DIGITAL STORAGE OSCILLOSCOPE

DCS-1000B SERIES

DCS-1072B

DCS-1102B

DCS-1054B

DCS-1074B

DCS-1104B

INSTRUCTION MANUAL

B71-0463-01

■ About a trademark, a registered trademark

A company name and the brand name mentioned in this instruction

manual are the trademark or the registered trademark of each

company or group in each country and region.

■ About this instruction manual

When copying the part or all of contents of this instruction manual,

seek the copyright holder.

In addition, the specifications of the product and the contents of

this instruction manual are subject to change without notice for

improvement. Please check to our website for the latest version.

This manual is the contents as of May 2018.

■ About export

When export or ship the product to overseas, please confirm laws

and regulations about the export.

Table of Contents

USING THE PRODUCT SAFELY...................................................Ⅰ-Ⅴ

1. GETTING STARTED ................................................................... 1

1-1. Main Features ...................................................................... 1

1-2. Accessories .......................................................................... 3

Panel Overview ........................................................................... 4

1-2-1. Front Panel ........................................................................................ 4

1-2-2. Rear Panel ........................................................................................ 9

1-2-3. Display............................................................................................. 10

1-3. Set Up ................................................................................ 11

1-3-1. Tilt Stand ......................................................................................... 11

1-3-2. Power Up ......................................................................................... 12

1-3-3. First Time Use ................................................................................. 12

1-3-4. How to Use This Manual ................................................................. 14

1-4. Built-in Help ....................................................................... 18

2. MEASUREMENT ...................................................................... 19

2-1. Basic Measurement ............................................................ 19

2-1-1. Channel Activation .......................................................................... 19

2-1-2. Autoset ............................................................................................ 20

2-1-3. Run/Stop ......................................................................................... 21

2-1-4. Horizontal Position/Scale................................................................. 22

2-1-5. Vertical Position/Scale ..................................................................... 23

2-2. Automatic Measurement ...................................................... 24

2-2-1. Measurement Items ......................................................................... 24

2-2-2. Add Measurement ........................................................................... 27

2-2-3. Remove Measurement .................................................................... 28

2-2-4. Gated mode ..................................................................................... 29

2-2-5. Display All mode .............................................................................. 29

2-2-6. High Low Function ........................................................................... 30

2-2-7. Statistics .......................................................................................... 31

2-2-8. Reference Levels ............................................................................ 33

2-3. Cursor Measurement .......................................................... 34

2-3-1. Use Horizontal Cursors ................................................................... 34

2-3-2. Use Vertical Cursors ....................................................................... 36

2-4. Math Operation ................................................................... 39

2-4-1. Basic Math Overview & Operators .................................................. 39

2-4-2. FFT Overview & Window Functions ................................................ 41

2-4-3. Advanced Math Overview ................................................................ 43

2-4-4. Advanced Math Operation ............................................................... 44

3. CONFIGURATION .................................................................... 46

3-1. Acquisition ......................................................................... 46

3-1-1. Select Acquisition Mode .................................................................. 46

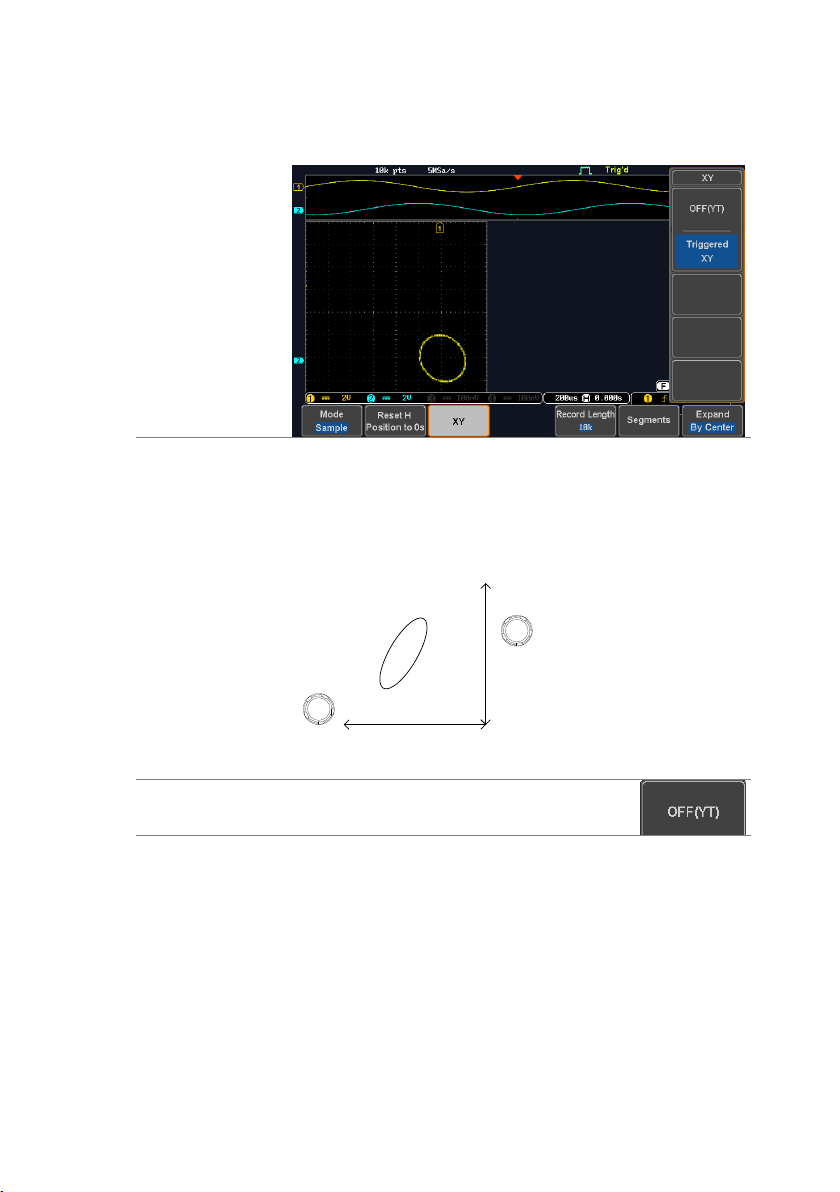

3-1-2. Show Waveform in XY Mode ........................................................... 47

3-1-3. Set the Record Length..................................................................... 49

3-2. Segmented Memory Acquisition (Option) .............................. 49

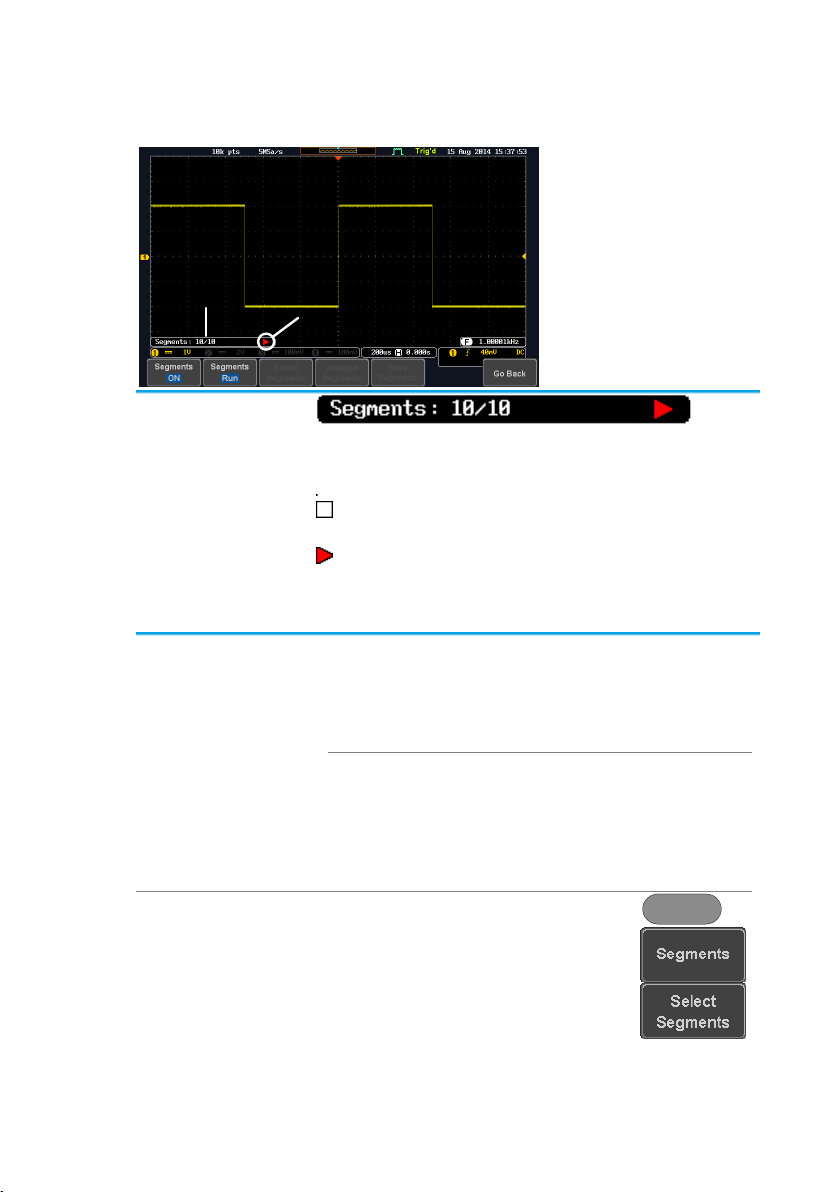

3-2-1. Segments Display ........................................................................... 51

3-2-2. Set the Number of Segments .......................................................... 51

3-2-3. Run Segmented Memory................................................................. 52

3-2-4. Navigate Segmented Memory ......................................................... 53

3-2-5. Play Through Each Segment ........................................................... 54

3-2-6. Segment Measurement ................................................................... 54

3-2-7. Automatic Measurement.................................................................. 54

3-2-8. Segment Info ................................................................................... 57

3-2-9. Save Segment ................................................................................. 57

3-3. Display ............................................................................... 60

3-3-1. Display Waveform as Dots or Vectors ............................................. 60

3-3-2. Set the Level of Persistence ............................................................ 60

3-3-3. Set the Intensity Level ..................................................................... 61

3-3-4. Select Display Graticule .................................................................. 62

3-3-5. Freeze the Waveform (Run/Stop) .................................................... 62

3-3-6. Turn Off Menu ................................................................................. 63

3-4. Horizontal View .................................................................. 63

3-4-1. Move Waveform Position Horizontally ............................................. 63

3-4-2. Select Horizontal Scale ................................................................... 64

3-4-3. Select reference point of the horizontal expansion .......................... 64

3-4-4. Select Waveform Update Mode ....................................................... 65

3-4-5. Zoom Waveform Horizontally .......................................................... 65

3-4-6. Play/Pause ...................................................................................... 67

3-5. Vertical View (Channel) ....................................................... 69

3-5-1. Move Waveform Position Vertically ................................................. 69

3-5-2. Select Vertical Scale ....................................................................... 69

3-5-3. Select Coupling Mode ..................................................................... 70

3-5-4. Input Impedance .............................................................................. 70

3-5-5. Invert Waveform Vertically ............................................................... 70

3-5-6. Limit Bandwidth ............................................................................... 71

3-5-7. Expand by Ground/Center ............................................................... 71

3-5-8. Select Probe Type ........................................................................... 72

3-5-9. Select Probe Attenuation Level ....................................................... 73

3-5-10. Set the Deskew ............................................................................. 73

3-6. Bus Key Configuration(Option) ............................................ 74

3-6-1. Bus Display ..................................................................................... 74

3-6-2. Serial Bus ........................................................................................ 75

3-6-3. Threshold Configuration .................................................................. 82

3-7. Trigger ............................................................................... 89

3-7-1. Trigger Type Overview .................................................................... 89

3-7-2. Trigger Parameter Overview ........................................................... 91

3-7-3. Setup Holdoff Level ......................................................................... 94

3-7-4. Setup Trigger Mode ......................................................................... 95

3-7-5. Using the Edge Trigger.................................................................... 95

3-7-6. Using Advanced Delay Trigger ........................................................ 96

3-7-7. Using Pulse Width Trigger ............................................................... 97

3-7-8. Using Video Trigger ......................................................................... 98

3-7-9. Pulse Runt trigger ............................................................................ 99

3-7-10. Using Rise and Fall Trigger ......................................................... 100

3-7-11. Using the Timeout Trigger ........................................................... 101

3-7-12. Using the Bus Trigger (Option) .................................................... 102

3-7-13. Bus Trigger Mode ........................................................................ 109

3-8. Search (Option) ................................................................. 110

3-8-1. Configuring Search Events ............................................................ 110

3-8-2. Copying Search Event To/From Trigger Events ............................ 111

3-8-3. Search Event Navigation ............................................................... 112

3-8-4. Save Search Marks ....................................................................... 112

3-8-5. Setting/Clearing Single Search Events .......................................... 113

3-8-6. FFT Peak ....................................................................................... 113

3-9. System Settings and Miscellaneous Settings ....................... 116

3-9-1. Select Menu Language.................................................................. 116

3-9-2. View System Information ............................................................... 116

3-9-3. Erase Memory ............................................................................... 117

3-9-4. Probe Compensation Frequency ................................................... 117

4. Applications ............................................................................ 118

4-1. Overview ................................................................ ........... 118

4-2. Running Applications ......................................................... 118

4-3. Using Go-NoGo ................................................................. 119

4-4. Using the DVM (Option) ..................................................... 123

4-5. Using the Data Logger (Option) .......................................... 124

4-6. Using the Digital Filter (Option) .......................................... 126

4-7. Remote Disk ...................................................................... 127

5. SAVE/RECALL ........................................................................ 130

5-1. File Format/Utility .............................................................. 130

5-1-1. Image File Format ......................................................................... 130

5-1-2. Waveform File Format ................................................................... 130

5-1-3. Spreadsheet File Format ............................................................... 131

5-1-4. Setup File Format .......................................................................... 132

5-2. Create/Edit Labels ............................................................. 134

5-3. Save ................................................................................. 136

5-3-1. File Type/Source/Destination ........................................................ 136

5-3-2. Save Image ................................................................................... 136

5-3-3. Save Waveform ............................................................................. 138

5-3-4. Save Setup .................................................................................... 139

5-4. Recall ............................................................................... 141

5-4-1. File Type/Source/Destination ........................................................ 141

5-4-2. Recall Default Panel Setting .......................................................... 141

5-4-3. Recall Waveform ........................................................................... 143

5-4-4. Recall Setup .................................................................................. 144

5-5. Reference Waveforms ........................................................ 145

5-5-1. Recall and Display Reference Waveforms .................................... 145

6. FILE UTILITIES ...................................................................... 147

6-1-1. File Navigation ............................................................................... 147

6-1-2. Create Folder ................................................................................ 148

6-1-3. Rename File .................................................................................. 149

6-1-4. Delete File or Folder ...................................................................... 150

6-1-5. Copy File to USB ........................................................................... 150

6-1-6. Installing Optional Apps and Functions ......................................... 151

7. HARDCOPY ............................................................................ 152

7-1-1. Printer I/O Configuration ................................................................ 152

7-1-2. Print Output ................................................................................... 152

7-1-3. Save - Hardcopy Key..................................................................... 153

8. REMOTE CONTROL ............................................................... 155

8-1-1. Configure USB Interface................................................................ 155

8-1-2. Configure the Ethernet Interface ................................................... 155

8-1-3. Configure Socket Server ............................................................... 157

8-1-4. USB Functionality Check ............................................................... 158

8-1-5. Socket Server Functionality Check ................................................ 158

9. MAINTENANCE ...................................................................... 163

9-1-1. How to use SPC function............................................................... 163

9-1-2. Vertical Accuracy Calibration ......................................................... 163

9-1-3. Probe Compensation ..................................................................... 164

10. APPENDIX ............................................................................ 166

10-1. FAQ ................................................................................ 166

10-2. Updating the Firmware ..................................................... 168

10-3. SPECIFICATIONS ............................................................ 169

10-3-1. Model Specifications.................................................................... 169

10-3-2. Common Specifications ............................................................... 169

10-3-3. Probe Specifications .................................................................... 172

10-4. DIMENSIONS .................................................................. 173

USING THE PRODUCT SAFELY

<Pictorial indication>

Some part of this product or the instruction

manual may shows this pictorial indication. In

this case, if the product is incorrectly used in that

part, a serious danger may be brought about on

the user’s body or the product.

To use the part with this pictorial indication, be

sure to refer to this instruction manual.

WARNING

!

If you use the product, ignoring this indication,

you may get killed or seriously injured. This

indication shows that the warning item to avoid

the danger is provided.

CAUTION

!

If you incorrectly use the product, ignoring this

indication, you may get slightly injured or the

product may be damaged. This indication shows

that the caution item to avoid the danger is

provided.

■ Preface

To use the product safely, read this instruction manual to the end.

Before using this product, understand how to correctly use it.

If you read this manual but you do not understand how to use it, please

ask us or your local dealer. After you read this manual, save it so that

you can read it, anytime as requied.

■ Pictorial indication

This instruction manual and product show the warning and caution items

required to safely use the product. The following pictorial indication and

warning character indication are provided.

Please be informed that we are not responsible for any damages to the user

or to the third person, arising from malfunctions or other failures due to

wrong use of the product or incorrect operation, except such responsibility

for damages as required by law.

I

USING THE PRODUCT SAFELY

WARNING

!

CAUTION

!

■ Do not remove the product’s covers and panels

Never remove the product’s covers and panels for any purpose.

Otherwise, the user’s electric shock or fire may be incurred.

■ Warning on using the product

Warning items given below are to avoid danger to user’s body and life and

avoid the damage or deterioration of the product.

Use the product, observing the following warning and caution items.

■ Warning items on power supply

● Power supply voltage

The rated power supply voltages of the product are 100, 120, 220

and 240VAC. The rated power supply voltage for each product

should be confirmed by reading the label attached on the back of

the product or by the “rated” column shown in this instruction manual.

The specification of power cord attached to the products is rated to

125VAC for all products which are designed to be used in the

areas where commercial power supply voltage is not higher than

125VAC. Accordingly, you must change the power cord if you want

to use the product at the power supply voltage higher than 125VAC.

If you use the product without changing power cord to 250VAC

rated one, electric shock or fire may be caused.

When you used the product equipped with power supply voltage

switching system, please refer to the corresponding chapter in the

instruction manuals of each product.

● Power cord

(Important) The attached power cord set can be used for this

device only.

If the attached power cord is damaged, stop using the product and

call us or your local dealer. If the power cord is used without the

damage being removed, an electric shock or fire may be caused.

● Protective fuse

If an input protective fuse is blown, the product does not operate. For a

product with external fuse holder, the fuse may be replaced. As for

how to replace the fuse, refer to the corresponding chapter in this

instruction manual.

If no fuse replacement procedures are indicated, the user is not

permitted to replace it. In such case, keep the case closed and

consult us or your local dealer. If the fuse is incorrectly replaced, a

fire may occur.

II

USING THE PRODUCT SAFELY

■ Warning item on Grounding

If the product has the GND terminal on the front or rear panel surface,

be sure to ground the product to safely use it.

■ Warnings on Installation environment

● Operating temperature and humidity

Use the product within the operating temperature indicated in the

“rating” temperature column. If the product is used with the vents of

the product blocked or in high ambient temperatures, a fire may occur.

Use the product within the operating humidity indicated in the “rating”

humidity column. Watch out for condensation by a sharp humidity

change such as transfer to a room with a different humidity. Also, do

not operate the product with wet hands. Otherwise, an electric shock

or fire may occur.

● Use in gas

Use in and around a place where an inflammable or explosive gas or

steam is generated or stored may result in an explosion and fire. Do

not operate the product in such an environment.

Also, use in and around a place where a corrosive gas is generated or

spreading causes a serious damage to the product. Do not operate

the product in such an environment.

● Installation place

Avoid installing the product on inclined places or on places subject to

vibration. Otherwise, the product may slip or fall down to cause

damages or injury accidents.

■ Do not let foreign matter in

Do not insert metal and inflammable materials into the product from its

vent and spill water on it. Otherwise, electric shock or fire may occur.

