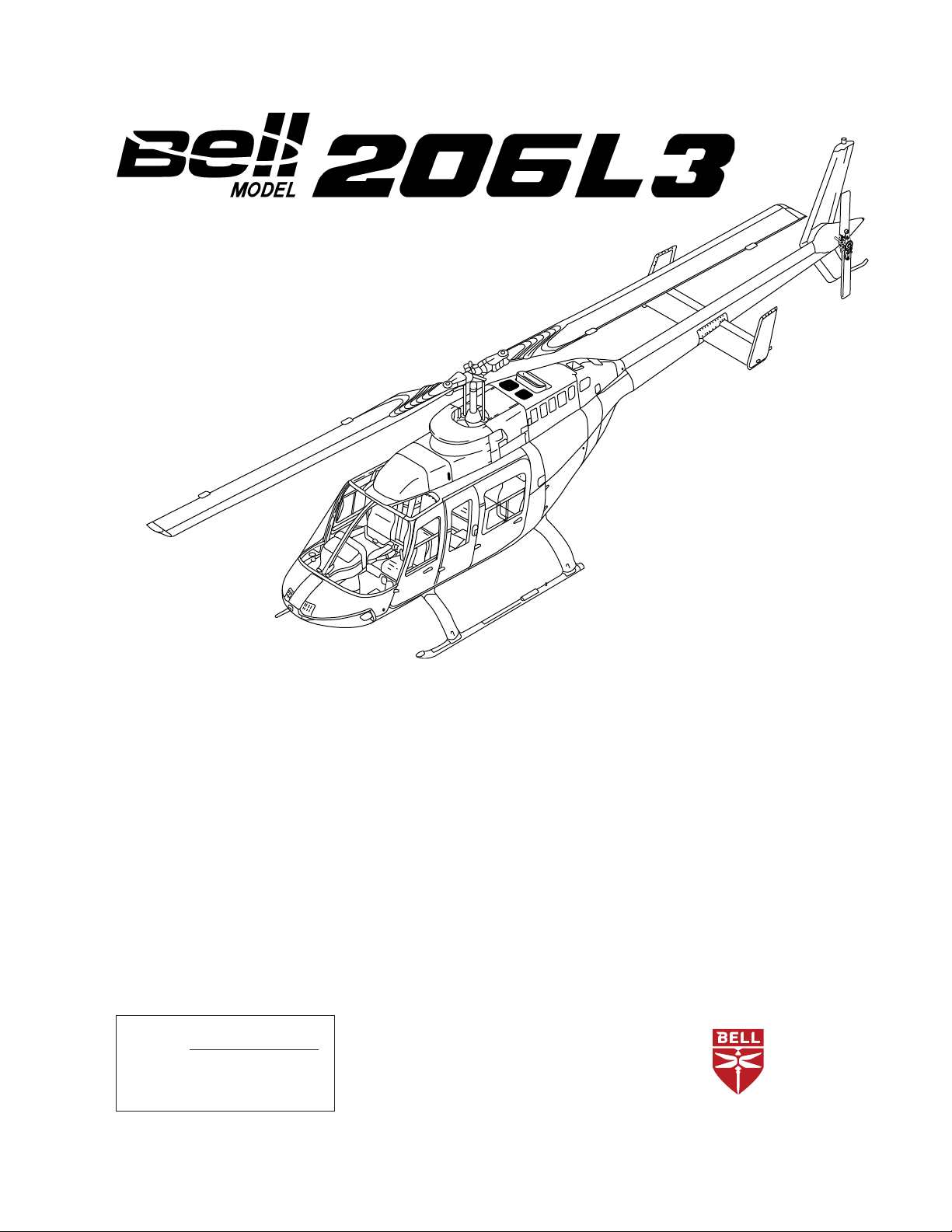

Page 1

BHT-206L3-MM-1

32672)),&(%2;)257:257+7(;$6

COPYRIGHT NOTICE

COPYRIGHT

201

BELL

®

HELICOPTER TEXTRON INC.

AND BELL HELICOPTER TEXTRON

CANADA LTD.

ALL RIGHTS RESERVED

MAINTENANCE MANUAL

GENERAL INFORMATION

The instructions set forth in this manual, as supplemented or modified by Alert Service Bulletins (ASB) or

other directions issued by Bell Helicopter Textron Inc. and Airworthiness Directives (AD) issued by the

applicable regulatory agencies, shall be strictly followed.

Maintenance Manual also applicable to 206L3+ helicopters (Increased Gross Weight kit 206-706-530

installed per BHT-206-SI-2052).

Export Classification C, ECCN EAR99

VOLUME 1

NOTICE

REISSUE — 27 AUGUST 1992

REVISION 24 — 25 JUNE 2019

Page 2

BHT-206L3-MM-1

PROPRIETARY RIGHTS NOTICE

These data are proprietary to Bell Helicopter Textron Inc. Disclosure,

reproduction, or use of these data for any purpose other than helicopter

operation or maintenance is forbidden without prior written authorization from

Bell Helicopter Textron Inc.

DESTINATION CONTROL STATEMENT

WARNING — This document contains technical data whose export is restricted

by the Arms Export Control Act (Title 22, U.S.C., Sec 2751, et. seq.) or the Export

Administration Act of 1979, as amended, Title 50, U.S.C., App. 2401 et. seq.

Violations of these export laws are subject to severe criminal penalties.

Disseminate in accordance with provisions of DoD Directive 5230.25.

Additional copies of this publication may be obtained by contacting:

PN Rev. 24 25 JUN 2019

Commercial Publication Distribution Center

Bell Helicopter Textron Inc.

P. O . B o x 4 8 2

Fort Worth, Texas 76101-0482

Export Classification C, ECCN EAR99

Page 3

WARNING

THIS MANUAL APPLIES ONLY TO HELICOPTERS AND COMPONENTS

MAINTAINED IN ACCORDANCE WITH BELL HELICOPTER TEXTRON

(BELL) APPROVED PROCEDURES USING BELL APPROVED PARTS.

ALL INSPECTION, REPAIR AND OVERHAUL PROCEDURES PUBLISHED

BY BELL, INCLUDING PART RETIREMENT LIFE, ARE BASED SOLELY ON

THE USE OF BELL PARTS THAT HAVE BEEN MAINTAINED USING BELL

APPROVED DATA. THE DATA PUBLISHED HEREIN OR OTHERWISE

SUPPLIED BY BELL IS NOT APPLICABLE TO NON-BELL PARTS OR

PARTS THAT HAVE BEEN REPAIRED USING DATA AND/OR PROCESSES

NOT APPROVED BY BELL.

BELL IS NOT RESPONSIBLE FOR ANY PART OTHER THAN THOSE THAT

IT HAS APPROVED.

BEFORE PERFORMING ANY PROCEDURE CONTAINED IN THIS MANUAL

YOU MUST INSPECT THE AFFECTED PARTS AND RECORDS FOR

EVIDENCE OF ANY MANUFACTURE, REPAIR, REWORK OR USE OF A

PROCESS NOT APPROVED BY BELL.

IF YOU IDENTIFY OR SUSPECT THE USE OF PARTS NOT AUTHORIZED

BY BELL, EITHER REMOVE THE AFFECTED ITEM FROM THE AIRCRAFT

OR OBTAIN INSTRUCTIONS FOR CONTINUED AIRWORTHINESS FROM

THE MANUFACTURER OR THE ORGANIZATION THAT APPROVED THE

REPAIR.

BHT-206L3-MM-1

Export Classification C, ECCN EAR99

25 JUN 2019 Rev. 24 Warning

Page 4

BHT-206L3-MM-1

Flying smart means that no matter where you are, or what time it is, you can make a call

and get additional information, clarification, or advice on a technical or operational issue

concerning your helicopter or information contained in our Technical Publications.

Product Support Engineering (PSE) is just a phone call away and may be contacted as

follows:

CUSTOMER SUPPORT AND SERVICES

Model 206, 407, or 505

Phone: 450-437-2862 or 800-363-8023 (U.S./Canada)

Fax: 450-433-0272

E-mail: productsupport@bellflight.com

Model 222, 230, 427, 429, or 430

Phone: 450-437-2077 or 800-463-3036 (U.S./Canada)

Fax: 450-433-0272

E-mail: productsupport@bellflight.com

Model 204, 205, 212, or 412

Phone: 450-437-6201 or 800-363-8028 (U.S./Canada)

Fax: 450-433-0272

E-mail: productsupport@bellflight.com

Model 210, HUEY II, and All Bell’s Active and

Military Medium Helicopter Models

Phone: 817-280-3548

Fax: 817-280-2635

E-mail: mts-medium@bellflight.com

Model OH-58, TH-67, TH-57, Both Active and

Military

Phone: 817-280-3548

Fax: 817-280-2635

E-mail: mts-light@bellflighth.com

Surplus

Surplus

For additional information on Customer Support and Services as well as Product Support

Engineering (PSE) and your local Customer Service Engineering (CSE) network, please

access http://www.bellflight.com/support-and-service/support.

