Textron Inc 898353, 898353EE, 898354, 898354EE, 898356 MAINTENANCE MANUAL

...

PARTS AND

MAINTENANCE MANUAL

TITAN VEHICLE

MODELS:898353, 898353EE,

898354, 898354EE,

898356, 898356EE,

898355, 898355EE,

898357, 898357EE

Part No. 4113731

1 GENERAL INFORMATION

1.1 GENERAL INFORMATION

IMPORTANT!

THIS MANUAL WILL AID YOU IN THE SAFE

OPERATION AND PROPER MAINTENANCE OF

YOUR EQUIPMENT. READ MANUAL THOROUGHLY

BEFORE ATTEMPTING OPERATION. IF ANY

PORTION IS NOT CLEARLY UNDERSTOOD,

CONTACT AN AUTHORIZED DEALER FOR

CLARIFICATION.

To make sure you are fully aware of safety and service

information, the following two symbols are used

throughout this manual.

!

WARNING

Altering this equipment in any manner which

adversely affects the equipments operation,

performance, durability or use, may cause hazardous conditions.

Direct any inquiries to:

Textron Golf, Turf and Specialty Products

Attn: Director of Engineering Services

P.O. Box 82409

Lincoln, NE 68501–2409 USA

SPECIFICATION INFORMATION

!

This symbol is used throughout the manual to

alert you to information about unsafe actions or

situations, and will be followed by the word DANGER,

WARNING, or CAUTION. DANGER indicates

immediate hazards that may result in severe injury or

death. WARNING indicates unsafe actions or situations

that may cause severe injury, death and/or major

equipment or property damage. CAUTION indicates

unsafe actions or situations that may cause injury , and/or

minor equipment or property damage.

NOTE:

Additional manuals are available through your dealer.

THIS EQUIPMENT SHOULD NOT BE MODIFIED OR

ADDED TO WITHOUT THE MANUFACTURER’S

AUTHORIZATION.

This appears next to information or instructions

which will help you operate and maintain your

equipment the right way.

!

WARNING

The information and instructions included in

this manual alert you to certain things you

should do very carefully. If you do not, you

could:

• hurt yourself or others

• hurt the next person who operates the

equipment

• damage the equipment.

This manual contains essential operation and

safety information and must remain with the

unit at all times, within easy access of any operator.

IMPORTANT!

All information contained in this manual is the latest

available at the time of printing. Textron Golf, Turf and

Specialty Products reserves the right to make changes

at any time without notice.

Whenever a name brand product is specified, an

equivalent product may be used unless stated otherwise.

CHANGE OF OWNERSHIP OR ADDRESS

Textron Golf, Turf and Specialty Products makes every

effort to keep owners informed of all safety related

information. Therefore, changes in ownership and/or

address should be reported to the manufacturer.

Your dealer has REGISTRATION CHANGE FORMS

which will be filled out and filed by the dealer for his

records, and a copy will be sent to the manufacturer.

DEALER INFORMATION

For your nearest dealer location write to:

Textron Golf, Turf and Specialty Products

Attn: Sales Coordinator

P.O. Box 82409

Lincoln, NE 68501–2409 USA

In the USA and Canada call 1–888–922–8873 (dealer

information only).

MODELS

898353 & 898353EE – 36 Volt Swing Out Batteries

3000 Pound – 13 M.P.H.

898354 & 898354EE – 48 Volt Swing Out Batteries

4000 Pound – 9 M.P.H.

898356 & 898356EE – 48 Volt Swing Out Batteries

5000 Pound – 7 M.P.H.

898355 & 898355EE – 36 Volt Four Passenger

3000 Pound – 13 M.P.H.

898357 & 898357EE – 36 Volt

3000 Pound – 13 M.P.H.

250–1–02–CU

Lincoln, Nebraska • All Rights Reserved.

2002 Textron Inc.

Printed in U.S.A.

TABLE OF CONTENTS

SECTION PAGE

1 General Information Inside Front Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 General Information Inside Front Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Identification

2.1 Vehicle Identification 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Model Number 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Serial Number 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Service

3.1 Service 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Maintenance Guide 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Chassis Lubrication Guide 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 Chassis Lubrication Chart 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 Bulbs, Fuses And Flashers 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Specifications

4.1 Vehicle Specifications 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Battery Specifications 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Maintenance

5.1 Battery Charging 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Battery Location 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 Battery Charger 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4 Differential 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5 Jacks And Jacking Locations 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6 Solid Tires 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.7 Pneumatic Tires 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.8 Tire Air Pressure 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.9 Touch-up Paint 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Controller Parameters

6.1 36 Volt Controller Parameters 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 36 Volt Max Speed Adjustment 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 48 Volt Controller Parameters 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 Torque Chart 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 Parts

8.1 Frame, Deck, Front Panel, Tie Downs 18–19. . . . . . . . . . . . . . . . . . . . . . . .

8.2 Frame, Deck, Front Panel, Tie Downs 20–21. . . . . . . . . . . . . . . . . . . . . . . .

8.3 Frame, Deck, Front Panel, Tie Downs 22–23. . . . . . . . . . . . . . . . . . . . . . . .

8.4 Front Axle, King Pin Pivots, Spring Perch, Spring, Brackets 24–25. . . . .

8.5 Front Spring, Front Frame Brace, Arm And Bushing 26. . . . . . . . . . . . . . .

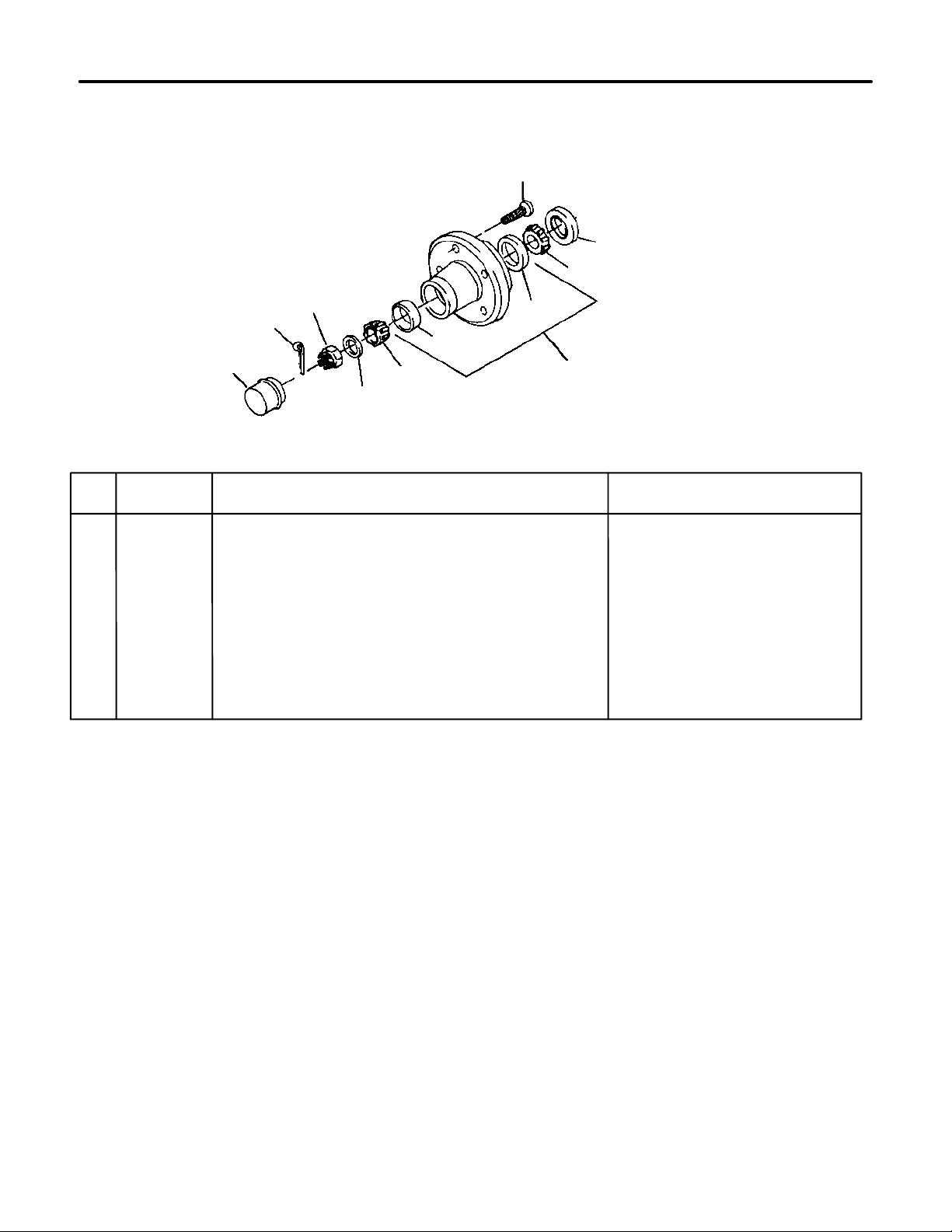

8.6 Front Hub Without Front Brake 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.7 Seat, Backrest [Stopwall] Frame, Backrest, Seat Switch 28–29. . . . . . . .

8.8 Rear Seat, Folding 30–31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.9 Brakes (Rear Hydraulic) 32–33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.10 Brakes (Rear Hydraulic) 34–35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.11 Brakes (Four Wheel Hydraulic) 33–37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.12 Master Cylinder (Rear Brakes) 38–39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.13 Master Cylinder (Four Wheel Brakes) 40–41. . . . . . . . . . . . . . . . . . . . . . . .

8.14 Wheel Cylinder 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.15 Brake Pedal 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.16 Front Brake And Hub 44–45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.17 Brake (Rear Wheel) 46–47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

TABLE OF CONTENTS

SECTION PAGE

8 Parts

8.18 Brake, Hub (Rear Wheel) 48–49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.19 Parking Brake Controls 50–51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.20 Parking Brake 52–53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.21 Rear Springs, Spacer, Shackles, U–bolts 54–55. . . . . . . . . . . . . . . . . . . . .

8.22 Shock Absorbers 56–57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.23 Differential (13.00:1 ratio) 58–61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.24 Differential (Full Floating, 13.00:1 ratio) 62–63. . . . . . . . . . . . . . . . . . . . . . .

8.25 Differential (Full Floating, 15.67:1 ratio) 64–67. . . . . . . . . . . . . . . . . . . . . . .

8.26 Differential (15.67:1 ratio) 68–71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.27 Steering Gear 72–73. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.28 Steering Linkage 74–75. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.29 Speed Control Pedal 76–77. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.30 Motor (36 Volt) 78–79. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.31 Motor (48 Volt) 80–81. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.32 Belts & Pulleys (48 Volt) 82–83. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.33 Belts & Pulleys (3000 Lb. Capacity) 84–85. . . . . . . . . . . . . . . . . . . . . . . . . .

8.34 Belts & Pulleys (6 MPH) 86. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.35 Battery Hold Down 87. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.36 Battery Hold Down 88–89. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.37 Swing Out Battery Box 90–91. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.38 Battery Hold Down 92. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.39 Tire And Wheel And Spare Tire Accessory 93. . . . . . . . . . . . . . . . . . . . . . .

8.40 Tire And Wheel Accessory 94. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.41 Solid Tire And Wheel 95. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.42 Clamps, Clips, Grommets, Plugs And Tie 96–97. . . . . . . . . . . . . . . . . . . . .

8.43 Decals 98–99. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.44 Controller 100–103. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.45 Electrical Components 104–109. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.46 Charger Box Motor Splash Guard 110. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.47 Charger 111–116. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.48 Accessory Tool Box & Bumper 117. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.49 Accessory Bumper & Hitch 118–119. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.50 Accessory Turn Signal Set Part No. 886465 120. . . . . . . . . . . . . . . . . . . .

8.51 Accessory Turn Signal Set Part No. 886465, wiring 121. . . . . . . . . . . . . .

8.52 Accessory Headlight Set Part No. 886466 122. . . . . . . . . . . . . . . . . . . . . .

8.53 Accessory Box Sides And Tailgate Set Part No. 886467 123. . . . . . . . . .

8.54 Accessory Cab Set Part No. 886468 124–125. . . . . . . . . . . . . . . . . . . . . .

8.55 Accessory Fiberglass Door Set Part No. 886469 126–127. . . . . . . . . . .

8.56 Accessory Cloth Door Set Part No. 886940 128–129. . . . . . . . . . . . . . . .

8.57 Accessory Hour Meter & Spare Tire Mount 130. . . . . . . . . . . . . . . . . . . . .

8.58 Accessory Lift Out Battery Rack Set 131–134. . . . . . . . . . . . . . . . . . . . . .

8.59 Charger Relay Set Part No. 887496 135. . . . . . . . . . . . . . . . . . . . . . . . . . .

8.60 Modification 328, 346 Less Charger 136. . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.61 Electrical Connectors 137. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.62 Seat Brake Modification 411 138–139. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.63 Accessory Tilt Steering 140–141. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.64 Accessory Controller Programmer 142. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.65 EE Components 143. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 Wiring Diagram

9.1 Wiring Diagram 36v 144–145. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2 Wiring Diagram 48v 146–147. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2

IDENTIFICATION 2

2.1 VEHICLE IDENTIFICATION

THESE IDENTIFICATION NUMBERS MUST APPEAR

ON ALL CORRESPONDENCE CONCERNING THIS

VEHICLE.

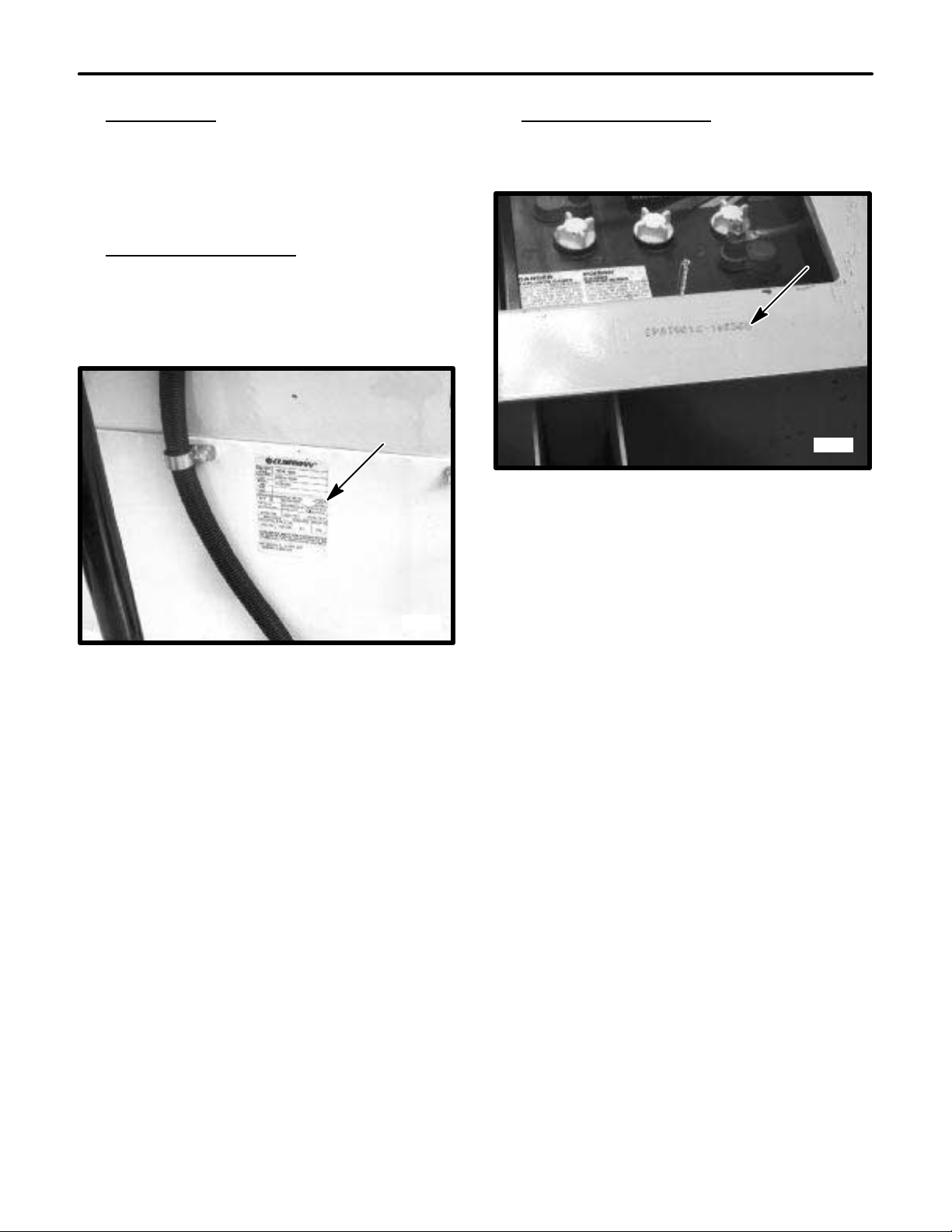

2.2 MODEL NUMBER

The vehicle model number and serial number are

stamped on the vehicle nameplate attached to the left

kick panel in front of the steering column.

2.3 SERIAL NUMBER

The serial number and model number are stamped on

the center crossmember under the rear deck.

3937

IMPORTANT!

INDENTED PART NAMES INDICATE THESE PARTS

ARE INCLUDED IN THE PRECEDING ASSEMBLY.

3936

AFTER YOU IDENTIFY A PART BY THE REFERENCE

NUMBER AND THE CUSHMAN PART NUMBER,

ALWAYS READ THE DESCRIPTION OF THE PART T O

BE SURE IT IS WHAT YOU WANT.

3

3 SERVICE

3.1 SERVICE

!

WARNING

When replacement parts are required, use genuine CUSHMAN parts or parts with equivalent

characteristics including type, strength and

material. Failure to do so may result in product

malfunction and possible injury to the operator

and/or bystanders.

