TGB BR8, BR9, BF9, BH8, BK8 Service Manual

...

1

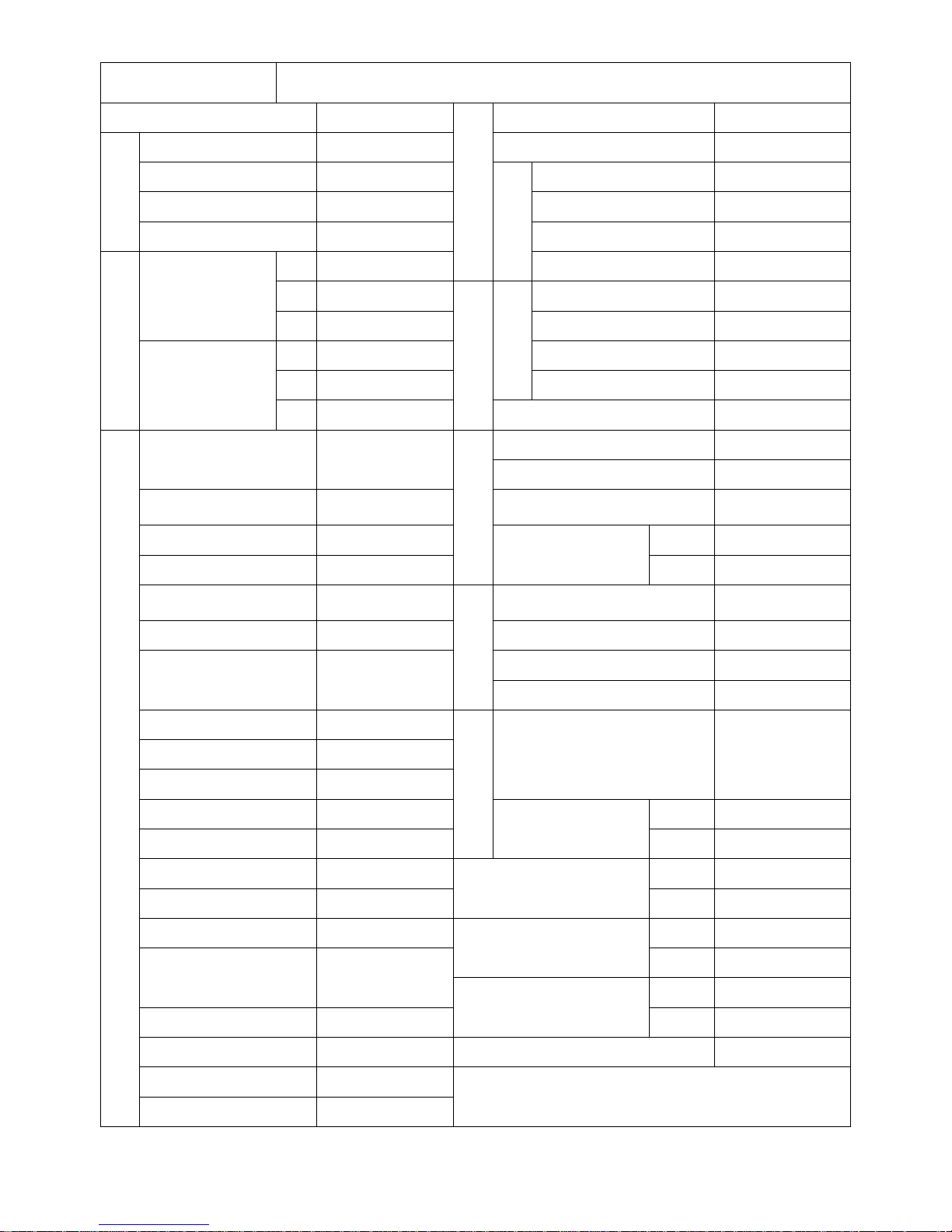

TABLE OF CONTENTS

1. GENERAL INFORMATION

PAGE

1-1 SPECIFICATIONS

3

1-2 INSPECTION PRECAUTIONS

1-3 SAFETY PRECAUTIONS

1-4 SPECIAL TOOLS

1-5 TIGHTENING TORQUE

1-6 LUBRICATION POINTS

1-7 PARTS NAME

1-8 TROUBLE SHOOTING

1-8-1 Troubleshooting for Failure in Starting the Engine

1-8-2 Troubleshooting for Poor skip of Spark Plugs

1-8-3 Troubleshooting for No-Skip of Spark Plugs

1-8-4 Troubleshooting for Slow Run (Troubled Engine

1-8-5 Poor Acseleration and Horse Power

10

11

12

14

16

18

19

22

23

24

25

2.INSPECTION AND ADJUSTMENT

2-1 REGULAR MAINTENANCE SCHEDULE

2-2 INSPECTION AND CHANGE OF ENGINE OIL

2-3 FINAL GEAR OIL

2-4 BRAKE SYSTEM

2-5 TIRE AND TIRE PRESSURE

2-6 AIR CLEANER

2-7 BATTERY

2-8 SPARK PLUG

2-9 FUEL FILTER

2-10 CARBURETOR IDLE SPEED

2-11 THROTTLE VALVE

2-12 VALVE

2-13 HEADLIGHT AXLE

2-14 V BELT

2-15 CYLINDER PRESSUR

27

28

29

30

35

35

36

37

37

38

38

39

40

40

42

3. REMOVAL AND INSTALLATION OF ENGINE

3-1 STANDANTD PREPARATION DATA&SIMPLIFIED

TROUBLESHOOTING

3-2 RELEASE THE ENGINE

3-3 INSTALLATION OF THE ENGINE

3-4 CHECK THE ENGINE PARTS

43

45

45

45

2

3-5 FUEL FEED CIRCUIT

3-6 LUBRICATION

3-7 DRIVING PULLY-CLUTCH-DTIVEN PULLEY

3-8 STARTER ARM

54

59

60

67

4. CHASSIS

4-1 REMOVAL OF COVER

4-2 TROUBLESHOOTING OF CHASSIS

4-3 FRONT WHEEL

4-4 REAR WHEEL

4-5 REAR SHOCK ABSORBER

70

72

76

78

80

5. ELECTRICAL SYSTEM

5-1 OPERATING CAUTIONS & TROUBLESHOOTING

5-2 BATTERY

5-3 SHORT CIRCUIT TEST

5-4 RECTIFIER

5-5 STARTER RELAY

5-6 STARTER MOTOR

5-7 A.C. GENERATOR

5-8 RESISTOR

5-9 CDI UNIT

APPENDIX

CIRCUIT DIAGRAM FOR BR8

81

86

87

87

88

90

92

94

95

98

3

1. GENERAL INFORMATION

1-1.SPECIFICATIONS

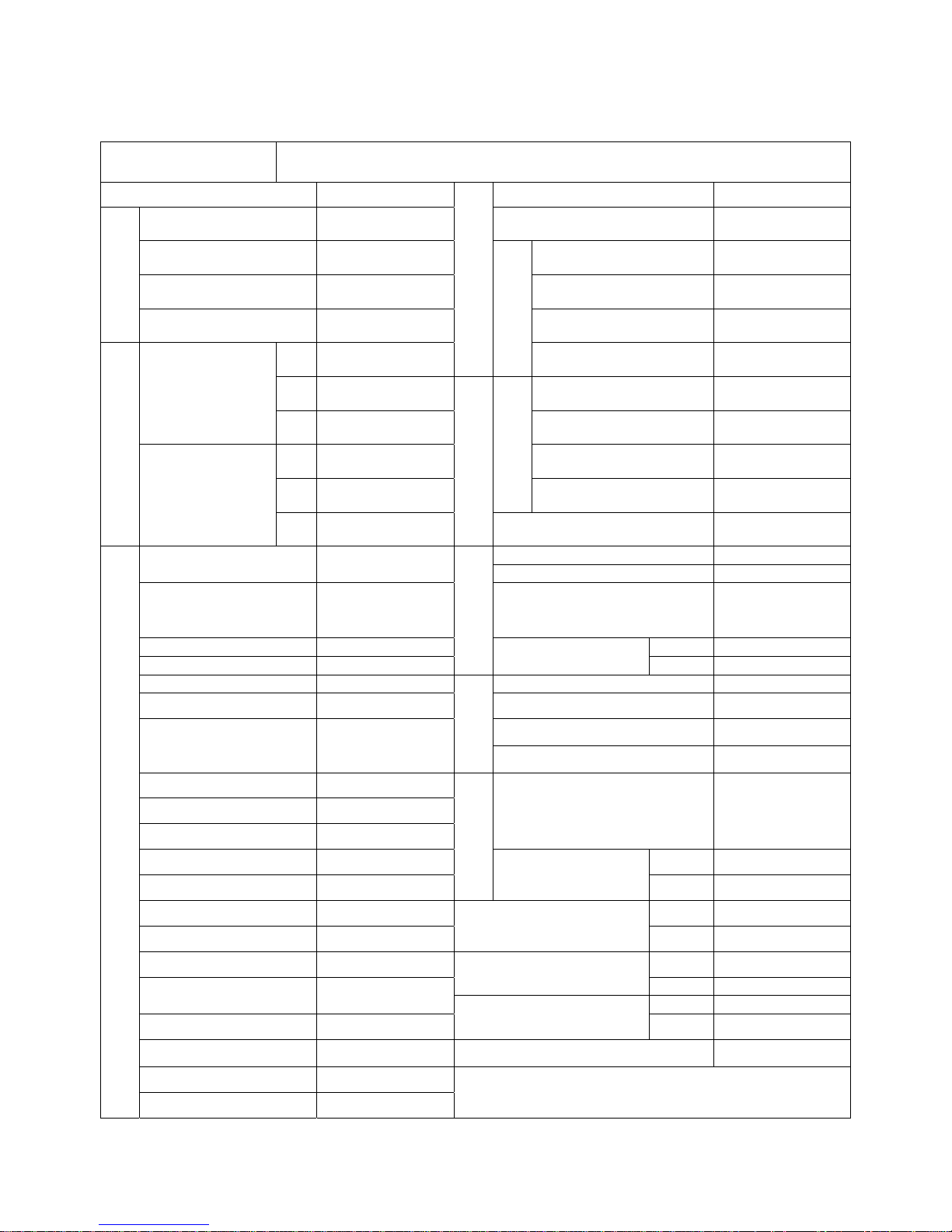

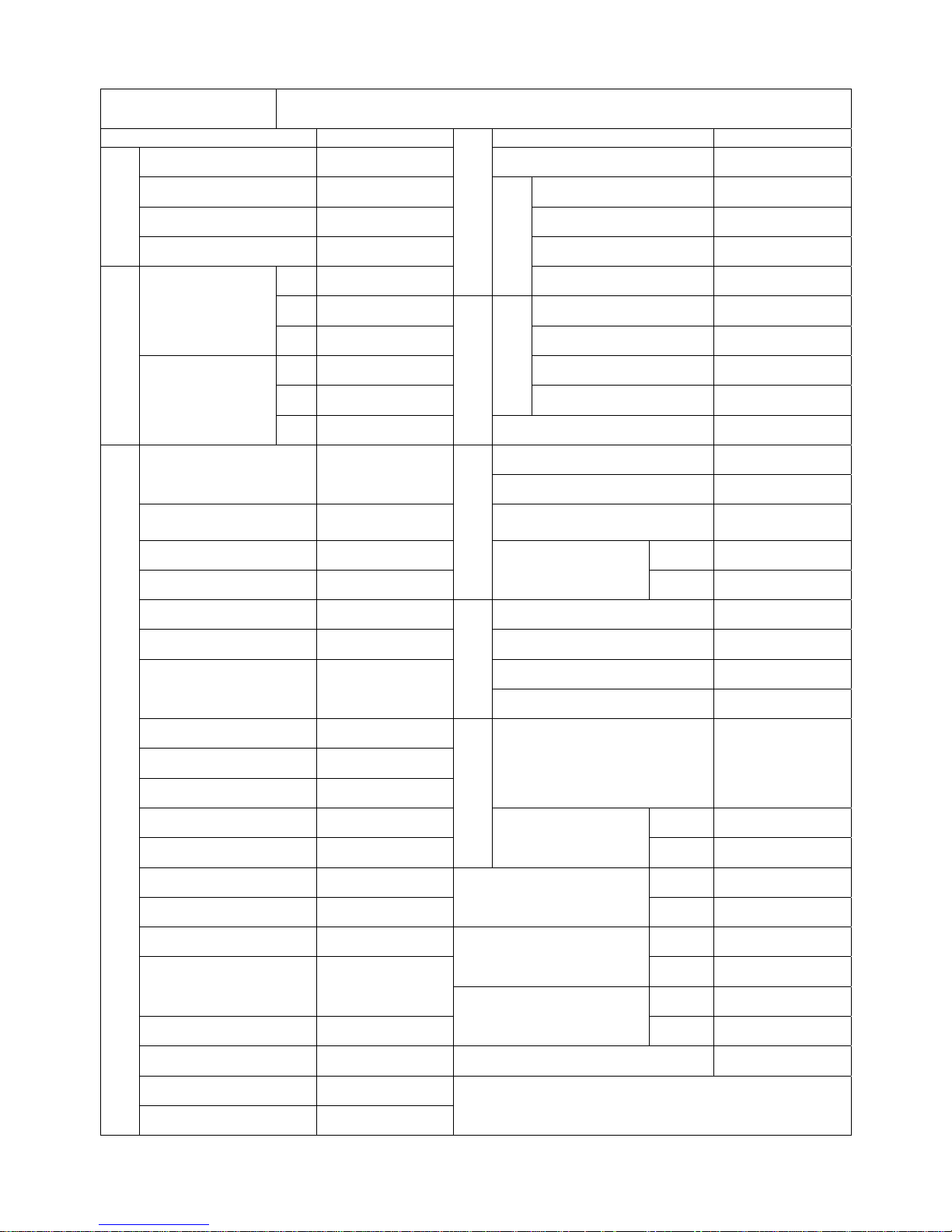

BR8 PRODUCT SPECIFICATION

MODE BR8 AIR CLEANER TYPE PAPER FILTER

TOTAL LENGTH (mm) 1860 FUEL TANK (ℓ) 6.8

TOTAL WIDTH (mm) 675 TYPE CVK

TOTAL HEIGHT (mm) 1145 THROTTLE VALVE DIA. (㎜) 24

DIMENSION

WHEEL BASE (mm) 1270 VENTURI DIA. (㎜) 22.1

FRONT 43

FUEL SYSTEM

CARBURETOR

THROTTLE VALVE TYPE BUTTERFLY

REAR 68 TYPE C.D.I.

