Textron Bell 412, Bell 412EP Maintenance Manual

BHT-412-MM-1

COPYRIGHT NOTICE

COPYRIGHT

201

BELL

®

HELICOPTER TEXTRON INC.

AND BELL HELICOPTER TEXTRON

CANADA LTD.

ALL RIGHTS RESERVED

The instructions set forth in this manual, as supplemented or modified by Alert Service Bulletins (ASB) or

other directions issued by Bell Helicopter Textron Inc. and Airworthiness Directives (AD) issued by the

applicable regulatory agencies, shall be strictly followed.

Export Classification C, ECCN EAR99

MAINTENANCE MANUAL

VOLUME 1

GENERAL INFORMATION

NOTICE

REISSUE — 23 JUNE 1994

REVISION 27 — 25 SEPTEMBER 2018

BHT-412-MM-1

PROPRIETARY RIGHTS NOTICE

These data are proprietary to Bell Helicopter Textron Inc. Disclosure,

reproduction, or use of these data for any purpose other than helicopter

operation or maintenance is forbidden without prior written authorization from

Bell Helicopter Textron Inc.

DESTINATION CONTROL STATEMENT

WARNING — This document contains technical data whose export is restricted

by the Arms Export Control Act (Title 22, U.S.C., Sec 2751, et. seq.) or the Export

Administration Act of 1979, as amended, Title 50, U.S.C., App. 2401 et. seq.

Violations of these export laws are subject to severe criminal penalties.

Disseminate in accordance with provisions of DoD Directive 5230.25.

Additional copies of this publication may be obtained by contacting:

PN Rev. 16 26 FEB 2013

Commercial Publication Distribution Center

Bell Helicopter Textron Inc.

P. O. Box 482

Fort Worth, Texas 76101-0482

Export Classification C, ECCN EAR99

WARNING

THIS MANUAL APPLIES ONLY TO HELICOPTERS AND COMPONENTS

MAINTAINED IN ACCORDANCE WITH BELL HELICOPTER TEXTRON

(BELL) APPROVED PROCEDURES USING BELL APPROVED PARTS.

ALL INSPECTION, REPAIR AND OVERHAUL PROCEDURES PUBLISHED

BY BELL, INCLUDING PART RETIREMENT LIFE, ARE BASED SOLELY ON

THE USE OF BELL PARTS THAT HAVE BEEN MAINTAINED USING BELL

APPROVED DATA. THE DATA PUBLISHED HEREIN OR OTHERWISE

SUPPLIED BY BELL IS NOT APPLICABLE TO NON-BELL PARTS OR

PARTS THAT HAVE BEEN REPAIRED USING DATA AND/OR PROCESSES

NOT APPROVED BY BELL.

BELL IS NOT RESPONSIBLE FOR ANY PART OTHER THAN THOSE THAT

IT HAS APPROVED.

BEFORE PERFORMING ANY PROCEDURE CONTAINED IN THIS MANUAL

YOU MUST INSPECT THE AFFECTED PARTS AND RECORDS FOR

EVIDENCE OF ANY MANUFACTURE, REPAIR, REWORK OR USE OF A

PROCESS NOT APPROVED BY BELL.

IF YOU IDENTIFY OR SUSPECT THE USE OF PARTS NOT AUTHORIZED

BY BELL, EITHER REMOVE THE AFFECTED ITEM FROM THE AIRCRAFT

OR OBTAIN INSTRUCTIONS FOR CONTINUED AIRWORTHINESS FROM

THE MANUFACTURER OR THE ORGANIZATION THAT APPROVED THE

REPAIR.

BHT-412-MM-1

Export Classification C, ECCN EAR99

26 FEB 2013 Rev. 16 W arning

BHT-412-MM-1

Flying smart means that no matter where you are, or what time it is, you can make a call

and get additional information, clarification, or advice on a technical or operational issue

concerning your helicopter or information contained in our Technical Publications.

Product Support Engineering (PSE) is just a phone call away and may be contacted as

follows:

CUSTOMER SUPPORT AND SERVICES

Model 206, 505, or 407

Phone: 450-437-2862 or 800-363-8023 ( U.S./Canada)

Fax: 450-433-0272

E-mail: productsupport@bellflight.com

Model 222, 230, 427, 429, or 430

Phone: 450-437-2077 or 800-463-3036 ( U.S./Canada)

Fax: 450-433-0272

E-mail: productsupport@bellflight.com

Model 204, 205, 212, or 412

Phone: 450-437-6201 or 800-363-8028 ( U.S./Canada)

Fax: 450-433-0272

E-mail: productsupport@bellflight.com

Model 210, HUEY II, and All Bell’s Active and

Military Medium Helicopter Models

Phone: 817-280-3548

Fax: 817-280-2635

E-mail: mts-medium@bellflight.com

Model OH-58, TH-67, TH-57, Both Active and

Military

Phone: 817-280-3548

Fax: 817-280-2635

E-mail: mts-light@bellflight.com

Surplus

Surplus

For additional information on Customer Suppo rt a nd Ser vices as well as Pr oduct Su pp ort

Engineering (PSE) and your local Customer Service Engineering (CSE) network, please

access http://www.bellflight.com/support-and-service/support.

CSS Rev. 27 25 SEP 2018

Export Classification C, ECCN EAR99

H

ELP

E

VALUATE

L

OGISTICS

P

UBLICATIONS

Have you found something wrong with this manual — an

error, an inconsistency, unclear instructions, etc.? Although

we strive for accuracy and clarity, we may make errors on

occasion. If we do and you discover it, we would appreciate

your telling us about it so that we can change whatever is

incorrect or unclear. Please be as specific as possible.

Your complaint or suggestion will be acknowledged and we

will tell you what we intend to do.

You may use the enclosed Customer Feedback form, as

applicable, to inform us where we have erred.

Your assistance is sincerely appreciated.

Export Classification C, ECCN EAR99

CUSTOMER FEEDBACK

Manual Title:

Manual Number (if assigned):

Date of Issue:

Date of Last Revision:

Section, Chapter, Paragraph Affected:

Your Feedback:

Now Reads:

Should Read:

Your Name:

Address:

Position: Telephone No .:

Comp

any:

Fax No.:

Reference No. (your initials and date):

(If you choose to mail this form, fold in thirds with address exposed, tape and mail.)

Export Classification C, ECCN EAR99

Return by fax to Product Support Engineering (450) 433-0272, e-mail to

publications@bellflight.com, or mail to the address on the next page.

