Page 1

Safety and Operation Manual

Sikkerheds og Instruktionsbog

HR3806

Series: DZ - Engine type: Kubota V1505-E

Product codes: LHAD003

24686G-DK (rev.0)

WARNING: If incorrectly used this machine can cause severe

injury. Those who use and maintain this machine should be

trained in its proper use, warned of its dangers and should

read the entire manual before attempting to set up, operate,

adjust or service the machine.

AD VARSEL: Den ne maski ne kan fo rårsage al vorlig

personskade, hvis den bruges forkert. Alle, der bruger og

vedligeholder denne maskine, skal være korrekt uddannet til

de tte, sk al ad va res o m fa rerne o g læse he le

instruktionsbogen, før maskinen forberedes, bruges, justeres

eller serviceres.

RJ 100 / 012004

YEARS OF MOWING

EXCELLENCE

Page 2

© 2004, Ransomes Jacobsen Limited. All Rights Reserved

Page 3

1 CONTENTS

CONTENTS P AG E

2 INTRODUCTION

2.1 IMPORTANT.............................................................................................................. 2

2.2 PRODUCT IDENTIFICATION....................................................................................... 2

3 SAFETY INSTRUCTIONS

3.1 OPERATING INSTRUCTIONS ..................................................................................... 3

3.2 SAFETY SIGNS .......................................................................................................... 3

3.3 STARTING THE ENGINE ............................................................................................. 3

3.4 DRIVING THE MACHINE ............................................................................................ 3

3.5 TRANSPORTING ........................................................................................................3

3.6 LEAVING THE DRIVING POSITION ............................................................................ 4

3.7 SLOPES..................................................................................................................... 4

3.8 BLOCKED CUTTING DECKS ......................................................................................4

3.9 ADJUSTMENTS, LUBRICATION AND ........................................................................ 4

4 SPECIFICA TIONS

4.1 ENGINE SPECIFICATION ............................................................................................6

4.2 MACHINE SPECIFICATION ........................................................................................ 6

4.3 DIMENSIONS .............................................................................................................6

4.4 VIBRATION LEVEL ....................................................................................................7

4.5 SLOPES..................................................................................................................... 8

4.6 RECOMMENDED LUBRICANTS ................................................................................. 8

4.7 CUTTING PERFORMANCE (AREA) ............................................................................ 8

4.8 CONFORMITY CERTIFICATES ..................................................................................9

RANSOMES HR3806 Series: DZ

SAFETY AND OPERATORS MANUAL

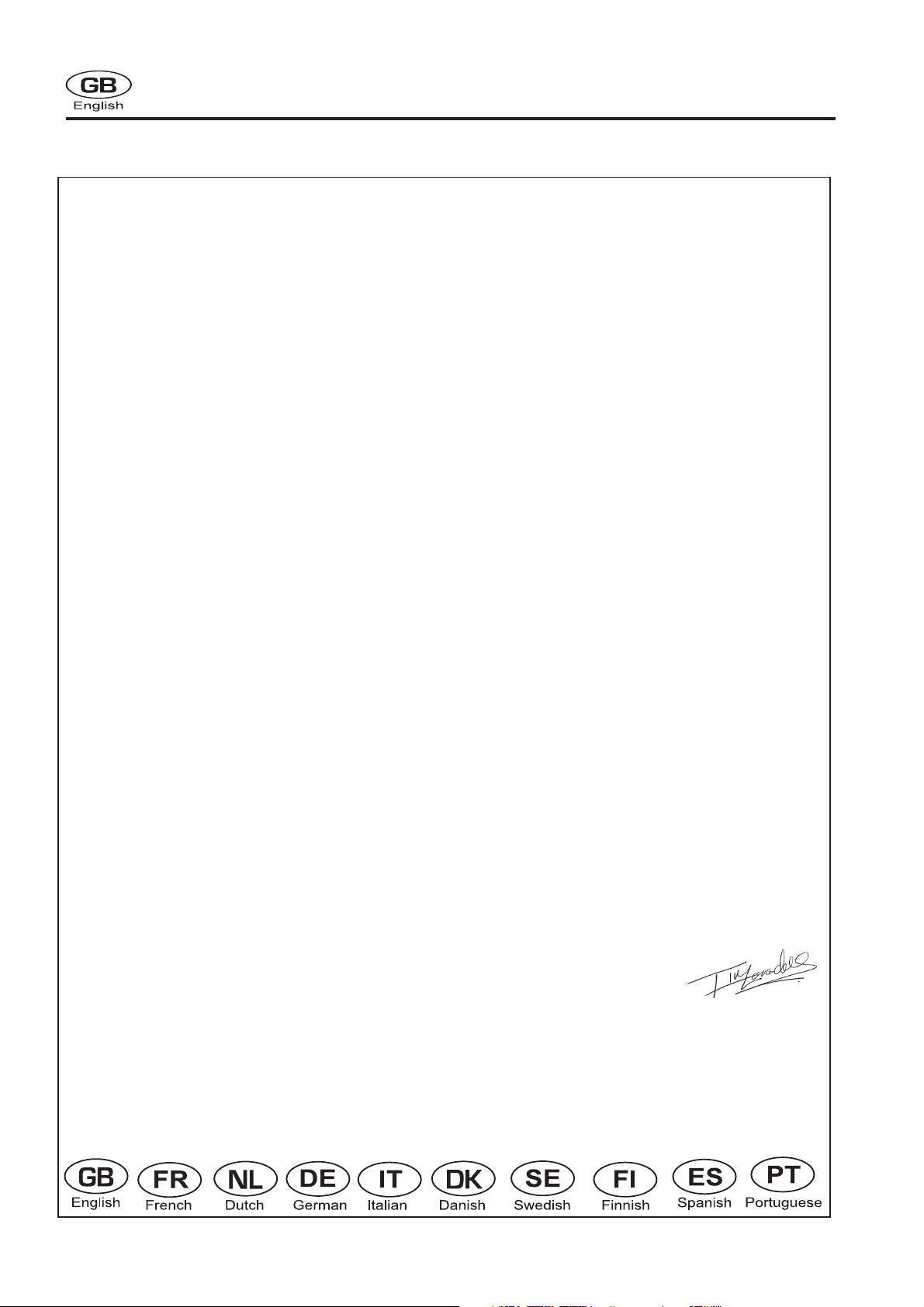

5 DECALS

5.1 SAFETY DECALS ..................................................................................................... 11

5.2 INSTRUCTION DECALS ............................................................................................ 11

6 CONTROLS

6.1 STARTER KEY SWITCH ............................................................................................12

6.2 THROTTLE CONTROL LEVER .................................................................................. 12

6.3 STEERING WHEEL RAKE ADJUSTMENT .................................................................. 12

6.4 TRACTION FOOT PEDAL ......................................................................................... 12

6.5 SPEED LIMITER ........................................................................................................ 12

6.6 P ARKING BRAKE ...................................................................................................... 13

6.7 DIFF LOCK CONTROL .............................................................................................. 13

6.8 HYDRAULIC LIFT LEVERS .......................................................................................14

6.9 CUTTING UNIT SWITCHES ....................................................................................... 14

6.10 INSTRUMENT PANEL ...............................................................................................15

6.11 HOURMETER ............................................................................................................ 16

6.12 HORN ........................................................................................................................ 16

6.13 BONNET RELEASE KEY ............................................................................................ 16

7 OPERATION

7.2 TRAILER TIE DOWNS FOR REAR. ............................................................................. 17

7.1 DAILY INSPECTION .................................................................................................. 17

7.3 OPERATOR PRESENCE AND SAFETY INTERLOCK SYSTEM ................................... 18

7.4 OPERA TING PROCEDURE ......................................................................................... 19

7.5 STARTING THE ENGINE ............................................................................................ 20

7.6 DRIVING ................................................................................................................... 20

7.7 MOWING .................................................................................................................. 21

7.8 TO STOP THE ENGINE .............................................................................................. 21

7.9 PUSHING THE MACHINE WITH THEENGINE STOPPED .............................................21

8 ADJUSTMENTS

8.1 SEA T (GS85/90)....................................................................................................... 22

8.2 HEIGHT OF CUT ....................................................................................................... 23

9 MAINTENANCE

9.1 LUBRICATION AND MAINTENANCE CHART ............................................................ 24

9.2 DAILY CHECKS (EVERY 8 WORKING HOURS) ..........................................................26

10 GUARANTEE / SALES & SERVICE ............................................................................ 28

GB-1

Page 4

2 INTRODUCTION

RANSOMES HR3806 Series: DZ

SAFETY AND OPERATORS MANUAL

2.1 IMPORTANT

IMPORTANT: This is a precision machine and the service obtained from it depends on the way it is

operated and maintained.

This SAFETY AND OPERATORS MANUAL should be regarded as part of the machine. Suppliers of both

new and second-hand machines are advised to retain documentary evidence that this manual was provided

with the machine.

This machine is designed solely for use in customary grass cutting operations. Use in any other way is

considered as contrary to the intended use. Compliance with and strict adherence to the conditions of

operation, service and repair as specified by the manufacturer, also constitute essential elements of the

intended use.

Before attempting to operate this machine, ALL operators MUST read through this manual and make

themselves thoroughly conversant with Safety Instructions, controls, lubrication and maintenance.

Accident prevention regulations, all other generally recognized regulations on safety and occupational

medicine, and all road traffic regulations shall be observed at all times.

Any arbitrary modifications carried out on this machine may relieve the manufacturer of liability for any

resulting damage or injury.

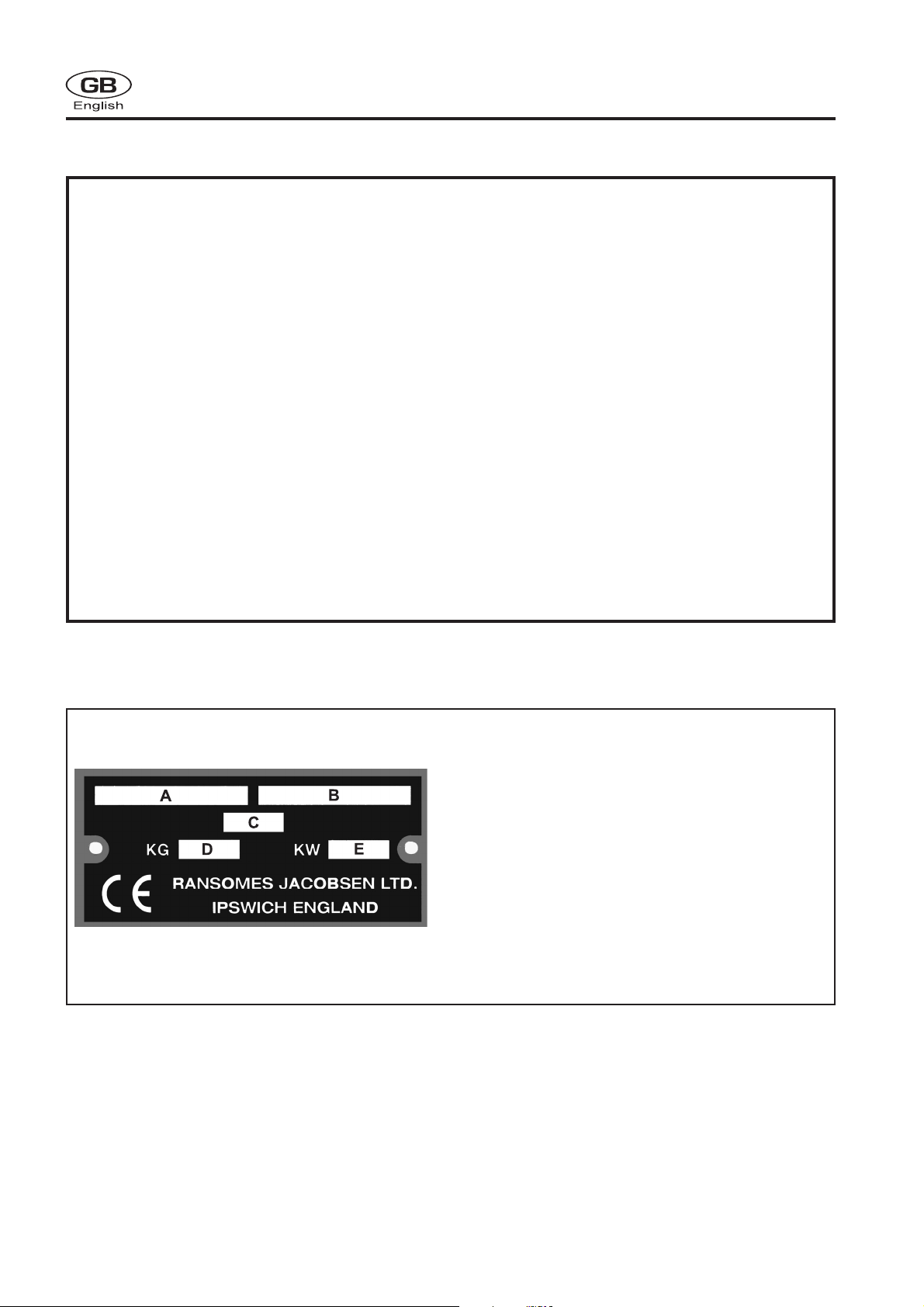

2.2 PRODUCT IDENTIFICATION

A

C

D

B

A Machine Name

B Serial Number

C Year of Manufacture

D Machine Weight

E Engine Power

GB-2

Page 5

3 SAFETY INSTRUCTIONS

RANSOMES HR3806 Series: DZ

SAFETY AND OPERATORS MANUAL

This safety symbol indicates important safety

messages in this manual. When you see this

symbol, be alert to the possibility of injury, carefully

read the message that follows, and inform other

operators.

