Page 1

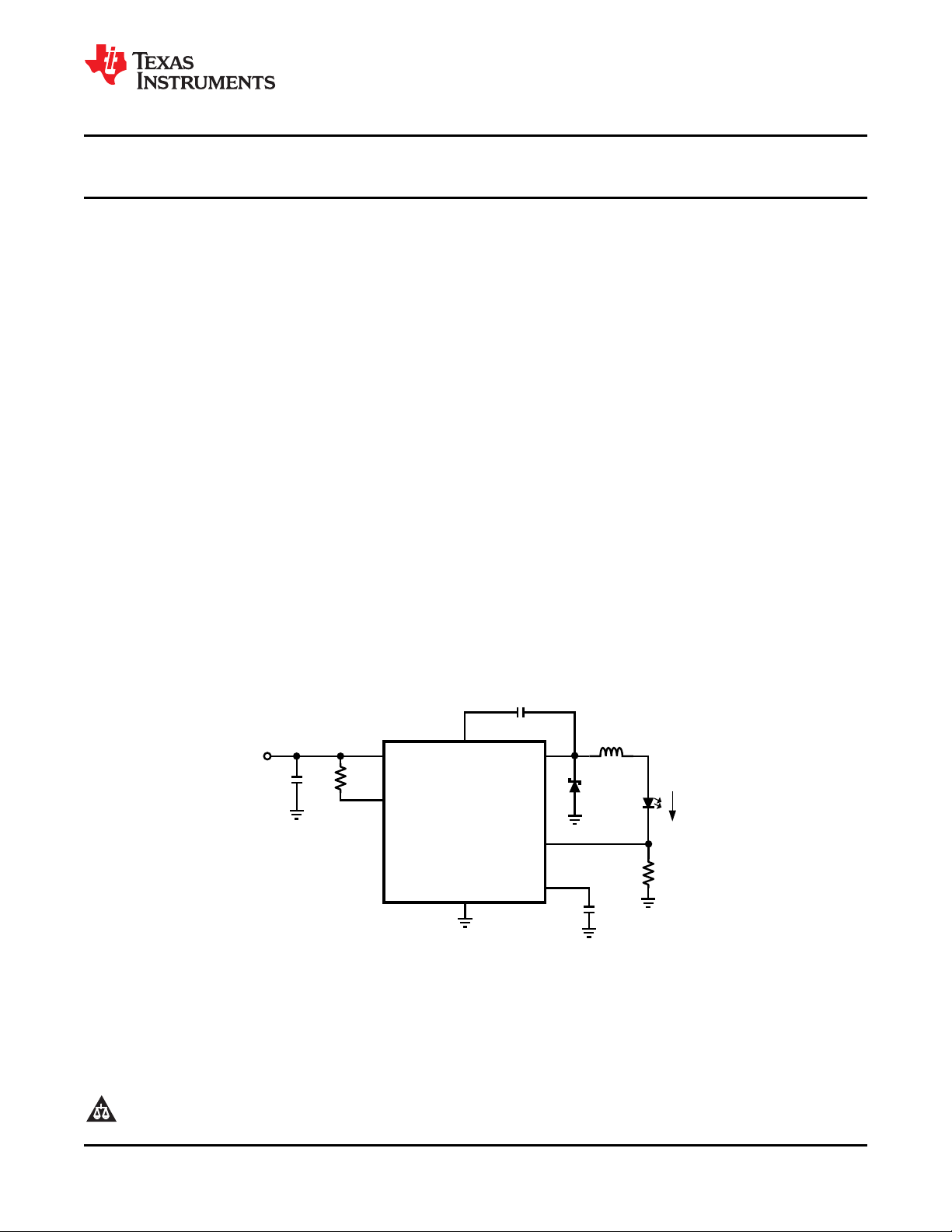

GND

DIM

BOOT SW

CS

RON

LM3404/04HV

VIN

D1

L1

C

B

R

SNS

C

F

R

ON

C

IN

V

IN

I

F

VCC

LM3404, LM3404HV

www.ti.com

1.0A Constant Current Buck Regulator for Driving High Power LEDs

Check for Samples: LM3404, LM3404HV

1

FEATURES

2

• Integrated 1.0A MOSFET

• VINRange 6V to 42V (LM3404)

• VINRange 6V to 75V (LM3404HV)