■ Warning item on abnormality while in use

In abnormal situations, such as “smoke”, “fire”, “abnormal smell” or

“irregular noise” occur from the product while in use, stop using the

product, turn off the switch, and remove the power cord plug from the

outlet. After confirming that no other devices catch fire, ask us or your

local dealer.

III

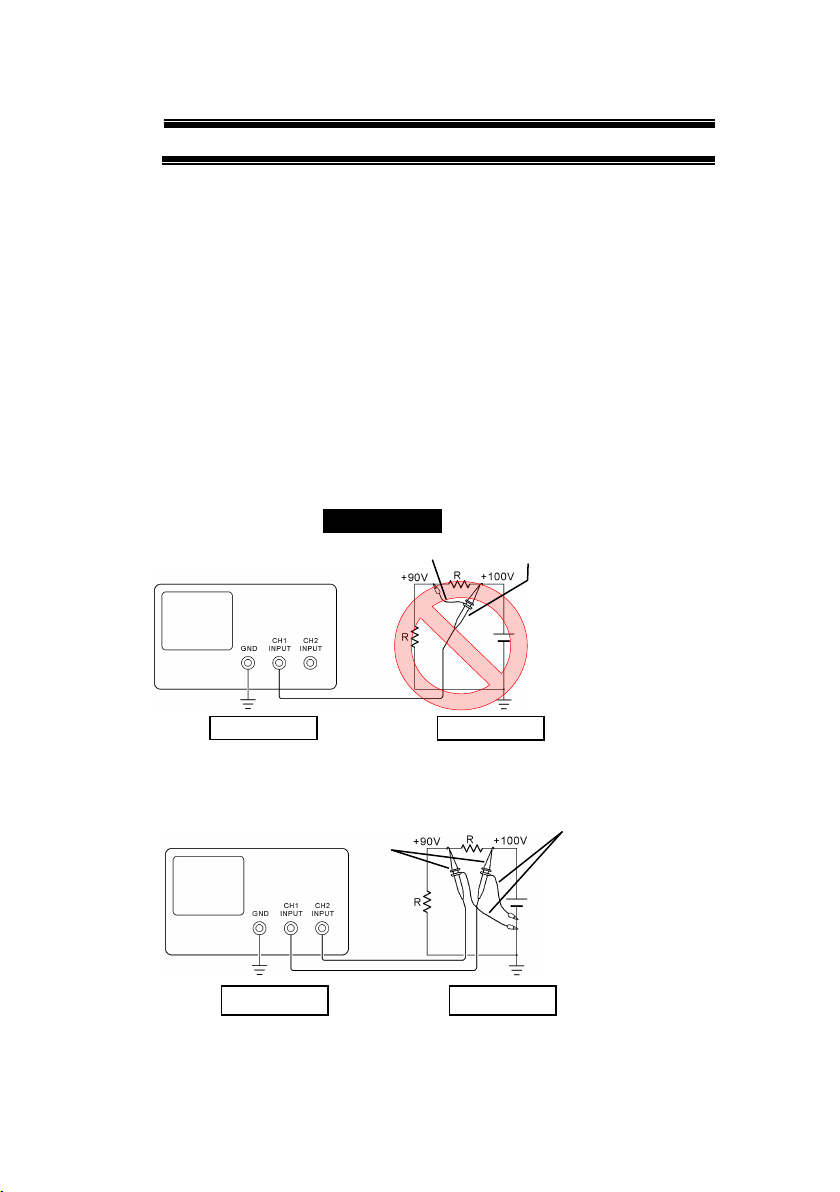

USING THE PRODUCT SAFELY

At connecting as Bad

Example, +90V and chassis

are shorted, and damages

substance a measured.

Therefore do not make such

connection.

If the instrument is not

grounded, a potential of the

chassis is +90V.

Ground a chassis, in order to

prevent an electric shock

accident.

Setting of panel switches of an

oscilloscope

CH2 INV: ON (CH2 inverted)

ADD : ON (CH1+CH2)

Grounding

Oscilloscope

Earth Lead

Probe

Grounding

Oscilloscope

Grounding

Grounding

Earth Lead

Probe

■ Warning Item for the Measurement

● When you measure a part of a high voltage, be careful not to touch a

hand to a measurement part directly. There is a risk of an electric shock.

● Be sure to connect the probe or the cable and the ground side of the input

connector to the ground potential (ground) of the substance measured.

Since the chassis of this instrument is connected to the ground of the

input block, connecting the earth lead of the probe to the potential

floating from the ground potential may result in the following:

Electric shock

A high current flows and damages the substance measured, this

instrument, and other connected device.

The following parts are connected to the chassis:

Probe for each channel and ground side of the input BNC connector

Grounding conductor of the accessory 3-core power cord

Ground pin for an interface signal

“Bad example” Prohibition

When measuring the floating potential, a differential method of

measurement is recommended ( refer to the figure below ).

“Good example”

IV

USING THE PRODUCT SAFELY

■ Input / Output terminals

Maximum input to terminal is specified to prevent the product

from being damaged. Do not supply input, exceeding the

specifications that are indicated in the "Rating" column in the

instruction manual of the product.

Also, do not supply power to the output terminals from the

outside.

Otherwise, a product failure is caused.

■ Calibration

Although the performance and specifications of the product are

checked under strict quality control during shipment from the factory,

they may be deviated more or less by deterioration of parts due to their

aging or others.

It is recommended to periodically calibrate the product so that it is used

with its performance and specifications stable.

For consultation about the product calibration, ask us or your local

dealer.

■ Daily Maintenance

When you clean off the dirt of the product covers, panels, and

knobs, avoid solvents such as thinner and benzene. Otherwise, the

paint may peel off or resin surface may be affected.

To wipe off the covers, panels, and knobs, use a soft cloth with neutral

detergent in it. During cleaning, be careful that water, detergent, or

other foreign matters do not get into the product.

If a liquid or metal gets into the product, an electric shock and fire are

caused. During cleaning, remove the power cord plug from the outlet.

Use the product correctly and safely, observing the above warning and

caution items. Because the instruction manual indicates caution items even

in individual items, observe those caution items to correctly use the product.

If you have questions or comments about the instruction manual, ask us or

E-Mail us.

V

Model name

Frequency

bandwidth

Input

channels

Real-time

Sampling Rate

DCS-1054B

50MHz

4

1GSa/s

DCS-1074B

70MHz

4

1GSa/s

DCS-1104B

100MHz

4

1GSa/s

DCS-1072B

70MHz

2

1GSa/s

DCS-1102B

100MHz

2

1GSa/s

Note

This instruction manual has been described as the

4ch model. In 2ch model, Can't set the ch3 and ch4.

1. GETTING STARTED

This chapter describes the DCS-1000B in a nutshell, including its

main features and front / rear panel introduction. After going through

the overview, follow the Set Up section to properly set up the

oscilloscope for first time use. The Set Up section also includes a

starter on how to use this manual effectively.

1-1. Main Features

1

Features

7 inch, 800 x 480, WVGA TFT display.

Available from 70MHz to 100MHz.

Real-time sampling rate of 1GSa/s.

Deep memory: 10M points record length.

Waveform capture rate of 50,000 waveforms per

second.

Vertical sensitivity: 1mV/div~10V/div.

On-screen Help.

32 MB internal flash disk.

Go-NoGo application.

Remote Disk application.

Additional

Feature

Segmented Memory: Optimizes the acquisition

memory to selectively capture only the

important signal details. Up to 29000 successive

waveform segments can be captured with a

time-tag resolution of 4ns.

Waveform Search: Allows the scope to search

for a number of different signal events.

Serial Bus Decode: Serial bus decoding of

UART, I2C, SPI, CAN & LIN buses.

Interface

USB host port: front panel, for storage devices.

USB device port: rear panel, for remote control

or printing.

Probe calibration output with selectable output

frequency (1kHz ~ 200kHz).

Ethernet port (4ch Model Only)

Calibration output.

2

Standard

Accessories

Part number

Description

Power cord

N/A region dependent

Passive probe

x4 or x2

for 50MHz

/70MHz

Model

GTP-070B-4

70 MHz probe

for 100MHz

Model

GTP-100B-4

100MHz probe

Standard

Apps

Name

Description

Go-NoGo

Go-NoGo testing app.

Remote Disk

Allows the scope to mount a

network share drive.

Optional

Apps

Name

Description

Data Log

Waveform or image data logging

app.

DVM

Digital Volt Meter app.

Digital Filter

High or low pass digital filter for

analog inputs.

Optional

Function

Part number

Description

Segment

Segment memory Function

Search

Search Function

Bus

Bus trigger & analysis Function

Optional

Accessories

Part number

Description

GTC-001

Instrument cart, 470(W)x430(D)mm

(U.S. type input socket)

GTC-002

Instrument cart, 330(W)x430(D)mm

(U.S. type input socket)

GTL-110

test lead, BNC to BNC heads

GTL-246

USB2.0 A - B type cable

Drivers

USB driver

1-2. Accessories

* Note: We reserves the right to change the probe model type at anytime without

notice for probe model types of similar specification.

3

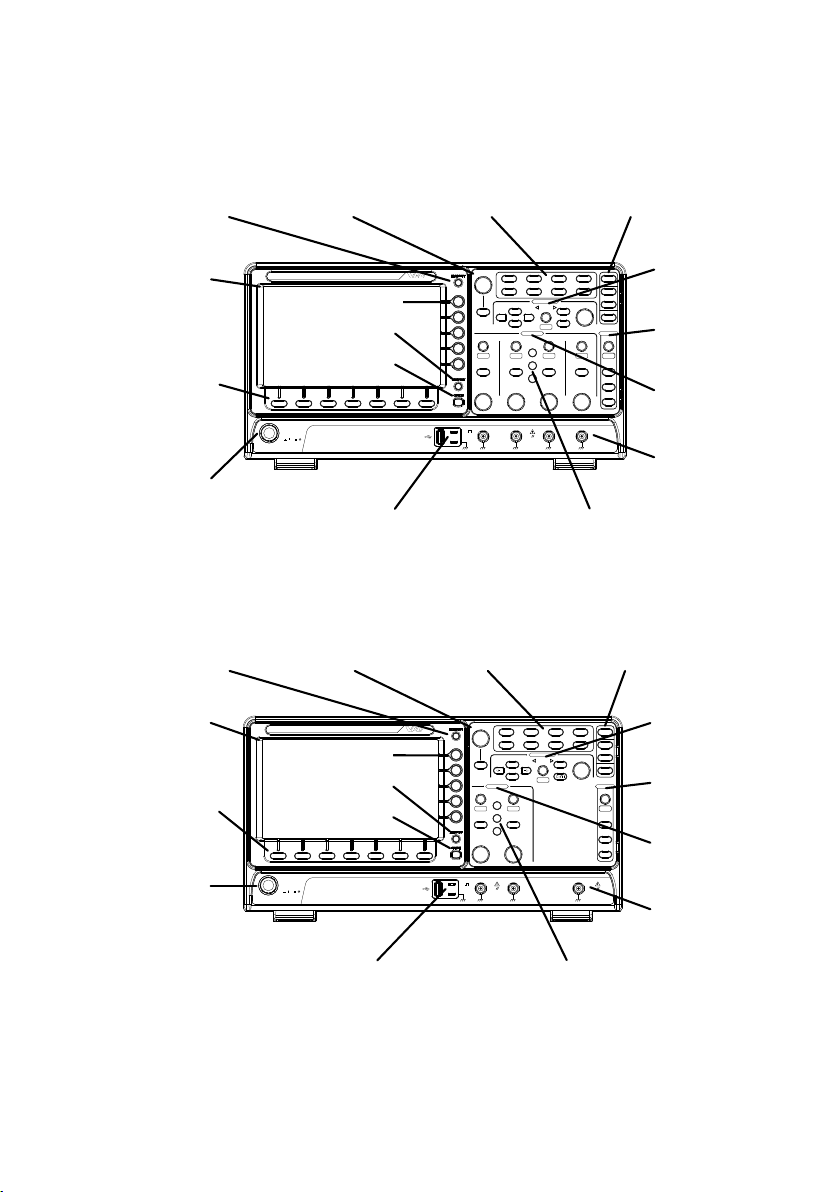

VARIABLE

POSITION

HORIZONTAL

POSITION

POSITION

POSITION

POSITION

VERTICAL

MATH

REF

BUS

TRIGGER

LEVEL

PUSH TO

ZERO

PUSH TO

ZERO

PUSH TO

ZERO

PUSH TO

ZERO

PUSH TO

ZERO

PUSH TO

ZERO

SCALE

POWER

CH1 CH2 CH3 CH4

2V

1MW16pF

Digital Storage Oscilloscope

200 MHz 1 GS/s

Visual Persistence Oscilloscope

LCD

Variable knob

and Select key

Autoset, Run/Stop, Single

and Default settings

CH1~CH4

Trigger

controls

Function

keys

USB Host port, Probe

Compensation terminals

Power

button

Hardcopy key

Option key

Math, Reference

and Bus keys

Bottom

menu

keys

Horizontal

controls

Menu key

Vertical

controls

Side menu keys

VARIABLE

POSITION

HORIZONTAL

TRIGGER

LEVEL

PUSH TO

ZERO

PUSH TO

ZERO

SCALE

Measure

Display

Cursor

Help

App

Save/Recall

Acquire

Utility

Autoset

Run/Stop

Single

Default

Select

Search

Set/Clear

Zoom

Menu

50 %

Force-Trig

POSITION

POSITION

VERTICAL

MATH

REF

BUS

PUSH TO

ZERO

PUSH TO

ZERO

M

R

B

Digital Storage Oscilloscope

200 MHz 1 GS/s

Visual Persistence Oscilloscope

POWER

CH1 CH2 EXT TRIG

2V

1MW16pF 1MW16pF

LCD

Variable knob

and Select key

Autoset, Run/Stop, Single

and Default settings

CH1~CH2,

EXT TRIG

Trigger

controls

Function

keys

USB Host port, Probe

Compensation terminals

Power

button

Hardcopy key

Option key

Math, Reference

and Bus keys

Bottom

menu

keys

Horizontal

controls

Menu key

Vertical

controls

Side menu keys

Panel Overview

1-2-1. Front Panel

4ch Model

2ch Model

4

LCD Display

7” WVGA TFT color LCD. 800 x 480 resolution,

wide angle view display.

Menu Off Key

Use the Menu Off key to hide the

onscreen menu system.

Option Key

The Option key is used to access

future installed options.

Menu Keys

The side menu and bottom menu keys are used to

make selections from the soft-menus on the LCD

user interface.

To choose menu items, use the 7 Bottom menu

keys located on the bottom of the display panel.

To select a variable or option from a menu, use the

side menu keys on the side of the panel. See page

14 for details.

Digital Storage Oscilloscope

GDS-2202E

200 MHz 1 GS / s

Visual Persistence Oscilloscope

Side menu

keys

Bottom menu keys

Hardcopy Key

The Hardcopy key is a quick-save

or quick-print key, depending on its

configuration.

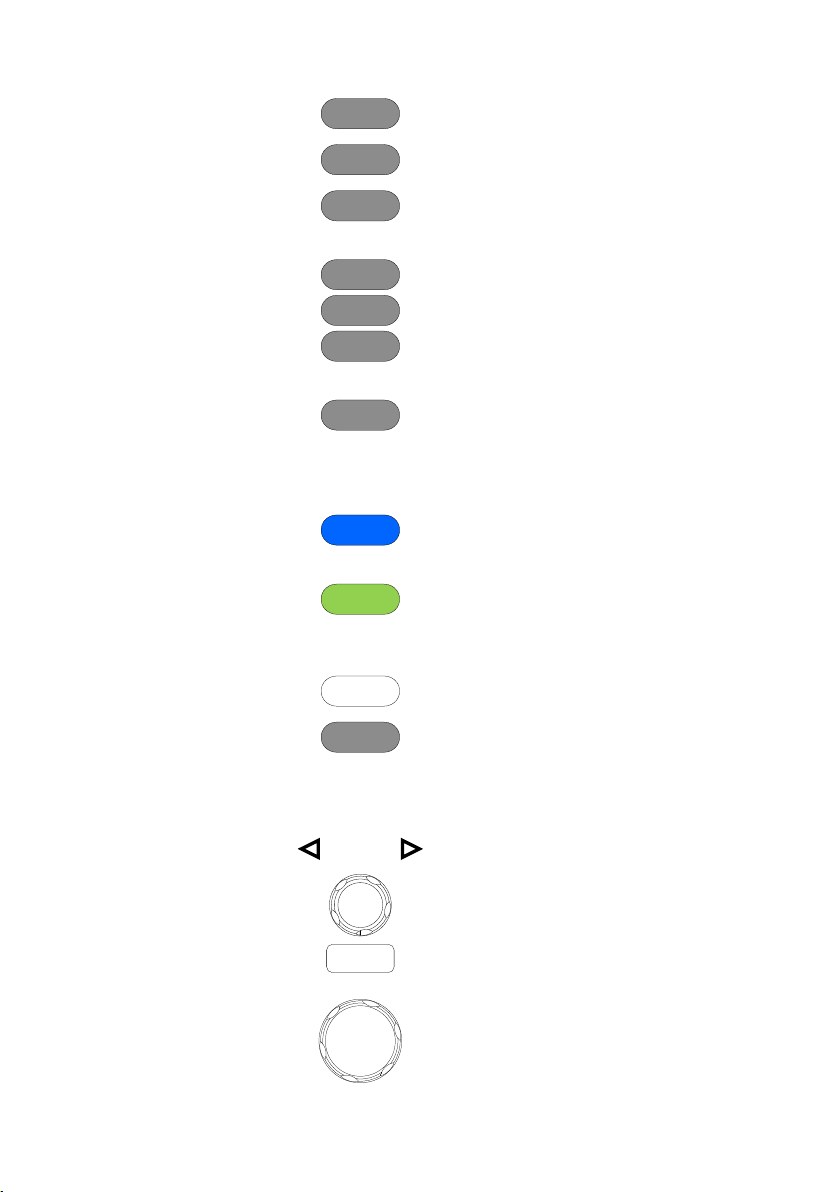

Variable Knob

and Select Key

Select

VARIABLE

The Variable knob is used to

increase/decrease values or to

move between parameters.

The Select key is used to make

selections.

Function Keys

The Function keys are used to enter and configure

different functions on the DCS-1000B.

Measure

Measure

Configures and runs automatic

measurements.

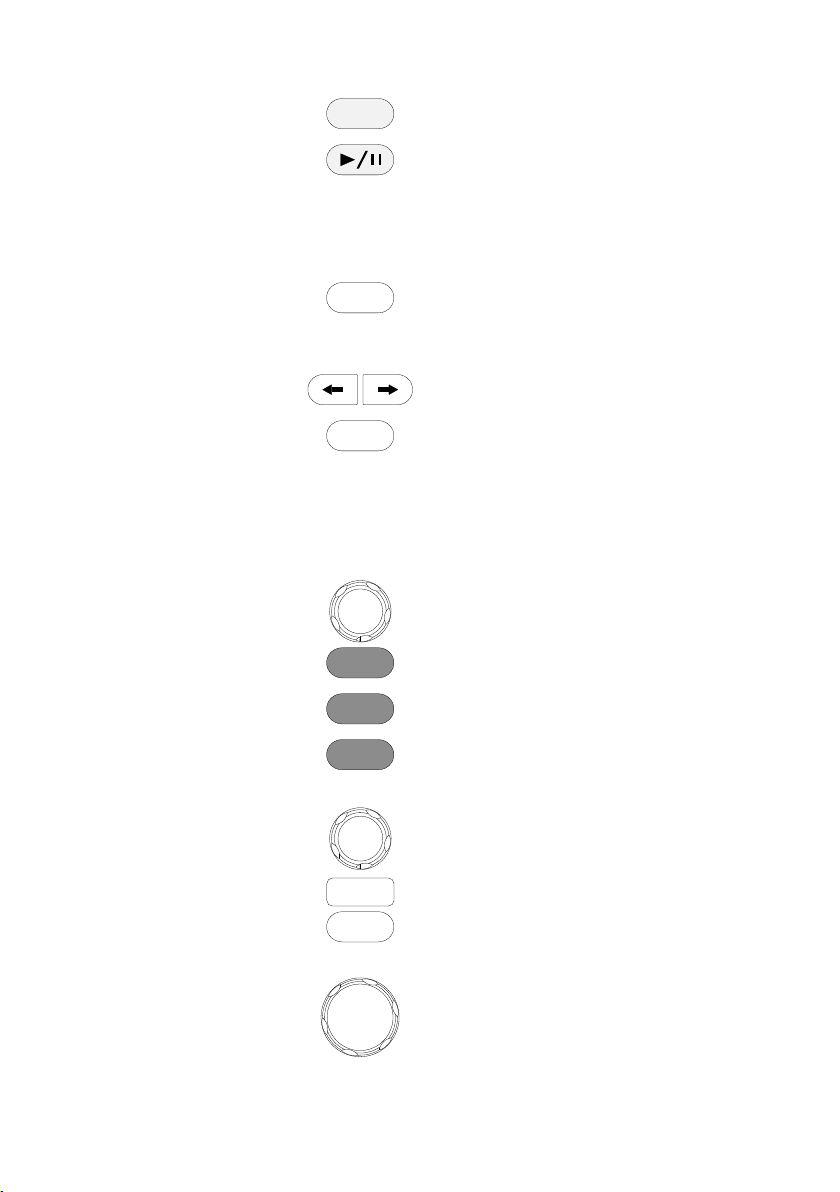

5

Cursor

Cursor

Configures and runs cursor

measurements.

