Textron Bell 212 Maintenance Manual

BHT-212-MM-1

COPYRIGHT NOTICE

COPYRIGHT

201

BELL

®

HELICOPTER TEXTRON INC.

AND BELL HELICOPTER TEXTRON

CANADA LTD.

ALL RIGHTS RESERVED

The instructions set forth in this manual, as supplemented or modified by Alert Service Bulletins (ASB) or

other directions issued by Bell Helicopter Textron Inc. and Airworthiness Directives (AD) issued by the

applicable regulatory agencies, shall be strictly followed.

Export Classification C, ECCN 9E991

MAINTENANCE MANUAL

VOLUME 1

GENERAL INFORMATION

NOTICE

REISSUE — 7 JUNE 1993

REVISION 16 — 15 NOVEMBER 2018

BHT-212-MM-1

PROPRIETARY RIGHTS NOTICE

These data are proprietary to Bell Helicopter Textron Inc. Disclosure,

reproduction, or use of these data for any purpose other than helicopter

operation or maintenance is forbidden without prior written authorization from

Bell Helicopter Textron Inc.

DESTINATION CONTROL STATEMENT

WARNING — This document contains technical data whose export is restricted

by the Arms Export Control Act (Title 22, U.S.C., Sec 2751, et. seq.) or the Export

Administration Act of 1979, as amended, Title 50, U.S.C., App. 2401 et. seq.

Violations of these export laws are subject to severe criminal penalties.

Disseminate in accordance with provisions of DoD Directive 5230.25.

Additional copies of this publication may be obtained by contacting:

PN Rev. 15 29 NOV 2013

Commercial Publication Distribution Center

Bell Helicopter Textron Inc.

P. O. Box 482

Fort Worth, Texas 76101-0482

Export Classification C, ECCN 9E991

WARNING

THIS MANUAL APPLIES ONLY TO HELICOPTERS AND COMPONENTS

MAINTAINED IN ACCORDANCE WITH BELL HELICOPTER TEXTRON

(BELL) APPROVED PROCEDURES USING BELL APPROVED PARTS.

ALL INSPECTION, REPAIR AND OVERHAUL PROCEDURES PUBLISHED

BY BELL, INCLUDING PART RETIREMENT LIFE, ARE BASED SOLELY ON

THE USE OF BELL PARTS THAT HAVE BEEN MAINTAINED USING BELL

APPROVED DATA. THE DATA PUBLISHED HEREIN OR OTHERWISE

SUPPLIED BY BELL IS NOT APPLICABLE TO NON-BELL PARTS OR

PARTS THAT HAVE BEEN REPAIRED USING DATA AND/OR PROCESSES

NOT APPROVED BY BELL.

BELL IS NOT RESPONSIBLE FOR ANY PART OTHER THAN THOSE THAT

IT HAS APPROVED.

BEFORE PERFORMING ANY PROCEDURE CONTAINED IN THIS MANUAL

YOU MUST INSPECT THE AFFECTED PARTS AND RECORDS FOR

EVIDENCE OF ANY MANUFACTURE, REPAIR, REWORK OR USE OF A

PROCESS NOT APPROVED BY BELL.

IF YOU IDENTIFY OR SUSPECT THE USE OF PARTS NOT AUTHORIZED

BY BELL, EITHER REMOVE THE AFFECTED ITEM FROM THE AIRCRAFT

OR OBTAIN INSTRUCTIONS FOR CONTINUED AIRWORTHINESS FROM

THE MANUFACTURER OR THE ORGANIZATION THAT APPROVED THE

REPAIR.

BHT-212-MM-1

Export Classification C, ECCN EAR99

26 JUN 2013 Rev. 14 Warning

BHT-212-MM-1

Flying smart means that no matter where you are, or what time it is, you can make a call

and get additional information, clarification, or advice on a technical or operational issue

concerning your helicopter or information contained in our Technical Publications.

Product Support Engineering (PSE) is just a phone call away and may be contacted as

follows:

CUSTOMER SUPPORT AND SERVICES

Model 206, 407 or 505

Phone: 450-437-2862 or 800-243-6407 ( U.S./Canada)

Fax: 450-433-0272

E-mail: productsupport@bellflight.com

Model 222, 230, 427, 429, or 430

Phone: 450-437-2077 or 800-463-3036 ( U.S./Canada)

Fax: 450-433-0272

E-mail: productsupport@bellflight.com

Model 204, 205, 212, or 412

Phone: 450-437-6201 or 800-363-8028 ( U.S./Canada)

Fax: 450-433-0272

E-mail: productsupport@bellflight.com

Model 214, 210, HUEY II and All Bell’s Active and

Surplus Military Medium Helicopter Models

Phone: 817-280-3548

Fax: 817-280-2635

E-mail: mts-medium@bellflight.com

Model OH-58, TH-67, TH-57, Both Active and

Military

Phone: 817-280-3548

Fax: 817-280-2635

E-mail: mts-light@bellflight.com

Surplus

For additional information on Customer Suppo rt a nd Ser vices as well as Pr oduct Su pp ort

Engineering (PSE) and your local Customer Service Engineering (CSE) network, please

access http://www.bellflight.com/support-and-service/support.

CSS Rev. 16 15 NOV 2018 Export Classification C, ECCN EAR99

H

ELP

E

VALUATE

L

OGISTICS

P

UBLICATIONS

Have you found something wrong with this manual — an

error, an inconsistency, unclear instructions, etc.? Although

we strive for accuracy and clarity, we may make errors on

occasion. If we do and you discover it, we would appreciate

your telling us about it so that we can change whatever is

incorrect or unclear. Please be as specific as possible.

Your complaint or suggestion will be acknowledged and we

will tell you what we intend to do.

