Page 1

LM3407

Application Note 1763 LM3407 Evaluation Board Reference Design

Literature Number: SNVA308A

Page 2

LM3407 Evaluation Board Reference Design AN-1763

LM3407 Evaluation Board

Reference Design

Introduction

The LM3407 is a Pulse-Width-Modulation (PWM) floating

buck converter with an integrated N-channel power MOSFET

designed to provide precision constant current output for driving high power LEDs, such as the Lumileds Luxeon® power

LEDs and OSRAM Golden DRAGON® LEDs. The switching

frequency is selectable between 300 kHz and 1 MHz by

changing the value of the frequency setting resistor, allowing

for the use of small external components. The LM3407 features a Pulse Level Modulation (PLM) control scheme which

ensures the accuracy of the constant current output well within 10% over input voltage and operating temperature ranges

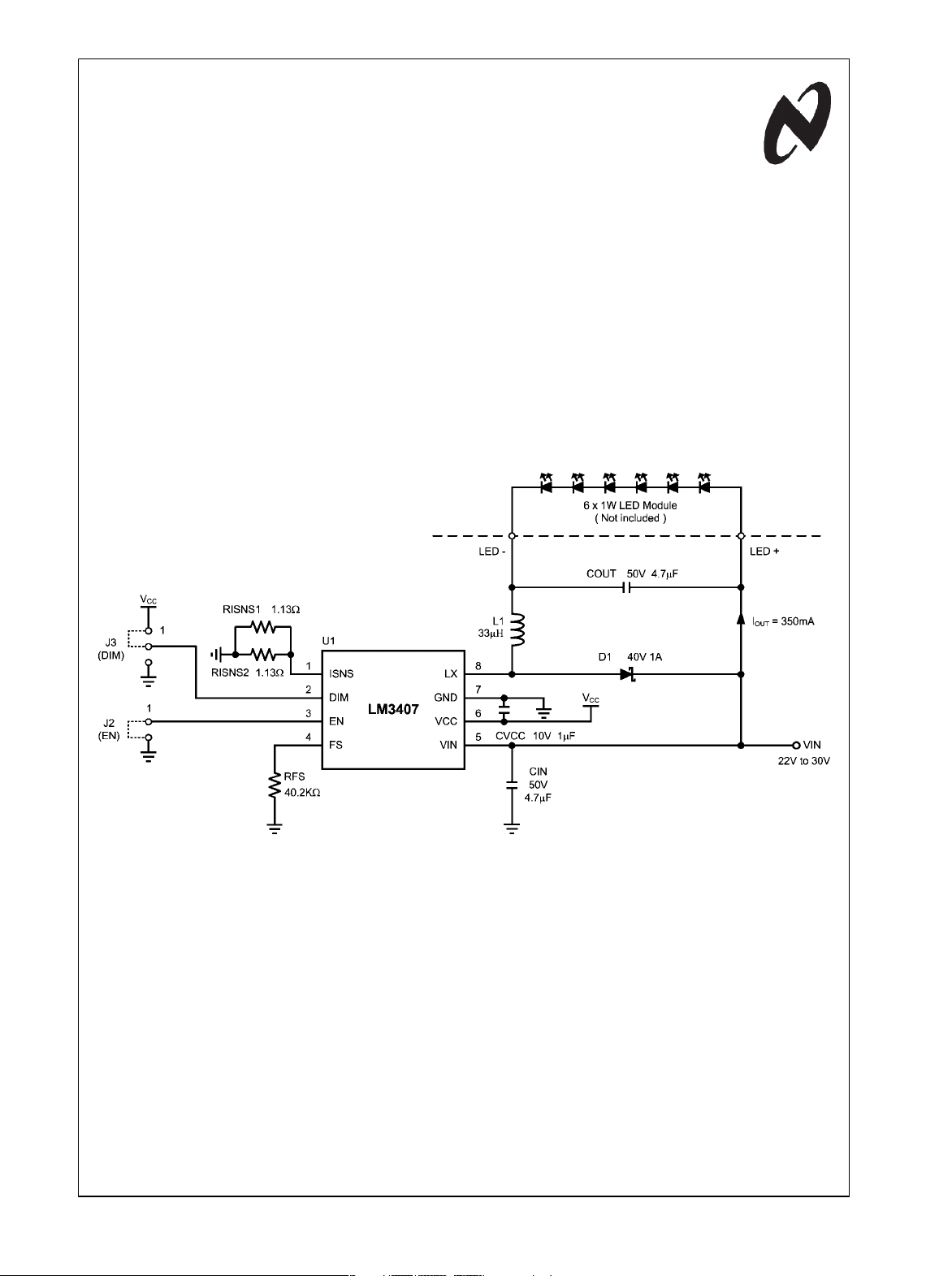

Evaluation Board Schematic

National Semiconductor

Application Note 1763

SH Wong

January 21, 2009

with an external 1% thick film current setting resistor. The

converter features a DIM pin which accepts standard logic

pulses for controlling the brightness of the LED array, making

the LM3407 ideal for use as a precision power LED driver or

constant current source.

This application note introduces the design of a sample circuit

with the LM3407 providing 350 mA constant current to drive

an LED array of 6 high power LEDs connected in series. The

board can accept an input voltage ranging from 22V to 30V.

The schematic, PCB layout, bill of materials, and circuit design criteria are shown in detail. Typical performance and

operating waveforms are also provided for reference.