TAPE HERE

From

POSTAGE

NECESSARY

Product Support Engineering

12,800 rue de l’Avenir

Mirabel, Québec, Canada, J7J 1R4

FOLD ON DOTTED LINES AND TAPE

TAPE HERE

Export Classification C, ECCN EAR99

IMPORTANT

HELICOPTER SALES NOTICE

Model of Helicopter Sold or Purchased ___________________________________________

Serial and Registration Number _________________________________________________

Name of New Owner (company or individual) ______________________________________

Name of New Operator _______________________________________________________

Future Publications to be mailed to this address:

Address ____________________________________________________________________

City _______________________________________________________________________

State/Province _______________________________________________________________

Zip/Postal Code _____________________________________________________________

Country ____________________________________________________________________

Fax No. ___________________________ Telephone No. ____________________________

E-mail Address ______________________________________________________________

Please complete this form and return by mail, e-mail (publications@bellflight.com), or fax

(817-280-6466, Attention: CPDC). This will ensure that the new owners/operators receive

updates to their Bell Helicopter Textron Technical Manuals and Bulletins.

Register for access to electronic publications at www.bellflight.com

Export Classification C, ECCN EAR99

TAPE HERE

From

NO POSTAGE

NECESSARY

IF MAILED

IN THE

UNITED STATES

COMMERCIAL PUBLICATION DISTRIBUTION CENTER

P.O. BOX 482

FORT WORTH, TEXAS 76101-0482

FOLD ON DOTTED LINES AND TAPE

BUSINESS REPLY MAIL

FIRST CLASS PERMIT NO. 1744 FORT WORTH, TEXAS

Export Classification C, ECCN EAR99

SPARE PARTS WARRANTY

ONE YEAR/1,000 HOURS PRORATED

WARRANTY AND REMEDY: Seller warrants each new helicopter part or helicopter part reconditioned by seller to be free from defect

in material and workmanship under normal use and service and if installed on Bell model helicopters. Seller’s sole obligation under this

warranty is limited to replacement or repair of parts which are determined to Seller’s reasonable satisfaction to have been defective

with 1,000 hours of operation or one (1) year after installation, whichever occurs first and reimbursement of reasonable freight charges.

After 200 hours of use, there will be a prorated charge to the Purchaser for replacement parts (prorating the hours of total use against

the then applicable part life or 2,000 hours, whichever is the lesser). Defective parts must be reported in writing to the Seller’s Warranty

Administration within 90 days of being found defective. Replacement of parts may be with either new or reconditioned parts, at Seller’s

election. Warranty adjustment is contingent upon the Purchaser complying with the Warranty Remedies as described in the

Commercial Warranty Information brochure and the Seller’s Warranty Administration disposition instructions for defective parts. Failure

to comply with all of the terms of this paragraph may, at Seller’s sole option, void this warranty.

NOTE: Parts, components and assemblies of all new helicopters may have been restored or reworked due to mars, blemishes, dents

or other irregularities during the manufacturing process. Such restoration and/or rework is permitted under Seller’s approved

manufacturing and engineering processes and guidelines. The restoration and/or rework so completed does not render such items

defective in material or workmanship.

THIS WARRANTY IS GIVEN AND ACCEPTED IN PLACE OF (i) ALL OTHER WARRANTIES OR CONDITIONS, EXPRESS OR

IMPLIED, INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES OR CONDITIONS OF MERCHANT ABILITY AND

FITNESS FOR A PARTICULAR PURPOSE AND (ii) ANY OBLIGATION, LIABILITY, RIGHT, CLAIM OR REMEDY IN CONTRACTOR

IN TORT (DELICT), INCLUDING PRODUCT LIABILITIES BASED UPON STRICT LIABILITY, NEGLIGENCE, OR IMPLIED

WARRANTY IN LAW.

This warranty is the only warranty made by Seller. The Purchaser’s sole remedy for a breach of this warranty or any defect in a part is

the repair or replacement of helicopter parts and reimbursement of reasonable freight charges as provided herein. Seller excludes

liability, whether as a result of a breach of contract or warranty, negligence or strict product liability, for incidental or consequential

damages, including without limitation, damage to the helicopter or other property, costs and expenses resulting from required changes

or modifications to helicopter components and assemblies, changes in retirement lives and overhaul periods, local customs fees and

taxes, and costs or expenses for commercial losses or lost profits due to loss of use or grounding of helicopters or otherwise.

Seller makes no warranty and disclaims all liability in contract or in tort (delict), including, without limitation, negligence and strict tort

(delictual) liability, with respect to work performed by third parties at Purchaser’s request and with respect to engines, engine

accessories, batteries, radios, and avionics, except Seller assigns each manufacturer’s warranty to Purchaser to the extent such

manufacturer’s warranty exists and is assignable.

This warranty shall not apply to any helicopter part which has been repaired or altered outside Seller ’s factory in any way so as, in

Seller’s judgment, to affect its stability, safety or reliability, or which has been subject to misuse, negligence or accident, or which has

been installed in any aircraft which has been destroyed unless that helicopter has been rebuilt by Bell. A list of destroyed aircraft is

obtainable from Bell Product Support. Repairs and alterations which use or incorporate parts and components other than genuine Bell

parts or parts approved by Bell for direct acquisition from sources other than Bell itself are not warranted by Bell, and this warranty shall

be void to the extent that such repairs and alterations, in Seller’s sole judgment, affect the stability, safety or reliability of the helicopter

or any part thereof, or damage genuine Bell or Bell-approved parts. No person, corporation or organization, including Bell Customer

Service Facilities, is authorized by Seller to assume for it any other liability in connection with the sale of its helicopters and parts.

NO STATEMENT, WHETHER WRITTEN OR ORAL, MADE BY ANY PERSON, CORPORATION OR ORGANIZATION, INCLUDING

BELL CUSTOMER SERVICE FACILITIES MAY BE TAKEN AS A WARRANTY NOR WILL IT BIND SELLER.

Seller makes no warranty and disclaims all liability with respect to components or parts damaged by, or worn due to, corrosion. Seller

makes no warranty and disclaims all liability for consumables (wear items) which are defined as items required for normal and routine

maintenance or replaced at scheduled intervals shorter than the warranty period. “Consumables” include but are not limited to engine

and hydraulic oil, oil filters, packings and o-rings, anti-corrosion and/or sealing compounds, brush plating material, nuts, bolts, washers,

screws, fluids, compounds, and standard aircraft hardware that is readily available to aircraft operators from sources other than Seller.