CSS Rev. 24 25 JUN 2019

Export Classification C, ECCN EAR99

Page 5

BHT-206L3-MM-1

LOG OF REVISIONS

Insert latest revision pages and dispose of superseded ones.

On a revised page, the text and/or illustration affected by the latest revision is shown by a vertical line. A revised

page with only a vertical line next to the page number indicates that text has shifted or that non-technical

correction(s) were made on that page.

Original ........ 0 ........... 01 AUG 82

Revision....... 1 ........... 01 MAR 83

Revision....... 2............30 APR 83

Revision....... 3 .............16 JUL 84

Revision....... 4 ........... 07 MAR 85

Revision....... 5............15 APR 87

Reissue........ 0 ............ 01 JAN 90

Reissue........ 0........... 27 AUG 92

Revision....... 1 .............21 JUL 93

Revision....... 2............23 APR 01

Revision....... 3 ............15 MAY 02

Page No. Rev No.

VOLUME 1

Cover .......................................24

Title ..........................................24

PN ............................................24

Warning....................................24

CSS..........................................24

A – D ........................................24

Help..........................................20

Customer Feedback.................24

Helicopter Sales Notice............24

Warranty...................................24

BR ............................................24

TR ............................................24

i/ii..............................................24

Chapter 1

1/2 ............................................10

3 ...............................................19

4 – 6 .........................................10

Chapter 4

1 – 12 .......................................24

13/14 ........................................24

Chapter 5

1 – 3 .........................................22

4 – 5 .........................................16

6 ...............................................21

Revision ...... 4............09 DEC 02

Revision ...... 5............22 DEC 03

Revision ...... 6............. 07 JUL 06

Revision ...... 7............ 30 APR 08

Revision ...... 8............ 06 APR 09

Revison ....... 9............ 26 MAY 09

Revision ...... 10........... 20 JUL 09

Revision ...... 11 .......... 25 SEP 09

Revision ...... 12..........30 NOV 09

Revision ...... 13.......... 04 FEB 10

Revision ...... 14.......... 30 APR 10

LOG OF PAGES

Page No. Rev No.

6A/6B....................................... 21

7............................................... 16

8............................................... 21

9............................................... 16

10............................................. 21

11 – 12 ..................................... 16

13/14........................................ 16

15/16........................................ 16

17............................................. 16

18............................................. 22

19 – 23..................................... 16

24 – 26..................................... 21

27 – 29..................................... 16

30 – 32..................................... 17

33 – 36..................................... 16

37/38........................................ 16

39 – 46..................................... 16

47/48........................................ 16

49 – 52..................................... 16

53/54........................................ 16

55 – 60..................................... 16

61/62........................................ 16

63 – 66..................................... 16

67 – 68..................................... 17

69 – 79..................................... 16

80............................................. 22

81/82........................................ 16

83 – 86..................................... 16

87/88........................................ 16

Revision .......15 ..........27 SEP 10

Revision .......16 ..........25 FEB 11

Revision .......17 ..........08 APR 11

Revision .......18 ..........29 FEB 12

Revision .......19 ..........01 JUN 12

Revision .......20 .........07 NOV 12

Revision .......21 ..........07 JUN 13

Revision .......22 ......... 15 MAY 15

Revision .......23 .........23 MAR 17

Revision .......24 ..........25 JUN 19

Page No. Rev No.

89 .............................................22

90 – 98 .....................................16

99/100 ......................................16

101/102 ....................................16

103 – 106 .................................16

107/108 ....................................16

109/110 ....................................16

111 – 112..................................16

113/114.....................................22

115/116.....................................19

117 – 120 .................................22

121/122 ....................................21

123/124 ....................................22

125/126 ....................................16

127/128 ....................................16

129/130 ....................................16

131 ...........................................19

132 ...........................................16

133/134 ....................................16

135 – 138 .................................16

139/140 ....................................16

141 – 142 .................................16

143/144 ....................................16

145/146 ....................................23

147/148 ....................................22

149 ...........................................23

150 – 152 .................................16

153/154 ....................................16

155 – 156 .................................21

Export Classification C, ECCN EAR99

25 JUN 2019 Rev. 24 A

Page 6

BHT-206L3-MM-1

LOG OF PAGES (CONT)

Page No. Rev No.

157........................................... 16

158........................................... 21

159/160.................................... 21

161........................................... 16

162 – 163................................. 21

164........................................... 19

165 – 168................................. 16

169........................................... 21

170........................................... 16

171/172.................................... 21

173........................................... 16

174........................................... 21

175........................................... 16

176........................................... 21

177/178.................................... 16

179........................................... 16

180........................................... 21

181 – 184................................. 16

185........................................... 21

186........................................... 16

187 – 192................................. 21

193/194.................................... 16

195........................................... 23

196........................................... 21

197/198.................................... 17

VOLUME 2

Cover ....................................... 22

Title.......................................... 22

PN............................................ 21

Chapter 6

1/2.............................................. 0

3 – 6........................................... 0

Chapter 7

1/2.............................................. 0

3 – 4........................................... 0

5/6.............................................. 0

Chapter 8

1/2............................................ 13

3 – 9......................................... 10

10............................................. 22

11 ............................................. 16

12............................................. 17

12A – 12B................................ 16

13 – 14..................................... 10

15............................................. 22

Page No. Rev No. Page No. Rev No.

16– 19 ..................................... 13

20 ............................................ 22

Chapter 9

1/2 ............................................. 0

3 – 4 .......................................... 0

Chapter 10

1/2 ............................................. 0

3 – 6 .......................................... 0

7/8 ........................................... 10

Chapter 11

1/2 ........................................... 10

3 – 12 ...................................... 10

13 ............................................ 22

14 – 16 .................................... 10

Chapter 12

1 .............................................. 21

2 .............................................. 22

3/4 ............................................. 6

5 .............................................. 21

6 ................................................ 6

7/8 ............................................. 6

9 ................................................ 6

10 – 12 .................................... 10

13 – 14 ...................................... 6

15/16 ....................................... 10

17 – 19 .................................... 10

20 – 21 ...................................... 6

22 – 23 .................................... 10

24 .............................................. 6

25 – 28 .................................... 22

29/30 ......................................... 6

31 – 32 .................................... 17

32A/32B .................................. 17

33 – 41 .................................... 23

42 .............................................. 6

43 – 44 .................................... 22

Chapter 18

1 – 2 ........................................ 22

3/4 ........................................... 22

5 – 10 ...................................... 22

11/12 ....................................... 22

13 – 82 .................................... 22

83/84 ....................................... 22

VOLUME 3

Cover ....................................... 10

Title.......................................... 10

PN............................................ 10

Chapter 21

1/2.............................................. 0

3 – 10......................................... 0

Chapter 25

1 – 2........................................... 0

3/4.............................................. 0

5 – 44......................................... 0

Chapter 26

1/2.............................................. 0

3 – 4........................................... 0

VOLUME 4

Cover ....................................... 22

Title.......................................... 23

PN............................................ 22

Chapter 28

1................................................. 0

2............................................... 14

3/4.............................................. 0

5 – 14......................................... 0

15............................................. 14

16 – 20....................................... 0

21............................................. 14

22............................................... 0

23............................................... 1

24 – 31....................................... 0

32 – 33....................................... 1

34 – 40....................................... 0

41............................................. 14

42............................................. 22

43............................................. 14

44............................................... 0

45/46........................................ 14

Chapter 29

1 – 34....................................... 23

VOLUME 5

Cover ....................................... 22

Title.......................................... 22

PN............................................ 22

B Rev. 24 25 JUN 2019 Export Classification C, ECCN EAR99

Page 7

LOG OF PAGES (CONT)

BHT-206L3-MM-1

Page No. Rev No.

Chapter 30

1/2 ..............................................0

3/4 ............................................10

Chapter 32

1/2 ..............................................6

3 – 6 ...........................................6

6A – 6B ....................................22

6C/6D.......................................22

7 .................................................6

8 – 12 .........................................0

13/14 ..........................................0

Chapter 52

1 – 6 ...........................................0

7 ...............................................10

8 – 11 .........................................0

12 .............................................10

13 – 16 .......................................0

17 .............................................10

18 – 19 .......................................0

20 – 21 .....................................10

22 – 30 .......................................0

31 – 32 .....................................10

33 – 34 .......................................0

35 .............................................10

36 – 58 .......................................0

59 .............................................14

60 – 64 .......................................0

65/66 ..........................................0

Chapter 53

1 .................................................6

2 ...............................................14

3 – 4 ...........................................6

5/6 ..............................................6

7 ...............................................14

8 – 10 .........................................6

10A – 10B ................................14

10C/10D...................................14

11 .............................................14

12 .............................................22

13 – 14 .......................................6

15/16 ........................................14

17 – 22 .......................................6

23/24 ..........................................6

VOLUME 6

Cover .......................................22

Page No. Rev No. Page No. Rev No.

