Page 1

6DIHW\2SHUDWLRQ0DQXDO

.l\WW|MDWXUYDOOLVXXVRKMHHW

AR-5

68080 – AR-5, Kubota V2003-M-T, 5 Gang, 4WD

4133107-FI

VAROITUS: Laitteen virheellinen käyttö voi aiheuttaa vakavia

vahinkoja. Laitteen käyttäjille ja huoltajille on opetettava laitteen

asianmukainen käyttö, heitä on varoitettava mahdollisista

vaaroista ja heidän on luettava koko käyttöopas ennen laitteen

valmistelua, käyttöä, säätämistä ja huoltamista.

WARNING:If incorrectly used, this machine can cause severe injury. Those who

use and maintain this machine should be trained in its proper use, warned of its

dangers and should read the entire manual before attempting to set up, operate,

adjust or service the machine.

Page 2

FORWORD

This manual contains Safety and Operating instructi on s fo r

your new Jacobsen machine. A Parts & Maintenance

Manual has also been included that contains adjustment,

maintenance, troubleshooting instructions and parts list.

Both manuals should be stored in the literature pouch

behind the seat for reference during operation.

Before you operate your machine, you and each operator

you employ should read both manuals carefully in their

entirety. By following the safety, operating and maintenance

instructions, you will prolong the life of your mower and

maintain its maximum efficiency.

If additional information is needed, contact your Jacobsen

Dealer.

CONTENTS

CONTENTS

CONTENTS

SAFETY

1.1 Operating Safety . . . . . . . . . . . . . . . . . . . . . . 3

1.2 Important Safety Notes . . . . . . . . . . . . . . . . . 4

DECALS

INITIAL INSPECTION

3.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.2 Initial Inspection . . . . . . . . . . . . . . . . . . . . . . 6

CONTROLS

5.1 Icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5.2 Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.3 Control Panel . . . . . . . . . . . . . . . . . . . . . . . 10

5.4 Operator Alerts . . . . . . . . . . . . . . . . . . . . . . 12

The mower serial plate is located on the right frame rail,

behind the fuel tank. Jacobsen recommends you record

these numbers below for easy reference.

®

A Textron Company

CHARLOTTE, NC MADE IN U.S.A.

68080

OPERATION

6.1 Daily Inspection . . . . . . . . . . . . . . . . . . . . . .13

6.2 Interlock System . . . . . . . . . . . . . . . . . . . . .13

6.3 Operating Procedures . . . . . . . . . . . . . . . . .14

6.4 Starting . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

6.5 Stopping / Parking . . . . . . . . . . . . . . . . . . . .15

6.6 To Drive / Transport . . . . . . . . . . . . . . . . . . .16

6.7 Mowing . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

6.8 Mowing Speed . . . . . . . . . . . . . . . . . . . . . . .16

6.9 Towing / Trailering . . . . . . . . . . . . . . . . . . . .17

6.10 Hillside Operation . . . . . . . . . . . . . . . . . . . .17

6.11 Daily Maintenance . . . . . . . . . . . . . . . . . . . .18

6.12 Long Term Storage . . . . . . . . . . . . . . . . . . .19

Proposition 65 Warning

Engine exhaust from this product

contains chemicals kno wn to the State

of California to cause cancer, birth

defects, and other reproductive harm

© COPYRIGHT 2004, TEXTRON INC.

“All rights reserved, including the right to reproduce this book or portions thereof in any form”.

All information in this publication is based on information available at time of approval for printing. Jacobsen reserves the

right to make changes at any time without notice and without incurring any obligation.

LITHO IN U.S.A. 5-2004

GB-2

Page 3

SAFETY 1

!

1 SAFETY

1.1 OPERATING SAFETY _____________ ___ __ __ ___ ________________ __ ___ __________

WARNING

EQUIPMENT OPERATED IMPROPERLY OR BY UNTRAINED PERSONNEL CAN BE DANGEROUS.

Familiarize yourself with the location and proper use of all controls. Inexperienced operator’s should receive

instruction from someone familiar with the equipment before being allowed to operate the machine.

1. Safety is dependent upon the awareness, concern and

prudence of those who operate or service the equipment. Never allow minors to operate any equipment.

2. It is your responsibility to read this manual and all

publications associated with this equipment (Safety

and operation manual, engine manual, accessories

and attachments). If the operator can not read English

it is the owner’s responsibility to explain the material

contained in this manual to them.

3. Learn the proper use of the machine, the location and

purpose of all the controls and gauges before you

operate the equipment. Working with unfamiliar

equipment can lead to accidents.

4. Never allow anyone to operate or service the machine

or its attachments without proper training and

instructions; or while under the influence of alcohol or

drugs.

5. Wear all the necessary protective clothing and

personal safety devices to protect your head, eyes,

ears hands and feet. Operate the machine only in

daylight or in good artificial light.

6. Evaluate the terrain to determine what accessories and

attachments are needed to properly and safely perform

the job. Only use accessories and attachments

approved by Jacobsen.

7. Stay alert for holes in the terrain and other hidden

hazards.

8. Inspect the area where the equipment will be used.

Pick up all the debris you can find before operating.

Beware of overhead obstructions (low tree limbs,

electrical wires, etc.) and also underground obstacles

(sprinklers, pipes, tree roots, etc.) Enter a new area

cautiously. Stay alert for hidden hazards.

9. Never direct discharge of material toward bystanders,

nor allow anyone near the machine while in operation.

The owner/operator can prevent and is responsible for

injuries inflicted to themselves, to bystanders and

damage to property.

10. Do not carry passengers. Keep bystanders and pets a

safe distance away.

11. Never operate equipment that is not in perfect working

order or is without decals, guards, shields, discharge

deflectors or other protective devices securely fastened

in place.

12. Never disconnect or bypass any switch.

13. Do not change the engine governor setting or

overspeed the engine

14. Carbon monoxide in the exhaust fumes can be fatal

when inhaled. Never operate the engine without proper

ventilation or in an enclosed area.

15. Fuel is highly flammable, handle with care.

16. Keep the engine clean. Allow the engine to cool before

storing and always remove the ignition key.

17. Disengage all drives and engage parking brake before

starting the engine (motor). Start the engine only when

sitting in operator’s seat, never while standing beside

the unit.

18. Equipment must comply with the latest federal, state,

and local requirements when driven or transported on

public roads. Watch out for traffic when crossing or

operating on or near roads.

19. Local regulations may restrict the age of the operator.

20. Never use your hands to search for oil leaks. Hydraulic

fluid under pressure can penetrate the skin and cause

serious injury.

21. Operate the machine up and down the face of the

slopes (vertically), not across the face (horizontally).

22. To prevent tipping or loss of control, do not start or

stop suddenly on slopes. Reduce speed when making

sharp turns. Use caution when changing directions.

23. Always use the seat belt when operating tractors

equipped with a ROPS.

Never use a seat belt when operating tractors

without a ROPS.

24. Keep legs, arms and body inside the seating

compartment while the vehicle is in motion.

This machine is to be operated and maintained as specified in this manual and is intended for the pr ofession al

maintenance of specialized turf grasses. It is not intended for use on rough terrain or long grasses.

GB-3

Page 4

1 SAFETY

!

!

1.2 IMPORTANT SAFETY NOTES________________________________________________

This safety alert symbol is used to alert you to potential hazards.

!

DANGER - Indicates an imminently hazardous situation which, if not avoided, WILL result in death or serious injury.

WARNING - Indicates a potentially hazardous situation which, if not avoided, COULD result in death or serious injury.

CAUTION - Indicates a potentially hazardous situation which, if not avoided, MAY result in minor or moderate injury and

property damage. It may also be used to alert against unsafe practices.

For pictorial clarity, some illustrations in this manual may show shields, guards or plates open or removed. Under no

circumstances should this equipment be operated without these devices securely fastened in place

WARNING

The Interlock System on this tractor pre vents the tractor from starting un less

the brake lever is engaged, mower switch is off and traction pedal is in

neutral. The system will stop the engine if the operator leaves the seat

without engaging the parking brake or setting the mower switch off.

NEVER operate tractor unless the Interlock System is working.

WARNING

1. Before leaving the operator’s position for any reason:

a. Return traction pedal to neutral.

b. Disengage all drives.

c. Lower all implements to the ground.

d. Engage parking brake.

e. Stop engine and remove the ignition key.

2. Keep hands, feet, hair and clot hing away fr om moving parts. Wait for all

movement to stop before you clean, adjust or service the machine.

3. Keep the area of operation clear of all bystanders and pets.

4. Never carry passengers, unless a seat is provided for them.

5. Never operate mowing equipment without the discharge deflector

securely fastened in place.

By following all instructions in this manual, you will prolong the life of your machine and maintain its maximum efficiency.

Adjustments and maintenance should always be performed by a qualified technician.

If additional information or service is needed, contact your Authorized Jacobsen Dealer who is kept informed of the latest

methods to service this equipment and can provide prompt and efficient service. Use of other than original or authorized

Jacobsen parts and Accessories will void the warranty.

GB-4

Page 5

DECALS 2

2 DECALS

Familiarize yourself with the decals they are critical to the safe operation of the machine.

REPLACE DAMAGED DECALS IMMEDIATELY.

WARNING

!

1. Read operator’s manual.

Do not allow untrained

operators to use

machine.

2. Keep shields in place

and hardware securely

fastened.

3. Before you clean, adjust

or repair this equipment,

disengage all drives,

engage parking brake

and stop engine.

4. Keep hands, feet and

clothing away from

moving parts.

5. Never carry passengers.

6. Keep bystanders away.

7. Inspect hoses and fabric

covers daily. If worn or

damaged, replace with

original quality parts.

8. Do not use on slopes

greater than 20°

! ADVERTENCIA

1. Leer el manual del operador. No permitir que personas

no capacitadas para ello usen la maquina.

2. Mantener los protectores en su lugar y sus tornillos

debidamente fijados.

3. Antes de limpiar, ajustar o reparar este equipo,

apagar todas los mandos, aplicar el freno de

estacionamiento y apagar el motor.

4. Mantener las manos, los pies y la ropa alejados de las

piezas en movimiento.

5. No conducir como pasajero ni llevar pasajeros en

maquinas sin asiento para ello.

6. Mantener a las demas personas alejadas durante

el funcionamiento de la maquina.

7. Si no sabe leer ingles, solictarle a otra persona que le

lea y explique el contenido de las etiquetas y del

manual de le maquina.

340623

! WARNING

TO PREVENT POSSIBLE INJURY TO YOU OR OTHERS,

DO NOT OPERATE THIS UNIT WITH GUARD REMOVED.

521760

! DANGER

To avoid injury when working with battery:

1. Always connect the black ground (-) cable last and

remove it first.

2. Keep sparks and flames away, and avoid contact

with acid.

To avoid injury when jumping battery:

1. Connect positive (+) terminal to positive (+)

terminal.

2. Connect negative (-) terminal on good battery to

frame of vehicle that has dead battery.

3001435

DANGER

! WARNING

To prevent serious injury

never disconnect or tamper

with the seat switch.

Read manual for more information.

365339

KEEP HANDS AND FEET AWAY

! WARNING

RADIATOR IS UNDER PRESSURE. REMOVE

CAP SLOWLY TO AVOID BODILY INJURY.

365956

! WARNING

• Fit roll over protective

structure before using

this machine on slopes

greater than 14°.

• Do not use on slopes

greater than 21°.

• Keep bystanders away

835892

3002529

GB-5

Page 6

3 INITIAL INSPECTION

!

!

3 INITIAL INSPECTION

3.1 GENERAL_______________ __ ________________ _________________ __ ____________

The inspection and te sting of the unit should always be

performed by a trained technician, familiar with the

operation of this equipment.

Read each instruction completely and make sure you

understand it before proceedi ng. Stay alert for potential

hazards and obey all safety precautions.

The RIGHT and LEFT, FRONT and REAR of the

machine are referenced fr om the operator’s seat , facing

forward.

Accessories not included with this product must be

ordered separately. See instructions provided with

accessory for installation and parts.

CAUTION

Do not attempt to drive the tractor unless you are

familiar with this type of equipment and know how to

operate all controls correctly.

3.2 INITIAL INSPECTION___________________________ ________________ __ __________

CAUTION

The initial inspection should be performed only when the engine is off and all fluids are cold. Lower mowers to the

ground, engage the parking brake, Stop engine and remove ignition key.

1. Perform a visual inspection o f th e entire unit, look for

signs of wear, loose hardware, and componen ts that

may have been damaged during transport.

