Page 1

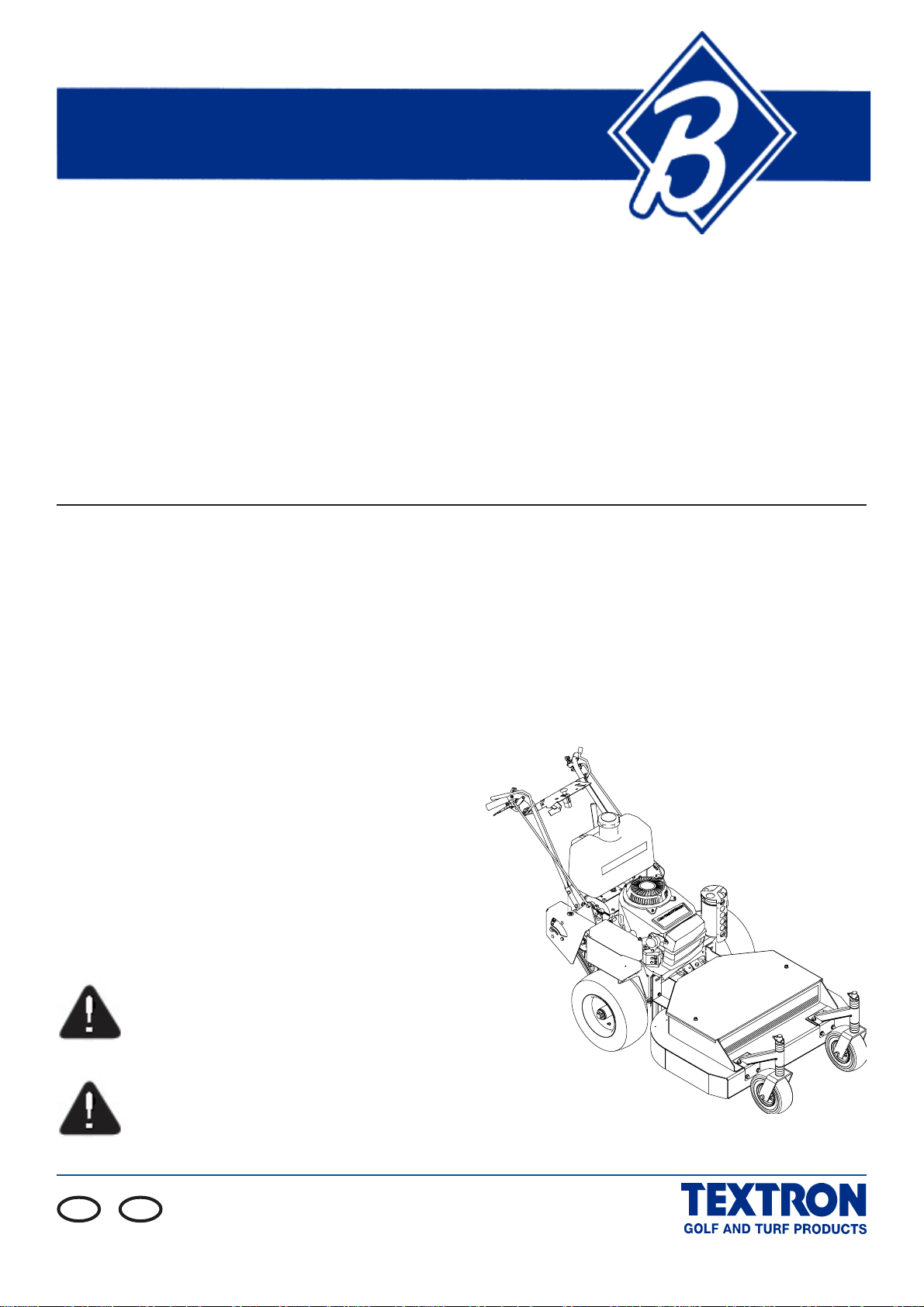

®

BUNTON

Setup, Parts and Maintenance Manual

Manuel de maintenance et de piéces de montage

EC Hydro Midsize

Model: 930024 - Engine type: kawasaki FH451V

GBGB

GB

GBGB

WARNING: If incorrectly used this machine can cause severe injury. Those who use and maintain this machine should

be trained in its proper use, warned of its dangers and should

read the entire manual before attempting to set up, operate,

adjust or service the machine.

AVERTISSEMENT : Risque de blessures graves en cas

d’utilisation incorrecte de la machine. Les opérateurs et le

personnel d’entretien doivent être formés et conscients des

dangers encourus. Ils doivent lire avec attention le manuel

avant d’essayer de monter, d’utiliser, de régler ou maintenir

la machine.

FF

F

FF

BUNTON

Part No. 24514G (rev.0)(RJ 100 012002)

Page 2

© 2002, Textron Inc. All Rights Reserved

Page 3

EC

CONTENTS

Hydro

Midsize

IMPORTANT MESSAGE

Thank you for purchasing this Bunton product. You have purchased a world class mowing product, one of the best

designed and built anywhere.

This machine comes with an Operation and Safety Manual and a separate Setup, Parts and Maintenance Manual.

The useful life and good service you receive from this machine depends to a large extent on how well you read

and understand these manuals. Treat your machine properly, lubricate and adjust it as instructed, and it will give

you many years of reliable service.

Your safe use of this Bunton product is one of our prime design objectives. Many safety features are built in, but

we also rely on your good sense and care to achieve accident-free operation. For best protection, study the

manuals thoroughly. Learn the proper operation of all controls. Observe all safety precautions. Follow all

instructions and warnings completely. Do not remove or defeat any safety features. Make sure those who operate

this machine are as well informed and careful in its use as you are.

See a Bunton dealer for any service or parts needed. Bunton service ensures that you continue to receive the

best results possible from Bunton’ products. You can trust Bunton replacement parts because they are

manufactured with the same high precision and quality as the original parts.

Bunton designs and builds its equipment to serve many years in a safe and productive manner. For longest life,

use this machine only as directed in the manuals, keep it in good repair and follow safety warnings and instructions.

You'll always be glad you did.

T extron Golf, T urf & Specialty Products

Central Avenue, Ransomes Europark

Ipswich, England, IP3 9QG

T ABLE OF CONTENTS FIGURES PAGE

SAFETY ......................................................................................................................................................... 2

ASSEMBLY/SET-UP INSTRUCTIONS...................................................................................................... 3-12

LUBRICATION ....................................................................................................................................... 13, 14

MAINTENANCE ...................................................................................................................................... 15-17

SERVICE CHART ........................................................................................................................................ 18

SERVICE RECORD ..................................................................................................................................... 19

ADJUSTMENTS...................................................................................................................................... 20-23

BELT REPLACEMENT................................................................................................................................. 24

PARTS SECTION......................................................................................................................................... 25

UPPER ENGINE DECK ASSY ........................... FIGURE 1.................................................................. 26, 27

LOWER ENGINE DECK ASSY/CLUTCH........... FIGURE 2.................................................................. 28, 29

DRIVE WHEELS ................................................ FIGURE 3.................................................................. 30, 31

P ARKING BRAKE .............................................. FIGURE 4.................................................................. 32, 33

ELECTRIC ST A RT UPPER HANDLE................. FIGURE 5.................................................................. 34, 35

TRACTION CONTROLS .................................... FIGURE 6.................................................................. 36, 37

ELECTRIC START BATTERY............................ FIGURE 7.................................................................. 38, 39

HYDRAULICS .................................................... FIGURE 8.................................................................. 40, 41

DECALS ............................................................. FIGURE 9.................................................................. 42, 43

HYROGEAR PUMP............................................ FIGURE 10................................................................ 44, 45

CUTTERDECK MOUNTING .............................. FIGURE 11................................................................ 46, 47

ELECTRICAL DIAGRAM.................................... FIGURE 12................................................................ 48, 49

ELECTRICAL SCHEMA TIC................................ FIGURE 13...................................................................... 50

11-2001-TGTSP

GB-1

Page 4

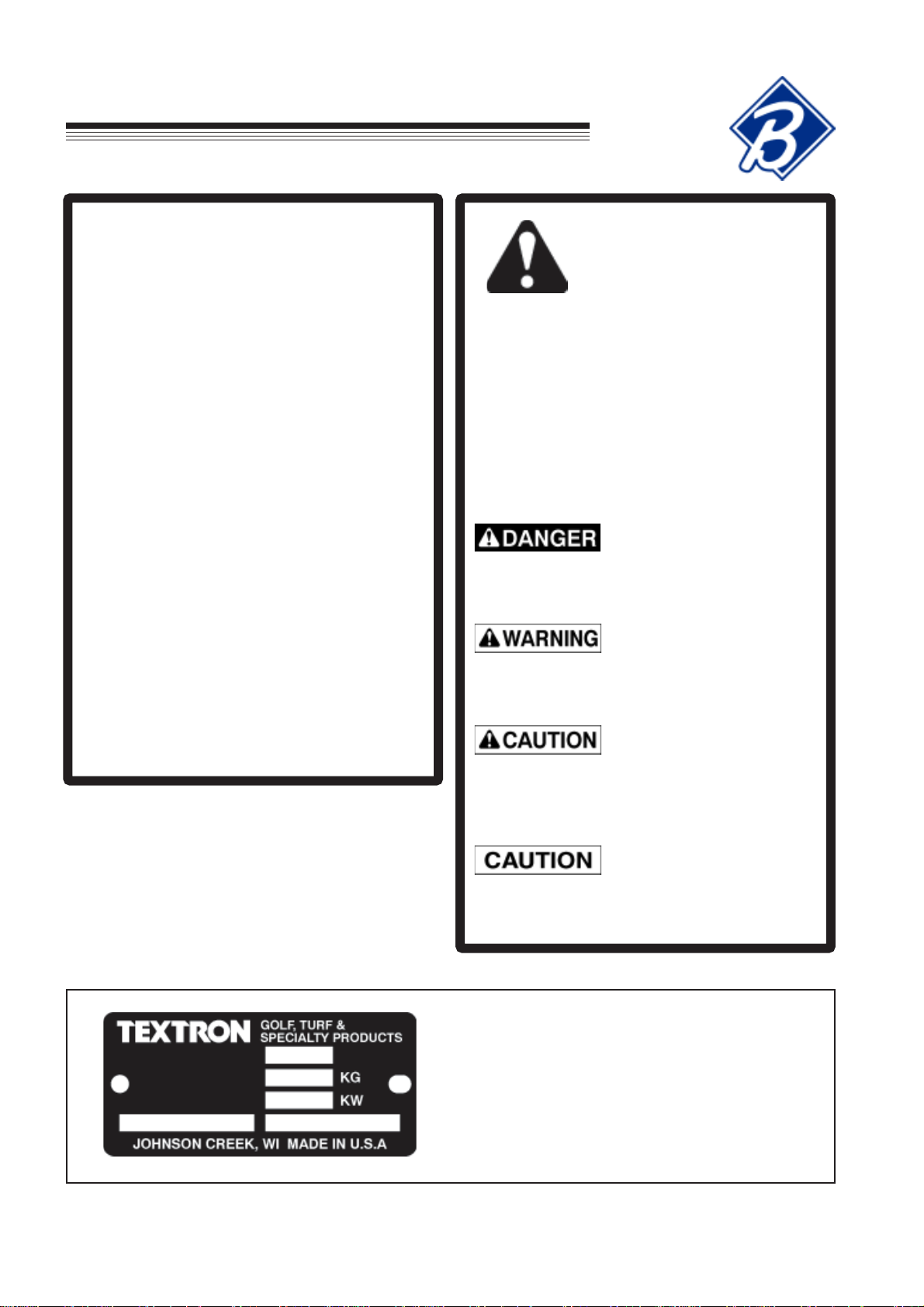

SAFETY

EC

Hydro

Midsize

NOTICE !!!

Unauthorized modifications may present extreme

safety hazards to operators and bystanders and

could also result in product damage.

Textron Golf, Turf & Specialty Products strongly

warns against, rejects and disclaims any modifications, add-on accessories or product alterations that

are not designed, developed, tested and approved

by Textron Golf, Turf & Specialty Products Engineering Department. Any Textron Golf, Turf & Specialty

Products product that is altered, modified or changed

in any manner not specifically authorized after original manufacture–including the addition of “aftermarket” accessories or component parts not specifically approved by Textron Golf, Turf & Specialty

Products–will result in the Textron Golf, Turf & Specialty Products Warranty being voided.

Any and all liability for personal injury and/or property

damage caused by any unauthorized modifications,

add-on accessories or products not approved by

Textron Golf, Turf & Specialty Products will be considered the responsibility of the individual(s) or company designing and/or making such changes. Textron

Golf, Turf & Specialty Products will vigorously pursue

full indemnification and costs from any party responsible for such unauthorized post-manufacture modifications and/or accessories should personal injury

and/or property damage result.

This symbol means:

ATTENTION!

BECOME ALERT!

Your safety and the safety of others is involved.

Signal word definitions:

The signal words below are used to identify levels of

hazard seriousness. These words appear in this

manual and on the safety labels attached to Textron

Golf, Turf & Specialty Products machines. For your

safety and the safety of others, read and follow the

information given with these signal words and/or the

symbol shown above.

DANGER indicates an imminently hazardous

situation which, if not avoided, WILL result in death

or serious injury.

WARNING indicates a potentially hazardous situation

which, if not avoided, COULD result in death or

serious injury.

CAUTION indicates a potentially hazardous situation

which, if not avoided, MAY result in minor or moderate

injury. It may also be used to alert against unsafe

practices or property damage.

GB-2

CAUTION used without the safety alert symbol

indicates a potentially hazardous situation which, if

not avoided, MAY result in property damage

MODEL NUMBER: This number appears on

sales literature, technical manuals and price lists.

SERIAL NUMBER: This number appears only

on your mower. It contains the model number

followed consecutively by the serial number. Use

this number when ordering parts or seeking

warranty information.

SERIAL TAG

Page 5

EC

ASSEMBLY/SET-UP INSTRUCTIONS

Hydro

Midsize

GENERAL NOTE: FRONT, REAR, RIGHT HAND AND LEFT HAND REFERENCES BELOW

ARE WITH RESPECT TO AN OPERATOR AT THE CONTROLS.

1. UNCRATE - Place both power unit and cutterdeck crates on a level surface. Remove sides and top from

both the power unit and cutterdeck crates.

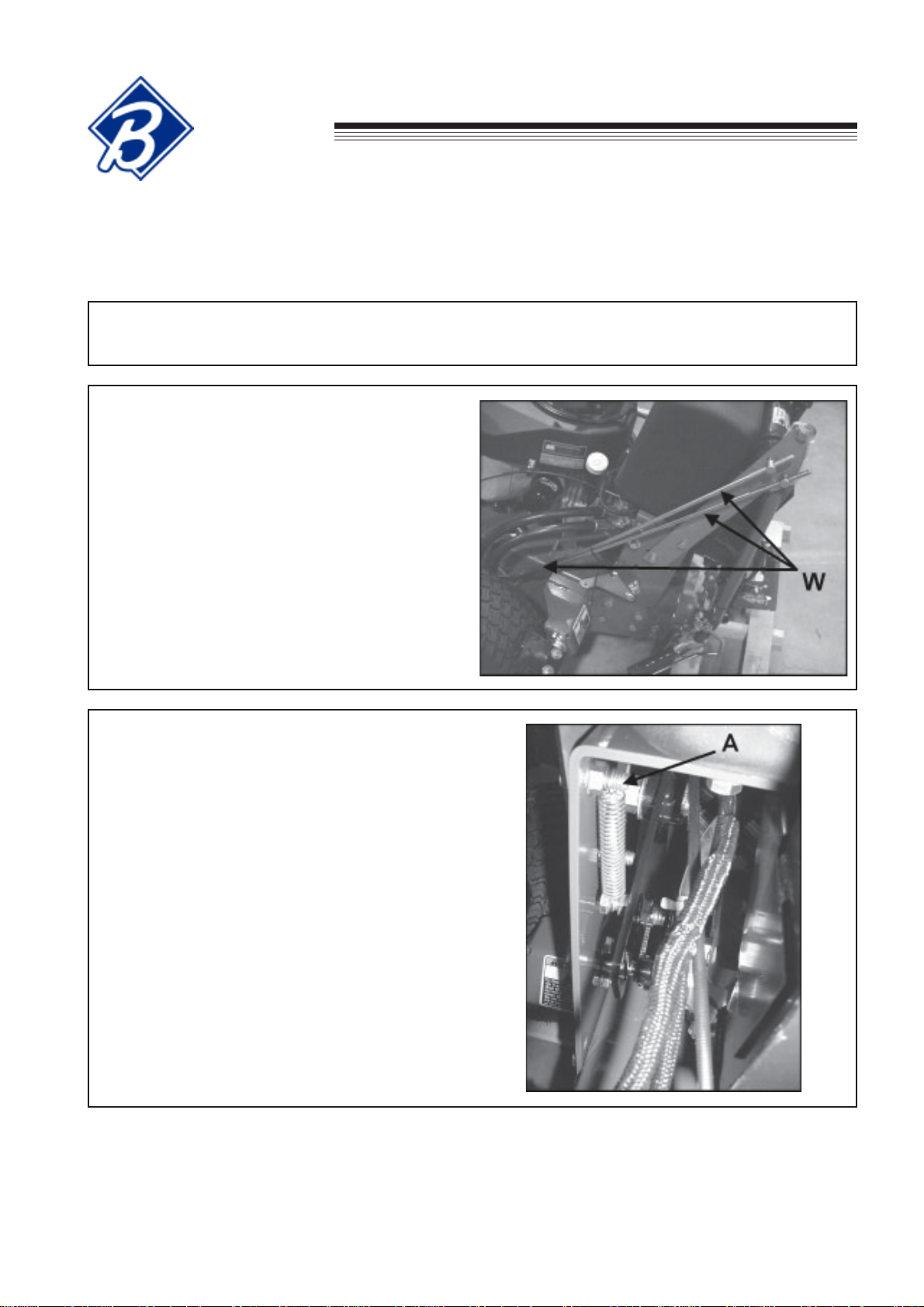

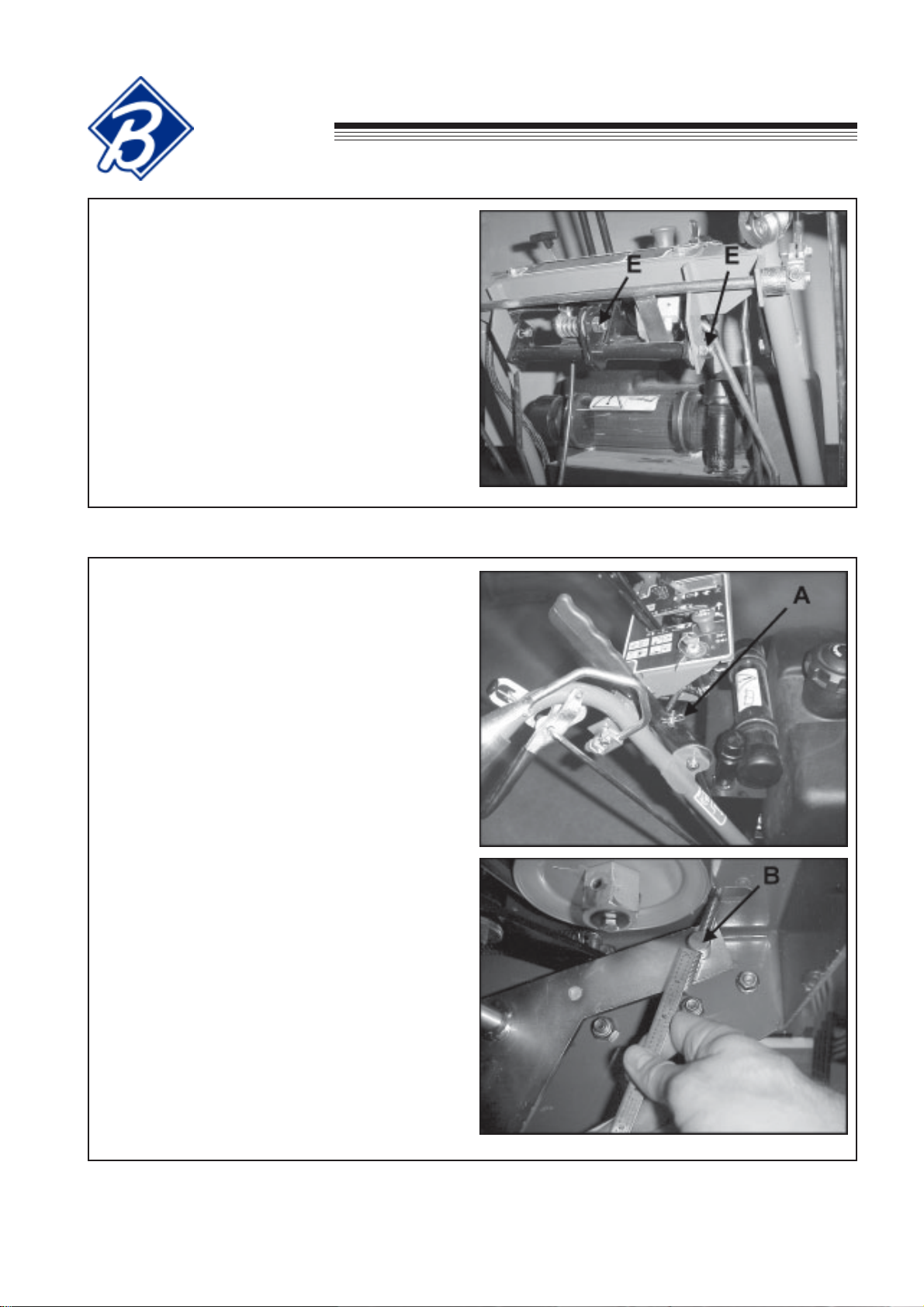

2. Remove three rods W on left and two rods W on

the right from the upper handle shipping bracket

and set them aside for later use.