3.1 OPERATING INSTRUCTIONS

• Ensure that the instructions in this book are

read and fully understood.

• No person should be allowed to operate this

machine unless they are fully acquainted with

all the controls and the safety procedures.

• Never allow children or people unfamiliar with

these instructions to use this machine. Local

regulations may restrict the age of the

operator.

3.2 SAFETY SIGNS

• It is essential all safety labels are kept

legible, if they are missing or illegible they

must be replaced. If any part of the machine

is replaced and it originally carried a safety

label, a new label must be affixed to the

replacement part. New safety labels are

obtainable from Ransomes dealers.

3.3 STARTING THE ENGINE

• Before starting the engine check that the

brakes are applied, drives are in neutral,

guards are in position and intact, and

bystanders are clear of the machine.

• Do not run the engine in a building without

adequate ventilation.

3.4 DRIVING THE MACHINE

• Before moving the machine, check to ensure

that all parts are in good working order,

paying particular attention to brakes, tyres,

steering and the security of cutting blades.

• Replace faulty silencers, mow only in daylight

or good artificial light

• Always observe the Highway Code both on

and off the roads. Keep alert and aware at all

times. Watch out for traffic when crossing or

near roadways.

• Stop the blades rotating before crossing

surfaces other than grass.

• Remember that some people are deaf or

blind and that children and animals can be

unpredictable.

• Keep travelling speeds low enough for an

emergency stop to be effective and safe at

all times, in any conditions.

• Remove or avoid obstructions in the area to

be cut, thus reducing the possibility of

injury to yourself and/or bystanders.

• When reversing, take special care to

ensure that the area behind is clear of

obstructions and/or bystanders. DO NOT

carry passengers.

• Keep in mind that the operator or user is

responsible for accidents or hazards

occurring to other people or their property.

• When the machine is to be parked, stored

or left unattended, lower the cutting means

unless the transport locks are being used.

• While mowing, always wear substantial

footwear and long trousers. Do not operate

the equipment when barefoot or wearing

open sandals.

• Check the grass catcher frequently for wear

or deterioration. After striking a foreign

object, Inspect the lawnmower for damage

and make repairs before restarting and

operating the equipment.

• If the machine starts to vibrate abnormally,

check immediately.

3.5 TRANSPORTING

• Ensure that the cutting units are securely

fastened in the transport position. Do not

transport with cutting mechanism rotating.

• Drive the machine with due consideration of

road and surface conditions, inclines and

local undulations.

• Sudden decelerating or braking can cause

the rear wheels to lift.

• Remember that the stability of the rear of

the machine is reduced as the fuel is used.

GB-3

Page 6

3 SAFETY INSTRUCTIONS

RANSOMES HR3806 Series: DZ

SAFETY AND OPERATORS MANUAL

3.6 LEAVING THE DRIVING POSITION

• Park the machine on level ground.

• Before leaving the driving position, stop the

engine and make sure all moving parts are

stationary. Apply brakes and disengage all

drives. Remove the starter key.

3.7 SLOPES

TAKE EXTRA CARE WHEN WORKING ON

SLOPES

• Local undulations and sinkage will change the

general slope. Avoid ground conditions which

can cause the machine to slide.

• Keep machine speeds low on slopes and

during tight turns.

• Sudden decelerating or braking can cause the

rear wheels to lift. Remember there is no

such thing as a “safe” slope.

• Travel on grass slopes requires particular

care.

DO NOT USE ON SLOPES GREATER THAN 15°

IMPORTANT: When working on any slope set the

weight transfer, if fitted to its maximum (+) setting.

3.8 BLOCKED CUTTING DECKS

• Stop the engine and make sure all moving

parts are stationary.

• Apply brakes and disengage all drives.

• Release blockages with care. Keep all parts

of the body away from the cutting edge.

Beware of energy in the drive which can

cause rotation when the blockage is released.

• Keep other people away from the cutting units

as rotation of one cylinder can cause the

others to rotate.

• Do not dismantle the machine without

releasing or restraining forces which can

cause parts to move suddenly.

• Do not alter engine speed above maximum

quoted in Engine Specification. Do not

change the engine governor settings or

overspeed the engine. Operating the engine

at excessive speed may increase the hazard

of personal injury.

• When refuelling, STOP THE ENGINE, DO

NOT SMOKE. Add fuel before starting the

engine, never add fuel while the engine is

running.

• Use a funnel when pouring fuel from a can into

the tank.

• Do not fill the fuel tank beyond the bottom of

the filler neck.

• Replace all fuel tank and container caps

securely.

• Store fuel in containers specifically designed

for this purpose.

• Refuel outdoors only and do not smoke while

refuelling.

• If fuel is spilled, do not attempt to start the

engine but move the machine away from the

area of spillage and avoid creating any source

of ignition until fuel vapours have dissipated.

• Allow the engine to cool before storing in any

enclosure.

• Never store the equipment with fuel in the

tank inside a building where fumes may reach

an open flame or spark.

• If the fuel tank has to be drained, this should

be done outdoors.

• Do not spill fuel onto hot components.

• When servicing batteries, DO NOT SMOKE,

and keep naked lights away.

• Do not place any metal objects across the

terminals.

3.9 ADJUSTMENTS, LUBRICATION AND

MAINTENANCE

• Stop the engine and make sure all moving

parts are stationary.

• Apply brakes and disengage all drives.

• Read all the appropriate servicing instructions.

• Use only the replacement parts supplied by

the original manufacturer.

• Make sure that other people are not touching

any cutting units, as rotation of one unit can

cause the others to rotate.

• To reduce the fire hazard, keep the engine,

silencer and battery compartments free of

grass, leaves or excessive grease.

• Replace worn or damaged parts for safety.

• When working underneath lifted parts or

machines, make sure adequate support Is

provided.

GB-4

Page 7

3 SAFETY INSTRUCTIONS

RANSOMES HR3806 Series: DZ

SAFETY AND OPERATORS MANUAL

DANGER - Indicates an imminently hazardous

situation which, if not avoided, WILL result in death

or serious injury.

WARNING - Indicates a potentially hazardous

situation which, if not avoided, COULD result in

death or serious injury.

CAUTION - Indicates a potentially hazardous

situation which, if not avoided, MAY result in minor

or moderate injury and property damage. It may

also be used to alert against unsafe practices.

WARNING

Hydraulic Fluid escaping under pressure

can penetrate skin and do serious

damage. Immediate medical assistance

must be sought.

WARNING

IMPORTANT: Transport speed is for highway

use only. Never select transport speed on

grass areas or uneven or unsurfaced roads or

tracks.

WARNING

California Proposition 65

Engine Exhaust, some of its constituents,

and certain vehicle components contain

or emit chemicals known to the state of

California to cause cancer and birth

defects or other reproductive harm.

WARNING

DO NOT USE ON SLOPES GREATER THAN 15°

Batteries produce explosive gases and

contain corrosive acid and supply levels

of electrical current high enough to

cause burns.

WARNING

Before releasing transport latches it is

important that all cutting units are fully

raised.

1. Park the machine on level ground.

2. With the engine running at operating

speed raise the cutting units to their

maximum position by operating lift

levers whilst seated in the driving

position.

3. Disengage drives, stop the engine and

make sure all moving parts are

stationary. Apply brakes and remove

the starter key.

4. transport latches can now be released.

GB-5

Page 8

4 SPECIFICATIONS

RANSOMES HR3806 Series: DZ

SAFETY AND OPERATORS MANUAL

4.1 ENGINE SPECIFICATION

TYPE: Kubota 28KW @ 3000 RPM, 4

cylinder (in line) vertical Diesel

engine, 4 stroke, water cooled,

1498cc with 12V electric start.

Model: V1505- BBS-EC-1

Maximum Speed: 3000 ± 50 RPM (No load)

Idle Speed: 1500 +100/-0 RPM

Oil Sump Capacity:6 litres

Fuel: No. 2-D Diesel fuel (ASTM D975)

4.2 MACHINE SPECIFICATION

Frame construction:Heavy duty formed steel chassis

with box section frame rails.

Cutting unit drive: Fixed displacement hydraulic

motors coupled to cutting means

through drive belt.

Transmission: Full time 4-wheel drive. Direct

coupled variable displacement

pump to direct coupled 280cc

front, 237cc rear wheel motors.

Speeds:

Cutting: 0 - 12km/h FORWARD

Transport: 0 - 22km/h FORWARD

Reverse: 0 - 12km/h

Steering: Hydrostatic power steering, with

adjustable tilt steering wheel.

Ground pressure: 1 kg/cm

2

4.3 DIMENSIONS

Width of cut:

1.52 meter

1.60 meter

1.80 meter

Overall width (transport)

1.52 metre Rear Discharge Deck

1.56meters

1.60 meter Side Discharge Deck

Chute down 1.92meters

Chute up 1.75meters

1.82 meter Side Discharge Deck

Chute down 2.16meters

Chute up 1.88meters

1.82 meter rear Discharge Deck

1.86meters

Overall height: 1.35 metres

Overall length of machine with:

1.52 meter Deck 3.14meters

1.60 meter Deck 3.19meters

1.82 meter Deck 3.26meters

Overall weight of machine with:

1.52 meter Deck 1240 kg

1.60 meter Deck 1266 kg

1.82 meter Deck 1311 kg

Brakes, Service: Positive hydrostatic braking.

Parking: Fail safe, Oil immersed wet disc

brakes.