You may use the enclosed Customer Feedback form, as

applicable, to inform us where we have erred.

Your assistance is sincerely appreciated.

Export Classification C, ECCN EAR99

CUSTOMER FEEDBACK

Manual Title:

Manual Number (if assigned):

Date of Issue:

Date of Last Revision:

Section, Chapter, Paragraph Affected:

Your Feedback:

Now Reads:

Should Read:

Your Name:

Address:

Position: Telephone No .:

Comp

any:

Fax No.:

Reference No. (your initials and date):

(If you choose to mail this form, fold in thirds with address exposed, tape and mail.)

Export Classification C, ECCN EAR99

Return by fax to Product Support Engineering (450) 433-0272, e-mail to

publications@bellflight.com, or mail to the address on the next page.

TAPE HERE

From

POSTAGE

NECESSARY

Product Support Engineering

12,800 rue de l’Avenir

Mirabel, Québec, Canada, J7J 1R4

FOLD ON DOTTED LINES AND TAPE

TAPE HERE

Export Classification C, ECCN EAR99

IMPORTANT

HELICOPTER SALES NOTICE

Model of Helicopter Sold or Purchased ___________________________________________

Serial and Registration Number _________________________________________________

Name of New Owner (company or individual) ______________________________________

Name of New Operator _______________________________________________________

Future Publications to be mailed to this address:

Address ____________________________________________________________________

City _______________________________________________________________________

State/Province _______________________________________________________________

Zip/Postal Code _____________________________________________________________

Country ____________________________________________________________________

Fax No. ___________________________ Telephone No. ____________________________

E-mail Address ______________________________________________________________

Please complete this form and return by mail, e-mail (publications@bellflight.com), or fax

(817-280-6466, Attention: CPDC). This will ensure that the new owners/operators receive

updates to their Bell Helicopter Textron Technical Manuals and Bulletins.

Register for access to electronic publications at www.bellflight.com

Export Classification C, ECCN EAR99

TAPE HERE

From

NO POSTAGE

NECESSARY

IF MAILED

IN THE

UNITED STATES

COMMERCIAL PUBLICATION DISTRIBUTION CENTER

P.O. BOX 482

FORT WORTH, TEXAS 76101-0482

FOLD ON DOTTED LINES AND TAPE

BUSINESS REPLY MAIL

FIRST CLASS PERMIT NO. 1744 FORT WORTH, TEXAS

Export Classification C, ECCN EAR99

SPARE PARTS WARRANTY

ONE YEAR/1,000 HOURS PRORATED

WARRANTY AND REMEDY: Seller warrants each new helicopter part or helicopter part reconditioned by seller to be free from defect

in material and workmanship under normal use and service and if installed on Bell model helicopters. Seller’s sole obligation under this

warranty is limited to replacement or repair of parts which are determined to Seller’s reasonable satisfaction to have been defective

with 1,000 hours of operation or one (1) year after installation, whichever occurs first and reimbursement of reasonable freight charges.

After 200 hours of use, there will be a prorated charge to the Purchaser for replacement parts (prorating the hours of total use against

the then applicable part life or 2,000 hours, whichever is the lesser). Defective parts must be reported in writing to the Seller’s Warranty

Administration within 90 days of being found defective. Replacement of parts may be with either new or reconditioned parts, at Seller’s

election. Warranty adjustment is contingent upon the Purchaser complying with the Warranty Remedies as described in the

Commercial Warranty Information brochure and the Seller’s Warranty Administration disposition instructions for defective parts. Failure

to comply with all of the terms of this paragraph may, at Seller’s sole option, void this warranty.

NOTE: Parts, components and assemblies of all new helicopters may have been restored or reworked due to mars, blemishes, dents

or other irregularities during the manufacturing process. Such restoration and/or rework is permitted under Seller’s approved

manufacturing and engineering processes and guidelines. The restoration and/or rework so completed does not render such items

defective in material or workmanship.

THIS WARRANTY IS GIVEN AND ACCEPTED IN PLACE OF (i) ALL OTHER WARRANTIES OR CONDITIONS, EXPRESS OR

IMPLIED, INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES OR CONDITIONS OF MERCHANT ABILITY AND

FITNESS FOR A PARTICULAR PURPOSE AND (ii) ANY OBLIGATION, LIABILITY, RIGHT, CLAIM OR REMEDY IN CONTRACTOR

IN TORT (DELICT), INCLUDING PRODUCT LIABILITIES BASED UPON STRICT LIABILITY, NEGLIGENCE, OR IMPLIED

WARRANTY IN LAW.

This warranty is the only warranty made by Seller. The Purchaser’s sole remedy for a breach of this warranty or any defect in a part is

the repair or replacement of helicopter parts and reimbursement of reasonable freight charges as provided herein. Seller excludes

liability, whether as a result of a breach of contract or warranty, negligence or strict product liability, for incidental or consequential

damages, including without limitation, damage to the helicopter or other property, costs and expenses resulting from required changes

or modifications to helicopter components and assemblies, changes in retirement lives and overhaul periods, local customs fees and

taxes, and costs or expenses for commercial losses or lost profits due to loss of use or grounding of helicopters or otherwise.

Seller makes no warranty and disclaims all liability in contract or in tort (delict), including, without limitation, negligence and strict tort

(delictual) liability, with respect to work performed by third parties at Purchaser’s request and with respect to engines, engine

accessories, batteries, radios, and avionics, except Seller assigns each manufacturer’s warranty to Purchaser to the extent such

manufacturer’s warranty exists and is assignable.

