Textron Jacobsen Tri-King 67139, Jacobsen Tri-King 67141, Jacobsen Tri-King 67140 Instruction Sheet

Page 1

Instruction

Sheet

When Performance Matters.

™

WARNING

If incorrectly used, this machine can cause severe injury. Those who use

and maintain this machine should be trained in its proper use, warned of its

dangers and should read the entire manual before attempting to set up,

operate, adjust, or service the machine.

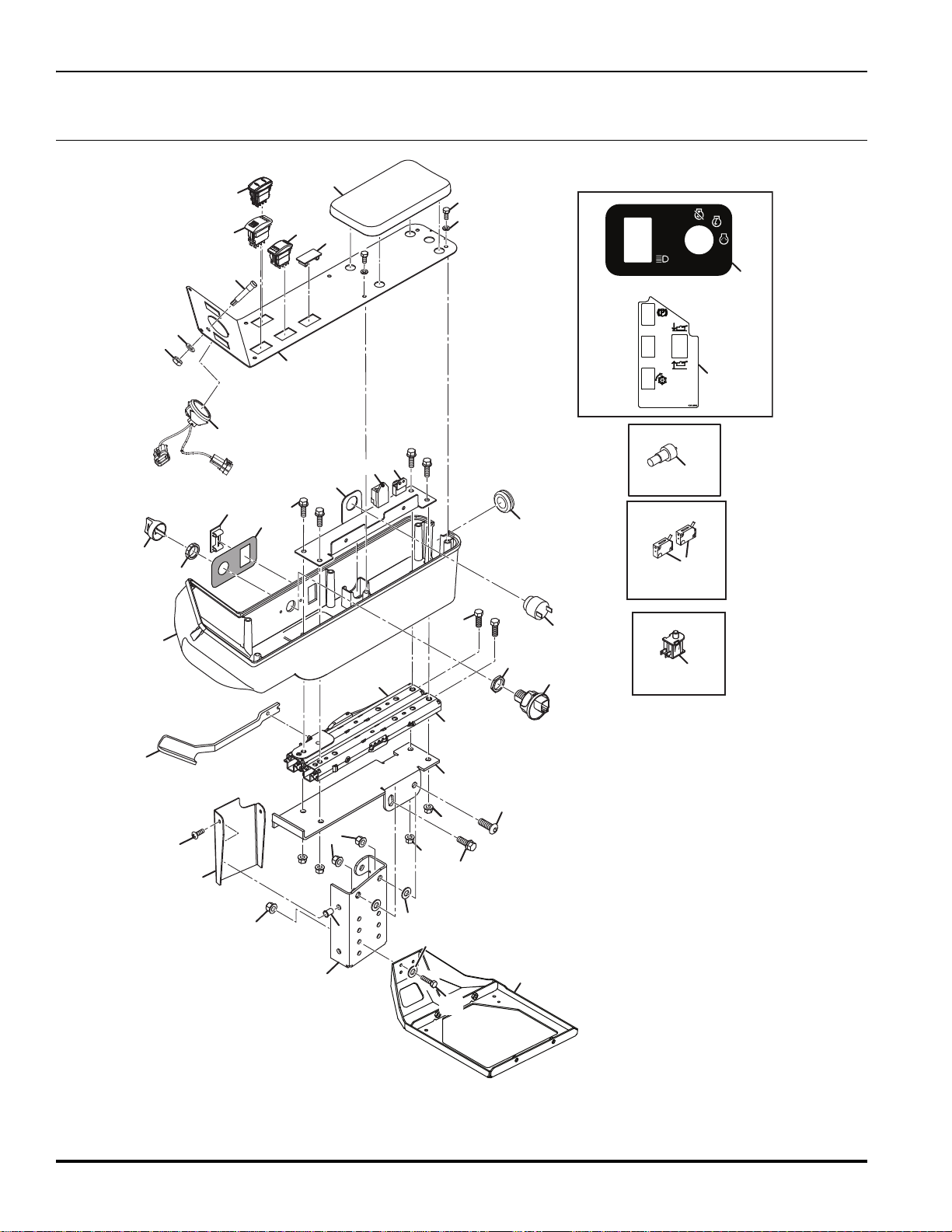

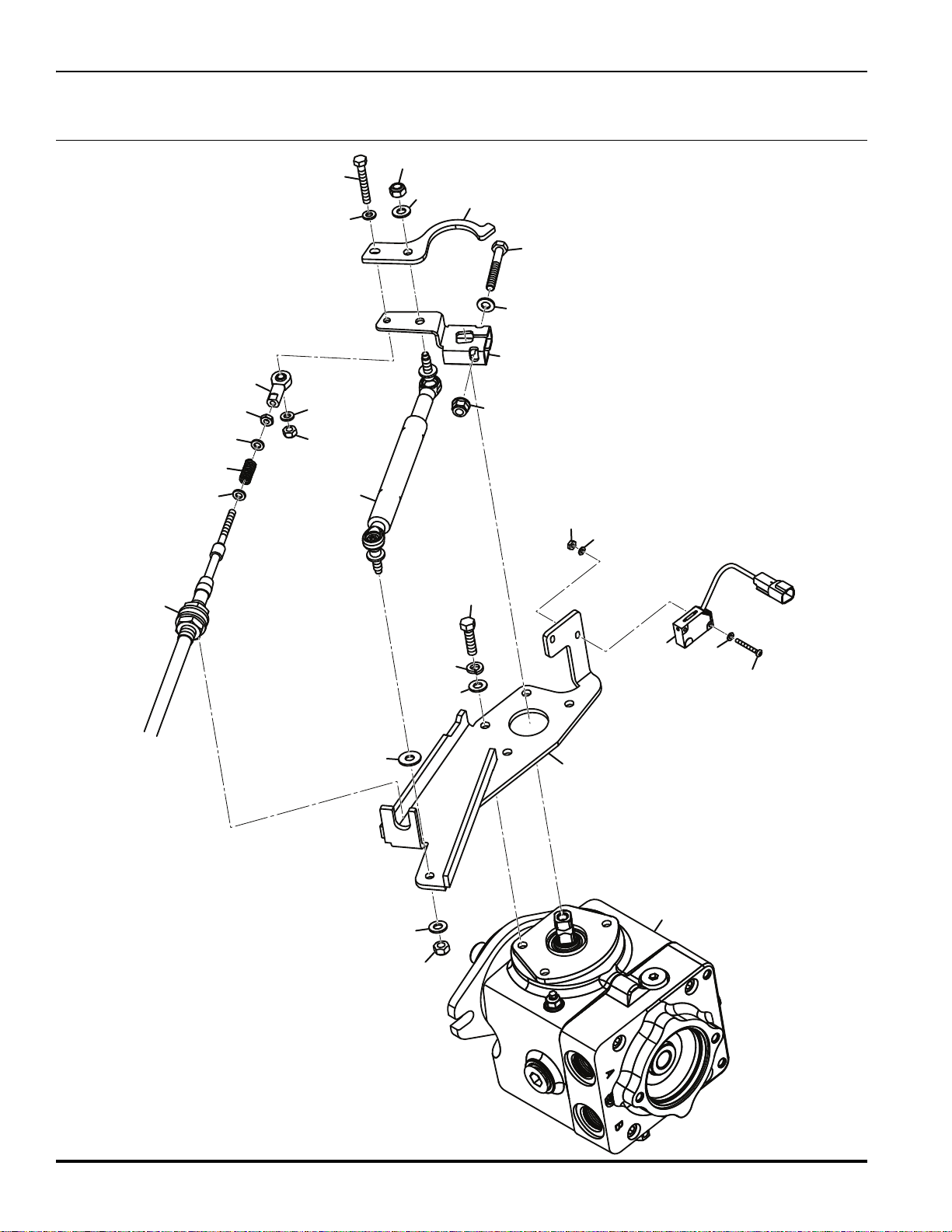

19

17

18

13

6

5

9

15

16

7

8

10

4

3

11

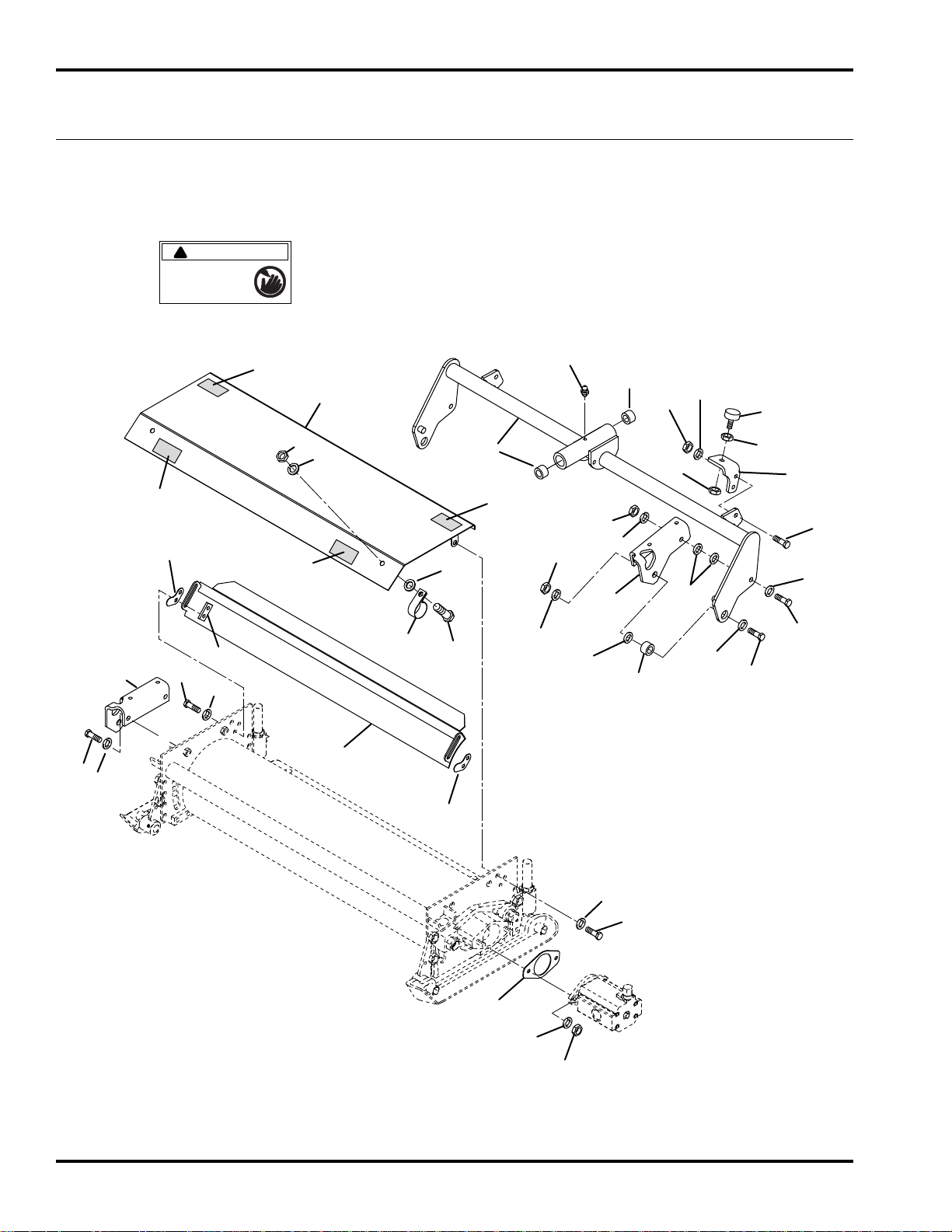

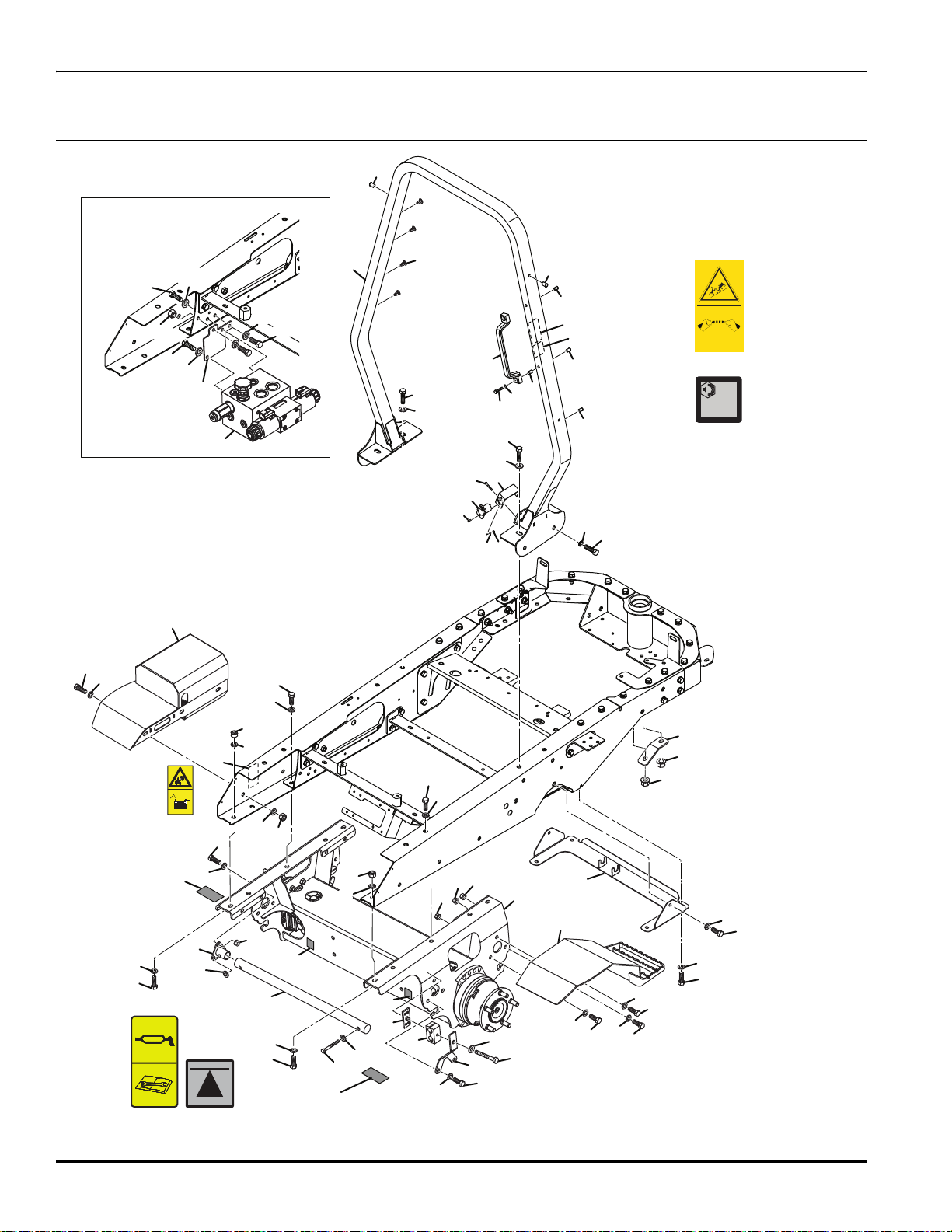

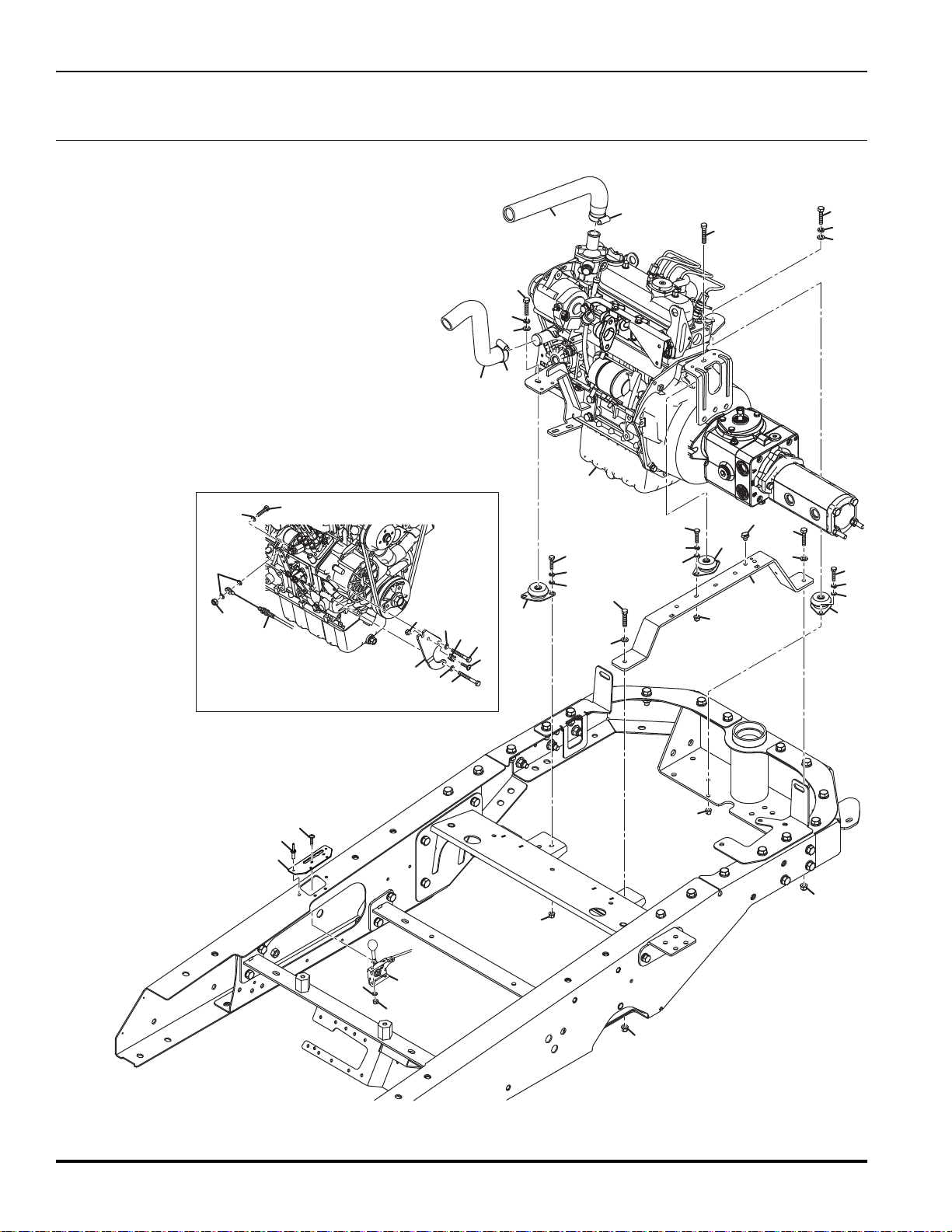

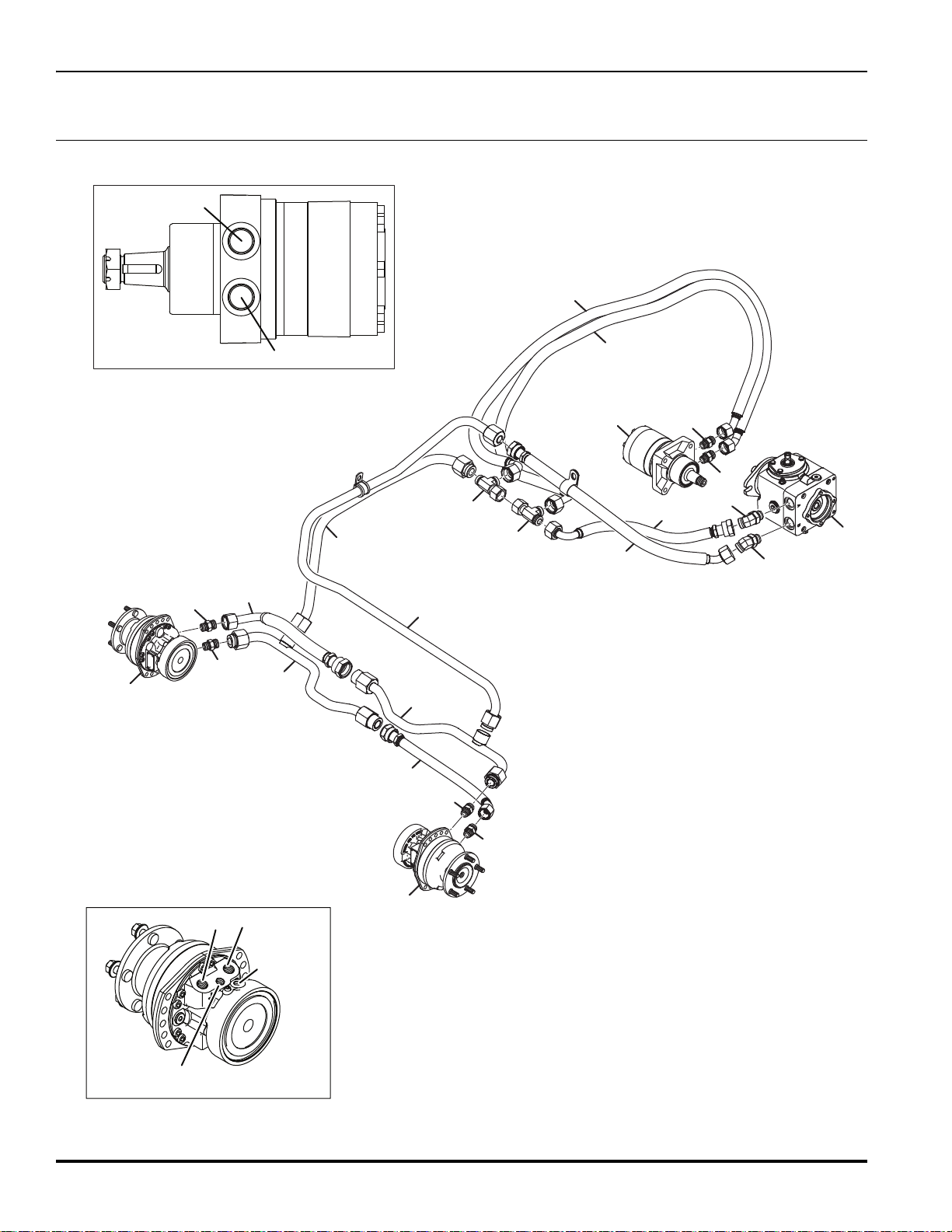

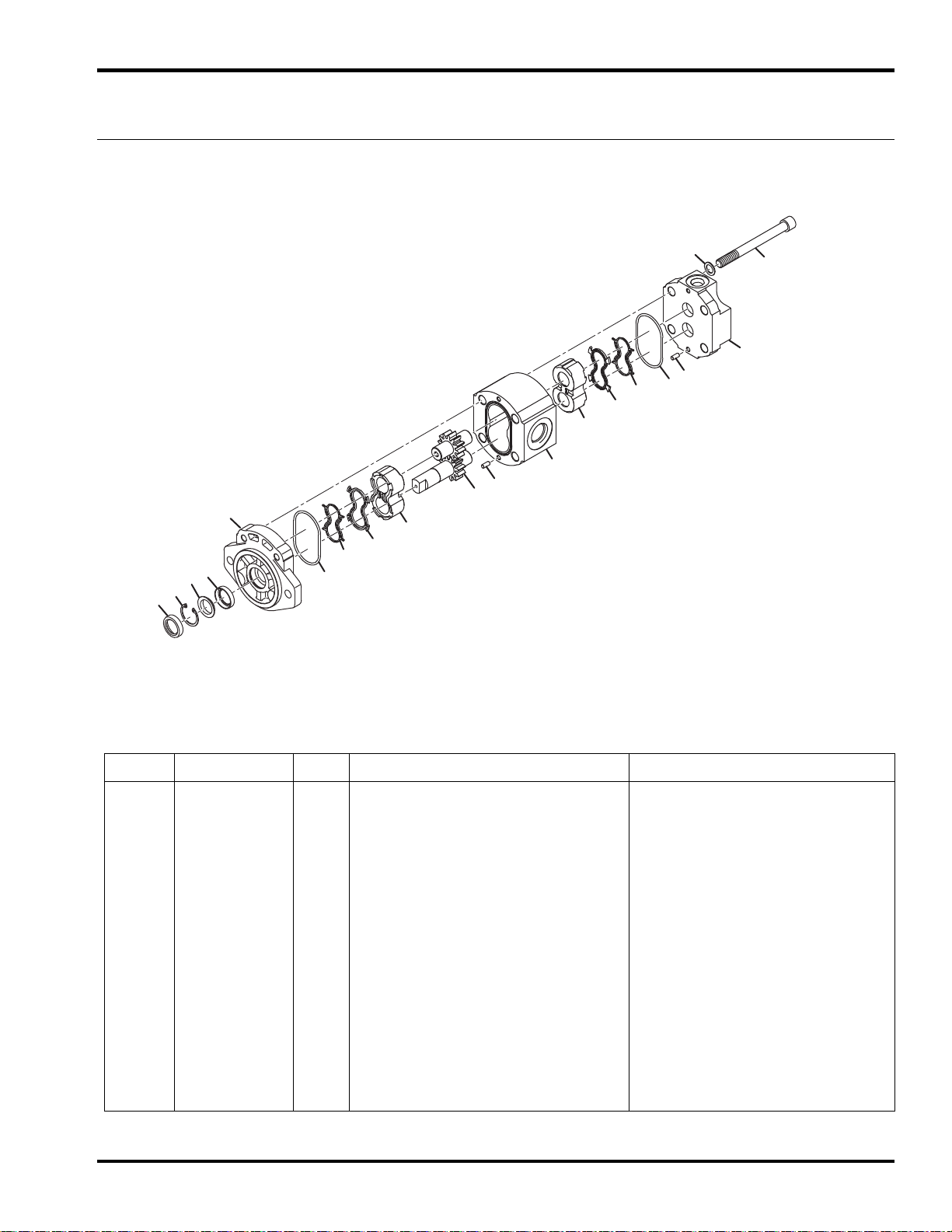

1 - INCLUDES ITEMS 3 - 16

4113401

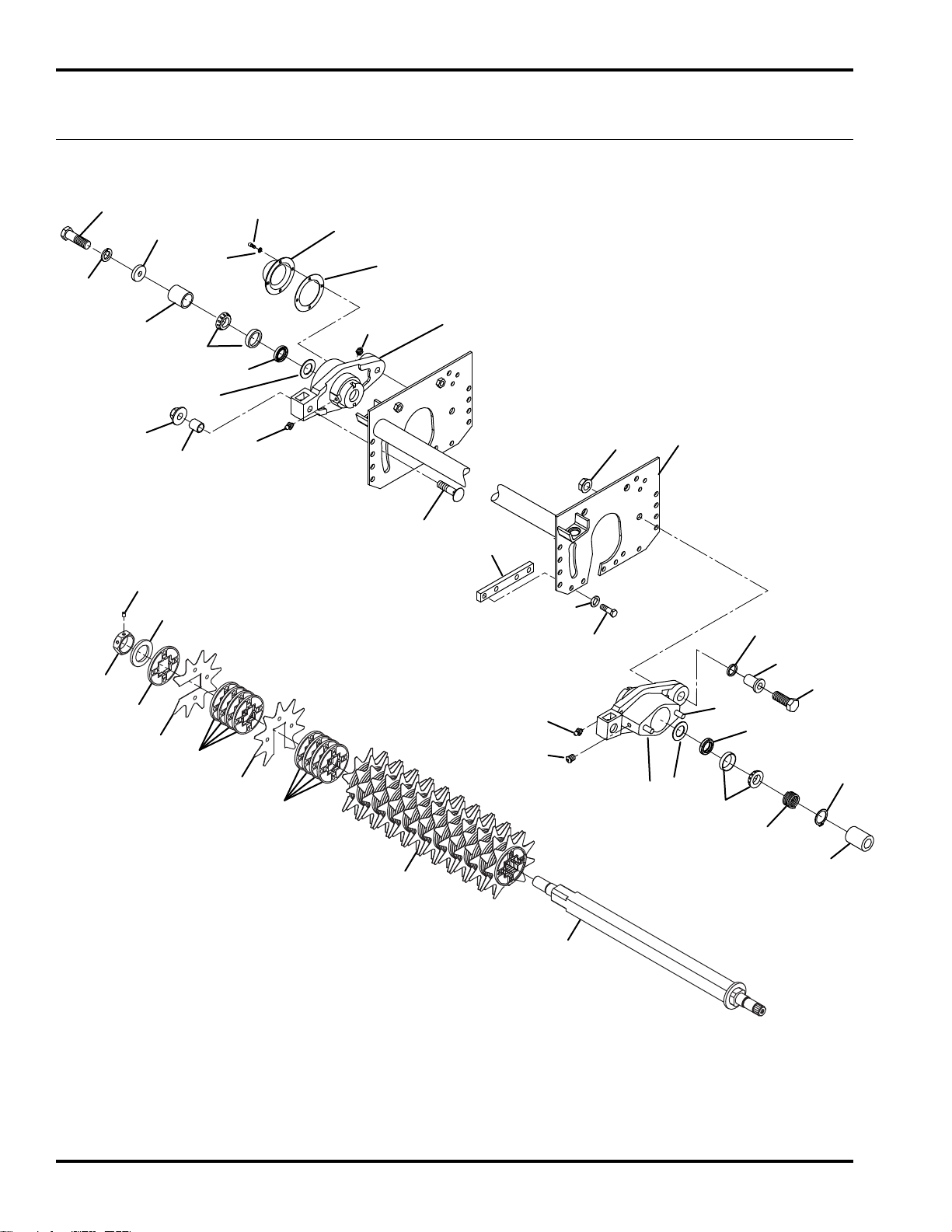

Tri-King® Vertical Mower

Left Front Mower Product No. 67139

Right Front Mower Product No. 67140

Center Mower Product No. 67141

Page 2

This kit is intended for use on Jacobsen® Tri-King™ 1800G and

!

!

1900D mowers.

WARNING

CAUTION

Read the Safety & Operation Manual and become

familiar with the controls and proper use of the

equipment.

Stay alert for potential hazards and follow all safety

precautions. Read all instructions completely and make

sure you understand them before proceeding with the

assembly.

PREPARATION ___________________________________________________________________________________

1. Park the mower on a flat and level surface, fully lower the

cutting units to the ground, engage the parking brake,

stop the engine and remove key from ignition switch.

a. Wait for all movement to stop before making any

adjustments or modifications.

b. Take this opportunity to thoroughly inspect the

equipment and perform other maintenance.

c. For all steps, refer to the Parts List for part

identification.

2. Following instructions given in the Parts & Maintenance

Manual remove any existing cutting units from mower

and place protective plug over the bearing housing cavity.

Note: This kit will fit a Tri-King with existing 26” cutting units

directly. If your machine is equipped with 30” cutting units, or

does not have cutting units, contact your nearest Jacobsen

dealer to order parts required for installation.

If your machine is equipped with 30” cutting units, the following

parts are required:

2811280 - 1 - Right Lift Arm

2811281 - 1 - Left Lift Arm

2811128 - 2 - Spring Plate

Before you clean, adjust, or repair this equipment,

disengage all drives, lower cutting units to the ground,

engage parking brake, stop engine, remove key from switch

and disconnect Negative (BLACK) battery cable to prevent

injuries

If your machine does not have cutting units, the following parts

are required:

2811280 - 1 - Right Lift Arm

2811281 - 1 - Left Lift Arm

400260 - 2 - Screw, 3/8-16 x 7/8" (Front Mowers to Lift Arm)

446142 - 2 - Lockwasher, 3/8 Heavy (Front Mowers to Lift Arm)

364781 - 2 - Washer (Mower to Lift Arm)

3002718 - 1 - Collar (Center Mower to Lift Arm)

3005435 - 1 - Pin, Spring Lock

400262 - 4 - Screw, 3/8-16 x 1" (Spring Plug to Spring Plate)

446142 - 4 - Lockwasher, 3/8 Heavy (Spring to Spring Plate)

441904 - 2 - Carriage Bolt, 1/2-13 x 10" (Spring Plate to Lift Arm)

452012 - 2 - Flat Washer, 1/2 (Spring Plate to Lift Arm)

443118 - 2 - Nut, 1/2-13 Hex (Spring Plate to Lift Arm)

2811128 - 2 - Spring Plate