DRY WEIGHT (kg)

TOTAL 111 SPARK ADVANCE BTDC 13°/ 2950rpm

FRONT 72 SPARK PLUG NGK CR7HSA

REAR 114

IGNITION

SPARK PLUG GAP (㎜) 0.6~0.7

WEIGHT

TOTAL WEIGHT (kg)

1 PERSON (75kg)

TOTAL 186

ELECTRIC SYSTEM

BATTERY 12V 7AH

PRIMA TRANSM. C.V.T.

TYPE 4T

SECONDARY TRANSM. GEAR

FUEL TYPE

92/95 UNLEADED

GASOLINE

CLUTCH TYPE

CENTRIFUGAL

TYPE

CYLINDER NO. SINGLE PRIMA 1/0.90~2.40

BORE ∗ STORKE (mm) 52.4 ∗ 57.8

TRANSMISSION

REDUCTION RATIO

SECOND

1/9.45 (14/43×13/40)

DISPLACEMENT (c.c.) 124 HEAD LAMP (H / L) 12V 35W/35W×1

STARTER ELECTRIC&KICK REAR LAMP 12V 5W×1

BRAKE LAMP 12V 21W×1

COOLING

FORCED AIR

COOLING

LAMP

TURN LAMP 12V 10W×4

LUBRICATION PUMP&SPLASH 130/60-13&130/60-13

INTAKE VALVE GAP (mm) 0.08~0.10 or120/70-12&130/70-12

EXHAUST VALVE GAP (mm) 0.08~0.10

FRONT&REAR

or120/70-12&120/70-12

TOP SPEED (km/hr) 90 FRONT 175

IDLING SPEED (rpm) 1800 ±100

TIRE

TIRE PRESSURE

(kPa)

REAR 210

MAX. TORQUE (N-m/rpm) 7.90 / 7800 LEFT 45

MAX. POWER (kW/rpm) 6.47 /7800

STEERING ANGLE ( °)

RIGHT 45

COMPRESSION RATIO 9.2:1 FRONT DISK

BRAKE

REAR DRUM

CYLINDER PRESSURE

(㎏/cm

2

– rpm)

12.8-570

FRONT TELESCOPE

ENGINE OIL TYPE SAE 10W - 40

SUSPENSION SYSTEM

REAR ROCKER ARM

ENGINE OIL QUANTITY (c.c.) 900 FRAME STEEL TUBE

GEAR OIL TYPE SAE 90#

ENGINE

GEAR OIL QUANTITY (c.c.) 120

4

BF8 PRODUCT SPECIFICATION

MODE BF8 AIR CLEANER TYPE PAPER FILTER

TOTAL LENGTH (mm) 1890 FUEL TANK (ℓ) 6.8&3.9

TOTAL WIDTH (mm) 715 TYPE CVK

TOTAL HEIGHT (mm) 1115 THROTTLE VALVE DIA. (㎜) 24

DIMENSION

WHEEL BASE (mm) 1280 VENTURI DIA. (㎜) 22.1

FRONT 47

FUEL SYSTEM

CARBURETOR

THROTTLE VALVE TYPE BUTTERFLY

REAR 68 TYPE C.D.I.

DRY WEIGHT (kg)

TOTAL 115 SPARK ADVANCE

BTDC 13°/ 2950rpm

FRONT 78 SPARK PLUG NGK CR7HSA

REAR 112

IGNIITION

SPARK PLUG GAP (㎜) 0.6~0.7

WEIGHT

TOTAL WEIGHT (kg)

I PERSON (75kg)

TOTAL 190

ELECTRIC SYSTEM

BATTERY 12V 7AH

PRIMA TRANSM. C.V.T.

TYPE 4T

SECONDARY TRANSM. GEAR

FUEL TYPE

92/95 UNLEADED

GASOLINE

CLUTCH TYPE

CENTRIFUGAL

TYPE

CYLINDER NO. SINGLE PRIMA 1/0.90~2.40

BORE ∗ STORKE (mm) 52.4 ∗ 57.8

TRANSMISSION

REDUCTION RATIO

SECOND

1/9.45 (14/43×13/40)

DISPLACEMENT (c.c.) 124 HEAD LAMP (H / L) 12V 35W/35W×1

STARTER ELECTRIC&KICK REAR LAMP 12V 5W×1

BRAKE LAMP 12V 21W×1

COOLING

FORCED AIR

COOLING

LAMP

TURN LAMP 12V 10W×4

LUBRICATION PUMP&SPLASH 130/60-13&130/60-13

INTAKE VALVE GAP (mm) 0.08~0.10 or120/70-12&130/70-12

EXAUST VALVE GAP (mm) 0.08~0.10

FRONT&REAR

or120/70-12&120/70-12

TOP SPEED (km/hr) 90 FRONT 175

IDLING SPEED (rpm) 1800 ±100

TIRE

TIRE PRESSURE

(kPa)

REAR 210

MAX. TORQUE (N-m/rpm) 7.90 / 7800 LEFT 45

MAX. POWER (kW/rpm) 6.47 /7800

STEERING ANGLE ( °)

RIGHT 45

COMPRESSION RATIO 9.2:1 FRONT DISK

BRAKE

REAR DRUM

CYLINDER PRESSURE

(㎏/cm

2

– rpm)

12.8-570

FRONT TELESCOPE

ENGINE OIL TYPE SAE 10W - 40

SUSPENSION SYSTEM

REAR ROCKER ARM

ENGINE OIL QUANTITY (c.c.) 900 FRAME STEEL TUBE

GEAR OIL TYPE SAE 90#

ENGINE

GEAR OIL QUANTITY (c.c.) 120

5

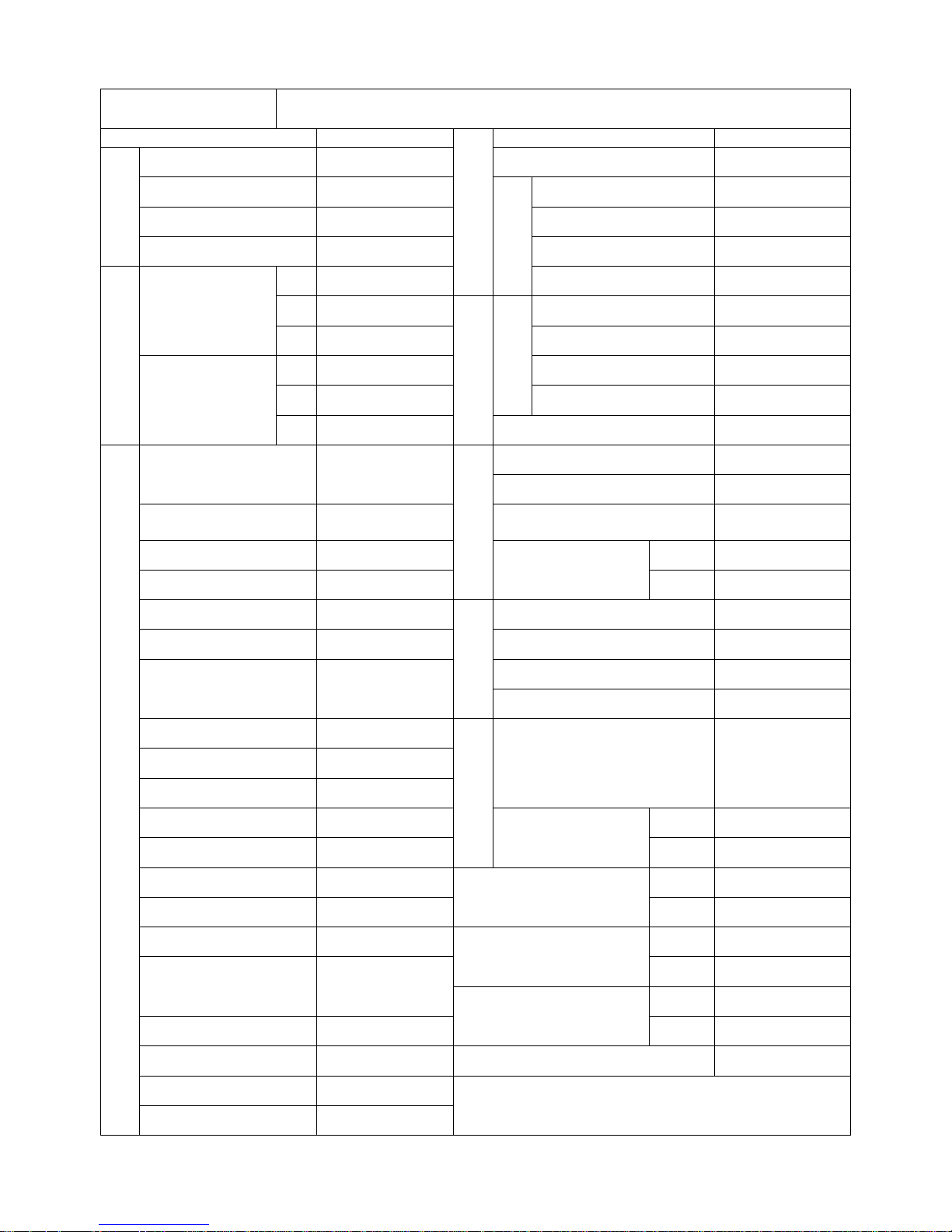

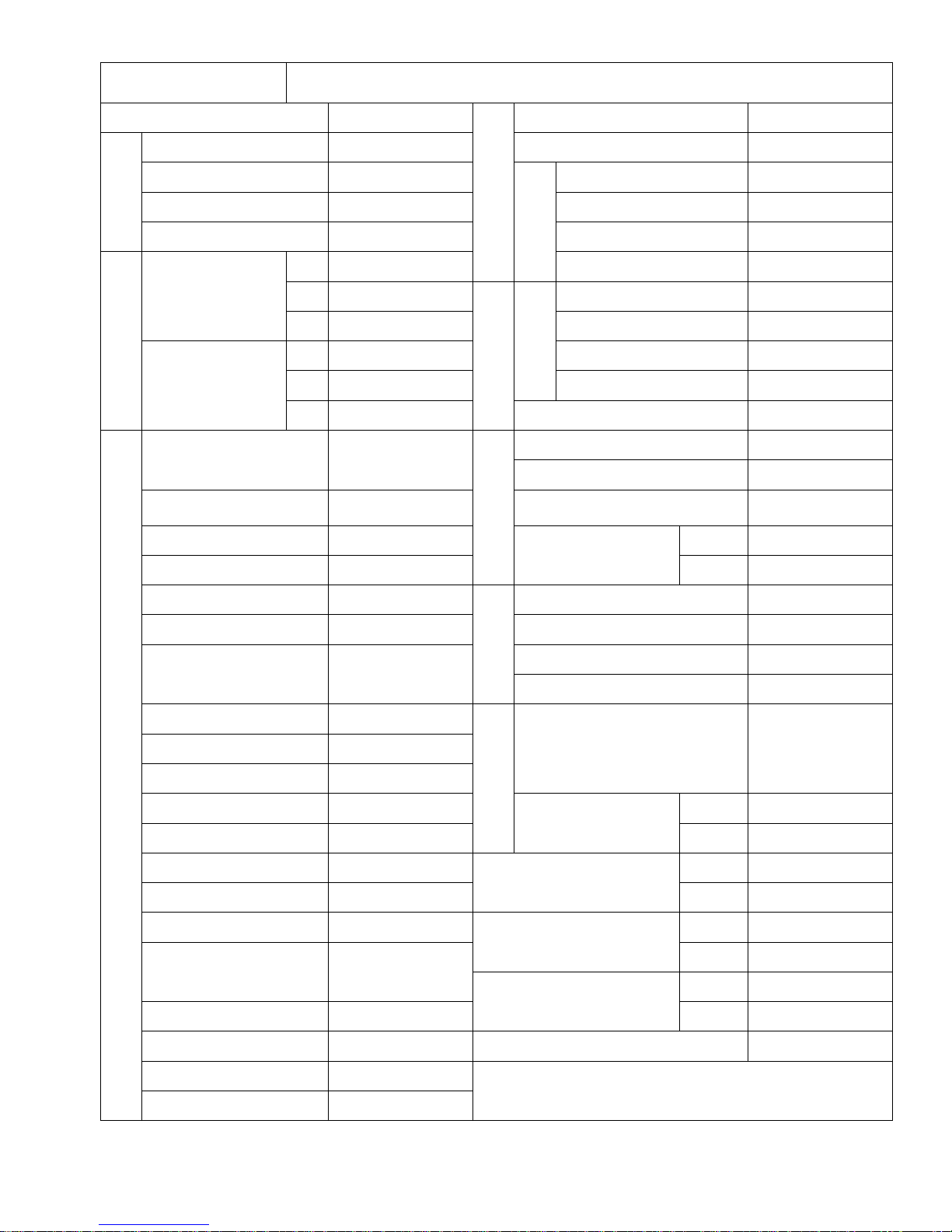

BR9 PRODUCT SPECIFICATION

MODE BR9 AIR CLEANER TYPE PAPER FILTER

TOTAL LENGTH (mm) 1860 FUEL TANK (ℓ) 6.8&3.9

TOTAL WIDTH (mm) 675 TYPE CVK

TOTAL HEIGHT (mm) 1145 THROTTLE VALVE DIA. (㎜) 26

DIMENSION

WHEEL BASE (mm) 1270 VENTURI DIA. (㎜) 23

FRONT 44

FUEL SYSTEM

CARBURETOR

THROTTLE VALVE TYPE BUTTERFLY

REAR 74 TYPE C.D.I.

DRY WEIGHT (kg)

TOTAL 118 SPARK ADVANCE BTDC 13°/ 2950rpm

FRONT 72 SPARK PLUG NGK CR7HSA

REAR 121

IGNIITION

SPARK PLUG GAP (㎜) 0.6~0.7

WEIGHT

TOTAL WEIGHT (kg)

I PERSON (75kg)

TOTAL 193

ELECTRIC SYSTEM

BATTERY 12V 7AH

PRIMA TRANSM. C.V.T.