NEVER attempt to perform service or maintenance functions on this vehicle if you are UNTRAINED or UNAUTHORIZED. Improper maintenance can cause hazardous conditions. See your authorized CUSHMAN dealer

for necessary maintenance and service.

When it is necessary to raise the vehicle for any repair or

service, use jackstands to provide adequate support. Do

not rely on hydraulic or mechanical jacks.

The average miles traveled per hours of operation for

CUSHMAN vehicles is usually very low . A vehicle used

inside a manufacturing facility or on a security system

patrol may be used for 8 hours while traveling only 20 or

25 miles. It is advisable that your vehicle be equipped

with an hour meter (set #884737) to record hours of

operation. A good maintenance schedule can then be

established.

3.2 MAINTENANCE GUIDE

WEEKLY

Check tire pressure(exclude solid tires).

Fill batteries to proper level and check specific gravity.

AS REQUIRED

Remove and clean wire terminals, battery terminals and

batteries, reinstall wire terminals.

EVERY 200 HOURS

Perform previous services

Check brake fluid level (BF)

Check differential oil level

Lubricate chassis*

EVERY 600 HOURS OR YEARLY

Perform previous services

Repack front wheel bearings (PG)

Repack rear wheel bearings (PG)

Change differential oil (EP)

Check brake linings

Adjust brakes as required

Check motor brushes

*Use lithium base pressure gun grease on all grease fittings and

lubrication points.

The following maintenance guide provides a check list for

servicing your vehicle. The guide is set up for average

use on clean, paved surfaces. Vehicles used in dusty

areas, for winter driving or operated in mud, snow or

water require more frequent service.

LUBRICATION CODE

PG – Pressure gun grease

(lithium base)

EP – Extreme pressure lube

SAE 80–90 Multigrade

BF – Brake fluid DOT (3)

4

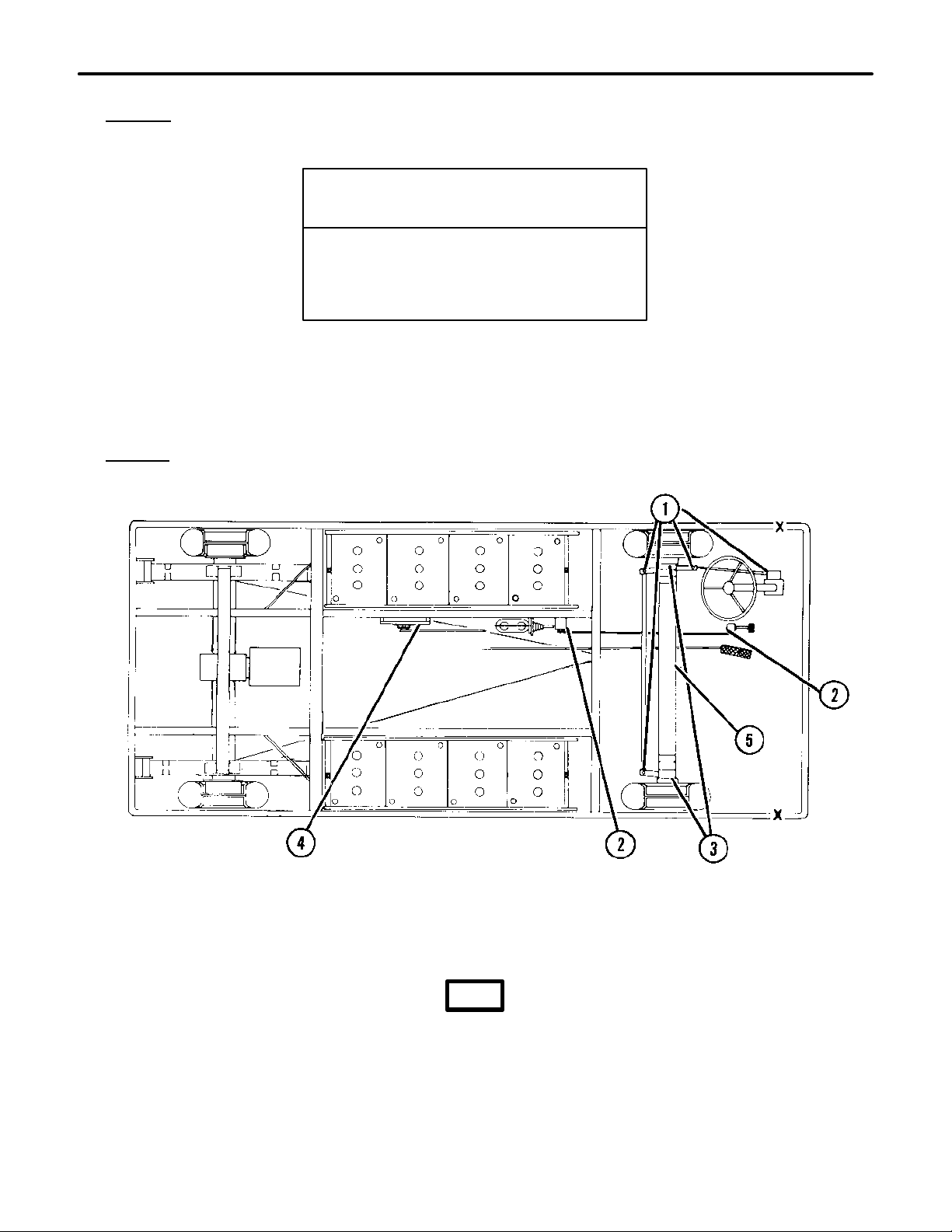

3.3 CHASSIS LUBRICATION GUIDE

Perform every 200 hours

SERVICE 3

LUBRICATION AREA

1. Steering linkage 4

2. Brake pivots 2

3. King pin bushings 2

4. Selector switch contacts, pivot

and shaft spacer 11

5. Wheel arm pivots 2

* Use a lithium base pressure gun grease on all grease fittings

and lubrication points.

Use 30 wt. oil on selector switch pivot shaft.

3.4 CHASSIS LUBRICATION CHART

♦

NUMBER OF

LUBRICATION POINTS

OR FITTINGS*

♦

♦

♦

IMPORTANT

X TOW LINE ATTACHING POINTS

♦ JACKING LOCATIONS

NOTE

• Illustration shows eight batteries and direct drive

motor. Some models use six batteries and/or belt

drive motor.

5

3 SERVICE

3.5 BULBS, FUSES AND FLASHERS

Description Specification or Trade No. Cushman No.

BULBS

Headlight (accessory) 35 Watt No. 4411 820594

(3000 CP)

Light, Rear Left,

Stop, Tail and Turn Signal (accessory) 32–4 CP No. 1157 822049

Light, Rear Right,

Stop, Tail and Turn Signal (accessory) 32–4 CP No. 1157 822049

Turn Signal, Front (accessory) 32–4 CP No. 1157 822049

Turn Signal, Pilot (accessory) 1 CP No. 53 811953

Power On Light 2 CP No. 1893 828473

FLASHERS

Hazard and Turn Signal (accessory) 822867

FUSES (Located under instrument panel)

Five Required 20 AMP 826000

6

4.1 VEHICLE SPECIFICATIONS

Model Number Traction Type Differential Speed

Motor Ratio Range

898353 36 Volt DC 13.00:1 13 MPH (21Km/h)

898353EE Direct Drive UP TO

to Differential 35 MILES(56 Km)

898354 48 Volt DC 13.00:1 9 MPH (14.5 Km/h)

898354EE Belt Drive UP TO

to Differential 35 MILES(56 Km)

898356 48 Volt DC 15.67:1 7 MPH (11Km/h)

898356EE Belt Drive UP TO

to Differential 30 MILES (48 Km)

898355 36 Volt DC 13.00:1 13 MPH (21Km/h)

898355EE Direct Drive UP TO

to Differential 35 MILES(56 Km)

898357 36 Volt DC 13.00:1 13 MPH (21Km/h)

898357EE Direct Drive UP TO

to Differential 35 MILES(56 Km)

SPECIFICATIONS 4

Determining factors affecting the range are: battery condition and size, payload, the number of stops,

speed and operating terrain.

4.2 BATTERY SPECIFICATIONS

SPECIFICATIONS

These vehicles require “golf cart type” 6 volt batteries

each with a MINIMUM capacity of 180 A.H. (ampere–

hours at the SAE 20–hour rate) and 5/16” (8 mm) stud

posts.

The MAXIMUM case dimensions are:

• Length 10 3/8” (264 mm)

• Width 7 3/16” (183 mm)

• Height 11 5/8” (295 mm)

(including posts)

OR

FOR THE 36 VOLT VEHICLE

Two “industrial type” 18 volt batteries each with a MINIMUM capacity of 450 A.H. (ampere hours at the SAE

20–hour rate) or 294 A.H. (ampere hours at the 3–hour

rate) with 5/16 (8 mm) stud type posts.

The MAXIMUM case dimensions are:

• Length 29 13/16” (776 mm)

• Width 12 15/16” (329 mm)

• Height 13 1/2” (343 mm)

OR

FOR THE 48 VOLT VEHICLE

Two “industrial type” 24 volt batteries each with a MINIMUM capacity of 375 A.H. (ampere hours at the SAE

20–hour rate) or 245 A.H. (ampere hours at the 3–hour

rate) with 5/16 (8 mm) stud type posts.

The MAXIMUM case dimensions are:

• Length 30 9/16” (776 mm)

• Width 12 15/16” (329 mm)

• Height 13 1/2” (343 mm)

7

5 MAINTENANCE

5.1 BATTERY CHARGING

NOTICE

• DO NOT attempt to recharge the batteries with a

charger not designed for this vehicle.

• Industrial batteries may require special chargers.

Obtain charger recommendations from the battery

supplier.

See your authorized CUSHMAN dealer for information

about lifting devices.

!

WARNING

UNTRAINED/UNAUTHORIZED persons

should NEVER attempt to service or recharge

the batteries of this vehicle.

T o avoid injury, use an adequate lifting device

to lift the batteries and/or rack.

NEVER use metal chains, etc., to lift the batteries and/or rack. They can cause electrical arcing resulting in battery explosion.

Stay clear when lifting, lowering or moving the

batteries and/or rack. Do NOT place hands on

the batteries and/or rack or the vehicle.

See your authorized CUSHMAN dealer for information

about lifting devices.

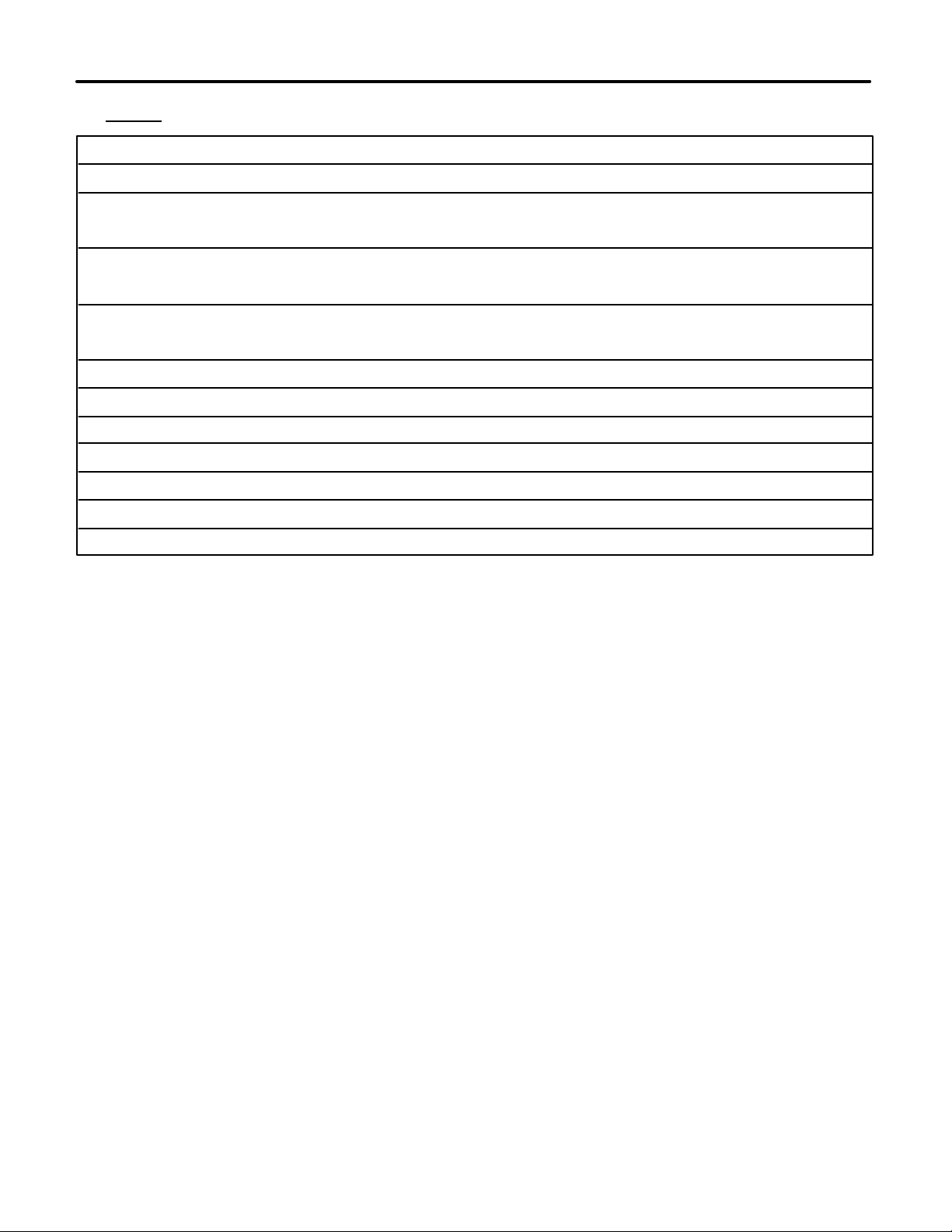

3111

Latch Handle

!

WARNING

Fully engage battery tray latch pin in innermost slot. If tray is not properly latched and

swings open when vehicle is in motion

• Bystanders may be struck

• Vehicle and surroundings may be dam-

aged.

5.3 BATTERY CHARGER

The standard vehicle is equipped with a built in fully automatic AC charger located under the deck at the rear of

the vehicle.

Accessory chargers of various types are also available.

5.2 BATTERY LOCATION

The batteries are located under the rear deck.

Model 898355, 898355EE, 898357 and 898357EE are

equipped with fixed battery racks.

Models 898353, 898353EE, 898354, 898354EE,

898356, and 898356EE are equipped with swing out battery racks accessible from each side of the vehicle, both

secured in position with a latch handle (shown). Make

sure racks are securely latched before operating the

vehicle.

8

• Follow the instructions on the charger or the

vehicle.

• ALWAYS place the charger cord in the pocket

designed for it on the standard vehicle.

NOTICE

• New HIGH CAPACITY batteries will have a finish

charge rate of 2 to 4 amps after charging for 16

hours. LOWER CAPACITY batteries may require a

shorter charging time. This MAXIMUM charging

time is required ONLY after operating (driving) the

vehicle for 2 hours or more, i.e.: Shorter operating

(driving) time requires shorter charging time.

MAINTENANCE 5

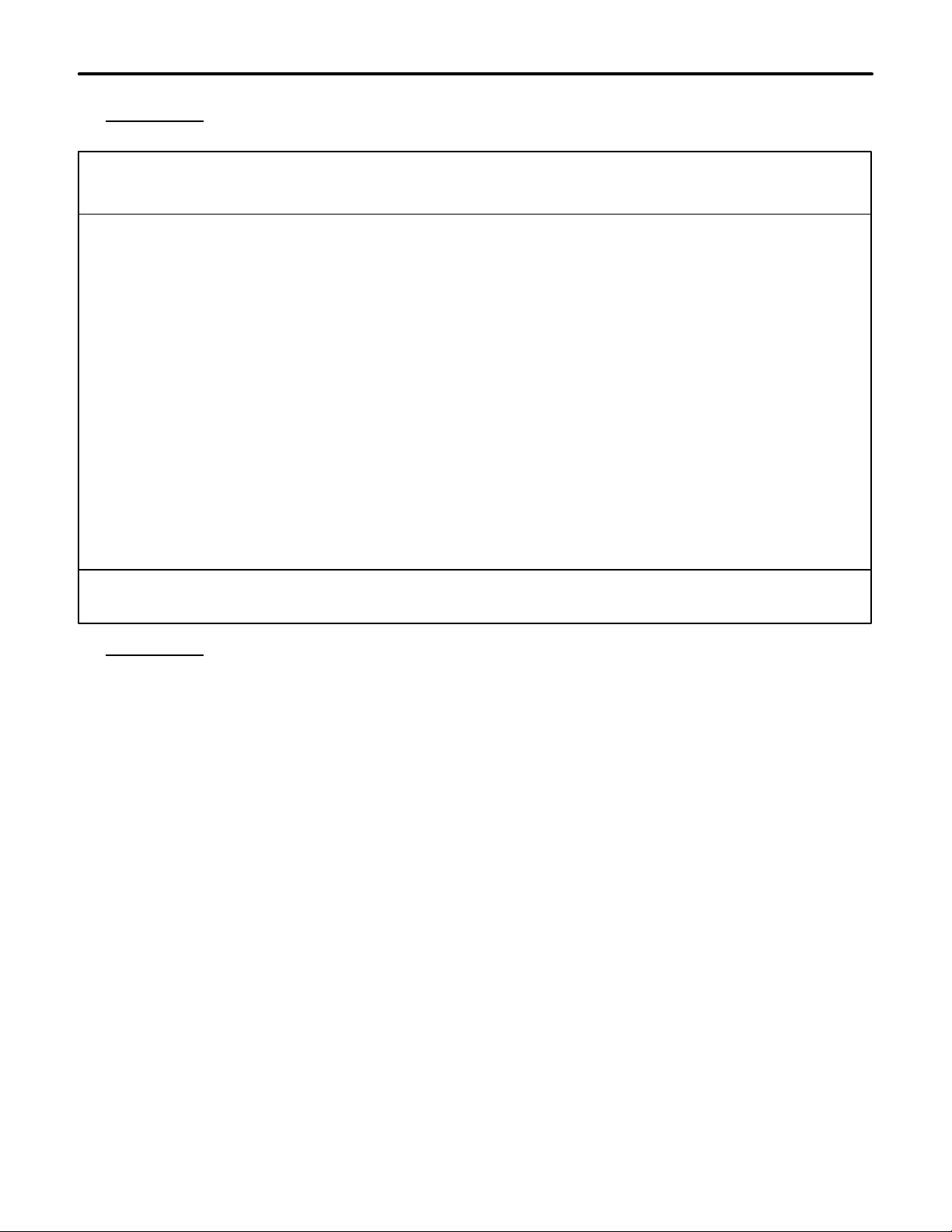

5.4 DIFFERENTIAL

The filler plug and the drain plug are illustrated. Check oil

level every 200 hours. It should always be up to the level

of the filler hole.

