Page 1

SERVICE MANUAL

854DX

Electric Bender

Read and understand all of the instructions and

safety information in this manual before operating

or servicing this tool.

Register this product at www.greenlee.com

52067682 © 2014 Greenlee Textron Inc. 5/14

Page 2

854DX Electric Bender

Table of Contents

Safety ............................................................................ 2

Purpose of this Manual ................................................. 2

Other Publications ......................................................... 2

Important Safety Information .....................................3–5

Service Instructions ..................................................6–14

Illustrations .............................................................15–17

Parts List ................................................................18–23

Bending Attachments .............................................24–25

Wiring Diagram ............................................................ 26

Safety

Safety is essential in the use and maintenance of

Greenlee tools and equipment. This manual and any

markings on the tool provide information for avoiding

hazards and unsafe practices related to the use of this

tool. Observe all of the safety information provided.

Purpose of this Manual

This manual is intended to familiarize authorized

Greenlee service center personnel with the safe

operation and maintenance procedures for the

Greenlee˛854DX Electric Bender.

Keep this manual available to all personnel.

Replacement manuals are available upon request at no

charge at www.greenlee.com.

Other Publications

Instruction Manual: Publication 52067681

Do not discard this product or throw away!

For recycling information, go to www.greenlee.com.

All specications are nominal and may change as design

improvements occur. Greenlee Textron Inc. shall not be liable for

damages resulting from misapplication or misuse of its products.

KEEP THIS MANUAL

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

2

Page 3

IMPORTANT SAFETY INFORMATION

SAFETY

ALERT

SYMBOL

This symbol is used to call your attention to hazards

or unsafe practices which could result in an injury or

property damage. The signal word, dened below,

indicates the severity of the hazard. The message

after the signal word provides information for preventing or avoiding the hazard.

Immediate hazards which, if not avoided, WILL result

in severe injury or death.

854DX Electric Bender

Electric shock hazard:

• Inspect the power cord before

use. Repair or replace the cord if

damaged.

• Connect the power cord to a

120 volt, 20 amp receptacle on a

ground fault protected circuit only.

Refer to “Grounding Instructions.”

• Do not modify the power cord or

plug.

• Disconnect the unit from power

before servicing.

Failure to observe this warning could

result in severe injury or death.

Hazards which, if not avoided, COULD result in

severe injury or death.

Hazards or unsafe practices which, if not avoided,

MAY result in injury or property damage.

Read and understand all of the

instructions and safety information

in this manual before operating or

servicing this tool. Refer also to the

Instruction Manual, which is listed

under “Other Publications.”

Failure to observe this warning will

result in severe injury or death.

Do not use this tool in a hazardous

environment. Hazards include ammable liquids, gases, or other materials. Using this tool in a hazardous

environment can result in a re or

explosion.

Failure to observe this warning will

result in severe injury or death.

For continued protection against risk of re and

electric shock, replace ONLY with same manufacturer,

type, and rating of fuse. Refer to the “Maintenance”

section of the Instruction Manual, which is listed

under “Other Publications.”

Failure to observe this warning could result in severe

injury or death.

• Do not use in dangerous environment. Do not use power tools in

damp or wet locations, or expose

them to rain. Keep work area well

lighted.

• Do not immerse the pendant switch

in water or any other liquid.

Failure to observe these warnings

could result in severe injury or death.

Always use safety glasses. Everyday

glasses only have impact resistant

lenses; they are NOT safety glasses.

When using in dusty environment, use

face or dust mask.

Failure to wear eye protection could

result in serious eye injury from ying

debris.

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

3

Page 4

854DX Electric Bender

IMPORTANT SAFETY INFORMATION

• Keep guards in place and in

working order.

• Remove any tools from bender

before operating. Form habit of

checking to see that all tools are

removed from bender before

turning it on.

Failure to observe these warnings

could result in severe injury or death.

Extension cords:

• Use only three-wire, 12 AWG extension cords that have three-prong

grounding-type plugs and threehole receptacles that accept the

tool’s plug.

• Do not use extension cords that are

longer than 30 m (100').

• Repair or replace damaged extension cords.

Failure to observe these warnings

could result in severe injury or death.

Pinch points:

• Keep hands away from bending

shoe, rollers, and conduit when

bender is in use.

• Support conduit when unloading.

Conduit can become loose and fall

if not properly supported.

Failure to observe these warnings

could result in severe injury or death.

• Reduce the risk of unintentional starting. Make sure

switch is in off position before plugging in.

• Never leave tool running unattended. Turn power

off. Do not leave tool until it comes to a complete

stop.

• Disconnect tools before servicing and when changing accessories such as shoes, rollers, and the like.

Accidental start-up could result in serious injury.

Failure to observe these warnings could result in

severe injury or death.

• Never stand on tool. Serious injury could occur if

the tool is tipped.

• Do not overreach. Keep proper footing and balance

at all times.

Failure to observe these warnings could result in

severe injury or death.

Adjust fork spacing to match fork tubes on bender.

Ensure front wheel brakes are engaged before inserting forks into fork tubes.

Failure to observe this warning could result in severe

injury or death.

• Select the appropriate shoe groove and support

roller for the type and size of conduit before

bending.

• Do not bend conduit over 96 degrees. Overbending

could result in the other shoe hook colliding with

the conduit.

Failure to observe these precautions may result in

injury or property damage.

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

4

Page 5

854DX Electric Bender

IMPORTANT SAFETY INFORMATION

• Conduit moves rapidly as it is bent. The path of

the conduit must be clear of obstructions. Be sure

clearance is adequate before starting the bend.

• Wear proper apparel. Do not wear loose clothing,

gloves, neckties, rings, bracelets, or other jewelry

which may get caught in moving parts. Nonslip

footwear is recommended. Wear protective hair

covering to contain long hair.

• Do not force rollers or alter tool. It will do the

job better and safer at the rate for which it was

designed.

• Use right tool. Do not force tool or attachment to do

a job for which it was not designed.

• Use this tool for the manufacturer’s intended

purpose only. Use other than that which is

instructed in this manual can result in injury or

property damage.

Failure to observe these precautions may result in

injury or property damage.

• Keep work area clean. Cluttered areas and benches

invite accidents.

• Keep children away. All visitors should be kept safe

distance from work area.

• Make workshop kid proof with padlocks, master

switches, or by removing starter keys.

Failure to observe these precautions may result in

injury or property damage.

• Inspect the bender before use. Replace worn,

damaged, or missing parts with Greenlee replacement parts. A damaged or improperly assembled component could break and strike nearby

personnel.

• Maintain tools with care. Keep tool clean for best

and safest performance. Follow instructions for

lubricating and changing accessories.

• Check damaged parts. Before further use of the

tool, a guard or other part that is damaged should

be carefully checked to determine that it will

operate properly and perform its intended function. Check for alignment of moving parts, binding

of moving parts, breakage of parts, mounting, and

any other conditions that may affect its operation.