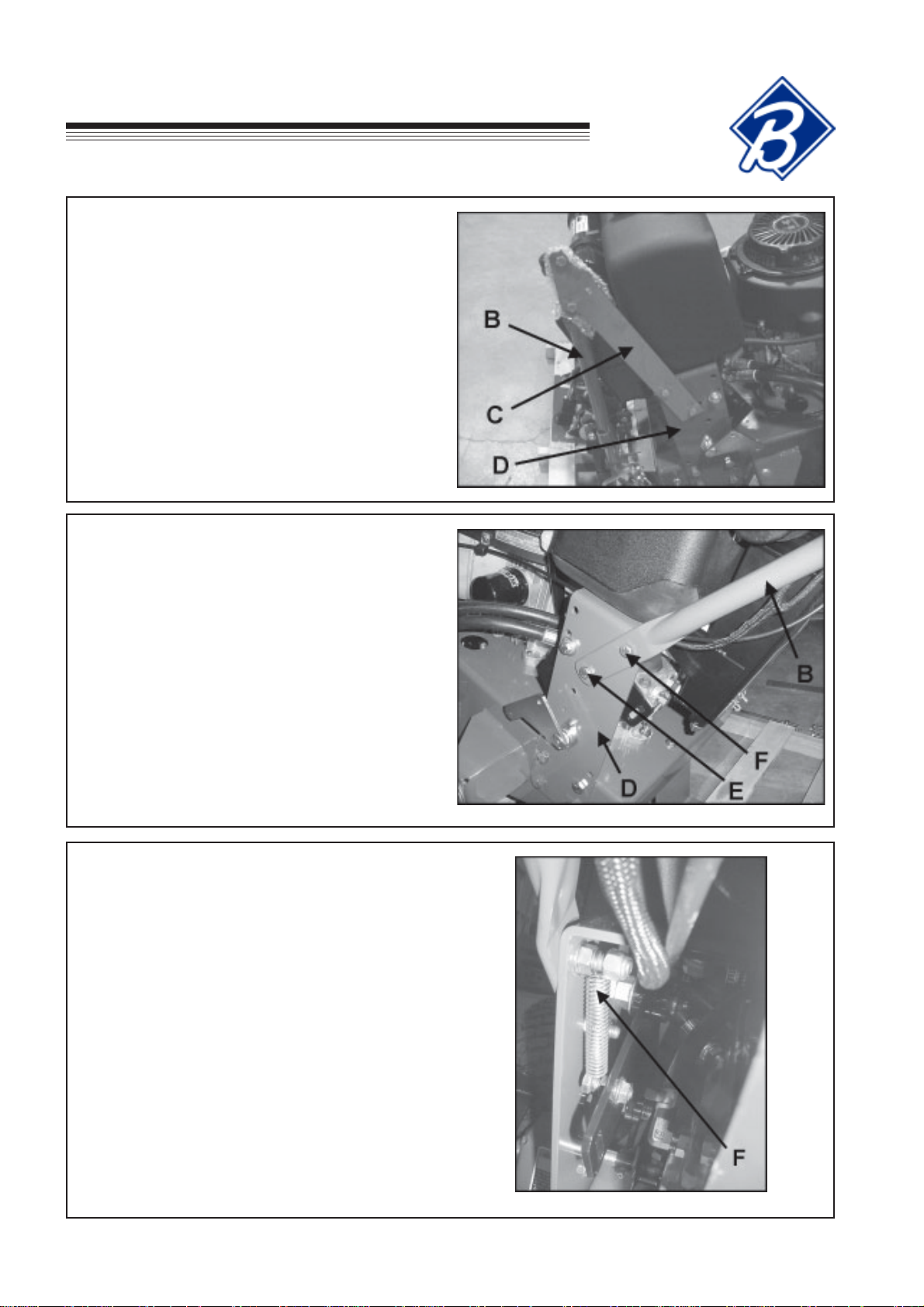

3. Remove spring from bolt A. Repeat for other

side.

GB-3

Page 6

ASSEMBLY/SET-UP INSTRUCTIONS

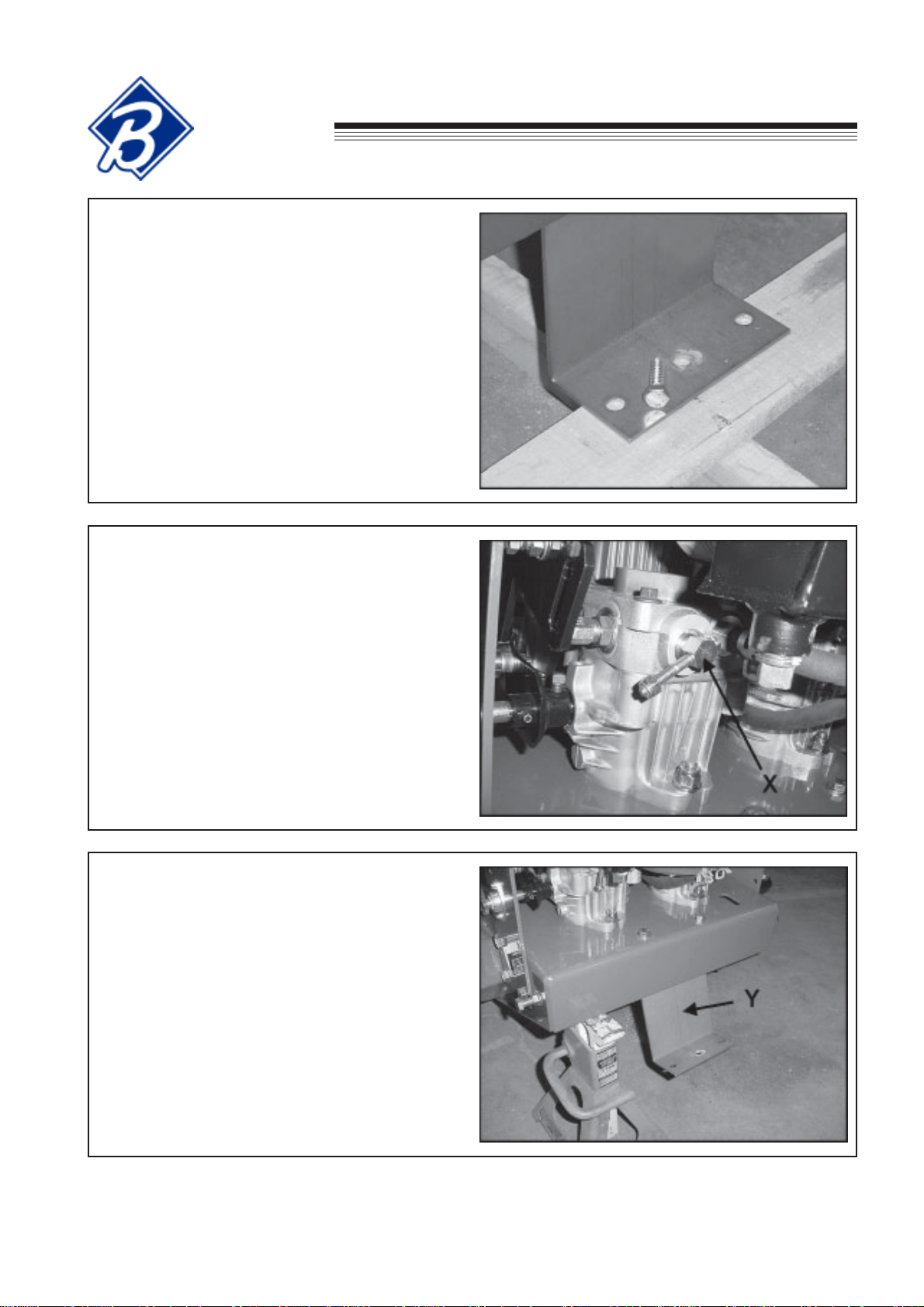

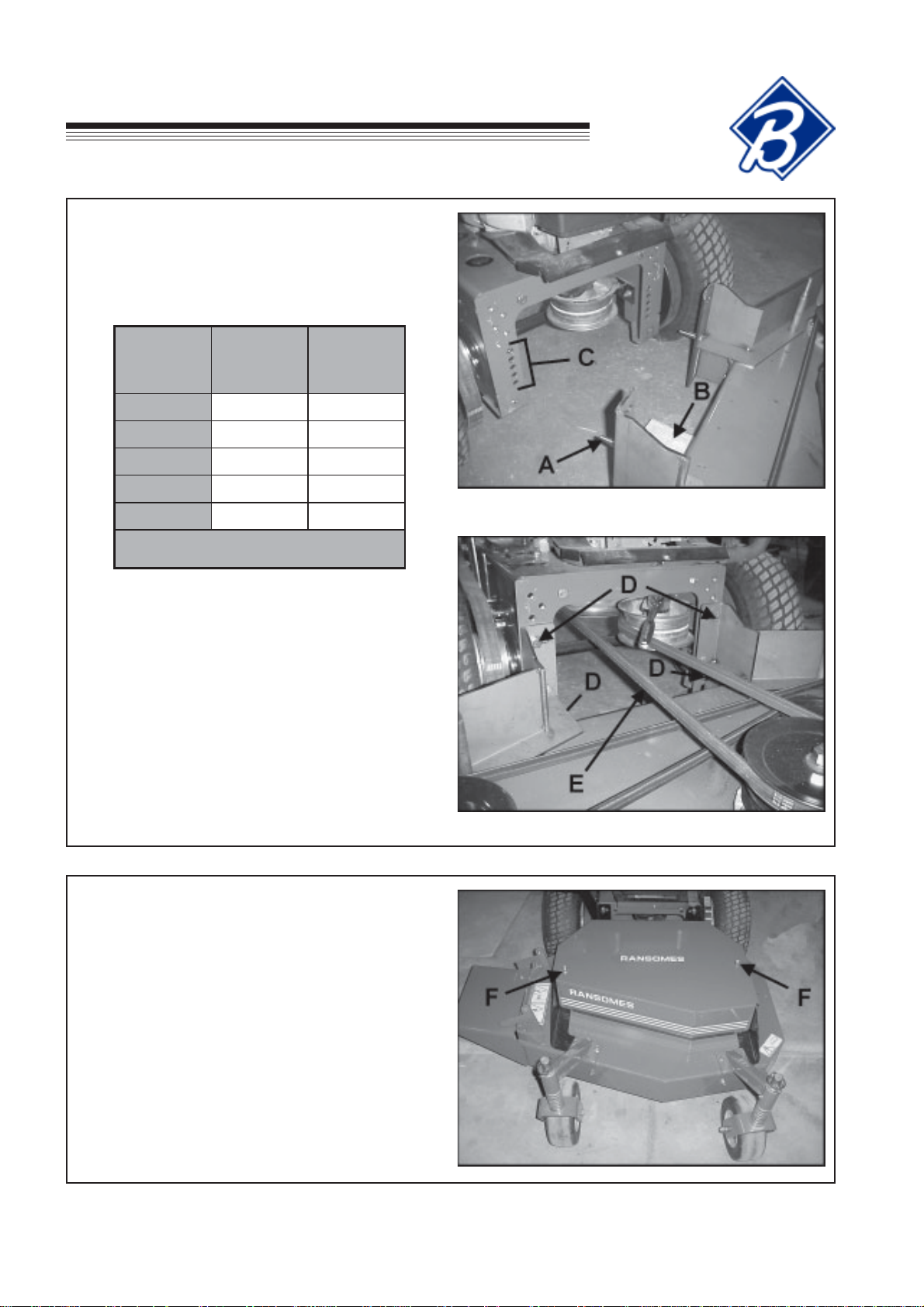

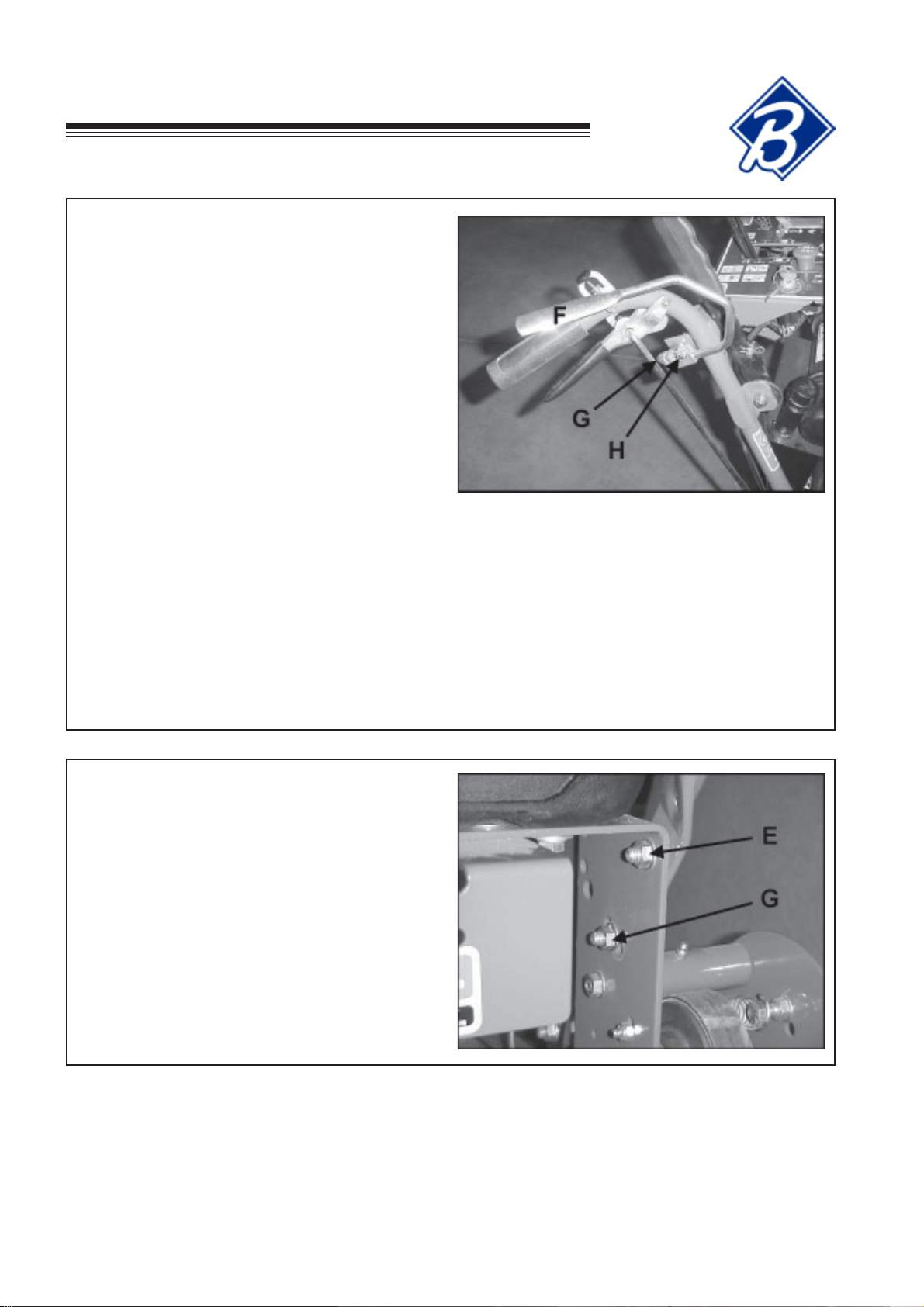

4. Unbolt upper handle B from shipping bracket C.

Unbolt shipping bracket C from lower handle D.

Retain fasteners removed for later use.

5. Bolt upper handle B to lower handle D with

(2) 3/8-16 X 1" bolts and nuts at location E bolts

removed in the previous step and

(2) 3/8-16 X 1-1/2" bolts and nuts at location F.