Title.......................................... 22

PN............................................ 22

Chapter 62

1 – 42....................................... 22

43/44........................................ 22

Chapter 63

1............................................... 10

2............................................... 16

3 – 4......................................... 22

4A/4B....................................... 22

5 – 7......................................... 10

8................................................. 0

9 – 11....................................... 10

12 – 14....................................... 0

15 – 18..................................... 10

18A – 18D................................ 10

18E/18F ................................... 10

18G – 18N ............................... 10

19 – 20..................................... 10

20A/20B................................... 10

21............................................. 19

22 – 25..................................... 10

26............................................. 22

27............................................. 14

28 – 30..................................... 16

30A – 30H................................ 16

31............................................. 10

32............................................... 0

33 – 51..................................... 10

52 – 56..................................... 22

56A – 56H................................ 22

56I............................................ 10

56J .......................................... 22

56K/56L ................................... 22

57 – 61..................................... 10

62............................................. 14

63 – 70..................................... 10

71 – 72..................................... 22

73 – 74..................................... 10

75/76........................................ 10

VOLUME 7

Cover ....................................... 22

Title.......................................... 23

PN............................................ 21

Chapter 64

1/2 ............................................22

3 – 12 .......................................22

13/14 ........................................22

15 – 28 .....................................22

Chapter 65

1 – 3 .........................................23

4 .................................................0

4A/4B .......................................10

5 – 7 ...........................................0

8 ...............................................10

9 .................................................0

10 .............................................10

11 ...............................................0

12 – 15 .....................................10

16 – 18 .....................................23

19 – 20 .....................................10

21 – 24 .....................................23

24A/24B ...................................23

25 ...............................................0

26 – 27 .....................................10

28 .............................................23

29 .............................................10

30 .............................................17

31 – 33 .....................................23

34 – 36 .....................................10

37 .............................................14

38 – 40 .....................................23

VOLUME 8

Cover .......................................22

Title ..........................................22

PN ............................................22

Chapter 67

1 – 2 .........................................22

3/4 ............................................22

5 – 10 .........................................0

11 .............................................14

12 .............................................10

13 .............................................14

14 – 16 .....................................22

17 – 24 .......................................0

25 ...............................................1

26 ...............................................0

27 – 30 .....................................22

30A/30B ...................................22

31 .............................................10

Export Classification C, ECCN EAR99

25 JUN 2019 Rev. 24 C

Page 8

BHT-206L3-MM-1

LOG OF PAGES (CONT)

Page No. Rev No.

32............................................. 14

33 – 34....................................... 0

35............................................. 22

36 – 37..................................... 14

38 – 39....................................... 0

40 – 42..................................... 14

43 – 44....................................... 0

45............................................. 14

46 – 47....................................... 0

48............................................. 14

49............................................... 0

50............................................. 14

51 – 52..................................... 22

53 – 54....................................... 0

55 – 56..................................... 10

57............................................... 0

58............................................. 14

59 – 64....................................... 0

65............................................. 10

66............................................... 0

67 – 70..................................... 10

71............................................... 0

72– 73...................................... 10

74 – 77....................................... 0

78............................................... 5

79 – 82....................................... 0

83/84.......................................... 0

VOLUME 9

Cover ....................................... 22

Title.......................................... 22

PN............................................ 22

Chapter 71

1 – 4......................................... 10

5 – 6........................................... 0

7............................................... 10

8............................................... 14

9 – 10....................................... 10

11 – 12 ..................................... 14

Page No. Rev No. Page No. Rev No.

13 – 17 ...................................... 0

18 – 20 .................................... 10

21 .............................................. 0

22 ............................................ 16

23 .............................................. 0

24 ............................................ 10

25 .............................................. 0

26 – 28 .................................... 10

29/30 ....................................... 10

Chapter 75

1/2 ............................................. 0

3 .............................................. 10

4 ................................................ 0

Chapter 76

1/2 ........................................... 22

3 – 22 ...................................... 22

Chapter 79

1/2 ............................................. 0

3 .............................................. 10

4 ................................................ 0

5 .............................................. 10

6 – 7 .......................................... 0

8 – 9 ........................................ 10

10 .............................................. 0

VOLUME 10

Cover ...................................... 22

Title ......................................... 22

PN ........................................... 22

Chapter 95

1 – 2 ........................................ 10

3 – 11 ........................................ 0

12 .............................................. 1

13 – 18 ...................................... 0

19 .............................................. 1

20 .............................................. 0

21............................................. 17

22............................................... 0

23............................................. 10

24............................................. 14

24A/24B................................... 14

25/26.......................................... 0

Chapter 96

1................................................. 0

2 – 4......................................... 22

5/6.............................................. 0

7 – 25......................................... 0

26 – 28..................................... 22

29 – 32....................................... 0

33............................................. 14

34 – 36..................................... 22

36A/36B................................... 22

37 – 44....................................... 0

VOLUME 11

Cover ....................................... 10

Title.......................................... 10

PN............................................ 10

Chapter 97

1 – 22......................................... 0

VOLUME 12

Cover ....................................... 22

Title.......................................... 22

PN............................................ 22

Chapter 98

1 – 2......................................... 22

3/4............................................ 22

5 – 58....................................... 22

59/60........................................ 22

D Rev. 24 25 JUN 2019 Export Classification C, ECCN EAR99

Page 9

H

ELP

E

VALUATE

L

OGISTICS

P

UBLICATIONS

Have you found something wrong with this manual — an

error, an inconsistency, unclear instructions, etc.? Although

we strive for accuracy and clarity, we may make errors on

occasion. If we do and you discover it, we would appreciate

your telling us about it so that we can change whatever is

incorrect or unclear. Please be as specific as possible.

Your complaint or suggestion will be acknowledged and we

will tell you what we intend to do.

You may use the enclosed Customer Feedback form, as

applicable, to inform us where we have erred.

Your assistance is sincerely appreciated.

Export Classification C, ECCN EAR99

Page 10

Page 11

CUSTOMER FEEDBACK

RETURN VIA FAX TO PRODUCT SUPPORT ENGINEERING (450) 433-0272

Manual Title: ___________________________________________________________

Manual Number (if assigned): _____________________________________________

Date of Issue: ___________________________________________________________

Date of Last Revision: ___________________________________________________

Section, Chapter, Paragraph Affected: ______________________________________

Your Feedback: ________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

Now Reads: ____________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

Should Read: ___________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

Your Name: _____________________________________________________________

Address: _______________________________________________________________

Export Classification C, ECCN EAR99

Page 12

TAPE HERE

From

POSTAGE

NECESSARY

Product Support Engineering

12,800 rue de l’Avenir

Mirabel, Québec, Canada, J7J 1R4

FOLD ON DOTTED LINES AND TAPE

TAPE HERE

Export Classification C, ECCN EAR99

Page 13

IMPORTANT

HELICOPTER SALES NOTICE

Please complete this form and return by mail, e-mail (publications@bHOOIOLJKW.com), or fax

(817-280-6466, Attention: CPDC). This will ensure that the new owners/operators receive

updates to their BellHelicopter Textron Technical Manuals and Bulletins.

Model of Helicopter Sold or Purchased ___________________________________________

Serial and Registration Number _________________________________________________

Name of New Owner (company or individual) ______________________________________

Name of New Operator _______________________________________________________

Future Publications to be mailed to this address:

Address ____________________________________________________________________

City _______________________________________________________________________

State/Province _______________________________________________________________

Zip/Postal Code _____________________________________________________________

Country ____________________________________________________________________

Fax No. ___________________________ Telephone No. ____________________________

E-mail Address ______________________________________________________________

Register for access to electronic publications at www.bellIOLJKW.FRP

Export Classification C, ECCN EAR99

Export Classification C, ECCN EAR99

Page 14

TAPE HERE

From

NO POSTAGE

NECESSARY

IF MAILED

IN THE

UNITED STATES

COMMERCIAL PUBLICATION DISTRIBUTION CENTER

P.O. BOX 482

FORT WORTH, TEXAS 76101-0482

FOLD ON DOTTED LINES AND TAPE

BUSINESS REPLY MAIL

FIRST CLASS PERMIT NO. 1744 FORT WORTH, TEXAS

Export Classification C, ECCN EAR99

Page 15

BHT-206L3-MM-1

SPARE PARTS WARRANTY

ONE YEAR/1,000 HOURS PRORATED

WARRANTY AND REMEDY: Seller warrants each new helicopter part or helicopter part reconditioned by seller to be free from defect

in material and workmanship under normal use and service and if installed on Bell model helicopters. Seller’s sole obligation under this

warranty is limited to replacement or repair of parts which are determined to Seller’s reasonable satisfaction to have been defective

with 1,000 hours of operation or one (1) year after installation, whichever occurs first and reimbursement of reasonable freight charges.