TYPE

4T

SECONDARY TRANSM. GEAR

FUEL TYPE

92/95 UNLEADED

GASOLINE

CLUTCH TYPE

CENTRIFUGAL

TYPE

CYLINDER NO. SINGLE PRIMA 1/0.90~2.40

BORE ∗ STORKE (mm) 57.4 ∗ 58.4

TRANSMISSION

REDUCTION RATIO

SECOND

1/7.8 (15/42×14/39)

DISPLACEMENT (c.c.) 151 HEAD LAMP (H / L) 12V 35W/35W×1

STARTER ELECTRIC&KICK REAR LAMP 12V 5W×1

BRAKE LAMP 12V 21W×1

COOLING

FORCED AIR

COOLING

LAMP

TURN LAMP 12V 10W×4

LUBRICATION PUMP & SPLASH 130/60-13&130/60-13

INTAKE VALVE GAP (mm) 0.08~0.10 or120/70-12&130/70-12

EXAUST VALVE GAP (mm) 0.08~0.10

FRONT&REAR

or120/70-12&120/70-12

TOP SPEED (km/hr) 97 FRONT 175

IDLING SPEED (rpm) 1800 ±100

TIRE

TIRE PRESSURE

(kPa)

REAR 210

MAX. TORQUE (N-m/rpm) 11.14 / 6500 LEFT 45

MAX. POWER (kW/rpm) 7.89 /7250

STEERING ANGLE ( °)

RIGHT 45

COMPRESSION RATIO 10.8:1 FRONT DISK

BRAKE

REAR DRUM

CYLINDER PRESSURE

(㎏/cm

2

– rpm)

11.7-700

FRONT TELESCOPE

ENGINE OIL TYPE SAE 10W - 40

SUSPENSION SYSTEM

REAR ROCKER ARM

ENGINE OIL QUANTITY (c.c.) 1000 FRAME STEEL TUBE

GER OIL TYPE SAE 90#

ENGINE

GEAR OIL QUANTITY (c.c.) 120

6

BF9 PRODUCT SPECIFICATION

MODE BF9 AIR CLEANER TYPE PAPER FILTER

TOTAL LENGTH (mm) 1890 FUEL TANK (ℓ) 6.8&3.9

TOTAL WIDTH (mm) 715 TYPE CVK

TOTAL HEIGHT (mm) 1115 THROTTLE VALVE DIA. (㎜) 26

DIMENSION

WHEEL BASE (mm) 1280 VENTURI DIA. (㎜) 23

FRONT 48

FUEL SYSTEM

CARBURETOR

THROTTLE VALVE TYPE BUTTERFLY

REAR 76 TYPE C.D.I.

DRY WEIGHT (kg)

TOTAL 124 SPARK ADVANCE BTDC 13°/ 2950rpm

FRONT 77 SPARK PLUG NGK CR7HSA

REAR 122

IGNIITION

SPARK PLUG GAP (㎜) 0.6~0.7

WEIGHT

TOTAL WEIGHT (kg)

I PERSON (75kg)

TOTAL 199

ELECTRIC SYSTEM

BATTERY 12V 7AH

PRIMA TRANSM. C.V.T.

TYPE

4T

SECONDARY TRANSM. GEAR

FUEL TYPE

92/95 UNLEADED

GASOLINE

CLUTCH TYPE

CENTRIFUGAL

TYPE

CYLINDER NO. SINGLE PRIMA 1/0.90~2.40

BORE ∗ STORKE (mm) 57.4 ∗ 58.4

TRANSMISSION

REDUCTION RATIO

SECOND

1/7.8 (15/42×14/39)

DISPLACEMENT (c.c.) 151 HEAD LAMP (H / L) 12V 35W/35W×1

STARTER ELECTRIC&KICK REAR LAMP 12V 5W×1

BRAKE LAMP 12V 21W×1

COOLING

FORCED AIR

COOLING

LAMP

TURN LAMP 12V 10W×4

LUBRICATION PUMP&SPLASH 130/60-13&130/60-13

INTAKE VALVE GAP (mm) 0.08~0.10 or120/70-12&130/70-12

EXAUST VALVE GAP (mm) 0.08~0.10

FRONT&REAR

or120/70-12&120/70-12

TOP SPEED (km/hr) 97 FRONT 175

IDLING SPEED (rpm) 1800 ±100

TIRE

TIRE PRESSURE

(kPa)

REAR 210

MAX. TORQUE (N-m/rpm) 11.14 / 6500 LEFT 45

MAX. POWER (kW/rpm) 7.89 /7250

STEERING ANGLE ( °)

RIGHT 45

COMPRESSION RATIO 10.8:1 FRONT DISK

BRAKE

REAR DRUM

CYLINDER PRESSURE

(㎏/cm

2

– rpm)

11.7-700

FRONT TELESCOPE

ENGINE OIL TYPE SAE 10W - 40

SUSPENSION SYSTEM

REAR ROCKER ARM

ENGINE OIL QUANTITY (c.c.) 1000 FRAME STEEL TUBE

GEAR OIL TYPE SAE 90#

ENGINE

GEAR OIL QUANTITY (c.c.) 120

7

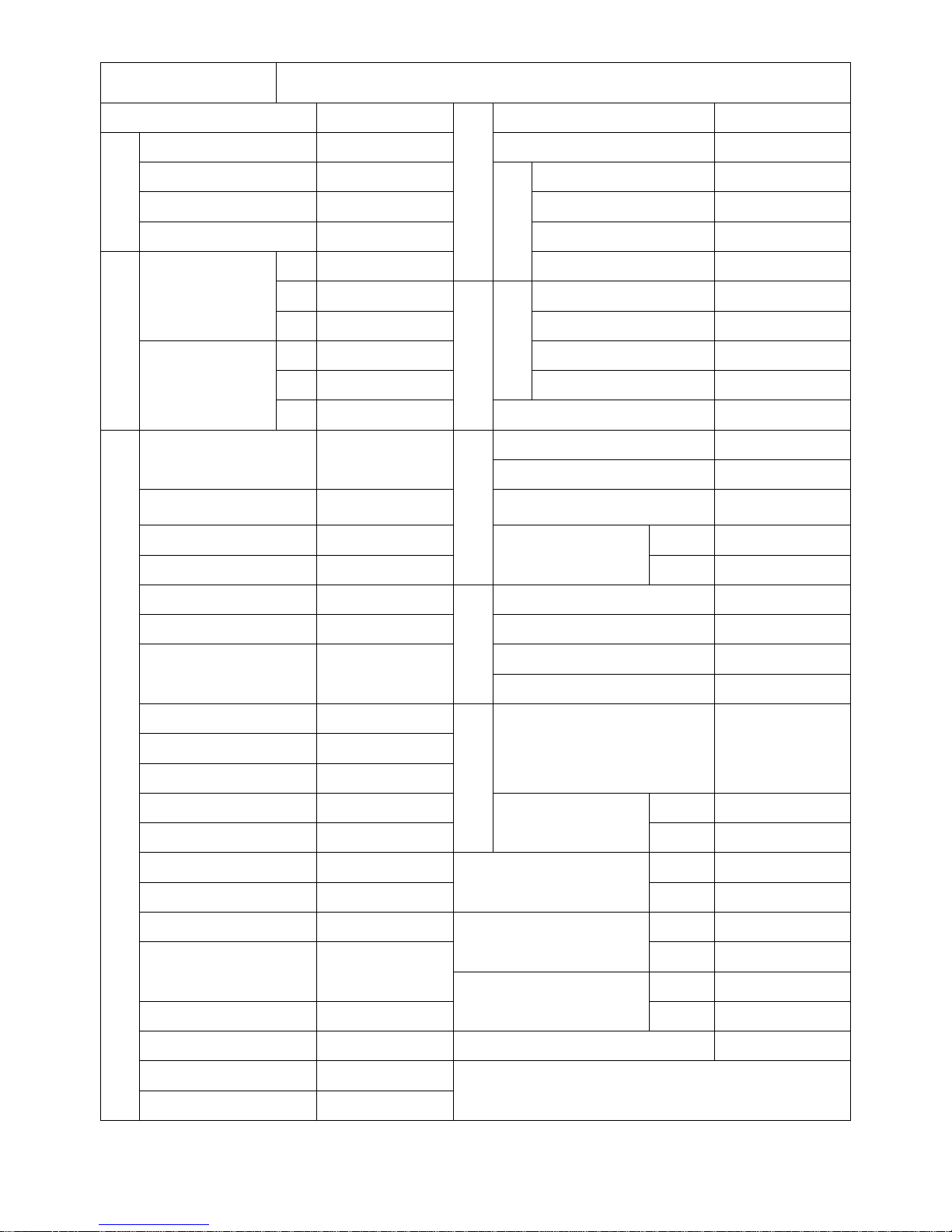

BH8 PRODUCT SPECIFICATION

MODE BH8 AIR CLEANER TYPE PAPER FILTER

TOTAL LENGTH (mm) 1790 FUEL TANK (ℓ) 6.8

TOTAL WIDTH (mm) 675 TYPE CVK

TOTAL HEIGHT (mm) 1080 THROTTLE VALVE DIA. (㎜) 24

DIMENSION

WHEEL BASE (mm 1240 VENTURI DIA. (㎜) 22.1

FRONT 35

FUEL SYSTEM

CARBURETOR

THROTTLE VALVE TYPE BUTTERFLY

REAR 58 TYPE C.D.I.

DRY WEIGHT (kg)

TOTAL 93 SPARK ADVANCE BTDC 13°/ 2950rpm

FRONT 63 SPARK PLUG NGK CR7HSA

REAR 105

IGNIITION

SPARK PLUG GAP (㎜) 0.6~0.7

WEIGHT

TOTAL WEIGHT (kg)

I PERSON (75kg)

TOTAL 168

LECTRIC SYSTEM

BATTERY 12V 7AH

PRIMA TRANSM. C.V.T.

TYPE 4T

SECONDARY TRANSM. GEAR

FUEL TYPE

92/95 UNLEADED

GASOLINE

CLUTCH TYPE

CENTRIFUGAL

TYPE

CYLINDER NO. SINGLE PRIMA 1/0.77~1/2.19

BORE ∗ STORKE (mm) 52.4 ∗ 57.8

TRANSMISSION

REDUCTION RATIO

SECOND

1/8.61 (15/42×13/40)

DISPLACEMENT (c.c.) 124 HEAD LAMP (H / L)

12V 35W/35W×1

or 18W /18W×2

STARTER ELECTRIC&KICK REAR LAMP 12V 5W×1

BRAKE LAMP 12V 21W×1

COOLING

FORCED AIR

COOLINE

LAMP

TURN LAMP 12V 10W×4

LUBRICATION PUMP&SPLASH

INTAKE VALVE GAP (mm) 0.08~0.10

EXAUST VALVE GAP (mm) 0.08~0.10

FRONT&REAR

120/90-10&110/90-10

TOP SPEED (km/hr) 87 FRONT 175

IDLING SPEED (rpm) 1800 ±100

TIRE

TIRE PRESSURE

(kPa)

REAR 210

MAX. TORQUE (N-m/rpm) 7.90 / 7800 LEFT 45

MAX. POWER (kW/rpm) 6.47 /7800

STEERING ANGLE ( °)

RIGHT 45

COMPRESSION RATIO 9.2:1 FRONT DISK

BRAKE

REAR DRUM

CYLINDER PRESSURE

(㎏/cm

2

– rpm)

12.8-570

FRONT TELESCOPE

ENGINE OIL TYPE SAE 10W - 40

SUSPENSION SYSTEM

REAR ROCKER ARM

ENGINE OIL QUANTITY (c.c.) 900 FRAME STEEL TUBE

GEAR OIL TYPE SAE 90#

ENGINE

GEAR OIL QUANTITY (c.c.) 110

8

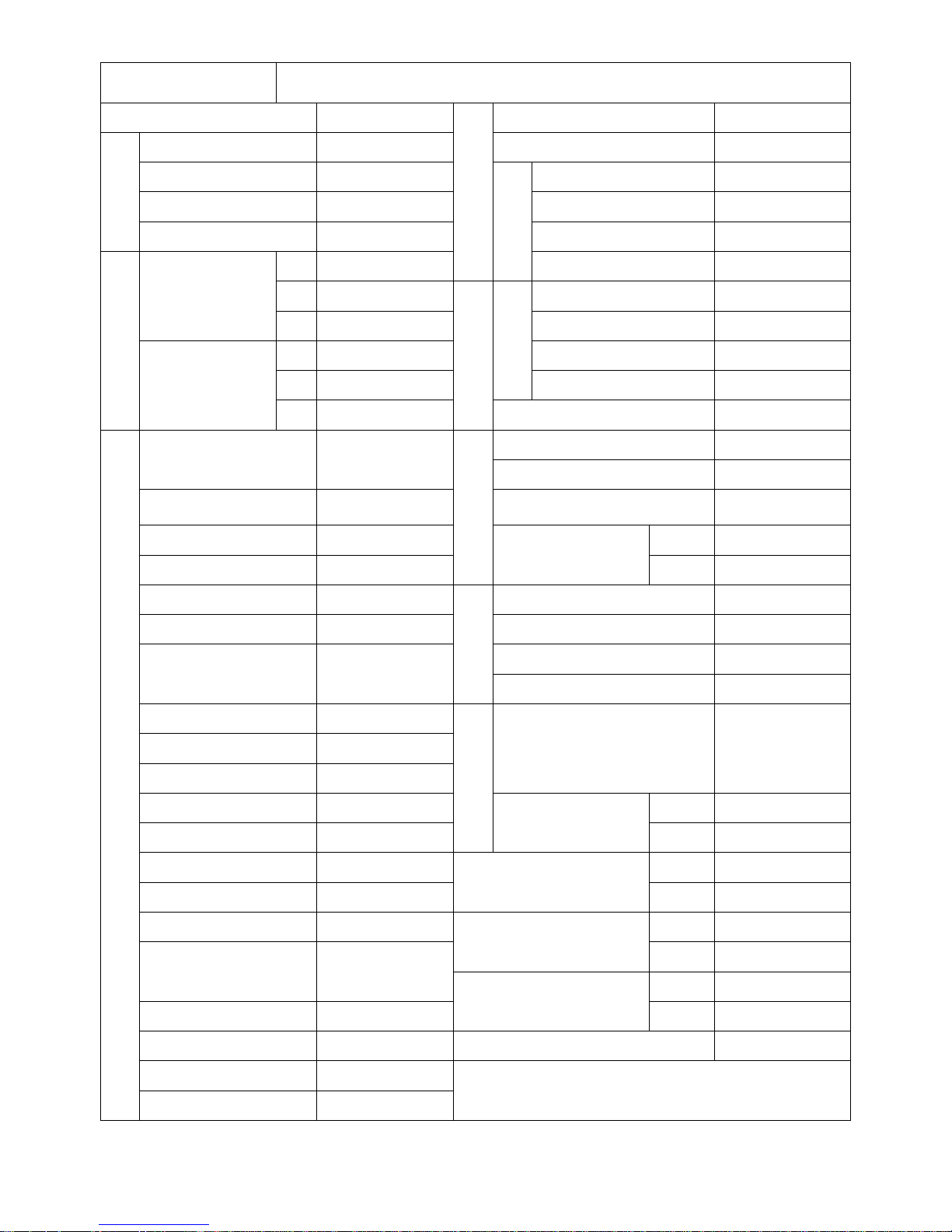

BK8 PRODUCT SPECIFICATION

MODE BK8 AIR CLEANER TYPE PAPER FILTER

TOTAL LENGTH (mm) 1880 FUEL TANK (ℓ) 6.8

TOTAL WIDTH (mm) 715 TYPE CVK

TOTAL HEIGHT (mm) 1160 THROTTLE VALVE DIA. (㎜) 24

DIMENSION

WHEEL BASE (mm) 1304 VENTURI DIA. (㎜) 22.1

FRONT 38

FUEL SYSTEM

CARBURETOR

THROTTLE VALVE TYPE BUTTERFLY

REAR 70 TYPE C.D.I.

