Page 1

Gas Sensor Platform Reference Design User's

Guide

User's Guide

Literature Number: SNOA922

April 2013

WEBENCH is a registered trademark of Texas Instruments.

SmartRF is a trademark of Texas instruments.

iPhone, iPad, iPhone 4S, iPad 3 are registered trademarks of Apple Inc.

App Store is a trademark of Apple Inc. (service mark).

Embedded Workbench is a registered trademark of IAR Systems.

I2C is a trademark of NXP.

Bluetooth is a registered trademark of SIG, Inc.

All other trademarks are the property of their respective owners.

Page 2

Contents

1 Gas Sensor Platform Reference Design User's Guide .............................................................. 5

1.1 Introduction .................................................................................................................. 5

1.1.1 Fundamental Blocks of LMP91000: ............................................................................. 7

1.1.2 Examples of Firmware and iOS Calculation .................................................................... 8

1.1.2.1 O

1.2 CO Sensor Example ........................................................................................................ 9

1.2.1 Postprocessing Steps as Implemented in the iOS ............................................................ 9

1.3 Supported Sensor Types .................................................................................................. 9

1.3.1 WEBENCH

2 Features ........................................................................................................................... 12

2.1 Gas Sensor Platform With BLE Design Features ..................................................................... 12

2.2 Featured Applications ..................................................................................................... 14

2.3 Highlighted Products ...................................................................................................... 14

2.4 Block Diagram ............................................................................................................. 15

3 Hardware Description ........................................................................................................ 16

3.1 Getting Started ............................................................................................................. 16

3.2 Battery Life Calculation ................................................................................................... 18

4 Antenna Simulations .......................................................................................................... 19

4.1 Simulations With the Battery Board (SAT0009) ....................................................................... 19

4.2 Summary of Findings ..................................................................................................... 24

4.3 Conclusion .................................................................................................................. 24

4.4 FCC Reports ............................................................................................................... 24

5 Schematics and Bill Of Materials ......................................................................................... 25

5.1 SAT Gas Sensor Platform With BLE .................................................................................... 25

5.1.1 Power Board Schematic and BOM ............................................................................. 25

5.2 BLE and AFE Section ..................................................................................................... 27

6 Layout .............................................................................................................................. 32

6.1 SAT Gas Sensor Platform With BLE .................................................................................... 32

6.1.1 SAT0009 (Power Board) Layer Plots .......................................................................... 32

6.1.2 SAT0010 (AFE and BLE Board) Layer Plots ................................................................. 32

7 Practical Applications ........................................................................................................ 34

7.1 iOS Application ............................................................................................................ 34

7.2 Firmware Section .......................................................................................................... 37

A SAT0009 Power Board Files ................................................................................................ 41

A.1 Gerber Files ................................................................................................................ 41

A.2 Altium Project Files ........................................................................................................ 41

Sensor Example ......................................................................................... 8

2

®

Support ............................................................................................. 11

2

Contents SNOA922–April 2013

Copyright © 2013,Texas Instruments Incorporated

Submit Documentation Feedback

Page 3

www.ti.com

1-1. Sensor Design............................................................................................................... 7

1-2. CO Setup..................................................................................................................... 9

1-3. O

1-4. 3-Lead Amperometric Cell................................................................................................ 10

1-5. 2-Lead Galvanic Cell In Potentiostat Configuration................................................................... 10

1-6. WEBENCH CO ............................................................................................................ 11

1-7. WEBENCH O

2-1. Block Diagram of Gas-Sensing Platform With Bluetooth Low Energy.............................................. 15

3-1. Installing the Sensor on the Platform .................................................................................. 16

3-2. CR2032 Battery............................................................................................................ 17

3-3. System Running With LED Flashing.................................................................................... 17

3-4. Current Consumption ..................................................................................................... 18

3-5. Current Consumption-Active vs Sleep Modes......................................................................... 18

4-1. Ansoft Antenna Simulation Setup ....................................................................................... 19

4-2. Antenna Simulations With Power Board ............................................................................... 20

4-3. Antenna Simulations Matching With Power Board.................................................................... 20

4-4. Antenna Simulations Electrical Field Propagation With Power Board.............................................. 21

4-5. Antenna Simulations Setup Without Battery Board................................................................... 21

4-6. Antenna Simulations Matching Without Battery Board ............................................................... 22

4-7. Antenna Simulations Field Propagation Without Battery Board..................................................... 23

4-8. Improved Antenna Matching............................................................................................. 23

5-1. Power Section.............................................................................................................. 25

5-2. BLE Section ................................................................................................................ 27

5-3. AFE Section................................................................................................................ 28

5-4. CO - O

5-5. Filter......................................................................................................................... 31

6-1. Power Board ............................................................................................................... 32

6-2. BLE and AFE Board ...................................................................................................... 33

7-1. Application Icon............................................................................................................ 34

7-2. Locating the Sensors ..................................................................................................... 35

7-3. Updating the Sensors..................................................................................................... 35

7-4. Connecting to a Sensor................................................................................................... 36

7-5. Main Menu.................................................................................................................. 36

7-6. CC Debugger .............................................................................................................. 37

7-7. Launching IAR ............................................................................................................. 37

7-8. IAR Version in Use ........................................................................................................ 38

7-9. Main Loop .................................................................................................................. 38

7-10. Communication Settings.................................................................................................. 39

7-11. Sensor Section............................................................................................................. 39

7-12. CO Settings ................................................................................................................ 40

7-13. Adding New Sensor....................................................................................................... 40

A-1. Power Board ............................................................................................................... 41

A-2. AFE and BLE Board ...................................................................................................... 42

List of Figures

Setup...................................................................................................................... 9

2

............................................................................................................. 11

2

..................................................................................................................... 31

2

SNOA922–April 2013 List of Figures

Submit Documentation Feedback

Copyright © 2013, Texas Instruments Incorporated

3

Page 4

www.ti.com

List of Tables

4-1. Antenna Simulations Results Without Battery Board ................................................................. 22

5-1. Power Section BOM ...................................................................................................... 26

5-2. BLE Section BOM ........................................................................................................ 29

4

List of Tables SNOA922–April 2013

Copyright © 2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 5

Gas Sensor Platform Reference Design User's Guide

1.1 Introduction

The intent of this user's guide is to describe in detail the Gas Sensor Platform with Bluetooth®LowEnergy Reference Design from Texas Instruments. After reading this user's guide, a user should better

understand the features and usage of this reference design platform.

Chapter 1

SNOA922–April 2013

SNOA922–April 2013 Gas Sensor Platform Reference Design User's Guide

Submit Documentation Feedback

Copyright © 2013, Texas Instruments Incorporated

5

Page 6

Introduction

The Gas Sensor Platform with Bluetooth low-energy (BLE) is intended as a reference design that

customers can use to develop end-products for consumer and industrial applications to monitor gases like

carbon monoxide (CO), oxygen (O2), ammonia, fluorine, chlorine dioxide etc. . BLE adds a wireless

feature to the platform that enables seamless connectivity to an iPhone®or an iPad®. Customers can

easily replace the targeted gas sensor based on their application, while keeping the same analog frontend (AFE) and BLE design. The system runs on a CR2032 coin-cell battery. AFE from TI — LMP91000 —

interfaces directly with the electrochemical cell. The LMP91000 interfaces with CC2541 which is a BLE

system on a chip from TI.

An iOS application running on an iPhone 4S®and newer generations or an iPad 3®and newer

generations lets customers interface with this reference platform. Customers can use and customize the

iOS application, the hardware files and firmware source code of CC2541, which TI provides as an open

source. The Gas Sensor Platform with BLE provides customers with a low-power, configurable AFE and

the option to integrate wireless features in gas-sensing applications. This platform helps customers access

the market faster and helps differentiate from performance, power, and feature sets.

The platform complies with the below certifications on wireless:

• EN 300 328 compliant

• FCC 15.247 compliant

• IC RSS-210 compliant

The platform complies with the below certifications on EMC:

• FCC – FEDERAL COMMUNICATIONS COMMISSION Part 15, Class B

• IC – INDUSTRY CANADA ICES-003 Class B

• EN 301 489-17

The heart of this reference platform is the AFE from TI, the LMP91000. The LMP91000 is perfect for use

in micropower, electrochemical-sensing applications. The LMP91000 provides a complete signal-path

solution between a sensor and a microcontroller that generates an output voltage proportional to the cellcurrent. This device provides all of the functionality for detecting changes in gas concentration based on a

delta current at the working electrode.

The LMP91000 is programmed to support multiple electrochemical sensors, such as 3-lead toxic gas

sensors (see Figure 1-4) and 2-lead galvanic cell sensors (see Figure 1-5) with a single design as

opposed to multiple discrete solutions. The AFE supports gas sensitivities over a range of 0.5 to 9500

nA/ppm. It also allows for an easy conversion of current ranges from 5 to 750 µA, full scale.