After 200 hours of use, there will be a prorated charge to the Purchaser for replacement parts (prorating the hours of total use against

the then applicable part life or 2,000 hours, whichever is the lesser). Defective parts must be reported in writing to the Seller’s Warranty

Administration within 90 days of being found defective. Replacement of parts may be with either new or reconditioned parts, at Seller’s

election. Warranty adjustment is contingent upon the Purchaser complying with the Warranty Remedies as described in the

Commercial Warranty Information brochure and the Seller’s Warranty Administration disposition instructions for defective parts. Failure

to comply with all of the terms of this paragraph may, at Seller’s sole option, void this warranty.

NOTE: Parts, components and assemblies of all new helicopters may have been restored or reworked due to mars, blemishes, dents

or other irregularities during the manufacturing process. Such restoration and/or rework is permitted under Seller’s approved

manufacturing and engineering processes and guidelines. The restoration and/or rework so completed does not render such items

defective in material or workmanship.

THIS WARRANTY IS GIVEN AND ACCEPTED IN PLACE OF (i) ALL OTHER WARRANTIES OR CONDITIONS, EXPRESS OR

IMPLIED, INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES OR CONDITIONS OF MERCHANT ABILITY AND

FITNESS FOR A PARTICULAR PURPOSE AND (ii) ANY OBLIGATION, LIABILITY, RIGHT, CLAIM OR REMEDY IN CONTRACTOR

IN TORT (DELICT), INCLUDING PRODUCT LIABILITIES BASED UPON STRICT LIABILITY, NEGLIGENCE, OR IMPLIED

WARRANTY IN LAW.

This warranty is the only warranty made by Seller. The Purchaser’s sole remedy for a breach of this warranty or any defect in a part is

the repair or replacement of helicopter parts and reimbursement of reasonable freight charges as provided herein. Seller excludes

liability, whether as a result of a breach of contract or warranty, negligence or strict product liability, for incidental or consequential

damages, including without limitation, damage to the helicopter or other property, costs and expenses resulting from required changes

or modifications to helicopter components and assemblies, changes in retirement lives and overhaul periods, local customs fees and

taxes, and costs or expenses for commercial losses or lost profits due to loss of use or grounding of helicopters or otherwise.

Seller makes no warranty and disclaims all liability in contract or in tort (delict), including, without limitation, negligence and strict tort

(delictual) liability, with respect to work performed by third parties at Purchaser’s request and with respect to engines, engine

accessories, batteries, radios, and avionics, except Seller assigns each manufacturer’s warranty to Purchaser to the extent such

manufacturer’s warranty exists and is assignable.

This warranty shall not apply to any helicopter part which has been repaired or altered outside Seller ’s factory in any way so as, in

Seller’s judgment, to affect its stability, safety or reliability, or which has been subject to misuse, negligence or accident, or which has

been installed in any aircraft which has been destroyed unless that helicopter has been rebuilt by Bell. A list of destroyed aircraft is

obtainable from Bell Product Support. Repairs and alterations which use or incorporate parts and components other than genuine Bell

parts or parts approved by Bell for direct acquisition from sources other than Bell itself are not warranted by Bell, and this warranty shall

be void to the extent that such repairs and alterations, in Seller’s sole judgment, affect the stability, safety or reliability of the helicopter

or any part thereof, or damage genuine Bell or Bell-approved parts. No person, corporation or organization, including Bell Customer

Service Facilities, is authorized by Seller to assume for it any other liability in connection with the sale of its helicopters and parts.

NO STATEMENT, WHETHER WRITTEN OR ORAL, MADE BY ANY PERSON, CORPORATION OR ORGANIZATION, INCLUDING

BELL CUSTOMER SERVICE FACILITIES MAY BE TAKEN AS A WARRANTY NOR WILL IT BIND SELLER.

Seller makes no warranty and disclaims all liability with respect to components or parts damaged by, or worn due to, corrosion. Seller

makes no warranty and disclaims all liability for consumables (wear items) which are defined as items required for normal and routine

maintenance or replaced at scheduled intervals shorter than the warranty period. “Consumables” include but are not limited to engine

and hydraulic oil, oil filters, packings and o-rings, anti-corrosion and/or sealing compounds, brush plating material, nuts, bolts, washers,

screws, fluids, compounds, and standard aircraft hardware that is readily available to aircraft operators from sources other than Seller.

All legal actions based upon claims or disputes pertaining to or involving this warranty including, but not limited to, Seller’s denial of any

claim or portion thereof under this warranty, must be filed in the courts of general jurisdiction of Tarrant County, Texas or in the United

States District Court for the Northern District of Texas, Ft. Worth Division located in Ft. Worth, Tarrant County, Texas. In the event that

Purchaser files such an action in either of the court systems identified above, and a final judgment in Seller’s favor is rendered by such

court, then Purchaser shall indemnify Seller for all costs, expenses and attorneys’ fees incurred by Seller in defense of such claims. In

the event Purchaser files such a legal action in a court other than those specified, and Seller successfully obtains dismissal of that

action or transfer thereof to the above described court systems, then Purchaser shall indemnify Seller for all costs, expenses and

attorneys’ fees incurred by Seller in obtaining such dismissal or transfer.

January 2007

Export Classification C, ECCN EAR99

25 JUN 2019 Rev. 24 Warranty

Page 16

Page 17

TC APPROVED BHT-206L3-MM-1

TABLE OF CONTENTS

Paragraph Chapter/Section Page

Number Title Number Number

FIGURES

Figure Page

Number Title Number

TABLES

Table Page

Number Title Number

The Airworthiness Limitations Schedule is approved by the Minister and specifies the maintenance required by

any applicable airworthiness or operational rules unless an alternative program has been approved by the

Minister.

CHAPTER 4 — AIRWORTHINESS LIMITATIONS SCHEDULE

AIRWORTHINESS LIMITATIONS SCHEDULE

4-1 Airworthiness Limitations Schedule ............................................... 4-00-00 5

4-1 Tailboom Upper Left Attachment Fitting (206-032-409-001)

— Recurring 110-Hour Inspection ...................................................................... 13

4-1 Airworthiness Limitations Schedule .................................................................... 6

4-2 Inspection Limitations Schedule ......................................................................... 12

Chief Engineering

Aircraft Certification

Transport Canada

Export Classification C, ECCN EAR99

25 JUN 2019 Rev. 24 Page 1

4-00-00

Page 18

BHT-206L3-MM-1 TC APPROVED

REVISION NO. DATE OF SIGNATURE APPROVAL SIGNATURE

Original N/A N/A

Reissue N/A N/A

Reissue 27 August 1992

1N/A N/A

2N/A N/A

3N/A N/A

4 09 December 2002

5 22 December 2003

6N/A

7 30 October 2007

N/A

4-00-00

Page 2 Rev. 24 25 JUN 2019

Export Classification C, ECCN EAR99

Page 19

TC APPROVED BHT-206L3-MM-1

REVISION NO. DATE OF SIGNATURE APPROVAL SIGNATURE

8 20 August 2008

9 26 May 2009

10 N/A N/A

11 25 September 2009

12 N/A

13 N/A

14 N/A

15 N/A

16 N/A N/A

N/A

N/A

N/A

N/A

17 8 April 2011

Export Classification C, ECCN EAR99

4-00-00

25 JUN 2019 Rev. 24 Page 3

Page 20

BHT-206L3-MM-1 TC APPROVED

REVISION NO. DATE OF SIGNATURE APPROVAL SIGNATURE

18 29 February 2012

19 1 June 2012

20 7 November 2012

21 N/A

22 N/A

23 N/A

24 25 JUNE 2019

N/A

N/A

N/A

4-00-00

Page 4 Rev. 24 25 JUN 2019

Export Classification C, ECCN EAR99

Page 21

TC APPROVED BHT-206L3-MM-1

AIRWORTHINESS LIMITATIONS SCHEDULE

4-1. AIRWORTHINESS LIMITATIONS

SCHEDULE

WARNING

ALL REPAIR AND OVERHAUL

PROCEDURE LIVES PUBLISHED BY

BELL HELICOPTER TEXTRON,

INCLUDING COMPONENT RETIREMENT

LIFE, ARE BASED SOLELY ON THE USE

OF BELL APPROVED PARTS AND

PROCESSES. IF PARTS OR

PROCESSES DEVELOPED OR

APPROVED BY PARTIES OTHER THAN

BELL HELICOPTER ARE USED, THEN

THE DATA PUBLISHED OR OTHERWISE

SUPPLIED BY BELL HELICOPTER ARE

NOT APPLICABLE. THE USER IS

WARNED TO NOT RELY ON BELL

HELICOPTER DATA FOR PARTS AND

PROCESSES NOT APPROVED BY BELL

HELICOPTER. ALL APPLICABLE

INSPECTIONS AND REPAIR METHODS

MUST BE OBTAINED FROM THE

SUPPLIER OF THE PARTS OR

PROCESSES NOT APPROVED BY BELL

HELICOPTER. BELL HELICOPTER IS

NOT RESPONSIBLE FOR PARTS OR

PROCESSES OTHER THAN THOSE

WHICH IT HAS ITSELF DEVELOPED OR

APPROVED.