IMPORTANT!

DRAIN DIFFERENTIAL AFTER FIRST 100 HOURS OF

SERVICE AND REFILL WITH EP80–90 MULTIGRADE

EXTREME PRESSURE LUBRICANT. THEREAFTER

LUBRICANT SHOULD BE CHANGED PER MAINTENANCE GUIDE.

REPAIRING THIS REAR AXLE IS A MAJOR SERVICE

OPERATION AND SHOULD BE PERFORMED BY

YOUR AUTHORIZED CUSHMAN DEALER WHO HAS

THE NECESSARY EQUIPMENT AND INFORMATION.

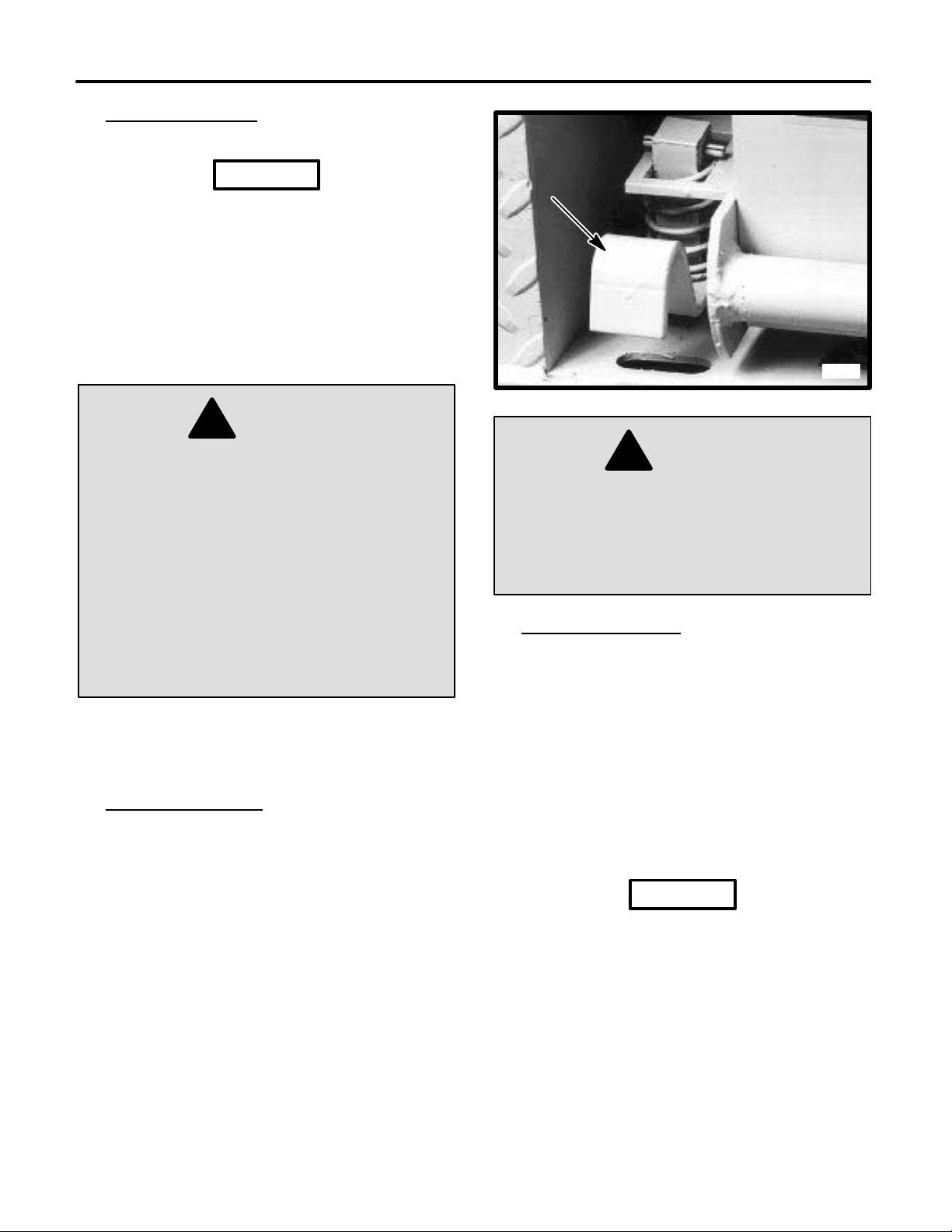

5.6 SOLID TIRES

FRONT AND REAR TIRE REMOVAL

2

1

3569

1. Valve Stem Hole

2. Wheel Retaining Nuts

Remove and reinstall as follows:

• Remove the wheel retaining nuts and remove

wheel assembly from hub.

1

2

3112

1. Filler Plug

2. Drain Plug

5.5 JACKS AND JACKING LOCATIONS

A scissors type jack with a 1 1/2 ton (1361 Kg) (minimum)

capacity is required.

The jacking locations are shown on the chassis lubrication chart illustration (page 10). Raise the vehicle ONLY

enough to perform maintenance required.

• Remove wheel hardware.

• Remove and discard tire.

• Press new tire in place.

• Reinstall and tighten wheel hardware.

• Reinstall tire and wheel and tighten wheel retain-

ing nuts to 70 to 100 ft.–lbs. (95 to 140 N·m)

torque.

• Make sure the valve stem hole is located toward

the outside.

NOTICE

• The valve stem hole in the wheel half MUST be

towards the outside so the wheel retaining nuts will

tighten properly.

NOTICE

• Use replacement tires equivalent to or exceeding

original equipment specifications.

9

5 MAINTENANCE

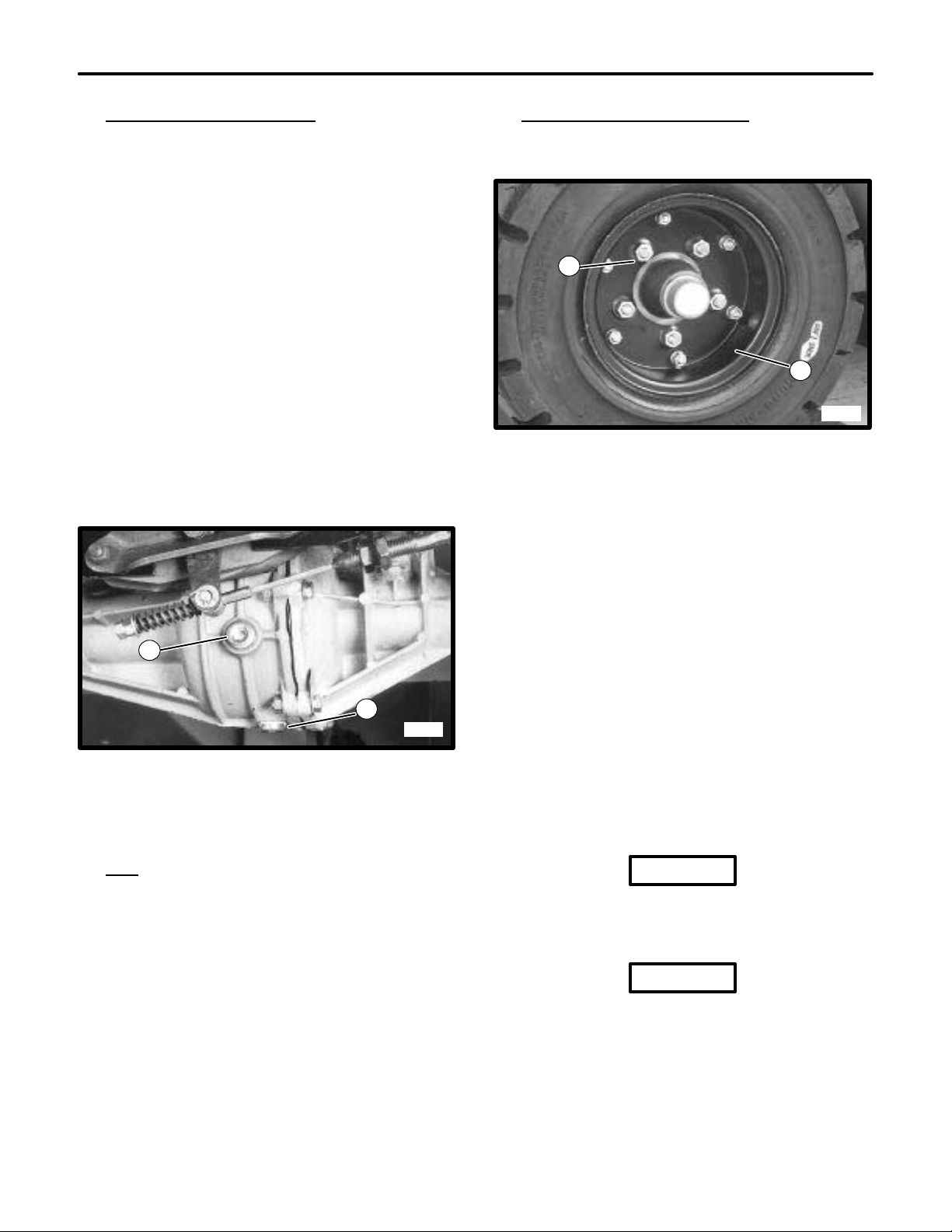

5.7 PNEUMATIC TIRES

FRONT AND REAR TIRE REMOVAL

2

1

3110

1. Wheel Retaining Nuts

2. Valve Stem

NOTICE

• Air pressure needed is determined by the payload

carried. Adjust pressure as required.

Lower pressure will help avoid leaving tire marks in

soft turf. Higher pressures may be required for

heavy loads. NEVER exceed maximum pressure

indicated on tire.

• Improper inflation will shorten the life of your tires

considerably.

• If the vehicle is operated on any surface other than

smooth and level, the use of foam filled or solid tires

could cause premature failure of tires, axles and suspension components.

• The 5.70 x 8 load range C (steel guard) and D tires

are only to be used on the welded one piece wheel

only.

• Use replacement tires equivalent to or exceeding

original equipment specifications.

Remove and reinstall as follows:

• Remove the wheel retaining nuts and remove

wheel assembly from hub.

• Reinstall tire and wheel by reversing above

sequence and tighten wheel retaining nuts to 70

to 100 ft.–lbs. (95 to 140 N·m) torque.

• Make sure the valve stem is located toward the

outside.

5.8 TIRE AIR PRESSURE

Keep tires inflated according to the specifications corresponding to the particular tire size.

Tire Size

5.70 x 8

Cold Inflation Pressure

45 PSI (310 kPa)

5.9 TOUCH-UP PAINT

Safety Yellow

• 16 oz. (0.5L) spray can LEAD FREE. Order part

number 833252.

• 1 quart (0.9L) can LEAD FREE. Order part number

833251.

Inflat tires with care. Use a pressure gauge before connecting an air hose to a partly inflated tire. Due to the low

air volume needed, over–inflation may be reached in a

matter of two or three seconds.

10

CONTROLLER PARAMETERS 6

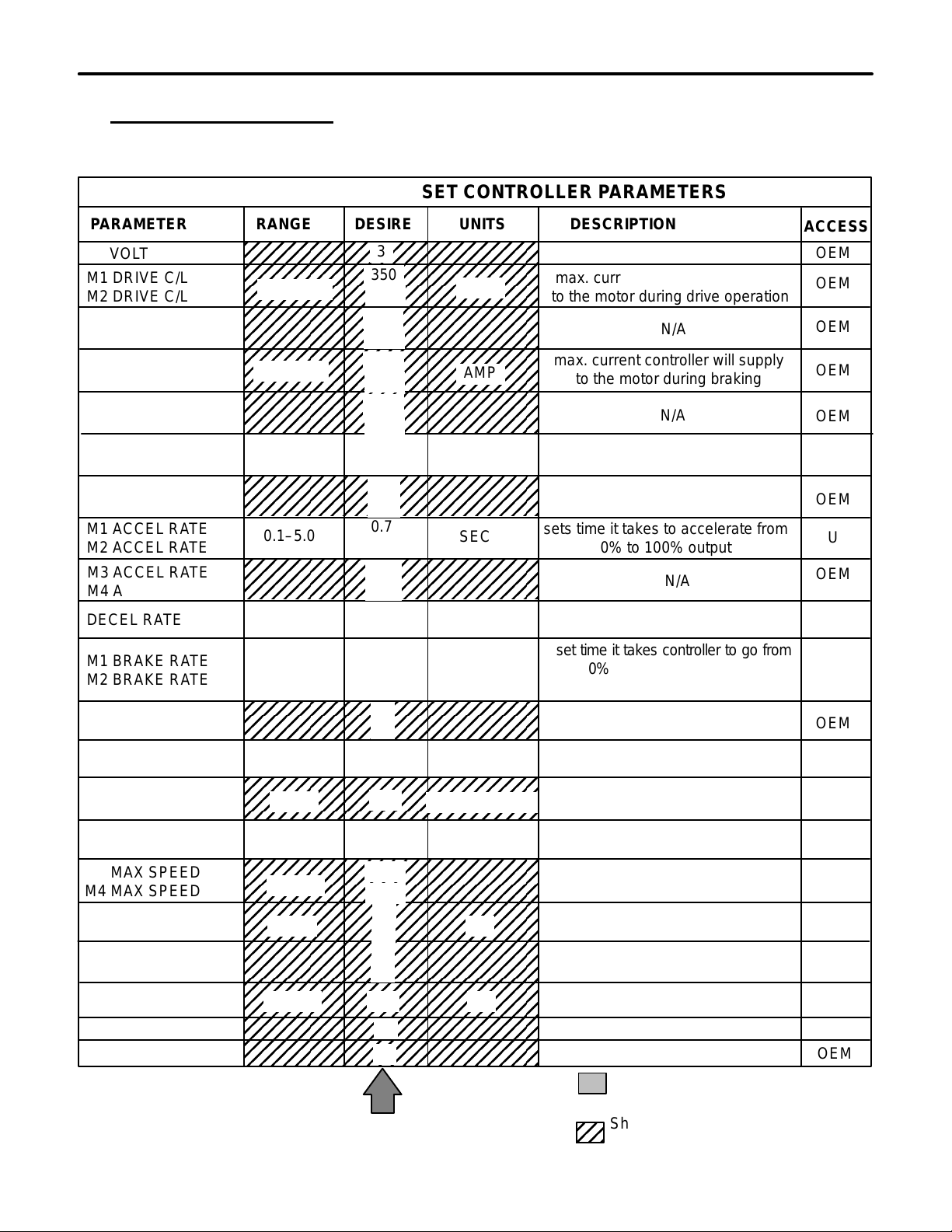

6.1 36 VOLT PROGRAMMING

CURTIS 1244-5406 (2703504) CONTROLLER PARAMETERS

FOR MOTOR (2703945) GE MODEL NO. 5BC49JB2056

CUSHMAN FACTORY SET CONTROLLER PARAMETERS

PARAMETER RANGE DESIRE UNITS DESCRIPTION

VOLT

M1 DRIVE C/L

M2 DRIVE C/L

M3 DRIVE C/L

M4 DRIVE C/L

M1 BRAKE C/L

M2 BRAKE C/L

M3 BRAKE C/L

M4 BRAKE C/L

M1 THRT BRK %

M2 THRT BRK %

M3 THRT BRK %

M4 THRT BRK %

M1 ACCEL RATE

M2 ACCEL RATE

M3 ACCEL RATE

M4 ACCEL RATE

DECEL RATE

M1 BRAKE RATE

M2 BRAKE RATE

M3 BRAKE RATE

M4 BRAKE RATE

QUICK START

M1 MAX SPEED

M2 MAX SPEED

M3 MAX SPEED

M4 MAX SPEED

M1 CREEP SPEED

M2 CREEP SPEED

M3 CREEP SPEED

M4 CREEP SPEED

REGEN SPEED

CTRL MODE

THROTTLE TYPE

100–400

100–400

0–100

0.1–5.0

0–10 1.5

0.1–5.0

0–10

0–64TAPER RA TE

0–100

0–100

0–25 %

0–100 10 %

3

350

350

350

350

170

170

170

170

34

34

34

34

0.7

0.7

0.7

0.7

4

4

4

4

6

64

100

60

100

100

0

0

0

0

2

AMP

AMP

%

SEC

SEC

SEC

1/32 of a SEC

%

1

max. current controller will supply

to the motor during drive operation

max. current controller will supply

to the motor during braking

establishes the braking force

(% of regen braking current limit)

sets time it takes to accelerate from

0% to 100% output

sets time it takes controller to

respond to throttle decrease

set time it takes controller to go from

0% to 100% braking when

changing directions

provides faster than normal accel-

eration upon sudden throttle demand

controls feel of vehicle as it slows

down & approaches zero speed

max. controller output at full throttle

(see max speed adjustment section)

N/A

defines initial controller output when

controller initiates regenerative braking

N/A

defines vehicle speed above which

controller initiates regenerative braking

N/A

N/A

N/A

N/A

N/A

ACCESS

OEM

OEM

OEM

OEM

OEM

U

OEM

U

OEM

U

U

OEM

U

OEM

U

OEM

OEM

OEM

OEM

OEM

OEM

M1 = FORWARD DIRECTION

M2 = REVERSE DIRECTION

FACTORY SETTINGS

Shaded area indicates where

parameters have been changed.