2. Inspect paint and decals for damage or scratches.

Decals provide important operating and safety

information. Notify d ealer and replace all m issing or

hard to read decals.

3. All fluids must be at th e full level mark with engine

cold

Check:

a. Radiator coolant level

b. Engine oil level

c. Hydraulic fluid level

4. Make sure air filter connections are tigh t and cover

is securely in place.

5. Check tires for proper inflation. Tires have been

over inflated for transport. Correct tire pressure

should be set to:

Front......................... 16 psi (111 kPa)

Rear.......................... 12 psi (86 kPa

6. Check belt tension.

[Parts & Maintenance Manual, Section 3.3]

7. Inspect battery connections and electrolyte level.

Check that battery is fully charged.

8. Check for fuel or oil leaks.

1. Inspect lube points on decks and tractor for proper

lubrication.

[Parts & Maintenance Manual, Section 6.3]

GB-6

Page 7

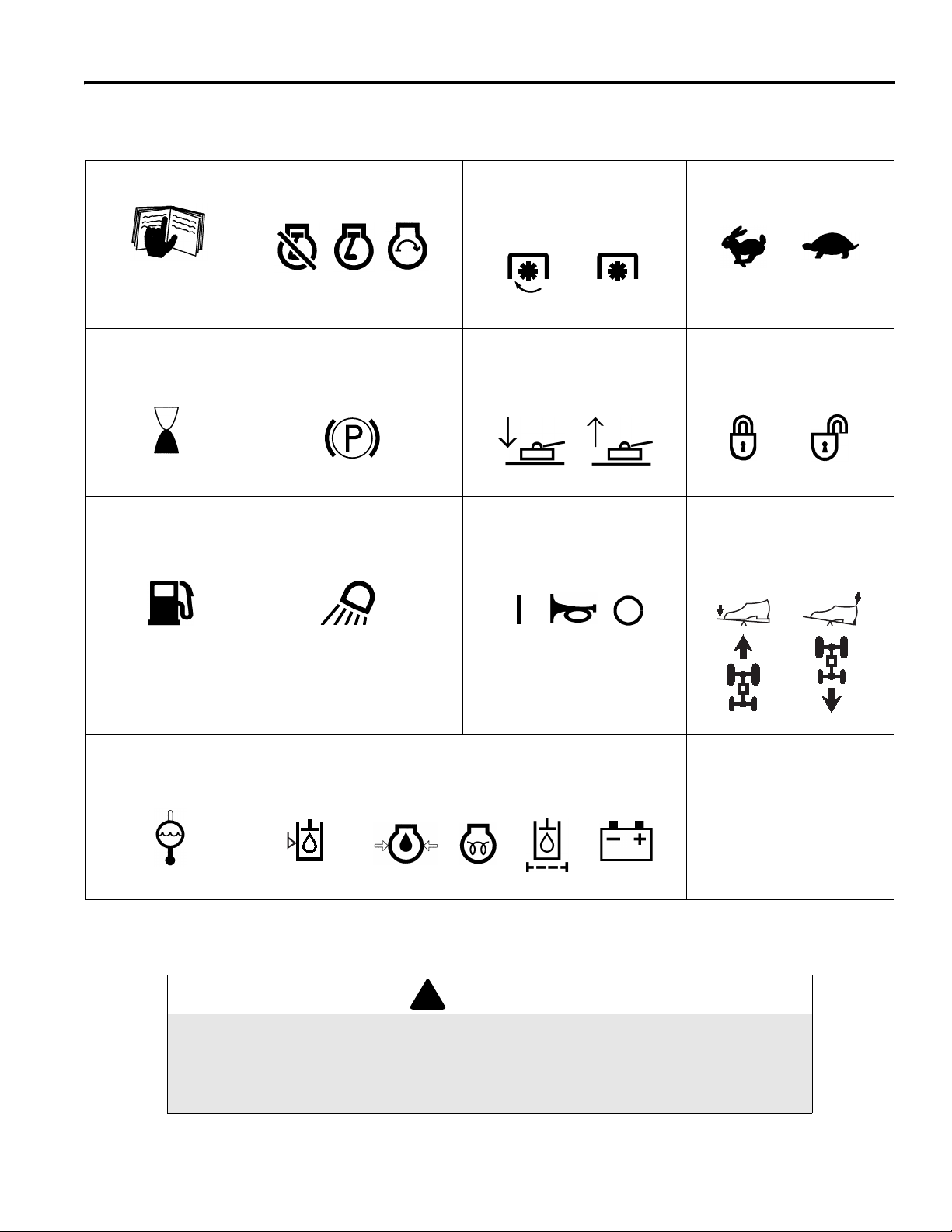

CONTROLS 4

!

4 CONTROLS

4.1 ICONS ____________ ___ __ ________________ _________________ ________________ _

Read Manual

Hour Meter

Fuel

D

Engine

Off Run

Parking Brake

Work Lights

Start

PTO

ON

Lower Raise

Oil Level Switch

On Off/Test

OFF

Mowers

Engine Throttle

High Low

Cruise Control

Lock Unlock

Travel

Forward Reverse

Coolant

Temperature

Never attempt to drive the trac tor unless you have read th e Safety and Operation Manua l

and know how to operate all controls correctly.

Familiarize yourself with the icons shown above and what they represent. Learn the

location and purpose of all the controls and gauges before operating this tractor.

Hydraulic Oil

Level

Warning Lights

Engine Oil

Pressure

Glow

Plug

Hydraulic

Oil Filter

WARNING

Battery

Charge

GB-7

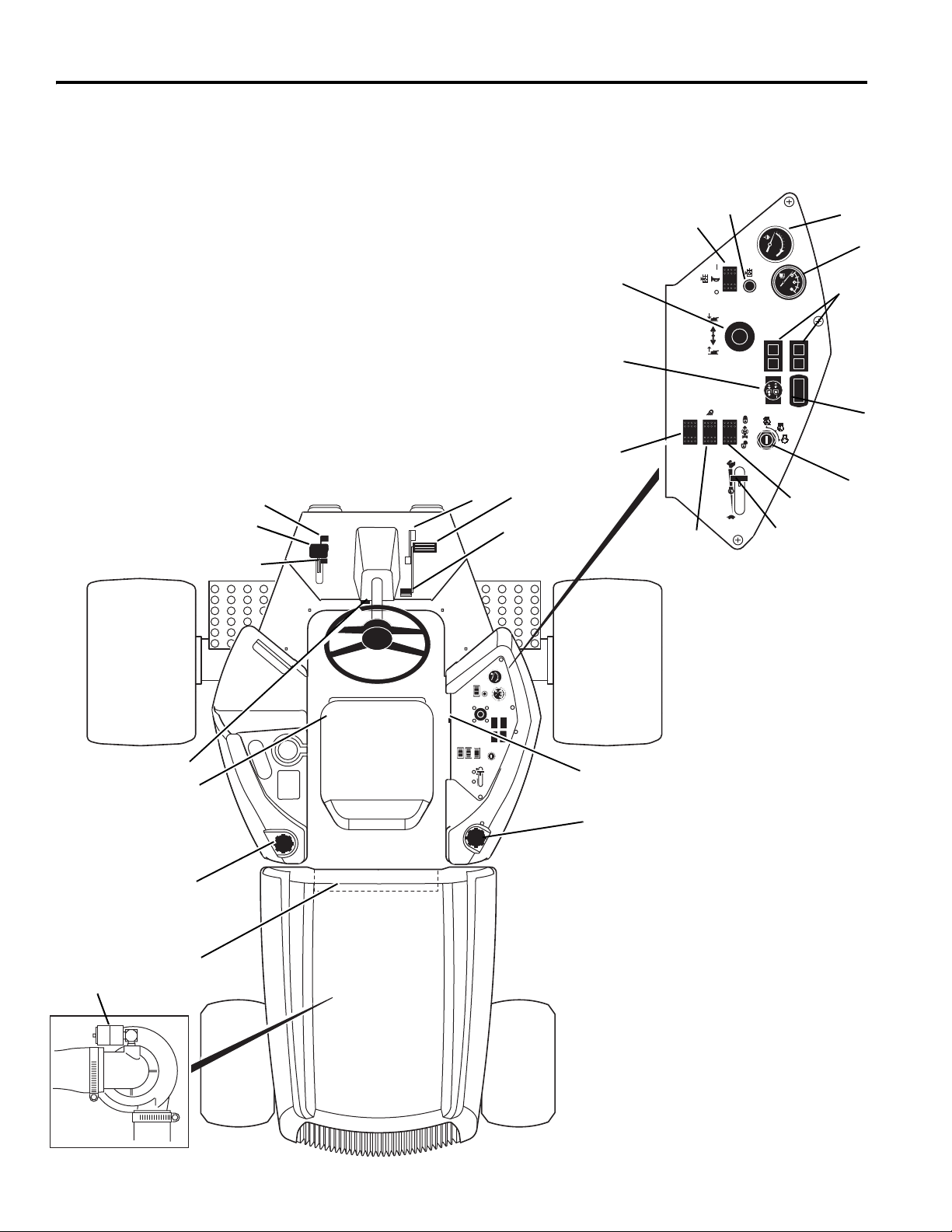

Page 8

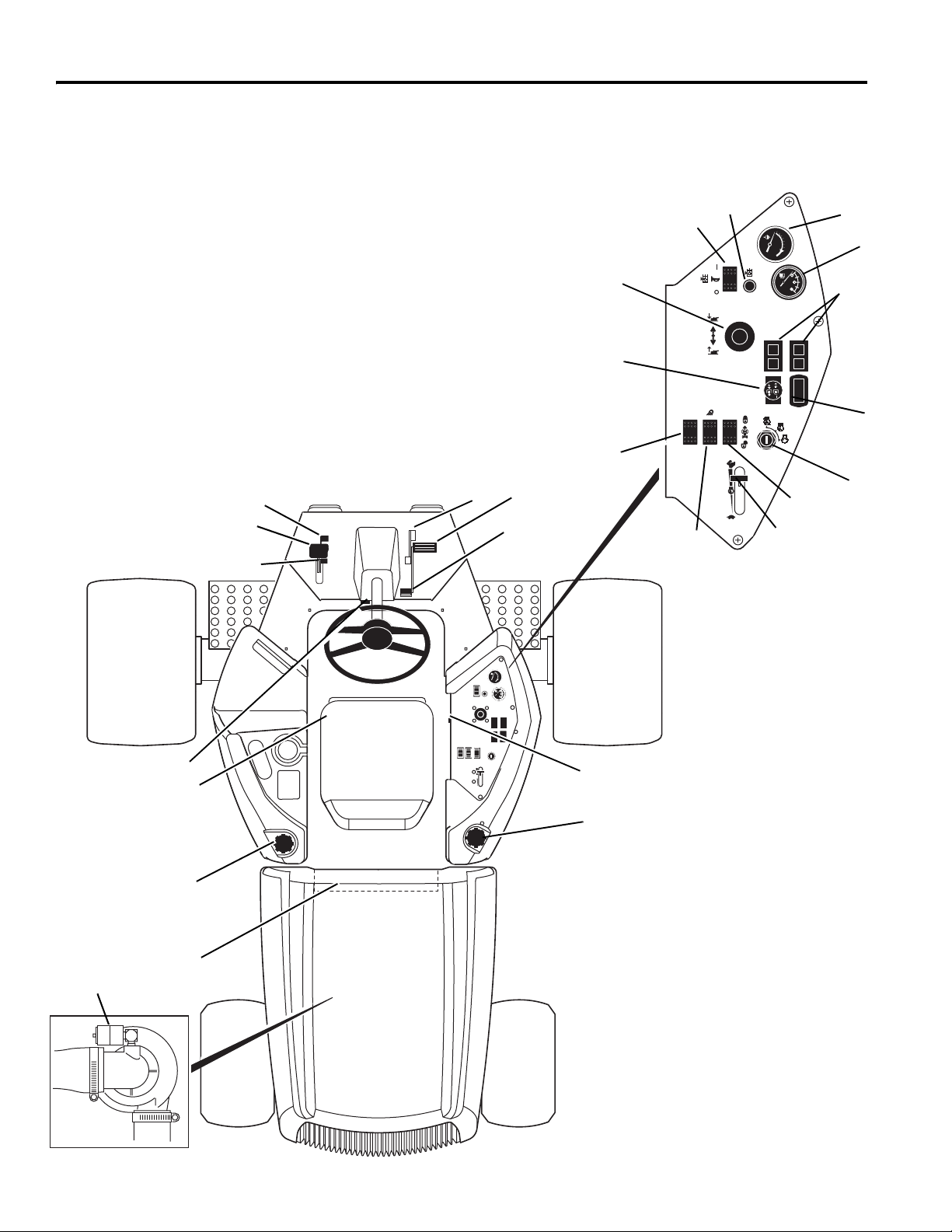

4 CONTROLS

4.2 CONTROLS ______________________________________________________________

A Tilt Steering Lever

B1 Parking Brake Lock

B2 Parking Brake Release

C Parking Brake

D

Mow Speed Stop

E Traction Pedal - Forward

F Tr action Pedal - Reverse

G

Seat Adjustment

H Hydraulic Oil Cap/Dipstick

I Fuel Cap

J Air Cleaner Indicator

K (Not Used)

L Alarm

M Controller / Fuses

N Hyd. Oil Level Light

O Hyd. Oil Level Switch

P Mower Lift Lever

B

1

C

B

2

Q PTO Switch

R Traction Control

S Light Switch

T Engine Throttle

U Cruise Control (Option)

V Ignition Switch

W Hour Meter

X Fuel Gauge

Y Warning Lights

Z Engine Coolant

Temperature

D

N

O

Z

X

P

Y

Q

W

R

V

E

F

S

U

T

GB-8

A

L

G

I

H

M

J

Page 9

CONTROLS 4

!