A guard or other part that is damaged should be

properly repaired or replaced.

• Use recommended accessories. Consult the

instruction manual for recommended accessories.

The use of improper accessories may cause risk of

injury to persons.

• Some bender parts and accessories are heavy

and may require more than one person to lift and

assemble.

Failure to observe these precautions may result in

injury or property damage.

Note: Keep all decals clean and legible, and replace

when necessary.

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

5

Page 6

Service Instructions

854DX Electric Bender

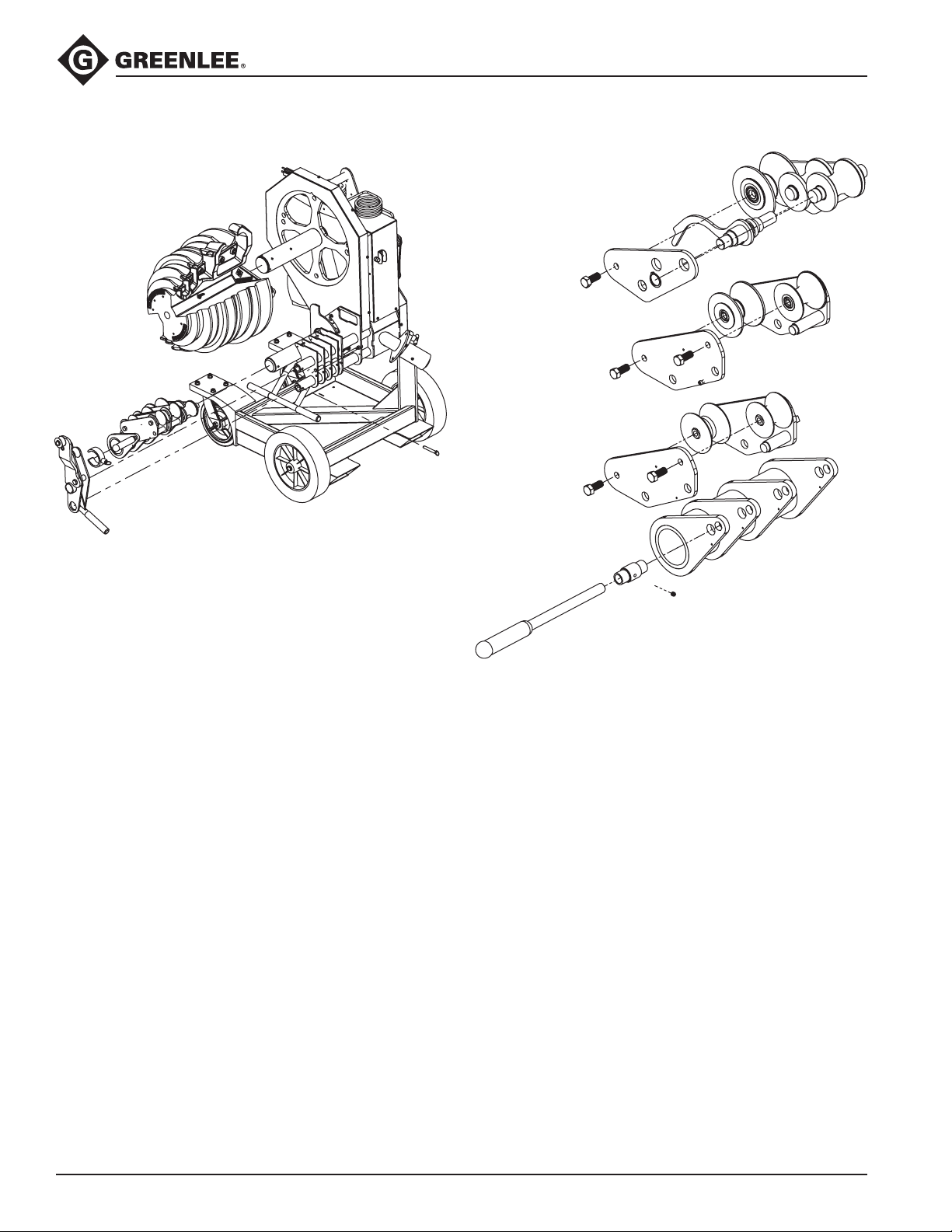

Roller Assembly Removal

1. Position the bender head in the vertical position.

2. Pull the ring of the lock pin in the shoe, and while

pulling the lock pin slide the shoe off the main

spindle.

3. Remove the detent pin and the 1/2" to 1" roller

support along with the lifting handle.

4. Disconnect the roller return spring from the roller

arm weldment.

5. Disconnect the spring from the 1-1/2" rollers group.

6. Slide the roller assembly and the roller support

assembly outward together about an inch until the

2" tail roller shaft is free from the slot in the roller

stop plate.

7. Remove the lock collar that retains the roller

assembly.

8. Rotate the roller assembly counterclockwise until

the roller plates are clear of the support plates.

9. Slide the roller assembly out to remove.

10. Reassemble in reverse order noting the following:

When sliding the roller assembly onto the support

shaft, keep the arm weldment between the 12 and

1o’clock position to prevent damaging the arm

position switch.

Roller Assembly Disassembly

1. Loosen the set screw on the collar that secures the

roller engagement handle, and pull out the handle,

1-1/4" roller group, and 1-1/2" roller group.

2. Loosen the set screw on the cam release mechanism, pull or drive out the pivot shaft, and remove

the 2" roller group.

3. Disassemble the 1-1/4" roller group.

a. Remove the two hex screws securing the outer

plate and the outer plate.

b. Remove the two rollers.

c. Reassemble in reverse order noting the

following:

• The slightly larger diameter roller mounts to

the left.

• Apply molybdenum grease to the roller shafts.

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

6

Page 7

Service Instructions (cont’d)

4. Disassemble the 1-1/2" roller group.

a. Remove the two hex screws securing the outer

plate and the outer plate.

b. Remove the tail roller.

c. Remove the O-rings, pivot balls, split rollers, and

belleville washers noting their orientation.

d. Reassemble in reverse order noting the

following:

• Assemble the Belleville washers so they form a

“V” open outward.

• Place the O-rings between the split rollers until

both screws have been tightened and then slip

them over the split rollers so they form a seal

between the rollers and the pivot ball.

• Apply molybdenum grease to the tail roller

shaft and pivot balls.

5. Disassemble the 2" roller group.

a. Remove the hex screw, retaining ring, and outer

plate.

b. Remove the middle roller, middle shaft, tail roller,

and tail shaft.

c. Remove the O-rings, pivot balls, split rollers, and

spacer.

d. Reassemble in reverse order noting the

following:

• Place the O-rings between the split rollers until

the screw has been tightened and then slip

them over the split rollers so they form a seal

between the rollers and the pivot ball.

• Apply molybdenum grease to the middle roller

shaft and pivot balls.