The adjustable cell-bias and transimpedance amplifier (TIA) gain are programmed through the I2C™

interface. The I2C interface can also be used for sensor diagnostics. An integrated temperature sensor can

be read by the user through the VOUT pin and used to provide additional signal correction in the µC or

monitored to verify temperature conditions at the sensor. The AFE is optimized for micropower

applications, and operates over a voltage range of 2.7 to 5.25 V. The total current consumption can be

less than 10 μA. Additional power-saving capabilities are possible by switching off the TIA and shorting the

reference electrode to the working electrode with an internal switch

The LMP91000 supports many different toxic gases and sensors, and is configured to address the critical

parameters of each gas.

www.ti.com

6

Gas Sensor Platform Reference Design User's Guide SNOA922–April 2013

Copyright © 2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 7

www.ti.com

Introduction

Figure 1-1. Sensor Design

1.1.1 Fundamental Blocks of LMP91000:

Transimpedance Amplifier — TIA provides an output voltage that is proportional to the cell current. TIA

provides seven programmable internal-gain resistors and allows the external-gain resistor to

connect to the LMP91000.

(V

ref_div–Vout

V

out

Input — The LMP91000 provides a 3-electrode solution — counter electrode (CE), reference electrode

(RE), working electrode (WE) (see Figure 1-4), as well as a 2-electrode solution — short the CE

and RE (see Figure 1-5).

Variable Bias — Variable bias provides the amount of bias voltage required by a biased gas sensor

between RE and WE. This bias voltage can be programmed to be 1% to 24% of the supply, or it

can be VREF. The bias can also be negative or positive depending on the type of sensing element.

V

Divider — This is the voltage at the noninverting pin at TIA. This voltage can be programmed to be

ref

either 20%, 50%, or 67% of the supply, or it can be VREF. The V

of the full-scale input range of the analog-to-digital converter (ADC) and sufficient headroom for the

counter electrode of the sensor to swing in case of sudden changes in the gas concentration.

• How to select the appropriate V

– If the current at pin WE (Iwe) is flowing into the TIA, then the V

of V

– If Iweis flowing out of the TIA, then the V

• Assume V

• Assume Variable Bias is set to 2% of V

• Assume V

= (V

ref

The V

) / (RTIA) = I

) – (RTIA × Iwe) (2)

ref_div

.

divider in that case would be 0.82 V. The noninverting input to A1 woul;d be

ref

ref_divider

= 4.1V.

ref

we

is set to 20% of V

0.902 V, which is 22% of V

divider:

ref

ref

(1)

Divider provides the best use

ref

divider should be set to 67%

ref

divider should be set to 20% of V

ref

.

ref

.

ref

.

ref

.

SNOA922–April 2013 Gas Sensor Platform Reference Design User's Guide

Submit Documentation Feedback

Copyright © 2013, Texas Instruments Incorporated

7

Page 8

Introduction

Control Amplifier A1 — A1 is a differential amplifier used to compare the potential between WE and RE.

The error signal is amplified and applied to the CE. Changes in the impedance between the WE

and RE cause a change in the voltage applied to CE in order to maintain the constant voltage

between WE and RE.

Temperature Sensor — An on-board temperature sensor provides a ±3˚C accuracy. The sensor can be

used by an external µC to correct for performance over temperature.

Serial Interface — Calibration and programming is done through the I2C digital interface. Calibration and

state-of-health monitoring is enabled by the I2C interface. As mentioned before, health monitoring

is very important because chemical cells can degrade over time.

1.1.2 Examples of Firmware and iOS Calculation

This section explains the signal path and signal processing as implemented in the Gas Sensor Platform,

from the sensor to LMP91000, to CC2541 and to the iOS application.

1.1.2.1 O2Sensor Example

The following example uses the O2sensor from the Alphasense A2 series (see Section 1.3.1).

A change in µA current of the sensor indications a change in gas concentration. The LMP91000

processes the current and uses the linear TIA stage to convert the current to analog voltage (see

Figure 1-1). The analog voltage is then sent to CC2541. The CC2541 then converts the raw analog

voltage to a digital signal through a 12-bit ADC and transmits the signal through the Bluetooth radio to an

iOS device. The iOS device then performs postprocessing.

www.ti.com

1.1.2.1.1 Postprocessing Steps as Implemented in the iOS

• Covert voltage (binary to decimal).

– In this example, we assume that CC2541 transmits 0348h in its VOUT field. iOS software converts

this hexadecimal voltage into a decimal value:

0348h = 840 (3)

• Since the ADC is inside the CC2541 is a 12-bit resolution (2s complementary).

– Thus the ADC resolution inside CC2541:

2.5 V / (211-1) = 0.001221 (4)

– Note: LM4120 provides a fixed 2.5V precision reference to both LMP91000 and CC2541 in this

reference platform and thus we have used 2.5 V above to calculate the ADC resolution inside

CC2541 .

• Multiply the decimal value from Equation 8 with the ADC resolution:

840 × 0.001221 = 1.025 V (5)

(V

ref_div–Vout

) / (RTIA) = I

• V

• RTIA above is set to 7000.

• Thus current at pin WE (Iwe) flowing into the TIA is ~91 µA (fresh air calibration). (6)

here is 67% of V

ref_div

we_fresh air

.

ref

• To change the O2concentration, if you exhale (breathe out) on the O2sensor; the VOUT would

increase. Let's assume that CC2541 transmits 03B0h in its VOUT field. 03B0h will translate to 944 in

decimal. (see Equation 8).

– 944 × 0.001221 = 1.152 V

• Thus current at pin WE (Iwe) flowing into the TIA in this case would be: (1.667– 1.152) / 7000 =

73.5 µA

• In Equation 11, the calibrated fresh air WE (Iwe) value is 91 µA. For calibration, this can be set to

correspond - 20.9%.

• When we exhale (breathe out) on the O2sensor; the normalized O2percentage would then be:

(73.5 × 20.9) / 91 = 16.88% (7)

8

Gas Sensor Platform Reference Design User's Guide SNOA922–April 2013

Copyright © 2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 9

www.ti.com

1.2 CO Sensor Example

The following example uses the CO sensor from the Alphasense CO-AF series (see Section 1.3.1).

A change in µA current of the sensor indications a change in gas concentration. The LMP91000

processes the current and uses the linear TIA stage to convert the current to analog voltage (see

Figure 1-1). The analog voltage is then sent to CC2541. The CC2541 then converts the raw analog

voltage to a digital signal through a 12-bit ADC and transmits the signal through the Bluetooth radio to an

iOS device. The iOS device then performs postprocessing.

1.2.1 Postprocessing Steps as Implemented in the iOS

• Covert voltage (binary to decimal).

– In this example, we assume that CC2541 transmits 019Fh in its VOUT field. iOS software converts

this hexadecimal voltage into a decimal value:

019Fh = 415 (8)

• Since the ADC is inside the CC2541 is a 12-bit resolution (2s complementary).

– Thus the ADC resolution inside CC2541:

2.5 V / (211-1) = 0.001221 (9)

– Note: LM4120 provides a fixed 2.5V precision reference to both LMP91000 and CC2541 in this

reference platform and thus we have used 2.5 V above to calculate the ADC resolution inside

CC2541 .

• Multiply the decimal value from Equation 8 with the ADC resolution:

415 × 0.001221 = 0.506 V (10)

(V

ref_div–Vout

• Based on the CO-AF specification, the sensitivity of the sensor is 55-90nA/ppm. In the iOS software,

the sensitivity is set to 70nA/ppm (~average of the range).

– 857nA × 70nA/ppm= ~12ppm

• Note: The RTIA for the CO-AF sensor is set to 7000. This ensures that the full range of the CO-AF

sensor (0-5000ppm) can be utilized without clipping.

) / (RTIA) = - I

• As Iweis flowing out of the TIA in case of CO sensor, then the V

• RTIA above is set to 7000.

• Thus current at pin WE (Iwe) flowing out of the TIA is ~857nA (fresh air calibration). (11)

we_fresh air

CO Sensor Example

divider should be set to 20% of V

ref

.