• 1.2A Output Current Over Temperature

• Cycle-by-Cycle Current Limit

• No Control Loop Compensation Required

• Separate PWM Dimming and Low Power

Shutdown

• Supports All-ceramic Output Capacitors and

Capacitor-less Outputs

• Thermal Shutdown Protection

• SOIC-8 Package, So PowerPAD-8 Package

APPLICATIONS

• LED Driver

• Constant Current Source

• Automotive Lighting

• General Illumination

• Industrial Lighting

SNVS465F –OCTOBER 2006–REVISED MAY 2013

DESCRIPTION

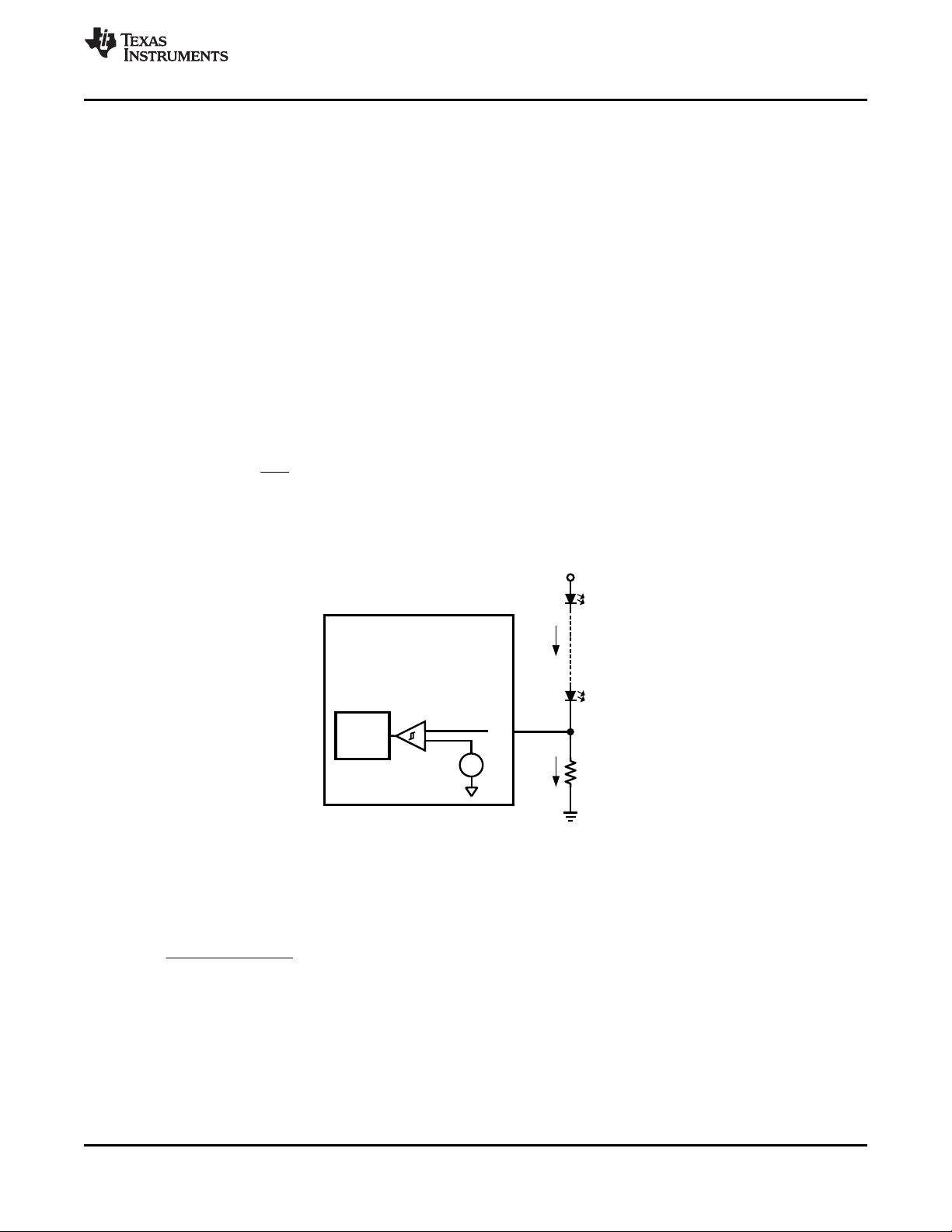

The LM3404/04HV are monolithic switching

regulators designed to deliver constant currents to

high power LEDs. Ideal for automotive, industrial, and

general lighting applications, they contain a high-side

N-channel MOSFET switch with a current limit of

1.5A (typical) for step-down (Buck) regulators.

Hysteretic controlled on-time and an external resistor

allow the converter output voltage to adjust as

needed to deliver a constant current to series and

series-parallel connected LED arrays of varying

number and type. LED dimming via pulse width

modulation (PWM), broken/open LED protection, lowpower shutdown and thermal shutdown complete the

feature set.

Typical Application

1

2All trademarks are the property of their respective owners.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

