Page 1

OPERATOR'S

MANUAL

Lycoming

0-235

AIRCRAFT ENGINES

4th Edition

Part No. 60297-9

and 0-290

Approved by F.A.A.

SERIES

January 1988

Page 2

LYCOMING OPERATOR'S MANUAL

ATTENTION

OWNERS, OPERATORS

MAINTENANCE PERSONNEL

This operator's manual contains a description of the engine, its

specifications, and detailed information on how to operate and maintain

Such maintenance procedures

it.

with periodic inspections are also included. This manual is intended for

use by owners, pilots and maintenance

Avco Lycoming powered aircraft.

are contained

nel should refer to these for such procedures.

Neglecting to follow

periodic

and power loss. Also, if power and speed limitations specified in this

manual are exceeded, for any reason, damage to the engine and personal

injury can happen.

ty.

SERVICE BULLETINS,

Although the information contained in this manual is up-to-date at

time of publication, users are

through Avco

ters which

factory by subscription.

L114 for subscription information.

in Avco Lycoming overhaul

SAFETY WARNING

the operating instructions

maintenance procedures

Consult your local FAA approved

Lycoming Service Bulletins,

are available from all Avco Lycoming

Consult the latest edition

that may be required in conjunction

Modifications and repair

can result in poor engine performance

INSTRUCTIONS

urged to keep abreast of later

AND

personnel responsible

manuals; maintenance person-

and to carry out

maintenance facili-

AND LETTERS

Instructions and Service Let-

distributors or from the

of Service Letter No.

for care of

procedures

information

SPECIAL NOTE

illustrations, pictures and drawings

The

typical of the subject matter they portray; in no instance are they to be

interpreted as examples of any specific engine, equipment or part

thereof.

shown in this publication

are

Page 3

TEXTRON LYCOMING OPERATOR'S MANUAL

IMPORTANT

Proper service

operation

by

operations. Some of

specially

and as recommended.

It is important

tain various Warnings

order to minimize the risk of

vice methods that may damage the engine or render it unsafe.

It is also important to

are

evaluate or advise

vice might be done

be involved.

satisfy themselves

ty will be

of all aircraft engines. The service

Textron Lycoming

designed for the task. These

not all inclusive. Textron

and repair is essential

are effective

these service operations require

to note that most Textron Lycoming

and Cautions which

understand that these Warnings

the service trade of all conceivable

or of the possible hazardous

Acordingly,

jeopardized

anyone who

thoroughly

by the service

SAFETY

personal injury or the use of

Lycoming could not possibly

that neither

NOTICE

to increase the safe, reliable

procedures recommended

methods

special tools must be used

uses a service

procedure

for performing

the use of tools

publications con-

must be carefully read in

improper ser-

and Cautions

ways in which ser-

consequences that may

procedure must

their safety

nor aircraft safe-

they select.

service

when

know,

first

Page 4

NEWAND REMANUFACTURED

(LIMITED)

RECIPROCATING AIRCRAFT ENGINE

WHAT TEXTRON

Textron Lycoming warrants each new and remanufactued reciprocating engine sold by it to be free from defects in

material and

acceptance testing The date of first operationmust not exceed two (2) years from the date ofshipment from Textron

Lycoming.

change basis, of the engine or any

in material or workmanship.

Lycomig will also bear the cost for labor in connection with the repair or replacement as provided in Textron

Lycoming's

the period

from the date of first operation, whichever occurs first, Textron Lycoming will reimburse you for a pro rata portion of the

charge for the repair or replacement (at its choice) with Textron Lycoming parts,ofparts required tobe repairedorre-

placed, or a replacement

during the proration period extends to major parts of the engine, which are limited to crankcase, crankshaft, camshaft,

cylinders, connecting rods, pistons, sump, accessory housing and gears. The proration policy does not extend to labor or

to accessories, including but not limited to magnetos, caburetors or fuel injectors, fuel pumps, sarers, alternators and

turbochargers and their controllers.

Lycoming distributor within 30 days of the appearance of the defect in material or workmanship.

the part of Textron Lycoming set forth above are your exclusive remedy and the exclusive liability of Textron Lycoming.

This warranty allocates the risk of product failure between you and Textron Lycoming, as permitted by applicable law.

been subject to accident or used, adjusted, altered,

manual, or if non-genuine Textron Lycoming parts are installed in or on the engine and are determined tobeapossible

cause of the incident for which the warranty application is filed.

such alterations in engines or parts previously sold.

workmanship appearing within one (1) year from

Textron Lycoming's

In addition, if Textron Lycoming determines

until the expiration of Textron Lycoming's recommended

Any engine or

The

engine must have

Textron Lycoming's warranty does

Textron Lycoming

Textron Lycoming may change the

obligation under this warranty shall be limited

part of the engine, when Textron Lycoming has determined

Such repair or replacement will be made

then current Removal and

part so repaired or

reserves the right

Installation Labor Allowance Guidebook.

engine, if it determines that engine replacement

replaced will be

received normal

not cover normal maintenance expenses or consumable

construction of engines at any time without incurring

LYCOMING PROMISES

the date of first operation, excluding necessary aircraft

to its choice of repair or replacement, on anex-

by Textron Lycoming at no charge to you. Textron

that the engine proves to be defective in material

entitled to warranty

OBLIGATIONS

YOUR

use and service.

to deny any warranty claim

handled, maintained or stored other than as directed

Time Between Overhaul (TBO), or

is required. Textron Lycoming's obligation

for the remainder

You must apply

for warranty

if it reasonably determines

YOU

that the engine is defective

or workmanship during

two (2) years

of the original

with an authorized

any obligation to incorporate

waranty period.

Textron

items. The obligations on

that the engine or part

in your operator's

has

Page 5

THIS LIMITED

TATIONS,

LIMITED TO ANY WARRANTY OF MERCHANTABILITY

AND ANY IMPLIED WARRANTY

TRADE USAGE. THIS

CLAIM, WHETHER IN CONTRACT OR IN TORT, INCLUDING ANY RIGHT IN STRICT LIABILITY IN

TORT

TEXTRON LYCOMING'S LIABILITY ON

CABLE TO THE ENGINE

WARRANTY IS EXCLUSIVE AND IN LIEU

EXPRESS OR IMPLIED OR STATUTORY,

WARRANTY IS ALSO IN LIEU OF ANY OTHER

OR ANY RIGHT ARISING FROM NEGLIGENCE

ARISING FROM ANY COURSE OF PERFORMANCE

OR PART WHICH GIVES RISE

WHETHER WRITTEN OR ORAL, INCLUDING

SUCH CLAIM SHALL NNO CASE EXCEED

OF ALL. OTHER WARRANTIES AND REPRESEN-

OR FITNESS FOR ANY PARTICULAR

OBLIGATION, LIABILITY, RIGHT OR

ON THE PART OF TEXTRON LYCOMING,

TO THE CLAIM.

BUT NOT

PURPOSE,

OR DEALING OR

THE PRICE ALLO-

AND

LIMITATION

IN NO EVENT, WHETHER

LIGENCE, SHALL TEXTRON LYCOMING

DAMAGES, INCLUDING BUTNOT LIMITED TOLOSSOF PROFITSOR REVENUES, LOSS OF USE OF THE

ENGINE OR COST OF A

No agreement varying

Lycoming unless in writing signed by a duly authorized representative of Textron Lycoming.

Effective October

AS A RESULT OF A BREACH OF WARRANTY,

REPLACEMENT.

this warranty or Textron Lycoming's obligations

1, 1995 Revision

"J'

OF LIABILITY

BE LIABLE FOR SPECIAL OR CONSEQUENTIAL

CONTRACT OR ALLEGED NEG-

under it will be binding upon Textron

Textron

Williamsport, Pennsylvania

OR ANY OTHER

Lycoming

Page 6

WARRANTY

REPLACEMENT

Textron Lycoming

inmaterial and

must not exceed

tion.

Textron

basis, of te

change

workmanship.

ment as provided

part so repaired

Any

The engine

warranty

workmanship.

Textron

part of Textron

the

This warranty

Textron

been subject to

manual, or if non-genuine

cause of the

Textron

such alterations

THIS LIMITED

TATIONS,

LIMITED

AND ANY

USAGE.

TRADE

CLAIM,

OR ANY

TORT

TEXTRON

CABLE TO THE

warrants each

workmanship appearing

two (2) years from

Lycoming's obligation

replacement part,

Lycoming will

Textron

in Textron Lycoming's

in which

with an authorized

Lycoming's

Lycoming

the risk of

allocates

Lycoming reserves

accident or used,

incident for

may change the

Lycoming

engines or

in

WARRANTY

OR IMPLIED

EXPRESS

ANY WARRANTY

TO

WARRANTY

IMPLIED

THIS WARRANTY

WHETHER

IN CONTRACT

RIGHT ARISING

LYCOMING'S

ENGINE OR PART

PART -RECIPROCATING

(LIMITED)

WHAT TEXTRON

new reciprocating aircraft

under this

when TextronLycoming

also reimburse you

will be warranted

or replaced

the replacement

Textron Lycoming

does not cover

warranty

which the warranty

above are your

set forth

product failure

the right

adjusted, altered,

Textron Lycoming parts are installed

construction of

pars previously

IS EXCLUSIVE

OR STATUTORY,

OF MERCHANTABILITY

ARISING

IS ALSO IN

FROM

LIABILITY

WHICH GIVES

LYCOMING

one (I) year from

within

the date of shipment

warranty shall

then current Removal

for the remainder

OBLIGATIONS

YOUR

part is installed

distributor

normal maintenance

exclusive

between

any warranty

to deny

handled, minained

application

engines at any time

sold.

AND IN

FROM

LIEU OF ANY

OR IN TORT,

NEGLIGENCE

CLAIM

ON SUCH

AIRCRAFT

PROMISES

engine replacement pat

from Textron

be limited to its

has

for the costs

and Installation

have received

must

within 30 days

remedy and

you and Textron

claim if it reasonably

in or on the engine and are determined to be a possible

is filed.

LIEU OF

WHETHER

OR FITNESS

ANY COURSE

INCLUDING

ON

SHALL

RISE TO THE

first operation. The

its date of

Lycoming.

choice of repair

determined that

for labor in connection

Labor Allowance Guidebook

original warranty

of the

normal use

of the appearance

consumable

expenses or

the exclusive

Lycoming,

or stored other

without incurring

ALL OTHER

OTHER

THE PART

OR

WRITTEN

FOR

OF PERFORMANCE

OBLIGATION,

RIGHT IN

ANY

OF TEXTRON

IN NO CASE

CLAIM.