ref

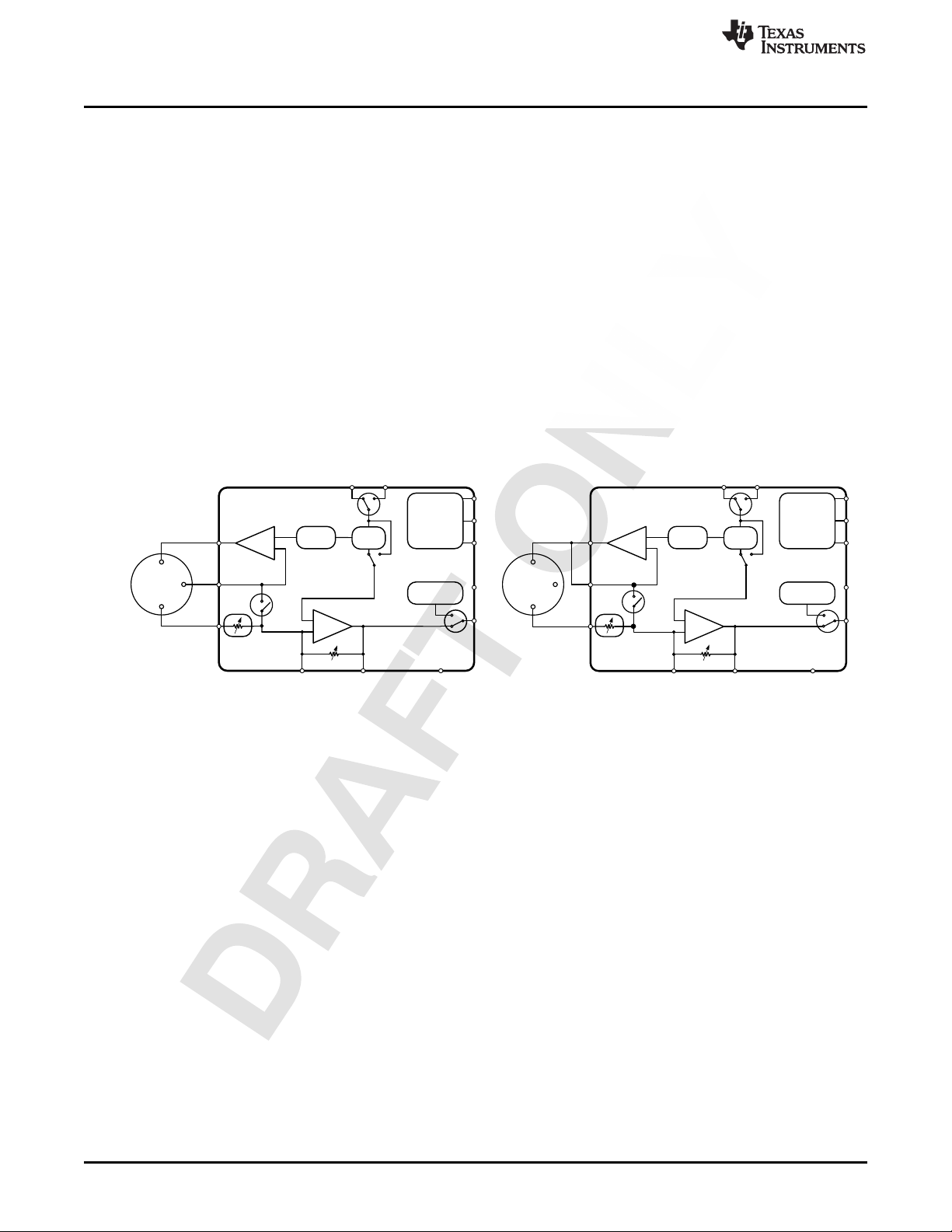

1.3 Supported Sensor Types

The Gas Sensor Platform from TI can be used either with a 3-lead amperometric cell (not included) (see

Figure 1-4) and a 2-lead galvanic cell (not included) in potentiostat configuration (see Figure 1-5) by a

minor resistor change shown in Figure 5-4.

• For a 3-lead amperometric cell (CO), R43 must be un-installed.

• For a 2-lead galvanic cell (O2) R43 must be installed.

SNOA922–April 2013 Gas Sensor Platform Reference Design User's Guide

Submit Documentation Feedback

Copyright © 2013, Texas Instruments Incorporated

9

Page 10

I2C INTERFACE

AND

CONTROL

REGISTERS

RE

VREF

VDD

AGND

CE

WE

VOUT

C1

SCL

TEMP

SENSOR

VREF

DIVIDER

C2

SDA

R

Load

VARIABLE

BIAS

MENB

DGND

A1

+

-

TIA

+

-

R

TIA

VE-

VE+

NC

LMP91000

2-wire Sensor

such as Oxygen

I2C INTERFACE

AND

CONTROL

REGISTERS

RE

VREF

VDD

AGND

CE

WE

VOUT

C1

SCL

TEMP

SENSOR

VREF

DIVIDER

C2

SDA

R

Load

VARIABLE

BIAS

MENB

DGND

A1

+

-

TIA

+

-

R

TIA

CE

WE

RE

3-Lead

Electrochemical

Cell

LMP91000

Supported Sensor Types

www.ti.com

Figure 1-2. CO Setup Figure 1-3. O2Setup

Figure 1-4. 3-Lead Amperometric Cell Figure 1-5. 2-Lead Galvanic Cell In Potentiostat

Configuration

10

Gas Sensor Platform Reference Design User's Guide SNOA922–April 2013

Copyright © 2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 11

www.ti.com

1.3.1 WEBENCH®Support

TI recommends that customers use WEBENCH for their sensor-type design. Refer to Figure 1-6, Figure 1-

7, and the WEBENCH open design tool at http://www.ti.com/product/lmp91000. The WEBENCH tool lists

all of the sensor types compatible with LMP91000.

NOTE: The default firmware and the iOS software in the Gas Sensor Platform from TI are designed

to support the CO-AF from Alphasense (http://www.alphasense.com/industrial-

sensors/alphasense_sensors.html) as well as the O2-A2 from Alphasense. Customers can

easily update the firmware and the iOS software to support additional sensor types. For

firmware updates see Section 7.2.

Supported Sensor Types

Figure 1-6. WEBENCH CO

Figure 1-7. WEBENCH O

2

SNOA922–April 2013 Gas Sensor Platform Reference Design User's Guide

Submit Documentation Feedback

Copyright © 2013, Texas Instruments Incorporated

11

Page 12

2.1 Gas Sensor Platform With BLE Design Features

• Coin-cell operation (CR2032)

• Low-power configurable AFE (LMP91000) that provides flexibility for customers to use the same AFE

for different gas-sensing platforms and configure different platforms with a simple firmware update

• Provides reference design for BLE antenna design - leveraging low-cost trace antenna

• Enables customers to use the platform to incorporate wireless features in gas-sensing applications

• TI provides BLE firmware and iOS application software as open-source to help customers get to the

market faster.

• The platform is comprised of two boards that are stacked together and are referred to as SAT0009

(power board) and SAT0010 (AFE and Bluetooth board).

LMP91000

• Supply voltage 2.7 to 5.25 V

• Supply current (average over time) <10 μA

• Cell-conditioning current up to 10 mA

• Reference electrode bias-current (85°C) 900 pA (max)

• Output drive-current 750 μA

• Complete potentiostat circuit to interface to most chemical cells

• Programmable cell-bias voltage

• Low-bias voltage drift

• Programmable TIA gain 2.75 to 350 kΩ

• Sink and source capability

• I2C-compatible digital interface

• Ambient operating temperature –40°C to +85°C

• Package: 14-pin WSON

• Supported by WEBENCH Sensor AFE Designer

LM4120

• Small SOT23-5 package

• Low dropout voltage: 120 mV Typ @ 1 mA

• High output voltage accuracy: 0.2%

• Source and sink current output: ±5 mA

• Supply current: 160 μA Typ.

• Low temperature coefficient: 50 ppm/°C

• Enable pin

• Fixed output voltages: 1.8, 2.048, 2.5, 3.0, 3.3, 4.096 and 5.0 V

• Industrial temperature range: –40°C to +85°C

TPS61220

• Up to 95% efficiency at typical operating conditions

• 5.5-μ quiescent current

Chapter 2

SNOA922–April 2013

Features

12

Features SNOA922–April 2013

Copyright © 2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 13

www.ti.com

• Startup into load at 0.7-V input voltage

• Operating input voltage from 0.7 to 5.5 V

• Pass-through function during shutdown

• Minimum switching current 200 mA

• Output overvoltage, overtemperature, input undervoltage lockout protection

• Adjustable output voltage from 1.8 to 5.5 V

• Fixed output voltage versions

• Small 6-pin SC-70 package

CC2541

• Radio

• Layout

• Low power

• Peripherals

Gas Sensor Platform With BLE Design Features

– 2.4-GHz low-energy compliant and Proprietary RF System-on-Chip (SoC)

– Supports 250-kbps, 500-kbps, 1-Mbps, 2-Mbps data rates

– Excellent link budget, enabling long-range applications without external front-end

– Programmable output power up to 0 dBm

– Excellent receiver sensitivity (–94 dBm at 1 Mbps), selectivity and blocking performance

– Suitable for systems-targeting compliance with worldwide radio frequency regulations

– ETSI EN 300 328 and EN 300 440 Class 2 (Europe), FCC CFR47 Part 15 (US), and ARIB STD-

T66 (Japan)

– Few external components

– Reference design provided

– 6-mm × 6-mm QFN-40 package

– Pin-compatible with CC2540 (when not using USB or I2C)

– Active-mode RX down to: 17.9 mA

– Active-mode TX (0 dBm): 18.2 mA

– Power mode 1 (4-μs Wake-Up): 270 μA

– Power mode 2 (Sleep Timer On): 1 μA

– Power mode 3 (External Interrupts): 0.5 μA

– Wide supply-voltage range (2 V – 3.6 V)

– TPS62730-compatible low power in active mode

– RX down to: 14.7 mA (3-V supply)

– TX (0 dBm): 14.3 mA (3-V supply)

– Powerful 5-Channel direct memory access (DMA)

– General-purpose timers (one, 16-bit; two, 8-bit)

– IR generation circuitry

– 32-kHz sleep timer with capture

– Accurate digital RSSI support

– Battery monitor and temperature sensor

– 12-bit ADC with eight channels and configurable resolution

– AES security coprocessor

– Two powerful UARTs with support for several serial protocols

– 23 general-purpose I/O pins

• (21 × 4 mA, 2 × 20 mA)

SNOA922–April 2013 Features

Submit Documentation Feedback

Copyright © 2013, Texas Instruments Incorporated

13

Page 14

Featured Applications

– I2C interface

– Two I/O pins with LED-driving capabilities

– Watchdog timer

– Integrated high-performance comparator

• Development tools

– CC2541 Evaluation Module Kit (CC2541EMK)

– CC2541 Mini Development Kit (CC2541DK-MINI)

– SmartRF™ software

– IAR Embedded Workbench®available

2.2 Featured Applications

The Gas Sensor Platform with BLE Reference Platform is designed to demonstrate how a configurable

AFE can be used with a low-power wireless radio to provide a reference platform that will help customers

develop their next-generation gas-sensing solutions for:

• Industrial: gas-sensing application

• Consumer: carbon monoxide-sensing application

• Healthcare facilities: gas-sensing application

2.3 Highlighted Products

The Gas Sensor Platform with Bluetooth Low-Energy Reference Design features the following devices:

• LMP91000: Sensor AFE System: Configurable AFE potentiostat for low-power chemical-sensing

applications.