All legal actions based upon claims or disputes pertaining to or involving this warranty including, but not limited to, Seller’s denial of any

claim or portion thereof under this warranty, must be filed in the courts of general jurisdiction of Tarrant County, Texas or in the United

States District Court for the Northern District of Texas, Ft. Worth Division located in Ft. Worth, Tarrant County, Texas. In the event that

Purchaser files such an action in either of the court systems identified above, and a final judgment in Seller’s favor is rendered by such

court, then Purchaser shall indemnify Seller for all costs, expenses and attorneys’ fees incurred by Seller in defense of such claims. In

the event Purchaser files such a legal action in a court other than those specified, and Seller successfully obtains dismissal of that

action or transfer thereof to the above described court systems, then Purchaser shall indemnify Seller for all costs, expenses and

attorneys’ fees incurred by Seller in obtaining such dismissal or transfer.

January 2007

BHT-412-MM-1

Export Classification C, ECCN EAR99

26 FEB 2013 Rev. 16 Warranty

FAA APPROVED BHT-412-MM-2

TABLE OF CONTENTS

Paragraph Chapter/Section Page

Number Title Number Number

FIGURES

Figure Page

Number Title Number

TABLES

Table Page

Number Title Number

CHAPTER 4 — AIRWORTHINESS LIMITATIONS SCHEDULE

AIRWORTHINESS LIMITATIONS SCHEDULE

4-1 Airworthiness Limitations Schedule............................................... 4-00-00 5

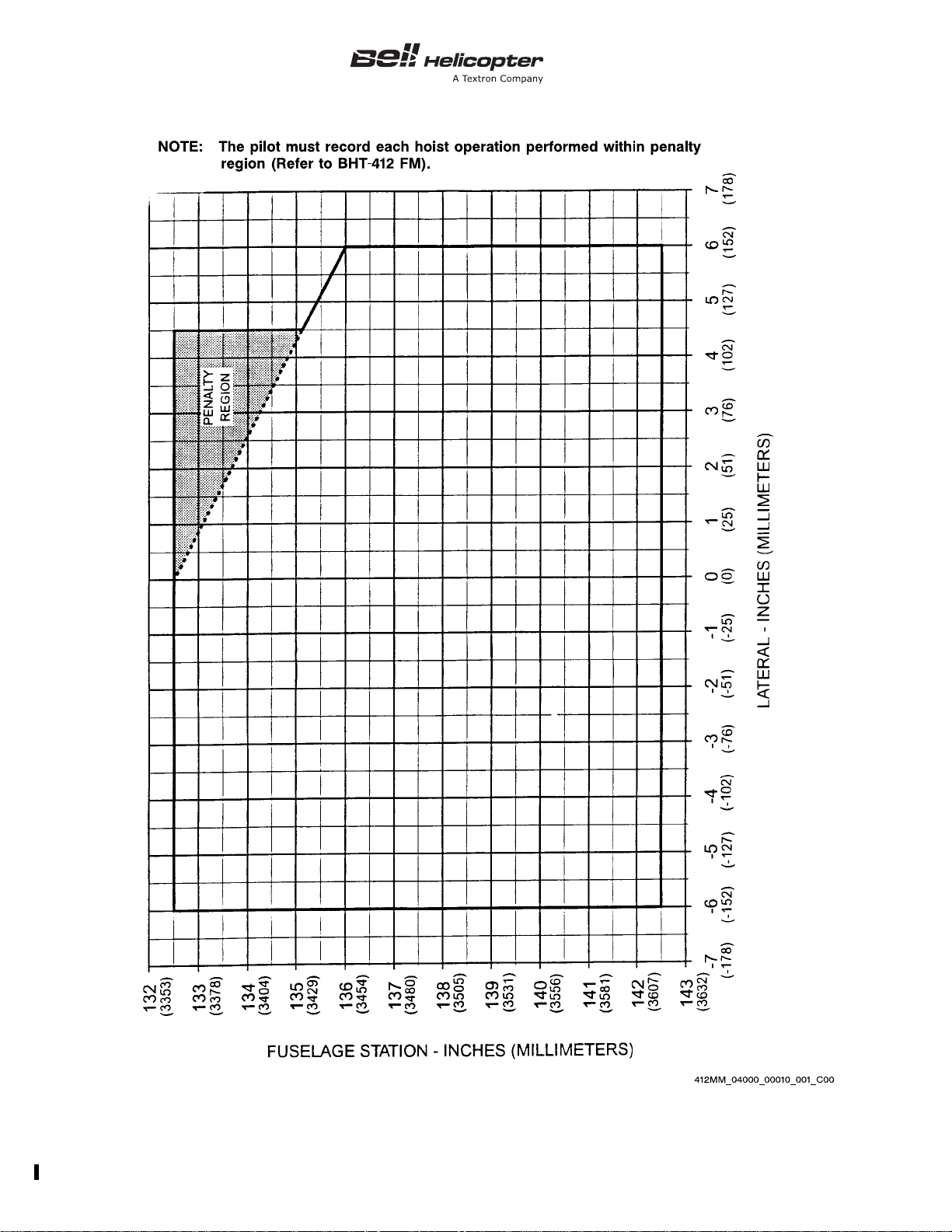

4-1 Longitudinal/Lateral CG Envelope for Hoist Operations ..................................... 16

4-1 Airworthiness Limitations Schedule.................................................................... 6

Export Classification C, ECCN EAR99

15 SEP 2016 Rev. 24 Page 1

4-00-00

BHT-412-MM-2 FAA APPROVED

REVISION

NO.

Original 1 January 1981

1 15 May 1981

2 15 November 1981

3 24 February 1982

4 9 November 1982

5 9 December 1982

6N/A N/A

7 31 March 1983

DATE OF SIGNATURE FAA/ODA* SIGNATURE

8N/A N/A

9N/A N/A

10 20 October 1983

11 N/A N/A

12 N/A N/A

13 N/A N/A

14 30 July 1984

15 N/A N/A

16 19 November 1984

17 N/A N/A

18 3 June 1987

4-00-00

Page 2 Rev. 24 15 SEP 2016

Export Classification C, ECCN EAR99

FAA APPROVED BHT-412-MM-2

REVISION

NO.

Reissue 29 March 1990

1 20 February 1991

2N/A N/A

3N/A N/A

Reissue N/A N/A

1N/A N/A

Reissue 23 June 1994

1 12 April 1995

2N/A N/A

3N/A N/A

DATE OF SIGNATURE FAA/ODA* SIGNATURE

4N/A N/A

5N/A N/A

6 1 October 2002

7N/A N/A

8N/A N/A

9N/A N/A

10 N/A N/A

11 30 March 2007

12 27 February 2009

13 N/A

14 N/A

N/A

N/A

Export Classification C, ECCN EAR99

4-00-00

15 SEP 2016 Rev. 24 Page 3

BHT-412-MM-2 FAA APPROVED

REVISION

NO.

