Page 1

Page 2

This vehicle can be hazardous to operate.

A collision or rollover can occur quickly, even during what you think are routine

maneuvers such as driving or turning on flat terrain, driving on hills, or crossing

obstacles, if you fail to take proper precautions. For your safety, understand and follow all the warnings contained in this Operator’s Manual and on the labels on this

vehicle.

Keep this Operator’s Manual with this vehicle at all times. If you lose your manual,

contact your authorized dealer for a free replacement. The labels should be considered permanent parts of the vehicle. If a label comes off or becomes hard to read, contact your authorized dealer for a free replacement. Contact Textron Off Road Service

Department, P.O. Box 810, Thief River Falls, MN 56701, for proper registration

information.

FAILURE TO FOLLOW THE WARNINGS CONTAINED IN THIS MANUAL

CAN RESULT IN SERIOUS INJURY OR DEATH.

Particularly important information is distinguished in this manual by the following

notations:

FREE ROV TRAINING

Free training is available for Recreation Off-Highway Vehicles (ROV) operators and

passengers from Recreational Off-Highway Vehicle Association (ROHVA). The

manufacturer recommends that you complete this course before you first use your

new ROV.

This web-based course takes approximately two hours to complete and presents you

with a certificate of accomplishment as soon as you complete the course. The course

does not have to be completed all at one time. It will remember where you left off and

bring you back to that point when you return.

To receive this free training, visit www.ROHVA.org.

California Proposition 65

Always use common sense when operating this

vehicle.

!

The Safety Alert Symbol means ATTENTION!

BE ALERT! YOUR SAFETY IS INVOLVED.

! WARNING

WARNING indicates a hazardous situation

which, if not avoided, could result in death or

serious injury.

CAUTION

CAUTION, without the safety alert symbol, is

used to address practices not related to personal injury.

NOTE:

A NOTE provides key information to make procedures easier or more clear.

! WARNING

This product contains or emits chemicals known to the State of California to

cause cancer and birth defects or other reproductive harm.

Page 3

Foreword

Congratulations and thank you for purchasing an Textron Off Road Prowler

500. Built with American engineering

and manufacturing know-how, it is

designed to provide superior ride, comfort, utility, and dependable service.

This Operator’s Manual is furnished to

ensure that the operator is aware of safe

operating procedures. It also includes

information about the general care and

maintenance of this vehicle.

Carefully read the following pages. If

you have any questions regarding this

vehicle, contact an authorized Textron

Off Road (hereinafter “authorized

dealer(s)”) for assistance. Remember,

only authorized dealers have the knowledge and facilities to provide you with

the best service possible.

• Become familiar with all local and

state/provincial laws governing ROV

operation,

• Respect your vehicle,

• Respect the environment, and

• Respect private property and do not

trespass.

We also advise you to strictly follow the

recommended maintenance program as

outlined. This preventive maintenance

program is designed to ensure that all

critical components on this vehicle are

thoroughly inspected at various intervals.

All information in this manual is based

on the latest product data and specifications available at the time of printing. We

reserve the right to make product changes

and improvements which may affect

illustrations or explanations without

notice.

You have chosen a quality vehicle

designed and manufactured to give

dependable service. Be sure, as the

owner/operator of this vehicle, to become

thoroughly familiar with its basic operation, maintenance, and storage procedures. Read and understand the entire

Operator’s Manual before operating this

vehicle to ensure safe and proper use.

Always operate the vehicle within your

level of skill and current terrain conditions.

Division II of this manual covers operator-related maintenance, operating

instructions, and storage instructions. If

major repair or service is ever required,

contact an authorized dealer for professional service.

At the time of publication, all information and illustrations in this manual were

technically correct. Some illustrations

used in this manual are used for clarity

purposes only and are not designed to

depict actual conditions. Because we constantly refine and improve our products,

no retroactive obligation is incurred.

Operation of this vehicle is restricted to

people 16 years of age and older who

possess a valid driver’s license. Passengers must be able to place both feet flat

on the floor while keeping their back

against the back of the seat and holding

on to an available hand hold.

Protect Your Sport

Parts and Accessories

When in need of replacement parts, oil,

or accessories for this vehicle, be sure to

use only GENUINE PARTS, OIL, AND

ACCESSORIES. Only genuine parts,

oil, and accessories are engineered to

meet the standards and requirements

of this vehicle. For a complete list of

accessories, refer to the current ATV/

ROV Accessory Catalog.

To aid in service and maintenance procedures on this vehicle, a Service Manual is available through your local

authorized dealer.

Page 4

2

Table of Contents

Foreword .................................................. 1

Parts and Accessories............................ 1

Division I - Safety

Safety Alert .............................................. 4

Warning Labels..................................... 5-6

Location of Parts and Controls .............. 7

Warnings ............................................. 8-16

Division II - Operation/

Maintenance

Specifications ........................................ 17

Vehicle Operation ............................. 18-22

General Information ......................... 23-32

Control Locations and Functions.......... 23

Occupant Side Restraints .................... 25

Speedometer/LCD (Digital) .................. 25

Diagnostic Trouble Codes .................... 28

Oil Level Stick....................................... 29

Load Capacity Ratings Chart ............... 29

Trailering and Towing ........................... 29

Transporting ......................................... 30

Gasoline-Oil-Lubricant ......................... 31

Engine Break-In ................................... 32

Burnishing Brake Pads......................... 32

General Maintenance ....................... 33-54

Maintenance Schedule......................... 33

Liquid Cooling System ......................... 34

Shock Absorbers.................................. 34

General Lubrication.............................. 35

Hydraulic Brake.................................... 36

Gas Hoses ........................................... 37

Protective Rubber Boots ...................... 37

Battery.................................................. 38

Spark Plug............................................ 41

Air Filter/Housing Drain ........................ 41

Draining V-Belt Cover........................... 42

Tires ..................................................... 43

Wheels ................................................. 43

Muffler/Spark Arrester .......................... 43

Light Bulb Replacement ....................... 44

Checking/Adjusting Headlight Aim ....... 45

Fuses ................................................... 46

Electrical Output Terminals .................. 46

Storage Compartments/Tools............... 46

Seat Belts............................................. 47

Occupant Side Restraints .................... 47

ROPS ................................................... 47

Preparation For Storage ....................... 48

Preparation After Storage..................... 49

Maintenance Record ........................50-51

Limited Warranty ................................... 52

Warranty Procedure/Owner

Responsibility.................................... 53

U.S. EPA Emission Control Statement/

Warranty Coverage - ROV (U.S. Only)54

Change of Address, Ownership, or

Warranty Transfer.............................. 55

Identification Numbers Record ......Inside

Back Cover

Page 5

! WARNING

Indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

3

Division I - Safety

This vehicle is not a toy

and can be hazardous

to operate.

•Always go slowly and be extra careful when operating on unfamiliar terrain. Always

be alert to changing

terrain conditions when operating

this vehicle.

•Never

operate on excessively rough,

slippery, or loose terrain.

•Always

follow proper procedures for

turning as described in this manual.

Practice turning at slow speeds

before attempting to turn at faster

speeds. Do not turn at excessive

speed.

•Always

have the vehicle checked by

an authorized dealer if it has been

involved in an accident.

•Never

operate on hills too steep for

your abilities. Practice on smaller

hills before attempting larger hills.

•Always

follow proper procedures for

climbing hills as described in this

manual. Check the terrain carefully

before you start up any hill. Never

climb hills with slippery or loose surfaces. Never

depress the accelerator

suddenly or make gear changes

while moving. Never go over the top

of any hill at high speed.

•Always

follow proper procedures for

going down hills and for braking on

hills as described in this manual.

Check the terrain carefully before

you start down any hill. Never

go

down a hill at high speed. Avoid

going down a hill at an angle which

would cause the vehicle to lean

sharply to one side. Go straight

down the hill where possible.

•Always

be careful when you decide

to climb or descend a hill and never

turn on a hill. Drive straight up or

down inclines and not across them.

If you must cross the side of a hill,

drive slowly and stop or turn downhill

if you feel the vehicle may tip over.

•Always

use proper procedures if you

stall or roll backward when climbing

a hill. To avoid stalling, maintain a

steady speed when climbing a hill. If

you stall or roll backwards, follow the

special procedure for braking

described in this manual.

•Always

check for obstacles before

operating in a new area. Never

attempt to operate over large obstacles, such as large rocks or fallen

trees. Always

follow proper procedures when operating over obstacles

as described in this manual.

•Always

be careful of skidding or sliding. On slippery surfaces, such as

ice, go slowly and be very cautious

in order to reduce the chance of

skidding or sliding out of control.

•Never

operate this vehicle in fast

flowing water or in water deeper than

the floorboard. Remember that wet

brakes may have reduced stopping

capability. Test your brakes after

leaving water. If necessary, apply

them lightly several times to let friction dry out the pads.

•Always

be sure there are no obstacles or people behind you when you

operate in reverse. When it is safe to

proceed in reverse, go slowly. Avoid

turning at sharp angles in reverse.

•Always

use the size and type tires

specified in this manual. Always

maintain proper tire pressure as

described in this manual.

•Never

improperly install or improp-

erly use accessories on this vehicle.

•Never

exceed the stated load capacity for this vehicle. Cargo should be

properly distributed and securely

attached. Reduce speed and follow

instructions in this manual for carrying cargo or pulling a trailer and

allow greater distance for braking.

• Operation of this vehicle is restricted

to people 16 years of age and older

who possess a valid driver’s license.

Passengers must be able to place

both feet flat on the floor while keeping their back against the back of the

seat and holding on to an available

hand hold.

Page 6

! WARNING

Indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

4

Safety Alert

You should be aware that THIS VEHICLE IS NOT A TOY AND CAN BE

HAZARDOUS TO OPERATE. This

vehicle handles differently from other

vehicles, including motorcycles and cars.

A collision or rollover can occur quickly,

even during what you think are routine

maneuvers such as turning, driving on

hills, and going over obstacles, if you fail

to take proper precautions.

TO AVOID SERIOUS

INJURY OR DEATH:

*Always read the Operator’s Manual

carefully and follow the operating

procedures described. Pay special

attention to the warnings contained in

the manual and on all labels.

*Always

wear the seat belt when oper-

ating or riding in this vehicle.