EC

Hydro

Midsize

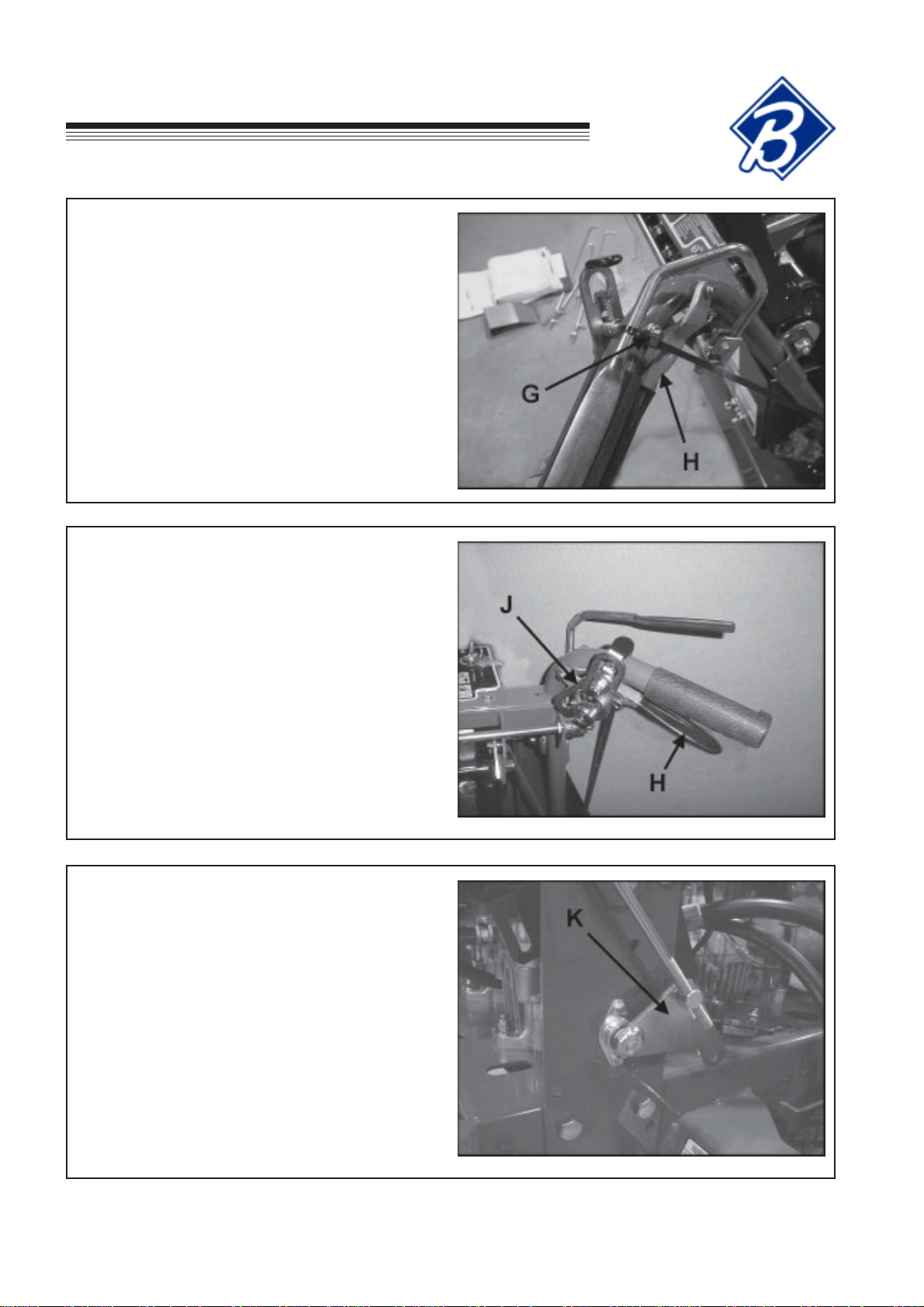

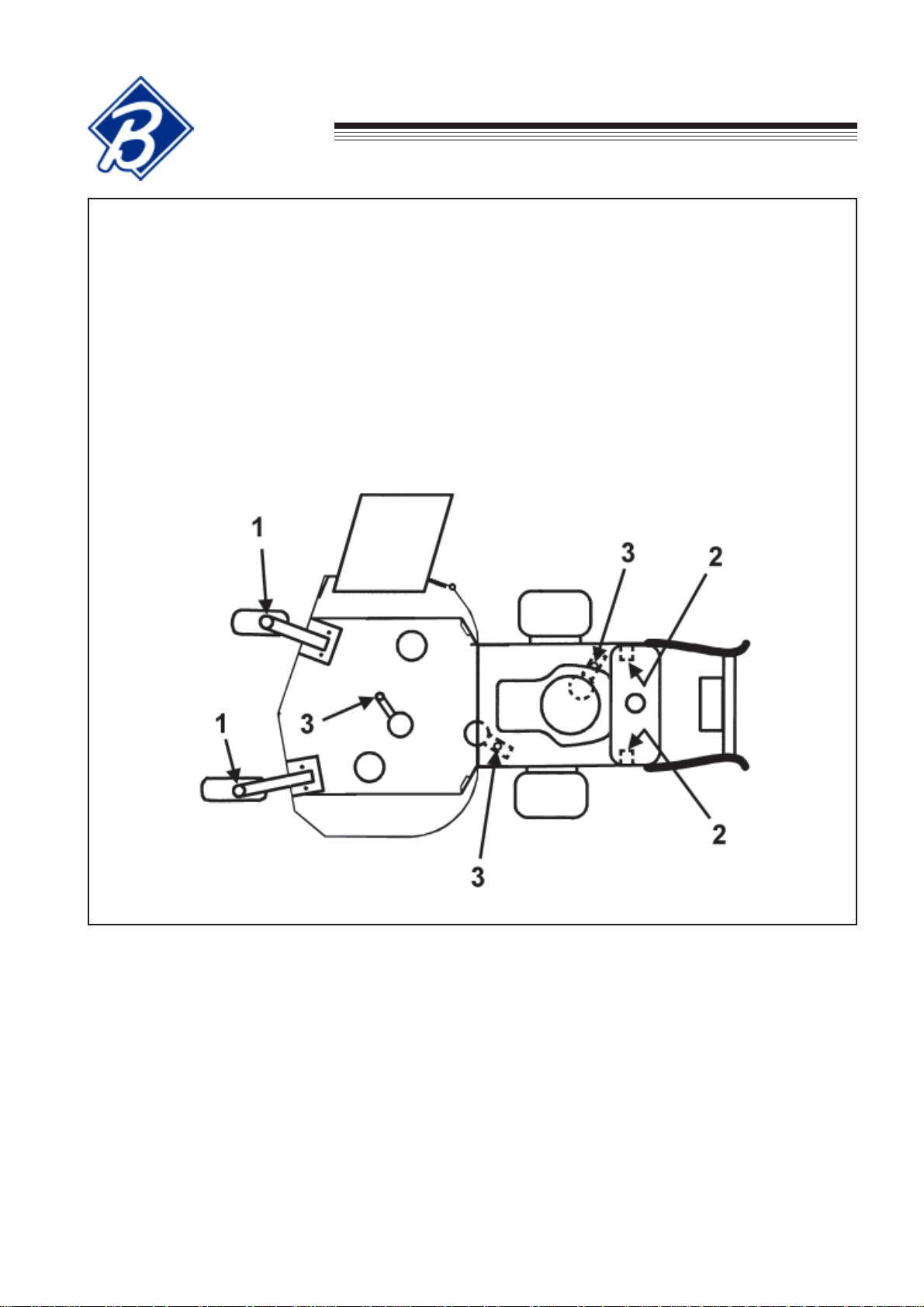

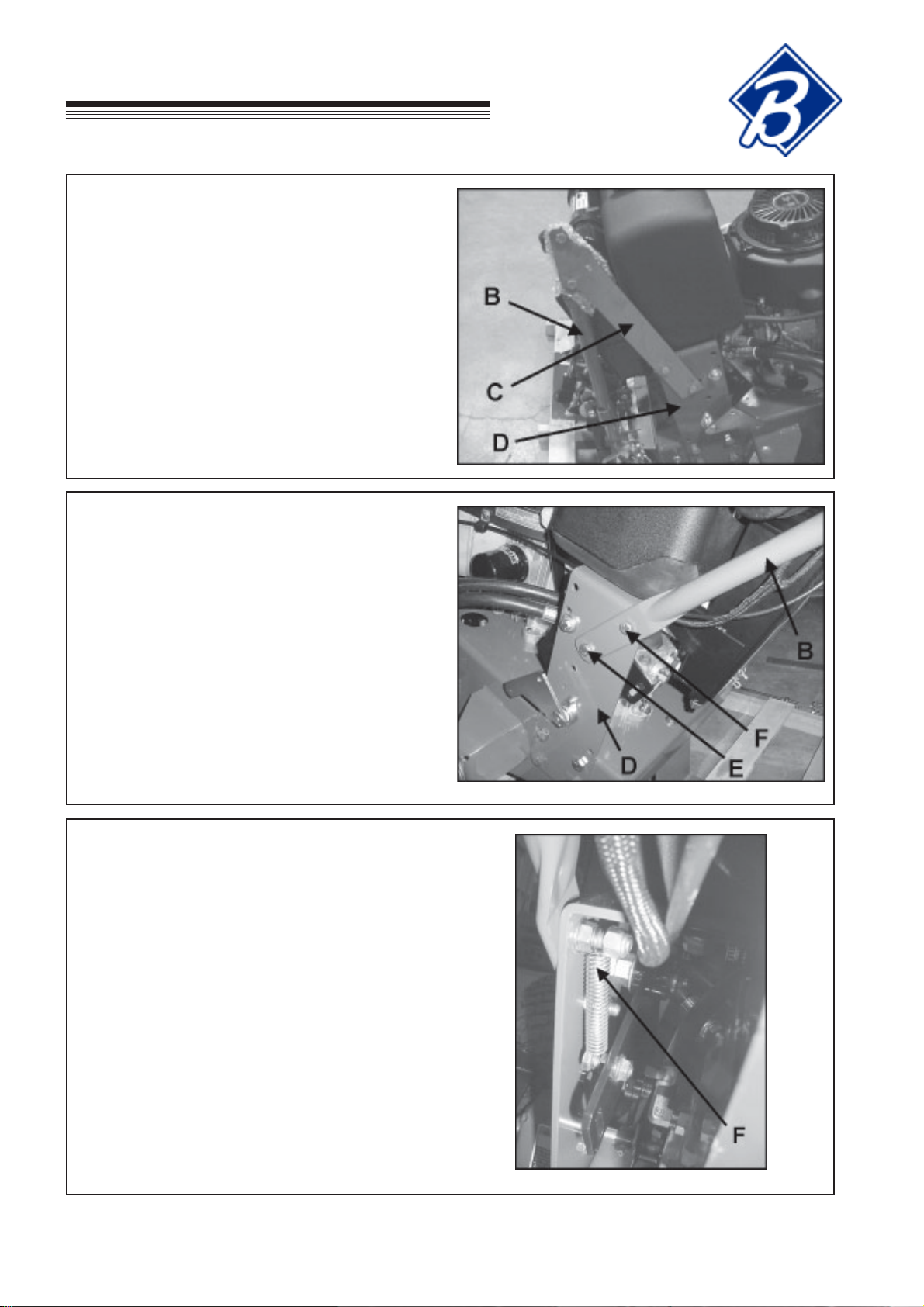

6. Reinstall spring F to bolt on both sides. Install

3/8-16 nylon locknut to end of bolt on both sides

as shown.

GB-4

Page 7

EC

Hydro

Midsize

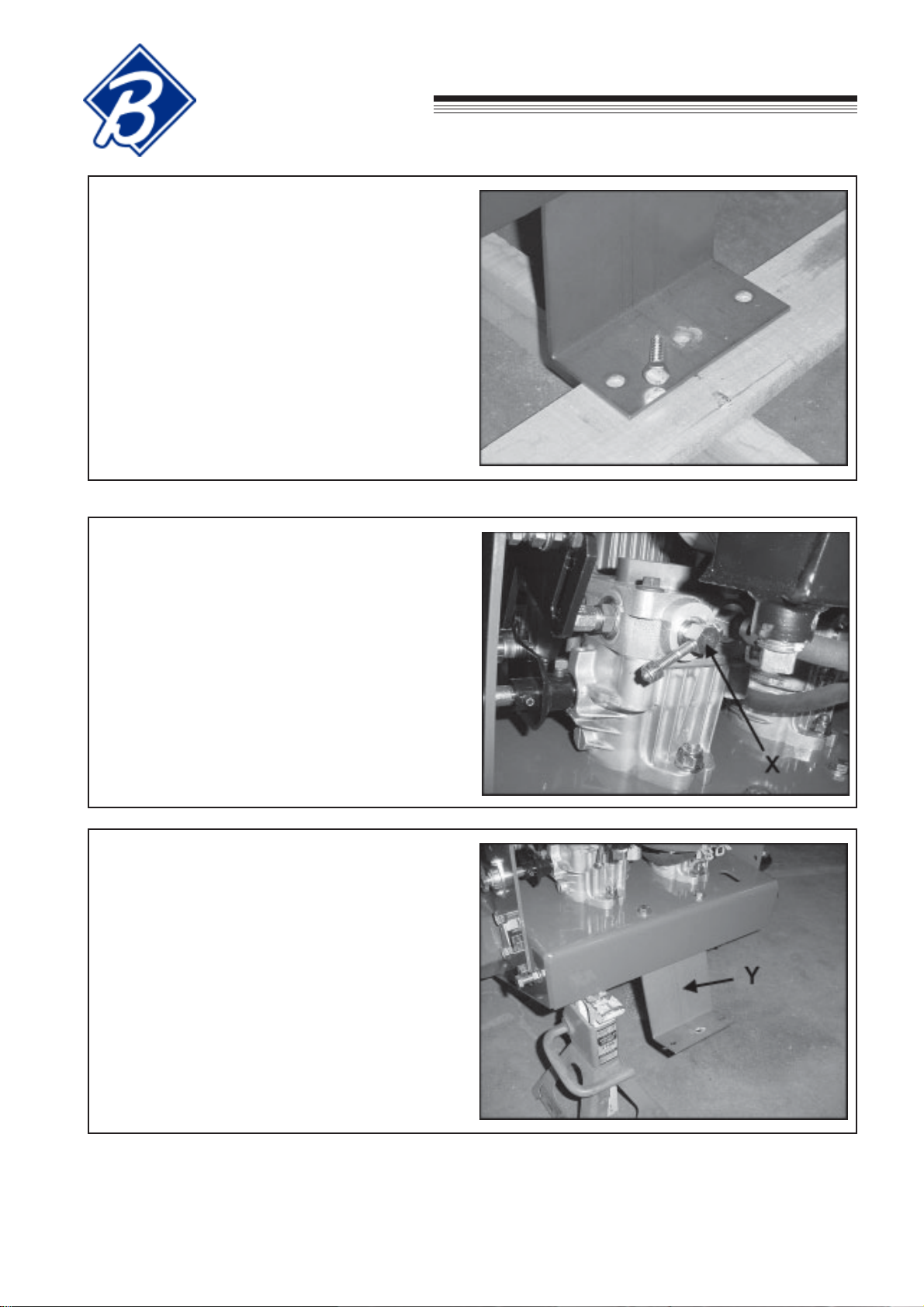

7. Unbolt shipping bracket from crate.

ASSEMBLY/SET-UP INSTRUCTIONS

8. Open the bypass valves X on each pump by

rotating handle counter-clockwise two revolutions.

9. Remove the power unit from the crate and

support the rear of the power unit with a jack

stand.

10. Unbolt shipping bracket Y from power unit and

discard.

GB-5

Page 8

ASSEMBLY/SET-UP INSTRUCTIONS

11. Cut and remove tie wrap G from the traction

control lever H.

EC

Hydro

Midsize

12. Locate the two longest rods removed in Step 2.

Install the two traction control rods through the

traction control lever H, flatwasher and traction

lock J and secure with hairpin. Repeat on other

side of upper handle.

13. With the traction locks J in the neutral position,

apply tension to the traction control rod to remove

any slack and align swivel on traction control rod

with the hole in pump arm K. Repeat for other

side.

NOTE: The pump arm has some rotational play.

Adjust the swivel on the traction control rod to the

center of this play and secure to the pump arm

with a flatwasher and hairpin as shown.

GB-6

Page 9

EC

ASSEMBLY/SET-UP INSTRUCTIONS

Hydro

Midsize

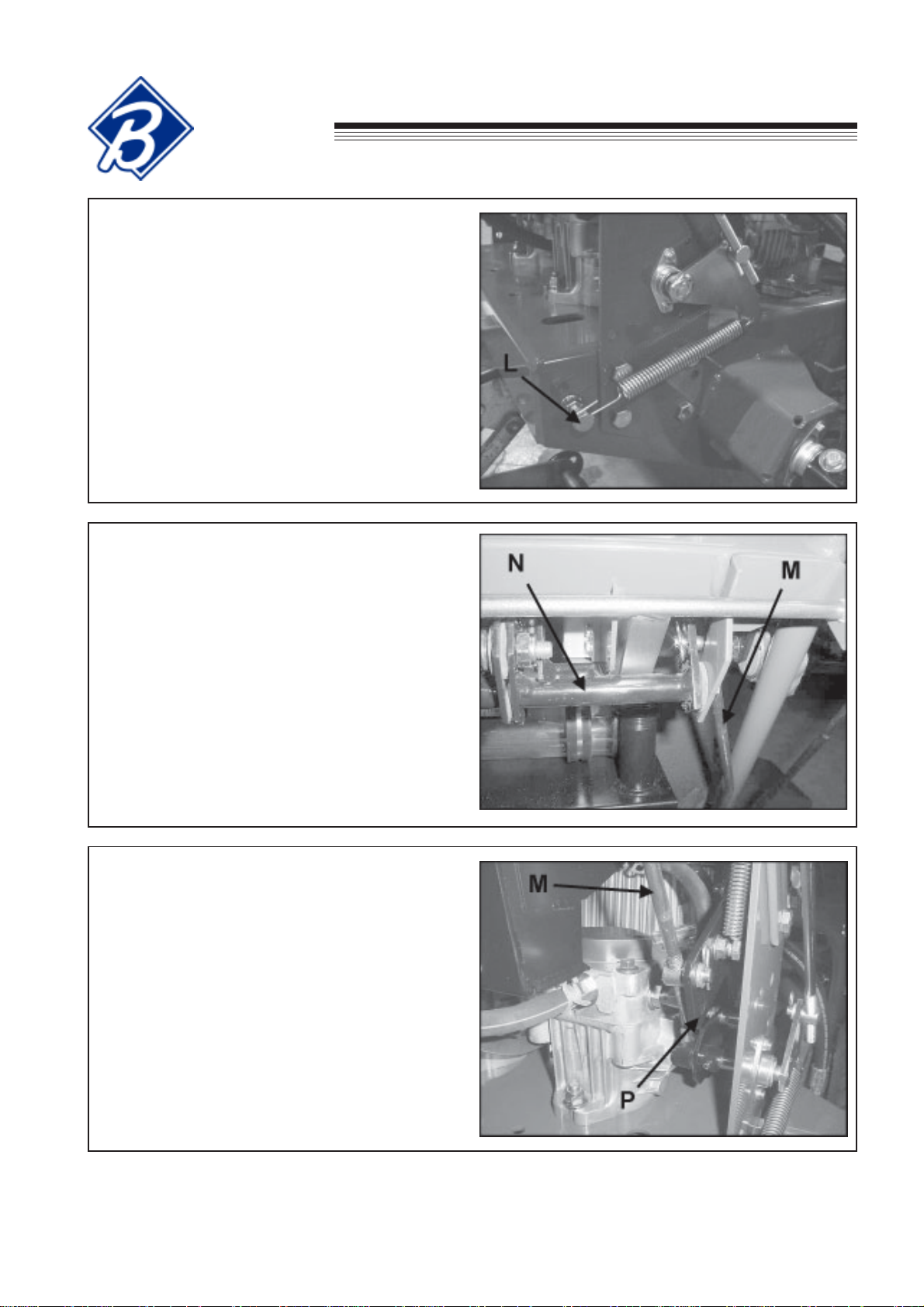

14. Attach spring to pump arm and then to bolt L.

Repeat for other side.

15. Connect speed control rod M to the speed control

levers N and secure with hairpin. Repeat for

other side.

16. Set the speed control levers to neutral and adjust

the swivel on the lower end of the speed control

rod M so they engage the very top of the slot on

the neutral plates P and secure with flatwasher

and hairpin as shown. Repeat for other side.