This warranty shall not apply to any helicopter part which has been repaired or altered outside Seller ’s factory in any way so as, in

Seller’s judgment, to affect its stability, safety or reliability, or which has been subject to misuse, negligence or accident, or which has

been installed in any aircraft which has been destroyed unless that helicopter has been rebuilt by Bell. A list of destroyed aircraft is

obtainable from Bell Product Support. Repairs and alterations which use or incorporate parts and components other than genuine Bell

parts or parts approved by Bell for direct acquisition from sources other than Bell itself are not warranted by Bell, and this warranty shall

be void to the extent that such repairs and alterations, in Seller’s sole judgment, affect the stability, safety or reliability of the helicopter

or any part thereof, or damage genuine Bell or Bell-approved parts. No person, corporation or organization, including Bell Customer

Service Facilities, is authorized by Seller to assume for it any other liability in connection with the sale of its helicopters and parts.

NO STATEMENT, WHETHER WRITTEN OR ORAL, MADE BY ANY PERSON, CORPORATION OR ORGANIZATION, INCLUDING

BELL CUSTOMER SERVICE FACILITIES MAY BE TAKEN AS A WARRANTY NOR WILL IT BIND SELLER.

Seller makes no warranty and disclaims all liability with respect to components or parts damaged by, or worn due to, corrosion. Seller

makes no warranty and disclaims all liability for consumables (wear items) which are defined as items required for normal and routine

maintenance or replaced at scheduled intervals shorter than the warranty period. “Consumables” include but are not limited to engine

and hydraulic oil, oil filters, packings and o-rings, anti-corrosion and/or sealing compounds, brush plating material, nuts, bolts, washers,

screws, fluids, compounds, and standard aircraft hardware that is readily available to aircraft operators from sources other than Seller.

All legal actions based upon claims or disputes pertaining to or involving this warranty including, but not limited to, Seller’s denial of any

claim or portion thereof under this warranty, must be filed in the courts of general jurisdiction of Tarrant County, Texas or in the United

States District Court for the Northern District of Texas, Ft. Worth Division located in Ft. Worth, Tarrant County, Texas. In the event that

Purchaser files such an action in either of the court systems identified above, and a final judgment in Seller’s favor is rendered by such

court, then Purchaser shall indemnify Seller for all costs, expenses and attorneys’ fees incurred by Seller in defense of such claims. In

the event Purchaser files such a legal action in a court other than those specified, and Seller successfully obtains dismissal of that

action or transfer thereof to the above described court systems, then Purchaser shall indemnify Seller for all costs, expenses and

attorneys’ fees incurred by Seller in obtaining such dismissal or transfer.

January 2007

BHT-212-MM-1

Export Classification C, ECCN EAR99

26 JUN 2013 Rev. 14 Warranty

BHT-212-MM-1

TABLE OF CONTENTS

Paragraph Chapter/Section Page

Number Title Number Number

CHAPTER 5 — INSPECTIONS

INSPECTIONS

5-1 General.......................................................................................... 5-00-00 5

5-2 Inspection Requirements............................................................... 5-00-00 6

5-3 Crash Damage............................................................................... 5-00-00 6

5-4 Types of Inspections...................................... .... ............................ 5-00-00 6

5-5 Definitions...................................................................................... 5-00-00 7

5-6 Inspection and Overhaul Tolerance............................................... 5-00-00 8

SCHEDULED INSPECTIONS

5-7 Scheduled inspections................................................................... 5-00-00 11

5-8 Daily Inspection — Part A.............................................................. 5-00-00 13

5-9 100 Hours/12 Calendar Months — Part A ..................................... 5-00-00 29

5-10 1000 Hours — Part A..................................................................... 5-00-00 53

5-11 3000 Hours/5 Years — Part A ....................................................... 5-00-00 55

5-12 25 Hours/30 Days — Part B........................................................... 5-00-00 61

5-13 300 Hours — Part B....................................................................... 5-00-00 79

5-14 600 Hours/12 Months — Part B..................................................... 5-00-00 91

5-15 3000 Hours/ 5 Years — Part B ...................................................... 5-00-00 99

SPECIAL INSPECTIONS

5-16 Special Inspection.......................................................................... 5-00-00 105

5-17 Daily Inspection.............................................................................. 5-00-00 107

5-18 Daily or Each 10 Hours of Flight Operation, Whichever Occurs

First Until 250 Hours...................................................................... 5-00-00 109

5-19 Between 5 and 10 Hours of Flight AFter Each Installation ............ 5-00-00 115

5-20 Fin Spar Cap Inspection Every 8 Hours......................................... 5-00-00 117

5-21 Each 25 Hours for the next Four Inspections................................. 5-00-00 119

5-22 Each 25 Hours of Flight Operation................................................. 5-00-00 121

5-23 Each7DaysinaCorrosiveEnvironment and Each 30 Days in a

Noncorrosive Environment............................................................. 5-00-00 127

5-24 50 Hours After Installation of Components .................................... 5-00-00 129

5-25 Each 50 Hours of Component Operation....................................... 5-00-00 131

5-26 Each 100 Hours of Main Rotor Blade Operation — Deleted. ......... 5-00-00 133

5-27 Each 100 Hours/12 Months of Transmission Operation............. ... 5-00-00 135

5-28 Each 100 Hours/12 Months of Intermediate Gearbox Operation... 5-00-00 137

5-29 Each 100 Hours/12 Months of Tail Rotor Gearbox Operation....... 5-00-00 139

5-30 Each 100 Hours/12 Months of Battery System Operation............. 5-00-00 141

5-31 100 Hours After Installation of Tailboom........................................ 5-00-00 143

5-32 Each 150 Hours of Starter Generator P/N 200SG119Q

Operation....................................................................................... 5-00-00 145

5-33 Fin Spar Cap Inspection Every 300 Hours..................................... 5-00-00 147

5-34 Each 300 Hours/12 Months of Transmission Operation............. ... 5-00-00 149