*Always

follow these age recommen-

dations:

• Operation of this vehicle is restricted

to people 16 years of age and older

who possess a valid driver’s license.

Passengers must be able to place

both feet flat on the floor while keeping their back against the back of the

seat and holding on to the hand

hold.

* Never carry a passenger in the cargo

box of this vehicle.

* Never

operate this vehicle on a public

road, even a dirt or gravel one,

because you may not be able to avoid

colliding with other vehicles.

* Never

operate this vehicle without an

approved motorcycle helmet, eye

protection, boots, gloves, long pants

and a long-sleeved shirt or jacket.

*Never consume alcohol or drugs

before or while operating this vehicle.

*Never

operate this vehicle at excessive speeds. Go at a speed which is

proper for the terrain, visibility conditions, and your experience.

*Never

attempt to do wheelies, jumps,

or other stunts.

*Always

be careful when operating

this vehicle, especially when

approaching hills, turns, and obstacles and when operating on unfamiliar or rough terrain.

*Never

operate this vehicle with the

cargo box lifted or removed.

*Never

operate this vehicle in fast

flowing water or in water deeper than

the floorboard.

*Never

operate this vehicle with the

ROPS (Roll Over Protective Structure) removed. The ROPS provides a

structure helping to limit intrusions

by branches or other objects and may

reduce your risk of injury in accidents.

*Never

put your hands or feet outside

the vehicle for any reason while the

vehicle is in motion. Do not hold onto

the ROPS or hip restraint bar. If you

think or feel the vehicle may tip, do

not put your hands or feet outside the

vehicle as they will not be able to prevent the vehicle from tipping. Any

part of your body (arms, legs, or

head) outside the vehicle can be

crushed by passing objects, the vehicle, or ROPS.

* Always fasten occupant side

restraints prior to moving the vehicle.

Page 7

! WARNING

Indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

5

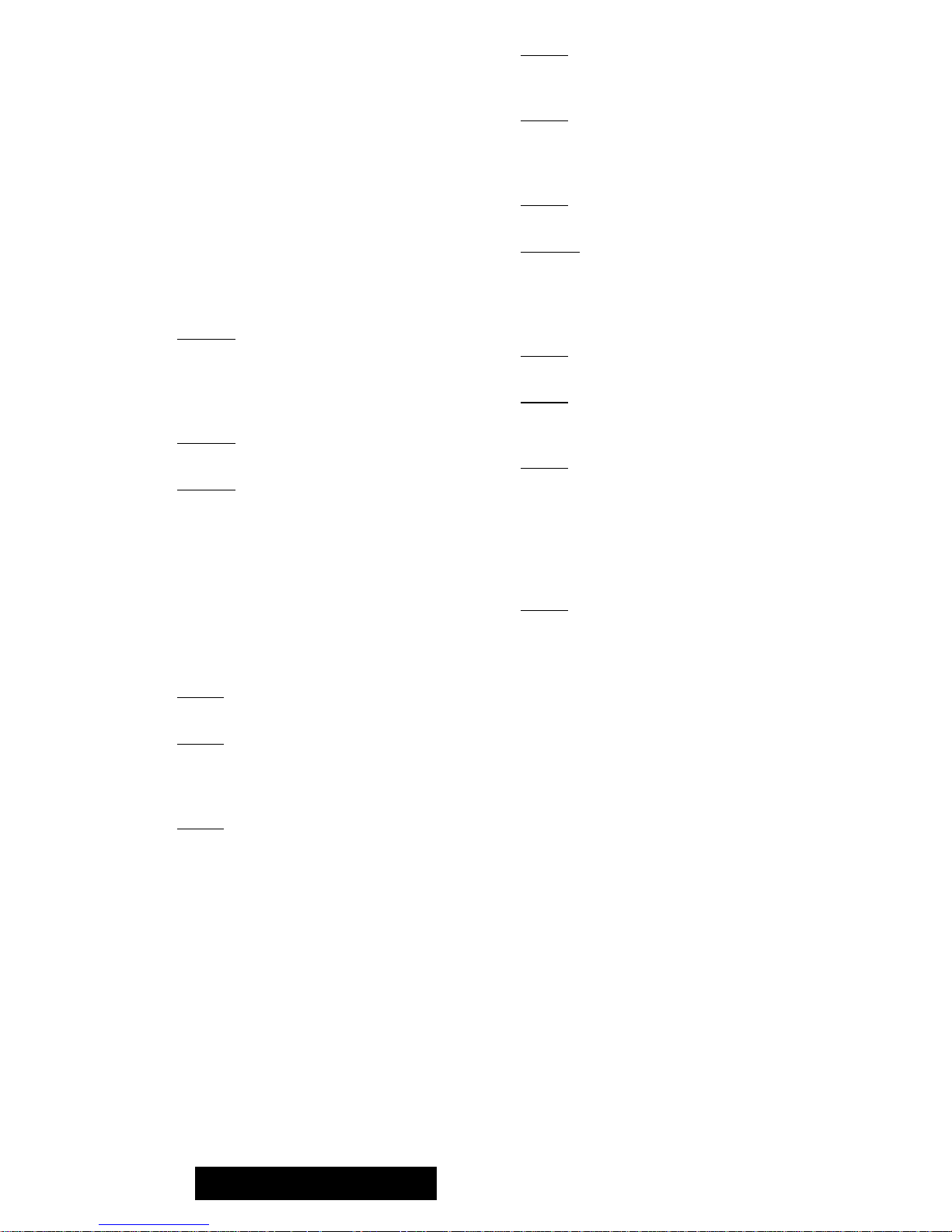

Warning Labels

Pour commander des Étiquettes de Mise en Garde gratuites, voyez votre concessionnaire

agréé pour le numéro de pièce

1436-444.

