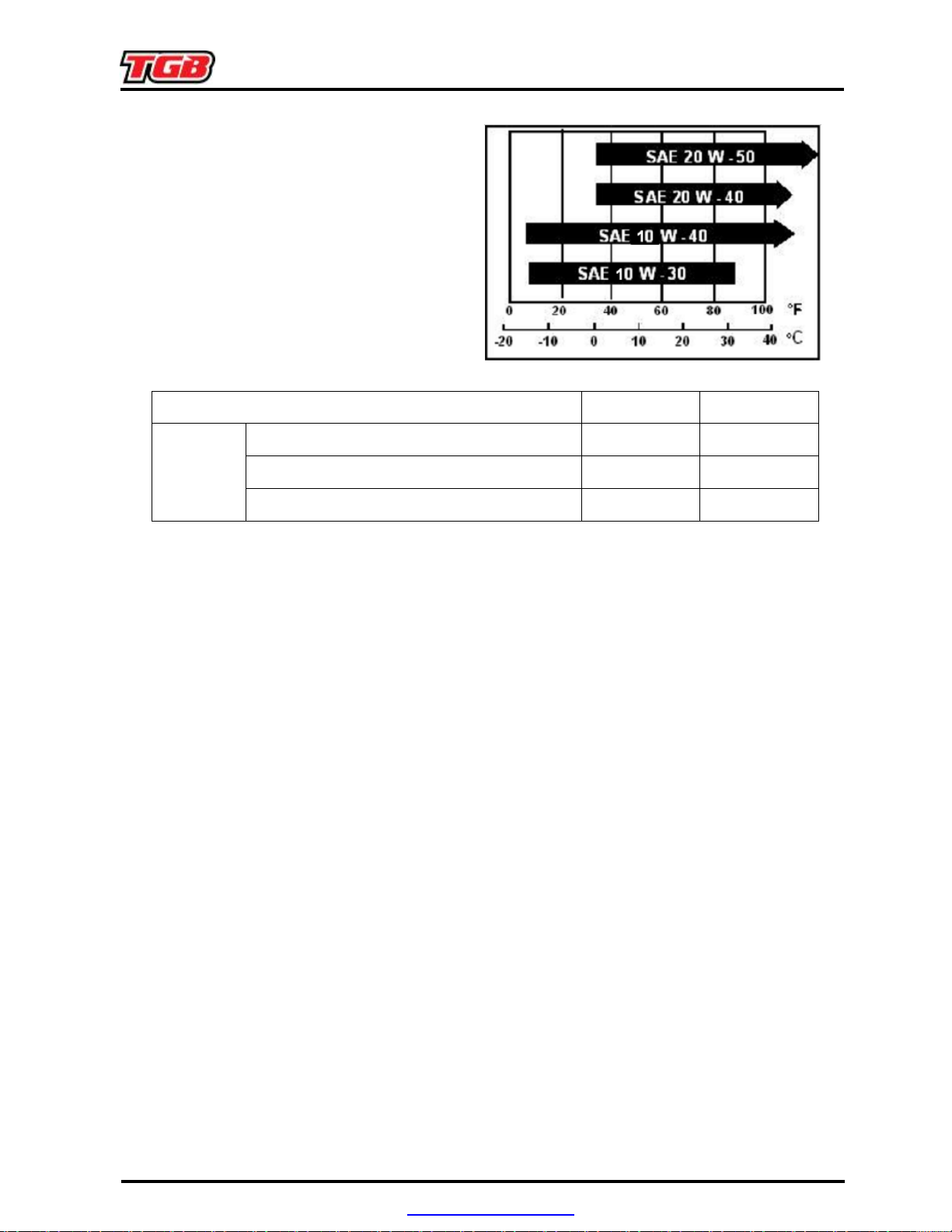

Oil viscosity SAE 10W-40

Oil pump

Torque value

Torque value oil filter cover 1.2 kgf-m

Engine oil drain bolt

Troubleshooting

Low engine oil level

●

Oil leaking

●

Valve guide or seat worn out

●

Piston ring worn out

● Camshaft worn out

Items

Inner rotor clearance

Clearance between outer rotor and body

Clearance between rotor side and body

2

.4 kgf-m

Standard (mm) Limit (mm)

0.15~0.20

0.15

0.20

0.04~0.09

0.25

0.12

● Camshaft main bearing worn out

Low oil pressure

●

Low engine oil level

●

Clogged in oil strainer, circuits or pipe, oil radiator gasket

●

Oil pump damage

● Oil pressure valve, oil filter

Dirty oil

●

No oil change in periodical

●

Cylinder head gasket damage

●

Piston ring worn out

● Camshaft worn out

● Camshaft main bearing worn out

PDF created with pdfFactory Pro trial version www.pdffactory.com

3.LUBRICATION SYSTEM

Engine oil can be very hot. Wait until engine

Oil condition gives information about the

gives an indication of failure inside the engine.