APP

APP

Configures and runs optional

applications.

Acquire

Acquire

Configures the acquisition mode,

including Segmented Memory

acquisition.

Display

Display

Configures the display settings.

Help

Help

Shows the Help menu.

Save/Recall

Save/Recall

Used to save and recall

waveforms, images, panel

settings.

Utility

Utility

Configures the Hardcopy key,

display time, language, probe

compensation and calibration. It

also accesses the file utilities

menu.

Autoset

Autoset

Press the Autoset key to

automatically set the trigger,

horizontal scale and vertical scale.

Run/Stop Key

Run/Stop

Press to Freeze (Stop) or continue

(Run) signal acquisition. The run

stop key is also used to run or stop

Segmented Memory acquisition .

Single

Single

Sets the acquisition mode to single

triggering mode.

Default Setup

Default

Resets the oscilloscope to the

default settings.

Horizontal

Controls

The horizontal controls are used to change the

position of the cursor, set the time base settings,

zoom into the waveforms and search for events.

Horizontal

Position

POSITION

PUSH TO

ZERO

The Position knob is used to

position the waveforms

horizontally on the display screen.

Pressing the knob will reset the

position to zero.

SCALE

SCALE

The Scale knob is used to change

the horizontal scale (TIME/DIV).

6

Zoom

Zoom

Press Zoom in combination with

the horizontal Position knob.

Play/Pause

The Play/Pause key allows you to

view each search event in

succession – to effectively “play”

through each search event. It is

also used to play through a

waveform in zoom mode.

Search

Search

The Search key accesses the

search function menu to set the

search type, source and threshold.

(Optional function)

Search Arrows

Use the arrow keys to navigate the

search events. (Optional function)

Set/Clear

Set/Clear

Use the Set/Clear key to set or

clear points of interest when using

the search function.

(Optional function)

Trigger Controls

The trigger controls are used to control the trigger

level and options.

Level Knob

LEVEL

Used to set the trigger level.

Pressing the knob will reset the

level to zero.

Trigger Menu

Key

Menu

Used to bring up the trigger menu.

50% Key

50 %

Sets the trigger level to the half

way point (50%).

Force - Trig

Force-Trig

Press to force an immediate

trigger of the waveform.

Vertical

POSITION

POSITION

PUSH TO

ZERO

Sets the vertical position of the

waveform. Push the knob to reset

the vertical position to zero.

Channel Menu

Key

CH1

Press the CH1~4 key to set and

configure the channel.

VOLTS/DIV

Knob

VOLTS/DIV

Sets the vertical scale of the

channel (VOLTS/DIV).

7

External Trigger

Input

EXT TRIG

Accepts external trigger signals

(page 89). Only on 2 channel

models.

Input impedance: 1MΩ

Voltage input: ±15V(peak), EXT

trigger capacitance:16pF.

Math Key

MATH

M

Use the Math key to set and

configure math functions.

Reference Key

REF

R

Press the Reference key to set or

remove reference waveforms.

BUS Key

BUS

B

The Bus key is used for parallel

and serial bus (UART, I2C, SPI,

CAN, LIN) configuration.

Channel Inputs

CH1

Accepts input signals.

Input impedance: 1MΩ.

Capacitance: 16pF

CAT I 300V

USB Host Port

2V

TypeA, 1.1/2.0 compatible.

Used for USB memory.

Ground Terminal

2V

Accepts the DUT ground lead for

common ground.

Probe

Compensation

Outputs

2V

The probe compensation output is

used for probe compensation. It

also has an adjustable output

frequency.

By default this port outputs a

2Vpp, square wave signal at 1kHz

for probe compensation.

Power Switch

POWER

Used to turn the power on/off.

: ON

: OFF

8

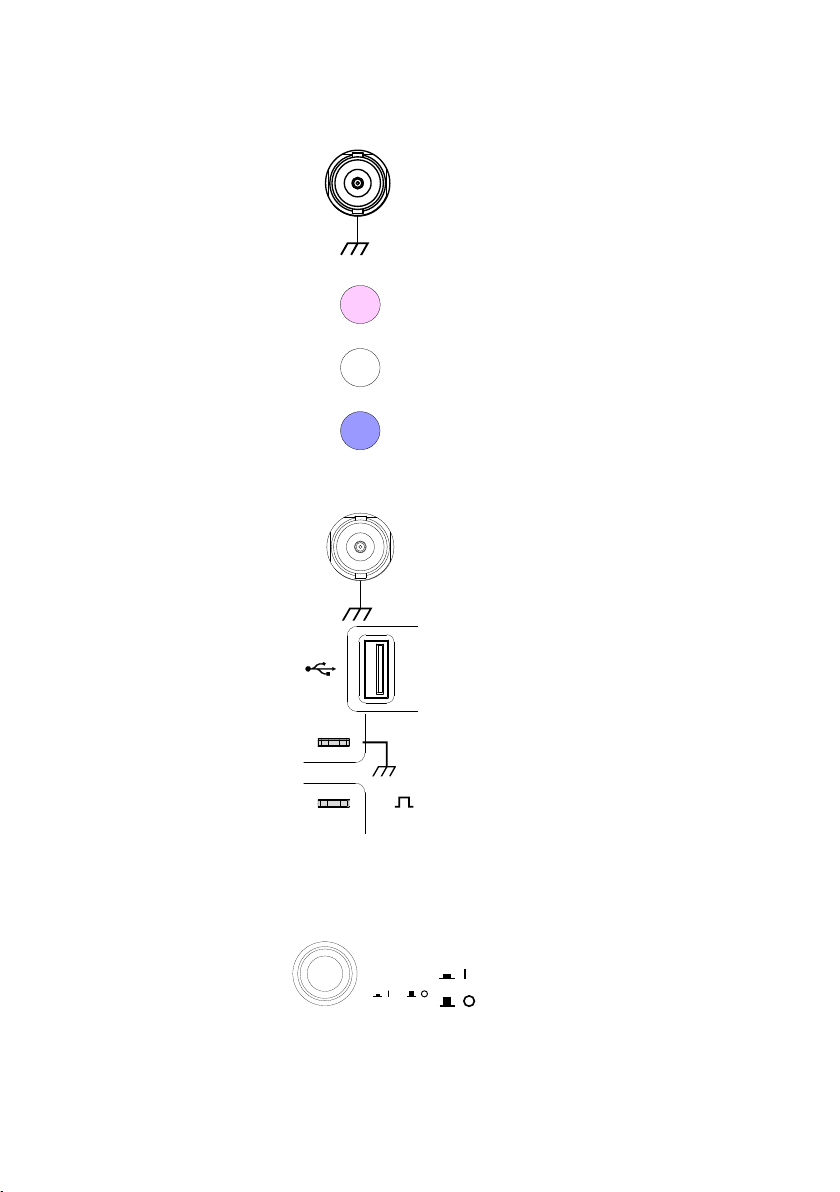

Calibration

output

Key lock Power input socketFan

Go/ No Go

output

LAN portUSB Device port

LINE VOLTAGE

AC 100 240V

RANGE

FREQUENCY 50 60Hz

POWER MAX. 30 Watts

CAUTION

TO AVOID ELECTRIC SHOCK THE POWER CORD PROTECTIVE GROUNDING

DO NOT REMOVE COVERS. REFER SERVICING TO QUALIFIED PERSONNEL.

CONDUCTOR MUST BE CONNECTED TO GROUND.

Ser. No. Label

Calibration

Output

Outputs the signal for vertical scale

accuracy calibration.

USB Device Port

The USB Device port is used for

remote control.

LAN (Ethernet)

Port

The LAN port is used for remote

control over a network or when

combined with the Remote Disk

app, allows the scope to be

mounted to a share disk.

The LAN port is only available for

the 4 channel models

Power Input

Socket

Power cord socket accepts AC

mains, 100 ~ 240V, 50/60Hz.

Security Slot

Kensington security slot compatible.

1-2-2. Rear Panel

9

Go-No Go

Output

Outputs Go-No Go test results as a

500us pulse signal.

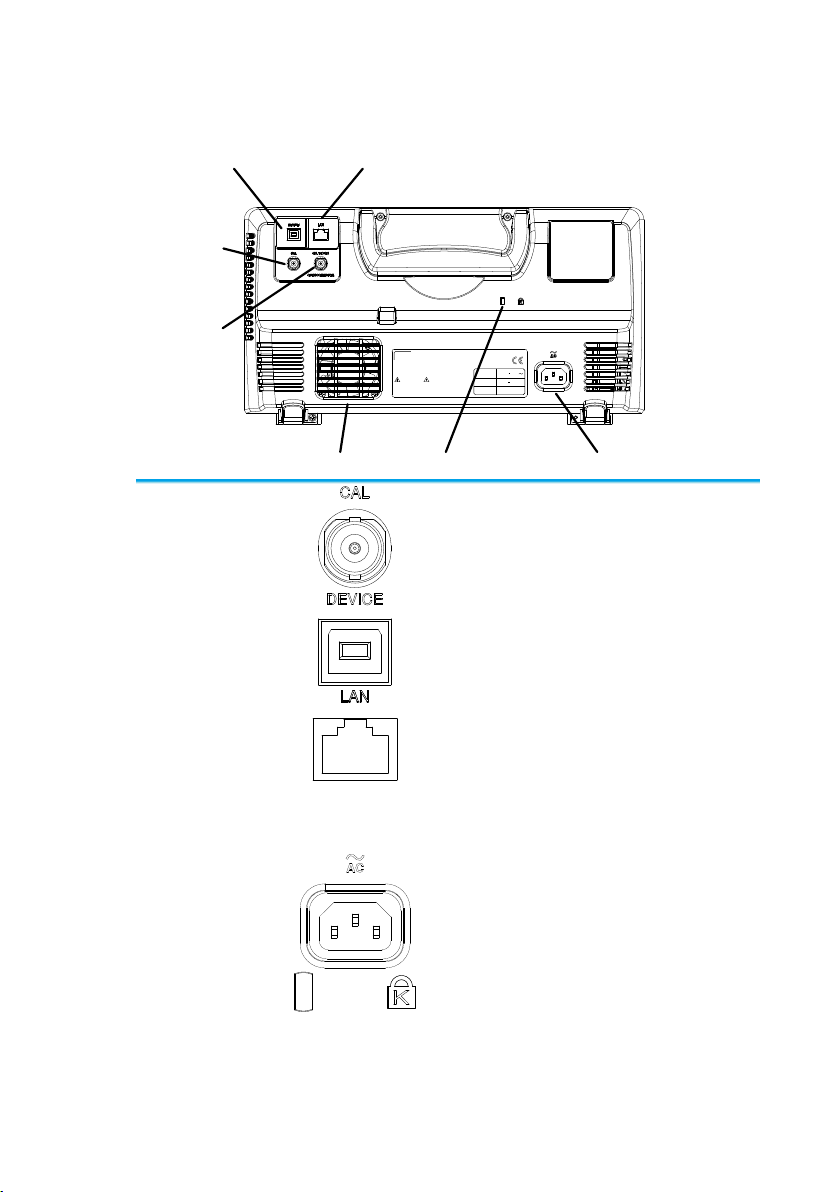

Memory bar

Reference

waveform

Analog

Waveform

Bus

Channel status Horizontal status

Trigger

configuration

Waveform

frequency

Trigger position

Trigger status

Acquistion mode

Trigger level

Channel

Indicators

Memory length

and sample rate

Analog

Waveforms

Shows the analog input signal waveforms.

Channel 1: Yellow

Channel 2: Blue

Channel 3: Pink

Channel 4: Green

Bus Waveforms

Shows the bus waveforms for serial buses. The

values are displayed in hex or binary.

Channel

Indicators

The channel indicators show the zero volt level of

the signal waveform for each activated channel.

Any active channel is shown with a solid color.

Analog channel indicator

Bus indicator(B)

Reference waveform indicator

Math indicator

Trigger Position

Shows the position of the trigger.

Horizontal

Status

Shows the horizontal scale and position.

Trigger Level

Shows the trigger level on the graticule.

Memory Bar

The ratio and the position of the displayed

waveform compared to the internal memory

1-2-3. Display

10

Trigger Status

Trig’d

Triggered.

PrTrig

Pre-trigger.

Trig?

Not triggered, display not updated.

Stop

Trigger stopped. Also appears in

Run/Stop (page 21).

Roll

Roll mode.

Auto

Auto trigger mode.

For trigger details, see page 89.

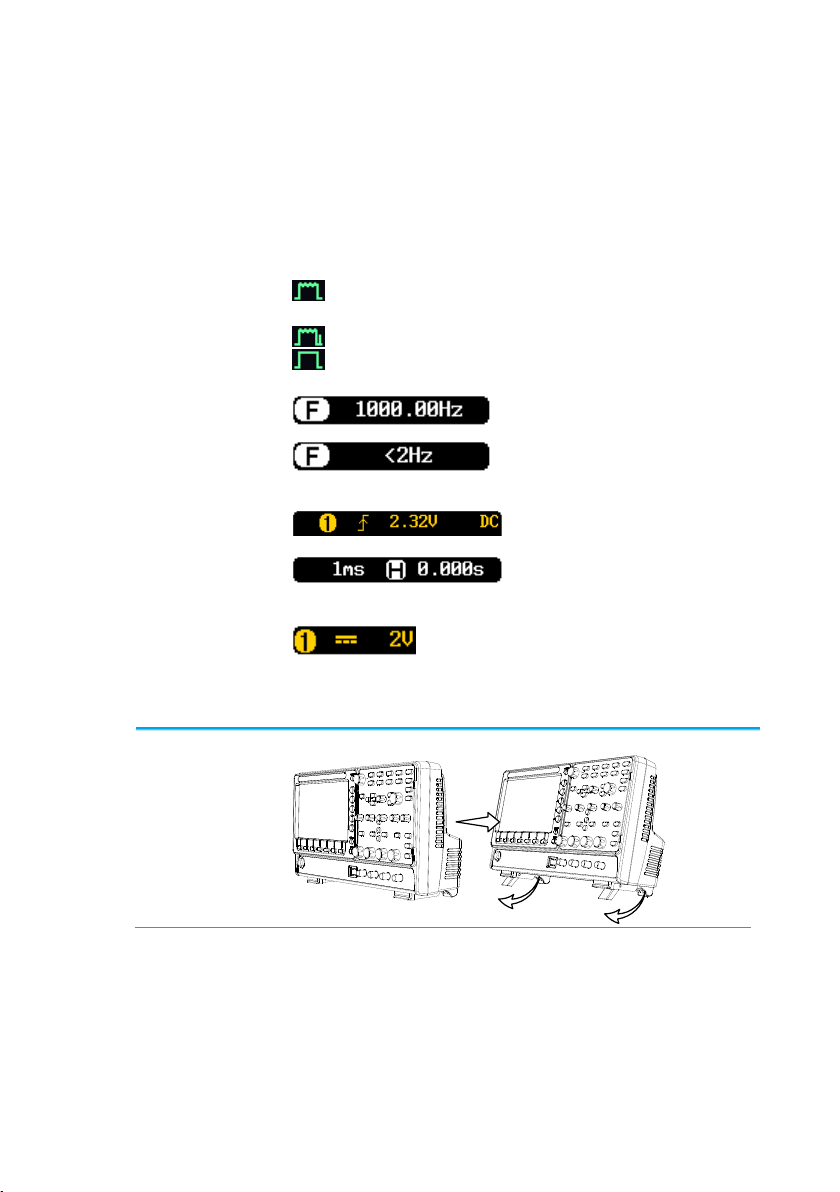

Acquisition

Mode

Normal mode

Peak detect mode

Average mode

For acquisition details, see page 46.

Signal

Frequency

Shows the trigger source

frequency.

Indicates the frequency is

less than 2Hz (lower

frequency limit).

Trigger

Configuration

Trigger source, slope,

voltage, coupling.

Horizontal

Status

Horizontal scale,

horizontal position.

For trigger details, see page 89.

Channel Status

Channel 1, DC coupling, 2V/Div.

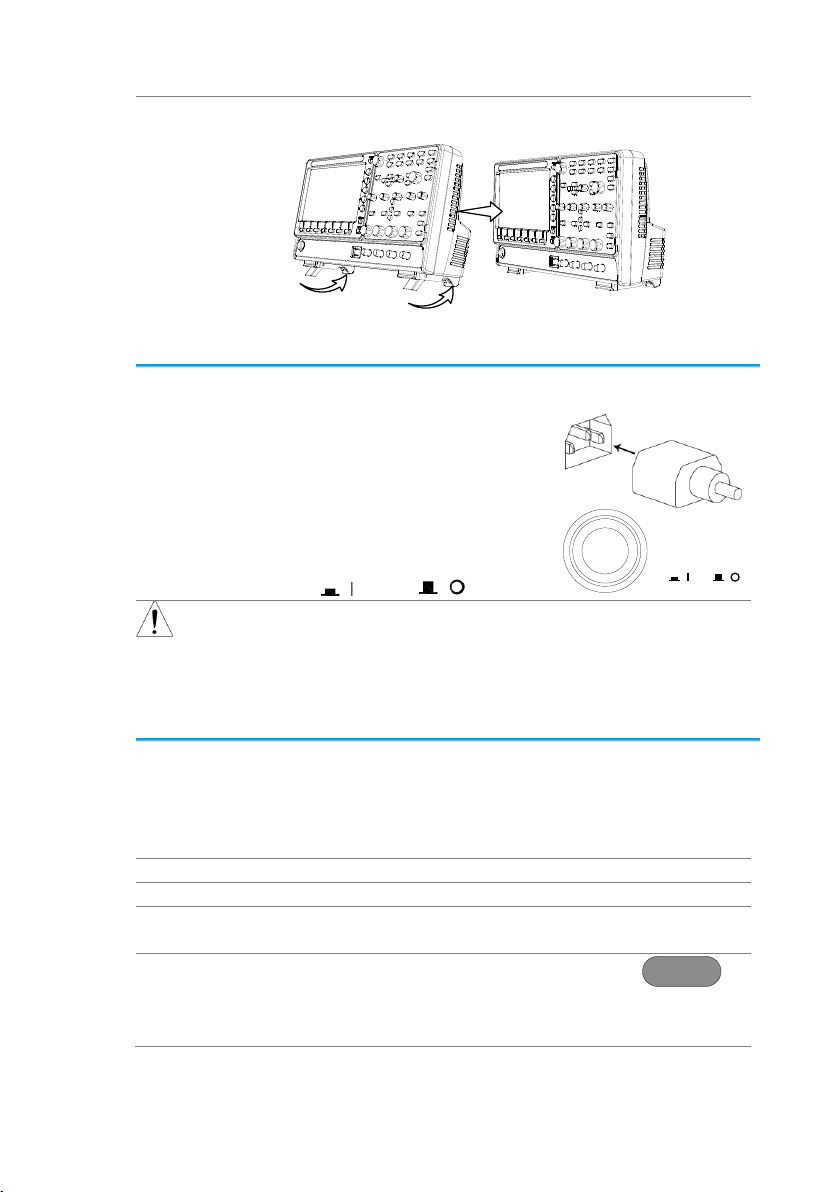

Tilt

To tilt, pull the legs forward, as shown below.