30046701

FIGURE 1. LM3407 Evaluation Board Schematic

© 2009 National Semiconductor Corporation 300467 www.national.com

Page 3

AN-1763

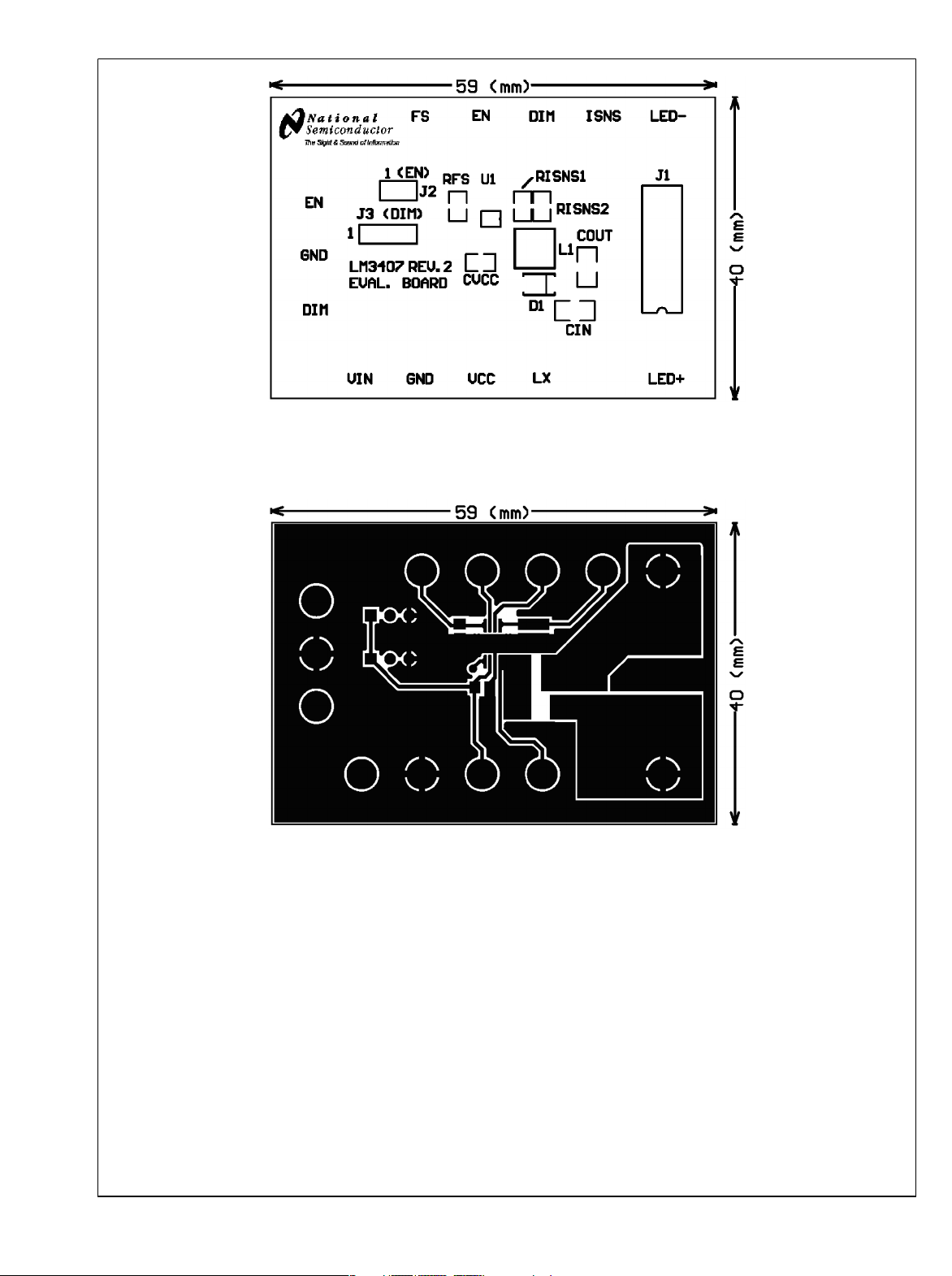

30046702

FIGURE 2. LM3407 Evaluation Board PCB Top Overlay

FIGURE 3. LM3407 Evaluation Board PCB Top View

www.national.com 2

30046703

Page 4

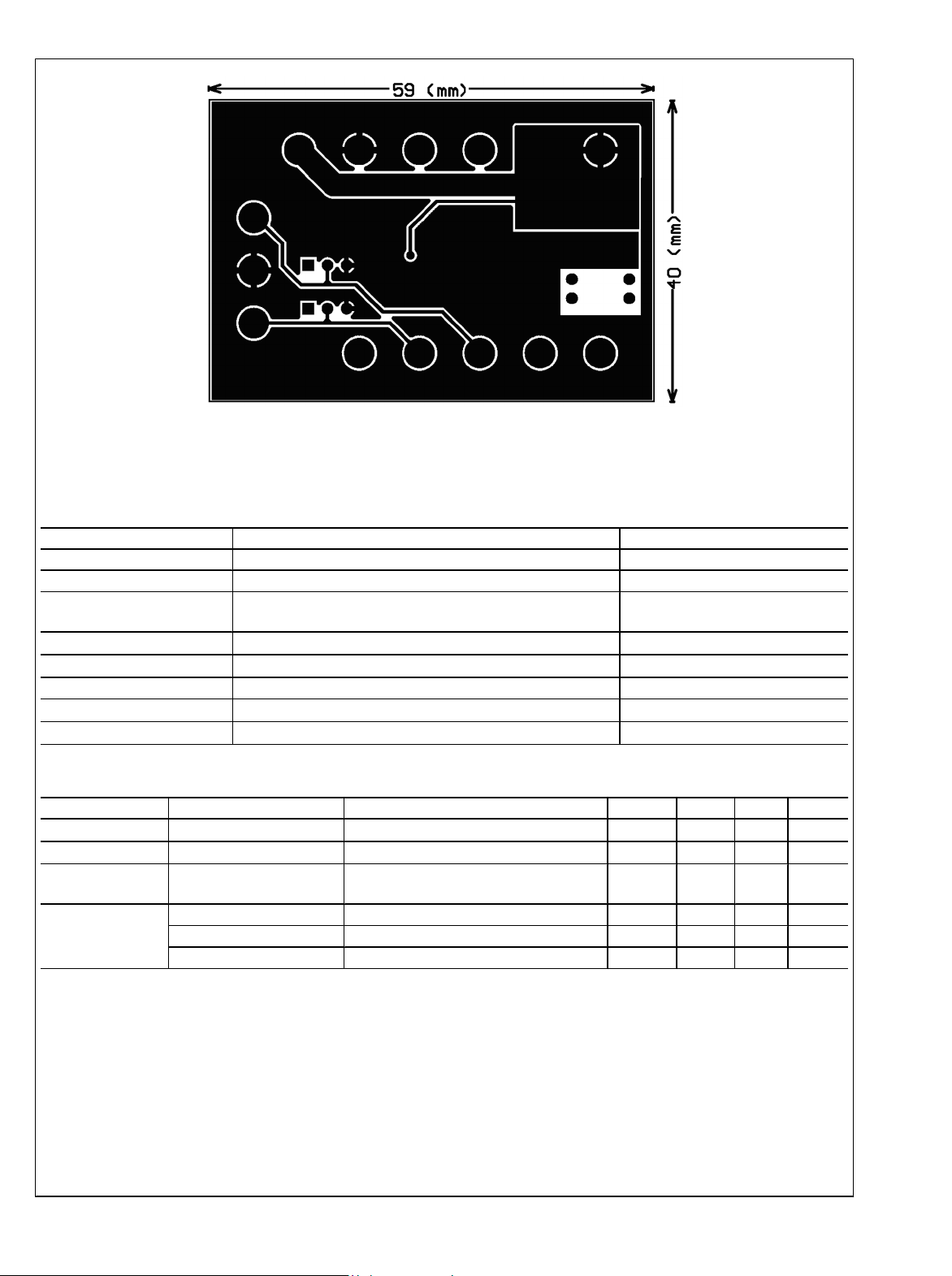

FIGURE 4. LM3407 Evaluation Board PCB Bottom View

Evaluation Board Quick Setup Procedures

AN-1763

30046704

Step Procedure Notes

1 Remove all jumpers on the evaluation board.

2 Connect the LED array of 6 power LEDs to J1.

3 Connect Power Supply output to the VIN terminal of the

evaluation board.

4 Set the power supply output voltage to 24V. VIN should not exceed 30V

6 Check the voltage of the VCC terminal of the board. VCC = 4.5V ± 8%

7 Short pin 1 and 2 of J3 by using a jumper. LEDs fully turned ON

8 Check the LED current (I

9 Short J2 by using a jumper to check the shutdown function. I

) by using an ammeter. I

OUT

= 350mA ± 6%

OUT

= 0

OUT

Evaluation Board Performance Characteristic

Description Symbol Condition Min Typ Max Unit

Input Voltage V

Output Current I

Output Current

|ΔI

OUT

OUT

IN

DIM pin connected to VCC 330 350 370 mA

|

All VIN and I

Variation

Efficiency No. of LED = 6 93 96 %