• CC2541: –2.4-GHz Bluetooth low-energy and proprietary SoC.

• LM4120: Precision micropower low dropout voltage reference.

• TPS61220: Low input voltage, 0.7-V boost converter with 5.5-μA quiescent current.

For more information on each of these devices, go to the respective product folders at ti.com.

www.ti.com

14

Features SNOA922–April 2013

Copyright © 2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 15

www.ti.com

2.4 Block Diagram

Figure 2-1 shows the block diagram for TI's Gas-Sensor Solution with BLE.

Block Diagram

Figure 2-1. Block Diagram of Gas-Sensing Platform With Bluetooth Low Energy

SNOA922–April 2013 Features

Submit Documentation Feedback

Copyright © 2013, Texas Instruments Incorporated

15

Page 16

3.1 Getting Started

Requirements:

• Gas sensor: use the recommended CO-AF from Alphasense.

• CR2032: Coin-cell

• An iOS device: iPhone 4S and newer generations; iPad 3 and newer generations; fifth generation iPod

(Apple.com).

Download the (?) application from the Apple App Store™ at iTunes.com.

NOTE: CC-DEBUGGER is the debug tool to load the firmware to CC2541 (ti.com/tool/cc-debugger).

The debug tool is needed only if changes to the firmware are required.

Chapter 3

SNOA922–April 2013

Hardware Description

16

Figure 3-1. Installing the Sensor on the Platform

Hardware Description SNOA922–April 2013

Copyright © 2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 17

www.ti.com

By default the Gas Sensor Platform supports the 3-lead amperometric cell (R43 not installed, see

Section 1.3). By default, the firmware and iOS software support the Alphasense CO-AF sensor. TI

recommends installing the CO-AF sensor (not included) from Alphasense into the socket on the SAT0010

board (see Figure 3-2).

1. Install the sensor onto the platform (see Figure 3-1).

2. Load the CR2032 (not included in the kit) into the coin-cell holder on the SAT0009 board.

3. Turn the on/off switch to the right (with respect to the orientation shown in Figure 3-3).

Getting Started

Figure 3-2. CR2032 Battery

NOTE: A blue LED flashes when the default firmware is loaded.

4. Download the application from the App Store.

5. Use an iOS device to access the Gas Sensor Platform and interface with the platform (see

Section 7.1).

6. If needed, connect the CC-DEBUGGER (not included in the kit) to the 10-pin header as shown in

Figure 3-3. If changes to the default firmware are needed, see Section 7.2.

Figure 3-3. System Running With LED Flashing

SNOA922–April 2013 Hardware Description

Submit Documentation Feedback

Copyright © 2013, Texas Instruments Incorporated

17

Page 18

Battery Life Calculation

3.2 Battery Life Calculation

For battery life calculations, it is highly recommended that the customer reviews CC2541 Battery Life

Calculation, SWRA347.

It is impossible to use a single metric to compare the power consumption of a BLE device to another

device. For example, a device gets rated by its peak current. While the peak current plays a part in the

total power consumption, a device running the BLE stack only consumes current at the peak level during

transmission. Even in very high throughput systems, a BLE device is only transmitting for a small

percentage of the total time that the device is connected (see Figure 3-4).

www.ti.com

Figure 3-4. Current Consumption

In addition to transmitting, there are other factors to consider when calculating battery life. A BLE device

can go through several other states, such as receiving, sleeping, and waking-up from sleep. Even if the

current consumption of a device in each different state is known, there is not enough information to

determine the total power consumed by the device. Each layer of the BLE stack requires a certain amount

of processing to remain connected and to comply with the specifications of the protocol. The MCU takes

time to perform this processing, and during this time, current is consumed by the device. In addition, some

power might be consumed while the device switches between states (see Figure 3-5). All of this must be

considered in order to get an accurate measurement of the total current consumed.

18

Figure 3-5. Current Consumption-Active vs Sleep Modes

Hardware Description SNOA922–April 2013

Copyright © 2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 19

The following data was simulated using the High-Frequency Structural Simulator (HFSS) from ANSYS

(www.ansys.com/hfss).

The Gas Sensor Platform with BLE platform is a stackup of two 1-inch diameter boards (see Figure 4-1).

The goals of the antenna simulations include the following:

• Validate that the 2.45-GHz antenna performs as expected.

• Estimate the influence of the battery board, by running simulations with and without the battery board.

4.1 Simulations With the Battery Board (SAT0009)

Both boards were used in the first simulation to determine the affect of the power board (SAT0009) on the

BLE antenna located on SAT0010 (see Figure 4-2, Figure 4-3, and Figure 4-4).

Chapter 4

SNOA922–April 2013

Antenna Simulations

Figure 4-1. Ansoft Antenna Simulation Setup

SNOA922–April 2013 Antenna Simulations

Submit Documentation Feedback

Copyright © 2013, Texas Instruments Incorporated

19

Page 20

Simulations With the Battery Board (SAT0009)

Figure 4-2. Antenna Simulations With Power Board

www.ti.com

20

Figure 4-3. Antenna Simulations Matching With Power Board

Antenna Simulations SNOA922–April 2013

Copyright © 2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 21

www.ti.com

Simulations With the Battery Board (SAT0009)

Figure 4-4. Antenna Simulations Electrical Field Propagation With Power Board

The power board (SAT0009) was used in the next simulation to determine if the BLE antenna resulted in

an improvement to the performance of SAT0010 (see Figure 4-5, Figure 4-6, and Figure 4-7).

Figure 4-5. Antenna Simulations Setup Without Battery Board

SNOA922–April 2013 Antenna Simulations

Submit Documentation Feedback

Copyright © 2013, Texas Instruments Incorporated

21

Page 22

Simulations With the Battery Board (SAT0009)

Table 4-1. Antenna Simulations Results Without Battery Board

Quantity Value Units

Max U 0.00043244 W/sr

Peak Directivity 1.1138

Peak Gain 0.66408

Peak Realized Gain 0.54344

Radiated Power 0.0048793 W

Accepted Power 0.0081833 W

Incident Power 0.01 W

Radiation Efficiency 0.59625

Front-to-Back Ratio Not Applicable

Decay Factor 0

www.ti.com

22

Figure 4-6. Antenna Simulations Matching Without Battery Board

Antenna Simulations SNOA922–April 2013

Copyright © 2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 23

www.ti.com

Simulations With the Battery Board (SAT0009)

Figure 4-7. Antenna Simulations Field Propagation Without Battery Board

Figure 4-8. Improved Antenna Matching

Antenna matching was improved by increasing the inductor from 3 to 5 nH (see Figure 4-8. The increase

resulted in a better return loss value of 10 dB.

SNOA922–April 2013 Antenna Simulations

Submit Documentation Feedback

Copyright © 2013, Texas Instruments Incorporated

23

Page 24

Summary of Findings

4.2 Summary of Findings

• The battery board does not significantly influence the antenna (see Table 4-1).

• Good omnidirectional radiation pattern is found.

– Low peak gain of 1.2.

• Antenna radiation efficiency is estimated at 54%.

4.3 Conclusion

• Overall board size is very small.

– Reduces the antenna efficiency from an estimated 70% to 54%.

– Influences the match of the antenna to become only 6 dB.

• By increasing the last inductor from 3 to 5 nH, the match is improved.

4.4 FCC Reports

The Gas Sensor Platform is compliant with FCC and EU radiation requirements. For additional

information, see the following documents:

• ETSI EN 301 489-17, v2.1.1.

http://processors.wiki.ti.com/index.php/File:10240453EEU1_301_489_report.pdf

• FCC part 15, subpart B & ICES-003, Issue 4.

http://processors.wiki.ti.com/index.php/File:10240453EUS1_FCC_Report.pdf

• EN 300 328: v1.7.1. http://processors.wiki.ti.com/index.php/File:10240453REU1.pdf

www.ti.com

24

Antenna Simulations SNOA922–April 2013

Copyright © 2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 25

GN D

GN D

GN D

GN D

V_COIN_CELL

CR2032 COIN CELL BATTER Y

GN DGN D

VDD

12 L5

1 2

BT1

VDD EXPECTED 3V

EN

6

GN D

3

L

5

VOU T

4

FB

2

VIN

1

U3

10uF 6.3V

12

C22

10uF 6.3V

12

C23

6

6

3

3

C2

5

4

4

C1

2

1

1

U2

1M

R16

200 kohm

R17

0.1uF 10V

12

C20

1

2

J2

VDD

GN D

1

2

J3

1uF 6.3V

12

C38

1J61J81

J9

47uF 6.3V

12

C21

5.1 SAT Gas Sensor Platform With BLE

5.1.1 Power Board Schematic and BOM

A PDF of the SAT0009 (Power Board) can be found here:

http://processors.wiki.ti.com/index.php/File:SAT0009_Rev_E1.pdf.

