Page 1

TI Confidential – NDA Restrictions

CC3235MODSF SimpleLink™ Wi-Fi®and IoT Solution With MCU LaunchPad™ Hardware

User's Guide

Literature Number: SWRU548A

February 2019

Page 2

TI Confidential – NDA Restrictions

Contents

1 Introduction......................................................................................................................... 6

1.1 CC3235MODSF LaunchPad™ ........................................................................................ 6

1.2 LAUNCHCC3235MOD Key Features ................................................................................. 7

1.3 What's Included .......................................................................................................... 7

1.4 REACH Compliance ..................................................................................................... 7

1.5 Regulatory Compliance ................................................................................................. 8

1.6 First Steps: Out-of-Box Experience ................................................................................... 8

1.7 Next Steps: Looking into the Provided Code ........................................................................ 8

1.8 Trademarks ............................................................................................................... 9

2 Hardware .......................................................................................................................... 10

2.1 Block Diagram........................................................................................................... 11

2.2 Hardware Features ..................................................................................................... 13

2.3 Electrical Characteristics .............................................................................................. 27

2.4 Antenna Characteristics ............................................................................................... 27

2.5 BoosterPack™ Header Pin Assignment ............................................................................ 28

3 Layout Guidelines .............................................................................................................. 29

3.1 LAUNCHCC3235MOD Board Layout ................................................................................ 29

3.2 General Layout Recommendations .................................................................................. 33

3.3 RF Layout Recommendations ........................................................................................ 33

3.4 Antenna Placement and Routing .................................................................................... 35

3.5 Transmission Line Considerations ................................................................................... 35

4 Operational Setup and Testing ............................................................................................ 37

4.1 Measuring the CC3235MOD Current Draw ........................................................................ 38

4.2 RF Connections ........................................................................................................ 39

4.3 Design Files ............................................................................................................ 40

4.4 Software ................................................................................................................. 40

5 Development Environment Requirements ............................................................................. 40

5.1 CCS ...................................................................................................................... 40

5.2 IAR........................................................................................................................ 40

6 Additional Resources ......................................................................................................... 41

6.1 CC3235MODx Product Page ......................................................................................... 41

6.2 Download CCS, IAR ................................................................................................... 41

6.3 SimpleLink™ Academy for CC3235 SDK .......................................................................... 41

6.4 TI E2E Community ..................................................................................................... 41

7 Assembly Drawing and Schematics ..................................................................................... 42

7.1 Assembly Drawing ..................................................................................................... 42

7.2 Schematics ............................................................................................................. 43

Revision History.......................................................................................................................... 48

1 ........................................................................................................................................ 49

2 RF Function and Frequency Range....................................................................................... 49

3 FCC and IC Certification and Statement ................................................................................ 49

2

Table of Contents

Copyright © 2019, Texas Instruments Incorporated

SWRU548A–February 2019

Submit Documentation Feedback

Page 3

TI Confidential – NDA Restrictions

www.ti.com

3.1 FCC....................................................................................................................... 49

3.2 CAN ICES-3(B) and NMB-3(B) Certification and Statement...................................................... 50

3.3 End Product Labeling .................................................................................................. 51

3.4 Device Classifications.................................................................................................. 51

3.5 FCC Definitions ......................................................................................................... 51

3.6 Simultaneous Transmission Evaluation.............................................................................. 52

4 EU Certification and Statement ............................................................................................ 52

4.1 RF Exposure Information (MPE)...................................................................................... 52

4.2 Simplified DoC Statement ............................................................................................. 52

4.3 Waste Electrical and Electronic Equipment (WEEE)............................................................... 53

4.4 OEM and Host Manufacturer Responsibilities ...................................................................... 53

4.5 Antenna Specifications................................................................................................. 53

5 CC3235MODx Approved Antennas ....................................................................................... 53

SWRU548A–February 2019

Submit Documentation Feedback

Copyright © 2019, Texas Instruments Incorporated

Contents

3

Page 4

TI Confidential – NDA Restrictions

User's Guide

SWRU548A–February 2019

CC3235MODSF LaunchPad™ Development Kit

(LAUNCHCC3235MOD)

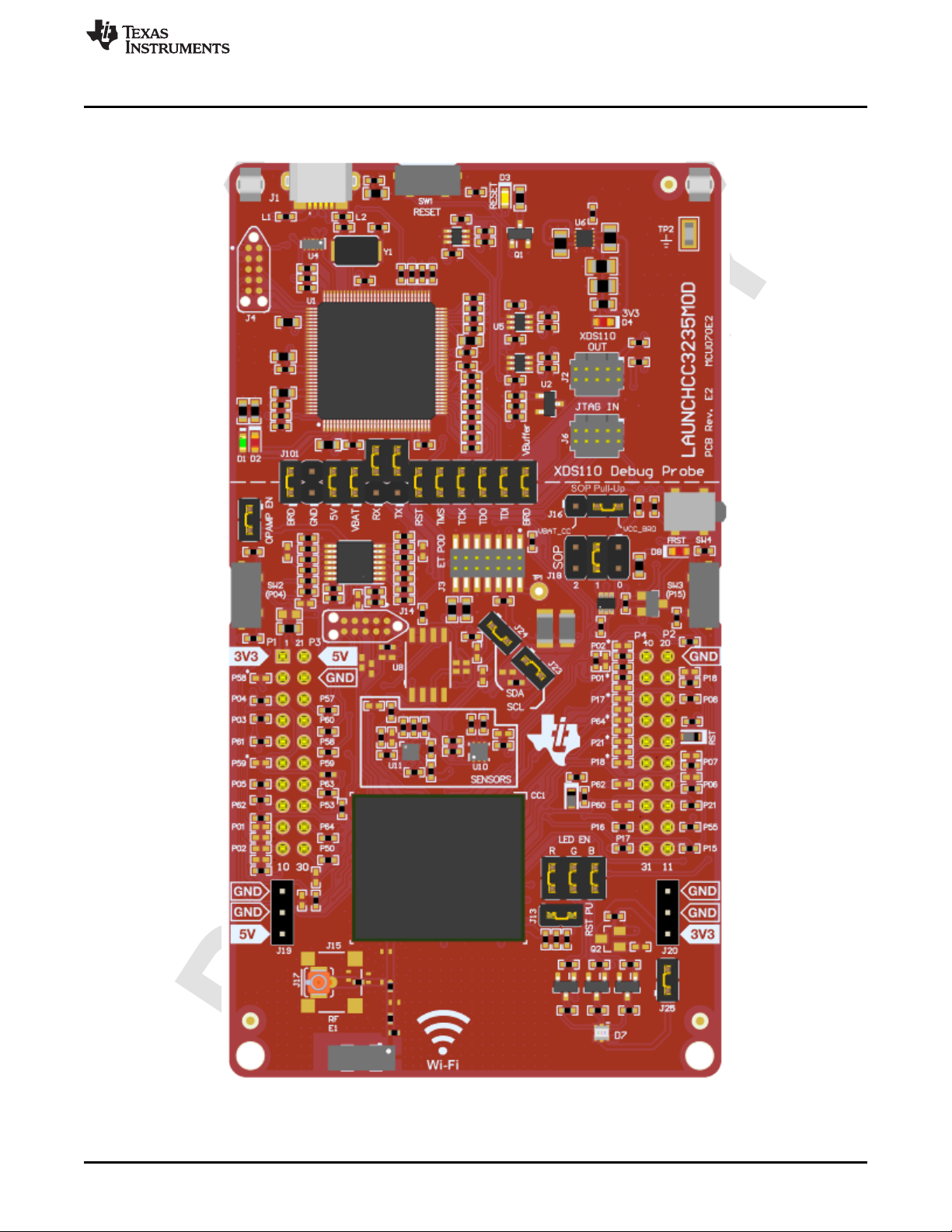

Start your design with the industry's first programmable FCC, IC/ISED, ETSI/CE, and MIC Certified

SimpleLinkTMWi-Fi® CC3235MOD Dual-Band Wireless Microcontroller Module with built-in DualBand (2.4 GHz and 5 GHz) Wi-Fi®connectivity. Created for the Internet-of-Things (IoT), the SimpleLink™

CC3235MODx family of devices from Texas Instruments™ are wireless modules that integrate two

physically separated, on-chip MCUs:

• An application processor – Arm®Cortex®-M4 MCU with a user-dedicated 256KB of RAM and an

optional 1MB of Serial Flash.

• A network processor MCU to run all Wi-Fi and Internet logic layers. This ROM based subsystem

includes an 802.11 a/b/g/n radio, baseband, and MAC with a powerful crypto engine for fast, secure

internet connections with 256-bit encryption.

The CC3235MODx comes in 2 variants:

• CC3235MODSM2MOB

– Requires an external antenna

• CC3235MODSF12MOB

– Requires an external antenna

– Contains 1MB of Serial Flash

The LAUNCHCC3235MOD is a low-cost evaluation platform for MCUs based on Arm®Cortex®-M4

devices. The LaunchPad™ design highlights the CC3235MODSF fully-integrated industrial module

solution and Dual-Band Wi-Fi capabilities. The LAUNCHCC3235MOD also features temperature and

accelerometer sensors, programmable user buttons, an RBG LED for custom applications, and onboard

emulation for debugging. The stackable headers interface demonstrates how easy it is to expand the

functionality of the LaunchPad when interfacing with other peripherals on existing BoosterPack™ add-on

boards, such as graphical displays, audio codec, antenna selection, environmental sensing, and more.

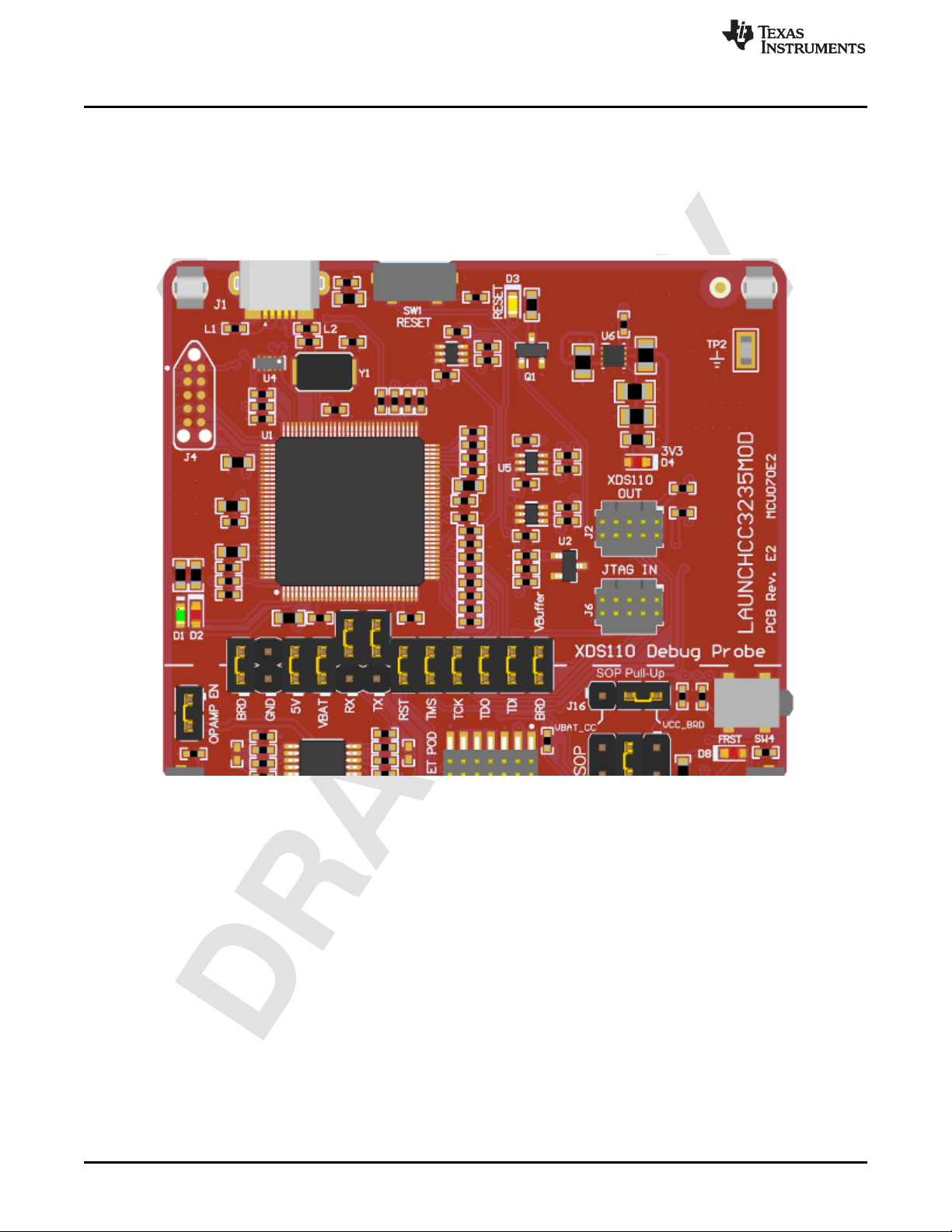

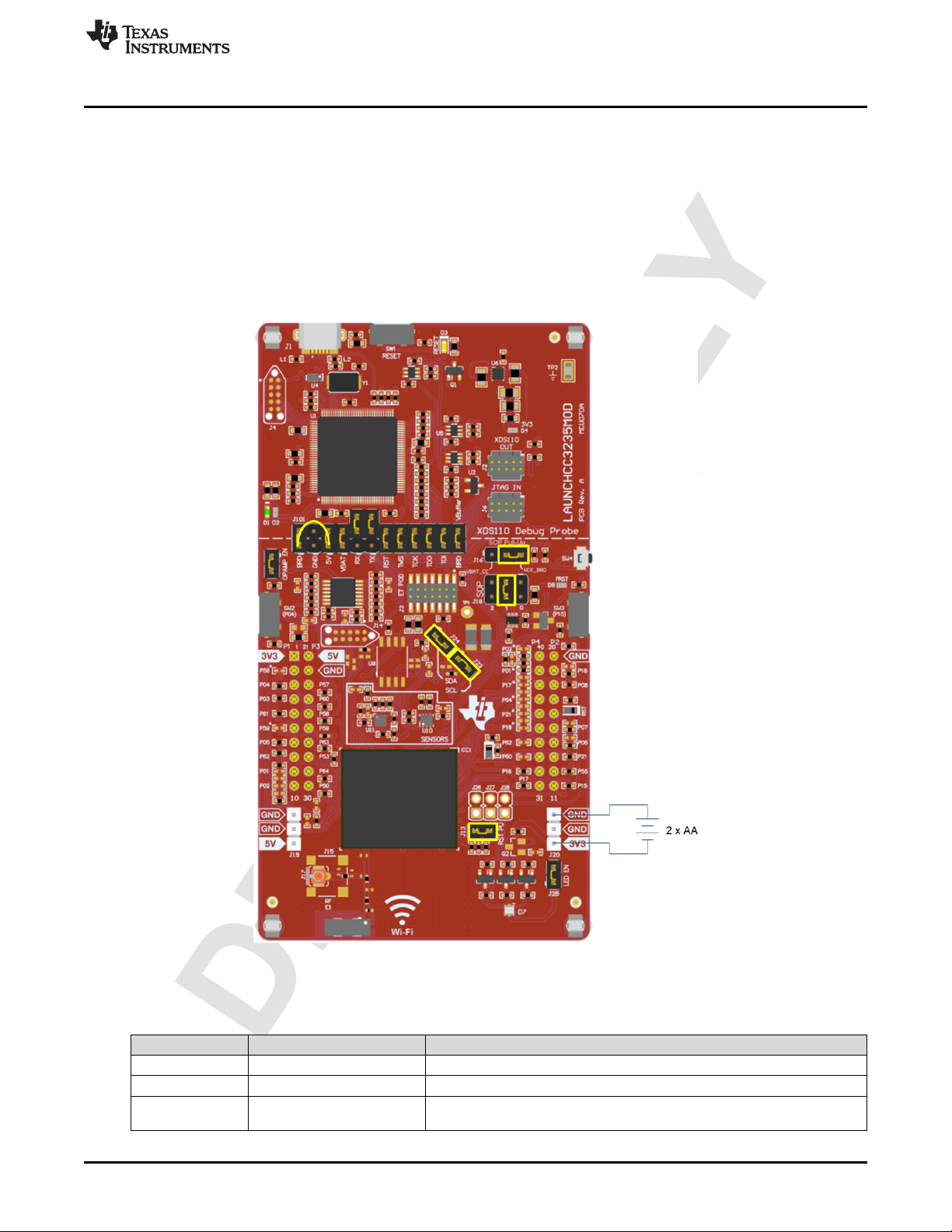

Figure 1 shows the CC3235MODSF LaunchPad development kit.