PK015B

4411-964

A

4411-883

B

4411-965

C

3411-970

D

Page 8

! WARNING

Indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

6

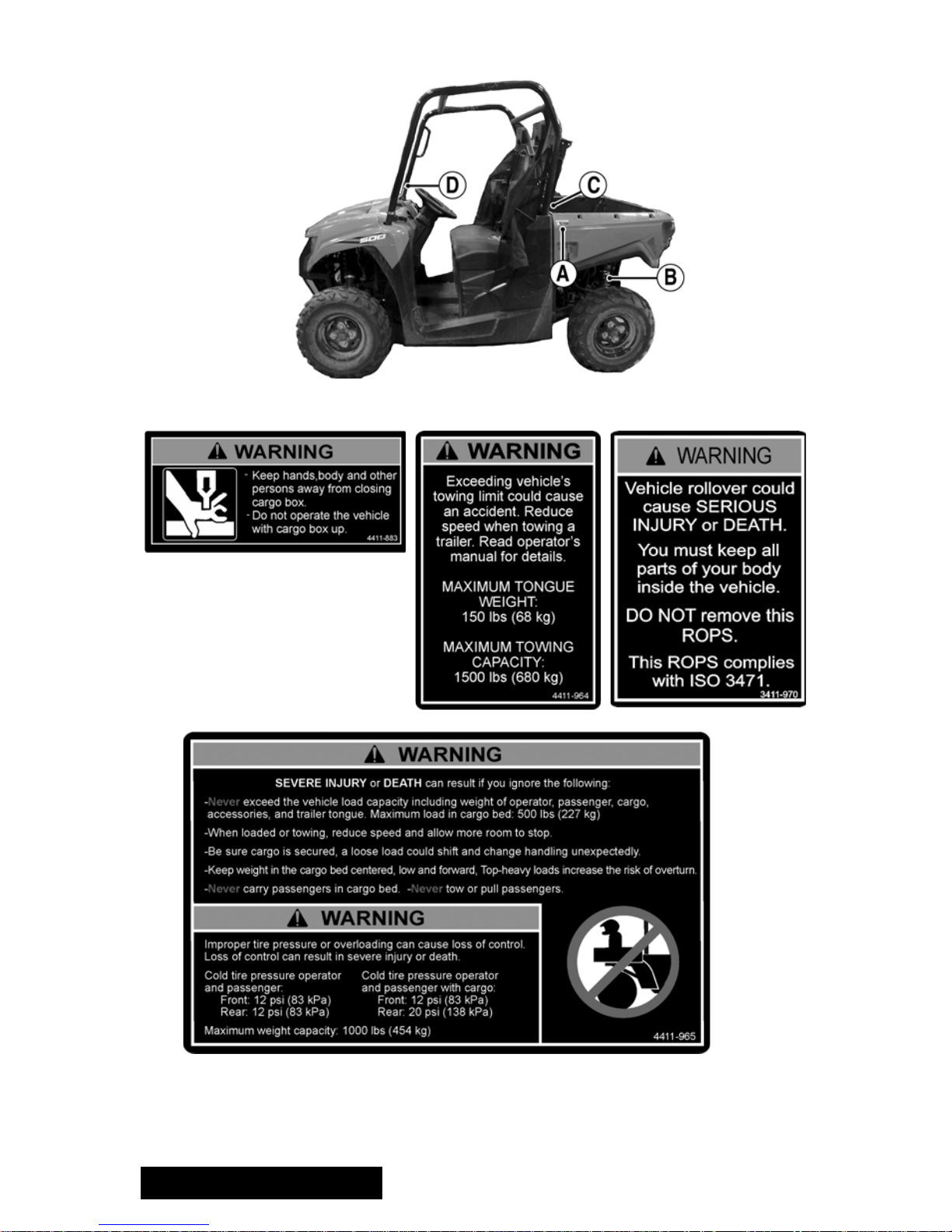

Warning Labels

TXR003B

4411-961

A

4411-960

B

4411-963

C

4411-962

D

Page 9

! WARNING

Indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

7

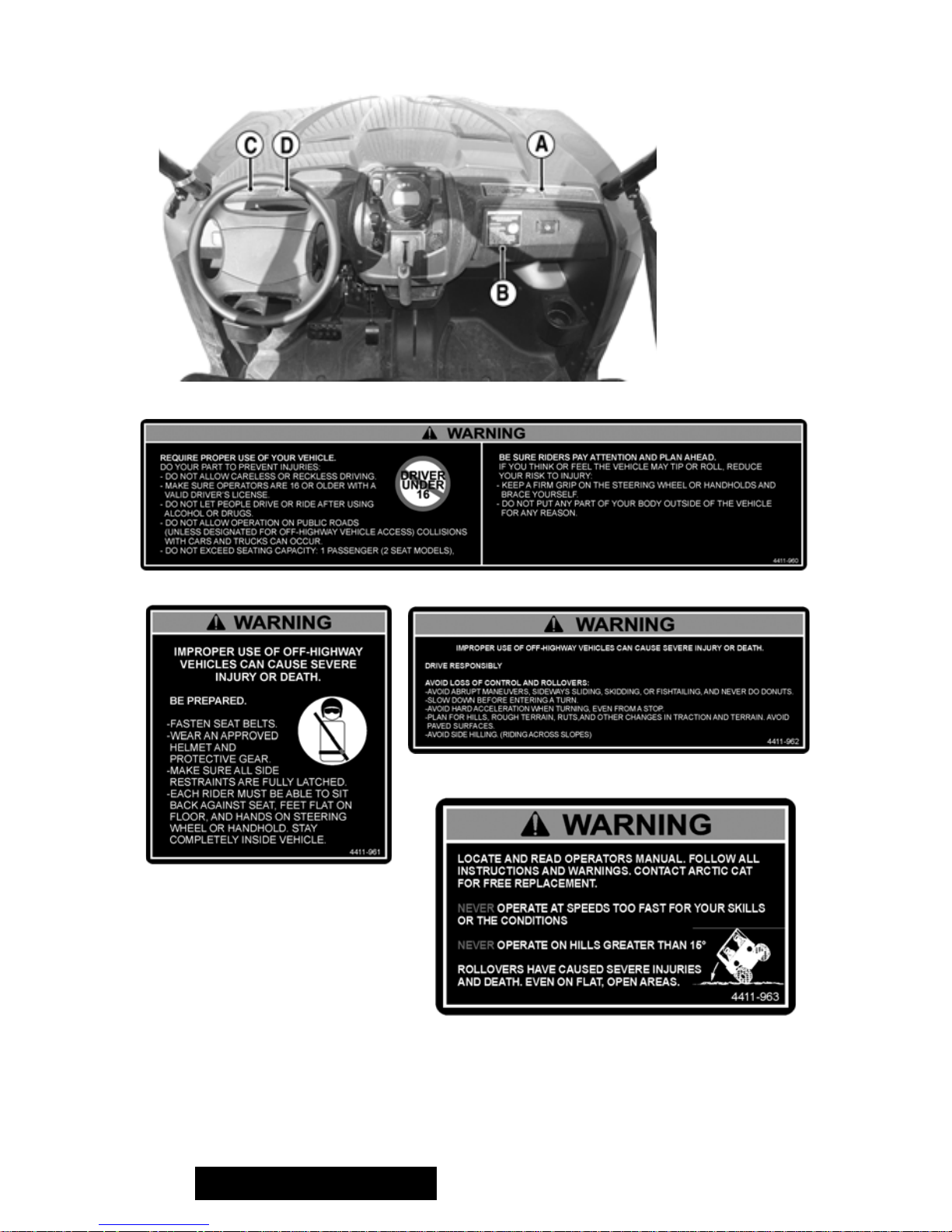

Location of Parts and Controls

TXR003A

PK016A

PK015A

PK014A

1. Accelerator Pedal

2. Brake Pedal

3. In-Dash Storage Compartment

4. DC Power Outlets

5. Reverse Override Switch

6. Drive Select Switch

7. Ignition/Start Switch

8. Headlight Switch

9. Shift Lever

10. Headlights

11. Passenger Side Restraint Latch

12. Operator’s Manual Location

13. Passenger Seat Belt

14. Passenger Side Restraints

15. Gas Tank Cap

16. Outboard Passenger Hand Hold

17. Battery

18. Under-Hood Storage Compartment

19. Fuses

20. Cargo Box Latch Handle

21. Driver Seat Belt

22. Tilt Steering Lever

23. Tool Kit

24. Driver Side Restraint

25. Driver Side Restraint Latch

26. Hitch Receiver

27. Under-Seat Storage Compartment

28. Tailgate Latch

29. Tailgate Storage Latch

30. Taillight/Brakelight

Page 10

! WARNING

Indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

8

Warnings

! WARNING

POTENTIAL HAZARD

Operating this vehicle without proper instruction.

WHAT CAN HAPPEN

The risk of an accident is greatly increased if the operator does not know how to

operate this vehicle properly in different situations and on different types of terrain.

HOW TO AVOID THE HAZARD

All operators of this vehicle must read and understand this Operator’s Manual and

all warning and instruction labels prior to operating this vehicle.

! WARNING

POTENTIAL HAZARD

Allowing anyone under age 16 to operate this vehicle.

WHAT CAN HAPPEN

Use of this vehicle by children can lead to serious injury or death of the child.

Children under the age of 16 may not have the skills, abilities, or judgment needed

to operate this vehicle safely and may be involved in a serious accident.

HOW TO AVOID THE HAZARD

Only people 16 years of age or older with a valid driver’s license should operate

this vehicle.

! WARNING

POTENTIAL HAZARD

Operating or riding in the vehicle without wearing a properly-secured seat belt.

WHAT CAN HAPPEN

Serious injury or death. Occupants can strike objects in the passenger compartment, fall out of the vehicle during maneuvers, or be crushed or otherwise injured

in the event of an accident.

HOW TO AVOID THE HAZARD

ALWAYS WEAR YOUR SEAT BELT and require others to wear their seat belts.

See the Operation/Maintenance section of this manual for more information on

using your seat belt and both operator and passenger wearing an approved helmet.

! WARNING

POTENTIAL HAZARD

Operating this vehicle on public streets, roads, or highways.

WHAT CAN HAPPEN

You can collide with another vehicle.

HOW TO AVOID THE HAZARD

Never operate this vehicle on any public street, road, or highway.

In many states it is illegal to operate a vehicle of this type on public streets, roads,

or highways. Always check state and local laws and regulations.

Page 11

! WARNING

Indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

9

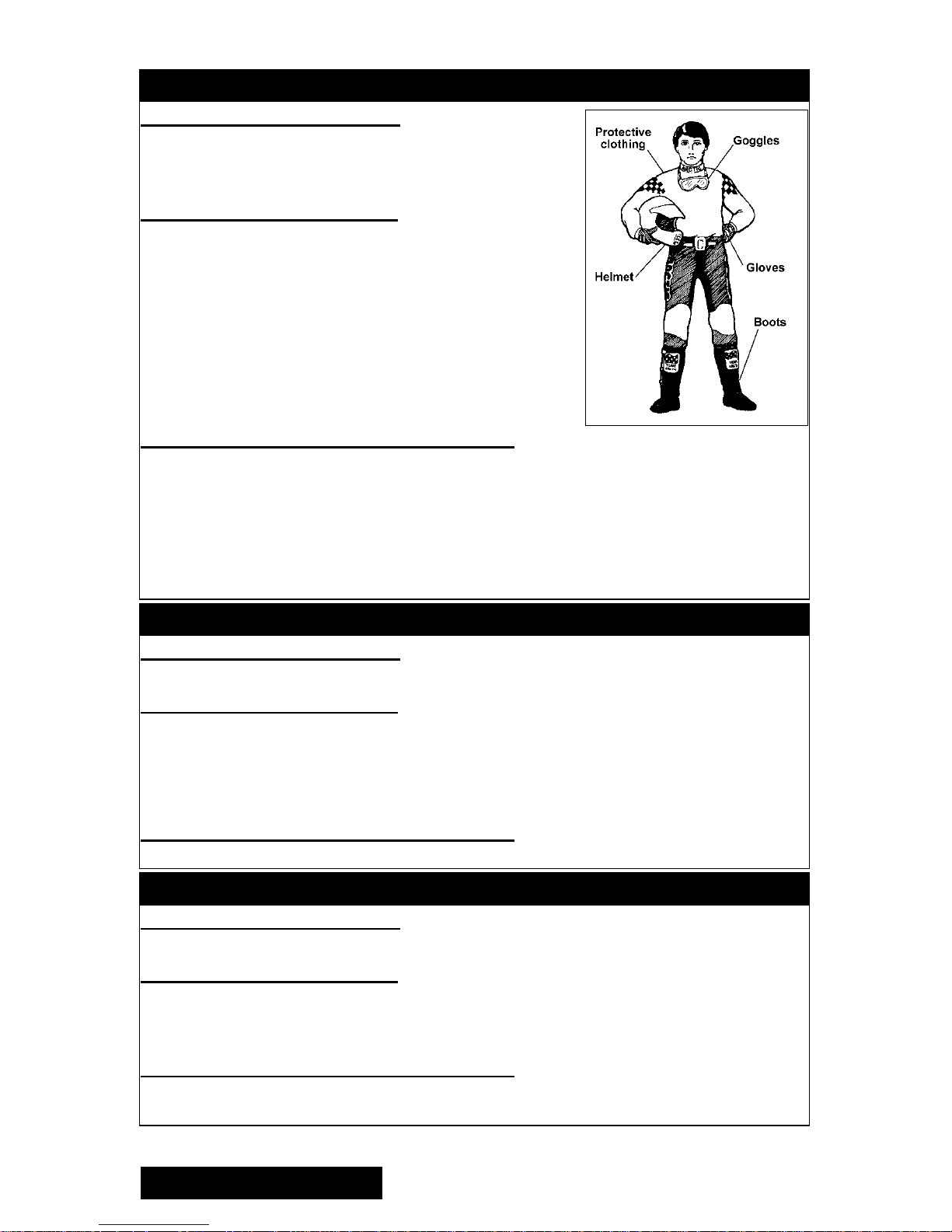

! WARNING

POTENTIAL HAZARD

Operating or riding in this vehicle without wearing an

approved helmet, eye protection, and protective clothing.

WHAT CAN HAPPEN

Operating or riding without an approved helmet

increases your chances of a serious head injury or

death in the event of an accident.

Operating or riding without eye protection can result in

an accident and increases your chances of a serious

injury in the event of an accident.

Operating or riding without protective clothing

increases your chances of serious injury in the event

of an accident.

HOW TO AVOID THE HAZARD

Always wear an approved helmet that fits properly.