1-3. Set Up

1-3-1. Tilt Stand

11

Stand

To stand the scope upright, push the legs back

under the casing as shown below.

Requirements

The DCS-1000B accepts line voltages of 100 ~

240V at 50 or 60Hz.

Step

1. Connect the power cord to

the rear panel socket.

2. Press the POWER key.

The display becomes

active in ~ 30 seconds.

: ON : OFF

POWER

Note

The DCS-1000B recovers the state right before the

power is turned OFF. The default settings can be

recovered by pressing the Default key on the front

panel. For details, see page 141.

Background

This section describes how to connect a signal,

adjust the scale, and compensate the probe.

Before operating the DCS-1000B in a new

environment, run these steps to make sure the

instrument performs at its full potential.

1. Power On

Follow the procedures on the previous page.

2. Firmware

Update to the latest firmware.

Page 168

3. Optional

appliction

Add the Optional application,

depending on the necessity.

Page 118

4. Reset System

Reset the system by recalling the

factory settings. Press the Default key

on the front panel. For details, see

page 141.

Default

1-3-2. Power Up

1-3-3. First Time Use

12

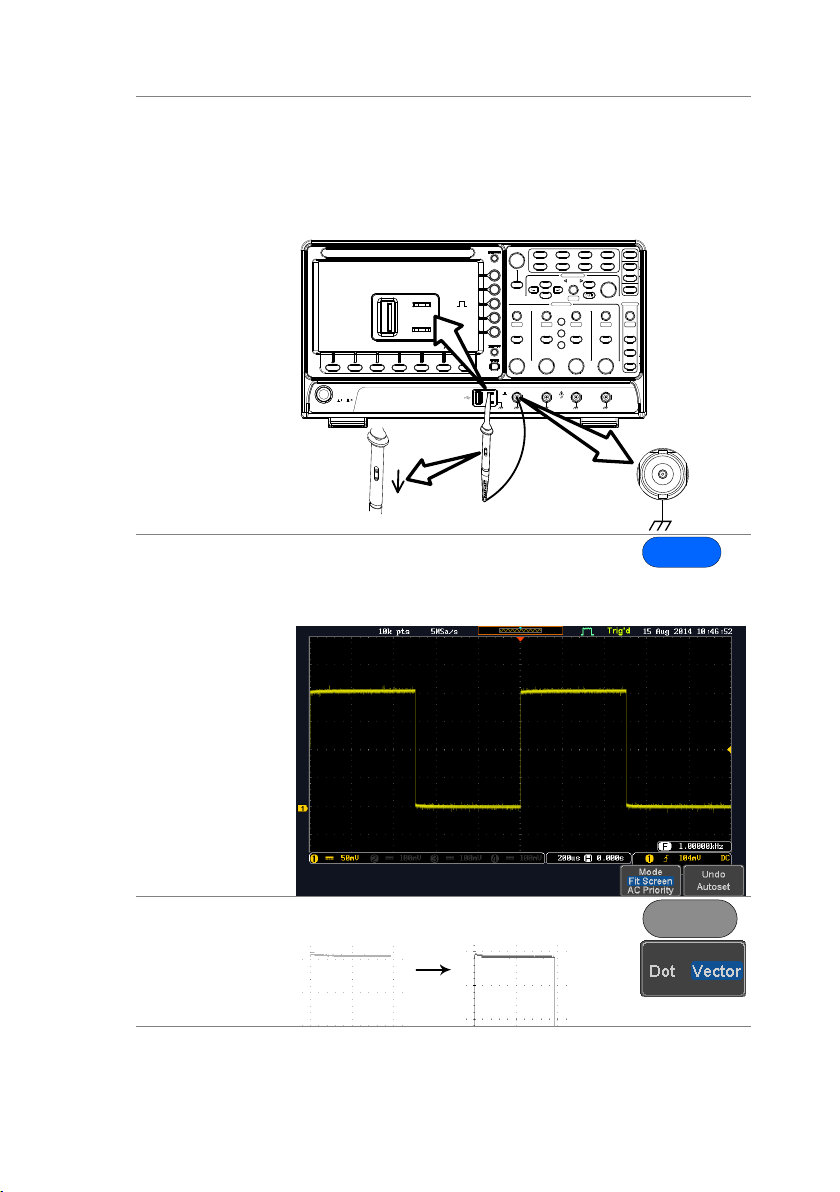

5. Connect

Probe

Connect the probe to the Channel 1 input and to

the CAL signal output. This output provides a 2Vpp, 1kHz square wave for signal compensation by

default.

Set the probe attenuation to x10 if the probe has

adjustable attenuation.

VARIABLE

POSITION

HORIZONTAL

POSITION

POSITION

POSITION

POSITION

VERTICAL

MATH

REF

BUS

TRIGGER

LEVEL

PUSH TO

ZERO

PUSH TO

ZERO

PUSH TO

ZERO

PUSH TO

ZERO

PUSH TO

ZERO

PUSH TO

ZERO

SCALE

POWER

CH1 CH2 CH3 CH4

2V

1MW 16pF

.

Measure

Display

Cursor

Help

Test

Save/Recall

Acquire

Utility

Autoset

Run/Stop

Single

Default

Select

Search

Set/Clear

Zoom

CH1 CH2 CH3 CH4

M

R

B

Menu

50 %

Force-Trig

x1

x10

X

10

X

1

CH1

2V

6. Capture

Signal (Autoset)

Press the Autoset key. A square

waveform appears on the center of

the screen. For Autoset details, see

page 20.

Autoset

7. Select Vector

Waveform

Press the Display key, and set the

display to Vector on the bottom menu.

Display

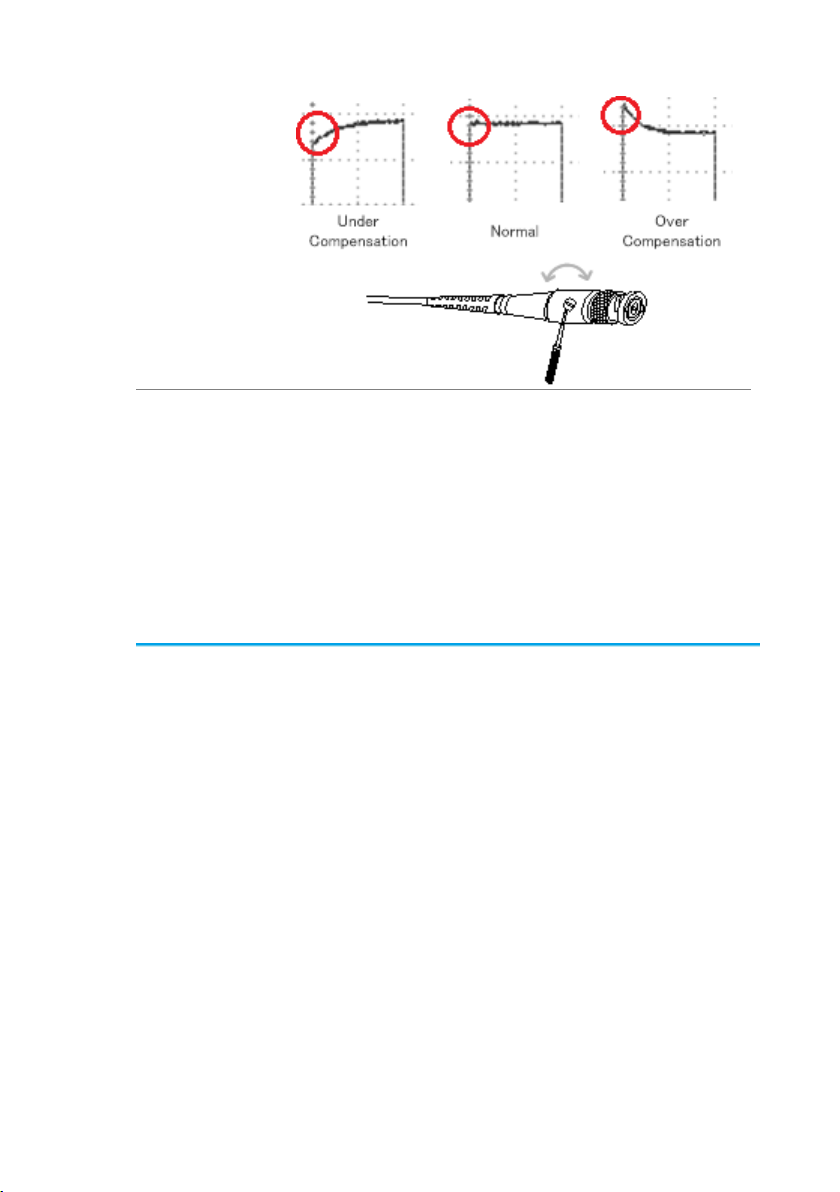

8. Compensate

Probe

Turn the adjustment point on the probe to make

the square waveform edge flat.

13

9. Start

Operation

Continue with the other operations.

Measurement:

page 19

Configuration:

page 46

Save/Recall:

page 130

File Utilities:

page 147

Apps:

page 118

Hardcopy key:

page 152

Remote Control:

page 155

Maintenance:

page 163

Background

This section describes the conventions used in

this manual to operate the DCS-1000B.

Throughout the manual any reference to pressing

a menu key refers to the keys directly below or

beside any menu icons or parameters.

When the user manual says to “toggle” a value or

parameter, press the corresponding menu item.

Pressing the item will toggle the value or

parameter.

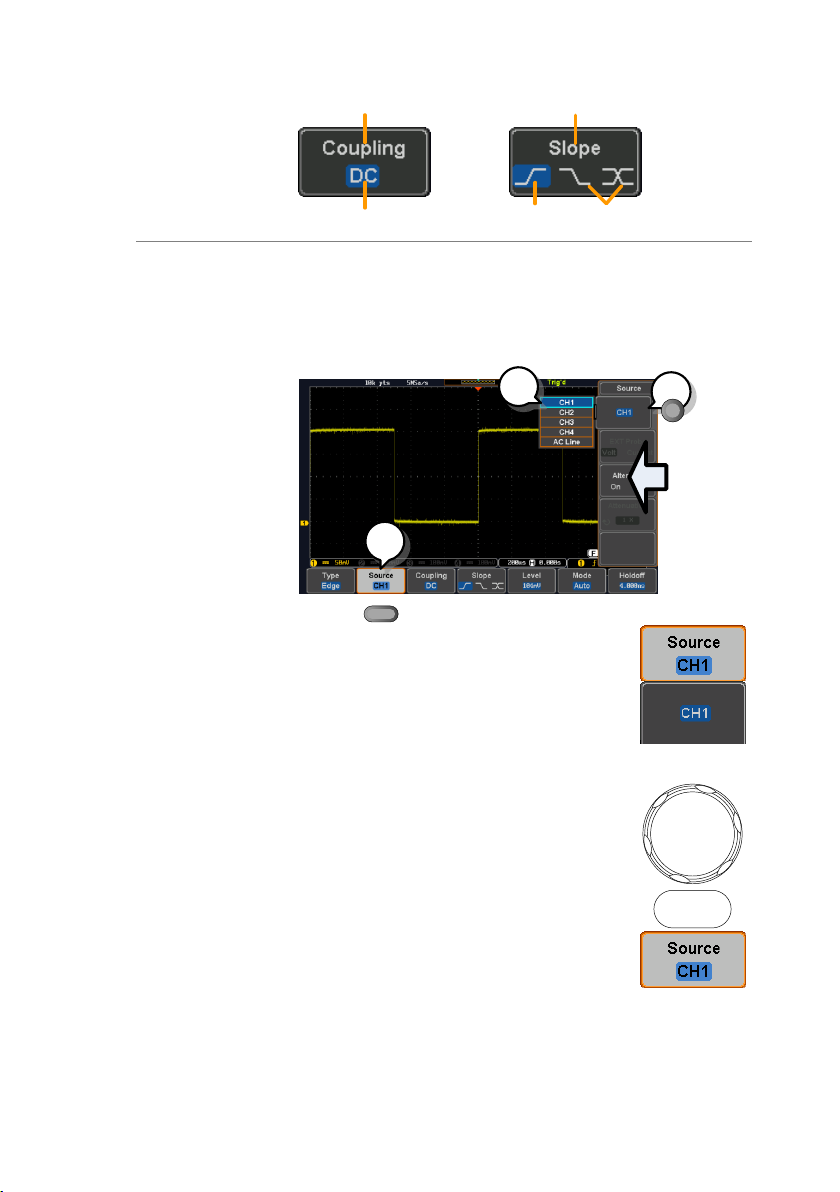

Active parameters are highlighted for each menu

item. For example in the example below, Coupling

is currently set to DC.

If a menu item can be toggled from one value or

parameter to another, the available options will be

visible, with the current option highlighted. In the

example below the slope can be toggled from a

rising slope to a falling slope or either slope.

1-3-4. How to Use This Manual

14

Menu item

Parameter

Menu item

Active

parameter

Optional

parameters

Menu item

Selecting a

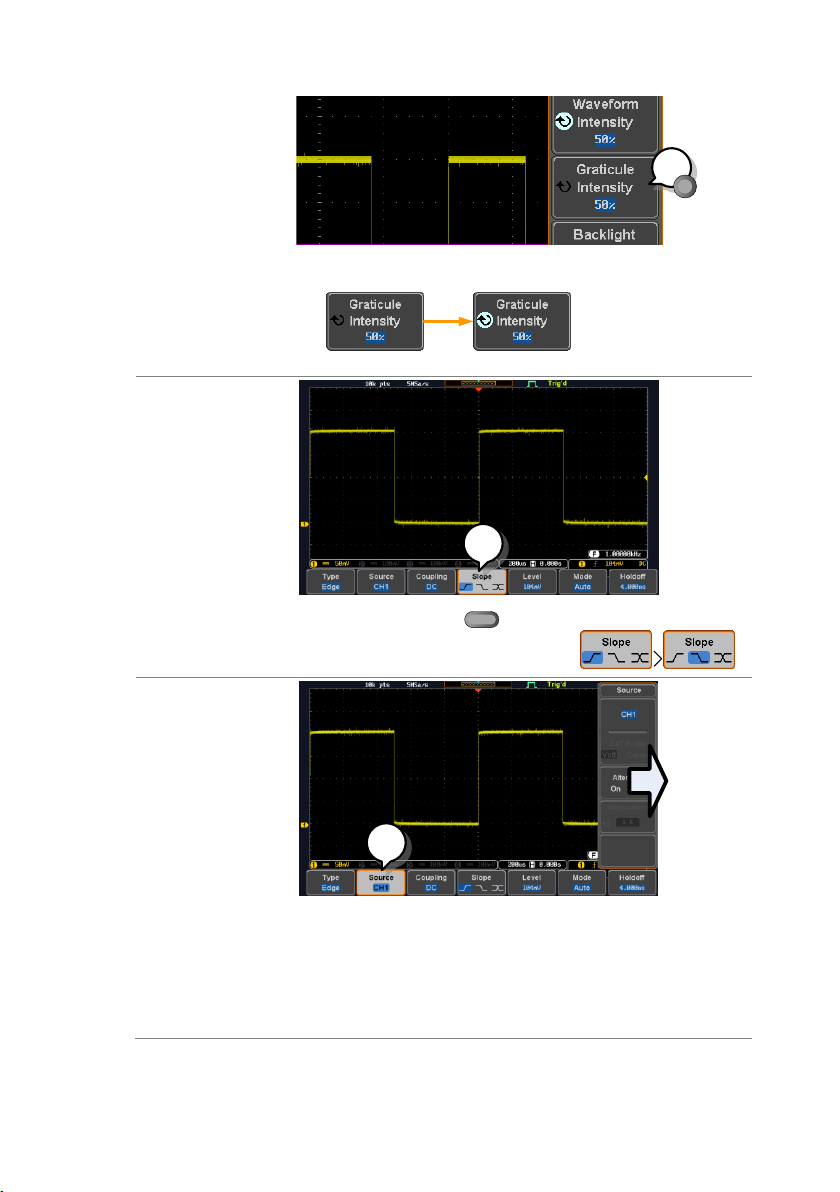

Menu Item,

Parameter or

Variable

When the user manual says to “select” a value

from one of the side menu parameters, first press

the corresponding menu key and use the Variable

knob to either scroll through a parameter list or to

increase or decrease a variable.

Example 1

1

2

3

1. Press a bottom menu key to

access the side menu.

2. Press a side menu key to either

set a parameter or to access a sub

menu.

3. If accessing a sub menu or setting

a variable parameter, use the

Variable knob to scroll through

menu items or variables. Use the

Select key to confirm and exit.

VARIABLE

Select

4. Press the same bottom menu key

again to reduce the side menu.

Example 2

For some variables, a circular arrow icon indicates

that the variable for that menu key can be edited

with the Variable knob.

15

1

1. Press the desired menu key to select it. The

circular arrow will become highlighted.

2. Use the Variable knob to edit the value.

Toggling a Menu

Parameter

1

1. Press the bottom menu key

to toggle the parameter.

Reduce Side

Menu

1

2. To reduce the side menu, press the

corresponding bottom menu that brought up

the side menu.

For example: Press the Source soft-key to

reduce the Source menu.

16

Reduce Lower

Menu

1. Press the relevant function

key again to reduce the

bottom menu. For example:

press the Trigger Menu key

to reduce the trigger menu.

POSITION

POSITION

TRIGGER

LEVEL

PUSH TO

ZERO

PUSH TO

ZERO

PUSH TO

ZERO

SCALE

Test

Save/Recall

Acquire

Utility

Autoset

Run/Stop

Single

Default

Zoom

Menu

50 %

Force-Trig

1

Remove All

Menus

1. Press the Menu Off key to

reduce the side menu,

press again to reduce the

bottom menu.

VARIABLE

POSITION

HORIZONTAL

POSITION

POSITION

POSITION

POSITION

VERTICAL

MATH

REF

BUS

SCALE

TRIGGER

LEVEL

PUSH TO

ZERO

SCALESCALE

PUSH TO

ZERO

PUSH TO

ZERO

PUSH TO

ZERO

PUSH TO

ZERO

PUSH TO

ZERO

SCALE

CH1 CH2 CH3 CH4

2V

Measure

Display

Cursor

Help

Test

Save/Recall

Acquire

Utility

Autoset

Run/Stop

Single

Default

Select

Search

Set/Clear

Zoom

CH1 CH2 CH3 CH4

M

R

B

Menu

50 %

Force-Trig

1

17

Remove OnScreen

Messages

2. The Menu Off key can also

be used to remove any on

screen messages.