WARNING

CONTINUED USE OF ANY TIME/

CALENDAR/RIN LIFE LIMITED

COMPONENT PAST ITS STATED LIMITS

IS NOT PERMITTED AS IT COULD

SERIOUSLY AFFECT THE

AIRWORTHINESS OF THE HELICOPTER.

THE COMPONENT MUST BE REMOVED

FROM THE HELICOPTER NOT LATER

THAN THE END OF THE LIFE LIMIT. IT

MUST EITHER BE MADE

UNSERVICEABLE OR MARKED IN A

CONSPICUOUS MANNER TO PREVENT

CONTINUED USE, EVEN INADVERTENT

USE.

WHEN A REPLACEMENT PART IS

INSTALLED, THE PART NAME, PART

NUMBER, SERIAL NUMBER, AND

CURRENT OPERATING HOURS, IF

APPLICABLE, MUST BE RECORDED IN

THE HISTORICAL SERVICE RECORD

FOR THE ASSEMBLY OR HELICOPTER.

NOTE

The requirements stated in Chapter 5 are to

be complied with and the appropriate

maintenance actions are to be performed.

NOTE

The airworthiness life or inspection interval

for any part number contained in this

schedule applies to all the successive dash

numbers for that component unless it is

otherwise specified.

The mandatory Airworthiness Limitations Schedule

(Tab le 4- 1) summarizes the mandatory maximum life,

in hours, years or by Retirement Index Number (RIN)

of components with a limited airworthiness life. Parts

that are not on the schedule have an unlimited

airworthiness life. The Inspection Limitations Schedule

(Tab le 4- 2) summarizes the mandatory inspection

interval in hours.

Refer to the engine manufacturer’s publications for the

airworthiness limitations of the power plant

components.

Export Classification C, ECCN EAR99

4-00-00

25 JUN 2019 Rev. 24 Page 5

Page 22

BHT-206L3-MM-1 TC APPROVED

CAUTION

1

21

22

8

11

12

11

17

APPLICABLE SERVICE INSTRUCTION

WARNING

(SI) OR MAINTENANCE MANUAL

SUPPLEMENT (MMS) FOR KIT

COMPONENT SCHEDULES.

SOME PARTS ARE INSTALLED AS

ORIGINAL EQUIPMENT ON BOTH

MILITARY AND COMMERCIAL

HELICOPTERS AND MAY HAVE A

LOWER AIRWORTHINESS LIFE AND/OR

OVERHAUL SCHEDULE WHEN USED

ON A MILITARY HELICOPTER. IN

ADDITION, CIRCUMSTANCES

SURROUNDING THEIR USE MAY CALL

FOR OPERATION OF THE MILITARY

The retirement life given, or the failure to

give a retirement life to a component, does

not constitute a warranty of any kind. The

only warranty applicable to the helicopter or

any component is the warranty included in

the Purchase Agreement for the helicopter

or the component.

NOTE

HELICOPTER OUTSIDE OF THE

APPROVED COMMERCIAL FLIGHT

ENVELOPE. CONSEQUENTLY, PARTS

THAT HAVE BEEN USED ON MILITARY

HELICOPTERS SHOULD NOT BE USED

ON COMMERCIAL HELICOPTERS.

The airworthiness lives given to the components and

assemblies are determined by experience, tests, and

the judgment of Bell Helicopter engineers. The lives

cannot be changed without the approval of the

Minister of Transport Canada.

Prior to disposing of unsalvageable helicopter parts

and materials, caution should be exercised to ensure

that the parts and material are disposed of in a manner

that does not allow them to be returned for service.

AIRWORTHINESS LIFE OF SOME KIT

COMPONENTS IS NOT COVERED IN

THIS SCHEDULE. REFER TO

Refer to FAA Advisory Circular 21-38 for guidance on

the disposal of unsalvageable aircraft parts and

materials.

Table 4-1. Airworthiness Limitations Schedule

COMPONENT

PART NUMBER

AIRWORTHINESS LIFE

MAIN ROTOR HUB AND BLADES

Main Rotor Trunnion 206-011-120-103/-105 24,000 RIN

Strap Retention Pin 206-011-125-001 1200 hours

Main Rotor Grip 206-011-132-009/-113 4800 hours

Tension Torsion Strap 206-011-147-007 1200 hours/24 months

Strap Retention Fitting 206-011-150-101/-105 2400 hours

Tension Torsion Strap 206-011-154-103/-107 1200 hours/24 months

Latch Bolt 206-011-260-101 1200 hours

4-00-00

Page 6 Rev. 24 25 JUN 2019

Export Classification C, ECCN EAR99

Page 23

TC APPROVED BHT-206L3-MM-1

1

13

31

38

31

39

24

37

25

37

26

9

21

23

14

10

Table 4-1. Airworthiness Limitations Schedule (Cont)

COMPONENT

PART NUMBER

AIRWORTHINESS LIFE

MAIN ROTOR HUB AND BLADES (CONT)

Main Rotor Blade 206-015-001-001/-103/-105/

4000 hours

-107/-109/-111/-113/-115/-117/

-119/-121

Main Rotor Blade 206-015-001-125/-127/-129/-131 2300 hours

Tension Torsion Strap 206-310-004-103 1200 hours/48 months

SWASHPLATE AND SUPPORT

Lower Cyclic Tube 206-001-193-001 4800 hours

Collective Idler Link 206-010-407-001 4800 hours

Swashplate Support Assembly 206-010-445-105 4800 hours

Swashplate Support Assembly 206-010-445-113 14,400 hours

Collective Idler Link 206-010-446-105 1200 hours

Collective Idler Link 206-010-446-107 14,400 hours

Collective Lever 206-010-447-105 1200 hours

Collective Lever 206-010-447-109 14,400 hours

Swashplate Support Assembly 206-010-452-109 4800 hours

Swashplate Support Assembly 206-010-452-113 Unlimited

Collective Sleeve Assembly 206-010-454-107/-109/-113 14,400 hours

Collective Lever 206-010-467-001/-105 4800 hours

POWER TRAIN

Tail Rotor Gearbox Duplex

206-040-410-003/-005/-101 3000 hours

Bearing

Main Rotor Mast 206-040-535-101/-105/-109 5000 hours/44,000 RIN

Sun Gear 206-040-662-101

Freewheel Assembly Clutch CL41742-1 3000 hours

Freewheel Assembly Clutch CL42250-1 3000 hours

TAIL ROTOR HUB AND BLADES

Tail Rotor Yoke 206-011-819-101/-105/-109 5000 hours

4-00-00

Export Classification C, ECCN EAR99

25 JUN 2019 Rev. 24 Page 7

Page 24

BHT-206L3-MM-1 TC APPROVED

1

15321516303236

19

19

18

18

27

28

29

34

33

35

1

2

3

4

Table 4-1. Airworthiness Limitations Schedule (Cont)

COMPONENT

PART NUMBER

AIRWORTHINESS LIFE

TAIL ROTOR HUB AND BLADES (CONT)

Tail Rotor Blade 206-016-201-001/-107/-113 2400 hours

Tail Rotor Blade 206-016-201-127/-131/-135 2500 hours

AIRFRAME

Horizontal Stabilizer 206-023-119-167

MISCELLANEOUS KITS

Fixed Floats Landing Gear Aft

206-050-169-011/-013

Crosstube

Fixed Floats Landing Gear

206-050-169-031

Forward Crosstube

High Landing Gear Crosstube 206-053-109-ALL

Standard Landing Gear

206-053-119-ALL

Crosstube

Fixed Floats Landing Gear Aft

206-053-211-103

Crosstube

Emergency Floats Reservoir 1269556-3/-4 15 years

Emergency Floats Reservoir 1271226 15 years

Emergency Floats Squib 29022968

Emergency Floats Squib 94455

Hoist Cable Cutter Assembly Y-1265-11-1

POWER PLANT

Turboshaft Engine 250-C30P Refer to Rolls Royce 250-C30P Operation

and Maintenance Manual, 14W2

NOTES:

Airworthiness limitation for part number listed applies to all successive dash numbers for that component

unless otherwise specified.