GB-7

Page 10

ASSEMBLY/SET-UP INSTRUCTIONS

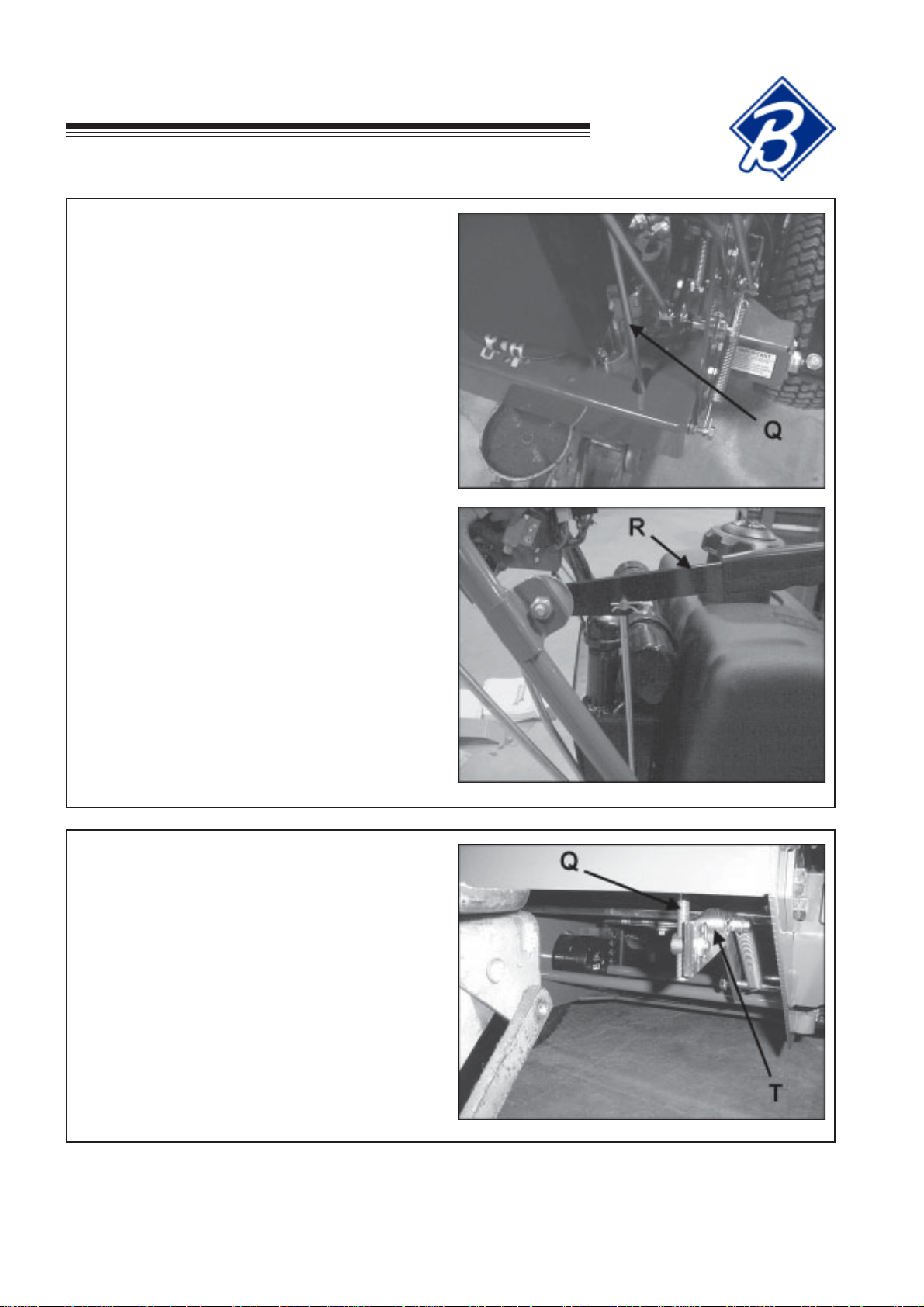

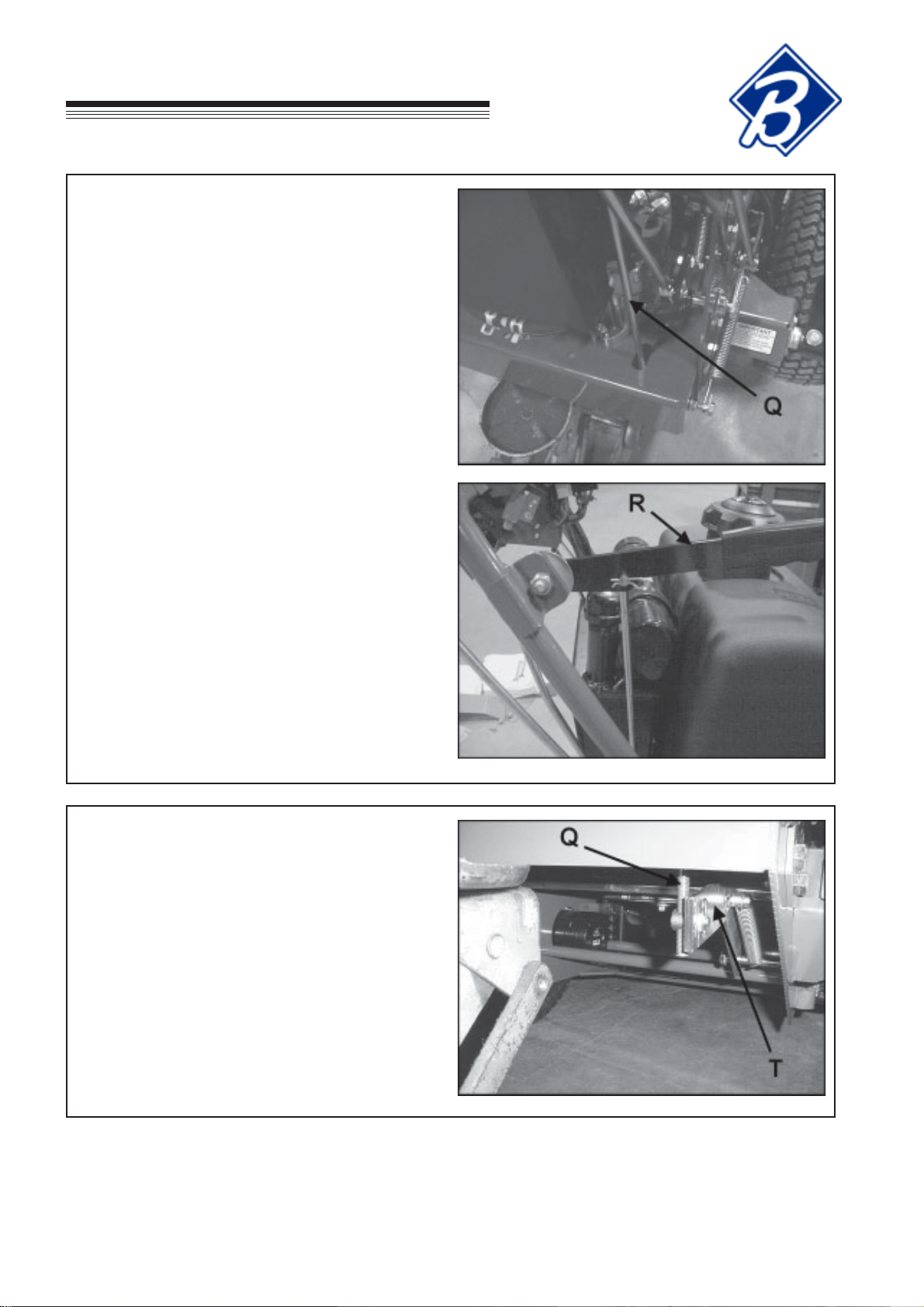

17. Insert threaded end of brake rod Q through the

slot on the engine deck and attach the other end

to the brake control arm R and secure in place

with hairpin as shown.

EC

Hydro

Midsize

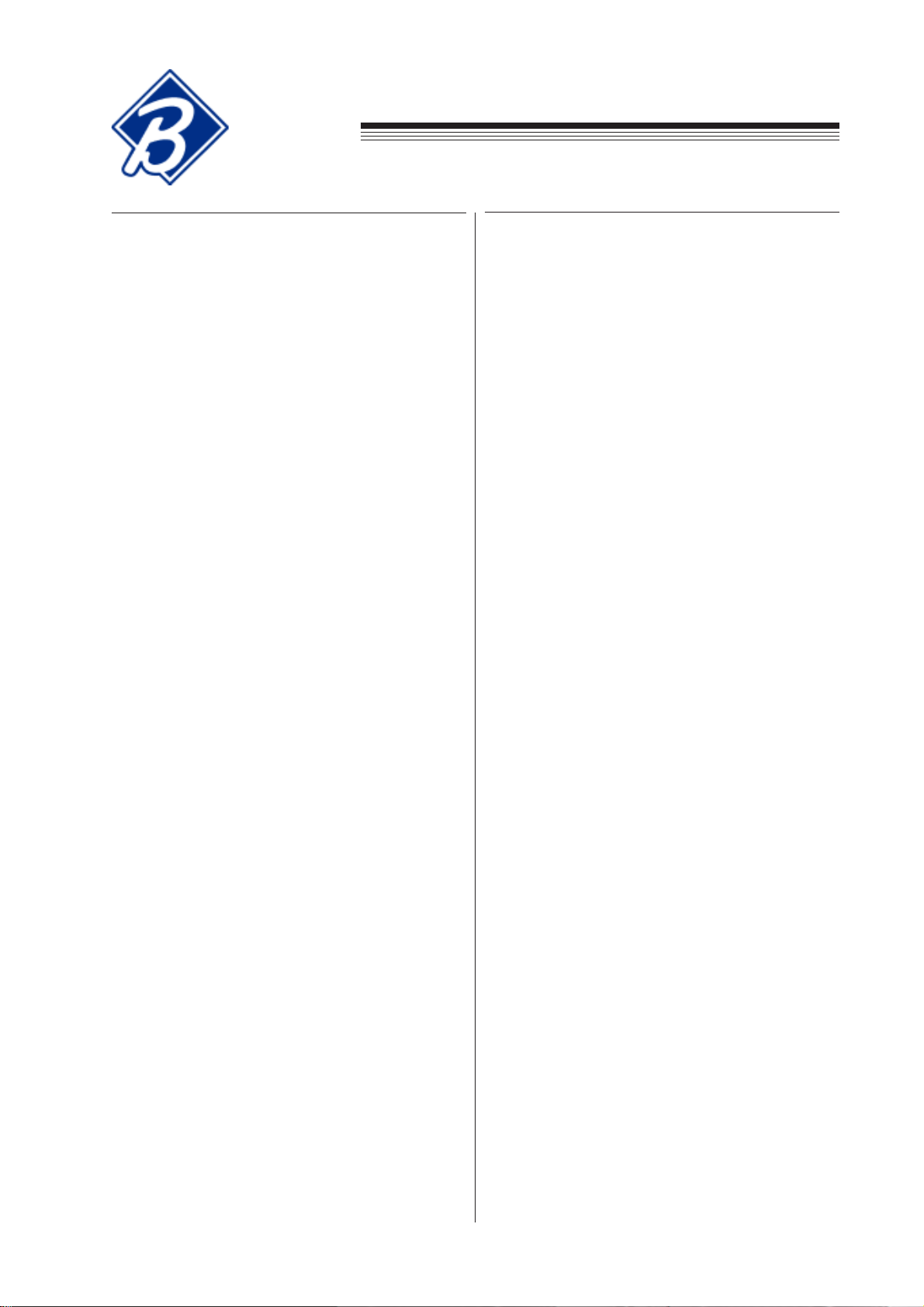

18. Connect swivel on threaded end of brake rod Q to

the brake arm T and secure in place with

flatwasher and hairpin as shown. Adjust swivel to

provide adequate braking when the brake control

arm R is engaged. See adjustment section of

this manual.

GB-8

Page 11

EC

ASSEMBLY/SET-UP INSTRUCTIONS

Hydro

Midsize

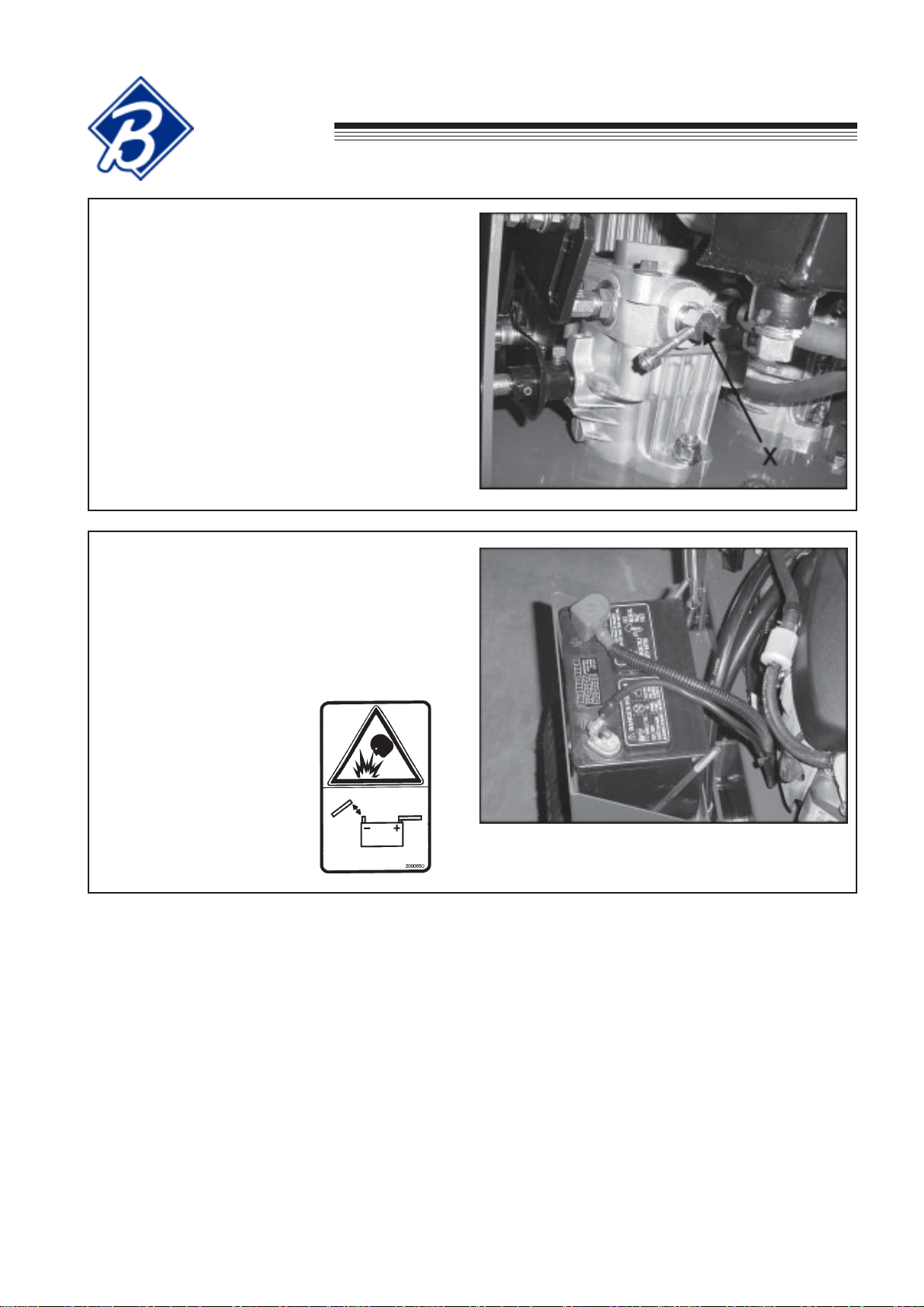

19. Close bypass valve X by rotating clockwise until

firmly seated.

20. Remove the battery cover and the battery from

the machine. Fill the battery to the bottom of the

vent wells with electrolyte and trickle charge for

several hours. Replace the battery in the

machine and make the connections, red to

positive first, then black (ground) to negative.

Install battery cover and secure with previously

removed nuts.

Batteries Produce

Explosive Gases

- Keep sparks and

flame away .

- Disconnect negative

terminal first.

- Reconnect negative

terminal last.

GB-9

Page 12

ASSEMBLY/SET-UP INSTRUCTIONS

EC

Hydro

Midsize

21. Attach cutterdeck per the instructions on the following pages then return to Step 22 of this section.

22. Fill engine with oil. (See engine manual for specifications.)

23. Fill fuel tank with clean, fresh unleaded fuel.

GASOLINE IS HIGHLY FLAMMABLE!

• Fill fuel tank with good quality, clean, regular unleaded gasoline.

• Do not use hi-test fuel.

• Do not smoke.

• Do not spill fuel.

• Fill outdoors.

• Do not overfill. Fill to 25 mm below bottom of filler neck to allow room for expansion.

• USE A FUNNEL TO FILL GAS TANK

24. Check oil level in hydraulic oil reservoir and adjust as necessary.

25. Adjust tire pressure in drive wheels and casters to 1 kg/cm2.

26. Before attempting to start the mower, read and understand all sections of the Operation & Safety manual.

NOTICE: Special setup instructions.

• Before engaging the cutterdeck, run the engine for five minutes at full RPM. This is recommended for

new engine installation to permit complete engine lubrication prior to load.

• Do not engage the cutterdeck at full throttle. Set the throttle half way between the highest and lowest

engine speed, engage the PTO switch and increase the engine speed to full before cutting.

•

Do not use this machine without an approved grasscatcher, grass discharge chute or mulching plate(s)

correctly fitted.

GB-10

Page 13

EC

ASSEMBLY/SET-UP INSTRUCTIONS

Hydro

Midsize

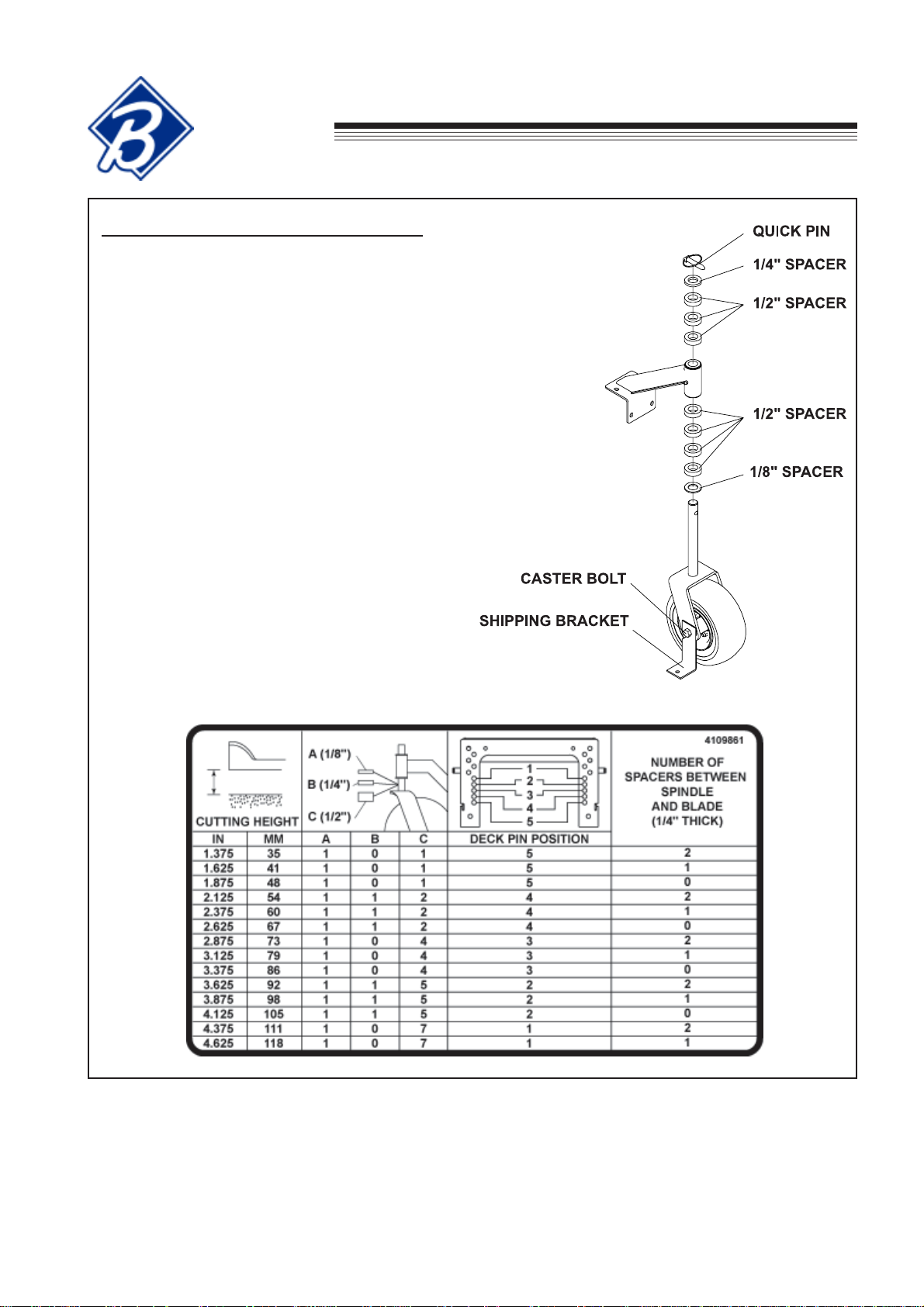

FIXED CUTTERDECK ATTACHMENT

1. Remove the cutterdeck from the crate.

2. Unbolt the caster wheels and the shipping

brackets from the crate.

3. Remove the shipping bracket from the caster

wheel by loosening the caster bolt and sliding

the shipping bracket off and retighten caster bolt.

4. Remove quick pin and remove the appropriate

number of spacers for the desired height of cut.

See height of cut chart below.

NOTE: Height of cut chart is also located on

bottom of belt cover or in the Operation & Safety

Manual.

5. Repeat for other caster wheel assembly.

GB-11

Page 14

ASSEMBLY/SET-UP INSTRUCTIONS

6. Remove belt cover and set aside.

7. Block the rear of the cutterdeck with the

appropriate height block for the desired height of

cut B. See Support Block Chart below.

EC

Hydro

Midsize

ELOH

GNITTUC

THGIEH

"526.1-"573.15"52.1

"573.2-"578.14"00.2

"521.3-"526.23"57.2

"578.3-"573.32"05.3

"526.4-"521.41"52.4

8. Position the power unit behind the cutterdeck.

9. Move the power unit towards the cutterdeck until

the guide pins A engage the appropriate hole C

on the power unit for the desired height of cut.

Fasten with (4) M12-1.75 X 30 bolts at D.

10. Loop the PTO belt E around the electric clutch

pulley. Using a 3/8" ratchet wrench or 3/8"

breaker bar rotate the PTO belt idler while looping

the PTO belt around the cutterdeck pulley.

NONOITISOP

ENIGNE

*KCED

.kcedenigneehtno

KCOLB

TATHGIEH

FORAER

)B(KCED

elohtsehgihehtsi1noitisoP*

11. Reinstall belt cover and fasten in place with

nuts F previously removed.

12. Remove support block from the rear of

cutterdeck.

13. Remove support from the rear of the power unit.

GB-12

Page 15

EC

LUBRICATION

Hydro

Midsize

MACHINE LUBRICATION

Every 50 Working Hours - Lubricate the following points with grease:

1) Caster wheel pivots (2 points)

2) Neutral eccentric pin (2 points)

3) Idler pivot bearings:

a) Engine to cutterdeck belt tensioner

b) Cutterdeck belt tensioner

c) Hydro drive belt tensioner

NOTE: The spindles used on these machines use a superior sealed bearing which does not require

relubrication.