!

A. Steering Tilt Control

Pull lever up to release steering column. Tilt column up

or down to position desired. Release lever to lock

steering column in place.

CAUTION: Never adjust steering while trac-

tor is moving. Stop unit and set parking brake

before adjustin

B. Parking Brake Lock/Release

To lock parking brake, hold brake pedal (C) down and

press lock (B

brake pedal release (B

Note: The engine will automatically shut down if the

traction pedal is held down for more than 10 seconds

with the parking brake engaged.

) until it engages. To disengage, press

1

C. Parking Brake

To engage parking brake press pedal down.

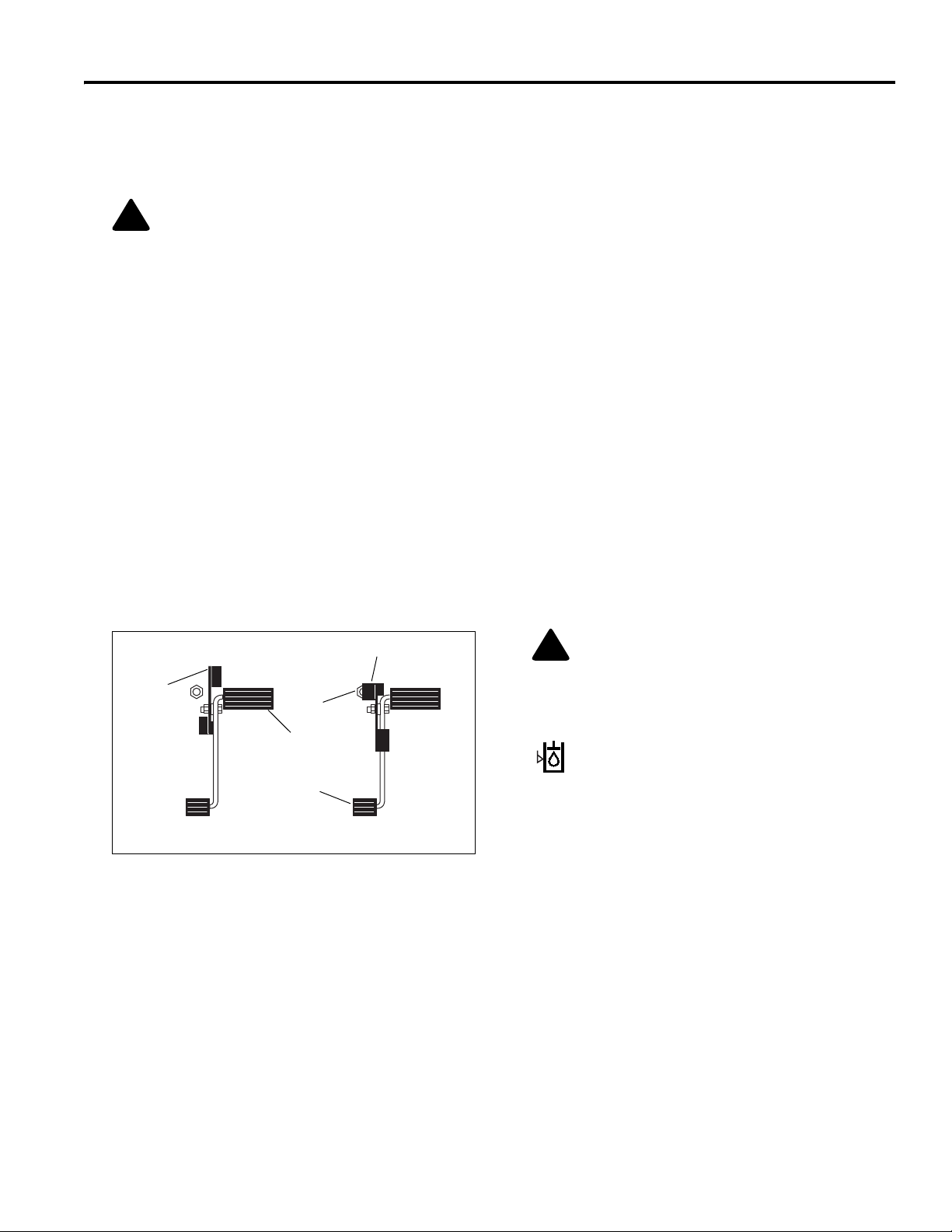

D. Mow Speed Stop

Limits forward speed while mowing. To operate at lower

travel speed while mowing, rotate lever so it contacts

stop screw (D

pedal is pressed. To travel at full speed, set lever in

position shown (D

set specific mow speeds. See Parts & Maintenance

Manual.

1

g.

).

2

) on floor board when forward travel

). Stop screw (D2) can be adjusted to

3

H. Hydraulic Oil Cap/Dipstick

Fill to mark on dipstick using clean hydraulic fluid while

machine is cool. Do not overfill

I. Fuel Cap

Fill fuel tank with No. 2 diesel fuel, minimum cetane

rating of 45. Section 5.11

J. Air Cleaner Indicator

Indicates condition of air cleaner on engine. Clean or

replace air filter when red band appears in clear window

of indicator. See Parts & Maintenance Manual

K. (Not Used)

L. Alarm

The alarm, along with the warning lights (N, Y), sounds

to alert the operator to conditions requiring immediate

attention. See Section 4.4.

M. Controller & Fuses

The controller is located under the rear hood directly

behind the operator’s seat. It is equipped with four

banks of LEDs to aid in monitoring and troubleshooting

the electrical system of the tractor. See Parts &

Maintenance Manual

Four spade type fuses are located next to the controller.

To replace fuses remove the front panel from the

controller.

D

1

D

3

D

2

E

F

Tra n sport Speed

E. Forward Travel (Traction Pedal)

Press front of pedal down for forward travel. Release

pedal to slow tractor and stop.

F. Reverse Travel (Traction Pedal)

Press rear of pedal down for reverse travel. Release

pedal to slow tractor and stop. Allow tractor to come to a

complete stop before reversing directions.

G. Seat Adjustment

Pull left side lever out to adjust seat froward or

backward. To adjust spring tension under seat turn

adjusting knob on front of seat.

Mow Speed

Figure 4A

LF002

CAUTION: Service to the electrical system

must be performed by a trained technician.

Before replacing fuses turn tractor off and

remove key from ignition.

N. Hydraulic Oil Level Light

Alerts the operator of a low fluid level in hydraulic tank. This light operates in combination with

the alarm. See Section 4.4.

Note: The warning light will remain on as long as a low

oil level is detected. If the alarm sounds due to low oil

level, it can be disabled by turning switch (O) to OFF.