6. Reassemble the full assembly in reverse order

noting the following:

a. The end of the 2" pivot shaft should be ush

outside of the adjacent arm.

b. The end of the engagement handle should be

ush with the inside of the same arm.

c. The cam release mechanism should be installed

with the spring on the inboard side of the lever.

d. The tail of the 1-1/4" roller group must be

trapped below the tail of the 1-1/2" roller group.

854DX Electric Bender

Roller Support Assembly Removal

1. Remove the roller assembly (refer to previous

instruction).

2. Slide the roller support assembly off the frame

tubes.

3. Reassemble in reverse order noting the following:

Fit the spring retainer with the two springs over the

lower frame tube between the second and third

support plates (as counted from the outside).

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

7

Page 8

Service Instructions (cont’d)

854DX Electric Bender

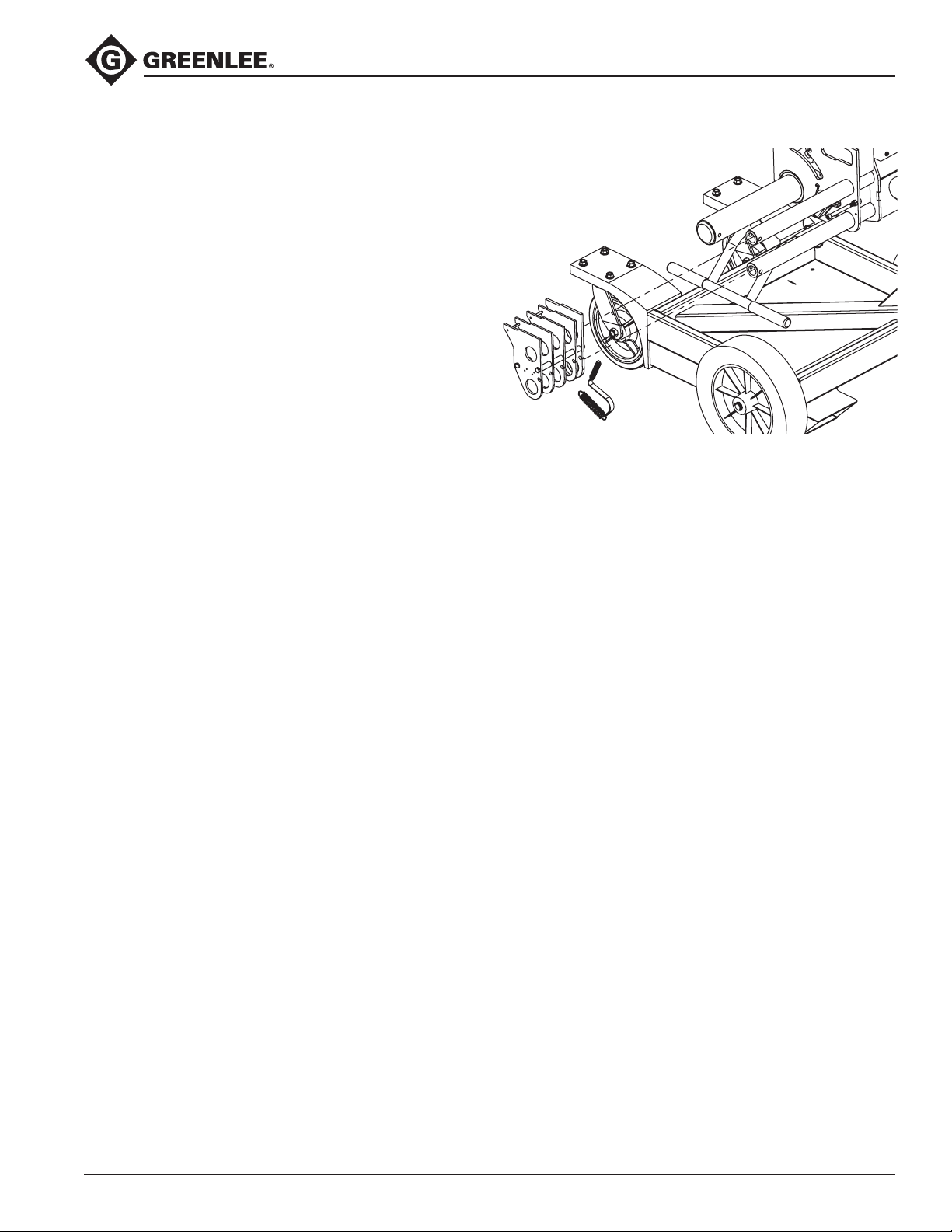

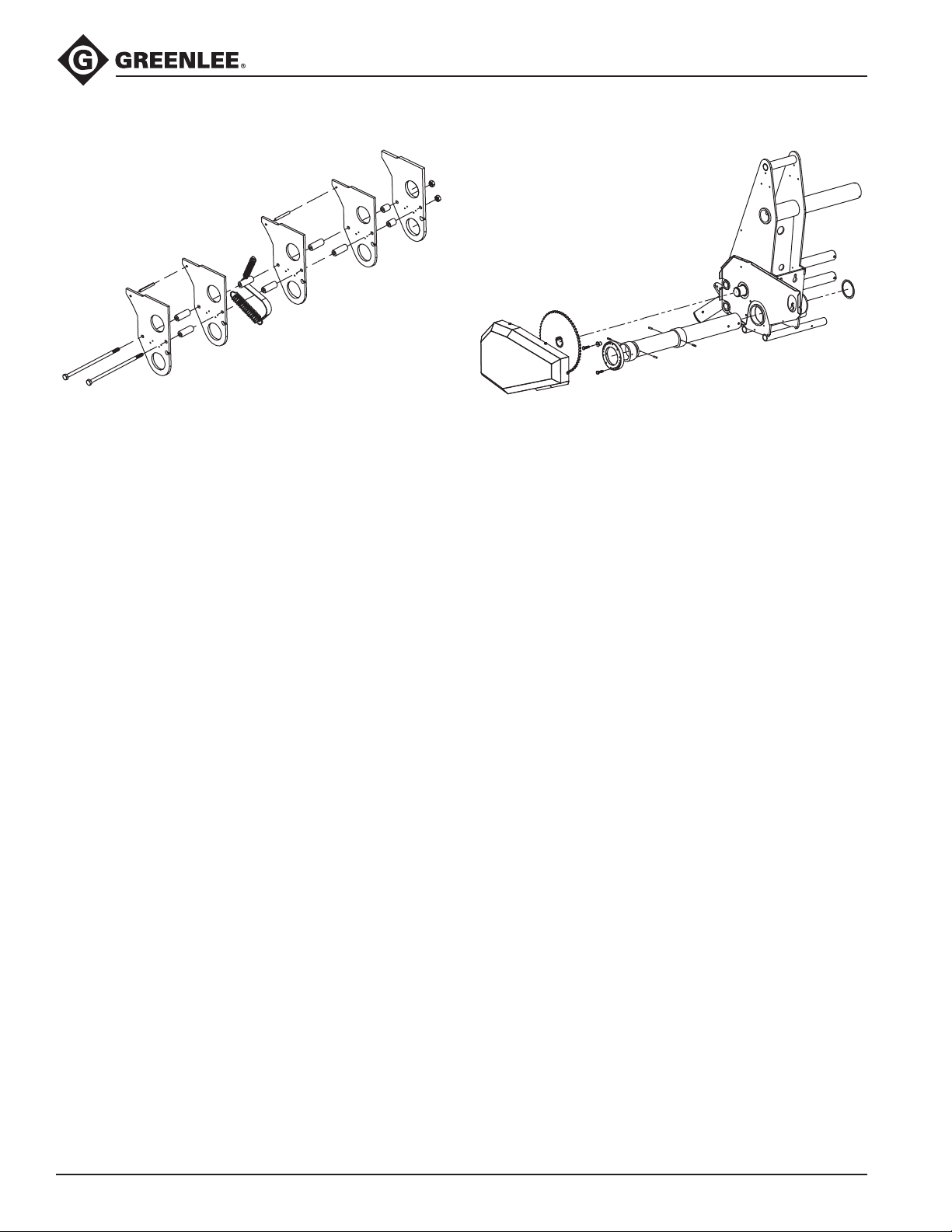

Roller Support Assembly Disassembly

1. Remove the two hex nuts securing all the support

plates.

2. Remove the rst plate and two short spacers.

3. Pry the plate from the rollpin, and remove the

second plate and two long spacers.

4. Remove the third plate and two long spacers.

5. Pry the plate from the rollpin, and remove the fourth

plate and two long spacers.

6. Remove the screws from the last support plate.

7. Reassemble in reverse order noting the following:

a. Slip joint pliers can be used to press the spring

anchor rollpins into the support plates by

squeezing the plates together over the rollpin.

b. Slide the completed assembly onto the frame

tubes with the nuts loose and tighten on the

frame to ease mounting and future removal.

c. With the assembly fully pushed in, the tip of the

right side 6" screw should t inside the hex head

of the 5/16" screw attached to the roller stop

plate.

Eccentric Roller Shaft

1. Remove the roller assembly (refer to previous

instruction).

2. Remove the ber thrust washer from the front of the

shaft.

3. Remove seven screws and rear chain guard.

4. Remove two screws securing squeeze adjuster and

the retainer on the top screw. Note which hole the

lower screw is in.

5. Remove the adjuster.

6. Remove the rollpins by driving them into the ID of

the shaft.

7. Pull out the shaft from the front and the rear eccentric from the rear.

8. Remove the front eccentric same as the rear if

needed.

9. Reassemble in reverse order noting the following:

a. Slide the front eccentric over the shaft so the

3/16" holes are closest to the rear.

b. Drive the rollpins into the holes so that they do

not protrude.

c. Lubricate the eccentrics with molybdenum

grease.

d. Insert the shaft into the frame from the front.

e. Insert the rear eccentric into the frame and over

the shaft so the 3/16" holes are visible.

f. Align the holes in the eccentric and shaft

together, making sure that thick part of both

eccentrics are oriented together.

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

8

Page 9

Service Instructions (cont’d)

g. Drive the rollpins into the holes leaving 1/4" pro-

truding on both sides.

h. Orient the shaft so that the thick part of the

eccentric is at 3 o’clock as viewed from the rear

of the bender.

i. Place the adjuster over the rear eccentric so that

the original hole used is on the right side.

j. Insert the hex screw through the retainer so

screw head abuts the ange and screw into the

top hole.

k. Insert the second screw into the original hole

and rotate the shaft until the screw can be

threaded into its hole.

854DX Electric Bender

Roller Stop Plate