Reserved.

Reserved.

Reserved.

4-00-00

Page 8 Rev. 24 25 JUN 2019

Export Classification C, ECCN EAR99

Page 25

TC APPROVED BHT-206L3-MM-1

567

8

9

10

11

12

13

14

15

16

17

18

19

20

Table 4-1. Airworthiness Limitations Schedule (Cont)

NOTES (CONT):

Reserved.

Reserved.

Reserved.

Selected serial numbers of main rotor grip 206-011-132-009 will have been removed from service upon

reaching 1200 hours in service. Refer to ASB 206L-80-15, dated 29 July 1980 for list of serial numbers

affected.

Selected serial numbers of main rotor mast 206-040-535-105 will have been returned to Bell Helicopter

Textron (BHT) for metallurgical evaluation no later than 31 May 1987. Affected masts inspected at BHT

and found to be acceptable have the suffix “U” added to the serial number. Refer to ASB 206L-87-44,

dated 23 April 1987 for list of serial numbers affected.

Selected serial numbers of tail rotor yoke 206-011-819-101 will have been returned to Bell Helicopter

Textron (BHT) for inspection and rework no later than 1 April 1988. Refer to ASB 206L-88-51, dated

23 April 1987 for list of serial numbers affected.

Main rotor hub tension torsion straps 206-011-147 and 206-011-154 have airworthiness lives of

1200 hours or 24 months, whichever occurs first. The calendar life of 24 months starts when new straps

are installed in a main rotor hub and blade assembly, and are subjected to rotation on the helicopter.

Refer to ASB 206L-80-12, dated 2 June 1980.

Selected serial numbers of main rotor hub tension torsion strap 206-011-147-007 must be removed from

service. Refer to ASB 206L-89-60, dated 29 August 1989 for list of serial numbers affected.

Selected serial numbers of main rotor blades 206-015-001-001/-103/-105 must be removed from service.

Refer to ASB 206L-89-64 Rev. A, dated 29 November 1989 for list of serial numbers affected.

Selected serial numbers of sun gear 206-040-662-101 must be removed from service. Refer to

ASB 206L-90-69 Rev. A, dated 15 January 1991 for list of serial numbers affected.

Selected serial numbers of tail rotor blades 206-016-201-113/-127 must be removed from service. Refer

to ASB 206L-90-70, dated 27 June 1990 for list of serial numbers affected.

Selected serial numbers of tail rotor blade 206-016-201-127 will have been returned to Bell Helicopter

Textron (BHT) for evaluation no later than 30 September 1990. Affected blades inspected at BHT and

found to be acceptable have the suffix “M” added to the serial number. Refer to ASB 206L-90-71 Rev. A,

dated 31 October 1990 for list of serial numbers affected.

Selected serial numbers of main rotor latch bolt 206-011-260-101 must be removed from service. Refer to

ASB 206L-92-86, dated 3 December 1992 for list of serial numbers affected.

Landing gear crosstubes 206-053-109-ALL and 206-053-119-ALL (all dash numbers) will have been

removed from service no later than 30 September 1994. Refer to ASB 206L-94-93, dated 11 April 1994.

Landing gear crosstubes 206-050-169-011/-031 will have been removed from service no later than

31 January 1995. Refer to ASB 206L-94-97, dated 17 August 1994.

Reserved.

4-00-00

Export Classification C, ECCN EAR99

25 JUN 2019 Rev. 24 Page 9

Page 26

BHT-206L3-MM-1 TC APPROVED

21

22

23

24

25

26

27

28

29

30

31

Table 4-1. Airworthiness Limitations Schedule (Cont)

NOTES (CONT):

Each component with a retirement life sensitive to torque events will be assigned a maximum Retirement

Index Number (RIN). This RIN corresponds to maximum allowed fatigue damage resulting from lifts and

takeoffs. A torque event is defined as a takeoff (one takeoff plus subsequent landing = one RIN) or a lift

(internal or external). For example, if an operator performs six takeoffs and 10 slingloads, this would total

16 torque events; (6 takeoffs = 6 events, 10 slingloads = 10 events, 6 + 10 = 16 torque events total).

Pilots are to record total number of torque events for each flight. This allows maintenance personnel to

convert torque events to RIN by applying the appropriate RIN adjustment factor. Refer to ASB 206L-94-99

Rev. B, dated 10 August 2001. A new component will begin with an accumulated RIN of zero, that will be

increased as lifts and takeoffs are performed. Operator will record number of lifts and takeoffs (torque

events), and increase accumulated RIN accordingly. When maximum RIN is reached or retirement flight

hours, whichever occurs first, component will be removed from service.

The retirement life of trunnion 206-011-120-103/-105 is based solely on RIN. Retire trunnion when

RIN = 24,000. For each takeoff/lift, add one RIN if the trunnion is installed on 206L, 206L1, or 206L3

(includes 206L3 with Increased Power Operation kit installed per BHT-206-SI-2039) and two RIN if the

trunnion is installed on a 206L4 (also applicable to 206L3+ helicopters (Increased Gross Weight Upgrade

Kit 206-706-530 installed per BHT-206-SI-2052)). Refer to ASB 206L-94-99 Rev. B, dated

10 August 2001.

Retire main rotor mast 206-040-535-001/-005/-101/-105/-109 when RIN = 44,000. For each takeoff/lift,

add one RIN if the mast is installed on 206L, 206L1, or 206L3 (includes 206L3 with Increased Power

Operation kit installed per BHT-206-SI-2039) and two RIN if the mast is installed on a 206L4 (also

applicable to 206L3+ helicopters (Increased Gross Weight Upgrade Kit 206-706-530 installed per

BHT-206-SI-2052)). Refer to ASB 206L-94-99 Rev. B, dated 10 August 2001.

Collective idler link 206-010-446-105, serial numbers A-1 through A-27, inclusively, and serial numbers

RE-238 through and including RE-270 will be retired from service at 1200 hours service time. Refer to

ASB 206L-98-110, dated 6 May 1998.

Collective lever 206-010-447-105, serial numbers A-1 through A-22, inclusively, will be retired from

service at 1200 hours service time. Refer to ASB 206L-98-110, dated 6 May 1998.

Swashplate support assemblies 206-010-452-109 must be inspected every 50 hours after the swashplate

support has accumulated 1500 hours in service. Refer to ASB 206L-93-89 Rev. B, dated 4 April 1994.

Landing gear aft crosstube 206-053-211-103 has an airworthiness life of 33,000 landings. Refer to

ASB 206L-94-97, dated 17 August 1994.

Reservoir per DOT-3HT specification and Exemption Letter DOT-E-7218. Life starts from date of

manufacture.

Reservoir per DOT-3HT specification and Exemption Letter DOT-E-8162. This reservoir is a detail part of

reservoir assembly 206-073-848-121. Life starts from date of manufacture.

Tail rotor blade 206-016-201-127 and subsequent, retirement life increased to 2500 hours. Refer to

TB 206L-89-147, dated 2 June 1989.

Main rotor blades 206-015-001-ALL (all dash numbers). It is permissible to use any main rotor blade (mix

and match) on 206L, 206L1, 206L3, and 206L4 provided that all conditions are met. Refer to

TB 206L-87-142, dated 1 October 1987, and IL 206L-00-68 Rev. A or subsequent.

4-00-00

Page 10 Rev. 24 25 JUN 2019

Export Classification C, ECCN EAR99

Page 27

TC APPROVED BHT-206L3-MM-1

32

33

34

35

36

37

38

39

Table 4-1. Airworthiness Limitations Schedule (Cont)

NOTES (CONT):

Tail rotor blades 206-016-201-ALL (all dash numbers). It is permissible to use any tail rotor blade on 206L,

206L1, 206L3, and 206L4 provided that all conditions are met. Refer to TB 206L-94-167 Rev. A, dated

1 May 1995.

Part of squib assembly 30908. Retire squib no later than 15 years after date of manufacturing. Dispose of

time expired squib in accordance with local regulations.

Part of squib assembly 29022971 and approved alternate for squib 30908. Retire squib no later than

15 years after date of manufacturing. Dispose of time expired squib in accordance with local regulations.

Storage life of cutter assembly Y-1265-11-1, in original sealed container, is set at 60 months. Service life

is 36 months from the time the cutter assembly is removed from the original sealed container. The

36-month service life must be contained within the 60-month storage life. Dispose of time expired squib in

accordance with local regulations.

Example 1 – Cutter assembly stored for 24 months: 60 - 24 = 36-month service life.

Example 2 – Cutter assembly stored for 48 months: 60 - 48 = 12-month service life.

Example 3 – Cutter assembly stored for 1 month: 60 - 1 = 59 months, reduced to 36 months maximum

service life.