Copyright © 2006–2013, Texas Instruments Incorporated

Page 2

SW

1

RON

2

VIN

3

BOOT

4

VCC

8

GND

7

DIM

6

CS

5

SW

1

RON

2

VIN

3

BOOT

4

VCC

8

GND

7

DIM

6

CS

5

DAP

LM3404, LM3404HV

SNVS465F –OCTOBER 2006–REVISED MAY 2013

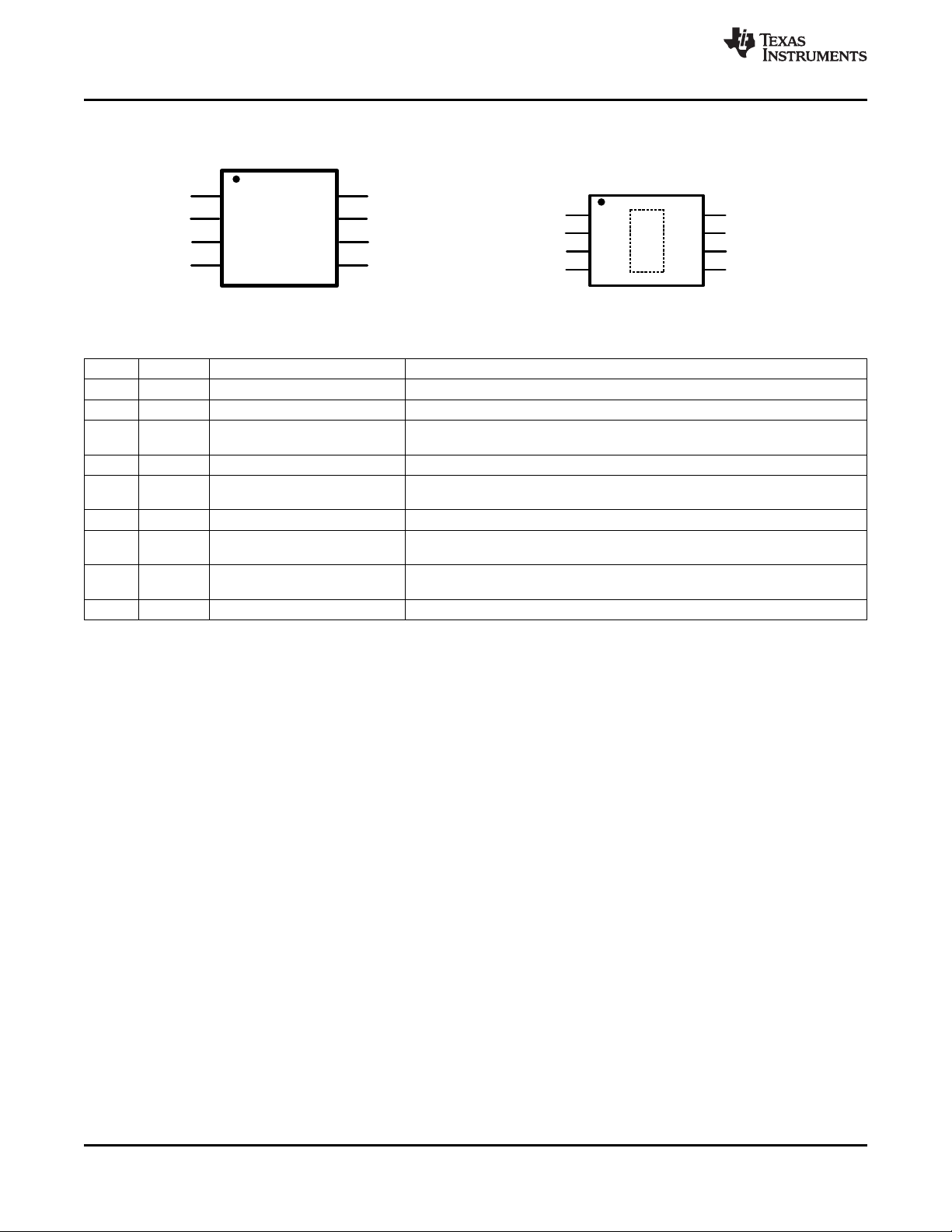

Connection Diagrams

Figure 1. 8-Lead Plastic SOIC-8 Package Figure 2. 8-Lead Plastic So PowerPAD-8 Package

PIN DESCRIPTIONS

Pin(s) Name Description Application Information

1 SW Switch pin Connect this pin to the output inductor and Schottky diode.

2 BOOT MOSFET drive bootstrap pin Connect a 10 nF ceramic capacitor from this pin to SW.

3 DIM Connect a logic-level PWM signal to this pin to enable/disable the power

4 GND Ground pin Connect this pin to system ground.

5 CS Set the current through the LED array by connecting a resistor from this pin to

6 RON On-time control pin A resistor connected from this pin to VIN sets the regulator controlled on-time.

7 VCC Output of the internal 7V linear Bypass this pin to ground with a minimum 0.1 µF ceramic capacitor with X5R or

8 VIN Nominal operating input range for this pin is 6V to 42V (LM3404) or 6V to 75V

DAP GND Thermal Pad Connect to ground. Place 4-6 vias from DAP to bottom layer ground plane.

Input for PWM dimming

Current sense feedback pin

MOSFET and reduce the average light output of the LED array.

ground.

regulator X7R dielectric.

Input voltage pin

(LM3404HV).

www.ti.com

2 Submit Documentation Feedback Copyright © 2006–2013, Texas Instruments Incorporated

Product Folder Links: LM3404 LM3404HV

Page 3

LM3404, LM3404HV

www.ti.com

These devices have limited built-in ESD protection. The leads should be shorted together or the device placed in conductive foam

during storage or handling to prevent electrostatic damage to the MOS gates.

ABSOLUTE MAXIMUM RATINGS(LM3404)

(1)

SNVS465F –OCTOBER 2006–REVISED MAY 2013

If Military/Aerospace specified devices are required, please contact the Texas Instruments Semiconductor Sales

Office/ Distributors for availability and specifications.