26 JUN 2013 Rev. 14 Page 1Export Classification C, ECCN EAR99

5-00-00

BHT-212-MM-1

TABLE OF CONTENTS (CONT)

Paragraph Chapter/Section Page

Number Title Number Number

5-35 Each 300 Hours/3 Months of Driveshaft Operation ....................... 5-00-00 151

5-35A Each 300 Hours/12 Months Inspection of Tail Rotor

Control Tube and Bearing.............................................................. 5-00-00 152A

5-36 Main Rotor Grip Ultrasonic Inspection........................................... 5-00-00 153

5-37 Each 500 Hours/6 Months of Blade Service .................................. 5-00-00 155

5-38 Each 600 Hours of Transmission Operation.................................. 5-00-00 157

5-39 600 Hours/6 Months of Tail Rotor Driveshaft Coupling

Operation....................................................................................... 5-00-00 159

5-40 600 Hours/12 Months of Main Driveshaft Operation...................... 5-00-00 161

5-40A Each 600 Hours/12 Months Inspection of Magnetic Brake

Assembly ....................................................................................... 5-00-00 162A

5-40B Each 600 Hours/12 Months Inspection of Fire Extinguisher

Discharge Tubes............................................................................ 5-00-00 162C

5-41 Each 1000 Hours of Component Operation .................................. 5-00-00 163

5-42 First 1000 Hours of Component Time and Each 3000 Hours

Thereafter of Component Time...................................................... 5-00-00 165

5-43 Each 1000 Hours/12 Months of Main Rotor Blade Operation........ 5-00-00 169

5-44 Each 1200 Hours/24 Months of Component Operation................. 5-00-00 171

5-45 Each 1200 Hours of Main Rotor Hub Pin Operation — Deleted.... 5-00-00 175

5-45A Every 12 months/2500 Landings High Forward Crosstube

Deflection Check...................................... ... ................................... 5-00-00 176A

5-45B Every 12 months/5000 Landings High Forward Crosstube

Fluorescent Penetrant Inspection.................................................. 5-00-00 176C

5-46 Each 24 Months of Flight Control System Bolt Operation........ .... .. 5-00-00 177

5-47 Each 3000 Hours of Component Operation................................... 5-00-00 181

5-48 10,000 Hour Total Airframe Time and Each 300 Hours/12 Months

Main Beam Cap Operation ............................................................ 5-00-00 187

CONDITIONAL INSPECTIONS

5-49 Condition Inspection ...................................................................... 5-00-00 189

5-50 After Hard Landing......................................................................... 5-00-00 191

5-51 After Blade Strike or Other Rotating System Torque Spike........... 5-00-00 197

5-52 After Overspeed............................................................................. 5-00-00 205

5-53 After Overtorque ............................................................................ 5-00-00 209

5-54 After Engine Compressor Stall or Surge........................................ 5-00-00 213

5-55 After Lightning Strikes.................................................................... 5-00-00 219

5-56 After Engine Combining Gearbox Clutch Nonengagement,

Misengagement, or In-flight Slippage ............................................ 5-00-00 227

COMPONENT OVERHAUL SCHEDULE

5-57 Component Overhaul Schedule..................................................... 5-00-00 231

5-00-00

Page 2 Rev. 16 15 NOV 2018 Export Classification C, ECCN EAR99

BHT-212-MM-1

FIGURES

Figure Page

Number Title Number

TABLES

Table Page

Number Title Number

5-1 Fuselage Tailboom Attachment Inspection......................................................... 50

5-2 Inspection of Beam Caps.................................................................................... 51

5-3 Collective Stick Tube .......................................................................................... 104

5-4 Inspection of Main Rotor Hub Grip Tangs, Barrel and Drag Brace Attachment

Lugs.................................................................................................................... 108

5-5 Spiral Bevel Gears Serial Numbers.................................................................... 111

5-6 Inspection of Spiral Bevel Gear ............................................................ ... .... ... ... . 112

5-6A Tail Rotor Blade - Detailed Inspection ................................................................ 126B

5-7 Inspection of Main Rotor Hub Grip (1200 Hours/24 Months)................... .... ... .... 174

5-1 Component Overhaul Schedule.......................................................................... 231

Export Classification C, ECCN EAR99

15 NOV 2018 Rev. 16 Page 3/4

5-00-00

INSPECTIONS

WARNING

NOTE

BHT-212-MM-1

5-1. GENERAL

This chapter contains the requirements for the

Scheduled, Special, and Conditional Inspections and a

Component Overhaul Schedule.

FAILURE TO CORRECT CONDITIONS

SUCH AS, BUT NOT LIMITED TO,

CORROSION, EROSION, MECHANICAL

DAMAGE, OR OBVIOUS WEAR FOUND

DURING A SCHEDULED INSPECTION

COULD SERIOUSLY AFFECT THE

AIRWORTHINESS OF THE HELICOPTER.

These inspection requirements constitute an approved

inspection program for the Bell H elicopter Model 212.

For the convenience of the operator, two separate

Scheduled Inspections are provided as follows:

Part A scheduled inspections consists of a daily

inspection, 100 hour/12 calendar month inspection,

1000 hour inspection, and a 3000 hour/5 year

inspection.

Part B scheduled inspections consists of a 25 hour/

30 day inspection, 300 hour inspection, 600 hour/

12 month inspection, and a 3000 hour/5 year

inspection.

Either Part A or Part B inspection program may be

utilized. However, once a helicopter has been started

on an inspection program, it shall be maintained on

that program except as follows:

The helicopter may then be changed to the Part A

inspection program beginning with a Daily

Inspection.

The inspection intervals given in this chapter are the

maximum permitted. Do not exceed these intervals.