ENGINE

YOU

sold by it to be free from

or replacement,

the pan is defective

with the repair

period.

and service.

of the defect in

items. The obligations

liability of Textron

as permitted

that

determines

than as directed

any obligation

WARRANTIES

ORAL, INCLUDING

ANY PARTICULAR

LIABILITY,

STRICT

EXCEED

date of first opera-

on an ex-

in material or

or replace-

apply for

You must

material or

Lycoming.

by applicable

or part has

the engine

in your operator's

to incorporate

REPRESEN-

AND

BUT NOT

PURPOSE,

OR DEALING

RIGHT

LIABILITY

LYCOMING,

PRICE

THE

defects

law.

OR

OR

AND

ALLO-

on

IN

Page 7

IN

NO

EVENT,

LIGENCE,

DAMAGES,

ENGINE

OR COST

No agreement

Lycoming

Effective

WHETHER

SHALL

TEXTRON

INCLUDING

OF A REPLACEMENT.

varying

unless in

writing

October

AS ARESULT

BUT

this warranty

signed

1, 1995

LIMITATION

LYCOMING

NOT LIMITED

or

Textron

by a duly

authorized

Revision

"J"

OF

OF A BREACH

BE LIABLE

TO LOSS

Lycoming's

representative

LIABILITY

OF WARRANTY,

FOR

SPECIAL

OF

PROFTS

obligations

of

Textron

CONTRACT

OR

CONSEQUENTIAL

OR

REVENUES,

under

it will

Lycoming.

Williamsport,

OR ALLEGED

OR

LOSS

OF USE

be binding

Textron

Pennsylvania

NEG-

ANY OTHER

OF THE

upon

Textron

Lycoming

Page 8

I

. Lycoming

WARRANTY

(LIMITED)

RECIPROCATING

OVERHAULED

AIRCRAFT

ENGINE

WHAT TEXTRON

Textron Lycoming warrants

workmanship appearing

testing.

The date of first

Textron Lycoming's

change basis, of the

in material or

Lycoming

will also bear the cost

Lycoming's

Any engine

The engine

Lycoming distributor

Textron

Lycoming's

the pan ofTextron

This

warranty allocates the

Textron Lycoming reserves

been subject to accident

manual,

or if non-genuine

cause of the

Textron Lycoming

such alterations

THIS LIMITED

TATIONS, EXPRESS

LIMITED TO

AND ANY

TRADE

USAGE. THIS

CLAIM, WHETHER

TORT

OR ANY RIGHT

TEXTRON LYCOMING'S

CABLE TO THE

within one (1) year

obligation under

engine or any part of the

workrmanship. Such repair

then current Removal and

or part so repaired

must have received

within

warranty does

Lycoming set forth

or used, adjusted,

incident for which

may change

in engines or

WARRANTY IS

OR IMPLIED

ANY WARRANTY OF

IMPLIED WARRANTY

WARRANTY

IN CONTRACT

ENGINE OR

each overhauled

operation must

or replaced will

reciprocating engine sold

from the date of first

not exceed two

thi:; warranty shall be limited

engine, when Textron Lycoming

or replacement will be made

for labor in connection

Installation Labor Allowance Guidebook.

be entitled to warranty

YOUR

normal

30 days of

risk of product failure between

Textron Lycoming

parts previously sold.

ARISING

LIABILITY

use and service.

the appearance

not cover nominal

abovt are your exclusive

the right to deny any

altered, handled, maintained

the warranty

PART WHICH GIVES

parts are installed

rpplication

the construction

EXCLUSIVE AND IN

OR STATUTORY,

MERCHANTABILITY

ARISING FROM

IS ALSO IN

O IN TORT, INCLUDING

FROM NEGLIGENCE

ON SUCH CLAIM SHALL

of engines at any

LYCOMING PROMISES

by it to be free from defects

operation, excluding necessary

(2) years from the

date of shipment

to its choice of repair

has determined

by Textron Lycoming

with the repair or

for the remainder

replacement as provided

OBLIGATIONS

You must apply

of the defect

maintenance

you and Textron Lycoming,

warranty claim if it reasonably

is filed.

LIEU OF ALL OTHER

WHETHER

ANY COURSE OF PERFORMANCE

LIEU OF ANY

ON THE

RISE TO

for warranty with

in material

or workmanship.

expenses or consumable

remedy and the exclusive

determines that

or stored other than as

in or on the

engine and are

time without incurring

WRITTEN

OR FITNESS FOR ANY

OTHER OBLIGATION,

THE CLAIM.

WARRANTIES AND REPRESEN-

OR ORAL, INCLUDING

ANY RIGHT

PART OF TEXTRON

IN NO CASE EXCEED

YOU

in material and

aircraft acceptance

from Textron

at no charge to you. Textron

of the original

liability of Textron Lycoming.

as permitted by

determined to be

any obligation

PARTICULAR PURPOSE,

IN STRICT LIABILITY

Lycoming.

or replacement, on

that the engine is defective

in Textron

warranty

an authorized

items. The

obligations on

applicable law.

the engine or part has

directed in your operator's

to incorporate

OR DEALING

LIABILITY,

RIGHT OR

LYCOMING,

THE PRICE ALLO-

an ex-

period.

Textron

a possible

BUT

NOT <

OR

AND

<

IN

Page 9

I

IN

NO EVENT,

LIGENCE,

DAMAGES,

ENGINE

OR

No

agreement

Lycoming

Effective

WHETHER

SHALL

INCLUDING

COST

unless

in

October

TEXTRON

OF

A

varying

writing

1, 1995

AS

A RESULT

LYCOMING

BUT

NOT

signed

warranty

by a

LIMITED

or

duly

REPLACEMENT.

this

Revision

LIMITATION

OF

A BREACH

BE LIABLE

TO

LOSS

Textron

Lycoming's

authorized

representative

J"

OF

LIABILITY

OF

WARRANTY,

FOR

SPECIAL

OF PROFITS

obligations

OR

OR

of Textron

CONTRACT

CONSEQUENTIAL

REVENUES,

under

Lycoming.

it will

LOSS

be

Williamsport,

OR

ALLEGED

OR

OF

binding

Textron Lycoming

NEG-

ANY

OTHER

USE OF

THE

upon

Textron

Pennsylvania

i

i

Page 10

LYCOMING

TABLE OF CONTENTS

OPERATOR'S

MANUAL

Page

SECTION 1

SECTION 2

SECTION 3

SECTION 4

SECTION 5

SECTION 6

SECTION 7

SECTION 8

DESCRIPTION

SPECIFICATIONS

OPERATING INSTRUCTIONS

PERIODIC INSPECTIONS

MAINTENANCE PROCEDURES

TROUBLE-SHOOTING

INSTALLATION AND STORAGE

TABLES

1-1

2-1

3-1

4-1

5-1

6-1

7-1

8-1

Page 11

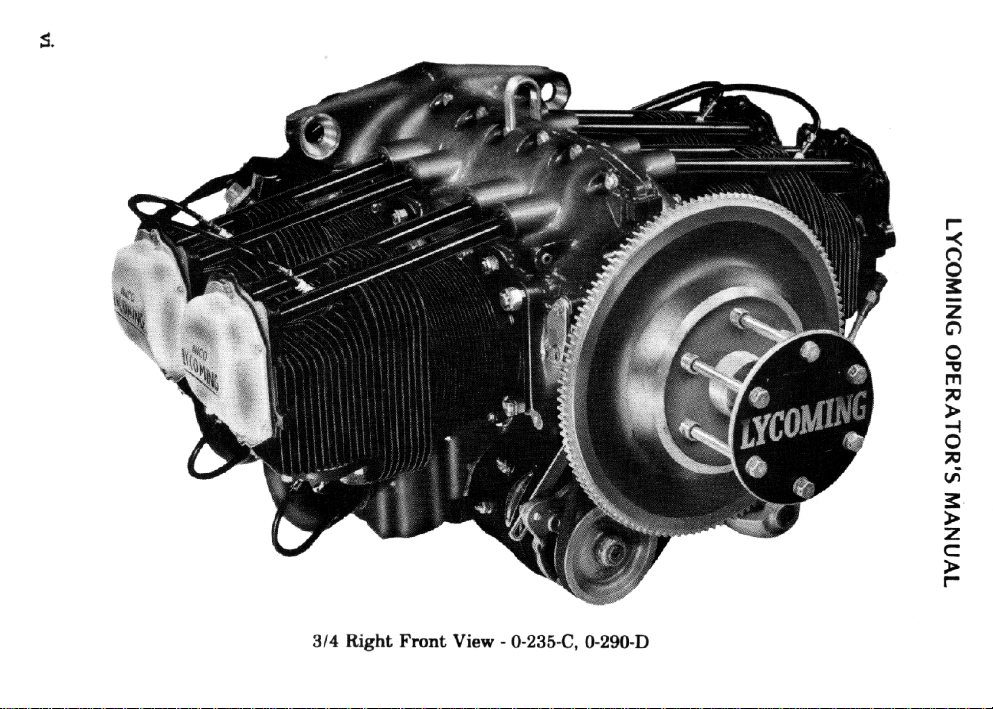

5.

314 Right Fmnt View - 0-235-C, 0-290-D

Page 12

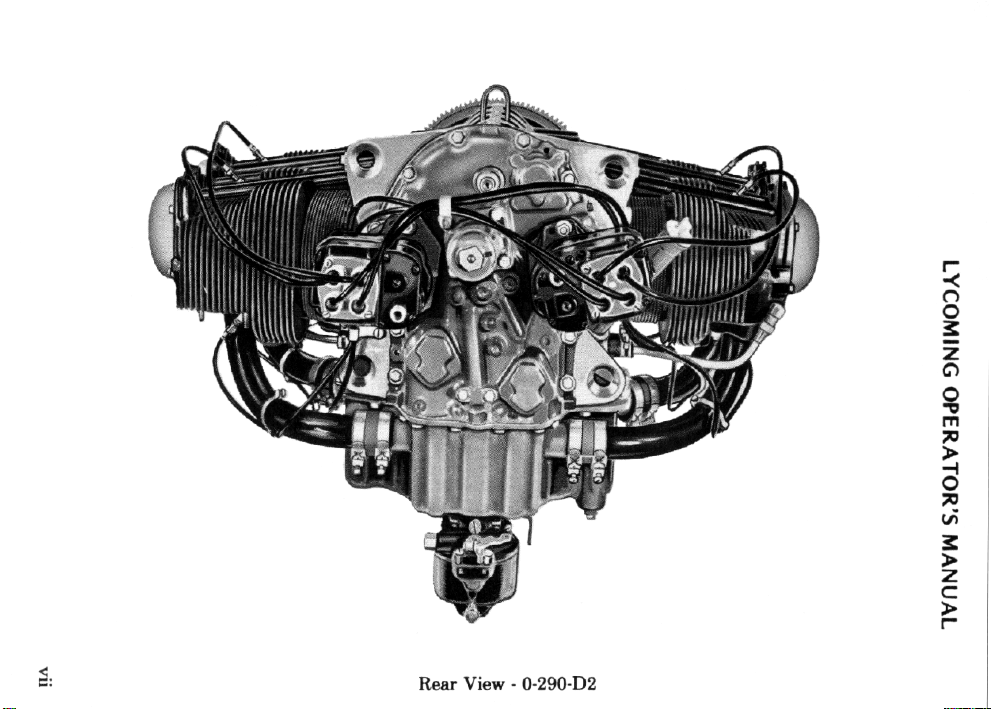

Rear View - O-290-D2

Page 13

LYCOMING

DESCRIPTION

General ................................................ 1-1

Cylinders .............................................. 1-1

Valve Operating

Crankshaft ............................................