GB-9

Page 10

4 CONTROLS

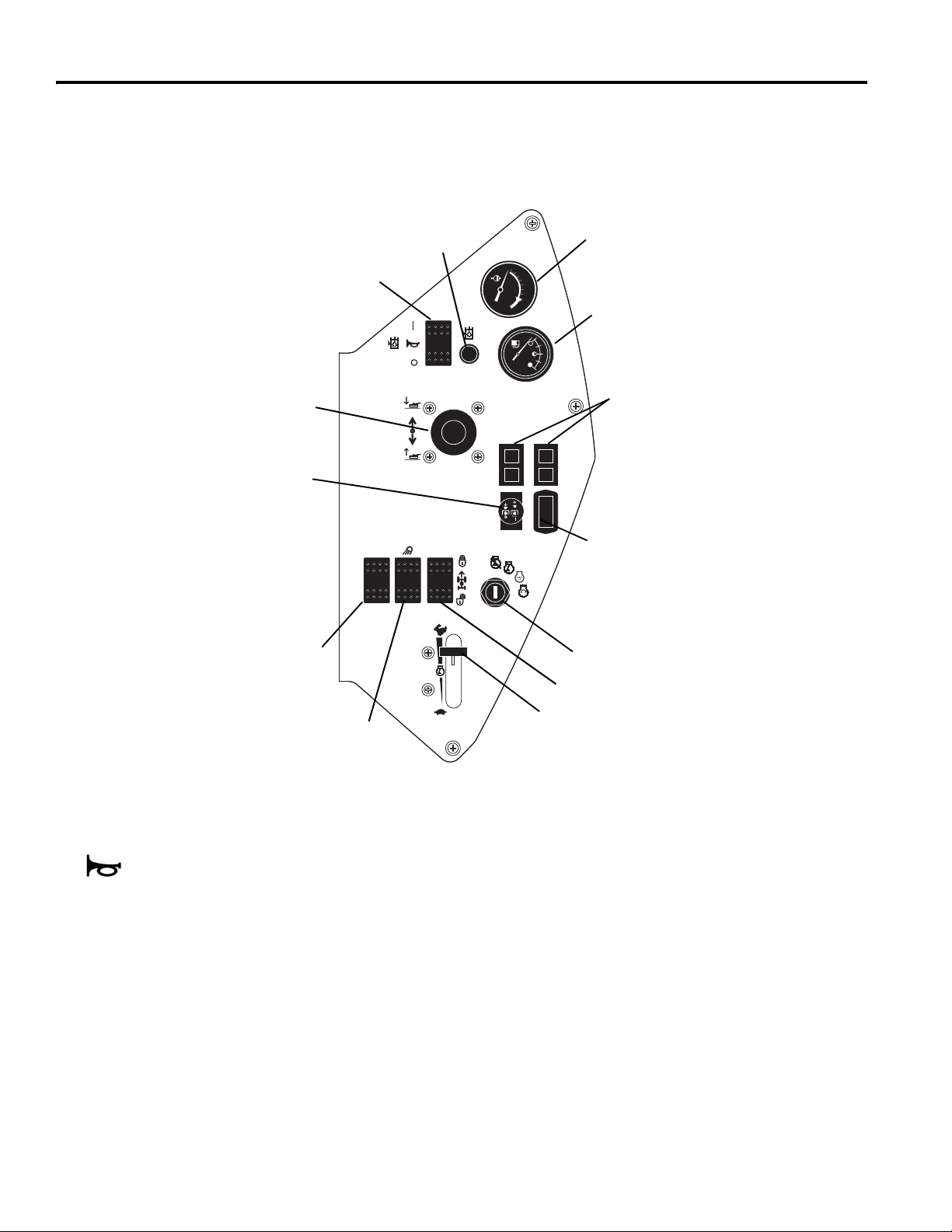

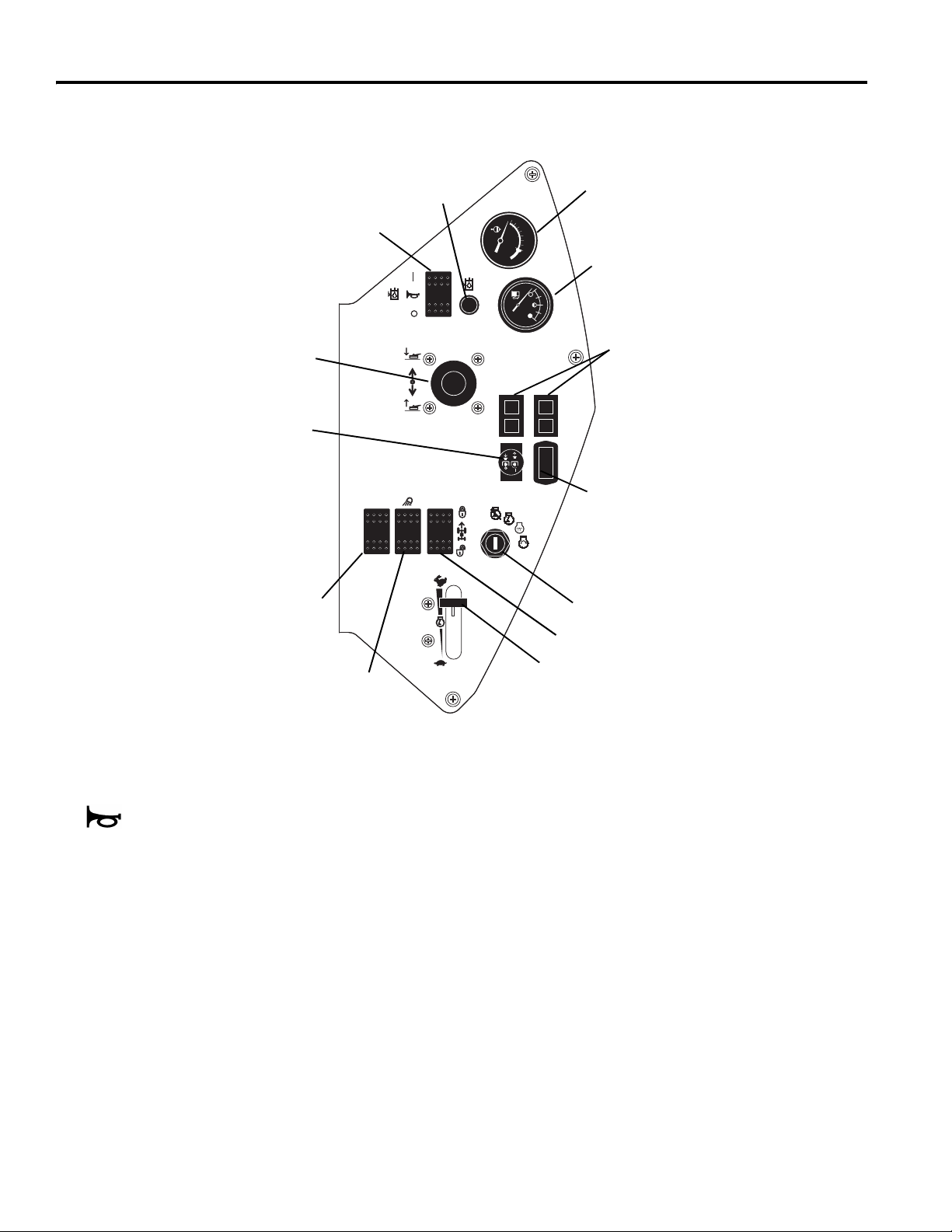

4.3 CONTROL PANEL _________________________________________________________

Q

P

R

O

N

Z

X

Y

W

V

S

O. Low Oil Level Switch

This switch is used to test the alarm system or

disable the alarm after a low oil level has been

detected. Keep switch in its ON position when

starting and operating tractor. To test alarm, set switch

to OFF and turn ignition key to RUN. See Section 4.4.

P. Mower Lift lever

The mower lever raises and lowers the mowers and

operates in either automatic or manual mode. Push

lever forward to lower mowers, pull back to raise

mowers.

Manual Mode - Set mow switch (Q) in its OFF (down)

position. In this position all mowers will raise or lower

while pressure is applied to the lift lever.

Automatic Mode - Set mow switch (Q) in its ON (up)

position. In automatic mode the mowers will lower and

start automatically with a momentary forward movement

of the lift lever. In this mode mowers will only raise to a

GB-10

U

T

Figure 4B

“crosscut” position with a momentary backward

movement of the lift lever.

To raise mowers to their transport position, hold lever

until mowers are fully raised.

To raise mowers to their transport position, hold lever

until mowers are fully raised.

NOTE: While in an Automatic Mode lift or lower cycle,

that lasts approximately 3 seconds, moving the lift lever

in the opposite direction will turn all mowers off and

manual mode will start for the position selected.

Q. PTO Switch

The PTO switch is a 2-position knob type switch used to

turns the mowers On or off. It also sets the mower lift

lever (P) in manual or automatic mode. Set mower

switch in its OFF (down) position when starting the

tractor.

Page 11

R. Traction Control

Press and release switch to activate traction control

system. This system

reduces down pressure on decks

by pulsing the lift circuit, transferring weight to tractor.

Reducing down pressure i mproves traction but may

cause decks to float up creati ng an unev en c ut. Light

in switch will turn on when system is active.

Press switch again to deactivate traction control. This

may reduce traction but improves dec k contact with

ground.

NOTE: The traction control system must be reset after

shutting off engine.

S. Lights

Controls operation of work lights.

T. Engine Throttle

Controls engine speed. Run machine at full throttle

during normal machine operation.

U. Cruise Control (Option)

When switched ON the cruise control will lock the

traction pedal in its current position. Cruise will unlock

when switched OFF, or if parking brake is applied.

CONTROLS 4

V. Ignition Switch

The ignition switch has three positions. OFF- RUN (ON)

- START. In the RUN (ON) position the controller

program is running and input and output circuits are

being monitored. See Section 5.4 and Parts &

Maintenance Manual.

W. Hour Meter

Records engine operating hours. Use hour meter to

schedule periodic maintenance.

X. Fuel Gauge

Indicates current fuel level. Check fuel gauge daily

before starting machine.

Y. Warning Lights

Alerts the operator to conditions requiring immediate

action. See Section 4.4.

Z. Temperature Gauge

Indicates engine coolant temperature. Normal operating

temperature should be between 160° - 230°F (71°110°C). If temperature rises above 230° (110°F), alarm

will sound. See Section 4.4.

GB-11

Page 12

4 CONTROLS

!

!

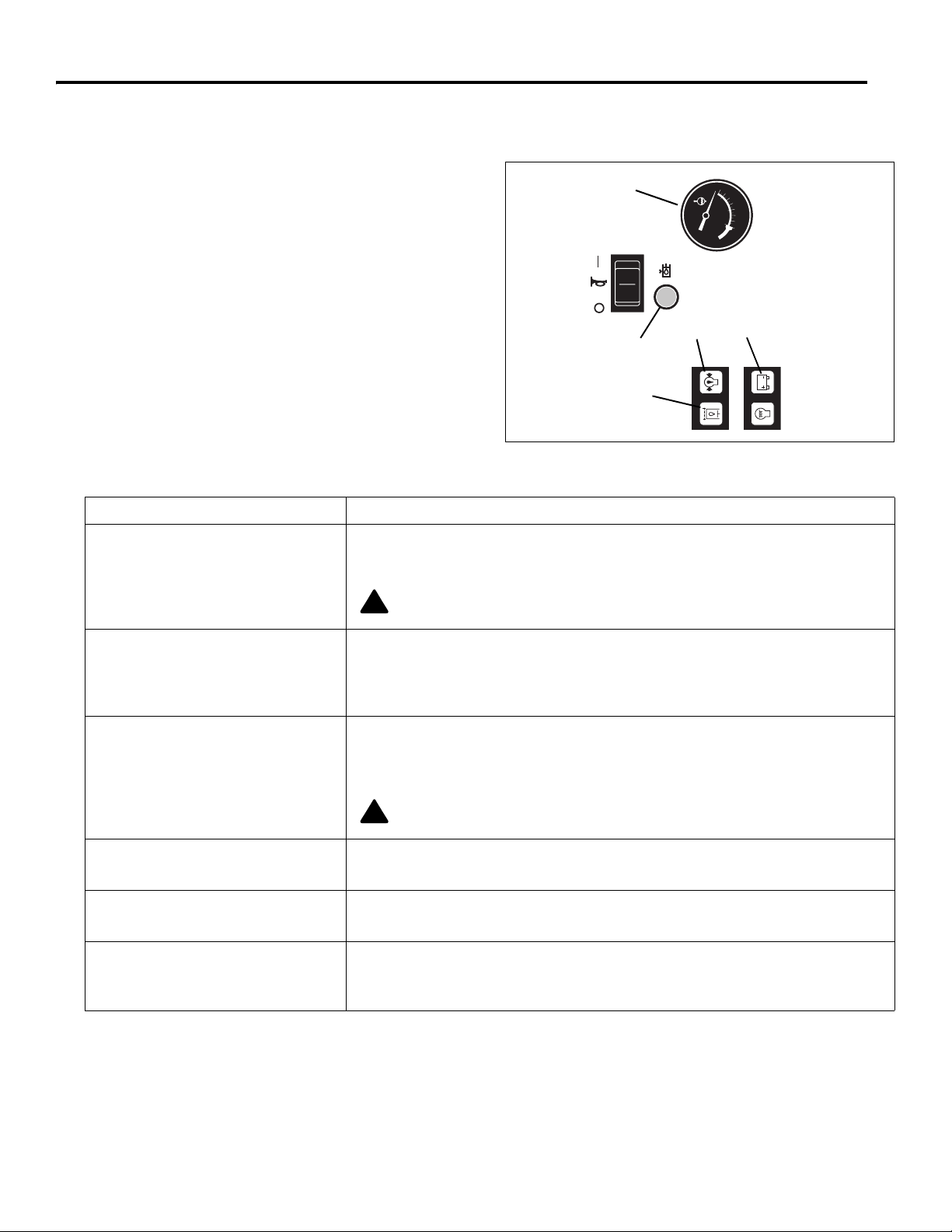

4.4 OPERATOR ALERTS _______________________________________________________

The electronic controller monitors vital machine systems. It

uses an audible alarm and warning lights to alert the

operator of conditions requiring immediate action. When an

alert occurs follow the general guidelines listed in the chart

below, and any specific actions outlined by the grounds

superintendent or service manager.

To test alarm system:

Turn ignition switch to RUN. All lights will come on for one

second or more and the alarm will sound briefly.

This system monitors:

1. Hydraulic fluid level

2. Engine oil pressure

3. Engine coolant temperature

4. Hydraulic oil filter

5. Battery voltage

6. Dual activation of brake and traction pedal.

Alert Action

3

2

5

1

4

LF004

Figure 4C

1. Hydraulic fluid level - alarm

sounds and hydraulic fluid warning

light comes on. Hydraulic fluid is

below recommended level.

2. Engine Oil Pressure - alarm

sounds and oil pressure light

comes on. Oil pressure low.

3. Engine Coolant Temperature

Alarm sounds. Engine coolant

temperature high.

4. Hydraulic oil filter - Oil filter

warning light remains on.

5. Battery Voltage - Warning light

comes on.

6. Driving with brake on - Alarm

Sounds

Stop tractor immediately, lower implements and shut off engine! Visually

inspect tractor for obvious signs of leaks around connections, hoses and

hydraulic components. Return tractor to service area for maintenance.

CAUTION: Hydraulic fluid is under pressure. Turn engine off and allow

fluid to cool before checking fluid level or adding oil to hydraulic tank.

Stop tractor immediately, lower implements and shut off engine! Inspect oil

level in engine. If oil light remains on with oil at proper level, shut off engine and

tow or trailer tractor back to a service area. NEVER operate engine with oil light

on, severe damage to the engine can occur.

Stop tractor immediately, lower implements and shut off engine! Remove

debris such as leaves and grass clippings that may be restricting air flow through

rear screen on hood and area between radiator and oil cooler. If engine

continues to run hot, return tractor to a service area.

CAUTION: Engine coolant is under pressure. Turn engine off and allow

fluid to cool before checking fluid level or adding coolant to radiator.

Return tractor to a service area as soon as possible. Change hydraulic oil

filters.

Return tractor to a service area as soon as possible. Inspect battery and

battery charging system.

Disengage parking brake, or remove foot pressure from either pedal.

Continued operation with both brake and traction pedal depressed will cause

engine to stop in 10 - 60 seconds, depending on the order of pedal application.

GB-12

Page 13

OPERATION 5

!

!

5 OPERATION

5.1 DAILY INSPECTION_________________________ __ ________________ _____________

2. Check the fuel supply, radiator coolant level, crankcase

CAUTION

The daily inspection should be performed only when

the engine is off and all fluids are cold. Lower mowers

to the ground, engage the parking brake, Stop engine

and remove ignition key.

oil and air cleaner indicator. All fluids must be at the full

level mark with engine cold.