15 1 May 2012

16 N/A N/A

17 26 March 2013

18 N/A N/A

19 N/A N/A

20 N/A N/A

21 N/A N/A

22 N/A N/A

23 N/A N/A

24 15 September 2016

DATE OF SIGNATURE FAA/ODA* SIGNATURE

25 N/A

26 14 June 2018

27 25 SEP 2018

4-00-00

Page 4 Rev. 27 25 SEP 2018

Export Classification C, ECCN EAR99

FAA APPROVED BHT-412-MM-2

WARNING

WARNING

NOTE

AIRWORTHINESS LIMITATIONS SCHEDULE

4-1. AIRWORTHINESS LIMITATIONS

SCHEDULE

The Airworthiness Limitations section is FAA approved

and specifies maintenance required under Secs. 43.16

and [91.403] of the Federal Aviation Regulations

unless an alternative program has been FAA

approved.

ALL REPAIR AND OVERHAUL

PROCEDURES LIVES PUBLISHED BY

BELL HELICOPTER TEXTRON,

INCLUDING COMPONENT RETIREMENT

LIFE, ARE BASED SOLELY ON THE USE

OF BELL APPROVED PARTS AND

PROCESSES. IF PARTS OR

PROCESSES DEVELOPED OR

APPROVED BY PARTIES OTHER THAN

BELL HELICOPTER ARE USED, THEN

THE DATA PUBLISHED OR OTHERWISE

SUPPLIED BY BELL HELICOPTER ARE

NOT APPLICABLE. THE USER IS

WARNED TO NOT RELY ON BELL

HELICOPTER DATA FOR PARTS AND

PROCESSES NOT APPROVED BY BELL

HELICOPTER. ALL APPLICABLE

INSPECTIONS AND REPAIR METHODS

MUST BE OBTAINED FROM THE

SUPPLIER OF THE PARTS OR

PROCESSES NOT APPROVED BY BELL

HELICOPTER. BELL HELICOPTER IS

NOT RESPONSIBLE FOR PARTS OR

PROCESSES OTHER THAN THOSE

WHICH IT HAS ITSELF DEVELOPED OR

APPROVED.

COMPONENT PAST ITS STATED LIMITS

IS NOT PERMITTED AS IT COULD

SERIOUSLY AFFECT THE

AIRWORTHINESS OF THE HELICOPTER.

THE COMPONENT MUST BE REMOVED

FROM THE HELICOPTER NOT LATER

THAN THE END OF THE LIFE LIMIT. IT

MUST EITHER BE MADE

UNSERVICEABLE OR MARKED IN A

CONSPICUOUS MANNER TO PREVENT

CONTINUED USE, EVEN INADVERTENT

USE.

WHEN A REPLACEMENT PART IS

INSTALLED, THE PART NAME, PART

NUMBER, SERIAL NUMBER, AND

CURRENT OPERATING HOURS, IF

APPLICABLE, MUST BE RECORDED IN

THE HISTORICAL SERVICE RECORD

FOR THE ASSEMBLY OR HELICOPTER.

The mandatory airworthiness limitations schedule

(Table 4-1) summarizes the mandatory maximum life,

in hours, years or by Retirement Index Number (RIN)

of components with a limited airworthiness life. Parts

that are not on the schedule have an unlimited

airworthiness life.

Refer to the engine manufacturer's publications for the

airworthiness limitations schedule of the engine and

components. For the PT6T-3 series engine, refer to

the Pratt and Whitney Service Bulletin No. 5002. For

the PT6T-9 Engine, refer to the Pratt and Whitney

Maintenance Manual airworthiness limitation section.

CONTINUED USE OF ANY TIME/

CALENDAR/RIN LIFE LIMITED

Export Classification C, ECCN EAR99

The airworthiness life or inspection interval

for any part number contained in this

schedule applies to all the successive dash

numbers for that component unless it is

otherwise specified.

4-00-00

25 SEP 2018 Rev. 27 Page 5

BHT-412-MM-2 FAA APPROVED

WARNING

CAUTION

NOTE

1

5

7

38

5

33

5

7

22

APPLICABLE SERVICE INSTRUCTION

(SI) OR MAINTENANCE MANUAL

SUPPLEMENT (MMS) FOR KIT

COMPONENTS SCHEDULE.

SOME PARTS ARE INSTALLED AS

ORIGINAL EQUIPMENT ON BOTH

MILITARY AND COMMERCIAL

HELICOPTERS AND MAY HAVE A

LOWER AIRWORTHINESS LIFE AND/OR

OVERHAUL SCHEDULE WHEN USED

ON A MILITARY HELICOPTER. IN

ADDITION, CIRCUMSTANCES

SURROUNDING THEIR USE MAY CALL

FOR OPERATION OF THE MILITARY

The airworthiness life given or the failure to

give an airworthiness life to a component

does not constitute a warranty of any kind.

The only warranty applicable to the

helicopter or any component is the

warranty included in the Purchase

Agreement for the helicopter or the

component.

HELICOPTER OUTSIDE OF THE

APPROVED COMMERCIAL FLIGHT

ENVELOPE. CONSEQUENTLY, PARTS

THAT HAVE BEEN USED ON MILITARY

HELICOPTERS SHOULD NOT BE USED

ON COMMERCIAL HELICOPTERS.

The airworthiness lives given to the components and

assemblies are determined by experience, tests and

the judgement of Bell Helicopter engineers. The

airworthiness lives and inspection intervals cannot be

changed without the approval of the FAA.

Prior to disposing of unsalvageable helicopter parts

and materials, caution should be exercised to ensure

that the parts and materials are disposed of in a

manner that does not allow them to be returned for

AIRWORTHINESS LIFE OF SOME KIT

COMPONENTS MAY NOT BE COVERED

IN THIS SCHEDULE. REFER TO

service. Refer to FAA Advisory Circular 21-38 for

guidance on the disposal of unsalvageable aircraft

parts and materials.