No. of LED = 4 90 95 %

No. of LED = 2 85 92 %

22 24 30 V

Conditions 6 %

OUT

3 www.national.com

Page 5

Design Procedure

CONNECTING TO LED ARRAY

AN-1763

The LM3407 evaluation board features a female 6-pin SIP

connector J1 for board-to-board connection of the LED array.

Figure 5 shows the pin-out of J1. To avoid damaging the

components, do not connect the LED array with incorrect polarity or alter the connections of the LED array when the

evaluation board is connected to power. It is highly recommended to attach the LED array to a heat sink for heat

dissipation and to apply force ventilation to the LED array as

necessary.

FIGURE 5. Connecting an LED Array to the LM3407 Evaluation Board

SETTING THE LED CURRENT

The output current of the evaluation board is adjustable by

changing the current setting resistors RISNS1 and RISNS2.

By default, the value of both RISNS1 and RISNS2 is 1.13Ω

at 1% tolerance, which results in a resistance of 0.565Ω. This

value of R

value of R

sets the output current (I

ISNS

can be calculated by using the equation:

ISNS

) at 350 mA. The

OUT

When selecting the value of the current setting resistors

(RISNS1 and RISNS2), it is important to ensure the rated

powers of the resistors are not exceeded. For example, when

I

is set at 350mA, the total power dissipation on RISNS1

OUT

and RISNS2 in steady state is 0.35 mA2 x 0.565Ω, which

equals 69 mW, indicating a resistor of 1/8W power rating is

appropriate.

30046705

SETTING THE SWITCHING FREQUENCY

The switching frequency of the LM3407 evaluation board is

programmable by adjusting the value of the frequency setting

resistor RFS. The default value of the RFS pre-installed on

the evaluation board is 40.2 kΩ, at which the switching frequency is 1MHz. In order to guarantee good current regulation, it is suggested to set the switching frequency between

300KHz and 1MHz. The switching frequency is calculated by

the expression shown below:

for 40kΩ ≤ RFS ≤ 150 kΩ

For the convenience of selecting the value of RFS, a selection

chart of fSW against RFS is provided:

www.national.com 4

Page 6

AN-1763

Switching Frequency VS. R

(TA = 25°C)

FS

30046707

The LM3407 is internally compensated and requires no external components for feedback compensation. The components of this evaluation board are optimized for driving 6

power LEDs with the input voltage between 22V and 30V. If

different conversions are required, such as changes to input

voltage and loading conditions, L1 and RFS may need to be

changed to ensure stable operation.