VARIABLE

POSITION

HORIZONTAL

POSITION

POSITION

POSITION

POSITION

VERTICAL

MATH

REF

BUS

SCALE

TRIGGER

LEVEL

PUSH TO

ZERO

SCALESCALE

PUSH TO

ZERO

PUSH TO

ZERO

PUSH TO

ZERO

PUSH TO

ZERO

PUSH TO

ZERO

SCALE

CH1 CH2 CH3 CH4

2V

Measure

Display

Cursor

Help

Test

Save/Recall

Acquire

Utility

Autoset

Run/Stop

Single

Default

Select

Search

Set/Clear

Zoom

CH1 CH2 CH3 CH4

M

R

B

Menu

50 %

Force-Trig

2

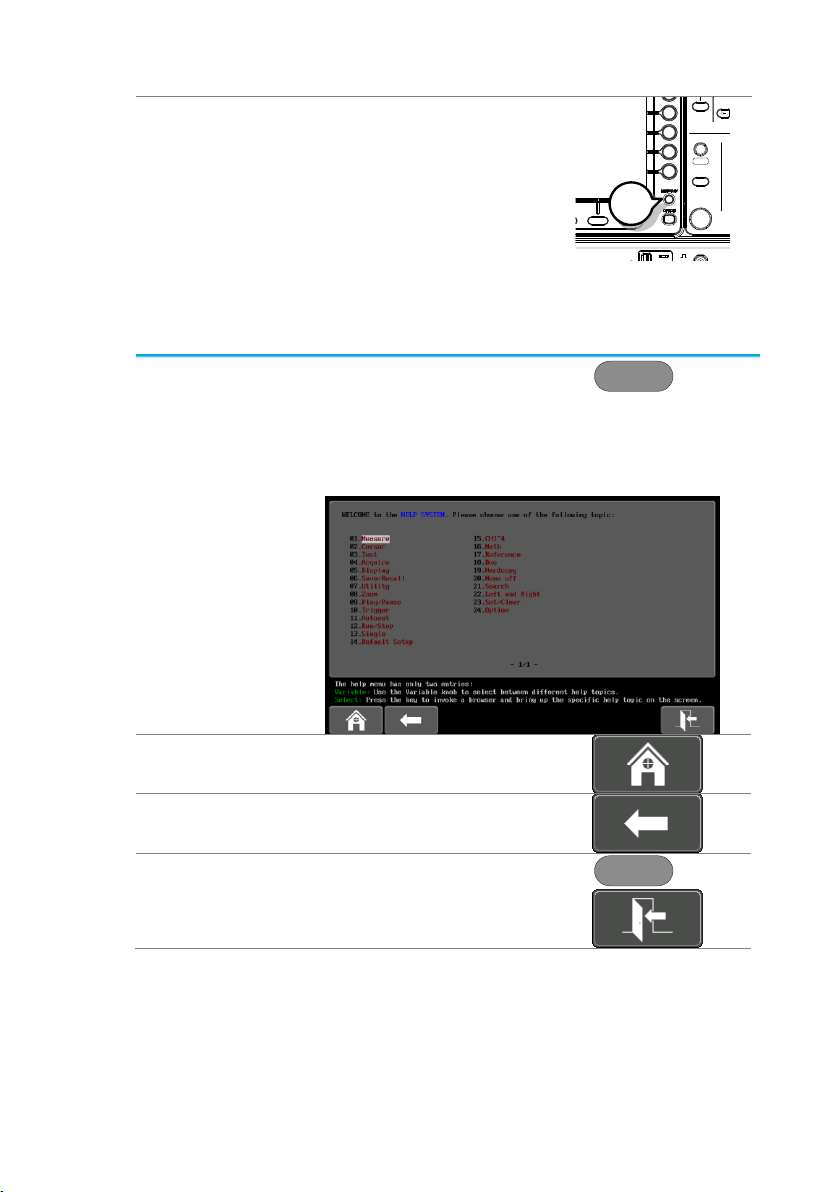

The Help key accesses a context sensitive help menu. The help

menu contains information on how to use the front panel keys.

Panel Operation

1. Press the Help key. The

display changes to Help

mode.

Help

2. Use the Variable knob to scroll up and down

through the Help contents. Press Select to view

the help on the selected item.

Example: Help

on the Display

key

Home Key

Press the Home key to return to

the main help screen.

Go Back

Press the Back key to go to the

previous menu page.

Exit

Press the Help key again or

press the Exit key to exit the

Help mode.

Help

1-4. Built-in Help

18

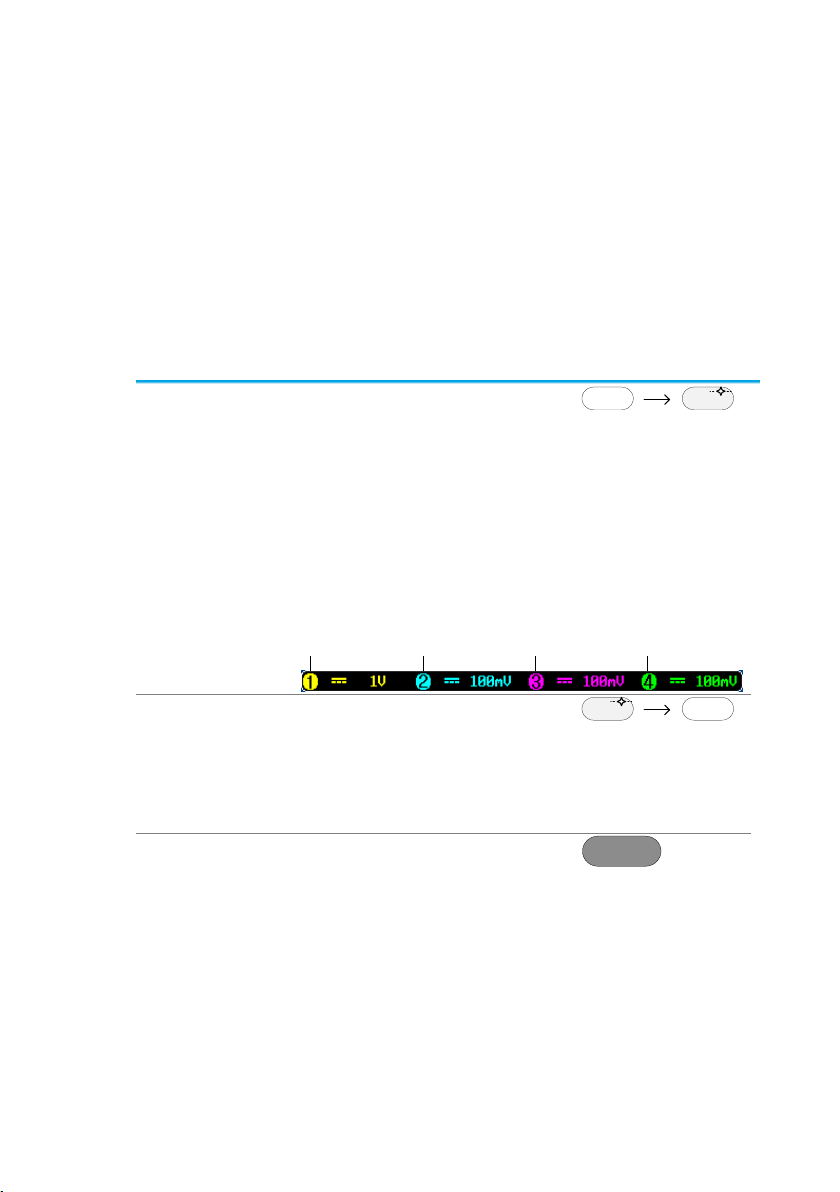

Activate

Channel

To activate an input channel,

press a channel key.

When activated, the channel

key will light up. The

corresponding channel menu

will also appear.

CH1 CH1

Each channel is associated with the color shown

beside each channel’s VOLT/DIV knob: CH1:

yellow, CH2: blue, CH3: pink and CH4: green.

When a channel is activated, it is shown above the

bottom menu system.

CH1 CH3CH2 CH4

De-activate

Channel

To de-activate a channel, press

the corresponding channel key

again. If the channel menu is

not open, press the channel

key twice (the first press shows

the Channel menu).

CH1 CH1

Default Setup

To activate the default state,

press Default.

Default

2. MEASUREMENT

2-1. Basic Measurement

This section describes the basic operations required in capturing

and viewing the input signal. For more detailed operations, see the

following chapters.

Cursor Measurement → from page 34

Configuration → from page 46

Before operating the oscilloscope, please see the Getting Started

chapter, page4.

2-1-1. Channel Activation

19

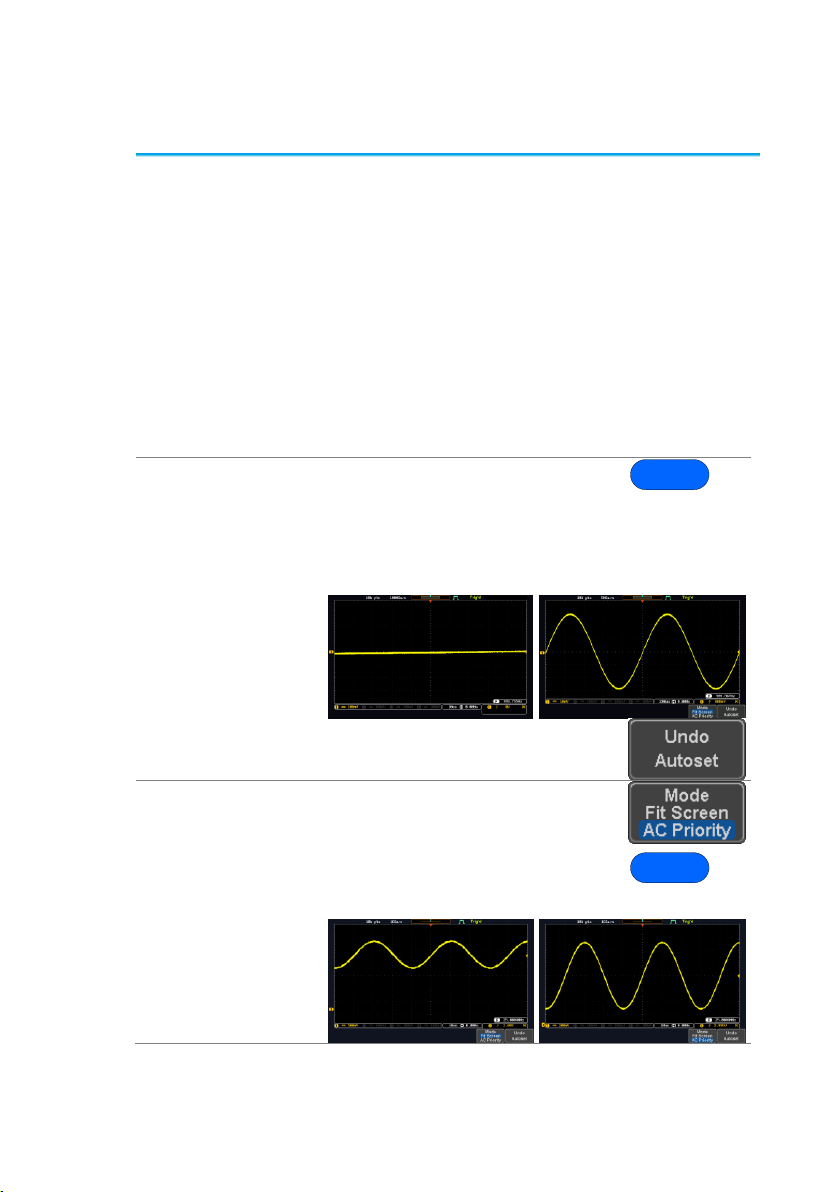

Background

The Autoset function automatically configures the

panel settings to position the input signal(s) to the

best viewing condition. The DCS-1000B

automatically configures the following parameters:

Horizontal scale

Vertical scale

Trigger source channel

There are two operating modes for the Autoset

function: Fit Screen Mode and AC Priority Mode.

Fit Screen Mode will fit the waveform to the best

scale, including any DC components (offset). AC

priority mode will scale the waveform to the screen

by removing any DC component.

Panel Operation

1. Connect the input signal to the

DCS-1000B and press the

Autoset key.

Autoset

2. The waveform appears in the center of the

display.

Before

After

3. To undo Autoset, press Undo

Autoset from the bottom menu.

Change modes

4. Choose between Fit Screen

Mode and AC Priority Mode from

the bottom menu.

5. Press the Autoset key again to

use Autoset in the new mode.

Autoset

Fit Screen Mode

AC Priority

2-1-2. Autoset

20

Limitation

Autoset does not work in the following situations:

Input signal frequency is less than 20Hz

Input signal amplitude is less than 10mV

Note

The Autoset key does NOT automatically activate

the channels to which input signals are connected.

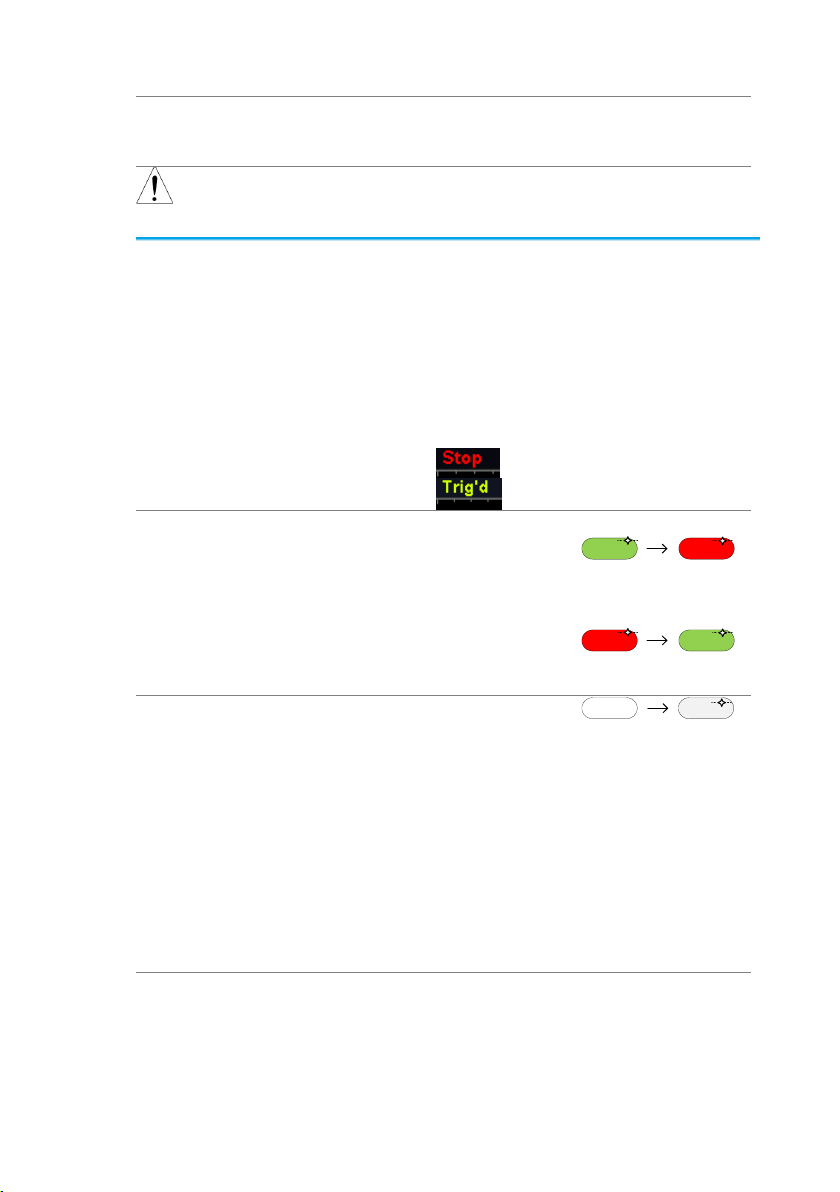

Background

By default, the waveform on the display is

constantly updated (Run mode). Freezing the

waveform by stopping signal acquisition (Stop

mode) allows flexible observation and analysis. To

enter Stop mode, two methods are available:

pressing the Run/Stop key or using the Single

Trigger mode.

Stop mode icon

When in Stop mode, the Stop icon

appears at the top of the display.

Triggered icon

Freeze

Waveform using

the Run/Stop

Key

Press the Run/Stop key once.

The Run/Stop key turns red.

The waveform and signal

acquisition freezes.

Stop:

Run/Stop Run/Stop

To unfreeze, press the

Run/Stop key again. The

Run/Stop key turns green

again.

Run:

Run/Stop Run/Stop

Freeze

Waveform by

Single Trigger

Mode

Press the Single key to go into

the Single Trigger mode. The

Single key turns bright white.

In the Single Trigger mode, the

scope will be put into the pretrigger mode until the scope

encounters the next trigger

point. After the scope has

triggered, it will remain in Stop

mode, until the Single key is

pressed again or the Run/Stop

key is pressed.

SingleSingle

Waveform

Operation

The waveform can be moved or scaled in both Run

and Stop mode, but in different manners. For

details, see page 63 (Horizontal position/scale) and

page 69 (Vertical position/scale).

2-1-3. Run/Stop

21

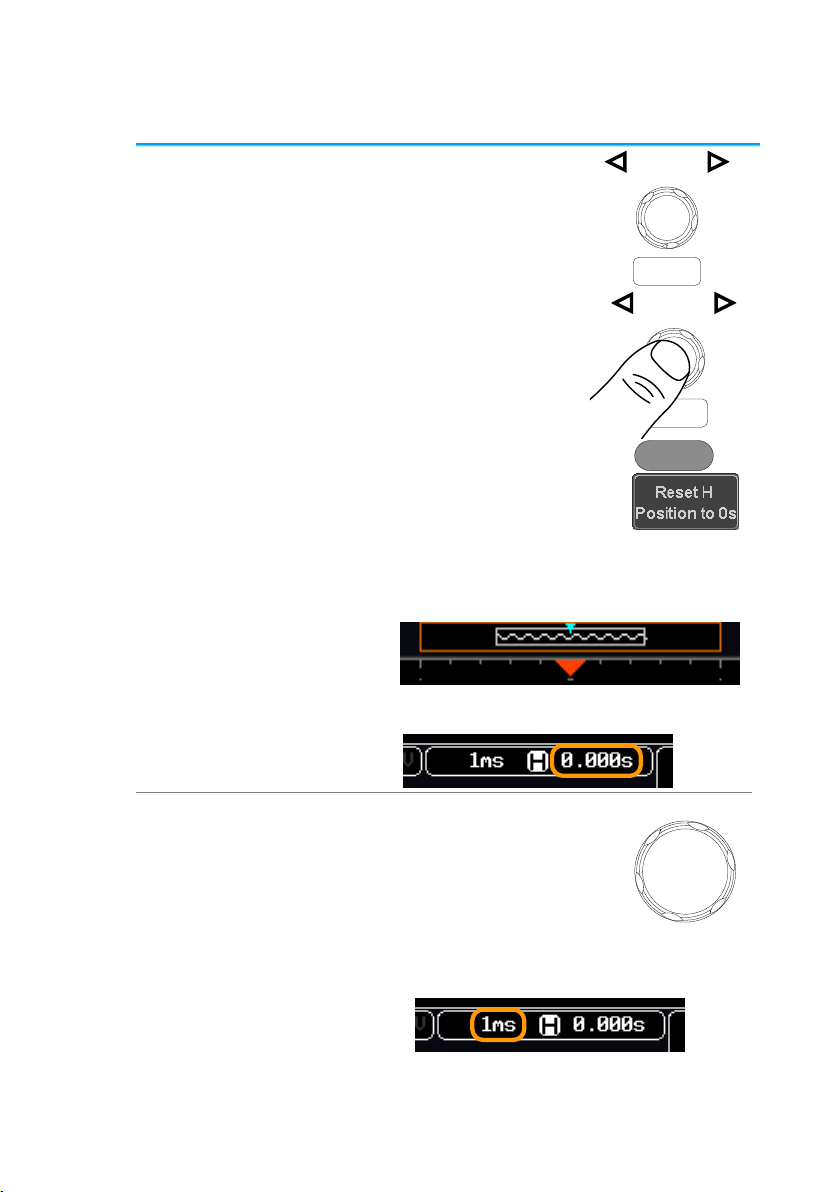

Set Horizontal

Position

The horizontal position knob

moves the waveform left and

right.

POSITION

PUSH TO

ZERO

Set Horizontal

Position to 0

Pressing the horizontal position

knob will reset the horizontal

position to 0.

POSITION

PUSH TO

ZERO

Alternatively, pressing the Acquire

key and then pressing Reset H

Position to 0s from the bottom menu

will also reset the horizontal position.

Acquire

As the waveform moves, the display bar on the top

of the display indicates the portion of the waveform

currently shown on the display and the position of

the horizontal marker on the waveform.

Position

Indicator

The horizontal position is shown at the bottom of

the display grid to the right of the H icon.

Select

Horizontal Scale

To select the timebase, turn the

horizontal SCALE knob; left (slow) or

right (fast).

SCALE

Range

5ns/div ~ 100s/div, 1-2-5 increments

The scale is displayed to the left of the H icon at

the bottom of the screen.

2-1-4. Horizontal Position/Scale

For more detailed configuration, see page 63.