Fuel Tank

Capacity: 45.4 litres

Hydraulic Tank

Capacity: 18.8 litres

Battery: Exide 065

tcudorP

eziSeryTepyTeryTerusserPeryTeziSeryTepyTeryTerusserPeryT

sixxaM

6083RH21-00.31x42

leehWtnorF leehWraeR

rp4S561-Cnrettapdaert

)ralveK(xxamfruTsixxaM

rp4s561-Cnrettapdaert

GB-6

isp02rab73.1

isp22-02rab05.1-73.1

SERUSSERPERYT

8-00.01x02

rp6carTfruTnatiTisp02-41rab73.1-00.1

)ralveK(xxamfruTsixxaM

rp4s561-Cnrettapdaert

isp22-02rab05.1-73.1

Page 9

4 SPECIFICATIONS

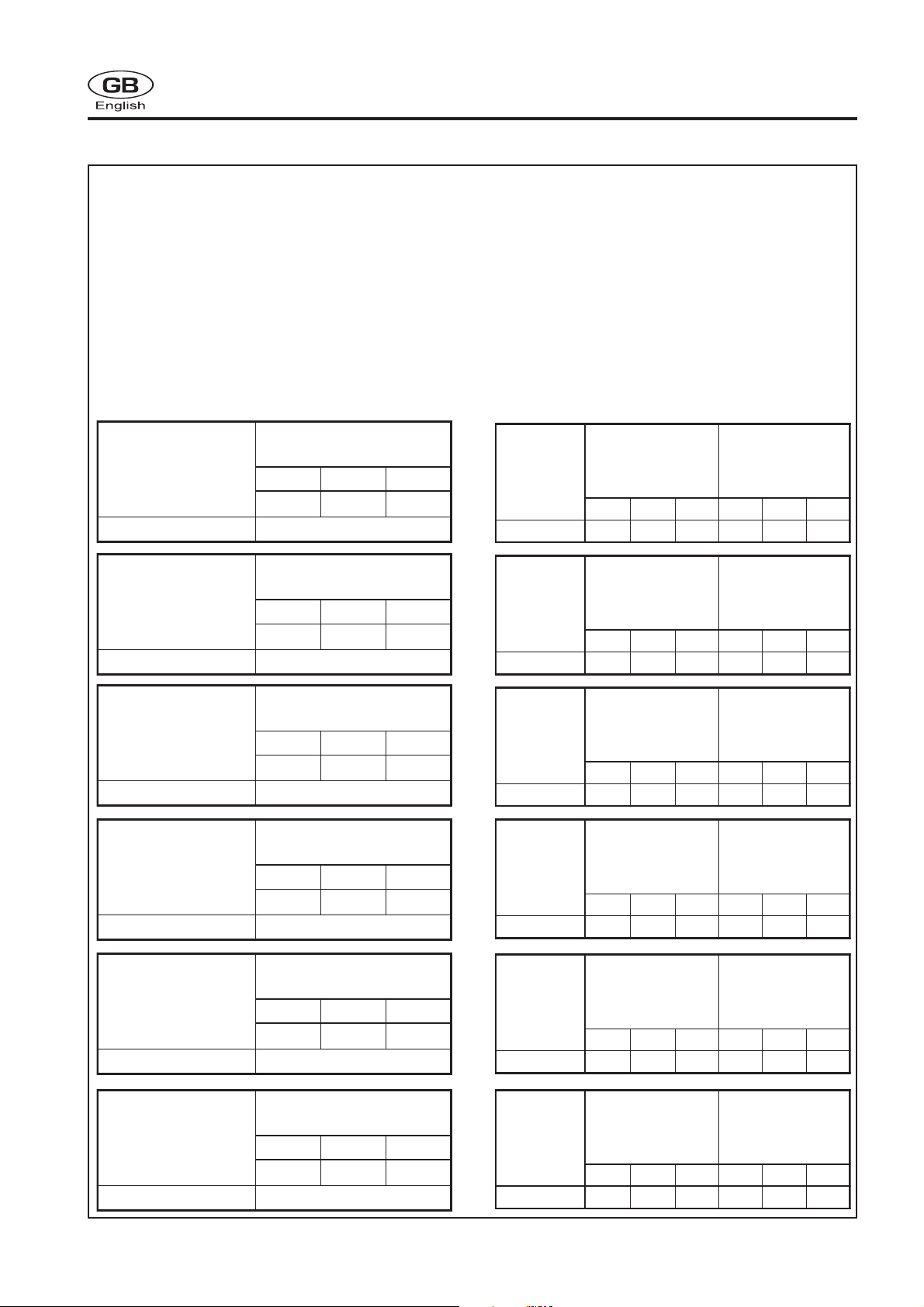

4.4 VIBRATION LEVEL

The machine was tested for whole body and hand/

arm vibration levels. The operator was seated in the

normal operating position with both hands on the

steering mechanism. The engine was running and

the cutting device was rotating with the machine

stationary.

RANSOMES HR3806 Series: DZ

SAFETY AND OPERATORS MANUAL

Standard ISO 5349: 1986 Mechanical vibration.

Guidelines for the measurement and the

assessment of human exposure to hand-transmitted

vibration.

6083RHSEMOSNAR

)"06(m25.1htiwZDseireS

kceDegrahcsiDraer

noitareleccAmrA/dnaH

level

eulaVtnanimoD913.0

6083RHSEMOSNAR

)"36(m06.1htiwZDseireS

kceDegrahcsiDediS

noitareleccAmrA/dnaH

level

eulaVtnanimoD924.0

6083RHSEMOSNAR

)"27(m28.1htiwZDseireS

kceDegrahcsiDediS

noitareleccAmrA/dnaH

level

eulaVtnanimoD085.0

qeAXqeAYqeAZ

913.0132..0922.0

qeAXqeAYqeAZ

924.0623..0232.0

qeAXqeAYqeAZ

085.0662..0012.0

HRroHLxaM

2

s/msnoitareleccA

HRroHLxaM

2

s/msnoitareleccA

HRroHLxaM

2

s/msnoitareleccA

Standard ISO 2631-1: 1985 Evaluation of human

exposure to whole body vibration -- Part 1: General

requirements.

SEMOSNAR

6083RH

htiwZDseireS

raeR)"06(m25.1

kceDegrahcsiD

ydoBelohW

levelnoitareleccA

xyzxyz

naeM2710.05510.09770.01350.02420.07640.0

SEMOSNAR

6083RH

htiwZDseireS

ediS)"36(m06.1

kceDegrahcsiD

ydoBelohW

levelnoitareleccA

xyzxyz

naeM8610.08320.01080.07440.01810.04650.0

SEMOSNAR

6083RH

htiwZDseireS

ediS)"27(m28.1

kceDegrahcsiD

ydoBelohW

levelnoitareleccA

xyzxyz

naeM2910.08420.0101.07240.07420.06620.0

noitacoLroolF

2

s/msnoitareleccA

noitacoLroolF

2

s/msnoitareleccA

noitacoLroolF

2

s/msnoitareleccA

noitacoLtaeS

s/msnoitareleccA

noitacoLtaeS

s/msnoitareleccA

noitacoLtaeS

s/msnoitareleccA

2

2

2

6083RHSEMOSNAR

)"27(m28.1htiwZDseireS

kceDegrahcsiDraeR

noitareleccAmrA/dnaH

level

eulaVtnanimoD554.0

6083RHSEMOSNAR

)"06(m25.1htiwZDseireS

kcedorivnE

noitareleccAmrA/dnaH

level

eulaVtnanimoD985.0

6083RHSEMOSNAR

)"27(m28.1htiwZDseireS

kcedorivnE

noitareleccAmrA/dnaH

level

eulaVtnanimoD734.0

HRroHLxaM

s/msnoitareleccA

qeAXqeAYqeAZ

554.0572..0142.0

HRroHLxaM

s/msnoitareleccA

qeAXqeAYqeAZ

085.0593..0985.0

HRroHLxaM

s/msnoitareleccA

qeAXqeAYqeAZ

734.0804..0762.0

SEMOSNAR

2

2

2

6083RH

htiwZDseireS

raeR)"27(m28.1

kceDegrahcsiD

ydoBelohW

levelnoitareleccA

xyzxyz

naeM0510.05820.01460.03250.08920.00940.0

SEMOSNAR

6083RH

htiwZDseireS

)"06(m25.1

kcedorivnE

ydoBelohW

levelnoitareleccA

xyzxyz

naeM5810.06920.03880.05530.00320.01640.0

SEMOSNAR

6083RH

htiwZDseireS

)"27(m28.1

kcedorivnE

ydoBelohW

levelnoitareleccA

xyzxyz

naeM6410.01910.0521.02320.08720.02320.0

noitacoLroolF

2

s/msnoitareleccA

noitacoLroolF

2

s/msnoitareleccA

noitacoLroolF

2

s/msnoitareleccA

noitacoLtaeS

2

s/msnoitareleccA

noitacoLtaeS

2

s/msnoitareleccA

noitacoLtaeS

2

s/msnoitareleccA

GB-7

Page 10

4 SPECIFICATIONS

4.5 SLOPES

DO NOT USE ON SLOPES GREATER THAN 15°

The slope 15° was calculated using static stability

measurements according to the requirements of

EN 836.

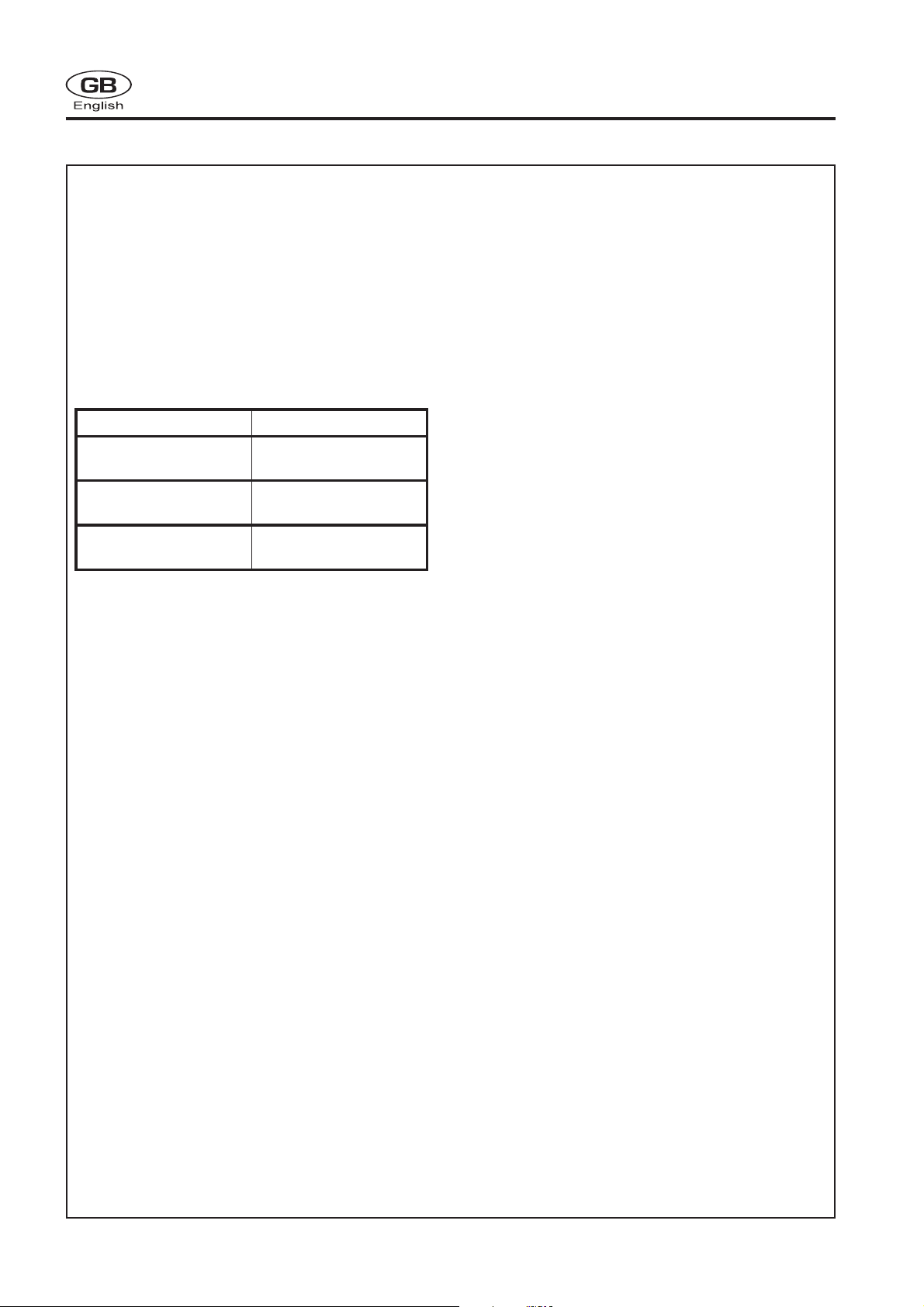

4.6 RECOMMENDED LUBRICANTS

Engine oil: Should be to MIL-L-2104C or to

A.P.I. ClassificationCD grades.

[10W-30]

ERUTAREPMETYTISOCSIVLIO

)F°77(C°52EVOBA03EASro

)F°77otF°23(C°52otC°002EASro

)F°23(C°0WOLEBW01EASro

RANSOMES HR3806 Series: DZ

SAFETY AND OPERATORS MANUAL

03-W01EAS

04-W01EAS

03-W01EAS

04-W01EAS

03-W01EAS

04-W01EAS

Hydraulic Oil: Shell Tellus 46

Grease: Shell Darina R2, or equivalent.

4.7 CUTTING PERFORMANCE (AREA)

152cm Model:

1.44 hectares/hr. at 12 km/hr.

160cm Model:

1.52 hectares/hr. at 12 km/hr.

182cm Model:

1.73 hectares/hr. at 12 km/hr.

10% allowance is included for normal overlaps and

turning at the end of each cut.