3. Make sure all mowers are adjusted to the same cutting

height.

4. Visually check tires for proper inflation.

1. Perform a visual inspection of the entire unit, look for

signs of wear, loose hardware, and missing or damaged

components. Check for fuel or oil leaks to ensure connections are tight and hoses and tubes are in good condition.

5. Test the interlock system.

Note: For more detailed maintenance information,

adjustments and maintenance/lube charts, see the

Parts & Maintenance manual.

5.2 Interlock System __________________________________________________________

1. The interlock system prevents the engine from starting

unless the parking brake is engaged, the traction pedal

is in neutral and the mower switch(es) is “OFF”. The

system also stops the engine if the operator leaves the

seat with the mower switch(es) “ON”, traction pedal out

of NEUTRAL, or parking brake “DISENGAGED”.

WARNING

Never operate equipment with the Interlock System

disconnected or malfunctioning. Do not disconnect or

bypass any switch.

2. Perform each of the following tests to insure the

interlock system is functioning properly. Stop the test

and have the system inspected and repaired if any of

the tests

● the engine does not start in test 1;

● the engine does start during tests 2,3 or 4;

● the engine continues to run during tests 5 or 6.

fail as listed below:

3. Refer to the chart below for each test and follow the

check (

between each test.

Test 1: Represents normal starting procedure. The

operator is seated, parking brake is engaged, the

operator’s feet are off the pedals, and the mower

switch(es) is ‘OFF”. The engine should start.

Test 2: The engine must not start if the mower switch is

“ON”.

Test 3: The engine must not start if the parking brake is

“DISENGAGED”.

Test 4: The engine must not start if the traction pedal is

pressed.

Test 5: Start the engine in the normal manner then turn

mower switch “ON” and lift your weight off the seat.

Test 6: Start the engine in the normal manner then

disengage parking brake and lift your weight off the

seat.

9) marks across the chart. Shut engine off

Interlock System Check

Test

1

2

3

4

5

6

Operator

Seated

Yes No On Off Yes No On Off Yes No

Parking

Brake

Traction Pedal

in Neutral

Mower

Switch

Engine

Starts

999 99

9999 9

99999

99 999

9999

9 99 9

Lift your weight off seat. The cutting units must stop rotating within seven (7) seconds.

GB-13

Page 14

5 OPERATION

!

!

!

!

5.3 OPERATING PROCEDURES_________________________________________________

WARNING

A Rollover Protection Structure (RO PS) for this tractor i s available as an optio nal accessory. Evaluate the terrain

and working conditions to dete r min e i f a ROP S i s requi red. S ea t bel ts mus t b e worn when ev er a ROP S i s ins talle d

on the tractor. Always keep seat belt snugly adjusted. DO NOT use seat belts on a tractor without a ROPS.

If a ROPS is installed and the tract or is overturning, hold onto the steer ing wheel. Do not attempt to jump out or

leave the seat.

CAUTION

To prevent injury, always wear safety glasses, leather work shoes or boots, a hard hat, and ear protection.

1. Under no circumstances should the engine be

started without the operator seated on the tractor.

Never start the engine with operator or bystanders

standing behind a discharge chute.

2. Never run the engine in an enclosed area.

3. Keep hands and feet away from moving parts and

cutting units. If possible, do not make adjustments with

the engine running.

4. Do not operate tractor or attachments with loose,

damaged or missing components. Whenever

possible mow when grass is dry.

5. First mow in a test area to become thoroughly

familiar with the operation of the tractor and control

levers.

6. Study the area to determine the best and safest

operating procedure. Consider the height of the

grass, type of terrain, and condition of the surface.

Each condition will require certain adjustments or

precautions.

7. Be aware of mower discharge direction and never

direct discharge of material toward bystanders.

Never allow anyone near the machine while in

operation. The owner/operator is responsible for

injuries inflicted to bystanders and/or damage to

their property.

CAUTION

Before mowing, pick up all debris such as rocks, toys

and wire which can be thrown by the machine. Enter a

new area cautiously. Always operate at speeds that

allow you to have complete control of the mower.

8. Use discretion when mowing near gravel areas

(roadway, parking areas, cart paths, etc.). Stones

discharged from the implement may cause serious

injuries to bystanders and/or damage the

equipment.

9. Always turn PTO switch off to stop blade s when not

mowing.

10. Disengage the drive motors, raise the mowers and

slow down when crossin g paths or roadways. L ook

out for traffic.

11. Stop and inspect the equipment for damage

immediately after striking an obstruction or if the

machine begins to vibrate abnormally. Have the

equipment repaired before resuming operation.

WARNING

Before you clean, adjust, or repair this

equipment, always disengage all drives, lower

implements to the groun d, e ngag e parki ng b r ake ,

stop engine and remov e key from ignition swi tch

to prevent injuries.

12. Slow down and use extra care on hillsides. Read

Section 5.10. U se caution when operating n ear drop

offs.

13. Look behind and down before backing up to be sur e

the path is clear. Use care when approaching blind

corners, shrubs, tress or other objects that may

obscure vision.

14. Never use your hands to clean cuttin g units. Use a

brush to remove grass clippings from blades.

Blades are extremely sha rp and can cause serious

injuries.

GB-14

Page 15

OPERATION 5

!

5.4 STARTING________________________________________________________________

IMPORTANT: Do not use starting assist fluids. Use of

such fluids in the air intake system may be potentially

explosive or cause a “Runaway” engine condition and could

result in serious engine damage.

WARNING

To prevent injuries, sit in the seat, engage

parking brake, place tracti on pedal in neutral an d

PTO switch in OFF position before attemp ting to

start the engine.

1. Sit in operator’s seat, make sure the PTO switch (Q) is

“OFF” (down) and the parking brake is engaged.

Remove feet from pedals. Always use the seat belt

when operating tractors equipped with a ROPS.

2. Set throttle lever (T) to half throttle and check that

alarm switch (O) is “ON”.

3. Turn ignition switch (V) to “ON” ( ) position.

Note: At this time the warning lights (N, Y) on the

instrument panel will come on. Check that lights are

operating.

4. Wait until glow plug light goes out, then immediately

turn ignition key to “START” ( ) position. Release as

soon as engine starts.

Note: Do not hold key in “ST ART” position for more than

10 seconds at a time. After 10 seconds the starting

circuit will shutdown and must be reset by returning the

key to the OFF position.

Allow 30 seconds between start-up attempts to allow

time for engine starter motor to cool.

All warning lights should go off after engine starts.

Allow engine to gradually become warm before

operating at high RPM.

N

O

Q

Y

V

T

LF003

Figure 5A

5.5 STOPPING / PARKING______________________________________________________

To stop:

Remove your foot from traction pedal.

automatically brake when the traction pedal returns to

neutral.

remove key before leaving operator seat for any reason.

To park the tractor under normal conditions:

1. Disengage the PTO switch (Q) then raise and lock the

2. Select a flat and level area to park.

Always engage parking brake, shut off engine and

implements in the transport position and move away

from the area of operation.

a. Release traction pedal to bring the tractor to a com-

plete stop.

b. Disengage all drives, lower implements to the

ground, engage parking brake, reduce throttle to

idle and allow engine to operate at no load for three

to five minutes.

The tractor will

Permanent damage to th e turbocharger may occur if

the engine is shut down without allowing the

turbocharger time to cool.

To prevent damage, operate the engine at idle with no

load for 3 to 5 minutes before shutting off engine.

3. Engage parking brake, stop the engine and always

remove the ignition key.

If an emergency arises and the tractor must be parked in the

area of operation, follow the guidelines outlined by the

grounds superintendent.

If the tractor is parked on an incline, chock or block the

wheels.

CAUTION

GB-15

Page 16

5 OPERATION

!

5.6 TO DRIVE / TRANSPORT____________________________________________________

Read and follow all safety notes contained in this manual

when driving or transporting tractor. When operating in

reverse look behind you to ensure you have a clear path.

Important: If this tractor is driven on public roads, it must

comply with federal, state and local ordinances. Contact

local authorities for regulations and equipment

requirements.

To raise mowers to their transport position:

Set PTO switch to OFF (center position). Pull mower lever

back. Hold lever until mowers are up and lift arms are in their

fully raised (transport) position.

Important: The mow switch should be OFF (center position)

while transporting tractor.

5.7 MOWING_________________________________________________________________

position. To lift mowers to their transport position

WARNING

To prevent serious injuries, keep hands, feet and

clothing away from cutting unit when the blades are

moving.

NEVER use your hands to clean cutting units. Use a

brush to remove grass clippings from b lades. Blades

can be sharp and could cause injuries.

DO NOT operate mowers without rear discharge

chutes or mulching plate installed.

To mow:

1. Set PTO switch to its ON (Up) position. This also sets

the mower lever to automatic mode. See Mower Lift

Lever, page 8.

2. Press mower lever forward momentarily to lower

mowers. Mowers will begin turning automatically when

cutting units have lowered.

3. To lift mowers, pull mower lever back and release.

Mowers will stop turning and raise to their crosscut

continue to hold lever until mowers are completely

raised.

4. Activate traction control (R) as required to improve

weight distribution between decks and tractor. [See

4.3]

Always mow with the engine at full throttle.

To install mulching plate:

An optional mulching plate can be used instead of the rear

discharge chute. Do not operate mower without rear

discharge chute or mulching plate installed.

1. Place PTO switch in OFF (down) position, lower mowers to the ground, engage parking brake and stop

engine.

2. Remove three nuts securing discharge chute to mower

housing.

3. Remove discharge chute and assemble mulching

plate. Secure with three nuts remove previously. Store

the discharge chute in a safe location for future use.

5.8 MOWING SPEED __________________________________________________________

Cutting quality is better at speeds well below the transport

speed of the tractor. An initial mow speed of 6 to 7 MPH (10

to 11 kph) is set at the factory and should be satisfactory for

most cutting conditions. Local turf conditions however may

respond better to a different speed. If an adjustment is

needed, refer to the Parts and Maintenance manual.

GB-16

Page 17

OPERATION 5

!

!

5.9 TOWING / TRAILERING _____________________________________________________

If the tractor experiences problems and must be shut down

and removed from the area, it should be loaded onto a trailer

for transport. If a trailer is not available, the unit can be

towed slowly short distances.

Use care when loading and unloading tractor. Fasten tractor

to trailer to prevent tractor from rolling or shifting during

transport.

Long Distance Trailering / Transport. If the tractor is to

be trailered on the highway, before strapping to trailer,

close fuel shut off valve and inflate tires maximum

pressure listed on side of tire. Reduce tire pressure to

normal after removing from trailer. [See 5.9]

Before towing, open tow valve. The tow valve permits

moving the tractor without starting the engine and prevents

possible damage to hydraulic components.

The tow valve (A) is located on the hydraulic drive pump

beneath the operators seat. Remove cover from floor in front

of operator’s seat. To open valve, use a wrench or insert a

pin or small screw driver into the small hole in the valve

stem. Turn the valve counterclockwise one full turn.

Before towing make sure cutting units are raised. If they

cannot be raised, remove them from the tractor.

Close valve completely and replace cover after towing.

NOTE: Do not exceed 2 MPH (3.2 KPH) while towing. Long

distance towing is not recommended

.

A

LF006

Figure 5B

5.10 HILLSIDE OPERATION _____________________________________________________

3. If the tractor tends to slide or the tires begin to “mark”

WARNING

To minimize the possibility of overturning, the safest

method for operating on hills and terraces is to travel up

and down the face of the slope (vertically), not across the

face (horizontally). Avoid unnecessary turns, travel at

reduced speeds, and stay alert for hidden hazards.

CAUTION

A Rollover Protection System (ROPS), designed for this

tractor, is available as an optional accessory.

ROPS before operating on slopes greater than 14°.

Do not operate this tractor on slopes greater than 20°.

The tractor has been designed for good traction and stability

under normal mowing conditions; however, use caution

when operating on slopes, especially when the grass is wet.

Wet grass reduces traction and steering control.

1. Always mow with the engine at full throttle but reduce

forward speed to maintain the proper cutting frequency.

Install a

the turf, angle tractor into a less steep grade until

traction is regained or tire marking stops.

4. If tractor continues to slide or mark the turf, the grade

is too steep for safe operation. Do not make another

attempt to climb, back down slowly.

5. When descending a steep slope, always lower

implements to the ground to reduce the risk of tractor

overturning.