22

Display bar

The display bar indicates how much

of the waveform is displayed on the

screen at any given time. Changes to

timebase will be reflected on the

display bar.

Fast

Medium

Slow

Stop mode

In the Stop mode, the waveform size

changes according to the scale.

Note

The Sample rate changes according to the

timebase and record length. See page 49.

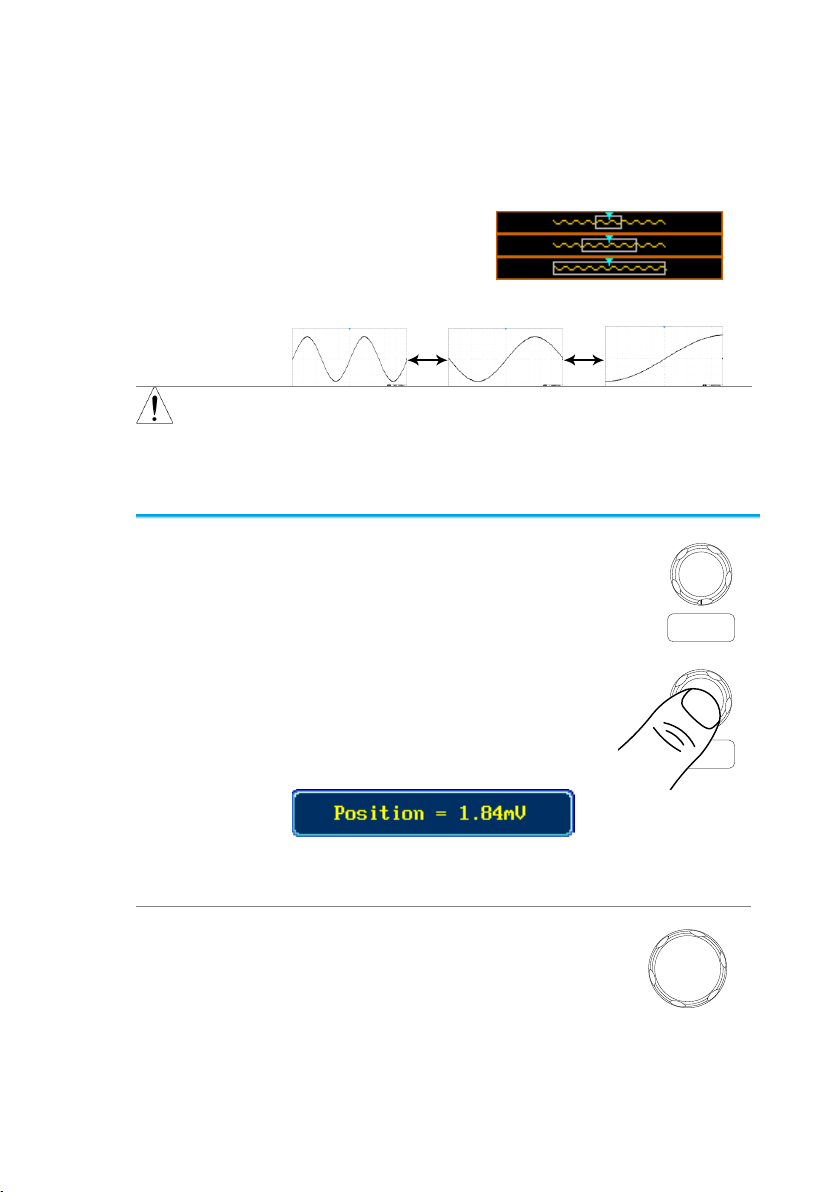

Set Vertical

Position

To move the waveform up or down, turn

the vertical position knob for each

channel.

POSITION

PUSH TO

ZERO

Push the vertical position knob to

reset the position to 0.

As the waveform moves, the

vertical position of the cursor

appears on the display.

POSITION

PUSH TO

ZERO

Run/Stop

mode

The waveform can be moved

vertically in both Run and Stop

mode.

Select Vertical

Scale

To change the vertical scale, turn the

vertical VOLTS/DIV knob; left (down) or

right (up).

VOLTS/DIV

Range

1mV/div ~ 10V/div

1-2-5 increments

2-1-5. Vertical Position/Scale

For more detailed configuration, see page 69.

23

The vertical scale indicator for

each channel on the bottom of

the display changes

accordingly.

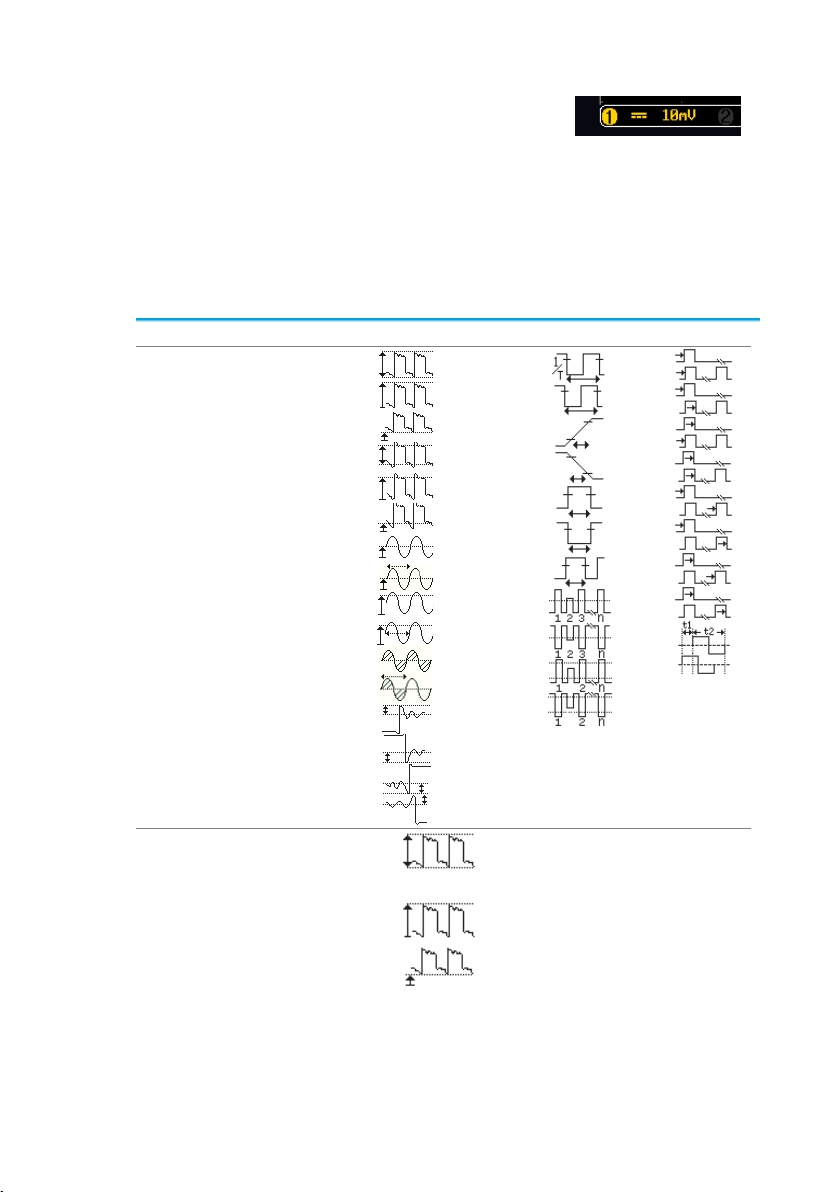

V/I Measurements

Time Meas.

Delay Meas.

Overview

FPREShoot

RPREShoot

FOVShoot

ROVShoot

Cycle Area

Area

Cycle RMS

RMS

Cycle Mean

Mean

Low

High

Amplitude

Min

Max

Pk-Pk

Frequency

Dutycycle

-Width

+Width

FallTime

RiseTime

Period

-Edges

+Edges

-Pulses

+Pulses

FRR

FRF

FFR

Phase

LFF

LFR

LRF

LRR

FFF

Voltage/Current

Measurement

Pk-Pk

(peak to

peak)

Difference between positive

and negative peak.

(=max − min)

Max

Positive peak.

Min Negative peak.

2-2. Automatic Measurement

The automatic measurement function measures and updates major

items for Voltage/Current, Time, and Delay type measurements.

2-2-1. Measurement Items

24

Amplitude

Difference between the

global high value and the

global low value, measured

over the entire waveform or

gated region. (=high − low)

High

Global high voltage. See

page 30 for details.

Low

Global low voltage. See page

30 for details.

Mean

The arithmetic mean value is

calculated for all data

samples as specified by the

Gating option.

Cycle

Mean

The arithmetic mean value is

calculated for all data

samples within the first cycle

found in the gated region.

RMS

The root mean square of all

data samples specified by

the Gating option.

Cycle RMS

The root mean square value

is calculated for all data

samples within the first cycle

found in the gated region.

Area

Measures the positive area

of the waveform and

subtracts it from the negative

area. The ground level

determines the division

between positive and

negative areas.

Cycle Area

The Summation based on all

data samples within the first

cycle found in the gated

region.

ROVShoot

Rise overshoot

FOVShoot

Fall overshoot

RPREShoot

Rise preshoot

FPREShoot

Fall preshoot

25

Time

Measurement

Frequency

Frequency of the waveform.

Period

Waveform cycle time.

(=1/Freq)

RiseTime

The time required for the

leading edge of the first pulse

to rise from the low reference

value to the high reference

value.

FallTime

The time required for the

falling edge of the first pulse

to fall from the high reference

value to the low reference

value.

+Width

Positive pulse width.

–Width

Negative pulse width.

Duty Cycle

Ratio of signal pulse

compared with whole cycle.

=100x (Pulse Width/Cycle)

+Pulses

Measures the number of

positive pulses.

-Pulses

Measures the number of

negative pulses.

+Edges

Measures the number of

positive edges.

-Edges

Measures the number of

negative edges.

Delay

Measurement

FRR

Time between:

Source 1 first rising edge and

Source 2 first rising edge.

FRF

Time between:

Source 1 first rising edge and

Source 2 first falling edge.

FFR

Time between:

Source 1 first falling edge

and Source 2 first rising

edge.

FFF

Time between:

Source 1 first falling edge

and Source 2 first falling

edge.

26

LRR

Time between:

Source 1 first rising edge and

Source 2 last rising edge.

LFR

Time between:

Source 1 first rising edge and

Source 2 last falling edge.

LRF

Time between:

Source 1 first falling edge

and Source 2 last rising

edge.

LFF

Time between:

Source 1 first falling edge

and Source 2 last falling

edge.

Phase

The phase difference of two

signals, calculated in

degrees.

360x

t2

t1

Note

The in-built help system can be used to see

detailed automatic measurement definitions.

Add

Measurement

Item

1. Press the Measure key.

Measure

2. Press Add Measurement from the

bottom menu.

3. Choose either a V/I, Time or Delay

measurement from the side menu

and choose the type of

measurement you wish to add.

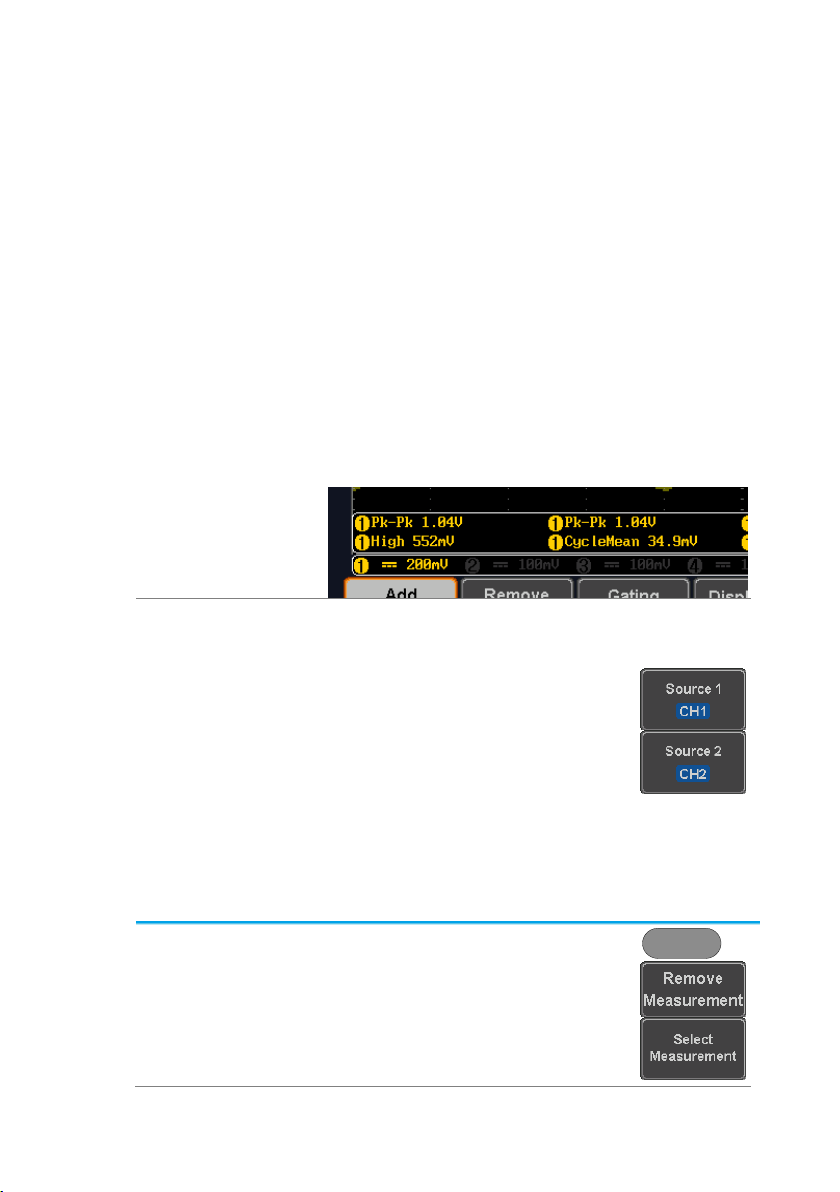

2-2-2. Add Measurement

The Add Measurement function allows you to add up to eight

automatic measurement items on the bottom of the screen from any

channel source.

27

V/I

(Voltage/

Current)

Pk-Pk, Max, Min, Amplitude, High,

Low, Mean, Cycle Mean, RMS,

Cycle RMS, Area, Cycle Area,

ROVShoot, FOVShoot,

RPREShoot, FPREShoot

Time

Frequency, Period, RiseTime,

FallTime, +Width, –Width, Duty

Cycle, +Pulses, -Pulses, +Edges, Edges

Delay

FRR, FRF, FFR, FFF, LRR, LRF,

LFR, LFF, Phase

4. All of the chosen automatic measurements will

be displayed in a window on the bottom of the

screen. The channel number and channel color

indicate the measurement source.

For the analog inputs: yellow = CH1,

blue = CH2, pink = CH3, green = CH4.

Choose a

Source

The channel source for measurement items can be

set either before or when selecting a measurement

item.

5. To set the source, press either the

Source1 or Source2 key from the

side menu and choose the source.

Source 2 is only applicable for

delay measurements.

Range

CH1~ CH4, Math

Remove

Measurement

Item

1. Press the Measure key.

Measure

2. Press Remove Measurement from

the bottom menu.

3. Press Select Measurement and

select the item that you want to

remove from the measurement list.

2-2-3. Remove Measurement

Individual measurements can be removed at any time using the

Remove Measurement function.

28

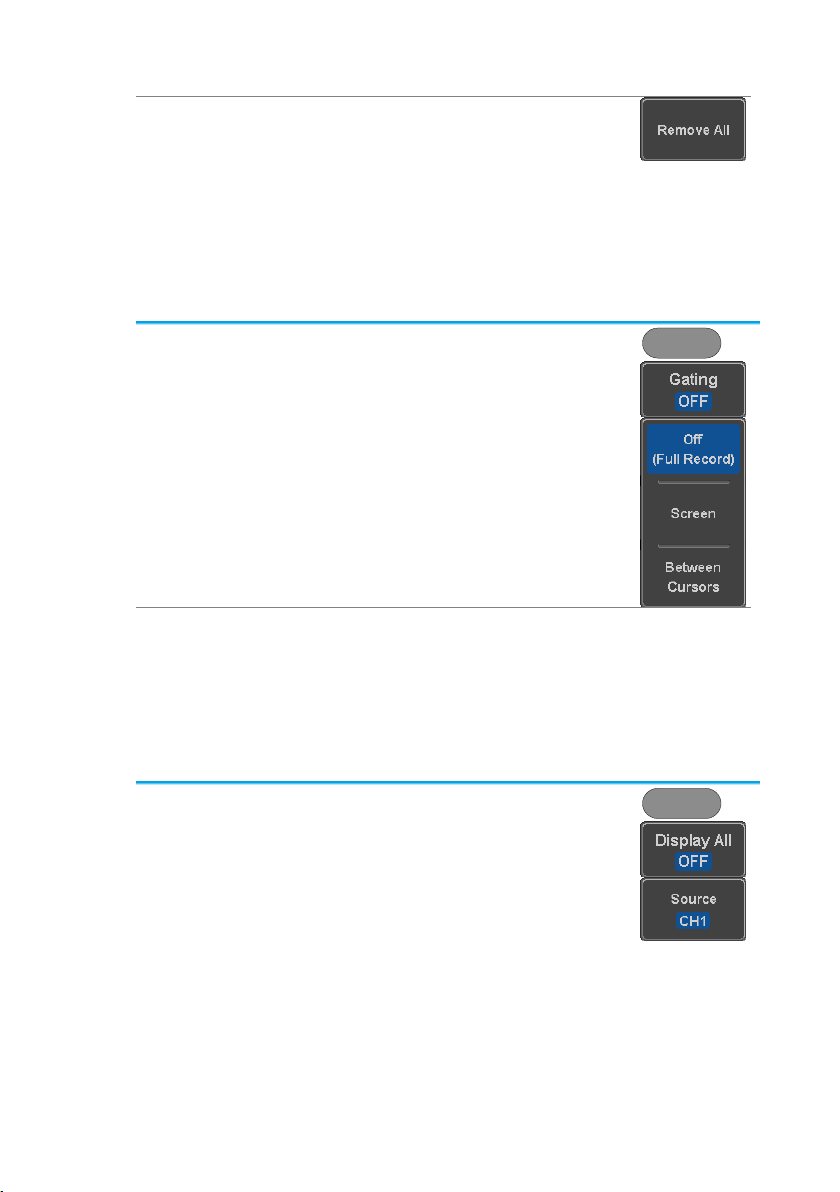

Remove All

Items

Press Remove All to remove all the

measurement items.

Set Gating Mode

1. Press the Measure key.

Measure

2. Press Gating from the bottom

menu.

3. Choose one of the gating modes

from the side menu: Off (full

record), Screen, Between Cursors.

Cursors On

Screen

If Between Cursors is selected, the

cursor positions can be edited by

using the cursor menu.

Page 34

View

Measurement

Results

1. Press the Measure key.

Measure

2. Press Display All from the bottom

menu.

3. Press Source from the side menu

and choose a measurement

source.

Range

CH1~CH4, Math

4. The results of Voltage and Time type

measurements appear on the display.

2-2-4. Gated mode

Some automatic measurements can be limited to a “gated” area

between cursors. Gating is useful for measuring a magnified

waveform or when using a fast time base. The Gated mode has

three possible configurations: Off (Full Record), Screen and

Between Cursors.

2-2-5. Display All mode

Display All mode shows and updates all items from Voltage and

Time type measurements.

29

Remove

Measurements

To remove the measurement results,

press OFF.

Delay

Measurements

Delay type measurements are not available in this

mode as only one channel is used as the source.

Use the individual measurement mode (page 27)

instead.