GB-8

Page 11

4 SPECIFICATIONS

EC Declaration of Conformity • Déclaration de Conformité CE •

EG Conformiteits-Declaratie • EG-Konformitatsbescheinigung •

Certificato di Conformità CE • EF Konformitetserklæring •

EU Uppfyllandecertifikat • Ilmoitus yhdenmukaisuudesta ey:n sääntöjen kanss •

Declaración de Conformidad de la CE • Declaração de Conformidade da CE

We the undersigned • Nous, soussignés • Wij, ondergetekenden • Wir, die Unterzeichnenden • Noi sottoscritti Undertegnede •

Undertecknarna • Me allekirjoittaneet • Los abajo firmantes • Nós, abaixo assinados

Ransomes Jacobsen Limited

West Road, Ransomes Europark,

Ipswich, England, IP3 9TT

Declare that the machine Described Below • Certifions que la machine suivante • verklaren dat onderstaand beschreven machine •

erklären, dass die nachfolgend beschriebene Maschine • Dichiariamo che la macchina descritta di seguito • Erklærer, at følgende maskine •

Deklarerar att den maskin som beskrivs nedan • vahvistamme, että alla kuvattu kone • Certificamos que la máquina descrita abajo •

declaramos que a máquina a seguir descrita

Make & Type • Nom & Type • Merk & Type • Marke und Typ • Marca e tipo •

Fabrikat og type • Fabrikat & typ • Malli ja tyyppi • Marca y Tipo • Marca & Tipo .............. Ransomes HR3806

Category • Modèle •Categorie • Kategorie • Categoria • Kategori • Luokka •

Categoría • Categoria ......................................................................................................... Ride on Rotary Mower

Series • Série • Serie • Sarja .............................................................................................. DZ

Engine • Motor • Moteur • Motore • Moottori ....................................................................... Kubota

Type • Typ • Tipo • Tyyppi ..................................................................................................V1505-E

Net Installed Power • Puissance nette • Netto geïnstalleerd vermogen •

installierte Antriebsleistung • Potenza installata netta • Nettoeffekt installere •

Installerad nettoeffekt • Asennettu nettoteho • Potencia instalada neta •

Potência real instalada ....................................................................................................... 28 KW

Cutting Width • Largeur de coupe • Maaibreedte • Schnittbreite •

Larghezza di taglio • Klippebredde • Klippbredd • Leikkuuleveys •

Anchura de corte • Potência real instalada ....................................................................... 152cm - 182cm

Complies with the provisions of the following European directives and amendments and the regulations transposing it into national law •

Est conforme aux prescriptions des normes, modifications et règles européennes suivantes • voldoet aan de bepalingen van de volgende

Europese Richtlijnen en Amendementen, alsmede aan de verordeningen die deze omzetten in nationale wetgeving • den Bestimmungen der

folgenden Europa-Richtlinien einschließlich aller Änderungen und Ergänzungen sowie den Vorschriften, die diese in das nationale Recht

umsetzen, entspricht • soddisfa quanto previsto dalle seguenti direttive ed emendamenti europei e dalle normative che li riportano in legge

nazionale • Overholder bestemmelserne i følgende EF-direktiver med ændringer og i de forordninger, hvorved de omsættes til national lov •

Uppfyller kraven i följande europeiska direktiv med tillägg och regler transponerade till nationell lagstiftning • täyttää seuraavana mainittujen

Euroopan direktiivien ja muutosten ja säännösten asettamat edellyt

Machinery Safety Directive • Directive de sécurité des machines •

Richtlijn Machineveiligheid • Richtlinie zur Maschinensicherheit •

Direttiva sulla sicurezza del macchinario • Maskinsikkerhedsdirektivet •

Maskinsäkerhetsdirektiv • Koneen turvallisuutta koskeva direktiivi •

Directiva de seguridad de maquinaria • Directiva de segurança de máquinas ................98/37/EC

EMC Directive • Directive de compatibilité électromagnétique • EMC Richtlijn •

EMK-Richtlinie • Direttiva EMC • EMC-direktivet • Elektromagnetiskt kompatibilitetsdirektiv •

EMC-direktiivi • Directiva EMC .............................................................................................89/336/EC

ROPS Directive • Directive de ROPS • ROPS Richtlijn • ROPS-Richtlinie •

Direttiva ROPS • ROPS-direktivet • ROPS direktiv • ROPS-direktiivi • Directiva ROPS ...... 86/298/EC

Noise in the Environment Directive • Directiv • Richtlijn Milieulawaa •

Richtlinie zum Umgebungslärm • Direttiva sulla rumorosità nell’ambiente •

Støjemissionsdirektivet • Bullerdirektiv • Melu ympäristöä koskevassa direktiivissä •

Directiva sobre ruido en el ambiente • Directiva Ruído no Ambiente ................................ 2000/14/EC

Measured Sound Power Level • Niveau de puissance sonore assuré •

Gegarandeerd geluidsvermogenniveau • Garantierter Schallleistungspege •

Livello di potenza del suono misurato • Målt lydeffektniveau • Uppmätt ljudfraftsnivå •

Mitattu åånitehon taso • Nivel de Potencia Sonora • Nívelde intensidade de som medido .. 104 dB(A) LWA

Guaranteed Sound Power Level • Niveau de puissance sonore assuré •

Gegarandeerd geluidsvermogenniveau • Garantierter Schallleistungspege •

Livello di potenza del suono misurato • Garanteret lydeffektniveau •

Garanterad ljudtrycksnivå • Taattu äänitehon taso • Nivel Garantizado de Potencia Sonora •

Nível garantido de intensidade sonora .............................................................................. 105 dB(A) LWA

RANSOMES HR3806 Series: DZ

SAFETY AND OPERATORS MANUAL

4.8 CONFORMITY CERTIFICATES

GB-9

Page 12

4 SPECIFICATIONS

RANSOMES HR3806 Series: DZ

SAFETY AND OPERATORS MANUAL

Conformity Assessment Procedure • Procédure de conformité•évaluation • Conformiteitsbeoordelingsprocedur • Verfahren zur Beurteilung

der Konformität • Procedura di valutazione conformità • Procedure for overensstemmelsesvurdering • Procedur för utvärderande av

uppfyllande • Yhdenmukaisuuden arviointiproseduuri • Procedimiento de evaluación de conformidad • Processo de avaliação de

conformidade

Annex VI, Part 1• Annexe VI, Part 1 • Bijlage VI, Part 1 • Anlage VI, Part 1 • Allegato VI, Part 1 • Anneks VI, Part 1 • Annex VI,

Part 1 • Liite VI, Part 1 • Anexo VI, Part 1 • Anexo VI, Part 1

U.K. Notifiable Body (No.1088) • Institut britannique à notifie(No.1088)r • Britse onderzoeksinstantie (No.1088) • in GB zu informierende

Institution (No.1088) • Ente notificabile Gran Bretagna • (No.1088) • Organ, som skal underrettes (No.1088) • Brittiskt meddelandeorgan

(No.1088) • Ison-Britannian ilmoitusosapuoli (No.1088) • Cuerpo notificable en el Reino Unido (No.1088) • Entidade a notificar no Reino

Unido ( No.1088)

Sound Research Laboratories Limited

Holbrook House, Little Waldingfield

Sudbury, Suffolk CO10 0TH

Operator Ear Noise Level • Bruit au niveau des oreilles de l’opérateur •

Geluidsniveau op oorhoogte bediener • Schallpegel am Ohr des Fahrers •

Livello rumorosità orecchio operatore • Støjniveau ved betjening •

Bullernivå vid operatörens öron • Käyttäjän korvaan kohdistuva äänitaso •

Nivel de ruido en el oido del operari • Nível de ruído nos ouvidos do operador ............... 87.8 dB(A)Leq (98/37/EC)

Complies with the following harmonised standard or technical provisions • est conforme aux normes harmonisées • Voldoet aan de

volgende geharmoniseerde norm of technische bepalingen • Diese Maschine entspricht den folgenden harmonisierten Normen oder

technischen Bestimmungen • Rispetta il seguente standard armonizzato o requisiti tecnici • Overholder følgende harmoniserede

standardbestemmelser eller tekniske bestemmelser • Uppfyller följande harmoniserade standard eller tekniska definitione • täyttää

seuraavat harmonisoidut standardit tai tekniset edellytykset • Cumple con los siguientes estándares de hramonización o provisiones

técnicas • Está em conformidade com a norma harmonizada ou com as provisões técnicas seguintes

Machinery Safety • Sécurité des machines • Machineveiligheid •

Maschinensicherhei • Sicurezza del macchinario • Maskinsikkerhed •

Maskinsäkerhet • Koneen turvallisuus • Seguridad de maquinaria •

Segurança de máquinas ....................................................................................................EN836

Hand Transmitted Vibration • Vibrations transmises aux mains •

Via de hand overgebrachte trilling • Auf das Hand-Arm-System übertragene Schwingungen •

Vibrazione trasmessa dalla mano • Håndoverført vibration •

Handöverförda vibrationer • Käsivälitteinen tärinä • Vibración transmitida a la mano •

Vibrações transmitidas através das mãos........................................................................ ISO5349: 1986

Whole Body Vibration • Vibrations du corps entier • Trilling hele lichaam •

Auf den gesamten Körper übertragene Schwingungen • Vibrazione di tutto il corpo •

Vibration i hele kroppen • Hel kropps vibrationer • Koko kehoon kohdistuva tärinä •

Vibración de todo el cuerpo • Vibração em todo o corpo ................................................. ISO2631-1: 1985

Keeper of Technical File, Place & Date of Declaration • Lieu & Date de déclaration • Plaats & datum verklaringsaflegging • Ort und Datum

dieser Erklärung • Luogo e data della dichiarazione • Sted og dato for erklæringen • Plats & datum för deklaration • Lausunnon paikka ja

päivämäärä • Lugar y fecha de la declaración • Local e data da declaração

Technical Director

Ransomes Jacobsen Limited

West Road, Ransomes Europark,

Ipswich, England, IP3 9TT

01.09.2004

T Lansdell

Technical Director

Certificate Number • Numéro du certificat • Certificaatnummer • Zertifikat Nummer •

Numero certificato • Certifikatnummer • Certifikat nummer • Sertifikaattinumero •

Número de certificado • Número do Certificado 4132834 (Rev.1)

GB-10

Page 13

5 DECALS

5.1 SAFETY DECALS

A903491 Read Operator's Manual.

A903489 Keep a Safe Distance from the Machine.

A903492 Stay Clear of Hot Surfaces.

RANSOMES HR3806 Series: DZ

SAFETY AND OPERATORS MANUAL

A903488 Do Not Open or Remove Safety Shields While

the Engine is Running.

A903496 Caution Rotating Blades.

A903493 Avoid Fluid Escaping Under Pressure. Consult

Technical Manual for Service Procedures.

A903490 Do Not Remove Safety Shields While Engine is

Running.

A911410 Danger of Explosion if the Battery Terminals

are Short Circuited.

A911416 Maximum permitable working slope.

A911434 Caution Diesel Fuel

2000643 Blade bolt installation. Fit conical washer as

shown. See manual.

009239810 See Above. Where relevant and -

Hydraulic oil: See manual.

Fire Hazard: Remove debris from under seat

plate and in engine compartment.

Service/Maintenance: Stop engine, remove

key and spark plug before performing service

or maintenance.

2000643

009239810

5.2 INSTRUCTION DECALS

Description

A. Diesel Fuel

B. Hydraulic Oil

C. Jacking Point

D. Speed Limiter Position

E. Fwd./Rev Traction Pedal

F. Cutter Engage

G. Hydraulic Oil Filter

H. Parking Brake

I. Diff Lock Foot Switch

K. Pressure: Hydraulic Oil

L. Maximum Sound Power Level

M. Engine Rev's

N. Air Filter End Cap Upright Decal

O. Various Safety and Lift/Lower Deck

Control.

105

O

L

WA

dB

GB-11

Page 14

6 CONTROLS

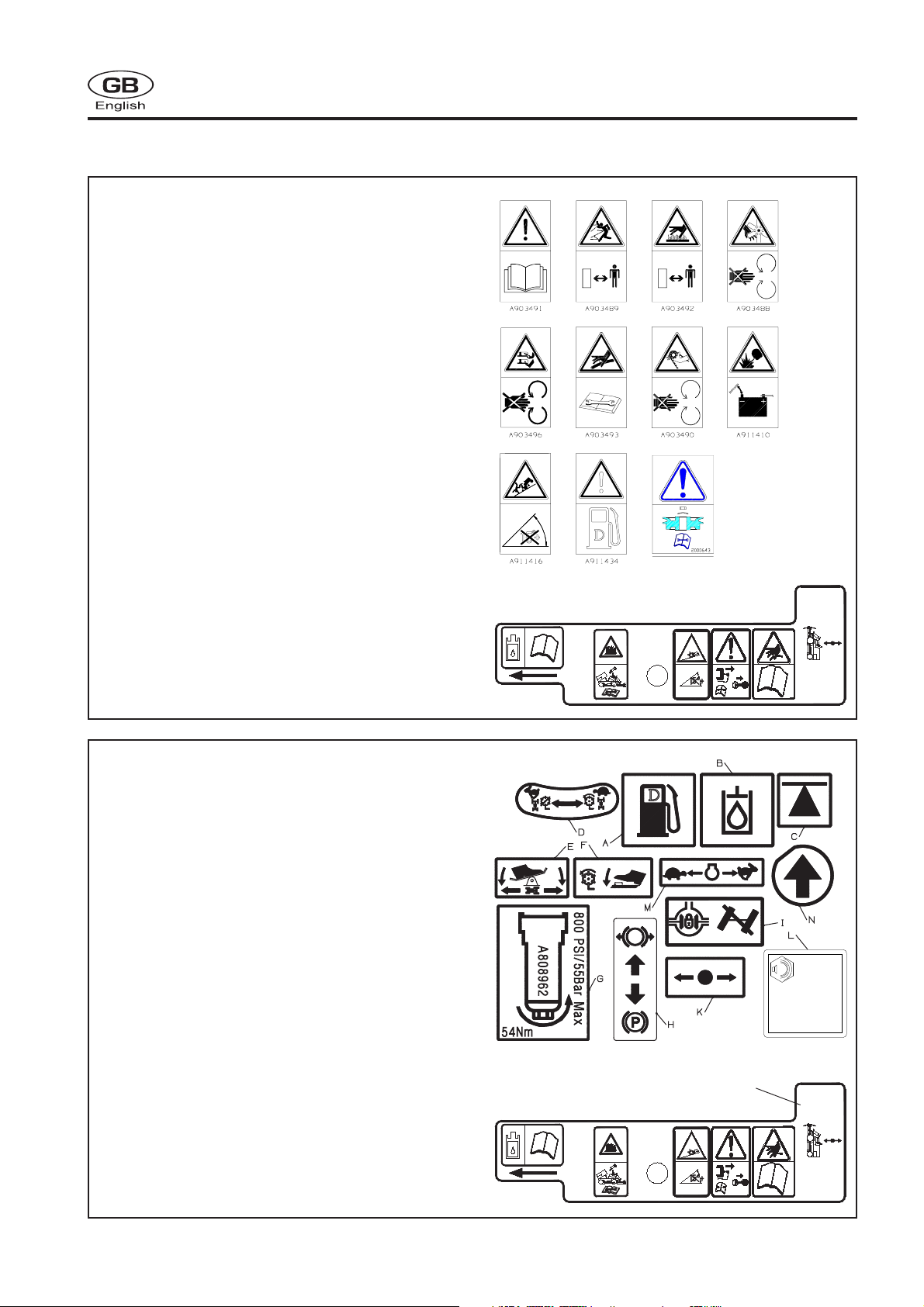

6.1 STARTER KEY SWITCH

The starter key (A) should be turned clockwise to

the 'pre-heat' (No. 2) position to heat the glowplugs

when the green warning lamp goes out, on warning

lamp display module, turn the starter key clockwise

to the 'start' (No. 3) position to start the engine. After

starting, the key should be released and allowed to

return automatically to the 'on' (No. 1) position for

normal running.