Shaded area should not be changed

from factory settings.

11

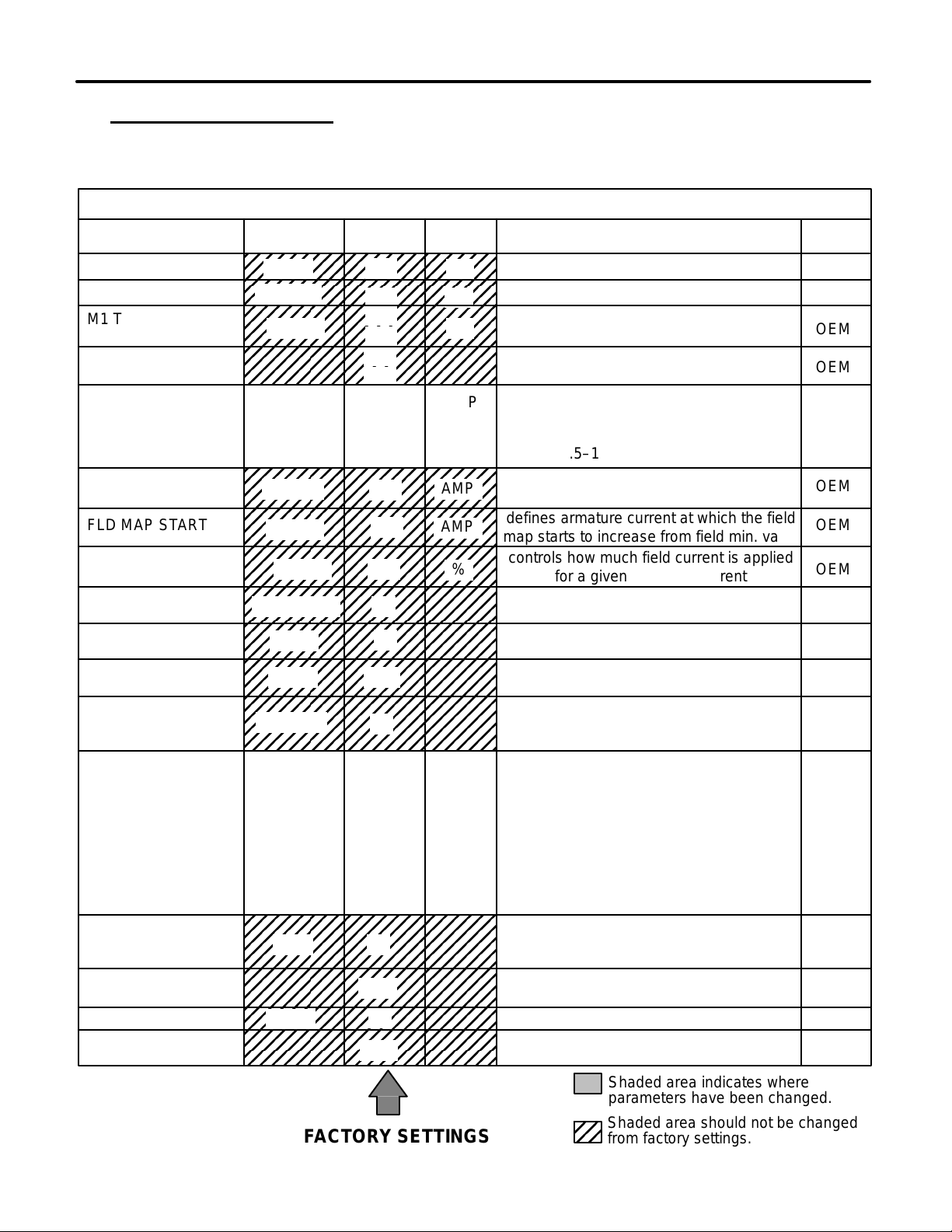

6 CONTROLLER PARAMETERS

ÉÉ

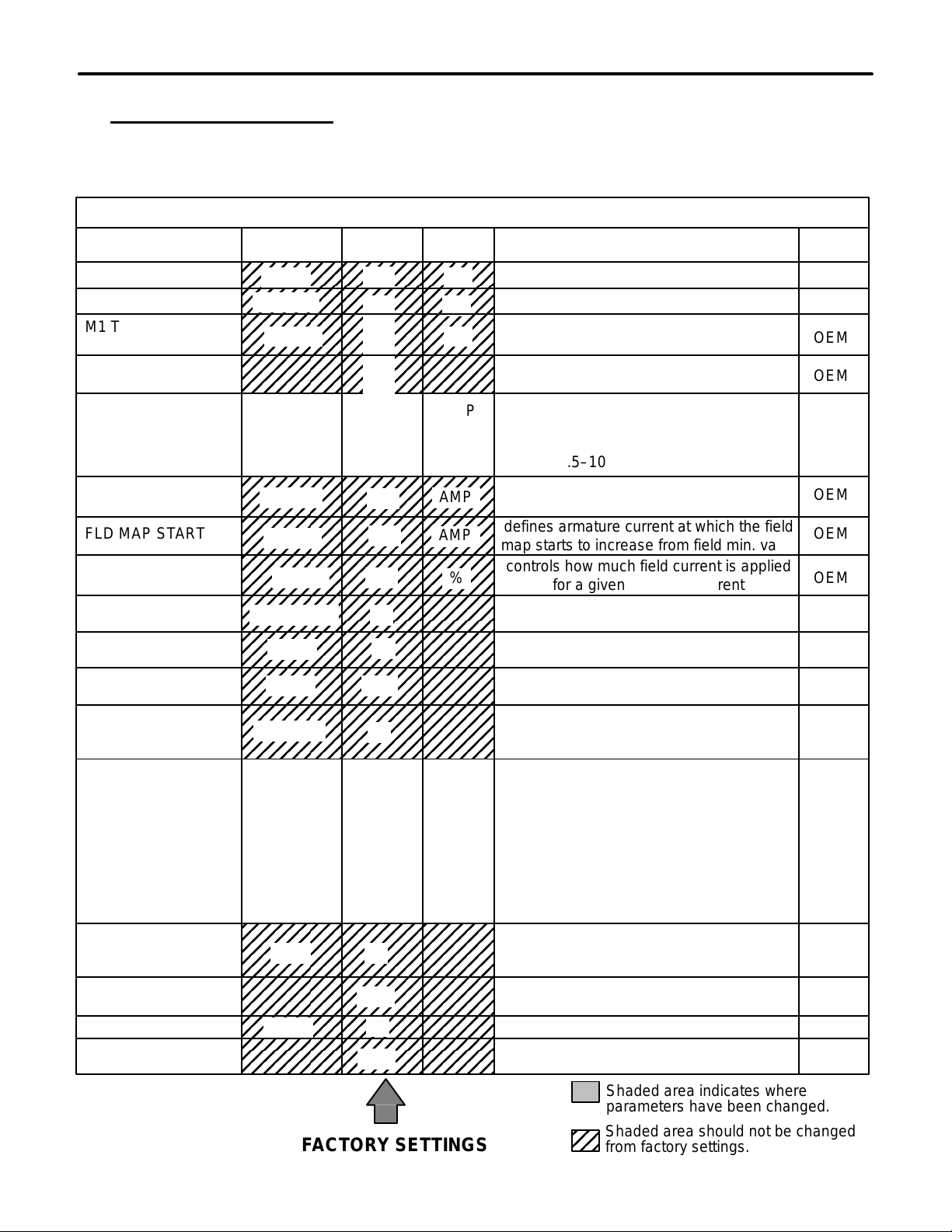

6.1 36 VOLT PROGRAMMING

CURTIS 1244-5406 (2703504) CONTROLLER PARAMETERS

FOR MOTOR (2703945) GE MODEL NO. 5BC49JB2056

CUSHMAN FACTORY SET CONTROLLER PARAMETERS

PARAMETER RANGE DESIRE UNITS DESCRIPTION

THRTL DEADBAND

THROTTLE MAX

M1 THRTL MAP

M2 THRTL MAP

M3 THRTL MAP

M4 THRTL MAP

FIELD MIN

FIELD MAX

FLD MAP START

FIELD MAP

CURRENT RATIO

RESTRAINT

LOAD COMP.

HPD

SRO

0–30

60–100

20–80 %

2–20

( DO NOT

adjust <4.5

or >10)

7.5–30

0–240

0–100

1, 2, 4 or 8

1–10

0–25

0, 1 or 2

0, 1, 2 or 3

10

90 %

40

40

40

40

4.5

30

60

50

2

3

0.0

1

0 or 1

%

AMP

AMP

AMP

%

motor’s field winding (see max speed

adjustment section) must keep within

defines armature current at which the field

map starts to increase from field min. valve

controls how much field current is applied

determine the maximum torque the motor

determine how strongly the controller

adjust applied motor voltage as a function

high pedal disable (prevents vehicle from

driving if greater than 25% throttle is applied

static return to off prevents vehicle from

Type 0: no SRO

Type 1: SRO on (interlock input plus a

direction input)

Type 2: Not used

Type 3: Not used

sets the throttle neutral range

sets the throttle full output point

modifies the vehicle’s response to

defines minimum allowed current in

4.5–10 for safe operation

defines maximum allowed current in

motor’s field winding

for a given armature current

can provide at partial throttle

attempts to limit vehicle speed

of motor load current

when controller turned on

being started when “in gear”

throttle input

N/A

ACCESS

OEM

OEM

OEM

OEM

U

OEM

OEM

OEM

OEM

OEM

OEM

OEM

U

SEQUENCING DLY

MAIN CONT INTR

MAIN OPEN DLY

WELD CHECK

M1 = FORWARD DIRECTION

M2 = REVERSE DIRECTION

12

sets time to allow interlock switch to be

0–3

0–40 main contactor dropout delay

2

ON

1

ON

FACTORY SETTINGS

cycled to prevent inadverted activation

of HPD or SRO

request for interlock input before

vehicle operation

enables main contactor checks for

welded circuit

Shaded area indicates where

parameters have been changed.

Shaded area should not be changed

from factory settings.

OEM

OEM

OEM

OEM

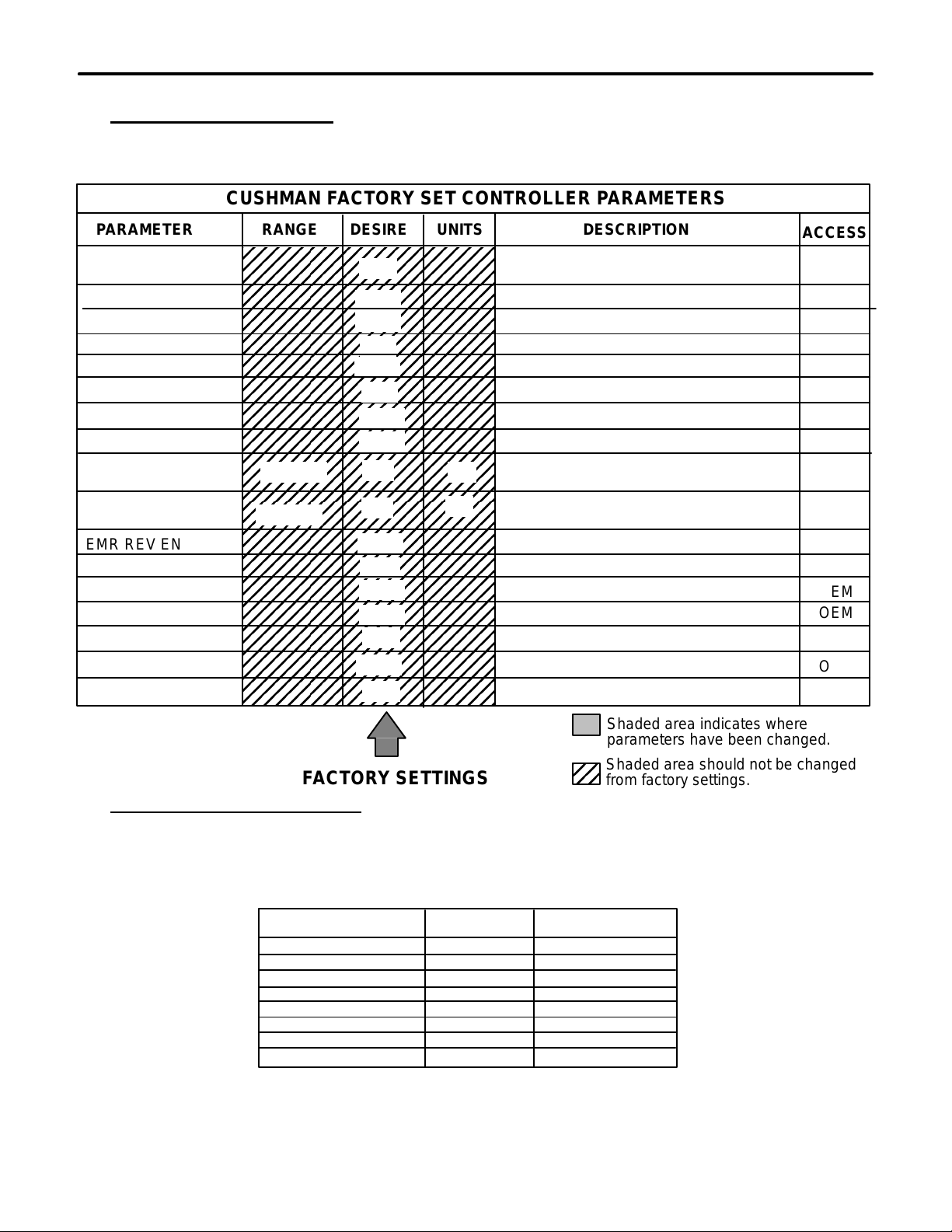

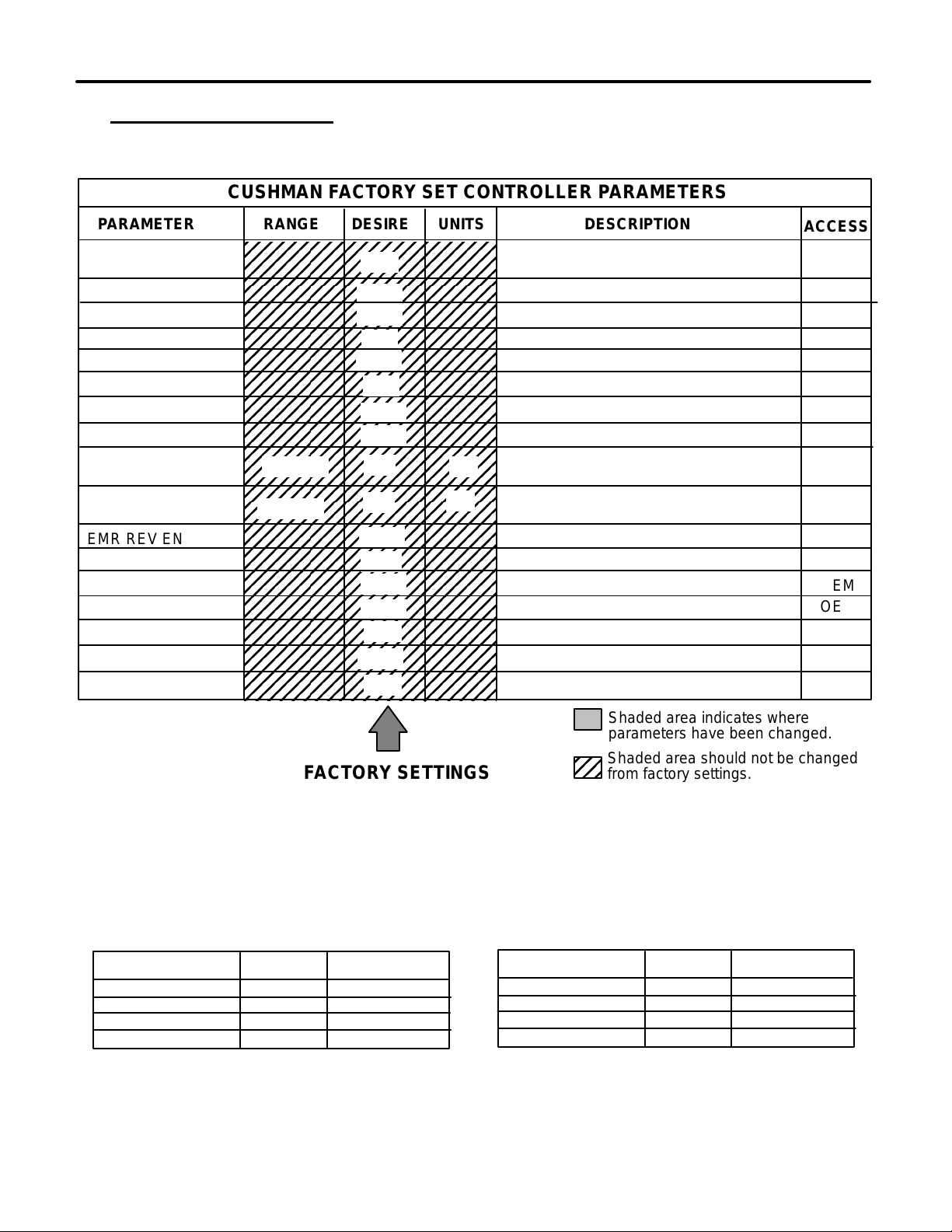

CONTROLLER PARAMETERS 6

6.1

36 VOLT PROGRAMMING

CURTIS 1244-5406 (2703504) CONTROLLER PARAMETERS

FOR MOTOR (2703945) GE MODEL NO. 5BC49JB2056

CUSHMAN FACTORY SET CONTROLLER PARAMETERS

PARAMETER RANGE DESIRE UNITS DESCRIPTION

MAIN CHECK

AUX ENABLE

EM BRAKE

AUX DELAY 0.0

AUX CHECK

EM BRAKE DELAY

EM BRAKE CHECK

REV DRVR CHECK

CONT PULL IN

CONT HOLDING

EMR REV ENABLE

EMR REV C/L

EMR REV. CHECK OFF

ANTI–TIEDOWN

FAULT CODE

PEDAL INTRLCK

PRE CHARGE

20–100 %

20–100

ON

OFF

OFF

OFF

0.0

OFF

OFF

34

26

OFF

350

OFF

ON

OFF

ON

%

enables main contactor checks for

open circuit

N/A

N/A

N/A

N/A

N/A

N/A

N/A

defines contactor pull–in voltage as %

of nominal battery voltage

defines contactor holding voltage – in

voltage 95% of nominal battery voltage

N/A

N/A

N/A

N/A

allows faults to be displayed

N/A

enables or disables pre–charge function

ACCESS

OEM

OEM

OEM

OEM

OEM

OEM

OEM

OEM

OEM

OEM

OEM

OEM

OEM

OEM

OEM

OEM

OEM

M1 = FORWARD DIRECTION

M2 = REVERSE DIRECTION

FACTORY SETTINGS

Shaded area indicates where

parameters have been changed.