Table 4-1. Airworthiness Limitations Schedule

NOMENCLATURE PART NUMBER AIRWORTHINESS LIFE

MAIN ROTOR HUB

Y oke Assembly 412-010-101-109 700 hours

Y oke Assembly 412-010-101-123 5000 hours

Y oke Assembly 412-010-101-137 4500 hours

Y oke Assembly 412-010-101-139 3000 hours

Spindle Assembly 412-010-156-105 5000 hours

Spindle and Damper Bearing Assembly 412-010-190-101 5000 hours

Spindle and Damper Bearing Assembly 412-010-190-103 10,000 hours

Spindle and Shear Bearing Assembly 412-310-102-101 10,000 hours

4-00-00

Page 6 Rev. 27 25 SEP 2018

Export Classification C, ECCN EAR99

FAA APPROVED BHT-412-MM-2

1

27

224

4

4

2

32

Table 4-1. Airworthiness Limitations Schedule (Cont)

NOMENCLATURE PART NUMBER AIRWORTHINESS LIFE

MAIN ROTOR HUB (CONT)

Pitch Horn Assembly 412-01 0-149-105 5000 hours

Pitch Horn Assembly 412-010-149-111 15,000 hours

Retention Bolt 412-010-124-105 5000 hours

Retention Bolt (Expandable) 412-010-137-103 5000 hours

Damper Bridge 412-010-104-101 5000 hours

Damper Bridge 412-010-183-101 10,000 hours

Damper Bridge 412-010-183-109 15,000 hours

Damper Bridge 412-010-185-101 10,000 hours

Damper Bridge 412-010-185-109 15,000 hours

Damper Bridge 412-018-068-101 10,000 hours or

180 months

Damper Bridge 412-010-170-101 10,000 hours or

180 months

Pivot Bearing 412-010-106-101 On condition

Fitting 412-010-111-101 5000 hours

Damper Yoke Set 412-010-145-101 On condition

Damper Yoke Set 412-310-146-103 On condition

MAIN ROTOR DROOP RESTRAINT

Bolt (8) MS-21250-H05-006 120 months

MAIN ROTOR SIMPLE PENDULUM ABSORBERS

Bolt, Bracket (16) EWB0420D-7-36 15,000 hours

MAIN ROTOR CONTROLS

Rephasing Lever Assembly 412-010-403-109 1250 hours

Rephasing Lever Assembly 412-010-403-113 5000 hours

Drive Link Assembly 412-010-405-101 5000 hours

Swashplate Outer Ring 412-010-407-105 2500 hours

4-00-00

Export Classification C, ECCN EAR99

25 SEP 2018 Rev. 27 Page 7

BHT-412-MM-2 FAA APPROVED

1

24

363537394019282930

282930

2930282930

282930

29

30

Table 4-1. Airworthiness Limitations Schedule (Cont)

NOMENCLATURE PART NUMBER AIRWORTHINESS LIFE

MAIN ROTOR CONTROLS (CONT)

Swashplate Outer Ring 412-010-407-1 17 10,000 hours

Pitch Link Rod End Bearing 412-010-412-101 5000 hours

Pitch Link Rod End Bearing 412-010-438-101 5000 hours

Swashplate Link Rod End Bearing 412-010-412-101 5000 hours

Swashplate Link Rod End Bearing 412-010-448-101 5000 hours

Swashplate Link Rod End Bearing 412-310-400-103 5000 hours

Swashplate Support Assembly 412-010-409-105 5000 hours

Swashplate Support Assembly 412-010-443-101 5000 hours

Swashplate Support Assembly 412-010-453-101 5000 hours

Swashplate Support Assembly 412-010-453-105 15,000 hours

Gimbal Ring Assembly 204-010-404-001 9000 hours

Gimbal Ring Assembly 212-010-416-101 9000 hours

Collective Sleeve 204-011-408-003 9000 hours

Collective Sleeve 212-011-412-101 9000 hours

Collective Lever Assembly 412-010-408-101 10,000 hours

Collective Lever Assembly 412-010-408-105 2500 hours

Collective Lever Assembly 412-010-464-101 20,000 hours

Collective Lever Pin 412-010-465-101 20,000 hours

MAIN ROTOR CONTROL SYSTEM BOLTS

Pitch Horn to Pitch Link (4) 20-057-5-25D 2500 hours

Pitch Horn to Pitch Link (4) 20-057-5-28D 2500 hours

Pitch Link-to-Rephasing Lever (4) 20-057-6-36D 2500 hours

Pitch Link-to-Rephasing Lever (4) 20-057-6-52D 2500 hours

Drive Link-to-Rephasing Lever (4) 20-057-6-36D 2500 hours

Swashplate Link-to-Rephasing Lever (3) 20-057-6-38D 2500 hours

Swashplate Link-to-Rephasing Lever (2) 20-057-6-52D 2500 hours

4-00-00

Page 8 Rev. 27 25 SEP 2018

Export Classification C, ECCN EAR99

FAA APPROVED BHT-412-MM-2

1

282930

282930

252829

30

282930

2829302829

30

282930

2930282930

31

645789

7

810789

Table 4-1. Airworthiness Limitations Schedule (Cont)

NOMENCLATURE PART NUMBER AIRWORTHINESS LIFE

MAIN ROTOR CONTROL SYSTEM BOLTS (CONT)

Swashplate Link-to-Rotating Ring (2) 20-057-6-36D 2500 hours

Gimbal Ring-to-Swashplate Support (2) 204-011-463-105 2500 hours

Gimbal Ring-to-Swashplate Inner

204-011-463-001 1000 hours

Ring (2)

Gimbal Ring-to-Swashplate Inner

204-011-463-109 2500 hours

Ring (2)

Collective Lever-to-Swashplate

20-057-8-92D 2500 hours

Support (1)

Boost Tube-to-Universal (3) 20-057-5-24D 2500 hours

Universal-to-Boost Cylinder (3) 20-057-5-24D 2500 hours

Boost Cylinder-to-Lower Support (3) 212-001-323-001 2500 hours

Rephasing Lever-to-Hub (4) 20-057-6-82D 1250 hours

Rephasing Lever-to-Hub (4) 20-057-8-84D 2500 hours

MAIN ROTOR SUPPLEMENTAL CONTROL SYSTEM BOLTS

Swashplate Inner Ring-to-R.H.

20-057-5-24D 2500 hours

Cyclic Boost (1)

Swashplate Inner Ring-to-L.H.