3007908 - 4 - Plug, Spring

364157 - 4 - Spring, Down Pressure

364160 - 4 - Shackle (Spring to Mower)

1001854 - 4 - Shackle (Lift Arm to Mower)

3004065 - 2 - Chain, Lift (Lift Arm to Mower)

TO ORDER PARTS ___________________________________________

1. Write your full name and complete address on the order.

2. Explain where and how to make shipment.

3. Give product number, name and serial number that is stamped on the name plate or serial plate of your product.

4. Order by the quantity desired, the part number, and description of the part as given in the parts list.

5. Send or bring the order to an Authorized Jacobsen Dealer.

6. Inspect all shipments on receipt. If any parts are damaged or missing, file a claim with the carrier before accepting.

7. Return material to an Authorized Jacobsen Dealer with a letter of explanation, listing the parts being returned. Transportation charges must be prepaid.

Use of other than original Jacobsen parts or Jacobsen authorized parts will void the warranty.

2

Litho in U.S.A. 9-2008

Page 3

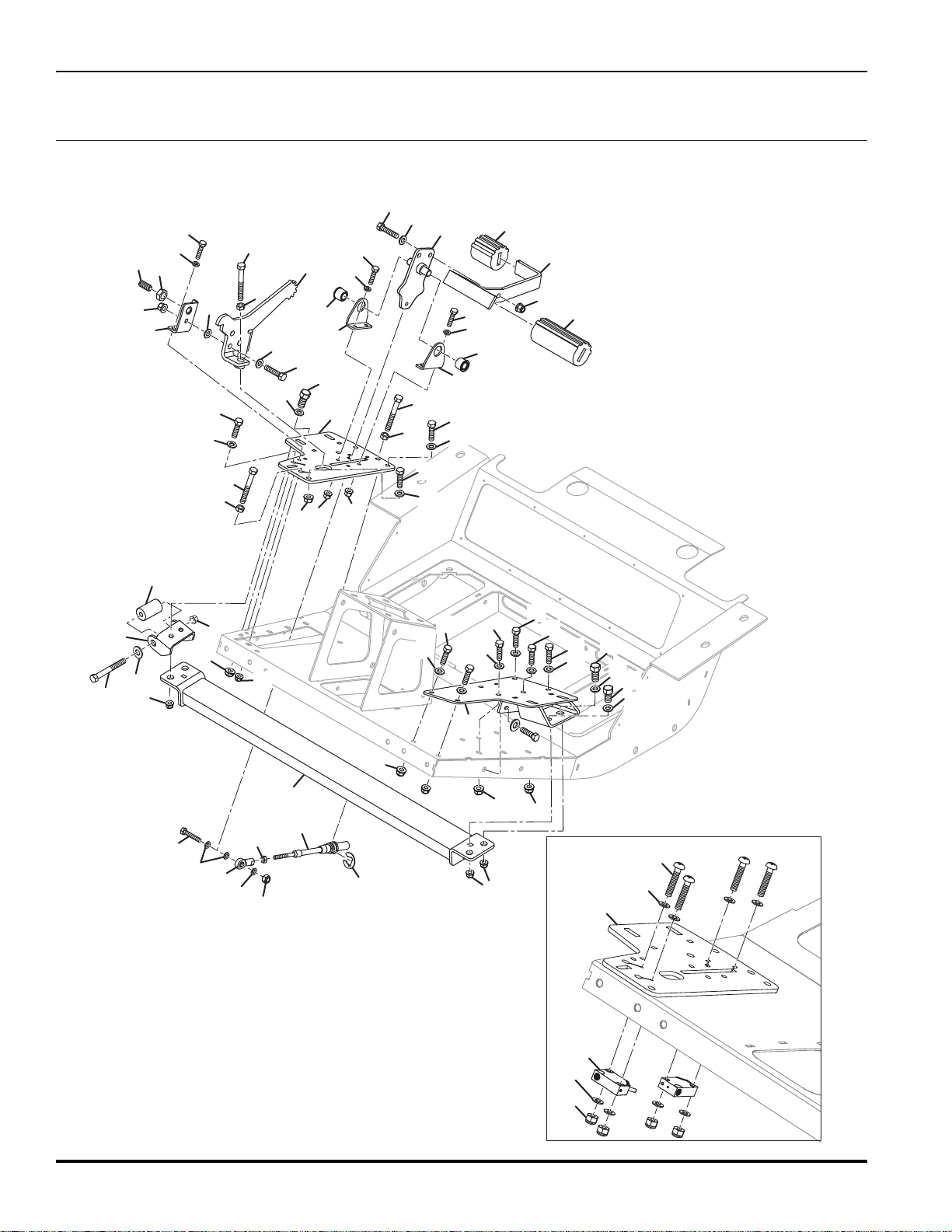

LIFT ARM INSTALLATION (UNITS WITH 30” REELS OR UNITS WITHOUT EXISTING REELS ___________________

J

1. Assemble lift arms (J) to the mower

a. Remove nut and bolt (K) then remove pin (L).

b. Place lift arm (J) in cradle and slide pin (L) through

the cradle and lift arm. Secure pin with hardware

(K).

c. Assemble shackles (N) to the chains then assemble

each chain to crank (M). Secure with pins (P).

d. Assemble free end of chain to lift arm (J) and

secure with pins (P).

e. Repeat Steps a-d for the other side.

DO NOT assemble Down Pressure Springs. They will be

installed after vertical mowers.

L

K

J

K

Figure 1

M

N

P

J

Figure 2

FRONT MOWERS _________________________________________________________________________________

1. Remove the left and right mower assemblies from the

shipping crates. Remove hardware (H) from lift arm (J).

2. Assemble the front mowers to the lift arms with

hardware (H).

3. Remove the cover plate (S) from the drive end of each

mower. Retain hardware (U) and gasket (R). Store

cover plate (S) for future use.

4. Install motors on mowers with hardware (U) and

gasket (R). Nut (T) must be facing upwards as shown.

R

U

S

T

Figure 3A

Figure 3B

3

Page 4

CENTER (REAR) MOWER___________________________________________________________________________

A

B

C

D

C

B

A

1. Remove center mower from its shipping crate and

position behind the rear lift arm (Z). Slide the mower onto

the lift arm and secure with collar (V) and spring clip pin

(W).

2. Remove the cover plate (S) from the drive end of center

mower. Retain hardware (U) and gasket (R). Store cover

plate (S) for future use.

3. Install motor on cutting unit with hardware (U) and

gasket (R). Nut (T) must be facing upwards as shown.

4. Secure hose bracket (X) to stud of center mower with

3/8-16 hardware (Y).

DOWN PRESSURE SPRINGS (UNITS WITH 30” MOWERS AND UNITS WITHOUT EXISTING MOWERS ___________

1. Start the engine and fully raise the lift arms.

2. Stop the engine and lock the arms in transport position.

a. Remove pin (A) and slide handle (B) from the top slot

(C) to the bottom slot (D).

T

U

R

Y

X

S

Z

W

V

Figure 3

b. Insert pin (A) to lock handle (B) in place.

Note: To prevent damage to the mower, the transport

lock must be disengaged before the cutting units can be

lowered.