Oil Level Verification

NOTE:

wrong oil level may be indicated.

Strictly follow this procedure, otherwise

▪ Ensure vehicle is on a level surface.

▪ Start engine and let idle for a few minutes.

▪ Stop engine, wait a few minutes to allow oil to

flow down to crankcase then check oil level.

▪ Fully screw in dipstick to check oil level.

▪ Remove dipstick and read the oil level.

▪ Oil level must be between minimum and

maximum marks on dipstick.

▪ Refill oil as necessary. Do not overfill.

▪ Reinstall dipstick.

Oil Filter Change

▪ Ensure the vehicle is on a level surface.

▪ Oil and oil filter must be replaced at the same

time. Oil change and oil filter replacement

should be done with a warm engine.

Engine Type

Upper Level

Low Level

WARNING

oil is warm

▪ Place a drain pan under the engine drain plug

area.

▪ Clean the drain plug area.

▪ Unscrew drain plug and discard the gasket

ring.

▪ Remove dipstick.

▪ Allow oil to drain completely from crankcase.

NOTE:

engine condition.

▪ clean the magnetic drain plug from metal

shavings and residue. Presence of debris

Check engine to correct the problem.

▪ Install a NEW gasket ring on drain plug.

TORQUE:

2

.4 kgf-m

PDF created with pdfFactory Pro trial version www.pdffactory.com

3.LUBRICATION SYSTEM

CAUTION

Never use the gasket ring a second time.

Always replace by a new one.

▪ Replace oil filter.

▪ Refill engine with recommended engine oil.

▪ Oil change capacity with filter: 2.0 L.

▪ After filling, check the oil level with dipstick.

▪ Run engine to ensure oil filter and drain plug

areas are not leaking.

▪ Dispose oil and filter as per your local

environmental regulation.

INSPECTION

ENGINE OIL PRESSURE

NOTE:

done with a warm engine 90℃ and the

recommended oil.