GB-13

Page 16

LUBRICATION

ENGINE

DAILY

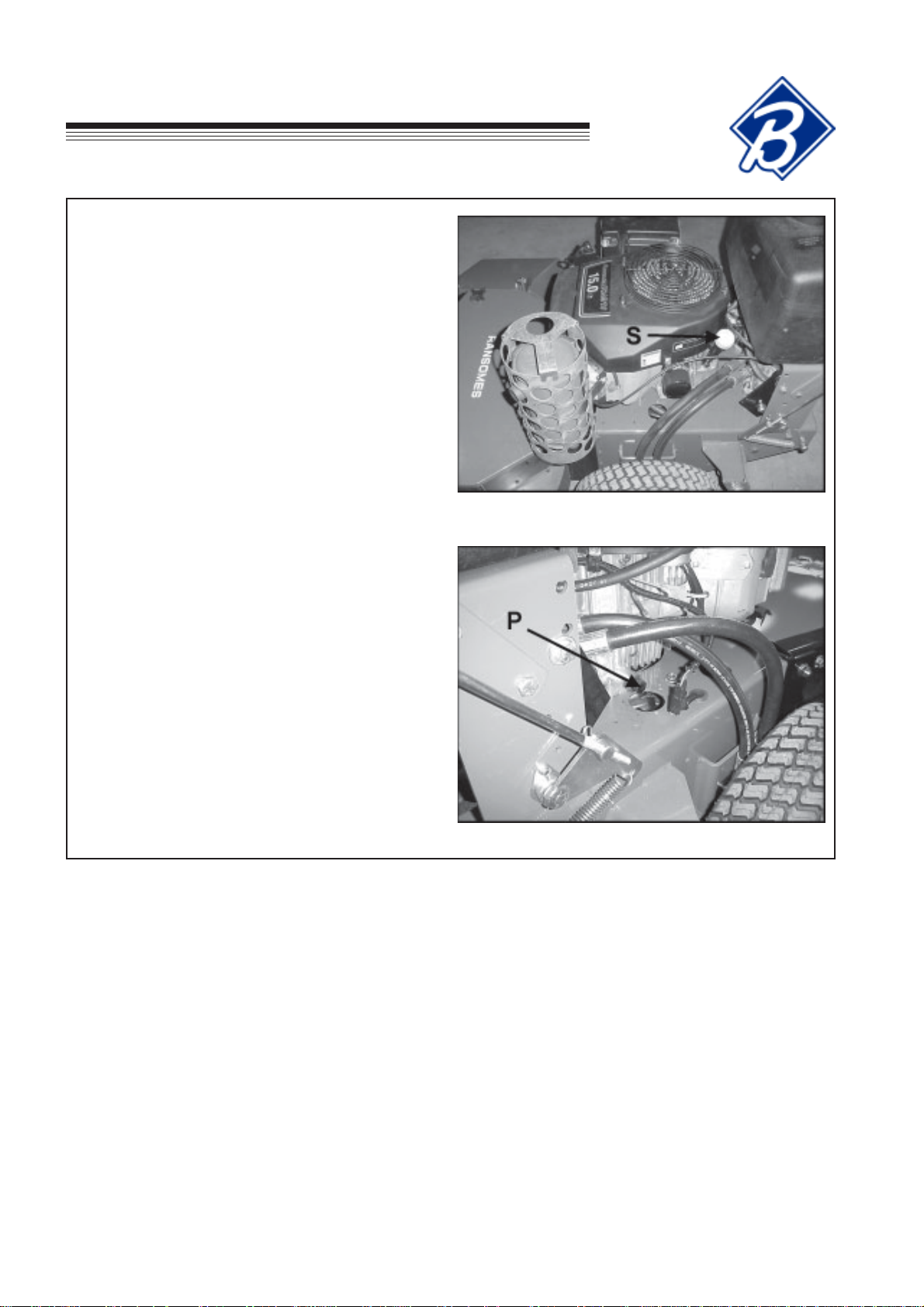

Remove the dipstick S and check that the oil level

reaches the full mark. If necessary, top off with fresh oil.

To obtain the correct oil level, the machine must be

level. See engine manufacturer’s manual for proper oil

viscosity and grade.

DO NOT OVER FILL!

AFTER THE FIRST 5 WORKING HOURS

While the engine is warm, remove the drain plug P and

drain the crankcase. Replace oil filter. Clean and

replace the plug. Fill the crankcase through the filler

hole with fresh oil to the full mark. See engine manufacturers manuals for oil and filter change intervals.

Engine operator’s manuals are shipped with each

machine. Shop manuals for the engines are available

from your local engine dealer/distributor.

EC

Hydro

Midsize

• For Kawasaki FH451V, order: 99920-2129-03.

GB-14

Page 17

EC

Hydro

Midsize

The maintenance schedule detailed is for average

operating conditions. Under extreme conditions

(dusty, dirty or more than 8 hrs continuous use)

maintain more frequently.

Engine (daily)

Check the engine for oil leaks.

Cooling Fins and Air Intake screen (daily)

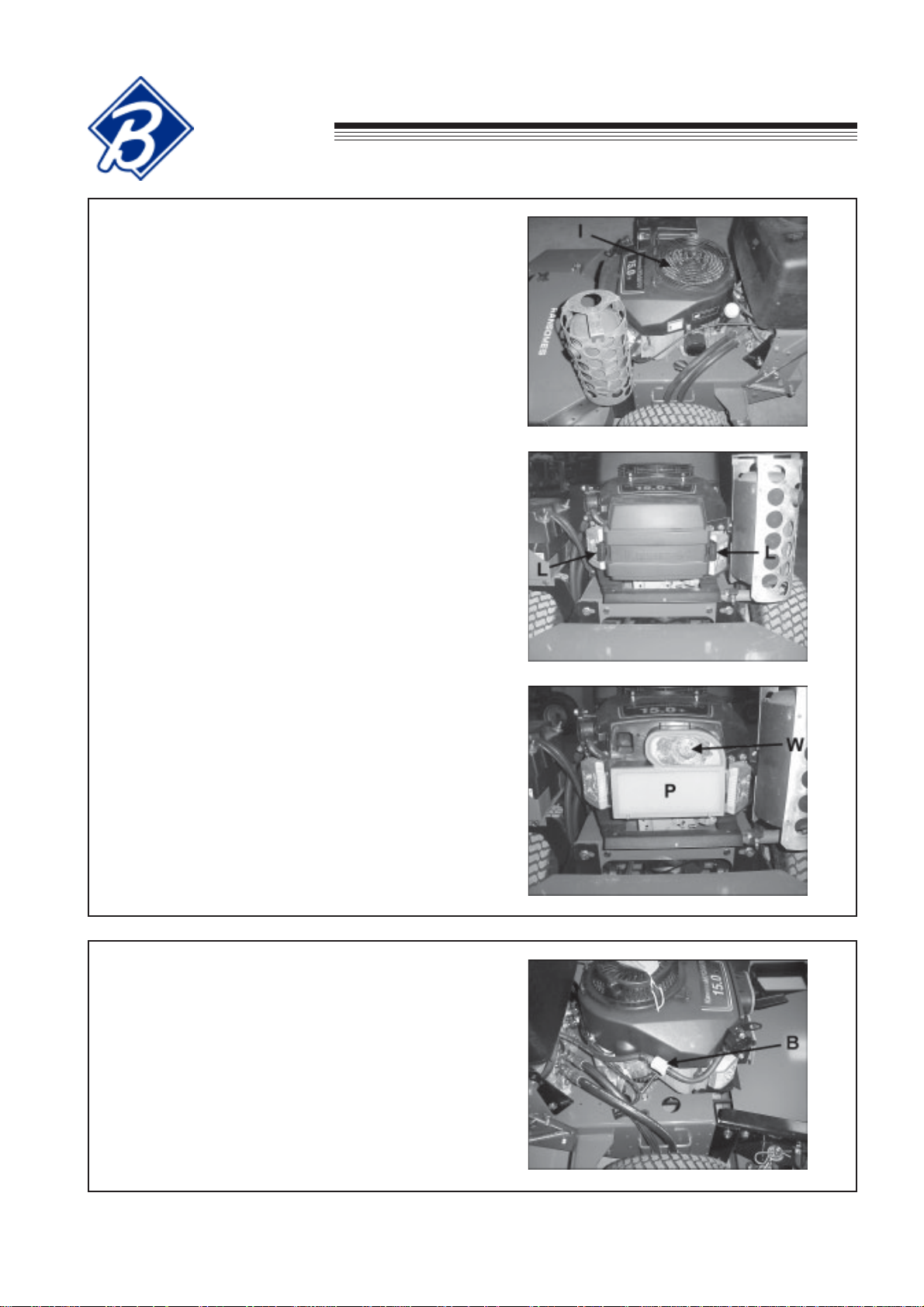

Ensure that the cooling fins and air intake screen I

are cleaned daily. Continued operation with a

clogged cooling system will cause severe overheating

and result in engine damage.

Air Cleaner (every 25 hours)

Service more frequently if operating in very dusty or

dry conditions. Extensive damage will result from

operating with a dirty air cleaner.

MAINTENANCE

1. Remove the air cleaner cover by releasing

latches L.

2. Remove the foam precleaner P by sliding it off

the paper cartridge. Wash in kerosene or

detergent and water. Dry thoroughly. Saturate in

engine oil. Squeeze to remove excess oil.

3. Reinstall all parts.

NOTES:

• Every 50 hours remove the paper element by

loosening wing nut W. If dirty, replace.

• DO NOT use petroleum solvents to clean the

paper element. They may cause it to deteriorate.

• DO NOT use pressurized air to clean or dry

element.

• See the Setup, Parts & Maintenance manual for

service part numbers.

In-Line Fuel Filter

When required, the fuel filter B may be replaced. See

the Setup, Parts & Maintenance manual for service

part numbers.

GB-15

Page 18

MAINTENANCE

EC

Hydro

Midsize

Blade Sharpening

Blades may be sharpened by filing or grinding, but with either method the balance of the blades must be

maintained at 0.004 Nm or less. Failure to maintain balance causes excess vibration, wear and shortened life

of not only the blades, but most all components of the machine. To balance a blade after sharpening: attach

3.9 g of weight 127mm from center on the light end. This should make the light end the heavy end. If it does

not: File or grind the heavy end until the addition of weight makes the light end the heavy end.

NOTE:

• Do not overheat or weaken the blades.

• Do not straighten bent blades. Replace with new

Bunton blades.

If lift portion of blade is worn thin replace with a new

Bunton blade.

• ALWAYS replace with Bunton blades—do not use

another manufacturer’s blades as this could be

dangerous.

• Replace cracked or bent blades.

BLADE REMOVAL

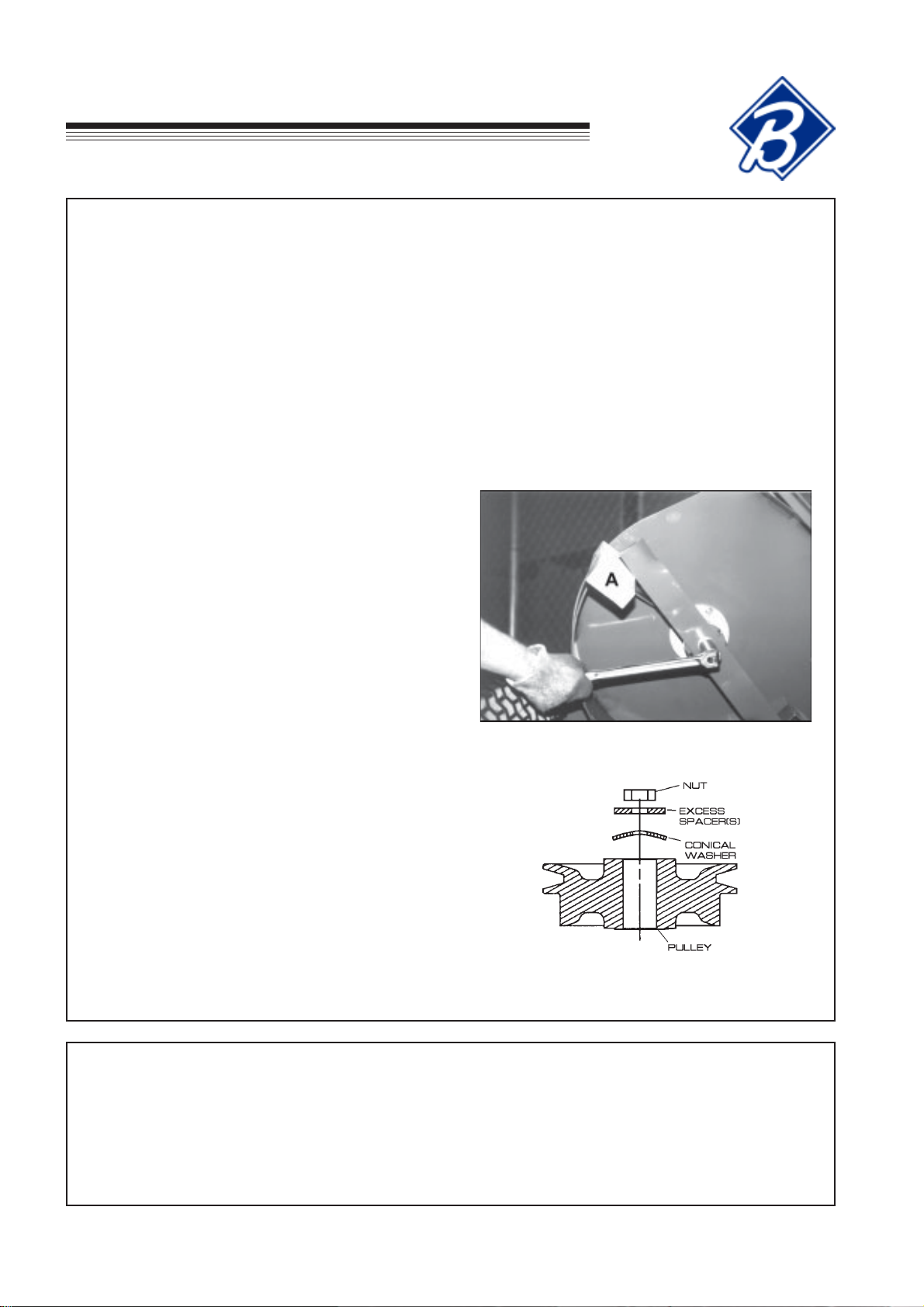

1. Use a box wrench or socket with a long breaker bar

to remove spindle bolt under cutterdeck.

2. Slip tube over breaker bar or wrench if necessary to

gain leverage.

3. Keep hands clear as blades may rotate when bolt

releases.

4. When changing blades, wear thickly padded gloves.

5. Block blades from turning by using a piece of wood.

6. Follow these instructions to prevent injury when bolt

releases.

NOTE: To prevent blade from turning, place block of

wood at A, with grain perpendicular to blade.

BLADE RE-INSTALLATION

1. Place the desired number of spacers (no more than

2) on the spindle bolt below the cutterdeck between

the blade and spindle shaft.

2. Insert the cutter spindle bolt (from bottom) complete

with washer, blade and spacers.

3. Place remaining spacer(s) on the spindle bolt above

the cutterdeck between the conical washer and nut

(as shown). Replace nut and tighten to 95 Nm.

Cutterdeck Pulley Assembly

SPARK PLUG

• Remove plug and check condition.

• Good operating conditions are indicated if the plug has a light grey or tan deposit. A white blistered coating

may indicate overheating. A black coating usually means an “over rich” fuel mixture caused by a clogged

air cleaner or improper carburetor adjustment. Do not sandblast, wire brush or otherwise try to clean a

dirty plug. Best results are obtained with a new plug.

• See engine manufacturers manual for proper spark plug gap.

GB-16

Page 19

EC

Hydro

Midsize

HYDRAULIC RESERVOIR

CHECK, DRAIN AND FILL

Check level every 100 hours or when a leak has

occurred. To check level: Remove reservoir cap. Add

10W30 oil until the oil level reaches the bottom of the

filler tube. Do not overfill.

EVERY 500 HOURS:

Change hydraulic oil and filter. Remove plug D to

drain reservoir. Remove and replace filter. Filter is

located on front of tank at G. Reinstall plug and fill

with 10W30 oil to the bottom of the filler tube F.

MAINTENANCE

GB-17

Page 20

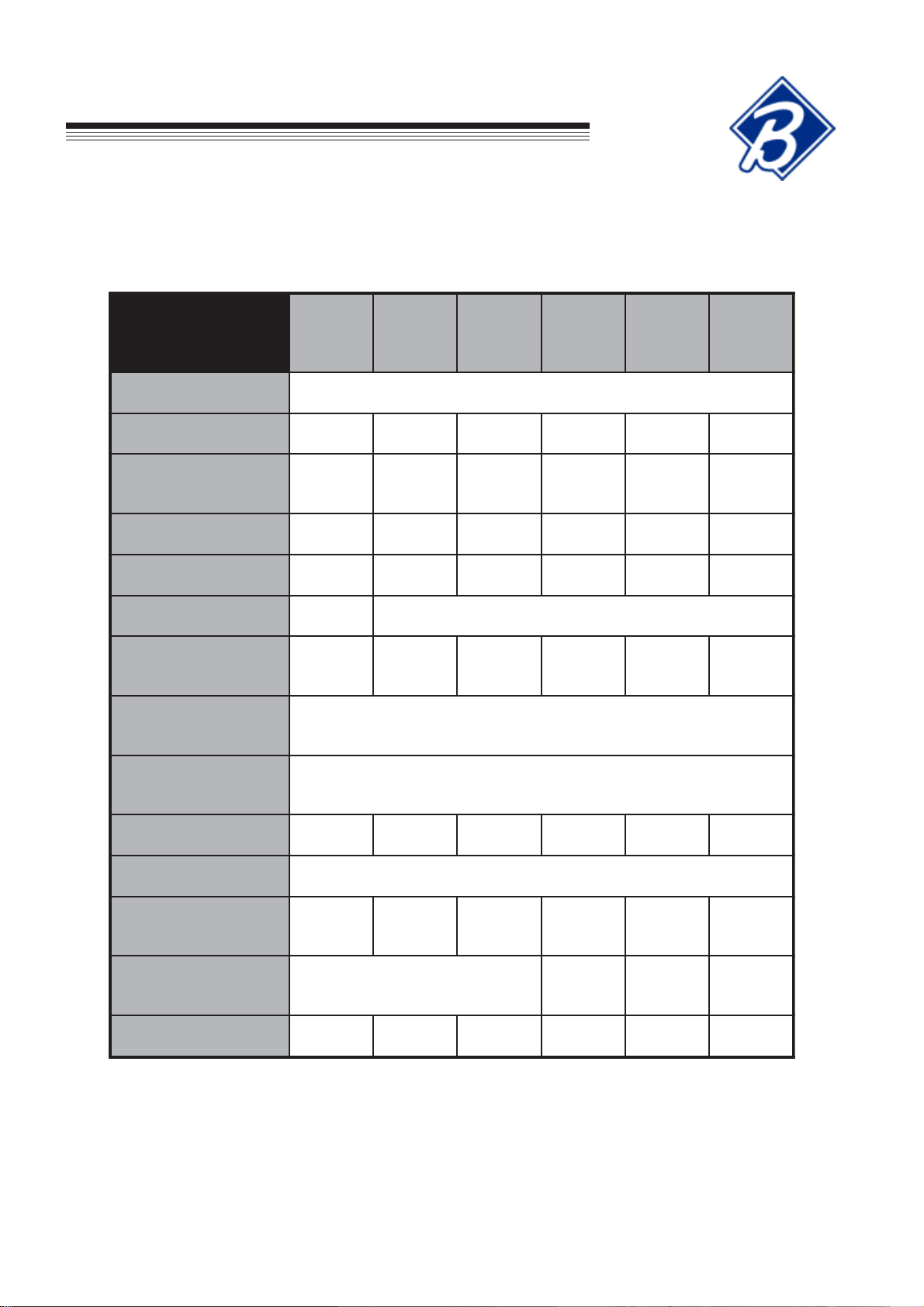

SERVICE CHART

EC

Hydro

Midsize

NOTE: CHANGE ENGINE OIL AND FILTER AFTER FIRST 5 HOURS OF

OPERATION.

ECIVRES

NOITAREPO

ENIGNE

leveLliOkcehCX

riA&liOrofkcehC

skaeL

ekatnIriAnaelCX

renaelCriAnaelCX

*retliF&liOegnahCX *LAUNAMS'RERUTCAFUNAMENIGNEEES

tnemideSleuFnaelC

lwoB

tsujdA/ecalpeR

gulPkrapS

5TSRIF

SRUOH

YLIAD

X

YREVE

52

SRUOH

05

X

YREVE

SRUOH

YREVE

001

SRUOH

LAUNAMS'RERUTCAFUNAMENIGNEEES

YREVE

005

SRUOH

LIOCILUARDYH

RIOVESER

leveLliOkcehC X

ENIHCAM

eriTkcehC

serusserP

snoisneTtleBkcehC

stnioPllAetacirbuLX

X

RH2/1TSRIFRETFAKCEHC

SRH4TSRIFRETFADNA

X

Consult the manufacturer’s manual for your engine

for further information and instructions.