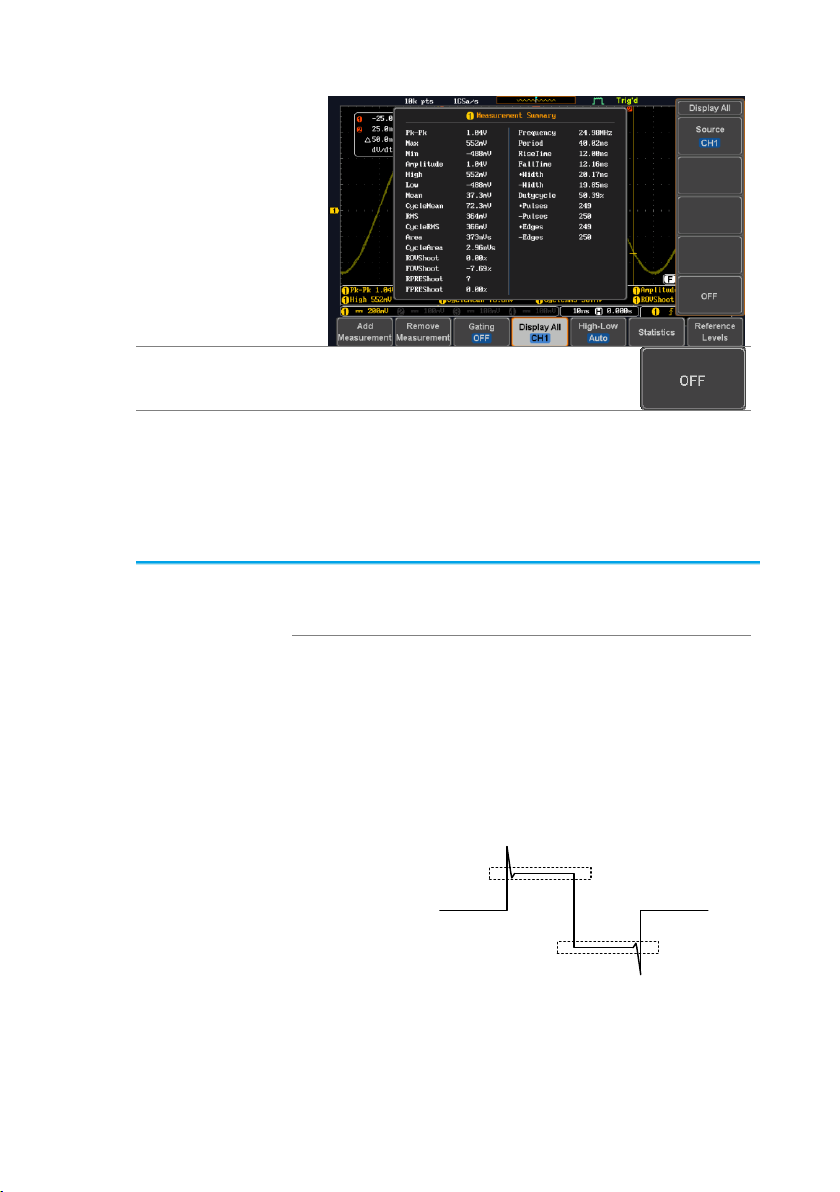

Background

The High-Low function is used to select the

method for determining the value of the High-Low

measurement values.

Auto

Automatically chooses the best

high-low setting for each waveform

when measuring.

Histogram

Uses histograms to determine the

high-low values. This mode

ignores any preshoot and

overshoot values. This mode is

particularly useful for pulse-type

waveforms

low

high

2-2-6. High Low Function

30

Min-max

Sets the high-low values as the

minimum or maximum measured

values.

low

high

Set High-Low

1. Press the Measure key.

Measure

2. Press High-Low from the bottom

menu.

3. Select the type of High-Low settings from the

side menu.

High-Low Settings:

Histogram, Min-Max, Auto

Restore Default

High-Low

Settings

To return to the default High-Low

settings, press Set to Defaults.

Background

The Statistics function can be used to view a

number of statistics for the selected automatic

measurements. The following information is

displayed with the Statistics function:

Value

Currently measured value

2-2-7. Statistics

31

Mean

The mean value is calculated from

a number of automatic

measurement results. The number

of samples used to determine the

mean can be user-defined.

Min

The minimum value observed from

a series of measured results for

the selected automatic

measurement items.

Max

The maximum value observed

from a series of measured results

for the selected automatic

measurement items.

Standard

Deviation

The variance of the currently

measured value from the mean.

The standard deviation equals the

squared root of the variance value.

Measuring the standard deviation

can, for example, determine the

severity of jitter in a signal.

The number of samples used to

determine the standard deviation

can be user-defined.

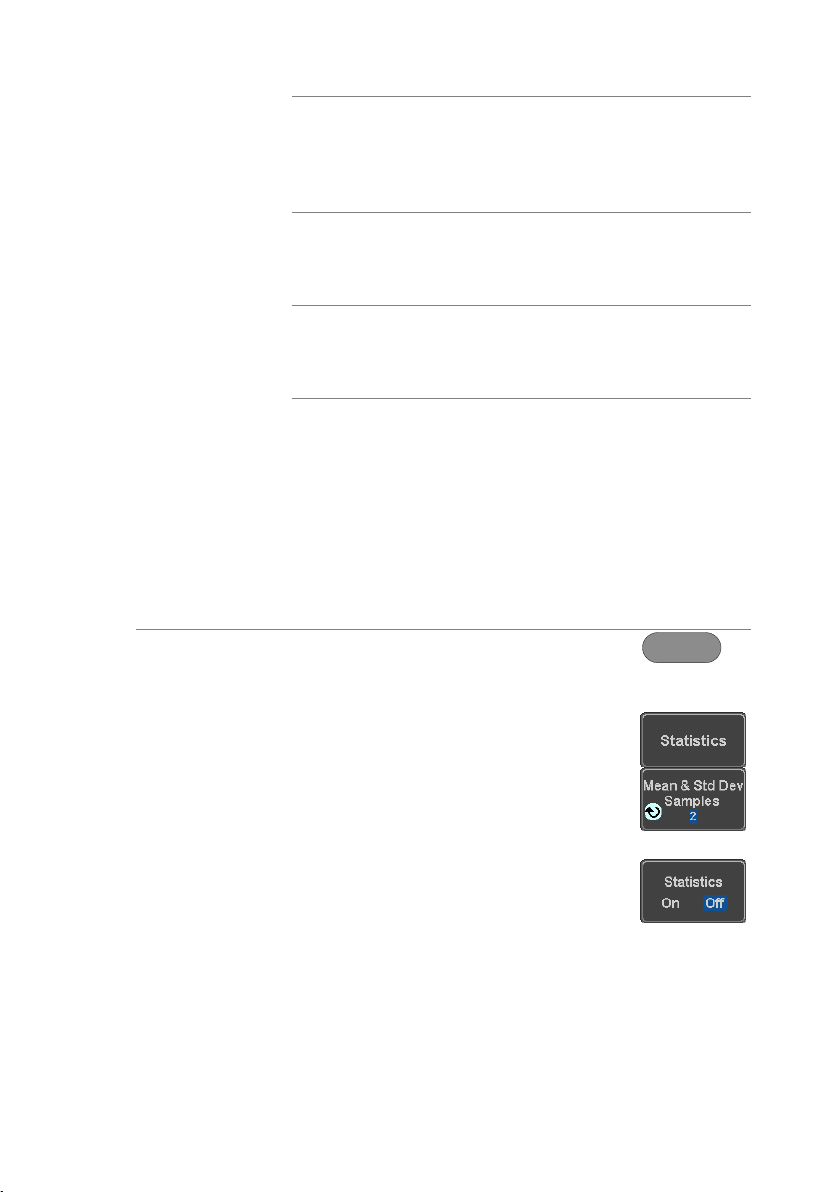

Panel Operation

1. Press the Measure key.

Measure

2. Select at least one automatic

measurement.

Page 27

3. Press Statistics from the bottom

menu.

4. Set the number of samples to be

used in the mean and standard

deviation calculations.

Samples:

2~1000

5. Press Statistics and turn Statistics

on.

6. The statistics for each automatic measurement

will appear at the bottom of the display in a

table.

32

Reset Statistics

To reset the standard deviation

calculations, press Reset Statistics.

Background

The reference level settings determine the

measurement threshold levels for some

measurements like the Rise Time measurement.

High Ref: Sets the high reference

level.

Mid Ref: Sets the middle reference

for the first and second

waveforms.

Low Ref: Sets the low reference

level.

Panel Operation

1. Press the Measure key.

Measure

2. Press Reference Levels from the

bottom menu.

3. Set the reference levels from the side menu.

Ensure the reference levels do not cross over.

High Ref

0.0% ~ 100%

Mid Ref(1)

0.0% ~ 100%

Mid Ref(2)

0.0% ~ 100%

Low Ref

0.0% ~ 100%

Default Settings

4. Press Set to Defaults to set the

reference levels back to the default

settings.

2-2-8. Reference Levels

33

Panel Operation

1. Press the Cursor key once.

Cursor

2. Press H Cursor from the bottom

menu if it is not already selected.

3. When the H Cursor is selected,

repeatedly pressing the H Cursor

key or the Select key will toggle

which cursor is selected.

OR

Select

Range

Description

Left cursor ( ) movable, right

cursor position fixed

Right cursor ( ) movable, left

cursor position fixed

Left and right cursor ( + )

movable together

4. The cursor position

information appears on the

top left hand side of the

screen

Cursor

Hor. position, Voltage/Current

Cursor

Hor. position, Voltage/Current

Delta (difference between cursors)

dV/dt or dI/dt

5. Use the Variable knob to move the

movable cursor(s) left or right.

VARIABLE

Select Units

6. To change the units of the

horizontal position, press H Unit.

Units

S, Hz, % (ratio), ˚(phase)

2-3. Cursor Measurement

Horizontal or vertical cursors are used to show the position and

values of waveform measurements and math operation results.

These results cover voltage, time, frequency and other math

operations. When the cursors (horizontal, vertical or both) are

activated, they will be shown on the main display unless turned off.

2-3-1. Use Horizontal Cursors

34

Phase or Ratio

Reference

7. To set the 0% and 100% ratio or

the 0˚ and 360˚ phase references

for the current cursor positions,

press Set Cursor Positions As

100%.

Example

Horizontal

cursors

FFT

FFT cursors can use different

units. For FFT details, see page

41. Cursor

Hor. position, dB/Voltage

Cursor

Hor. Position, dB/Voltage

Delta (difference between cursors)

dV/dt or d/dt

Example

Horizontal

cursors

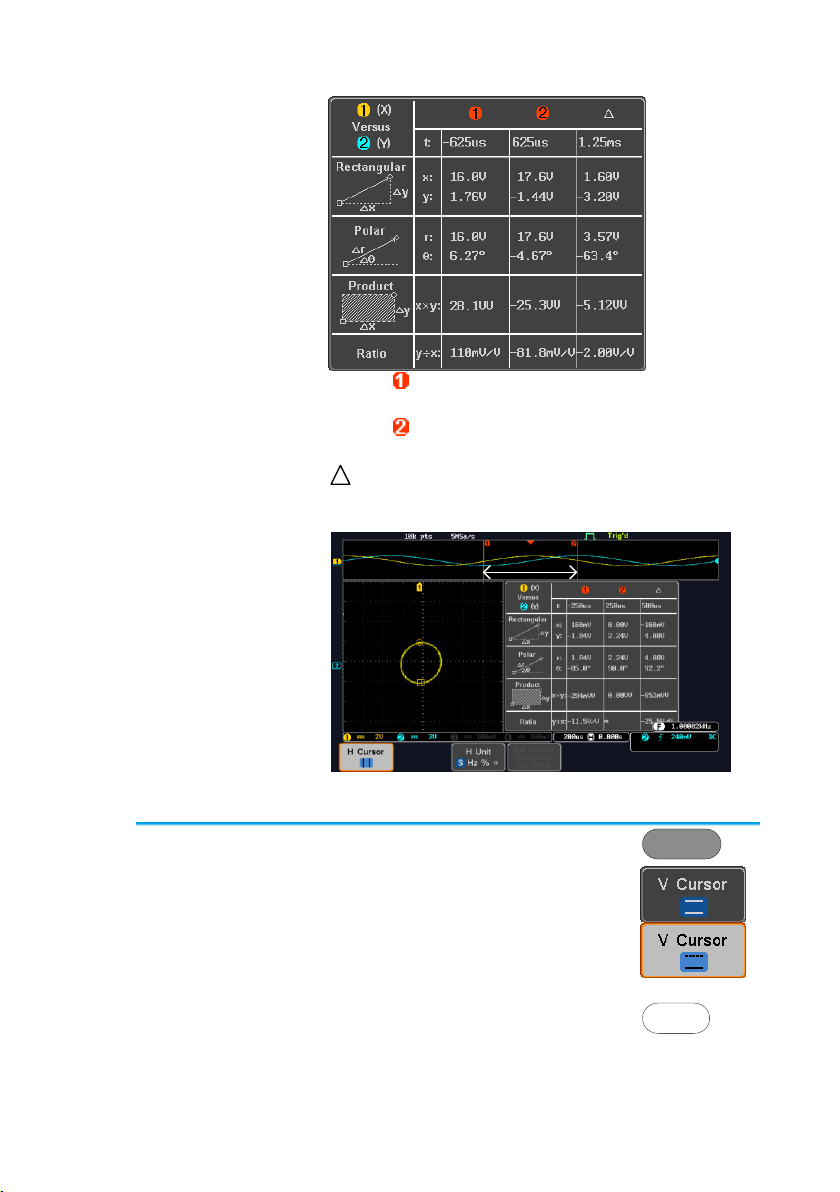

XY Mode

XY mode cursors measure a number of X by Y

measurements.

35

Cursor

Time, rectangular, polar coordinates, product, ratio.

Cursor

Time, rectangular, polar coordinates, product, ratio.

Delta (difference between cursors)

Example

Horizontal

cursors

Panel Operation/

Range

1. Press the Cursor key twice.

Cursor

x2

2. Press V Cursor from the bottom

menu if it is not already selected.

3. When the V Cursor is selected,

repeatedly pressing the V Cursor

key or the Select key will toggle

which vertical cursor is selected.

OR

Select

2-3-2. Use Vertical Cursors

36

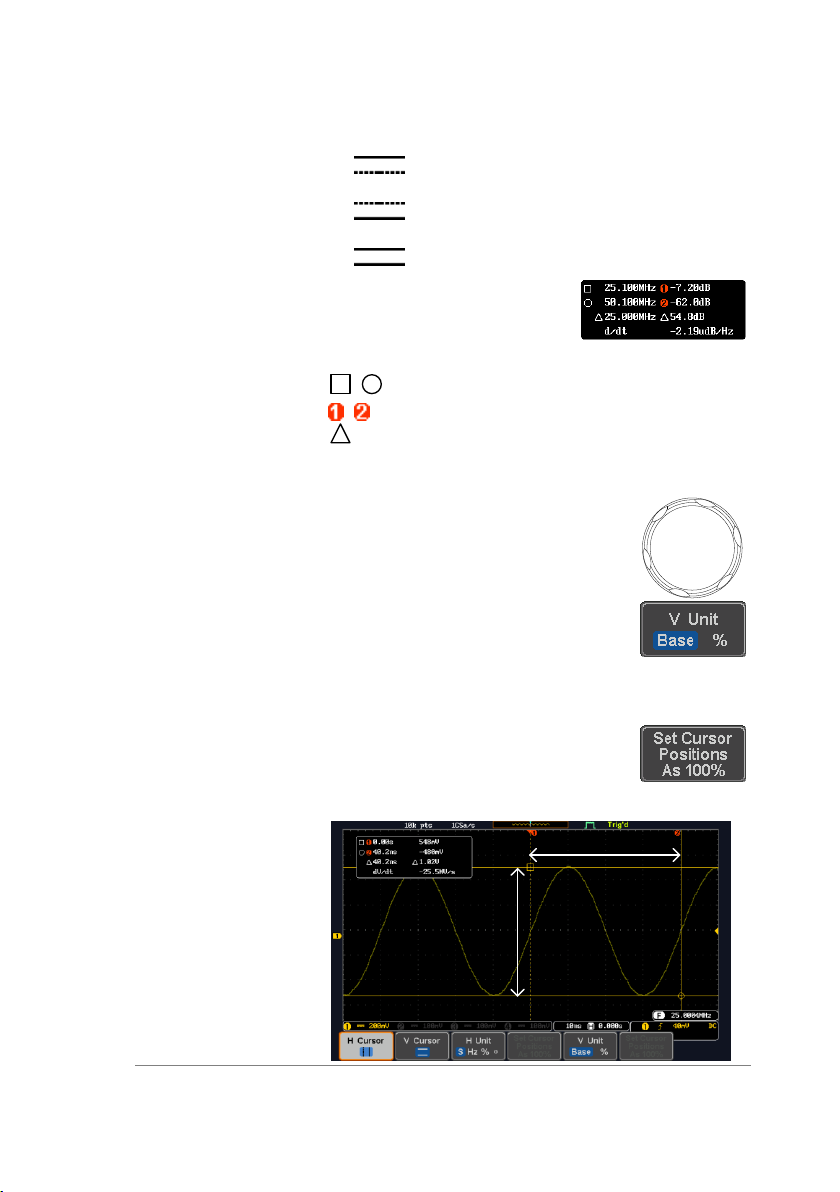

Range

Upper cursor movable, lower

cursor position fixed

Lower cursor movable, upper

cursor position fixed

Upper and lower cursor movable

together

4. The cursor position

information appears on the

top left hand side of the

screen.

,

Time: cursor 1, cursor 2

,

Voltage/Current: cursor1, cursor2

Delta (difference between cursors)

dV/dt or dI/dt

5. Use the Variable knob to move the

cursor(s) up or down.

VARIABLE

Select Units

6. To change the units of the vertical

position, press V Unit.

Units

Base (source wave units), %

(ratio)

Base or Ratio

Reference

7. To set the 0% and 100% ratio

references for the current cursor

position, press Set Cursor

Positions As 100%.

Example

Horizontal

cursors

Vertical

cursors

37

FFT

FFT has different content. For

FFT details, see page 41.

,

Frequency/Time: cursor1, cursor2

,

dB/V: cursor1, cursor2

Delta (difference between cursors)

d/dt

Example

Horizontal

cursors

Vertical

cursors

XY Mode

XY mode cursors measure a number of X by Y

measurements.

Cursor

Rectangular, polar co-ordinates,

product, ratio.

Cursor

Rectangular, polar co-ordinates,

product, ratio.

Delta (difference between cursors)

38

Example

Horizontal

cursors

Vertical

cursors

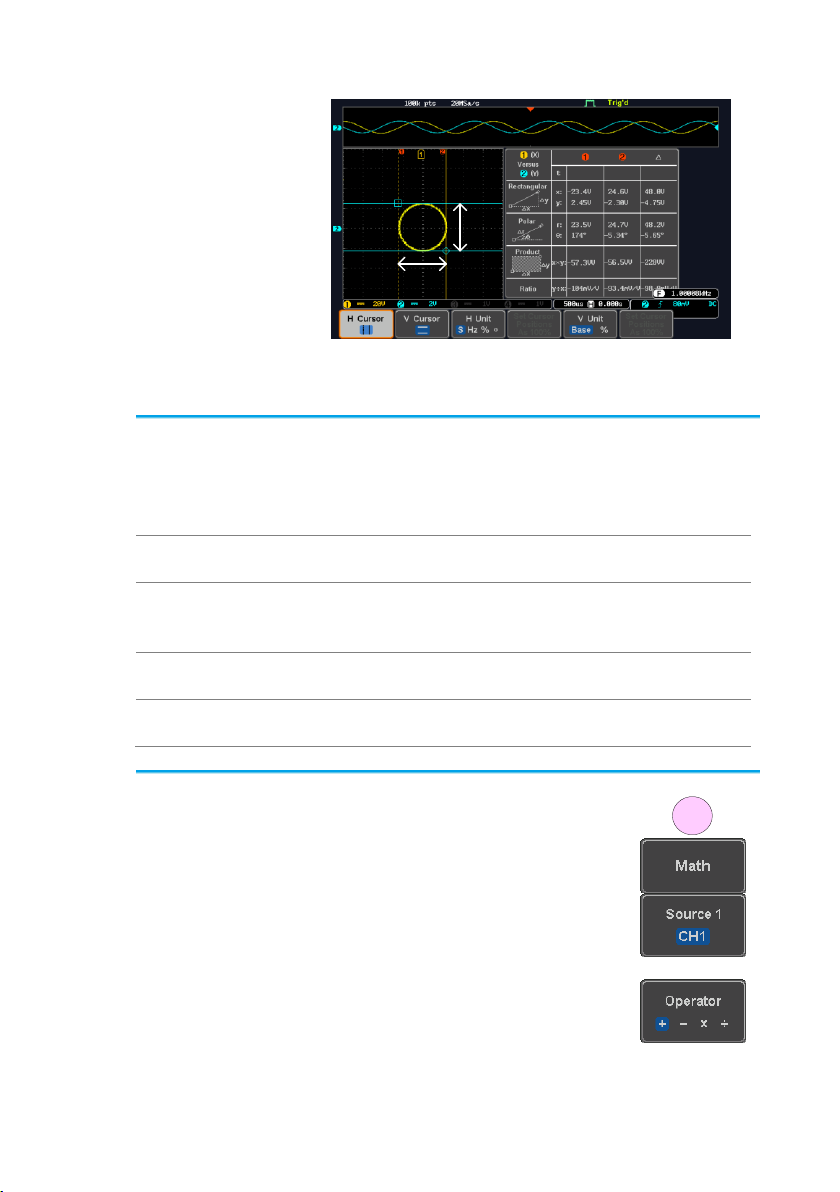

Background

The Math function performs basic math functions

(addition, subtraction, multiplication, division) on

the input signals or the reference waveforms. The

resultant waveform will be shown on the screen in

real-time.