Shaded area should not be changed

from factory settings.

6.2 MAX SPEED ADJUSTMENT

36 VOLT PROGRAMMING

CURTIS 1244–5406 (2703504) CONTROLLER

FOR MOTOR (2703945) G.E. MODEL NO. 5BC49JB2056

MAX SPEED CHART

MAX SPEED (MPH) FIELD MIN MI/MAX SPEED

13 4.5 100

12 5.5 100

11 6.5 100

10 7.5 100

9 8.5 100

8 10 100

71090

61075

Max speed in the forward mode may be limited by adjusting the field MIN and M1 max speed parameters as shown

in the chart above. Max speed in the reverse direction may be increased from factory setting by adjusting the M2

max speed parameter only. Never adjust M2 to be larger than M1 (don’t adjust reverse speed to be faster than forward speed)

13

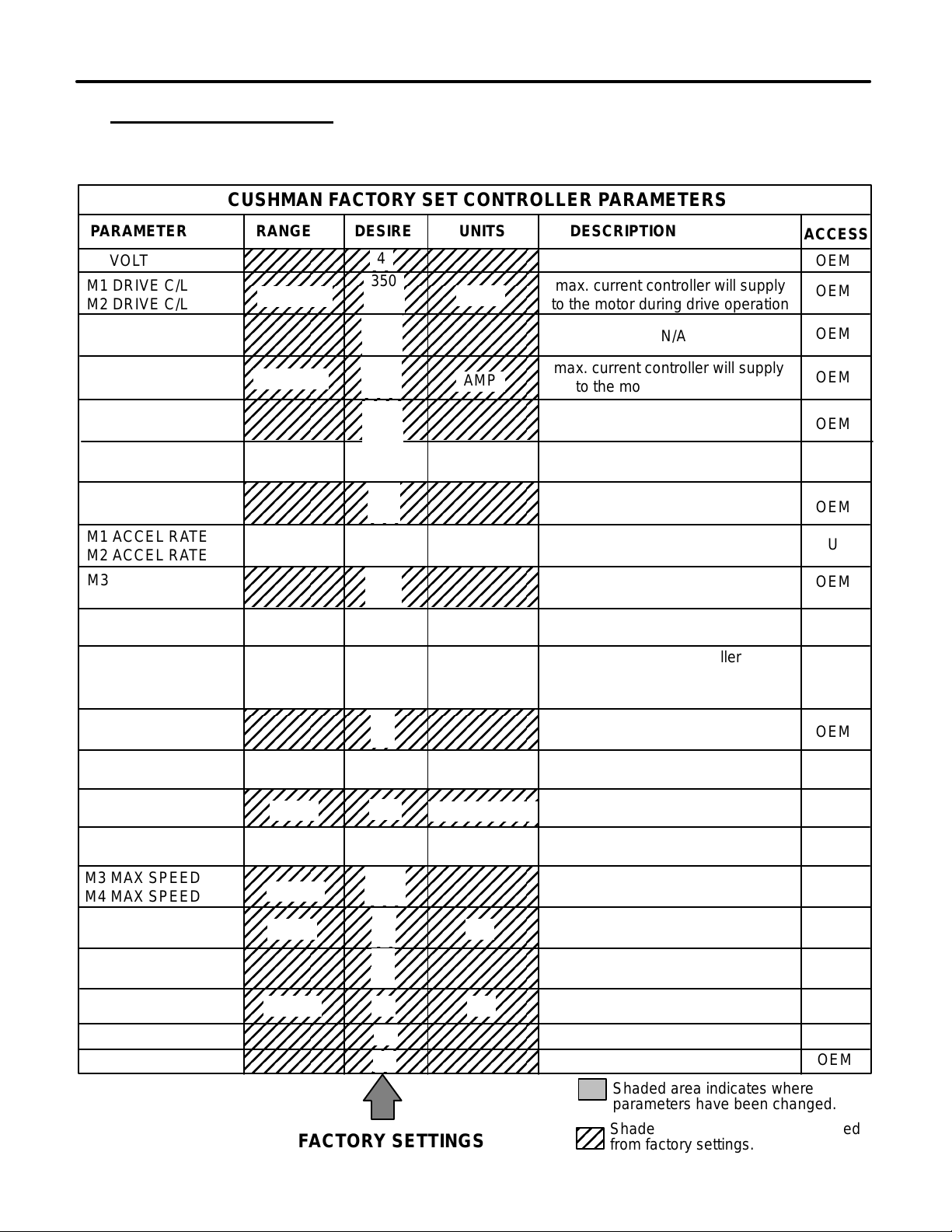

6 CONTROLLER PARAMETERS

6.3

48 VOLT PROGRAMMING

CURTIS 1244-5407 (2703505) CONTROLLER PARAMETERS

FOR MOTOR (2703946) GE MODEL NO. 5BC49JB2061

CUSHMAN FACTORY SET CONTROLLER PARAMETERS

PARAMETER RANGE DESIRE UNITS DESCRIPTION

VOLT

M1 DRIVE C/L

M2 DRIVE C/L

M3 DRIVE C/L

M4 DRIVE C/L

M1 BRAKE C/L

M2 BRAKE C/L

M3 BRAKE C/L

M4 BRAKE C/L

M1 THRT BRK %

M2 THRT BRK %

M3 THRT BRK %

M4 THRT BRK %

M1 ACCEL RATE

M2 ACCEL RATE

M3 ACCEL RATE

M4 ACCEL RATE

DECEL RATE

M1 BRAKE RATE

M2 BRAKE RATE

M3 BRAKE RATE

M4 BRAKE RATE

QUICK START

M1 MAX SPEED

M2 MAX SPEED

M3 MAX SPEED

M4 MAX SPEED

M1 CREEP SPEED

M2 CREEP SPEED

M3 CREEP SPEED

M4 CREEP SPEED

REGEN SPEED

CTRL MODE

THROTTLE TYPE

M1 = FORWARD DIRECTION

M2 = REVERSE DIRECTION

100–400

100–400

0–100

0.1–5.0

0–10

0.1–5.0

0–10

0–64TAPER RA TE

0–100

0–100

0–25 %

0–100 0 %

FACTORY SETTINGS

4

350

350

350

350

165

165

165

165

14

14

14

14

0.7

0.7

0.7

0.7

1.5

4

4

4

4

6

64

100

60

100

100

0

0

0

0

2

AMP

AMP

%

SEC

SEC

SEC

1/32 of a SEC

%

1

max. current controller will supply

to the motor during drive operation

max. current controller will supply

to the motor during braking

establishes the braking force

(% of regen braking current limit)

sets time it takes to accelerate from

0% to 100% output

sets time it takes controller to

respond to throttle decrease

set time it takes controller to go

from 0% to 100% braking when

changing directions

provides faster than normal accel-

eration upon sudden throttle demand

controls feel of vehicle as it slows

down & approaches zero speed

max. controller output at full throttle

(see max speed adjustment section)

N/A

defines initial controller output when

controller initiates regenerative braking

defines vehicle speed above which

controller initiates regenerative braking

Shaded area indicates where

parameters have been changed.

Shaded area should not be changed

from factory settings.

N/A

N/A

N/A

N/A

N/A

N/A

ACCESS

OEM

OEM

OEM

OEM

OEM

U

OEM

U

OEM

U

U

OEM

U

OEM

U

OEM

OEM

OEM

OEM

OEM

OEM

14

6 CONTROLLER PARAMETERS

6.3

48 VOLT PROGRAMMING

CURTIS 1244-5407 (2703505) CONTROLLER PARAMETERS

FOR MOTOR (2703946) GE MODEL NO. 5BC49JB2061

CUSHMAN FACTORY SET CONTROLLER PARAMETERS

PARAMETER RANGE DESIRE UNITS DESCRIPTION

THRTL DEADBAND

THROTTLE MAX

M1 THRTL MAP

M2 THRTL MAP

M3 THRTL MAP

M4 THRTL MAP

FIELD MIN

FIELD MAX

FLD MAP START

FIELD MAP

CURRENT RATIO

RESTRAINT

LOAD COMP.

HPD

SRO

0–30

60–100

20–80 %

2–20

( DO NOT

adjust <3.5

or >10)

7.5–30

0–240

0–100

1, 2, 4 or 8

1–10

0–25

0, 1 or 2

0, 1, 2 or 3

10

90 %

40

40

40

40

3.5

30

60

50

2

3

0.0

1

0 or 1

%

AMP

AMP

AMP

%

motor’s field winding (see max speed

adjustment section) must keep within

defines armature current at which the field

map starts to increase from field min. valve

controls how much field current is applied

determine the maximum torque the motor

determine how strongly the controller

adjust applied motor voltage as a function

high pedal disable (prevents vehicle from

driving if greater than 25% throttle is applied

static return to off prevents vehicle from

Type 0: no SRO

Type 1: SRO on (interlock input plus a

direction input)

Type 2: Not used

Type 3: Not used

sets the throttle neutral range

sets the throttle full output point

modifies the vehicle’s response to

defines minimum allowed current in

3.5–10 for safe operation

defines maximum allowed current in

motor’s field winding

for a given armature current

can provide at partial throttle

attempts to limit vehicle speed

of motor load current

when controller turned on

being started when “in gear”

throttle input

N/A

ACCESS

OEM

OEM

OEM

OEM

U

OEM

OEM

OEM

OEM

OEM

OEM

OEM

U

SEQUENCING DLY

MAIN CONT INTR

MAIN OPEN DLY

WELD CHECK

M1 = FORWARD DIRECTION

M2 = REVERSE DIRECTION

0–40 main contactor dropout delay

0–3

2

ON

1

ON

FACTORY SETTINGS

sets time to allow interlock switch to be

cycled to prevent inadverted activation

of HPD or SRO

request for interlock input before

vehicle operation

enables main contactor checks for

welded circuit

Shaded area indicates where

parameters have been changed.

Shaded area should not be changed

from factory settings.

OEM

OEM

OEM

OEM

15

6 CONTROLLER PARAMETERS

ÉÉ

6.3

48 VOLT PROGRAMMING

CURTIS 1244-5407 (2703505) CONTROLLER PARAMETERS

FOR MOTOR (2703946) GE MODEL NO. 5BC49JB2061

CUSHMAN FACTORY SET CONTROLLER PARAMETERS

PARAMETER RANGE DESIRE UNITS DESCRIPTION

MAIN CHECK

AUX ENABLE

EM BRAKE

AUX DELAY

AUX CHECK

EM BRAKE DELAY

EM BRAKE CHECK

REV DRVR CHECK

CONT PULL IN

CONT HOLDING

EMR REV ENABLE

EMR REV C/L

EMR REV. CHECK OFF

ANTI–TIEDOWN

FAULT CODE

PEDAL INTRLCK OFF

PRE CHARGE

20–100 %

20–100

ON

OFF

OFF

0.0

OFF

0.0

OFF

OFF

24

20

OFF

350

OFF

ON

ON

%

enables main contactor checks for

open circuit

N/A

N/A

N/A

N/A

N/A

N/A

N/A

defines contactor pull–in voltage as %

of nominal battery voltage

defines contactor holding voltage – in

voltage 95% of nominal battery voltage

N/A

N/A

N/A

N/A

allows faults to be displayed

N/A

enables or disables pre–charge function

ACCESS

OEM

OEM

OEM

OEM

OEM

OEM

OEM

OEM

OEM

OEM

OEM

OEM

OEM

OEM

OEM

OEM

OEM

M1 = FORWARD DIRECTION

M2 = REVERSE DIRECTION

FACTORY SETTINGS

Shaded area indicates where

parameters have been changed.

Shaded area should not be changed

from factory settings.

MAX SPEED ADJUSTMENT

48 VOLT PROGRAMMING

CURTIS 1244–5407 (2703505) CONTROLLER

FOR MOTOR (2703946) G.E. MODEL NO. 5BC49JB2061

MAX SPEED CHART

FOR

MODEL 898354 – 4000 LBS.

MAX SPEED (MPH) FIELD MIN MI/MAX SPEED

9 3.5 100

8 4.5 100

7 6 100

6 8 100

Max speed in the forward mode may be limited by adjusting the field MIN and M1 max speed parameters as shown

in the chart above. Max speed in the reverse direction may be increased from factory setting by adjusting the M2

max speed parameter only. Never adjust M2 to be larger than M1 (don’t adjust reverse speed to be faster than forward speed)

MAX SPEED (MPH) FIELD MIN MI/MAX SPEED

MAX SPEED CHART

FOR

MODEL 898356 – 5000 LBS.

7 3.5 100

6 5.0 100

16

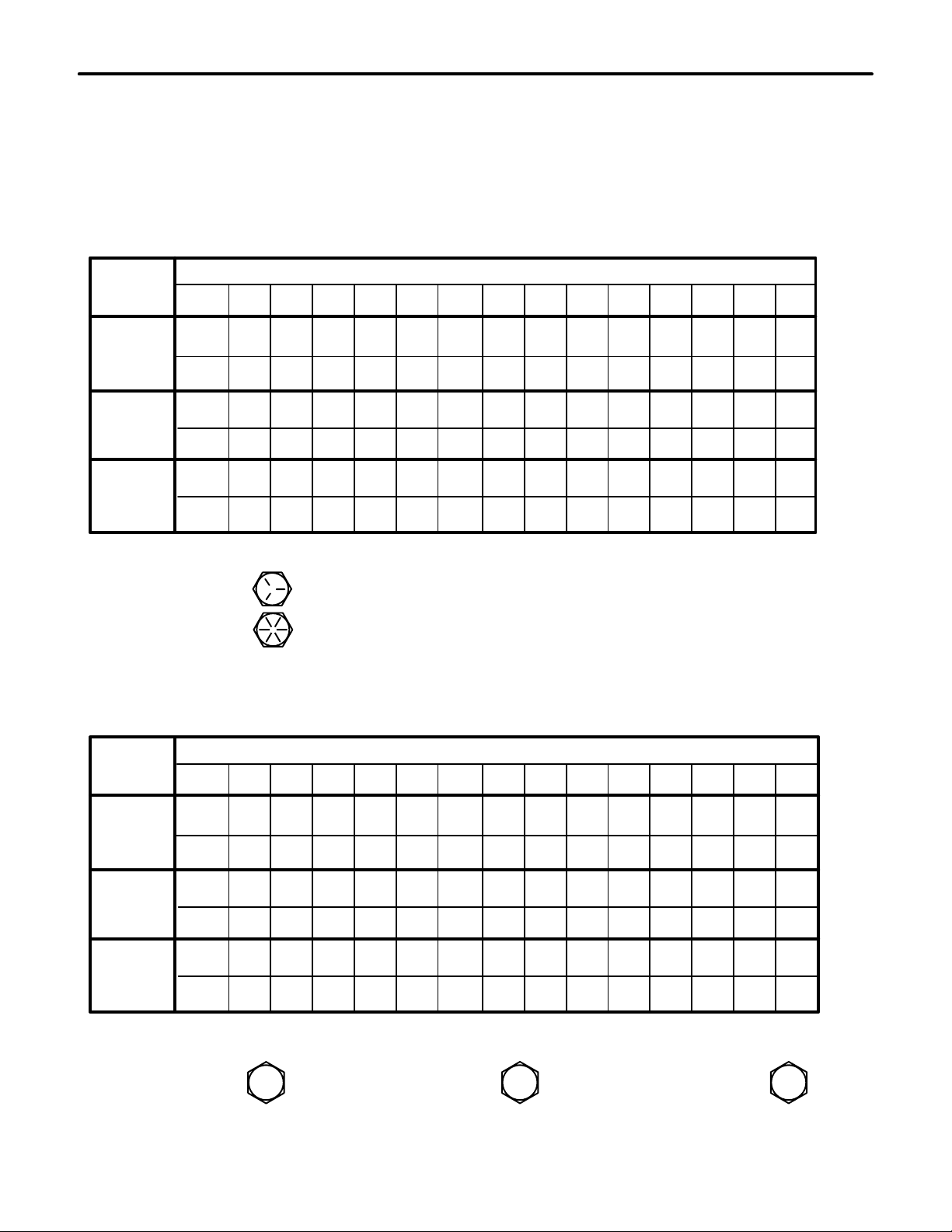

TORQUE CHART 7

TORQUE SPECIFICATIONS

HEX HEAD CAP SCREWS

The torque values shown should be used as a general guideline when specific torque values are not given.