20-057-5-24D 2500 hours

Cyclic Boost (1)

Collective Lever-to-Collective Boost (1) 20-057-5-24D 2500 hours

PROPULSION AND DRIVE SYSTEM

Planetary Spider 204-040-785-003 On condition

Planetary Spider 412-040-785-101 2500 hours

Planetary Spider 412-040-785-103 On condition

Main Rotor Mast Assembly 412-040-101-105 10,000 hours or

80,000 RIN

Main Rotor Mast Assembly

(used on helicopters with Mast Torque

412-040-101-121 10,000 hours or

60,000 RIN

Systems)

Main Rotor Mast Assembly 412-040-101-127 10,000 hours or

80,000 RIN

4-00-00

Export Classification C, ECCN EAR99

25 SEP 2018 Rev. 27 Page 9

BHT-412-MM-2 FAA APPROVED

1

7

8

10

7

8

14

7

8467

8

144747

47811

12810

Table 4-1. Airworthiness Limitations Schedule (Cont)

NOMENCLATURE PART NUMBER AIRWORTHINESS LIFE

PROPULSION AND DRIVE SYSTEM (CONT)

Main Rotor Mast Assembly

(used on helicopters with Mast Torque

412-040-101-129 10,000 hours or

60,000 RIN

Systems)

Main Rotor Mast Assembly

(used on helicopters with Mast Torque

412-040-101-135 5000 hours or

60,000 RIN

Systems and with BHT-412 -SI-62, Slope

Landing Kit)

Main Rotor Mast Assembly 412-040-114-101 2,500 hours or

25,000 RIN

Main Rotor Mast Assembly

(used on helicopters with Mast Torque

412-704-012-105 5000 hours or

60,000 RIN

Systems and with BHT-412 -SI-62, Slope

Landing Kit)

Cap Retention 412-010-161-101 10,000 hours

Cap Retention 412-010-171-101 10,000 hours

Cap Retention 412-010-171-103 10,000 hours

Mast Cap 412-010-171-105 5,000 hours

Cone 412-010-165-101 10,000 hours

Cone 412-010-165-103 5,000 hours

Drive Pin 412-010-166-101 10,000 hours

Drive Pin 412-010-166-103 5,000 hours

Upper Cone Seat 412-010-164-101 10,000 hours

Upper Cone Seat 412-010-174-101 10,000 hours

Upper Cone Seat 412-010-186-101 10,000 hours

Upper Cone Seat 412-010-186-107 5,000 hours

Upper Cone Seat 412-010-286-101 2,500 hours

Splined Plate Assembly 412-010-177-101 Life limited

(see notes)

Splined Plate Assembly 412-010-177-105 10,000 hours or

60,000 RIN

4-00-00

Page 10 Rev. 27 25 SEP 2018

Export Classification C, ECCN EAR99

FAA APPROVED BHT-412-MM-2

1

8

9

8

14

8108

46

8

111247

777

773

41

17

Table 4-1. Airworthiness Limitations Schedule (Cont)

NOMENCLATURE PART NUMBER AIRWORTHINESS LIFE

PROPULSION AND DRIVE SYSTEM (CONT)

Splined Plate Assembly 412-010-177-109 10,000 hours or

80,000 RIN

Splined Plate Assembly 412-010-177-121 5,000 hours or

60,000 RIN

Splined Plate Assembly 412-010-177-113 10,000 hours or

60,000 RIN

Splined Plate Assembly 412-010-277-101 2,500 hours or

25,000 RIN

Splined Plate Assembly 412-010-167-105 Life limited

(see notes)

Cone 412-010-169-103 10,000 hours

Cone 412-010-179-101 10,000 hours

Cone 412-010-179-105 10,000 hours

Cone 412-010-179-107 5,000 hours

Lower Cone Seat 412-010-168-105 10,000 hours

Lower Cone Seat 412-010-178-101 10,000 hours

Lower Cone Seat 412-010-056-101 2,500 hours

Lower Cone Seat 412-018-056-103 10,000 hours

Lower Cone Seat 412-018-056-109 5,000 hours

ELEV ATOR AND CONTROLS

Horn Assembly 205-001-914-103 On condition

AIRFRAME

Upper Aft Beam Cap 212-030-191-001 On condition

TAIL ROTOR INSTALLATION

Blade Assembly 212-010-750-009 5000 hours

Blade Assembly 412-016-100-1 11 5000 hours

Y oke Assembly 212-011-702-001 5000 hours

4-00-00

Export Classification C, ECCN EAR99

25 SEP 2018 Rev. 27 Page 11

BHT-412-MM-2 FAA APPROVED

1

153442

153442

18344234424344220

2

20

20

202020212121162020

26

20220

Table 4-1. Airworthiness Limitations Schedule (Cont)

NOMENCLATURE PART NUMBER AIRWORTHINESS LIFE

LANDING GEAR

High Aft Crosstube Assembly 412-050-011-101 10,000 events

High Aft Crosstube Assembly 412-050-045-107 20,000 events

High Aft Crosstube Assembly 412-321-104 20,000 events

High Aft Crosstube Assembly 412-321-901 12,000 events

FIRE EXTINGUISHER CARTRIDGES

HTL Industries P/N 13083-5 209-062-908-015 6 years service life/

9 years total life

HTL Industries P/N 30900400 209-062-908-019 6 years service life/

9 years total life

W. Kidde and Co. P/N 804943 209-062-908-013 6 years total life

W. Kidde and Co. P/N 804944 209-062-908-017 6 years total life

W. Kidde and Co. P/N 895408-1 209-062-908-113 10 years total life

W. Kidde and Co. P/N 895409-1 209-062-908-115 10 years total life

FLOATS

Float Hose 70-072M000C144 6 years calendar life

Float Hose 70-072M000C222 6 years calendar life

Float Hose 412-073-800-115A

6 years calendar life

(uses hose P/N

70-072L000B204)

Squib Cartridges, Floats 30908 15 years total life

Squib Cartridges, Floats 29022968 15 years total life

Cylinder Assembly, Floats 212-073-920-107 10 years total life

INTERNAL HOIST KIT

Cable Cutter Assembly (Squib) 1810-033-01 5 years service life/

10 years total life

4-00-00

Page 12 Rev. 27 25 SEP 2018

Export Classification C, ECCN EAR99

FAA APPROVED BHT-412-MM-2

1

234

56789

10

111213

14

Table 4-1. Airworthiness Limitations Schedule (Cont)

NOTES :

The airworthiness life or inspection interval for any part number contained in this schedule applies to all

the successive dash numbers for that component unless it is otherwise specified.

In-service life begins the day the component is entered into service. In-service life only remains in effect

while the component is installed on the helicopter.

Fail safe, refer to Chapter 5 for detailed 100-hour inspection.

On-condition subject to daily or 25-hour visual inspection interval (as applicable) per scheduled

inspections (Chapter 5).

The bushing 412-010-222 is installed on the main rotor yoke assemblies 412-010-101-127/-129/-133

-135/-137/-139. The bushing is assigned an unlimited ai rworthiness life. If removed, it is not reusable.

An on-condition retirement is assigned to spider 204-040-785-003 subject to passing a magnetic particle

inspection every 3100 hours per ASB 412-91-52A.

An additional 4 hours must be logged for each hoist operation performed within penalty CG region

(Figure 4-1). Refer to Chapter 5 and BHT-412-FM.