GB-18

Page 21

EC

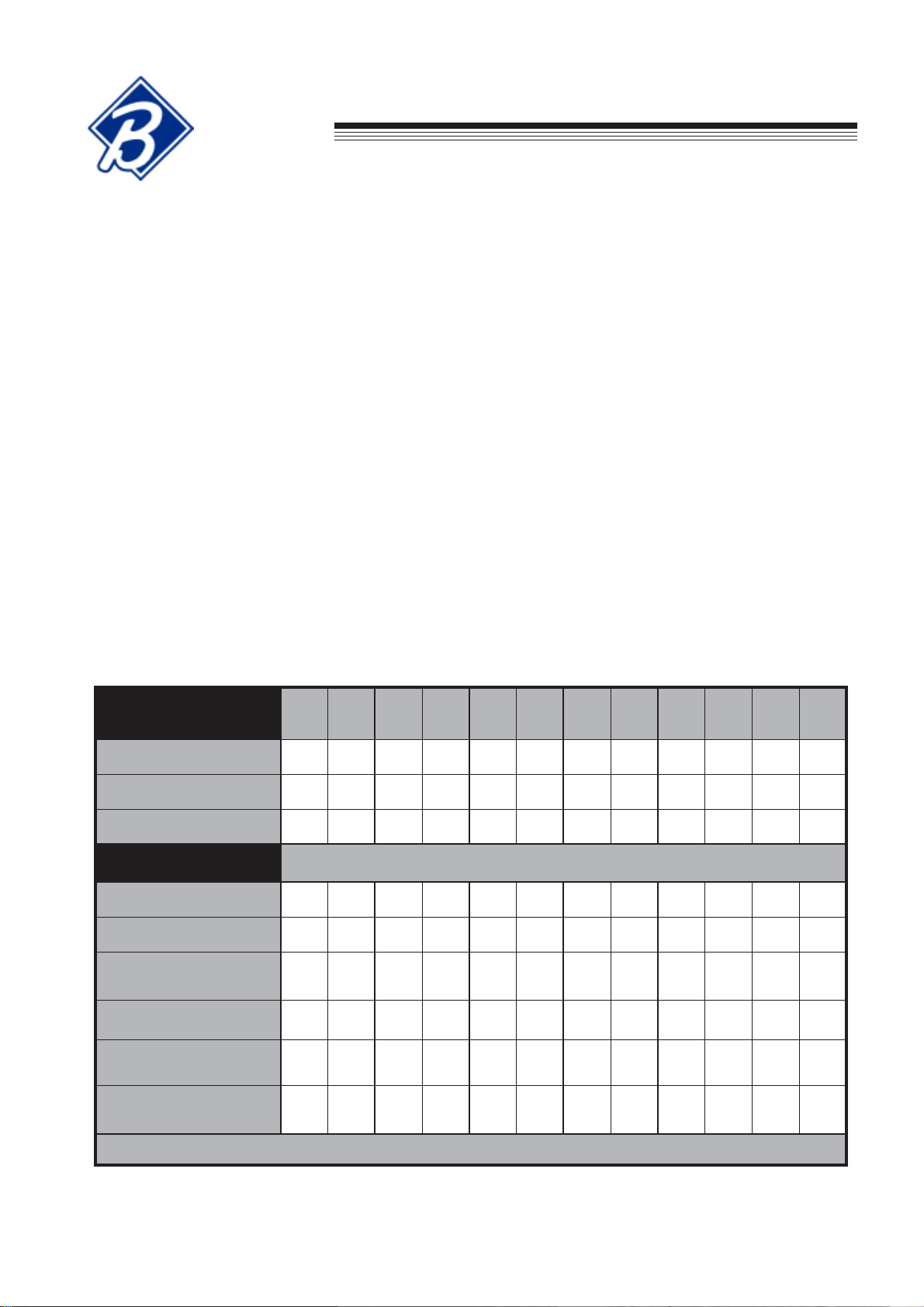

SERVICE RECORD

Hydro

Midsize

NOTES

_______________________________________________________________

____________________________________________________

________________________________________________________________________

_______________________________________________________________

____________________________________________________________

____________________________________________________

________________________________________________________________________

_______________________________________________________________

____________________________________________________________

_______________________________________________________________

____________________________________________________________

_______________________________________________________________

_______________________________________________________________

LARENEG

serusserperitkcehC

stniopllaetacirbuL

stlob&stunkcehC

ENIGNE

levelliokcehC

lioegnahC

naelC

tnemelerenaelcria

snifgniloocnaelC

ETAD SRH ETAD SRH ETAD SRH ETAD SRH ETAD SRH ETAD SRH

ecalpeR

tnemelerenaelcria

pag&naelC

sgulpkraps

.sretlifdnalioenigneecalpernoitarepofosruoh5tsrifretfA:ETON

GB-19

Page 22

ADJUSTMENTS

EC

Hydro

Midsize

NOTE: Make all adjustments with the engine shut off, spark plug wire disconnected and mower

drive disengaged.

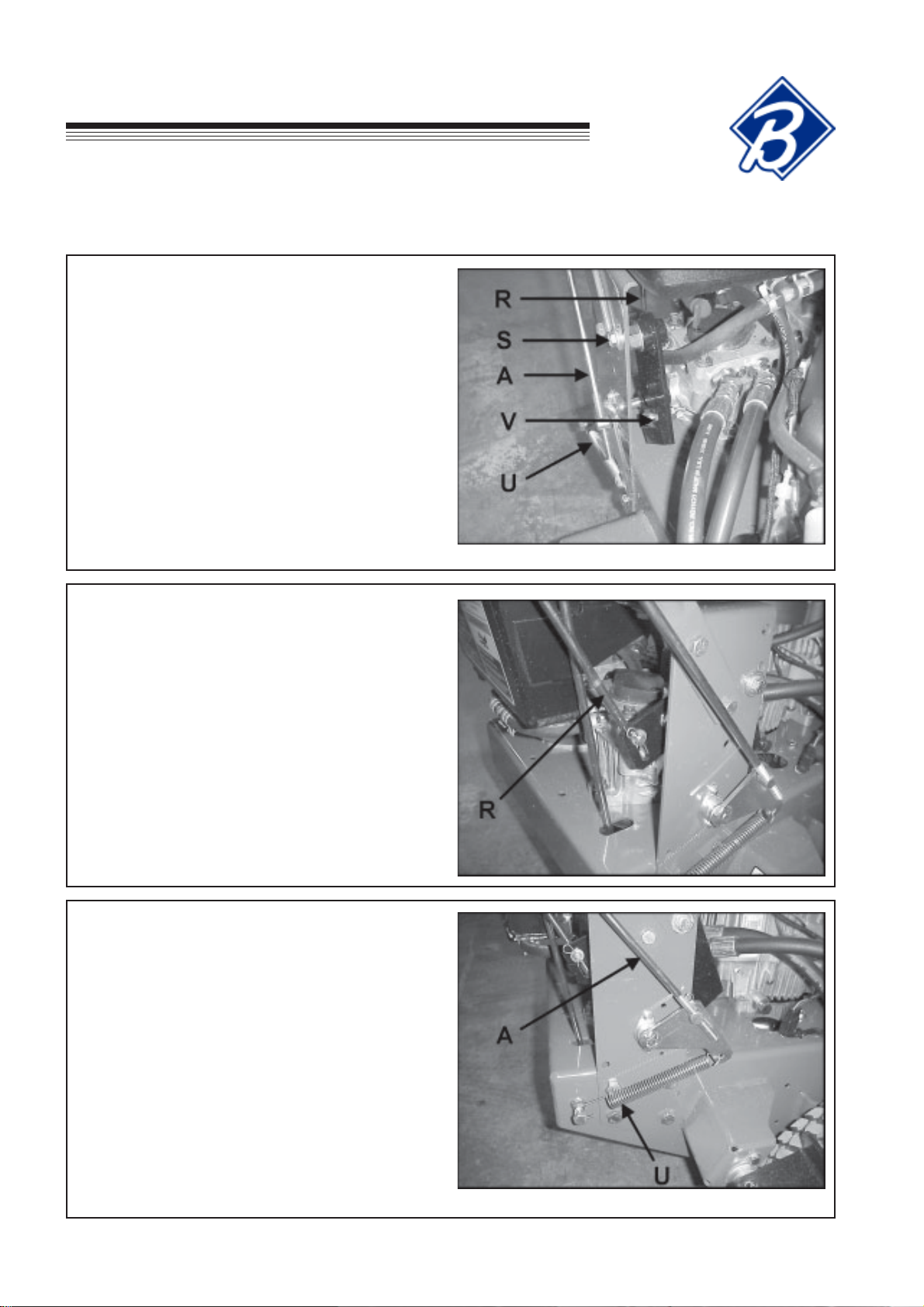

TRACTION DRIVE HYDROSTAT ADJUSTMENTS: The following adjustments must be done in order .

STEP 1 - Set Neutral

Neutral is set at the factory . If it should require

adjustment, raise the wheels off the ground by setting

the machine on jackstands or blocks. Disconnect the

traction control rod A and speed control rod R at each

pump end. Disconnect pump arm spring U from bolt

on engine deck. Loosen bolt S securing the neutral

plate eccentric shaft just enough to turn the shaft.

Start the engine and run at low speed. Turn eccentric

shaft T to raise or lower the point at which the

follower bearing is held in the center of the “V” until

the wheels stop turning. Tighten the eccentric shaft

bolt. Increase the throttle setting and check the

adjustment. Readjust if necessary . Shut the engine

off before proceeding to steps 2 and 3.

STEP 2 - Adjust Speed Control Rods

First adjust neutral, as outlined in Step 1. Set speed

control levers to neutral. Adjust swivels on lower

ends of speed control rods R so they just go into the

slots on the neutral plates.

NOTE: If the speed control levers do not have

adequate tracking adjustment, the swivel on one of

the rods needs to be turned 1 turn.

STEP 3 - Adjust Traction Levers

Set neutral and adjust speed control rods as outlined

in Steps 1 and 2. Set traction locks in the neutral

position. Grasp traction rod A and pull down on it to

take out any slack. The pump control arm has some

back and forth play . Adjust the swivel to the center of

the control arm play . Connect the swivel to the

control arm. Reattach pump arm spring U to bolt on

engine deck.

NOTE: More reverse speed may be gained by

adjusting the swivel to the rear of the control arm play .

A minimum of 1/16" play is required so the traction

controls can be put in neutral without the machine

backing up.

GB-20

Page 23

EC

Hydro

Midsize

Speed Control Lever Friction

The speed control lever is held where set by friction

pads. If the setting will not hold, tighten nuts E to

increase friction on the speed control lever.

ADJUSTMENTS

PARKING BRAKE - Apply parking brakes and open

the bypass valves on the hydraulic pumps. Try to

push the machine forward. If wheels rotate, adjust

brakes as follows.

TO ADJUST:

1. Remove the hairpin cotter A from the brake rod at

the brake lever as shown.

2. Slide the brake rod out of the brake lever and turn

the rod in or out of the brake swivel B as needed.

NOTE: The brake should initially be adjusted so

that the brake rod extends through swivel B

32mm as shown. If more brake pressure is

required adjust as necessary.

3. Reassemble brake rod to the brake lever using

hairpin A.

4. Apply parking brakes and try to push the machine

forward. If wheels rotate, readjust brakes.

5. Close bypass valves on the hydraulic pumps.

GB-21

Page 24

ADJUSTMENTS

OPERATOR PRESENT CONTROLS

The operator present (OP) controls should be adjusted to control the operation of the plunger of the

operator present switch (located under the right side

of the control panel). Depressing OP levers F should

depress the plunger; releasing the levers should

extend it.

TO ADJUST:

1. Loosen clamp bolts on both ends G so clamps

can rotate on shaft. Loosen clamps bolts H so

OP levers are free to move in clamps.

2. Hold OP levers to handles and adjust to fit.

Tighten bolts H.

EC

Hydro

Midsize

3. Rotate actuator lever to depress switch plunger.

Keep OP levers against handles and tighten bolts

G.

4. When released, the OP levers should rise and the

actuator lever should rotate away from the switch,

allowing the switch plunger to extend completely.

HANDLE BAR HEIGHT ADJUSTMENT

To adjust handle bar height: Remove bolts G and

loosen bolts E on each side of handlebars. Raise or

lower as required. Reposition upper handle and

reinsert bolts G into appropriate hole in lower handle

and tighten. Readjust traction control rods, parking

brakes and speed control rods.

GB-22

Page 25

EC

Hydro

Midsize

TRACKING WIDTH ADJUSTMENT

The tracking width originally set from the factory can

be increased an additional 83 mm overall by

performing the following steps.

1. Loosen wheel lug nuts on both drive tires.

2. Raise rear of unit so that drive tires are off the

ground. Support the unit with jack stands.

3. Remove wheel lug nuts and wheels. Reattach

wheels with the tires rotated so the wheel offset is

the opposite of when they were previously

installed. Reinstall and tighten lug nuts until they

are snug.

4. Lower machine off of the jack stands and torque

wheel lug nuts to 115 Nm.

ADJUSTMENTS

TIRE PRESSURE ADJUSTMENT

Tire pressures should be maintained at 1.0 kg/cm2.

GB-23

Page 26

BELT REPLACEMENT

PTO BELT

1. Rotate idler arm using a 3/8" ratchet or breaker

bar and remove belt.

EC

Hydro

Midsize

CUTTERDECK BELT

1. Remove PTO belt.

2. Rotate idler arm using a 3/8" ratchet or breaker

bar and remove belt.

3. Replace in the reverse order.

PUMP DRIVE BELT

1. Remove PTO belt from the engine clutch.

2. Disconnect the clutch wire harness.

3. Unbolt clutch bracket from clutch and rotate the

clutch to allow enough clearance to remove the

clutch bracket.

4. Rotate idler arm using a 3/8" ratchet or breaker

bar inserted into the square hole in the idler arm.

5. Remove pump drive belt.

6. Replace by following steps in reverse order.

GB-24

View under engine deck

Page 27

MACHINE

TABLE DES MATIERES

INTERMEDIAIRE

HYDROSTATIQUE CE

CONSIGNE IMPORTANTE

Nous vous remercions d’avoir acheté une machine Bunton. Vous venez d’acquérir un produit de classe mondiale

dans le domaine des tondeuses, de la meilleure conception et construction possibles actuelles.

Cette machine est accompagnée d’un manuel de sécurité et de fonctionnement ainsi que d’un autre manuel pour

sa mise en service, ses composants et sa maintenance. La durée de vie utile et le bon état de marche dont vous

bénéficierez dépendront dans une large mesure de la façon dont vous aurez lu et assimilé ces présents. Occupezvous soigneusement de votre machine, graissez et réglez-la comme indiqué et elle vous donnera de nombreuses

années de service fiable.

Votre utilisation en toute sécurité de cette machine Bunton est pour nous l’un de nos premiers objectifs. De

nombreuses caractéristiques de sécurité sont intégrées, mais nous nous fions également à votre bon sens et à

votre soin pour la faire fonctionner sans crainte d’accidents. Pour obtenir la meilleure protection possible, veuillez

étudier attentivement les manuels. Apprenez le bon fonctionnement de toutes les commandes. Observez toutes

les précautions de sécurité. Suivez attentivement toutes les consignes et tous les avertissements. Ne démontez

aucun des dispositifs de sécurité. Assurez-vous que ceux qui font fonctionner cette machine sont bien informés

et aussi soigneux dans son utilisation que vous l’êtes vous-même.

Consultez un revendeur Bunton pour tous travaux d’après-vente ou pièces de rechange dont vous aurez besoin. Le

service après-vente Bunton veille à ce que vous continuiez de recevoir les meilleurs résultats possibles avec les

produits Bunton. Vous pouvez faire confiance aux pièces de rechange Bunton car elles sont fabriquées avec la

même haute précision et la même qualité que les pièces d’origine.

Bunton conçoit et construit ces équipements pour donner de nombreuses années de service sûr et productif. Pour

obtenir de cette machine la plus grande durée de vie possible, ne l’utilisez que comme indiqué dans les manuels,

conservez-la en bon état et suivez les avertissements et consignes car vous ne le regretterez jamais.

Textron Golf, Turf And Specialty Products

Central Avenue, Ransomes Europark

Ipswich, IP3 9QG, Angleterre

T ABLE DES MATIERES P AGE

SECURITE ...................................................................................................................................................... 2

MONT AGE / CONSIGNES D’INSTALLA TION...............................................................................................3-12

GRAISSAGE............................................................................................................................................. 13-14

MAINTENANCE ........................................................................................................................................15-17

SERVICE CHART ..........................................................................................................................................18

REGISTRE DES REVISIONS.........................................................................................................................19

REGLAGES ..............................................................................................................................................20-23

REMPLACEMENT DES CURROIES ..............................................................................................................24

11-2001-TGTSP

F-1

Page 28

SECURITE

MACHINE

INTERMEDIAIRE

HYDROSTATIQUE CE

AVERTISSEMENT !!!

Des modifications non autorisées peuvent présenter

des dangers extrêmes pour la sécurité des opérateurs

et des observateurs et elles risquent d’endommager

aussi la machine.

La Société Textron Golf, Turf And Specialty Products

rejette et décline toute responsabilité concernant toutes

modifications, accessoires ajoutés ou modifications

du produit qui ne seraient pas conçus, mis au point,

testés ni agréés par le service technique de Textron

Golf, Turf And Specialty Products. Tout produit de

Textron Golf, Turf And Specialty Products qui aurait été

altéré, modifié ou changé d’une quelconque façon qui

n’aurait pas été spécifiquement autorisée après la

fabrication d’origine - y compris l’addition d’accessoires

ou composants « d’après marché » qui ne seraient pas

spécifiquement agréés par Textron Golf, Turf And

Specialty Products - annulera automatiquement la

garantie Textron Golf, Turf And Specialty Products.

La responsabilité pour tous dommages matériels ou

corporels causés par des modifications non autorisées,

accessoires ajoutés ou non-agréés par Textron Golf,

Turf And Specialty Products sera considérée celle de

l’individu ou de la société concevant et/ou effectuant de

tels changements. Textron Golf, Turf And Specialty

Products essayera par tous les moyens d’obtenir des

dommages et intérêts de toute personne responsable

de telle modification non autorisée après la fabrication

et/ou d’accessoires ajoutés si des dommages corporels

en résultaient.

Ce symbole signifie:

ATTENTION !

PRENEZ GARDE !

Votre sécurité et celle des autres est en jeu.

Définition des avertissements:

Les avertissements ci-dessous sont utilisés pour

indiquer différents niveaux de gravité du danger. Ces

avertissements apparaissent dans le présent manuel

et sur les étiquettes de sécurité fixées sur les

machines Bunton. Pour votre sécurité et celle des

autres, veuillez lire et suivre les informations données

avec les avertissements et/ou le symbole indiqué

au-dessus.

DANGER : Indique une situation dangereuse

imminente qui, si elle n’est pas évitée, risque de

provoquer de graves blessures, voire mortelles.

AVERTISSEMENT

AVERTISSEMENT : Indique une situation

potentiellement dangereuse qui, si elle n’était pas

évitée, risque de provoquer de graves blessures,

voire mortelles.

ATTENTION

ATTENTION : Indique une situation potentiellement

dangereuse qui, si elle n’était pas évitée, risque de

provoquer un incident mineur ou modéré. Il sert

également à signaler des méthodes peu sûres ou

des dommages matériels possibles.

F-2

VIGNETTE DE SERIE

ATTENTION

ATTENTION : Utilisé sans le symbole d’alerte de

sécurité indique une situation potentiellement

dangereuse qui, si elle n’était pas évitée, risque

de provoquer des dommages matériels.

NUMERO DE MODELE : Ce numéro se trouve dans

les brochures commerciales, manuels techniques et

liste de tarifs.

NUMERO DE SERIE : Ce numéro ne se trouve que sur

la machine. Le numéro du modèle est suivi par le

numéro de série. Ce numéro doit être utilisé pour

commander des pièces de rechange ou se renseigner

à propos de la garantie.

Page 29

MONTAGE /

MACHINE

CONSIGNES D’INSTALLATION

INTERMEDIAIRE

HYDROSTATIQUE CE

REMARQUE GENERALE : L’AVANT, L’ARRIERE, LES COTES DROIT ET GAUCHE MENTIONNES

CI-DESSOUS ONT TRAIT A L’OPERATEUR SE TROUVANT AU POSTE DE CONDUITE.

1. DEBALLAGE – Placez les caisses du module de puissance et du plateau de coupe sur une surface

nivelée. Retirez les côtés et le sommet de ces caisses.

2. Déposez les trois tiges W de gauche et les deux

tiges W de droite de la patte d’attache

d’emballage du manche supérieur et mettez-les de

côté pour pouvoir les utiliser ultérieurement.

3. Déposez le ressort du boulon A. Répétez la

même procédure de l’autre côté.

F-3

Page 30

MONTAGE /

CONSIGNES D’INSTALLATION

4. Déposez le manche supérieur B de la patte

d’attache d’emballage C. Déposez la patte

d’attache C du manche inférieur D. Conservez les

attaches retirées pour pouvoir les utiliser

ultérieurement.

MACHINE

INTERMEDIAIRE

HYDROSTATIQUE CE

5. Vissez le manche supérieur B au manche inférieur

D avec deux (2) boulons et écrous

3/8-16 X 1" (E) des boulons retirés précédemment

et deux (2) boulons et écrous 3/8-16 X 1-1/2" (F).

6. Reposez le ressort F que vous fixez des deux

côtés. Placez le contre-écrou Nyloc de

3/8 - 16 des deux côtés du boulon, tel qu’illustré.

F-4

Page 31

MACHINE

INTERMEDIAIRE

HYDROSTATIQUE CE

7. Déposez la patte d’attache d’emballage de la

caisse.

MONTAGE /

CONSIGNES D’INSTALLATION

8. Ouvrez la soupape de dérivation X de la pompe en

faisant tourner le manche deux tours complets

dans le sens contraire des aiguilles d’une montre.

9. Déposez le module de puissance de la caisse et

placez un cric pour maintenir l’arrière du module.

10. Déposez la patte d’attache d’emballage Y du

module de puissance et jetez-la.

F-5

Page 32

MONTAGE /

CONSIGNES D’INSTALLATION

11. Coupez et retirez l’emballage G du levier de

commande de traction H.