Chapter 5

SNOA922–April 2013

Schematics and Bill Of Materials

Figure 5-1. Power Section

SNOA922–April 2013 Schematics and Bill Of Materials

Submit Documentation Feedback

Copyright © 2013, Texas Instruments Incorporated

25

Page 26

SAT Gas Sensor Platform With BLE

www.ti.com

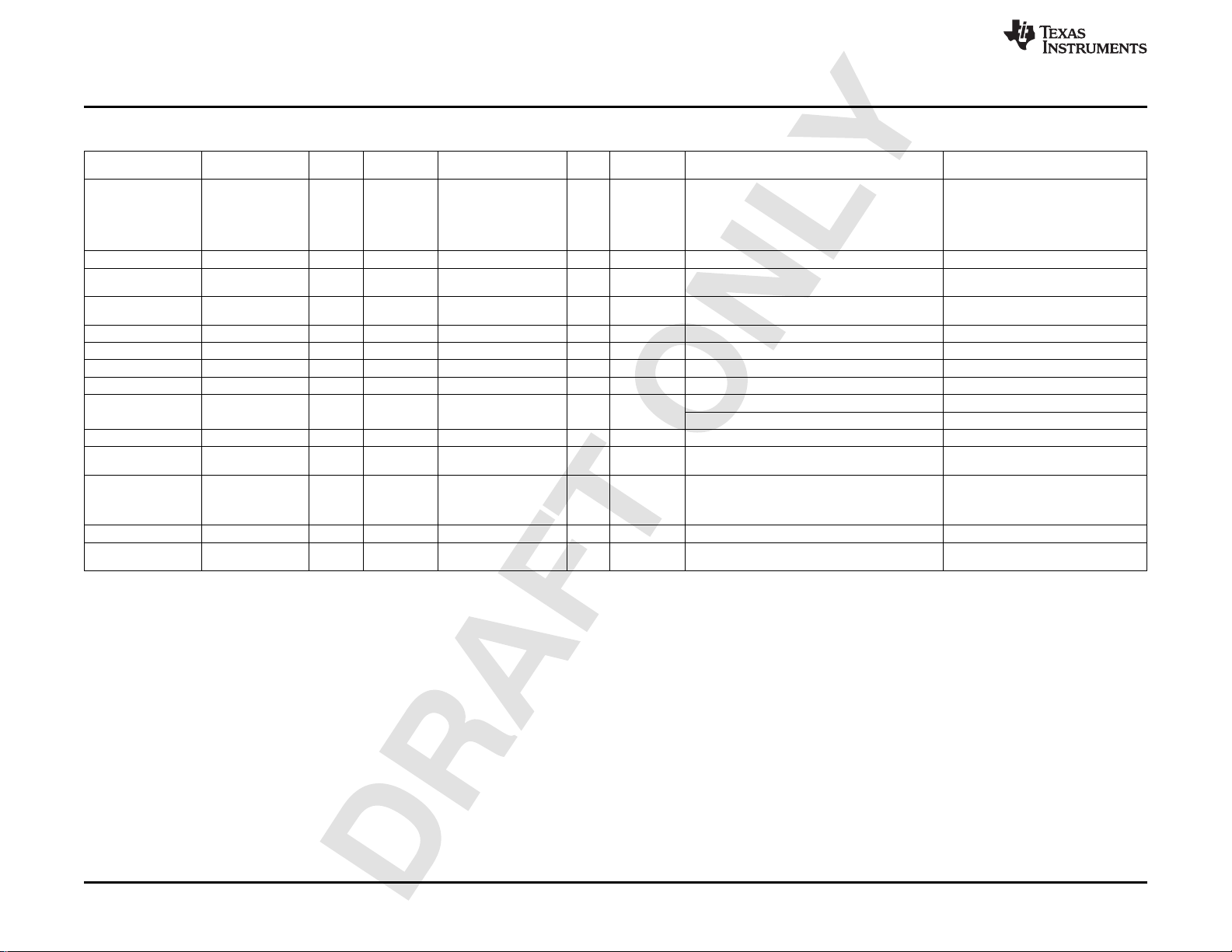

Table 5-1. Power Section BOM

Comment Description Designator Footprint LibRef Qty Manufacturer Part No. Supplier Part No.

BS-7-ND Battery Holder BT1 BATTHOLD-BS-7-CR2032 BS-7-ND 1 Digi-Key BS-7-ND

GRM155R71A104KA01D C20 C402-25RD GRM155R71A104KA01 1 GRM155R71A Digi-Key

TSW-101-07-G-S Conn Header 1POS C21, J6, J8, J9 JUMP1X1-382650CTR TSW-101-07-G-S 4 Samtec, Inc. Digi-Key SAM1029-01-ND

GRM188R60J106ME47 C22, C23 C603-35X45 GRM188R60J106ME47 2 GRM188R60J1 Digi-Key 490-3896-2-ND

GRM155R60J105KE190 C38 C402-25RD GRM155R60J105KE190 1 GRM155R60J1 Digi-Key 490-1320-2-ND

TBSTC-501-D-200-22-G J2, J3 JUMP1X2-3826-50CTR TBSTC-501-D-200-22-G 2 Major League TBSTC-501-D-2

EPL3015 L5 EPL3015-INDUCTOR EPL3015 1 Coilcraft EPL3015-427M

CRCW04021M00JNED RES 1.0 mΩ 1/6W R16 R402-25RD CRCW04021M00JNED 1 Digi-Key 541-1.0MJCT-ND

CRCW0402200KJNED Res 200 KΩ 1/6W R17 R402-25RD CRCW0402200KJNED 1 Digi-Key 541-200KJDKR-ND

EG1390B U2 EG1390-SWITCH EG1390B 1 Digi-Key EG4633TR-ND

TPS6120DCK U3 DCK6 TPS61220DCK 1 Digi-Key 296-32505-2-ND

Cap Cer 0.1 µF 10 GRM155R71A104KA01

V 10 D-ND

Cap Cer 10 µF 6.3

V 20

Cap Cer 1 µF 6.3 V

10%

Major League Elec

0.05

Power Inductor,

Shielder

26

Schematics and Bill Of Materials SNOA922–April 2013

Submit Documentation Feedback

Copyright © 2013, Texas Instruments Incorporated

Page 27

VDD

GN D

VDD _FILT

GN DGN DGN DGN DGN DGN DGN D

GN D

GN D

GN D

GN D

P2_1/DD

P0_5/SCK

P0_3/MISO

P0_2/MOSI

P2_2/DC

P0_4/SSN

RESET_N

GN D

SoC De bug/Fla sh

GN D

GN D

GN D

GN D

GN D

SCL

SDA

GN D

P1_0

P1_0

VOUT_P0_0

C2_P0_1

P2_1/DD

P2_2/DC

P0_2/MOSI

P0_3/MISO

P0_4/SSN

P0_5/SCK

GN D

GN D

GN DGN D

RESET_N

1 2

3 4

5 6

7 8

9 10

J1

BLM15HG102SN1D

1 2

FB1

1nF 50V

1 2

C19

GN D

1 2

34

X2

GN D

VREF

GN D

VDD _FILT

GN D

1

SCL

2

SDA

3

NC

4

P1_5

5

P1_4

6

P1_3

7

P1_2

8

P1_1

9

DVD D1

10

P1_0

11

P0_7

12

P0_6

13

P0_5

14

P0_4

15

P0_3

16

P0_2

17

P0_1

18

P0_0

19

RESET_N

20

AVDD 6

31

XOSC_ Q1

22

XOSC_ Q2

23

AVDD 5

21

RF_P

25

RF_N

26

AVDD 4

29

AVDD 3

24

AVDD 2

27

RBIAS

30

AVDD 1

28

P2_4

32

P2_3

33

P2_2

34

P2_1

35

P2_0

36

P1_7

37

P1_6

38

DVD D2

39

DC OU PL

40

THER M_PAD

41

U1

CC2541

1uF 6.3V

12

C1

1uF 6.3V

12

C15

2.2uF 6.3V

12

C8

0.1uF 10V

12

C2

0.1uF 10V

12

C4

0.1uF 10V

12

C3

0.1uF 10V

12

C5

0.1uF 10V

12

C7

12pF 50V

12

C17

12pF 50V

12

C18

15pF 50V

1 2

C14

15pF 50V

1 2

C16

18pF 50V

12

C11

18pF 50V

12

C12

1pF 50V

12

C13

1pF 50V

12

C10

1pF 50V

1 2

C9

220pF 50V

12

C6

1.0nH

12

L1

2.0nH

12

L3

2.0nH

12

L4

0 ohm

R1

0 ohm

R2

0 ohm

DNP

R3

0 ohm

R4

0 ohm

R5

0 ohm

R8

0 ohm

R13

0 ohm

R9

0 ohm

R14

0 ohm

R6

2.7K ohm

R10

56k ohm

R11

270 ohm

R12

32.768kHz

535-9544-2-ND

1 2

X1

BLUE

D1

1

2

A3

ANTENNA IIFA BLE

VDD

GN D

1

2

J5

1uF 6.3V

12

C36

1

2

J7

1M

DNP

R15

0 ohm

DNP

R7

5.1nH

12 L2

DN P = DO NOT POPU LATE AT ASSEMB LY

www.ti.com

5.2 BLE and AFE Section

A PDF of the SAT0010 AFE (LMP91000) and BLE (CC2541) can be found here:

http://processors.wiki.ti.com/index.php/File:SAT0010_Rev_E1.pdf.