4

CC3235MODSF LaunchPad™ Development Kit (LAUNCHCC3235MOD)

Copyright © 2019, Texas Instruments Incorporated

SWRU548A–February 2019

Submit Documentation Feedback

Page 5

TI Confidential – NDA Restrictions

www.ti.com

Figure 1. CC3235MODSF SimpleLink™ Wi-Fi®LaunchPad™ Development Kit

SWRU548A–February 2019

Submit Documentation Feedback

CC3235MODSF LaunchPad™ Development Kit (LAUNCHCC3235MOD)

Copyright © 2019, Texas Instruments Incorporated

5

Page 6

TI Confidential – NDA Restrictions

Introduction

1 Introduction

1.1 CC3235MODSF LaunchPad™

Created for the Internet of Things (IoT), the SimpleLink CC3235MODx is a wireless module with built-in

Dual-Band Wi-Fi connectivity for the LaunchPad ecosystem, which integrates a high-performance Arm

Cortex®-M4 MCU and lets customers develop an entire application with one device. With on-chip Wi-Fi,

Internet, and robust security protocols, no prior Wi-Fi experience is required for fast development.

The CC3235MODSF LaunchPad, referred to by its part number LAUNCHCC3235MOD, is a low-cost

evaluation platform for Arm®Cortex®-M4-based MCUs. The LaunchPad design highlights the

CC3235MODSF Internet-on-a chip solution and Dual-Band Wi-Fi capabilities. The CC3235MODSF

LaunchPad also features temperature and accelerometer sensors, programmable user buttons, an RGB

LED for custom applications, and onboard emulation for debugging. The stackable headers of the

CC3235MODSF LaunchPad XL interface demonstrate how easy it is to expand the functionality of the

LaunchPad when interfacing with other peripherals on many existing BoosterPack add-on boards, such as

graphical displays, audio codecs, antenna selection, environmental sensing, and more. Figure 1 shows

the CC3235MOD LaunchPad.

Multiple development environment tools are also available, including TI’s Eclipse-based Code Composer

Studio™ (CCS) integrated development environment (IDE) and IAR Embedded Workbench®. More

information about the LaunchPad, the supported BoosterPack modules, and the available resources can

be found at TI’s LaunchPad portal.

NOTE: The maximum RF power transmitted in each WLAN 2.4 GHz band is 19 dBm (EIRP power).

The maximum RF power transmitted in each WLAN 5 GHz band is 18.8 dBm (EIRP power).

www.ti.com

®

NOTE: The antennas used for this transmitter must be installed to provide a separation distance of

at least 20 cm from all persons, and must not be colocated or operating in conjunction with

any other antenna or transmitter.

6

CC3235MODSF LaunchPad™ Development Kit (LAUNCHCC3235MOD)

Copyright © 2019, Texas Instruments Incorporated

SWRU548A–February 2019

Submit Documentation Feedback

Page 7

TI Confidential – NDA Restrictions

www.ti.com

1.2 LAUNCHCC3235MOD Key Features

The LAUNCHCC3235MOD SimpleLink LaunchPad includes the following features:

• CC3235MODSF, SimpleLinkTMDual-Band Wi-Fi®module solution

– Integrated MCU

– 40.0-MHz Crystal

– 32.768-kHz Crystal (RTC)

– 32-Mbit SPI Serial Flash

– RF and Full Power-Management Components

• 40-pin LaunchPad standard that leverages the BoosterPack ecosystem

• TI standard, XDS110-based JTAG emulation with serial port for flash programming

• Supports 4-wire JTAG and 2-wire SWD

• Two buttons and one RGB LED for user interaction

• Back-channel universal asynchronous receiver/transmitter (UART) through USB to PC

• Onboard chip antenna with U.FL for conducted testing selectable using 0-Ω resistors

• Onboard accelerometer and temperature sensor for out-of-box demo with option to isolate the sensors

from the inter-integrated circuit (I2C) bus

• Micro-USB connector for power and debug connections

• Headers for current measurement and external JTAG connection (option to use the onboard XDS110

to debug customer platforms)

• Bus-powered device with no external power required for Wi-Fi

• Long-range transmission with highly optimized antenna (200 m typical in open air using an access

point with 6-dBi antenna AP)

• Can be powered externally, with two AA or two AAA alkaline batteries working down to 2.3-V typical

• Dimensions: 106.1 mm (L) × 58.42 mm (W)

Introduction

1.3 What's Included

1.3.1 Kit Contents

• CC3235MODSF LaunchPad development tool (LAUNCHCC3235MOD)

• Micro USB cable

• Quick start guide

1.3.2 Software Examples

• Out-of-Box Experience (OOBE) Software

1.4 REACH Compliance

In compliance with the Article 33 provision of the EU REACH regulation we are notifying you that this

EVM includes component(s) containing at least one Substance of Very High Concern (SVHC) above

0.1%. These uses from Texas Instruments do not exceed 1 ton per year. The SVHC’s are:

Component

Manufacturer

Abracon Crystal ABM3-16.000MHZ-D2Y-TDiboron Trioxide 1303-86-2

Abracon Crystal ABM3-16.000MHZ-D2Y-TLead Oxide 1317-36-8

Component type Component part

number

SVHC Substance SVHC CAS (when

available)

SWRU548A–February 2019

Submit Documentation Feedback

CC3235MODSF LaunchPad™ Development Kit (LAUNCHCC3235MOD)

Copyright © 2019, Texas Instruments Incorporated

7

Page 8

TI Confidential – NDA Restrictions

Introduction

1.5 Regulatory Compliance

Certifications in Process

Indoor Usage Restrictions:

The device is restricted to indoor use only when operating in the 5150 to 5350 MHz frequency range.

AT BE BG HR CY CZ DK

EE FI FR DE EL HU IE

IT LV LT LU MT NL PL

PT RO SK SI ES SE UK

1.6 First Steps: Out-of-Box Experience

An easy way to get started with the EVM is by using its preprogrammed out-of-box experience code. It

demonstrates some key features of the EVM.

1.6.1 Connecting to the Computer

Connect the LaunchPad development kit by connecting the included USB cable to a computer. A red

power LED should illuminate. For proper operation, the SimpleLink drivers and Service Pack from the

CC3235 Software Development Kit (SDK) are needed. The SDK is available at

http://www.ti.com/tool/simplelink-cc32xx-sdk.

www.ti.com

1.6.2 Running the Out-of-Box Experience

The CC3235MODSF LaunchPad development kit's Out-of-Box Experience (OOBE) demonstrates and

highlights the following features:

• Easy connection to the CC3235MODSF LaunchPad:

– Using the SimpleLinkTMWi-Fi® Starter Pro application (available on iOS and Android™), users can

use Access Point (AP) provisioning or SmartConfig™ provisioning for a fast CC3235MOD

connection.

– Configuring the device in AP mode gives users a direct connection to the CC3235MODSF

LaunchPad.

Once the device is provisioned and connected to an AP in station mode, the profile is stored on the

local file system so that any reset to the CC3235MODSF automatically connects it to the AP.

• Easy access to the CC3235MODSF through its internal web server, using either:

– The SimpleLinkTMWi-Fi® Starter Pro application

– Any browser; web pages stored on the serial flash are loaded on the browser, to provide ease of

use.

This feature demonstrates configuring and reading onboard sensors.

• Over-The-Air (OTA) updates that demonstrate an update of a full image. OTA service enables insystem updates of the MCU application, CC3235 firmware releases (Service Pack) made available by

TI, and other vendor files. An update procedure executed in a full-system integrity fashion, such as

failure to upgrade any image components, results in rolling back to the previous valid version.

Visit the CC3235 LaunchPad Out-of-Box Experience Guide on SimpleLink Academy (see Section 6.3) for

more details.

1.7 Next Steps: Looking into the Provided Code

After the EVM features have been explored, the user can open an integrated development environment

and start editing the code examples from the SDK. See Section 6.2 for available IDEs and where to

download them. The Out-of-Box source code and more code examples are provided in the CC3235 SDK.

Code is licensed under BSD, and TI encourages reuse and modifications to fit specific needs.

8

CC3235MODSF LaunchPad™ Development Kit (LAUNCHCC3235MOD)

Copyright © 2019, Texas Instruments Incorporated

SWRU548A–February 2019

Submit Documentation Feedback

Page 9

TI Confidential – NDA Restrictions

www.ti.com

With the onboard XDS110 debug probe, debugging and downloading new code is simple. A USB

connection between the EVM and a PC through the provided USB cable is all that is needed.

1.8 Trademarks

SimpleLink, Texas Instruments, LaunchPad, BoosterPack, Code Composer Studio are trademarks of

Texas Instruments.

Arm, Cortex are registered trademarks of Arm Limited.

IAR Embedded Workbench is a registered trademark of IAR Systems AB.

WPA, WPA2 are trademarks of Wi-Fi Alliance.

Wi-Fi, Wi-Fi Direct are registered trademarks of Wi-Fi Alliance.

All other trademarks are the property of their respective owners.

Introduction

SWRU548A–February 2019

Submit Documentation Feedback

CC3235MODSF LaunchPad™ Development Kit (LAUNCHCC3235MOD)

Copyright © 2019, Texas Instruments Incorporated

9

Page 10

TI Confidential – NDA Restrictions

Hardware

2 Hardware

Figure 2 shows the CC3235MODSF LaunchPad EVM.

www.ti.com

Figure 2. CC3235MODSF LaunchPad™ EVM Overview

10

CC3235MODSF LaunchPad™ Development Kit (LAUNCHCC3235MOD)

Copyright © 2019, Texas Instruments Incorporated

SWRU548A–February 2019

Submit Documentation Feedback

Page 11

TI Confidential – NDA Restrictions

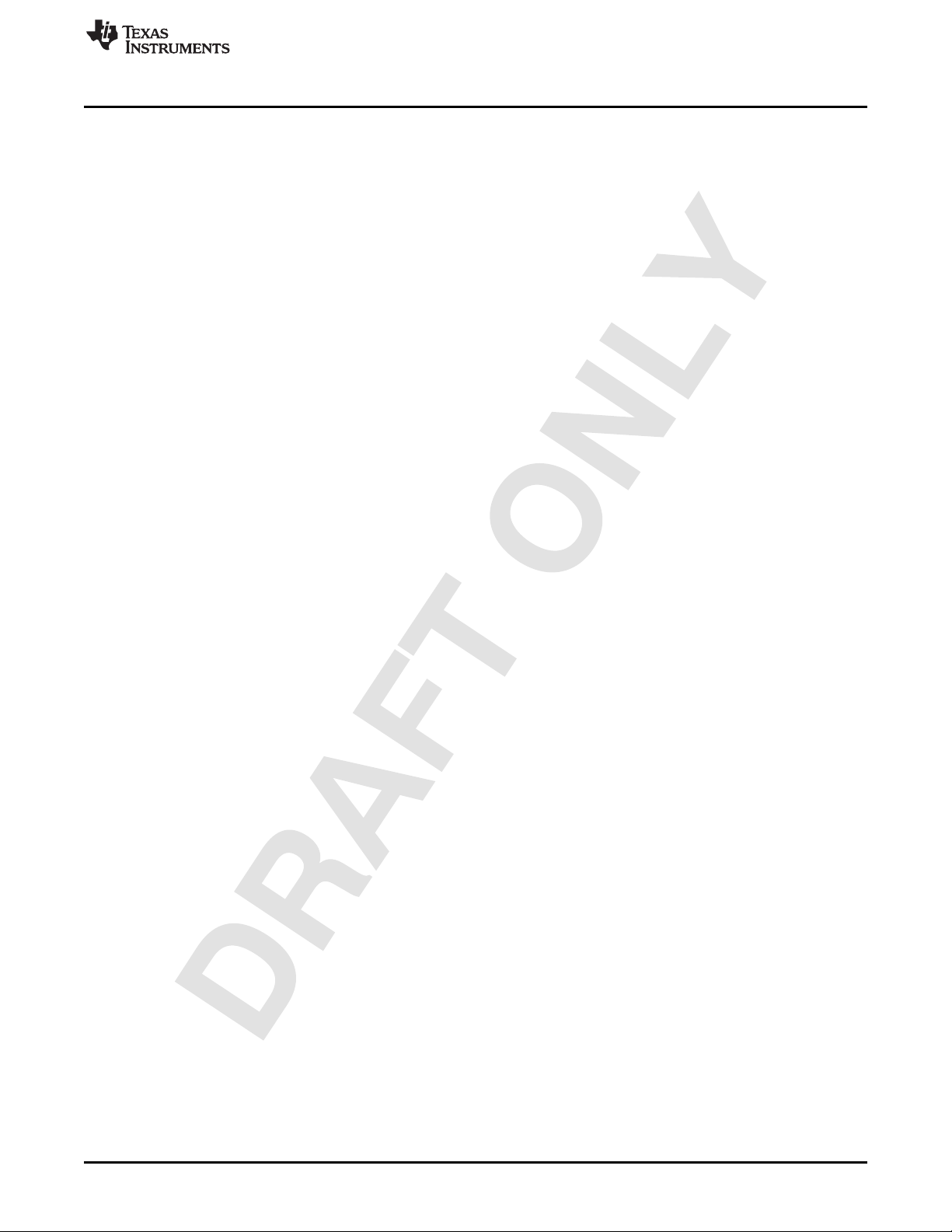

CC3235

MAC/PHY

WRF_BGN F

BGN

RF_ANT1

32-Mbit

SFlash

External SPI

Programming

40 MHz

32.768 kHz

UART

SPI

nReset

PM

2.3 V to 3.6 V

VBAT

User GPIOx

Aband

F

D

5 GHz

SPDT

WRF_A

www.ti.com

2.1 Block Diagram

Figure 3 shows a functional block diagram of the CC3235MODx module.