Correct tire pressure is essential for maximum traction.

Front .........................16 psi (111 kPa)

Rear.......................... 12 psi (86 kPa)

2. Activate traction control (R) as required to improve

weight distribution between decks and tractor. [See

4.3]

GB-17

Page 18

5 OPERATION

!

!

!

5.11 DAILY MAINTENANCE _____________________________________________________

Important: For more detailed maintenance information,

adjustments and maintenanc e/lubricatio n charts, see the

Parts& Maintenance manual.

1. Park the tractor on a flat and level surface. Fully

lower the cutting units to the ground, enga ge parking

brake, stop the engine and remove the key from ignition switch.

2. Grease and lubricate all points if required. To

prevent fires, wash the cuttin g units and tractor after

each use.

To prevent serious injury from hot, high pressure

oil, never use your h ands to check for oil leaks,

use paper or cardboard.

Hydraulic fluid escapi ng und er pres su re c an h ave

sufficient force to penetrate skin. If fluid is injected

into the skin, it must be s urgicall y remo ved within

a few hours by a doctor famili ar with this form of

injury or gangrene may result.

WARNING

a. Do not use high pressure spray.

b. Do not spray water directly at the instrument

panel, or any electrical components.

c. Do not spray water into coolin g air in take, or the

engine air intake.

Note: Do not wash a hot or running engine. Use

compressed air to clean the engine and radiator fins.

d. Clean the tires thoroughly. Check tire pressure.

e. Clean radiator and oil cooler passages using com-

pressed air (30 psi maximum).

3. Fill the tractors fuel tank at the end of each

operating day to within 1 in., (2 5 mm) below the fill er

neck.

Use clean fresh #2 diesel fuel. Minimum Cetane

Rating 45.

4. Handle fuel with care - it is highly flammable. Use

an approved container, the spout must fit inside the

fuel filler neck. Avoid using cans and funnels to

transfer fuel.

a. Never remove the fuel cap from the fuel tank, or

add fuel, when the engi ne is run ni ng or while th e

engine is hot.

b. Do not smoke when handling fuel. Never fill or

drain the tank indoors.

c. Never ov erfi ll or a llow th e tank to bec ome em pty.

Do not spill fuel. Clean any spilled fuel

immediately.

6. Inspect hydraulic hoses and tubes daily. Look for

wet hoses or oil spots and replace worn or

damaged hoses and tubes before operating the

machine.

WARNING

To prevent serious bodily injury from hot coolant or

steam blow-out, nev er attempt to remo ve the radiator

cap while the engine is running. Stop the engine an d

wait until it is cool. Even then, use extreme care when

removing the cap.

CAUTION

Do not pour cold water into a hot radiator. Do not operate

engine without a proper coolant mixture. Install cap and

tighten securely.

7. After engine has cooled, check coolant level.

Radiator should be full and recovery bottle should be

up to the cold mark.

8. Park machine in designated area. Engage parking

brake and remove key. Place key in a secure

location to prevent unauthorized use of equipment.

9. Check the engine oil and hydraulic oil at the start

and end of each day. If the oil level is low, remove

the oil filler cap and add oil as required. Do not

overfill.

d. Never handle or store fuel containers near an

open flame or any device t hat ma y create sparks

and ignite the fuel or fuel vapors.

5. Store fuel according to local, state or federal

ordinances and recommendations from your fuel

supplier.

GB-18

Page 19

OPERATION 5

!

!

5.12 LONG TERM S T ORA GE_________________ __ _________________ __ _______________

General

1. Wash the tractor thoroughly and lubricate. Repair and

paint damaged or exposed metal.

2. Inspect the tractor, tighten all hardware, replace worn

or damaged components.

3. Drain and refill radiator.

4. Clean the tires thoroughly and store the tractor so the

load is off the tires. If tractor is not on jack stands,

check tires at regular intervals and reinflate as

necessary.

5. Keep the machine and all its accessories clean, dry

and protected from the elements during storage. Never

store equipment near an open flame or spark which

could ignite fuel or fuel vapors.

Battery

1. Remove, clean and store battery in upright position in a

cool, dry place.

2. Check and recharge battery every 60 to 90 days while

in storage.

3. Store batteries in a cool, dry place. To reduce the self

discharge rate, room temperature should not be above

80°F (27°C) or fall below 20°F (-7°C) to prevent

electrolyte from freezing.

After Storage

1. Check and reinstall battery

2. Check or service fuel filter and air cleaner.

3. Check the radiator coolant level.

4. Check oil level in the engine crankcase and hydraulic

system.

5. Fill the fuel tank with fresh fuel. Bleed the fuel system.

6. Make certain that the tires are properly inflated.

7. Remove all oil from the blades. Adjust cutting height.

8. Start and operate the engine at 1/2 throttle. Allow

enough time for the engine to become properly

warmed and lubricated.

WARNING

Never operate the engine without proper ventilation;

exhaust fumes can be fatal when inhaled.

Engine

1. While the engine is warm, remove drain plug, drain the

oil from the crankcase and change oil filter. Install drain

plug and refill with fresh oil. Torque drain plug to 22 ft.

lb. (30 Nm).

2. Clean exterior of engine. Paint exposed metal or apply

a light coat of rust preventative oil.

3. Add a fuel conditioner or biocide to prevent gelling or

bacterial growth in fuel. See your local fuel supplier.

Cutting Units

1. Wash the cutting units thoroughly, then repair and paint

any damaged or exposed metal.

2. Lubricate all fittings and friction points.

3. Apply a light coat of rust preventative oil to the

sharpened edges of the blades.

CAUTION

To prevent personal injury and damage to the cutting

edges, handle the blades with extreme care

GB-19

Page 20

ESIPUHE

Tämä ohje sisältää uuden Jacobsen-traktorisi käyttö- ja

turvallisuusohjeet. Ohjeisiin sisältyy myös osaluettelo ja

huolto-ohje, jossa on säätö- ja huolto-ohjeet sekä

vianmääritysosio ja osaluettelo. Molemmat ohjekirjat on

säilytettävä istuimen takana sijaitsevassa pussissa, joka on

tarkoitettu huolto-ohjeille ja josta ne ovat nopeasti saatavilla.

Ennen kuin käytät konetta sinun, sekä kaikkien koneen

käyttäjien, on luettava molemmat käsikirjat huolellisesti ja

kokonaisuudessaan. Seuraamalla turvallisuus-, käyttö- ja

huolto-ohjeita pidennät koneesi elinikää ja pidät yllä sen

parhaan mahdollisen suorituskapasiteetin.

Jos haluat lisätietoja, ota yhteyttä lähimpään Jacobsenjälleenmyyjääsi.

SISÄLLYSLUETTELO

SISÄLLYSLUETTELO

SISÄLLYSLUETTELO

TURVALLISUUS

1.1 Käyttöturvallisuus. . . . . . . . . . . . . . . . . . . . . 3

1.2 Tärkeitä huomautuksia . . . . . . . . . . . . . . . . . 4

MERKINNÄT

ALKUTARKISTUS

3.1 Yleistä . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

3.2 Alkutarkistus. . . . . . . . . . . . . . . . . . . . . . . . . .6

SÄÄTIMET

4.1 Kuvakkeet . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.2 Säätimet . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.3 Kojetaulu . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.4 Varoitukset . . . . . . . . . . . . . . . . . . . . . . . . . 12

Koneen sarjanumero sijaitsee istuinkaukalossa istuimen

vasemmalla puolella. Jacobsen-yhtiö suosittelee, että

kirjoitat sarjanumeron muistiin, jotta se on tarvittaessa

kätevästi saatavilla.

®

A Textron Company

CHARLOTTE, NC MADE IN U.S.A.

68080

KÄYTTÖ

5.1 Päivittäinen tarkastus . . . . . . . . . . . . . . . . . .13

5.2 Lukitusjärjestelmä . . . . . . . . . . . . . . . . . . . .13

5.3 Ohjaustoimet . . . . . . . . . . . . . . . . . . . . . . . .14

5.4 Käynnistäminen . . . . . . . . . . . . . . . . . . . . . .15

5.5 Pysäyttäminen ja pysäköiminen . . . . . . . . .15

5.6 Ajaminen ja kuljettaminen . . . . . . . . . . . . . .16

5.7 Leikkaaminen . . . . . . . . . . . . . . . . . . . . . . . .16

5.8 Leikkuunopeus . . . . . . . . . . . . . . . . . . . . . . .16

5.9 Hinaaminen ja vetäminen . . . . . . . . . . . . . .17

5.10 Rinnekäyttö . . . . . . . . . . . . . . . . . . . . . . . . .17

5.11 Päivittäinen huolto . . . . . . . . . . . . . . . . . . . .18

5.12 Säilytys . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Varoitus

Tämän laitteen pakokaasu sisältää

kemikaaleja, jotka Kalifornian

osavaltion tietojen mukaan aiheuttavat

syöpää, synnynnäisiä vammoja ja

muita lisääntymishäiriöitä.

© COPYRIGHT 2004, TEXTRON INC.

“Kaikki oikeudet pidätetään. Tätä opasta tai sen osaa ei saa kopioida missään muodossa.”

Kaikki tässä julkaisussa olevat tiedot perustuvat ennen painamista käytössä olleisiin tietoihin. Jacobsen pidättää oikeuden

tehdä muutoksia milloin tahansa sitoumuksetta ja ilman erillistä ilmoitusta.

VALMISTUS YHDYSVALLOISSA 5-2004

FI-2

Page 21

TURVALLISUUS 1

!

1 TURVALLISUUS

1.1 KÄYTTÖTURVA LLIS U US__________________ ___ __ __ _________________ __ __ ______

VAROITUS

JOS LAITETTA KÄYTETÄÄN VÄÄRIN TAI SITÄ KÄYTTÄÄ HENKILÖKUNTA, JOTA EI OLE KOULUTETTU KO.

LAITTEEN KÄYTTÖÖN, SE VOI OLLA VAARALLINEN.

Tutustu alueeseen ja kaikkien hallintalaitteiden käyttöön. Kokemattomat kuljettajat on perehdytettävä laitteeseen ennen

kuin heidän sallitaan käyttää sitä.

1. Turvallisuus riippuu laitteen käyttäjien ja huoltajien

valppaudesta, huolellisuudesta ja varovaisuudesta. Älä

koskaan anna alaikäisten käyttää laitteita.

2. Sinun vastuullasi on lukea tämä käsikirja ja kaikki muut

laitteeseen liittyvät julkaisut (Käyttö- ja

turvallisuusopas, moottorin käyttöopas, lisälaitteet ja

varusteet). Jos käyttäjä ei osaa lukea englanninkielistä

ohjekirjaa, omistajan vastuulla on selittää heille tässä

ohjekirjassa annettu materiaali.

3. Opettele käyttämään konetta oikein sekä kaikkien

hallintalaitteiden ja mittareiden sijainti ja käyttö ennen

kuin käytät konetta. Outojen laitteiden kanssa

työskenteleminen voi johtaa tapaturmiin.

4. Älä koskaan anna kenenkään käyttää tai huoltaa

konetta tai sen lisälaitteita ilman asianmukaista

koulutusta ja ohjeita, tai alkoholin tai huumeiden

vaikutuksen alaisena.

5. Käytä tarvittavia suojahaalareita ja henkilösuojaimia

pään, silmien, korvien, käsien ja jalkojen suojana.

Käytä konetta ainoastaan päivänvalossa tai hyvässä

keinovalaistuksessa.

6. Arvioi maasto, jotta voit päätellä mitä apuvälineitä

tarvitset työn turvalliseen ja kunnolliseen

suorittamiseen. Käytä vain apuvälineitä ja lisälaitteita,

jotka Jacobsen on hyväksynyt.

7. Pysy valppaana maassa olevien kuoppien tai muiden

näkymättömien vaaratekijöiden varalta.

8. Tarkista alue, jossa laitetta käytetään. Poimi kaikki

roskat maasta ennen käyttöä. Varo pään yläpuolella

olevia esteitä (matalalla roikkuvia puun oksia,

sähköjohtoja jne.) ja maanalaisia esteitä (sadettajat,

putket, puun juuret jne.) Tutustu uuteen alueeseen

varovasti. Pysy valppaana näkymättömien

vaaratekijöiden varalta.

9. Älä koskaan suuntaa poistoaukkoa kohti

sivustakatsojia tai salli kenenkään tulla liian lähelle

konetta silloin, kun se on käynnissä. Omistaja / käyttäjä

on vastuusta itselleen, sivustakatsojille ja omaisuudelle

aiheutuneista vahingoista ja velvollinen estämään ne.