Affected horizontal stabilizer 206-023-119-167 must be removed from service no later than

30 September 2008. Refer to ASB 206L-06-141 for list of horizontal stabilizer serial numbers affected.

Applicable horizontal stabilizers must be inspected every 600 hours or annually until replaced. Refer to

ASB 206L-06-141 for inspection details.

Applicable to 206L3+ helicopters (Increased Gross Weight Upgrade Kit 206-706-530 installed per

BHT-206-SI-2052).

The airworthiness life of 4000 hours is only applicable to main rotor blades not affected by

ASB 206L-09-159 Rev. A, dated 13 November 2009, or subsequent. Refer to TCCA AD CF-2011-44 R1,

dated 1 February 2012, or subsequent for life applicable to blades affected by ASB 206L-09-159.

Main rotor hub tension torsion straps 206-310-004 have an airworthiness life of 1200 hours or 48 months,

whichever occurs first. The calendar life of 48 months starts when new straps are installed in a main rotor

hub and blade assembly, and are subjected to rotation on the helicopter.

4-00-00

Export Classification C, ECCN EAR99

25 JUN 2019 Rev. 24 Page 11

Page 28

BHT-206L3-MM-1 TC APPROVED

1

2

1

2

Table 4-2. Inspection Limitations Schedule

COMPONENT

Tailboom Upper Left Attachment

Fitting

NOTES:

Inspection limitation for the part number listed applies to all successive dash numbers for that

component unless otherwise specified.

You must do an inspection of the tailboom upper left attachment fitting 206-032-409-001 every

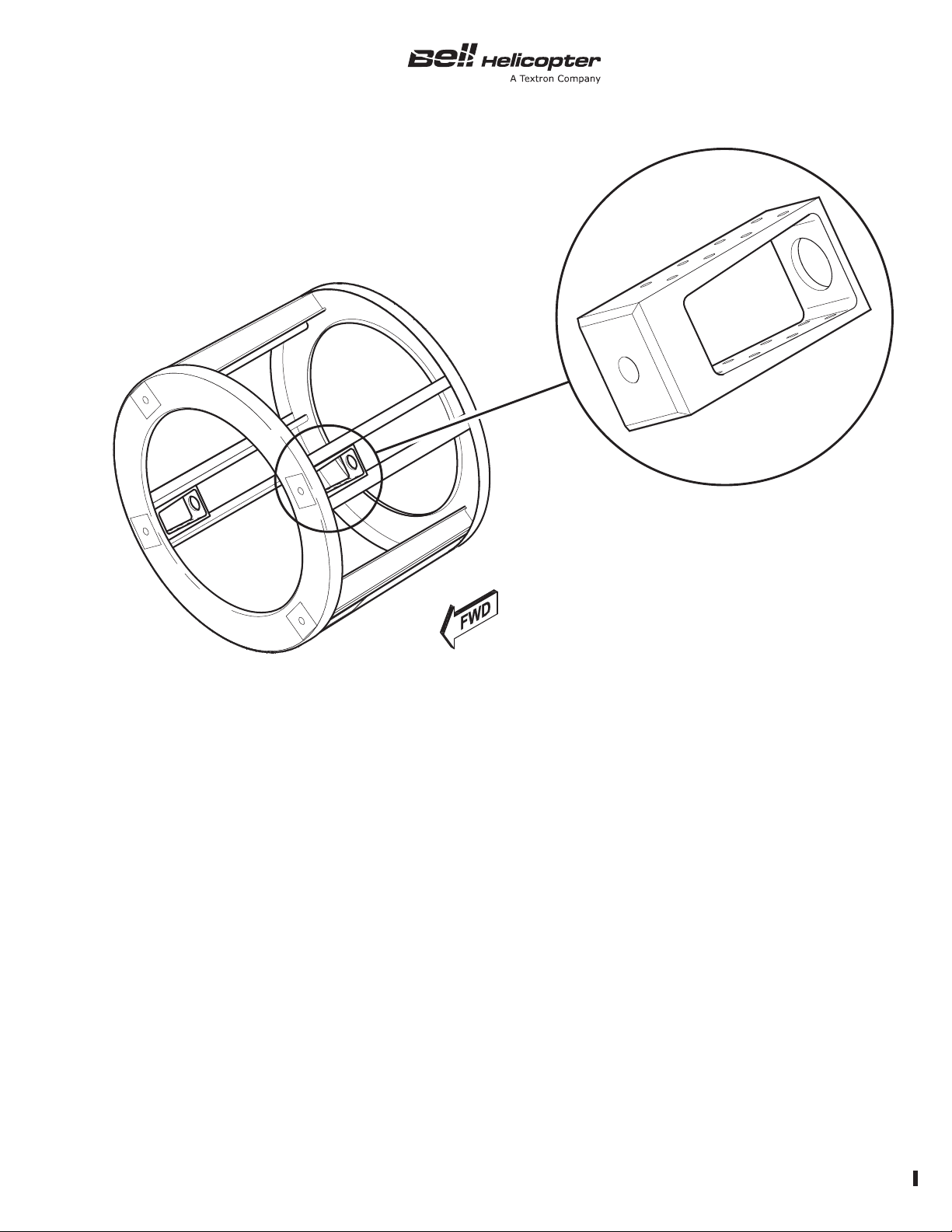

110 flight hours. Refer to ASB 206L-09-158 for a listing of affected tailbooms. Refer to Figure 4-1 for

inspection details.

PART NUMBER

206-032-409-001 110 hours

INSPECTION INTERVAL

(HOURS OPERATION TIME)

4-00-00

Page 12 Rev. 24 25 JUN 2019

Export Classification C, ECCN EAR99

Page 29

TC APPROVED BHT-206L3-MM-1

206LS_MM_04_0001+_c01

INSPECTION PROCEDURE:

1. Inspect upper left attachment fitting for cracks, mechanical damage, corrosion damage,

loose rivets, and general condition.

2. Refer to ASB 206L-09-158 for wear, damage, and repair limits.

3. Repair fitting in accordance with ASB 206L-09-158.

4. Replace cracked or damaged fitting or loose rivets in accordance with ASB 206L-09-158.

5. If a crack is found, contact Product Support Engineering .

(DETAILS OMITTED FOR CLARITY)

Figure 4-1. Tailboom Upper Left Attachment Fitting (206-032-409-001)

— Recurring 110-Hour Inspection

ECCN EAR99

25 JUN 2019 Rev. 24 Page 13/14

4-00-00

Page 30

Page 31

BHT-206L3-MM-1

TABLE OF CONTENTS

Paragraph Chapter/Section Page

Number Title Number Number

CHAPTER 5 — INSPECTIONS AND COMPONENT OVERHAUL SCHEDULE

INSPECTIONS

5-1 General .......................................................................................... 5-00-00 3

5-2 Items Not Covered and Inspection Responsibility ......................... 5-00-00 3

5-3 Crash Damage ............................................................................... 5-00-00 4

5-4 Types of Inspections ...................................................................... 5-00-00 4

5-5 Definitions ...................................................................................... 5-00-00 5

5-6 Inspection and Overhaul Tolerance ............................................... 5-00-00 6

SCHEDULED INSPECTIONS

5-7 Scheduled Inspections ................................................................... 5-00-00 7

5-8 Airframe Inspection Program .................................................... 5-00-00 7

5-9 Airframe Progressive Inspection Programs .............................. 5-00-00 7

5-10 100-Hour Airframe Progressive Inspection Program ................ 5-00-00 7

5-11 300-Hour Airframe Progressive Inspection Program ................ 5-00-00 8

5-12 Airframe Periodic Inspection Program ...................................... 5-00-00 9

5-13 100-Hour Airframe Periodic Inspection Program ...................... 5-00-00 9

5-14 300-Hour Airframe Periodic Inspection Program ...................... 5-00-00 9

5-15 Changing Inspection Program .................................................. 5-00-00 10

5-16 100-Hour Airframe Progressive Inspection — Event No. 1............ 5-00-00 17

5-17 100-Hour Airframe Progressive Inspection — Event No. 2............ 5-00-00 27

5-18 100-Hour Airframe Progressive Inspection — Event No. 3............ 5-00-00 33

5-19 100-Hour Airframe Progressive Inspection — Event No. 4............ 5-00-00 39

5-20 100-Hour Airframe Periodic Inspection .......................................... 5-00-00 47

5-21 300-Hour Airframe Progressive Inspection — Event No. 1............ 5-00-00 49

5-22 300-Hour Airframe Progressive Inspection — Event No. 2............ 5-00-00 55

5-23 300-Hour Airframe Progressive Inspection — Event No. 3............ 5-00-00 63

5-24 300-Hour Airframe Progressive Inspection — Event No. 4............ 5-00-00 69

5-25 300-Hour Airframe Progressive Inspection — Event No. 5............ 5-00-00 75