Hardware

Figure 3. CC3235MODx Functional Block Diagram

SWRU548A–February 2019

Submit Documentation Feedback

Copyright © 2019, Texas Instruments Incorporated

CC3235MODSF LaunchPad™ Development Kit (LAUNCHCC3235MOD)

11

Page 12

TI Confidential – NDA Restrictions

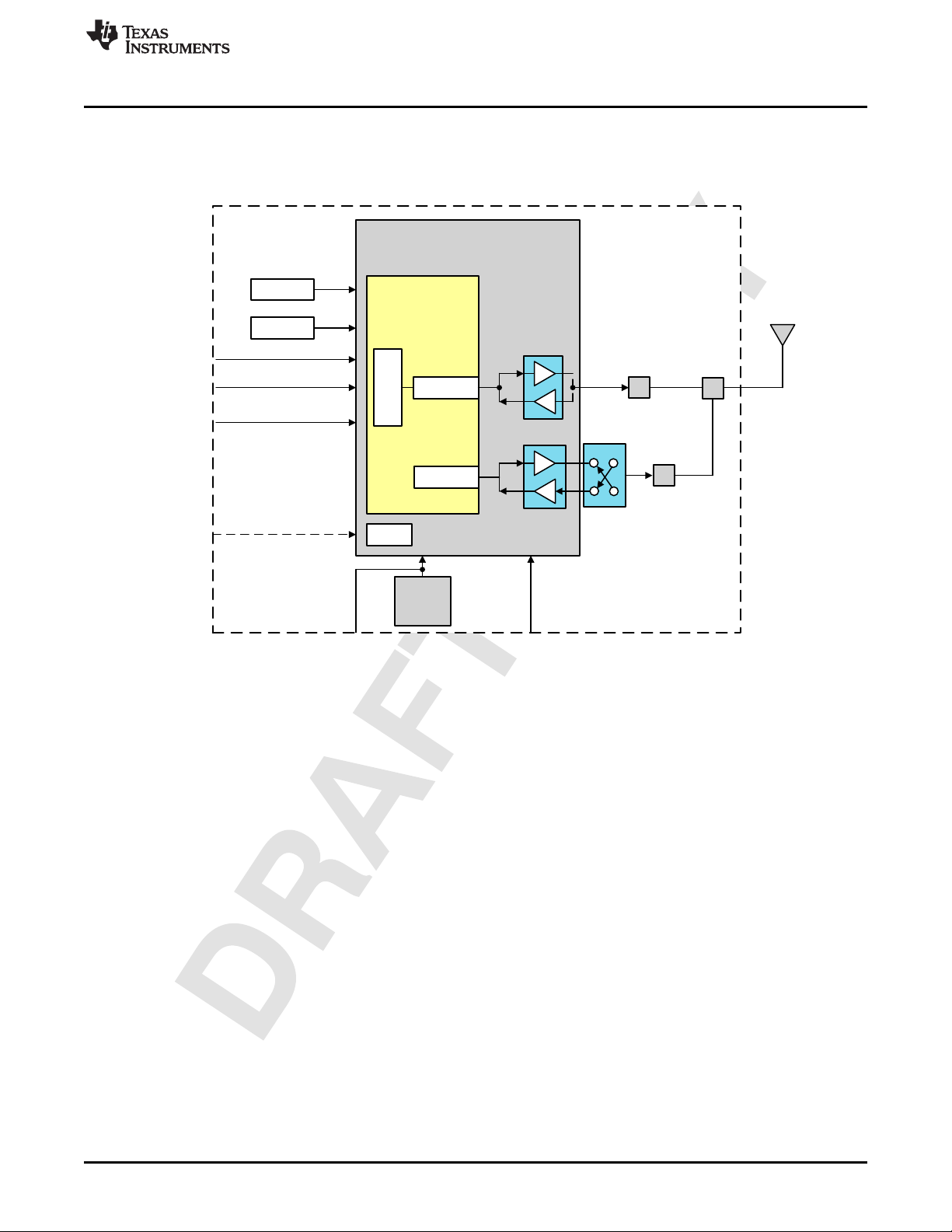

CC3235MODSF12MOBR

Acc

BMA280

Temperature

Sensor

TMP116

Two 20-pin LaunchPad headers

(compatible with TI MCU standard)

INT (GPIO13)

I2C

FTDI

FT2232D

and

SWD Circuit

USB

Connector

LDO

3.3 V

VCC

Two AA

Battery

Connectors

Reverse

Protection

Push buttons

GPIO13, GPIO22

RGB LED

GPIO9, GPIO10, GPIO11

JTAG and SWD

UART (Flashing)

Hardware

Figure 4 shows a functional block diagram of the LAUNCHCC3235MOD SimpleLink LaunchPad.

www.ti.com

Figure 4. LAUNCHCC3235MOD Functional Block Diagram

12

CC3235MODSF LaunchPad™ Development Kit (LAUNCHCC3235MOD)

Copyright © 2019, Texas Instruments Incorporated

SWRU548A–February 2019

Submit Documentation Feedback

Page 13

TI Confidential – NDA Restrictions

www.ti.com

2.2 Hardware Features

• CC3235MODSF, SimpleLinkTMDual-Band Wi-Fi®module solution with integrated MCU

• 40-pin LaunchPad™ standard that leverages the BoosterPack™ ecosystem

• TI Standard XDS110-based JTAG emulation with serial port for flash programming

• Supports both 4-wire JTAG and 2-wire SWD

• Two buttons and a RGB LED for user interaction

• Virtual COM port UART through USB on PC

• Onboard chip antenna with U.FL or SMA for conducted testing, selectable using 0-Ω resistors

• Onboard accelerometer and temperature sensor for out-of-box demo, with the option to isolate them

from the inter-integrated circuit (I2C) bus

• Micro USB connector for power and debug connections

• Headers for current measurement and external JTAG connection, with an option to use the onboard

XDS110 to debug customer platforms

• Bus-powered device, with no external power required for Wi-Fi

• Long-range transmission with a highly optimized antenna (200-meter typical in open air with a 6-dBi

antenna AP)

• Can be powered externally, working down to 2.3 V

2.2.1 Key Benefits

The CC3235MODx modules offer the following benefits:

• Fully Integrated and Green/RoHS Modules Includes All Required Clocks, SPI Flash, and Passives

• 802.11 a/b/g/n: 2.4 GHz and 5 GHz

• FCC, IC/ISED, ETSI/CE, and MIC Certified

• FIPS 140-2 Level 1 Validated IC Inside

• Multilayered security features, help developers protect identities, data, and software IP

• Low-Power Modes for battery powered application

• Coexistence with 2.4 GHz Radios

• Industrial Temperature: –40°C to +85°C

• CC3235MODx Multiple-core architecture, system-on-chip (SoC)

• 1.27-mm Pitch QFM Package for Easy Assembly and Low-Cost PCB Design

• Transferrable Wi-Fi Alliance®Certification

• Application microcontroller subsystem:

– Arm®Cortex®-M4 core at 80 MHz

– User-dedicated memory

• 256 KB RAM

• Optional 1 MB executable Flash

– Rich set of peripherals and timers

– 26 I/O pins with flexible multiplexing options

• UART, I2S, I2C, SPI, SD, ADC, and 8-bit parallel interface

• 8-bit Synchronous Image Interface

• Timers and PWM

– Debug Interfaces: JTAG, cJTAG, and SWD

Hardware

®

SWRU548A–February 2019

Submit Documentation Feedback

CC3235MODSF LaunchPad™ Development Kit (LAUNCHCC3235MOD)

Copyright © 2019, Texas Instruments Incorporated

13

Page 14

TI Confidential – NDA Restrictions

Hardware

• Wi-Fi network processor subsystem:

• Multilayered security features:

• Application Throughput

www.ti.com

– Wi-Fi®core:

• 802.11 a/b/g/n 2.4 GHz and 5 GHz

• Modes:

• Access Point (AP)

• Station (STA)

• Wi-Fi Direct®(only supported on 2.4 GHz)

• Security:

• WEP

• WPA™/WPA2™ PSK

• WPA2 Enterprise

– Internet and application protocols:

• HTTPs server, mDNS, DNS-SD, DHCP

• IPv4 and IPv6 TCP/IP stack

• 16 BSD sockets (fully secured TLS v1.2 and SSL 3.0)

– Built-in power management subsystem:

• Configurable low-power profiles (always, intermittent, tag)

• Advanced low-power modes

• Integrated DC/DC regulators

– Separate execution environments

– Networking security

– Device identity and key

– Hardware accelerator cryptographic engines (AES, DES, SHA/MD5, CRC)

– Application-level security (encryption, authentication, access control)

– Initial secure programming

– Software tamper detection

– Secure boot

– Certificate signing request (CSR)

– Unique per device key pair

– UDP: 16 Mbps

– TCP: 13 Mbps

14

CC3235MODSF LaunchPad™ Development Kit (LAUNCHCC3235MOD)

Copyright © 2019, Texas Instruments Incorporated

SWRU548A–February 2019

Submit Documentation Feedback

Page 15

TI Confidential – NDA Restrictions

www.ti.com

• Power-Management Subsystem:

• Additional Integrated Components

• Footprint Compatible QFM Package

• Module Supports SimpleLink Developer's Ecosystem

Hardware

– Integrated DC/DC converters support a wide range of supply voltage:

• VBAT wide-voltage mode: 2.3 V to 3.6 V

• VIO is always tied with VBAT

– Advanced low-power modes:

• Shutdown: 1 µA, hibernate: 5.5 µA

• Low-power deep sleep (LPDS): 120 µA

• Idle connected (MCU in LPDS): 710 µA

• RX traffic (MCU active): 59 mA

• TX traffic (MCU active): 223 mA

– Wi-Fi TX Power

• 2.4 GHz: 16.5 dBm at 1 DSSS

• 5 GHz: 15.1 dBm at 6 OFDM

– Wi-Fi RX Sensitivity

• 2.4 GHz: –94.5 dBm at 1 DSSS

• 5 GHz: –89 dBm at 6 OFDM

– 40.0 MHz Crystal

– 32.768 kHz Crystal (RTC)

– 32 Mbit SPI Serial Flash

– RF Filters, Diplexer and Passive Components

– CC3235MODx: 1.27-mm Pitch,

63-Pin, 20.5-mm × 17.5-mm

SWRU548A–February 2019

Submit Documentation Feedback

CC3235MODSF LaunchPad™ Development Kit (LAUNCHCC3235MOD)

Copyright © 2019, Texas Instruments Incorporated

15

Page 16

TI Confidential – NDA Restrictions

Hardware

2.2.2 XDS110-Based Onboard Debug Probe

To keep development easy and cost effective, TI's LaunchPad development kits integrate an onboard

debug probe, which eliminates the need for expensive programmers. The CC3235MODSF LaunchPad

has the XDS-110-based debug probe (see Figure 5), which is a simple and low-cost debugger that

supports nearly all TI Arm device derivatives.

Figure 5. XDS-110 Debug Probe

www.ti.com

16

The dotted line through J101 shown in Figure 5 divides the XDS110 debug probe from the target area.

The signals that cross this line can be disconnected by jumpers on J101, the isolation jumper block. More

details on the isolation jumper block are in Section 2.2.3.

The XDS110 debug probe also provides a "backchannel" UART-over-USB connection with the host, which

can be very useful during debugging and for easy communication with a PC. More details can be found in

Section 2.2.4.

The XDS110 debug probe hardware can be found in the schematics in Section 7.2 and in the

CC3235MOD LaunchPad hardware design files.

CC3235MODSF LaunchPad™ Development Kit (LAUNCHCC3235MOD)

Copyright © 2019, Texas Instruments Incorporated

SWRU548A–February 2019

Submit Documentation Feedback

Page 17

TI Confidential – NDA Restrictions

www.ti.com

2.2.3 Debug Probe Connection: Isolation Jumper Block

The isolation jumper block at jumper J101 allows the user to connect or disconnect signals that cross from

the XDS110 domain into the CC3235MOD target domain. This includes JTAG signals, application UART

signals, and 3.3-V and 5-V power.

Reasons to open these connections:

• To remove any and all influence from the XDS110 debug probe for high accuracy target power

measurements

• To control 3-V and 5-V power flow between the XDS110 and target domains

• To expose the target MCU pins for other use than onboard debugging and application UART

communication

• To expose the programming and UART interface of the XDS110 so that it can be used for devices

other than the onboard MCU.

Table 1. Isolation Block Connections

Jumper Description

BRD Board Power. Supplies the board power from the onboard DC-DC converter. The board power

includes the sensors, LED, and the OPAMP used to drive the ADC input.

GND Ground reference

5V 5-V VBUS from USB

VBAT 3.3-V rail, derived from VBUS in the XDS110 domain. Can also be used to measure the current

flowing into the CC3235MOD.

RX Backchannel UART: The target CC3235MODSF receives data through this signal.

TX Backchannel UART: The target CC3235MODSF sends data through this signal.

RST This pin functions as the RST signal (active low).

TMS Serial wire data input (SWDIO) / JTAG test mode select (TMS)

TCK Serial wire clock input (SWCLK) / JTAG clock input (TCK)

TDO JTAG test data out

TDI JTAG test data in

VBUFFER Used to power the level shifters located on the emulator side of the board. The level shifters can

be powered by shorting this pin with a jumper. Removing the jumper enables low current

measurement.

Hardware

SWRU548A–February 2019

Submit Documentation Feedback

CC3235MODSF LaunchPad™ Development Kit (LAUNCHCC3235MOD)

Copyright © 2019, Texas Instruments Incorporated

17

Page 18

TI Confidential – NDA Restrictions

Hardware

2.2.4 Application (or "Backchannel") UART

The board supports a USB-based virtual COM port, using the Tiva™ Arm®MCU. The LaunchPad is

shipped with the UART lines from the CC3235MODSF connected to the UART on the Tiva MCU. The

CC3235MODSF's UART can also be routed to the 20-pin connector for use as a GPIO or external UART.

The selection is performed using jumpers on the board.

Figure 6 shows the UART routed to USB COM port. Ensure that a jumper is also placed on the VBUFFER

header to power the level shifters located on the emulator side of the board. Figure 7 shows the UART

routed to 20-pin header connector.

Figure 6. UART Routed to USB COM Port

www.ti.com

Figure 7. UART Routed to 20-Pin Header Connector

18

CC3235MODSF LaunchPad™ Development Kit (LAUNCHCC3235MOD)

Copyright © 2019, Texas Instruments Incorporated

SWRU548A–February 2019

Submit Documentation Feedback

Page 19

TI Confidential – NDA Restrictions

www.ti.com

2.2.5 JTAG Headers

The headers are provided on the board to isolate the CC3235MOD from the onboard XDS110-based

JTAG emulator. These jumpers are shorted by default when the board is shipped from TI. Figure 5 and

Table 1 are for default configurations, and Figure 8 shows the external emulator connection. To connect

an external emulator, remove the isolation block JTAG jumpers and place the external emulator on the

JTAG IN connector.

Hardware

Figure 8. JTAG IN Connector (J6)

SWRU548A–February 2019

Submit Documentation Feedback

CC3235MODSF LaunchPad™ Development Kit (LAUNCHCC3235MOD)

Copyright © 2019, Texas Instruments Incorporated

19

Page 20

TI Confidential – NDA Restrictions

Hardware

2.2.6 Using the XDS110 Debug Probe with a Different Target

The XDS110 debug probe on the LaunchPad development kit can interface to most Arm®Cortex®-M

devices, not just the onboard target CC3235MODSF device. This functionality is enabled by the J2 10-pin

Cortex-M JTAG connector (see Figure 9) and a 10-pin cable, such as the FFSD-05-D-06.00-01-N (sold

separately from the LaunchPad development kit).

Figure 9. XDS110 OUT Connector (J2)

www.ti.com

20

Header J2 follows the Arm®Cortex®-M standard; however, pin 1 is not a voltage sense pin. The XDS110

outputs only 3.3-V JTAG signals. If another voltage level is needed, the user must provide level shifters to

translate the JTAG signal voltages.

1. Remove jumpers on the JTAG signals on the isolation block, including RST, TMS, TCK, TDO, and TDI.

2. Plug the 10-pin cable into J2, and connect to an external target.

a. J2 follows the Arm®Cortex®Debug Connector standard outlined in Cortex-M Debug Connectors.

3. Plug USB power into the LaunchPad development kit, or power it externally

a. JTAG levels are 3.3-V ONLY

CC3235MODSF LaunchPad™ Development Kit (LAUNCHCC3235MOD)

Copyright © 2019, Texas Instruments Incorporated

SWRU548A–February 2019

Submit Documentation Feedback

Page 21

TI Confidential – NDA Restrictions

www.ti.com

2.2.7 Power Connections

The board accommodates various power methods, including through the onboard XDS110 as well as

external or BoosterPack plug-in module power (see Figure 10).

Figure 10. LAUNCHCC3235MOD Power Block Diagram

Hardware

SWRU548A–February 2019

Submit Documentation Feedback

CC3235MODSF LaunchPad™ Development Kit (LAUNCHCC3235MOD)

Copyright © 2019, Texas Instruments Incorporated

21

Page 22

TI Confidential – NDA Restrictions

Hardware

2.2.7.1 XDS110 USB Power

The most common power-supply scenario is from USB through the XDS110 debugger. This provides 5-V

power from the USB and also regulates this power rail to 3.3 V for XDS110 operation and 3.3-V to the

target side of the LaunchPad development kit. Power from the XDS110 is controlled by jumper J101.

When the board is powered from the USB connector, ensure that the jumpers are placed on the following

headers, shown in Figure 11.