▪

▪

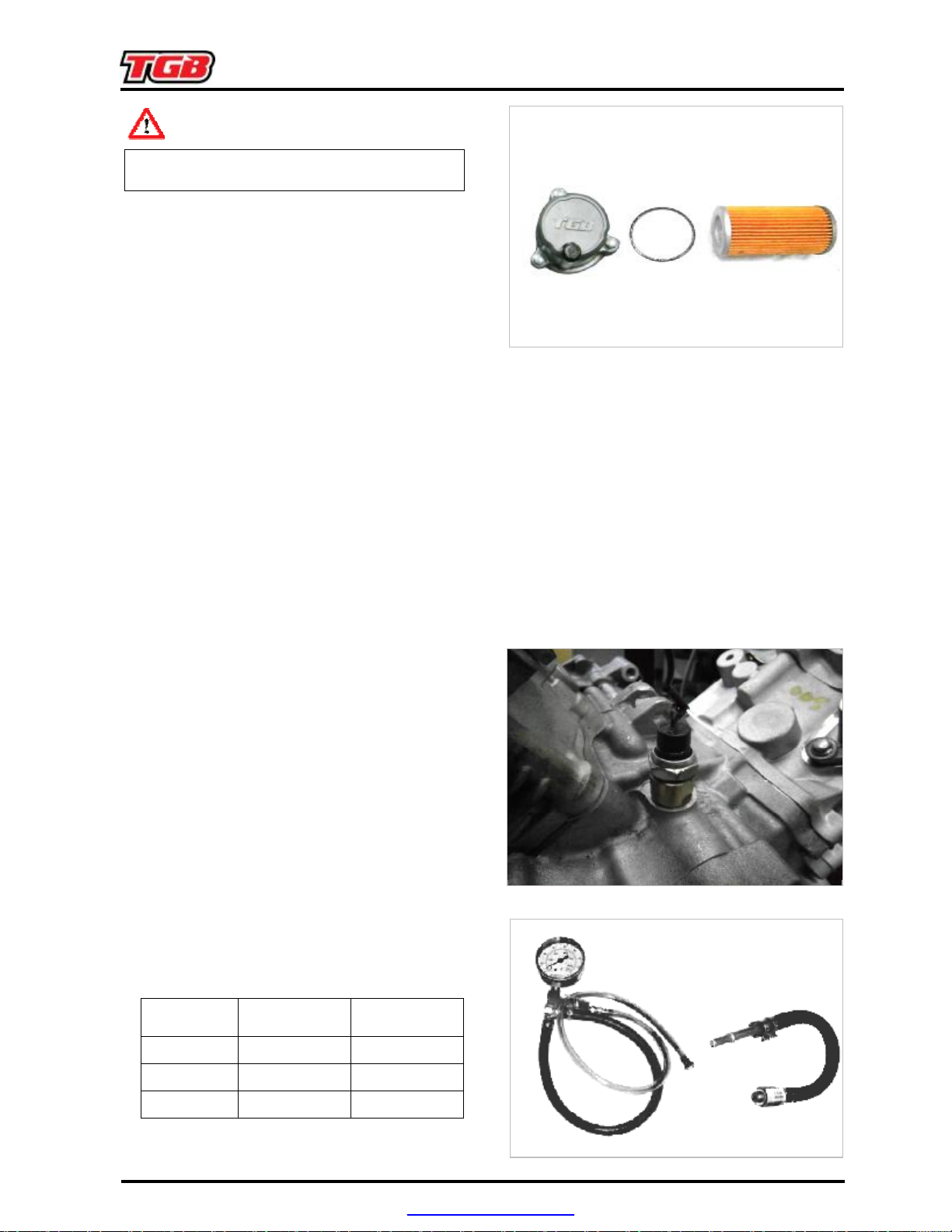

The engine oil pressure test should be

Remove the oil pressure switch.

PRESSURE GAUGE

Install

HOSE

.

and

ADAPTER

The engine oil pressure should be within the

following values.

OIL

PRESSURE

MINIMAL 10 psi 39 psi

NORMIAL

1250 RPM 6000 RPM

22 psi

46 psi

MAXIMAL

36 psi 70 psi

PDF created with pdfFactory Pro trial version www.pdffactory.com

3.LUBRICATION SYSTEM

▪

If the engine oil pressure is out of

specifications, check the points described in

troubleshooting section.

▪ Removal oil pressure gauge and adapter

hose.

NOTE:

pressure gauge, use the disconnect tool.

To remove adapter hose from oil

▪ Reinstall the oil pressure switch.

OIL FILTER

Oil Filter Removal

▪

Remove oil filter drain screw and washer.

▪

Drain out the oil inside the filter housing

▪

Remove three retaining screws and cover.

▪

Remove oil filter.

Oil Filter Inspection

Check and clean the oil filter inlet and outlet

area for dirt and other contaminations.

Oil Filter Installation

▪ Install a new O-ring on oil filter.

▪ Install the filter into the cover.

▪ Apply engine oil on O-ring and grease on the

end of filter.

▪ Install the cover on the engine.

TORQUE:

1.2

kgf-m

PDF created with pdfFactory Pro trial version www.pdffactory.com

3.LUBRICATION SYSTEM

switch

Install oil pressure switch with LOCTITE

OIL PRESSURE SWITCH

Oil Pressure Switch Activation

▪ Oil pressure switch works when engine oil

pressure is between 20 and 40 kPa.

▪ To check the function of the oil pressure

switch, an oil pressure test has to be

performed. If the engine oil pressure is good,

check the resistance of the oil pressure

while engine is off and while engine is running.

Oil Pressure Switch Test

▪ Disconnect the connector from oil pressure

switch.

▪ Use multimeter to check the continuity.

▪ Replace the oil pressure switch if necessary.

▪ If OK, check the continuity of the wiring

harness.

Oil Pressure Switch Removal

Unplug then unscrew the oil pressure switch.

Oil Pressure Switch Installation

NOTE:

243.

TORQUE:

ENGINE OIL PRESSURE VALVE

The oil pressure valve is located on the engine

magneto side (inside magneto cover).

NOTE:

when oil pressure exceeds 70 psi.

1.7

kgf-m

.