Crankcase .............................................

Oil Sum p .............................................. 1-2

Connecting Rods ...................................... 1-2

P isto n s . ... .. .... .. ... ... . ... .. .. .. . .... .. .. .... ... .... 1-2

Accessory Housing ..................................... 1-2

Gears ................................................. 1-2

Cooling System ........................................ 1-3

Lubricating System ..................................... 1-3

Induction System ....................................... 1-3

Ignition System

Table of M odels ........................................ 1-4

M echanism .............................

........................................

OPERATOR'S

MANUAL

Page

1-1

1-2

1-2

1-3

Page 14

LYCOMING

OPERATOR'S

MANUAL

0-235 AND

The

engines

air-cooled

In referring

are described

tional airframes.

the

accessory

bottom

located

made with

cylinder

The front

number

the

crankshaft,

Cylinders

with the

The

ed combustion

nickel

ground

0-290 SERIES

Lycoming

are four cylinder,

models.

to

in their

drive

and

the

is the top.

the observer

on the

cylinder

3. The

observer

heads

molybdenum

viewed

- The

two

are made

and

honed to

direction

facing

major

0-235 series,

the location

relationship

Thus

the power

section

opposite

References

left bank

on

the right

of rotation

the

from the

cylinders

parts,

from

chamber.

steel

a specified

SECTION 1

DESCRIPTION

direct drive,

of the various

to

take-off

the rear.

side of

the engine

to the left

facing

the rear

is

number

drive

are

head

an aluminum

The

forgings

2 and the

bank

for

pad. The

accessory

of conventional

and

barrel,

barrels,

with

finish.

0-290-D

the engine

The

is number

which

series

and 0-290-D2

horizontally opposed,

engine

components,the

as installed

end is considered

sump section

where

and right

of the

accessory

direction

end

screwed

alloy casting

deep integral

engine. Thus

rear

1 and

drives

of the

engine

air-cooled

are

machined

the

side of

cylinder

the rear

of rotation

and

with

SECTION

series

wet sump,

in conven-

the front and

is

considered

shroud

tubes

the engine

the

is number

cylinder

is determined

is clockwise.

shrunk

a fully

cooling

of

construction

together.

machin-

from

chrome

fins, are

1

parts

the

are

are

front

4.

is

by

the

The

valve

are cast

which

the

intake

ed

recesses

Valve Operating

on the

crankshaft

tuates

on full

steel

seats.

rocker

integrally

completely

valves,

in the

top side.

and operates

the valves

floating,

shaft bearing

with the

surround

Valve

guides and

head.

Mechanism

The

camshaft

in aluminum

by means

steel

shafts.

supports

head. The

the

area of

-The valve

is

of tappets.

The

valve springs

valves

the exhaust

valve

seats

operating

located

bearings.

The valve

and

the rocker

are

cooled by

valve

are shrunk

mechanism

parallel

The camshaft

rockers

bear against

box

means

and

into

to and

are supported

housing

of fins

portions

machin-

is located

above

in

turn ac-

hardened

of

the

1-1

Page 15

LYCOMING

OPERATOR'S

MANUAL

SECTION

Hydraulic

are employed

employed

latter

the valve rocker.

Crankshaft -Made from

bearing

crankshaft must

hydro

Crankcase

alloy castings

together by bolts

joined

for use

Oil Sump -

the intake

passes through

the riser.

Connecting

forgings. They

and

the crankshaft

each cap.

1

tappets which

on the

on the 0-235

models is

surfaces are

control or variable

without the

of precision

split type bronze

maintained by

be removed

- Crankcase

divided at

and nuts.

use of a gasket,

Incorporates an

riser and

the riser,

Rods - Made in the

have replaceable

ends are retained by means of

type main

intake pipe connections.

bushings in

0-235 AND 0-290

NOTE

automatically keep

0-290-D2 series

and 0-290D series.

means of an adjusting

a chrome nickel molybdenum

nitride hardened.

on those models

pitch propeller.

assembly consists

the center line

The mating surfaces

and main bearing

bearing

oil suction screen,

is vaporized

form of "H" sections from alloy

bearing

the piston ends.

the valve clearance

engines while

Proper valve

The expansion

employing a

of two reinforced

of the engine

inserts.

carburetor

The

by the heated

inserts in the

two bolts and nuts through

SERIES

solid tappets

clearance on

screw

located in

steel forging. All

plug

two position

aluminum

and fastened

of the crankcase

bores are

fuel-air mixture,

oil that surrounds

The bearing caps

machined

mounting pad,

crankshaft ends

at zero

are

the

in the

are

as it

steel

on

Piston

- Machined

an oil

regulating ring

series employs

of the

full floating

from touching

Accessory Housing -

the rear of

housing for

Gears - Are of to insure

an oil scraper

type with

the cylinder

the crankcase and the top

the oil pump

the conventional

long life

and satisfactory

from an aluminum

are employed

ring below the

a plug

wall.

Made from an aluminum casting

and the various

alloy. Two

on all pistons.

located at

type and precision

operating

piston pin. The

each end to

rear of the oil sump. It forms

accessory

qualities.

compression

In addition, the

piston pin is

prevent

and is fastened to

drives.

machined,

rings and

0-235

the pin

a

hardened

Page 16

LYCOMING OPERATOR'S MANUAL

0-235 AND 0-290 SERIES SECTION 1

Cooling

actuated by the forward

up

exhausted through gills or augmentor tubes usually located at the rear

of the cowling.

Lubrication System -The full

actuated by an impeller type oil pump contained within the accessory

housing.

Induction System - These engines are equipped with either of two

Marvel-Schebler carburetors, MA-3A or MA-3SPA. See Table 1 for

model

and are equipped with

ticularly

tained from

sump and is submerged in oil, insuring a more uniform vaporization of

fuel and aiding in cooling the

mixture is distributed to

Ignition

Table

tion

System -These engines are

speed of the aircraft. Close

a pressure and force the air through

application. Both carburetors

manual mixture control and

good distribution of the fuel-air

the center zone induction system,

each cylinder by individual

System - Dual ignition is

1 for proper model application.

wiring is so arranged as shown

designed to be cooled by air

pressure wet sump lubrication

oil in the sump. From the riser

furnished by two magnetos.

Depending on installation

in either figure 5-1, 5-2

pressure

fitting baffles build

the cylinder fins. The air

system is

are of the single barrel float

"idle cut-off". Par-

mixture to each cylinder is

which is integral with the

the fuel-air

intake pipes.

Consult

the igni-

or 5-3.

is then

type

ob-

Page 17

LYCOMING

OPERATOR'S

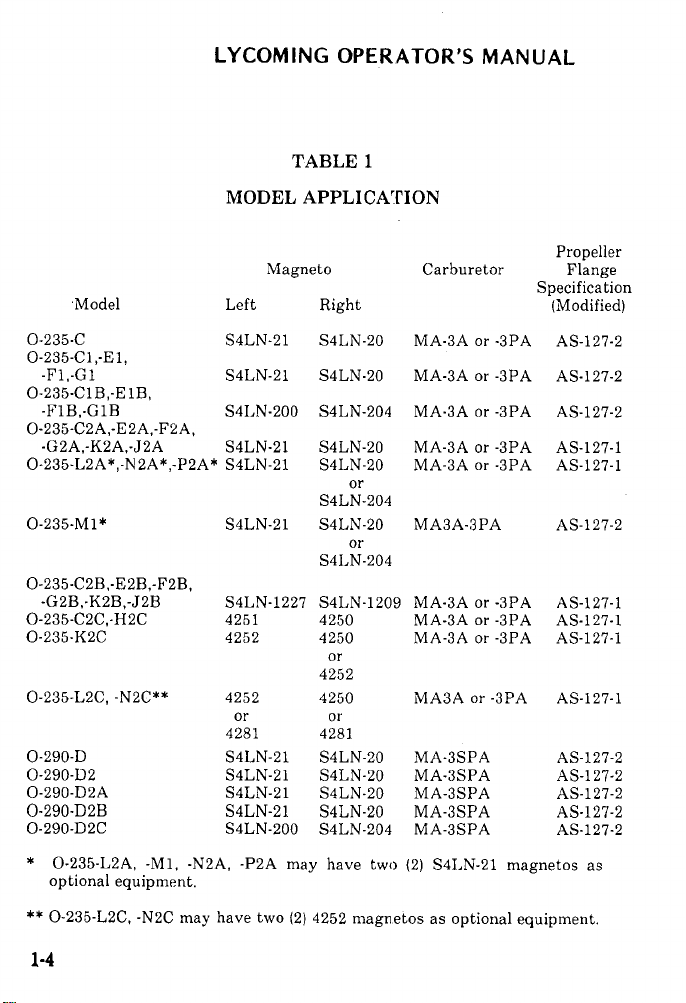

TABLE 1

MODEL APPLICATION

MANUAL

Model

0-235-C

0-235-C,-E1,

-F1,-G1

0-235-C1B,-E1B,

-F1B,-G1B

0-235-C2A,-E2A,-F2A,

-G2A,-K2A,-J2A

0-235-L2A*,-N2A*,-P2A*

0-235-M1*

0-235-C2B,-E2B,-F2B,

-G2B,-K2B,-J2B

0-235-C2C,-H2C

0-235-K2C

0-235-L2C, -N2C**

0-290-D

0-290-D2

0-290-D2A

0-290-D2B

0-290-D2C

* 0-235-L2A,

optional

-M1, -N2A, -P2A

equipment.