Figure 11. Powering the CC3235MODSF LP from USB

www.ti.com

22

CC3235MODSF LaunchPad™ Development Kit (LAUNCHCC3235MOD)

Copyright © 2019, Texas Instruments Incorporated

SWRU548A–February 2019

Submit Documentation Feedback

Page 23

TI Confidential – NDA Restrictions

www.ti.com

2.2.7.2 BoosterPack Plug-in Module and External Power Supply

Headers J19 and J20 are present on the board to supply external power directly when USB power is not

available. Use the following precautions before using the board with an external power supply.

1. Remove the USB cable.

2. Ensure that jumpers are only placed on the headers shown in Figure 12.

3. Use a jumper wire to connect VBAT and BRD.

4. Plug in the external power supply on J20 with the correct polarity.

Figure 12. Powering the CC3235MODSF LP from an External Power Supply

Hardware

The OPAMP EN and LED EN jumpers are also available to remove any current draw from the onboard

OpAmp and LEDs being driven by the GPIOs, see Table 2.

Reference Use Comments

J19 5-V power input Used to power the board from an external 5-V supply

J20 3.3-V power input Used to power the board from an external 3.3-V supply.

J21 OPAMP EN If uninstalled, the power supply to the operational amplifier is cut off. This can

SWRU548A–February 2019

Submit Documentation Feedback

Table 2. External Supply Connections and Enable Jumpers

be used to enable low-power measurements.

CC3235MODSF LaunchPad™ Development Kit (LAUNCHCC3235MOD)

Copyright © 2019, Texas Instruments Incorporated

23

Page 24

TI Confidential – NDA Restrictions

Hardware

Table 2. External Supply Connections and Enable Jumpers (continued)

Reference Use Comments

J26 LED EN If uninstalled, the LEDs connected to the GPIO are disabled; this can be used

2.2.8 Reset Pullup Jumper

Table 3 lists the reset pullup jumper.

Reference Use Comments

J13 RESET pullup Install this jumper to enable the pullup resistor on the nRESET pin of the

2.2.9 Clocking

All of the required clocks are inside the module. There is no need to supply any external clock.

www.ti.com

to enable low-power measurements.

Table 3. Reset Pullup Jumper

device, when the board is powered from an external supply.

24

CC3235MODSF LaunchPad™ Development Kit (LAUNCHCC3235MOD)

Copyright © 2019, Texas Instruments Incorporated

SWRU548A–February 2019

Submit Documentation Feedback

Page 25

TI Confidential – NDA Restrictions

www.ti.com

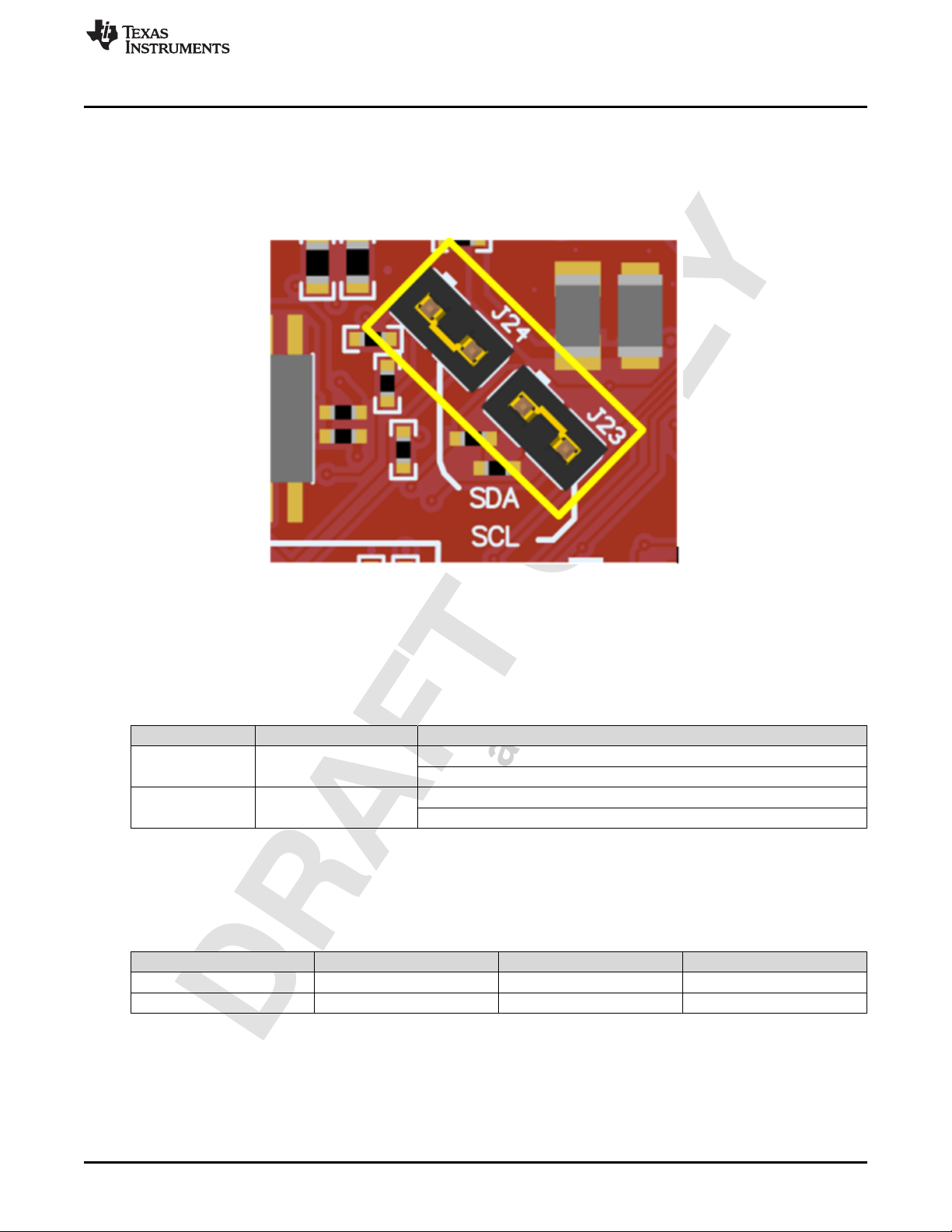

2.2.10 I2C Connection

The board features an accelerometer and a temperature sensor for the out-of-box demo. These are

connected to the I2C bus, and can be isolated using the jumpers provided (shown as yellow jumpers J23

and J24 in Figure 13).

Hardware

Figure 13. I2C Connections

By removing J23 and J24, the accelerometer and the temperature sensors are isolated from the I2C bus.

This measure also removes the I2C pullup resistors from the sensor side of the circuit, and therefore any

connection to the circuit requires the user to install external pullup resistors.

Table 4 lists the I2C jumper definitions.

Reference Use Comments

J23 I2C SCL Populated: CC3235MOD SCL connected to onboard sensors with pullup

J24 I2C SDA Populated: CC3235MOD SDA connected to onboard sensors with pullup

2.2.10.1 Default I2C Addresses

Table 5 lists the default I2C addresses of the onboard sensors.

Table 5. Default I2C Addresses (of Onboard Sensors)

Sensor Type Reference Designator on LP Part Number (Manufacturer) Default Slave Address (Hex)

Temperature (Digital ) U10 TMP116 (TI) 0x49

Accelerometer (Triaxial) U11 BMA280 (Bosch) 0x30

Table 4. I2C Jumper Definitions

Open: CC3235MOD SCL disconnected from onboard sensors

Open: CC3235MOD SDA disconnected from onboard sensors

SWRU548A–February 2019

Submit Documentation Feedback

CC3235MODSF LaunchPad™ Development Kit (LAUNCHCC3235MOD)

Copyright © 2019, Texas Instruments Incorporated

25

Page 26

TI Confidential – NDA Restrictions

Hardware

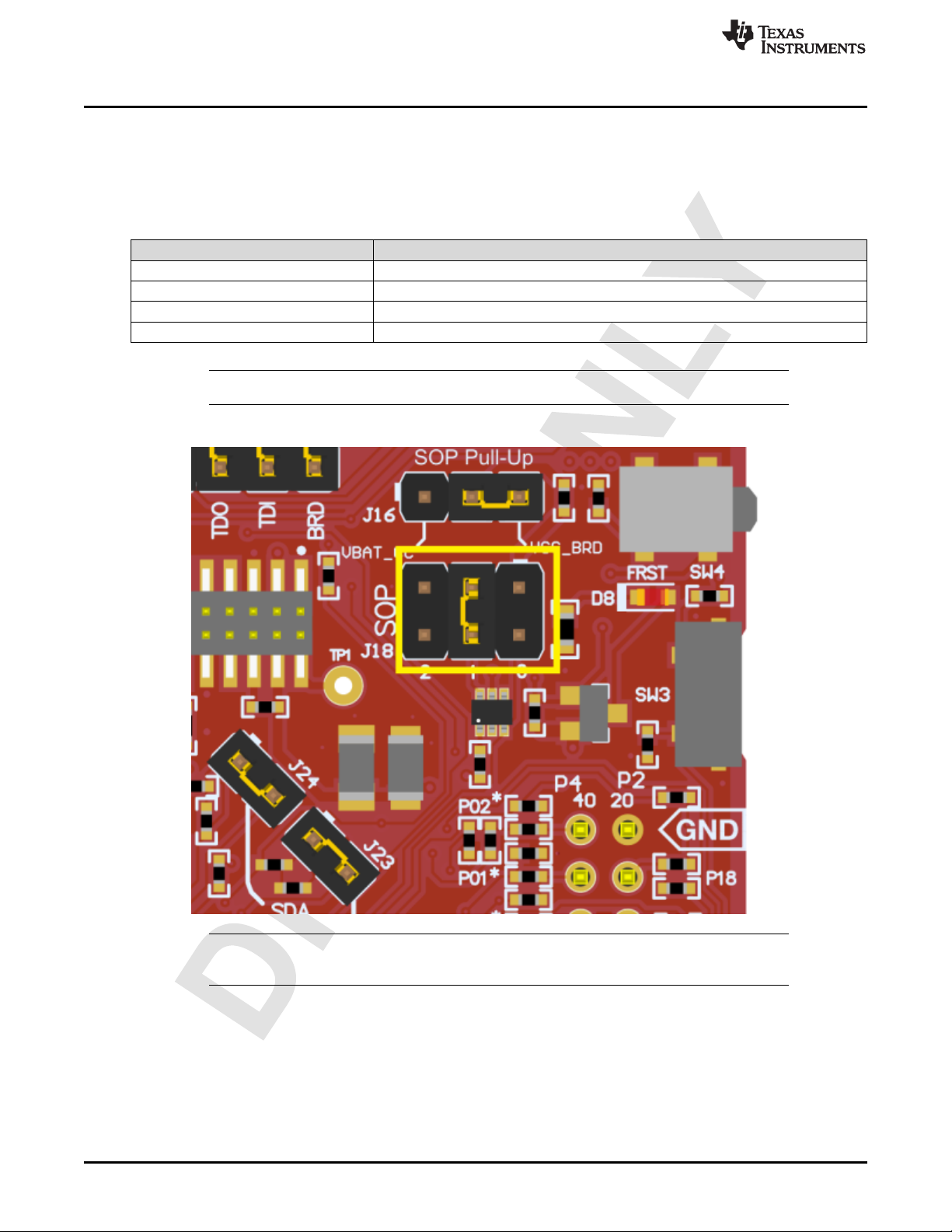

2.2.11 Sense on Power (SOP)

The CC3235MODx device can be set to operate in four different modes based on the state of the sense

on power (SOP) lines. The SOP lines are pins 23, 24, and 34 on the CC3235MODx module. Table 6

shows the state of the device and Figure 14 shows the SOP jumpers.

Binary Value Function

100 Flash programming

000 Functional mode + 4-wire JTAG

001 Functional mode + SWD

010 Functional mode + flash

NOTE: SOP[2:0] corresponds to J18 on the LaunchPad design.

Figure 14. SOP Jumpers (Default Setting Shown)

www.ti.com

Table 6. SOP[2:0]

26

NOTE: Placing no jumpers on the block ensures that the line is pulled low using 100K pull down

resistors. Placing the jumper pulls the pin high using a 10K resistor.

CC3235MODSF LaunchPad™ Development Kit (LAUNCHCC3235MOD)

Copyright © 2019, Texas Instruments Incorporated

Submit Documentation Feedback

SWRU548A–February 2019

Page 27

TI Confidential – NDA Restrictions

www.ti.com

2.2.12 Push-Buttons and LED Indicators

Table 7 lists the push-button definitions.

Table 7. Push-Button Definitions

Reference Use Comments

SW1 RESET This is used to reset the CC3235MOD device. This signal is also output on the

SW2 GPIO_13 When pushed, GPIO_13 is pulled to VCC.

SW3 GPIO_22 When pushed, GPIO_22 is pulled to VCC.

SW4 Factory default Pressing this button and toggling RESET restores the factory default image on

Table 8 lists the LED indicators.

Reference Color Use Comments

D1,D2 Green and Red Debug Indicates the state of the JTAG

D3 Yellow nRESET Indicates the state of the NRESET

D4 Red Power Indicates when the 3.3-V power is

D7 RGB GPIO_09 Glows when the GPIO is logic-1.

RGB GPIO_10

RGB GPIO_11

D8 Red Factory Reset Indicates that the push-button for

(1)

GPIO_10 and GPIO_11 are also used as I2C. Whenever the pullups are enabled, the LEDs glow by default without configuring

the GPIOs.

Hardware

20-pin connector to reset any external BoosterPack which may be stacked. The

reset can be isolated using the RST jumper at the isolation block.

the serial flash. This can be used to recover a corrupted serial flash, provided

the s-flash was programmed with a recovery image.

Table 8. LED Indicators

emulator. For TI use only.

pin. If this LED is on, the device is

functional.

supplied to the board.

(1)

(1)

Glows when the GPIO is logic-1.

Glows when the GPIO is logic-1.

the factory reset is pressed.

2.3 Electrical Characteristics

For electrical characteristics of the CC3235MODx modules, see CC3235MODx SimpleLink™ Wi-Fi

CERTIFIED®Dual-Band Wireless MCU Module data sheet.

2.4 Antenna Characteristics

The CC3235MODSM2MOB and the CC3235MODSF12MOB reference design detail the use of an onboard antenna. For more information on the antenna VSWR, efficiency, and electrical characteristics, see

M830520.

SWRU548A–February 2019

Submit Documentation Feedback

CC3235MODSF LaunchPad™ Development Kit (LAUNCHCC3235MOD)

Copyright © 2019, Texas Instruments Incorporated

27

Page 28

TI Confidential – NDA Restrictions

Hardware

2.5 BoosterPack™ Header Pin Assignment

The BoosterPack header pinout specification is at Build Your Own BoosterPack. Also see the BoosterPack Pinout Standard.