DRY WEIGHT (kg)

TOTAL 108 SPARK ADVANCE

BTDC 13°/ 2950rpm

FRONT 64 SPARK PLUG NGK CR7HSA

REAR 119

IGNIITION

SPARK PLUG GAP (㎜) 0.6~0.7

WEIGHT

TOTAL WEIGHT (kg)

I PERSON (75kg)

TOTAL 183

ELECTRIC SYSTEM

BATTERY 12V 7AH

PRIMA TRANSM. C.V.T.

TYPE 4T

SECONDARY TRANSM. GEAR

FUEL TYPE

92/95 UNLEADED

GASOLINE

CLUTCH TYPE

CENTRIFUGAL

TYPE

CYLINDER NO. SINGLE PRIMA 1/0.90~2.40

BORE ∗ STORKE (mm) 52.4 ∗ 57.8

TRANSMISSION

REDUCTION RATIO

SECOND

1/9.45 (14/43×13/40)

DISPLACEMENT (c.c.) 124 HEAD LAMP (H / L) 12V 35W/35W×1

STARTER ELECTRIC & KICK REAR LAMP 12V 5W×1

BRAKE LAMP 12V 21W×1

COOLING

FORCED AIR

COOLING

LAMP

TURN LAMP 12V 10W×4

LUBRICATION PUMP & SPLASH 80/80-14 & 110/80-14

INTAKE VALVE GAP (mm) 0.08~0.10 or

EXAUST VALVE GAP (mm) 0.08~0.10

FRONT&REAR

110/80-14 & 110/80-14

TOP SPEED (km/hr) 90 FRONT 175

IDLING SPEED (rpm) 1800 ±100

TIRE

TIRE PRESSURE

(kPa)

REAR 210

MAX. TORQUE (N-m/rpm) 7.90 / 7800 LEFT 45

MAX. POWER (kW/rpm) 6.47 /7800

STEERING ANGLE ( °)

RIGHT 45

COMPRESSION RATIO 9.2:1 FRONT DISK

BRAKE

REAR DRUM

CYLINDER PRESSURE

(㎏/cm

2

– rpm)

12.8-570

FRONT TELESCOPE

ENGINE OIL TYPE SAE 10W - 40

SUSPENSION SYSTEM

REAR ROCKER ARM

ENGINE OIL QUANTITY (c.c.) 900 FRAME STEEL TUBE

GEAR OIL TYPE SAE 90#

ENGINE

GEAR OIL QUANTITY (c.c.) 120

9

BK9 PRODUCT SPECIFICATION

MODE BK9 AIR CLEANER TYPE PAPER FILTER

TOTAL LENGTH (mm) 1880 FUEL TANK (ℓ) 6.8 & 3.9

TOTAL WIDTH (mm) 715 TYPE CVK

TOTAL HEIGHT (mm) 1160 THROTTLE VALVE DIA. (㎜) 26

DIMENSION

WHEEL BASE (mm) 1340 VENTURI DIA. (㎜) 23

FRONT 39

FUEL SYSTEM

CARBURETOR

THROTTLE VALVE TYPE BUTTERFLY

REAR 71 TYPE C.D.I.

DRY WEIGHT (kg)

TOTAL 110 SPARK ADVANCE BTDC 13°/ 2950rpm

FRONT 65 SPARK PLUG NGK CR7HSA

REAR 120

IGNIITION

SPARK PLUG GAP (㎜) 0.6~0.7

WEIGHT

TOTAL WEIGHT (kg)

I PERSON (75kg)

TOTAL 185

ELECTRIC SYSTEM

BATTERY 12V 7AH

PRIMA TRANSM. C.V.T.

TYPE

4T

SECONDARY TRANSM. GEAR

FUEL TYPE

92/95 UNLEADED

GASOLINE

CLUTCH TYPE

CENTRIFUGAL

TYPE

CYLINDER NO. SINGLE PRIMA 1/0.90~2.40

BORE ∗ STORKE (mm) 57.4 ∗ 58.4

TRANSMISSION

REDUCTION RATIO

SECOND

1/7.8 (15/42×14/39)

DISPLACEMENT (c.c.) 151 HEAD LAMP (H / L) 12V 35W/35W×1

STARTER ELECTRIC&KICK REAR LAMP 12V 5W×1

BRAKE LAMP 12V 21W×1

COOLING

FORCED AIR

COOLING

LAMP

TURN LAMP 12V 10W×4

LUBRICATION PUMP&SPLASH 80/80-14 & 110/80-14

INTAKE VALVE GAP (mm) 0.08~0.10 or

EXAUST VALVE GAP (mm) 0.08~0.10

FRONT&REAR

110/80-14 & 110/80-14

TOP SPEED (km/hr) 97 FRONT 175

IDLING SPEED (rpm) 1800 ±100

TIRE

TIRE PRESSURE

(kPa)

REAR 210

MAX. TORQUE (N-m/rpm) 11.14 / 6500 LEFT 45

MAX. POWER (kW/rpm) 7.89 /7250

STEERING ANGLE ( °)

RIGHT 45

COMPRESSION RATIO 10.8:1 FRONT DISK

BRAKE

REAR DRUM

CYLINDER PRESSURE

(㎏/cm

2

– rpm)

11.7-700

FRONT TELESCOPE

ENGINE OIL TYPE SAE 10W - 40

SUSPENSION SYSTEM

REAR ROCKER ARM

ENGINE OIL QUANTITY (c.c.) 1000 FRAME STEEL TUBE

GEAR OIL TYPE SAE 90#

ENGINE

GEAR OIL QUANTITY (c.c.) 120

10

1-2 INSPECTION PRECAUTIONS

1. The measurements use IS system for bolts and bolt heads. Please do not

use British system for the bolts and nuts, otherwise it can damage the

motorcycle.

2. Please clean parts outside deposits before maintenance. Otherwise, the

deposits may drop into engine and damage engine in operation.

3. Please use kerosene or diesel to clean-up disassembled parts. Check

and measure parts after clean-up. The parts’ contact and sliding surface

should apply engine oil for lubrication.

4. The packing, metal gasket, O-ring, seal, clamp, and clipper should be

replaced with new ones after disassembly.

5. Please pay attention to the orientation and relative positions of the major

components. Arrange the parts in order during disassembly. Make

marks if necessary to avoid mistakes in re-assembly.

6. Loosing the parts should start from small to big, from outside to inside, and

in alternative parts. Assembly is in reverse order of disassembly

procedures.

7. The oil seals should be replaced with new ones after disassembly. The

contact surface should be cleaned-up. Check if the contact axle has

scratches or burry. Use special tools for assembly to avoid damaging

seal lip area, which may lead to oil leak. The manufacturer logo should

face outward in assembly. Apply grease at seal lip area.

8. Please do not presses, twist, and over scratch the wire cable to avoid bad

wire contact.

9. Disconnect the battery negative (-) terminal before maintenance.

Connect the positive (+) terminal first in assembly. Apply a thin layer of

grease on terminals, and cover with terminal caps.

11

1-3 SAFETY PRECAUTIONS

Warning: Engine Exhaust

Please keep good ventilation during engine operation. Do not operate engine in

closed-room. The toxic carbon-oxygen (CO) in exhaust may lead human to loss

conscious and even death.

Warning: Gasoline

The gasoline is very easy to burn or explode. Forbid any fire during inspection of

gasoline tank or gasoline leak.

Warning: Battery H

2

and Battery Liquid

1. The battery liquid is toxic sodium liquid. Please do not contact the liquid with

skin or eye. If any contact happens, please wash with massive clean water

and contact with doctor.

2. The released H

2

from battery is explosive. Please keep good ventilation

during charging battery and forbid any fire.

Watch: Brake Fluid

The brake fluid can damage the painting on plastic. Please cover the plastic parts

with towel or cloth during maintenance of brake disk. If the brake fluid is split on

plastic component, please remove the fluid and wash the surface with water right

away.

Watch: High Temperature of Engine

The engine cover, cylinder, and exhaust pipe have high temperature after starting

of engine. Please wear glove in maintenance of parts during engine operation, or

maintenance should be waited until engine is cooled.

12

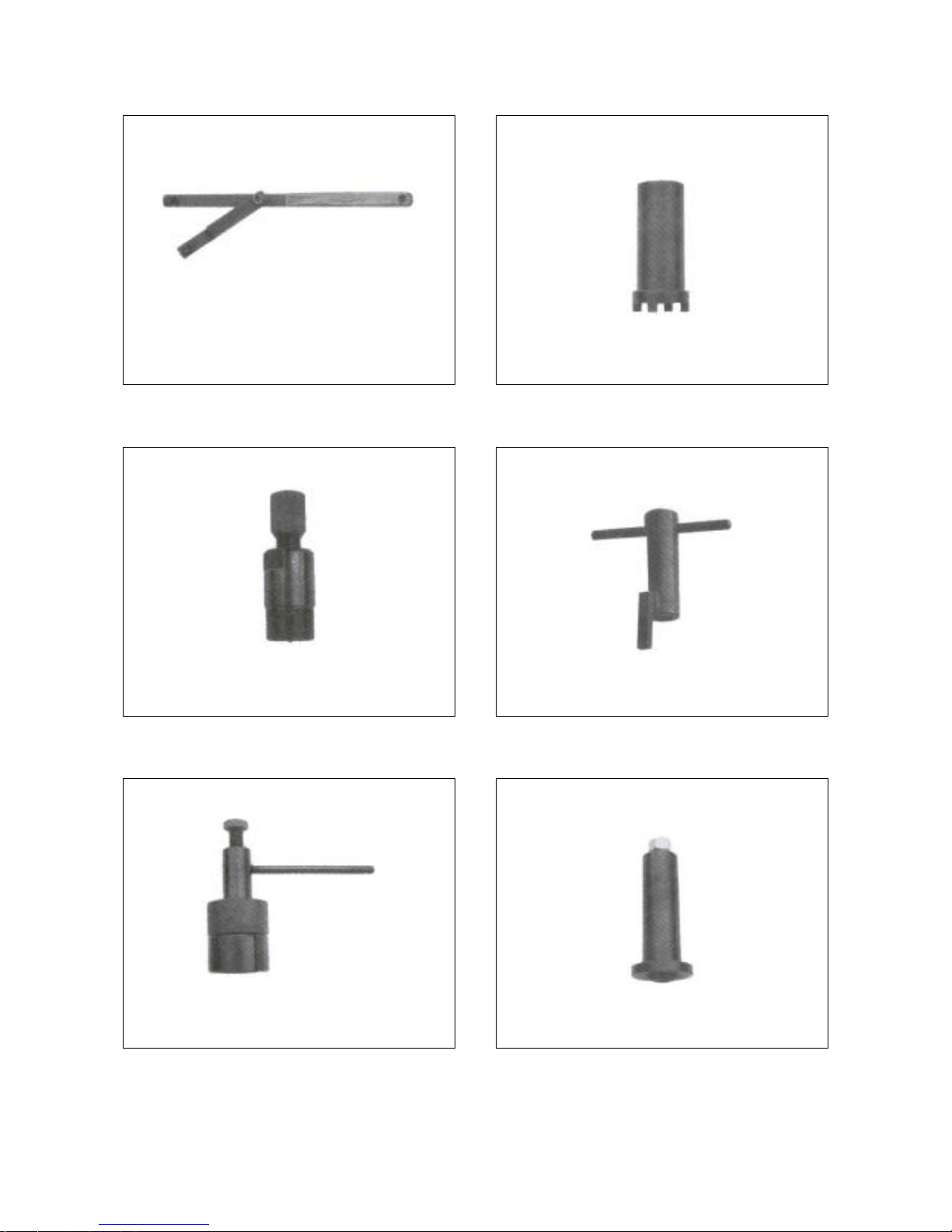

1-4 SPECIAL TOOLS

Universal Wrench 440601

Hold for removing flywheel.

Hold for removing belt driver pulley.

Hold for removing belt driven pulley.

Four Legs Sleeve 440604

Used for removing starter clutch

gear lock nut.

Flywheel Remover 440602

Used for removing flywheel.

Starter Spring Assembly Tool

440605

Used for starter spring assembly.

Gear Remover 440603

Used for removing starter driven

gear.

Crank Shaft & Right Hand Crank

Case 440606

To draw the crank shaft into the

right hand crank case.

13

Inner Chain Wrench 440607

For disassembly the camshaft inner

chain.

Bush Remover 440610

For removing the crankcase

suspension bush.

Socket of Valve Adjusting Bolt

440608

Adjust the clearance of valve stem

and rock arm.

Fixing Nut Socket 440611

Used for removing steering shaft

nut.