6.2 THROTTLE CONTROL LEVER

The lever (B) should be moved away from the

operator to increase the engine speed and towards

the operator to decrease the engine speed.

NOTE: Engine should be used at full speed.

RANSOMES HR3806 Series: DZ

SAFETY AND OPERATORS MANUAL

A

B

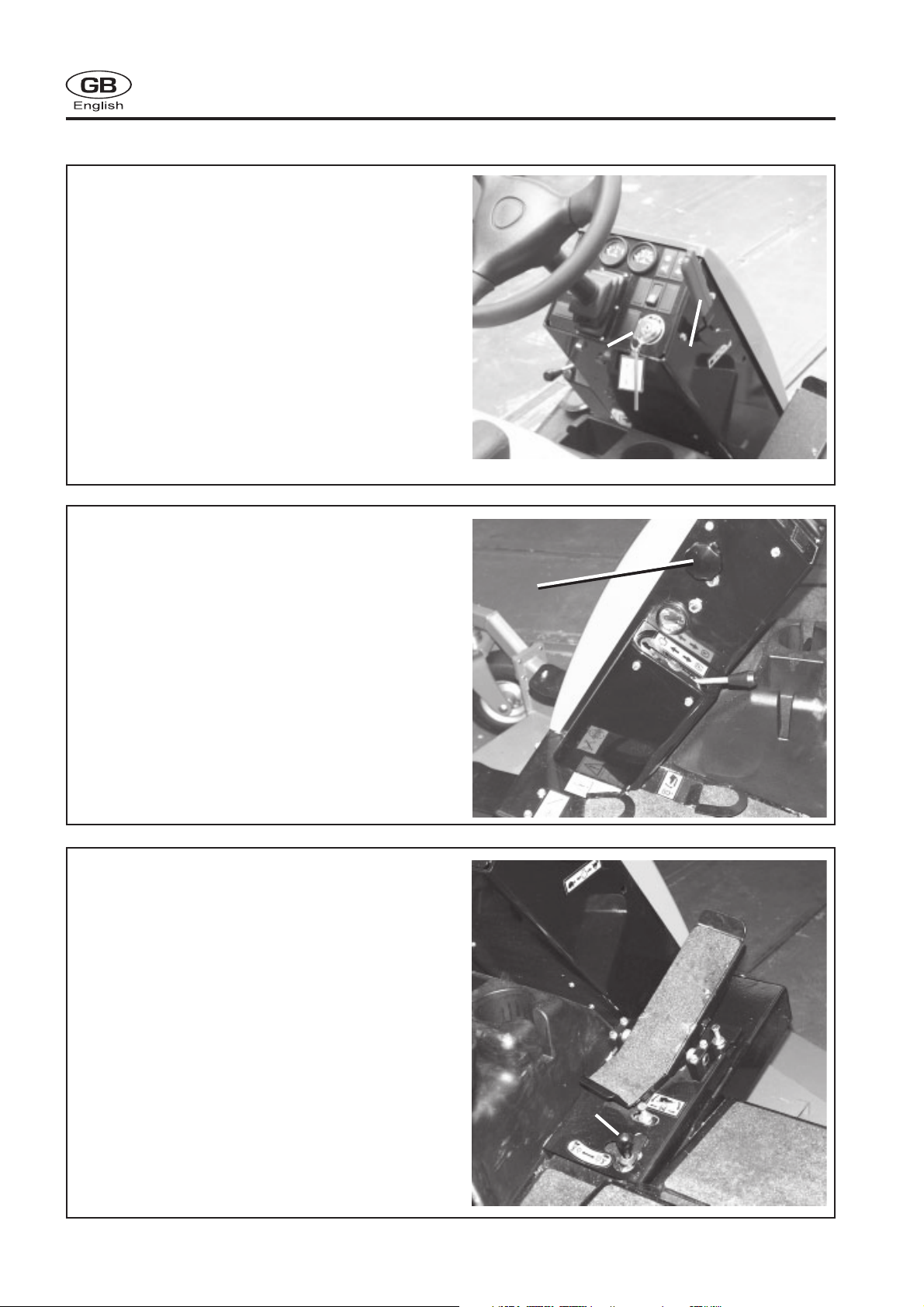

6.3 STEERING WHEEL RAKE ADJUSTMENT

The steering wheel is adjustable for rake. The

clamping release knob (A) is situated on the side of

the control console on the left hand side. To adjust

turn the clamping knob anticlockwise to release and

pivot the steering wheel backwards and forwards to

obtain desired setting then lock in position by

turning clamping knob clockwise.

6.4 TRACTION FOOT PEDAL

To move the machine forward press the front of the

foot pedal (A). To reverse depress the rear of the foot

pedal. When the pedal is released it will return to its

neutral position.

6.5 SPEED LIMITER

The speed limiter (B) is operated by sliding the black

knob to the right or left. When slid to the right the

machine is limited to cutting speed, when slid to the

left, transport speed is available. In transport mode,

reverse is not available.

A

A

IMPORTANT: To enable mow engage the speed

limiter must be in the cutting speed position. If

cutting units are rotating, moving the speed limiter

between the mow and transport positions will

engage and disengage cylinder rotation.

GB-12

B

Page 15

6 CONTROLS

6.6 PARKING BRAKE

The parking brake (B) is engaged when the lever is

moved toward the operator. The brake is fitted with a

micro switch that senses brake position. The brake

must be applied to start the machine, and when

stopping and leaving the seat.

CAUTION:- The parking brake must not be

applied whilst the vehicle is moving

RANSOMES HR3806 Series: DZ

SAFETY AND OPERATORS MANUAL

B

6.7 DIFF LOCK CONTROL

The Diff lock (A) is operated by depressing the foot

switch. When the foot switch is released the Diff

Lock ceases to operate. The Diff Lock should only

be used in severe situations, and should never be

used on hard sufaces, in transport mode or whilst

steering.

GB-13

Page 16

6 CONTROLS

6.8 HYDRAULIC LIFT LEVERS

The cutting unit can be raised and lowered by

control lever (A) situated on the right hand side of

the operators seat and can be operated as follows:

NOTE: If the unit is raised out of work then lowered into

work again the blade will not rotate until the mow foot

switch is depressed.

To lift: Move the lever backwards and hold in position

until the unit is at the required height.

To lower: Move the lever fully forwards and release, the

unit will lower to ground level. DO NOT hold lever in

forward position.

NOTE: The unit will only lift and lower when the engine

is running.

RANSOMES HR3806 Series: DZ

SAFETY AND OPERATORS MANUAL

IMPORTANT: If, when cutting, the lift control lever is

accidentally pulled back, the cutting unit will not float

over ground undulations until the lever is pushed fully

forward and allowed to return to neutral again.

6.9 CUTTING UNIT SWITCHES

To commence cutting ensure speed limiter is in

mow position and the units have been lowered.

Push bottom of the rocker switch (G) and depress

foot switch (A) Push top of rocker switch to stop

cutter unit rotation. (Cutting unit stop rotating

automatically when raised.)