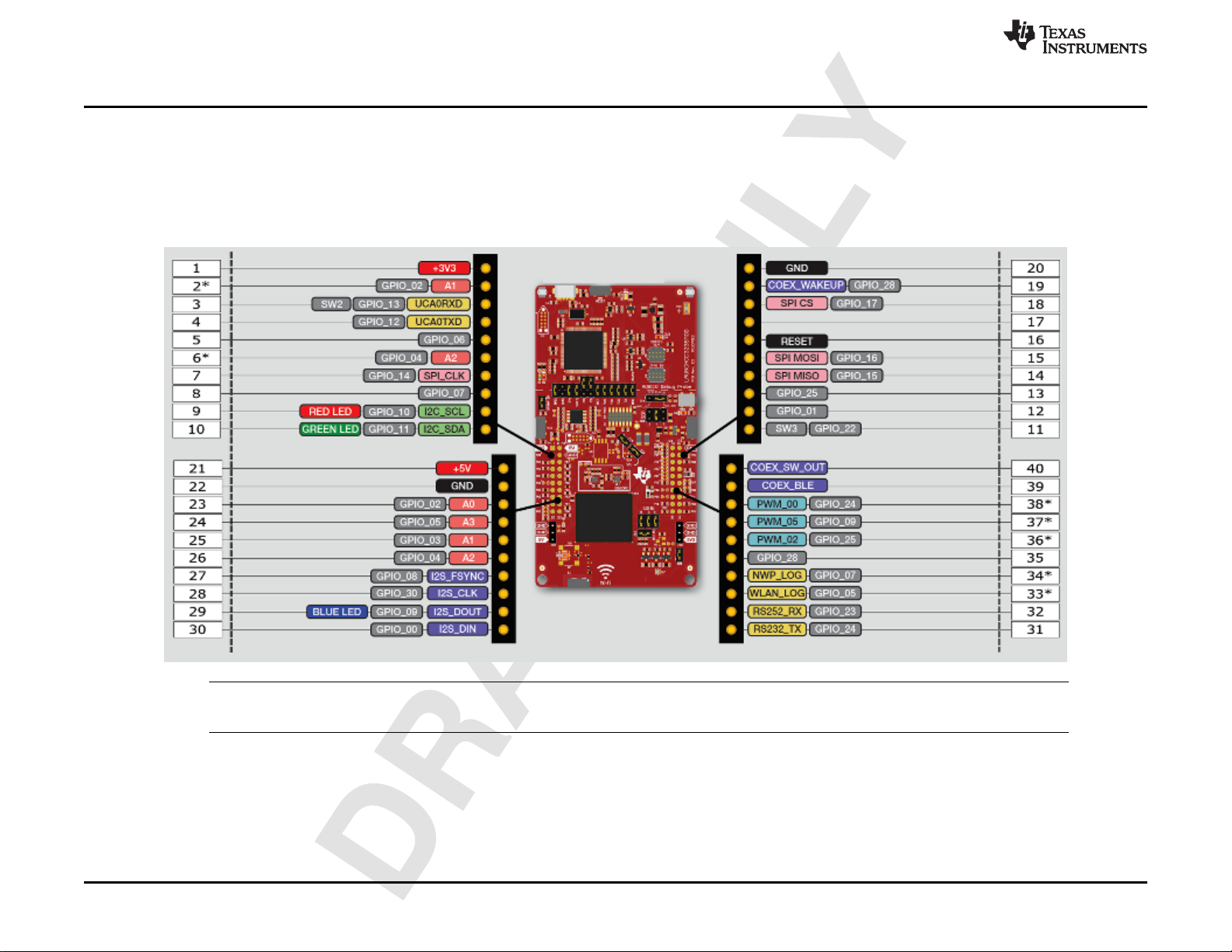

The CC3235MODSF LaunchPad follows this standard, with the exception of naming. (P1:P4 is used instead of J1:J4.). See Figure 15 for the

CC3235MODSF LaunchPad pin-mapping assignments and functions.

Figure 15. LAUNCHCC3235MOD BoosterPack™ Header Pin Assignments

www.ti.com

NOTE: RESET output is an open-drain-type output and can only drive the pin low. The pullup ensures that the line is pulled back high when the

button is released. No external BoosterPack can drive this pin low.

All the signals are referred to by the pin number in the SDK; Figure 15 shows the default mappings. Some of the pins are repeated across the

connector. For instance, pin 62 is available on P1 and P4, but only P1 is connected by default. The signal on P4 is marked with an asterisk (*) to

signify that it is not connected by default. The signal can be routed to the pin by using a 0-Ω resistor in the path. For the exact resistor placement,

see the CC3235MODSF SimpleLinkTMWi-Fi®Wireless MCU LaunchPad Board Design Files.

28

CC3235MODSF LaunchPad™ Development Kit (LAUNCHCC3235MOD)

SWRU548A–February 2019

Submit Documentation Feedback

Copyright © 2019, Texas Instruments Incorporated

Page 29

TI Confidential – NDA Restrictions

www.ti.com

3 Layout Guidelines

The integrator of the CC3235MODx modules must comply with the PCB layout recommendations

described in the following subsections to preserve and minimize the risk with regulatory certifications for

FCC, ISED/IC, ETSI/CE, and MIC. Also, TI recommends that customers follow the guidelines described in

this section to achieve similar performance.

3.1 LAUNCHCC3235MOD Board Layout

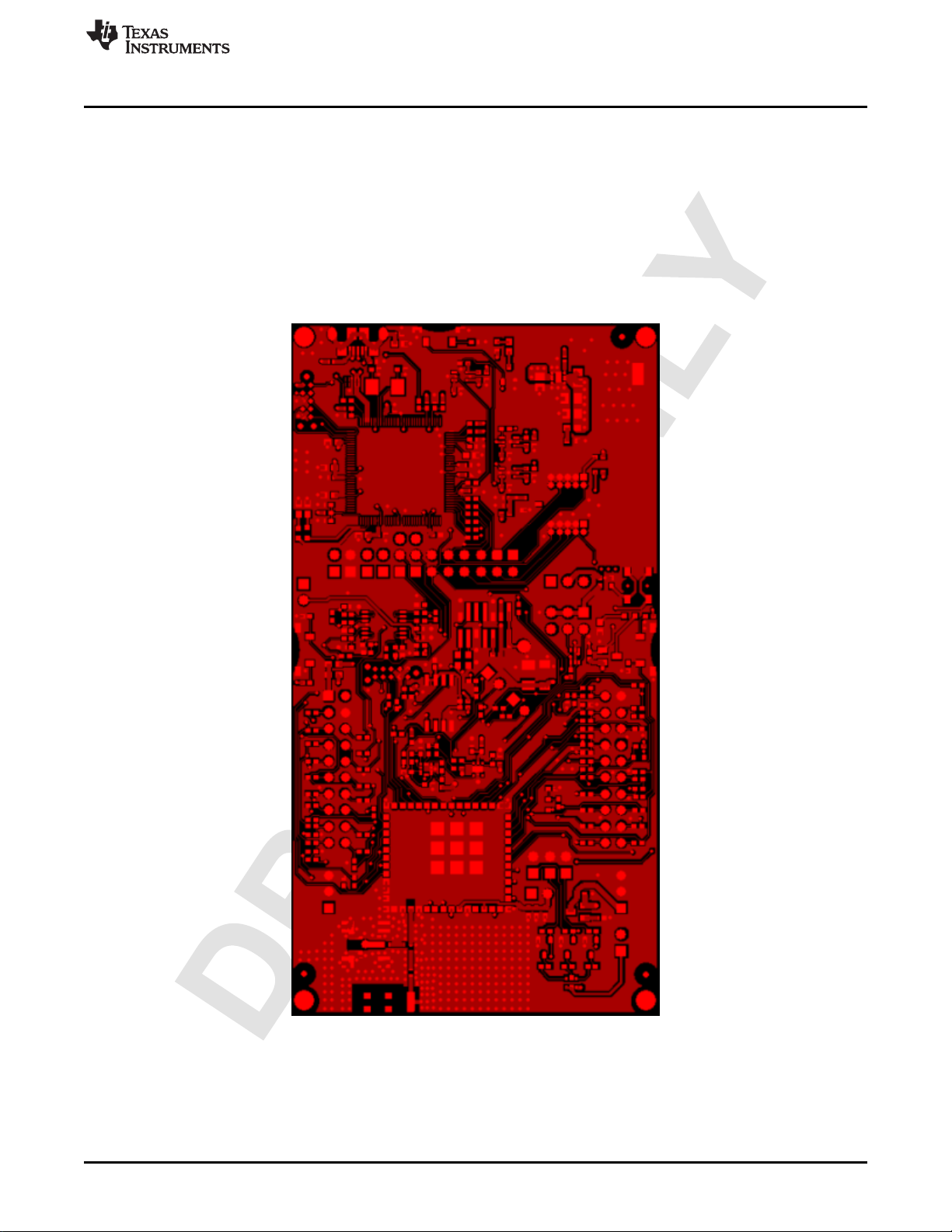

The reference layout consists of a four-layer design. Figure 16 shows the LAUNCHCC3235MOD top layer.

Figure 16. LAUNCHCC3235MOD Top Layer

Layout Guidelines

SWRU548A–February 2019

Submit Documentation Feedback

CC3235MODSF LaunchPad™ Development Kit (LAUNCHCC3235MOD)

Copyright © 2019, Texas Instruments Incorporated

29

Page 30

TI Confidential – NDA Restrictions

Layout Guidelines

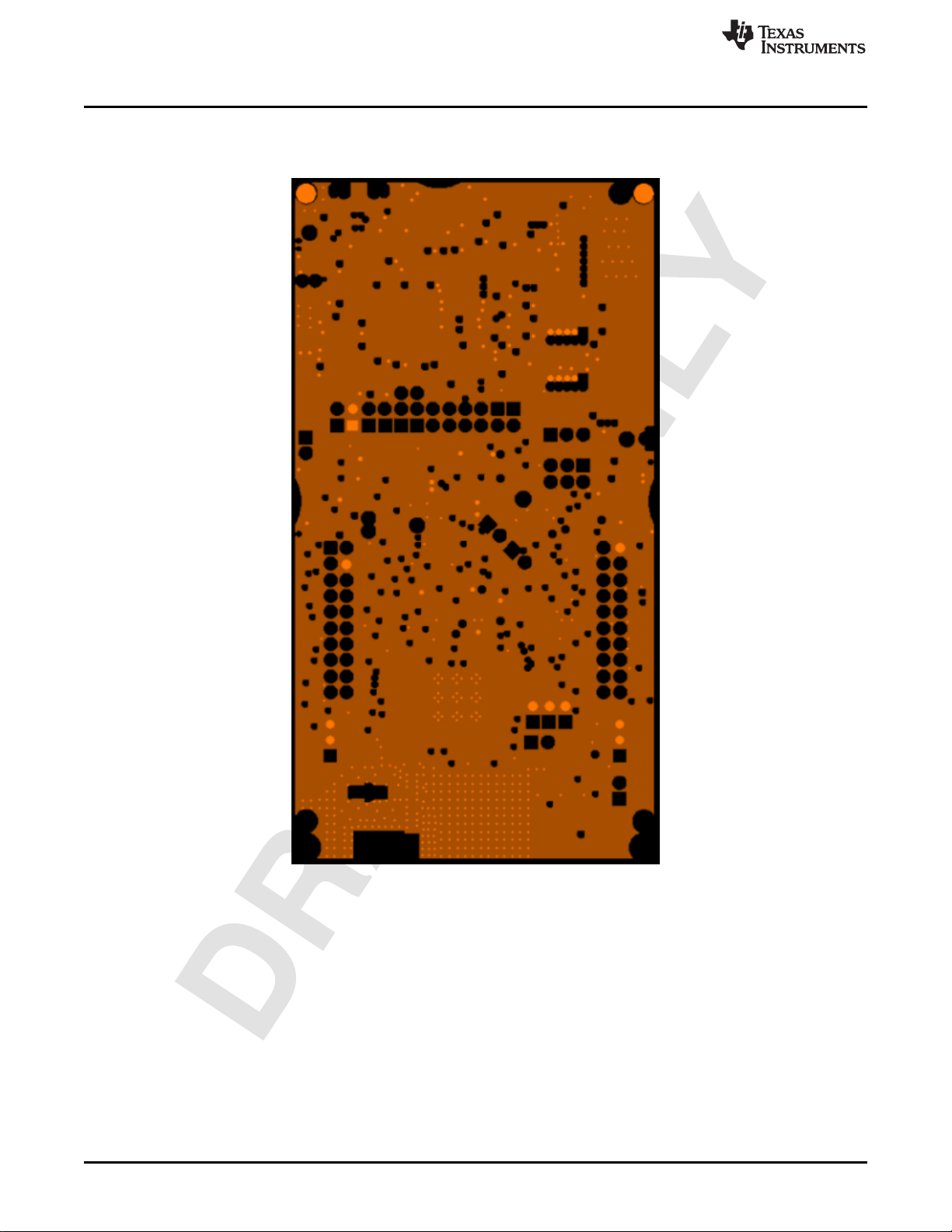

Figure 17 shows the LAUNCHCC3235MOD first inner layer.

www.ti.com

Figure 17. LAUNCHCC3235MOD First Inner Layer

30

CC3235MODSF LaunchPad™ Development Kit (LAUNCHCC3235MOD)

Copyright © 2019, Texas Instruments Incorporated

SWRU548A–February 2019

Submit Documentation Feedback

Page 31

TI Confidential – NDA Restrictions

www.ti.com

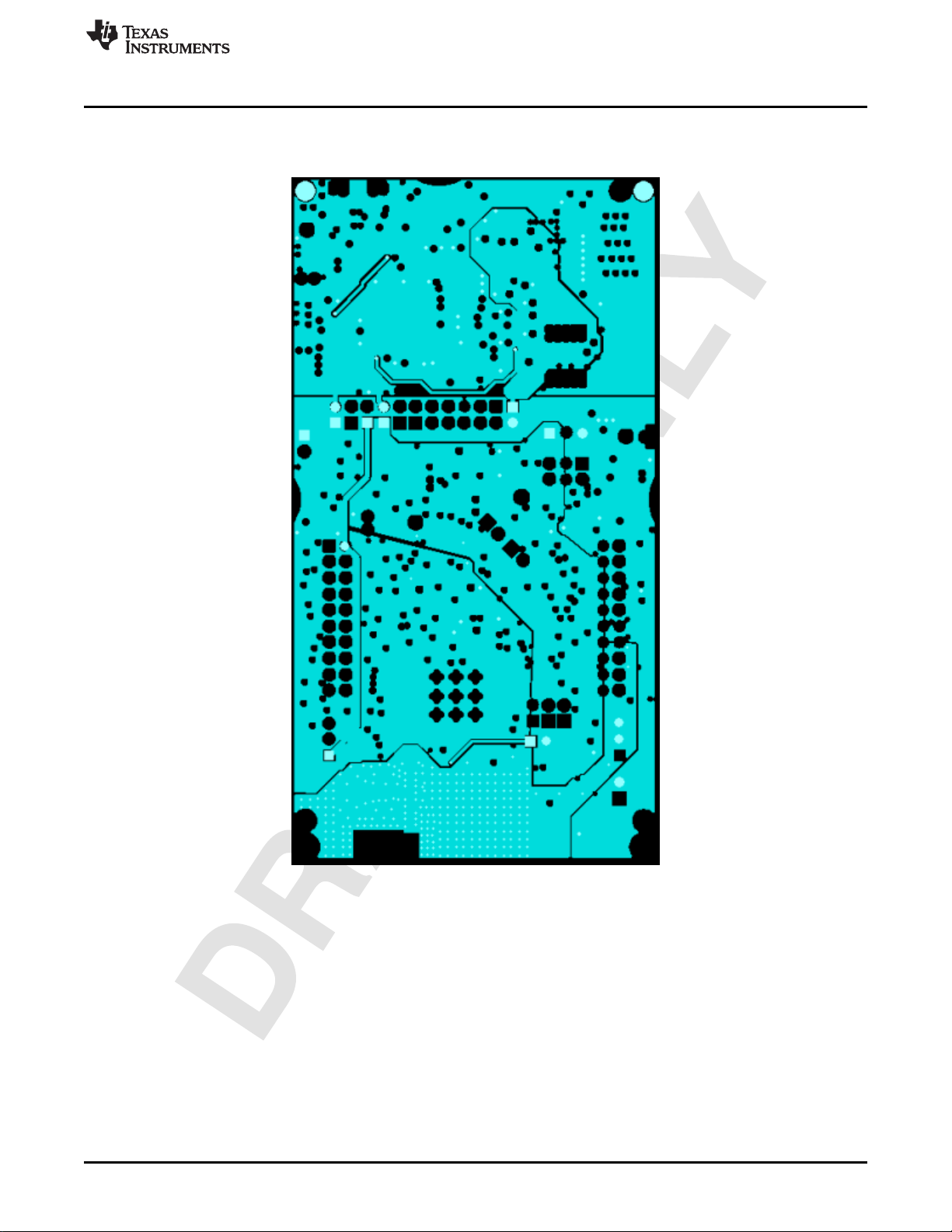

Figure 18 shows the LAUNCHCC3235MOD second inner layer.