VALUE / UNIT

VIN to GND –0.3 V to 45 V

BOOT to GND –0.3 V to 59 V

SW to GND –1.5 V to 45 V

BOOT to VCC –0.3 V to 45 V

BOOT to SW –0.3 V to 14 V

VCC to GND –0.3 V to 14 V

DIM to GND –0.3 V to 7 V

CS to GND –0.3 V to 7 V

RON to GND –0.3 V to 7 V

Junction Temperature 150°C

Storage Temp. Range –65°C to 125°C

ESD Rating

Soldering Information Lead Temperature (Soldering, 10sec) 260°C

(1) Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. Operating Ratings indicate conditions for

which the device is intended to be functional, but specific performance is not ensured. For specifications and the test conditions, see

Electrical Characteristics.

(2) The human body model is a 100 pF capacitor discharged through a 1.5 kΩ resistor into each pin.

(2)

Infrared/Convection Reflow (15sec) 235°C

2 kV

RECOMMENDED OPERATING CONDITIONS (LM3404)

V

IN

Junction Temperature Range –40°C to +125°C

Thermal Resistance θJA(SOIC-8 Package) 155°C/W

Thermal Resistance θJA(So PowerPAD-8 Package)

(1) Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. Operating Ratings indicate conditions for

which the device is intended to be functional, but specific performance is not ensured. For specifications and the test conditions, see

Electrical Characteristics.

(2) θJAof 50°C/W with DAP soldered to a minimum of 2 square inches of 1oz. copper on the top or bottom PCB layer.

(2)

(1)

VALUE / UNIT

6V to 42V

50°C/W

Copyright © 2006–2013, Texas Instruments Incorporated Submit Documentation Feedback 3

Product Folder Links: LM3404 LM3404HV

Page 4

LM3404, LM3404HV

SNVS465F –OCTOBER 2006–REVISED MAY 2013

ABSOLUTE MAXIMUM RATINGS (LM3404HV)

VIN to GND –0.3 V to 76 V

BOOT to GND –0.3 V to 90 V

SW to GND –1.5 V to 76 V

BOOT to VCC –0.3 V to 76 V

BOOT to SW –0.3 V to 14 V

VCC to GND –0.3 V to 14 V

DIM to GND –0.3 V to 7 V

CS to GND –0.3 V to 7 V

RON to GND –0.3 V to 7 V

Junction Temperature 150°C

Storage Temperature Range –65°C to 125°C

ESD Rating

Soldering Information Lead Temperature (Soldering, 10sec) 260°C

(1) Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. Operating Ratings indicate conditions for

which the device is intended to be functional, but specific performance is not ensured. For specifications and the test conditions, see

Electrical Characteristics.

(2) The human body model is a 100 pF capacitor discharged through a 1.5 kΩ resistor into each pin.

(2)

RECOMMENDED OPERATING CONDITIONS (LM3404HV)

V

IN

Junction Temperature Range –40°C to +125°C

Thermal Resistance θJA(SOIC-8 Package) 155°C/W

Thermal Resistance θJA(So PowerPAD-8 Package)

(2)

(1)

Infrared/Convection Reflow (15sec) 235°C

(1)

VALUE / UNIT

6 V to 75 V

50°C/W

www.ti.com

VALUE / UNIT

2 kV

(1) Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. Operating Ratings indicate conditions for

which the device is intended to be functional, but specific performance is not ensured. For specifications and the test conditions, see

Electrical Characteristics.

(2) θJAof 50°C/W with DAP soldered to a minimum of 2 square inches of 1oz. copper on the top or bottom PCB layer.