GB-14

Page 17

6 CONTROLS

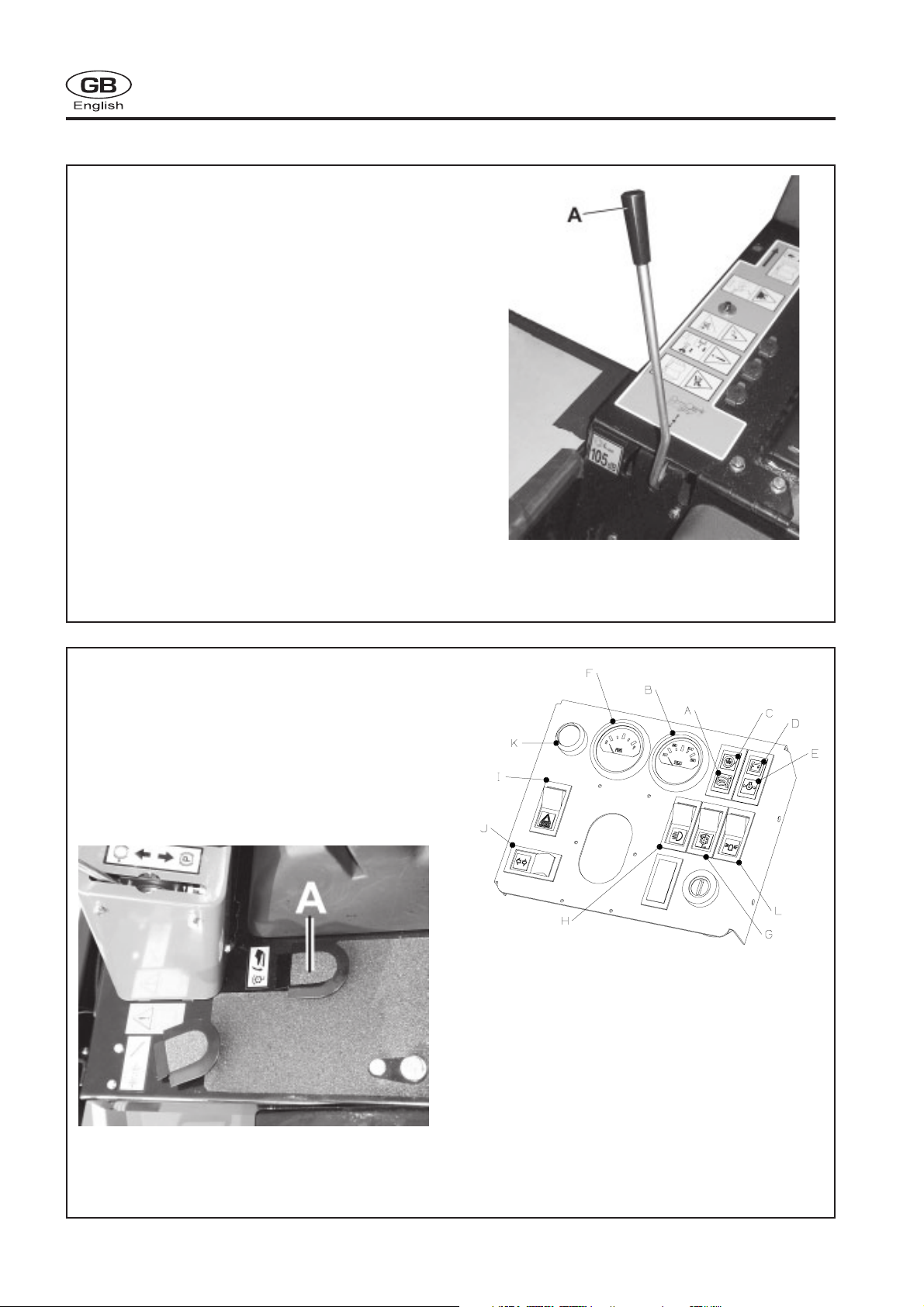

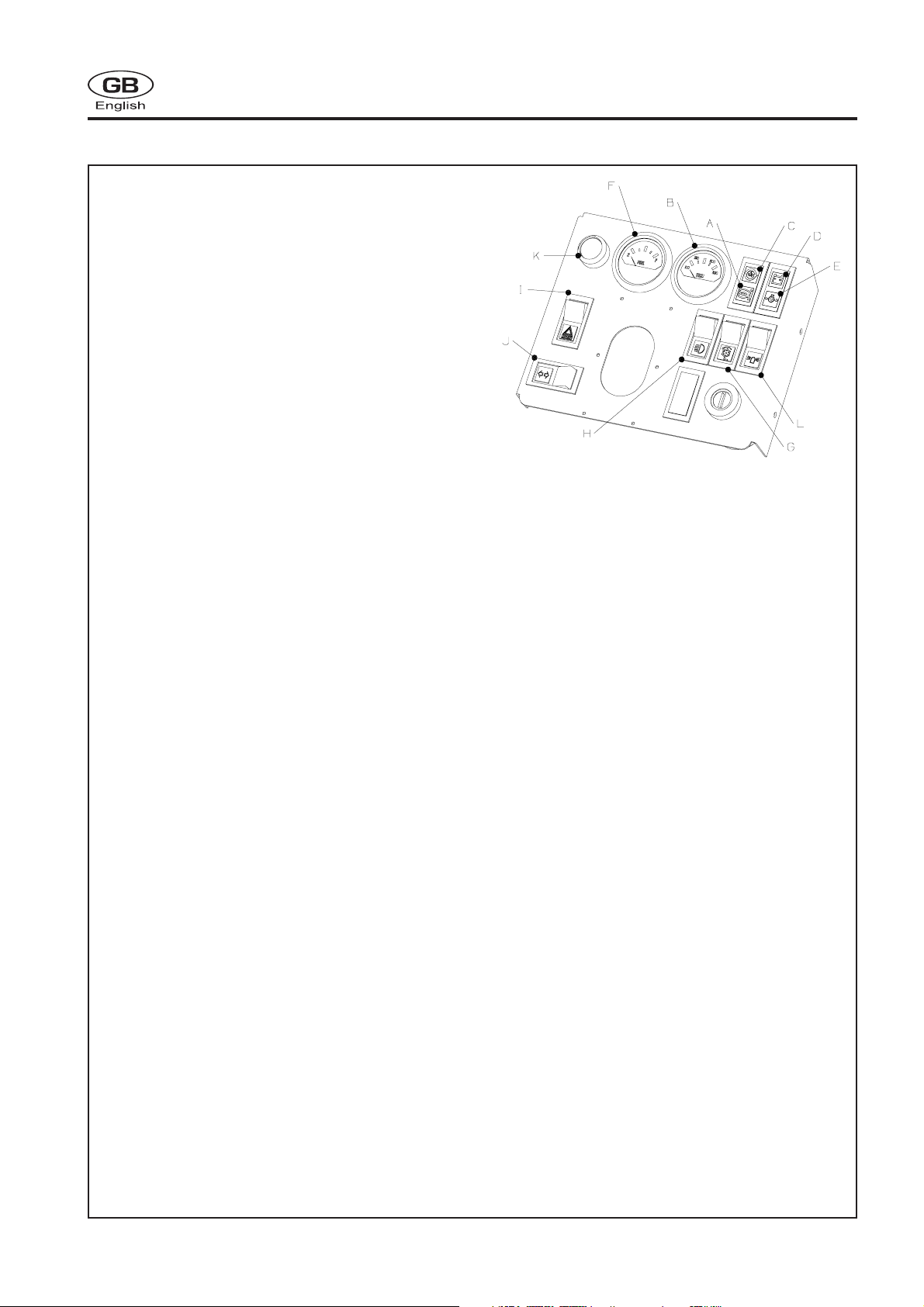

6.10 INSTRUMENT PANEL

A. ENGINE PREHEAT INDICATOR LAMP

Colour green, on when the ignition switch is turned

clockwise to the pre-heat position. Once the lamp

goes out the engine can be started.

B. ENGINE TEMPERATURE GAUGE

Indicates current temperature of engine, whilst

running.

C. HYDRAULIC OIL WARNING LAMP

Colour red, on when the hydraulic oil temperature

reaches a preset level. If the lamp comes on bring

the machine to a stop, disengage the cutting units,

apply the parking brake and stop the engine. The

lamp will also turn on when the charge filter is

blocked.

RANSOMES HR3806 Series: DZ

SAFETY AND OPERATORS MANUAL

D. CHARGING WARNING LAMP

Colour red, on when ignition is switched on and will

go out when the engine is started. If the light comes

on while the engine is running, the fan belt may be

slipping or broken or a fault in the electrical system

is indicated and should be investigated. STOP

IMMEDIATELY.

E. ENGINE OIL PRESSURE WARNING LAMP

Colour red, on when the ignition is switched on, and

will go out once the engine has started. If the light

comes on while the engine is running - STOP

IMMEDIATELY as this indicates that the engine oil

pressure is too low. Check the level of oil in the

sump and top up as necessary. Check the oil

pressure sender switch. Continued operation may

cause extensive damage to the engine.

F. FUEL GAUGE

Located to the left of the engine temperature gauge.

Monitors fuel level.

G : PTO SWITCH

To commence cutting ensure the decks have been

lowered Push bottom of the rocker switch (A) and

depress foot switch. Push top of rocker switch to

stop cutter unit rotation. (Cutting units stop rotating

automatically when raised.)

J: TURN SIGNAL LIGHTS SWITCH

(Optional equipment )-rotate switch handle

counterclockwise for L.H. turn and clockwise for a

R.H. turn.

K: HORN

(Optional equipment) press switch to operate the

horn.

L: ROTATING BEACON

(Optional equipment) Press the bottom half of the

switch to activate the flashing beacon.

H: HEADLIGHT SWITCH

(Optional equipment )-Push switch half way for

running lights. Push down fully for headlights

I: HAZARD LIGHTS SWITCH

(Optional equipment)- Push down for flashing hazard

lights.

GB-15

Page 18

6 CONTROLS

6.11 HOURMETER

Located on the left hand side of the steering tower,

above the parking brake. (A) Records engine running

hours.

RANSOMES HR3806 Series: DZ

SAFETY AND OPERATORS MANUAL

A

6.12 HORN

The horn is an audible alarm for the following

situations:

a) Horn (A) sounds continuously-this indicates a

high engine coolant temperature condition. If this

occurs, turn off the engine immediately and

resolve the problem.

b) Horn (A) sounds intermittently-this indicates a

low engine oil pressure condition. If this occurs,

turn off the engine immediately and resolve the

problem.

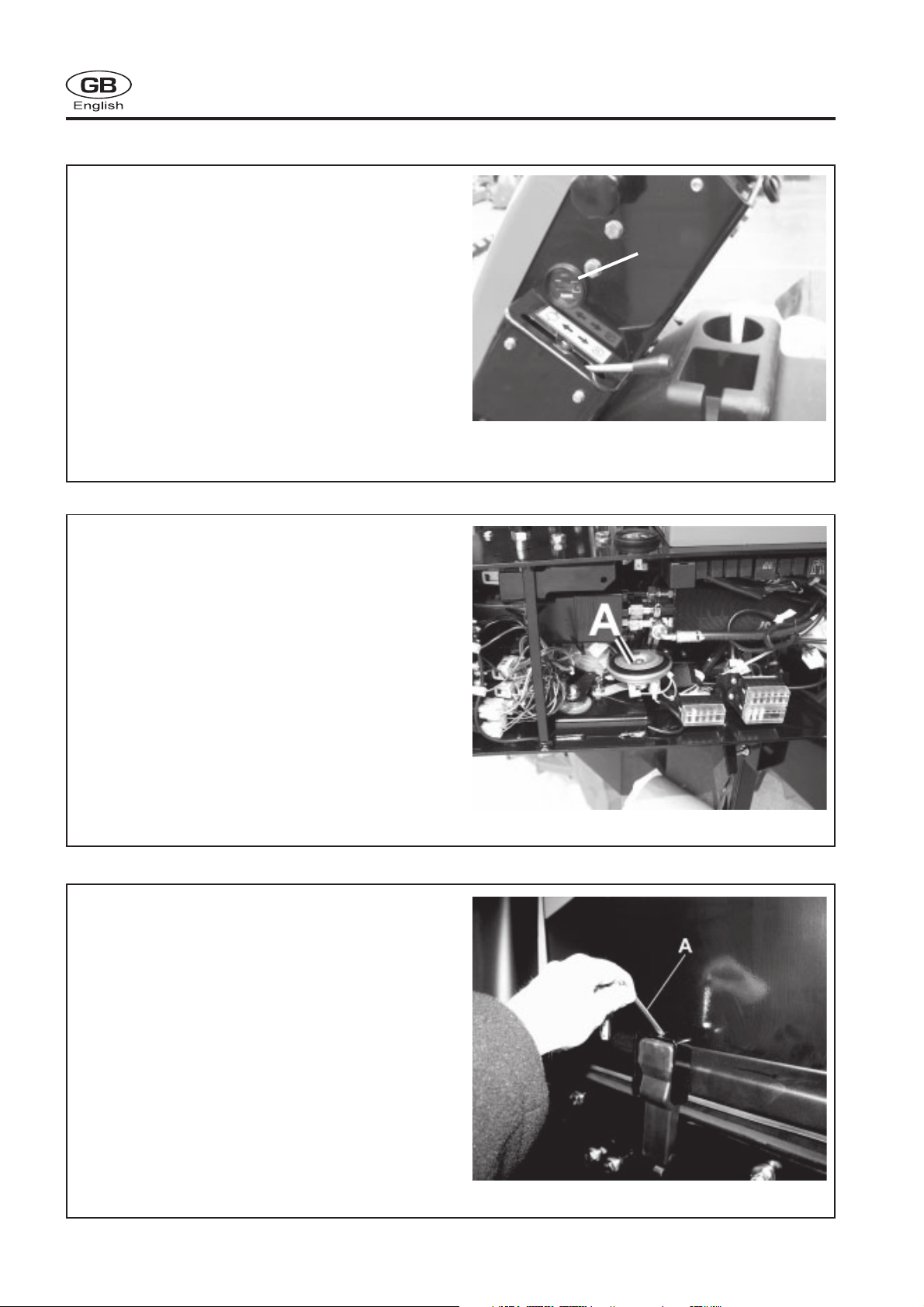

6.13 BONNET RELEASE KEY

Release bonnet by inserting key (A) into base of the

latch bracket and lever the rubber strap out of the

base.

GB-16

Page 19

7 OPERATION

RANSOMES HR3806 Series: DZ

SAFETY AND OPERATORS MANUAL

7.1 DAILY INSPECTION

CAUTION

The daily inspection should be performed

only when the engine is off and all fluids

are cold. Lower implements to the

ground, engage parking brake, stop

engine and remove ignition key.

1. Perform a visual inspection of the entire unit, look for signs of wear, lose hardware and missing or

damaged components. Check for fuel and oil leaks to ensure connections are tight and hoses and

tubes are in good condition.

2. Check the fuel supply, radiator coolant level, crankcase oil level and air cleaner indicator. All fluids

must be at the full mark with the engine cold.

3. Remove all grass debris from the machine.

4. Make sure all cutting units are adjusted to the same height of cut.

5. Check all tyres for proper inflation.

6. Test the operator presence and safety interlock system.

7. Remove all grass debris from the Pre-Cleaner.

7.2 TRAILER TIE DOWNS FOR REAR.

.

Two tie down loops are provided on the rear bumper

to enable the machine to be securely attached to a

trailer for transportation.

A

GB-17

Page 20

7 OPERATION

l

RANSOMES HR3806 Series: DZ

SAFETY AND OPERATORS MANUAL

7.3 OPERATOR PRESENCE AND SAFETY INTERLOCK SYSTEM

1. The operator presence & safety interlock system prevents the engine from starting unless the parking

brake is engaged, the mowing device is off and the operator is in the seat. The system also stops

the engine if the operator leaves the seat with the mowing device engaged or the park brake not

applied or the emergency brake valve lever is operated.

WARNING

Never operate the equipment with the

operator presence & safety interlock

system disengaged or malfunctioning. Do

not disconnect or bypass any switch.

2. Perform each of the following tests to ensure the operator presence & safety interlock system is

functioning properly. Stop the test and have the system inspected and repaired if any of the tests fai

as listed below:

• The engine does start in test 1;

• The engine does not start during tests 2,3;

• The engine continues to run during test 4.

3. Refer to the chart below for each test and follow the check tick marks across the chart. Shut engine

off between each test.

Test1: Represents normal starting procedure. The operator is seated, parking brake is

engaged, the operators feet are off the pedals and the mower engagement device is off. The

engine should start.

Test 2: The engine must not start if the mower engage device is on.

Test 3: The engine must not start if the park brake is not applied.

Test 4: Start the engine in the normal manner, push speed governor into Cut position, engage

mower switch on dash, engage cutting blades by depressing foot switch and lift your

weight off the seat.

tseT

rotarepO

detaeS

gnikraP

ekarB

deilppA

egagnEwoM

hctiwS

enignE

stratS

GB-18

)7(nevesnihtiwgnitatorpotstsumstinugnittucehT.taesffothgiewruoytfiL

seYoNseYoNtuC

1

2

3

4

99999999999999999999

99999999999999999999

99999999999999999999

999999999999999

sdnoces

-siD

seYoN

degagnE

Page 21

7 OPERATION

RANSOMES HR3806 Series: DZ

SAFETY AND OPERATORS MANUAL

7.4 OPERATING PROCEDURE

CAUTION

To help prevent injury, always wear safety

glasses, leather work shoes or boots, a

hard hat and ear protection.