RIN (Retirement Index Number) is the retirement life based on fatigue damage from normal helicopter lifts

and takeoffs. New components will begin with an accumulated RIN of zero that will be increased as lifts

and takeoffs are performed. Operators mu st record the number of lifts and takeoffs and increase the

accumulated RIN accordingly. When the maximum RIN or retirement flight hours is/are reached,

whichever occurs first, the component will be removed from service. Refer to Information Letter

GEN-94-54/Information Letter GEN-03-94.

Retire when the part has 10,000 flight hours or when the accumulated RIN = 80,000, whichever

occurs first. For manual tracking, increase the RIN count by 1 for each takeoff/lift recorded. If logging,

increase RIN count by 2 for each lift recorded.

Retire when the part has 10,000 flight hours or when the accumulated RIN = 60,000, whichever

occurs first. For manual tracking, increase the RIN count by 1 for each takeoff/lift recorded. If logging,

increase RIN count by 2 for each lift recorded.

This splined plate assembly can be used on all 412 models. When used on 412 HP/EP, it will be

vibroetched “412 HP" and will be retired when part has 10,000 flight hours or when the accumulated

RIN = 60,000, whichever occurs first. For manual tracking, increase the RIN count by 1 for each

takeoff/lift recorded. If logging, increase RIN count by 2 for each lift recorded (see Note 12).

This splined plate assembly can be used on all 412 models. When used on 412/412SP, it will not be

vibroetched "412 HP". Retire when part has 10,000 flight hours or when the accumulated RIN = 80,000,

whichever occurs first. For manual tracking, increase the RIN count by 1 for each takeoff/lift recorded. If

logging, increase RIN count by 2 for each lift recorded (see Note 11).

Deleted.

Retire when the part has 5000 flight hours or when the accumulated RIN = 60,000, whichever occ urs fir st.

For manual tracking, increase the RIN count by 1 for each takeoff/lift recorded. If logging, increase RIN

count by 2 for each lift recorded.

4-00-00

Export Classification C, ECCN EAR99

25 SEP 2018 Rev. 27 Page 13

BHT-412-MM-2 FAA APPROVED

15

161718

192021

22232425262728

29

303132

33

343536

Table 4-1. Airworthiness Limitations Schedule (Cont)

NOTES (CONT):

Per ASB 412-99-97.

Contained in inflation valve 30905. 30908 includes squib 944 55 and o-ring 568-905.

Per ASB 412-96-89, the tail rotor flapping stop/yield indicator 212-011-713-103 must be used with the tail

rotor yoke. The stop/yield indicator 212-011-713-103 must be inspected every 25 hours and at each

incident involving a hard landing, sudden stoppage , or any other incident involving excessive tail rotor

flapping. Refer to Chapter 5.

Manufactured by Aeronautical Accessories, Inc. Refer to AAI Report No. ICA AA-01136 Rev. C, or

subsequent, Inspection and Maintenance Instructions. Recurring visual inspection per

AAI Bulletin AA-07109 and ASB 412-08-129.

As per ASB 412-98-92, bolt 20-057-5-25D is replaced by 20-057-5-28D.

Total life begins from the date of component manufacture and cannot be interrupted.

Calendar life begins the day the component is entered into service and cannot be interrupted.

Not applicable to subsequent dash numbers.

Deleted.

Replacement bearing cartridges 412-310-400-107 are on-condition. Refer to IL 412-IL-03-49.

As per ASB 412-02-110, bolt 204-011-463-001 is replaced by 204-011-463-109.

29022968 contained in valve assembly 20022988 Rev. E and refurbishment kit 29022971.

As per ASB 412-93-73, bolt 412-010-124-105 is replaced by 412-010-124-109.

Included in bolt kit 412-704-112-101. Bolt kit 412-704-112-101 is replaced by bolt kit 412-704-112-105.

Included in bolt kit 412-704-112-103. Bolt kit 412-704-112-103 is replaced by bolt kit 412-704-112-105.

Included in bolt kit 412-704-112-105.

Not included in bolt kits 412-704-112-101/-103/-105.

Life reduction to 2500 hours per ASB 412-08-131; remove from service by 1 June 2009.

Refer to ASB 412-08-128.

Use aft crosstube retention strap kit per BHT-412-SI-58 when towing helicopters with a gross weight of

8900 pounds or greater.

Swashplate support assembly 412-010-443-101 was removed from service by ASB 412-93-71. All

subsequent dash numbers remain in service.

Swashplate support assembly 412-010-409-105 was removed from service by ASB 412-93-71.

4-00-00

Page 14 Rev. 27 25 SEP 2018

Export Classification C, ECCN EAR99

FAA APPROVED BHT-412-MM-2

37

383940

4142434445

46

47

Table 4-1. Airworthiness Limitations Schedule (Cont)

NOTES (CONT):

Swashplate support assembly 412-010-453-101 was removed from service by ASB 412-92-61. All

subsequent dash numbers remain in service.

500-hour penalty to be applied in accordance with AD 99-23-23 and ASB412-98-93.

AD 2012-22-11 imposes on collective lever 412-010-408-101 a visual inspection at in tervals not to excee d

100 hours Time-In-Service (TIS) (ASB 412-11-148 Rev. A).

Visual inspection at intervals not to exceed 100 hours Time-In-Service (TIS). Inspection requirements

same as listed in ASB 412-11-148 Rev. A.

AD 2000-18-09 imposes on the upper aft beam cap 212-030-191-001 a recurring visual inspection at

intervals not to exceed 100 hours Time-In-Service (TIS) (ASB 412-00-100). All aircraft with serial

numbers 38001–38999 and 39101–39999 require a visual inspection in intervals not to exceed

9 hours Time-In-Service (TIS), in accordance with AD 2000-18-09 pr ocedures.

For manual tracking, increase the event count by 1 for each takeoff r ecorded.

Part manufactured and part number assigned by AAI of Bristol, Tennessee. Retire part when event =

12,000 (event life).

1000-event penalty to be applied against accumulated events of high aft crosstube assembly if used with

increased gross weight kit 412-706-140 (BHT-412-FMS-74.5). 1000 event penalty to be applied on high

aft crosstube assembly 412-321-901 on all aircraft serial numbers 38001–38999 and 39101–39999.

On Condition indicates that there is no retirement life (i.e., unlimited). Any required inspections will be

addressed by additional specific notes.

Retire when the part has 2,500 flight hours or when the accumulated RIN is 25,000, whichever occurs

first. For manual tracking, increase the RIN count by 1 for each takeoff/lift recorded. If logging,

increase RIN count by 2 for each lift recorded.

Apply a one time 7,500 hours penalty for all aircraft with serial numbers 38001–38999 and 39101–39999

on retention cap, cones, and drive pins.