4 Submit Documentation Feedback Copyright © 2006–2013, Texas Instruments Incorporated

Product Folder Links: LM3404 LM3404HV

Page 5

LM3404, LM3404HV

www.ti.com

SNVS465F –OCTOBER 2006–REVISED MAY 2013

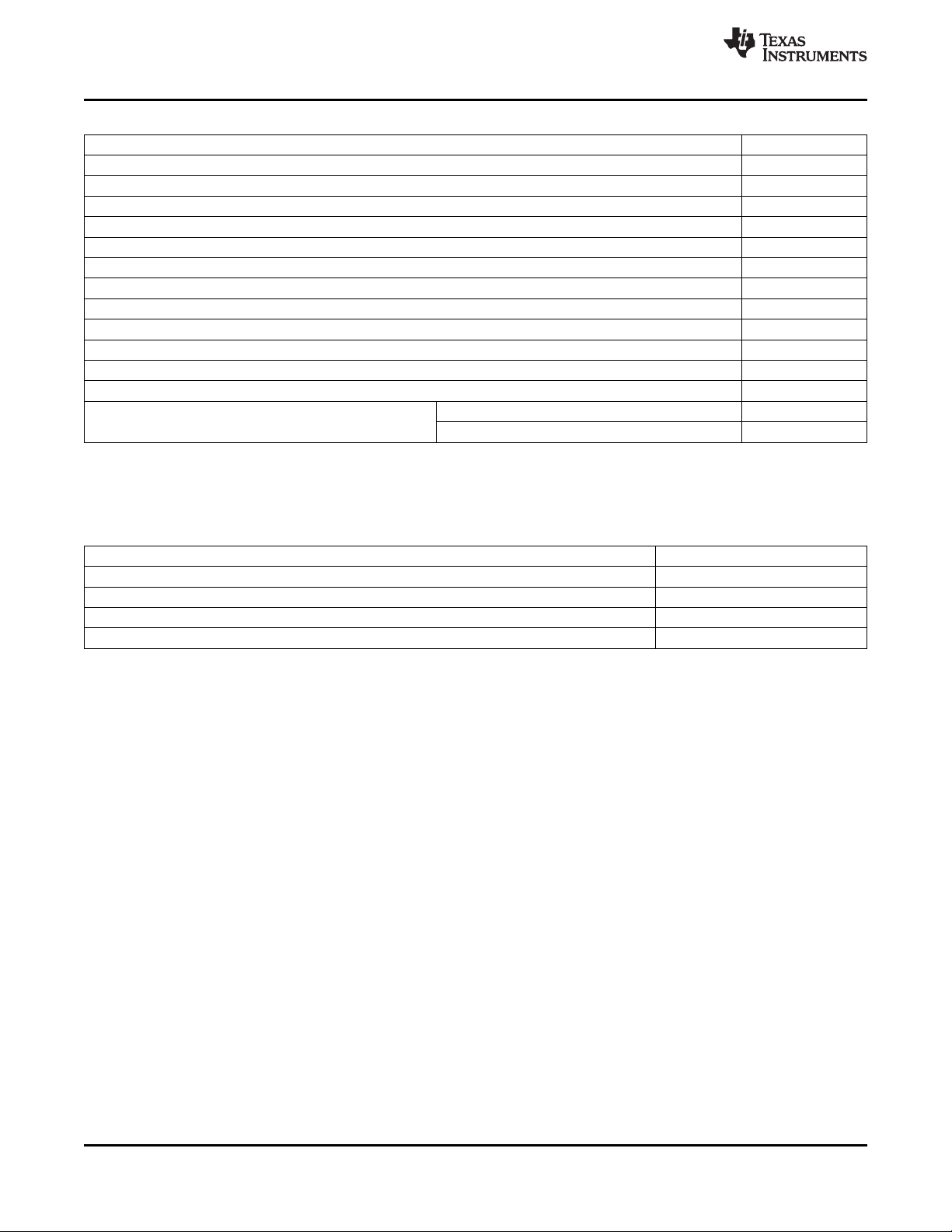

ELECTRICAL CHARACTERISTICS

LM3404

VIN= 24V unless otherwise indicated. Typicals and limits appearing in plain type apply for TA= TJ= 25°C.

in boldface type apply over full Operating Temperature Range. Datasheet min/max specification limits are specified by

design, test, or statistical analysis.

Symbol Parameter Conditions Min Typ Max Units

SYSTEM PARAMETERS

t

ON-1

t

ON-2

(1) Typical specifications represent the most likely parametric norm at 25°C operation.

On-time 1 VIN= 10V, RON= 200 kΩ 2.1 2.75 3.4 µs

On-time 2 VIN= 40V, RON= 200 kΩ 515 675 835 ns

(1)

Limits appearing

LM3404HV

Symbol Parameter Conditions Min Typ Max Units

SYSTEM PARAMETERS

t

ON-1

t

ON-2

LM3404/LM3404HV

Symbol Parameter Conditions Min Typ Max Units

REGULATION AND OVER-VOLTAGE COMPARATORS

V

REF-REG

V

REF-0V

I

CS

SHUTDOWN

V

SD-TH

V

SD-HYS

OFF TIMER

t

OFF-MIN

INTERNAL REGULATOR

V

CC-REG

V

IN-DO

V

CC-BP-TH

V

CC-BP-HYS

V

CC-Z-6

V

CC-Z-8

V

CC-Z-24

V

CC-LIM

V

CC-UV-TH

V

CC-UV-HYS

V

CC-UV-DLY

I

IN-OP

I

IN-SD

CURRENT LIMIT

I

LIM

DIM COMPARATOR

V

IH

V

IL

I

DIM-PU

On-time 1 VIN= 10V, RON= 200 kΩ 2.1 2.75 3.4 µs

On-time 2 VIN= 70V, RON= 200 kΩ 325 415 505 ns

(1)

CS Regulation Threshold CS Decreasing, SW turns on 194 200 206 mV

CS Over-voltage Threshold CS Increasing, SW turns off 300 mV

CS Bias Current CS = 0V 0.1 µA

Shutdown Threshold RON/ SD Increasing 0.3 0.7 1.05 V

Shutdown Hysteresis RON/ SD Decreasing 40 mV

Minimum Off-time CS = 0V 270 ns

VCCRegulated Output 6.4 7 7.4 V

VIN- V

CC

ICC= 5 mA, 6.0V < VIN< 8.0V 300 mV

VCCBypass Threshold VINIncreasing 8.8 V

VCCBypass Hysteresis VINDecreasing 230 mV

VIN= 6V 55

VCCOutput Impedance

(0 mA < ICC< 5 mA)