1. Under no circumstances should the engine be started without the operator seated on the tractor.

2. Do not operate tractor or attachments with loose, damaged or missing components. Whenever

possible mow when grass is dry

3. First mow in a test area to become thoroughly familiar with the operation of the tractor and control

levers.

4. Study the area to determine the best and safest operating procedure. Consider the height of the

grass, type of terrain, and condition of the surface. Each condition will require certain adjustments

or precautions.

5. Never direct discharge of material toward bystanders, nor allow anyone near the machine while in

operation. The owner/operator is responsible for injuries inflicted to bystanders and/or damage to their

property.

CAUTION

Pick up all debris you can find before

mowing. Enter a new area cautiously

Always operate at speeds that allow you to

have complete control of the tractor

6. Use discretion when mowing near gravel areas (roadway, parking areas, cart paths, etc.). Stones

discharged from the implement may cause serious injuries to bystanders and/or damage the

equipment.

7. Disengage the drive motors and raise the implements when crossing paths or roads. Look out for

traffic.

8. Stop and inspect the equipment for damage immediately after striking an obstruction or if the

machine begins to vibrate abnormally. Have the equipment repaired before resuming operation.

WARNING

Before you clean, adjust, or repair this

equipment, always disengage all drives,

lower implements to the ground, engage

parking brake, stop engine and remove

key from ignition switch to prevent injuries.

GB-19

Page 22

7 OPERATION

RANSOMES HR3806 Series: DZ

SAFETY AND OPERATORS MANUAL

WARNING

DO NOT USE ON SLOPES GREATER THAN 15°

9. Slow down and use extra care on hillsides. Read Section 3.7. Use caution when operating near drop

off points.

10. Never use your hands to clean cutting units. Use a brush to remove grass clippings from blades.

Blades are extremely sharp and can cause serious injuries

OPERATION OF THE

MACHINE

Read the Safety Instructions.

BEFORE OPERATING FOR THE FIRST TIME

• Check and adjust tyre pressure, if

necessary, see specifications.

• Add diesel fuel to tank if necessary.

• Check engine oil and top-up, if necessary.

• Check radiator coolant and top-up, if

necessary (50% antifreeze solution).

• Make sure you understand the information

contained in the proceeding General

Instructions and Instruments & Controls

sections.

7.5 STARTING THE ENGINE

The following procedure is for starting cold engines.

1. Ensure the FWD/RVS pedal is in the

neutral position, the speed limiter is in the

transport position, the mow switch off, the

throttle setting is in a mid position and the

parking brake is applied.

2. Turn the ignition switch to position No.2

and hold until the glow plug light goes off

(5-10 sec.)

3. Turn ignition key fully clockwise to the

start position and operate the starter motor

until the engine starts (should only take a

few seconds)

4. When the engine starts, release the key

immediately and it will return to the RUN

position.

5. If the engine does not start, preheat the

glow plugs and try again.

NOTES:

• Warm engine - When the engine is warm

because of surrounding temperature or

recent operation, step No.2 of the cold

engine starting procedure may be skipped

(no need to preheat glow plugs).

• If the engine fails to start after two tries

(with preheat if necessary), wait 20

seconds and try again.

• The starter motor should never be run

continuously for longer than 30 seconds

or it may fail.

7.6 DRIVING

• Release brake - Make sure the parking

brake is released before attempting to go

forward or reverse.

• Forward - Gently depress the top plate of

the FWD/RVS foot pedal to reach desired

ground speed.

• Reverse - Gently depress the bottom

plate of the FWD/RVS foot pedal to reach

desired ground speed.

• To stop - Gently return the FWD/RVS foot

pedal to the neutral position.

NOTES:

• Use complete foot to operate both forward

and reverse.

• Do not move pedal suddenly–always

operate slowly and smoothly. Never move

pedal violently from forward to reverse or

vice versa.

• Always keep foot firmly on the foot pedal–

a too relaxed foot control may result in a

jerky motion.

GB-20

Page 23

7 OPERATION

7.7 MOWING

1. Lower the decks with the cutting unit lift

control.

2. Ensure speed limiter is in mow position

3. Engage the cutting mechanism by pushing

on the lower half of cutting unit switch and

operating the floor mounted switch.

3. Release the parking brake and begin

driving forward.

NOTE: Always set the throttle to full for mowing,

even when the grass is heavy. When the

engine is labouring, reduce forward speed

by easing up on the FWD/RVS foot pedal.

7.8 TO STOP THE ENGINE

1. Disengage power to the cutting units with

the cutting unit switch.

2. Remove foot from the FWD/REV pedal.

3. Set the parking brake.

3. Move the throttle control lever to the

SLOW position.

4. Turn the ignition key to OFF.

RANSOMES HR3806 Series: DZ

SAFETY AND OPERATORS MANUAL

7.9 PUSHING THE MACHINE WITH THE

ENGINE STOPPED

1. To push, disengage the parking brake.

2. Turn Knob (A) located under the seat plate

counter clockwise until marker on the top

is fully out. Set the steering wheel so that

the rear wheels are pointing straight

ahead.

3. Under the LH front corner of the operator

platform turn the emergency brake valve

lever (B) towards the back of the machine.

4. Turn the steering wheel to the left until

resistance can be detected. The machine

is now ready to be pushed. If unable to

move the machine apply further pressure

to the steering wheel. Excessive force

should never be used on the steering

wheel. If the rear wheels start to turn too

much force is being applied.

5. After pushing, return valve (B) and knob (A)

to their previous positions.

A

GB-21

Page 24

8 ADJUSTMENTS

8.1 SEAT (GS85/90)

The seat can be adjusted for operator's weight and

leg reach to provide a comfortable position for

operating the machine.

1. ADJUSTMENT FOR OPERATOR

WEIGHT

To Adjust:

The position of the adjusting knob (A) is on the front

of the seat, in the centre below the seat cushion.

By rotating the knob clockwise the weight capacity

is increased and by rotating the knob anticlockwise

the weight capacity is decreased.

2. FORE AND AFT ADJUSTMENT

RANSOMES HR3806 Series: DZ

SAFETY AND OPERATORS MANUAL

To Adjust:

The position of the adjusting lever is on the right

hand side of the seat below the seat cushion (B).

By moving the lever towards the seat, the seat can

be slid backwards and forwards. When in the

desired position release the lever to locate in one of

the pre set positions.

3. BACK REST ADJUSTMENT

The back rest has three preset positions

To Adjust:

The position of the release lever is on the left hand

side of the seat back rest (C). Move the lever

upwards to move the upper part of the back rest

forward. Move the lever downwards to move the

upper part of the back rest rearwards.

NOTE: The seat is fitted with a microswitch to sense

operator presence. When the machine is fitted with

a ROPS frame or cab a lap belt is fitted and should

be worn at all times

GB-22

Page 25

8 ADJUSTMENTS

8.2 HEIGHT OF CUT ADJUSTMENT

The cutting height is determined by the position of

the blades in relation to the caster wheels. Changes

to this height are made at (4) points and can be

made in any order. Make adjustment selections for

each deck from the height of cut chart for that deck

included in this section.

NOTES

– Cutting height must be set the same for all

three decks.

– The actual height may vary slightly from

the chart value because of tire pressure or

condition.

HEIGHT OF CUT ADJUSTMENT

1. Raise the deck.

2. Remove the quick pin Q from the top of the

caster wheel pivot spindle

3. Remove the caster wheel from caster

support M.

4. Select either Position 1 or Position 2 for

wheel mounting bracket. To change,

remove (4) mounting bolts R, move to the

alternate location and bolt in place.

5. Place the selected size and number of

spacers below the caster support. Both Asize (6.5 mm) and B-size (12.5 mm)

spacers are provided. Place the remaining

spacers above the caster support.

6. Replace the quick pin.

7. Place pin P into the proper hole of bracket

for the selected height of cut.

RANSOMES HR3806 Series: DZ

SAFETY AND OPERATORS MANUAL

CENTER DECK HEIGHT OF CUT CHART

GB-23

Page 26

9 MAINTENANCE

9.1 LUBRICATION AND MAINTENANCE CHART

z retliFliO&liOenignEegnahC

05tsriF

sruoh

z noisneTtleBnaFkcehC

z leveLliOenignEkcehC

z metsySkcolretnIytefaSkcehC

01yliaD

z leveLtnalooCkcehC

sruoh

z leveLdiulFciluardyHkcehC

z erusserPeryTkcehC

z sirbeDrofyaBenignEkcehC

z stnenopmocesooLrofkcehC

z skaeLciluardyHrofkcehC

05yrevE

sruoh

z noitidnoCyrettaBkcehC

ylkeeW

z noisneTtleBnaFkcehC

z *tnemelEretliFriAnaelC

RANSOMES HR3806 Series: DZ

SAFETY AND OPERATORS MANUAL

TRAHCNOITACIRBULDNAECNANETNIAM

001yrevE

sruoh

052yrevE

sruoh

z retliFliO&liOenignEegnahC

ylhtnoM

005yrevE

z tnemelEretliFriAegnahC

sruoh

z sretliFleuFecalpeR

ylretrauQ

0001yrevE

sruoh

yllaunnA

z retliFliO&liOenignEegnahC

z *tnemelEretliFriAegnahC

dnE

fo

z sretliFleuFecalpeR

z sretliF&liOciluardyHegnahC

nosaeS

z knaTleuFnaelC&niarD

z metsySgnilooChsulF&niarD

GB-24

)trahCeeS(ylkeeWesaerGtneliviuqero2RaniraDllehShtiwsgnittifesaerGllaetacirbuL

snoitidnocytridninetfoeromecivreS*

Page 27

9 MAINTENANCE

RANSOMES HR3806 Series: DZ

SAFETY AND OPERATORS MANUAL

zz

z Lubricate every 50 working hours at arrows

zz

STNEMERIUQERDIULF

YTITNAUQEPYT

LIOENIGNE

)retlifhtiw(

LIOCILUARDYH

)retlifhtiw(

ROTAIDAR

TNALOOC

sertiL0.6)DC(03W01

sertiL0.7364sulleTllehS

sertiL5.5EZEERF-ITNA%05

GB-25

Page 28

9 MAINTENANCE

9.2 DAILY CHECKS (Every 8 working hours)

Oil Level.

Check level of oil in sump. Remove dipstick (B)

wipe and replace and check that oil is up to the

maximum mark. Top up if necessary (A). It is

important that this test is carried out with the engine

cold and the vehicle parked on level ground.

Hydraulic Oil Level.

Check hydraulic oil level in tank. The level of oil

should be maintained in the green mark, halfway

between the red marks on the sight glass (C). Top

up (D) with Shell Tellus 46 hydraulic oil or equivalent

if necessary. The oil level should be checked cold

with the machine parked on level ground.

IMPORTANT: Absolute cleanliness must be

observed when filling the hydraulic tank. Oil

must be filtered through a 25 micron filter

before entering the hydraulic tank.

RANSOMES HR3806 Series: DZ

SAFETY AND OPERATORS MANUAL

Cooling System.

Check coolant level in expansion tank the coolant

level should be between the marks indicated on the

expansion bottle. Top up if necessary using a 50%

antifreeze solution.

Air Filter.

If working in dusty conditions the air filter element

should be examined and cleaned/replaced every 8

working hours (E).

Cleaning the air filter.

Remove loose dirt from element with compressed air

working from the "clean" to "dirty" side.

Note: Compressed air must not exceed 6bar, with

the nozzle 50mm away from element. The element

should be replaced after 6 cleanings.

E

GB-26

Page 29

9 MAINTENANCE

Cooling System.

Check Bug Screen (F) Radiator & Oil cooler are all

free from dust /debris and there is an uninterrupted

air flow to the engine. The screen should be fitted

with the mesh facing the front of the machine. Any

debris should be removed with a soft hand brush.

Machine Maintenance.

Fire Hazard: Remove all debris from under the seat

plate and from within the engine compartment.

Area. (G)

RANSOMES HR3806 Series: DZ

SAFETY AND OPERATORS MANUAL

F

PRE-CLEANER.

Check Pre-Cleaner is free from debris. This is by

removing the Wing Nut & Washer from the top of the

Pre-Cleaner. The Cover (A) & Bowl (B) can then be

removed from the body, the Bowl (B) can then be

cleaned out.

A

B

GB-27

Page 30

10 GUARANTEE / SALES & SERVICE

SAFETY AND OPERATORS MANUAL

RANSOMES HR3806 Series: DZ

GUARANTEE

We GUARANTEE that should any defect in workmanship or material occur in the

goods within TWO YEARS or two thousand hours (on models equipped with hour

meters), or whichever occurs first.