The owner/operator is responsible for increasing the

scope and the frequency of the inspections as

necessary. Make sure the helicopter is maintained

safely during all unusual local changes, such as

environmental conditions, helicopter use, etc. You can

request changes to the requirements in this chapter

through the local Aviation Authority.

The inspection intervals and the component overhaul

schedule provided in this chapter a re applicable only

to Bell Helicopter Textron approved parts.

The time period given for the overhaul of a

component (or the failure to give a time

period for the overhaul of a component)

does not constitute a warranty of any kind.

The only warranty applicable to the

helicopter or any component is the

warranty included in the Purchase

Agreement for the helicopter or the

component.

The Time Between Over haul (T BO) a nd the inspection

periods are determined through experience, tests,

Lead The Fleet (LTF), or any other special programs

and the judgement of Bell Helicopter Textron

engineers. They are subject to change only by Bell

Helicopter Textron or an approved Airworthiness

Authority.

• If a helicopter is being inspected on the Part A

inspection program and it is preferable to change

to the Part B program, a complete Part A — 1000

Hour Inspection shall be accomplished. The

helicopter may then be changed to the Part B

inspection program beginning with a 25 Hour/15

Day Inspection.

• If a helicopter is being inspected on the Part B

inspection program and it is preferable to change

to the Part A program, a complete Part B — 600

Hour/12 Month Inspection shall be accomplished.

Changes to the TBO will be introduced by either

revision to this chapter or a Technical Bulletin.

Every calendar and hourly inspection is a thorough

visual inspection to determine the airworthiness of the

helicopter and the components. Qualified persons

must do the inspections in accordance with quality

standard aircraft practices and the applicable

maintenance manuals. Bell Helicopter Textron

considers that it is mandatory to obey all the

applicable Alert Service Bulletins (ASB) and the

Airworthiness Directives (AD).

5-00-00

26 JUN 2013 Rev. 14 Page 5Export Classification C, ECCN EAR99

BHT-212-MM-1

WARNING

Component operating time records are necessary for

components that have scheduled maintenance

procedures, which are different from those of the

airframe. It is the owner/operator’s responsibility to

keep the Historical Service Records (HSR) for the

applicable component and to do the necessary

maintenance procedures.

Before each inspection, remove or open the

necessary cowlings, fairing, inspection doors, and

panels.

5-2. INSPECTION REQUIREMENTS

This manual does not include specific inspections

required by the FAA or other government regulatory

authorities. These specific inspections are given by

your government regulatory authority. Refer to their

requirements for these specific inspectio ns .

The owner/operator of the helicopter is responsible for

the maintenance done on the helicopter. It is the

owner.operator’s responsibility to:

1. Establish, maintain, and review the log books for

discrepancies.

2. Make sure the Alert Service Bulletins (ASB), the

Airworthiness Directives (AD), and the special

inspections are done when they are required to be

done.

3. Make sure the scheduled inspections, the special

inspections, and the required tests for all of the

installed kits are complied with.

4. Make sure all parts and components for which

Historical Service Records are required have

documented traceability to their original installation in

the helicopter.

EXTENT THAT THERE IS NO CHANCE

OF REPAIR OR INSTALLATION ON ANY

HELICOPTER OR COMPONENT.

5. Make sure all limited life parts that have

completed their published operating limits are

replaced.

6. Make sure all of the components that have

completed their published overhaul periods are

overhauled.

7. Make sure all of the maintenance that is done on

the helicopter is done by an approved maintenance

organization.

The maintenance organization/person doing the

maintenance is responsible for the quality of the

maintenance done.

The owner/operator may choose to ask the

maintenance organization/person doing the

maintenance to perform the tasks listed by prior

arrangement through a separate formal agreement.

5-3. CRASH DAMAGE

Because of the many possible co mbinations that can

result from crash damage, it is not possible to include

the specific repair tasks in this category. The

helicopter mechanic must make an analysis of the

crash damage for each situation. Do the repair in

accordance with the degree of damage to the sp ecific

part and the applicable repair procedures in this

manual. Call Product Support Engineering with your

analysis of the crash damage.

5-4. TYPES OF INSPECTIONS

1. The maintenance procedures may include

scheduled inspections, special inspections, conditional

inspections, component interim inspections, and

component overhaul inspections.

ALL PARTS REMOVED, DUE TO

REACHING THEIR LIMITS OR AS A

RESULT OF AN ACCIDENT/INCIDENT

INSPECTION AND DEEMED

UNAIRWORTHY, SHALL BE

PERMANENTLY MARKED AS SCRAP OR

PHYSICALLY DESTROYED TO THE

5-00-00

Page 6 Rev. 14 26 JUN 2013 Export Classification C, ECCN EAR99

a. Scheduled inspections must occur at specified

operating intervals. The intervals may be in operating

time (hours), cycles, torque events (RIN), calendar

(days, months, years) or other assigned units. This

makes sure that the helicopter is airworthy.

• Scheduled inspections — Part A consists of:

BHT-212-MM-1

– Daily inspection — Accomplish daily before

flight operation.

– 100 hours/12 calendar months — Accomplish

each 100 hours of flight operation or

12 calendar months, whichever comes first.

– 1000 hours — Accomplish ea ch 100 0 hours of

flight operation.

– 3000 hours/5 years — Accomplish each

3000 hours of flight operation or each

60 calendar months, whichever comes first.

• Scheduled inspections — Part B consists of the

following:

– 25 hours/30 days — Accomplish each

25 hours of flight operation or each 30 days,

whichever comes first.

– 300 hours — Accomplish each 300 hours of

flight operation.

– 600 hours/12 months — Accomplish each

600 hours of flight operation or each

12 calendar months, whichever comes first.

– 3000 hours/5 years — Accomplish each

3000 hours of flight operation or each

60 calendar months, whichever comes first.