VIN= 8V 50

VIN= 24V 0.4

VCCCurrent Limit

(1)

VIN= 24V, VCC= 0V 16 mA

VCCUnder-voltage Lock-out Threshold VCCIncreasing 5.3 V

VCCUnder-voltage Lock-out Hysteresis VCCDecreasing 150 mV

VCCUnder-voltage Lock-out Filter Delay 100 mV Overdrive 3 µs

IINOperating Current Non-switching, CS = 0.5V 625 900 µA

IINShutdown Current RON / SD = 0V 95 180 µA

Current Limit Threshold 1.2 1.5 1.8 A

Logic High DIM Increasing 2.2 V

Logic Low DIM Decreasing 0.8 V

DIM Pull-up Current DIM = 1.5V 80 µA

Ω

(1) VCC provides self bias for the internal gate drive and control circuits. Device thermal limitations limit external loading.

Copyright © 2006–2013, Texas Instruments Incorporated Submit Documentation Feedback 5

Product Folder Links: LM3404 LM3404HV

Page 6

LM3404, LM3404HV

SNVS465F –OCTOBER 2006–REVISED MAY 2013

LM3404/LM3404HV

(1)

(continued)

Symbol Parameter Conditions Min Typ Max Units

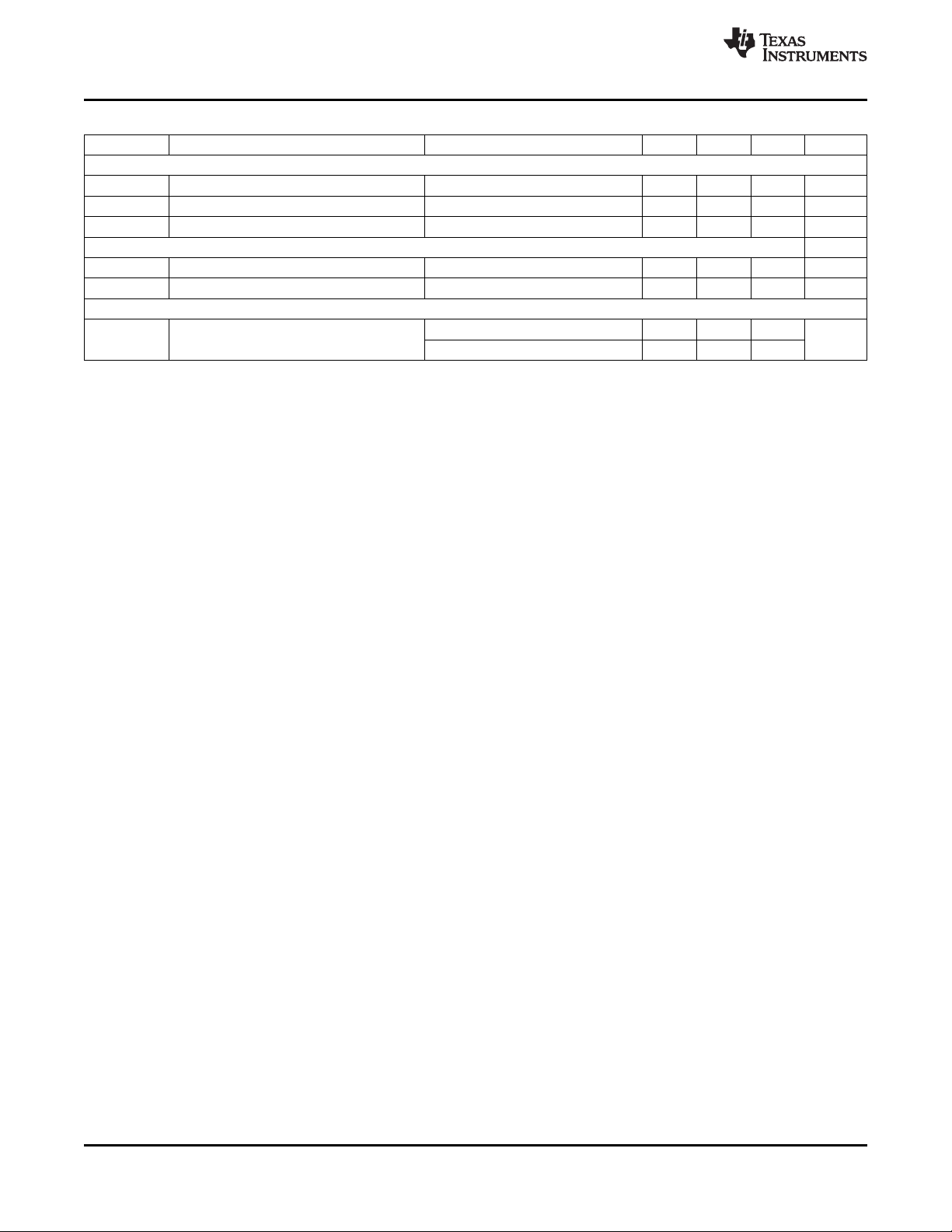