Magneto

Left

S4LN-21 S4LN-20

S4LN-21

S4LN-200 S4LN-204

S4LN-21 S4LN-20

S4LN-21 S4LN-20

S4LN-21

S4LN-1227

4251

4252

4252

or

4281

S4LN-21

S4LN-21

S4LN-21

S4LN-21

S4LN-200

Right

S4LN-20

or

S4LN-204

S4LN-20

or

S4LN-204

S4LN-1209

4250

4250

or

4252

4250

or

4281

S4LN-20

S4LN-20

S4LN-20

S4LN-20

S4LN-204

may have two

Carburetor Flange

MA-3A

MA-3A

MA-3A

MA-3A

MA-3A or -3PA AS-127-1

MA3A-3PA

MA-3A or -3PA

MA-3A or -3PA

MA-3A or -3PA

MA3A or -3PA

MA-3SPA

MA-3SPA

MA-3SPA

MA-3SPA

MA-3SPA

(2) S4LN-21

or -3PA AS-127-2

or -3PA

or -3PA

or -3PA

Propeller

Specification

(Modified)

AS-127-2

AS-127-2

AS-127-1

AS-127-2

AS-127-1

AS-127-1

AS-127-1

AS-127-1

AS-127-2

AS-127-2

AS-127-2

AS-127-2

AS-127-2

magnetos as

** 0-235-L2C,

1-4

-N2C may have

two (2) 4252

magnetos as optional

equipment.

Page 18

LYCOMING

SPECIFICATIONS

Specifications -0-235 ................................... 2-1

Specifications - 0-290 ................................... 2-2

Accessory Drives ...................................... 2-2

Alternate Power Ratings ..... .......................... 2-3

Detail Weights ........................................ 2-4

OPERATOR'S

MANUAL

Page

Page 19

LYCOMING

OPERATOR'S

MANUAL

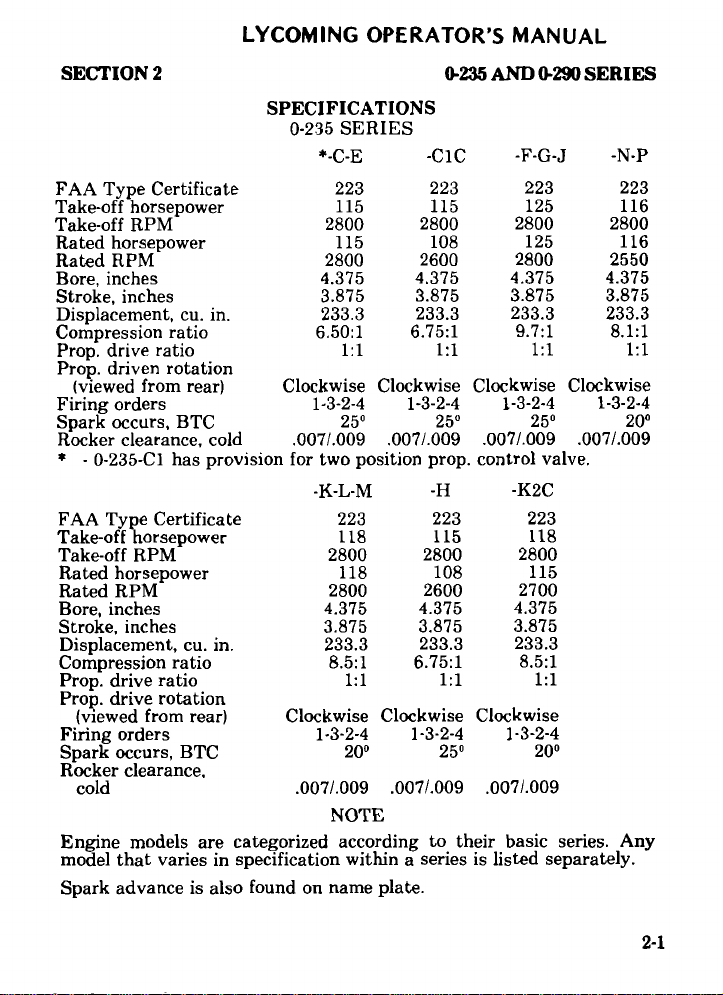

SECTION 2 0-235 AND 0-290 SERIES

SPECIFICATIONS

0-235 SERIES

*-C-E -C1C -F-G-J -N-P

FAA Type Certificate

Take-off horsepower

Take-off

RPM

Rated horsepower

Rated RPM

Bore, inches

Stroke, inches

Displacement,

cu. in.

223

115

2800 2800

115

2800

4.375 4.375

3.875

233.3 233.3

223

115

108

2600

3.875

Compression ratio 6.50:1 6.75:1

Prop. drive

ratio

1:1 1:1

223

125

2800

125

2800

4.375

3.875

233.3

9.7:1

1:1

223

116

2800

116

2550

4.375

3.875

233.3

8.1:1

Prop. driven rotation

(viewed

Firing

Spark

Rocker clearance,

* - 0-235-C1

from rear)

orders

occurs, BTC

cold .007/.009

has provision

FAA Type Certificate

Take-off

horsepower

Take-off RPM

horsepower

Rated

Rated RPM

Bore, inches

Stroke, inches

Displacement, cu. in.

Compression ratio

Prop. drive ratio

Clockwise Clockwise

1-3-2-4

25

1-3-2-4

25

.007/.009

for two position prop.

-K-L-M

223

118

2800

118

2800

4.375

3.875

233.3

8.5:1

1:1

-H -K2C

223

115

2800

108

2600

4.375

3.875

233.3

6.75:1

1:1

Clockwise

1-3-2-4 1-3-2-4

.007/.009 .007/.009

control valve.

Clockwise

25 20

223

118

2800

115

2700

4.375

3.875

233.3

8.5:1

1:1

Prop. drive rotation

20

Clockwise

1-3-2-4

25

Clockwise

1-3-2-4

20

.007/.009

(viewed from rear)

orders

Firing

Spark occurs, BTC

Rocker

clearance.

cold

Clockwise

1-3-2-4

.007/.009 .007/.009

NOTE

Engine

models

model that varies

Spark

advance

is also

are categorized

according to

in specification within a

found on

name plate.

their basic series.

series is listed separately.

Any

1:1

2-1

Page 20

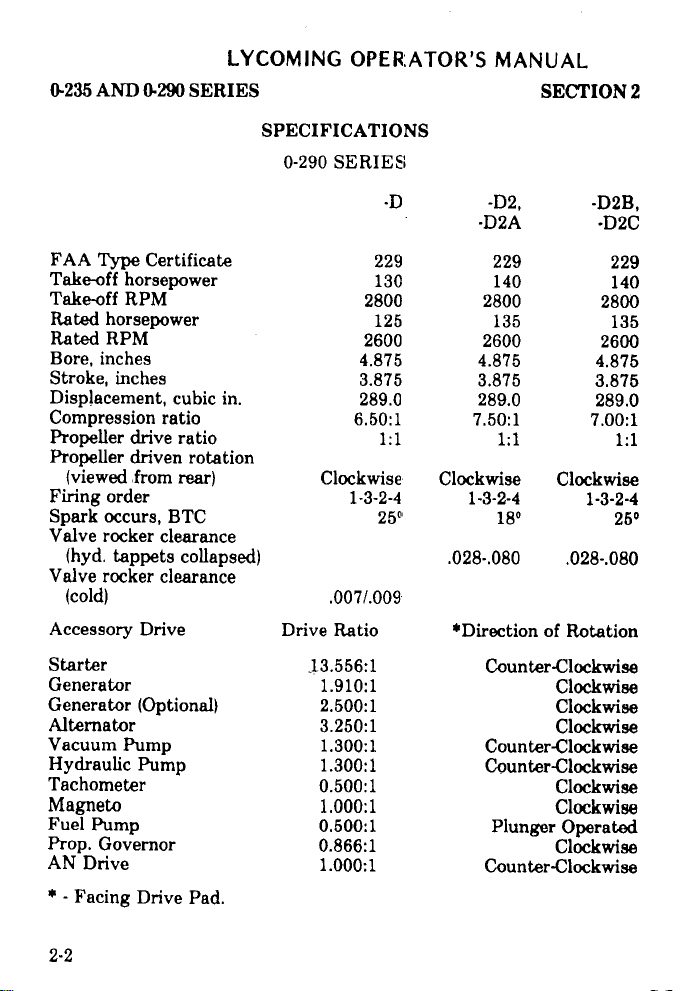

0-235

AND 0-290

LYCOMING

SERIES

OPERATOR'S

SPECIFICATIONS

0-290

SERIES

MANUAL

SECTION

2

FAA

Type

Take-off

Take-off

Rated

Rated RPM

Bore,

Stroke,

Displacement,

Compression

Propeller

Propeller

(viewed

Firing

Spark

Valve

(hyd.

Valve

(cold)

Accessory

Starter

Generator

Generator

Alternator

Vacuum

Hydraulic

Tachometer

Magneto

Fuel Pump

Prop.

AN

Drive

* -

Facing

Certificate

horsepower

RPM

horsepower

inches

inches

drive ratio

driven

from

order

occurs,

rocker

tappets

rocker

Drive

(Optional)

Pump

Pump

Governor

Drive

cubic

ratio

rotation

rear)

BTC

clearance

collapsed)

clearance

Pad.

in.