Valve Cotter Tool 440609

For assembling valve cotter

14

1-5 TIGHTENING TORQUE

*BR8 Representative Figure*

*Standard Torque Values of Bolts and Nuts *

Specification

T orque (kg-cm) Specification Torque (kg-cm)

5 mm Bolt and Nut 40 8 mm Bolt and Nut 220

5 mm Flange Bolt and Nut 50 8 mm Flange Bolt and Nut 270

6 mm Bolt and Nut 100 10 mm Bolt and Nut 350

6 mm Flange Bolt and Nut 120 10 mm Flange Bolt and Nut 400

6 mm SH Bolt and Nut 90 12 mm Bolt and Nut 550

* Torque Values of Chassis Components *

No. Tightening Location Specification Torque

(kg-cm)

1 Front Wheel Axle Self-lock Nut M12 500~600

2 Brake Disk Hex Bolt M5 180~280

3 Brake Clipper Tightening Bolt M8x35 210~250

4 Speed Meter Cable Nut X 60

5 Front Fork Bearing Tightening Nut M25x1.0 600~650

6 Rear Wheel Axle Self-lock Nut M16x10 600~900

7 Rear Brake Connecting Rod Bolt M16x32 50~80

8 Rear Brake Pin Self-lock Nut M8 250~270

9 Rear Upper Cushion Tightening Bolt M10×46 200~300

10 Rear Lower Cushion Tightening Bolt M8×35 200~300

15

* Torque Values of Engine components *

Tightening Location Specification Torque Quantities

(kg-cm)