1. Remove the roller assembly (refer to previous

instruction).

2. Remove the roller support assembly (refer to

previous instruction).

3. Remove the two screws securing the roller stop

plate.

4. Disconnect the trip switch cable.

5. Slide the roller stop plate off the shafts.

6. Remove the cam spring.

7. Remove the at head screw, nut, washer, spacer,

and cam.

8. Reassemble in reverse order.

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

Outer Control Box

1. Remove the two screws at the bottom front of the

control box (right side of bender).

2. Remove the two screws at the top rear of the

control box and remove the wire cover.

3. Lift the outer control box up and outward.

4. Pull off the two motor leads from the circuit board

noting their orientation.

5. Pull off the encoder cable from the circuit board.

6. Pull off the trip switch wire harness.

7. Reassemble in reverse order noting the following:

Connect motor leads to same tabs as removed

from.

9

Page 10

Service Instructions (cont’d)

854DX Electric Bender

Front Drive Chain

1. Remove the roller stop plate (refer to previous

instruction).

2. Remove the seven screws and the front guard.

3. Position the chain master link between the 10 and

11 o’clock position.

4. Remove the plastic chain stay roller.

5. Remove the two center screws securing the chain

guard stiffener along with the three screws securing

the back guard, and remove back guard.

6. Remove the master link and chain.

7. Reassemble in reverse order noting the following:

a. Use new cotter pins to attach the drive chain.

b. A new chain will be tight. Place one end of the

chain at 10–11 o’clock position and wrap the

remainder over the top of the big sprocket,

down and around the drive sprocket, and back

up to the big sprocket. Ensure that there is no

slack anywhere and hold the chain against the

outside of the sprocket. Force the chain into the

sprocket teeth at the point where it rst contacts

the sprocket. (A rubber hammer may be used to

persuade the chain.) While holding the chain in

the sprocket teeth, t the rest of the chain onto

the sprocket. Fit the connecting link.

Inner Control Box

1. Remove or loosen roller stop plate (refer to previous

instruction for removal or to pull roller assembly and

roller support assembly outward about an inch).

2. Remove outer control box (refer to previous

instruction).

3. Remove seven screws and rear chain guard.

4. Remove seven screws and front chain guard.

5. Remove the conduit nut securing the SealTite

conduit to the control box.

6. Pull the encoder and trip switch cables out through

the bushing.

7. Remove the hex nut inside the chain guard, and

back out the screws holding the control box.

8. Slide out the inner control box.

9. Reassemble in reverse order.

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

10

Page 11

Service Instructions (cont’d)

854DX Electric Bender

Front Sprocket Assembly

1. Remove the front drive chain (refer to previous

instruction).

2. Screw in the three set screws securing the spindle

cap about four turns and pull off the cap.

3. Push the sprocket fully inward to gain access to the

retaining ring.

4. Remove the retaining ring and large washer.

5. Slide the sprocket weldment off the bender.

6. Reassemble in reverse order noting the following:

a. With the sprocket pushed back against the

frame, press the outer part of the torque arm into

the slot of the spindle cap along the axis of the

spindle. Slide the sprocket fully outward while

tting the cap into the spindle.

b. Do not tighten the set screws so they protrude

beyond the outer diameter of the spindle.