Drive

13.556:1

229

130

2800

125

2600

4.875

3.875

289.0

6.50:1

1:1

Clockwise

1-3-2-4

25

.007/.009

Ratio

1.910:1

2.500:1

3.250:1

1.300:1

1.300:1

0.500:1

1.000:1

0.500:1

0.866:1

1.000:1

-D2,

-D2A

229

140

2800

135

2600

4.875

3.875

289.0

7.50:1

1:1

Clockwise

1-3-2-4

18

.028-.080

*Direction

Counter-Clockwise

Counter-Clockwise

Counter-Clockwise

Plunger

Counter-Clockwise

-D2B,

-D2C

229

140

2800

135

2600

4.875

3.875

289.0

7.00:1

1:1

Clockwise

1-3-2-4

25

.028-.080

of Rotation

Clockwise

Clockwise

Clockwise

Clockwise

Clockwise

Operated

Clockwise

2-2

Page 21

LYCOMING

OPERATOR'S

MANUAL

SECTION

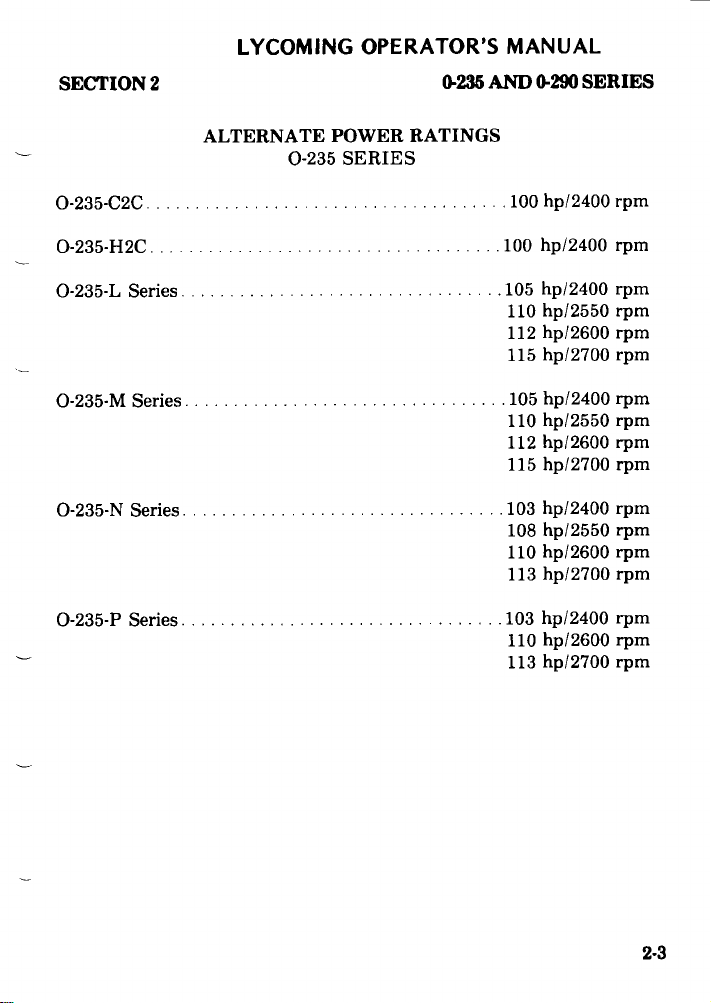

0-235-C2C

0-235-H2C

0-235-L

0-235-M

0-235-N

0-235-P

Series

Series

Series

Series

2

ALTERNATE

0-235

.....................................

.........................

................................

...........................

...........................

.................................

0-235

POWER RATINGS

SERIES

.........

AND 0-290

100

100

SERIES

hp/2400

hp/2400

105 hp/2400

110 hp/2550

112 hp/2600

hp/2700

115

hp/2400

105

110 hp/2550

112 hp/2600

115 hp/2700 rpm

103 hp/2400

hp/2550

108

hp/2600

110

hp/2700

113

hp/2400

103

110 hp/2600

hp/2700

113

rpm

rpm

rpm

rpm

rpm

rpm

rpm

rpm

rpm

rpm

rpm

rpm

rpm

rpm

rpm

rpm

2-3

Page 22

LYCOMING

OPERATOR'S

MANUAL

SECTION 2

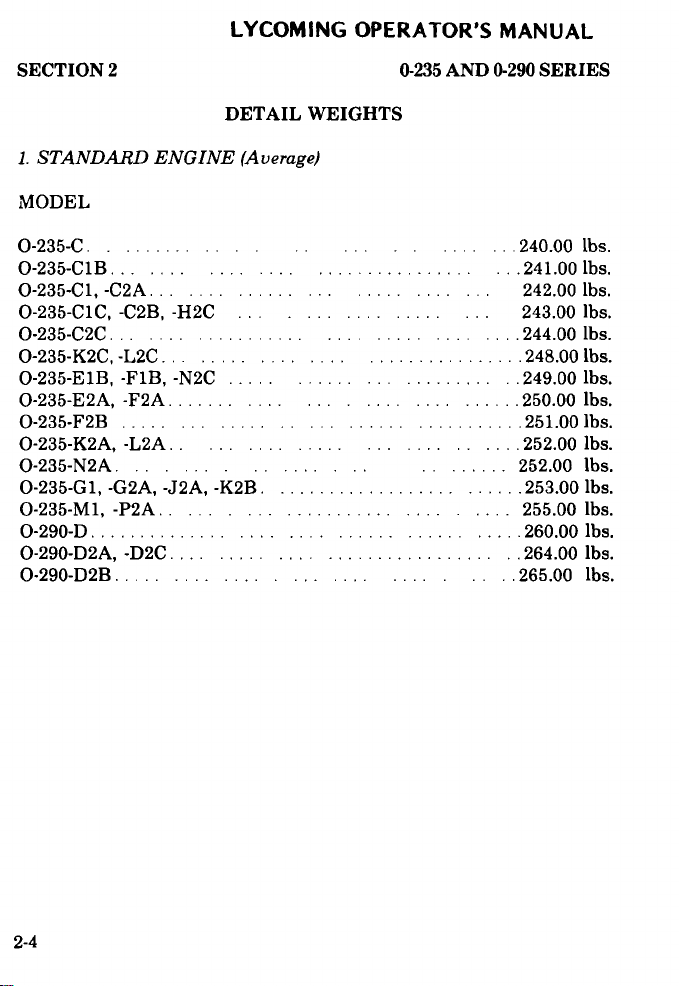

DETAIL

1. STANDARD ENGINE (Average)

MODEL

0-235-C. ......... ... .. ... .... ... 240.00 lbs.

0-235-C1B... .... ....................... ... 241.00 lbs.

0-235-C1, -C2A ...

0-235-C1C, -C2B, -H2C ... .......... ... 243.00 lbs.

O-235-C2C .. ................. ......... ..... 244.00 lbs.

O-235-K2C, -L2C .... ............................ 248.00 Lbs.

O-235-E B, -F1B, -N2C ..... .................. .. 249.00 lbs.

O-235-E2A, -F2A ....... ...... ......... ...... 250.00 lbs.

O-235-F2B . . ..... ..... ...... ........... 251.00 lbs.

O-235-K2A, -L2A .. ..................... .... 252.00 lbs.

O-235-N2A. ..................... 252.00 lbs.

0-235-G1, -G2A, -J2A, -K2B. ........................ 253.00 lbs.

0-235-M1, -P2A .................. ..... 255.00 lbs.

0-290-D ........................... ...... ...... 260.00 lbs.

O-290-D2A, -D2C .............................. .. 264.00 lbs.

0-290-D2B ............. ......... ..... 265.00 lbs.

............... ......

WEIGHTS

0-235 AND 0-290 SERIES

. 242.00 lbs.

2-4

Page 23

LYCOMING

OPERATOR'S

MANUAL

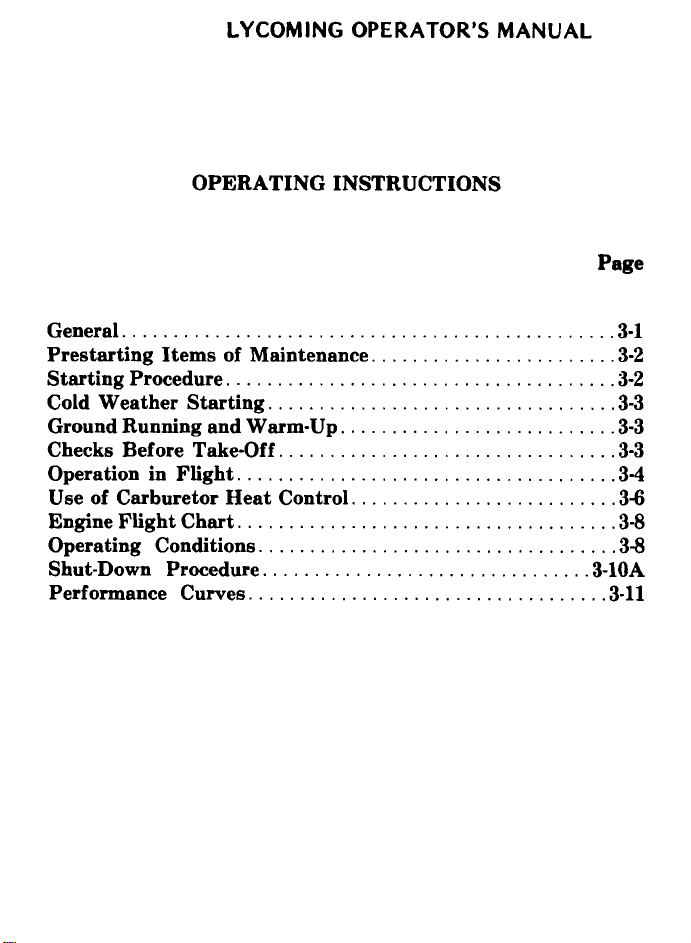

OPERATING

General ...................... ......................... 3-1

Prestarting Items of Maintenance ........................ 3-2

Starting Procedure .................... .................. 3-2

Cold W eather

Ground Running and

Checks Before Take-Off

Operation in Flight

Use of Carburetor Heat Control .......................... 3-6

Engine

Operating

Shut-Down Procedure

Performance Curves ............................

Flight Chart ....................

Starting ..................................

Warm-Up ...........................

.....................................

Conditions ..................................

................................

INSTRUCTIONS

.................................

.................

Page

3-3

3-3

3-3

3-4

3-8

3-8

3-10A

.. 3-11

Page 24

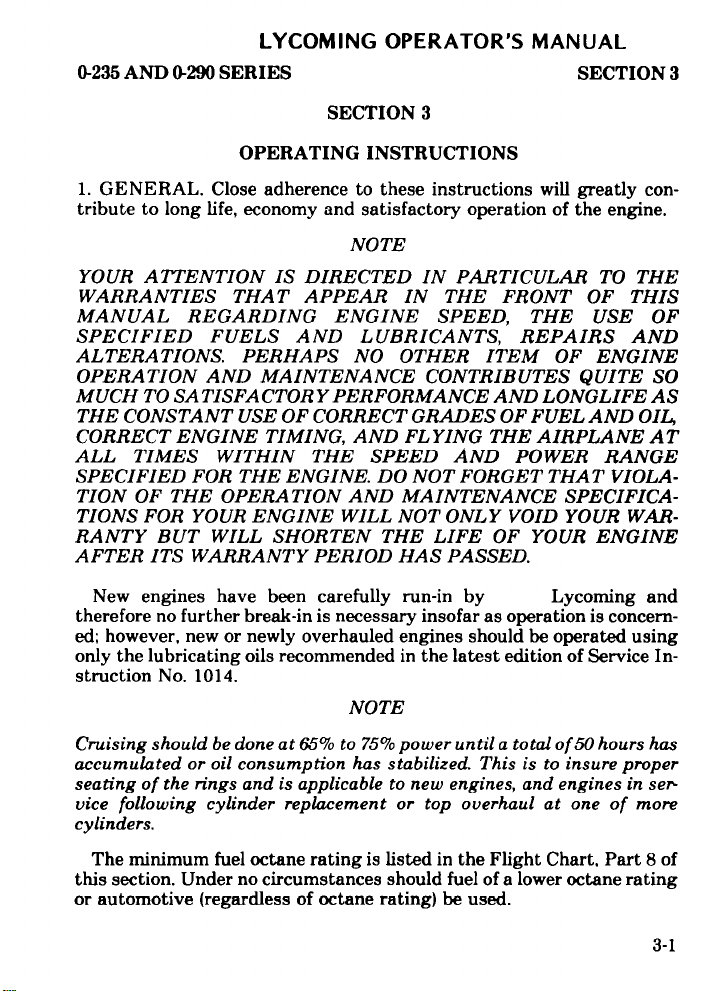

LYCOMING

0-235 AND 0-290 SERIES SECTION 3

OPERATOR'S

SECTION 3

MANUAL

OPERATING

1. GENERAL. tribute to long life, economy and satisfactory operation of the engine.

YOUR ATTENTION IS DIRECTED IN PARTICULAR TO THE

WARRANTIES THAT APPEAR IN THE FRONT OF THIS

MANUAL REGARDING

SPECIFIED

ALTERATIONS. PERHAPS NO OTHER ITEM OF ENGINE

OPERATION AND MAINTENANCE CONTRIBUTES QUITE SO

MUCH TO SATISFACTORY

THE CONSTANT USE

CORRECT ENGINE TIMING,

ALL TIMES WITHIN THE SPEED AND POWER RANGE

SPECIFIED FOR THE ENGINE. DO NOT FORGET THAT VIOLA-

TION OF

TIONS FOR YOUR

RANTY BUT WILL SHORTEN THE LIFE OF YOUR ENGINE

AFTER ITS WARRANTY PERIOD HAS PASSED.