MACHINE

INTERMEDIAIRE

HYDROSTATIQUE CE

12. Repérez les deux tiges les plus longues ayant été

retirées au paragraphe 2. Placez les deux tiges de

commande de traction au travers du levier de

commande de traction H, la rondelle plate et le

verrou de traction J puis fixez-les avec l’épingle à

cheveux. Répétez l’opération de l’autre côté du

manche supérieur.

13. Alors que les verrous de traction J se trouvent au

point mort, tendez la tige de commande de

traction pour éliminer toute détente et alignez la

rotule de la tige de commande à l’orifice de la

biellette de la pompe K. Répétez la procédure de

l’autre côté.

REMARQUE : La biellette de la pompe a un jeu

rotatif. Ajustez la rotule de la tige de commande

de traction au centre de ce jeu puis fixez la

biellette de la pompe avec une rondelle plate et

épingle à cheveux, tel qu’illustré.

F-6

Page 33

MACHINE

INTERMEDIAIRE

HYDROSTATIQUE CE

14. Attachez le ressort à la biellette de la pompe puis

au boulon L. Répétez la même procédure de

l’autre côté.

MONTAGE /

CONSIGNES D’INSTALLATION

15. Raccordez la tige de commande de vitesse M aux

leviers de commande de vitesse N puis fixez-la

avec une épingle à cheveux. Répétez la même

procédure de l’autre côté.

16. Placez les leviers de commande de vitesse au

point mort et ajustez la rotule du bout inférieur de

la tige de commande de vitesse M pour que les

leviers puissent s’enclencher au sommet de la

fente des plaques de point mort P puis fixez avec

une rondelle plate et épingle à cheveux, tel

qu’illustré. Répétez la même procédure de l’autre

côté.

F-7

Page 34

MONTAGE /

CONSIGNES D’INSTALLATION

17. Faites passer le bout fileté de la tige de frein Q

dans la fente située sur le plateau moteur et

attachez l’autre bout à la biellette de commande

de frein R puis fixez avec une épingle à cheveux,

tel qu’illustré.

MACHINE

INTERMEDIAIRE

HYDROSTATIQUE CE

18. Raccordez la rotule du bout fileté de la tige de

frein Q à la biellette de frein T et fixez-la avec une

rondelle plate et épingle à cheveux, tel qu’illustré.

Ajustez la rotule pour assurer un freinage adéquat

quand la biellette de commande de frein R se

serre. Reportez au chapitre intitulé “Réglages” de

ce manuel.

F-8

Page 35

MACHINE

INTERMEDIAIRE

HYDROSTATIQUE CE

19. Fermez la soupape de dérivation X en la faisant

tourner dans le sens des aiguilles d’une montre

jusqu’à ce qu’elle tienne solidement.

MONTAGE /

CONSIGNES D’INSTALLATION

20. Déposez le couvercle de la batterie et la batterie

de la machine. Remplissez la batterie d’électrolyte

puis effectuez une charge de compensation

plusieurs heures. Reposez ensuite la batterie

dans la machine et raccordez-la en branchant la

borne positive (rouge) en premier puis la borne

négative (terre). Reposez son couvercle et fixez-le

avec les écrous retirés au préalable.

Les batteries produisent des

gaz explosifs

- Eloignez-les des flammes

et étincelles.

- Débranchez, tout d’abord,

la borne négative.

- Rebranchez, en dernier,

la borne négative.

F-9

Page 36

MONTAGE /

CONSIGNES D’INSTALLATION

MACHINE

INTERMEDIAIRE

HYDROSTATIQUE CE

21. Fixez le plateau de coupe en suivant les recommandations figurant aux pages suivantes puis reportez-vous

au paragraphe 22 de ce chapitre.

22. Remplissez le moteur d’huile. (Reportez-vous au Manuel du moteur pour obtenir les spécifications).

23. Remplissez le réservoir carburant de diesel propre.

AVERTISSEMENT

LE DIESEL EST TRES INFLAMMABLE !

• Remplissez le réservoir carburant de diesel propre de bonne qualité.

• N’utilisez pas de carburant pour essais approfondis.

• Ne fumez pas.

• Ne renversez pas le carburant.

• Faites le plein à l’extérieur.

• Ne faites pas déborder. Laissez un vide de 25 mm sous le goulot de remplissage.

• IL FAUT UTILISER UN ENTONNOIR POUR REMPLIR LE RESERVOIR A GAZ.

24. Vérifiez le niveau d’huile du réservoir hydraulique et rétablissez-le, le cas échéant.

25. Ajustez la pression des roues motrices à 1 kg/cm2.

26. Il faut lire et assimiler le Manuel Opératoire et de Sécurité avant d’utiliser la machine.

REMARQUE : Consignes spéciales de mise en service

• Avant de vous servir du plateau de coupe, faites tourner cinq minutes le moteur à plein régime. Il est

recommandé d’agir ainsi car le moteur est neuf et ceci permet de le graisser avant de le charger.

• Ne mettez jamais en marche le plateau de coupe à plein régime mais placez la manette des gaz à mirégime entre le ralenti et plein régime. Utilisez l’interrupteur de la prise de force et augmentez le régime

moteur pour qu’il atteigne le plein régime avant de commencer à tondre.

•

AVERTISSEMENT

La machine ne doit pas être utilisée sans être munie d’un collecteur d’herbe agréé, d’un goulot de

déversement ou d’une (des) plaque(s) de paillage.

F-10

Page 37

MACHINE

INTERMEDIAIRE

HYDROSTATIQUE CE

MONTAGE /

CONSIGNES D’INSTALLATION

ACCESSOIRE DE PLATEAU DE COUPE

FIXE

1. Déposez le plateau de coupe de la caisse.

2. Dévissez les roues pivotantes et les pattes

d’attache d’emballage de la caisse.

3. Déposez la patte d’attache d’emballage de la roue

pivotante en desserrant son boulon et en faisant

glisser la patte d’attache pour la retirer puis en

resserrant le boulon de la roue pivotante.

4. Retirez la goupille à déclenchement instantané et

retirez le nombre d’entretoises requis pour obtenir

la hauteur désirée. A cet effet, reportez-vous au

tableau suivant.

REMARQUE : Le tableau des hauteurs de coupe

se trouve aussi en bas du carter de la courroie ou

dans le Manuel Opératoire et de Sécurité.

5. Répétez la procédure sur les autres roues

pivotantes.

GOUPILLE A

DECLENCHEMENT

INSTANTANE

ENTRETOISE 1/4”

ENTRETOISE 1/2”

ENTRETOISE 1/2”

ENTRETOISE 1/8”

BOULON DE

ROUE PIVOTANTE

PATTE D’ATTACHE

(EMBALLAGE)

HAUTEUR DE COUPE

NOMBRE

D’ENTRETOISES ENTRE

L’AXE ET LA LAME

(EPAISSEUR 0,60 CM)

POSITION DES GOUPILLES DE PLATEAU

F-11

Page 38

MONTAGE /

CONSIGNES D’INSTALLATION

6. Déposez le carter de la courroie et placez-le sur le

côté.

7. Bloquez l’arrière du plateau de coupe avec une

cale de hauteur adéquate pour obtenir la hauteur

de coupe requise B. Reportez-vous au tableau

suivant pour ce qui concerne les cales.

MACHINE

INTERMEDIAIRE

HYDROSTATIQUE CE

SEDNOITISOP

EDRUETUAH

EPUOC

60,4-mc64,3

mc

39,5-mc86,4

mc

18,7-mc65,6

mc

86,9-mc34,8

mc

,11-mc13,01

mc65

UDSECIFIRO

UAETALP

*RUETOM

5mc521,3

4mc5

3mc78,6

2mc57,8

1mc26,01

.ruetomuaetalpud

UDRUETUAH

ACOLB

EREIRRA’L

UAETALPUD

)B(

tuahsulpelecifiro’ltse1noitisoP*

8. Placez le module de puissance derrière le plateau

de coupe.

9. Avancez le module de puissance vers le plateau

de coupe pour enclencher les goupilles guides A

dans l’orifice C du module et obtenir la hauteur de

coupe requise. Serrez-les avec quatre (4) boulons

M12 – 1,75 X 30 (D).

10. Bouclez la courroie de la prise de force E autour

de la poulie d’embrayage électrique. A l’aide d’un

cliquet de 3/8" ou d’une poignée articulée de 3/8",

faites tourner la partie libre de la courroie de la

prise de force pendant que vous la bouclez autour

de la poulie du plateau de coupe.

11. Reposez le carter de la courroie et fixez-le avec

les écrous retirés au préalable.

12. Déposez le support à l’arrière du plateau de

coupe.

13. Déposez le support de l’arrière du module de

puissance.

F-12

Page 39

MACHINE

GRAISSAGE

INTERMEDIAIRE

HYDROSTATIQUE CE

GRAISSAGE DE LA MACHINE

Toutes les 50 heures d’horamètre – Graisser les points suivants :

1) Pivots de roue pivotante (2 points de graissage)

2) Goupille excentrique de point mort (2 points)

3) Roulements de pivots libres :

a) Moteur de tendeur de courroie de plateau de coupe

b) Tendeur de courroie du plateau de coupe

c) Tendeur de courroie d’entraînement hydrostatique

REMARQUE : Les axes de ces machines ont des roulements scellés de haute qualité graissés à vie.

F-13

Page 40

GRAISSAGE

MOTEUR

QUOTIDIENNEMENT

Retirez la jauge S et assurez-vous que le niveau

d’huile se trouve sur le point de repère Maxi.

Rétablissez, s’il y a lieu, le niveau avec de l’huile

propre. La machine doit être sur une surface plate pour

obtenir le niveau correct d’huile. A cet effet, reportezvous au manuel du fabricant du moteur pour obtenir la

liste des huiles recommandées.

IL NE FAUT JAMAIS FAIRE DEBORDER !

APRES LES 5 PREMIERES HEURES

D’HORAMETRE

Pendant que le moteur est chaud, retirez le bouchon

de vidange P et vidangez le carter-moteur. Remplacez

le filtre à huile. Nettoyez puis reposez le bouchon.

Remplissez le carter-moteur d’huile propre par l’orifice

de remplissage en veillant à ce que le niveau se situe

sur Maxi. Reportez-vous au manuel du fabricant du

moteur pour obtenir les intervalles de remplacement du

filtre et de l’huile.

MACHINE

INTERMEDIAIRE

HYDROSTATIQUE CE

Les machines sont toutes accompagnées d’un manuel

de l’opérateur pour ce qui concerne le moteur. Des

manuels de moteurs sont en vente chez votre

distributeur de moteurs régional.

• Pour Kawasaki FH451V, commandez : 999202129-03.

F-14

Page 41

MACHINE

INTERMEDIAIRE

HYDROSTATIQUE CE

Le programme de maintenance est destiné à des

conditions de fonctionnement moyennes. En cas de

conditions extrêmes (poussières, saletés ou plus de 8 h

d’utilisation continue), rapprochez les intervalles de

maintenance.

Moteur (quotidiennement)

Vérifiez l’absence de fuites d’huile du moteur.

Ailettes de refroidissement et tamis d’admission d’air

(quotidiennement)

Veillez à ce que les ailettes de refroidissement et le tamis

d’admission d’air I soient nettoyés quotidiennement. Un

fonctionnement continu de la machine contribue à bloquer

le circuit de refroidissement ce qui provoque la surchauffe

du moteur et l’endommage éventuellement.

Epurateur d’air (toutes les 25 heures)

Rapprochez ses intervalles de maintenance s’il est

soumis a beaucoup de poussières ou un environnement

très sec. Risque d’endommagement important quand

l’épurateur d’air est sale.

MAINTENANCE

1. Déposez le couvercle de l’épurateur d’air en

desserrant les attaches L.

2. Déposez le prénettoyeur de mousse P en le faisant

glisser de la cartouche en papier. Nettoyez-le avec du

kérosène ou un détergent et de l’eau. Séchez-le

ensuite à fond. Trempez-le ensuite dans de l’huile

moteur puis tordez-le pour éliminer l’excès d’huile.

3. Reposez toutes les pièces.

REMARQUES :

• Toutes les 50 heures d’horamètre, desserrez l’écrou à

oreilles W pour retirer l’élément en papier.

• IL NE FAUT PAS utiliser de produits de nettoyage à

base de vaseline pour nettoyer l’élément en papier car

ils risquent de l’endommager.

• IL NE FAUT PAS utiliser d’air comprimé pour nettoyer

ou sécher l’élément.

• Reportez-vous au manuel de “Mise en service,

Nomenclature des pièces de rechange &

Maintenance” pour obtenir les numéros de référence

des pièces.

Filtre carburant en ligne

Il est possible de remplacer le filtre carburant B. Reportezvous au manuel de “Mise en service, Nomenclature des

pièces de rechange & Maintenance” pour obtenir les

numéros de référence des pièces.

F-15

Page 42

MAINTENANCE

MACHINE

INTERMEDIAIRE

HYDROSTATIQUE CE

Affûtage des lames

L’affûtage des lames s’effectue en les limant ou en les meulant ; quelque soit la méthode utilisée, leur équilibre

doit être conservé à 0,004 Nm ou moins. En cas de déséquilibre des lames, des vibrations excessives se

produisent, elles s’usent prématurément et usent aussi la plupart des composants de la machine. Pour

équilibrer une lame après l’avoir affûtée : attachez un poids de 3,9 g à 127 mm du centre sur la partie plus

légère de la lame. Cette partie plus légère devient alors la plus lourde. Dans la négative : limez ou meulez la

partie la plus lourde jusqu’à ce que la lame s’équilibre.

REMARQUE :

• Ne surchauffez pas et n’affaiblissez pas les lames.

• Ne redressez pas les lames déformées. Remplacez-les par des lames Bunton.

Quand la partie de levage de la lame est usée, remplacez-la par une lame Bunton.

• Il faut TOUJOURS remplacer les lames par des lames Bunton et ne jamais utiliser de lames provenant

d’autres fournisseurs afin d’éviter les accidents.

• Remplacez les lames fissurées ou déformées.

DEPOSE DES LAMES

1. Utilisez une clé à douille ou clé munie d’une longue

poignée articulée pour déposer le boulon de l’axe

sous le plateau de coupe.

2. Faites passer le tube, s’il y a lieu, au-dessus de la

poignée articulée ou de la clé pour avoir plus de

force.

3. Eloignez les mains car les lames risquent de tourner

quand le boulon se desserre.

4. Portez des gants rembourrés pour remplacer la ou

les lames.

5. Placez une cale pour empêcher la lame de tourner.

6. Suivez ces consignes pour ne pas vous blesser

quand le boulon se desserre.

ECROU

REMARQUE : Placez une cale en bois A (le grain du

bois doit être perpendiculaire à la lame) pour empêcher

la lame de tourner.

ENTRETOISE(S) RESTANTE(S)

RONDELLE CONIQUE

REPOSE DES LAMES

1. Placez le nombre correct d’entretoises (pas plus de

2) sur le boulon d’axe au-dessous du plateau de

coupe, entre la lame et l’axe.

2. Posez le boulon d’axe de coupe (à partir du bas)

avec la rondelle, la lame et les entretoises.

3. Posez les entretoises restantes sur le boulon d’axe

au-dessus du plateau de coupe, entre la rondelle

conique et l’écrou (illustré). Reposez l’écrou que

vous couplez à 95 Nm.

BOUGIE DE PRECHAUFFAGE

• Déposez la bougie et vérifiez son état.

• Quand le dépôt sur la bougie est gris clair ou légèrement marron, les conditions de fonctionnement sont

bonnes. Quand le dépôt est blanc, une surchauffe est probable. Quand il est noir, le mélange de carburant

risque d’être “trop riche” résultant d’un épurateur d’air colmaté ou d’un mauvais réglage du carburateur. Ne

sablez pas, n’utilisez pas de gratte-brosses ou autre pour nettoyer une bougie sale. Les résultats les

meilleurs s’obtiennent en remplaçant la bougie.

• Reportez-vous au manuel du fabricant du moteur pour obtenir l’espace correct de la bougie de préchauffage.

Poulie du plateau de coupe

POULIE

F-16

Page 43

MACHINE

INTERMEDIAIRE

HYDROSTATIQUE CE

RESERVOIR HYDRAULIQUE

VERIFICATION, VIDANGE ET REMPLISSAGE

Vérifiez le niveau du réservoir toutes les 100 heures

d’horamètre ou en cas de fuites. Pour vérifier le niveau

: déposez le bouchon du réservoir, ajoutez de l’huile

10W30 jusqu’à ce que le niveau se situe en bas du

goulot de remplissage. Ne faites pas déborder.

TOUTES LES 500 HEURES D’HORAMETRE :

Remplacez le filtre et l’huile hydraulique. Déposez le

bouchon D pour vidanger le réservoir. Déposez et

remplacez le filtre. Le filtre se trouve à l’avant du

réservoir (G). Ajoutez de l’huile 10W30 jusqu’à ce que

le niveau se situe en bas du goulot de remplissage F

puis reposez le bouchon.

MAINTENANCE

F-17

Page 44

TABLEAU DES REVISIONS

MACHINE

INTERMEDIAIRE

HYDROSTATIQUE CE

REMARQUE : IL F AUT REMPLACER L ’HUILE MOTEUR ET LE

FIL TRE APRES LES 5 PREMIERES HEURES D’HORAMETRE.

SNOISIVER

RUETOM

uaevinelreifiréV

eliuh’d

edecnesba’lreifiréV

ria’dteeliuh’dsetiuf

rinetertnE

ria’dnoissimda’l

rinetertnE

ria’druetarupé’l

&eliuh’lrecalpmeR

*ertlifel

àesavelrinetertnE

edstnemidés

tnarubrac

retsujA/recalpmeR X

edeiguoB

egaffuahcérp

5

SEREIMERP

SERUEH

X

X

X

X

X

-ENNEIDITOUQ

TNEM

SETUOT

52SEL

SERUEH

SETUOT

05SEL

SERUEH

SETUOT

001SEL

SERUEH

RUETOMUDTNACIRBAFUDLEUNAMELRIOV

SETUOT

005SEL

SERUEH

*RUETOMUDTNACIRBAFUDLEUNAMELRIOV

EDETIOB

SESSETIV

uaevinelreifiréV

eliuh’d

ENIHCAM

noisserpalreifiréV

suenpsed

noisnetalreifiréV

seiorruocsed

selsuotressiarG

egassiargedstniop

X

TEH2/1EREIMERPALSERPAREIFIREV

SEREIMERP4SELSERPAETIUSNE

ERTEMAROH’DSERUEH

X

X8

X

Se reporter au manuel du fabricant du moteur pour tous renseignements

complémentaires et consignes à suivre.

F-18

Page 45

MACHINE

REGISTRE DES REVISIONS

INTERMEDIAIRE

HYDROSTATIQUE CE

REMARQUES

_______________________________________________________________

____________________________________________________

________________________________________________________________________

_______________________________________________________________

____________________________________________________________

____________________________________________________

________________________________________________________________________

_______________________________________________________________

____________________________________________________________

_______________________________________________________________

____________________________________________________________

_______________________________________________________________

_______________________________________________________________

SETILARENEG

suenp

egassiarged

&suorcéselreifiréV

snoluob

RUETOM

eliuh’lrecalpmeR

ria’druetarupé’l

ETAD SERUEH ETAD SERUEH ETAD SERUEH ETAD SERUEH ETAD SERUEH ETAD SERUEH

sednoisserpalreifiréV

stniopselsuotressiarG

eliuh’duaevinelreifiréV

edtnemélé’lrinetertnE

setteliaselrinetertnE

tnemessidiorfered

edtnemélé’lrecalpmeR

ria’druetarupé’l

reifirévterinetertnE

seiguobsedecapse’l

egaffuahcérped

.ertèmaroh’dseruehserèimerp5selsèrpasertlifselteruetomeliuh’lrecalpmeR:EUQRAMER

F-19

Page 46

REGLAGES

MACHINE

INTERMEDIAIRE

HYDROSTATIQUE CE

REMARQUE : Arrêtez le moteur, débranchez la bougie de préchauffage et désembrayez la machine avant

d’effectuer des réglages.

REGLAGES DE LA COMMANDE HYDROSTATIQUE : Les réglages suivants doivent être effectués dans l’ordre.

ETAPE 1 – Point mort

Le réglage du point mort est effectué en usine. S’il faut

le régler, relevez les roues en plaçant un cric ou des

cales sous la machine. Déconnectez la tige de

commande de traction A et la tige de commande de

vitesse R de chaque extrémité de la pompe.

Déconnectez le ressort de la biellette de la pompe U du

boulon se trouvant sur le plateau moteur. Desserrez

suffisamment le boulon S maintenant l’axe excentrique

de la plaque de point mort pour pouvoir faire tourner

l’axe. Démarrez le moteur et laissez-le tourner au

ralenti. Faites tourner l’axe excentrique T pour relever

ou descendre le point sur lequel le roulement est

maintenu au centre de V jusqu’à ce que les roues

cessent de tourner. Serrez le boulon de l’axe

excentrique. Augmentez les gaz et vérifiez le réglage.