SELECTION OF INDUCTOR AND DIODE

In order to achieve accurate constant current output, the

LM3407 is required to operate in Continuous Conduction

Mode (CCM) under all operating conditions. In general, the

magnitude of the inductor ripple current should be kept as

small as possible. If the PCB size is not limited, higher inductance values result in better accuracy of the output current.

However, in order to minimize the physical size of the circuit,

an inductor with minimum physical outline should be selected

such that the converter always operates in CCM and the peak

inductor current does not exceed the saturation current limit

of the inductor. The ripple and peak current of the inductor

can be calculated as follows:

Peak to Peak Inductor Ripple Current:

Peak Inductor Current:

where n is the number of LEDs in a string and VF is the forward

voltage of one LED.

The minimum inductance required for the specific application

can be calculated by:

Since the evaluation board is designed to drive a LED array

of 6 LEDs, the default value of the inductor is 33µH to ensure

CCM operation for the input voltage between 22V and 30V

with 1MHz switching frequency. For the applications with different input voltage or number of LEDs, the inductance of the

inductor may have to be changed to maintain accurate output

current. Table 1 shows the suggested inductance of the inductor for 500kHz and 1MHz switching frequency.

The output diode of the evaluation board circuit is selected

depending on the output voltage and current. The diode must

have a rated reverse voltage higher than the input voltage of

the regulator and the peak current rating must be higher than

the expected maximum inductor current. Using a schottky

diode with low forward voltage will decrease power dissipation and increase conversion efficiency.

TABLE 1. Suggested Inductance Value of the Inductor

Inductor selection table for fSW = 500 kHz, C

VIN/V Number of LED

1 2 3 4 5 6 7

5 22 µH

10 22 µH 22 µH

15 22 µH 22 µH 22 µH

20 22 µH 33 µH 22 µH 22 µH 22 µH

25 22 µH 33 µH 33 µH 22 µH 22 µH 22 µH

30 22 µH 47 µH 33 µH 33 µH 33 µH 22 µH 22 µH

Inductor selection table for fSW = 1 MHz, C

5 22 µH

10 22 µH 22 µH

15 22 µH 22 µH 22 µH

20 22 µH 22 µH 22 µH 22 µH 22 µH

25 22 µH 22 µH 22 µH 22 µH 22 µH 22 µH

30 22 µH 33 µH 22 µH 22 µH 22 µH 22 µH 22 µH

= 4.7 µF (1 µF for 1 LED)

OUT

= 4.7 µF (1 µF for 1 LED)

OUT

5 www.national.com

Page 7

LED DIMMING

There are two ways to disable the current output (I

evaluation board circuit. The current output of the LM3407

AN-1763

evaluation board can be disabled by connecting either the

DIM or EN pin to ground. Connecting the EN pin to ground

will shutdown the internal linear regulator and maintain minimal power consumption. Connecting the DIM pin to ground

will only disable the current output of the LM3407, while the

internal oscillator and control circuits remain active to facilitate

fast wake up.

In general, dimming of the LED array can be achieved by applying a logic pulse chain to the DIM terminal of the evaluation

board to periodically enable and disable the LM3407 and

control the average I

characteristics of a LED are closely related to the driving cur-

of the LED array. Since the color

OUT

rent, dimming by adjusting the current setting resistor causes

the color temperature to drift. To control the brightness of the

LED array effectively, PWM dimming should be used. PWM

dimming is a dimming method which controls the ON/OFF

time ratio of the LED(s) at fixed frequency.

The DIM terminal on the evaluation board is directly connected to the DIM pin of the LM3407, which provides a PWM

signal input for dimming of the LED array. In order to properly

enable and disable the LM3407, the PWM dimming signal

OUT

) of the

should have a logic low of 1V maximum and logic high of 2V

minimum. The DIM terminal is internally pulled down to

ground by a 400 kΩ resistor, which should be connected to

either logic high or low and should not be left open. In steady

state, the expression of the average LED driving current is:

LIMITS OF PWM DIMMING

The maximum PWM dimming frequency, minimum duty cycle, and maximum duty cycle are shown in Figure 6. The

maximum dimming frequency should not exceed 1/50 of the

switching frequency fSW of the LM3407. To avoid visible flicker, dimming frequencies lower than 100 Hz are not recommended. In Figure 6, T is the period of the PWM dimming

signal. The interval tD represents the time delay from a logic

high of the dimming signal and the onset of the output current.

tSU and tSD are the time needed for the output current to slew

up from zero to steady state and slew down to zero respectively. In the figure, it can be seen that the minimum duty cycle

of the dimming signal should not be shorter than the sum of

tSU and tSD of the output current.