Layout Guidelines

Figure 18. LAUNCHCC3235MOD Second Inner Layer

SWRU548A–February 2019

Submit Documentation Feedback

CC3235MODSF LaunchPad™ Development Kit (LAUNCHCC3235MOD)

Copyright © 2019, Texas Instruments Incorporated

31

Page 32

TI Confidential – NDA Restrictions

Layout Guidelines

Figure 19 shows the LAUNCHCC3235MOD bottom layer.

www.ti.com

Figure 19. LAUNCHCC3235MOD Bottom Layer

32

CC3235MODSF LaunchPad™ Development Kit (LAUNCHCC3235MOD)

Copyright © 2019, Texas Instruments Incorporated

SWRU548A–February 2019

Submit Documentation Feedback

Page 33

TI Confidential – NDA Restrictions

www.ti.com

3.2 General Layout Recommendations

Ensure that the following general layout recommendations are followed:

• Have a solid ground plane and ground vias under the module for stable system and thermal

dissipation.

• Do not run signal traces underneath the module on a layer where the module is mounted.

3.3 RF Layout Recommendations

The RF section of this wireless module gets top priority in terms of layout. It is very important for the RF

section to be laid out correctly to ensure optimum performance from the module. A poor layout can cause

low-output power, EVM degradation, sensitivity degradation, and mask violations.

Figure 20 shows the RF placement and routing of the CC3235MODSF module.

Figure 20. RF Section Layout

Layout Guidelines

SWRU548A–February 2019

Submit Documentation Feedback

CC3235MODSF LaunchPad™ Development Kit (LAUNCHCC3235MOD)

Copyright © 2019, Texas Instruments Incorporated

33

Page 34

TI Confidential – NDA Restrictions

Copyright © 2017, Texas Instruments Incorporated

Layout Guidelines

Use the following RF layout recommendations for the CC3235MODx module:

• RF traces must have 50-Ω impedance.

• RF trace bends must be made with gradual curves, and 90 degree bends must be avoided.

• RF traces must not have sharp corners.

• There must be no traces or ground under the antenna section.

• RF traces must have via stitching on the ground plane beside the RF trace on both sides.

• RF traces must be as short as possible. The antenna, RF traces, and the module must be on the edge

of the PCB product in consideration of the product enclosure material and proximity.

For optimal RF performance, ensure the copper cut out on the top layer under the RF-BG pin (pin 31) is

as shown in Figure 21.

www.ti.com

Figure 21. Top Layer Copper Pullback on RF Pads

34

CC3235MODSF LaunchPad™ Development Kit (LAUNCHCC3235MOD)

Copyright © 2019, Texas Instruments Incorporated

SWRU548A–February 2019

Submit Documentation Feedback

Page 35

TI Confidential – NDA Restrictions

www.ti.com

3.4 Antenna Placement and Routing

The antenna is the element used to convert the guided waves on the PCB traces to the free space

electromagnetic radiation. The placement and layout of the antenna are the keys to increased range and

data rates. Table 9 provides a summary of the recommended antennas to use with the CC3235MODx

module.

SR NO. GUIDELINES

1 Place the antenna on an edge or corner of the PCB.

2 Ensure that no signals are routed across the antenna elements on all the layers of the PCB.

3

4

5 Ensure that the antenna impedance is 50 Ω because the module is rated to work only with a 50-Ω system.

6 In case of printed antenna, ensure that the simulation is performed with the solder mask in consideration.

7 Ensure that the antenna has a near omnidirectional pattern.

8

Most antennas, including the chip antenna used on the LaunchPad, require ground clearance on all the layers of

the PCB. Ensure that the ground is cleared on inner layers as well.

Ensure that there is provision to place matching components for the antenna. These must be tuned for best

return loss when the complete board is assembled. Any plastics or casing must also be mounted while tuning

the antenna because this can impact the impedance.

The feed point of the antenna is required to be grounded. This is only for the antenna type used on the

CC3235MODx LaunchPad. See the specific antenna data sheets for the recommendations.

Layout Guidelines

Table 9. Antenna Guidelines

3.5 Transmission Line Considerations

The RF signal from the module is routed to the antenna using a Coplanar Waveguide with ground (CPWG) structure. CPW-G structure offers the maximum amount of isolation and the best possible shielding to

the RF lines. In addition to the ground on the L1 layer, placing GND vias along the line also provides

additional shielding. Figure 22 shows a cross section of the coplanar waveguide with the critical

dimensions.

Figure 22. Coplanar Waveguide (Cross Section)

SWRU548A–February 2019

Submit Documentation Feedback

CC3235MODSF LaunchPad™ Development Kit (LAUNCHCC3235MOD)

Copyright © 2019, Texas Instruments Incorporated

35

Page 36

TI Confidential – NDA Restrictions

S

W

Layout Guidelines

Figure 23 shows the top view of the coplanar waveguide with GND and via stitching.

The recommended values for the PCB are provided for 2-layer boards in Table 10 and for 4-layer boards

in Table 11.

www.ti.com

Figure 23. CPW With GND and Via Stitching (Top View)

Table 10. Recommended PCB Values for 2-Layer Board

(L1 to L2 = 42.1 mils)

PARAMETER VALUE UNIT

W 26 mils

S 5.5 mils

H 42.1 mils

Er (FR-4 substrate) 4.2 F/m

Table 11. Recommended PCB Values for 4-Layer Board

(L1 to L2 = 16 mils)

PARAMETER VALUE UNITS

W 21 mils

S 10 mils

H 16 mils

Er (FR-4 substrate) 4.5 F/m

36

CC3235MODSF LaunchPad™ Development Kit (LAUNCHCC3235MOD)

Copyright © 2019, Texas Instruments Incorporated

SWRU548A–February 2019

Submit Documentation Feedback

Page 37

TI Confidential – NDA Restrictions

www.ti.com

4 Operational Setup and Testing

A compatible BoosterPack can be stacked on top of the LaunchPad using the two, 20-pin connectors. The

connectors do not have a key to prevent the misalignment of the pins or reverse connection. Ensure that

the VCC and 5-V pins are aligned with the BoosterPack header pins. On the CC3235MODSF LaunchPad,

a small white symbol is provided near pin 1 (see Figure 24) to orient all BoosterPacks.

Figure 24. Pin 1 Marking on LaunchPad (3V3 Mark)

Operational Setup and Testing

SWRU548A–February 2019

Submit Documentation Feedback

CC3235MODSF LaunchPad™ Development Kit (LAUNCHCC3235MOD)

Copyright © 2019, Texas Instruments Incorporated

37

Page 38

TI Confidential – NDA Restrictions

Operational Setup and Testing

4.1 Measuring the CC3235MOD Current Draw

To measure the current draw of the CC3235MOD device using a multimeter, use the VBAT jumper on the

J101 isolation block. The current draw measured in this mode includes only the CC3235MOD device,

Serial Flash, any current drawn through the BoosterPack plug-in module headers. However, if a GPIO of

the CC3235MOD is driving a high current load like the LED, then that is also included in this

measurement.

4.1.1 Low-Current Measurement with USB Power (<1 mA)

See the following instructions to measure ultra-low power when powering with a USB cable (see ).

1. Remove the VBAT jumper in the J101 isolation block, and attach an ammeter across this jumper.

2. Consider the effect that the backchannel UART and any circuitry attached to the CC3235MOD may

have on current draw. Consider disconnecting these at the siolation jumper block, or at least consider

their current sinking and sourcing capability in the final measurement.

3. Begin target execution and set the device to low-power modes (LPDS or hibernate).

4. Measure the current. Remember that if the current levels are fluctuating, it may be difficult to get a

stable measurement. It is easier to measure quiescent states.

4.1.2 Active Current Measurements

See the following instructions to measure active power.

1. Remove the VBAT jumper (J18).

2. Solder a 0.1-Ω resistor on a wire which can be connected to a voltmeter/oscilloscope. Or, attach a

jumper across J18 so that it can be used with a current probe.

3. Measure the voltage across the resistor using an oscilloscope with a differential probe. For the current

probe, coil the wire around the sensor several times for good sensitivity.

• An ammeter can also be used for this measurement, but the results may be erroneous due to the

switching nature of the current

www.ti.com

38

CC3235MODSF LaunchPad™ Development Kit (LAUNCHCC3235MOD)

Copyright © 2019, Texas Instruments Incorporated

SWRU548A–February 2019

Submit Documentation Feedback

Page 39

TI Confidential – NDA Restrictions

www.ti.com

4.2 RF Connections

4.2.1 AP Connection Testing

By default, the board ships with the 2.4 GHz and 5 GHz RF signals routed to the onboard chip antenna,

as shown in Figure 25.

Figure 25. Using Onboard Antenna (Default Condition)

Operational Setup and Testing

A U.FL connector J17 provides a way to test in the lab using a compatible cable. Alternatively, trackpads

for an SMA connector J15 are provided onboard to replace the J17 U.FL connector for testing conducted

measurements. A rework must be performed before these connectors can be used; this involves swapping

the position of a resistor. Figure 26 shows the modified board.

Figure 26. Board Modified for External Antenna Connections (Measure 2.4 GHz or 5 GHz)

SWRU548A–February 2019

Submit Documentation Feedback

CC3235MODSF LaunchPad™ Development Kit (LAUNCHCC3235MOD)

Copyright © 2019, Texas Instruments Incorporated

39

Page 40

TI Confidential – NDA Restrictions

Operational Setup and Testing

4.3 Design Files

4.3.1 Hardware Design Files

Schematics can be found in Section 7.2.All design files, including schematics, layout, Bill of Materials

(BOM), Gerber files, and documentation are available for download from LAUNCHCC3235MOD.

4.4 Software

All design files, including firmware patches, software example projects, and documentation are available

from the CC3235 Software Development Kit. Inside of the SDK, a set of very simple CC3235 code

examples can be found that demonstrates how to use the entire set of CC3235 peripherals. When starting

a new project or adding a new peripheral, these examples serve as a great starting point.

5 Development Environment Requirements

The following software examples with the LaunchPad require an integrated development environment

(IDE) that supports the CC3235MOD.

The CC313x and CC323x SimpleLink™ Wi-Fi®Embedded Programming User's Guide has detailed

information about software environment setup with examples. See this document for further details on the

software sample examples.

5.1 CCS

CCS 6.0 or higher is required. When CCS is launched, and a workspace directory is chosen, use

Project → Import Existing CCS Eclipse Project. Direct it to the desired demo project directory containing

main.c.

www.ti.com

5.2 IAR

IAR 6.70 or higher is required. To open the demo in IAR, choose File → Open → Workspace…, and direct

it to the *.eww workspace file inside the \IAR subdirectory of the desired demo. All workspace information

is within this file.

The subdirectory also has an *.ewp project file; this file can be opened into an existing workspace, using

Project → Add-Existing-Project….

40

CC3235MODSF LaunchPad™ Development Kit (LAUNCHCC3235MOD)

Copyright © 2019, Texas Instruments Incorporated

SWRU548A–February 2019

Submit Documentation Feedback

Page 41

TI Confidential – NDA Restrictions

www.ti.com

6 Additional Resources

6.1 CC3235MODx Product Page

For more information on the CC3235MOD device, visit the CC3235MOD product page, which includes the

CC3235MODx SimpleLink™ Wi-Fi®Wireless and Internet-of-Things Solution, a Single-Chip Wireless MCU

data sheet and key documents such as the CC32xx SimpleLink™ Wi-Fi® and Internet-of-Things Technical

Reference Manual.

6.2 Download CCS, IAR

Although the files can be viewed with any text editor, more can be done with the projects if they are

opened with a development environment such as Code Composer Studio (CCS), IAR, or Energia. CCS

and IAR are each available in a full version, or a free, code-size-limited version. The full out-of-box demo

cannot be built with the free version of CCS or IAR (IAR Kickstart), due to the code-size limit. To bypass

this limitation, a code-size-limited CCS version is provided that has most functionality integrated into a

library. The code built into the library is able to be viewed by the user, but it cannot be edited. For full

functionality, download the full version of either CCS or IAR.

6.3 SimpleLink™ Academy for CC3235 SDK

The SimpleLink™ Academy is a collection of curated training modules developed by TI subject matter

experts to help developers get up and running as quickly as possible with a SimpleLink MCU device and

its SDK. The training is delivered using TI Resource Explorer, which offers a powerful cloud-enabled

environment that includes background information, interactive exercises, code snippets, quizzes, and

more.

Experience the SimpleLink™ Academy now using the TI Resource Explorer at dev.ti.com.

Additional Resources

Figure 27. CC32xx SimpleLink™ Academy

6.4 TI E2E Community

Search the forums at e2e.ti.com. If you cannot find your answer, post your question to the community!

SWRU548A–February 2019

Submit Documentation Feedback

CC3235MODSF LaunchPad™ Development Kit (LAUNCHCC3235MOD)

Copyright © 2019, Texas Instruments Incorporated

41

Page 42

TI Confidential – NDA Restrictions

Assembly Drawing and Schematics

7 Assembly Drawing and Schematics

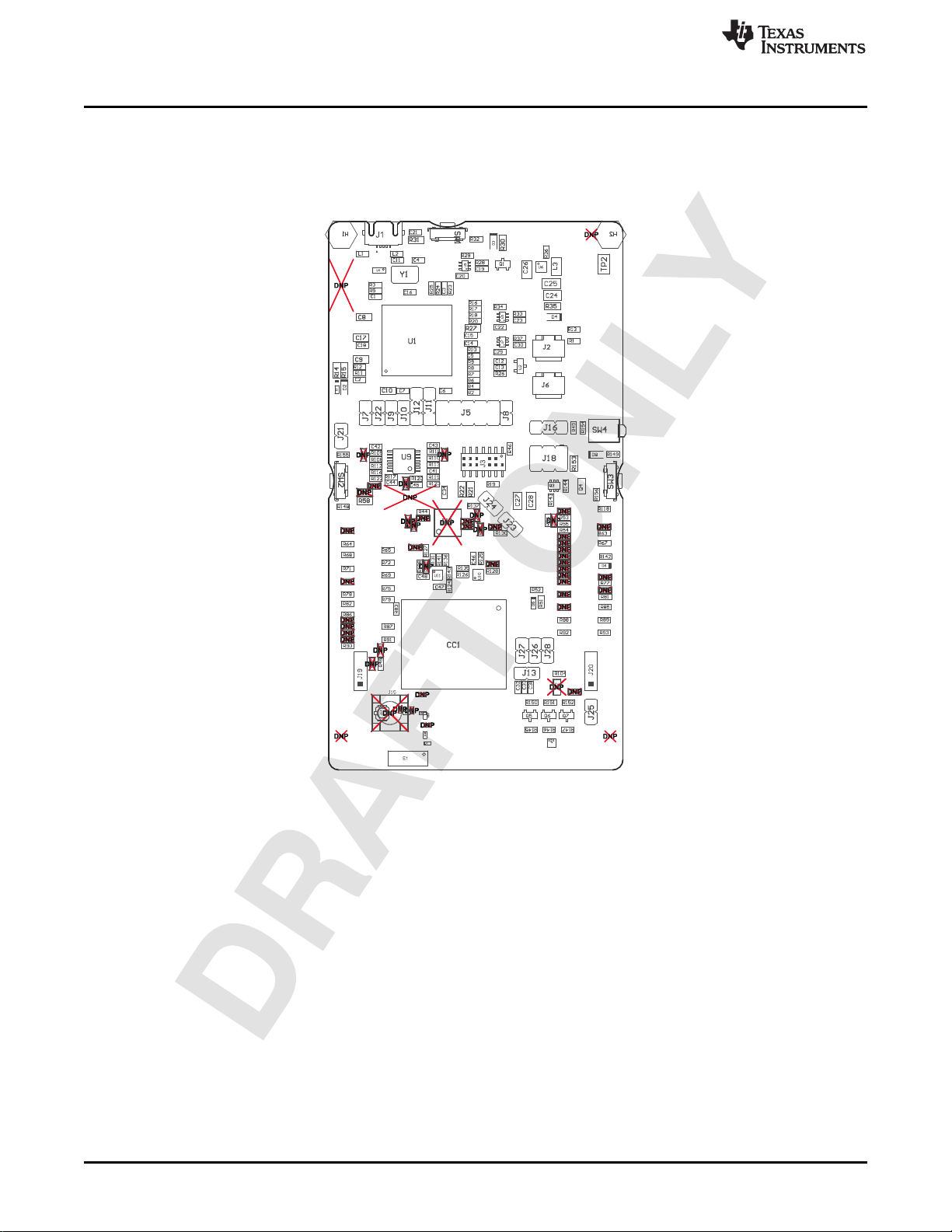

7.1 Assembly Drawing

Figure 28. LAUNCHCC3235MOD Top-Layer Assembly Drawing

www.ti.com

42

CC3235MODSF LaunchPad™ Development Kit (LAUNCHCC3235MOD)