Réajustez-le, s’il y a lieu. Arrêtez le moteur avant de

passer aux étapes 2 et 3.

ETAPE 2 – Tiges de commande de vitesse

Réglez, tout d’abord, le point mort comme indiqué dans

l’étape 1. Placez les leviers de vitesse au point mort.

Ajustez les rotules des bouts inférieurs des tiges de

commande de vitesse R de façon à ce qu’elles aillent

juste dans les fentes des plaques de point mort.

REMARQUE : Si les leviers de commande de vitesse

ne sont pas alignés correctement, donnez un tour à la

rotule de l’une des tiges.

ETAPE 3 – Leviers de traction

Réglez le point mort et ajustez les tiges de commande

de vitesse comme indiqué aux étapes 1 et 2. Placez

les verrous de traction au point mort. Appuyez sur la

tige de traction A pour éliminer toute détente. La

biellette de la pompe a un jeu avant et arrière. Placez la

rotule au centre du jeu de la biellette de la pompe et

raccordez la rotule à la biellette. Reposez le ressort de

la biellette de la pompe U que vous vissez au plateau

moteur.

REMARQUE : Une vitesse supplémentaire arrière

s’obtient en ajustant la rotule vers l’arrière de la

biellette. Il doit y avoir un jeu minimum de 1,6 mm pour

que les commandes de traction puissent passer au

point mort sans que la machine ne fasse marche

arrière.

F-20

Page 47

MACHINE

INTERMEDIAIRE

HYDROSTATIQUE CE

Adhérence du levier de vitesse

Il tient par des coussins. S’il ne tient pas

adéquatement, serrez les écrous E pour augmenter

son adhérence.

REGLAGES

FREIN DE STATIONNEMENT – Serrez le frein de

stationnement et ouvrez la soupape de dérivation de la

pompe hydraulique. Essayez de pousser la machine

en avant. Si ses roues tournent, ajustez les freins

comme suit.

REGLAGE :

1. Déposez l’épingle à cheveux A de la tige de frein

du levier, tel qu’illustré.

2. Faites glisser la tige de frein pour la sortir du levier

et faites tourner la tige vers l’intérieur ou l’extérieur

de la rotule de frein B.

REMARQUE : Le frein doit être ajusté de façon à

ce que sa tige traverse la rotule B de

32 mm, comme illustré. Quand il faut augmenter

la pression de freinage, ajustez en conséquence.

3. Reposez la tige de frein sur son levier à l’aide de

l’épingle à cheveux A.

4. Serrez le frein de stationnement et essayez de

pousser la machine en avant. Si ses roues

tournent, réajustez le frein.

5. Fermez la soupape de dérivation de la pompe

hydraulique.

F-21

Page 48

REGLAGES

Arrêtez le moteur, débranchez la bougie de

préchauffage et désembrayez la machine avant

d’effectuer des réglages.

CONTROLE DE PRESENCE DE L’OPERATEUR

Le contrôle de présence de l’opérateur (PO) doit être

ajusté pour pouvoir contrôler le fonctionnement de

l’interrupteur de présence de l’opérateur (il se situe

sous le côté droit du panneau de commande). Le fait

d’appuyer sur le levier F (PO) doit rétracter le

plongeur et le fait de le relâcher doit le déployer.

REGLAGES :

1. Desserrez les boulons de serrage des deux

extrémités G de façon à ce que les attaches

puissent tourner sur l’axe. Desserrez les boulons

de serrage H pour que les leviers PO puissent

bouger librement dans les attaches.

2. Maintenez le levier PO sur les poignées et ajustez

pour l’installation puis serrez les boulons H.

3. Faites tourner le levier du vérin pour appuyer sur

le plongeur. Maintenez le levier PO contre les

poignées puis serrez les boulons G.

4. Dès que le levier PO est relâché, il doit se

soulever et le levier du vérin doit tourner en

s’éloignant de l’interrupteur, permettant ainsi au

plongeur de se déployer complètement.

MACHINE

INTERMEDIAIRE

HYDROSTATIQUE CE

REGLAGE DE LA HAUTEUR DES MANCHES

Réglage de la hauteur des manches : Dévissez les

boulons G et desserrez les boulons E de chaque côté

des manches. Levez ou descendez les manches.

Repositionnez le manche supérieur et reposez les

boulons G dans les trous du manche inférieur puis

vissez-les. Réajustez les tiges de commande de

traction, freins et freins de stationnement.

F-22

Page 49

MACHINE

INTERMEDIAIRE

HYDROSTATIQUE CE

REGLAGE DE L’ALIGNEMENT

Il est possible d’augmenter de 83 mm l’alignement

effectué en usine. Procédez selon les étapes

suivantes pour l’ajuster.

1. Desserrez les écrous de roues des deux roues

motrices.

2. Relevez l’arrière de la machine pour soulever les

roues. Utilisez un cric comme moyen de support.

3. Déposez les écrous de roues et les roues.

Reposez les roues que vous tournez pour que leur

offset soit opposé à l’offset préalable.

4. Abaissez la machine et couplez les écrous de

roues à 115 Nm.

REGLAGES

REGLAGE DE LA PRESSION DES PNEUS

Leur pression doit toujours être de 1,0 kg/cm2.

F-23

Page 50

REMPLACEMENT DES CURROIES

COURROIE DE PRISE DE FORCE

1. Faites tourner la biellette folle à l’aide d’un cliquet

de 3/8" ou d’une poignée articulée puis retirez la

courroie.

MACHINE

INTERMEDIAIRE

HYDROSTATIQUE CE

COURROIE DE PLATEAU DE COUPE

1. Déposez la courroie de la prise de force.

2. Faites tourner la biellette folle à l’aide d’un cliquet

de 3/8" ou d’une poignée articulée puis retirez la

courroie.

3. La repose s’effectue dans le sens contraire de la

dépose.

COURROIE D’ENTRAINEMENT DE LA POMPE

1. Déposez la courroie de la prise de force de

l’embrayeur moteur.

2. Débranchez le faisceau d’embrayage.

3. Déposez la patte d’attache de l’embrayage et

faites tourner ce dernier pour obtenir suffisamment

de jeu et retirer la patte d’attache de l’embrayage.

4. Faites tourner la biellette folle à l’aide d’un cliquet

de 3/8" ou d’une poignée articulée que vous

insérez dans l’orifice carré de la biellette folle.

5. Déposez la courroie d’entraînement de la pompe.

6. La repose s’effectue dans le sens contraire de la

dépose.

COURROIE DE

PRISE DE FORCE

PATTE

D’ATTACHE DE

L’EMBRAYAGE

POULIE FOLLE

Vue du dessous du plateau moteur

POULIE MOTEUR

COURROIE

D’ENTRAINEMENT

DE POMPE

POULIES DE

POMPE

F-24

Page 51

EC

Hydro

Midsize

PARTS SECTION

PARTS

SECTION

GB-25

Page 52

UPPER ENGINE DECK ASSY

EC

Hydro

FIGURE 1

Midsize

Parts-26

Page 53

EC

Hydro

UPPER ENGINE DECK ASSY

Midsize

ITEM PART NO. DESCRIPTION QTY

1-1 2721520 CAP-FUEL GASOLINE 3.5 1

1-2 2722286 TANK-FUEL MID 1

(INCLUDES ITEMS 3 & 4)

1-3 48310 S BUSHING,FUEL TANK 1

1-4 38540 S FUEL SHUT-OFF VALV 1

1-5 88042N HOSE CLAMP 2

1-6 48016-8A HOSE,.25IDX.50ODX17" 16.5"

1-7 38666 FILTER, FUEL 1

1-8 2721105.2 WLDMT-ENGINE DECK 1

1-9 A1105061 BOLT-M12-1.75 X 30 8

1-10 64237-06 LOCKNUT-NYLON M12-1.75 8

1-11 48228-2A CABLE CLIP 3/4 W/INSTN 2

1-12 64163-31 WASHER 3

1-13 64006-03 LOCKWSHR-HELICAL 3/8 4

1-14 48228A CABLE CLIP-INSULATED 2

1-15 64229-02 LOCK NUT-NYLON 5/16-18 4

1-16 2306138 S-EC HYD RSVR W/LABS 1

1-17 64123-15 BLT-HEX 3/8-16X3/4 3

1-18 2722269.2 HANDLE-LOWER HYD 1

1-19 64018-9 BLT-CRG 5/16-18 X 3/4 4

1-20 38542 CLAMP-DOCU TUBE 2

1-21 64006-01 LOCKWSHR-HELICAL 1/4 2

1-22 64123-89 BLT-HEX 1/4-20 X 3/4 2

1-23 38061A COVER 2

1-24 2306144 S DOCU TUBE W/LAB 1

1-25 A1102966 BOLT-M6-1.00X16 1

1-26 * 4114119 ENGINE-15HP KAW ES 1

2722214 FILTER-OIL

2722207 FILTER-AIR

2722208 FILTER-PRE

4115262-01

FIGURE 1

ITEM PART NO. DESCRIPTION QTY

(SERVICE MANUAL 15 HP KAW #99920-2129-03)

1-27 64123-50 BLT-HEX 3/8-16 X 1 1

1-28 64211-01 WSHR-ALUM,BACKING 2

1-29 64002-04 L'WSHER, EXT. 5/16 1

1-30 64215-02 RIVET-POP IFI# 44 2

1-31 4116244 GUARD-MUFFLER 1

1-32 4116332 MUFFLER-15HP KAW EC 1

1-33 64215-04 RIVET-POP IFI# 42 5

1-34 4116243 COVER-MUFFLER 1

* AVAILABLE THROUGH KAWASAKI DEALER

Parts-27

Page 54

LOWER ENGINE DECK ASSY/CLUTCH

EC

Hydro

FIGURE 2

Midsize

Parts-28

Page 55

EC

Hydro

LOWER ENGINE DECK ASSY/CLUTCH

Midsize

ITEM PART NO. DESCRIPTION QTY

2-1 2721647 PULLEY-4.50E.O.D. 1

2-2 64163-31 WASHER, 25/64 X 1 X 12 5

2-3 2721110 CLUTCH-ELECTRIC 1

2-4 2721331.7 WLDMT-CLUTCH STOP MID 1

2-5 2721642 BELT-HA 49.0 1

2-6 2722244 PULLEY- A SECTION 4.50 2

2-7 38304-03 BRG-FLANGED PLASTIC 1

2-8 2721398 PIN-CLUTCH 1

2-9 64264-01 BLT-WLF M10-1.5 X 16 1

2-10 2721641.7 WLDMT-IDLER ARM 1

2-11 2721652 PIN-PIVOT 1

2-12 64163-65 WASHER 0.890 X 1.375 6

2-13 64163-82 WSHR-FLAT.406X1.44X9GA 2

2-14 64205-012 BLT-METRIC M10-1.50 X 90 1

2-15 64237-03 LOCKNUT-NYLON M10-1.5 3

2-16 2308000 PULLEY-IDLER 4.00 EOD 1

2-17 33148-01 SPACER 1

2-18 38219 SPRING-TENSION 1

2-19 64123-87 BLT-HEX 3/8-16 X 1-3/4 1

2-20 64141-4 NUT-WLF 3/8-16 1

2-21 64246-03 NUT-WHIZ M10-1.50 2

2-22 64197-005 BLT-TDFM 3/8-16X1-1/4 4

2-23 64123-155 BLT-HEX 7/16-20 X 3 1

2-24 64006-06 LOCKWSHR-HELICAL 7/1 1

2-25 64205-001 BLT-METRIC M8-1.25 X 20 2

2-26 64251-003 WHSR-M8 2

2-27 64237-05 LOCKNUT-NYLON M8-1.25 2

2-28 64164-12 1/4X1/4X1 SQ END KEY 1

2-29 64205-17 BLT-METRIC M10-1.50 X 75 2

2-30 2720949 ASSY-CLUTCH WIRE 1

2-31 2721615 PUMP-HYDRO LH 1

2-32 4112782 PUMP-HYDRO RH 1

2-33 2721541 PULLEY-IDLER 5 IN 1

2-34 2721401.7 WLDMT-IDLER ARM 1

2-35 64163-61 WSHR .81X.406X16GA 1

2-36 64205-036 BLT-METRIC M10-1.50 X 35 4

2-37 2188131 SPRING-EXTENSION 1

2-38 2721105.2 WLDMT-ENGINE DECK 1

2-39 2721723 PIN-PIVOT 1

2-40 64205-011 BLT-METRIC M10-1.50 X 40 1

2-41 64044-6 SCREW-SET 5/16-18X1/4 4

2-42 64238-03 KEY-METRIC 5MM SQ X 28 2

2-43 64209-09 WASHER-CONICAL SPRING 2

2-44 148034-08 INSUL. GROMMET 1.125OD 1

2-45 64205-013 BLT-METRIC M6-1 X 12 2

2-46 64265-05 NUT-FL NYLOCK M10-1.5 4

2-47 64163-51 WSHR.453 X 1.38 X 7GA 1

2-48 64163-31 WASHER, 25/64 X 1 X 12 1

4115262-02

FIGURE 2

ITEM PART NO. DESCRIPTION QTY

Parts-29

Page 56

DRIVE WHEELS

EC

Hydro

FIGURE 3

Midsize

Parts-30

Page 57

EC

Hydro

DRIVE WHEELS

Midsize

ITEM PART NO. DESCRIPTION QTY

3-1 2721105.2 WLDMT-ENGINE DECK 1

3-2 2721620.7 WLDMT-HUB 2

3-3 2721956 ASSY-WHEEL 16 X 7.50 X 8 2

2721956-01 TIRE-16X7.50 X 8 MLTI TRC 1

2721956-02 WHEEL W/ DUAL VALVES 1

3-4 64267-01 NUT-HEX FLANGED 1/2-20 8

3-5 64025-06 NUT-HEX 3/4-16 2A 2

3-6 2308051 MOTOR-WHEEL ROSS MF 2

3-7 64246-04 NUT-WHIZ M12-1.75 8

3-8 64164-28 #808 WOODRUFF KEY 2

3-9 64205-028 BLT-METRIC M12-1.75 X 60 8

4115262-03

FIGURE 3

ITEM PART NO. DESCRIPTION QTY

Parts-31

Page 58

P ARKING BRAKE

EC

Hydro

FIGURE 4

Midsize

Parts-32

Page 59

EC

Hydro

P ARKING BRAKE

Midsize

ITEM PART NO. DESCRIPTION QTY

4-1 2721637 WLDMT-BRAKE SHAFT 1

4-2 33103 SWIVEL 1

4-3 64168-2 COTTER-HAIRPIN.08X1.19 2

4-4 64246-03 NUT-WHIZ M10-1.50 2

4-5 64205-012 BLT-METRIC M10-1.50 X 90 1

4-6 2188131 SPRING-EXTENSION 1

4-7 64163-17 25/64 X 2 X 11GA WASHR 1

4-8 64171-2 WAVE WASHER 1

4-9 2188145 BEARING-.75ID SELF ALIGN 2

4-10 64205-001 BLT-METRIC M8-1.25 X 20 4

4-11 64246-02 NUT-WLF M8-1.25 4

4-12 2721725.7 WLDMT-SCRUBBER 2

4-13 64061-09 ROLL PIN-3/8 X 2 4

4-14 64237-03 LOCKNUT-NYLON M10-1.5 1

4-15 2721726 ROD-BRAKE 1

4-16 2721632.7 LEVER-BRAKE 1

4-17 38404-01 GRIP-CONTROL LEVER 1

4-18 A110406 BOLT-M10-1.5 X 30 1

4-19 64163-02 WSHR-.321 X .593 X 11GA 1

2721734-04

FIGURE 4

ITEM PART NO. DESCRIPTION QTY

Parts-33

Page 60

ELECTRIC START UPPER HANDLE

EC

Hydro

FIGURE 5

Midsize

Parts-34

Page 61

EC

Hydro

ELECTRIC START UPPER HANDLE

Midsize

ITEM PART NO. DESCRIPTION QTY

5-1 38360 GRIP-RECESSED 1 IN 2

5-2 * 2308121 ADHESIVE-3 GRAM TUBE 1

(USE WITH 38360 GRIP)

5-3 128010 KEY SWITCH 1

5-4 64152-46 SCR-SLT HH 10-24X1/2 2

5-5 4115089 S-CNTRL PNL W/LAB EC 1

5-6 2303023 CONNECTOR-OP 2

5-7 33030-09 IDLER-BUSHING 2

5-8 2308037 SPRING, TORSION OP 1

5-9 38371-01 BRG-NYLINER 3/8 2

5-10 64025-15 NUT-HEX #10-24 KEPS 2

5-11 2722269.2 HANDLE-LOWER 1

5-12 2308094 SWITCH-NCNC DBL POLE 1

5-13 2721583.2 WLDMT-HYD UPR HANDLE 1

5-14 64123-50 BOLT, 3/8-16X1 HEX 2

5-15 64123-70 BLT-HEX 3/8-16X1-1/2 2

5-16 2188178 SWITCH-RETAINER 1

5-17 64141-4 NUT-WLF 3/8-16 4

5-18 2308152 LEVER-OP LH 1

5-19 2308153 LEVER-OP RH 1

5-20 2306097 WLDMT-ACTUATOR-PLATD 1

5-21 2721505 SWITCH-PTO 1

5-22 38357-04 CONTROL-THROTTLE 1

5-23 48412 CLIP-CABLE 5/8 J X 8.74 1

5-24 64152-23 1/4-20X3/8 LG SP SCREW 4

5-25 64197-015 BLT-TDFM 10-32X1/2 TORX 4

5-26 64197-002 BLT-TDFM 1/4-20X3/4 4

5-27 108208 SWITCH DBL POLE 1

4115262-05

FIGURE 5

ITEM PART NO. DESCRIPTION QTY

* NOT ILLUSTRATED

Parts-35

Page 62

TRACTION CONTROLS

EC

Hydro

FIGURE 6

Midsize

Parts-36

Page 63

EC

Hydro

TRACTION CONTROLS

Midsize

ITEM PART NO. DESCRIPTION QTY

6-1 2722426 GRIP-TRACTION LOCK 2

6-2 38189 SPRING-COMPRESSION 2

6-3 64061-37 ROLL PIN-1/8 X 1.00 SS 2

6-4 33288 STUD-DOUBLE ENDED 2

6-5 62464-5A WASHER,THRUST 5/16X3/4 2

6-6 33243 SPACER 2

6-7 2722242 TRACTION LOCK LH 1

* 2722243 TRACTION LOCK RH 1

6-8 64229-02 5/16-18 NYLON LOCKNUT 4

6-9 64229-01 LOCK NUT NYL 1/4-20 2

6-10 2308002 BRG-RADIAL W/THD STUD 2

6-11 64175-01 PUSH NUT 2

6-12 2308080 BEARING SELF ALIGNED 2

6-13 2306083.7 WLDMT SPEED CNTRL RH 1

6-14 64168-2 HAIRPIN COTTER 8

6-15 2308065 SPRING EXTENSION 2

6-16 2721660 WLDMT-PUMP ARM RH 1

* 2721622 WLDMT-PUMP ARM LH 1

6-17 2722305 ROD-SPEED CONTROL 2

6-18 2306084.7 WLDMT SPEED CNTRL LH 1

6-19 64163-06 WSHR.768/.756X1.25X14GA 2

6-20 85010N ZERK, 1/4-28 STR 2

6-21 2721583.2 WLDMT-HYD UPPER HNDL 1

6-22 64061-28 ROLL PIN 3/16 X 1 1/4 2

6-23 2721617.7 WLDMT-SPEED CONTROL 2

6-24 2722269.2 HANDLE-LOWER 1

6-25 64123-50 BOLT, 3/8-16X1 HEX 2

6-26 2306081.7 WLDMT PUMP ARM 2

6-27 * 2308121 ADHESIVE 1

(USE WITH 38009N GRIP)

2721734-07

FIGURE 6

ITEM PART NO. DESCRIPTION QTY

6-48 2308076-02 BEARING-PLASTIC 2

6-49 64192-04 SCREW 5/16-18 2

6-50 2303058 ECCENTRIC SHAFT W/ZRK 2

6-51 64123-02 BLT HEX 3/8-24 X 1 2

6-52 64006-03 LOCKWASHER 3/8 2

6-53 64144-16 SNAP RING 2

6-54 64123-70 BLT-HEX 3/8-16X1-1/2 2

6-55 64141-4 NUT-WLF 3/8-16 4

6-56 64123-69 BOLT-5/16-18X1-1/2 HEX 2

6-57 64163-31 WASHER, 25/64 X 1 X 12 4

TRACTION LOCK ASSY'S ARE ALSO AVAILABLE

4113565 S-TRCTN LOCK ASSY RH 1

(INCLUDES ITEMS 1-4, 6, 7, 9-12)

4113564 S-TRCTN LOCK ASSY LH 1

(INCLUDES ITEMS 1-4, 6, 7, 9-12)

* NOT ILLUSTRATED

6-28 64123-67 BLT-HEX 3/8-16X2 1

6-29 64123-68 BLT-HEX 5/16-18 X 1 2