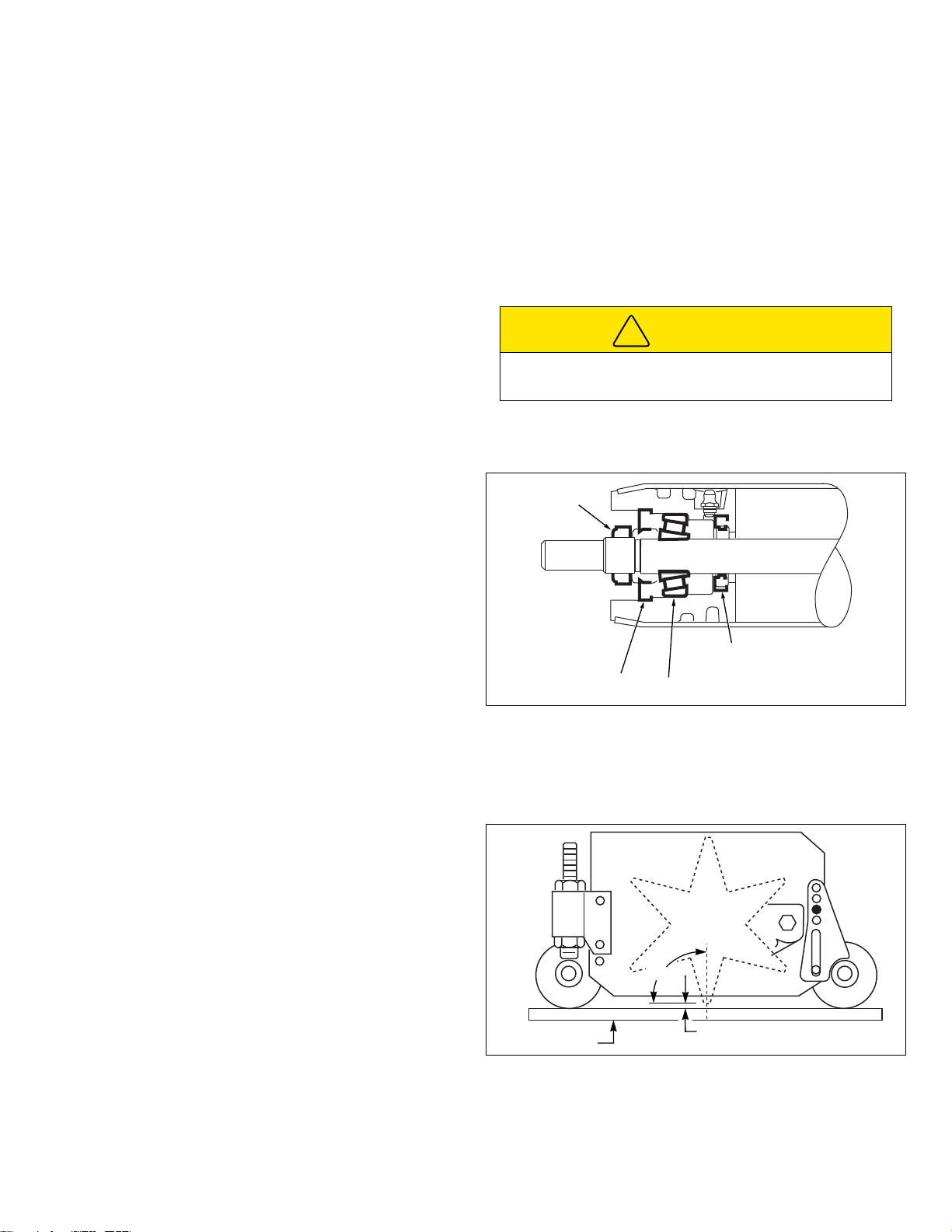

3. Assemble plug (H) into each spring (J).

4. Assemble 3/8-16 x 1” bolt (E), lockwasher (F) and plate

(G) as shown. [Figure 5]

5. Assemble 1/2-13 x 10” bolt (P), flat washer (Q) and nut

(R) as shown. Thread bolt (P) at least 1-1/2” into plate

(G).

6. Manually raise the front lift arms as far as possible then

tether the arms together.

7. For 26 in. cutting units assemble shackles (K) to each tab

(M) and secure with clevis and cotter pin (L).

8. Connect springs (J) to shackles (K) then remove tethers

and transport lock.

9. Adjust down pressure. [See Parts & Maintenance]

P

Q

R

E

Figure 4

F

G

L

K

H

J

L

M

Figure 5

4

Page 5

OPERATION________________________________________________________________________________________

!

A

B

C

D

+

Desired Depth

Gauge

Rear

Roller

Front

Roller

90˚

1. The vertical mowers operate in forward rotation allowing

each blade tip to break (cut) new turf and therefore

requires more power than normal mowing.

a. Do not operate the vertical mowers when the

hydraulic reel motors are loaded to a point where

they stall or slow down.

b. The operator must adjust the ground speed to

accommodate for the cutting conditions and power

requirements.

c. If the mower slows down under load, it is an

indication that the cut may be too deep.

2. The vertical mowers were designed to mow at depths of

1/8 to 1/4” (3.2 - 6.4 mm) above the roller, depending on

turf conditions and operations being performed. A greater

cutting depth may damage the root structure and

increase power requirements. It is recommended to begin

with a higher setting and gradually lower blades until

desired results are obtained.

ROLLERS __________________________________________________________________________________________

1. When replacing the bearing (A) the cup and cone should

be replaced in sets. Hand pack each bearing cone with a

good grade of multi purpose Moly 2 EP grease.

2. To remove the bearing cup use a blind hole bearing

puller.

3. When installing the seals (B and C) be sure the lip is

towards the center of the roller.

4. After complete reassembly of the roller tighten locknut (D)

to 10 - 30 ft./lbs. to seat bearings. Readjust locknut to

develop 3 to 7 in./lb. rotational torque resistance on shaft.

Check torque resistance of roller after 25 - 50 hours of

operation and every 250 hours after that.

5. If lubricant inside of roller has been flushed during

disassembly, apply 15 - 20 pumps of multi purpose Moly

2 EP grease with a hand gun into fitting after roller has

been reassembled.

a. Grain control (light and frequent operation) - half of

normal cutting height.

d. Thatch removal (every 60 to 90 days) - 1/8” to 1/4”

setting.

e. Renovation (heavy thatch removal) - not

recommended with Tri-King vertical mowers.

3. Vertical mowing is an operation that can create a lot of

dust and debris. Special care must be taken to clean the

air intake system on the Tri-King at regular intervals.

Check the air intake system if the water temperature

gauge (Diesel Units) indicates an elevated temperature

level.

CAUTION

To prevent contamination of the engine compartment, do

not operate the mowers in reverse rotation.

Figure 6

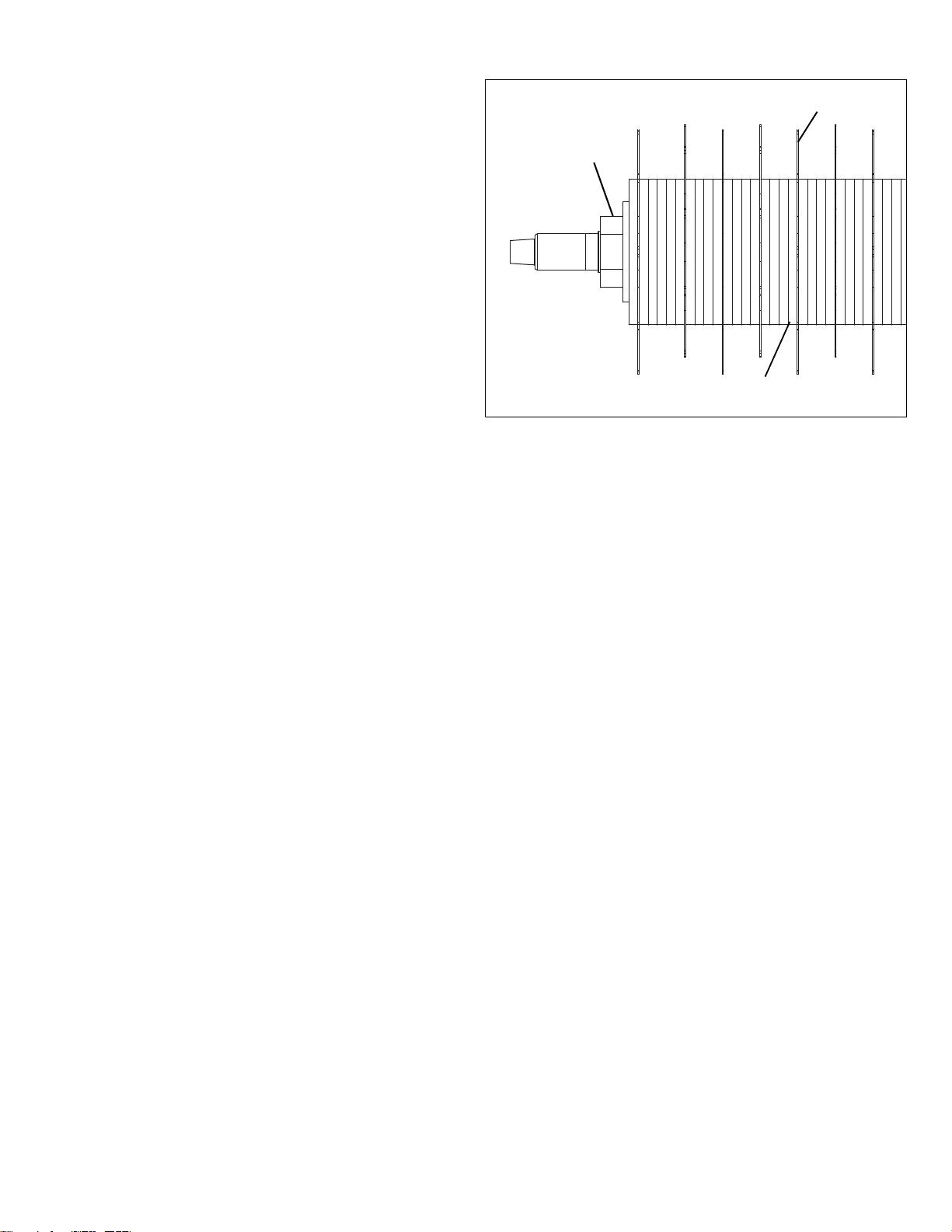

CUTTING DEPTH ADJUSTMENT _______________________________________________________________________

1. To achieve the desired depth of cut, place an adjusting

gauge at either end of the cutting unit across the two

rollers as shown. [Figure 3]

2. Adjust the cutting depth of the blade with the rear

adjusting nuts. For most applications front adjusters

should be positioned with the top bolt passing through the

second hole from bottom as shown. [Figure 7]

a. Turn the end blade so that one tooth of the blade is at

90 degrees to the top of the gauge as shown.

b. The blades should be adjusted to be at the same

depth at both ends of the cutting unit. [within 1/64”

3. The ground line should be close to parallel with the

(.4mm) inch]

bottom of the mower frame to assure proper cutting and

discharge angle. As the blade wears the front adjuster

can be repositioned to allow proper cutting angle and

depth.

Figure 7

5

Page 6

ADDING, REMOVING OR REPLACING BLADES ________________________________________________________

B

C

D

1. Blades may be replaced without removing the cutting unit

from the frame.

2. Loosen blade nut (B) from 1/4” to 3/8” (6.3 to 9.5 mm)

towards the frame.

a. Pull spacer (C) next to the blade (D) to be removed

toward the nut to disengage it from the locking lugs

on the spacer.

b. Remove blade from the shaft. Install replacement

blade with the slot in blade in same position as blade

that was removed and retighten nut (B) securely.

(Torque nut to 12-15 ft. lb. (16-20 N.m)

3. Blade spacing can be adjusted for different modes of

operation, from 1/2” (13 mm) to 1-1/2” (32 mm) in 1/4”

increments (6 mm).

a. 1” (25 mm) spacing between blades is the standard

factory setting.

b. 3/4” (19 mm) to 1-1/2” (38 mm) spacing is

recommended for fairways, greens surrounds and

sport fields.

c. 3/4” (19 mm) to 1” (25 m) spacing is recommended

for tee tops.

Figure 8

6

Page 7

MAINTENANCE _____________________________________________________________________________________

!

!

a. Keep the mower clean and all moving parts properly

WARNING

Before you clean, adjust, or repair this equipment, disengage

all drives, lower cutting units to the ground, engage parking

brake, stop engine, remove key from switch and disconnect

battery to prevent injuries

Proper adjustments and regular maintenance are essential to the

performance of your machine. If proper adjustment cannot be

made, contact an Authorized Jacobsen Dealer.

1. Inspect your machine on a regular basis and replace

worn or damaged parts before operating machine or

before actual breakdown occurs.

2. Establish a regular maintenance schedule.

3. Wash the unit after each use.

4. Clean all plastic or rubber trim with a mild soap solution

5. Repair damaged metal surfaces and use Jacobsen

adjusted.

b. Keep shields in place and all hardware securely

tightened.

CAUTION

Do not wash any portion of the equipment while it is hot.

Do not use high pressure spray or steam. Use cold water

and automotive cleaners.

or use commercially available vinyl/rubber cleaners.

Orange touch-up paint.

Support ___________________________________________________________

If you encounter any problems while installing this kit,

contact your Jacobsen Dealer or contact the Jacobsen

Customer Care department.

7

Jacobsen, A Textron Comany

11108 Quality Drive

Charlotte, NC 28273

800-848-1636

http://www.Jacobsen.com

Page 8

4

3

2

9

33

34

35

24

30

31

8

7

6

5

27

13

18

19

20

20

21

21

21

22

23

29

26

36

32

25

28

12

13

11

10

2

3

4

6

5

1

14

15

16

17

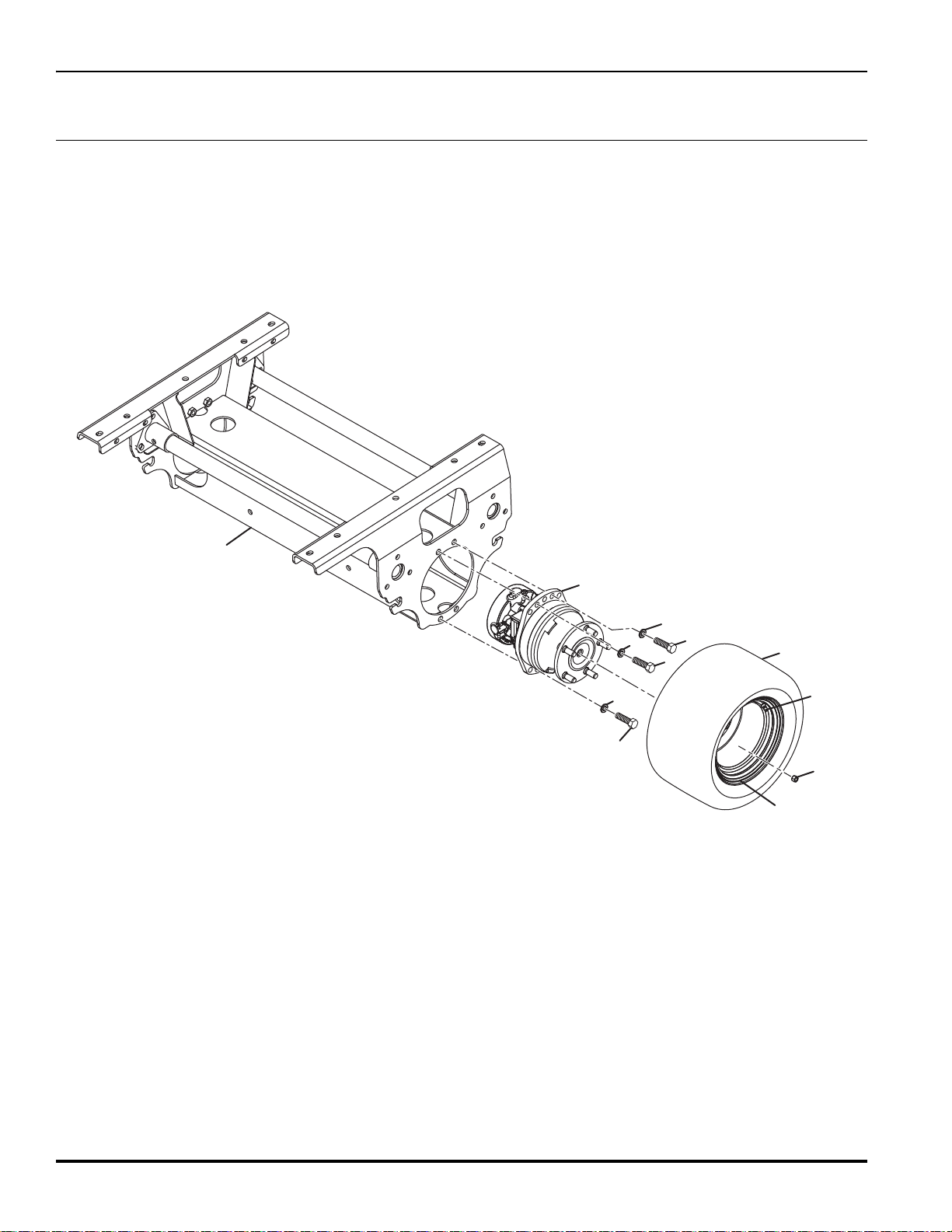

TRI-KING VERTICAL MOWER

1.1 Bearing Housing

Serial No. All

8

Page 9

TRI-KING

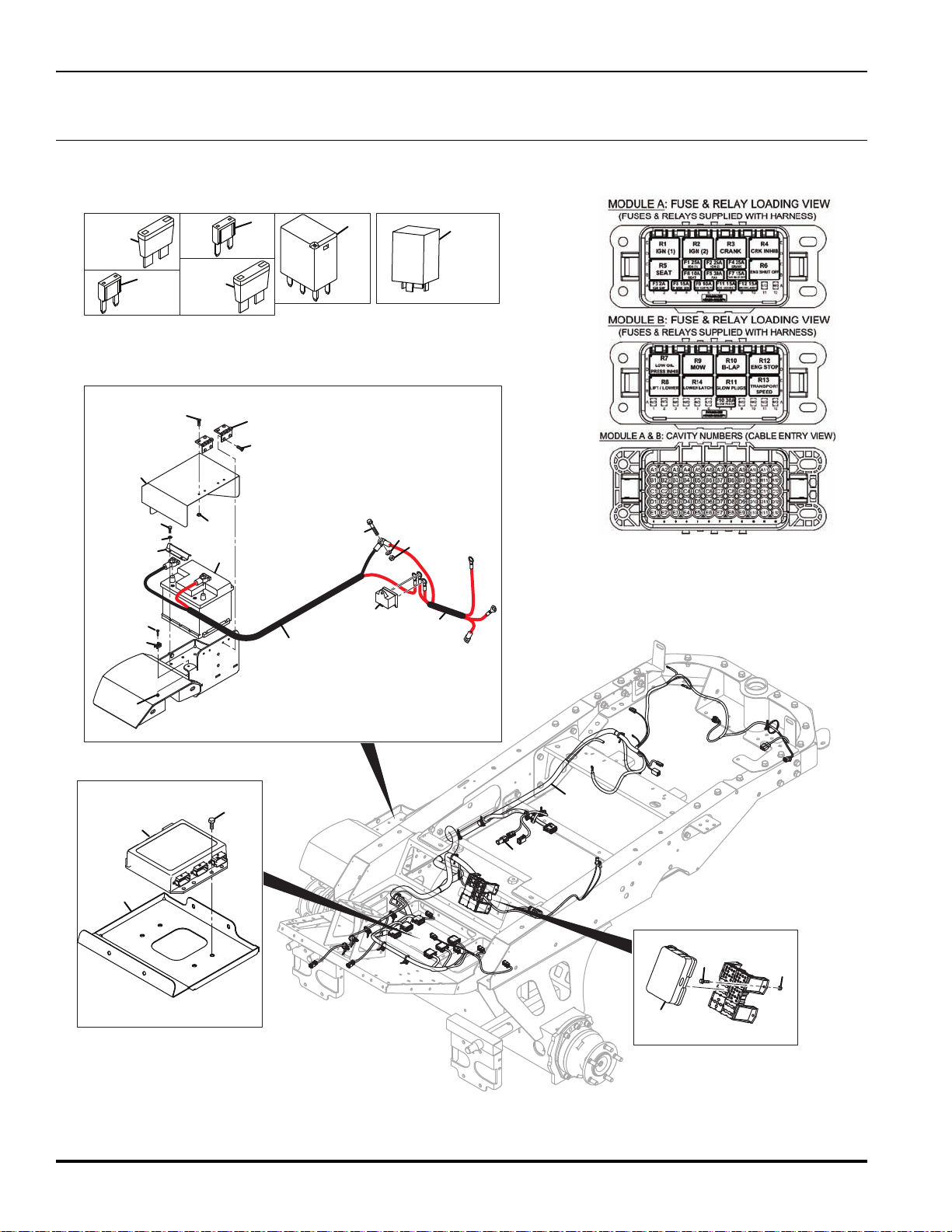

Item Part No. Qty. Description Serial Numbers/Notes

1

2 500596 2 • Bearing, Cup and Cone

3 3000983 1 • Oil Seal

4 3001152 1 • Washer

5 471214 1 • Grease Fitting

6 471242 1 • Relief Fitting

7 5001607 1 Motor Housing (Includes 2 ~ 6 and 8)