5-26 300-Hour Airframe Progressive Inspection — Event No. 6............ 5-00-00 83

5-27 300-Hour Airframe Periodic Inspection .......................................... 5-00-00 87

5-28 100-Hour Inspection....................................................................... 5-00-00 89

5-29 300-Hour Inspection....................................................................... 5-00-00 93

5-30 1000-Hour Inspection..................................................................... 5-00-00 101

5-31 1200-Hour Inspection..................................................................... 5-00-00 103

5-32 As Required by Manufacturer ........................................................ 5-00-00 109

5-33 Weekly Inspection .......................................................................... 5-00-00 111

5-34 12-Month Inspection ...................................................................... 5-00-00 113

5-35 12 Months of Component Operation .............................................. 5-00-00 115

5-36 24-Month Inspection ...................................................................... 5-00-00 117

5-37 60-Month Inspection ...................................................................... 5-00-00 121

5-38 300-Hour or 12-Month Inspection .................................................. 5-00-00 123

5-39 600 Hours of Component Operation .............................................. 5-00-00 125

5-40 600 Hours or 12 Months of Component Operation ........................ 5-00-00 127

5-41 1200 Hours of Component Operation ............................................ 5-00-00 129

Export Classification C, ECCN EAR99

15 MAY 2015 Rev. 22 Page 1

5-00-00

Page 32

BHT-206L3-MM-1

TABLE OF CONTENTS (CONT)

Paragraph Chapter/Section Page

Number Title Number Number

FIGURES

Figure Page

Number Title Number

TABLES

Table Page

Number Title Number

5-42 1500 Hours of Component Operation ............................................ 5-00-00 131

5-43 1500 Hours of Component Operation and Every 50 Hours

Thereafter ...................................................................................... 5-00-00 133

5-44 2250 Hours or 60 Months of Component Operation ...................... 5-00-00 135

5-45 3000 Hours of Component Operation ............................................ 5-00-00 137

SPECIAL INSPECTIONS

5-46 Special Inspections ........................................................................ 5-00-00 139

5-47 After Fuel System Maintenance and/or Component Change ........ 5-00-00 141

5-48 1 to 5 Hours After Each Installation ............................................... 5-00-00 145

5-49 3 to 8 Hours After Each Installation ............................................... 5-00-00 147

5-50 10 to 25 Hours After Each Installation ........................................... 5-00-00 149

5-51 100 Hours After Each Installation .................................................. 5-00-00 151

CONDITIONAL INSPECTIONS

5-52 Conditional Inspections .................................................................. 5-00-00 153

5-53 Hard Landing ................................................................................. 5-00-00 155

5-54 Sudden Stoppage/Acceleration ..................................................... 5-00-00 161

5-55 Overspeed Main Rotor — 114% or Greater................................... 5-00-00 169

5-56 Overtorque ..................................................................................... 5-00-00 173

5-57 Engine Compressor Stall or Surge ................................................ 5-00-00 179

5-58 Lightning Strike .............................................................................. 5-00-00 187

5-59 Engine Overtemp ........................................................................... 5-00-00 193

COMPONENT OVERHAUL SCHEDULE

5-60 Component Overhaul Schedule..................................................... 5-00-00 195

5-1 Maintenance Zones ............................................................................................ 15

5-2 Inspection of Main Rotor Flight Control Bolts/Nuts ............................................. 119

5-1 100-Hour Airframe Progressive Inspection Events ............................................. 7

5-2 300-Hour Airframe Progressive Inspection Events ............................................. 8

5-3 300-Hour Airframe Progressive or 300-Hour Airframe Periodic Inspection

Program Prerequisites ........................................................................................ 11

5-4 Component Overhaul Schedule .......................................................................... 195

5-00-00

Page 2 Rev. 22 15 MAY 2015

Export Classification C, ECCN EAR99

Page 33

INSPECTIONS

WARNING

NOTE

BHT-206L3-MM-1

5-1. GENERAL

This chapter contains the time limit intervals and the

requirements for the Scheduled Inspection, Special

Inspection, Conditional Inspection, and for the

Component Overhaul Schedule.

FAILURE TO CORRECT CONDITIONS

SUCH AS, BUT NOT LIMITED TO,

CORROSION, EROSION, MECHANICAL

DAMAGE, OR OBVIOUS WEAR FOUND

DURING A SCHEDULED INSPECTION

COULD SERIOUSLY AFFECT THE

AIRWORTHINESS OF THE HELICOPTER.

The inspection intervals given in this chapter are the

maximum permitted. Do not exceed these intervals.

The owner/operator is responsible for increasing the

scope and the frequency of the inspections as

necessary. Make sure the helicopter is maintained

safely during all unusual local changes, such as

environmental conditions, helicopter use, etc. You can

request changes to the requirements in this chapter

through the local Aviation Authority.

Helicopter Textron or an approved Airworthiness

Authority.

Changes to the TBO will be introduced by either

revision to the Maintenance Manual, Chapter 5 or a

Technical Bulletin.

Every calendar and hourly inspection is a thorough

visual inspection to determine the airworthiness of the

helicopter and the components. Qualified persons

must do the inspections in accordance with quality

standard aircraft practices and the applicable

maintenance manuals. Bell Helicopter Textron

considers that it is mandatory to obey all the

applicable Alert Service Bulletins (ASB) and the

Airworthiness Directives (AD).

Component operating time records are necessary for

components that have scheduled maintenance

procedures, which are different from those of the

airframe. It is the owner/operator’s responsibility to

keep the Historical Service Records for the applicable

component and to do the necessary maintenance

procedures.

Before each inspection, remove or open the

necessary cowlings, fairing, inspection doors, and

panels.

The inspection intervals and the component overhaul

schedule provided in this chapter are applicable only

to Bell Helicopter Textron approved parts.

The time period given for the overhaul of a

component (or the failure to give a time

period for the overhaul of a component)

does not constitute a warranty of any kind.

The only warranty applicable to the

helicopter or any component is the

warranty included in the Purchase

Agreement for the helicopter or the

component.

The Time Between Overhaul (TBO) and the inspection

periods are determined through experience, tests,

Lead The Fleet (LTF), or any other special programs

and the judgement of Bell Helicopter Textron

engineers. They are subject to change only by Bell

Export Classification C, ECCN EAR99

5-2. ITEMS NOT COVERED AND

INSPECTION RESPONSIBILITY

This manual does not include the specific inspection

intervals for some components such as the compass

calibration and the pitot static test. These specific

inspection intervals are given by your government

regulatory authority. Refer to their requirements for

these specific inspections.

The owner/operator of the helicopter is responsible for

the maintenance done on the helicopter and for

ensuring that the specific time interval of any

inspection procedure is not exceeded. It is the owner/

operator’s responsibility to:

1. Establish, maintain, and review the log books for

discrepancies.

2. Make sure the Alert Service Bulletins (ASB), the

Airworthiness Directives (AD), and the special

5-00-00

15 MAY 2015 Rev. 22 Page 3

Page 34

BHT-206L3-MM-1

inspections are done when they are required to be

done.

3. Make sure the scheduled inspections, the special

inspections, and the required inspections for all of the

installed kits are complied with.

4. Make sure all parts and components for which

Historical Service Records are required have

documented traceability to their original installation in

the helicopter.

5. Make sure all limited life parts that have

completed their published operating limits are

replaced.

6. Make sure all of the components that have

completed their published overhaul periods are

overhauled.

7. Make sure all of the maintenance that is done on

the helicopter is done by an approved maintenance

organization.

The maintenance organization/person doing the

maintenance is responsible for the quality of the

maintenance done.

The owner/operator may choose to ask the

maintenance organization/person doing the

maintenance to perform the tasks listed by prior

arrangement through a separate formal agreement.

5-3. CRASH DAMAGE

a. Scheduled inspections must occur at specified

operating intervals. The intervals may be in operating

time (hours), cycles, torque events (RIN), calendar

(days, months, years) or other assigned units. This

makes sure that the helicopter is airworthy.

b. Special inspections are of a temporary nature

or of a special interval that is not consistent with the

scheduled inspections.

c. Conditional inspections do not occur at a

specified time. A conditional inspection is the result of

a known or suspected unusual event, known or

suspected malfunctions, or defects.

d. An interim inspection occurs between

overhauls.

e. The component overhaul schedule gives the

elapsed operating time at which a component must be

removed, disassembled, examined for condition, and

overhauled, in accordance with data approved by Bell

Helicopter Textron.

2. Lubrication and servicing requirements are in

addition to those stated in this chapter (Chapter 12).

3. For corrosion control, refer to the Corrosion

Control Guide, CSSD-PSE-87-001 and the

BHT-ALL-SPM.

4. For the 250-C30 series engine, refer to the

Rolls-Royce Operations and Maintenance Manual