4-00-00

Export Classification C, ECCN EAR99

25 SEP 2018 Rev. 27 Page 15

BHT-412-MM-2 FAA APPROVED

Figure 4-1. Longitudinal/Lateral CG Envelope for Hoist Operations

4-00-00

Page 16 Rev. 24 15 SEP 2016

Export Classification C, ECCN EAR99

BHT-412-MM-2

TABLE OF CONTENTS

Paragraph Chapter/Section Page

Number Title Number Number

CHAPTER 5 — INSPECTIONS

INSPECTIONS

5-1 General.......................................................................................... 5-00-00 3

5-2 Inspection Requirements............................................................... 5-00-00 4

5-3 Crash Damage............................................................................... 5-00-00 4

5-3A Types of Inspections.......................................... ... ... ... .... ... ... ... ... ... 5-00-00 4

5-3B Definitions...................................................................................... 5-00-00 5

5-3C Inspection and Overhaul Tolerance................... ... ......................... 5-00-00 6

SCHEDULED INSPECTIONS

5-4 Scheduled Inspections................................................................... 5-00-00 7

5-5 Daily Inspection — Part A.............................................................. 5-00-00 9

5-6 100 Hour/12 Month Inspection — Part A.................... .... ... ... ... ... ... 5-00-00 27

5-7 1000 Hour Inspection — Part A ..................................................... 5-00-00 49

5-8 5000 Hour/5 Year Inspection — Part A.......................................... 5-00-00 51

5-9 25 Hour/30 Day Inspection — Part B............................................. 5-00-00 57

5-10 300 Hour/12 Month Inspection — Part B................. ... .... ... ... ... ... ... 5-00-00 79

5-11 600 Hour/12 Month Inspection — Part B................. ... .... ... ... ... ... ... 5-00-00 93

5-12 5000 Hour/5 Year Inspection — Part B.......................................... 5-00-00 101

SPECIAL INSPECTIONS

5-13 Special Inspection.......................................................................... 5-00-00 107

5-14 Daily/10 Hour Inspection, Whichever Occurs First

Until 250 Hours.............................................................................. 5-00-00 109

5-15 Between 1 and 5 Flight Hours After Main Rotor Hub Installation... 5-00-00 113

5-15A Between 1 and 25 Flight Hours After Expandable Blade Bolt

Installation...................................................................................... 5-00-00 114A

5-16 Between 5 and 10 Hours of Flight After Each Installation.............. 5-00-00 115

5-17 Each 25 Hours for the Next Four Inspections................................ 5-00-00 117

5-18 Each 25 Hours of Tail Rotor Operation.......................................... 5-00-00 119

5-19 50 Hours After Installation of Components .................................... 5-00-00 123

5-20 100 Hours After Installation of Tailboom........................................ 5-00-00 125

5-21 Each 100 Hours of Collective Lever Operation ............................. 5-00-00 127

5-22 Each 150 Hours of Starter Generator (200SG119Q) Operation.... 5-00-00 131

5-22A Each 300 Hours or 6 Months of Expandable Blade Bolt

Operation....................................................................................... 5-00-00 132A

5-23 Each 600 Hours of Tail Rotor Driveshaft Operation or 12 Months 5-00-00 133

5-24 Each 600 Hours of Main Driveshaft Operation or 12 Months ........ 5-00-00 136

5-25 Each 1000 Hours of Component Operation................................... 5-00-00 138

5-26 Each 12 Months or 2500 Landings of Aft High Crosstube

Operation....................................................................................... 5-00-00 140

5-27 Each 24 Months of Control Bolt Operation .................................... 5-00-00 148

5-27A Each 24 Months of Main Rotor Mast Operation............................. 5-00-00 150A

5-28 Each 2500 Hours of Main Rotor Hub Assembly Operation............ 5-00-00 151

Export Classification C, ECCN EAR99

01 JUN 2018 Rev. 26 Page 1

5-00-00

BHT-412-MM-2

TABLE OF CONTENTS (CONT)

Paragraph Chapter/Section Page

Number Title Number Number

FIGURES

Figure Page

Number Title Number

5-29 Each 2500 Hours of Main Rotor Blade Operation.......................... 5-00-00 153

5-30 Each 2500 or 3000 Hours of Main Rotor Mast (4 12 - 04 0- 3 66 -1 09

and Subsequent) Operation........................................................... 5-00-00 155

5-31 Each 2500 Hours of Tail Rotor Drive System Operation ............... 5-00-00 159

5-32 Each 3000 Hours of Main Rotor Mast

(412-040-366-103 and -105) Operation ........................................ 5-00-00 169

5-33 Each 3000 Hours of Transmission (412-040-002) Operation.. ...... 5-00-00 173

5-34 Each 3000 Hours of Transmission (412-040-004) Operation.. ...... 5-00-00 177

5-35 3600 Hours Total Airframe Time and Each 300 Hours/12 Months

Inspection....................................................................................... 5-00-00 185

CONDITIONAL INSPECTIONS

5-36 Conditional Inspection.................................................................... 5-00-00 187

5-37 After Hard Landing......................................................................... 5-00-00 189

5-38 Sudden Stoppage — Power On or Off .......................................... 5-00-00 195

5-39 After Overspeed............................................................................. 5-00-00 203

5-40 After Overtorque ............................................................................ 5-00-00 207

5-41 After Compressor Stall or Surge.................................................... 5-00-00 213

5-42 After Lightning Strikes.................................................................... 5-00-00 219

5-43 After Engine Combining Gearbox Clutch Non-engagement,

Misengagement, or In-flight Slippage ............................................ 5-00-00 225

COMPONENT OVERHAUL SCHEDULE

5-44 Component Overhaul Schedule..................................................... 5-00-00 233

5-1 Collective Stick Tube — Part A........................................................................... 59

5-1A Cabin Frame Inspection — Part A ...................................................................... 60

5-2 Collective Stick Tube — Part B........................................................................... 109

5-2A Cabin Frame Inspection — Part B ...................................................................... 110

5-3 Tail Rotor Blade — Special Inspection ............................................................... 121

5-4 Collective Lever — Special Inspection................................................................ 129

5-4A Expandable Blade Bolt — Special Inspection..................................................... 136

5-5 Aft High Crosstube — Special Inspection........................................................... 146

5-6 Fuselage Tailboom Attachment Inspection......................................................... 229

5-7 Spiral Bevel Gear Inspection .............................................................................. 230

5-00-00

Page 2 Rev. 26 01 JUN 2018

Export Classification C, ECCN EAR99

Loading...

Loading...