Encoder Assembly

1. Remove front sprocket assembly (refer to previous

instruction).

2. Remove the outer control box (refer to previous

instruction).

3. Disconnect the encoder cable and pull cable out of

inner control box bushing.

4. Screw in the three set screws securing the encoder

mount about four turns and pull out the mount

complete with encoder and cable. Feed the cable

through the spindle while pulling the encoder mount

out.

5. Pull off the encoder cable.

6. Remove the encoder cover by prying out the plastic

locking tabs.

7. Remove the two socket head screws securing the

encoder case.

8. Pull the encoder magnet off the shaft.

9. Loosen the set screw securing the torque arm and

remove it and the thrust washer.

10. Pull out the encoder shaft.

11. Reassemble in reverse order noting the following:

a. Press the magnet onto the shaft 0.002" from the

base.

b. After securing the torque arm to the shaft,

ensure that the shaft turns freely.

c. Pry the decorative cap from the rear end of

the spindle shaft to gain access for feeding

the encoder cable through the grommet to the

control box.

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

11

Page 12

Service Instructions (cont’d)

d. Re-zero the bender after bender assembly is

complete minus the shoe:

• Position the drive sprocket so that the spoke

with two holes is around the 3 o’clock position.

• Accurately align the hole now at the 12 o’clock

position with the round centering hub behind

the sprocket.

• Set the zero point to memory by pressing and

holding the CLEAR button on the pendant and

then pressing the JOG button simultaneously.

Motor

1. Remove the outer control box (refer to previous

instruction).

2. Pull off the two motor leads from the circuit board

noting their orientation.

3. Disconnect the SealTite connector at the motor.

4. Remove the four screws attaching the motor to

the gearbox. (If access to the front inside screw is

not attainable with a 7/16" ex socket or stubby

wrench, access can be gained by removing the front

sprocket assembly and the front guard backing

plate.)

5. Pull off the motor while feeding the motor leads out

of the SealTite conduit.

6. Reassemble in reverse order noting the following:

a. Fitting the keyway between the motor and

gearbox may require staking it to keep it in

place.

b. For easiest tting of the SealTite connector,

rotate the motor into the connector before tting

the motor mounting screws.

854DX Electric Bender

Gearbox (Option 1)

1. Remove seven screws and rear chain guard.

2. Remove connecting link and rear chain.

3. Loosen the two set screws securing the drive

sprocket on the gearbox and push the sprocket

inward.

4. Slide the collar inward and pry off the C clip.

5. Remove the collar and sprocket.

6. Loosen the four screws securing the gearbox to the

frame.

7. Slide the gearbox downward (gravity may have

already done this) and remove it by pulling the

screw heads through the keyholes in the frame.

8. Reassemble in reverse order noting the following:

Slide the gearbox fully upward after installing the

chain and tighten the mounting screws to tension

the chain.

Note: The gearbox and motor can be removed as a unit

by removing the two inner motor mounting screws and

following the instructions for disconnecting the motor at

the control box.

Gearbox (Option 2)

1. Remove seven screws and rear chain guard.

2. Remove connecting link and rear drive chain.

3. Loosen the two set screws securing the drive

sprocket on the gearbox and push the sprocket

inward.

4. Slide the collar inward and pry off the C clip.

5. Remove the collar and sprocket.

6. Remove the inner chain guard (refer to previous

instruction).

7. Support the gearbox, remove the four screws securing the gearbox, and remove it.

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

12

Page 13

Service Instructions (cont’d)

854DX Electric Bender

8. Reassemble in reverse order noting the following:

Slide the gearbox fully upward after installing the

chain and tighten the mounting screws to tension

the chain.

Note: The gearbox and motor can be removed as a unit

by following the instructions for disconnecting the motor

at the control box.

Countershaft

1. Remove seven screws and rear chain guard.

2. Remove connecting link and rear drive chain.

3. Remove the front drive chain (refer to previous

instruction).

4. Remove a retaining ring from the countershaft.

5. Pull off the sprocket, key, and thrust washer.

6. Pull out the countershaft from the opposite side.

7. Remove the other thrust washer, sprocket, and key.

8. Reassemble in reverse order.

3. Remove the retaining ring at the end of the bender

pivot shaft.

4. Use a hoist to lift the bender head while sliding the

wheeled base off the pivot shaft.

5. Set the bender head down gently on the transport handle receptacle tubes using wood 2x4s for

support.

6. Reassemble in reverse order noting the following:

Apply molybdenum grease to the pivot shaft.

Wheeled Base Disassembly

1. Pull off the pivot detent bracket by loosening one

set screw.

2. Remove a retaining ring from the axle and pull off

the wheel axle and second wheel.

3. Remove the four screws and nuts for each swivel

caster and the caster wheels.

4. Reassemble in reverse order noting the following:

The bender head can be leveled using the two

set screws on the pivot detent bracket. One turn

approximates 1°.

Wheeled Base Removal

1. Remove the bending shoe.

2. Remove the transport handle.

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

13

Page 14

Service Instructions (cont’d)

854DX Electric Bender

Control Board Unit

1. Remove outer control box (refer to previous

instruction).

2. Disconnect the power connections to the board

from the circuit breaker and power cord.

3. Disconnect the pendent receptacle cable.

4. Remove the three button head screws attaching

the control board assembly to the enclosure, and

remove the control board assembly.

5. Reassemble in reverse order.

Pendant Switch

1. Remove three screws holding the housing halves

together and separate.

2. Unplug the pendant cord from the circuit board and

remove strain relief from housing.

3. Remove the three screws and the circuit board.

4. Unplug the keypad from the circuit board.

5. Remove the three screws from the bottom housing

to remove the magnets.

6. Peel the keypad membrane from the top housing.

7. Reassemble in reverse order noting the following:

Clean all residue from the mounting surface.

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

14

Page 15

Illustration

854DX Electric Bender

16B

23B

41C

41

41B

23

41C

19B

47

19

19A

48

16D

16

15A

16A

16C

23C

16C

16D

52

17A

16B

17

40A

40D

40

40C

55

40E

40F

5

40B

22

22A

22B

4B

21

2C

21D

21B

21C

21A

16B

2D

42

43

12D

18

18A

2C

19C

23B

24

24A

25A

12F

43

4B

4

4A

3C

3A

44

23A

8AD

25

23D

23C

41A

3B

3

3D

1A

46

1B

45

1

2

2B

2A

20D

51

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

15

20

20C

20B

20A

Page 16

Illustration —Base

854DX Electric Bender

5E

5D

5F

6B

7

Illustration —Control Box

5C

5G

6C

7A

5Q

6A

5A

50

14

8Y

8N

8AE

8

8O

8J

10

8P

8AC

8K

8S

8B

8R

8W8AD8AB

8AF

8A

8L

8V

8X

8Z

11

49

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

16

Page 17

854DX Electric Bender

Illustration

31F

31B

31C

31J

34G

34D

31A

31

34

34A

34H

34E

34I

31G

31I

34C

36D

35E

34F

36E

31H

23C

34B

36B

31J

36C

36

36G

36F

36A

38

38A

37F

38C

64

66

68

37E

12E

65

38B

61

59

62

56

56

31D

31E

31D

30

31B

30A

31C

31L,31M,

31K

or 31N

29E*

35E

35D

12B

35A

26A

26C

26B

26

56

57

35

30G

30H

35C

30I**

17

35B

to threads.