U.S. Standard Hardware

Shank Size (Diameter in inches, fine or coarse thread)

Grade

1/4 5/16 3/8 7/16 1/2 9/16 5/8 3/4 7/8 1 1 1/8

SAE

grade

5 *

SAE

grade

8 **

Flangelock

Screw w/

Flangelock

Nut

* Grade 5 marking – Minimum commercial quality (Lower quality not recommended).

** Grade 8 marking –

ft.-lbs. 9 18 31 50 75 110 150 250 378 583 782

N·m 12 24 42 68 102 150 203 339 513 790 1060

ft.-lbs. 13 28 46 75 115 165 225 370 591 893 1410

N·m 18 38 62 108 156 224 305 502 801 1211 1912

ft.-lbs. 24 40

N·m 33 54

Metric Standard Hardware

Shank Size (Diameter in millimeters, fine or coarse thread)

Grade

M4 M5 M6 M7 M8 M10 M12 M14 M16 M18 M20 M22 M24 M27

Grade

8.8*

Grade

10.9**

Grade

12.9 ***

* Grade 8.8 marking – ** Grade 10.9 marking – *** Grade 12.9 marking –

ft.-lbs. 1.5 3 5.2 8.2 13.5 24 43.5 70.5 108 142 195 276 353 530

N·m 2 4 7 11 18 32 58 94 144 190 260 368 470 707

ft.-lbs. 2.2 4.5 7.5 12 18.8 35.2 62.2 100 147 202 275 390 498 747

N·m 3 6 10 16 25 47 83 133 196 269 366 520 664 996

ft.-lbs. 2.7 5.2 8.2 15 21.8 43.5 75 119 176 242 330 471 596 904

N·m 3.6 7 11 20 29 58 100 159 235 323 440 628 794 1205

8.8 10.9 12.9

17

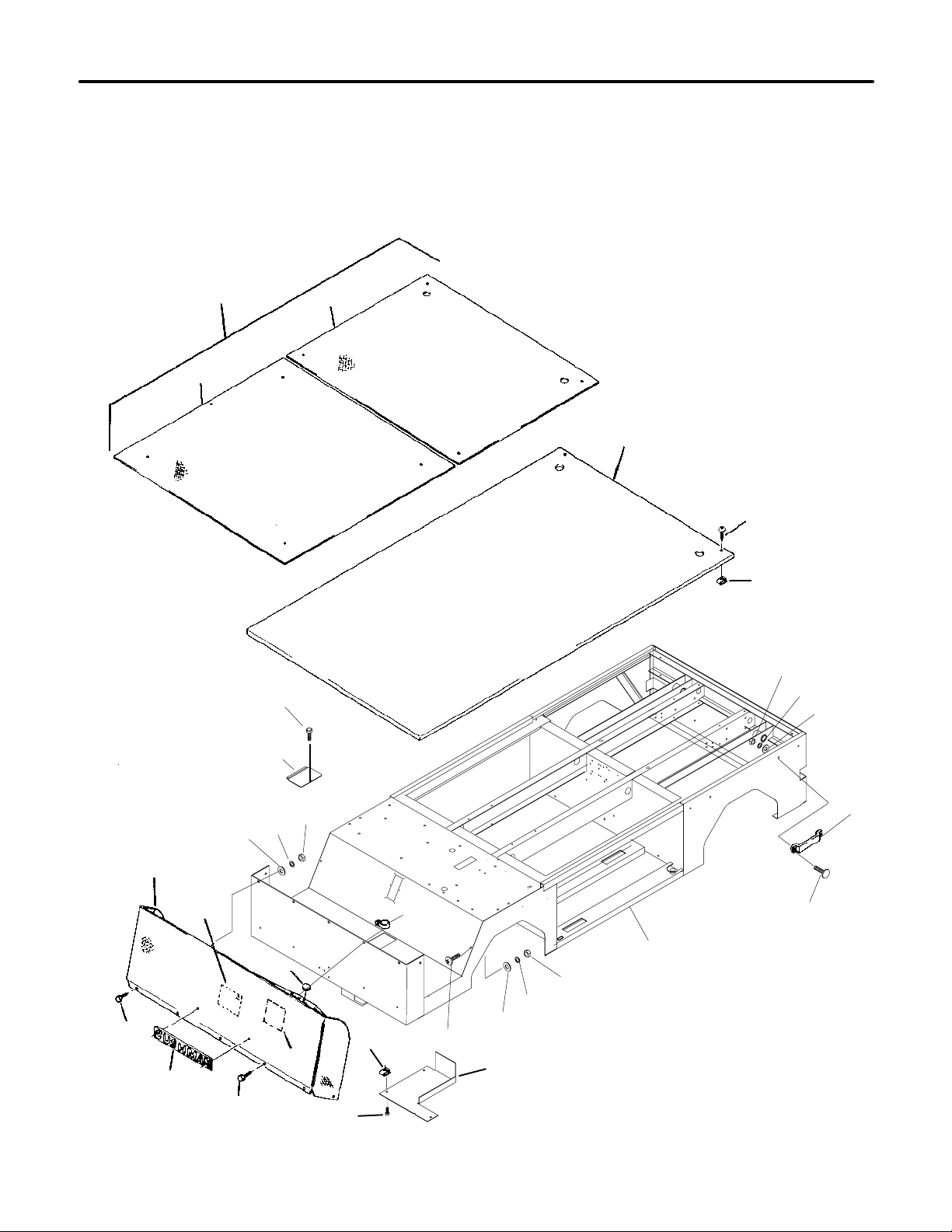

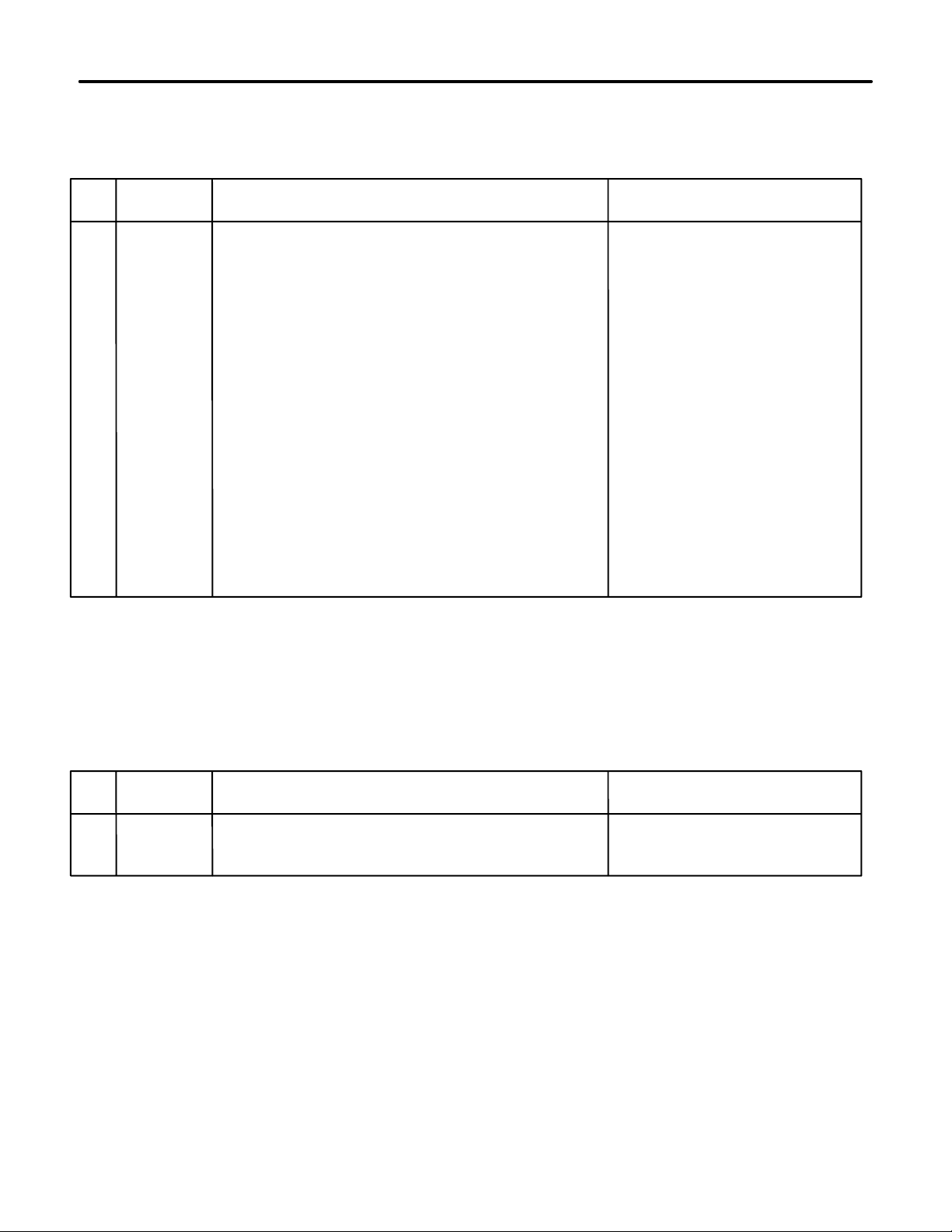

8.1 FRAME

MODELS 898353, 898353EE, 898354,

898354EE, 898356, 898356EE

AND

ACCESSORY FLOOR PLATE DECK

PART NO. 886659

MODELS 898353, 898353EE, 898354,

898354EE, 898356, 898356EE

25

23

9

24

12

5

8

4

2

1

18

3

16

14

17

3

1

15

2

10

18

4

21

8

11

13

6

19

22

4

2

1

7

20

MODELS 898353, 898353EE, 898354, 898354EE, 898356, 898356EE

FRAME 8.1

Ref.

No.

1 103867 Washer, 5/16 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 306325 Lockwasher, 5/16 17. . . . . . . . . . . . . . . . . . . . . . . . . . .

3 306416 Screw, 5/16–18 x 1 7. . . . . . . . . . . . . . . . . . . . . . . . . . .

4 306932 Nut, 5/16–18 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 800017 Screw, 1/4–20 x 1, P.T.H. 2. . . . . . . . . . . . . . . . . . . . .

6 800085 Bolt, carriage, 5/16–18 x 1 8. . . . . . . . . . . . . . . . . . . .

7 800177 Screw, 5/16–18 x 3/4, P.T.H. 2. . . . . . . . . . . . . . . . . . .

8 800279 Nut, speed, 1/4–20 5. . . . . . . . . . . . . . . . . . . . . . . . . . .

9 800331 Screw, tapping, #14 x 3/4 1. . . . . . . . . . . . . . . . . . . . .

10 825922 Plug 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11 828889 Clamp 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12 829337 Floor, wood 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13 829865 Bracket, tie down 4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

14 830790 Plate, Cushman 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15 837613 Cover, master cylinder 1. . . . . . . . . . . . . . . . . . . . . . . .

16 886855 Panel, front w/decals 1. . . . . . . . . . . . . . . . . . . . . . . . .

17 827664 •Decal, warning/operation 1. . . . . . . . . . . . . . . . . . . . .

18 830926 •Decal, charger 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

19 889888 Frame, (A Models) 1. . . . . . . . . . . . . . . . . . . . . . . . . . .

20 841193 Cover, foot pedal (B models) 1. . . . . . . . . . . . . . . . . .

21 306419 Screw, 1/4–20 x 1/2 3. . . . . . . . . . . . . . . . . . . . . . . . . .

22 893237 Frame, (B Models) 1. . . . . . . . . . . . . . . . . . . . . . . . . . .

•INDENTED PART NAMES INDICATE THESE PARTS ARE INCLUDED IN PRECEDING ASSEMBLY.

Part

No.

No.

Description Notes

Req’d

ACCESSORY FLOOR PLATE DECK

PART NO. 886659

MODELS 898353, 898353EE, 898354, 898354EE, 898356, 898356EE

Ref.

No.

23 886659 Deck, floor plate 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24 829863 •Deck, REAR half 1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

25 829993 •Deck, FRONT half 1. . . . . . . . . . . . . . . . . . . . . . . . . .

Part

No.

Description Notes

No.

Req’d

19

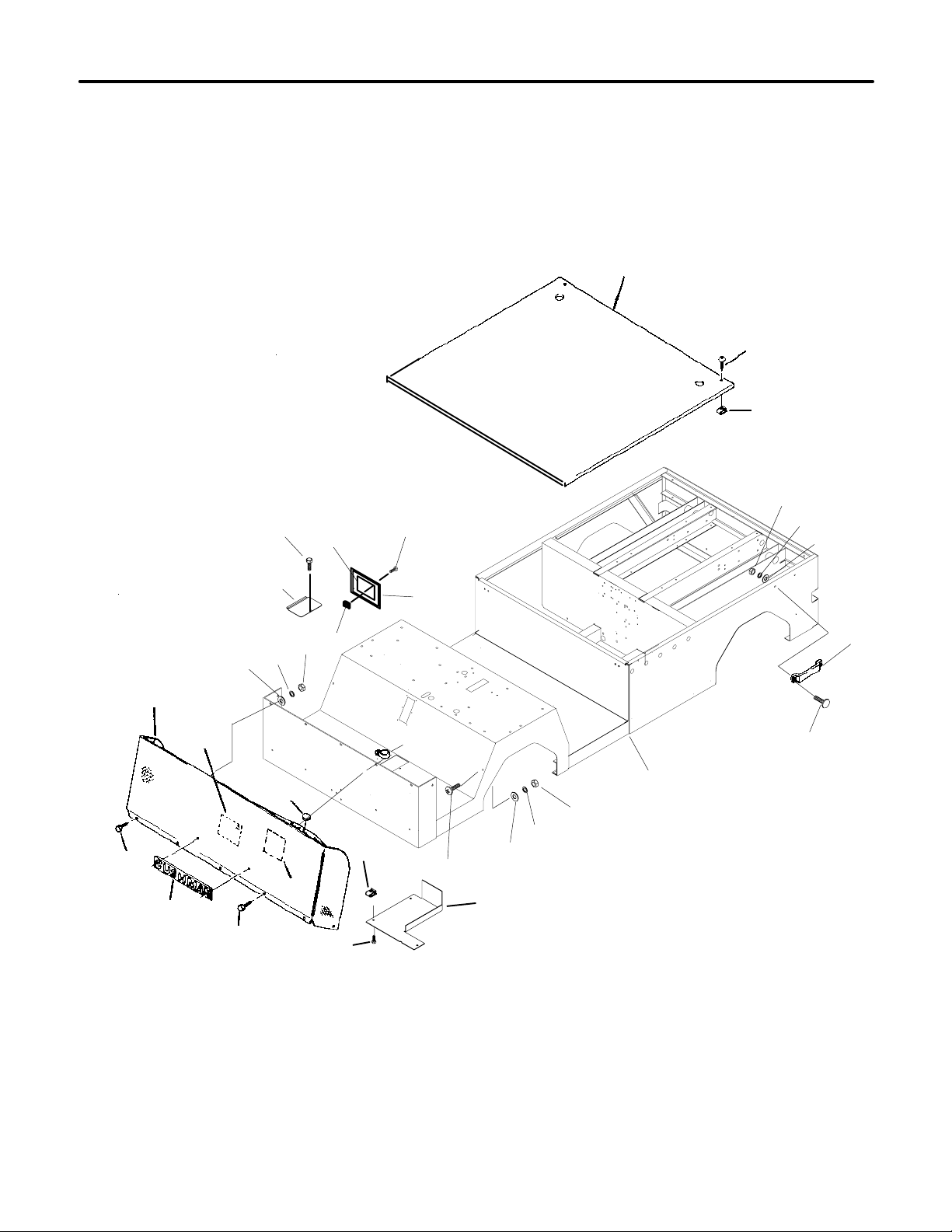

8.2 FRAME

9

24

MODELS 898355, 898355EE

20

15

5

8

4

2

1

3

16

13

17

3

1

14

2

10

18

4

25

20

8

11

23

12

6

19

22

4

2

1

7

21

20

MODELS 898355, 898355EE

FRAME 8.2

Ref.

No.

1 103867 Washer, 5/16 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 306325 Lockwasher, 5/16 13. . . . . . . . . . . . . . . . . . . . . . . . . . .

3 306416 Screw, 5/16–18 x 1 7. . . . . . . . . . . . . . . . . . . . . . . . . . .

4 306932 Nut, 5/16–18 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 800017 Screw, 1/4–20 x 1, P.T.H. 2. . . . . . . . . . . . . . . . . . . . .

6 800085 Bolt, carriage, 5/16–18 x 1 4. . . . . . . . . . . . . . . . . . . .

7 800177 Screw, 5/16–18 x 3/4, P.T.H. 8. . . . . . . . . . . . . . . . . . .

8 800279 Nut, speed, 1/4–20 2. . . . . . . . . . . . . . . . . . . . . . . . . . .

9 800331 Screw, tapping, #14 x 3/4 5. . . . . . . . . . . . . . . . . . . . .

10 825922 Plug 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11 828889 Clamp 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12 829865 Bracket, tie down 4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

13 830790 Plate, Cushman 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14 837613 Cover, master cylinder 1. . . . . . . . . . . . . . . . . . . . . . . .

15 837630 Floor, wood 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16 886855 Panel, front w/decals 1. . . . . . . . . . . . . . . . . . . . . . . . .

17 827664 •Decal, warning/operation 1. . . . . . . . . . . . . . . . . . . . .