Cylinder Head Bolt M6 80~100 4

Cylinder Stud Bolt M8x182.5 500~800 2

M8x195.5 2

Cylinder Intake Pipe Stud Bolt M6x50 500~800 2

Muffler and Exhaust Pipe Tightening Screw M6 100~120 2

Muffler & Right Crankcase Upper Tightening Screw M8x42 300~400 1

Muffler & Right Crankcase Lower Tightening Screw M8x38 300~400 1

Spark Plug M10 100~120 1

Valve Gap Adjust Lock Bolt M5 50~90 2

Fuel Filter Nut Cap M30 150~200 1

Cooler Fan Lock CR M6x18 500~800 4

Wire Assembly Lock Screw M6x20 800~1000 2

Start Clutch Gear ightening Nut M22 (R.T.) 800~1000 1

Driven Belt Pully Assembly M12 400~600 1

Gearbox Cover Tightening Bolt M6x28 100~1200 3

M6x35 3

Gearbox Oil Fill Cover Screw M8 90~150 1

Gearbox Oil Drain Cover Screw M8x12 90~150 1

Clutch Side Cover Screw M6x40 50~80 6

M6x65 2

Starter Arm Tightening Screw M6x22 100~120 1

16

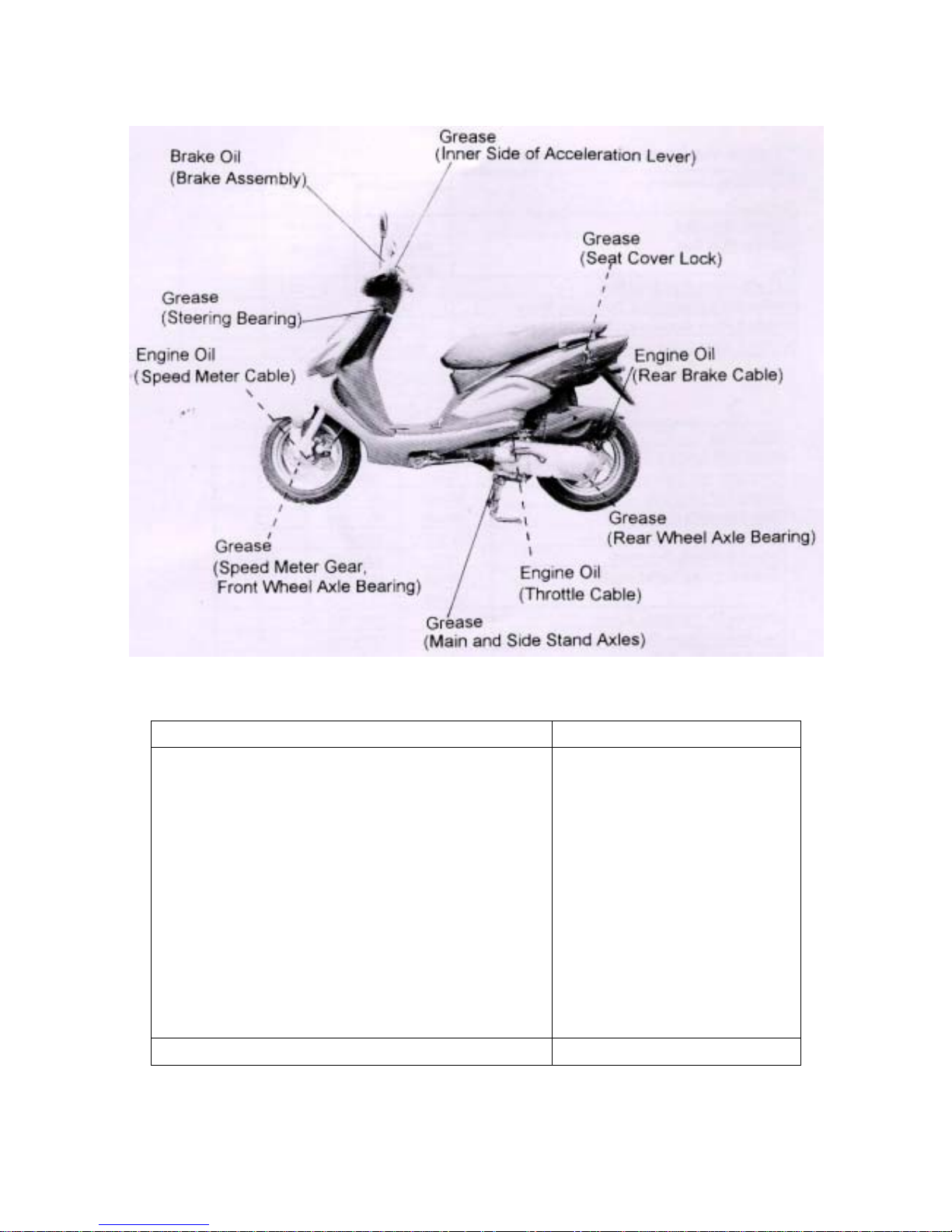

1-6 LUBRICATION POINTS

*BR8 Representative Figure*

* Chassis *

Lubrication Area Lubrication Type

Inner Side of Acceleration Lever Grease

Steering Bearing

Speed Meter Gear

Front Wheel Axle Bearing

Front Wheel Axle

Main and Side Stand Axles

Rear Wheel Bearing

Seat Cover Lock

Speed Meter Cable

Throttle Wire

Rear Brake Cable

Brake Assembly Brake Fluid

17

* Engine *

Lubrication Area Lubrication Type

Piston and Piston Rings

Piston Pin

Big End of Connecting Rod

Rocker Arm Frictional Contact Area

Cam Shaft and Chain

Cylinder Frictional Area

Oil Pump Chain

Gears Contact Surface

Bearing Operation Area

O Rings

Seal Lip Area

Satisfy SAE 10W-40 and API SE,SG Engine Oil

Starter Frictional Surface

Starting Cam Gear

Spring Operation Frictional Area

High Temperature Durable Grease

Generator Connector

Gearbox Ventilation Tube

Adhesives

18

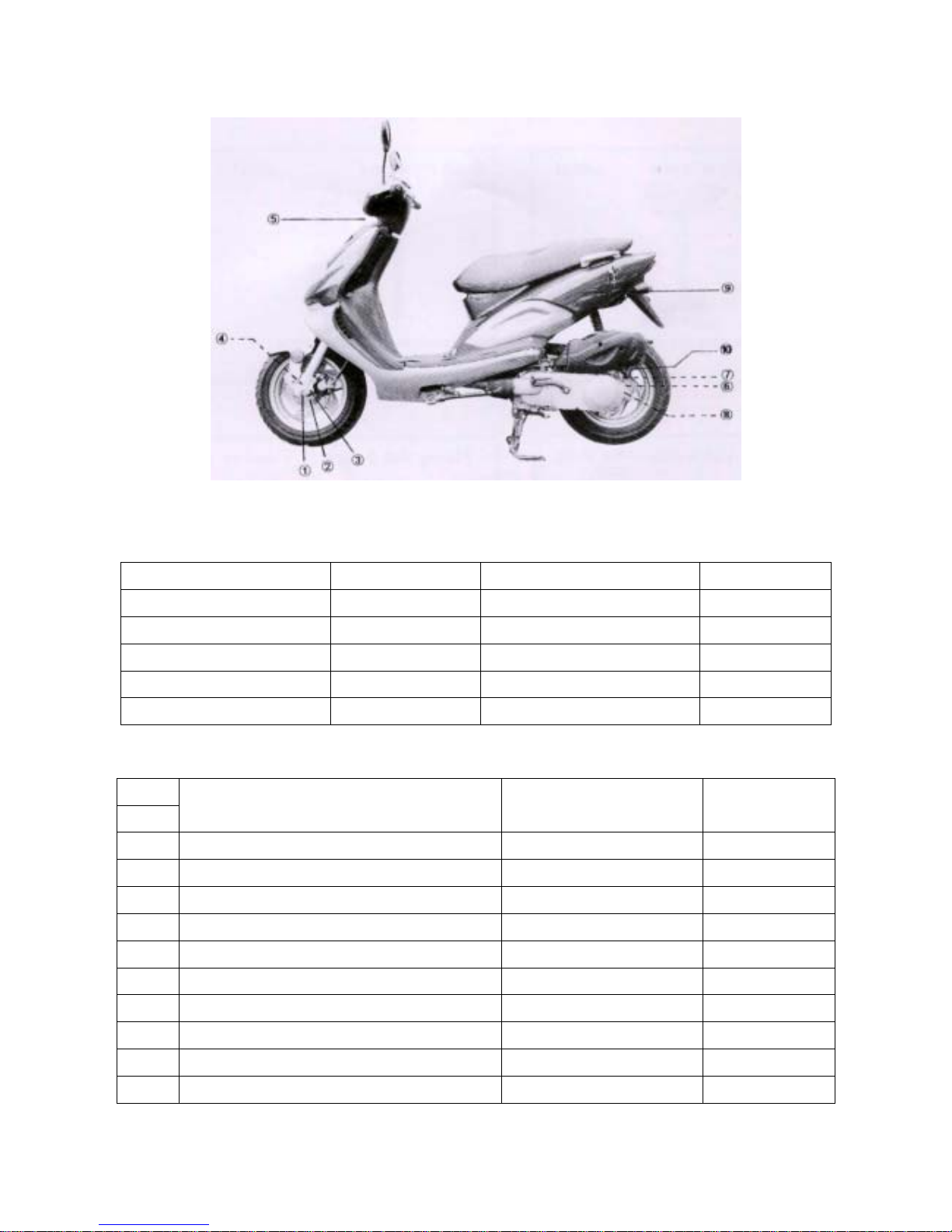

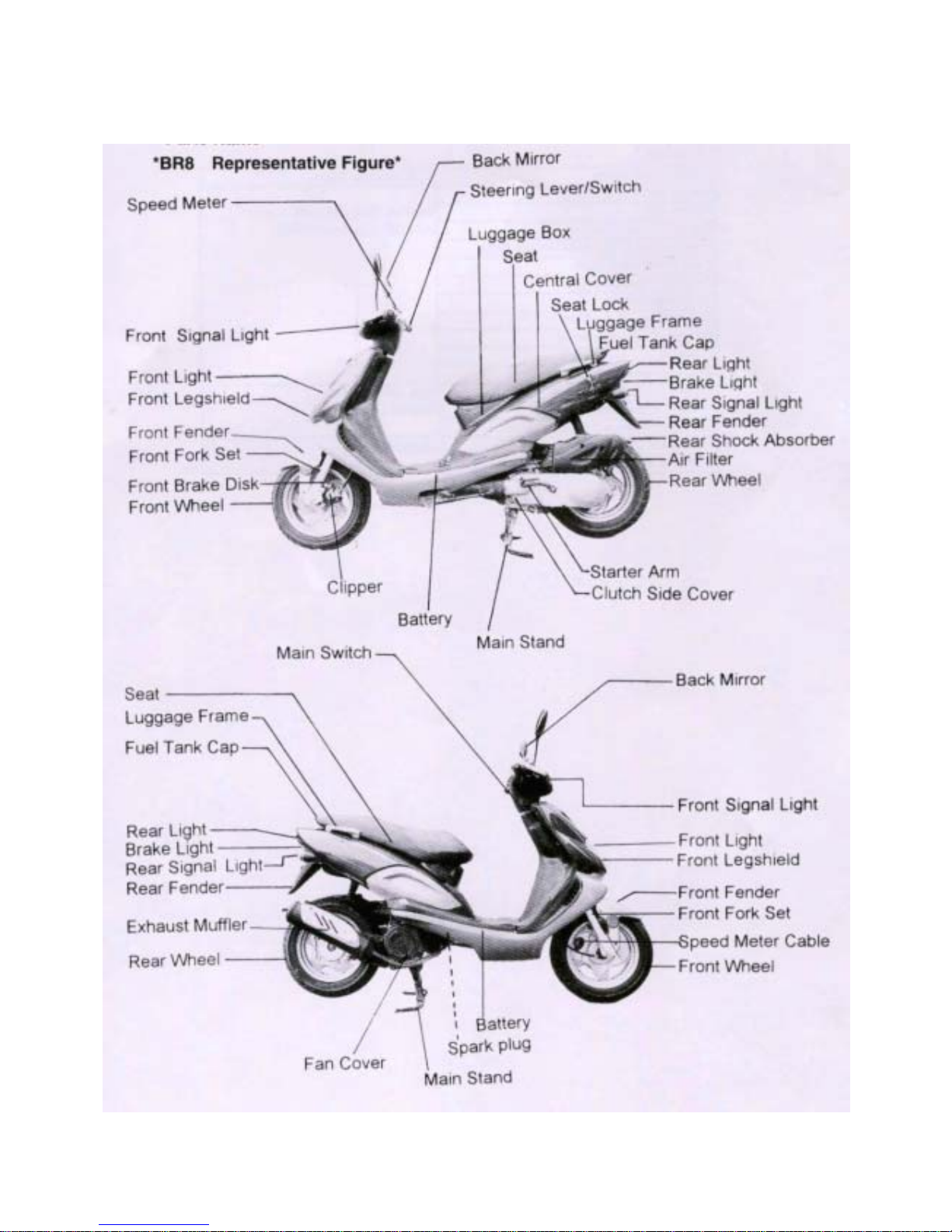

1-7 PARTS NAME AND WIRING DIAGRAM

* Parts Name *

*BR8 Representative Figure*

19

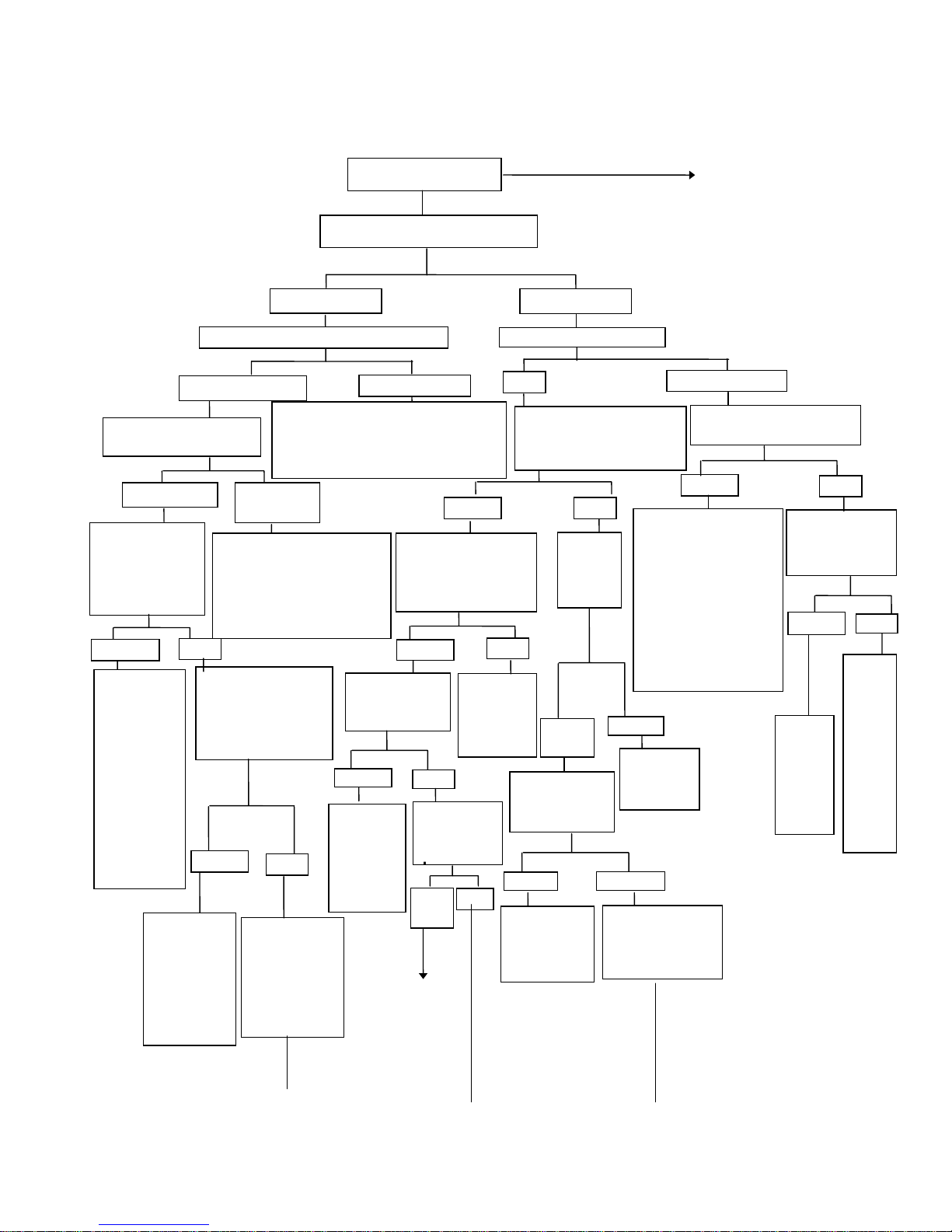

1-8 TROUBLE SHOOTING

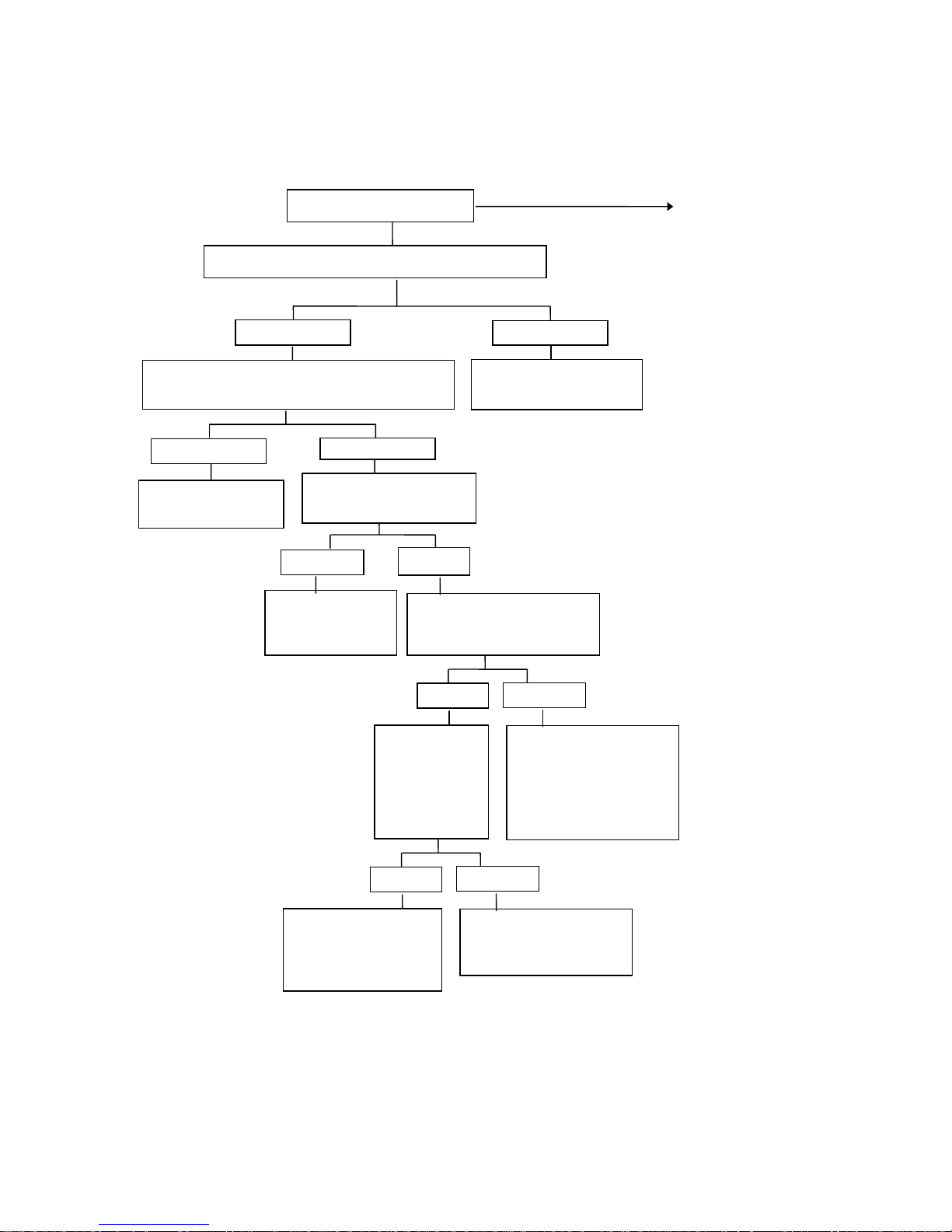

1-8-1 Troubleshooting for failure in starting the engine

b

a c

Does not work

Works

Check if the battery is

properly charged

Check if the starting gear and the

speeding clutch of the starting

motor suffer critical wear, if yes,

replace them

Bright light

Dim light or

light off

Check the

solenoid switch

of the starting

motor for noise

during work

Charge the battery or

replace it. In case of poor

charging, in addition to

recharging, check the

charging system of the

p

ower plant for failure.

No noise

Noise

a. Poor

contact of

starting

switch

b. Starting

relay

breaks or

in short

circuit

c. Loose

contact or

wiring

Check the starting

gear and speeding

gear of the starting

motor for abnormal

engagement.

Poor

Fai

r

Correct the

engagement

of the

starting

motor with

the speeding

clutch.

Replacement

of new

starting motor

and check for

work.

Engine does not start

Analysis of potential causes

Check if the crank shaft works

Does not work

works

Check if the starting motor works

Poor (too slow

)

Fai

r

Check battery charging

and contact of pins

Loosen the carburetor

leakage screw to check

for inlet of fuel.

Fai

r

Poo

r

Check for existence

of water or other

impurities in the

carburetor buoyant

Check

for fuel

in the

fuel tank

Fai

r

Poo

r

Check for fuel

spill in the

carburetor

Clean the

carburetor

and the

fuel filter

Poor

Fair

Repair or

replace

new

buoyant

and needle

valve

Check skips

in spark

No

skip

Ski

p

Refer to

1-8-3 No Skip

in Spark

Plugs for

checking

Poor

Fai

r

Recharge the battery

and be sure the pin is

properly secured.(In

case of poor

charging, proceed

with a new charging

and check the

charging system of

the power plant for

failure.

)

Check the

starting motor

and the switch

Poo

r

Fair

Repair

or

replace

with

new

ones

Check

the

engine

inside

(piston,

bearing

and

others)

for

failure

With

fuel

No fuel

Check the fuel

filter and the

tubing

Add in

designated

fuel

Poo

r

Fair

Clean fuel

filter and fuel

tubing or

replacement

Check fuel tank

ventilation

tubing for

obstruction

See page 17

20

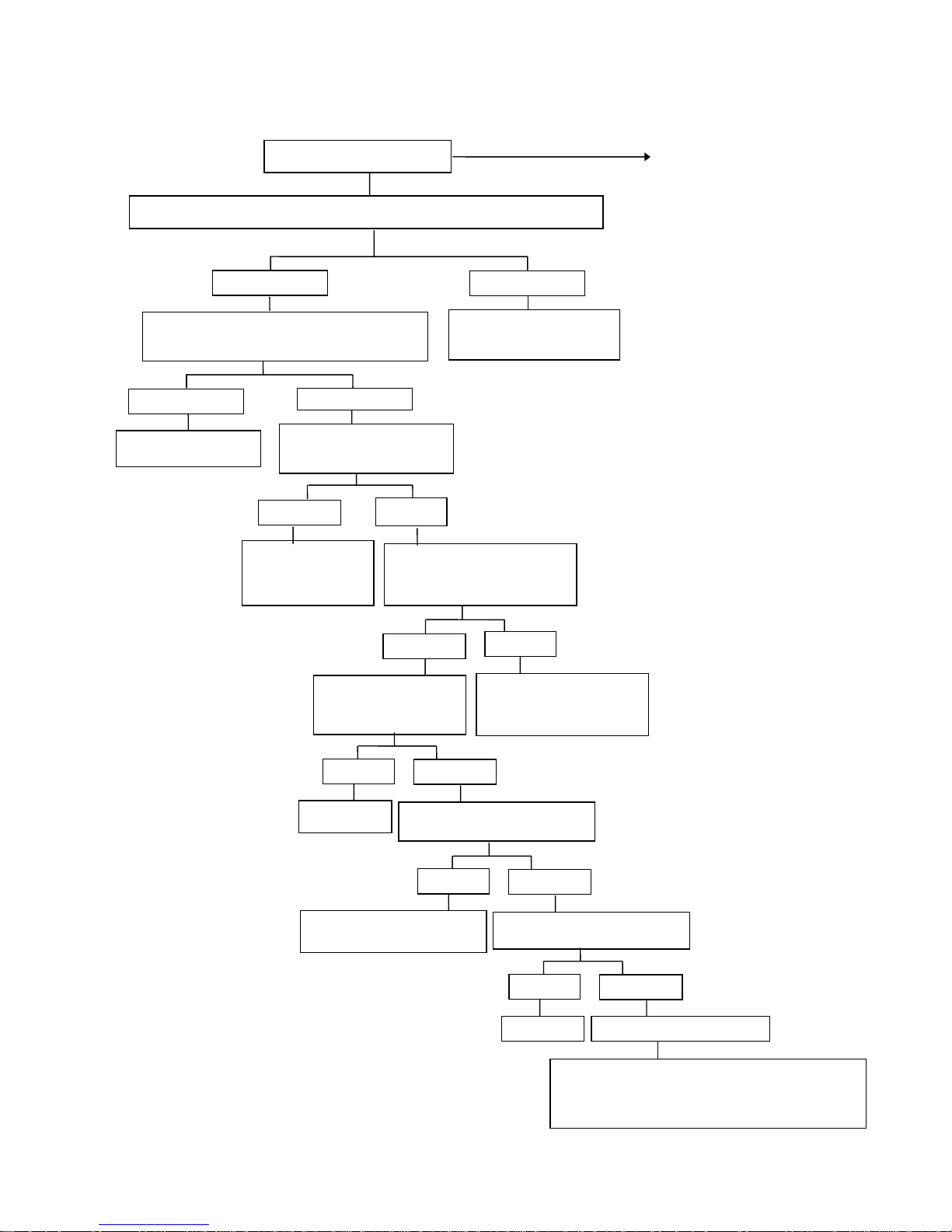

a

c

b

Poor

Fair

Check engine

pistons,

bearings and

others

Replace the

original

starting motor

or repair it.