New engines

therefore no further break-in is necessary insofar as operation is concern-

ed; however, new or newly overhauled engines should be operated using

only the lubricating oils recommended in the latest edition of Service In-

struction

Close adherence to these

FUELS AND

OF CORRECT GRADES OF

THE OPERATION AND MAINTENANCE

ENGINE WILL NOT ONLY

have been carefully run-in

No. 1014.

INSTRUCTIONS

instructions will greatly con-

NOTE

ENGINE SPEED, THE

LUBRICANTS, REPAIRS

PERFORMANCE

AND FLYING THE AIRPLANE

NOTE

AND LONGLIFE AS

FUEL AND OIL

SPECIFICA-

VOID YOUR WAR-

by Lycoming and

USE OF

AND

AT

Cruising should be done at 65% to 75% power until a total of 50 hours has

accumulated or oil consumption

seating of the rings and is applicable to new engines, and engines in ser-

vice following cylinder replacement or top overhaul at one of more

cylinders.

The minimum fuel octane rating is listed in the Flight Chart, Part 8 of

this section. Under no circumstances should fuel of a lower octane rating

or automotive (regardless of octane rating) be used.

has stabilized. This is to

insure proper

3-1

Page 25

LYCOMING OPERATOR'S

SECTION 3 0-235 AND 0-290 SERIES

2. PRESTARTING ITEMS OF MAINTENANCE. Before starting the

aircraft engine for the first

maintenance inspection

Section 4 under Daily

before the

3. STARTING PROCEDURE.

a. Perform pre-flight inspection.

b. Head airplane into wind.

c. Lock wheels by either wheel brakes or chocks.

d. Set carburetor heat control in "cold" position.

engine is started.

flight of the day, there are several

that should be performed.

Pre-Flight Inspection. They

MANUAL

items of

These are described in

must be observed

e. Set propeller governor

f. Turn fuel valve to "on" position.

g. Set throttle at 1/4 travel.

h. Move mixture control to "Full Rich".

i. Turn boost pump on.

j. Pump throttle to full open

for a cold engine. If engine is equipped with a priming system, cold

engine may

k. Set magneto selector switch. Consult airframe manufacturer's

handbook for correct position.

1. Engage starter.

m. When engine fires, place magneto switch in "Both" position.

n. Check oil pressure gage. If oil pressure is not indicated within thirty

seconds, stop engine and determine trouble.

3-2

be primed with 1 to 3

(if applicable) in "Full RPM"

and back to idle position for

strokes of the priming pump.

position.

2 to 3 strokes

Page 26

LYCOMING

OPERATOR'S

MANUAL

0-235 AND

4. COLD

0-290

SERIES

WEATHER STARTING.

be necessary to preheat

5. GROUND

pressure

maintain

operating

recommended

Any ground check

three minutes,

the maximum

RUNNING AND

cooled and depend

proper

cooling.

these engines

that the

that requires

or less if

as stated in this

a. Head the aircraft

b. If

a controllable

the ground only

c.

Leave the mixture

pitch propeller

with the propeller in minimum

d. Avoid prolonged

fouled plugs.

warm engine

e. Use of the

solute minimum.

Limit ground

for take-off.

carburetor air

On some

the air filter and dirt

engine

with the resultant

heat should be

ing

properly.

used on the ground

During

the engine and oil

extreme cold

before starting.

WARM-UP.

on the forward

Particular

on the ground.

following procedures

care

is necessary,

To prevent

movement

be

NOTE

the indicated cylinder

into the

full throttle

manual

wind.

operation must

head temperature

is installed, operated

control in "Full Rich".

idling at

low RPM as

running

to minimum

this practice may

heat on the ground

installations

the air does

and foreign substances can

cylinder

and piston ring

only to

make certain it

SECTION

weather, it

Subject engines

of the aircraft

therefore,

overheating,

observed.

be limited to

the engine

blade angle setting.

time necessary

must be held

not pass through

be taken into the

wear. Carburetor

is function-

3

may

are air

to

when

it is

exceeds

on

result in

to

to an ab-

air

6. CHECKS BEFORE

a. Warm

b. Check both

c. Set carburetor

Loss

fixed pitch

will

up as directed

oil temperature

air heat

of manifold pressure

or controllable

result if the

control is working

position after check.

TAKE-OFF.

above.

and oil pressure.

control for "full

or RPM

pitch propeller

(or both), depending

heat" to check

is installed

properly.

Return control

operation.

on whether

on the aircraft,

to "cold"

3-3

a

Page 27

LYCOMING

OPERATOR'S

MANUAL

SECTION 3

d. A proper magneto check

the ignition system,

output, propeller pitch and

that the engine runs

variables listed above. Make

following

(1) Controllable Pitch

angle, set the engine to produce

manifold

position. At these settings

work harder

Under these conditions, ignition

Magneto checks

distribution quality.

Aircraft

with manifold

operating

(2) Switch from both

both until engine

note drop-off, then

and should not exceed 50

smooth drop-off past

mixture.

(3) Do not

seconds

fouling.

procedures:

pressure gage. Mixture

that are equipped with fixd pitch

pressure

at approximately 1800 RPM

operate on a single magneto

is usually sufficient to check

affect magneto drop-off. They

smoothly because drop-off

because

of the greater

at low power settings will

gage, may check

magnetos to one and note

regains speed and switch

return to both. Drop-off should

normal is usually a sign of a

0-235 AND 0-290

is important. Additional factors,

mixture strength. The important

the magneto check in accordance

Propeller - With propeller

50 to 65% power as indicated

control should be in the

the ignition system and spark

pressure within

problems, if they exist,

NOTE

propellers, or not equipped

magneto drop-off

(2000 RPM maximum).

RPM difference between

for too long a period, 2 to

drop-off and will minimize

is affected by the

in minimum pitch

only indicate fuel-air

drop-off, return to

to the other magneto and

too lean or too rich

SERIES

other then

are, load-power

thing is

with the

by the

full rich

plugs must

the cylinders.

will occur.

with engine

not exceed 175

magnetos. A

3

plug

7. OPERATION IN FLIGHT.

A. See airframe manufacturer's instructions for correct manifold

pressure for power settings.

B.

Fuel Mixture Leaning Procedure

flight is

take-off and climb

manual provide proper

engines, they

eliminating excessive

replacement. It is therefore

responsible for many engine

power settings. The procedures

fuel-air mixture when leaning

have proven to be both economical

fuel consumption and reducing

recommended that operators

-Improper fuel-air mixture

problems, particularly during

described in this

Avco Lycoming

and practical by

damaged parts

of all Avco

during

Page 28

LYCOMING OPERATOR'S MANUAL

AND 0-290 SERIES

0-235

Lycoming

tion any time

Never exceed

continuous operation

For

tained

On direct drive

control in "Full Rich"

tinuous,

from high elevation airport

result from over-richness.

may

enough to obtain

struments for temperature rise.

mixture is most likely

Always enrich

C. LEANING TO

(1) Above 75% power -Never lean beyond 150°F. on rich side of peak

EGT unless aircraft operator's manual shows otherwise. Monitor

cylinder head temperature.

(2)

D. LEANING WITH MANUAL MIXTURE CONTROL. (At 75%

power or

(1) Slowly move mixture control from "Full Rich" position toward

lean position.

aircraft powerplants

the fuel-air

LEANING

the maximum red line cylinder

below 435°F.

climb and cruise

75% power and below

less without

(224°C.).

engines with manual mixture

position for rated take-off rated

smooth operation - not

to be encountered at altitude

mixture before increasing

EXHAUST GAS TEMPERATURE

flowmeter

utilize the

mixture is

PRECAUTIONS

cylinder

powers above

or during climb, roughness or

head temperatures

such a case adjust

In

Rough operation due to over-rich

-Operate at peak

or EGT

instructions

adjusted during

head temperature limit.

control maintain mixture

75%. However,

mixture control

for economy. Observe in-

power.

EGT.

gage.)

SECTION

in this publica-

flight.

should be

maxmimum con-

during take-off

loss of power

fuel-air

above 5,000 feet.

GAGE.

3

main-

only

(2) Continue leaning until engine roughness is noted.

(3) Enrich until

E. ALTERNATE

propellers.)

(1) Slowly move

watching tachometer.

(2) At this point enrich until

is obtained at this point.

engine runs smoothly

METHOD. (In calm

mixture control toward lean

Continue leaning until

RPM just peaks. Correct

and power is regained.

air and engines with fixed pitch

position while closely

RPM decreases.

fuel-air ratio

3-5

Page 29

LYCOMING OPERATOR'S MANUAL

SECTION 3 0-235 AND 0-290 SERIES

NOTE

Leaning may be done at any altitude that the engine will accept leaning:

The greater the altitude the more important leaning becomes. Proper

leaning is important because more engine power and increased air speed

are obtained along with decreased fuel consumption, longer spark plug

life, less lead fouling,

temperatures. Engine damage from leaning the mixture does not occur

at the specified cruise power

power plant, but is the result of improper leaning atpower settings above

recommended

Use of Carburetor Heat Control

F.

conditions, it is possible for ice to form in the induction system even in

summer weather. This is due to the high air velocity through the car-

buretor venturi and the absorption of heat from this air by

evaporization of the fuel. The temperature in the mixture chamber

may drop 20°F. to 70°F. below

this air contains a large

cause

begin in the vicinity of the

extent that a drop in manifold power output results. This loss of power

is reflected by a drop in manifold

with constant

RPM in

detected, this condition will continue to such an extent that the

reduced power will cause complete engine stoppage.