The oil pressure valve system works

PDF created with pdfFactory Pro trial version www.pdffactory.com

3.LUBRICATION SYSTEM

Clean bore and thread in the magneto housing

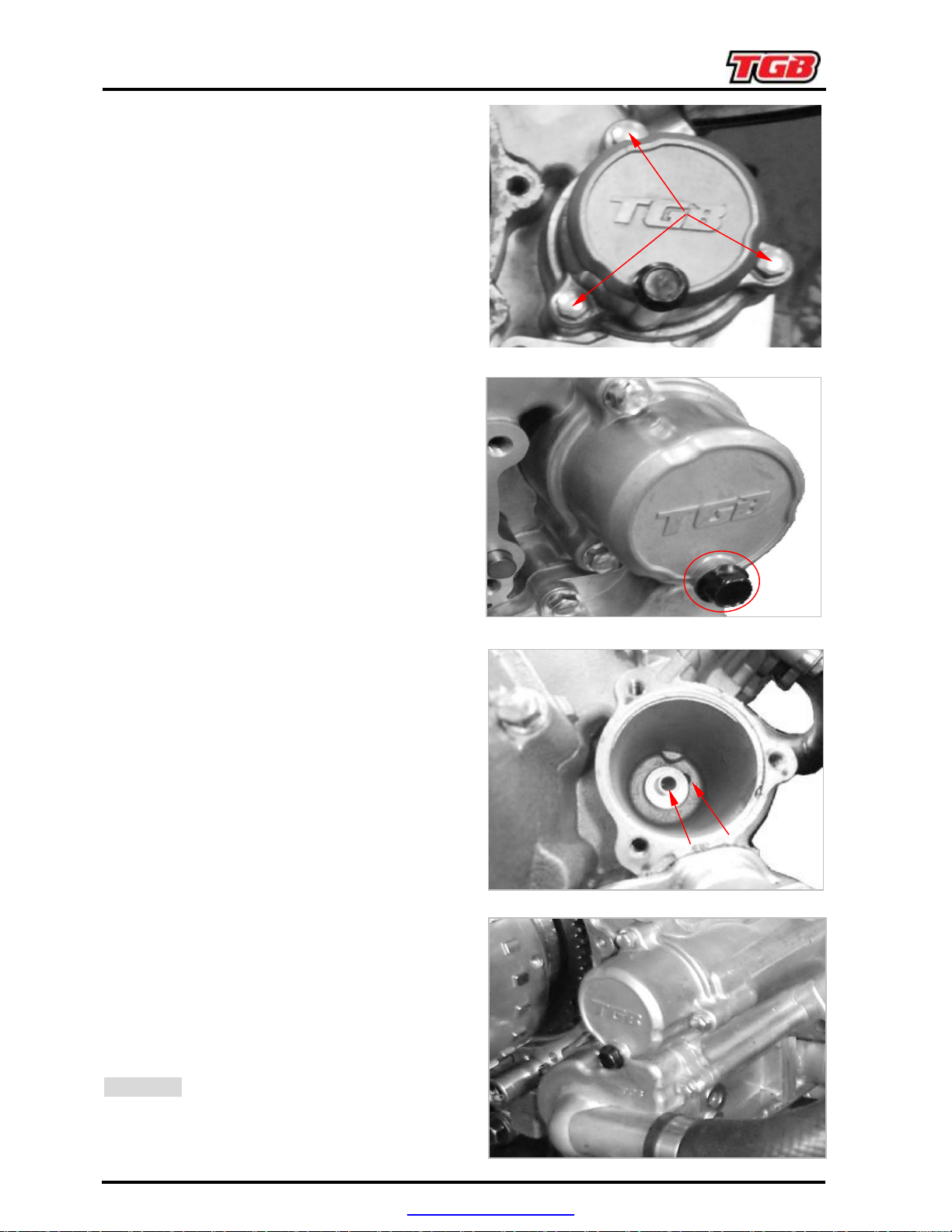

Removal

▪ Remove the bolts and the ACG cover.

▪ Pull out the oil pressure valve and washer.

Inspection

▪ Inspect pressure valve housing, O-ring and

valve for scoring or other damages.

▪

from metal shavings and other contamination.

Installation

For installation, reverse the removal procedure.

NOTE: At installation, always replace the

gasket ring.

OIL RADIATOR

Oil Radiator Removal

▪ Drain engine oil.

▪ Drain coolant.

▪ Remove oil radiator cap retaining bolts.

▪ Place rags or towels under oil cooler to catch

remaining oil and coolant.