Addition (+)

Adds the amplitude of two signals.

Source

CH1~4, Ref1~4

Subtraction (–)

Extracts the amplitude difference between two

signals.

Source

CH1~4, Ref1~4

Multiplication (×)

Multiplies the amplitude of two signals.

Source

CH1~4, Ref1~4

Division (÷)

Divides the amplitude of two signals.

Source

CH1~4, Ref1~4

Panel Operation

1. Press the Math key.

MATH

M

2. Press the Math key on the lower

bezel.

3. Select Source 1 from the side

menu

Range

CH1~4, Ref1~4

4. Press Operator to choose the math

operation.

Range

+, -, ×, ÷

2-4. Math Operation

2-4-1. Basic Math Overview & Operators

2-4-1-1. Addition/Subtraction/Multiplication/Division

39

5. Select Source 2 from the side

menu.

Range

CH1~4, Ref1~4

6. The math measurement result appears on the

display. The vertical scale of the math waveform

appears at the bottom of the screen.

From left: Math function, source1, operator,

source2, Unit/div

Example

Math

Source 2

Source 1

Position and

Unit

To move the math waveform vertically,

press the Position key from the side

menu and use the Variable knob to set

the position.

Range

–12.00 Div ~ +12.00 Div

To change the unit/div settings, press

Unit/div, then use the Variable knob to

change the unit/div.

The units that are displayed depend

on which operator has been selected,

and whether the probe for the

selected channel has been set to

voltage or current.

Operator:

Unit/div:

Multiplication

Division

Addition/Subtraction

VV, AA or W

V/V, A/A

V or A

Turn Off Math

To turn off the Math result from the

display, press the Math key again.

MATH

M

40

Background

The FFT Math function performs a Fast Fourier

Transform on one of the input signals or the

reference waveforms. The resultant spectrum will

be shown on the screen in real-time. Four types of

FFT windows are available: Hanning, Hamming,

Rectangular, and Blackman, as described below.

Hanning FFT

Window

Frequency resolution

Good

Amplitude resolution

Not good

Suitable for....

Frequency measurement on

periodic waveforms

Hamming FFT

Window

Frequency resolution

Good

Amplitude resolution

Not good

Suitable for....

Frequency measurement on

periodic waveforms

Rectangular FFT

Window

Frequency resolution

Very good

Amplitude resolution

Bad

Suitable for....

Single-shot phenomenon

(this mode is the same as

having no window at all)

Blackman FFT

Window

Frequency resolution

Bad

Amplitude resolution

Very good

Suitable for....

Amplitude measurement on

periodic waveforms

Panel Operation

1. Press the Math key.

MATH

M

2. Press FFT from the bottom menu.

3. Select the Source from the side

menu.

Range

CH1~4, Ref~4

4. Press the Vertical Units key from

the side menu to select the vertical

units used.

Range

Linear RMS, dBV RMS

2-4-2. FFT Overview & Window Functions

2-4-2-1. FFT Operation

41

5. Press the Window key from the

side menu and select the window

type.

Range

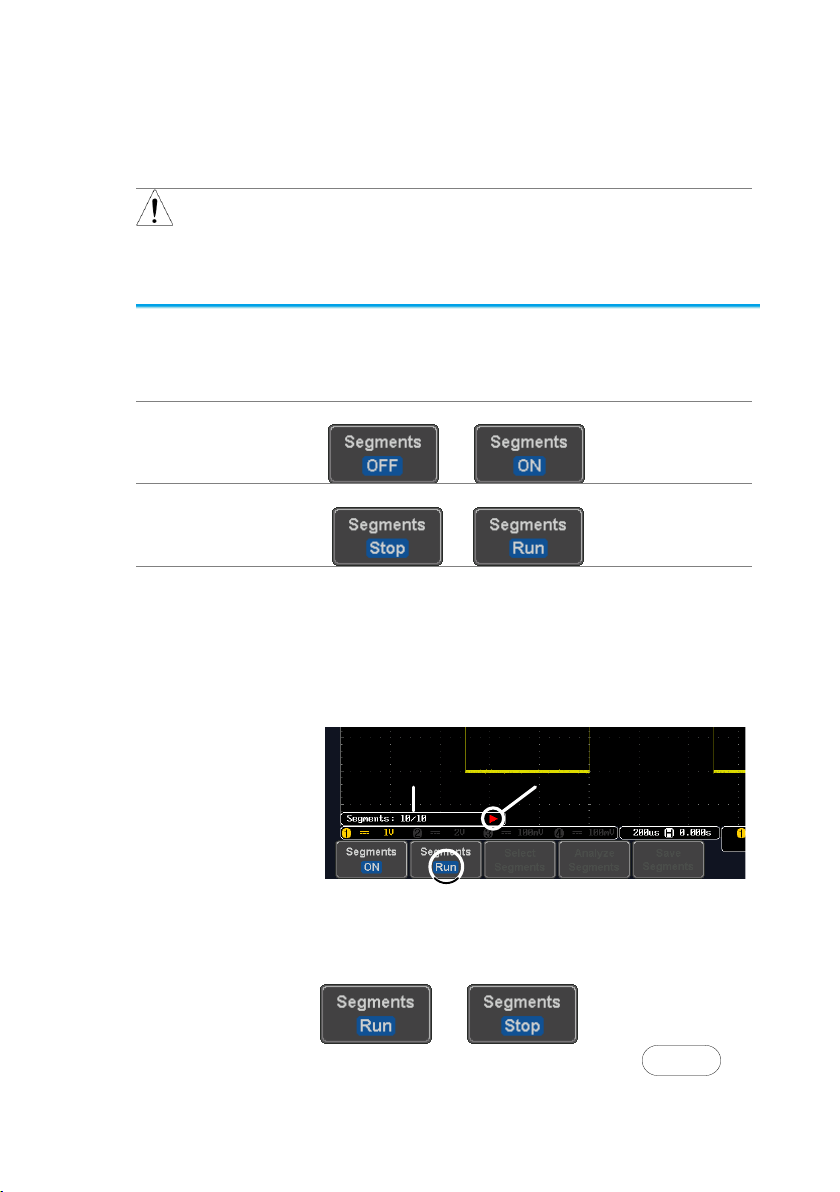

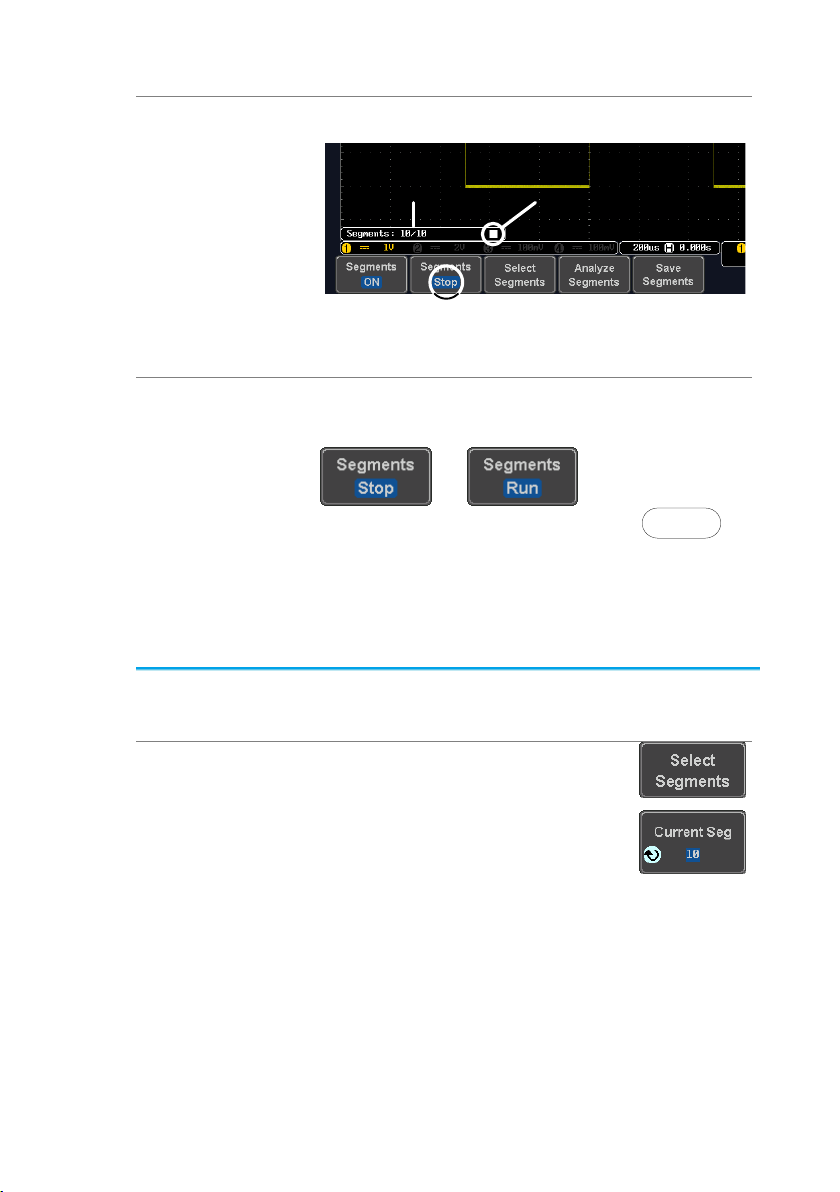

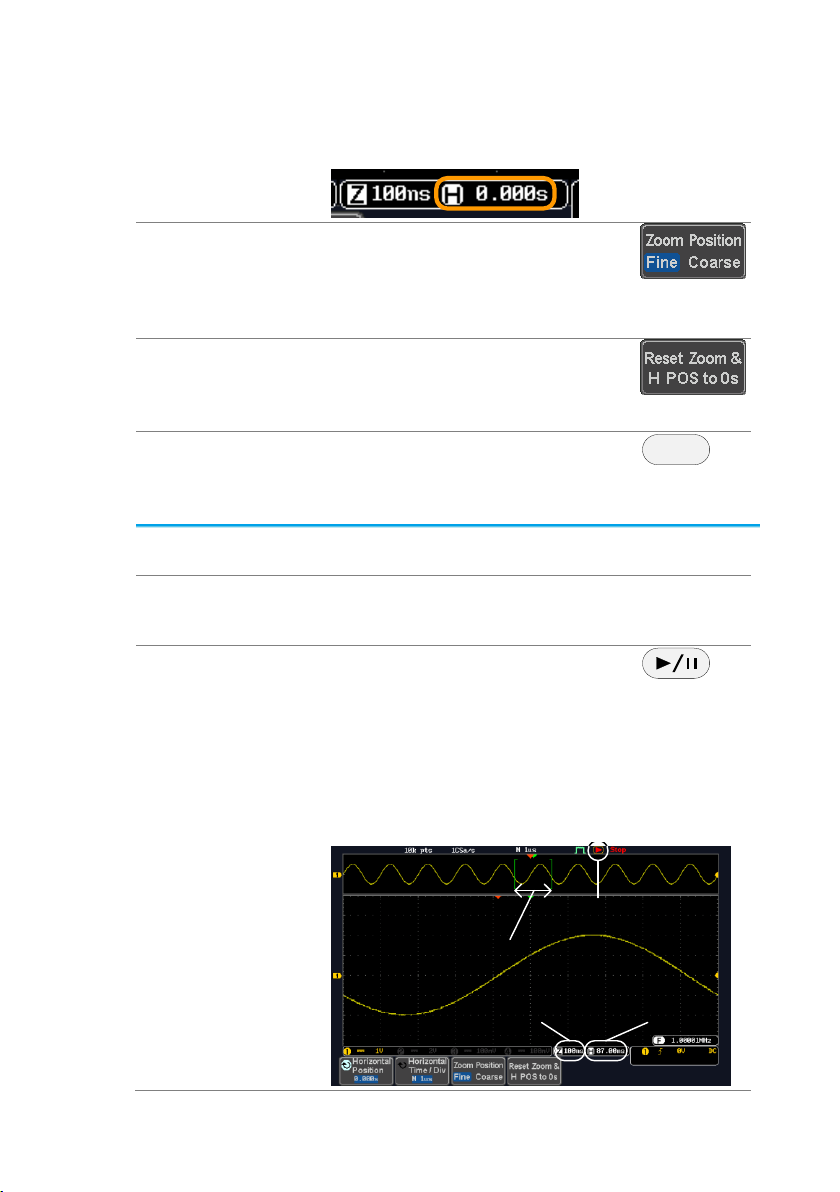

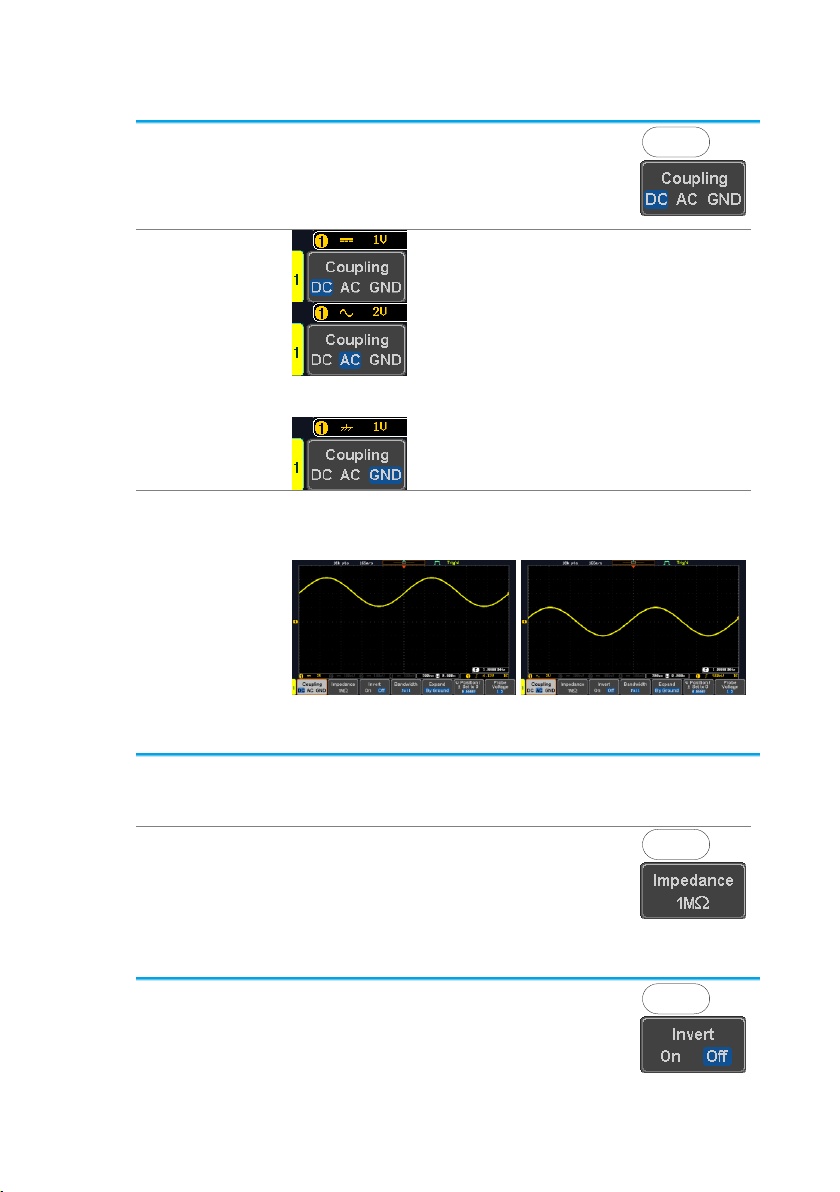

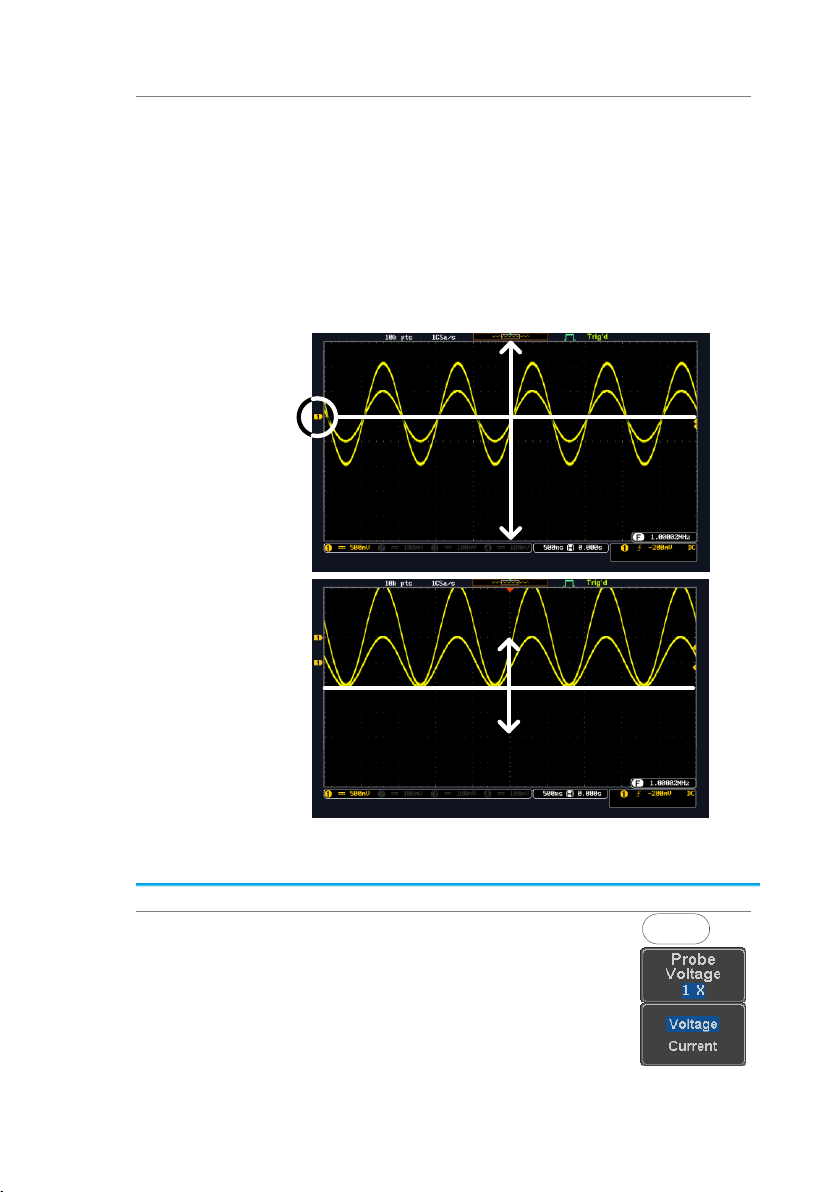

Hanning, Hamming, Rectangular,