8 3003086 2 • Stud

9 364148 1 Compression Spring

10 364283 1 Tube, Spacer

11 364259 1 Washer, Bearing Retainer

12 400264 1 Screw, 3/8-16 x 1-1/4” Hex Head

13 446142 5 Lockwasher, 3/8 Hvy

14 364147 1 Gasket, Cover

15 338585 1 Cover

16 446116 4 Lockwasher, #10

17 434038 4 Screw, #10-24 x 1/2”

18 2812091 1 Vertical Reel Assembly

19 2812090 1 • Shaft

20 2812086 22 • Blade

21 3007137 86 • Spacer, Blade

22 2812085 1 • Collar

23 348576 1 • Nut, 1-3/4 - 5 Hex

24 415522 1 • Set Screw, 5/16-18 x 3/8” Soc Hd

25 4112881 2 Carriage Bolt, 5/8-11 x 2”

26 4112921 2 Nut, 5/8-11 Spiralock Flange

27 400258 4 Screw, 3/8-16 x 3/4” Hex Head

28 364282 1 Support Plate

29 4112882 2 Spacer

30 3003389 2 Housing, Pivot Bushing

31 400446 2 Screw, 1/2-20 x 2” Hex Head

32 445789 2 Nut, 1/2-20 Spiralock

33 458039 1 External Snap Ring

34 503684 1 Motor Coupler

35 364151 2 Wave Washer

36 1001643 1 Frame

5001606 1 Housing

> Change from previous revision

9

Page 10

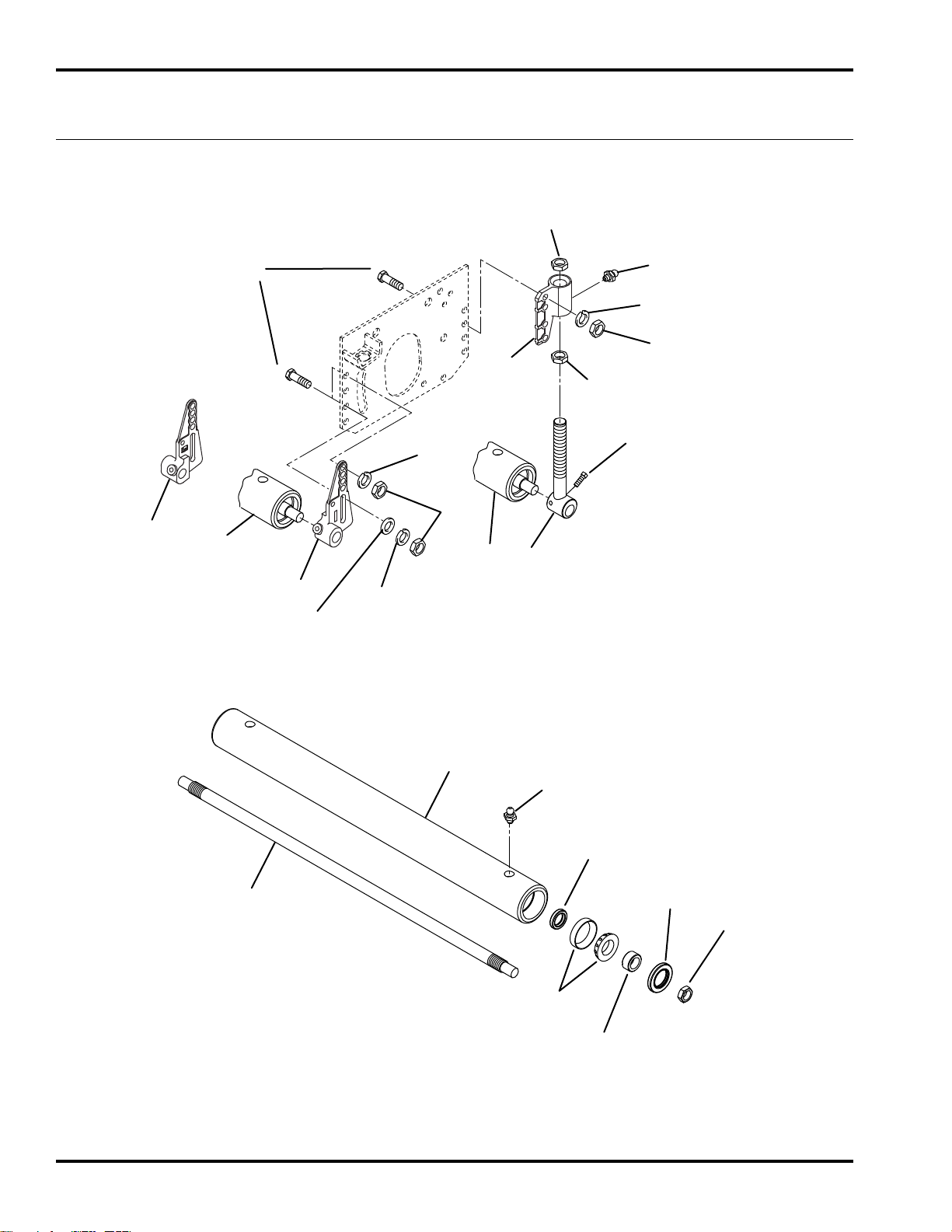

TRI-KING VERTICAL MOWER

13

10

10

20

11

19

17

15

17

13

10

14

18

16

12

7

4

8

9

1

1

5

2

6

3

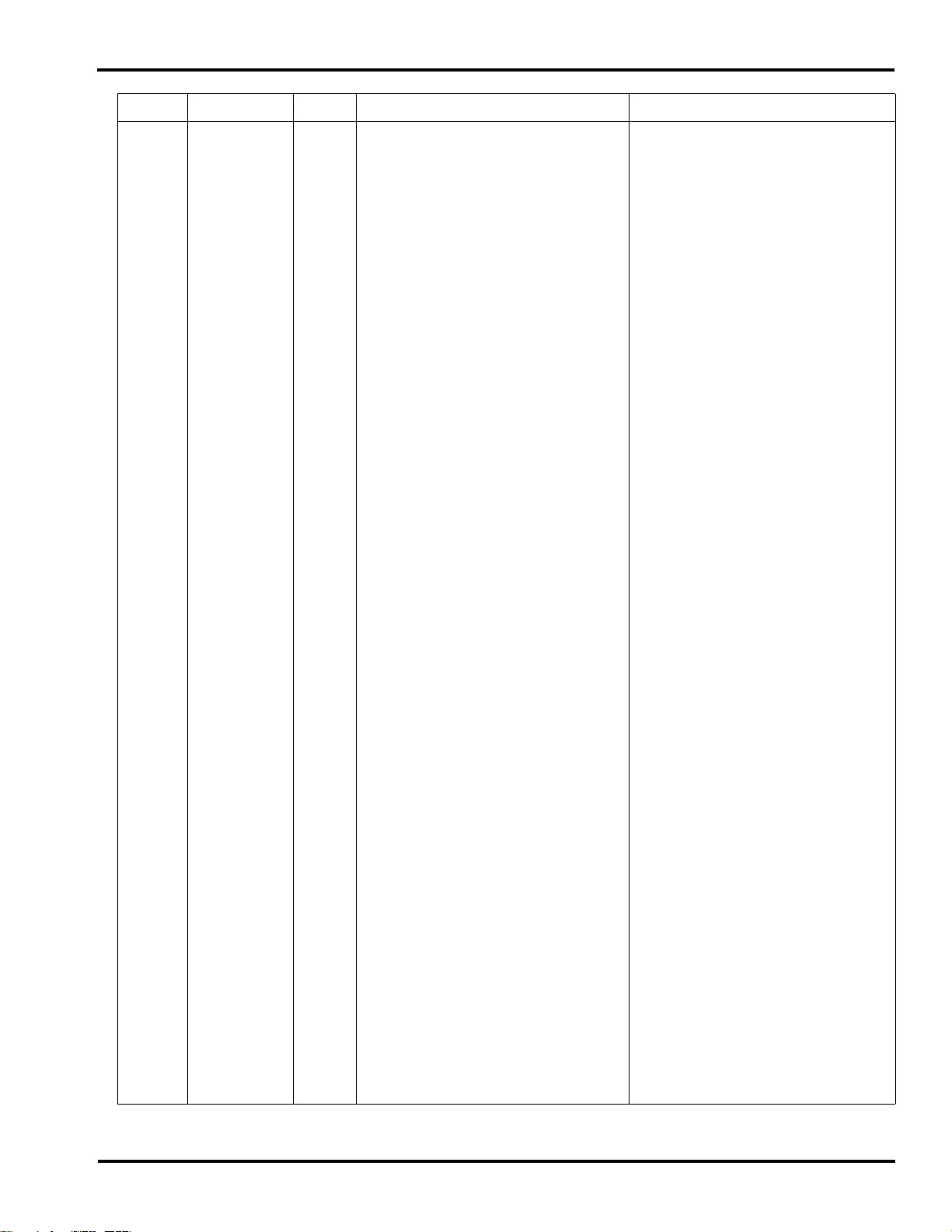

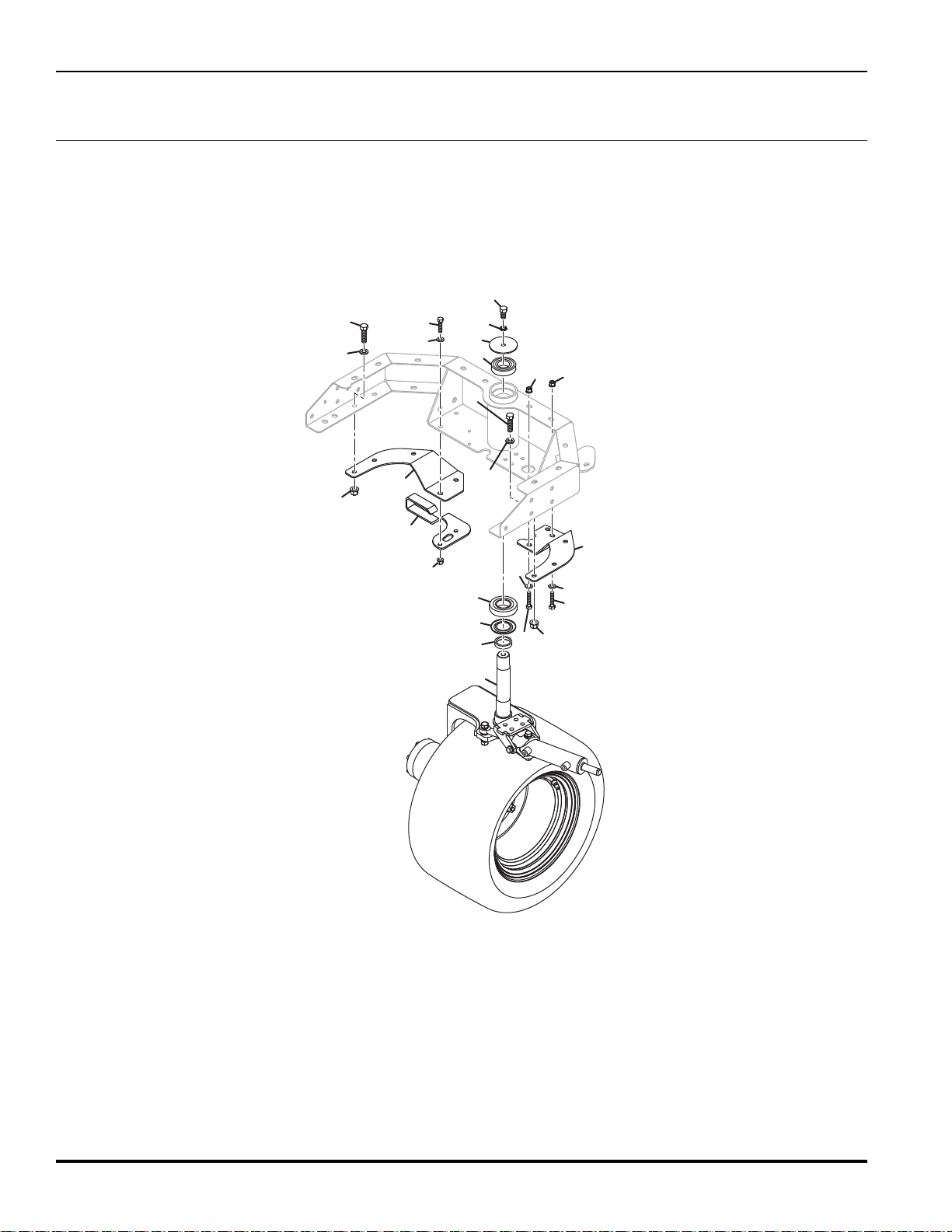

2.1 Rollers

Serial No. All

10

Page 11

TRI-KING VERTICAL MOWER

Item Part No. Qty. Description Serial Numbers/Notes

1

2 3005156 2 • Wear Sleeve

3 3004882 2 • Oil Seal

4 338647 2 • Oil Seal

5 500534 2 • Bearing, Cup and Cone

6 367029 2 • Nut

7 471214 2 • Grease Fitting

8 N/S 1 • Tube, Roller

9 3003415 1 • Shaft, Roller

10 446142 8 Lockwasher, 3/8 Hvy

11 3008359 1 L.H. Front Roller Bracket

12 3008360 1 R.H. Front Roller Bracket

13 443110 8 Nut, 3/8-16 Hex

14 471214 2 Grease Fitting

15 3007673 2 Housing

16 132680 2 Rear Roller Adjuster

17 3000313 4 Adjusting Nut

18 412015 4 Set Screw, 5/16-18 x 5/8”

19 400264 8 Screw, 3/8-16 x 1-1/4” Hex Head

20 366653 2 Washer

132639 2 Roller

> Change from previous revision

11

Page 12

12

11

10

28

13

24

25

10

8

7

6

4

12

11

10

9

19

18

18

17

20

21

6

5

15/16

27

26

26

22/23

20

31

13

11

3

2

29

11

30

11

12

14

1

1

25

(67141)

25

(67139)

25

(67141)

25

(67140)

To prevent injury, disengage

all drives, engage parking

brake and stop engine before

working in machine or

emptying grass catchers.

!

DANGER

TRI-KING VERTICAL MOWER

3.1 Shields and Pivot Arm

Serial No. All

12

Page 13

TRI-KING VERTICAL MOWER

Item Part No. Qty. Description Serial Numbers/Notes

1

1 116849 1 Right Pivot Arm 67140 Only

1 1000848 1 Center Pivot Arm 67141 Only

2 338561 1 Reel Pivot Bracket

3 338562 1 Reel Pivot Bracket

4 364302 2 Pivot Spacer

5 400408 2 Screw, 1/2-13 x 1-1/2” Hex Head

6 452012 4 Flat Washer, 1/2

7 446154 2 Lockwasher, 1/2 Hvy

8 443118 2 Nut, 1/2-13 Hex

9 400264 2 Screw, 3/8-16 x 1-1/4” Hex Head

10 453011 AR Washer, 3/8

11 446142 12 Lockwasher, Hvy

12 443110 6 Nut, 3/8-16 Hex

13 400260 6 Screw, 3/8-16 x 7/8” Hex Head

14 471214 1 Grease Fitting

15 3002813 1 Reel Bumper Bracket (Shown) 67141 Only

16 3002814 1 Reel Bumper Bracket 67141 Only

17 361723 2 Rubber Bumper 67141 Only

18 443810 4 Nut, 3/8-16 Jam 67141 Only

19 400190 4 Screw, 5/16-18 x 1-1/4” Hex Head 67141 Only

20 446136 4 Lockwasher, 5/16 Hvy 67139 and 67140 Only

20 446136 8 Lockwasher, 5/16 Hvy 67141 Only

21 443106 4 Nut, 5/16-18 Hex 67141 Only

22 122875.6 1 Rear Shield (Front Mowers) 67139 and 67140 Only

23 1003056.6 1 Rear Shield (Rear Mower) 67141 Only

24 5003650 1 Shield

25 361877 AR • Decal, Danger

26 3000718 2 Shield Shim

27 364281 2 Backup Nut

28 364150 2 Clamp

29 364777 1 Gasket

30 400258 2 Screw, 3/8-16 x 3/4” Hex Head

31 400186 4 Screw, 5/16-18 x 7/8” Hex Head

116850 1 Left Pivot Arm 67139 Only

364156 2 • Bushing 67139 Only

364156 2 • Bushing 67140 Only

364140 2 • Bushing 67141 Only

> Change from previous revision

13

Page 14

Jacobsen, A Textron Company

11108 Quality Drive, Charlotte, NC 28273

www.Jacobsen.com

800-848-1636

Equipment from Jacobsen is built to exacting

standards ensured by ISO 9001 and ISO 14001

registration at all of our manufacturing locations.

A worldwide dealer network and factory trained

technicians backed by Jacobsen Parts Xpress

provide reliable, high-quality product support.

When Performance Matters.

™

Page 15

WARNING

Warning: If incorrectly used, this machine can

cause severe injury. Those who use and maintain

this machine should be trained in its proper use,

warned of its dangers, and must read the entire

manual before attempting to set up, operate, adjust,

or service the machine.

When Performance Matters.

™

677799-Rev A

Parts Manual

Jacobsen TR320 Ride on Cylinder Trim Mower

68021-B000 – TR320, Kubota® D1105-E4B, 3WD, Trea

ded Tires

68021-B100 – TR320, Kubota® D1105-E4B, 3WD, Treaded Tires

68021-B200 – TR320, Kubota® D1105-E4B, 3WD, Treaded Tires

GB

Page 16

CHARLOTTE, NC PRODUCT OF U.S.A.

®

A Textron Company

FOREWORD

This manual contains adjustment, maintenance,

troubleshooting instructions and parts list for your new

Jacobsen machine. This manual should be stored with

the equipment for reference during operation.

Before you operate your machine, you and each operator

you employ should read the manual carefully in its

entirety. By following the safety, operating and

maintenance instructions, you will prolong the life of your

equipment and maintain its maximum efficiency.

If additional information is needed, contact your

Jacobsen Dealer.