10. Älä ota matkustajia. Pidä sivustakatsojat ja

lemmikkieläimet riittävän etäisyyden päässä.

11. Älä koskaan käytä laitetta, joka ei ole erinomaisessa

toimintakunnossa tai jonka tarrat, suojakaiteet, kilvet,

poistoaukon ilmansuuntain tai muut suojavarusteet

eivät ole tiukasti paikoillaan.

12. Älä poista käytöstä tai ohita mitään kytkintä.

13. Älä muuta moottorin käynnintasaimen säätöjä tai aja

ylinopeutta.

14. Pakokaasujen hiilimonoksidi voi olla hengenvaarallista.

Älä koskaan käytä moottoria suljetussa tilassa tai

paikassa, jossa ei ole kunnollista ilmanvaihtoa.

15. Polttoaine on tulenarkaa, käsittele sitä varoen.

16. Pidä moottori puhtaana. Anna moottorin jäähtyä ennen

varastointia ja poista aina virta-avain varastoinnin

ajaksi.

17. Vapauta kaikki vaihteet ja kytke käsijarru päälle ennen

kuin käynnistät moottorin. Käynnistä moottori vain

silloin, kun itse istut kuljettajan paikalla.

18. Laitteiden on oltava voimassa olevien kansallisten ja

paikallisten lakien mukaisia, jos ajoneuvolla liikutaan

maanteillä. Varo muuta liikennettä, jos olet ylittämässä

tietä tai toimit teiden lähettyvillä.

19. Paikalliset lait voivat rajoittaa kuljettajan ikävaatimusta.

20. Älä koskaan yritä etsiä vuotoja käsin. Paineistettu

hydraulineste voi läpäistä ihon ja aiheuttaa vakavan

vamman.

21. Aja rinteissä ala- ja ylämäkeen (pystysuunnassa), älä

sivuttain (vaakasuunnassa).

22. Älä käynnistä tai pysäytä laitetta äkillisesti rinteissä,

jotta se ei kaatuisi etkä menettäisi laitteen hallintaa.

Vähennä nopeutta jyrkissä mutkissa. Ole varovainen

vaihtaessasi suuntaa.

23. Käytä aina turvavyötä, kun ohjaat ROPSturvaohjaamolla varustettua traktoria.

Älä koskaan käytä turvavyötä, kun ohjaat traktoria,

jossa ei ole ROPS-turvaohjaamoa.

24. Pidä kädet, jalat ja vartalo istuinosan sisäpuolella

ajoneuvon ollessa liikkeellä.

Tätä laitetta on käytettävä ja huollettava tässä oppaassa kuvattavalla tavalla. Laite on tarkoitettu erityisten

ruohoturvekenttien ammattimaiseen huoltoon. Sitä ei ole tarkoitettu käytettäväksi epätasaisessa maastossa eikä

pitkässä ruohikossa.

FI-3

Page 22

1 TURVALLISUUS

!

!

1.2 TÄRKEITÄ HUOMAUTUKSIA ________________________________________________

Tämä varoitusmerkki varoittaa sinua mahdollisista vaaratekijöistä.

!

HENGENVAARA - Osoittaa välitöntä vaaratil annetta, joka JOHTAA kuolemaan tai vakavaan lou kkaantum iseen,

jos sitä ei pystytä välttämään.

VAROITUS - Osoittaa mahdollis ta vaar ati la nne tta, joka VOI johtaa kuolemaan tai vakavaan louk k aan tumi seen , jos

sitä ei pystytä välttämään.

VAARA - O soittaa mahdollista vaarati lannetta, joka VOI johtaa lievää n tai vakavaan louk kaantumisee n tai kiinteän

omaisuuden vahingoittumiseen, jos sitä ei pystytä välttämään. Voidaan käyttää myös osoittamassa vaarallista

käyttötapaa.

Jotta tämän käyttöoppaan kuvat olisivat mahdollisimman selkeitä, joissakin kuvissa suojukset tai kannet on voitu avata

tai poistaa. Laitetta ei kuitenkaan saa missään olosuhteissa käyttää ilman, että ne on kiinnitetty tiukasti paikoilleen.

VAROITUS

Tämän traktorin lukitusjärjestelmä estää traktorin käynnistymisen, jollei jarrupoljin

ole painettuna, leikkuukytkin poissa päältä ja vetopoljin vapaalla. Järjestelmä

sammuttaa moottorin, jos käyttäjä nousee istuimelta kytkemättä seisontajarrua tai

kytkemättä leikkuukytkintä pois päältä.

ÄLÄ KOSKAAN käytä traktoria, jos lukitusjärjestelmä ei toimi.

VAROITUS

1. Toimi aina seuraavasti, ennen kuin lähdet käyttäjän istuimelta:

a. Vaihda vetopoljin vapaalle.

b. Vapauta kaikki käyttölaitteet.

c. Laske kaikki leikkuuyksiköt maahan.

d. Kytke seisontajarru.

e. Sammuta moottori ja poista virta-avain.

2. Pidä kädet, jalat ja vaatteet erossa liikkuvista osista. Odota, että kaikki liikkuvat

osat pysähtyvät, ennen kuin alat puhdistaa, säätää tai huoltaa laitetta.

3. Älä laske käyttöalueelle sivustakatsojia tai eläimiä.

4. Älä koskaan ota matkustajia, jollei traktorissa ole heitä varten tarkoitettua

istuinta.

5. Älä koskaan käytä ruohonleikkuukonetta, jos poistoaukon suuntainta ei ole

kiinnitetty tiukasti paikalleen.

Noudattamalla tässä käyttöoppaassa annettavia ohjeita pidennät laitteen käyttöikää ja ylläpidät sen maksimaalista

tehokkuutta. Säätöjä ja huoltotoimia saa tehdä vain niihin koulutuksen saanut henkilö.

Jos tarvitset lisätietoja tai jos laitetta on huollettava, ota yhteys Jacobsen in valtuutettuun jälleenmyyjään, jolla on

viimeisimmät tiedot laitteen huoltotoimista ja jolta saa nopeaa ja tehokasta palvelua. Muiden kuin alkuperäisten tai

valtuutettujen Jacobsen -osien ja lisävarusteiden käyttö mitätöi takuun.

FI-4

Page 23

MERKINNÄT 2

2 MERKINNÄT

Tutustu merkintöihin. Niiden tunteminen on erittäin tärkeää laitteen turvallisen käytön

kannalta. KORJAA VIOITTUNEET MERKINNÄT HETI.

VAROITUS

!

1. Lue käyttöohje. Älä anna

kouluttamattomien käyttäjien

käyttää konetta.

2. Pidä suojalaitteet paikoillaan

ja varmista, että kaikki osat

ovat tiukasti kiinni.

3. Vapauta kaikki käyttölaitteet,

kytke seisontajarru ja

sammuta moottori ennen

laitteen puhdistamista,

säätämistä ja korjaamista.

4. Pidä kädet, jalat ja vaatteet

erossa liikkuvista osista.

5. Älä ota matkustajia.

6. Pidä sivustakatsojat loitolla.

7. Tarkista letkut ja

kangaspeitteet päivittäin. Jos

ne ovat kuluneet tai

vaurioituneet, vaihda

alkuperäisiin laatuosiin.

Älä käytä laitetta rinteissä ,

8.

joiden kaltevuus on yli

20°.

ÄLÄ KÄYTÄ TÄTÄ KONETTA SUOJUS POISTETTUNA,

ETTEI ITSELLESI TAI MUILLE AIHEUDU VAMMOJA.

JÄÄHDYTTIMESSÄ ON PAINETTA. POISTA

KORKKI HITAASTI VAHINKOJEN VÄLTTÄMISEKSI.

! HENGENVAARA

Toimi seuraavasti, jotta välttäisit loukkaantumisen akkua

käsitellessäsi:

1. Kytke musta maadoituskaapeli (-) aina viimeisenä ja irrota

se ensimmäisenä.

2. Älä käsittele tulta akun läheisyydessä ja vältä joutumista

kosketuksiin hapon kanssa.

! VAROITUS

521760

! VAROITUS

365956

! VAROITUS

• Asenna kaatumissuojarakenne ennen kuin käytät

konetta yli 14° kaltevilla

alustoilla.

• Älä käytä mäissä, joiden

kaltevuus on yli 21°.

• Pidä sivulliset etäällä.

3002529

DANGER

KEEP HANDS AND FEET AWAY

Toimi seuraavasti, jotta välttäisit loukkaantumisen

apukäynnistyskaapeleita käyttäessäsi:

1. Kytke positiivinen napa (+) toiseen positiiviseen napaan (+).

2. Kytke toimivan akun negatiivinen napa (-) sen ajoneuvon

runkoon, jossa on tyhjä akku.

3001435

! VAROITUS

Älä irrota tai leiki istui men kytkimellä,

ettei vakavia vammoja aiheudu.

Lue lisätietoja opaskirjasta.

365339

835892

FI-5

Page 24

3 ALKUTARKISTUS

!

!

3 Alkutark is tus

3.1 YLEISTÄ______ ___ __ __ ___ _________________________________________________

Ammattitaitoisen teknikon, joka tuntee laitteen, on

testattava se aina ennen käyttöönottoa.

Lue kaikki ohjeet ko kona a n ja va rm ist a , et tä ym m är rät ne

ennen kuin jatkat. Pysy valppaana mahdollisten vaar an

aiheuttajien tunnistamiseksi ja noudata kaikkia

turvallisuusohjeita.

Laitteen suunnista OIKE A ja VASEN, ETU ja TAKA ovat

suuntia kuljettajasta katsoen, kun istutaan kuljettajan

paikalla katse eteenpäin.

Lisävarusteet eivät kuulu toimitukseen j a ne on tilattava

erikseen. Katso lisävarusteiden asennusohjeet ja

osaluettelot.

VAARA

Älä yritä ajaa konetta ellet ole tutustunut

tämäntyyppiseen laiteeseen ja ellet tiedä, kuinka

hallintalaitteita käytetään asianmukaisesti.

3.2 ALKUTARKISTUS _________________________________________________________

VAARA

Alkutarkistus on tehtävä moottorin ollessa sammuneena ja kaikkien nesteiden ollessa kylmiä. Laske lisälaitteet

maahan, kytke käsijarru päälle ja pysäytä moottori sekä poista virta-avain.

1. Tarkista koko runko silmämääräisesti. Tarkkaile

erityisesti kuluneita osia tai irtonaisia laitteita ja

komponentteja, jotka ovat voineet vaurioitua

kuljetuksen aikana .

2. Tarkista maalipinta ja tarrat vaurioiden ja naarmuje n

varalta. Tarroissa on tärkeit ä käyttö- ja turval lisuusohjeita. Ilmoita jälleenmyyjällesi heti puuttuvista

tarroista ja korvaa puuttuvat tai vaikeasti luettavat

tarrat välittömästi.

3. Kaikkien nestepintojen on osoitettava täyttä säiliötä

moottorin ollessa kylmä.

Tarkista:

a. Jäähdyttimen jäähdytinnesteen taso.

b. Moottorin öljyntaso.

c. Hydr aul ine st een taso.

5. Tarkista, että renkaissa on oikea rengaspaine.

Renkaat on täytetty liian täyteen kuljetusta varten.

Aseta oikeat rengaspaineet seuraavasti:

Etu ......................... 111 kPa

Taka........................ 86 kPa

6. Tarkista hihnan kireys.

[Osa- ja huolto-oh je, kappale 3.3]

7. Tarkista akun liitännät ja elektrolyyttitaso. Tarkista,

että akku on kokonaan ladattu.

8. Tarkista, että polttoainetta tai öljyä ei vuoda.

9. Tarkista, että voitelupisteissä on riittävä voitelun.

[Osa- ja huolto-oh je, kappale 6.3]

4. Varmista, että ilmansuodattimen liitännät ovat

kunnossa ja että suojus on tiukasti paikallaan.

FI-6

Page 25

SÄÄTIMET 4

!