Check spark plug for cleanliness,

normal gap, pollution by gasoline. If

yes, check the choke of the

carburetor

Fai

r

Poo

r

Clean and adjust

spark plug gap or

replace with new

ones

Poo

r

Fai

r

Refer to

1-8-2 Poor

skip in

Spark

Plugs for

checking

Check if the

adjustment

screws of the

carburetor need to

be regulated

Poo

r

Fai

r

Test the

compression

Clean or replace the slow

nozzle or correct, replace

with new threshold

Check choke of

the carburetor

for troubles

Readjustment

Poo

r

Fai

r

Adjust or

replace new

choke parts

Check if the slop

nozzle of the

carburetor is

obstructed or the

threshold fails

Poo

r

Fair

Check air filter grill

for obstruction

Check cylinder washer for leakage,

check cylinder, piston, piston ring

for wear, with correction,

adjustment or replacement

Poor

skip

Fair

skip

Poo

r

Fair

Clean

ventilation

tubing

Adjustment or

replacement of

carburetor buoyant

needle valve

21

z No fuel

z Dirty fuel filter

z Obstructed fuel tubing

z Obstructed ventilation tubing of the fuel tank

z Poor carburetor buoyant needle valve

z Carburetor buoyant with impurities

z Poor carburetor buoyant

z No skip in spark plugs

z Poor skip in spark plugs

z Dirty spark plugs

z Incorrect spark plugs gap

z Dirty and wet spark plugs

z Loose adjustment screws in the carburetor

z Carburetor choke

z Obstructed carburetor slow nozzle

z Ailing carburetor threshold

z Obstructed air filter grill

z Leakage in cylinder washer

z Seriously damaged cylinder, piston, piston

z Dead battery

z Poor contact of battery pin and conductors

z Starting switch with poor or failure

z Starting relay with broken wire or short circuit

z Loose contact and wiring

z Starting gear and speeding clutch gear seriously worn

z Starting gear and speeding clutch gear in poor engagement

z Poor starting motor

22

1-8-2 Troubleshooting for poor skip of spark plugs

Poor skip of spark plugs

Analysis of potential causes

Check for spark plug cap, ignition coil

Normal

Loose

Replacement of new spark plug and

try skip again

Load in the spark plug

cap

Poor skip

z Loosen spark plugs

z Poor spark plugs

z Poor high-voltage wiring

z Poor distributor coils

z Poor PICK Ups

z Poor main switches

z Wiring relay

Poor or abnormal

C.D.I. or plugs,

replacement of

C.D.I. and mount

properly the plug

Check high-voltage

coils, main switches,

PICK UP, distributor

coil for normality

High sparks

Check for loose C.D.I.

plugs, terminal

conduction and

resistance values

Replacement of poor

spark plug

Abnormal

Normal

Poor high-voltage

coils, main

switches, PICK

Ups, distributor

coils

Abnormal

Normal

Check for

correct main

wiring contacts

and terminals, if

necessary,

correct them

23

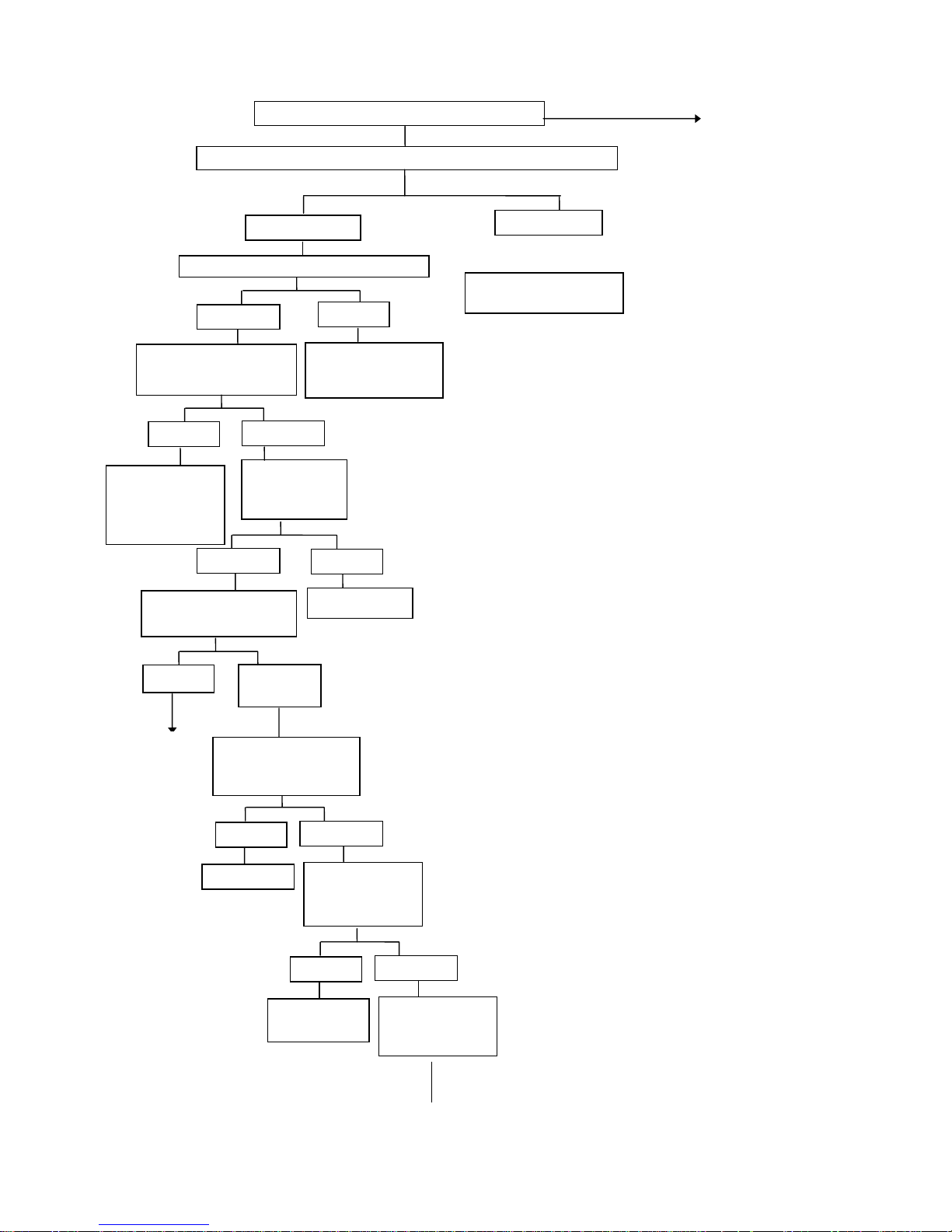

1-8-3 Troubleshooting for no-skip of spark plugs

No skip of spark plugs

Analysis of potential causes

Check for proper loading of the spark plug cap

Fair

Poor

Replacement spark plug and test the

intensit

y

of the spark plugs

Load properly the spark

plug cap

Intense sparks

z Loose spark plug cap

z Poor spark plug

z Loose C.D. adapter

z Poor C.D.I.

z Poor PICK UP

z Poor distributor

high-voltage wiring

z Poor main switch

z Main wiring broken or in

short circuit

z Ignition coil broken or in

short circuit

z Poor adapter contact

Load properly the

C.D.I. adapter

Check C.D.I. terminals

passage and testing of

resistance

Weak sparks

Replacement of

p

oor spark plugs

Check for loose C.D.I.

contacts

Loose

Normal

a. Poor PICK UP

b. Poor main switch

c. Poor contact of

adapter

d. Broken main wiring

of short circuit

Abnormal

Normal

Use C.D.I. tester

for checks of

C.D.I.

Replacement of the poor

C.D.I.

Abnormal

Normal

Check ignition coil for

breaking or short

circuit, replace when

necessary

24

1-8-4 Troubleshooting for slow run (troubled engine)

Poor slow run

Analysis of potential causes

Check for contamination in spark plugs and excessive gap

Fair

Poor

Alarming abnormality of ignition timing

Cleaning and

adjustment

Poor

z Dirty spark plugs

z Incorrect spark plug

gaps

z Incorrect ignition

timing

z Obstructed air filter

grill

z Poor carburetor

buoyant needle valve

z Poor carburetor choke

valve

z Poor engagement of

carburetor and inlet

tube

z Obstructed carburetor

slow injection

z Poor engagement of

cylinder head washer

z Severe wear of

cylinder, piston, piston

ring

Replacement of

the filter grill

Is the carburetor buoyant

level normal ?

Fair

adjustment

Is the air filter grill

obstructed?

Poor

Fair

Adjustment or

replacement of the

buoyant needle valve

Fair

Poor

Check if the choke

valve fails (valve

does not open) ?

Check of for air between the

carburetor and the air inlet

Fair

Poor

Correction

Check for obstruction in the

carburetor slow injection

Fair

Poor

Add tightening force or

replacement of the washer

Fair

Poor

Cleaning T est the compression

Check for air leakage in the cylinder washer,

check wear of cylinder, piston, piston ring

and other elements with correction,

ad

j

ustment or replacement

25

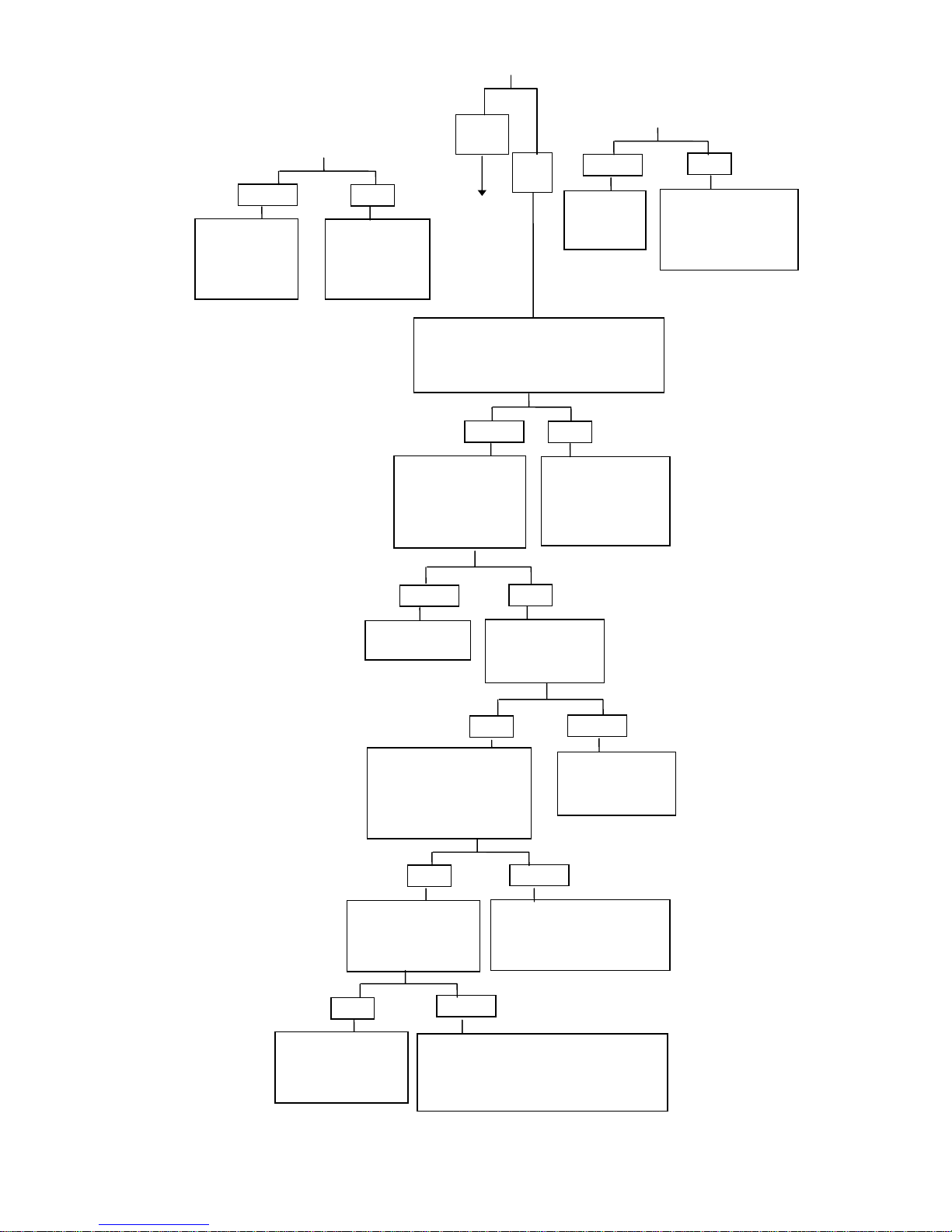

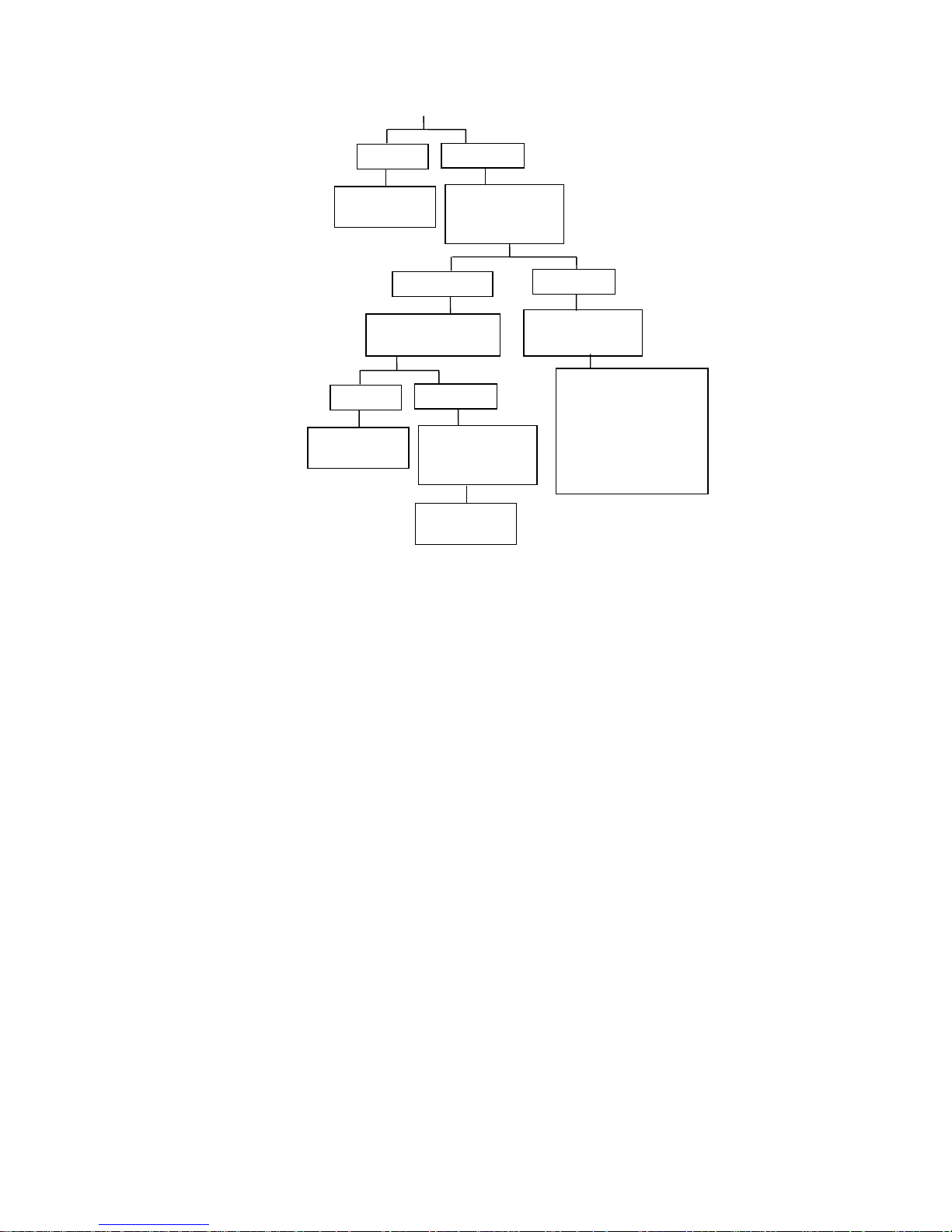

1-8-5 Poor acceleration and horse power

a

Poor acceleration and horse power

Breakdown of potential causes

Check for drag of braking drum by braking plate

Fair

Poor

Check for obstructed air filter

Adjust or replace

braking plate

z Braking plate retaining braking

drum

z Air filter grill obstructed

z Dirty spark plugs

z Incorrect gap in spark plugs

z Incorrect ignition timing

z Poor skip in spark plugs

z Incorrect adjustment of

carburetor adjustment screw

z Poor choke valve in carburetor

z Dirty or obstructed carburetor

injection nozzle

z Poor carburetor buoyant needle

valve

z Dirty fuel filter

z Obstructed fuel circuitry

z Poor engagement of cylinder

washer

z Serious damage of cylinder,

piston, piston ring

Cleaning,

adjustment of

replacement of

new spark plugs

Check for

normal ignition

timing

Check for burn of spark

plugs and the gap

Replacement of the

filter grill

Intense

sparks

Poor skip

Check for normal

choke valve action

Adjustment

Check carburetor for

proper adjustment

Fair

Poor

Fair

Poor

Test of spark plugs,

sparks

Timing

Fair

Poor

See 1-8-2 poor

skip of spark

plug for

checking

methods

Fair

Poor

Check for

obstructed

injection nozzle

Correction or

replacement

Fair

Poor

26

a

Check for leakage in

cylinder washer; check

cylinder, piston, piston

ring for wear. Correct,

adjustment or

replacement when

necessary

Check for normal

fluid level in the

buoyant

Cleaning or

replacement

Fair

Poor

Check the

compression

Check of needle

valve and buoyant

Fair

Poor (low level)