FIGURE 6. Limits of the PWM Dimming Signal

www.national.com 6

30046712

Page 8

AN-1763

PCB LAYOUT GUIDE

Since copper traces of PCBs carry resistance and parasitic

inductance, the longer the copper trace, the higher the resistance and inductance. These factors introduce voltage and

current spikes to the switching nodes and impair the performance of the whole circuit. To optimize the performance of

the LM3407, the rule of thumb is to keep the connections between components as short and direct as possible. Since true

average current regulation is achieved by detecting the average switch current, the current setting resistors RISNS1 and

RISNS2 must be located as close to the LM3407 as possible

to reduce the parasitic inductance of the copper trace and

avoid noise pick-up. The connections between LX pin, recti-

fier D1, inductor L1 and output capacitor COUT should be

kept as short as possible to reduce the voltage spikes at the

LX pin. CVCC is the output filter capacitor for the internal linear regulator of the LM3407, it is recommended to be placed

close to the pin VCC. The input filter capacitor CIN should be

located close to L1 and the cathode of D1. If CIN is connected

to the VIN pin by a long trace, a 0.1µF capacitor should be

added close to pin VIN for noise filtering. In normal operation,

heat will be generated inside the LM3407 and may damage

the device if no thermal management is applied. For more

detail on switching power supply layout considerations see

Application Note AN-1149: Layout Guidelines for Switching

Power Supplies.

Bill of Materials

Designation Description Package Manufacture Part # Vendor

U1 LED Driver IC, LM3407 eMSOP-8 LM3407 NSC

L1 Inductor 33µH 0.58A 4.0 x 4.0 x 1.8 (mm) LPS4018-333ML Coilcraft

* Inductor 33µH 0.56A 4.8 x 4.3 x 3.5 (mm) CR43NP-330K Sumida

D1 Schottky Diode 40V 1.0A DO-214AC (SMA) SS14 Vishay

CIN, COUT Cap MLCC 50V 4.7µF X7R 1210 GRM32ER71H475K88L Murata

CVCC Cap MLCC 10V 1.0µF X5R 0805 GRM188R61A105KA61D Murata

RISNS1, RISNS2

RFS

J1 6-pin Connector DIP-12 535676-5 Tyco Electronics

J2 2-way Jumper System 2.54 (mm) Pitch

J3 3-way Jumper System 2.54 (mm) Pitch

VCC, GND, EN, DIM,

ISNS, LX

VIN, GND Terminal pin 1.57 (mm) Dia. 160-1512 Cambion

PCB LM3407 Evaluation Board 59 x 40 (mm) NSC

J3 2-pin Jumper

*Alternative Supplier

Chip Resistor 1.13Ω 1%

Chip Resistor 40.2kΩ 1%

Terminal pin 2.29 (mm) Dia. 160-1026 Cambion

0805 CRCW08051R13F Vishay

0805 CRCW08054022F Vishay

7 www.national.com

Page 9

Typical Performance and Waveforms All curves and waveforms taken at T

specified.

AN-1763

Efficiency vs Input Voltage

(TA = -40°C)

Efficiency vs Input Voltage

(TA = 25°C)

= 25°C unless otherwise

A

Efficiency vs Input Voltage

(TA = 125°C)

Inductor Current @ fSW = 1MHz

(VIN = 12V, 2LEDs, L = 33µH)

30046713

30046715

30046714

Output Current vs Input Voltage

(TA = 25°C)

30046716

Inductor Current @ fSW = 500kHz

(VIN = 12V, 2LEDs, L = 33µH)

30046718

www.national.com 8

30046719

Page 10

AN-1763

Inductor Current @ fSW = 1MHz

(VIN = 24V, 2LEDs, L = 33µH)

30046720

DIM Pin Enable

(VIN = 24V, 2LEDs, L = 33µH, fSW = 500kHz)

Inductor Current @ fSW = 500kHz

(VIN = 24V, 2LEDs, L = 33µH)

30046721

DIM Pin Disable

(VIN = 24V, 2LEDs, L = 33µH, fSW = 500kHz)