MOSFET AND DRIVER

R

DS-ON

V

DR-UVLO

V

DR-HYS

Buck Switch On Resistance ISW= 200mA, BST-SW = 6.3V 0.37 0.75 Ω

BST Under-voltage Lock-out Threshold BST–SW Increasing 1.7 3 4 V

BST Under-voltage Lock-out Hysteresis BST–SW Decreasing 400 mV

THERMAL SHUTDOWN

T

SD

T

SD-HYS

Thermal Shutdown Threshold 165 °C

Thermal Shutdown Hysteresis 25 °C

THERMAL RESISTANCE

θ

JA

Junction to Ambient °C/W

SOIC-8 Package 155

So PowerPAD-8 Package

(2)

50

(2) θJAof 50°C/W with DAP soldered to a minimum of 2 square inches of 1oz. copper on the top or bottom PCB layer.

www.ti.com

6 Submit Documentation Feedback Copyright © 2006–2013, Texas Instruments Incorporated

Product Folder Links: LM3404 LM3404HV

Page 7

LM3404, LM3404HV

www.ti.com

SNVS465F –OCTOBER 2006–REVISED MAY 2013

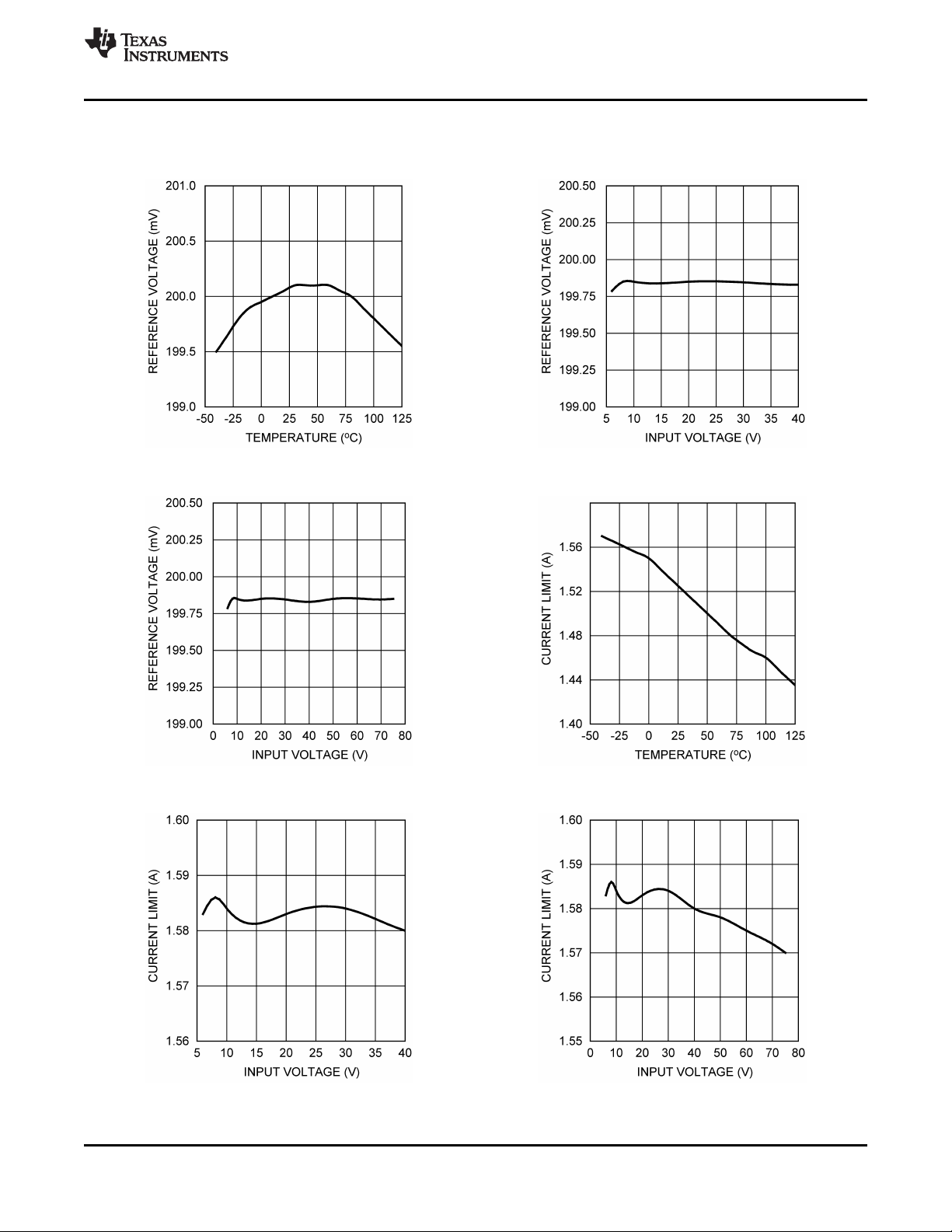

TYPICAL PERFORMANCE CHARACTERISTICS

spacer

V

vs Temperature (VIN= 24V) V

REF

Figure 3. Figure 4.