3. Lubrication and servicing requirements are in

addition to those stated in this chapter (Chapter 12).

4. For corrosion control refer to the Corrosion

Control Guide, CSSD-PSE-87-001 and the

BHT-ALL-SPM.

5. For the PT6T-3/-3B engines, refer to the Pratt &

Whitney Canada Maintenance Manual for the

scheduled inspection, special inspection, conditional

inspection, and component overhaul schedule.

6. For the common Bell Helicopter Textron approved

optional equipment that is integrated into this

maintenance manual, refer to this chapter for the

scheduled inspection, conditional inspection,

component interim inspection, and component

overhaul inspection.

7. For all other Bell Helicopter Textron approved

equipment, refer to the applicable Service Instruction

for the scheduled inspection, special inspection,

conditional inspection, component interim inspection,

and component overhaul inspection.

8. For the inspection requirements for optional

equipment approved under Supplement Type

Certificate (STC), refer to the applicable STC

documentation. Maintenance and inspection of these

items are the responsibility of the owner/operator.

b. Special inspections are of a temporary nature

or of a special interval that is not consiste nt with the

scheduled inspections.

c. Conditional inspections do not occur at a

specified time. A conditional inspection is the result of

known or suspected unusual event, known or

suspected malfunctions, or defects.

d. An interim inspection occurs between

overhauls.

e. The component overhaul schedule gives the

elapsed operating time at which a component must be

removed, disassembled, examined for condition, and

overhauled, in accordance with data approved by Bell

Helicopter Textron.