* Tighten to 40–45 ft-lb torque.

** Apply Loctite 242 adhesive

33D 33A

33E

33B

33C

33E

33F

56

32B

32

32A

39A

33G

33

30B

29F

30F

30B

29E*

30D

30C

29A

29

29B

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

30D

29C

30E

29D

29G

Page 18

854DX Electric Bender

Parts List

Group Key Part No. Description Qty

1 52056409 Cap kit, motor

1A Cap, motor ................................................................................................................ 1

1B Screw, #10-32 x 5/16, hex head slotted ...................................................................3

2 52067860 Guard kit, front main sprocket

2A Guard, front chain ..................................................................................................... 1

2B Decal, stub and offset .............................................................................................. 1

2C Screw, #10-16 x 1/2, thread-forming ........................................................................ 7

2D Decal, bend angle chart ............................................................................................ 1

3 52056411 Sprocket kit, gearbox output

3A Sprocket, #40-13 tooth ............................................................................................. 1

3B Collar ......................................................................................................................... 1

3C Ring, retaining, round ................................................................................................1

3D Key, square, .249 x 1.06............................................................................................1

4 52056624 Sprocket kit, main

4A Sprocket weldment ................................................................................................... 1

4B Bearing, berglide .....................................................................................................2

5 52067871 Base kit

5A Decal, fork lifting ....................................................................................................... 1

5Q Decal, bender pivot ................................................................................................... 1

5C Trunnion weldment .................................................................................................... 1

6A Axle ........................................................................................................................... 1

5D Caster, 8" w/side lock ...............................................................................................2

5E Screw, ange, 3/8-16 x 1.00 ..................................................................................... 8

5F Nut, lock, hex, 3/8-16 ............................................................................................... 8

7A Wheel, rubber (12 x 3) ............................................................................................... 2

6B Ring, retaining, .750 Truarc #5160 EX ....................................................................... 2

5G Fitting, grease, 1/4 alemite #1743-B ......................................................................... 1

6C Washer, .81 x 1.50 x .14 ............................................................................................ 4

6 52056626 Axle kit, wheel

6A Axle ........................................................................................................................... 1

6B Ring, retaining, .750 Truarc #5160 EX ....................................................................... 2

6C Washer, .81 x 1.50 x .14 ............................................................................................ 4

7 52056417 Wheel kit, replacement

7A Wheel, rubber (12 x 3) ............................................................................................... 2

8 52067872 Box kit, control

8A Control board assembly ............................................................................................ 1

8B Cover, box ................................................................................................................. 1

8J Screw, 1/4-20 x .50 btn head skt .............................................................................. 3

8K Receptacle unit, cannon .......................................................................................... 1

8L Guard, switch ............................................................................................................ 1

8N Bushing, strain relief .................................................................................................. 1

8O 91863856 Circuit breaker ........................................................................................................... 1

8P Screw, 4-40 x .50 at head, Taptite II ........................................................................ 2

8R Locknut, 1/2" conduit steel ....................................................................................... 1

8S Cord unit, power ....................................................................................................... 1

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

18

Page 19

854DX Electric Bender

Parts List (cont’d)

Group Key Part No. Description Qty

8V Washer, lock, internal, #6 .......................................................................................... 2

8W Screw, #6-32 x 3/8 phillips pan head ........................................................................1

8X Nut, #6-32 nylon lock ................................................................................................ 1

8Y Strap, velcro .............................................................................................................. 1

8Z Wire assembly ........................................................................................................... 1

8AB Decal, identication ................................................................................................... 1

8AC Decal, operating instructions ....................................................................................1

8AD Screw, #10-32 x 5/16, hex head slotted ................................................................... 2

8AE Holder, fuse ............................................................................................................... 1

8AF 52056934 Fuse (package consisting of 5 fuses) ........................................................................ 1

10 52067873 Assembly kit, control board

8A Control board assembly ............................................................................................ 1

8J Screw, cap, 1/4-20 x .50 btn skt head ...................................................................... 3

11 52056422 Screw kit, ground

8Z Wire assembly (ground) ............................................................................................ 1

8W Screw, #6-32 x 3/8 phillips pan head machine .........................................................1

8X Nut, hex, #6-32 lock .178 thk zp ............................................................................... 1

8V Washer (#6 star, intern, CZ/ST) ................................................................................. 2

12 52067874 Decal kit

5A Decal, fork lifting ....................................................................................................... 1

12B Decal, engage rollers ................................................................................................ 1

8AC Decal, operating instructions ....................................................................................1

8AB Decal, identication ................................................................................................... 1

5Q Decal, bender pivot ................................................................................................... 1

12D Decal, squeeze ..........................................................................................................1

12E Decal, cam release .................................................................................................... 1

12F Decal, lifting .............................................................................................................. 1

2B Decal, stub and offset .............................................................................................. 1

2D Decal, bend angle chart ............................................................................................ 1

29G Decal, cam ................................................................................................................ 1

13 8O 91863856 Breaker, circuit ........................................................................................................1

14 52056426 Cord unit, power

8S Power cord unit ......................................................................................................... 1

8N Bushing, strain relief .................................................................................................. 1

8Y Strap, velcro .............................................................................................................. 1

8R Nut, lock, 1/2" conduit .............................................................................................. 1

15 52056427 Bearing kit

15A Bearing, phenolic ...................................................................................................... 2

4B Bearing, berglide ..................................................................................................... 2

16 52056428 Sprocket kit, #40B60

16A Sprocket, #40 60T (includes 2 set screws) ...............................................................1

16B Ring, retaining, 1.50 Truarc #5100 EX .......................................................................1

16C Key, countershaft ......................................................................................................1

16D Bearing, thrust, 1.50 x 2.62 x .093 ............................................................................ 1

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

19

Page 20

854DX Electric Bender

Parts List (cont’d)

Group Key Part No. Description Qty

17 52056429 Sprocket kit, #60BS14

17A Sprocket, #60 14T (includes 2 set screws) ...............................................................1

16B Ring, retaining, 1.50 Truarc #5100 EX .......................................................................1

16C Key, countershaft ......................................................................................................1

16D Bearing, thrust, 1.50 x 2.62 x .093 ............................................................................ 1

18 52056631 Guard kit, rear chain

18A Guard, rear ................................................................................................................ 1