Exception to this warranty will be Aeration products, which are covered for a period

of TWO-YEARS or five hundred hours (on models equipped with hour meters) or

whichever occurs first.

We will repair, or at our option, replace the defective part without making any charge

for labour or for materials, provided that the claim under this guarantee is made

through an authorised dealer and that the defective part shall, if we so request, be

returned to us or to the dealer.

This guarantee is in addition to, and does not exclude, any condition or warranty

implied by law, except that we accept no liability in respect of used/second-hand

goods, or in respect of defects which in our opinion are in any way or to any extent

attributable to misuse, lack of reasonable care or ordinary wear and tear, or to the

fitting of spares, replacements, or extra components which are not supplied or

approved by us for the purpose. The use of non-recommended oil or lubricant

nullifies the guarantee.

Damage through transport or normal wear does not come under the guarantee.

The warranty is extended to the original purchaser only and is not transferable to

subsequent owners. The warranty period begins on the date the product is delivered

to the end user (customer), unless otherwise agreed with the manufacturer. At the

end of the first year the owner must have the product serviced by an authorised

dealer to be eligible for the second year of warranty coverage.

SALES & SERVICE

A network of authorised Sales and Service dealers has been established and these

details are available from your supplier.

When service attention, or spares, are required for the machine, within or after the

guarantee period your supplier or any authorised dealer should be contacted.

Always quote the registered number of the machine.

If any damage is apparent when delivery is made, report the details at once to the

supplier of the machine.

KEY NUMBERS. It is recommended that all key numbers are noted here:

Starter Switch :- ...............

Diesel tank :- ...............

It is also recommended that the machine and engine numbers are recorded.

The machine serial number is located on the registration plate and the engine serial

number can be found under the exhaust maifold above the starter motor.

Machine Number :- ...............

Engine Number :- ...............

GB-28

Page 31

1 INDHOLDSFORTEGNELSE

INDHOLDSFORTEGNELSE SIDE

2 INDLEDNING

2.1 VIGTIGT ....................................................................................................................2

2.2 PRODUKTIDENTIFIKA TION ........................................................................................2

3 SIKKERHEDSREGLER

3.1 BETJENINGSVEJLEDNING ......................................................................................... 3

3.2 ADVARSELSSKIL TNING ............................................................................................ 3

3.3 SÅLEDES STARTER MAN MOTOREN........................................................................ 3

3.4 SÅLEDES KØRER MAN MED MASKINEN .................................................................. 3

3.5 TRANSPORT ............................................................................................................. 3

3.6 SÅLEDES FORLADER MAN KØREPOSITIONEN ......................................................... 4

3.7 SKRÅNINGER .............................................................................................................4

3.8 BLOKEREDE KLIPPEAGGREGA TER ........................................................................... 4

3.9 JUSTERINGER, SMØRING OG VEDLIGEHOLDELSE .................................................. 4

4 MASKINSPECIFIKA TION

4.1 MOTORSPECIFIKATION ............................................................................................ 6

4.2 MASKINSPECIFIKATION ...........................................................................................6

4.3 MÅL ..........................................................................................................................6

4.4 VIBRATIONSNIVEAU ................................................................................................. 7

4.5 SKRÅNINGER .............................................................................................................8

4.6 ANBEFALEDE SMØREMIDLER .................................................................................. 8

4.7 KLIPPEKAPACITET (OMRÅDE) ................................................................................. 8

4.8 KONFORMITETSATTESTER ......................................................................................9

RANSOMES HR3806 - serie: DZ

SIKKERHEDS- OG BETJENINGSVEJLEDNING

5 LABELS

5.1 SIKKERHEDSLABELS ............................................................................................... 11

5.2 INSTRUKTIONSLABELS ........................................................................................... 11

6 BETJENING

6.1 TÆNDINGSLÅS ........................................................................................................ 12

6.2 GASHÅNDTAG ......................................................................................................... 12

6.3 JUSTERING AF RATVINKEL .....................................................................................12

6.4 TRAKTIONSFODPEDAL ............................................................................................ 12

6.5 HASTIGHEDSBEGRÆNSER ....................................................................................... 12

6.6 P ARKERINGSBREMSE .............................................................................................. 13

6.7 DIFFERENTIALESPÆRRE ......................................................................................... 13

6.8 HYDRAULISKE LØFTEARME .................................................................................... 13

6.9 KLIPPEENHEDSKONT AKTER .................................................................................... 13

6.10 INSTRUMENTBRÆT ................................................................................................. 15

6.11 TIMETÆLLER .......................................................................................................... 16

6.12 HORN ........................................................................................................................ 16

6.13 ÅBNINGSNØGLE TIL MOTORHJELM....................................................................... 16

7 DRIFT

7.1 DAGLIG INSPEKTION ............................................................................................... 17

7.2 TRÆK TIL PÅSÆTNING AF TRAILER BAG PÅ MASKINEN .....................................17

7.3 OPERATØRTILSTEDEVÆRELSES- OG SIKKERHEDSLÅSESYSTEM ........................ 18

7.4 BETJENINGSPROCEDURE ........................................................................................ 19

7.5 ST ART AF MOTOREN............................................................................................... 20

7.6 KØRSEL ...................................................................................................................20

7.7 KLIPNING ................................................................................................................. 21

7.8 SÅDAN STANDSER DU MOTOREN ...........................................................................21

7.9 SÅDAN SKUBBER DU MASKINEN MED STANDSET MOTOR ....................................21

8 JUSTERINGER

8.1 SÆDE ....................................................................................................................... 2 2

8.2 JUSTERING AF KLIPPEHØJDE ................................................................................. 23

9 VEDLIGEHOLDELSE

9.1 SMØRINGS- OG VEDLIGEHOLDELSESPLAN ........................................................... 24

9.2 DAGLIGE EFTERSYN ................................................................................................26

10 GARANTI / SALG OG SERVICE ................................................................................ 28

DK-1

Page 32

2 INDLEDNING

RANSOMES HR3806 - serie: DZ

SIKKERHEDS- OG BETJENINGSVEJLEDNING

2.1 VIGTIGT

VIGTIGT: Dette er en præcisionsmaskine, og hvor meget glæde du får af maskinen,afhænger af hvordan den

bliver brugt og vedligeholdt.

Denne SIKKERHEDS- OG BETJENINGSVEJLEDNING udgør en del af maskinen. Leverandører af nye eller

brugte maskiner anbefales at opbevare bevis for, at denne vejledning blev leveret med maskinen.

Maskinen er designet ene og alene til brug for almindelig plæneklipning. Enhver anden anvendelse anses for at

være i modstrid med den tiltænkte anvendelse. Efterlevelse og streng overholdelse af betingelserne for drift,

service og vedligeholdelse som specificeret af producenten udgør ligeledes vigtige elementer i den tiltænkte

anvendelse.

Før der gøres forsøg på at anvende maskinen, SKAL ALLE brugere læse denne manual og gøre dem selv

fortrolig med sikkerhedsinstrukserne, reguleringer, smøring og vedligeholdelse.

Regler for forebyggelse af uheld, alle andre generelt anerkendte regler for sikkerhed og arbejdsmedicin, og alle

færdselsregler skal iagttages til enhver tid.

Vilkårlig modifikation af denne maskine kan fritage producenten for ansvar for evt. skade eller kvæstelser som

følge heraf.

2.2 PRODUKTIDENTIFIKATION

A Maskinens navn

B Serienummer

C Fabrikationsår

D Maskinens vægt

E Motoreffekt

DK-2

Page 33

3 SIKKERHEDSREGLER

RANSOMES HR3806 - serie: DZ

SIKKERHEDS- OG BETJENINGSVEJLEDNING

Dette sikkerhedssymbol angiver vigtig

sikkerhedsinformation i denne vejledning. Når du ser

dette symbol, skal du være opmærksom på risikoen

for skade, læse den efterfølgende information

omhyggeligt igennem, og give den videre til andre

brugere.

3.1 BETJENINGSVEJLEDNING

• Husk at læse og bide mærke i instrukserne i

denne bog.

• Kun personer med fuldt kendskab til

kontrolgrebene og sikkerhedsreglerne bør have

adgang til at betjene denne maskine.

• Børn, og andre der ikke har kendskab til

nærværende anvisninger, bør ikke have adgang

til at bruge maskinen. Der er muligvis lokale

restriktioner med hensyn til førerens alder.

3.2 ADVARSELSSKILTNING

• Det er meget vigtigt, at advarselsmærkater er

nemme at læse, og hvis de mangler eller er

ulæselige, skal de udskiftes. Hvis en del af

maskinen skal udskiftes, og den oprindelige

del er forsynet med et advarselsmærkat, skal

den nye del også forsynes med et lignende

mærkat. Nye advarselsmærkater kan fås ved

henvend-else til Ransomes’

reservedelsafdeling.

3.3 SÅLEDES STARTER MAN MOTOREN

• Inden man starter motoren, skal man

kontrollere, at bremserne er slået til,

kraftoverføringen er i neutral, skærm-pladerne

er i stilling og intakte, og at der ingen andre

personer befinder sig i nærheden af maskinen.

• Motoren må ikke køre i en bygning, medmindre

der er tilstrækkelig ventilation.

3.4 SÅLEDES KØRER MAN MED MASKINEN

• Inden man begynder at arbejde med maskinen,

skal det kontrolleres, at alle dele er i god

driftsmæssig stand, især bremser, dæk,

styretøj og skærestålets sikkerhedsværn.

• Defekte lyddæmpere bør udskiftes. Slå kun græs

ved dagslys eller god kunstig belysning.

• Husk altid at overholde færdselsreglerne både

på og udenfor vejbanen. Ved kørsel over eller i

nærheden af en vej bør man have

opmærksomheden henvendt på trafikken.

• Inden der køres hen over andre belægninger

end græs, skal knivene standses.

• Vær hele tiden på vagt og årvågen. Husk, at

der er folk, som er enten døve eller blinde, og

at børn og dyr ofte kan være uberegnelige.

• Sørg for at farten er lav nok til at foretage en

effektiv og sikker katastrofeopbremsning til

enhver tid og i alle situationer.

• Fjern eller undgå forhindringer på området, der

skal klippes, så hverken du selv eller

eventuelle omkringstående kommer til skade.

• I bakgear skal man især passe på, at der ikke

findes forhindringer og/eller andre personer

bag maskinen. Der må IKKE medbringes

passagerer.

• Husk, at føreren/brugeren har ansvaret for

eventuelle ulykker og skader der påføres

andre mennesker eller deres ejendom.

• Når maskinen parkeres, oplægges eller

efterlades uden opsyn, skal slåmekanismen

sænkes, medmindre transportlåsene er i

brug.

• Under arbejdet bør man altid have solidt fodtøj

og lange bukser på. Undgå at arbejde med

maskinen uden fodtøj eller med åbne sandaler

på.

• Opsamleren bør undersøges hyppigt for

slitage og forringelse. Hvis maskinen støder

mod noget, bør den straks undersøges for

skader. En eventuel reparation skal foretages,

inden den startes igen.

• Hvis maskinen begynder at vibrere unormalt,

bør dette straks undersøges nærmere.

3.5 TRANSPORT

• Kontroller, at skærestålene er fastmonteret i

transportstilling. Må ikke transporteres med

roterende klippemekanisme.

• Under kørslen skal der tages hensyn til vejens

og overfladens art, tillige med skråninger og

lokale undulationer.

• Pludselig hastighedsnedsættelse eller

opbremsning kan få baghjulene til at løfte sig

fra jorden.

• Husk, at stabiliteten i maskinens bagende

reduceres, efterhånden som brændstoffet

bliver brugt.

DK-3

Page 34

3 SIKKERHEDSREGLER

RANSOMES HR3806 - serie: DZ

SIKKERHEDS- OG BETJENINGSVEJLEDNING

3.6 SÅLEDES FORLADER MAN

KØREPOSITIONEN

• Parker maskinen på et jævnt område.

• Inden man forlader kørepositionen, skal man

slukke for motoren og kontrollere, at alle

bevægelige dele er faststående.

Slå bremsen i og udryk alle drevene. Tag

startnøglen ud af tændingen.

3.7 SKRÅNINGER

VÆR ISÆR FORSIGTIG UNDER ARBEJDE PÅ

SKRÅNINGER

• Lokale undulationer og fordybninger ændrer

skråningens almindelige udseende. Undgå

jordforhold, som kan få maskinen til at glide.

Maskinens kørehastighed bør holdes nede på

skråninger, og når der drejes skarpt.

• Pludselig hastighedsnedsættelse eller

opbremsning kan få baghjulene til at løfte sig

fra jorden.

• Husk, at der er ingen skråninger, der er “sikre”.

• Ved kørsel på græsskråninger skal der udvises

stor forsigtighed for ikke at risikere at vælte.

MASKINEN MÅ IKKE ANVENDES PÅ

HÆLDNINGER, DER ER STØRRE END 15°.

VIGTIGT: Under arbejde på enhver skråning skal