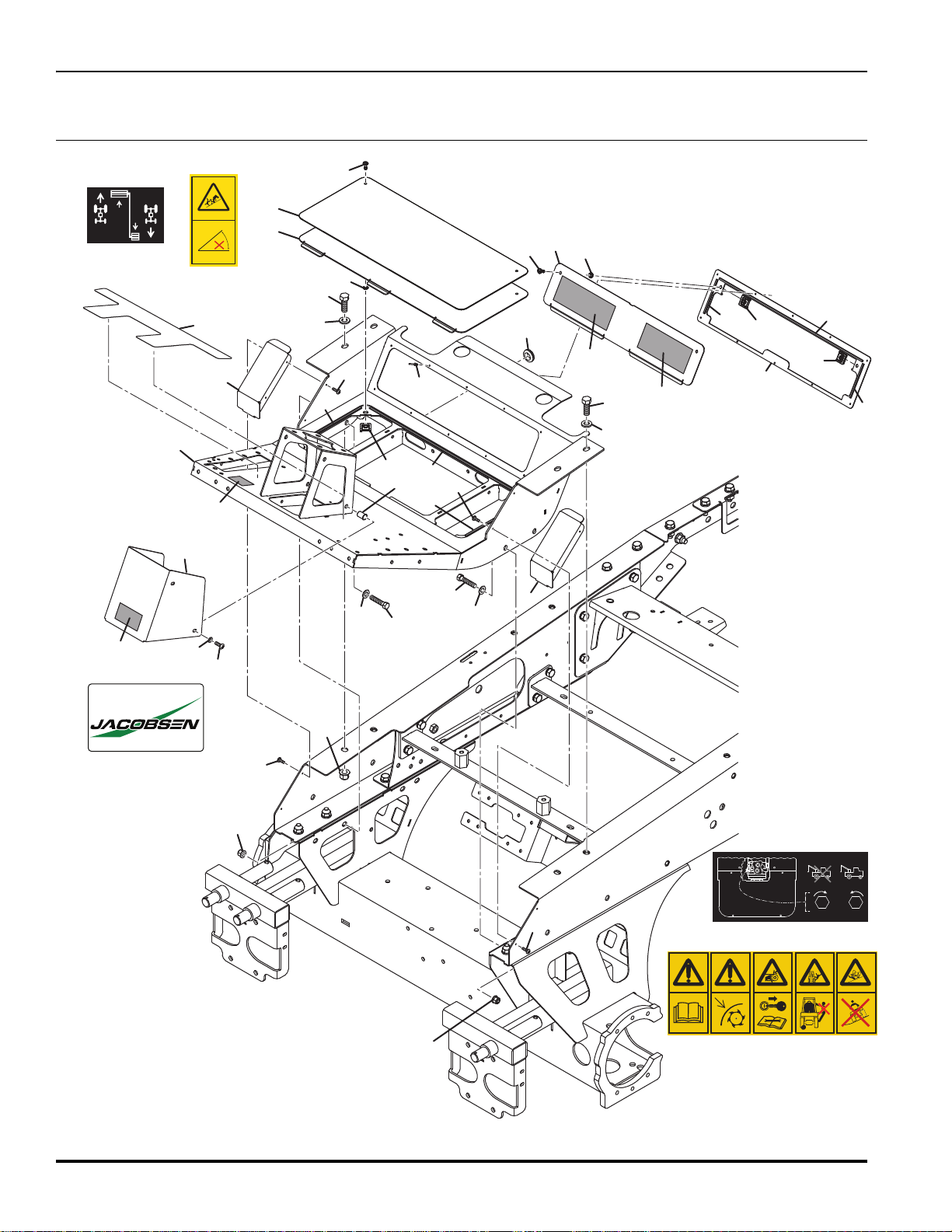

The serial plate is located on the left rear frame rail.

Jacobsen recommends you record these numbers below

for easy reference.

Suggested Stocking Guide

To Keep your Equipment fully operational and productive, Jacobsen suggests you maintain a stock of the more

commonly used maintenance items. We have included part numbers for additional support materials and training aids.

To order any of the following material:

1. Write your full name and complete address on your

order form.

2. Explain where and how to make shipment:

❑

UPS ❑ Regular

❑Overnight ❑2nd Day

Mail

3. Order by the quantity desired, the part number, and

the description of the part.

4. Send or bring the order to your authorized Jacobsen

Dealer.

Qty. Part No. Description Qty. Part No. Description

4113986

5000913 Element, Engine Air Filter 4176550 Engine Fan Belt

550489 Cartridge, Engine Fuel Filter

2811255 Charge Filter

Engine Oil Filter 4283654 Ignition Key

Service Support Material

Qty. Part No. Description

677802

677799

TBD Service Manual

This manual may not re repr oduced in whole or in part without the

express permission of TSV (Augusta) Technical Communications

2

Safety & Operation Manual

Parts Manual

Copyrighted Material

Department.

Qty. Part No. Description

Diesel Engine Parts Manual

Proposition 65 Warning

This product contains or emits

chemicals known to State of California

to cause cancer and birth defects or

other reproductive harm.

02-2018

Service Parts

Page 17

Table of Contents

1

1.1......... Operator Platform ............................................... 4

1.1......... Seat Option .......................................................... 1

3.1......... Armrest and Control Panel ................................ 8

4.1......... Traction Pedal ................................................... 10

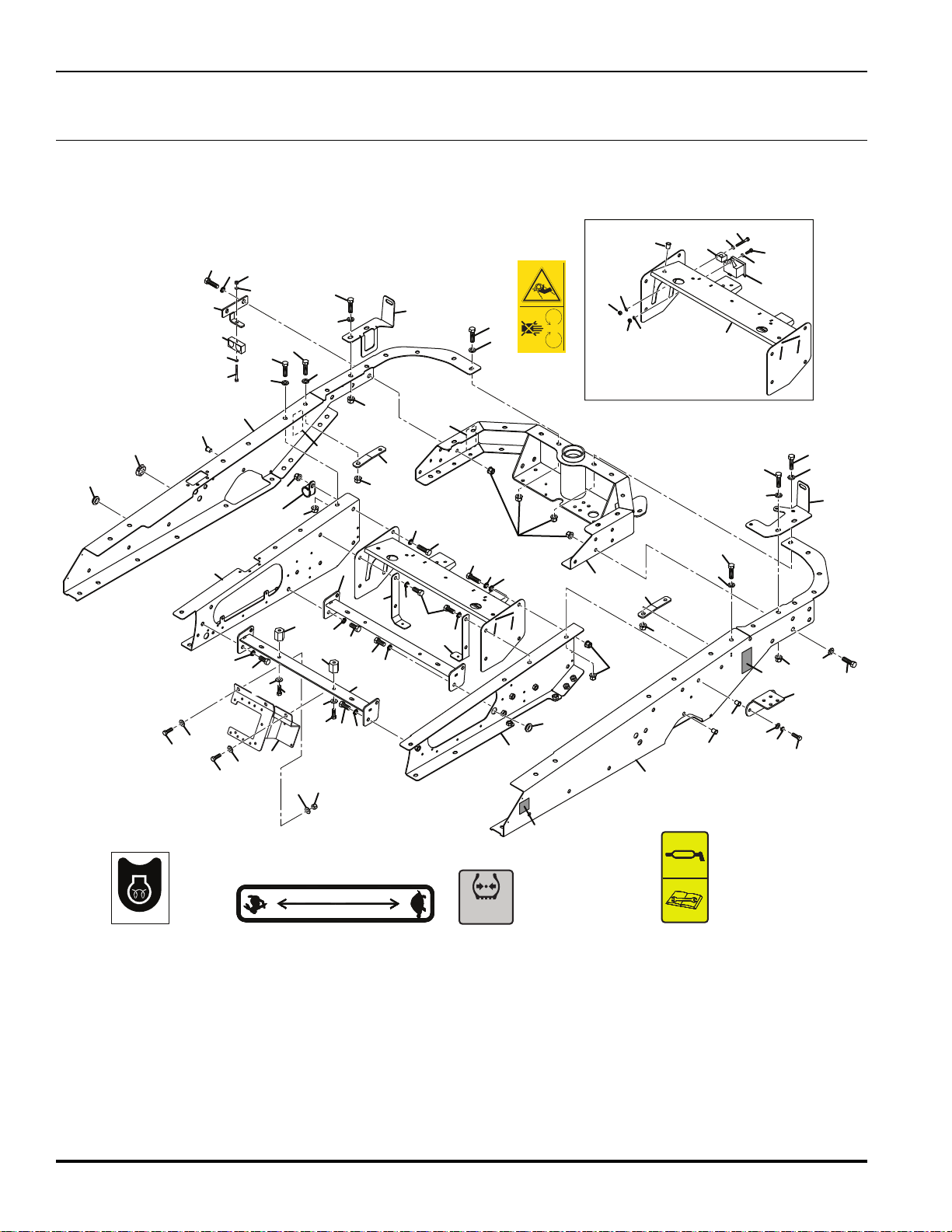

5.1......... Traction Linkage ............................................... 12

6.1......... Chassis .............................................................. 14

7.1......... Front Axle Assembly ........................................ 16

8.1......... Front Axle .......................................................... 18

9.1......... Rear Axle Assembly ......................................... 20

10.1....... Rear Axle ........................................................... 22

11.1....... Air Filter ............................................................. 24

12.1....... Radiator ............................................................. 26

13.1....... Remote Engine Oil Cooler and Filter .............. 28

14.1....... Engine Mounting ............................................... 30

15.1....... Engine and Pumps............................................ 32

16.1....... Engine Exhaust ................................................. 34

17.1....... Fuel Tank and Routing ..................................... 36

18.1....... Hydraulic Tank and Hood................................. 38

19.1....... Hydraulic Valve Assembly ............................... 40

20.1....... 3WD Traction Hydraulics ................................. 42

21.1....... 3WD Gear Pump and Steering Hydraulics...... 44

22.1....... Front And Rear Reel Hydraulics...................... 46

23.1....... Front And Rear Lift Hydraulics ........................ 48

24.1....... Drain Hydraulics ............................................... 50

25.1....... Brake Valve and Charge Hydraulics ............... 52

26.1....... Oil Cooler Hydraulics ....................................... 54

27.1....... Electrical ........................................................... 56

28.1....... Mounting And Lift Arms .................................. 58

29.1....... Pivot Arms ......................................................... 60

30.1....... Inner Reel Assembly......................................... 62

31.1....... Outer Reel .......................................................... 64

32.1....... Roller Brackets and Skids................................ 66

33.1....... Standard Unit Fixing ......................................... 68

34.1....... Grass Catcher ................................................... 70

35.1....... Brake Valve....................................................... 72

36.1....... Reel Valve .......................................................... 73

37.1....... Lift-Weight Transfer Valve ............................... 74

38.1....... Reel Motor ......................................................... 75

39.1....... Steering Cylinder .............................................. 76

40.1....... Front Lift Cylinder ............................................. 78

41.1....... Rear Lift Cylinder .............................................. 79

42.1....... Steering Valve ................................................... 80

43.1....... Gear Pump ......................................................... 82

44.1....... Traction Pump ................................................... 84

44.1....... Traction Pump (Continued).............................. 86

45.1....... 3WD Rear Wheel Motor .................................... 88

46.1....... Electrical Schematic ......................................... 90

47.1....... Hydraulic Schematic......................................... 94

Page 18

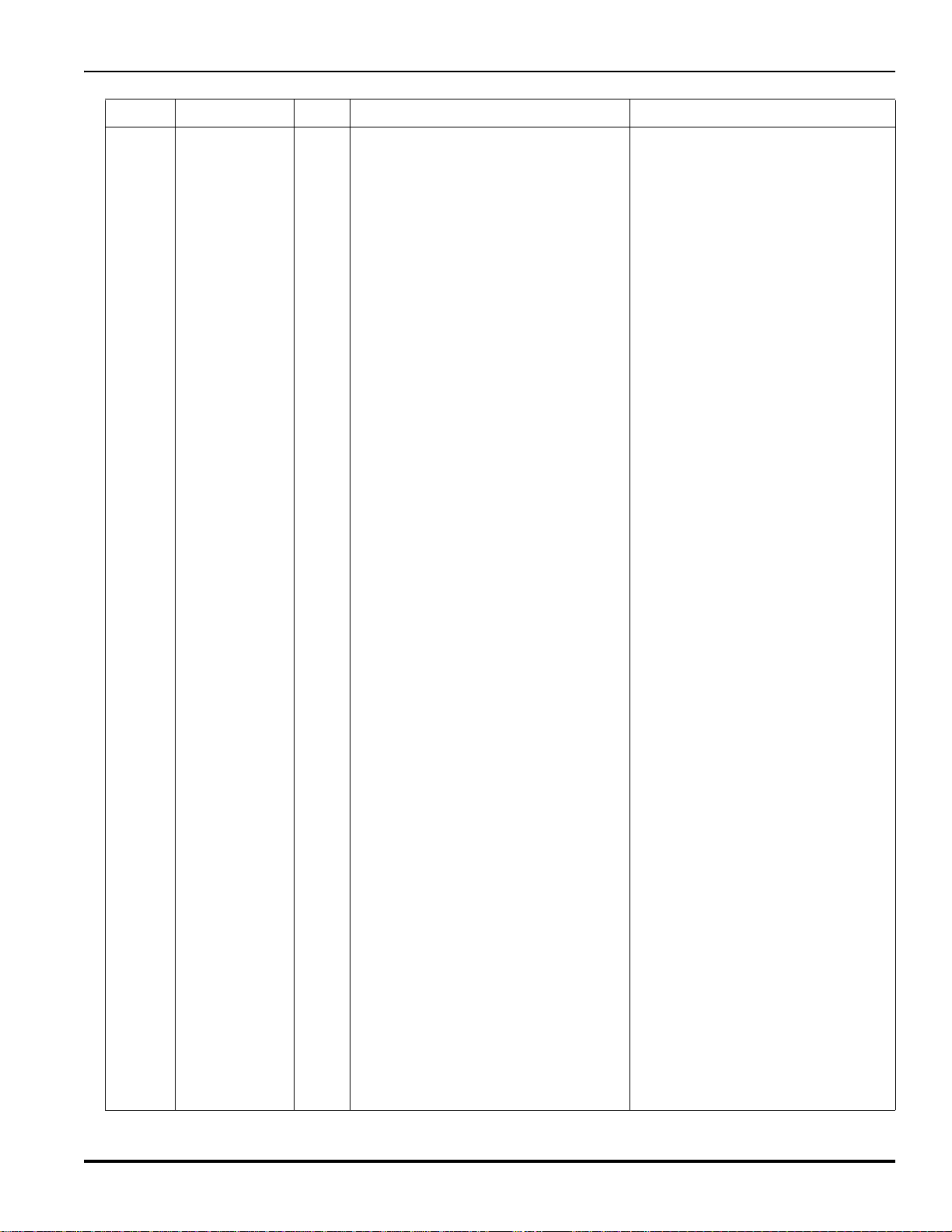

TR320

1

1

1

1

2

3

4

4

5

5

5

6

6

7

8

9

10

10

11

12

12

13

14

31

15

16

16

17

17

18

19

20

20

21

21

27

27

26

26

28

28

29

29

22

23

23

24

25

4397486

®

3008682

4181865 REV B

3

30

32

14°+

1.1 Operator Platform

Serial No. All

009114550

4

Page 19

TR320

Item Part No. Qty. Description Serial Numbers/Notes

1

2 001496150 16 Pop Rivet, 3.2 x 10 mm Stainless Steel

3 4314427 4 1/4 Turn Fastener

4 4314429 4 1/4 Turn Steel Retainer

5 4314430 4 1/4 Turn Receptacle

6 4394747 2 Cover, Chassis End

7 671357 1 Platform, Operator

8 4395663 1 Cover, Steering Tower

9 671682 1 Adhesive Foam, 578 mm

10 4395665 2 Adhesive Foam, 3 x 4 x 90 mm

11 4395666 1 Adhesive Foam, 4 x 5 x 529 mm

12 4395667 2 Adhesive Foam, 3 x 5 x 202 mm

13 671556 1 Plate, Rear Backing

14 671585 1 Panel, Rear Service

15 4395869 1 Panel, Floor Service

16 450029 4 Hex Head Screw, M10-1.5 x 35 mm

17 450241 4 Hex Head Screw, M12-1.75 x 30 mm

18 450357 4 Nut, M6-1 Insert (0.7 to 4.2)

19 450389 4 Washer, M6 x 12.5 x 1.8

20 450391 4 Washer, M10 x 21 x 2.2

21 450392 4 Washer, M12 x 24 x 2.7

22 450541 4 Pan Head Screw, M6-1 x 16 mm

23 452437 4 Nut, M10-1.5 Flange Nyloc

24 452438 2 Nut, M12-1.75 Flange Nyloc

25 002953223 3 Grommet, 20.6 x 31.8 x 9.5 mm

26 4397486 1 Decal, Traction Pedal

27 669813 1 Decal, Jacobsen Decal

28 4181865 1 Decal, Mower Warning

29 3008682 1 Decal, Tow Valve

30 4420394 1 Floor Board Grip Tape

31 4420395 1 Access Panel Grip Tape

32 009114550 1 Decal, Max Slope 14 Deg

001191331 4 Screw, M5-0.8 x 16 mm Taptite

> Change from previous revision

5

Page 20

TR320

1.1 Seat Option

Serial No. All

Standard Seat Option

13

17

13

5

20

26

12

2

17

8

14

16

17

15

21

1

16

11

15

17

3

4

5

9

22

17

20

9

26

13

13

25

27

17

13

13

25

24

23

18

1

7

24

23

18

6

7

19

10

6

Page 21

TR320

Item Part No. Qty. Description Serial Numbers/Notes

1 4202462 1 Standard Seat

2 4204341 1 Bracket, Right Side Seat Belt

3 4205942 1 Spacer, Seat Belt Bracket

4 4256475 1 Bracket, Left Side Seat Belt

5 4257812 1 Seat Belt Includes latch and retractor

6 4376646 2 Boss, Seat Mount

7 4376647 2 Rail, Seat Mounting

8 4376648 1 Armrest Seat Support

9 4378526 2 Support, Standard Seat

10 450120021 4 Nut, 5/16 - 18 Grade 1

11 450190 4 Screw, M8-1.25 x 16 mm Hex Head

12 672483 2 Bracket, Seat Travel Limiter

13 450214 6 Screw, M10-1.5 x 25 mm Hex Head

14 450378 4 Nut, M8-1.25 Hex Nyloc

15 450379 2 Nut, M10-1.5 Hex Nyloc

16 450390 4 Flat Washer, M8 x 17 x 1.8

17 450391 8 Flat Washer, M10 x 21 x 2.2

18 450392 2 Washer, M12 x 24 x 2.7

19 450411 8 Lockwasher, M8 x 12.75 x 2

20 450412 4 Lockwasher, M10 x 15.9 x 2.5

21 4193341 1 Adjuster, Seat Rail

22 4193344 1 Adjuster, Seat Rail with Handle

23 450413 2 Lockwasher, M12 x 17.9 x 2.5

24 450240 2 Screw, M12-1.75 x 25 mm Hex Head

25 450401 2 Washer, M10 x 24 x 2.2

26 4203220 4 Screw, M8-1.25 x 20 mm Square Hd

27 4384346 1 Fuel Tank Strap

> Change from previous revision

2

Page 22

TR320

9

4

5

11

35

22

38

23

24

25

20

16

26

8

3

18

31

33

36

28

21

2

1

6

17

29

37

14

19

15

35

41

33

39

40

42

10

10

7

11

13

34

27

20

30

32

12

10

42

32

3.1 Armrest and Control Panel

Serial No. All

8

Page 23

TR320

Item Part No. Qty. Description Serial Numbers/Notes

1

2 4193344 1 Adjuster, Seat Rail with Handle Replace handle with Item 4

3 4362366 1 Plate, Armrest Support

4 672316 1 Rod, Armrest

5 4370626 1 Armrest

6 4395147 1 Top Plate, Armrest Support

7 672309 1 Armrest Cover

8 450192 4 Screw, M8-1.25 x 25 mm Hex Head

9 450357 2 Nut, M6-1 Insert (0.7-4.2)

10 450453 4 Nut, M8-1.25 Hex Flange

11 450471 7 Screw, M8-1.25 x 20 mm Hex Flange

12 450541 2 Screw, M6-1 x 16 Grade 4.8

13 2188154 1 Module Delay REFERENCE U4, See 46.1

14 363996 1 Switch

15 4125831 2 Switch, Neutral Proximity

16 4139764 1 Switch, Parking Brake REFERENCE SW6, See 46.1

17 4150539 1 Horn REFERENCE U3, See 46.1

18 4212121 1 LED Indicator

19 4217502 1 Switch, Seat REFERENCE SW3, See 46.1

20 4225220 2 Plug, Panel Refer to Optional Kit

21 4270811 1 Gauge, Fuel/Hourmeter

22 4283269 1 Switch, 3 Position Key REFERENCE SW1, See 46.1

23 4283653 1 • Nut, M22-1.5 Key Switch Backing

24 4283652 1 • Nut, M22-1.5 Key Switch Face

25 4283654 1 • Key, Replacement

26 4324707 1 Switch, Rocker DPDT (MOM)

27 4343926 1 Switch, Yellow Rocker DPDT REFERENCE SW2, See 46.1

28 4381566 1 Pad, Armrest

29 4382209 1 Grommet

30 450168 8 Screw, M6-1 x 12 mm Hex He

1 450331 1 Hex Nut, M8-1.25 Grade 8

3

32 450477 1 Screw, M10 - 1.5 x 20 mm Hex Flange

33 450390 1 Washer, M8 x 17 x 1.