2C Screw, thread-forming, #10-16 x .50 ........................................................................7

12D Decal, squeeze arrow ................................................................................................ 1

19 52056431 Adjustment kit, squeeze cam

19A Adjuster, squeeze ...................................................................................................... 1

19B Screw, cap, 1/4-20 x 1.00 hex head ......................................................................... 2

19C Guide, adjuster .......................................................................................................... 1

20 52056432 Handle kit, replacement

20A Handle weldment ...................................................................................................... 1

20B Grip ........................................................................................................................... 2

20C Pin, safety snap......................................................................................................... 2

20D Lanyard ..................................................................................................................... 1

21 52056433 Encoder kit

21A Encoder, sub-assembly ............................................................................................1

21B Cap, encoder ............................................................................................................ 1

21C Screw, set, 1/4-20 x .375 skt ....................................................................................3

16B Ring, retaining, 1.50 Truarc #5100 EX .......................................................................1

21D Retainer ..................................................................................................................... 1

22 52056434 Idler kit, chain

22A Stay, chain .................................................................................................................1

22B Washer, at, 2.50 x 3.00 x .031 ber .........................................................................1

23 52056633 Rear guard kit, main sprocket

23A Guard, chain, back .................................................................................................... 1

23B Screw, cap, 1/4-20 x .750 hex head ......................................................................... 3

23C Nut, hex, 1/4-20 ........................................................................................................ 1

23D Hub, centering .......................................................................................................... 1

24 52056436 Back guard kit, rear chain

24A Guard, back, rear ......................................................................................................1

23C Nut, hex, 1/4-20 ........................................................................................................ 2

23B Screw, cap, 1/4-20 x .750 hex head ......................................................................... 3

25 52056437 Guard kit, top frame

25A Cover, wire ................................................................................................................1

8AD Screw, #10-32 x 5/16, hex head slotted ................................................................... 2

26 52067875 Spring kit, roller

26A Spring, lever .............................................................................................................. 1

26B Spring, return ............................................................................................................ 1

26C Anchor, spring ...........................................................................................................1

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

20

Page 21

854DX Electric Bender

Parts List (cont’d)

Group Key Part No. Description Qty

29 52056635 Roller assembly kit, 1-1/4"

29A Support weldment, 1-1/4" ........................................................................................1

29B Roller, lead, 1-1/4" ....................................................................................................1

29C Roller, tail, 1-1/4" ......................................................................................................1

29D Shaft, support, 1-1/4" ............................................................................................... 1

29E Screw, cap, hex head, 7/16-14 x 1.00 ......................................................................2

29F Plate, 1-1/2" outer roller ............................................................................................ 1

29G Decal, cam ................................................................................................................ 1

30 52056636 Roller assembly kit, 1-1/2"

30A Support weldment, 1-1/2" ........................................................................................1

30B O-ring, 1.50 x 1.62 x .062 nitrile ................................................................................ 2

30C Ball, half, 1-1/2" ........................................................................................................ 2

30D Roller, 1-1/2" .............................................................................................................2

30E Washer, belleville, .803 x 1.362 x .043 ...................................................................... 2

30F Roller, 1-1/2" IMC .....................................................................................................1

30G Shaft, support, 1-1/2" ............................................................................................... 1

30H Plate, 1-1/2" outer roller ............................................................................................ 1

29E Screw, cap, hex head, 7/16-14 x 1.00 ......................................................................2

30I Screw, cap, #8-32 x .500 skt head ...........................................................................1

31 52056637 Roller assembly kit, 2"

31A Support weldment, 2" ............................................................................................... 1

31B Ball, 2" half ................................................................................................................ 2

31C O-ring, 1.75 x 1.87 x .062 nitrile ................................................................................ 2

31D Roller, 2" .................................................................................................................... 2

31E Spacer, roller, 2" ........................................................................................................ 1

29E Screw, cap, hex head, 7/16-14 x 1.00 ......................................................................1

31F Shaft, 2" middle roller ............................................................................................... 1

31G Roller, 2" tail .............................................................................................................. 1

31H Shaft, tail, 2".............................................................................................................. 1

31I Roller unit, 2" ............................................................................................................ 1

31J Ring, retaining, .875 .................................................................................................. 2

31K Plate, 2" outer roller ..................................................................................................1

31L Washer, shim, 1.00 x 1.50 x .032 steel ..................................................................... 1

31M Washer, at, .625 x 1.00 x .031 (shim) ...................................................................... 1

31N Washer, at, .625 x 1.00 x .062 (shim) ...................................................................... 1

32 52056638 Handle kit, lift

32A Handle weldment, grab ............................................................................................ 1

32B Grip .......................................................................................................................... 1

33 52067876 Roller kit, 1/2"–1" EMT, IMC, rigid

33A Support weldment, 1" ............................................................................................... 1

33B Arm weldment ........................................................................................................... 1

33C Roller, 1/2".................................................................................................................1

33D Roller, 3/4".................................................................................................................1

33E Retaining ring, Truarc #5100-75 EX ..........................................................................2

33F Retaining ring, Truarc #5160-87 EX ..........................................................................1

33G Wave washer ............................................................................................................. 1

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

21

Page 22

854DX Electric Bender

Parts List (cont’d)

Group Key Part No. Description Qty

34 52056640 Cam kit

34A Cam ........................................................................................................................... 1

34B Screw, cap, 1/4-20 x .750 skt at head .................................................................... 1

34C Nut, hex, #8-32 ......................................................................................................... 2

34D Screw, button head, 8-32 x 3/8 ................................................................................1

34E Spring, cam ............................................................................................................... 1

34F Washer, at, .253 x .725 x .070 .................................................................................1

34G Nut, hex, 1/4-20 jam zp ............................................................................................ 1

34H Screw, cap, #8-32 x .750 skt head ...........................................................................1

34I Bushing ..................................................................................................................... 1

35 52056641 Arm kit, roller

35A Arm weldment ........................................................................................................... 1

35B Grip, rubber ............................................................................................................... 1

35C Handbar .................................................................................................................... 1

35D Sleeve, pivot, 1-1/2" ................................................................................................. 1

35E Screw, set, 1/4-28 x .250 skt ....................................................................................1

12B Decal, engage rollers ................................................................................................ 1

12E Decal, cam release .................................................................................................... 1

36 52055878 Lever assembly, release

36A Lever ......................................................................................................................... 1

36B Spring, clutch ............................................................................................................ 1

36C Collar ......................................................................................................................... 1

36D Ring, retaining, 1.00 Truarc #5100 EX ....................................................................... 1

36E Spacer ....................................................................................................................... 1

35E Screw, set, 1/4-28 x .250 skt ....................................................................................1

36F Washer, at #10.........................................................................................................1

36G Screw, #10-32 x .375 skt btn head cap .................................................................... 1

38 52056644 Stop kit, roller

38A Plate, switch .............................................................................................................. 1