30046722

30046723

9 www.national.com

Page 11

Notes

For more National Semiconductor product information and proven design tools, visit the following Web sites at:

Products Design Support

Amplifiers www.national.com/amplifiers WEBENCH® Tools www.national.com/webench

Audio www.national.com/audio App Notes www.national.com/appnotes

Clock and Timing www.national.com/timing Reference Designs www.national.com/refdesigns

Data Converters www.national.com/adc Samples www.national.com/samples

Interface www.national.com/interface Eval Boards www.national.com/evalboards

LVDS www.national.com/lvds Packaging www.national.com/packaging

Power Management www.national.com/power Green Compliance www.national.com/quality/green

Switching Regulators www.national.com/switchers Distributors www.national.com/contacts

LDOs www.national.com/ldo Quality and Reliability www.national.com/quality

LED Lighting www.national.com/led Feedback/Support www.national.com/feedback

Voltage Reference www.national.com/vref Design Made Easy www.national.com/easy

PowerWise® Solutions www.national.com/powerwise Solutions www.national.com/solutions

Serial Digital Interface (SDI) www.national.com/sdi Mil/Aero www.national.com/milaero

Temperature Sensors www.national.com/tempsensors Solar Magic® www.national.com/solarmagic

Wireless (PLL/VCO) www.national.com/wireless Analog University® www.national.com/AU

THE CONTENTS OF THIS DOCUMENT ARE PROVIDED IN CONNECTION WITH NATIONAL SEMICONDUCTOR CORPORATION

(“NATIONAL”) PRODUCTS. NATIONAL MAKES NO REPRESENTATIONS OR WARRANTIES WITH RESPECT TO THE ACCURACY

OR COMPLETENESS OF THE CONTENTS OF THIS PUBLICATION AND RESERVES THE RIGHT TO MAKE CHANGES TO

SPECIFICATIONS AND PRODUCT DESCRIPTIONS AT ANY TIME WITHOUT NOTICE. NO LICENSE, WHETHER EXPRESS,

IMPLIED, ARISING BY ESTOPPEL OR OTHERWISE, TO ANY INTELLECTUAL PROPERTY RIGHTS IS GRANTED BY THIS

DOCUMENT.

TESTING AND OTHER QUALITY CONTROLS ARE USED TO THE EXTENT NATIONAL DEEMS NECESSARY TO SUPPORT

NATIONAL’S PRODUCT WARRANTY. EXCEPT WHERE MANDATED BY GOVERNMENT REQUIREMENTS, TESTING OF ALL

PARAMETERS OF EACH PRODUCT IS NOT NECESSARILY PERFORMED. NATIONAL ASSUMES NO LIABILITY FOR

APPLICATIONS ASSISTANCE OR BUYER PRODUCT DESIGN. BUYERS ARE RESPONSIBLE FOR THEIR PRODUCTS AND

APPLICATIONS USING NATIONAL COMPONENTS. PRIOR TO USING OR DISTRIBUTING ANY PRODUCTS THAT INCLUDE

NATIONAL COMPONENTS, BUYERS SHOULD PROVIDE ADEQUATE DESIGN, TESTING AND OPERATING SAFEGUARDS.

EXCEPT AS PROVIDED IN NATIONAL’S TERMS AND CONDITIONS OF SALE FOR SUCH PRODUCTS, NATIONAL ASSUMES NO

LIABILITY WHATSOEVER, AND NATIONAL DISCLAIMS ANY EXPRESS OR IMPLIED WARRANTY RELATING TO THE SALE

AND/OR USE OF NATIONAL PRODUCTS INCLUDING LIABILITY OR WARRANTIES RELATING TO FITNESS FOR A PARTICULAR

PURPOSE, MERCHANTABILITY, OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY

RIGHT.

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR

SYSTEMS WITHOUT THE EXPRESS PRIOR WRITTEN APPROVAL OF THE CHIEF EXECUTIVE OFFICER AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

Life support devices or systems are devices which (a) are intended for surgical implant into the body, or (b) support or sustain life and

whose failure to perform when properly used in accordance with instructions for use provided in the labeling can be reasonably expected

to result in a significant injury to the user. A critical component is any component in a life support device or system whose failure to perform

can be reasonably expected to cause the failure of the life support device or system or to affect its safety or effectiveness.