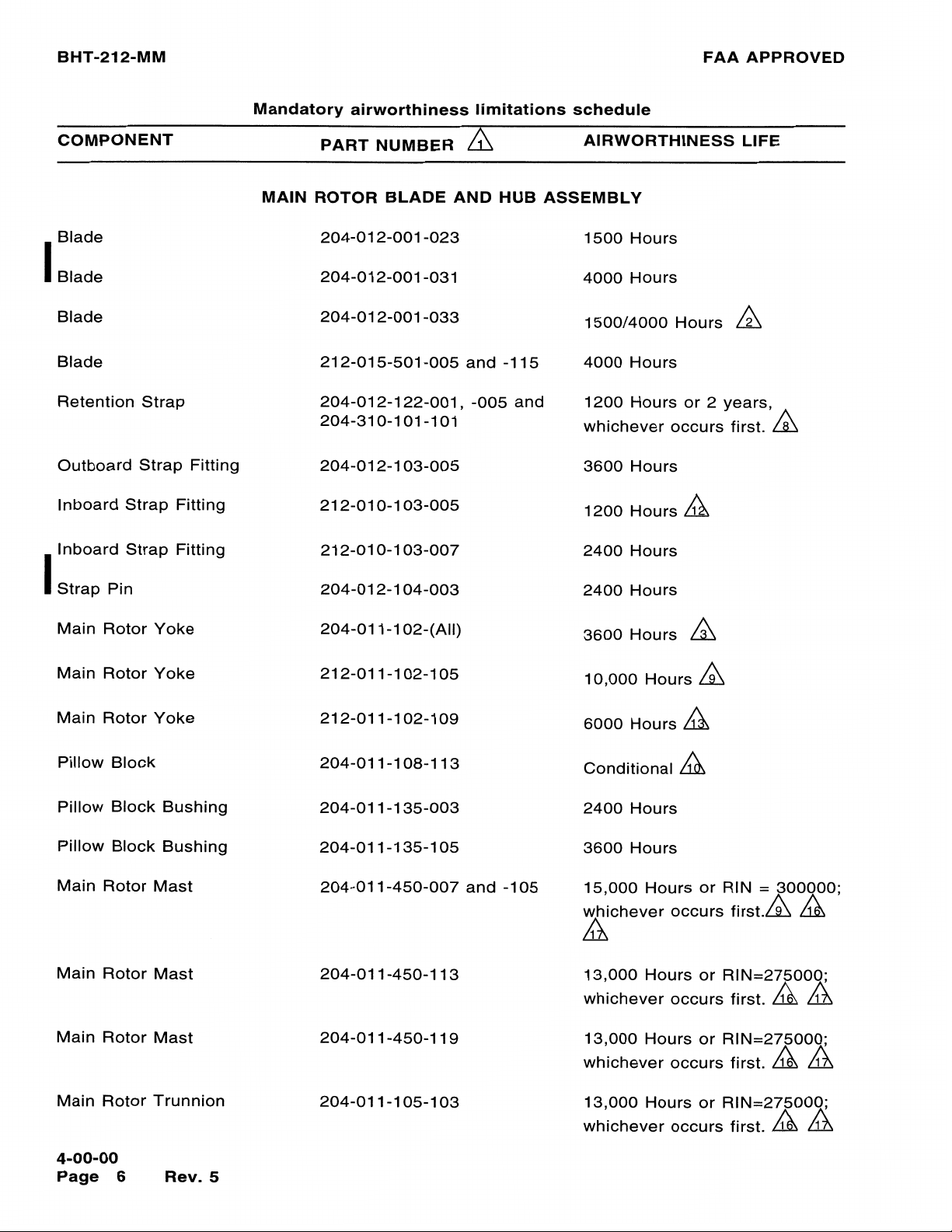

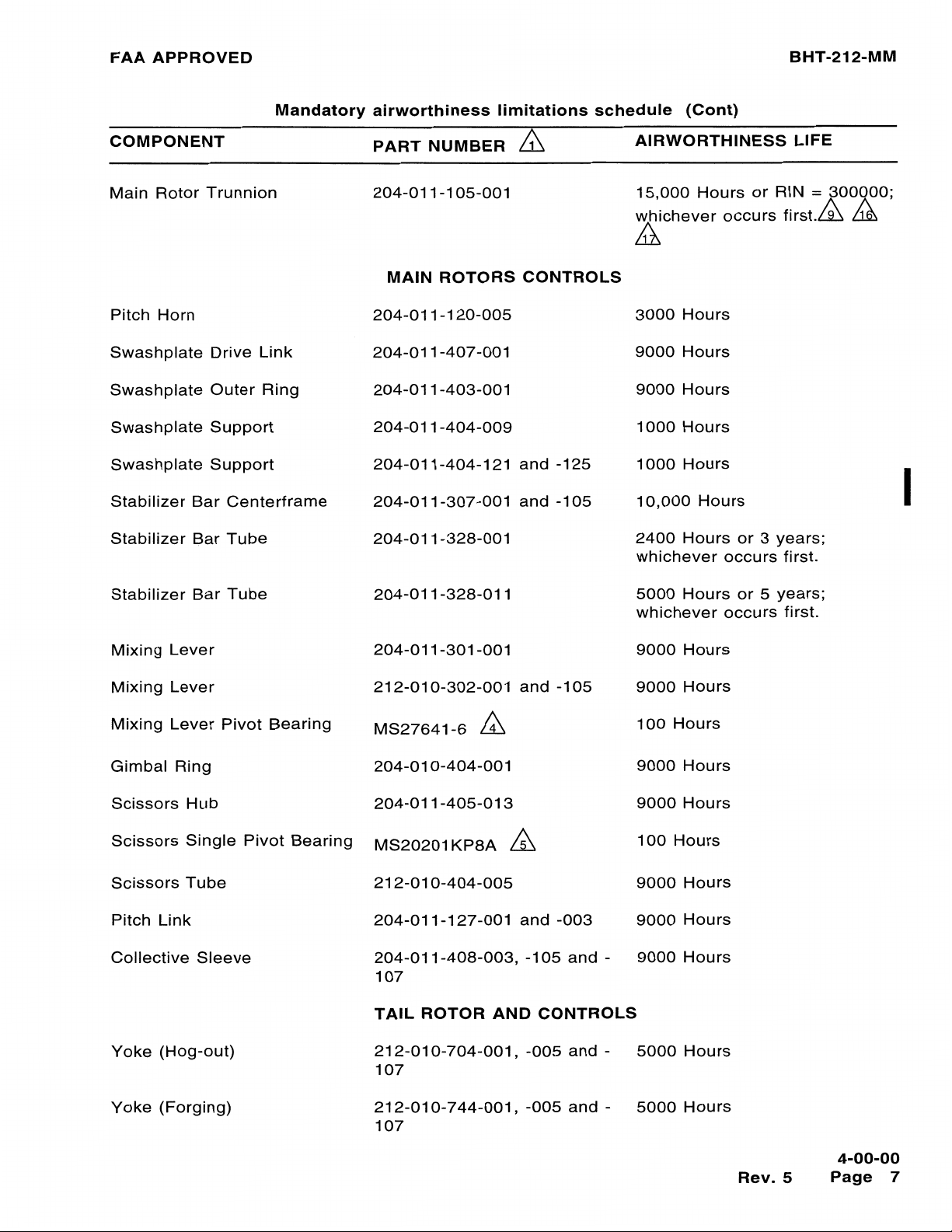

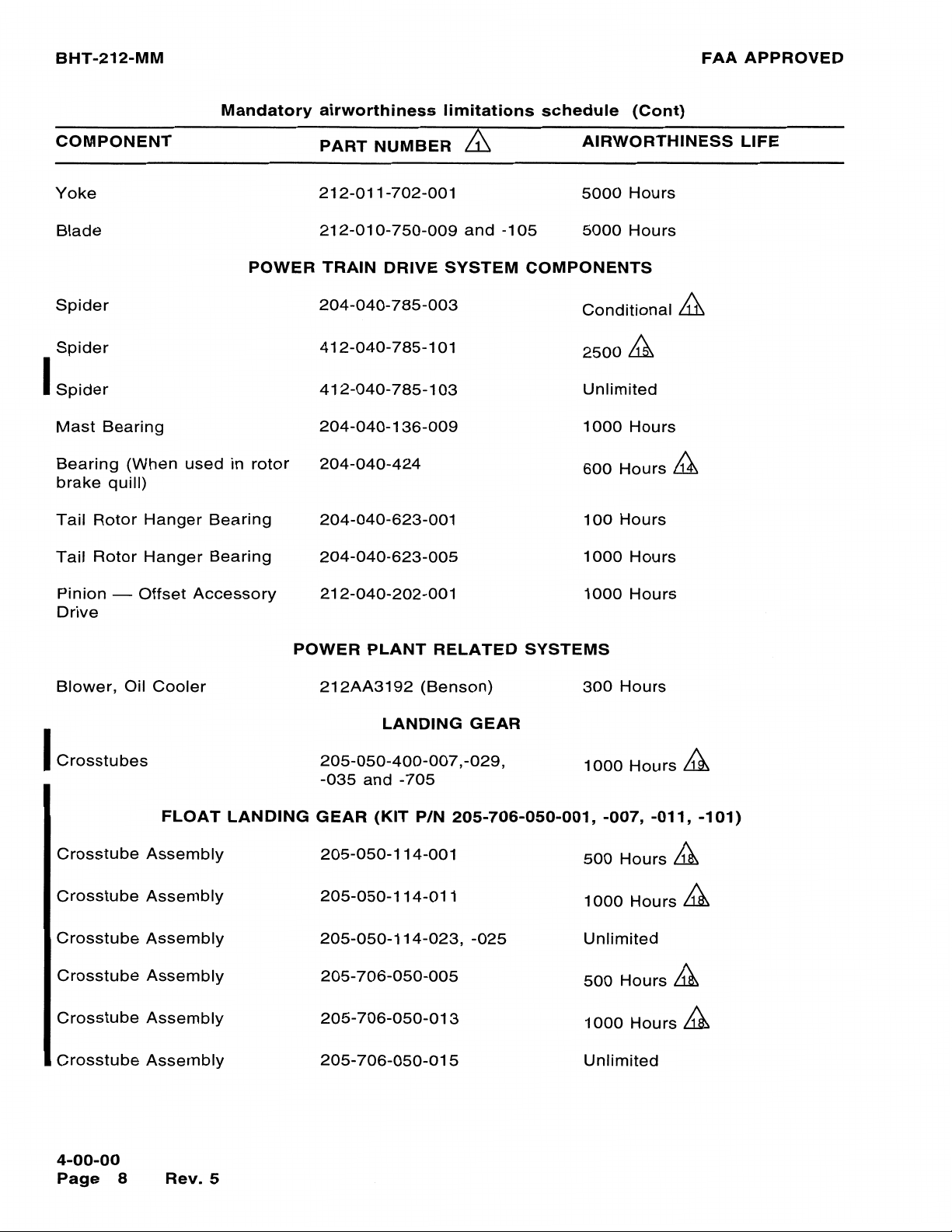

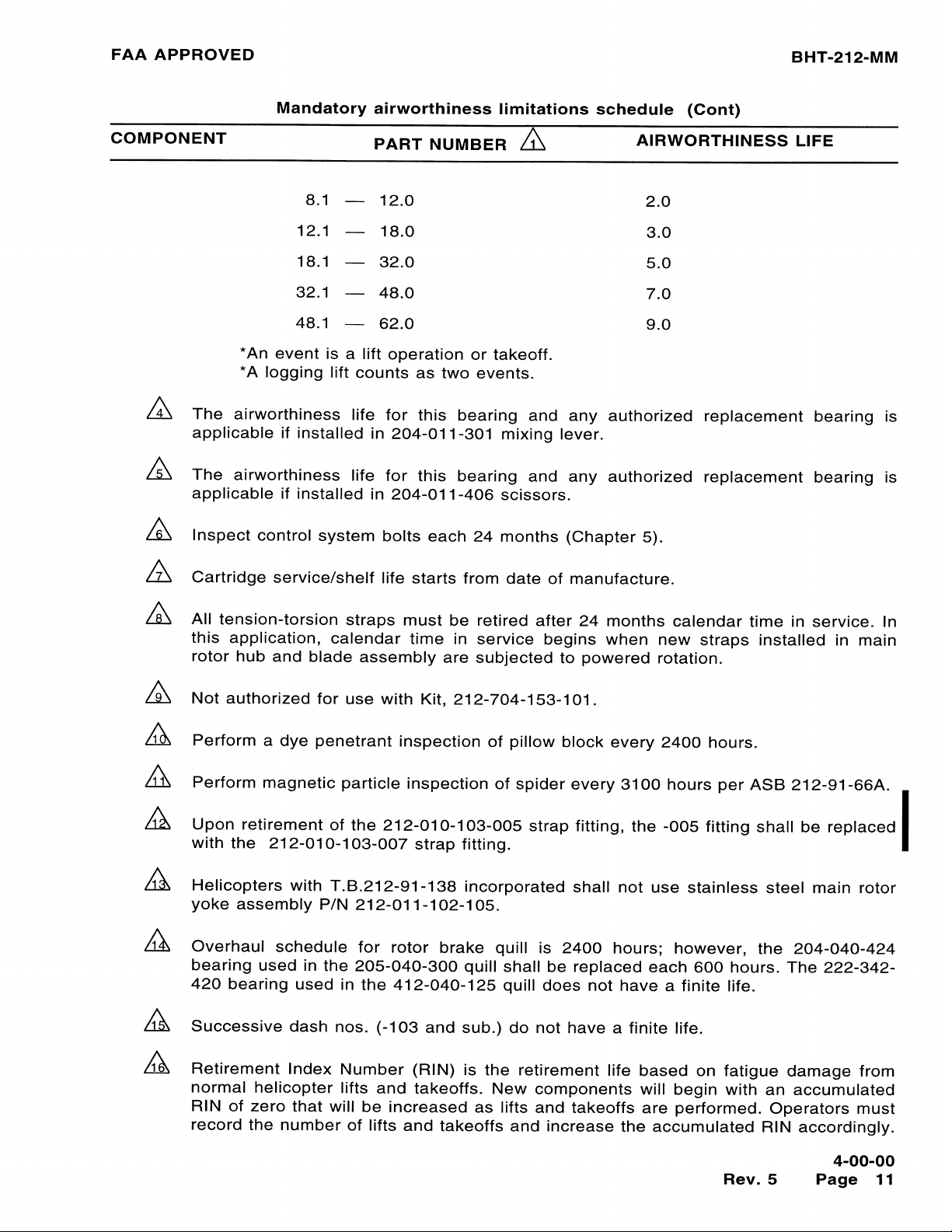

2. Airworthiness limitations — Replace components

in accordance with Airworthiness Limitations Schedule

(Chapter 4).

5-5. DEFINITIONS

• Inspect, check, examine — Determine condition

relative to an established standard.

• Condition — The state of being of an item as

related to serviceable or unserviceable standard.

• Security — The presence of attaching parts that

are properly tightened or appear to be, and the

presence of properly installed (as required)

locking devices such as lockwire, cotter pins, or

other.

• Standard — An established rule or measure to

determine condition.

• Damage — Physical deterioration whereby the

standard renders the condition or an item

acceptable or not acceptable for continuous use.

5-00-00

26 JUN 2013 Rev. 14 Page 7Export Classification C, ECCN EAR99

Loading...

Loading...