You should also wear: Eye protection (goggles or face shield)

Gloves

Boots

Long sleeved shirt or jacket

Long pants

! WARNING

POTENTIAL HAZARD

Operating this vehicle after or while consuming alcohol or drugs.

WHAT CAN HAPPEN

Could seriously affect your judgment.

Could cause you to react more slowly.

Could affect your balance and perception.

Could result in an accident.

HOW TO AVOID THE HAZARD

Never consume alcohol or drugs before or while driving this vehicle.

! WARNING

POTENTIAL HAZARD

Allowing passengers to ride in the cargo bed.

WHAT CAN HAPPEN

Serious injury or death. This vehicle is not designed to carry passengers in the

cargo bed. Passengers in the cargo bed can be thrown around or from the vehicle

during operation or in an accident.

HOW TO AVOID THE HAZARD

Do not permit passengers to ride in the cargo bed. Do not install any seating in the

cargo bed.

Page 12

! WARNING

Indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

10

! WARNING

POTENTIAL HAZARD

Operating or riding in the vehicle without occupant side restraints properly

secured.

WHAT CAN HAPPEN

Serious injury or death. Occupants or their body parts can strike objects outside

the vehicle, be crushed by the vehicle, or fall out of the vehicle during maneuvers

or in the event of an accident.

HOW TO AVOID THE HAZARD

Do not remove the occupant side restraints. Make sure both driver and passenger

occupant side restraints are secure before operating or riding in the vehicle. Stay

seated with your seat belt and helmet on and keep your body completely inside the

vehicle during operation. See the Operation/Maintenance section of this manual

for more information.

! WARNING

POTENTIAL HAZARD

Failing to keep all parts of your body inside the passenger compartment during

operation.

WHAT CAN HAPPEN

Serious injury or death. Body parts could strike objects outside of vehicle or be

crushed in the event of a rollover or accident.

HOW TO AVOID THE HAZARD

Do not place your head, arms, hands, legs, or feet outside of the passenger compartment during operation. Stay seated with your seat belt and helmet on and

occupant side restraints properly secured. Keep your feet and legs inboard of the

foot restraints at all times. Do not attempt to stop movement or tipping of the vehicle with your hands or feet. If you feel the vehicle tipping, brace your feet flat on the

floor, keep hands firmly gripping the steering wheel and hand holds, and keep all

body parts inside the passenger compartment.

! WARNING

POTENTIAL HAZARD

Operating this vehicle at excessive speeds.

WHAT CAN HAPPEN

Increases your chances of losing control of the vehicle, which can result in an accident.

HOW TO AVOID THE HAZARD

Always ride at a speed that is proper for the terrain, visibility, load, and operating

conditions.

Page 13

! WARNING

Indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

11

! WARNING

POTENTIAL HAZARD

Attempting abrupt maneuvers, sideways sliding, skidding, fishtailing, or donuts.

WHAT CAN HAPPEN

Increases the chance of an accident including a rollover.

HOW TO AVOID THE HAZARD

Never attempt abrupt maneuvers, sideways sliding, skidding, fishtailing, or donuts.

Don’t try to show off.

! WARNING

POTENTIAL HAZARD

Failure to inspect this vehicle before operating.

Failure to properly maintain this vehicle.

WHAT CAN HAPPEN

Increases the possibility of an accident or equipment damage.

HOW TO AVOID THE HAZARD

Always inspect this vehicle each time you use it to make sure it is in safe operating

condition.

Always follow the inspection and maintenance procedures and schedules

described in this Operator’s Manual.

! WARNING

POTENTIAL HAZARD

Failure to use extra care when operating this vehicle on unfamiliar terrain.

WHAT CAN HAPPEN

You can come upon hidden rocks, bumps, or holes without enough time to react.

Could result in the vehicle overturning or going out of control.

HOW TO AVOID THE HAZARD

Go slowly and be extra careful when operating on unfamiliar terrain.

Always be alert to changing terrain conditions when operating this vehicle.

! WARNING

POTENTIAL HAZARD

Failure to use extra care when operating on rough, slippery, or loose terrain.

WHAT CAN HAPPEN

Could cause loss of traction or control, which could result in an accident including

a rollover.

HOW TO AVOID THE HAZARD

Do not operate on rough, slippery, or loose terrain until you have learned and practiced the skills necessary to control this vehicle on such terrain.

Always be especially cautious on these kinds of terrain.

Page 14

! WARNING

Indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

12

! WARNING

POTENTIAL HAZARD

Failing to use care in turns; turning too sharply or aggressively.

WHAT CAN HAPPEN

The vehicle could go out of control causing a collision, tip over, or rollover.

HOW TO AVOID THE HAZARD

Always follow proper procedures for turning as described in this Operator’s Manual. Practice turning at slow speeds before attempting to turn at faster speeds. Do

not turn at excessive speed or too sharply for the conditions and for your experience level. See the Operation/Maintenance section of this manual for more information on turning on flat ground, hills, sand, ice, mud, or water.

! WARNING

POTENTIAL HAZARD

Operating on steep hills.

WHAT CAN HAPPEN

This vehicle can overturn more easily on steep hills than on level surfaces or small

hills.

HOW TO AVOID THE HAZARD

Never operate the vehicle on hills too steep for the vehicle or for your abilities.

Practice on smaller hills before attempting larger hills.

! WARNING

POTENTIAL HAZARD

Operating with the ROPS removed.

WHAT CAN HAPPEN

Could lead to serious injury or death.

HOW TO AVOID THE HAZARD

Never operate this vehicle with the ROPS removed.

! WARNING

POTENTIAL HAZARD

Going down a hill improperly.

WHAT CAN HAPPEN

Could cause loss of control or cause the vehicle to overturn.

HOW TO AVOID THE HAZARD

Always follow proper procedures for going down hills as described in this Operator’s Manual.

Always check the terrain carefully before you start down any hill.

Never go down a hill at high speed.

Avoid going down a hill at an angle that would cause the vehicle to lean sharply to

one side. Go straight down the hill where possible.

Page 15

! WARNING

Indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

13

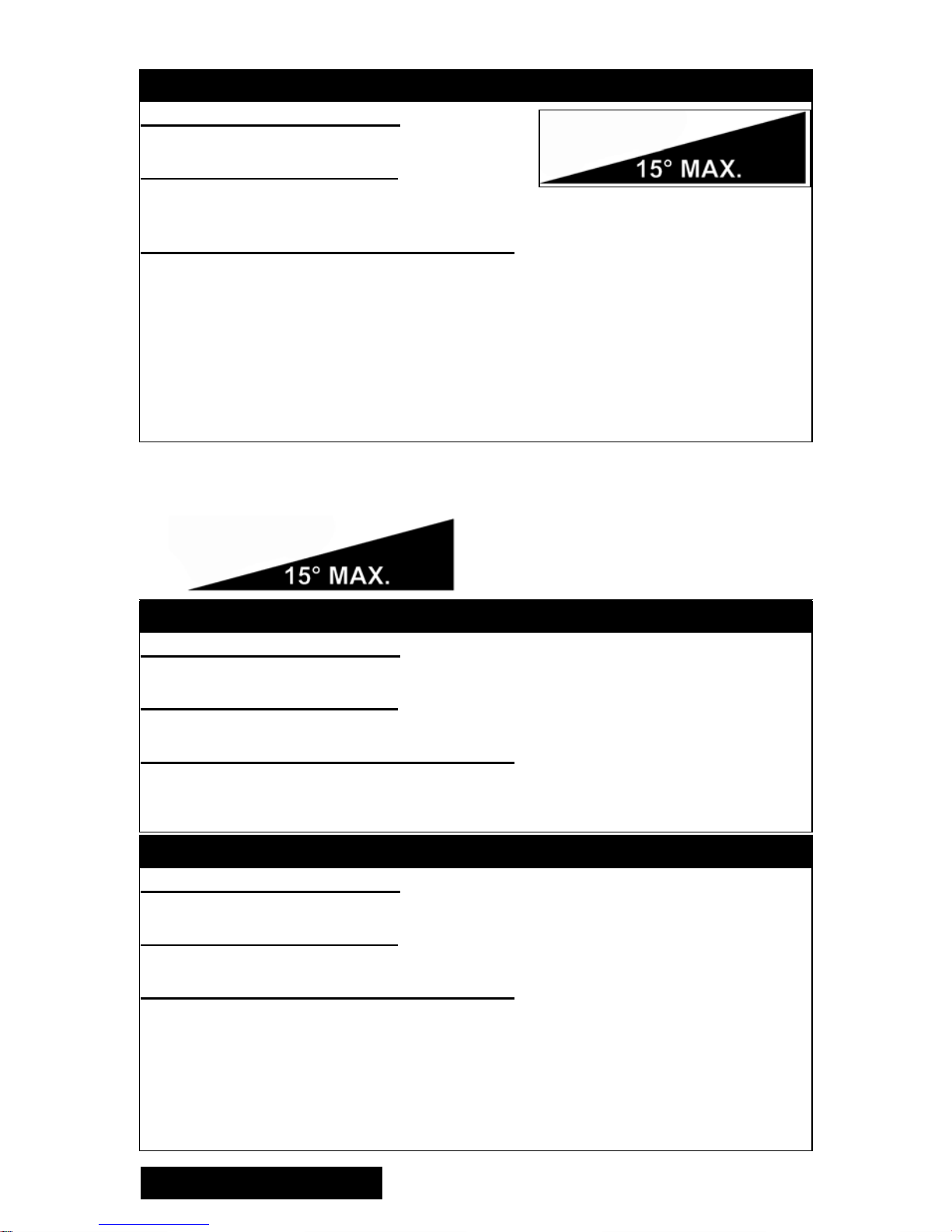

Never Operate Up Or

Down Hills Steeper

Than 15°

! WARNING

POTENTIAL HAZARD

Climbing hills improperly.

WHAT CAN HAPPEN

Could cause loss of control or cause the vehicle

to overturn.

HOW TO AVOID THE HAZARD

Always follow proper procedures for climbing hills as described in this Operator’s

Manual.

Always check the terrain carefully before you start up any hill.

Never climb hills with slippery or loose surfaces.

Never open the throttle suddenly or make sudden gear changes. The vehicle could

flip over backwards.