BLE and AFE Section

SNOA922–April 2013 Schematics and Bill Of Materials

Submit Documentation Feedback

Figure 5-2. BLE Section

Copyright © 2013, Texas Instruments Incorporated

27

Page 28

1

2

3

4

5

6

7

8

9

10

11

12

13

14

A1

TIA

VARIABLE

BIAS

Vref

DIVIDER

CE

RLOAD

RTA

TEMP

SENSOR

RE

WE

INTERFACE

AND

CONTROL

REGISTERS

NC C1 C2 DAP AGND

VOUT

DGND

MENB

SDA

SCL

VDDVREF

I2C

LMP91000

Configurable Potentiostat AFE

LMP91000SDE/NOPBTR-ND

U5

LMP91000SD

GN D

VDD

GN D

VDD

GN D

SDA

SCL

C2_P0_1

GN D

GN D

VOUT_P0_0

VREFGN D

GN D

GN D

GN D

GN D

Ve+

1

Ve-

2

3

3

10F7941

S1

LM4120AIM5-2.5

REF

1

GN D

2

EN

3

IN

4

OUT

5

LM4120AIM5-2.5CT-ND

U4

CE

WE

RE

VDD

1uF 6.3V

12

DNP

C29

0.1uF 10V

12

C30

1uF 6.3V

1 2

DNP

C31

1uF 6.3V

12

DNP

C32

0.1uF 16V

1 2

C24

0.1uF 16V

12

DNP

C26

56pF 50V

12

C27

0 ohm

R18

0 ohm

R22

0 ohm

DNP

R21

0.022uF 16V

12

C25

0.022uF 16V

12

C28

10.0 kohm

R19

10.0 kohm

R20

0 ohm

R43

VREF EXPECTED 2.5 V

DNP = DO NOT POPULATE AT ASSEMBLY

BLE and AFE Section

www.ti.com

28

Schematics and Bill Of Materials SNOA922–April 2013

Figure 5-3. AFE Section

Copyright © 2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 29

www.ti.com

BLE and AFE Section

Table 5-2. BLE Section BOM

Comment Description Footprint LibRef Qty ASSY_Option Manufacturer PartNo. Supplier Part No.

ANTENNA IIFA BLE Antenna IIFA BLE A3 Antenna 1 order or place

GRM155R60J105KE19D C402-25RD GRM155R60J105KE19D 3 GRM155R60J105KE19D Digi-Key 490-1320-2-ND

GRM155R71A104KA01D C4, C5, C402-25RD GRM155R71A104KA01D 6 GRM155R71A104KA01D Digi-Key

GRM1555C1H221JA01D C6 C402-25RD GRM1555C1H221JA01D 1 GRM1555C1H221JA01D Digi-Key 490-1293-2-ND

GRM155R60J225ME15D C8 C402-25RD GRM155R60J225ME15D 1 GRM155R60J225ME15D Digi-Key 490-4519-1-ND

GRM1555C1H1R0CA01D C402-25RD GRM1555C1H1R0CA01D 3 GRM1555C1H1ROCA01D Digi-Key 490-3199-2-ND

GRM1555C1H180JZ01D C11, C12 C402-25RD GRM1555C1H180JZ01D 2 GRM1555C1H180JZ01D Digi-Key 490-1281-2-ND

GRM1555C1H150JA01D C14, C16 C402-25RD GRM1555C1H150JA01D 2 GRM1555C1H150JA01D Digi-Key 490-5888-2-ND

GRM1555C1H120JA01D C17, C18 C402-25RD GRM1555C1H120JA01D 2 GRM1555C1H120JA01D Newark 14T3292

GRM1555C1H102JA01D C19 C402-25RD GRM1555C1H102JA01D 1 GRM1555C1H102JA01D Digi-Key 490-324-2-ND

C0402C104K4RAC7411 C24 C402-25RD C0402C104K4RAC7411 1 C0402C104K4RAC7411 Digi-Key 399-7352-2-ND

GRM155R71C223KA01J C25, C28 C402-25RD GRM155R71C223KA01J 2 GRM155R71C223KA01J Digi-Key 709-1128-2-ND

C0402C104K4RAC7411 C26 C402-25RD C0402C104K4RAC7411 1 DNP C0402C104K4RAC7411 Digi-Key 399-7352-2-ND

VJ0402D560JXAAJ C27 C402-25RD VJ0402D560JXAAJ 1 VJ0402D560JXAAJ Digi-Key 720-1293-2-ND

GRM155R60J105KE19D C402-25RD GRM155R60J105KE19D 3 DNP GRM155R60J105KE19D Digi-Key 490-1320-2-ND

LED 0402 BLUE 465NM LED 0402 BLUE465NM

TRANSPARENT TRANSPARENT

BLM15HG102SN1D FB1 l402-25 BLM15HG102SN1D 1 BLM15HG102N1D Digi-Key 490-3999-2-ND

FTSH-105-01-FDH J1 FTSH-105-01-FDH 1 Arrow 2745567S5787043N1004

TBSTC-501-D- 200-22-G- .050x.050 cl Thicker JUMP1X2- TBSTC-501-D- 200-22-G300-LF Brd Stacker Term 3826-50CTR 300- LF

LQG15HS1N0S02D 1 nH, I0402-25 L1 l402-25 LQG15HS1N0S02D 1 Murata Elec LQG15HS1N0S02D Digi-Key 490-2610-2-ND

LQG15HH5N1S02D L2 l402-25 LQG15HH5N1S02D 1 Murata Elec LQG15HH5N1S02D Mouser 81-LQG15HH5N1S02D

LQG15HS2N0S02D 2.0 nH, I0402-25 L3, L$ l402-25 LQG15HS2N0S02D 2 Murata LQG15HS2N0S02D Mouser 81-LQG15HS2N0S02D

Cap Cer 1 µF 6.3 V C1, C15,

10% X5R C36

Cap Cer 0.1 µF 10 V GRM155R71A104KA01D

10% X7R -ND

Cap Cer 220 pF 50 V

5% NP0

Cap Cer 2.2 µF 6.3 V

20% X5R

Cap Cer 1 pF 50 V C9, C10,

NP0 C13

Cap Cer 18 pF 50 V

5% NP0

Cap Cer 15 pF 50 V

5% NP0

Cap, 0402, C0G, 50 V,

12 pF

Cap Cer 1000 pF 50 V

5% NP0

Cap Cer 0.1 µF 16 V

10% X7R

Cap Cer 0.022 µF 16 V Johanson Dielectrics

10% X7R Inc.

Cap Cer 0.1 µF 16 V

10% X7R

Cap Cer 56PF 50 V

5% NP0

Cap Cer 1UF 6.3 V C29, C31,

10% X5R C32

Filter Chip 1000 Ω 250

mA

Major League Elec

Strips - Custom

5.1 nH ±0.3 nH, I040225

Designat

or

Antenna_IIFA

_BLE

C2, C3,

C7, C30

D1 1 Digi-Key 511-1615-1-ND

J5, J7 2 Major League Elec TBSTC-501-D-200-22-G-300-LF

LED-SML31SQ

FTSH2X5110X29

No part to

at ASSY

SNOA922–April 2013 Schematics and Bill Of Materials

Submit Documentation Feedback

Copyright © 2013, Texas Instruments Incorporated

29

Page 30

BLE and AFE Section

www.ti.com

Table 5-2. BLE Section BOM (continued)

Comment Description Footprint LibRef Qty ASSY_Option Manufacturer Part No. Supplier Part No.

ERJ-2GE0R00X Res 0 Ω 1/10W R402-25RD ERJ-2GE0R00X 12 Digi-Key P0.0JTR-ND

ERJ-2GE0R00X Res 0 Ω 1/10W R3, R21 R402-25RD ERJ-2GE0R00X 2 DNP Digi-Key P0.0JTR-ND

CR0402-J/-000G R7 R402-25RD CR0402-J/-000G 1 DNP Newark 02J1955

CRCW04022K70FKED R10 R402-25RD CRCW04022K70FKED 1 Digi-Key 541-2.70KLCT-ND

CRCW040256K0FKED Res 56 KΩ 1/16W 1% R11 R402-25RD CRCW040256K0FKED 1 Digi-Key 541-56.0KLCT-ND

CRCW0402270RFKED Res 270 Ω 1/16W 1% R12 R402-25RD CRCW0402270RFKED 1 Digi-Key 541-270LCT-ND

CRCW04021M00JNED Res 1 mΩ 1/16W 5% R15 R402-25RD CRCW04021M00JNED 1 DNP Digi-Key 541-1.0MJCT-ND

CRCW040210K0FKED Res 10 KΩ 1/16W 1% R19, R20 R402-25RD CRCW040210K0FKED 2 Digi-Key 541-10.0KLCT-ND

Socket and OxygenSensor

CC2541 Single Chip BLE U1 CC2541 1 TI CC2541F256RHAR

LM4120AIM5- 2.5/NOPB U4 LM4120AIM5-2.5/NOPB 1 Digi-Key LM4120AIM5-2.5CT-ND

LMP91000SD U5 LMP91000SD 1 TI Digi-Key

ABS07- 32.768kHz-9 Oscillator X1 XTAL2-ABS07 ABS07-32.768kHz-9 1 Digi-Key 535-9544-2-ND

FA128 Oscillator X2 FA128 1 Epson Q22FA1280009200

Resistor Chip, Jumper,

0 Ω, 1%

Res 2.70 KΩ 1/16W

1%

IC VREF Series Prec SOT23-27X39-

2.5 V 5

Configurable AFE

Potentiostat for Low- NHL0014B- LMP91000SDE/NOPBTR

Power Chemical WSON -ND

Sensing

Designat

or

R1, R2,

R4, R5,

R6, R8,

R9, R13,

R14, R18,

R22, R43

S1 SKT_O2-A1 Socket and Oxygen-Sensor 1

XTAL4-37X34FA128

Alphasense (Sensor) 02-A1 Newark 10F7941

Cambion (Socket) 450-3326-01-03-00

30

Schematics and Bill Of Materials SNOA922–April 2013

Submit Documentation Feedback

Copyright © 2013, Texas Instruments Incorporated

Page 31

www.ti.com

BLE and AFE Section

NOTE: Capacitors C29 and C32 on SAT0010 provide low-pass filtering to the analog output signals

(Vout and C2) from LMP91000. In the schematic, they are placed as placeholders and

shown as DNP (Do not populate). During testing of this platform it was noted that a value of

.01 µF was most optimized for C29 and C32 for this particular platform. Customers can finetune this selection based on their system design.