Copyright © 2019, Texas Instruments Incorporated

SWRU548A–February 2019

Submit Documentation Feedback

Page 43

TI Confidential – NDA Restrictions

PD0/AIN15/C0O/I2C7SCL/SSI2XDAT1/T0CCP0

1

PD1/AIN14/C1O/I2C7SDA/SSI2XDAT0/T0CCP1

2

PD2/AIN13/C2O/I2C8SCL/SSI2FSS/T1CCP0

3

PD3/AIN12/I2C8SDA/SSI2CLK/T1CCP1

4

PE3/AIN0/U1DTR

12

PE2/AIN1/U1DCD

13

PE1/AIN2/U1DSR

14

PE0/AIN3/U1RTS

15

PC7/C0-/EPI0S4/U5TX

22

PC6/C0+/EPI0S5/U5RX

23

PC5/C1+/EPI0S6/RTCCLK/U7TX

24

PC4/C1-/EPI0S7/U7RX

25

PH0/EPI0S0/U0RTS

29

PH1/EPI0S1/U0CTS

30

PH2/EPI0S2/U0DCD

31

PH3/EPI0S3/U0DSR

32

PA0/CAN0RX/I2C9SCL/T0CCP0/U0RX

33

PA1/CAN0TX/I2C9SDA/T0CCP1/U0TX

34

PA2/I2C8SCL/SSI0CLK/T1CCP0/U4RX

35

PA3/I2C8SDA/SSI0FSS/T1CCP1/U4TX

36

PA4/I2C7SCL/SSI0XDAT0/T2CCP0/U3RX

37

PA5/I2C7SDA/SSI0XDAT1/T2CCP1/U3TX

38

PA6/EPI0S8/I2C6SCL/SSI0XDAT2/T3CCP0/U2RX/USB0EPEN

40

PA7/EPI0S9/I2C6SDA/SSI0XDAT3/T3CCP1/U2TX/USB0EPEN/USB0PFLT

41

PF0/EN0LED0/M0PWM0/SSI3XDAT1/TRD2

42

PF1/EN0LED2/M0PWM1/SSI3XDAT0/TRD1

43

PF2/M0PWM2/SSI3FSS/TRD0

44

PF3/M0PWM3/SSI3CLK/TRCLK

45

PF4/EN0LED1/M0FAULT0/SSI3XDAT2/TRD3

46

PG0/EN0PPS/EPI0S11/I2C1SCL/M0PWM4

49

PG1/EPI0S10/I2C1SDA/M0PWM5

50

PB2/EPI0S27/I2C0SCL/T5CCP0/USB0STP

91

PB3/EPI0S28/I2C0SDA/T5CCP1/USB0CLK

92

PB0/CAN1RX/I2C5SCL/T4CCP0/U1RX/USB0ID

95

PB1/CAN1TX/I2C5SDA/T4CCP1/U1TX/USB0VBUS

96

PC3/SWO/TDO

97

PC2/TDI

98

PC1/SWDIO/TMS

99

PC0/SWCLK/TCK

100

PB5/AIN11/I2C5SDA/SSI1CLK/U0RTS

120

PB4/AIN10/I2C5SCL/SSI1FSS/U0CTS

121

PE4/AIN9/SSI1XDAT0/U1RI

123

PE5/AIN8/SSI1XDAT1

124

PD4/AIN7/SSI1XDAT2/T3CCP0/U2RX

125

PD5/AIN6/SSI1XDAT3/T3CCP1/U2TX

126

PD6/AIN5/SSI2XDAT3/T4CCP0/U2RTS/USB0EPEN

127

PD7/AIN4/NMI/SSI2XDAT2/T4CCP1/U2CTS/USB0PFLT

128

PQ0/EPI0S20/SSI3CLK

5

PQ1/EPI0S21/SSI3FSS

6

PQ2/EPI0S22/SSI3XDAT0

11

PK0/AIN16/EPI0S0/U4RX

18

PK1/AIN17/EPI0S1/U4TX

19

PK2/AIN18/EPI0S2/U4RTS

20

PK3/AIN19/EPI0S3/U4CTS

21

PQ3/EPI0S23/SSI3XDAT1

27

PK7/EPI0S24/I2C4SDA/M0FAULT2/RTCCLK/U0RI

60

PK6/EN0LED1/EPI0S25/I2C4SCL/M0FAULT1

61

PK5/EN0LED2/EPI0S31/I2C3SDA/M0PWM7

62

PK4/EN0LED0/EPI0S32/I2C3SCL/M0PWM6

63

PM7/T5CCP1/TMPR0/U0RI

71

PM6/T5CCP0/TMPR1/U0DSR

72

PM5/T4CCP1/TMPR2/U0DCD

73

PM4/T4CCP0/TMPR3/U0CTS

74

PM3/EPI0S12/T3CCP1

75

PM2/EPI0S13/T3CCP0

76

PM1/EPI0S14/T2CCP1

77

PM0/EPI0S15/T2CCP0

78

PL0/EPI0S16/I2C2SDA/M0FAULT3/USB0D0

81

PL1/EPI0S17/I2C2SCL/PHA0/USB0D1

82

PL2/C0O/EPI0S18/PHB0/USB0D2

83

PL3/C1O/EPI0S19/IDX0/USB0D3

84

PL4/EPI0S26/T0CCP0/USB0D4

85

PL5/EPI0S33/T0CCP1/USB0D5

86

PL7/T1CCP1/USB0DM

93

PL6/T1CCP0/USB0DP

94

PQ4/DIVSCLK/U1RX

102

PP2/EPI0S29/U0DTR/USB0NXT

103

PP3/EPI0S30/RTCCLK/U0DCD/U1CTS/USB0DIR

104

PP4/U0DSR/U3RTS/USB0D7

105

PP5/I2C2SCL/U3CTS/USB0D6

106

PN0/U1RTS

107

PN1/U1CTS

108

PN2/EPI0S29/U1DCD/U2RTS

109

PN3/EPI0S30/U1DSR/U2CTS

110

PN4/EPI0S34/I2C2SDA/U1DTR/U3RTS

111

PN5/EPI0S35/I2C2SCL/U1RI/U3CTS

112

PJ0/EN0PPS/U3RX

116

PJ1/U3TX

117

PP0/C2+/SSI3XDAT2/U6RX

118

PP1/C2-/SSI3XDAT3/U6TX

119

TM4C1294NCPDTI3R

U1A

VDD

7

VDDA8GNDA

10

VDD

16

GND

17

VDD

26

VDD

28

VDD

39

VDD

47

GND

48

VDD

51

VDD

52

GND

55

GND

58

VBAT

68

VDD

69

VDD

79

GND

80

VDDC

87

VDD

90

VDD

101

VDD

113

GND

114

VDDC

115

VDD

122

TM4C1294NCPDTI3R

U1C

33.0R2

33.0R4

33.0R6

33.0R7

33.0R8

33.0R9

33.0R10

XDS_UART_RX

XDS_UART_TX

XDS_JTAG_TCK

XDS_JTAG_TMS

XDS_JTAG_TDO

XDS_JTAG_TDI

ITCK

ITMS

ITDI

ITDO

330k

R11

VBUS_USB1

220k

R12

0.01uF

C2

GND

Red

D2

220

R15

LED0

Green

D1

LED1

220

R14

GND

1.0kR16

1.0kR17

1.0kR18

1.0kR20

VCC_LDO_3V3

GND

XDSET_P

XDSET_N

51R23

VCC_LDO_3V3

1uF

C3

GND

GND

0.01uFC50.01uFC60.01uFC70.1uFC80.1uFC90.1uF

C10

GND

0.01uF

C14

1uF

C15

GND

2.2uF

C16

0.1uF

C17

1uF

C18

GND

VCC_LDO_3V3

TM4C HOST MCU FOR EMULATION

XDSET_P

XDSET_N

0R3

XDSET_ID

100R5 VBUS_USB1

0.1uF

C1

GND

ID -> PK[7:4] =0x07

XDS_JTAG_TCK

XDS_JTAG_TMS

XDS_JTAG_TDO

XDS_JTAG_TDI

XDS_nRESET

XDSET_ID

VCC_LDO_3V3

1.0k

R1

VCC_BRD

1 2

3 4

5 6

7 8

9 10

J6

1.0k

R13

VCC_LDO_3V3

1 2

3 4

5 6

7 8

9 10

J2

P55_GPIO_01

P57_GPIO_02

1.0k

R19

33

R22

33

R21

P01_GPIO_10

P02_GPIO_11

TP1

1 2

3 4

5 6

7 8

9 10

11 12

13 14

J3

VBAT_CC

VBAT_CC

GND

GND GND

GND

WAKE

64

HIB

65

XOSC0

66

XOSC1

67

RST

70

OSC0

88

OSC1

89

EN0RXIN

53

EN0RXIP

54

EN0TXON

56

EN0TXOP

57

VREFA+

9

RBIAS

59

TM4C1294NCPDTI3R

U1B

10k

R24

VCC_LDO_3V3

100

R25

IRSTN

GND

VREFA

4.87k

R27

GND

1

2

16MHz

Y1

22pF

C11

22pF

C4

GND

VCC_LDO_3V3

1.0k

R26

123

LM4040B25IDBZR

U2

0.01uF

C12

1uF

C13

GND

VREFA

VCC_LDO_3V3

GND

ITMS

ITCK

ITDO

ITDI

IRSTN

1

2

3

4

5 6

7

8

9

10

J4

CMP-0075101-1

DNP

XDS_JTAG_TMS

XDS_JTAG_TCK

XDS_JTAG_TDO

XDS_JTAG_TDI

XDS_CC_nRESET

P20_JTAG_TMS

P19_JTAG_TCK

P17_JTAG_TDO

P16_JTAG_TDI

CC_nRESET

www.ti.com

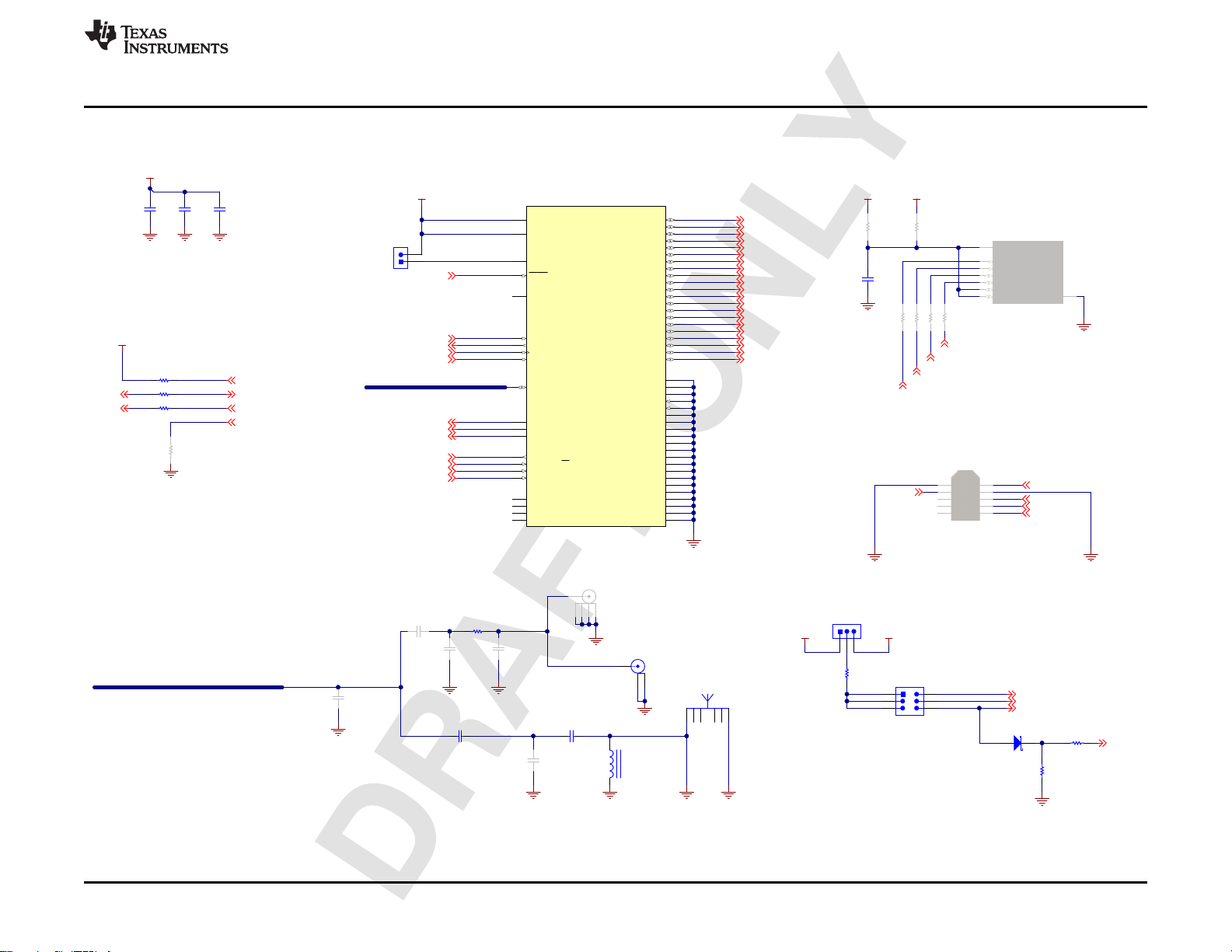

7.2 Schematics

Assembly Drawing and Schematics

Figure 29. Schematics (1 of 5)

SWRU548A–February 2019

Submit Documentation Feedback

Copyright © 2019, Texas Instruments Incorporated

CC3235MODSF LaunchPad™ Development Kit (LAUNCHCC3235MOD)