Never go over the top of any hill at high speed. An obstacle, a sharp drop, or

another vehicle or person could be on the other side of the hill.

! WARNING

POTENTIAL HAZARD

Crossing hills or turning on hills.

WHAT CAN HAPPEN

Could cause loss of control or cause the vehicle to overturn.

HOW TO AVOID THE HAZARD

Avoid crossing the side of a hill or turning on a hill whenever possible. Never

attempt to turn the vehicle around on any hill. If you must cross the side of a hill,

drive slowly and stop or turn downhill if you feel the vehicle may tip.

! WARNING

POTENTIAL HAZARD

Stalling, rolling backwards, or improperly dismounting while climbing a hill.

WHAT CAN HAPPEN

Could result in the vehicle overturning.

HOW TO AVOID THE HAZARD

Use proper gear and maintain steady speed when climbing a hill.

If you lose all forward speed:

Apply the brakes. Place the transmission in park after you are stopped.

If you begin rolling backwards:

Gradually apply the brakes while rolling backwards.

When fully stopped, place the transmission in park.

Page 16

! WARNING

Indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

14

! WARNING

POTENTIAL HAZARD

Improperly operating over obstacles.

WHAT CAN HAPPEN

Could cause loss of control or a collision. Could cause the vehicle to overturn.

HOW TO AVOID THE HAZARD

Before operating in a new area, check for obstacles.

Never attempt to ride over large obstacles, such as large rocks or fallen trees.

When you go over obstacles, always follow proper procedures as described in this

Operator’s Manual.

! WARNING

POTENTIAL HAZARD

Improperly operating in reverse.

WHAT CAN HAPPEN

You could hit an obstacle or person behind you, resulting in serious injury or death.

HOW TO AVOID THE HAZARD

Before you engage reverse gear, make sure there are no obstacles or people

behind you. When it is safe to proceed, go slowly.

! WARNING

POTENTIAL HAZARD

Skidding or sliding.

WHAT CAN HAPPEN

You could lose control of the vehicle.

You could also regain traction unexpectedly, which may cause the vehicle to over-

turn.

HOW TO AVOID THE HAZARD

Learn to safely control skidding or sliding by practicing at slow speeds and on level,

smooth terrain.

On extremely slippery surfaces, such as ice, go slowly and be very cautious in

order to reduce the chance of skidding or sliding out of control.

! WARNING

POTENTIAL HAZARD

Overloading the vehicle or carrying or towing improperly.

WHAT CAN HAPPEN

Could cause changes in handling, which could lead to an accident.

HOW TO AVOID THE HAZARD

Never exceed the stated load capacity for this vehicle.

Cargo should be properly distributed and securely attached.

Reduce speed when carrying cargo or pulling a trailer. Allow greater distance for

braking. Always follow the instructions in this Operator’s Manual for carrying cargo

or pulling a trailer.

Page 17

! WARNING

Indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

15

! WARNING

POTENTIAL HAZARD

Operating this vehicle through deep or fast flowing water.

WHAT CAN HAPPEN

Tires may float, causing loss of traction and loss of control, which could lead to an

accident.

HOW TO AVOID THE HAZARD

Never operate this vehicle in fast flowing water or in water deeper than the floorboard.

Remember that wet brakes may have reduced stopping capability.

Test the brakes after leaving water. If necessary, apply them several times to dry

out the pads.

! WARNING

POTENTIAL HAZARD

Operating the vehicle with improper tires or with improper or uneven tire pressure.

WHAT CAN HAPPEN

Use of improper tires on the vehicle, or operating the vehicle with improper or

uneven tire pressure, could cause loss of control increasing your risk of accident.

HOW TO AVOID THE HAZARD

Always use the size and type tires specified in this Operator’s Manual for this vehicle.

Always maintain proper tire pressure as described in this Operator’s Manual.

! WARNING

POTENTIAL HAZARD

Operating this vehicle with improper modifications.

WHAT CAN HAPPEN

Improper installation of accessories or modification of the vehicle may cause

changes in handling which could lead to an accident.

HOW TO AVOID THE HAZARD

Never modify this vehicle through improper installation or improper use of accessories. All parts and accessories added to this vehicle should be approved components designed for use on this vehicle and should be installed and used according

to instructions. If you have questions, consult an authorized dealer.

! WARNING

POTENTIAL HAZARD

Failing to avoid pinch-points when lowering the cargo box.

WHAT CAN HAPPEN

Fingers, hands, or arms could be seriously injured when lowering the cargo box.

HOW TO AVOID THE HAZARD

Always be aware of and avoid lowering cargo box until everyone is clear of pinchpoints.

Page 18

16

! WARNING

POTENTIAL HAZARD

Operating through or over thick or sharp brush, timber, debris, or rocks.

WHAT CAN HAPPEN

Serious injury or death. Brush, branches, debris, and rocks can enter or penetrate

the passenger compartment and strike occupants. Running over sharp branches,

rocks, or other large objects can also cause loss of control.

HOW TO AVOID THE HAZARD

Be alert. Slow down. Wear all recommended protective gear specified in this Operator’s Manual. Avoid operating through or over thick brush, timber, debris, or large

rocks whenever possible. Watch for and avoid sharp branches, rocks, or other

large objects that could impede or impact the vehicle or enter the passenger compartment.

! WARNING

POTENTIAL HAZARD

Securing a person improperly in the vehicle due to physical size.

WHAT CAN HAPPEN

Serious injury or death. Occupant could strike objects in the passenger compartment, fall out of the vehicle during maneuvers, or be ejected and crushed in the

event of an accident.

HOW TO AVOID THE HAZARD

Always make sure a passenger can sit with both feet flat on the floor and their back

against the seat while being able to reach any provided hand holds.

! WARNING

POTENTIAL HAZARD

Operating this vehicle on paved surfaces.

WHAT CAN HAPPEN

The vehicle’s tires are designed for off-road use only, not for use on pavement.

Paved surfaces may seriously affect handling and control of the vehicle and may

cause the vehicle to go out of control.

HOW TO AVOID THE HAZARD

Whenever possible, avoid operating the vehicle on any paved surfaces including

sidewalks, driveways, parking lots, and streets. If operating on paved surfaces is

unavoidable, travel slowly (less than 10 MPH) and avoid sudden turns and stops.

Page 19

17

Division II - Operation/Maintenance

Specifications

Specifications subject to change without notice.

ENGINE

Type Four-Cycle/Liquid Cooled

Bore x Stroke 89 mm x 71.2 mm (3.5 x 2.8 in.)

Displacement 443 cc (27.0 cu in.)

Spark Plug Type NGK CR6E

Spark Plug Gap 0.7-0.8 mm (0.028-0.031 in.)

Brake Type Hydraulic Disc (front);

Shaft-Mounted Hydraulic Disc (rear)

CHASSIS

Length (Overall) 270.3 cm (106.4 in.)

Height (Overall) 194.8 cm (76.7 in.)

Width (Overall) 143.3 cm (56.4 in.)

Suspension Travel (Front/Rear) 19 cm (7.5 in.)

Tire Size (Front) 25 x 8-12

Tire Size (Rear) 25 x 10-12

Tire Inflation Pressure 82.7 kPa (12 psi)

MISCELLANY

Dry Weight (Approx) 497 kg (1095 lb)

ROPS Tested Curb Weight 997.9 kg (2200 lb)

Gas Tank Capacity 32.2 L (8.5 U.S. gal.)

Coolant Capacity 2.5 L (2.64 U.S. qt)

Differential Capacity 250 ml (8.5 fl oz)

Rear Drive Capacity 230 ml (7.8 fl oz)

Engine Oil Capacity (Approx) (Change w/filter) 2.4 L (2.5 U.S. qt)

Gasoline (Recommended) 87 Octane Regular Unleaded

Engine Oil (Recommended) ACX All Weather (Synthetic)

Front Differential/Rear Drive Lubricant SAE Approved 80W-90 Hypoid

Reverse Light 12V/5W

Taillight/Brakelight 12V/5W/21W

Headlight 12V/55W/60W

Starting System Electric

Page 20

18

Vehicle Operation

Pre-Start/Pre-Operation Checklist

Item Remarks

Brake System Pedal firm - near top of travel.

Fluid at proper level.

Check for fluid leaks.

Controls Steering free - no binding - no excessive free-play.

Shift lever in park.

Accelerator free - no binding - returns to idle position.

Fluids Coolant level to bottom of radiator neck and reservoir at least half

fill.

Check oil level.

Gas tank full of recommended gasoline.

Differential/rear drive at proper level.

Check for fluid leaks.

Suspension Ball joints/tie rod ends free - secure.

Shocks not leaking - mountings secure.

Shock spring pre-load equal on left and right.

Components free of all debris.

Lights/Switches Check headlight HI/LO beam - light switch to OFF.

Check taillight/brakelight - light switch to OFF.

Check drive select switch - set to 2WD.

Air Filter Drain caps clear of all debris.

Ducting secure - no holes or tears.

Tires/Wheels Properly inflated - tread adequate.

Check tires for cuts or tears.

Wheels secure to hubs - hubs secure to axles.

Check wheels for cracked or bent rims.

Seat Belts/Restraints Check condition - proper operation - proper adjustment.

Nuts/Bolts/Fasteners Check for loose nuts - bolts - tighten as necessary.

Check fasteners - latches - ROPS.

Secure hood, cargo box, seats.

Page 21

19

Vehicle Operation

Starting the Vehicle

Always start with the vehicle on a flat,

level surface. Carbon monoxide poisoning can kill you, so keep the vehicle outside while it’s running. Follow these

steps to start it up:

NOTE: This vehicle is equipped

with a driver’s seat belt sensor. If the

driver’s seat belt is not fastened, the

vehicle speed is limited to 15 mph

and the seat belt indicator on the

gauge will illuminate. The seat belt

indicator will remain illuminated until

the driver’s seat belt is fastened.

HDX323A

1. Step into the vehicle and sit down;

then fasten the operator seat belt and

the passenger seat belt (if applicable) and strap on your approved helmet and require your passenger to do

the same (if applicable). Check that

the occupant side restraints are

secured in place.

2. Place the transmission in park; then

depress the brake pedal.

3. Turn the ignition switch clockwise

to the START position; then when

the engine starts, release to the RUN

position. Do not increase engine

RPM above idle.