▪ Remove oil radiator and discard gasket.

Oil Radiator Inspection

▪ Check oil radiator for cracks or other damage.

▪ Replace if necessary.

Oil Radiator Installation

▪ For installation, reverse the removal

procedure.

▪ Wipe off any oil and coolant spillage.

▪ Install a new gasket.

▪ Refill engine oil with recommended oil and at

the proper oil level.

▪ Refill and bleeding cooling system.

PDF created with pdfFactory Pro trial version www.pdffactory.com

3.LUBRICATION SYSTEM

is located on the engine CVT side

OIL PUMP

The oil pump

(behind cover).

Removal

▪ Drain engine oil.

▪ Remove parts to access the CVT cover.

▪ Remove the CVT cover.

▪ Remove CVT assembly.

▪ Remove crankcase cover LH.

▪ Remove:

- retaining ring.

- oil pump gear.

- needle pin

- thrust washer.

- oil pump flange bolts.

- oil pump cover screws and pull oil pump

cover.

- oil pump shaft with inner rotor and outer

rotor.

Inspection

▪ Inspect oil pump for marks or other damages.

▪ Check for scratches din crankcase between

outer rotor and oil pump bore. If so, replace

damaged parts.

▪ Check inner rotor for corrosion pinholes or

other damages. If so, replace oil pump shaft

assembly.

PDF created with pdfFactory Pro trial version www.pdffactory.com

3.LUBRICATION SYSTEM

If clearance between outer rotor and its bore in

Difference between measurements should not

exceed 0.2 mm. If so, replace the complete oil

▪ Using a feeler gauge, measure the clearance

of inner and outer rotors as shown.

▪ If clearance of inner and outer rotors exceeds

the tolerance, replace oil pump shaft

assembly. Ensure to also check oil pump

cover. If damaged, replace the complete oil

pump assembly.

▪

crankcase exceeds the tolerance, replace the

complete oil pump assembly and/or the

crankcase.

▪ Using a depth gauge, measure the axial

clearance of the oil pump as shown.

▪

pump assembly.

NOTE:

pump shaft assembly increases, the oil

pressure decreases.

When the axial clearance of the oil

Installation

For installation, reverse the removal procedure.

NOTE:

marked. When installing, make sure both

markings are on the upper side.

After reinstallation of remaining parts, check for

smooth operation of the oil pump assembly.

The outer rotor and inner rotor are

Oil Pump Final Test

After engine is completely reassembled, start

engine and make sure oil pressure is within

specifications.