4 15694-65992 1 Lamp Timer REFERENCE U5, See 46.1

3

35 4374506 1 Decal, Key Switch

36 4395054 1 Control Panel, Standard Steel

37 4391886 1 Decal, Control Panel Standard

38 4376648 1 Armrest Seat Support See 2.1

39 672308 1 Side Bracket, Armrest Support

40 452436 3 Nut, M8 Flange Nyloc

41 450391 5 Washer, M10 x 21 x 2.2

42 4290433 2 Screw, Button Head M10 x 25

43 450379 2 Nut, M10 - 1.5 Hex Nyloc

4193341 1 Adjuster, Seat Rail

ad

8

> Change from previous revision

9

Page 24

TR320

16

1

4

4

5

5

6

7

8

9

10

11

12

28

28

26

14

15

15

23

17

17

27

18

20

20

20

20

21

21

21

22

25

29

39

25

2

3

16

20

15

21

29

16

16

28

17

29

22

25

19

34

38

35

36

37

21

21

13

26

26

27

16

21

24

24

31

32

30

31

33

29

29

29

23

16

16

16

21

21

16

22

27

4.1 Traction Pedal

Serial No. All

10

Page 25

TR320

Item Part No. Qty. Description Serial Numbers/Notes

1

2 3003474 1 Grip, Reverse Pedal

3 3003475 1 Grip, Forward Pedal

4 4185740 2 Bracket, Pedal Pivot

5 4185741 1 • Bearing, 1/2” Self Align

6 4200040 1 Screw, M12 - 1.75 Detent

7 4367106 1 Traction Lever

8 4377786 1 Lever, Mow Speed Stop

9 4377886 1 Bracket, Mow Speed Lever

10 4378832 1 Pedal

11 4382867 1 Roller Weldment Bracket, RH

12 450001 1 Hex Bolt, M6 - 1.0 x 30 mm

13 450014 2 Screw, M8-1.25 x 30 mm Hex Head Grade 8.8

14 450020231 1 Nut, 1/4-28 Thin Hex

15 450172 6 Screw, M6-1 x 25 mm Hex Head

16 450192 17 Screw, M8-1.25 x 25 mm Hex Head

17 450324 3 Nut, M8-1.25 Hex

18 450333 1 Nut, M12-1.75 Thin Hex

19 450377 1 Nut, M6 - 1.0 Hex

20 450389 9 Washer, M6 x 12.5 x 1.8

21 450390 19 Washer, M8 x 17 x 1.8

22 452435 6 Nut, M6-1 Flange Nyloc

23 452437 4 Nut, M10 Flange Nyloc

24 4397147 1 Roller Weldment Bracket, LH

25 4398009 1 Buffer Brace Weldment

26 450029 4 Hex Bolt, M10 - 1.5 x 35 mm

27 450391 4 Washer, M10 x 21 x 2.2

28 450198 3 Screw, M8 - 1.25 x 55 mm Hex Head

29 452436 18 Nut, M8 Flange Nyloc

30 4125831 2 Switch, Proximity

31 450386 8 Washer, M3 x 7 x 0.6

32 450511 4 Screw, M3-0.5 x 25 mm Pan Head

33 452716 4 Nut, M3-0.5 Hex

34

35 671673 2 Screw, M16 x 110 mm Hex Head Socket Drive Screw

36 450393 2 Washer, M16 x 30 x 3.3

37 452439 2 Nut, M16-2 Flange Nyloc

38 MBG1642 2 Roller, Wing Unit

39 4368187 1 Cable, Traction See 5.1 for other end of cable

128079 1 Rod End, 1/4-28

Nyloc

4397906 2 Bracket, Bottom Roller

> Change from previous revision

11

Page 26

TR320

1

2

3

4

5

6

7

8

8

9

22

9

9

9

10

10

10

10

11

12

13

14

15

16

17

17

18

19

20

21

23

5.1 Traction Linkage

Serial No. All

12

Page 27

TR320

Item Part No. Qty. Description Serial Numbers/Notes

1

2 4125831 1 Switch, Neutral Proximity REFERENCE SW12, See 46.1

3 4368187 1 Cable, Traction See 4.1 for other end of cable

4 4386927 1 Control Arm

5 450019 1 Screw, M8-1.25 x 55 mm Hex Head

6 450192 4 Screw, M8-1.25 x 25 mm Hex Head

7 450020231 1 Nut, 1/4-28 Thin Hex

8 450386 4 Washer, M3 x 7 x 0.6 mm

9 450389 4 Washer, M6 x 12.5 x 1.8

10 450390 7 Washer, M8 x 17 x 1.8

11 450411 4 Lockwasher, M8 x 12.75 x 2

12 450511 2 Screw, M3-0.5 x 25 mm Pan Head

13 450002 1 Screw, M6-1 x 35 mm Hex Head

14 452436 1 Nut, M8-1.25 Flange Nyloc

15 452716 2 Nut, M3-0.5 Hex Nyloc

16 450377 1 Nut, M6-1 Hex Nyloc

17 450378 2 Nut, M8-1.25 Hex Nyloc

18 4397226 1 Plate, Cable Sensor

19 4397230 1 Actuator, Neutral Switch

20 4397526 1 Damper, Self Centering

21 450400 1 Washer, M8 x 21 x 1.8

22 4231340 1 Spring, 11.13 x 1,42 x 25.4

23 4203740 1 Pump, LPV 35 cc Piston See 44.1 for Service Parts

128079 1 Rod End, 1/4”

> Change from previous revision

13

Page 28

TR320

19

20

1

1

1

28

48

1

1

1

2

3

3

4

5

6

7

8

9

10

34

34

44

45

35

35

35

42

36

11

12

14

15

16

17

18

19

19

20

20

20

33

33

20

20

20

20

20

20

20

22

23

23

23

24

24

26

26

26

26

27

28

28

28

28

28

30

31

31

31

31

31

31

31

31

32

46

47

29

4

25

29

13

28

0.7 bar

10 psi

673581

37

28

20

38

39

40

41

41

20

13

29

19

29

43

29

20

28

20

28

20

28

838363

670526

42

6.1 Chassis

Serial No. All

14

Page 29

TR320

Item Part No. Qty. Description Serial Numbers/Notes

1

2 4309904 1 3 Way Distribution Block

3 4350748 2 Bracket, Angled Brace

4 4350749 2 Cross Brace, Center

5 4362466 1 ROPS Rail, LH

6 4362467 1 ROPS Rail, RH

7 4365086 1 Cross Brace, Radiator

8 4371587 1 Bracket, Charge Filter

9 4393946 1 Rail, RH

10 4393948 1 Rail, LH

11 4375506 1 Bracket, LH Oil Tank

12 4375566 1 Bracket, RH Oil Tank

13 4376646 2 Boss, Seat Mount

14 4386646 1 Chassis, Rear

15 4394346 1 Bracket, Fuse Block & Brake Valve

16 4394471 1 Stauf Clamp

17 450003 1 Hex Head Screw, M6-1 x 40 mm

18 450171 1 Hex Head Screw, M6-1 x 20 mm

19 450214 4 Hex Head Screw, M10-1.5 x 25 mm

20 450242 42 Hex Head Screw, M12-1.75 x 35 mm Grade 8.8

21 450357 1 Insert, M6-1

22 450369 3 Nut, M8-1.25 Insert (0.7 to 3.8)

23 450371 4 Nut, M10-1.5 Insert (0.7 to 3.8)

24 450377 2 Nut, M6-1 Hex Nyloc

25 450379 3 Nut, M10-1.5 Hex Nyloc

26 450389 4 Washer, M6 x 12.5 x 1.8

27 450391 2 Washer, M10 x 21 x 2.2

28 450392 27 Washer, M12 x 24 x 2.7

29 450401 8 Washer, M10 x 24 x 2.2

30 450412 2 Lockwasher, M10 x 15.9 x 2.5

31 452438 29 Nut, M12-1.75 Flange Nylock

32 4139045 1 P-Clip, 1-5/16 Dia

33 4396546 2 Bracket, Tube Clamp

34 673581 1 Decal, Tire Pressure

35 4164580 2 Decal, Lubrication

36 009034900 1 Decal, Belt

37 002953223 1 Grommet, 20.6 x 31.8 x 9.5

38 4398766 1 Bracket, Hose Clamp

39 4398686 1 Clamp, Stauf - LBG-425, 4-PP

40 450005 1 Screw, M6-1 x 50 mm Hex Head

41 450389 2 Washer, M6 x 12.5 x 1.8

42 450377 1 Nut, M6-1 Hex Nyloc

43 450215 3 Screw, M10-1.5 x 30 mm Hex Head

44 838363 1 Decal, Throttle

45 670526 1 Decal, Glow Plug

46 673618 1 Blanking Plug, 38 mm

47 671358 1 Grommet, 38 x 32 mm

48 450413 1 Washer

49 48228-06 1 P-Clip, 1.23” Dia Not illustrated

4273470 15 AV Washer - 13 x 19.5 x 2.5

> Change from previous revision

15

Page 30

TR320

1

7

7

2

3

3

4

4

4

6

8

9

38

10

10

10

11

39

13

14

15

40

31

31

31

17

44

18

19

27

2

2

27

19

19

19

19

19

2

19

19

20

20

21

21

22

21

23

2

32

19

21

31

31

24

21

21

42

28

21

21

21

21

33

33

37

3733

30

34

34

35

35

36

36

21

21

41

37

16

105

dB

L

WA

5

21

31

43

20

Front Axle

26

26

45

47

46

45

12

29

25

7.1 Front Axle Assembly

Serial No. All

16

Page 31

TR320

Item Part No. Qty. Description Serial Numbers/Notes

1

2 4273470 18 AV Washer - 13 x 19.5 x 2.5

3 669479 5 Fir Tree Insert, 13.5 mm

4 4314627 8 Screw, M12-1.75 x 35 mm Hex Head Grade 10.9

5 4370266 1 ROPS

6 4395246 1 Bracket, Socket Mount

7 450402 4 Washer, M12 x 28 x 2.7

8 450192 2 Screw, M8-1.25 x 25 mm Hex Head Torque to 70 ft. lb. (97 Nm)

9 450321 2 Nut, M4-0.7 Hex

10 450357 3 Nut, M6-1 Insert (0.7 to 4.2)

11 450387 2 Washer, M4 x 9 x 0.9

12 452437 2 Nut, M10 Flange Nyloc

13 450532 2 Screw, M5-0.8 x 35 mm Pan Head

14 450594 2 Screw, M4-0.7 x 12 Countersunk

15 843942 1 Outlet, 12 V Accessory REFERENCE U5, See 46.1

16 669503 11 Mouting Button, 6.6 mm

17 4388428 1 Fender and Step

18 4393846 1 Fender and Battery Box

19 450242 22 Screw, M12-1.75 x 35 mm Hex Head

20 450380 6 Nut, M12-1.75 Hex Nyloc

21 450392 32 Washer, M12 x 24 x 2.7

22 450055 4 Bolt, M12-1.75 x 75 mm Hex Head

23 4381048 4 Carrier Support

24 4391327 2 Lower Ch Rail Bracket

25 450391 4 Washer, M10 x 21 x 2.2

26 456110066 2 Screw, 3/8-16 x 1 Hex Head

27 450243 2 Screw, M12-1.75 x 40 mm Hex Head

28 450240 2 Screw, M12-1.75 x 25 mm Hex Head

29 450215 2 Screw, M10-1.5 x 30 mm Hex Head

30 4393546 2 Cross Bar, Chassis

31 452438 20 Nut, M12 Flange Nyloc

32 450018 2 Bolt, M8-1.25 x 50 mm Hex Head

33 4164580 2 Decal, Lubrication

34 009114100 1 Decal, Battery

35 009114380 1 Decal, Seat Belt

36 009034770 1 Decal, Sound

37 4397046 2 Decal, Jacking

38 450370 2 Nut, M8-1.25 Insert

39 450390 2 Washer, M8 x 17 x 1.8

40 2208139 4 Hose Clamp Bottom

41 4122501 2 Bore Hose Clamp, 5/8”

42 450411 2 Lockwasher, M8 x 12.75 x 2

43 4400045 2 Hose Clamp Bracket, Front Unit

44 669323 1 Archway Panel Weldment

45 450412 2 Lockwasher, M10 x 15.9 x 2.5

46 4395186 1 Reel Valve Bracket

47 4355571 1 Reel Valve See 36.1 for Service Parts

4259710 1 Handle, ROPS

> Change from previous revision

17

Page 32

TR320

2

8

4

7

5

6

3

3

3

1

8

8

8.1 Front Axle

Serial No. All

18

Page 33

TR320

Item Part No. Qty. Description Serial Numbers/Notes

1

2 4379926 2 Wheel Motor, 235 cc

3 450242 8 Screw, M12-1.75 x 40 mm Hex Head

4

5 4375488 1 • Wheel, 10 x 8.5

6 4220940 1 • Tubeless Tire Valve

7 001341110 5 Nut, 1/2-20 Wheel

8

4a

5

6

4374927 1 Front Axle Weldment

4388026 2 Treaded Wheel and Tire Assembly

4233963 1 • Tire, 20 x 12-10 4 Ply Grassmaster

4273470 8

4375489

4233900

4375488

4220940

AV Washer - 13 x 19.5 x 2.5

2

Smooth Wheel and Tire Assembly

• Tire, 20 x 12-10 2 Ply OTR

1

• Wheel, 10 x 8.5

1

• Tubeless Tire Valve

1

> Change from previous revision

19

Page 34

TR320

1

2

3

4

5

7

6

6

6

8

8

9

9

9

10

10

11

11

11

12

12

13

14

15

16

17

9.1 Rear Axle Assembly

Serial No. All

20

Page 35

TR320

Item Part No. Qty. Description Serial Numbers/Notes

1

2 4391085 1 Gusset, RH Rear Chassis

3 4391106 1 Gusset, LH Rear Chassis

4 4399209 1 Bracket, Rear Motor

5 4273470 1 AV Washer - 13 x 19.5 x 2.5

6 450216 4 Hex Head Screw, M10-1.5 x 35 mm

7 450239 1 Hex Head Screw, M12-1.75 x 20 mm

8 450242 6 Hex Head Screw, M12-1.75 x 35 mm Grade 8.8

9 450391 4 Washer, M10 x 21 x 2.2

10 450392 6 Washer, M12 x 24 x 2.7

11 452437 4 Nut, M10-1.5 Flange Nyloc

12 452438 6 Nut, M12-1.75 Flange Nyloc

13 MBA2397A 1 Washer, 11 x 82 x 3

14 4397266 1 Collar, Rear Axle

15 4397488 1 Ball Bearing, 40 x 80 x 18

16 4397507 1 Nilos Ring

17 REF 1 3WD Rear Axle See 10.1

002036070 1 Ball Bearing, 35 x 72 x 10

> Change from previous revision

21

Page 36

TR320

1

2

3

3

4

5

6

7

8

9

9

9

10

11

12

13

14

25

26

27

15

16

17

18

19

20

21

22

23

24

24

28

9

10.1 Rear Axle

Serial No. All

22

Page 37

TR320

Item Part No. Qty. Description Serial Numbers/Notes

1

2 001399032 1 Nut, 1/2-20 Nyloc

3 002143004 4 Bush, 10 x 12 x 10

4 008006260 1 Nut, 1-20 Wheel Motor Torque to 400 ft. lb.

5 008145256 1 Rod End, 1/2-20

6 4183560 1 Screw, M6-1 x 20 mm Hex Socket

7 4192800 1 Hub, Wheel Nut

8 4244289 1 Cylinder, Steering See 36.1 for Service Parts

9 4273470 6 AV Washer - 13 x 19.5 x 2.5

10 4366566 1 Bracket, Journal Mounting

11 4370787 1 Wheel Hub

12 4379887 1

13 4386741 1 3WD Wheel Yoke

14 450020281 1 Nut, 1/2-20 Thin Hex

15 450056 4 Screw, M12-1.75 x 80 mm Hex Head

16 450214 4 Screw, M10-1.5 x 30 mm Hex Head

17 450391 4 Washer, M10 x 21 x 2.2

18 450392 2 Washer, M12 x 24 x 2.7

19 450413 4 Lockwasher, M12 x 17.9 x 2.5

20 450455 4 But, M12-1.75 Hex Flange Grade 10

21 672713 1 Hex Head Screw, 2.1/2 Grade 8

22 4399226 5 Stud, M14-1.5 x 50 mm

23 MBC5942 1 Journal

24 MBC5959A 4 Bolt, 1/2-20 x 12mm

25 4375487 1 • Tire, 20 x 10-10 4 Ply Grassmaster Treaded Tire

26 4375488 1 • Wheel, 10 x 8.5

27 4220940 1 • Tubeless Tire Valve

28 450412 4 Lockwasher, M10 x 15.9 x 2.5

25a

26

27

008008460 5 Nut, M14-1.5 x 34 mm Wheel

3

Motor, 28.7 in

4375486 1 Treaded Wheel and Tire Assembly

1

4375489

4233900

4220940

4375488

1

• Smooth Wheel and Tire Assembly

1

• Tire, 20 x 10-10 2 Ply OTR

1

• Wheel, 10 x 8.5

1

• Tubeless Tire Valve

Wheel

See 45.1 for Service Parts

Smooth Tire

> Change from previous revision

23

Page 38

TR320

1

1

2

3

4

5

6

7

8

10

11

12

9

9

7

12

11.1 Air Filter

Serial No. All

24

Page 39

TR320

Item Part No. Qty. Description Serial Numbers/Notes

1

2 3002365 1 Indicator, Air Cleaner

3 4378166 1 Hose, Air Cleaner Intake

4 4378646 1 Bracket, Air Cleaner

5 4395228 1 Rain Cap Includes Clamp

6 450192 2 Screw, M8-1.25 x 25 mm Hex Head

7 450242 2 Screw, M12-1.75 x 35 mm Hex Head

8 452436 2 Nut, M8-1.25 Flange Nyloc

9 452438 2 Nut, M12-1.75 Flange Nyloc

10 819028 1 Mount, Air Cleaner

11 4395230 1 Air Cleaner

12 450392 2 Washer, M12 x 24 x 2.7

001925570 2 Clamp, 45-60 mm Hose

5000913 1 • Element, Air Filter

5000912 1 • Cover, Assembly

5000914 1 • Valve, Vactuator

> Change from previous revision

25

Page 40

TR320

1

1

2

2

3

4

5

6

7

8

9

9

10

11

12

14

14

24

16

17

18

19

19

20

20

20

20

21

21

21

22

25

25

26

26

22

23

23

23

27

18

009034880

16

21

23

21

15

15

15

13

12.1 Radiator

Serial No. All

26

Page 41

TR320

Item Part No. Qty. Description Serial Numbers/Notes

1

2 108094-06 2 Hose Clamp

3 4123826 1 Expansion Tank

4 4348026 1 Fan, Electric 16 in. PWM REFERENCE M3, See 46.1

5 4399308 1 Shroud, Rear Radiator

6 4359066 1 Hose, Upper Expansion Tank

7 4359067 1 Hose, Lower Expansion Tank

8 4376688 1 Radiator and Hydraulic Oil Cooler

9 4378487 4 Spacer, Fan

10 4385186 1 Bracket, Expansion Tank

11 4399443 1 Shroud, Front Radiator

12 4394906 1 Seal, Radiator Foam

13 450000 1 Screw, M6-1 x 25 mm Hex Head

14 450008 4 Screw, M6-1 x 55 mm Hex Head

15 450191 5 Screw, M8-1.25 x 20 mm Hex Head

16 450192 6 Screw, M8-1.25 x 25 mm Hex Head

17 450323 1 Nut, M6-1 Hex

18 450324 3 Nut, M8-1.25 Hex

19 450357 4 Nut, M6-1 Insert (0.7 to 4.2)