4. Let the engine warm up.

Shifting

NOTE: The CVT is fully automatic

and shifts as a function of engine

RPM and vehicle loading.

PK059

1. To select reverse gear from park,

move the shift lever forward one

position until the letter “R” is displayed on the LCD gauge.

2. To select neutral from reverse, move

the shift lever forward one position

until the letter “N” is displayed on

the LCD gauge.

3. To select high range from neutral,

move the shift lever forward one

position until the letter “H” is displayed on the LCD gauge.

4. To select low range from high range,

move the shift lever forward one

position until the letter “L” is displayed on the LCD gauge.

! WARNING

Falling from a moving vehicle could

result in serious injury or death.

Always fasten your seat belt securely

and ensure the passenger seat belt is

properly and securely fastened prior

to operating or riding in this vehicle.

CAUTION

Increasing engine RPM above idle

while in Park will cause belt damage.

CAUTION

Do not run the starter motor for more

than eight seconds per starting

attempt. The starter motor may overheat causing severe starter motor

damage. Allow 15 seconds between

starting attempts to allow the starter

motor to cool.

CAUTION

Always come to a complete stop

before attempting to shift from one

range to the other or into reverse.

Always shift on level ground.

Page 22

20

NOTE: The high range is for nor-

mal driving with light loads. The low

range is for carrying heavy loads or

trailer towing. Compared to HIGH

range, the LOW range position provides slower speed and greater

torque to the wheels.

5. To select park, move the shift lever

completely down until the letter “P”

is displayed on the LCD gauge.

Driving the Vehicle

Once the engine is warm, the vehicle is

ready to be driven.

1. With the engine idling, press the foot

brake pedal to apply the brake; then

select the appropriate operating range

and/or direction with the shift lever.

2. Release the foot brake pedal and

press the accelerator to slowly add

power to start moving.

3. To slow down or stop, release the

accelerator and press the foot brake

pedal as necessary to slow or stop

the vehicle.

Braking/Stopping

Always allow plenty of room and time to

stop smoothly. Sometimes quick stops

are inevitable, so always be prepared.

Whether you’re stopping slowly or stopping quickly, do this:

1. Release the accelerator; then press

the foot brake pedal to apply the

brake.

2. If the wheels lock, release them for a

second; then apply them again. On

surfaces such as ice, mud, or loose

gravel, pump the brake pedal rapidly.

3. Never “ride” the brake. Even maintaining minimal pressure on the

brake pedal will cause the brake

pads to drag on the disc and may

overheat the brake fluid.

Parking

Parking involves following the previous

rules for braking; then:

1. After the vehicle stops, shift into

park.

2. Turn off the ignition.

3. If you have to park on a hill, block

the wheels on the downhill side.

Basic Turns

Steering effort is at its lowest in twowheel drive (2WD). Greater effort is

needed when in four-wheel drive (4WD).

The greatest effort is needed when in

four-wheel drive and the differential (if

equipped) is locked.

Slow down before entering a turn. The

basic turning technique is to drive at low

speed and gradually adjust the amount of

steering to suit the driving surface. Do

not make sudden sharp turns on any surface. Refer to the sub-sections Driving

Uphill, Driving Downhill, Crossing

Obstacles, Driving in Reverse, Skidding

or Sliding, Crossing Water, or Crossing

Roads for more information.

If your vehicle ever skids sideways

during a turn, steer in the direction of the

skid. Also, avoid hard braking or accelerating until you have regained directional

control.

CAUTION

Always shift into low range when

operating on wet or uneven terrain,

when towing or pushing heavy loads,

and when using a plow. Failure to follow this caution may result in premature V-belt failure or in damage to

related drive system components.

CAUTION

Never increase engine speed above

idle RPM when in park or belt damage

will occur.

! WARNING

Excessive repetitive use of the

hydraulic brake for high speed stops

will cause overheating of the brake

fluid and premature brake pad wear

which will result in an unexpected

loss of brakes.

! WARNING

Use only approved brake fluid. Never

substitute or mix different types or

grades of brake fluid. Brake loss can

result. Check brake fluid level and pad

wear before each use. Brake loss can

result in serious injury or death.

Page 23

21

Driving Uphill

Always drive straight up the hill and

always avoid hills steeper than 15°.

1. Keep both hands on the wheel.

2. Prior to starting the climb, shift into

low range, select four-wheel drive

for traction, and gradually press the

accelerator; then maintain a constant

speed.

3. If the vehicle stalls on a hill, press

the foot brake pedal to apply the

brake, shift into reverse, and slowly

back down the hill. Do not attempt

to turn around on a hill.

NEVER OPERATE UP OR

DOWN HILLS STEEPER

THAN 15°

Driving Downhill

Always drive straight down the hill and

always avoid hills steeper than 15°.

1. Keep both hands on the wheel.

2. Prior to descending the hill, shift

into low range and release the accelerator to allow maximum engine

braking. Do not use four-wheel drive

when descending a hill. Engine

braking can cause the front wheels

to slide reducing steering control.

NOTE: Use minimum braking (as

necessary) to maintain a slow speed.

Crossing Obstacles

Crossing obstacles can be hazardous.

There is always the possibility of the

vehicle tipping. If you cannot go around

an obstacle, follow these guidelines:

1. Stop the vehicle and place the transmission in park. Go out to inspect

the obstacle thoroughly from both

your approach side and the exit side.

If you believe you can cross the

obstacle safely, select four-wheel

drive (4WD).

NOTE: Selecting the LOCK posi-

tion on the differential lock control

may be beneficial; however, steering

effort will be increased.

2. Approach the obstacle as close as

possible to 90° to minimize vehicle

tipping.

3. Keep speed slow enough to maintain

control but fast enough to maintain

momentum.

4. Use only enough power to cross the

obstacle but still give yourself plenty

of time to react to changes in conditions. Crawl over the obstacle.

! WARNING

Use care in turns - turning the steering wheel too far or too fast can result

in loss of control or a rollover. Excessive speed, driving aggressively, or

making abrupt maneuvers, even on

flat, open areas, can cause loss of

control, tipping, or rollover. Uneven

terrain, rough terrain, soft surfaces,

slippery surfaces, and paved surfaces

can also cause a loss of control or

rollover in a turn. On loose or soft surfaces, allow yourself more time and

distance to turn and slow down.

! WARNING

Do not attempt to turn around on a hill.

! WARNING

Driving up hills improperly can cause

loss of control of the vehicle resulting

in serious injury or death. Use

extreme care when driving in hilly terrain.

! WARNING

Do not attempt to turn around on a

hill.

! WARNING

Driving down hills improperly can

cause loss of control of the vehicle

resulting in serious injury or death.

Never drive downhill at a high rate of

speed. Use extreme care when driving

in hilly terrain.

Page 24

22

NOTE: If there is any question

about your ability to cross the obstacle safely, you should turn around if

the ground is flat and you have room

or back up until you find a less difficult path.

Driving in Reverse

When operating in reverse, avoid sharp

turns and backing down a hill. When

using reverse, follow these guidelines:

1. Back up slowly. It’s hard to see

behind you.

NOTE: Avoid sudden braking while

backing up.

2. If possible, it is advisable to have

someone “spotting” for you while

backing up.

3. If you are unsure of what is behind the

vehicle, place the transmission in park

and get out and inspect the area

behind.

Skidding or Sliding

If you lose control after hitting sand, ice,

mud, or water, follow these guidelines:

1. Turn the steering wheel into the

direction of the slide.

2. Keep your foot off the brake until

you’re out of the skid.

3. Stop and shift into four-wheel drive.

Crossing Water

This vehicle can only operate in water up

to its floorboard. Stay away from fast

moving rivers. This vehicle’s tires can be

buoyant. In deep water, the vehicle may

lose traction due to floating.

1. Physically check the depth and current of the water, especially if you

can’t see the bottom. Also, check for

boulders, logs, or any other hidden

obstacles.

2. Keep speed slow while maintaining

momentum.

3. Make sure you have a way out on

the other side of the water.

4. Once you’ve cleared the water,

briefly apply the brakes to make sure

they work.

NOTE: Light pedal pressure or

pumping the brakes for a short distance will aid in drying the brakes.

Crossing Roads

It may be necessary to cross a road or

highway. If so, note the following guidelines.

1. Stop completely on the shoulder of

the road.

2. Check both directions for traffic.

3. Crossing near a blind corner or intersection is dangerous; avoid it if at all

possible.

4. Drive straight across to the opposite

shoulder.

5. Take into account that this vehicle

could stall while crossing; give

yourself enough time to get off the

road.

6. You have to assume that oncoming

cars don’t see you, and if they do,

they won’t be able to predict your

actions.

7. It’s illegal to cross public roads in

some places. Know your local laws.

! WARNING

Striking hidden obstacles can cause

serious injury or death. Reduce speed

and proceed with care in unfamiliar

terrain.

! WARNING

Never activate the override while the

throttle is open as a loss of control

may result. Use caution when using

the override switch as reverse speed

can greatly increase.

! WARNING

Do not operate this vehicle on a frozen

body of water unless you have first

verified the ice is sufficiently thick to

support the vehicle, cargo, and participants. The vehicle could break

through the ice causing serious injury

or death.

Page 25

23

General Information

Control Locations and

Functions

Ignition Switch Key

Two keys come with this vehicle. Keep

the spare key in a safe place. An identifying number is stamped on each key. Use

this number when ordering a replacement

key.

Ignition Switch

The ignition switch has three positions.

PK049

OFF position — All electrical circuits

except the accessory are off. The engine

will not start. The key can be removed in

this position.

NOTE: The accessory plugs are

powered by the battery at all times.

RUN position — The ignition circuit is

complete and the engine can run. The key

cannot be removed in this position.

START position — The ignition circuit

is complete and the starter is engaged.

When the key is released, the switch will

return to the RUN position. The key cannot be removed in this position.

NOTE: This vehicle has safety

interlock switches which prevent the

starter motor from activating when

the transmission is not in neutral.

Depress and hold the brake pedal to

engage starter when the transmission is not in neutral.

Shift Lever

This vehicle has a dual-range Constant

Variable Transmission (CVT) with

reverse and park.