Figure 5-4. CO - O

Figure 5-5. Filter

2

SNOA922–April 2013 Schematics and Bill Of Materials

Submit Documentation Feedback

Copyright © 2013, Texas Instruments Incorporated

31

Page 32

6.1 SAT Gas Sensor Platform With BLE

6.1.1 SAT0009 (Power Board) Layer Plots

A PDF of the SAT0009 (power board) layer plots can be found here:

http://processors.wiki.ti.com/index.php/File:SAT0009_Layer_Plot.PDF.

Chapter 6

SNOA922–April 2013

Layout

Figure 6-1. Power Board

6.1.2 SAT0010 (AFE and BLE Board) Layer Plots

A PDF of the SAT0010 (AFE and BLE board) layer plots can be found here:

http://processors.wiki.ti.com/index.php/File:SAT0009_Layer_Plot.PDF.

32

Layout SNOA922–April 2013

Copyright © 2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 33

www.ti.com

SAT Gas Sensor Platform With BLE

Figure 6-2. BLE and AFE Board

SNOA922–April 2013 Layout

Submit Documentation Feedback

Copyright © 2013, Texas Instruments Incorporated

33

Page 34

7.1 iOS Application

Figure 7-1, Figure 7-2, Figure 7-3, Figure 7-4, and Figure 7-5 show the TI BLE Sensor application as used

with an iPad.

Chapter 7

SNOA922–April 2013

Practical Applications

34

Figure 7-1. Application Icon

Practical Applications SNOA922–April 2013

Copyright © 2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 35

www.ti.com

iOS Application

Figure 7-2. Locating the Sensors

Figure 7-3. Updating the Sensors

SNOA922–April 2013 Practical Applications

Submit Documentation Feedback

Copyright © 2013, Texas Instruments Incorporated

35

Page 36

iOS Application

www.ti.com

Figure 7-4. Connecting to a Sensor

36

Figure 7-5. Main Menu

Practical Applications SNOA922–April 2013

Copyright © 2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 37

www.ti.com

7.2 Firmware Section

One of the development platforms for the CC2451 8051 microcontroller is the IAR development platform.

See http://www.iar.com/ for information on this platform.

To communicate to the development platform through IAR, the CC Debugger is required. See Section 3.1.

The CC Debugger must be connected to the 10-pin header on the SAT0010 board. Make sure that the

notch on the cable that connects to the 10-pin header is facing away from the sensor or toward the

outside. If connected properly, the LED on the CC Debugger should turn green.

Firmware Section

Figure 7-6. CC Debugger

Figure 7-7. Launching IAR

Launch the project file as shown in Figure 7-7.

SNOA922–April 2013 Practical Applications

Submit Documentation Feedback

Copyright © 2013, Texas Instruments Incorporated

37

Page 38

Firmware Section

www.ti.com

Figure 7-8. IAR Version in Use

Ensure that you are using the version used in Figure 7-8 or a newer version.

38

Figure 7-9. Main Loop

Highlight Main.c, as shown in Figure 7-9.

Practical Applications SNOA922–April 2013

Copyright © 2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 39

www.ti.com

Firmware Section

Figure 7-10. Communication Settings

The number of times the Bluetooth radio communicates with the iOS application can be easily changed by

using the highlighted variable shown in Figure 7-10.

Figure 7-11. Sensor Section

The firmware has a case statement to easily change from a CO sensor to an O2sensor, as shown in

Figure 7-11. Note the x in front of the CO option.

SNOA922–April 2013 Practical Applications

Submit Documentation Feedback

Copyright © 2013, Texas Instruments Incorporated

39

Page 40

Firmware Section

www.ti.com

Figure 7-12. CO Settings

All the key configuration settings for LMP91000 have been co-located for easy update to the firmware (see

Figure 7-12).

40

Figure 7-13. Adding New Sensor

New sensor services can be added to the firmware, as shown in Figure 7-13.

Practical Applications SNOA922–April 2013

Copyright © 2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 41

A.1 Gerber Files

The .zip file for the SAT0009 power board can be found here:

http://processors.wiki.ti.com/index.php/File:SAT0009_Rev_E1(Gerbers,_TPS61220)121008A.zip.

The .zip file for the SAT0010 AFE and BLE board can be found here:

http://processors.wiki.ti.com/index.php/File:SAT0009_Rev_E1(Gerbers,_TPS61220)121008A.zip.

A.2 Altium Project Files

The .zip file for the SAT0009 power board can be found here:

http://processors.wiki.ti.com/index.php/File:SAT0009_Layer_Plot.PDF.

Appendix A

SNOA922–April 2013

SAT0009 Power Board Files

Figure A-1. Power Board

The .zip file for the SAT0010 AFE and BLE board can be found here:

http://processors.wiki.ti.com/index.php/File:SAT0009_Layer_Plot.PDF.

SNOA922–April 2013 SAT0009 Power Board Files

Submit Documentation Feedback

Copyright © 2013, Texas Instruments Incorporated

41

Page 42

Altium Project Files

www.ti.com

Figure A-2. AFE and BLE Board

42

SAT0009 Power Board Files SNOA922–April 2013

Copyright © 2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 43

EVALUATION BOARD/KIT/MODULE (EVM) ADDITIONAL TERMS

Texas Instruments (TI) provides the enclosed Evaluation Board/Kit/Module (EVM) under the following conditions:

The user assumes all responsibility and liability for proper and safe handling of the goods. Further, the user indemnifies TI from all claims

arising from the handling or use of the goods.

Should this evaluation board/kit not meet the specifications indicated in the User’s Guide, the board/kit may be returned within 30 days from

the date of delivery for a full refund. THE FOREGOING LIMITED WARRANTY IS THE EXCLUSIVE WARRANTY MADE BY SELLER TO

BUYER AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED, IMPLIED, OR STATUTORY, INCLUDING ANY WARRANTY OF

MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE. EXCEPT TO THE EXTENT OF THE INDEMNITY SET FORTH

ABOVE, NEITHER PARTY SHALL BE LIABLE TO THE OTHER FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL

DAMAGES.

Please read the User's Guide and, specifically, the Warnings and Restrictions notice in the User's Guide prior to handling the product. This

notice contains important safety information about temperatures and voltages. For additional information on TI's environmental and/or safety

programs, please visit www.ti.com/esh or contact TI.

No license is granted under any patent right or other intellectual property right of TI covering or relating to any machine, process, or

combination in which such TI products or services might be or are used. TI currently deals with a variety of customers for products, and

therefore our arrangement with the user is not exclusive. TI assumes no liability for applications assistance, customer product design,

software performance, or infringement of patents or services described herein.

REGULATORY COMPLIANCE INFORMATION

As noted in the EVM User’s Guide and/or EVM itself, this EVM and/or accompanying hardware may or may not be subject to the Federal

Communications Commission (FCC) and Industry Canada (IC) rules.

For EVMs not subject to the above rules, this evaluation board/kit/module is intended for use for ENGINEERING DEVELOPMENT,

DEMONSTRATION OR EVALUATION PURPOSES ONLY and is not considered by TI to be a finished end product fit for general consumer

use. It generates, uses, and can radiate radio frequency energy and has not been tested for compliance with the limits of computing

devices pursuant to part 15 of FCC or ICES-003 rules, which are designed to provide reasonable protection against radio frequency

interference. Operation of the equipment may cause interference with radio communications, in which case the user at his own expense will

be required to take whatever measures may be required to correct this interference.

General Statement for EVMs including a radio

User Power/Frequency Use Obligations: This radio is intended for development/professional use only in legally allocated frequency and

power limits. Any use of radio frequencies and/or power availability of this EVM and its development application(s) must comply with local

laws governing radio spectrum allocation and power limits for this evaluation module. It is the user’s sole responsibility to only operate this

radio in legally acceptable frequency space and within legally mandated power limitations. Any exceptions to this are strictly prohibited and

unauthorized by Texas Instruments unless user has obtained appropriate experimental/development licenses from local regulatory

authorities, which is responsibility of user including its acceptable authorization.

For EVMs annotated as FCC – FEDERAL COMMUNICATIONS COMMISSION Part 15 Compliant

Caution

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This device may not cause

harmful interference, and (2) this device must accept any interference received, including interference that may cause undesired operation.