To avoid this condition, all installations are equipped with a system

for preheating the incoming air supply to the carburetor. In this way,

sufficient heat is added to replace the heat loss to vaporization of fuel,

and the mixing

point of water. This air preheater is essentially a tube or jacket

through which the exhaust pipe from one or more cylinders is passed,

and the air flowing over these surfaces is raised to the required

temperature before entering the carburetor. Consistently high

temperatures are to

decided variation of the mixture. High charge temperatures also favor

detonation and preignition, both of which are to be avoided if normal

service life

the proper method

cruise.

precipitation in the form

speed propellers and a drop

installations equipped with

chamber's temperature cannot

is to be expected from the

and more normal oil

for the model engine in a basically

-Under certain moist atmospheric

the temperature of the incoming

amount of moisture, the

of ice. These ice formations generally

butterfly and will often build

pressure in installations

fixed pitch propellers. If not

be avoided because of a loss

engine. The following outline

of utilizing the carburetor

and cylinder head

healthy

air. If

cooling process will

up to such an

equipped

in manifold pressure and

drop to the freezing

of power and a

is

heat control.

Page 30

0-235

AND 0-290 SERIES

LYCOMING

OPERATOR'S

MANUAL

SECTION

3

(1) Take-Off- Take-off

cold position. The possibility

remote.

(2) Flight

the cold

foggy or hazy

lookout

Operation -The carburetor

position during normal flight

days, regardless of outside temperature,

for loss of power. This

countable loss in manifold

whether

aircraft. When

and

a constant speed or fixed pitch

this situation arises, apply

open the throttle to limiting

in a slight additional

this drop will

system.

be regained

When the ice has been

the carburetor heat

In those aircraft

partial

heat may be used

freezing

Caution must

that do not have

form that

raised

crystals

ice due

carburetor.

aircraft that

point (32°F.).

would ordinarily

in temperature

are melted

to the temperature

It is advisable,

are not equipped with a carburetor

be exercised when operating

equipped

a carburetor

into liquid form.

should be made with

carburetor heat in full

of icing at wide throttle

air heat control should

operations. On damp, cloudy,

loss of power will be shown

pressure or RPM or

both, depending on

propeller is installed on the

full carburetor air heat

manifold pressure. This will

drop in manifold pressure which

as the ice is melted

out of the

melted from the induction

control should be returned to

to keep the

WARNING

air temperature

pass through

by use

drop as it

therefore,

with a carburetor

mixture temperature

the induction

of partial heat

This moisture

passes through

to use

air temperature

with partial heat on aircraft

gage. Moisture

to the point

can form carburetor

either full

air temperature gage.

opening is very

be left in

keep a sharp

by unac-

result

is normal and

induction

system,

the cold position.

gage,

above

the

in crystal

system, can

where the

the venturi of

heat or

no heat in

be

the

(3)

Landing Approach

- In making

buretor air heat should

However,

Heat" should

under

heat should

See aircraft

if icing

conditions are

be applied.

these conditions,

be returned to "Full Cold"

flight manual for specific

usually be in the "Full

an approach

known or suspected,

In the case

as for

that full power

an aborted

landing, the carburetor

prior to power application.

instructions.

for a landing,

Cold" position.

then

need be applied

car-

"Full

3-7

Page 31

LYCOMING

OPERATOR'S

MANUAL

SECTION 3 0-235 AND 0-290 SERIES

8. ENGINE FLIGHT CHART.

Fuel and Oil

Model

O-235-C, -E, -H2C

O-235-F, -G, -J, -K, -L, -M,

O-290-D, -D2 ....

* Refer to the latest edition of Service Instruction No. 1070.

Aviation grade

are

approved for continuous

. . . . . .....

100LL fuels in which the lead

.. . . . ................

-N, -P .... . 100/100LL

NOTE

content is limited to 2 c.c. per gallon

use in the above listed engines.

*Aviation Grade

. 80/87 octane minimum

octane minimum

. ..80/87 octane minimum

Fuel

**Recommended Grade Oil

Average

Ambient Air

All Temperatures

Above 80°F.

Above 60°F. (15.5°C.)

30 (-1.11°C.) to 90°F. (32.2°C.) SAE 40 SAE 40

0°(-17.8°C.) to 70°F.

Below 10°F. (-12.2 C.)

** Refer to the latest edition of Service Instruction No. 1014.

Oil Sump Capacity 6 Qts. 8 Qts.

Minimum Safe Quantity

of Oil in Sump

It is recommended that the lubricating oil be changed every 50 flying hours (or

every 25 hours,

Oil Pressure, psi

0-235 Series

-C, -E, -F, -G, -H2C, -J, -K, -M

-B,

-L*, -N

-P 90 55 15

* Front of engine

(26.6°C.)

(21.1°C.) SAE 30

if engine does not have

OPERATING CONDITIONS

MIL-L-6082

Grades

....--

SAE 60 SAE

SAE 50

SAE 20

0-235 Series -D2 Series

2 Qts.

a full-flow oil filter).

Maximum Minimum

90 60

90 60

90

MIL-L-22851

Ashless Dispersant

Grades

SAE 15W50 or 20W50

60

SAE 40 or SAE 50

SAE 40, 30 or 20W40

SAE 30 or 20W30

0-290-D,

2 Qts.

Idling

25

15

50 15

Page 32

LYCOMING

OPERATOR'S

MANUAL

SECTION 3

All 0-235

-L, -N, -P

0-290 Series

-D

-D2

-D2

Fuel

All

0-290-D

Above

30 (-1.11°C.)

0° (-17.8°C.) to 70°F.

Below

series,

pressure

0-235 models,

Average Ambien

(psi)

Temperature

60°F. (15.5°C.)

to 90°F.

10°F.

(-12.2°C.)

OPERATING

except

O-290-D2

290-D2

t Air

(32.2°C.)

(21.1°C.)

0-235 AND 0-290 SERIES

CONDITIONS

START/WARM-UP

100

115

Maximum

85

90 60 25

START/WARM-UP

100

Maximum

5

5

Desired

180°F.

180°F. (82°C.)

170°F.

160°F. (71°C.)

(Cont.)

Minimum

60

Desired Minimum

3

3

Oil Inlet Temperature

(82°C.)

(77°C.)

Idling

25

0.5

0.5

Maximum

245°F. (118°C.)

245"F.

(118°C.)

245 F. (118"C.)

245°F.

(118 C.)

Engine

operation.

oil temperatu

not be below 140"F.

(60"C.) during continuous

3-8A

Page 33

0-235

AND 0-290

LYCOMING

SERIES

OPERATOR'S

MANUAL

SECTION

3

OPERATING

Operation

Normal

Performance Cruise

Economy

Normal Rated

Performance Cruise

Economy

Take-Off

Normal

Performance Cruise

Economy Cruise

Rated

(75% Rated) 2350 86 7.3

(65%

(75% Rated)

(65% Rated)

(75%

(65%

Cruise

Rated)

Cruise

Rated

Rated) 2350

Rated)

RPM

2800 115

2250 75

2800

2500

2400

2800

2600

2250

CONDITIONS

HP

0-235-C,

0-235-F, -G, -J

125 10.7

94 7.3

81 5.8

0-290-D

130

125

94 7.5

81

0-290-D2

Fuel

Cons.

Gal./Hr.

-E

10.7

5.8

Series

11.9

6.5

Series

(CONT.)

Max. *Max.

Oil Cons.

Qts./Hr.

0.52

0.29

0.25

0.56

0.31

0.27

0.56

0.31

0.27

Cyl. Head

Temp.

500°F. (2600C.)

500°F. (260°C.)

500°F. (260°C.)

500°F. (260°C.)

500°F. (260°C.)

500°F. (260°C.)

500°F. (260°C.)

500°F.

(260°C.)

500°F.

(260°C.)

500°F.

(260°C.)

Take-Off

Normal

Performance Cruise

Economy Cruise

* - At

cylinder head

ing continuous

Rated

(75% Rated)

(65%

Rated) 2200

Bayonet Location

temperatures

operation.

2800

2600

2350 101

140

135

87 6.3

- For maximum

between 150°F.

12.6

7.2

service life

(65°C.) and 400°F.

0.60

0.34

0.29

500°F. (260°C.)

500°F.

(260°C.)

500°F.

(260°C.)

500°F.

(260°C.)

of the engine, maintain

(204°C.) dur-

3-9

Page 34

LYCOMING OPERATOR'S

MANUAL

SECTION 3

OPERATING

Operation

Normal

Performance Cruise

Economy Cruise

Take-off 2800

Normal Rated 2700

Performance Cruise

Economy Cruise

Take-off 2800

Normal Rated 2600

Performance Cruise

Economy Cruise

Rated

(75% Rated) 2500

(65% Rated) 2400

(75% Rated) 2425

(65% Rated) 2300

('75% Rated) 2350

(65% Rated) 2250

RPM HP Gal./Hr.

2800

CONDITIONS

Fuel

Cons.

0-235-K, -L, -M

118 9.5

89 6.7

77 5.8

0-235-K2C

118

115 9.2

86 6.4

75 5.6

0-235-H Series

115 --

108 10.7

81 7.3

70 5.8

0-235 AND 0-290 SERIES

(CONT.)

Max. Max.

Oil Cons. Cyl. Head

Qts./Hr.

.39 500°F. (260°C.)

.30

.27

.38

.29

.25

.36

.27

.23

Temp.

500°F. (260°C.)

500°F.

(260°C.)

500°F. (260°C.)

500°F. (260°C.)

500°F. (260°C.)

500°F. (260°C.)

500°F. (260°C.)

500°F. (260°C.)

500°F. (260°C.)

500°F. (260°C.)

Take-off 2800

Normal Rated 2550

Performance Cruise

(75% Rated) 2300

Economy Cruise

65% Rated) 2200

3-10

0-235-N, -P

116

108 9.2

81

70 5.3

6.2

.36

.27

.23

500°F. (260°C.)

500°F.

(260°C)

500°F. (260°C.)

500°F. (260°C.)

Page 35

LYCOMING

SECTION 3 0-235 AND 0-290 SERIES

.9 SHUT-DOWN PRO('EDURE.

a. Idle engine at approximately 800 to 900 RPM until there is a

decided drop in cylinder head temperature.

b. Move mixture control to "Idle Cut-Off".

c. After engine stops, set magneto switch at the "off" position; this

will prevent after-firing.

OPERATOR'S

MANUAL

Revised

March.