PK059

Drive Select Switch

PK019

This switch allows the operator to operate the vehicle in either two-wheel drive

(rear wheels) or four-wheel drive (all

wheels) as well as mechanically lock the

differential (if equipped) to apply equal

power to both front wheels. For normal

riding on flat, dry, hard surfaces, twowheel drive should be sufficient. In situations when additional traction is necessary, four-wheel drive would be the

desired choice.

To select 2WD, depress the bottom of the

switch. To select 4WD, move the switch

to the middle position. To engage the differential lock, slide the switch latch

slightly downward while pressing the top

of the switch forward.

NOTE: When the differential lock is

engaged on equipped models, the

indicator light will be illuminated.

CAUTION

Do not attempt to either engage or

disengage the front differential while

the vehicle is moving.

Page 26

24

NOTE: The differential lock is

intended for use where minimum

traction is available. Steering effort

will increase with the front differential lock engaged. Maneuverability

and handling characteristics will differ with the differential lock engaged.

Foot Brake

The foot brake should be applied whenever braking is needed.

Apply the brake by pressing the brake

pedal down.

Steering Wheel Tilt Latch

Pull on the lever located on the bottom of

the steering column and move the steering wheel to the desired position; then

release the lever and make sure the steering wheel locks securely.

PK020

Headlight Switch

PK021

With the ignition switch in the ON position, use the headlight switch to select

off, running, low, or high beam.

Reverse Override Switch

This vehicle is equipped with a reverse

speed limiter system. When additional

RPM is needed in reverse, depress and

hold the override switch located on the

center console.

NOTE: The vehicle must be in 4WD

to activate the reverse override.

Accelerator Pedal

Press down on the pedal to increase

engine RPM and vehicle speed; release

the pedal to decrease engine RPM and

vehicle speed.

NOTE: This vehicle is equipped

with an RPM limiter that retards ignition timing when maximum RPM is

approached. When the RPM limiter is

activated, it could be misinterpreted

as a high-speed misfire.

Seat Latches

1. To remove the seat, raise the front of

the seat and slide it forward.

2. To install the seat, slide the seat

brackets under the frame rails; then

press firmly on the front of the seat

to engage both front seat studs into

the receivers.

Seat Belts

This vehicle is equipped with seat belts

for the operator and the passenger. To

fasten and release the seat belt properly,

use the following procedure.

! WARNING

Make sure the steering wheel is

locked securely in place before moving the vehicle, or steering wheel

movement could occur causing loss

of control.

! WARNING

Never activate the override switch

while the throttle is open as a loss of

control could result. Use caution

when using the override switch as

reverse speed can greatly increase.

! WARNING

Make sure the seat is secure before

driving the vehicle. Serious injury or

death could result if the seat is not

properly secured.

Page 27

25

1. Place the seat belt across your lap as

low as possible without twisting the

belt making sure the shoulder strap

is below the neck and across the

chest.

2. Push the latch-plate into the buckle

slot until it “clicks” and latches

securely. The belt will retract when

the buckle is released.

Occupant Side Restraints

In addition to the seat belts, there are leftand right-side restraints to restrict arms

or legs from extending outside the vehicle. The restraints should always be

secured when the vehicle is moving.

To secure the restraint, connect the

restraint buckle to the receiving latch on

the front ROPS tube. To release the

restraint, squeeze the locking tabs of the

restraint buckle.

PK013A

Tailgate Latch

PK022

1. To open the tailgate, pivot the latch

levers outward.

2. To close the tailgate, lift up and push

forward firmly; then pivot the latch

levers inward

Cargo Box Latch Handles

PK023

1. To raise the cargo box, pivot the

latch forward; then raise the cargo

box.

2. To lower the cargo box, push down

firmly on the front of the box. The

box will automatically lock into

position.

Speedometer/LCD

(Digital)

WT103D

1. Left Button - Shifts top display

through speedometer, RPM, and

clock.

! WARNING

Only appropriate-sized passengers

may ride in this vehicle. Passengers

must be able to place both feet flat on

the floor while keeping their back

against the back of the seat and holding on to the hand holds.

! WARNING

Falling outside a moving vehicle could

result in serious injury or death.

Always fasten your seat belt securely

and ensure the passenger seat belt is

properly and securely fastened prior

to operating or riding in this vehicle.

Page 28

26

2. Middle Button - Shifts middle display through speedometer, RPM,

clock, odometer, trip 1, trip 2, and

engine hours.

3. Right Button - Shifts bottom display

through coolant temperature, battery voltage, intake air temperature,

and fuel level.

4. Speedometer/Tachometer/Clock

Display - Indicates approximate

vehicle speed in MPH or KM/H

when speedometer function is

selected, RPM when tachometer

function is selected, or time when

clock is selected. Press the Left Button to change which parameter is

being displayed. With speedometer

selected, press and hold the Left

Button to shift between standard

(MPH/miles/Fahrenheit) and metric

(km/h/kilometers/Celsius).

With the clock mode selected, press

and hold the Left Button to set the

clock. The option of selecting the

12-hour or 24-hour clock is available; press the Left Button to alternate between the two modes. Next,

press the Middle Button to set the

clock. Press the Left or Right to set

the hours; then press the Middle

Button to set the minutes. Press the

Left or Right Button to set the minutes. When the proper time has been

set, press the Middle Button to

return to the main gauge display.

5. Engine Hour Meter/Odometer/Trip

Meter/Speedometer/Tachometer/

Clock Display - Displays engine

hours, odometer, trip meter, speedometer, tachometer, or clock. Press

the Middle Button to change which

parameter is being displayed. The

Engine Hour Meter and Odometer

cannot be reset. To reset the trip

meter, select the Trip Meter; then

press and hold the Middle Button

until the trip meter display reads 0.

NOTE: The engine hour meter will

not activate until engine speed

exceeds 500 RPM.

NOTE: An item can only be dis-

played in this position if it is not

already being displayed in the top

display. To set the clock when the

clock is in this position, press and

hold the Middle Button; then use the

procedure found in step 4.

6. Coolant Temperature/Battery Voltage/Intake Air Temperature/Fuel

Level Display - Displays coolant

temperature, battery voltage, intake

air temperature, and fuel quantity.

Press the Right Button to change

which parameter is being displayed.

Press and hold the Right Button to

see the actual values associated with

the mode selected.

NOTE: High engine RPM, low vehi-

cle speed, or heavy load can raise

engine temperature. Decreasing

engine RPM, reducing load, and

selecting an appropriate transmission gear can lower the temperature.

NOTE: Debris in the engine com-

partment (or packed between the

cooling fins of the radiator) can

reduce cooling capacity. Using a garden hose, wash the radiator and the

engine to remove any debris preventing air flow.

7. Gear Position Indicator - Indicates

which gear is selected.

CAUTION

Continued operation with high engine

temperature may result in engine

damage or premature wear.

CAUTION

Do not use a pressure washer to

clean the radiator core. The pressure

may bend or flatten the fins causing

restricted air flow, and electrical components on the radiator could be

damaged. Use only a garden hose

with spray nozzle at normal tap pressure.

Page 29

27

8. EFI Malfunction Indicator - A diagnostic code (see list below) and

engine icon will be displayed on the

LCD whenever an EFI error is

detected. The LCD will be normal,

but the code and engine icon will

continue to be displayed on the LCD

until the error is corrected.

WT114C

NOTE: Take the vehicle to an

authorized dealer to have the error

corrected and the system error reset

as soon as possible.

9. Drive Select Indicator - Displays

4WD when selected by the drive

select switch.

10. Seat Belt Reminder Indicator - Each

time the ignition switch is turned

ON, the indicator will illuminate

until the driver’s seat belt is fastened.

! WARNING

The seat belt indicator does not indicate that all seat belts are properly

secured. It is the operator’s responsibility to ensure all vehicle occupants

are properly seated with seat belts

secure and side restraints are properly latched. Serious injury or death

could occur as a result of falling outside a moving vehicle.