18 830926 •Decal, charger 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

19 891994 Frame (A model) 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20 306419 Screw, 1/4–20 x 1/2 3. . . . . . . . . . . . . . . . . . . . . . . . . .

21 841193 Cover, foot pedal (B model) 1. . . . . . . . . . . . . . . . . . .

22 893238 Frame (B model) 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23 841739 Cover, access 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24 830355 Seal, weather, 35’ (10.7M) As Req’d.. . . . . . . . . . . .

25 800279 Nut, speed, 1/4–20 7. . . . . . . . . . . . . . . . . . . . . . . . . . .

Part

No.

Description Notes

No.

Req’d

•INDENTED PART NAMES INDICATE THESE PARTS ARE INCLUDED IN PRECEDING ASSEMBLY.

21

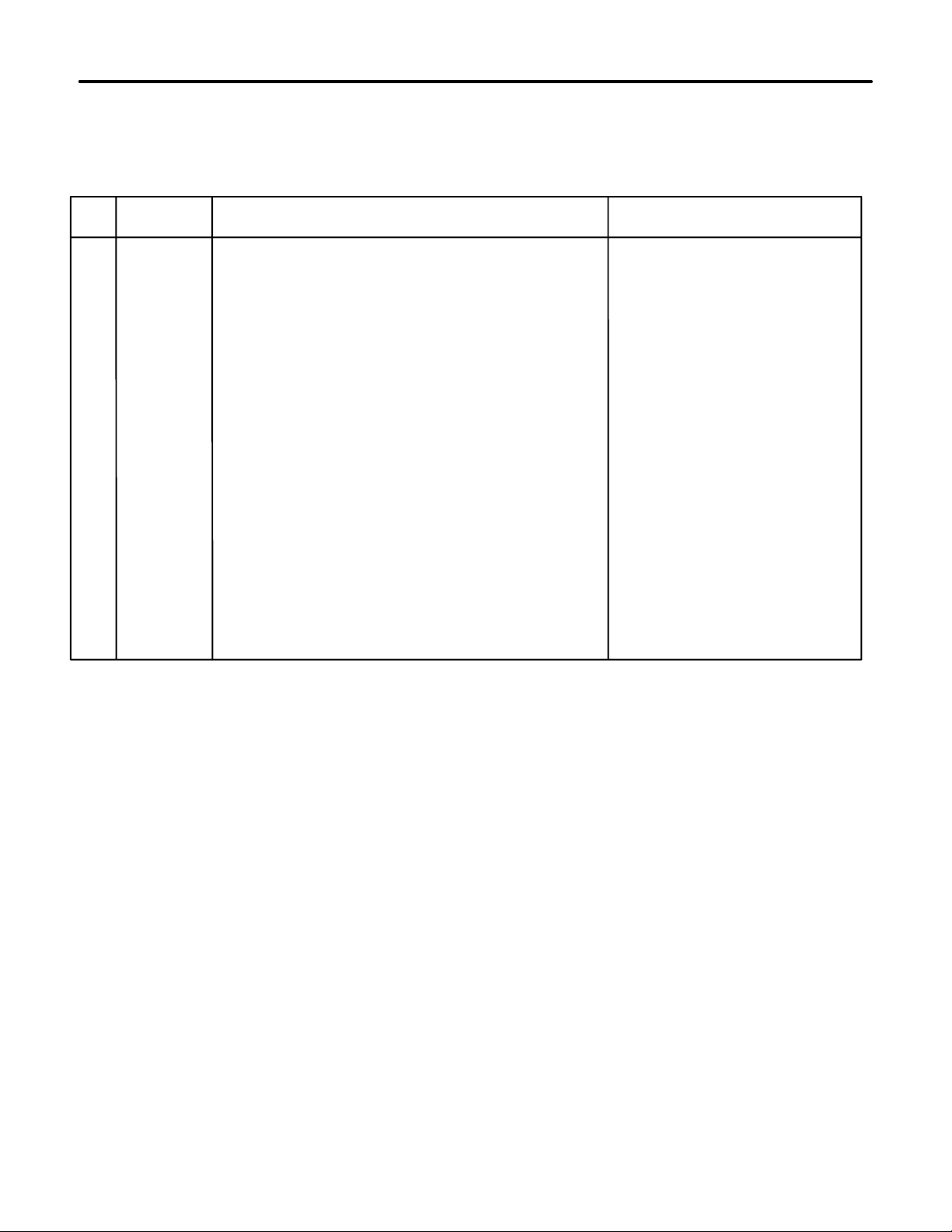

8.3 FRAME

MODEL 898357, 898357EE

AND

ACCESSORY FLOOR PLATE DECK

PART NO. 886659

24

22

9

23

12

5

8

4

2

1

22

3

16

14

17

3

1

15

2

10

18

4

20

8

11

13

6

19

4

2

1

7

21

MODEL 898357, 898357EE

AND

ACCESSORY FLOOR PLATE DECK

PART NO. 886659

FRAME 8.3

Ref.

No.

1 103867 Washer, 5/16 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 306325 Lockwasher, 5/16 17. . . . . . . . . . . . . . . . . . . . . . . . . . .

3 306416 Screw, 5/16–18 x 1 7. . . . . . . . . . . . . . . . . . . . . . . . . . .

4 306932 Nut, 5/16–18 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 800017 Screw, 1/4–20 x 1, P.T.H. 2. . . . . . . . . . . . . . . . . . . . .

6 800085 Bolt, carriage, 5/16–18 x 1 8. . . . . . . . . . . . . . . . . . . .

7 800177 Screw, 5/16–18 x 3/4, P.T.H. 2. . . . . . . . . . . . . . . . . . .

8 800279 Nut, speed, 1/4–20 5. . . . . . . . . . . . . . . . . . . . . . . . . . .

9 800331 Screw, tapping, #14 x 3/4 1. . . . . . . . . . . . . . . . . . . . .

10 825922 Plug 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11 828889 Clamp 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12 829337 Floor, wood 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13 829865 Braket, tie down 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14 830790 Plate, Cushman 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15 837613 Cover, master cylinder 1. . . . . . . . . . . . . . . . . . . . . . . .

16 886855 Panel, front w/decals 1. . . . . . . . . . . . . . . . . . . . . . . . .

17 827664 •Decal, warning/operation 1. . . . . . . . . . . . . . . . . . . . .

18 830926 •Decal, charger 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

19 893149 Frame 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20 306419 Screw, 1/4–20 x 1/2 3. . . . . . . . . . . . . . . . . . . . . . . . . .

21 841193 Cover, foot pedal 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

•INDENTED PART NAMES INDICATE THESE PARTS ARE INCLUDED IN PRECEDING ASSEMBLY.

Part

No.

No.

Description Notes

Req’d

ACCESSORY FLOOR PLATE DECK

PART NO. 886659

MODELS 898336A, 898341A

Ref.

No.

22 886659 Deck, floor plate 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23 829863 •Deck, REAR half 1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

24 829993 •Deck, FRONT half 1. . . . . . . . . . . . . . . . . . . . . . . . . .

•INDENTED PART NAMES INDICATE THESE PARTS ARE INCLUDED IN PRECEDING ASSEMBLY.

Part

No.

No.

Description Notes

Req’d

23

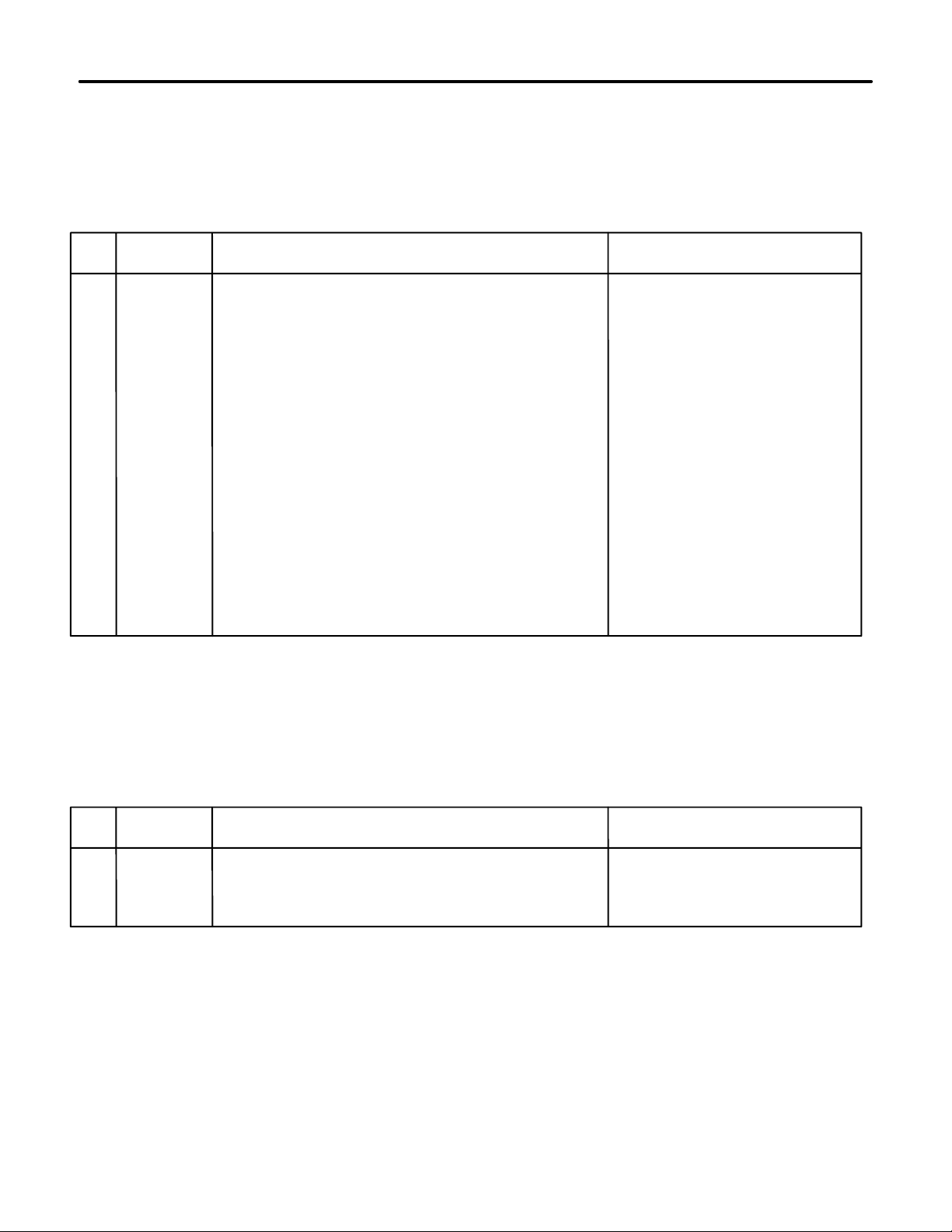

8.4 FRONT AXLE

6

33

34

RIGHT

LEFT

(MODELS:

898353, 898353EE

898355 , 898355EE

898357, 898357EE)

(MODELS

898354, 898354EE

898356, 898356EE

5 LEAF)

31

9

29

30

32

35

16

(MODELS:

898354,

898354EE

898356

898356EE)

23

20

8

14

5

7

2

4

27

9

REPRESENTATIVE

HARDWARE

1

6

10

11

13

19

17

28

15

9

1

1

16

21

12

24

41

36

MODELS: 898353, 898353EE

898353, 898354EE

898355, 898355EE

898357, 898357EE

39

40

41

22

FRONT

OF

VEHICLE

24

3

37

38

28

18

◊

25

26

24

FRONT AXLE 8.4

Ref.

No.

1 120166 Lockwasher, 1/2 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 120177 Lockwasher, 3/8 22. . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 306414 Screw, 3/8–16 x 1 4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 306562 Nut, 3/8–16 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 306834 Screw, 3/8–16 x 3/4 4. . . . . . . . . . . . . . . . . . . . . . . . . .

6 306835 Screw, 3/8–16 x 1 1/4 14. . . . . . . . . . . . . . . . . . . . . . .

7 306981 Washer, 3/8 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 306982 Washer, 7/16 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 308332 Nut, 1/2–13 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10 311745 Nut, 3/4–16 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11 312272 Lockwasher, 3/4 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12 316913 Screw, 1/2–13 x 4 2. . . . . . . . . . . . . . . . . . . . . . . . . . . .

13 548941 Screw, 1/2–13 x 4 1/2 4. . . . . . . . . . . . . . . . . . . . . . . .

14 800294 Nut, lock, 7/16–14 4. . . . . . . . . . . . . . . . . . . . . . . . . . .

15 807439 Fitting, lubrication 2. . . . . . . . . . . . . . . . . . . . . . . . . . . .

16 813850 Bumper, travel limiting 4. . . . . . . . . . . . . . . . . . . . . . . .

17 817891 Bearing, thrust 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18 827648 Shim 4 ◊ See Note.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

19 829251 Retainer, spring & king pin 2. . . . . . . . . . . . . . . . . . . .

20 889589 Plate 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21 830477 Washer, camber adjuster 2. . . . . . . . . . . . . . . . . . . . .

22 832998 Bushing 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23 833099 Bracket, reinforcement 2. . . . . . . . . . . . . . . . . . . . . . . .

24 833105 Washer, special 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

25 886225 Pin, king 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

26 829229 •Bushing 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27 886227 Axle 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

28 818238 •Bushing 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

29 886234 Spring and bushing, 898353, 898353EE

30 829229 •Bushing 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

31 888753 Spring and bushing (5 leaf)

32 829229 •Bushing 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

33 888200 Bracket, spring perch (RIGHT) 1. . . . . . . . . . . . . . . . .

34 888201 Bracket, spring perch (LEFT) 1. . . . . . . . . . . . . . . . . .

35 888203 Perch, spring 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

36 888310 Bracket, lower arm (REAR) 1. . . . . . . . . . . . . . . . . . . .

37 888321 Bracket, lower arm (FRONT) 1. . . . . . . . . . . . . . . . . .

38 888322 Bolt, lower arm 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

39 888325 Arm and bushing (LOWER) 2. . . . . . . . . . . . . . . . . . .

40 807439 •Fitting, lubrication 1. . . . . . . . . . . . . . . . . . . . . . . . . . .

41 818238 •Bushing 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part

No.

Description Notes

898355, 898355EE, 898357, 898357EE 1. . . . . . .

898354, 898354EE, 898356, 898356EE 1. . . . . . .

No.

Req’d

•INDENTED PART NAMES INDICATE THESE PARTS ARE INCLUDED IN PRECEDING ASSEMBLY.

◊ Use shims as required to obtain .001 to .011 clearance on opposite end.

25

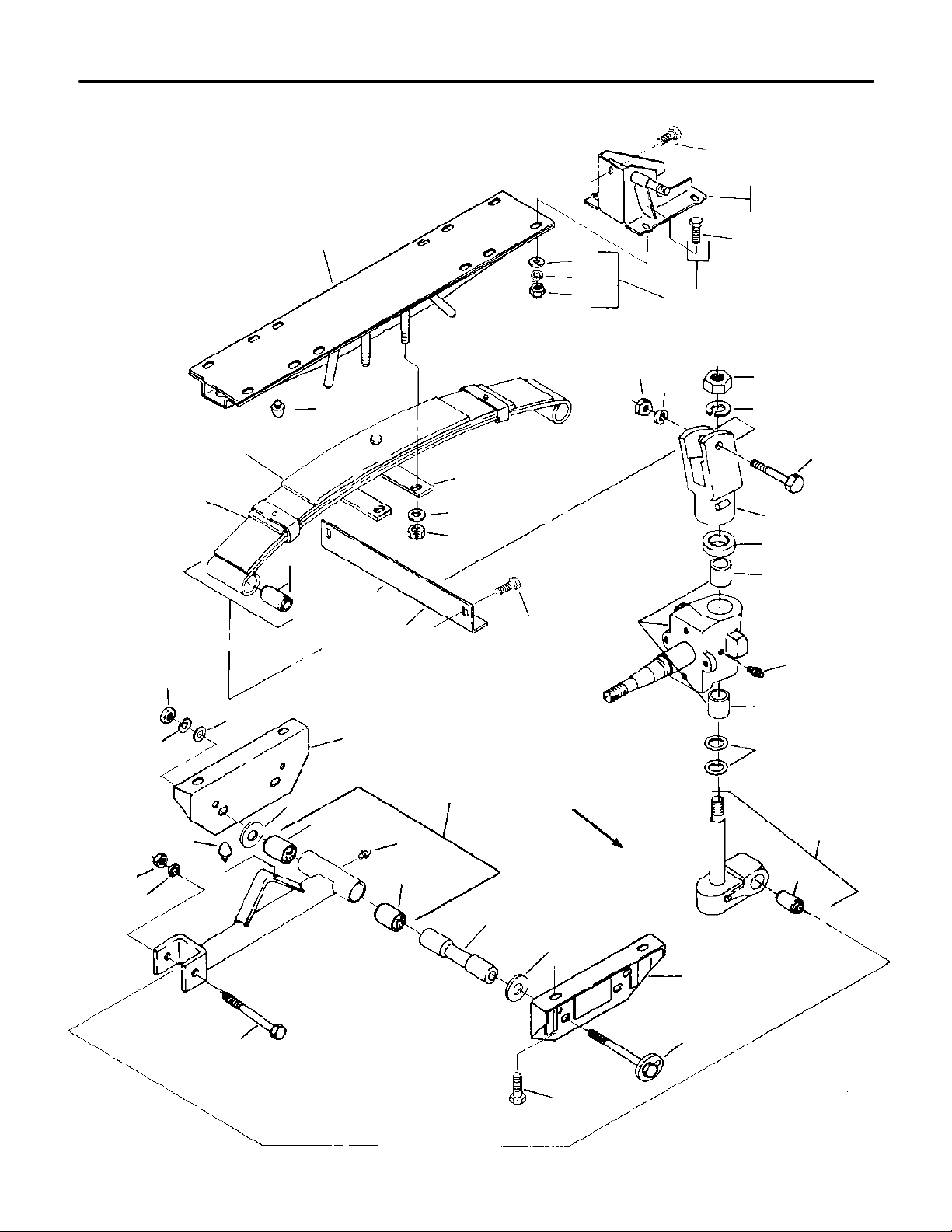

8.5 FRONT SPRING

FRONT FRAME BRACE, FRONT SPRING, ARM AND BUSHING

FRONT SPRING, MODELS 898354, 898354EE, 898356, 898356EE

MODELS 898356, 898356EE

4

5

2

1

3

9

7

8

9

6

Ref.