Check fuel pipe

and carburetor for

obstruction

Adjustment or

replacement

Fair

Poor

Cleaning or

replacement

27

2. INSPECTION AND ADJUSTMENT

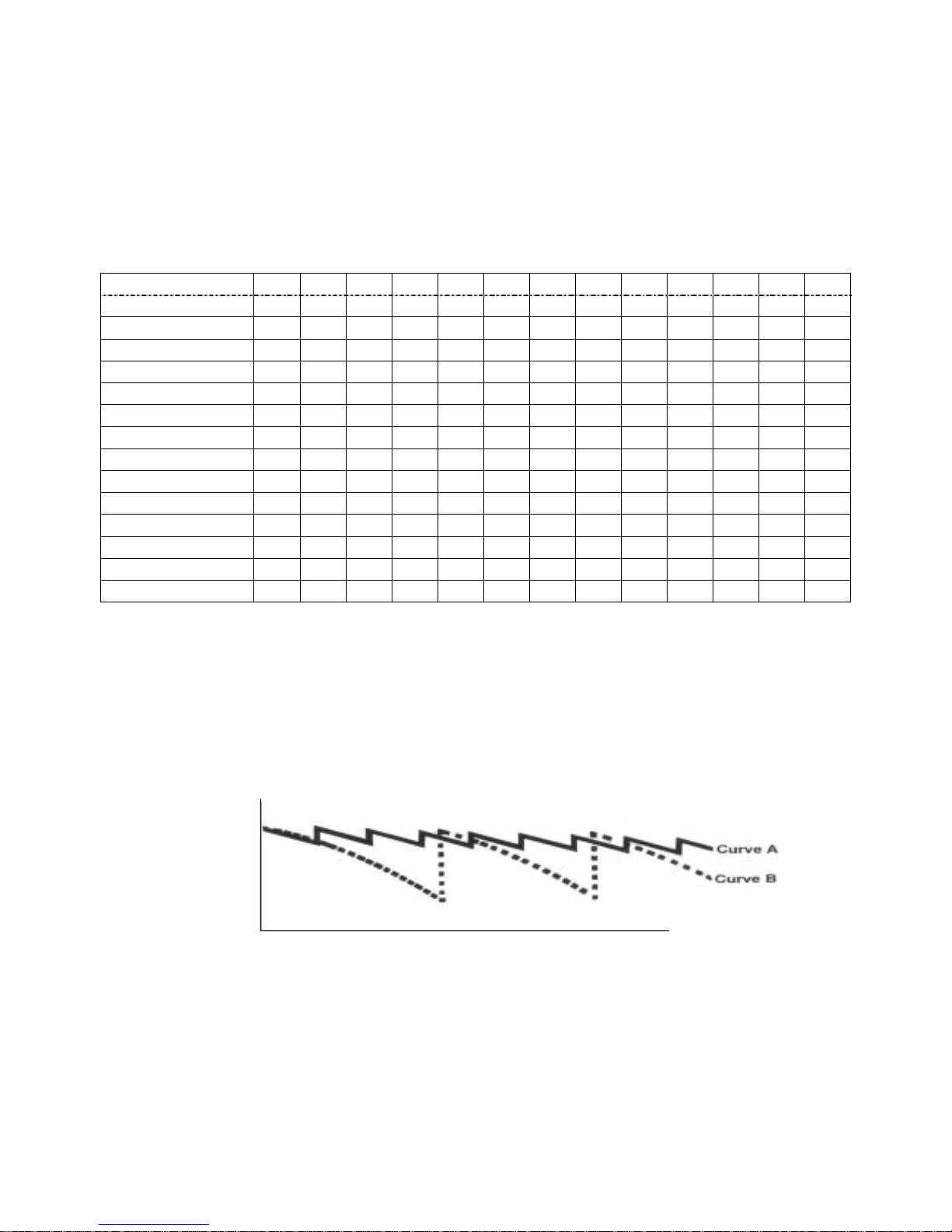

2-1 REGULAR MAINTENANCE SCHEDULE

Explanation:

(1) Please follow the regular maintenance schedule to ensure

the motorcycle’s function and life.

(2) I : Inspection (including clean up, lubrication, refill, or replace parts),

C: Clean, R: Replace, A: Adjust.

km or time

300 km 1000 km 2000 km 3000 km 4000 km 5000 km 6000 km 7000 km 8000 km 9000 km 10000 11000 12000

Maintenance Item

(1 mo.) (3 mo.) (6 mo.) (9 mo.) (12 mo.) (15 mo.) (18 mo.) (21 mo.) (24 mo.) (27 mo.) (30 mo.) (33 mo.) (36 mo.)

Engine Oil

R R R R R R R R R R R R R

Oil Strainer Screen

C C C

Gear Oil

R R R

Brake

I I I I I I I I I I I I I

Tire s

I I I

Air Cleaner

I R R

Battery

I I I

Spark Plug

C C C C

Fuel Filter

R R

Carburetor

I I C

Val ve

A A A A

V Belt

I

Bolts and Nuts

T

Note: (1) If ridden on dusty roads or raining days, please shorten the inspection and

replacement schedule for air filter.

(2) If ridden under heavy load, frequent long distance travel, please shorten the

replacement schedule for engine oil.

(3) Please clean the spark plug regularly, and replace the spark plug if necessary.

* Regularly Maintenance and Performance Relationship*

Performance100%

Ridden Time (or Mileage)

Curve A: With regular maintenance, the performance can be improved to optimal condition with

maintenance at scheduled time.

Curve B: Without regular maintenance, the performance drops and engine can be damaged.

Therefore, the engine needs repair to re-gain high performance, and the motorcycle’s

life can be shorten.

28

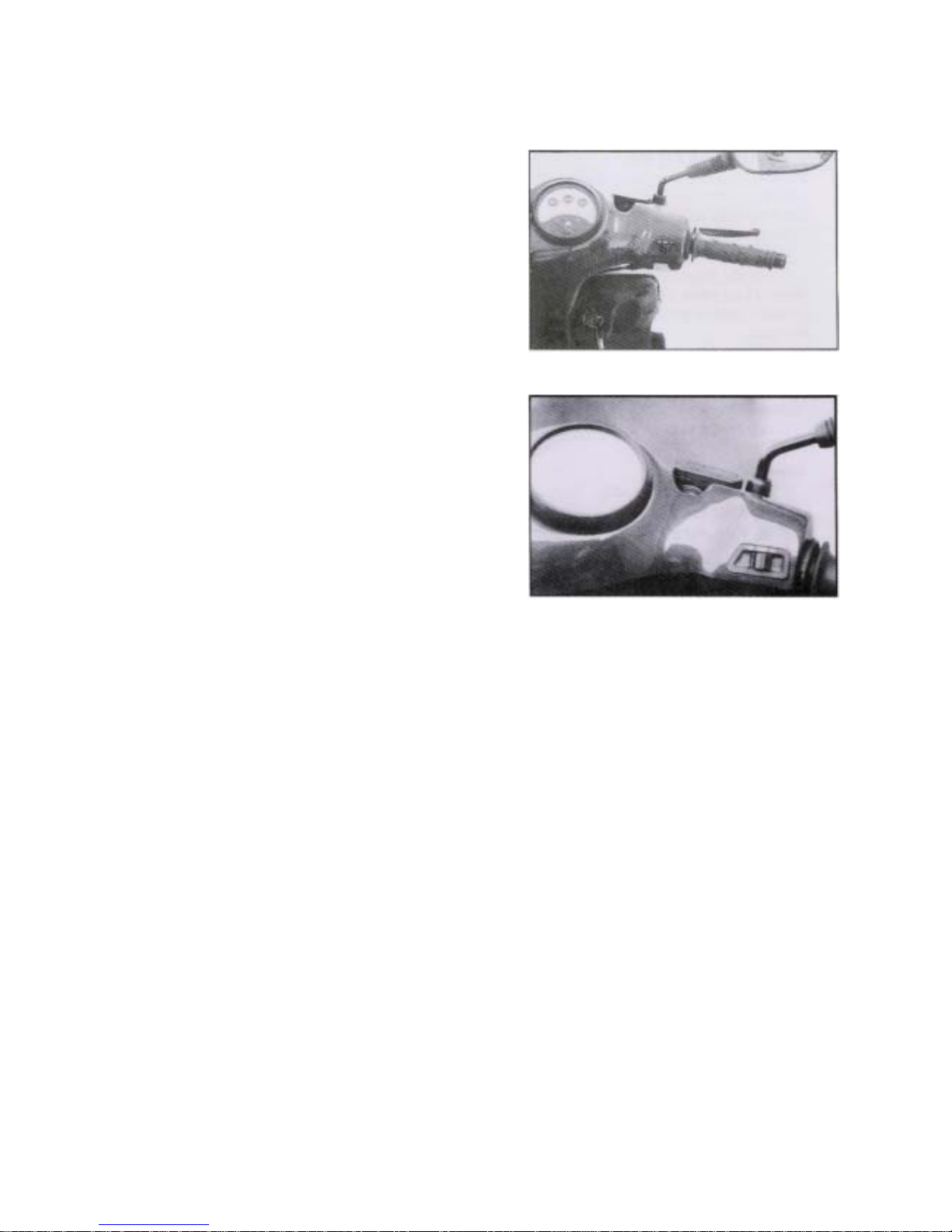

2-2 INSPECTION AND

CHANGE OF ENGINE OIL

Watch: Please place main stand to park the

motorcycle for inspection.

Inspection: Stop engine for 2~3 minutes when

it is warmed. Remove the engine oil level and

check if the oil level is bellow the lower limit.

Fill engine oil to the level between upper and

lower limits.

* Change Engine Oil *

Note: Please change engine oil according to

regular maintenance schedule. If ridden

on heavy load or long distance, please

shorten the maintenance schedule for oil

change.

● Please put oil tray under the left crankcase

and remove the oil drain plug. Re-install the

drain plug when the engine oil is drained.

* Clean up the oil filter *

Inspection:

(1) If O-ring is damaged, please replace with

new one.

(2) If there is any deposit, please use clean up

before re-assembly.

Note:

(1) Torque of oil strainer screen:

150 ~ 200 kg-cm.

(2) Lubrication Type: SAE 10W-40

Engine oil capacity

* BH8 / BR8 / BF8 *

125c.c. Engine disassembled : 900c.c.

change oil : 750 c.c.

* BR9 / BF9 *

151c.c. Engine disassembled : 1000c.c.

change oil : 900 c.c.

(3) Check if there is any leakage after oil

change. Warn the engine and check the

engine oil level again.

29

2-3 FINAL GEAR OIL

Watch: Please place main stand to park the

motorcycle for inspection. Clean grease

around the drain plug.

Disassembly:

Oil refill plug.◎

Oil drain plug.◎

Note: Put an used oil tray under the gearbox

before removing the drain bolt plug.

Inspection: Check if the oil drain plug washer

is damaged. Please replace with new one if it

is damaged.

Drain gear oil. ◎

Assembly:

■ Assembly drain plug.

■ Refill gearbox oil.

■ Reinstall oil refill plug.

Note:

(1) Torque on drain plug: 90 ~ 150 kg-cm.

(2) Oil type: SAE 90 #

(3) Oil capacity

* BH8 *

Gearbox disassembled : 110 c.c.

Regular Maintenance : 90 c.c.

* BR8 / BF8 / BR9 / BF9 *

Gearbox disassembled : 120 c.c.

Regular Maintenance : 100 c.c.

(4) Please check if there is any leaking after

oil refill.

30

2-4 BRAKE SYSTEM

A. Front Brake Lever Free Play

Note: Front brake lever free play is 10~20 mm.

Adjustment: This motorcycle uses “non-adjust

style”.

B. Brake Fluid

Inspection: The front brake fluid level should

above “MIN”. If it is below, refill the brake fluid

and check leakage of the brake system.

Warning: If there is low or no load when the

brake lever is hold, please check if there is air in

the brake system or fluid leakage.

C. Refill Brake Fluid

Watch: Please place main stand to park the motorcycle for inspection.

Disassembly:

2 tightening bolts on fuel cover. ◎

Fuel trap. ◎

Diaphragm.◎

Refill brake fluid to level between MIN and MAX.

Assembly: Assembly is in reverse order of disassembly procedures.

Warning:

(1) Please refill the same type of brake fluid. Different fluid type may create toxic chemical

ingredient and can damage the brake.

(2) Please do not let water into the master cylinder. Otherwise, the broil temperature may be

reduced and bubble can occur, then brake may not work.

(3) If the brake fluid is splashed on plastic parts or paints. Please wipe it out right away,

otherwise it may affect engine firing.

Loading...

Loading...