Page 30

28

Diagnostic Trouble Codes

Display Fault Description

C0063 Tilt Sensor Circuit High

C0064 Tilt Sensor Circuit Low/SG/Open

C1263 Backup/Reverse-Light Circuit Open

C1264 Backup/Reverse-Light Circuit High

C1265 Backup/Reverse-Light Circuit Low/SG

C1400 Fuel Level Sender Open

C1418 Memory Power Failure

P0030 O2 Heater Intermittent/Open

P0031 O2 Heater Low/SG

P0032 O2 Heater High/SP

P0107 MAP Sensor Circuit Low/SG/Open

P0108 MAP Sensor Circuit High/SP

P0112 Intake Air Temp Sensor Circuit Low/

SG

P0113 Intake Air Temp Sensor Circuit High/

Open

P0114 Intake Air Temp Sensor Circuit Inter-

mittent

P0116 Engine Coolant Temp Sensor Circuit

Range/Performance

P0117 Engine Coolant Temp Sensor Circuit

Low/SG

P0118 Engine Coolant Temp Sensor Circuit

High/Open/SP

P0119 Engine Coolant Temp Sensor Circuit

Intermittent

P0121 Throttle Position Sensor Range/Per-

formance

P0122 Throttle Position Sensor Circuit Low/

SG

P0123 Throttle Position Sensor Circuit High

P0130 O2 Sensor Intermittent/Open

P0131 O2 Sensor Low/SG or Air-Leak

P0132 O2 Sensor High/SP

P0171 O2 Feedback Below Minimum Correc-

tion

P0172 O2 Feedback Exceeds Maximum Cor-

rection

P0219 Engine Over-Speed Condition

P0231 Fuel Pump Relay Circuit Low/SG/

Open

P0232 Fuel Pump Relay Circuit High

P0233 Fuel Pump Relay Circuit

P0261 Cylinder #1 Fuel injector Circuit Low/

SG

P0262 Cylinder #1 Fuel injector Circuit High

P0263 Cylinder #1 Fuel injector Balance/

Open

P0264 Cylinder #2 Fuel injector Circuit Low/

SG

P0265 Cylinder #2 Fuel injector Circuit High

P0266 Cylinder #2 Fuel injector Balance/

Open

P0336 Crankshaft Angle Sensor Synchroni-

zation

P0337 Crankshaft Angle Sensor Circuit/SG

P0339 Crankshaft Angle Sensor Intermittent/

Erratic

P0340 Camshaft Angle Sensor Synchroniza-

tion

P0341 Camshaft Angle Sensor Circuit/SG

P0342 Camshaft Angle Sensor Intermittent/

Erratic

P0480 Fan-Primary/Right Relay Control Cir-

cuit

P0481 Fan-Secondary/Left Relay Control Cir-

cuit High

P0482 Fan-Secondary/Left Relay Control Cir-

cuit Low/SG/Open

P0483 Fan-Secondary/Left Relay Control Cir-

cuit

P0484 Fan-Primary/Right Relay Control Cir-

cuit High

P0485 Fan-Primary/Right Relay Control Cir-

cuit Low/SG/Open

P0500 Vehicle Speed-Sensor

P0508 Idle Air Control System Circuit Low/

SG

P0509 Idle Air Control System Circuit High/

Open

P0520 Engine Oil Sensor/Switch

P0562 System Voltage Low

P0563 System Voltage High

P0601 ECM CAN Communication Shutdown

P0615 Starter Relay Circuit

P0616 Starter Relay Circuit Low

P0617 Starter Relay Circuit High

P0630 VIN Not Programmed or Incompatible

P0642 Sensor Power Circuit Low

P0643 Sensor Power Circuit High

P2300 Ignition Coil #1 Primary Circuit Low/

SG/Open

P2301 Ignition Coil #1 Primary Circuit High

P2303 Ignition Coil #2 Primary Circuit Low/

Open

P2304 Ignition Coil #2 Primary Circuit High

P2531 Ignition Switch Circuit Low

P2532 Ignition Switch Circuit High

FUEL

OFF

Tilt Sensor Activation Code

Display Fault Description

Page 31

29

Oil Level Stick

There is an oil level stick for checking

the engine oil level. To check the oil

level, use the following procedure.

NOTE: The vehicle should be on

level ground when checking the

engine oil level.

1. Remove the seat.

2. Unscrew the oil level stick (located

on the right-side of the engine) and

wipe it with a clean cloth.

PK024A

3. Install the oil level stick.

NOTE: The oil level stick should be

threaded in for checking purposes.

4. Remove the oil level stick; the

engine oil level should be within the

operating range.

GZ461A

5. Add oil to the oil level stick opening

until proper operating level is

achieved.

6. Install the seat making sure it is

securely latched.

Load Capacity Ratings

Chart

This vehicle must always be loaded in

accordance with the Load Capacity Ratings chart. Under no circumstances

should the Vehicle Load Capacity rating

ever be exceeded.

Vehicle Load Capacity - Total weight of

operator, passenger, trailer tongue

weight, accessories, cargo, and storage

compartments.

Tongue Weight - Weight on trailer

tongue.

Accessory Weight - Winch, gun scabbard brackets, snow plow, etc.

Rear Tongue and Cargo Weight - Total

weight on trailer tongue and cargo box.

Towing Capacity - Total weight of

trailer and all cargo in the trailer.

Trailering and Towing

PK025

This vehicle is equipped with a rear

frame-mounted receiver for a standard

5.1 cm (2 in.) receiver hitch. The standard receiver hitch must be purchased

separately.

CAUTION

Do not overfill the engine with oil.

Always make sure the oil level is

within the operating range but not

above the FULL mark.

! WARNING

Overloading this vehicle could result

in loss of control resulting in serious

injury or death.

Item Specifications

(lb) (kg)

Vehicle Load Capacity 1000 454

Front Storage Compartment

(max)

25 11

Tongue Weight 150 68

Cargo Weight (max) 500 227

Rear Tongue and Cargo

Weight (max)

650 295

Towing Capacity 1500 680

Page 32

30

When loading a trailer properly, two

items are critical: Gross Trailer Weight

(the weight of the trailer plus cargo) and

Trailer Tongue Weight.

Trailer Tongue Weight is the downward

force exerted on the hitch by the trailer

coupler when the trailer is fully loaded

and the coupler is at its normal towing

height. Refer to the Load Capacity Ratings chart for tongue weight information.

Always maintain a slow speed when

trailering and towing and avoid sudden

accelerations, quick maneuvers, and sudden stops. Braking distance will be

affected when towing a trailer. When

towing a trailer, always maintain slow

speed and allow more stopping distance

than when not towing a trailer.

Transporting

When transporting, the vehicle must be

in its normal operating position (on all

four wheels) and the following procedure

must be used.

1. Place the transmission in park.

2. Secure the vehicle with load rated

hold-down straps.

PK083A

PK025A

NOTE: Suitable hold-down straps

are available from your authorized

dealer. Ordinary rope is not recommended because it can stretch under

load.

! WARNING

Make sure that the load in the trailer is

properly secured and will not shift

while moving. Also, do not overload

the trailer.

! WARNING

Never exceed any of the vehicle

weight restrictions.

! WARNING

Driving this vehicle without extra caution when towing a trailer will be hazardous. Trailer towing can affect the

handling and braking of the vehicle.

Tow only at low speeds and never

exceed 10 mph. Avoid sudden accelerations and stopping of the vehicle.

Do not make quick maneuvers. Avoid

uneven surfaces and do not tow on

hills.

! WARNING

Never tow people in or on any device

except when towing a disabled vehicle

with operable brakes and steering or

on a trailer designed for passengers

that has a rigid tow bar.

CAUTION

Failure to place the transmission in

park could allow the vehicle to roll off

the trailer in the event of tie-down

strap failure.

CAUTION

If using additional hold-down straps

in any other areas, care must be taken

not to damage the vehicle.

CAUTION

Always buckle the side restraints

when transporting to prevent buckle

damage to body panels.

Page 33

31

Gasoline-Oil-Lubricant

Filling Gas Tank

Since gasoline expands as its temperature

increases, the gas tank must be filled to

its rated capacity only. Expansion room

must be maintained in the tank particularly if the tank is filled with cold gasoline and then moved to a warm area.

Allow the engine to cool before filling

the gas tank. Care must be taken not to

overfill the tank. If overfilled, gas may

leak onto the engine creating a fire hazard.

1. To remove the gas tank cap, flip the

lid down; then rotate the cap counterclockwise ¼ turn.

PK061

2. After filling the tank, position the lid

towards the right side of the filler

neck and rotate the lid ¼ turn clockwise to secure. Flip the lid up.

Recommended Gasoline

The recommended gasoline to use in this

vehicle is 87 minimum octane regular

unleaded. In many areas, oxygenates are

added to the gasoline. Oxygenated gasolines containing up to 10% ethanol or 5%

methane are acceptable gasolines.

When using ethanol blended gasoline, it

is not necessary to add a gasoline antifreeze since ethanol will prevent the

accumulation of moisture in the fuel system.

Recommended Engine/

Transmission Oil

The recommended oil to use is ACX All

Weather synthetic engine oil, which has

been specifically formulated for use in

this engine. Although ACX All Weather

synthetic engine oil is the only oil recommended for use in this engine, use of any

API certified SM 0W-40 oil is acceptable.

OILCHARTJ

! WARNING

Always fill the gas tank in a well-ventilated area. Never add gasoline to the

gas tank near any open flames or with

the engine running or hot. DO NOT

SMOKE while filling the gas tank.

! WARNING

Do not over-flow gasoline when filling

the gas tank. A fire hazard could materialize. Always allow the engine to

cool before filling the gas tank.

! WARNING

Do not overfill the gas tank.

CAUTION

Do not use white gas. Only approved

gasoline additives should be used.

CAUTION

Any oil used in place of the recommended oil could cause serious

engine damage. Do not use oils which

contain graphite or molybdenum

additives. These oils can adversely

affect clutch operation. Also, not recommended are racing, vegetable,

non-detergent, and castor-based oils.

Page 34

32

Recommended Front

Differential/Rear Drive

Lubricant

NOTE: The manufacturer recom-

mends the use of genuine lubricants.

The recommended front differential/rear

drive lubricant is SAE approved 80W-90

hypoid. This lubricant meets all of the

lubrication requirements of this vehicle.

Engine Break-In

After the completion of the break-in

period, the engine oil and oil filter should

be changed. Other maintenance after

break-in should include checking of all

prescribed adjustments and tightening of

all fasteners. At the discretion and

expense of the owner/operator, the vehicle may be taken to an authorized dealer

for this initial service.

New vehicles and engines require a

“break-in” period. The first month is

most critical to the life of this vehicle.

Proper operation during this break-in

period will help assure maximum life and

performance from this vehicle.

During the first 10 hours of operation,

always use less than ½ throttle. Varying

the engine RPM during the break-in

period allows the components to “load”

(aiding the engine/transmission component mating process) and then “unload”

(allowing components to cool). Although

it is essential to place some stress on the

engine components during break-in, care

should be taken not to overload the

engine too often. Do not pull a trailer

during the break-in period.

When the engine starts, allow it to warm

up properly. Idle the engine several minutes until the engine has reached normal

operating temperature. Do not idle the

engine for excessively long periods of

time.

Burnishing Brake Pads

Brake pads must be burnished to achieve

full braking effectiveness. Braking distance will be extended until brake pads

are properly burnished.

1. Choose an area sufficiently large to

safely accelerate to 30 mph and to

brake to a stop.

2. Accelerate to 30 mph; then release

the accelerator pedal and press brake

pedal to decelerate to 0-5 mph.

3. Repeat procedure twenty times.

CAUTION

Any lubricant used in place of the recommended lubricant could cause

serious front differential/rear drive

damage.

! WARNING

Do not attempt sudden stops or put

yourself into a situation where a sudden stop will be required until the

brake pads are properly burnished.

Page 35

33

General Maintenance

NOTE: Proper maintenance of this

vehicle is important for optimum performance. Follow the Maintenance

Schedule and all ensuing maintenance instructions/information.

If, at any time, abnormal noises, vibrations, or improper functioning of any

component of this vehicle is detected,

DO NOT OPERATE THE VEHICLE.

Take the vehicle to an authorized dealer

for inspection and adjustment or repair.

A repair shop or person of the owner's

choosing may maintain, replace, or repair

emission-control devices and systems.

If the owner/operator does not feel qualified to perform any of these maintenance

procedures or checks, take the vehicle to

an authorized dealer for professional service.

NOTE: The following instructions