PDF created with pdfFactory Pro trial version www.pdffactory.com

3.LUBRICATION SYSTEM

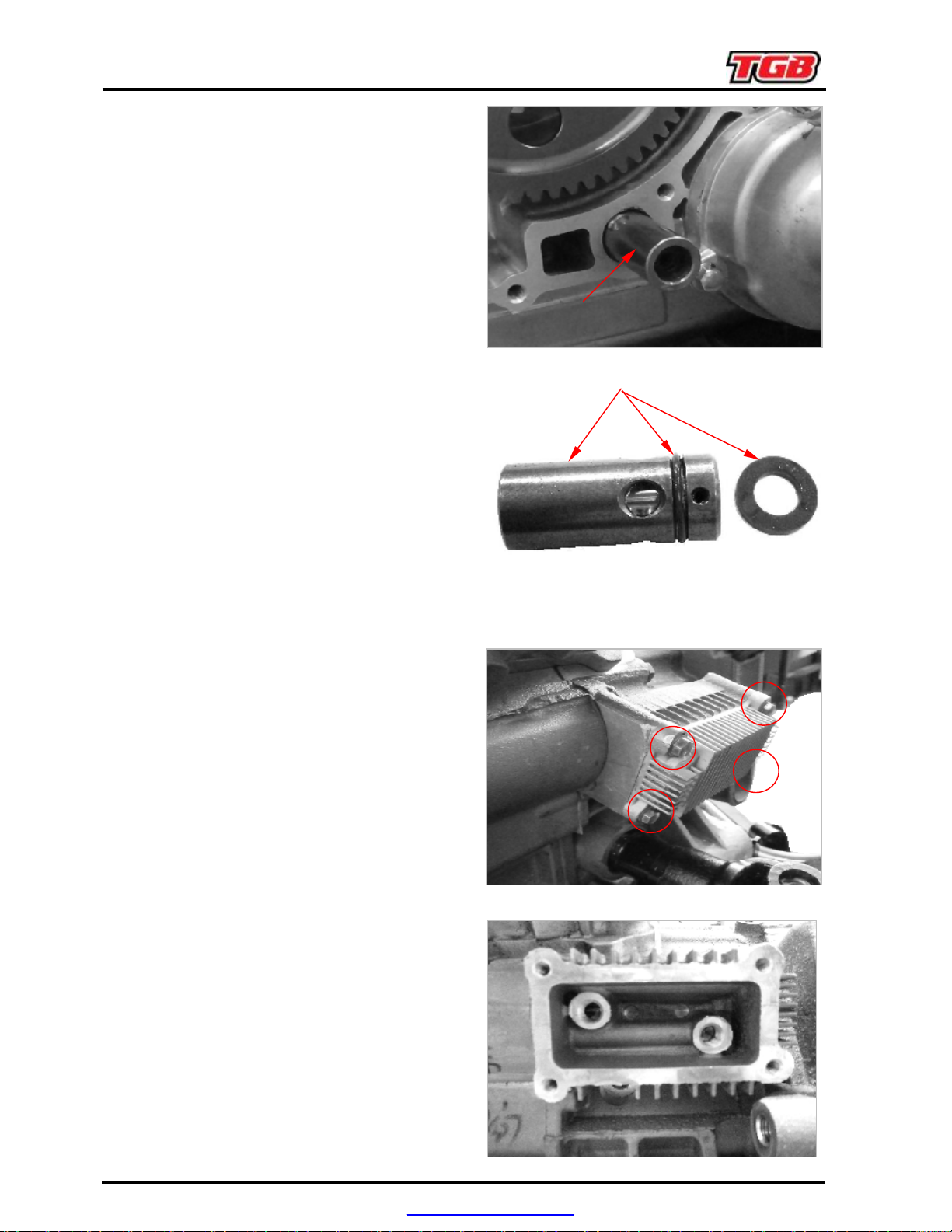

The engine oil strainer is located between both

cause a rash break out and injure your eyes.

①②③

ENGINE OIL STRAINER

▪

crankcase halves.

▪ Usually the strainer no needs to clean.

▪ During engine over hall, it will clean after

separate the crankcase half.

▪ Remove the retaining bolts and pull the oil

strainer out.

Cleaning and Inspection

▪ Clean engine oil strainer with a part cleaner

then use airgun to dry it.

WARNING

Always wear eye protector. Chemicals can

▪ Check engine oil strainer for cracks or other

damage. Replace if damaged.

Installation

For installation, reverse the removal procedure.

REED VALVE

The engine is equipped with reed valve, which

prevents accumulation of large oil quantities in

the crankcase. The reed valve is fitted into the

crankcase.

Valve Removal

Remove

- Reed valve three retaining bolts.

- Stopper plate.

- Reed valve.

Valve Inspection

Check reed valve for cracks or other damage.

NOTE:

Replace reed valve if damaged.

Valve installation

For installation, reverse the removal procedure.