4 SÄÄTIMET

4.1 KUVAKKEET______________ ___ __ ____________________________ __ ___ __ ________

Tutustu

käyttöoppaaseen

Tuntimittari

Polttoaine

D

Moottori

Pois Käynnissä Käynnistä

päältä

Seisontajarru

T yöskentelyvalot

PTO

Päällä

Laske Nosta

Öljytason testauskytkin

Päällä Poissa päältä

/ testi

Poissa

päältä

Kelat

Moottorin pyörintänopeus

Suuri Pieni

Vakionopeudennsäädin

Lukitse Vapauta

Ajo

Eteenpäin Taaksepäin

Jäähdytysnesteen

lämpötila

Älä koskaan aja traktoria, ellet ole lukenut käyttöopasta ja ellet tiedä, miten kaikkia säätimiä

tulee käyttää.

Tutustu yllä oleviin kuvakkeisiin ja niiden merkitykseen. Opettele kaikkien säädinten ja

mittareiden sijainti ja käyttötarkoitus ennen traktorin käyttöä.

Hydrauliöljyn

taso

Varoitusmerkkivalot

Moottoriöljyn

paine

-

Hydrauli-

öljyn

suodatin

Hehku-

tulppa

VAROITUS

Akun

varaus

FI-7

Page 26

4 SÄÄTIMET

4.2 SÄÄTIMET _______________________________________________________________

A Kallistussäädin

B1 Seisontajarrun lukituskytkin

B2 Seisontajarrun

vapautuskytkin

C Seisontajarru

D Leikkuunopeuden rajoitin

E Eteenpäinajo (vetopoljin)

F Peruutus (vetopoljin)

G

Istuimen säädin

H Hydrauliöljysäiliön korkki/

öljytikku

I Polttoainesäiliön korkki

J Ilmanpuhdistimen

merkkivalo

K (ei käytössä)

L Hälytin

B

1

C

B

2

M

Valotaulu ja sulakkeet

N Hydrauliöljyn merkkivalo

O Öl jytason testauskytkin

P

Leikkurin nostovipu

Q PTO-kytkin

R Vetoluistonesto

S Valokytkin

T Moottorin pyörintänopeus

U Vakionopeudensäädin

(lisävaruste)

V Virtalukko

W Tuntimittari

X Polttoainemittari

Y Varoitusvalot

Z Lämpömittari

D

F

E

P

Q

R

O

S

N

Z

X

Y

W

V

U

T

FI-8

A

L

G

I

H

M

J

Page 27

SÄÄTIMET 4

!

!

A. Kallistussäädin

Vapauta ohjauspylväs vetämällä säädintä ylöspäin.

Säädä ohjauspylväs haluamaasi asentoon ja lukitse

paikalleen vapauttamalla säädi

VAARA: Älä koskaan säädä ohjauspylvästä

traktorin ollessa liikkeessä. Pysäytä laite ja

kytke seisontajarru ennen säätämistä.

B. Seisontajarrun lukitus- ja vapautuskytkin

Jos haluat kytkeä seisontajarrun, pidä jarrupoljinta (C)

painettuna ja paina lukituskytkintä (B

kytkeytyy päälle. Jos haluat vapauttaa seisontajarrun,

paina seisontajarrun vapautuskytkintä (B

Huomaa: Moottori sammuu automaattisesti, jos

vetopoljinta pidetään painettuna yli kymmenen sekuntia

seisontajarrun ollessa kytkettynä.

), kunnes se

1

).

2

C. Seisontajarru

Kytke seisontajarru painamalla poljinta.

D. Leikkuunopeuden rajoitin

Rajoittaa eteenpäinajonopeutta leikattaessa. Jos haluat

hidastaa ajonopeutta, käännä vipua siten, että se

koskettaa lattiassa olevaa rajoitusruuvia (D

eteenpäinajopoljinta painetaan. Jos haluat käyttää

täyttä nopeutta, aseta kytkin kuvassa olevaan asentoon

). Voit määrittää haluamasi ajonopeudet rajoitus-

(D

3

ruuvia (D

varaosaoppaassa.

) säätämällä. Lisätietoja on huolto- ja

2

D

D

3

D

2

1

E

F

Kuljetusnopeus

Leikkuunopeus

), kun

1

LF002

Kuva 4A

H. Hydrauliöljysäiliön kork ki/öljyti kku

Kaada puhdasta hydrauliöljyä öljytikussa olevaan

merkkiin asti moottorin ollessa viileä. Älä täytä säiliötä

liian täyteen.

I. Polttoainesäiliön korkki

Kaada polttoainesäiliöön luokan 2 dieselpolttoainetta,

jonka setaaniluku on vähintään 45. Lisätietoja on

kohdassa 5.11.

J. Ilmanpuhdistimen merkkivalo

Osoittaa moottorin ilmanpuhdistimen tilan. Puhdista tai

vaihda ilmanpuhdistin, kun ilmaisimen ikkunassa näkyy

punainen viiva. Lisätietoja on huolto- ja

varaosaoppaassa.

K. (Ei käytössä)

L. Hälytin

Hälytin antaa merkkiäänen ja varoitusvalot (N,Y)

syttyvät, kun jokin edellyttää käyttäjän välittömiä toimia.

Lisätietoja on kohdassa 4.4.

M. Valotaulu ja sulakkeet

V al ot aulu s ijait s ee t ak immaisen k onepellin alla käy ttäjän

istuimen takana. Siinä on neljä merkkivaloriviä, joiden

avulla voidaan seurata traktorin sähköjärjestelmää ja

selvittää siinä esiintyviä ongelmia. Lisätietoja on

huolto- ja varaosaoppaassa.

Valotaulun vieressä on neljä lattaliitinsulaketta. Voit

vaihtaa sulakkeet irrottamalla valotaulun etupaneelin.

VAARA: Sähköjärjestelmän huoltajan on

oltava koulutettu sähköteknikko. Sammuta traktori ja poista avain virtalukosta ennen

sulakkeiden vaihtamista.

N. Hydrauliöljyn merkkivalo

Varoittaa käyttäjää, jos hydrauliöljyä on liian

vähän. Valo toimii yhdessä hälyttimen

kanssa. Lisätietoja on kohdassa 4.4.

Huomaa: Varoitusvalo palaa, kunnes öljy ä on lis ätty.

Jos kuulet myös äänimerkin, voit sammuttaa sen

kääntämällä kytkimen (O) POISSA PÄÄLTÄ asentoon.

E. Eteenpäinajo (vetopoljin)

Jos haluat ajaa eteenpäin, paina polkimen etuosaa.

Hidasta vauhtia ja pysäytä traktori vapauttamalla poljin.

F. Peruutus (vetopoljin)

Jos haluat peruuttaa, paina polkimen takaosaa. Hidasta

vauhtia ja pysäytä traktori vapauttamalla poljin. Anna

traktorin pysähtyä täydellisesti ennen suunnan

vaihtamista.

G. Istuimen säädin

Siirrä istuinta eteen- tai taaksepäin vetämällä

vasemmanpuoleista vipua ulospäin. Voit säätää

istuimen jousitusta kääntämällä istuimen etupuolella

olevaa nuppia.

FI-9

Page 28

4 SÄÄTIMET

4.3 KOJETAULU______________________________________________________________

Q

P

R

O

N

Z

X

Y

W

V

S

O. Öljytason testauskytkin

Tällä kytkimellä voidaan testata hälytintä tai

sammuttaa se, kun öljyn vähäisyys on

havaittu. Pidä kytkin PÄÄLLÄ-asennossa

traktoria käynnistäessäsi ja käyttäessäsi. Jos haluat

testata hälytintä, käännä kytkin POISSA PÄÄLTÄ asentoon ja virtalukko KÄYNNISSÄ-asentoon.

Lisätietoja on kohdassa 4.4.

P. Leikkurin nostovipu

Leikkurin vipu nostaa ja laskee leikkureita. Leikkuri

toimii joko automaattisessa tai manuaalisessa tilassa.

Laske leikkurit painamalla vipua eteenpäin. Nosta

leikkureita vetämällä taaksepäin.

Manuaalinen tila - Aseta leikkuukytkin (Q)

PÄÄLTÄ

leikkurit nousevat tai laskevat, kun nostovipuun

kohdistetaan painetta.

(alas) -asentoon. Tässä asennossa kaikki

POISSA

U

T

Automaattinen tila - Aseta leikkuukytkin (Q)

(ylös) -asentoon. Automaattisessa tilassa leikkurit

laskevat ja käynnistyvät automaattisesti, kun nostovipua

siirretään hetkeksi eteenpäin. Tässä tilassa leikkurit

nousevat vain "ristileikkuun" asentoon, kun nostovipua

siirretään hetkeksi taaksepäin.

Jos haluat nostaa leikkurit kuljetusasentoon, pidä vipua,

kunnes leikkurit ovat kokonaan ylhäällä.

HUOMAA: Automaattitilan noin 3 sekuntia kestävän

nosto- tai laskujakson aikana nostovivun siirtäminen

vastakkaiseen suuntaan kytkee kaikki leikkurit pois

päältä. Manuaalinen tila käynnistyy nyt valitun asennon

kohdalla.

Q. PTO-kytkin

PTO-kytkin on kaksiasentoinen nuppikytkin, jolla

leikkurit käynnistetään ja sammutetaan. Tällä kytkimellä

asetetaan myös leikkurin nostovipu (P) käsikäyttöiseen

tai automaattiseen tilaan. Aseta leikkurikytkin

PÄÄLTÄ

(alas) asentoon, kun käynnistät traktorin.

Kuva 4B

PÄÄLLÄ

POISSA

FI-10

Page 29

R. Vetoluistonesto

Vetoluistonestojärjestelmä aktivoidaan painamalla tätä

kytkintä. Tämä järjestelmä vähentää leikkuupöytien

alapainetta lähettämällä sykäyksiä nostopiiriin, mikä

siirtää painoa traktoriin

. Alapaineen vähentäminen

parantaa vetoa, mutta voi s aa da pöy dä t nous em aan ,

mikä aiheuttaa epätasaisen leikkuujäljen. Kytkimen

valo palaa, kun järjestelmä on aktivoituna.

Vetoluistonesto poistetaan käytöstä painamalla

kytkintä uudelleen. Järjestelmän käytöstä

poistaminen voi heikentää vetoa, mutta parantaa

pöydän maakosketusta.

HUOMAA: Vetoluistonestojärjestelmä on asetettava

uudelleen, kun moottori on sammutettu.

S. Valokytkin

Säätelee työskentelyvalojen käyttöä.

T. Moottorin pyörintänopeus

Säätelee moottorin pyörintänopeutta. Käytä laitetta

täydellä kaasulla normaalikäytössä.

SÄÄTIMET 4

U. Vakionopeudensäädin (lisävaruste)

Kun säädin asetetaan PÄÄLLÄ-asentoon, vetopoljin

lukittuu senhetkiseen asentoon. Poljin vapautuu kun

säädin asetetaan POISSA PÄÄLTÄ -asentoon tai jos

seisontajarru kytketään päälle.

V. Virtalukko

Virtalukossa on kolme asentoa: POISSA PÄÄLTÄ,

KÄYNNISSÄ (PÄÄLLÄ) ja KÄYNNISTÄ. KÄYNNISSÄ

(PÄÄLLÄ) -asennossa valotauluohjelma on käytössä

sekä tulo- ja antopiirejä valvotaan. Lisätietoja on

kohdassa 5.4 sekä huolto- ja varaosaoppaassa.

W. Tuntimittari

Pitää kirjaa moottorin käyttötunneista. Tuntimittarin

avulla voit ajoittaa huoltotoimet.

X. Polttoainemittari

Osoittaa polttoaineen määrän. Tarkista polttoaineen

määrä päivittäin ennen laitteen käynnistämistä.

Y. Varoitusvalot

Syttyvät, kun jokin edellyttää käyttäjän välittömiä toimia.

Lisätietoja on kohdassa 4.4.

Z. Lämpömittari

Osoittaa jäähdytysnesteen lämpötilan.

Normaalikäytössä lämpötilan tulee olla 71-110 °C. Jos

lämpötila on yli 110 °C, laite antaa äänimerkin.

Lisätietoja on kohdassa 4.4.

FI-11

Page 30

4 SÄÄTIMET

!

!

4.4 VAROITUKSET ____________________________________________________________

Valotaulu valvoo tärkeitä laitejärjestelmiä. Se varoittaa

käyttäjää äänimerkkien ja varoitusvalojen avulla, jos jokin

edellyttää välittömiä toimia. Noudata tällaisessa tilanteessa

alla olevassa taulukossa olevia ohjeita sekä kentänhoitajan

tai huoltopäällikön määräyksiä.

Hälyttimen testaaminen:

Käännä virtalukko KÄYNNISSÄ-asentoon. Kaikki valot