38B Screw, cap, 1/4-20 x 3.500 hex head ....................................................................... 2

38C Guard, lower spacer .................................................................................................. 1

23C Nut, hex, 1/4-20 ........................................................................................................ 2

39 52056645 Hardware kit, roller

39A Screw, cap, 1/4-20 x 6.00 hex head ......................................................................... 2

29E Screw, cap, hex head, 7/16-14 x 1.00 ......................................................................5

38B Screw, cap, 1/4-20 x 3.500 hex head ....................................................................... 2

23C Nut, hex , 1/4-20 ....................................................................................................... 4

37E Screw, 5/16-18 x 4 skt head cap ..............................................................................1

37F Nut, hex , 5/16-18 full ............................................................................................... 2

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

22

Page 23

854DX Electric Bender

Parts List (cont’d)

Group Key Part No. Description Qty

40 52056642 Release kit, pivot

40A Bracket weldment, detent ......................................................................................... 1

40B Screw, 3/8-24 x 1 oval point set ...............................................................................2

40C Handle, detent........................................................................................................... 1

40D Piston, trunnion lock ................................................................................................. 1

40E Pin, roll, .125 x .500 .................................................................................................. 1

40F Spring, comp, .502 x .600 x .625 .............................................................................. 1

41 52067877 Bar kit, guard stiffener

41A Bar, guard stiffener .................................................................................................... 1

41B Screw, 1/4-20 x 5/8 button head cap .......................................................................2

41C Screw, 1/4-20 x 3/8 button head cap .......................................................................2

Individual Items

42 52044514 Lock collar assembly, small ......................................................................................1

43 52047945 Cap, plastic, 2" ......................................................................................................... 2

44 90523881 Reductor ................................................................................................................... 1

45 52057563 Motor, 120V, bender .................................................................................................. 1

46 91864208 Brushes ..................................................................................................................... 2

47 90542509 Chain, roller, #60 (92 pitches) with connecting link ...................................................1

48 52055855 Chain, #40 (86 pitches) with connecting link ............................................................ 1

49 52055021 Switch unit, pendant ................................................................................................. 1

50 52054423 Cord assembly .......................................................................................................... 1

51 52067789 Shoe unit ................................................................................................................... 1

52 52020192 Pin, hitch, short ......................................................................................................... 1

55 90544625 Ring, retaining, Truarc #5100-200 .............................................................................1

56 52044547 Support, tail roller ...................................................................................................... 4

57 52044526 Spacer ....................................................................................................................... 6

59 52044527 Spacer, short ............................................................................................................. 2

61 52055238 Cover, switch .............................................................................................................1

62 52044548 Support, 2" tail roller ................................................................................................. 1

64 52056594 Switch unit, sensor .................................................................................................... 1

65 52055436 Plate, switch retainer ................................................................................................. 1

66 Screw, #4-40 x 1-1/4 socket head cap .....................................................................2

68 52044584 Shaft, release ............................................................................................................ 1

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

23

Page 24

Bending Attachments

Shoe Group for 1/2" to 2" EMT, IMC, and Rigid Conduit

72B

854DX Electric Bender

74

75

73A

72A

Key Part No. Description Qty Key Part No. Description Qty

51 52067789 Shoe unit, 1/2"–2" EMT, IMC, rigid

72 52067881 Hook kit, 1/2"–2" EMT

72A Hook, 1/2"–2" EMT ............................... 1

72B Shoulder screw, ø.75 x 1.50 x 5/8-11 ... 4

73 52067882 Hook kit, 1/2"–2" IMC/rigid

73A Hook, 1/2"–2" IMC/rigid .......................1

72B Shoulder screw, ø.75 x 1.50 x 5/8-11 ... 4

76

77

74 Screw, 1/2-13 x .625 skt hd cap ...........4

75 Cap, shoe stud .....................................1

76 52067880 Plunger, spring ...................................... 1

77 Decal, EMT grooves ..............................1

78 Decal, IMC/rigid grooves

(not shown) ...........................................1

72B

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

24

Page 25

854DX Electric Bender

Bending Attachments (cont’d)

02840 Shoe Group for 1/2" to 2" 40 Mil PVC-Coated Rigid Conduit

4A

74

1

72B

75

5A

4B

2

3G

3E

3

3J

3F

3L

3M

3N

3K

3H

3D

3B

3C

3T

3R

3A

Key Part No. Description Qty Key Part No. Description Qty

1 52067878 Shoe unit, 1/2"–2" PVC-coated rigid

4 52065323 Hook kit, 1/2"–1-1/4" PVC

4A Hook, 1/2"–1-1/4" PVC .........................1

4B Screw, 3/8-16 x 1-1/4 skt hd cap .........4

5 52065324 Hook kit, 1-1/2"–2" PVC

5A Hook, 1-1/2"–2" PVC ............................1

72B Shoulder screw, ø.75 x 1.50 x 5/8-11 ... 3

74 Screw, 1/2-13 x .625 skt hd cap ...........4

75 Cap, shoe stud .....................................1

2 52044571 Lock collar unit ................................... 1

3 52067879 Roller support, 1/2"–1-1/4"

3A Support weldment ................................1

3B Pivot pin ................................................ 1

3C Retaining ring, Truarc #5160-42 EX ..... 2

3D Roller support weldment....................... 1

3E Axle, 1-1/4" roller ..................................1

3F Roller, 1-1/4" .........................................1

3G Axle, 1" roller .........................................1

3H Roller, 1"................................................1

3J Axle, 3/4" roller .....................................1

3K Roller, 3/4" ............................................1

3L Axle, 1/2" roller ..................................... 1

3M Roller, 1/2 ..............................................1

3N Retaining ring, Truarc #5150-50 EX ...... 5

3P Cam ......................................................1

3Q Screw, shoulder, 3/8 x 3/8 x 1/4-20 ...... 1

3R Nut, 1/4-20 lock .................................... 1

3S O-ring, .375 x .562 x .093 .....................1

3T Rollpin, ø.187 x 1.62 ............................. 1

3P

3S

3Q

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

25

Page 26

Wiring Diagram

ENCODER

SWITCH

LINE

LOAD

FUSE

BLACK

BLACK

GREEN

854DX Electric Bender

GROUND

POWER CORD

GREEN

WHITE

PENDANT

RECEPTACLE

ROLLER

SWITCH

J14

J1

J20

MOTOR BLACK

J18

J11 J12

WHITE

J3

J9

BLACK

J6

J8 J5

RED

YELLOW

4455 Boeing Drive • Rockford, IL 61109-2988 • USA • 815-397-7070

An ISO 9001 Company • Greenlee Textron Inc. is a subsidiary of Textron Inc.

www.greenlee.com

USA Tel: 800-435-0786

Fax: 800-451-2632

Canada Tel: 800-435-0786

Fax: 800-524-2853

International Tel: +1-815-397-7070

Fax: +1-815-397-9247

Loading...

Loading...