National Semiconductor and the National Semiconductor logo are registered trademarks of National Semiconductor Corporation. All other

brand or product names may be trademarks or registered trademarks of their respective holders.

Copyright© 2009 National Semiconductor Corporation

For the most current product information visit us at www.national.com

National Semiconductor

Americas Technical

Support Center

Email: support@nsc.com

AN-1763 LM3407 Evaluation Board Reference Design

www.national.com

Tel: 1-800-272-9959

National Semiconductor Europe

Technical Support Center

Email: europe.support@nsc.com

German Tel: +49 (0) 180 5010 771

English Tel: +44 (0) 870 850 4288

National Semiconductor Asia

Pacific Technical Support Center

Email: ap.support@nsc.com

National Semiconductor Japan

Technical Support Center

Email: jpn.feedback@nsc.com

Page 12

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications, enhancements, improvements,

and other changes to its products and services at any time and to discontinue any product or service without notice. Customers should

obtain the latest relevant information before placing orders and should verify that such information is current and complete. All products are

sold subject to TI’s terms and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in accordance with TI’s standard

warranty. Testing and other quality control techniques are used to the extent TI deems necessary to support this warranty. Except where

mandated by government requirements, testing of all parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for their products and

applications using TI components. To minimize the risks associated with customer products and applications, customers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right, copyright, mask work right,

or other TI intellectual property right relating to any combination, machine, or process in which TI products or services are used. Information

published by TI regarding third-party products or services does not constitute a license from TI to use such products or services or a

warranty or endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual

property of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of TI information in TI data books or data sheets is permissible only if reproduction is without alteration and is accompanied

by all associated warranties, conditions, limitations, and notices. Reproduction of this information with alteration is an unfair and deceptive

business practice. TI is not responsible or liable for such altered documentation. Information of third parties may be subject to additional

restrictions.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that product or service voids all

express and any implied warranties for the associated TI product or service and is an unfair and deceptive business practice. TI is not

responsible or liable for any such statements.

TI products are not authorized for use in safety-critical applications (such as life support) where a failure of the TI product would reasonably

be expected to cause severe personal injury or death, unless officers of the parties have executed an agreement specifically governing

such use. Buyers represent that they have all necessary expertise in the safety and regulatory ramifications of their applications, and

acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements concerning their products

and any use of TI products in such safety-critical applications, notwithstanding any applications-related information or support that may be

provided by TI. Further, Buyers must fully indemnify TI and its representatives against any damages arising out of the use of TI products in

such safety-critical applications.

TI products are neither designed nor intended for use in military/aerospace applications or environments unless the TI products are

specifically designated by TI as military-grade or "enhanced plastic." Only products designated by TI as military-grade meet military

specifications. Buyers acknowledge and agree that any such use of TI products which TI has not designated as military-grade is solely at

the Buyer's risk, and that they are solely responsible for compliance with all legal and regulatory requirements in connection with such use.

TI products are neither designed nor intended for use in automotive applications or environments unless the specific TI products are

designated by TI as compliant with ISO/TS 16949 requirements. Buyers acknowledge and agree that, if they use any non-designated

products in automotive applications, TI will not be responsible for any failure to meet such requirements.

Following are URLs where you can obtain information on other Texas Instruments products and application solutions:

Products Applications

Audio www.ti.com/audio Communications and Telecom www.ti.com/communications

Amplifiers amplifier.ti.com Computers and Peripherals www.ti.com/computers

Data Converters dataconverter.ti.com Consumer Electronics www.ti.com/consumer-apps

DLP® Products www.dlp.com Energy and Lighting www.ti.com/energy

DSP dsp.ti.com Industrial www.ti.com/industrial

Clocks and Timers www.ti.com/clocks Medical www.ti.com/medical

Interface interface.ti.com Security www.ti.com/security

Logic logic.ti.com Space, Avionics and Defense www.ti.com/space-avionics-defense

Power Mgmt power.ti.com Transportation and Automotive www.ti.com/automotive

Microcontrollers microcontroller.ti.com Video and Imaging www.ti.com/video

RFID www.ti-rfid.com

OMAP Mobile Processors www.ti.com/omap

Wireless Connectivity www.ti.com/wirelessconnectivity

TI E2E Community Home Page e2e.ti.com

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2011, Texas Instruments Incorporated

Loading...

Loading...