PDF created with pdfFactory Pro trial version www.pdffactory.com

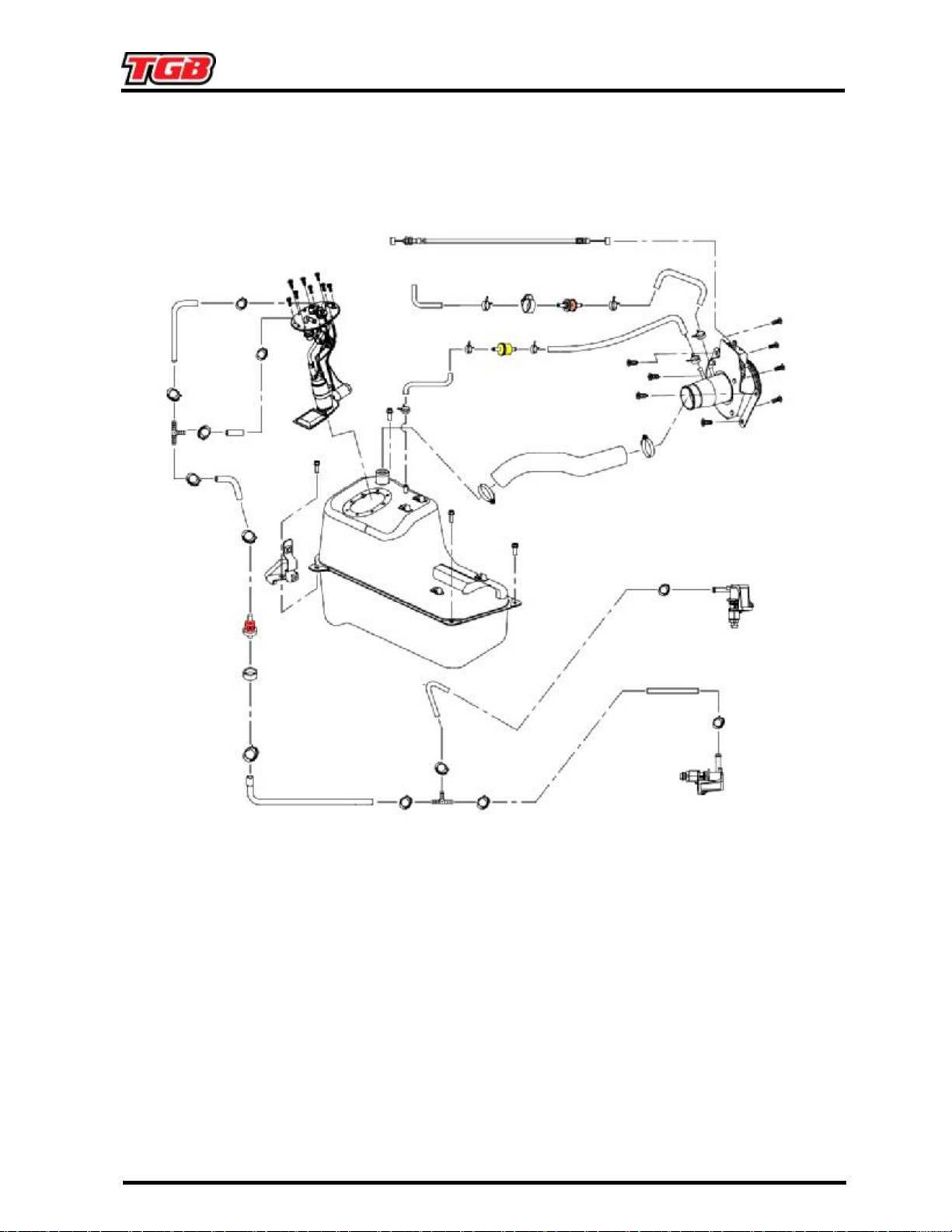

FUEL TANK AND FUEL PUMP

4-1. FUEL SYSTEM

4-1. FUEL SYSTEM

FUEL TANK AND FUEL PUMP

GENERAL

WARNING

Fuel is flammable and explosive under certain conditions. Ensure work area is well

ventilated. Do not smoke or allow open flames or sparks in the vicinity.

WARNING

Always disconnect battery prior to working on the fuel system.

WARNING

Torque wrench tightening specifications must strictly be adhered to.

Locking devices (e.g.: locking tabs, elastic stop nuts, self-locking fasteners, cotter pin, etc.)

must be replaced.

WARNING

Always proceed with care and use appropriate safety equipment when working on

pressurized fuel system. Wear safety glasses.

WARNING

Do not allow fuel to spill on hot engine parts and/or on electrical connectors.

▪ When the repair is completed, ensure that all hoses are connected and secured.

▪ Fuel lines remain under pressure at all times.

▪ Proceed with care when removing/installing high pressures test equipment.

▪ Disconnect the fuel pump electrical connector to disable fuel pump and crank engine to release fuel

pressure prior to disconnecting any fuel hose.

▪ Cover the fuel hose connections with an absorbent shop rag and carefully disconnect them to

minimize spilling.

▪ Wipe off any fuel spillage.

▪ Hoses, cables or locking ties removed during a procedure must be reinstalled as per factory

standards.

4-1. FUEL SYSTEM

out through the inlet of the vent system should

SYSTEM DESCRIPTION

Fuel Tank Vent System

▪ The fuel tank is equipped with a vent system

that ensures the fuel tank remains at ambient

pressure.

▪ Air can enter the fuel tank at all times through

the fuel tank vent valve. This prevents

negative pressure within the fuel tank, which

could cause fuel starvation.

▪ The vent valve also prevents fuel from flowing

the vehicle be overturned.