20 450389 6 Flat Washer, M6 x 12.5 x 1.8

21 450390 11 Flat Washer, M8 x 17 x 1.8

22 450410 4 Lockwasher, M6 x 9.6 x 1.5

23 450411 10 Lockwasher, M8 x 12.75 x 2

24 4365086 1 Cross Brace, Radiator

25 009034920 1 Decal, Hot Surface Warning

26 009034880 1 Decal, Fan Warning

27 669996 1 Wiring Bracket

28 48228-06 1 P-Clip Not Shown

001925400 2 Hose Clamp, 19-40 mm

4123828 1 • Pressure Cap, 13 psi

> Change from previous revision

27

Page 42

TR320

1

2

3

4

6

6

9

10

11

13

12

5

8

12

14

14

15

17

16

7

13.1 Remote Engine Oil Cooler and Filter

Serial No. All

28

Page 43

TR320

Item Part No. Qty. Description Serial Numbers/Notes

1

2 4133243 1 • Head, Filter

3 4113986 1 • Cartridge, Oil Filter

4 4398567 1 Fitting, -6 ORFS x M16-1.5 90°

5 450331 2 Nut, M8-1.25 Thin Hex

6 158065-03 2 Fitting, -8 ORFS x 1/2 NPTF Straight Can Use 4186441

7 4399007 1 Hose, Oil Cooler to Filter

8 672486 1 Panel, Radiator Bottom

9 4399008 1 Hose, Filter to Engine

10 4396366 1 Fitting, -6 ORFS x M16-1.5 Straight

11 672598 1 Shroud, Front Radiator

12 2198084 2 • Latch, Swell

13 4399434 2 • Shroud Front

14 4399229 2 Trim, 150 cm

15 450191 2 Screw, M8-1.25 x 20 mm Hex Head

16 450411 2 Lockwasher, M8 x 12.5 x 2

17 450390 2 Washer, M8 x 17 x 1.8

4399316 1 Engine, Kubota D1105-E4B

339909 1 • O-Ring, -6 ORFS

339910 1 • O-Ring, -8 ORFS

339909 1 • O-Ring, -6 ORFS

672591 1 Shroud, Front Assembly

> Change from previous revision

29

Page 44

TR320

1

Part of

Item 1

2

3

4

4

4

5

6

6

6

6

7

7

7

7

7

8

8

8

8

9

9

9

10

10

11

11

11

12

12

13

13

13

13

14

16

15

17

25

9

View Rotated 180° For Clarity

18

26

27

19

19

20

21

22

24

9

16

23

28

14.1 Engine Mounting

Serial No. All

30

Page 45

TR320

Item Part No. Qty. Description Serial Numbers/Notes

1

2 4244831 1 Hose, Radiator

3 4359048 1 Hose, Upper Radiator

4 4358026 3 Mount, Engine

5 4377767 1 Bracket, Engine Subframe

6 450193 4 Screw, M8-1.25 x 30 mm Hex Head

7 450389 9 Washer, M6 x 12.5 x 1.8

8 450390 4 Washer, M8 x 17 x 1.8

9 450410 8 Lockwasher, M6 x 9.6 x 1.5

10 450411 2 Lockwasher, M8 x 12.75 x 2

11 452435 6 Nut, M6-1 Flange Nyloc

12 452436 2 Nut, M8-1.25 Flange Nyloc

13 450172 7 Screw, M6-1 x 25 mm Hex Head

14 450377 1 Nut, M6-1 Hex Nyloc

15 450388 2 Washer, M5 x 10 x 1.1

16 450376 3 Nut, M5-0.8 Hex Nyloc

17 4393167 1 Plate, Throttle Cable

18 4306557 2 Screw, M5-0.8 Flange Button Head

19 48396 2 Hose Clamp (27-51 mm)

20 450194 1 Screw, M8-1.25 x 35 mm Hex Head

21 450006 1 Screw, M6-1 x 55 mm Hex Head

22 450005 1 Screw, M6-1 x 50 mm Hex Head

23 REF 1 Engine and Pump Assembly See 15.1

24 4395489 1 Connector, FIR Tree mounting

25 450528 1 Screw, M5-0.8 x 16 mm Pan Head

26 4399727 1 Plate, Throttle Cable

27 669840 4 Pop Rivet, 4.8 x 14 mm

28 4370167 1 Mount, Fir Tree Cable Tie

4393088 1 Lever, Engine Throttle

> Change from previous revision

31

Page 46

TR320

1

2

3

4

5

6

7

8

42

10

11

13

13

14

15

16

16

16

16

17

18

17

17

17

17

17

18

19

19

19

21

20

20

20

20

20

20

20

21

22

23

24

24

24

24

25

26

27

28

29

31

32

33

34

35

36

37

38

39

40

22

22

30

17

12

41

15

15.1 Engine and Pumps

Serial No. All

32

Page 47

TR320

Item Part No. Qty. Description Serial Numbers/Notes

1

2 006820550 2 Screw, M10-1.25 x 30 mm Hex Head

3 4395240 1 Coupling, 13 Tooth

4 4203740 1 Pump, LPV 35 cc Piston See 44.1 for Service Parts

5 4399316 1 Engine, Kubota D1105-E4B

6 553842 1 • Screw, M6 x 50 mm

7 4396226 1 Mount, Engine

8 4377606 1 Mount, Rear Engine

9 4387056 1 Bracket, Exhaust

10 450190 2 Screw, M8-1.25 x 16 mm Hex Head

11 450193 4 Screw, M8-1.25 x 30 mm Hex Head

12 4370167 1 Mount, Fir Tree Cable Tie

13 450242 5 Screw, M12-1.75 x 35 mm Hex Head

14 450358 2 Nut, M6-1 Insert (4.2-6.6)

15 450389 3 Washer, M6 x 12.5 x 1.8

16 450390 8 Washer, M8 x 17 x 1.8

17 450391 14 Washer, M10 x 21 x 2.2

18 450392 5 Washer, M12 x 24 x 2.7

19 450411 7 Lockwasher, M8 x 12.75 x 2

20 450412 17 Lockwasher, M10 x 15.9 x 2.5

21 450413 5 Lockwasher, M12 x 17.9 x 2.5

22 452435 8 Nut, M6-1 Flange Nyloc

23 452437 1 Nut, M10-1.5 Flange Nyloc

24 452751 10 Screw, M10-1.25 x 25 mm Hex Head

25 450172 2 Screw, M6-1 x 25 mm Hex Head

26 450376 2 Nut, M5-0.8 Nyloc Hex

27 4395239 1 Bell Housing

28 450378 1 Nut, M8-1.25 Nyloc Hex

29 450195 1 Screw, M8-1.25 x 40 mm Hex Head

30 4395489 2 Saddle Clip, Cable Tie Mount

31 450528 2 Screw, M5-0.8 x 16 Pan Head

32 4399299 1 Mount, Front Engine

33 4399300 1 Bracket, Exhaust

34 4399301 1 Guard, Belt

35 4398946 1 Bracket, Oil and Fuel Filter

36 4139045 1 P-Clip, 1 5/16 Dia Remote Filter Hose

37 450214 1 Screw, M10-1.5 x 25 mm Hex Head

38 002211520 1 O-Ring, 82.22 ID x 2.62 Section

39 456110448 2 Screw, 3/8-16 x 1-1/4 Hex Head

40 4134071 1 Pump, 2 Section Gear See 43.1 for Service Parts

41 450323 1 Nut, M6-1 Hex

42

400318 3 Screw, M10-1.25 x 30 mm SHCS

4113986

1 Engine Oil Filter

> Change from previous revision

33

Page 48

TR320

1

2

3

4

5

5

6

7

8

9

10

11

11

12

13

14

14

15

16

17

17

17

18

19

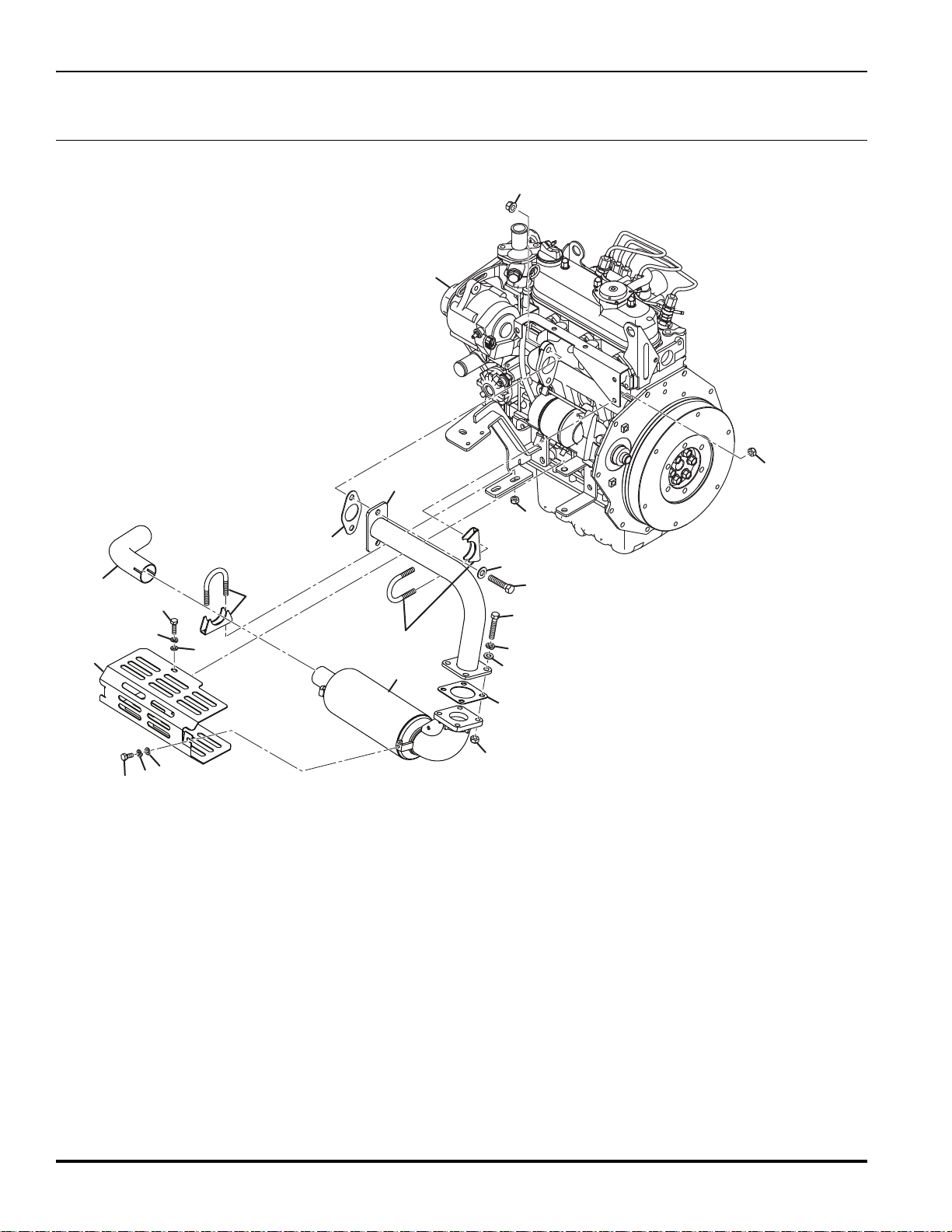

16.1 Engine Exhaust

Serial No. All

34

Page 49

TR320

Item Part No. Qty. Description Serial Numbers/Notes

1

2 1 • Gasket, Exhaust

3 1 • Gasket, Muffler

41•Muffler

5 001990072 2 U-Clamp, M8-1.25 x 38 mm

6 4378129 1 Head, Pipe

7 4387057 1 Cover, Exhaust

8 450168 2 Screw, M6-1 x 12 mm Hex Head

9 450171 2 Screw, M6-1 x 16 mm Hex Head

10 450216 2 Screw, M10-1.5 x 35 mm Hex Head

11 450389 4 Washer, M6 x 12.5 x 1.8

12 450390 4 Washer, M8 x 17 x 1.8

13 450391 2 Washer, M10 x 21 x 2.2

14 450410 4 Lockwasher, M6 x 9.6 x 1.5

15 450411 4 Lockwasher, M8 x 12.75 x 2

16 450194 4 Screw, M8-1.25 x 35 mm Hex Head

17 001339050 8 Nut, M8-1.25 Hex Staytite

18 450454 2 Nut, M10-1.5 Hex Flange

19 4378128 1 Tailpipe

4399316 1 Engine, Kubota D1105-E4B

> Change from previous revision

35

Page 50

TR320

A

B

A

B

1

2

10

4

5

5

5

6

7

8

9

42

11

12

12

13

13

14

14

15

16

17

18

19

20

21

22

23

24

25

26

27

27

28

28

29

30

30

31

31

31

31

31

31

31

31

31

32

33

34

35

41

41

36

37

38

39

40

S≤ 15 mg/kg

4324674

18

17.1 Fuel Tank and Routing

Serial No. All

36

Page 51

TR320

Item Part No. Qty. Description Serial Numbers/Notes

1

2 4387306 1 Vent Tube

3 4354952 1 Tank, Diesel Fuel

4 4287174 1 • Cap, Fuel Tank

5 672550 3 • Grommet

6 4291031 1 • Fitting, 1/4 Straight Barb

7 4382366 1 • Gauge, Fuel Level

8 4379146 1 • Tube, Fuel Pick Up 80 Mesh Screen On End

9 4386486 1 • Tube, Fuel Return Line

10 4379626 1 • Tank, Diesel Fuel

11 450214 2 Screw, M10-1.5 x 25 mm Hex Head

12 450389 3 Washer, M6 x 12.5 x 1.8

13 450391 3 Washer, M10 x 21 x 2.2

14 450410 3 Lockwasher, M6 x 9.6 x 1.5

15 450412 2 Lockwasher, M10 x 15.9 x 2.5

16 672728 1 Hose, Fuel Breather

17 450543 1 Screw, M6-1 x 25 mm Pan Head

18 469016509 2 P-Clip

19 4247950 1 Clip, Fuel Hose

20 452000327 1 Washer, 1/4 x 3/4 x .064

21 4384346 1 Strap, Fuel Tank See 2.1 for mounting

22 672789 1 Hose, Fuel Pump to Fuel Filter Cut Length 620 mm

23 672788 1 Hose, Tank to Pre-Filter Cut Length 900 mm

24 672790 1 Hose, Pre-Filter to Fuel Pump Cut Length 110 mm

25 672787 1 Hose, Fuel Filter to Engine Cut Length 665 mm

26 450172 1 Screw, M6-1 x 25 mm Hex Head

27 450390 3 Washer, M8 x 17 x 1.8

28 450411 3 Lockwasher, M8 x 12.75 x 2

29 452435 1 Nut, M6-1 Flange Nyloc

30 452436 3 Nut, M8-1.25 Flange Nyloc

31 4283232 10 Clamp, Hose (9.5-12 mm)

32 450194 2 Screw, M8-1.25 x 35 mm Hex Head

33 450192 1 Screw, M8-1.25 x 25 mm Hex Head

34 450454 1 Nut, M10-1.5 Hex Flange

35 4344103 1 P-Clip, 48 mm Rubber Sleeve

36 450213 1 Screw, M10-1.5 x 20 mm Hex Head

37 1 Fuel Pre-Filter

38 1 Fuel Pump REFERENCE M2, See 46.1

39 1 Fuel Filter

40 672715 1 Cut Length 1370 mm

41 4324674 1

42 450170 2

002497040 1 Breather

5001182

5001948

5001189

2500809

• Cartridge, Fuel Filter

1

Hose, Engine Return to Tank

Decal, Fuel

Screw, M6-1 x 16 mm Hex Head

> Change from previous revision

37

Page 52

TR320

23

2

2

2

3

3

3

3

4

4

4

4

4

5

5

6

7

8

9

10

11

12

14

15

15

15

16

16

17

17

18

19

20

25

26

21

22

22

24

TR320

B

I

O

D

E

G

R

A

D

A

B

L

E

F

L

U

I

D

21

13

15

1

2

15

17

27

28

18.1 Hydraulic Tank and Hood

Serial No. All

38

Page 53

TR320

Item Part No. Qty. Description Serial Numbers/Notes

1

2 450214 9 Screw, M10-1.5 x 25 mm Hex Head

3 450412 9 Lockwasher, M10 x 15.9 x 2.5

4 001599264 10 Washer, 25/64 x 1 x .106

5 4312406 2 Hinge, Dies Cast Zinc

6 4363146 1 Bracket, Hood Mount

7 4354951 1 Tank, Hydraulic

8 4370752 1 • Breather, Filter

9 4394849 1 • Strainer, Suction

10 671857 1 Lanyard, Hood

11 669840 4 Pop Rivet, 4.8 x 14

12 2198112 1 Draw Latch

13 N/S 1 • Latch, Keeper

14 4356728 1 Hood, Engine

15 450387 14 Washer, M4 x 9 x 0.9

16 450520 4 Screw, M4-0.7 x 20 mm Pan Head

17 452717 10 Nut, M4-0.7 Hex Nyloc

18 MBG6720 1 Bracket, Hood Latch

19 4334427 4 Screw, M6-1 x 20 mm Button Head

20 450452 4 Nut, M6-1 Hex Flange

21 4111408 1 Decal, Bio-Fluid

22 4164860 1 Decal, Hydraulic Fluid

23 450454 1 Nut, M10-1.5 Hex Flange

24 450477 1 Screw, M10-1.5 x 20 mm Hex Flange

25 4397106 2 Decal, Jacobsen

26 4399347 2 Decal, TR320

27 4389850 1 Cargo Net, Hood

28 450519 6 Screw, M4-0.7 x 16 mm Pan Head

450620 4 Screw, M6-1 x 20 mm Countersunk

339904 1 • • O-Ring, -32 ORB

> Change from previous revision

39

Page 54

TR320

1

2

3

3

3

4

5

6

7

8

9

10

11

12

13

14

15

21

22

16

17

19

20

3

18

18

19.1 Hydraulic Valve Assembly

Serial No. All

40

Page 55

TR320

Item Part No. Qty. Description Serial Numbers/Notes

1

2 450170 2 Screw, M6-1 x 16 mm Hex Head

3 450389 15 Washer, M6 x 12.5 x 1.8

4 4395287 1 Filter, Charge

5 450412 4 Lockwasher, M10 x 15.9 x 2.5

6 452000326 4 Washer, 3/8 x 3/4 x .072

7 456110066 4 Screw, 3/8-16 x 1” Hex Head

8 2811364 1 Steering Wheel

9 2811365 1 • Cap, Steering Wheel

10 4198282 1 Steering Column

11 450020338 1 • Nut, 5/8-18 Thin Hex

12 4375586 1 • Bellows

13 4375587 1 • Cover, Foot Pedal

14 450377 2 Nut, M6-1 Hex Nyloc

15 4393849 1 Valve, Steering See 42.1 for Service Parts

16 4394670 1 Manifold, Drain Header

17 4394753 1 Bracket, Drain Manifold

18 450737 4 Screw, M10-1.5 x 20 mm

1

9 450172 2 Screw, M6-1 x 25 mm Hex Head

20 452435 2 Nut, M6-1 Flange Nyloc

21 450712 4 Screw, M6-1 x 20

2

2 450410 4 Lockwasher, M6 x 9.6 x 1.