43

Page 44

TI Confidential – NDA Restrictions

100k

R31

0.01uF

C21

GND

10 ohm

L1

10 ohm

L2

VBUS_USB1

GND

D1+

1

D1-

2

GND

3

D2+

4

D2-

5

NC

6

NC

7

GND

8

NC

9

NC

10

TPD4S010DQAR

U4

GND

USB-INTERFACE

XDSET_N

XDSET_P

XDSET_ID

VCC_Buffer VCC_LDO_3V3

A

3

VCCA

1

B

4

DIR

5

GND

2

VCCB

6

SN74LVC1T45DCKR

U3

0.1uF

C20

XDS_nRESET

GND

GNDGND

0.1uF

C19

100k

R28

GND

12

34

56

78

910

J5

61301021121

10k R29

XDS_JTAG_TDI

XDS_JTAG_TDO

XDS_JTAG_TCK

XDS_JTAG_TMS

P19_JTAG_TCK

P20_JTAG_TMS

CC_nRESET

P17_JTAG_TDO

P16_JTAG_TDI

GND

VCC_Buffer

Yellow

D3

XDS_UART_RX

P55_GPIO_01

LP_GPIO_01

VCC_Buffer VCC_LDO_3V3

33.0

R34

A

3

VCCA

1

B

4

DIR

5

GND

2

VCCB

6

SN74LVC1T45DCKR

U5

0.1uF

C22

0.1uF

C23

100k

R33

123

J11

XDS_UART_TX

P57_GPIO_02

LP_GPIO_02

VCC_Buffer VCC_LDO_3V3

0.1uF

C29

0.1uF

C30

A

3

VCCA

1

B

4

DIR

5

GND

2

VCCB

6

SN74LVC1T45DCKR

U7

GND

GND

GND

GNDGND

GND

GND

GND

1

2

3

J12

33.0

R37

GND

to Host-MCUto Targ et

10uF

C24

100uF

C27

100uF

C28

10uF

C26

270

R35

J9

J10

J7 J8

2.2uH

L3

22uF

C25

100k

R36

CHECK LAYOUT GUIDE FROM DATASHEET

POWER MANAGEMENT

TPS62162DSGR

PGND

1

VIN

2

EN

3

AGND

4

FB

5

VOS

6

SW

7

PG

8

EP

9

U6

VBUS_USB1 VCC_MCU_5V

VCC_LDO_3V3 VCC_BRD VCC_Buffer

VBAT_CC

GND

GND GND GND GNDGND GND

VOLTA GE TRANSLATORS

Red

D4

XDS_CC_nRESET

1

2

3

Q1

BSS138

100

R32

VBUS

1

D-

2

D+

3

ID

4

GND

5

678

11109

J1

1

2

3

4

SW1

390

R30

Assembly Drawing and Schematics

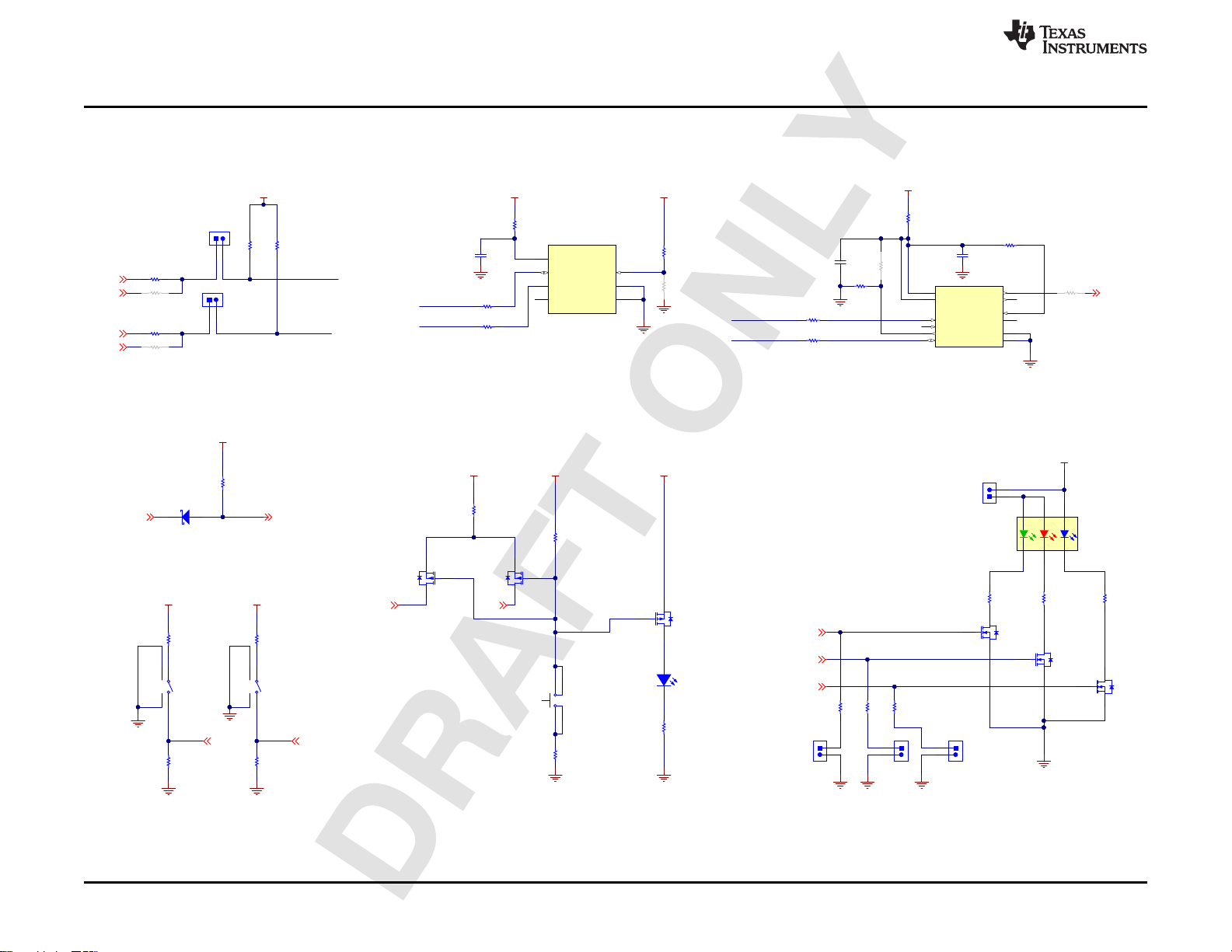

www.ti.com

Figure 30. Schematics (2 of 5)

CC3235MODSF LaunchPad™ Development Kit (LAUNCHCC3235MOD)

44

Copyright © 2019, Texas Instruments Incorporated

SWRU548A–February 2019

Submit Documentation Feedback

Page 45

TI Confidential – NDA Restrictions

P50_GPIO_00

P55_GPIO_01

P57_GPIO_02

P58_GPIO_03

P59_GPIO_04

P60_GPIO_05

P61_GPIO_06

P62_GPIO_07

P63_GPIO_08

P64_GPIO_09

P01_GPIO_10

P02_GPIO_11

P03_GPIO_12

P04_GPIO_13

P07_GPIO_16

P08_GPIO_17

P15_GPIO_22

P18_GPIO_28

P53_GPIO_30

P05_GPIO_14

P06_GPIO_15

RF_ABG

P20_JTAG_TMS

P19_JTAG_TCK

P17_JTAG_TDO

P16_JTAG_TDI

J13

VBAT_CC

CC_nRESET

100k

R47

DNP

GND

0R45

0R46

P17_GPIO_24

P16_GPIO_23

0.1uF

C31

0.1uF

C32

0.1uF

C33

GND GND GND

VBAT_CC

VBAT_CC

1

2

3

J16

VCC_BRD

1 2

3 4

5 6

J18

SOP1

100kR44

VBAT_CC

CS

1

SO/SIO1

2

WP/SIO2

3

GND

4

SI/SIO0

5

SCLK

6

RESET/SIO3

7

VCC

8

U8

MX25R6435FM2IL0

DNP

GND

0

R39

DNP

0

R38

DNP

0

R40

DNP

0

R41

DNP

0

R42

DNP

0

R43

DNP

VCC_BRD VBAT_CC

0.1uF

C34

GND

1

2

3

4

5 6

7

8

9

10

J14

TC2050-IDC-NL-FP

DNP

GND

GND

GND

D5

P21_GPIO_25

10k

R52

GND

2.2k

R51

OUTPUT ONLY

10k

R49

CC3235MOD TA RGET EXTERNAL FLASH

GANG PROGRAMMING CONNECTOR

SOP JUMPERS

SOP0

GND

1

2

345

6

E1

M830520

Feed

GND GND GND

GND

1

2

345

J15

DNP

GND

GNDGND

RF SECTION

RF_ABG

0.5pF

C40

DNP

GND

1

2

3

J17

SPI_MISO

SPI_CS_IN

SPI_CLK

SPI_MOSI

SPI_CS_IN

P17_JTAG_TDO

P16_JTAG_TDI

P19_JTAG_TCK

SOP2

SOP0

SOP1

SOP2

SPI_MISO

SPI_MOSI

SPI_CLK

SPI_CS_IN

SPI_CS_IN

SPI_CLK

SPI_MISO

SPI_MOSI

CC_nRESET

0.5pF

C36

DNP

0.5pF

C37

DNP

0.5pF

C38

DNP

GND

1

GND

2

GPIO10

3

GPIO11

4

GPIO14

5

GPIO15

6

GPIO16

7

GPIO17

8

GPIO12

9

GPIO13

10

GPIO22

11

JTAG_TDI

12

FLASH_SPI_MISO

13

FLASH_SPI_CS_IN

14

FLASH_SPI_CLK

15

GND

16

FLASH_SPI_MOSI

17

JTAG_TDO

18

GPIO28

19

NC

20

JTAG_TCK

21

JTAG_TMS

22

SOP2

23

SOP1

24

GND

25

GND

26

GND

27

GND

28

GND

29

GND

30

RF_ABG

31

GND

32

NC

33

SOP0

34

RESET

35

VBAT_RESET

36

VBAT1

37

GND

38

NC

39

VBAT2

40

NC

41

GPIO30

42

GND

43

GPIO0

44

NC

45

GPIO01

46

GPIO02

47

GPIO03

48

GPIO04

49

GPIO05

50

GPIO06

51

GPIO07

52

GPIO08

53

GPIO09

54

GND

55

GND

56

GND

57

GND

58

GND

59

GND

60

GND

61

GND

62

GND

63

CC3235MODSF12MOBR

CC1

1pF

C39

4.7nH

L4

0

C35

8.2pF

R50

8.2pF

R48

DNP

www.ti.com

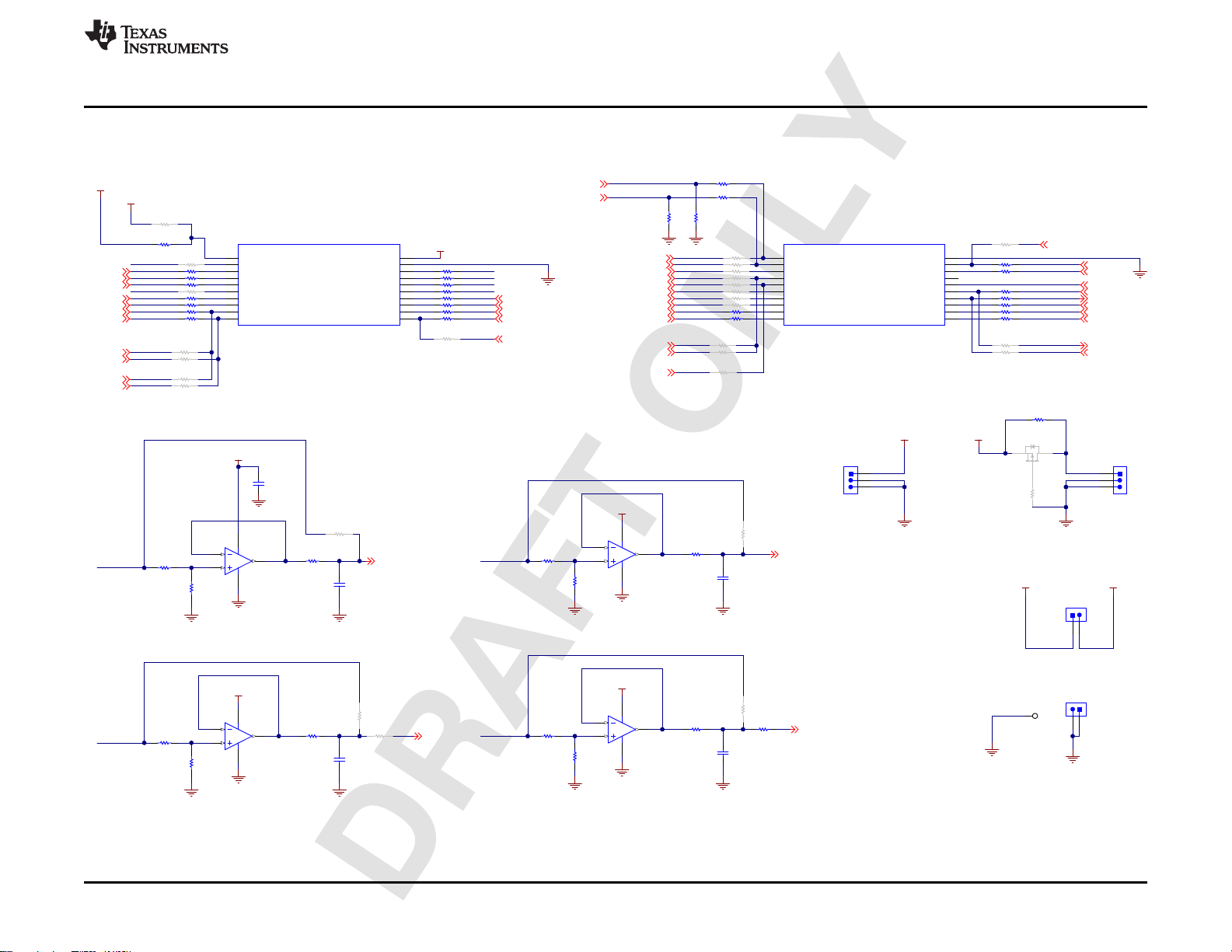

Assembly Drawing and Schematics

Figure 31. Schematics (3 of 5)

SWRU548A–February 2019

Submit Documentation Feedback

CC3235MODSF LaunchPad™ Development Kit (LAUNCHCC3235MOD)

Copyright © 2019, Texas Instruments Incorporated

45

Page 46

TI Confidential – NDA Restrictions

P17_GPIO_24

P02_GPIO_11

P01_GPIO_10

P16_GPIO_23

SENS_I2C_SCL

SENS_I2C_SDA

I2C BUS SELECTION

0R130

0R134

DNP

0R137

0R139

DNP

J23

J24

SWITCHES & FACTORY RESET

LP_RESET_OUTCC_nRESET

VCC_BRD

100k

R142

D6

CDBU00340

LED INDICAT ORS

P02_GPIO_11

P01_GPIO_10

P64_GPIO_09

GND GND GND

GND

1

2

3

Q5

BSS138

1

2

3

Q6

BSS138

1

2

3

Q7

BSS138

J26 J27 J28

100k

R150

100k

R151

100k

R152

TEMP SENSOR

VCC_BRD

GND

0

R125

0

R128

0

R132

DNP

0

R136

0

R135

SENS_I2C_SDA

SENS_I2C_SCL

0.1uF

C46

GND

GND

GND

ACCELEROMETER

P04_GPIO_13

SENS_I2C_SDA

SENS_I2C_SCL

VCC_BRD

0.1uF

C48

0.1uF

C47

0

R129

DNP

0

R131

0R138

0R141

0

R133

DNP

0

R124

GND

P04_GPIO_13 P15_GPIO_22

GND

GND

1.0k

R148

1.0k

R149

10k

R155

10k

R156

GND GND

SOP1 SOP0

VCC_BRDVCC_BRD

3.3k

R126

3.3k

R127

VCC_BRD VCC_BRD VCC_BRD

J25

100k

R144

2

1

6

Q3A BSS84DW-7-F

5

4

3

Q3B

413

2

SW4

EVQ-PSD02K

1.0k

R154

3

1

2

Q4

FDN358P

Red

D8

270

R153

VCC_BRD VCC_BRD

VCC_BRD

GND

GND GND

SCL

1

GND

2

ALERT

3

ADD0

4

V+

5

SDA

6

PAD

7

TMP116AIDRVR

U10

SDO

1

SDX

2

VDDIO

3

NC

4

INT1

5

INT2

6

VDD

7

GNDIO

8

GND

9

CSB

10

PS

11

SCX

12

U11

BMA280

0

R140

1

2

3

4

SW2

1

2

3

4

SW3

24

R147

110

R146

16

R145

1

42536

B

R

G

D7

19-337/R6GHBHC-A01/2T

10k

R143

Assembly Drawing and Schematics

www.ti.com

Figure 32. Schematics (4 of 5)

46

CC3235MODSF LaunchPad™ Development Kit (LAUNCHCC3235MOD)

Copyright © 2019, Texas Instruments Incorporated

SWRU548A–February 2019

Submit Documentation Feedback

Page 47

TI Confidential – NDA Restrictions

0

R105

DNP

0

R104

3

1

2

Q2

FDN358P

DNP

TP2

GND GND

GND

VCC_MCU_5V VBAT_CC

+3.3V

1

Analog_In

2

LP_UART_RX

3

LP_UART_TX

4

GPIO !

5

Analog In

6

SPI_CLK

7

GPIO !

8

I2C_SCL

9

I2C_SDA

10

+5V

21

GND

22

Analog_In

23

Analog_In

24

Analog_In

25

Analog_In

26

Analog_In/I2S_WS

27

Analog_In/I2S_SCLK

28

Analog_Out/I2S_SDout

29

Analog_Out/I2S_SDin

30

P1

VCC_MCU_5V

GND

GPIO !

31

GPIO !

32

GPIO !

33

GPIO !

34

Timer_Cap/GPIO !

35

Timer_Cap/GPIO !

36

PWM/GPIO !

37

PWM/GPIO !

38

PWM/GPIO !

39