Changes or modifications not expressly approved by the party responsible for compliance could void the user's authority to operate the

equipment.

FCC Interference Statement for Class A EVM devices

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to

cause harmful interference in which case the user will be required to correct the interference at his own expense.

Page 44

FCC Interference Statement for Class B EVM devices

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful interference in a residential installation. This equipment

generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause

harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular installation. If

this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and

on, the user is encouraged to try to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

For EVMs annotated as IC – INDUSTRY CANADA Compliant

This Class A or B digital apparatus complies with Canadian ICES-003.

Changes or modifications not expressly approved by the party responsible for compliance could void the user’s authority to operate the

equipment.

Concerning EVMs including radio transmitters

This device complies with Industry Canada licence-exempt RSS standard(s). Operation is subject to the following two conditions: (1) this

device may not cause interference, and (2) this device must accept any interference, including interference that may cause undesired

operation of the device.

Concerning EVMs including detachable antennas

Under Industry Canada regulations, this radio transmitter may only operate using an antenna of a type and maximum (or lesser) gain

approved for the transmitter by Industry Canada. To reduce potential radio interference to other users, the antenna type and its gain should

be so chosen that the equivalent isotropically radiated power (e.i.r.p.) is not more than that necessary for successful communication.

This radio transmitter has been approved by Industry Canada to operate with the antenna types listed in the user guide with the maximum

permissible gain and required antenna impedance for each antenna type indicated. Antenna types not included in this list, having a gain

greater than the maximum gain indicated for that type, are strictly prohibited for use with this device.

Cet appareil numérique de la classe A ou B est conforme à la norme NMB-003 du Canada.

Les changements ou les modifications pas expressément approuvés par la partie responsable de la conformité ont pu vider l’autorité de

l'utilisateur pour actionner l'équipement.

Concernant les EVMs avec appareils radio

Le présent appareil est conforme aux CNR d'Industrie Canada applicables aux appareils radio exempts de licence. L'exploitation est

autorisée aux deux conditions suivantes : (1) l'appareil ne doit pas produire de brouillage, et (2) l'utilisateur de l'appareil doit accepter tout

brouillage radioélectrique subi, même si le brouillage est susceptible d'en compromettre le fonctionnement.

Concernant les EVMs avec antennes détachables

Conformément à la réglementation d'Industrie Canada, le présent émetteur radio peut fonctionner avec une antenne d'un type et d'un gain

maximal (ou inférieur) approuvé pour l'émetteur par Industrie Canada. Dans le but de réduire les risques de brouillage radioélectrique à

l'intention des autres utilisateurs, il faut choisir le type d'antenne et son gain de sorte que la puissance isotrope rayonnée équivalente

(p.i.r.e.) ne dépasse pas l'intensité nécessaire à l'établissement d'une communication satisfaisante.

Le présent émetteur radio a été approuvé par Industrie Canada pour fonctionner avec les types d'antenne énumérés dans le manuel

d’usage et ayant un gain admissible maximal et l'impédance requise pour chaque type d'antenne. Les types d'antenne non inclus dans

cette liste, ou dont le gain est supérieur au gain maximal indiqué, sont strictement interdits pour l'exploitation de l'émetteur.

SPACER

SPACER

SPACER

SPACER

SPACER

SPACER

SPACER

SPACER

Page 45

【【Important Notice for Users of this Product in Japan】】

This development kit is NOT certified as Confirming to Technical Regulations of Radio Law of Japan

If you use this product in Japan, you are required by Radio Law of Japan to follow the instructions below with respect to this product:

1. Use this product in a shielded room or any other test facility as defined in the notification #173 issued by Ministry of Internal Affairs and

Communications on March 28, 2006, based on Sub-section 1.1 of Article 6 of the Ministry’s Rule for Enforcement of Radio Law of

Japan,

2. Use this product only after you obtained the license of Test Radio Station as provided in Radio Law of Japan with respect to this

product, or

3. Use of this product only after you obtained the Technical Regulations Conformity Certification as provided in Radio Law of Japan with

respect to this product. Also, please do not transfer this product, unless you give the same notice above to the transferee. Please note

that if you could not follow the instructions above, you will be subject to penalties of Radio Law of Japan.

(address) 24-1, Nishi-Shinjuku 6 chome, Shinjuku-ku, Tokyo, Japan

http://www.tij.co.jp

【ご使用にあたっての注】

本開発キットは技術基準適合証明を受けておりません。

本製品のご使用に際しては、電波法遵守のため、以下のいずれかの措置を取っていただく必要がありますのでご注意ください。

1. 電波法施行規則第6条第1項第1号に基づく平成18年3月28日総務省告示第173号で定められた電波暗室等の試験設備でご使用いただく。

2. 実験局の免許を取得後ご使用いただく。

3. 技術基準適合証明を取得後ご使用いただく。

なお、本製品は、上記の「ご使用にあたっての注意」を譲渡先、移転先に通知しない限り、譲渡、移転できないものとします。

上記を遵守頂けない場合は、電波法の罰則が適用される可能性があることをご留意ください。

日本テキサス・インスツルメンツ株式会社

東京都新宿区西新宿6丁目24番1号

西新宿三井ビル

http://www.tij.co.jp

Texas Instruments Japan Limited

SPACER

SPACER

SPACER

SPACER

SPACER

SPACER

SPACER

SPACER

SPACER

SPACER

SPACER

SPACER

SPACER

SPACER

SPACER

SPACER

SPACER

Page 46

EVALUATION BOARD/KIT/MODULE (EVM)

WARNINGS, RESTRICTIONS AND DISCLAIMERS

For Feasibility Evaluation Only, in Laboratory/Development Environments. Unless otherwise indicated, this EVM is not a finished

electrical equipment and not intended for consumer use. It is intended solely for use for preliminary feasibility evaluation in

laboratory/development environments by technically qualified electronics experts who are familiar with the dangers and application risks

associated with handling electrical mechanical components, systems and subsystems. It should not be used as all or part of a finished end

product.

Your Sole Responsibility and Risk. You acknowledge, represent and agree that:

1. You have unique knowledge concerning Federal, State and local regulatory requirements (including but not limited to Food and Drug

Administration regulations, if applicable) which relate to your products and which relate to your use (and/or that of your employees,

affiliates, contractors or designees) of the EVM for evaluation, testing and other purposes.

2. You have full and exclusive responsibility to assure the safety and compliance of your products with all such laws and other applicable

regulatory requirements, and also to assure the safety of any activities to be conducted by you and/or your employees, affiliates,

contractors or designees, using the EVM. Further, you are responsible to assure that any interfaces (electronic and/or mechanical)

between the EVM and any human body are designed with suitable isolation and means to safely limit accessible leakage currents to

minimize the risk of electrical shock hazard.

3. You will employ reasonable safeguards to ensure that your use of the EVM will not result in any property damage, injury or death, even

if the EVM should fail to perform as described or expected.

4. You will take care of proper disposal and recycling of the EVM’s electronic components and packing materials.

Certain Instructions. It is important to operate this EVM within TI’s recommended specifications and environmental considerations per the

user guidelines. Exceeding the specified EVM ratings (including but not limited to input and output voltage, current, power, and

environmental ranges) may cause property damage, personal injury or death. If there are questions concerning these ratings please contact

a TI field representative prior to connecting interface electronics including input power and intended loads. Any loads applied outside of the

specified output range may result in unintended and/or inaccurate operation and/or possible permanent damage to the EVM and/or

interface electronics. Please consult the EVM User's Guide prior to connecting any load to the EVM output. If there is uncertainty as to the

load specification, please contact a TI field representative. During normal operation, some circuit components may have case temperatures

greater than 60°C as long as the input and output are maintained at a normal ambient operating temperature. These components include

but are not limited to linear regulators, switching transistors, pass transistors, and current sense resistors which can be identified using the

EVM schematic located in the EVM User's Guide. When placing measurement probes near these devices during normal operation, please

be aware that these devices may be very warm to the touch. As with all electronic evaluation tools, only qualified personnel knowledgeable

in electronic measurement and diagnostics normally found in development environments should use these EVMs.

Agreement to Defend, Indemnify and Hold Harmless. You agree to defend, indemnify and hold TI, its licensors and their representatives

harmless from and against any and all claims, damages, losses, expenses, costs and liabilities (collectively, "Claims") arising out of or in

connection with any use of the EVM that is not in accordance with the terms of the agreement. This obligation shall apply whether Claims

arise under law of tort or contract or any other legal theory, and even if the EVM fails to perform as described or expected.

Safety-Critical or Life-Critical Applications. If you intend to evaluate the components for possible use in safety critical applications (such

as life support) where a failure of the TI product would reasonably be expected to cause severe personal injury or death, such as devices

which are classified as FDA Class III or similar classification, then you must specifically notify TI of such intent and enter into a separate

Assurance and Indemnity Agreement.

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2013, Texas Instruments Incorporated

Page 47

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, enhancements, improvements and other

changes to its semiconductor products and services per JESD46, latest issue, and to discontinue any product or service per JESD48, latest

issue. Buyers should obtain the latest relevant information before placing orders and should verify that such information is current and

complete. All semiconductor products (also referred to herein as “components”) are sold subject to TI’s terms and conditions of sale

supplied at the time of order acknowledgment.

TI warrants performance of its components to the specifications applicable at the time of sale, in accordance with the warranty in TI’s terms