4201021 1 Valve, Brake See 35.1 for Service Parts

2811255 1 • Cartridge, Filter Element

4395269 1 • Filter Head with Indicator

4395531 1 • • Indicator, Filter Service

4278451 1 • Kit, Gas Spring Pivot

4399466 1 • Kit, Steering Column Pivot

4397006 1 • Kit, Steering Column Pivot

4270219 1 • Kit, Universal Joint Service

4280351 1 • Gas Spring

SHCS

mm SHCS

5

> Change from previous revision

41

Page 56

TR320

14

14

Port L

Port R

Drain Tube

(Port 1)

Brake Tube

(Port X)

Port B

Port A

Rear Wheel

Motor Ports

6

6

6

11

13

12

6

1

2

3

16

4

10

10

9

8

7

7

5

2

15

15

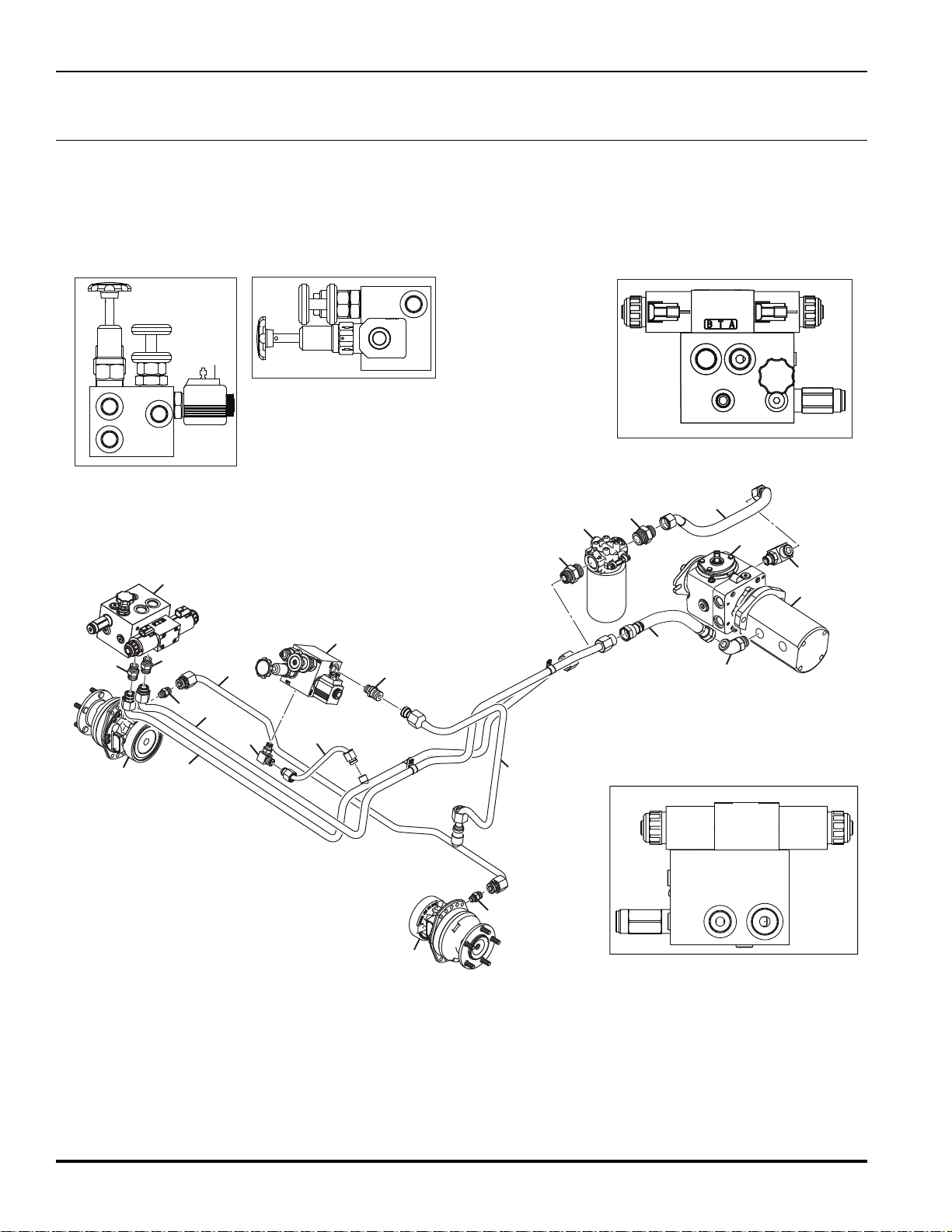

20.1 3WD Traction Hydraulics

Serial No. All

42

Page 57

TR320

Item Part No. Qty. Description Serial Numbers/Notes

1

2 340036 2 Fitting, -12 ORFS x -12 ORB 45°

3 4391257 1 Hose, Transmission Pressure Line Traction Pump Port B

4 4391006 1 Tube, Transmission Pressure Line

5 4390473 1 Tube, Front Motor Return Line

6 339989 4 Fitting, -10 ORFS x -10 ORB Straight

7 4379926 2 Wheel Motor, 235 cc See 8.1

8 4391026 1 Tube, Front Motor Transmission Line Left Motor Port L

9 4398266 1 Tube, Transmission Line Front Motors Right Motor Port L

10 340122 2 Fitting, -12 ORB Swivel Run Tee

11 4398746 1 Hose, Rear Motor Pressure Rear Motor Port A

12 4379887 1

13 4398747 1 Hose, Rear Motor Return Rear Motor Port B

14 339993 2 Fitting, -12 ORFS x -10 OR

15 4391566 2 Hose, Front Motor Transmission Line

16 4391258 1 Hose, Transmission Return Line Traction Pump Port A

4203740 1 Pump, LPV 35 cc Piston

339912 1 • O-Ring, -12 ORFS

339900 1 • O-Ring, -12 ORB

339911 1 • O-Ring, -10 ORFS

339899 1 • O-Ring, -10 ORB

339912 2 • O-Ring, -12 ORFS

3

Motor, 28.7 in

33

9912 1 • O-Ring, -1

9899 1 • O-Ring, -1

33

Wheel

2 ORFS

0 ORB

B

> Change from previous revision

43

Page 58

TR320

R

L

P

T

E

Hose (20)

To Lift Valve Port P

Hose (15)

From Pump

Hose (21)

To Lift Valve Port T

Steering Valve viewed from end

Hose (18)

To Steering Cylinder

Hose (17)

To Steering Cylinder

Front and Rear Reel Valve

Viewed From Rear

TP

2

1

3

4

5

6

17

7

15

16

15

8

14

9

10

11

12

13

21.1 3WD Gear Pump and Steering Hydraulics

Serial No. All

44

Page 59

TR320

Item Part No. Qty. Description Serial Numbers/Notes

1

2

3

4

5 339999 1 Fitting, 90° 16-16 Straight Thread

6 340030 1 Fitting, 45° 8-10 Straight Thread

7 4371126 1 Hose, Pump to Steeri

8 4391206 1 • Hose, Steering Valve to Cylinder Valve Port L, Cylinder Left Port

9 4391206 1 • Hose, Cylinder to Steering Valve Cylinder Right Port, Valve Port R

10 4399268 1 Tube, Pressure Line - Lift Valve

11 4399271 1 Tube, Return Line - Steering Valve

12 340062 1 Fitting, 90° 6-8 Straight Thread

13 4169021 1 Weight Transfer And Lift Valve

14 4393849 1 Valve, Steering

15 339972 2 Fitting, -4 ORFS x -4 ORB Straight

16 4244289 1 Steering Cylinder See 39.1 for Service Parts

4354951 1 Tank, Hydraulic

4394849 1 • Strainer, Suction

339

904 1 • • O-Ring, -3

340001 1 Fitting, -20 ORFS x -2

339

914 1 • O-Ring, -2

902 1 • O-Ring, -2

339

4391256 1 Hose, Tank Suction Line

4396209 1 Bundle, 3WD Steering Hose

339908 1 • O-Ring, -4 ORFS

339896 1 • O-Ring, -4 ORB

2 ORB

0 ORB

0 ORFS

0 ORB

ng Valve

Steering Valve Port P

> Change from previous revision

45

Page 60

TR320

1

3

4

5

6

7

11

8

9

10

10

10

10

1

1

2

10

10

22.1 Front And Rear Reel Hydraulics

Serial No. All

46

Page 61

TR320

Item Part No. Qty. Description Serial Numbers/Notes

1

2 4355571 1 Valve, Reel See 36.1

3 4391087 1 Hose, Pressure Line Rear Unit

4 4391086 1 Hose, Pressure Line Front RH Unit

5 4391088 1 Hose, Return Line Rear Unit

6 4399579 1 Tube, Return Line Cutter Unit

7 4399578 1 Tube, Pressure Line Cutter Unit

8 339985 1 Fitting, -8 ORFS x -10 ORB Straight

9

10 340067 6 Fitting, -8 ORFS x -10 ORB 90°

1

1 4391084 1 Hose, Pressure Line Front LH Unit

4140034 3 Motor, Reel See 24.1

339910 1 • O-Ring, -8

33

9899 1 • O-Ring, -1

340070 1 Fitting, 10-10 Straight Thread 90°

339910 1 • O-Ring, -8

33

9899 1 • O-Ring, -1

ORFS

0 ORB

ORFS

0 ORB

> Change from previous revision

47

Page 62

TR320

5

6

7

8

5

5

5

10

3

4

1

9

9

2

Lift Valve

Viewed From Front

CR

L

A

B

2

23.1 Front And Rear Lift Hydraulics

Serial No. All

48

Page 63

TR320

Item Part No. Qty. Description Serial Numbers/Notes

1

2 669395 2 Cylinder, Lift See 40.1 for Service Parts

3 4390979 1 Hose, Lift Arm Front LH

4 4399747 1 Hose, LIft Arm Front RH

5 340061 5 Fitting, -6 ORFS x -6 ORB 90°

6

7 4391047 1 Hose, Lift Ar

8 670815 1 Cylinder, Lift Rear

9 4287311 3 Disk, Orifice (0.029 Dia)

10 337317 1 Fitting, One Way Orif

4169021 1 Weight Transfer And Lift Valve See 37.1 for Service Parts

339909 1 • O-Ring, -6

33

9897 1 • O-Ring, -6

4186000 1 Fitting, 11/16 ORS

ORFS

ORB

m

Rear Unit

ice

> Change from previous revision

49

Page 64

TR320

1

21

22

8

6

1

1

6

T

4

Lift Valve Viewed From Rear

Port L

Port R

Drain Tube

(Port 1)

Brake Tube

(Port X)

Brake Valve

Viewed From Bottom

CHG

DR

PB1

CHG

DR

PB1

23

23

26

2

3

4

17

20

18

16

24

5

3

7

19

10

11

12

13

14

9

15

20

13

25

5

5

24.1 Drain Hydraulics

Serial No. All

50

Page 65

TR320

Item Part No. Qty. Description Serial Numbers/Notes

1

2 4201021 1 Valve, Brake See 35.1 for Service Parts

3 4379926 2 Wheel Motor, 235cc See 8.1

4 4169021 1 Weight Transfer And Lift Valve See 37.1 for Service Parts

5 339977 3 Fitting, -6 ORFS x -4 ORB Straight

6

7 4391082 1 Hose, Drain Line Front RH Unit

8 4383826 1 Tube, Manifold to Tank

9 4287314 1 Disk, Orifice (0.070 Dia)

10 4390644 1 Tube, Front Motor Drain Feeder Line

11 4390643 1 Tube, Front Motor Drain Line

12 4399271 1 Tube, Return Line - Steering Valve

13 339980 2 Fitting, -6 ORFS x -8 ORB Straight

4 340097 1 Fitting, M-Tee

1

15 4399269 1 Tube, Bypass Line Lift Valve

16 340067 1 Fitting, -8 ORFS x -10 ORB 90°

17

18 4391080 1 Hose, Drain Line Rear Unit

19 4391081 1 Hose, Drain Line Front LH Unit

20 340061 2 Fitting, -6 ORFS x -6 ORB 90

1 339984 1 Fitting, -8 ORFS x -8 ORB Straight

2

2

2 339980 1 Fitting, -6 ORFS x -8 ORB Straight

2

3 339979 3 Fitting, -6 ORFS x -6 ORB Straight

24

25 4394670 1 Header Manifold

26 4398306 1 Tube, Return Line Lift Valve

4140034 3 Motor, Reel

339909 1 • O-Ring, -6 ORFS

339896 1 • O-Ring, -4

340263 1 Fitting, 6-6 Straight Thread

339909 1 • O-Ring, -6

33

9898 1 • O-Ring, -8

339910 1 • O-Ring, -8

33

9899 1 • O-Ring, -1

4390640 1 Tube, Brake Valve Drain Line

33

9909 1 • O-Ring, -6

9897 1 • O-Ring, -6

33

339910 1 • O-Ring, -8

9898 1 • O-Ring, -8

33

339909 1 • O-Ring, -6

9898 1 • O-Ring, -8

33

339909 1 • O-Ring, -6

33

9897 1 • O-Ring, -6

4354951 1 Tank,

Hydraulic Se

ORB

ORFS

ORB

ORFS

0 ORB

ORFS

ORB

ORFS

ORB

ORFS

ORB

ORFS

ORB

°

e 18.1

> Change from previous revision

51

Page 66

TR320

8

8

Reel Valve Viewed From Rear

TP

Brake Valve

Viewed From Bottom

Brake Valve

Viewed From Left

CHG

DR

PB1

PB2

7

7

1

3

7

2

5

6

19

19

4

9

10

11

13

15

16

14

14

12

18

A

Reel Valve Viewed From Front

B

G

17

25.1 Brake Valve and Charge Hydraulics

Serial No. All

52

Page 67

TR320

Item Part No. Qty. Description Serial Numbers/Notes

1

2 4201021 1 Valve, Brake See 35.1 for Service Parts

3 4391338 1 Tube, Brake Line LH Front Motor

4 4390638 1 Tube, Brake Pressure Line

5 4390635 1 Tube, Cutter Valve Pressure Line

6 4390462 1 Hose, Cutter Valve to Filter

7 339979 3 Fitting, -6 ORFS x -6 ORB Straight

8 4379926 2 Wheel Motor, 235 cc See 8.1

9 4134071 1 Pump, Cutter And Steering

10 4203740 1 Pump, LPV 35 cc Piston

11 4398146 1 Hose, Return Line - Charge Filter

12 340074 1 Fitting, -12 ORFS x -10 OR

13 4395287 1 Filter, Charge

14 339996 2 Fitting, -12 ORFS x -16 OR

15 4391266 1 Hose, Cutter Valve Pressure Line

16 340033 1 Fitting, 45 Deg 10-10 Straight Thread

17 4390639 1 Tube, Brake Valve to Charge Filter

18 340061 1 Fitting, -6 ORFS x -6 ORB 90

1

9 339989 2 Fitting, -10 ORFS x -10 ORB Straight

4355571 1 Valve, Reel See 36.1 for Service Parts

339909 1 • O-Ring, -6

33

9897 1 • O-Ring, -6 ORB

33

9912 1 • O-Ring, -12 ORFS

339900 1 • O-Ring, -12 ORB

2811255 1 • Cartridge, Filter Element

4395269 1 • Filter Head with Indicator

4395531 1 • • Indicator, Filter Service

33

9912 1 • O-Ring, -12 ORFS

339901 1 • O-Ring, -16 ORB

9909 1 • O-Ring, -6

33

9897 1 • O-Ring, -6

33

339911 1 • O-Ring, -1

33

9899 1 • O-Ring, -1

ORFS

B

B

°

ORFS

ORB

0 ORFS

0 ORB

> Change from previous revision

53

Page 68

TR320

7

5

4

14

3

2

6

1

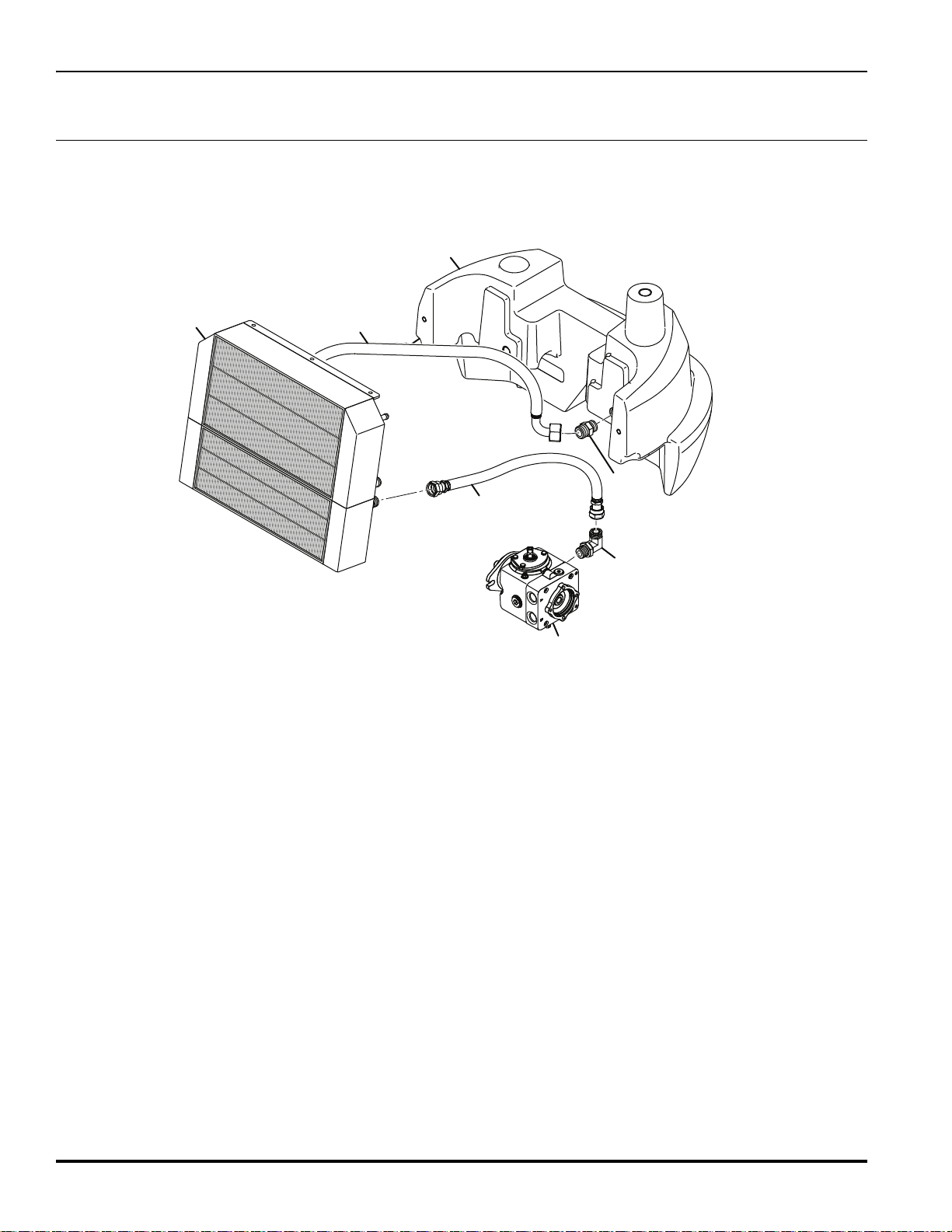

26.1 Oil Cooler Hydraulics

Serial No. All

54

Page 69

TR320

Item Part No. Qty. Description Serial Numbers/Notes

1

2 4391186 1 Hose, Cooler Return Line

3 4391546 1 Hose, Cooler inlet Line

4 339994 1 Fitting, 12 - 12 Straight Thread

5 340074 1 Fitting, -12 ORFS x -12 ORB 90°

6

7

4354951 1 Tank, Hydraulic See 18.1

339912 1 • O-Ring, -1

33

9900 1 • O-Ring, -1

4376688 1 Radiator

4203740 1 Pump, LPV 35 cc

2 ORFS

2 ORB

and Hydraulic Oil Cooler

Piston Se

e 44.1 for Service Parts

> Change from previous revision

55

Page 70

TR320

K1

F10

K3

15 20

F7

F4

K4

20 10

F8

F6

30

F5

K2

30

F3

40

F2

30

F9

K1-K14

F1, F2, F4

25

8

15

F7, F8, F11, F12

5

10

F6, F9

4

6

F5, F10

30

7

1

1

2

12

15

16

17

18

19

20

21

22

24

25

26

27

28

29

30

31

32