No.

1 120177 Lockwasher, 3/8 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 306414 Screw, 3/8–16 x 1 2. . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 306562 Nut, 3/8–16 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 834200 Brace 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 888753 Spring, front 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 829229 •Bushing 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 888892 Arm and bushing 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 807439 •Fitting, lubrication 1. . . . . . . . . . . . . . . . . . . . . . . . . . .

9 818238 •Bushing 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

•INDENTED PART NAMES INDICATE THESE PARTS ARE INCLUDED IN PRECEDING ASSEMBLY.

26

Part

No.

No.

Description Notes

Req’d

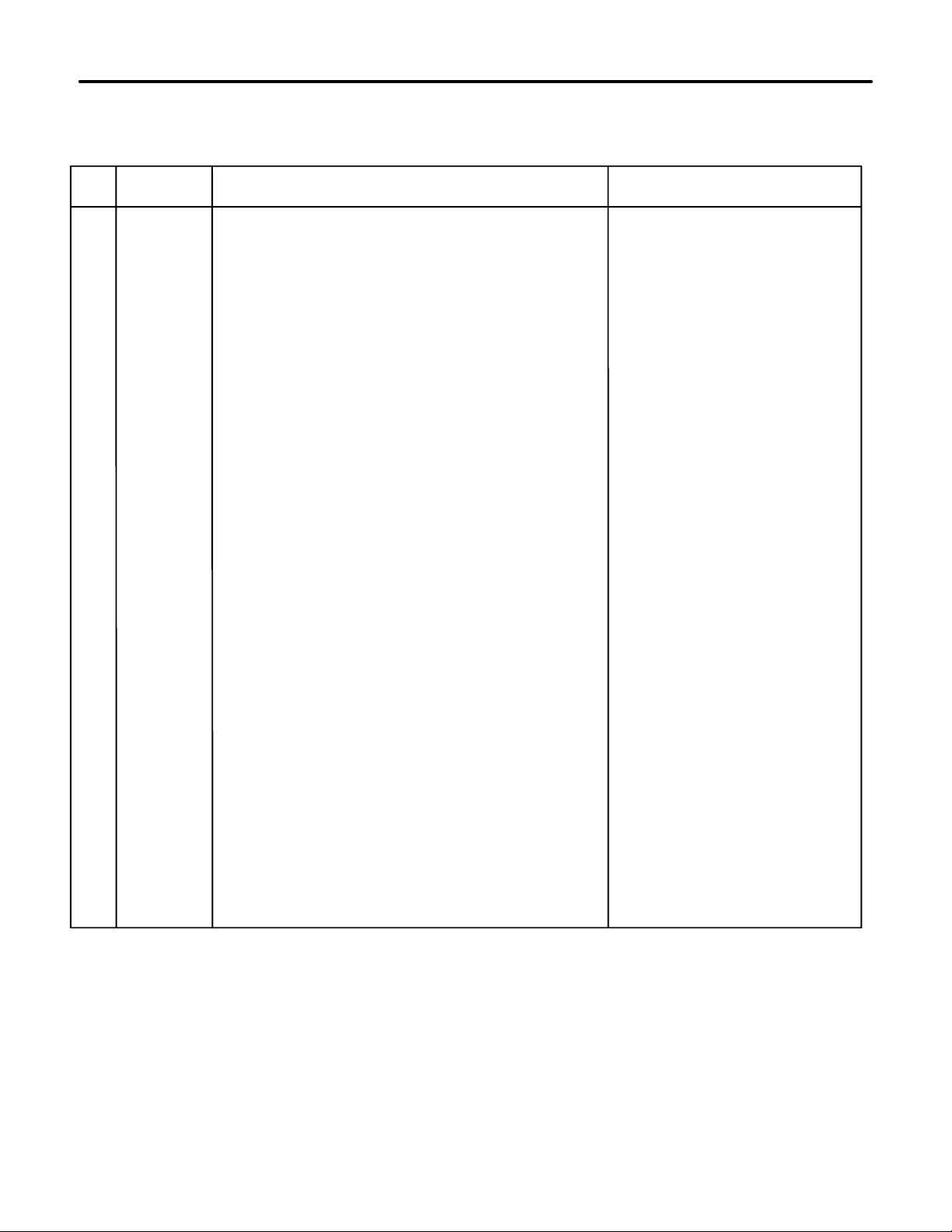

FRONT HUB 8.6

FRONT HUB WITHOUT FRONT BRAKE

MODELS 898353, 898353EE, 898355, 898355EE, 898357, 898357EE

10

7

5

4

2

11

6

Ref.

No.

1 103960 Washer, 13/16 2 Quantity indicated for both sides.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 304636 Pin, cotter, 1/8 x 1 1/8 2 Quantity indicated for both sides.. . . . . . . . . . . . . . . . . . . . . . . .

3 385174 Bearing, cone & roller (outer) 2 Quantity indicated for both sides.. . . . . . . . . . . . . . . . . .

4 311537 Nut, 3/4–16, castle 2 Quantity indicated for both sides.. . . . . . . . . . . . . . . . . . . . . . . . . . .

5 548136 Bearing, cone & roller (inner) 2 Quantity indicated for both sides.. . . . . . . . . . . . . . . . . .

6 817250 Cover 2 Quantity indicated for both sides.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 829256 Seal, grease 2 Quantity indicated for both sides.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 886223 Hub, complete 2 Quantity indicated for both sides.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 548135 •Cup, bearing (inner) 1 Quantity indicated for both sides.. . . . . . . . . . . . . . . . . . . . . . . . .

10 806274 •Screw, wheel mounting 5 Quantity indicated for both sides.. . . . . . . . . . . . . . . . . . . . . .

11 808088 •Cup, bearing (outer) 1 Quantity indicated for both sides.. . . . . . . . . . . . . . . . . . . . . . . . .

•INDENTED PART NAMES INDICATE THESE PARTS ARE INCLUDED IN PRECEDING ASSEMBLY.

Part

No.

Description Notes

3

1

9

8

No.

Req’d

27

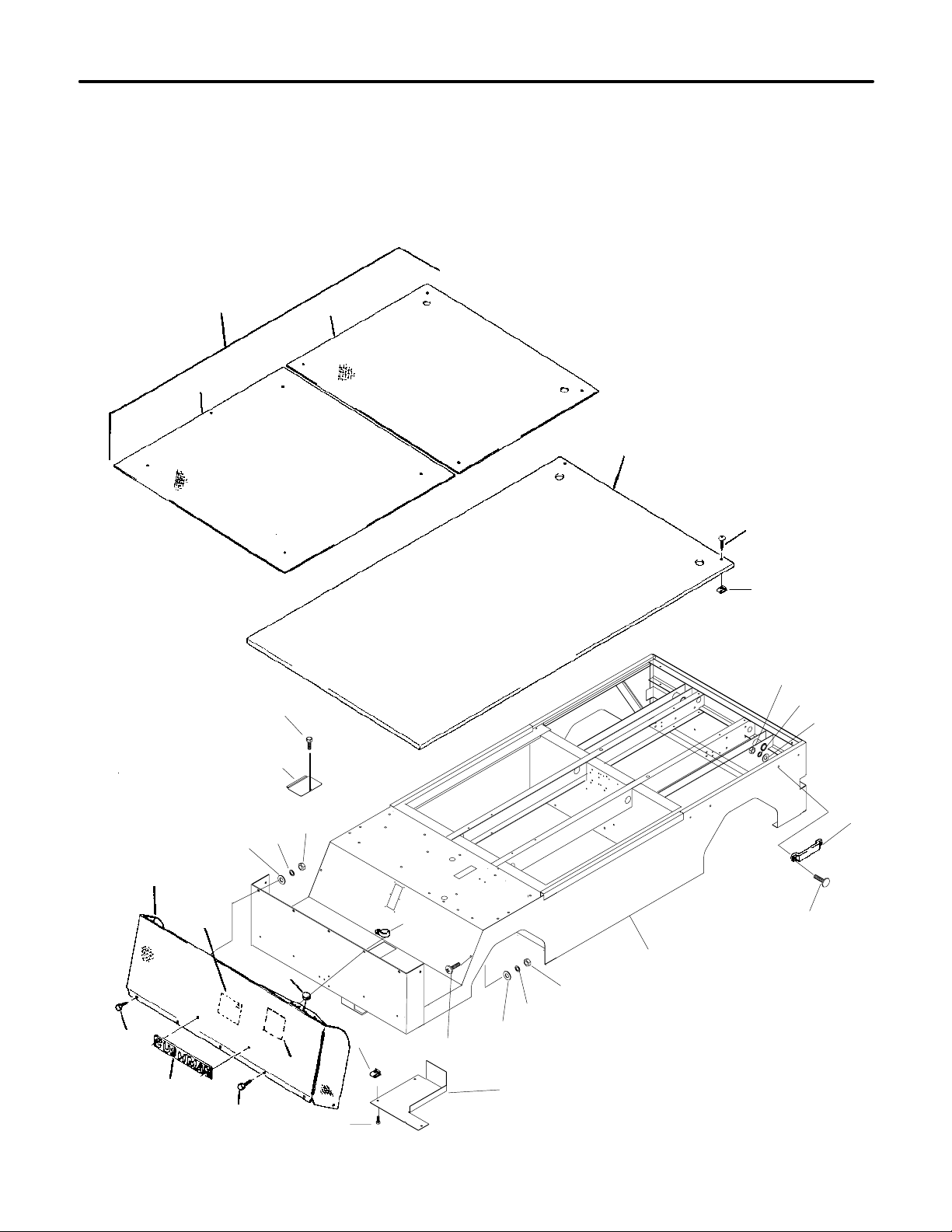

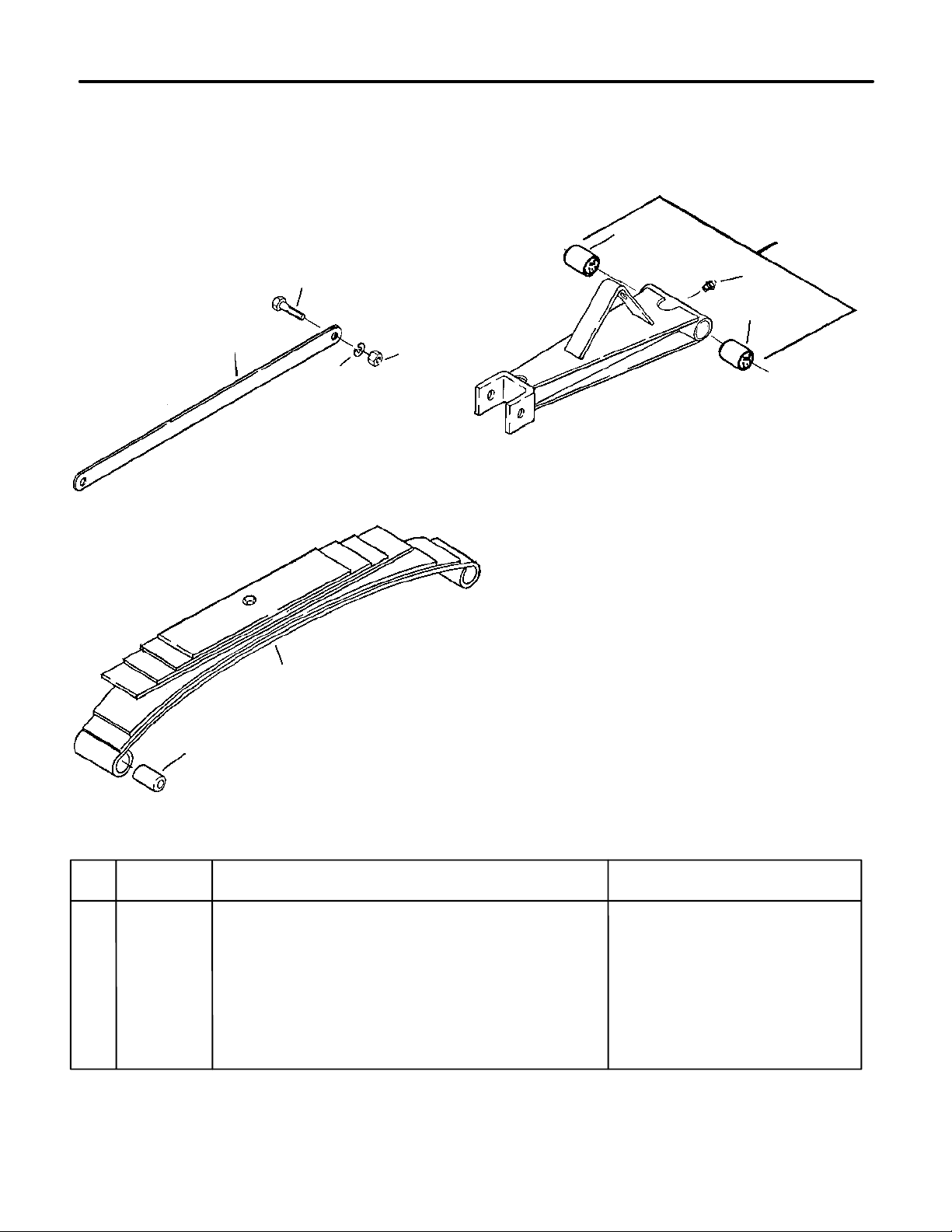

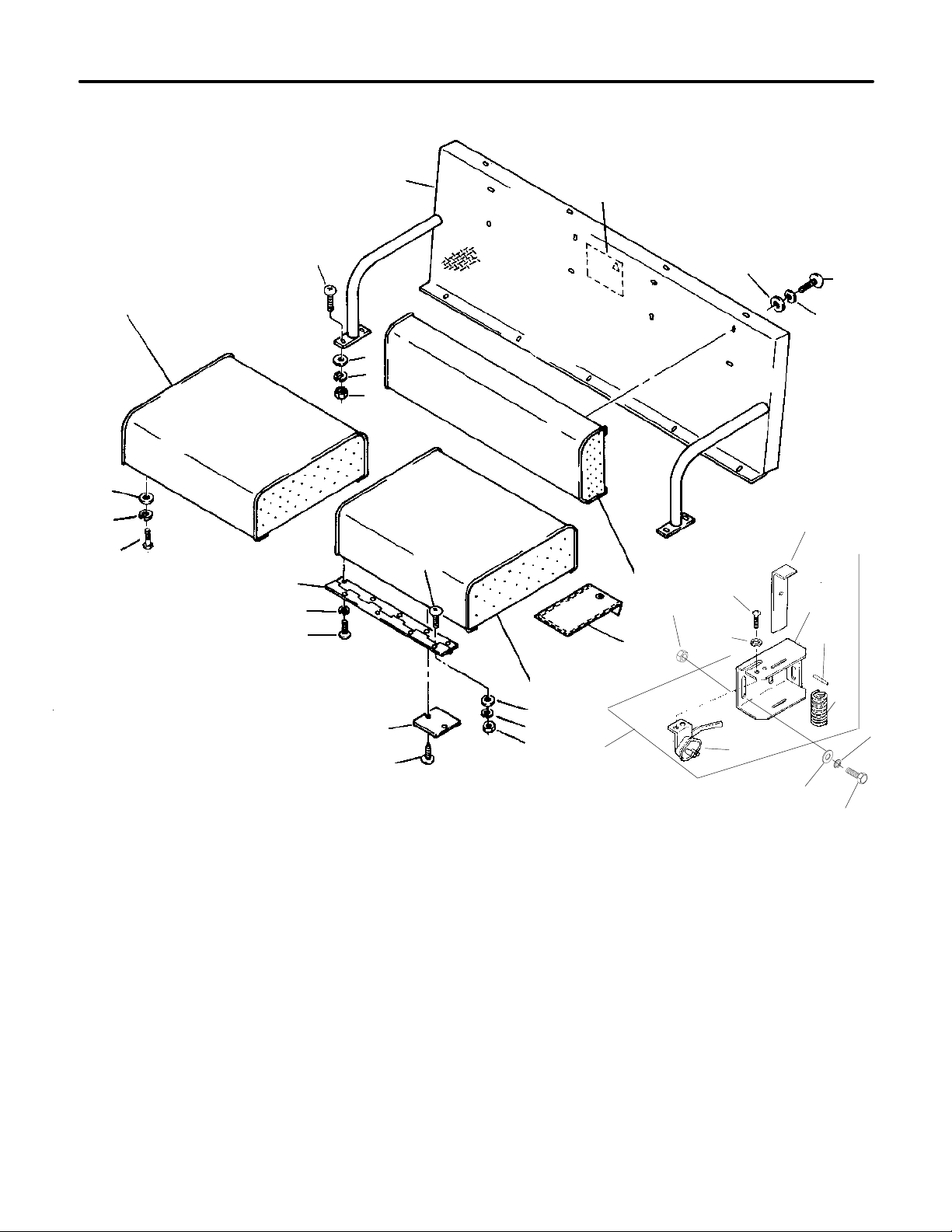

8.7 SEAT

5

3

1

20

11

3

7

6

2

5

3

21

7

22

23

9

5

2

15

13 14

7

3

19

18

10

8

20

5

3

2

12

17

3

16

5

4

28

Loading...

Loading...