1982

3-10A

Page 36

LYCOMING OPERATOR’S MANUAL

0-235 AND 0-290 SERIES

hRxNRE SETTING

SECTION 3

CURVE NO. 8210

Figure 3-l. Power and Fuel Consumption Curve

o-235-c

3-11

Page 37

Figure 3-2. Sea Level and Altitude

Performanc

e - 0-235-C1, -El, -H2 Series

Page 38

LYCOMING OPERATOR’S MANUAL

0-235 AND 0-290 SERIES SECTION 3

Figure 3-3. Fuel Flow vs Percent Rated Power.

0-235-C1, -El, -H2 Series

3-13

Page 39

Figure 3-4. Sea Level and Altitude Performance. 0-290-D

Page 40

LYCOMING OPERATOR’S MANUAL

0-235 AND 0-290 SERIES

.2-=---J-

SECTION 3

CURVE NO. 8583-A

--

Figure 3-5. Power and Fuel Consumption Curve-

0-290-D

3-15

Page 41

Page 42

LYCOMING OPERATOR’S MANUAL

0-235 AND 0-290 SERIES

SECTION 3

Figure 3.7. Power and Fuel Consumption Curve-

0-290-D2, -D2A

3-17

Page 43

Page 44

LYCOMING OPERATOR'S MANUAL

0-235 AND

The following is

Performance

horsepower

manifold pressure

from

1. Determine equivalent

mance curve

2400 RPM and

2. Repeat above

-Point "B").

3. Transfer

(Example - Point "C").

4. Connect point

5. Read

feet with a power setting of

99.5, Point "D").

6. Correct power approximately

air temperature

Add corrections for

temperatures

temperature of

variation.

approximately

add correction:

0-290 SERIES

USING

curve on opposite page)

CURVE TO FIND

an example of how to use the

curves,

being delivered

and air inlet

for observed

23.8 in. Hg., locate

procedure on sea level performance

value obtained

"A" and point "C"

horsepower

from the standard altitude

above

22°F. at an altitude

1% for

each 10°variation

3 horsepower.

99.5 + 3 = 102.5 horsepower,

printed

on line "CA" for

temperatures below standard,

standard.

ACTUAL HORSEPOWER

on these pages,

by the engine

temperature.

is for illustration purposes

full throttle horsepower

manifold pressure

Point "A").

in Step 2

2400 RPM and 23.8 in. Hg.,

to the altitude

with a straight line.

given altitude

1% for each 10°F. variation

(Example -

of 1800

is 3%. 3%

Since

temperature

Sea Level and Altitude

to determine

for given

This example

and RPM

temperature shown below.

With an air

feet, 52°F. - 22"F.

of 99.5 horsepower

Point "E").

SECTION

-

altitude, RPM,

(using figures

only.

on altitude perfor-

(Example

curve (Example

performance curve

(Example -At

horsepower is

is below standard,

actual

- At

1800

in intake

subtract for

inlet

= 30°F.

3

is

STANDARD

Pressure Altitude

(Thousands)

Standard Altitude

(Temperature

°F.)

ALTITUDE TEMPERATURES

SL

2 4 6 8 10

59 52 45

38 31 23 16 9

12 14 16 18

IN DEGREES

20 22 24

+ 2 -5 -12

F.

-19 -27

3-19

Page 45

LYCOMING OPERATOR’S MANUAL

SECTION 3 o-235 AND 0.290 SERIES

3-20

Figure 3-9. Power and Fuel Consumption Curve .

0-290-D2B,-D2C

Page 46

LYCOMING OPERATOR’S MANUAL

o-235 AND O-290 SERIES

SECTION 3

Figure 3-10. Fuel Flow vs Percent Rated Power -

0-235-F. -G Series

3-21

Page 47

Page 48

LYCOMING

OPERATOR'S

MANUAL

0-235

AND 0-290

9

SERIES

FUEL FLOW VS. PERCENT RATED POWER

AVCO LYCOMING 0-235-K, -L, -M SERIES

COMPRESSION RATIO 8 50 1

SPARK ADVANCE 20°BTC

CARBURETOR. MARVEL SCHEBLER MA-3A or MA-3PA

FUEL GRADE. MINIMUM 100/1OOLL

I

SECTION 3

PERCENT RATED POWER

Figure 3-12. Fuel Flow vs Percent Rated Power -

0-235-K, -L, -M Series

3-23

Page 49

3-24

Figure

SECTION

3-13.

Sea

Level

and

Altitude

Performance

-

0-235-K,

-L,

-M

Series

3

LYCOMING

OPERATOR'S

0-235

AND

MANUAL

0-290

SERIES

Page 50

0-235

0

I

AND

10

9

8

7

0-290

LYCOMING

OPERATOR'S

SERIES

FUEL FLOW vs. HORSEPOWER

LYCOMING

MINIMUM-ALLOWABLE FUEL FLOW

0-235-N,

MANUAL

-P SERIES

CURVE NO. 13401

SECTION

3

5

0

60

70 80

90

BRAKE HORSEPOWER

100

110

120

Figure 3-14. Fuel Flow vs. Horsepower

0-235-N, -P Series

3-25

Page 51

3-26

Figure

3-15. Sea Level

0-235-N,

and Altitude

-P

Series

Performance

SECTION 3

z

z

LYCOMING

OPERATOR'S

0-235 AND 0-290 SERIES

MANUAL

--

Page 52

LYCOMING

PERIODIC INSPECTIONS

Pre-Starting Inspection ................................. 4-1

Daily Pre-Flight ................................ ..... 4-2

25-Hour Inspection

50-Hour Inspection

100-Hour Inspection

400-Hour Inspection ..... ............................... 4-5

Non-Scheduled Inspection ............................... 4-5

.....................................

.....................................

....................................

OPERATOR'S

MANUAL

Page

4-2

4-2

4-4

Page 53

0-235

AND

0-290

LYCOMING

SERIES

OPERATOR'S

MANUAL

SECTION

4

Perhaps

the aircraft

regular

found.

The

pages

the

tion instructions.

Pre-Starting

aircraft

the

phasize.

responsible

centration,

carelessness

operator

do

engine

general

The

importance

Among

no other

and

checks

not constitute

only.

Inspection

prior to

condition

Statistics

to

the major

reluctance

bred

PERIODIC

factor

its components

for

minor

should

Consult

the

first flight

bear

of

of proper

prove

poor

pre-flight.

causes

by familiarity

SECTION

INSPECTION

NOTE

is quite

a

the

-The

the aircraft

troubles

in mind

complete

airframe

daily

of

so important

as

faithful

and

that

aircraft

manufacturer's

pre-flight

the day.

and engine.

pre-flight

several

hundred

of poor

pre-flight

to acknowledge

and

haste.

4

to safety

and diligent

prompt

the items

inspection,

inspection

This

inspection

inspection

accidents

inspection

the need

repair

listed

handbook

cannot

occur

for

and

durability

attention

when

in the

but

are

is a check

is to

be over

yearly

are lack

a

check

they are

following

meant

for

for addi-

of

the

determine

em-

directly

of

con-

list,

of

to

4-1

Page 54

LYCOMING OPERATOR'S MANUAL

SECTION

1. DAILY PRE-FLIGHT.

a. Be sure

b. Be sure magneto ground wires are connected.

c. Check oil level.

d. See that

e. Check

at 50 hour inspection. Repair any major leaks before aircraft is flown.

f. Open the fuel drain to remove

ment.

g. Make sure all shields and

missing or

aircraft is flown.

h. Check controls for general condition, travel and freedom of opera-

tion.

i. Induction system air filter should be inspected and serviced in ac-

cordance with the airframe manufacturer's recommendations.

2. 25-HOUR

time,

a 50 hour inspection including draining and renewing lubricating oil.

3. 50-HOUR

flight inspection,

every 50 hours of operation.

4

the "Off"

all switches

fuel tanks are

fuel and oil line connections,

damaged, repair or replacement

INSPECTION. After the

new, remanufactured or newly

INSPECTION. In addition

the following maintenance checks

are in

full.

cowling are in place and secure.

any accumulation of water

overhauled engines should

0-236 AND 0-290

position.

note minor indications for

should be made before the

first twenty-five hours operating

to the items listed for daily

should be made after

SERIES

repair

and sedi-

If any are

undergo

pre-

Ignition System - Remove

a.

Replace if necessary.

Examine spark plug leads of cable and ceramics for corrosion and

deposits. This condition

cleaning of the spark plug

proper

condition is found, clean the cable ends, spark plug walls and ceramics

with a dry, clean

ketone. All parts should be clean and dry before reassembly.

Check ignition harness for security of mounting clamps and be sure

connections are tight at spark plug and magneto terminals.

4-2

cloth or a clean cloth moistened

spark plugs; test, clean and

is evidence of either leaking

walls or connector ends. Where

spark plugs, im-

with methyl-ethyl

regap.

this

Page 55

LYCOMING OPERATOR'S MANUAL

0-235 AND 0-290 SERIES SECTION 4

b. Fuel and Induction System - Check primer lines for leaks and

security of clamps. Drain carburetor and clean carburetor fuel

strainer. Check mixture

freedom of movement, security of clamps and lubricate if necessary

Check carburetor air intake ducts for leaks, security, filter damage;

evidence of dust or other solid material in the ducts is indicative of

inadequate filter care or damaged filter. Check vent lines for evidence

of filter or oil seepage; if present, fuel pump may require replacement.

c. Lubrication System - Check oil lines for leaks, particularly at con-

nections; for security of anchorage and for wear due to rubbing or

vibration, for dents and cracks.

Drain and refill sump with new oil on installation not employing

replaceable external oil filter. See the latest revision to Service In-

struction

are listed in Section 3, Paragraph 8 of this manual.

Remove oil suction and oil pressure screens and clean thoroughly.

Note carefully for presence of metal particles that are indicative of

internal engine damage.

If engine is equipped with external oil filters, replace at this time.

Before disposing of filter, check interior for traces of metal particles

that might be evidence of internal engine damage.

No. 1014 for recommended

control and throttle

lubricating oils. Seasonal

linkage for travel,

grades

d. Exhaust

cylinders

removed and machined flat before they are reassembled and tightened.

Examine exhaust manifolds for general condition.

e. Cooling System - Check cowling for damage and secure anchorage.

Any damaged or missing part of the cooling system must be repaired

or replaced before the aircraft resumes operation.

f. Cylinders - Check rocker box covers for evidence of oil leaks. If

found, replace gasket and tighten screws to specified torque (50 inch

pounds).

Check cylinders for evidence of excessive heat which is indicated by

burned paint on the cylinder. This condition is indicative of internal

damage to the cylinder and, if found, its cause must be determined and

corrected before the aircraft resumes operation.

System - Check attaching