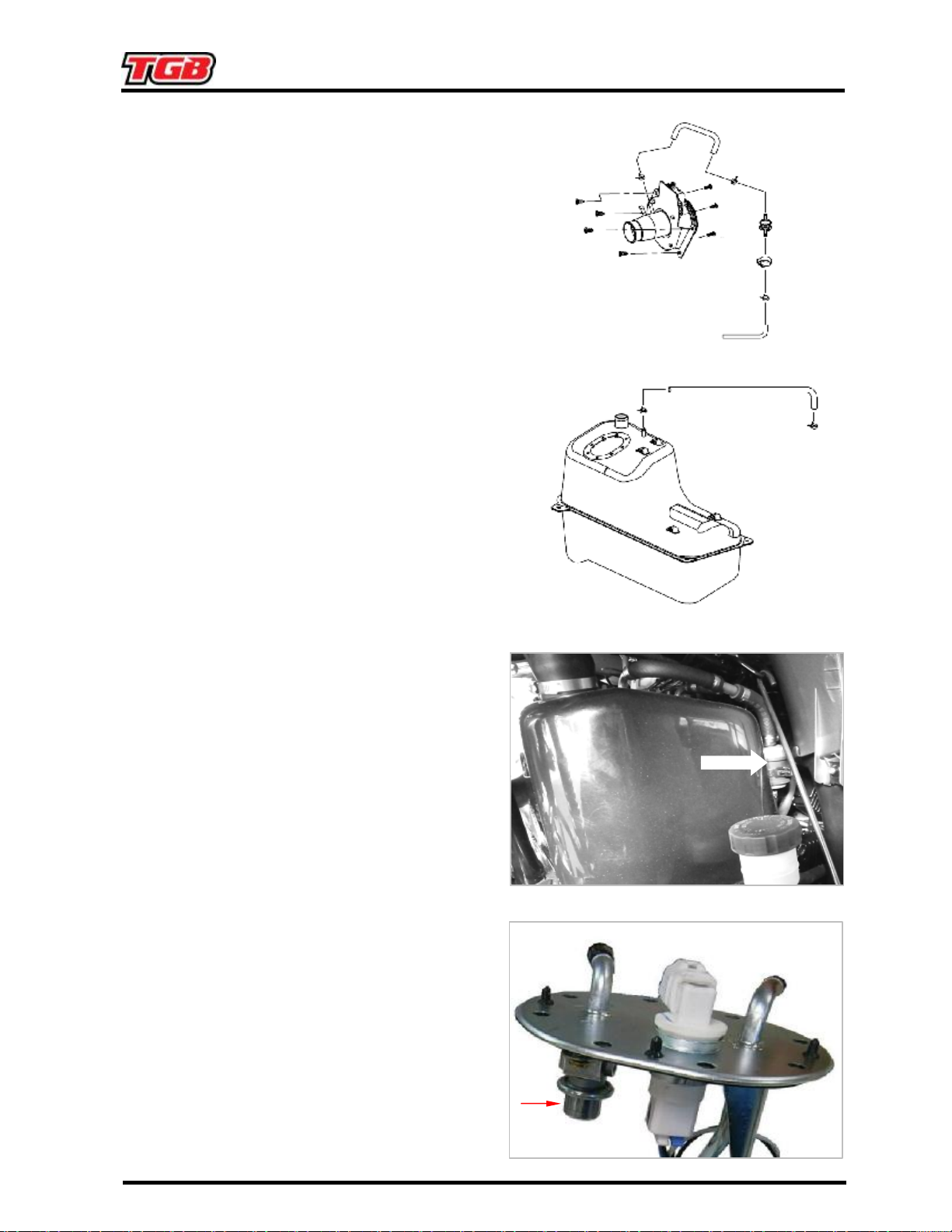

Fuel Pump Assembly

▪ The fuel pump assembly is inserted in the fuel

tank.

▪ It provides fuel delivery for EFI system and

encompasses the following components:

- Electric fuel pump.

- Fuel pre-filter.

- Fuel pressure regulator.

- Fuel level sender.

Fuel Filters

▪ The fuel filter is located on the right of the fuel

tank, which connected fuel line before go into

the fuel injector nozzle.

▪ For replace, please using Oetiker pliers to

remove the clamp..

Fuel Pump Pressure Regulator

▪ The fuel pressure is integral to the fuel pump

assembly. The pressure regulator maintains

proper fuel pressure for the EFI system.

Loading...

Loading...