V

vs VIN, LM3404HV (TA= 25°C) Current Limit vs Temperature (VIN= 24V)

REF

vs VIN, LM3404 (TA= 25°C)

REF

Figure 5. Figure 6.

Current Limi vs VIN, LM3404 (TA= 25°C) Current Limit vs VIN, LM3404HV (TA= 25°C)

Figure 7. Figure 8.

Copyright © 2006–2013, Texas Instruments Incorporated Submit Documentation Feedback 7

Product Folder Links: LM3404 LM3404HV

Page 8

LM3404, LM3404HV

SNVS465F –OCTOBER 2006–REVISED MAY 2013

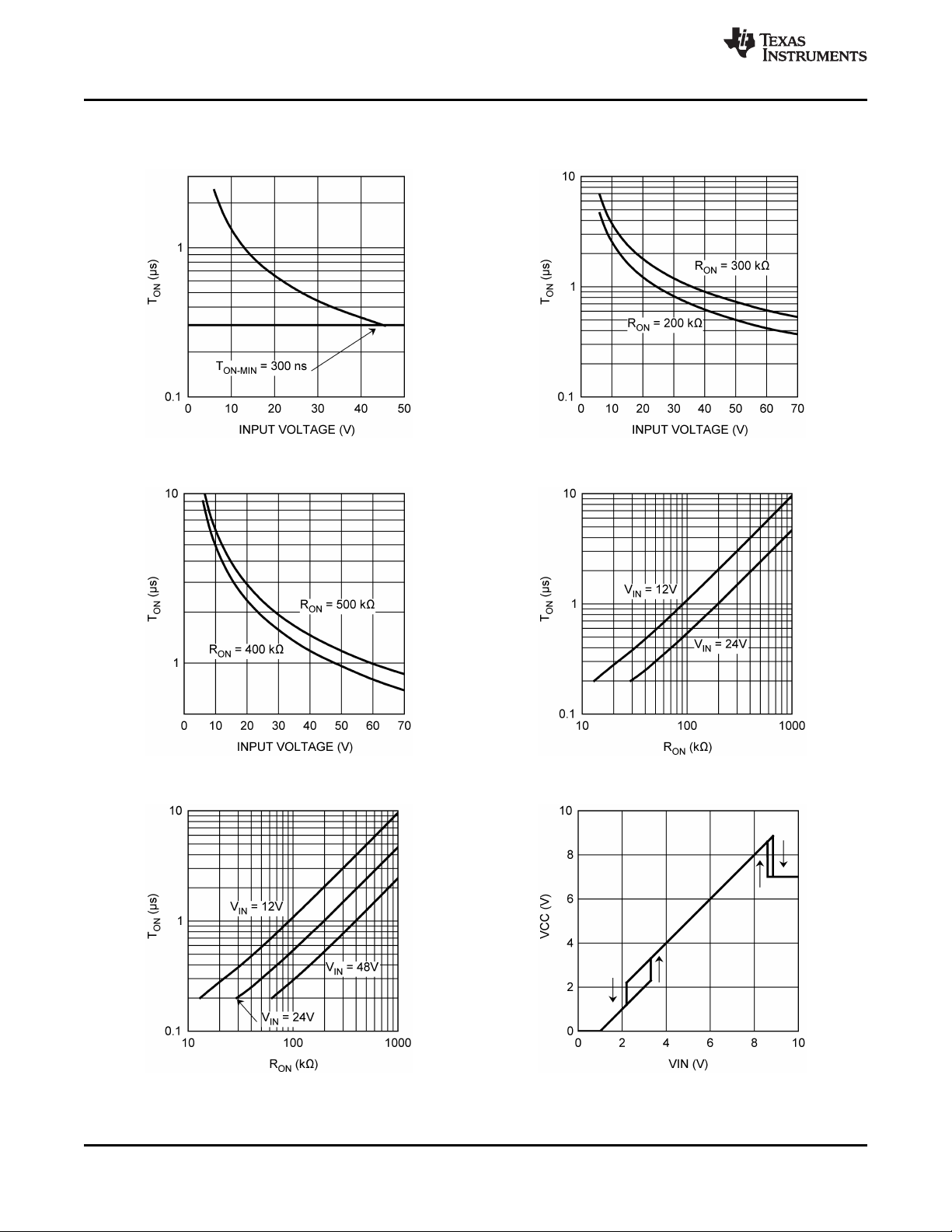

TYPICAL PERFORMANCE CHARACTERISTICS (continued)

spacer

TONvs VIN, RON= 100 kΩ (TA= 25°C) TONvs VIN, (TA= 25°C)

Figure 9. Figure 10.

TONvs VIN, (TA= 25°C) TONvs RON, LM3404 (TA= 25°C)

www.ti.com

Figure 11. Figure 12.

TONvs RON, LM3404HV (TA= 25°C) VCCvs VIN(TA= 25°C)

Figure 13. Figure 14.

8 Submit Documentation Feedback Copyright © 2006–2013, Texas Instruments Incorporated

Product Folder Links: LM3404 LM3404HV

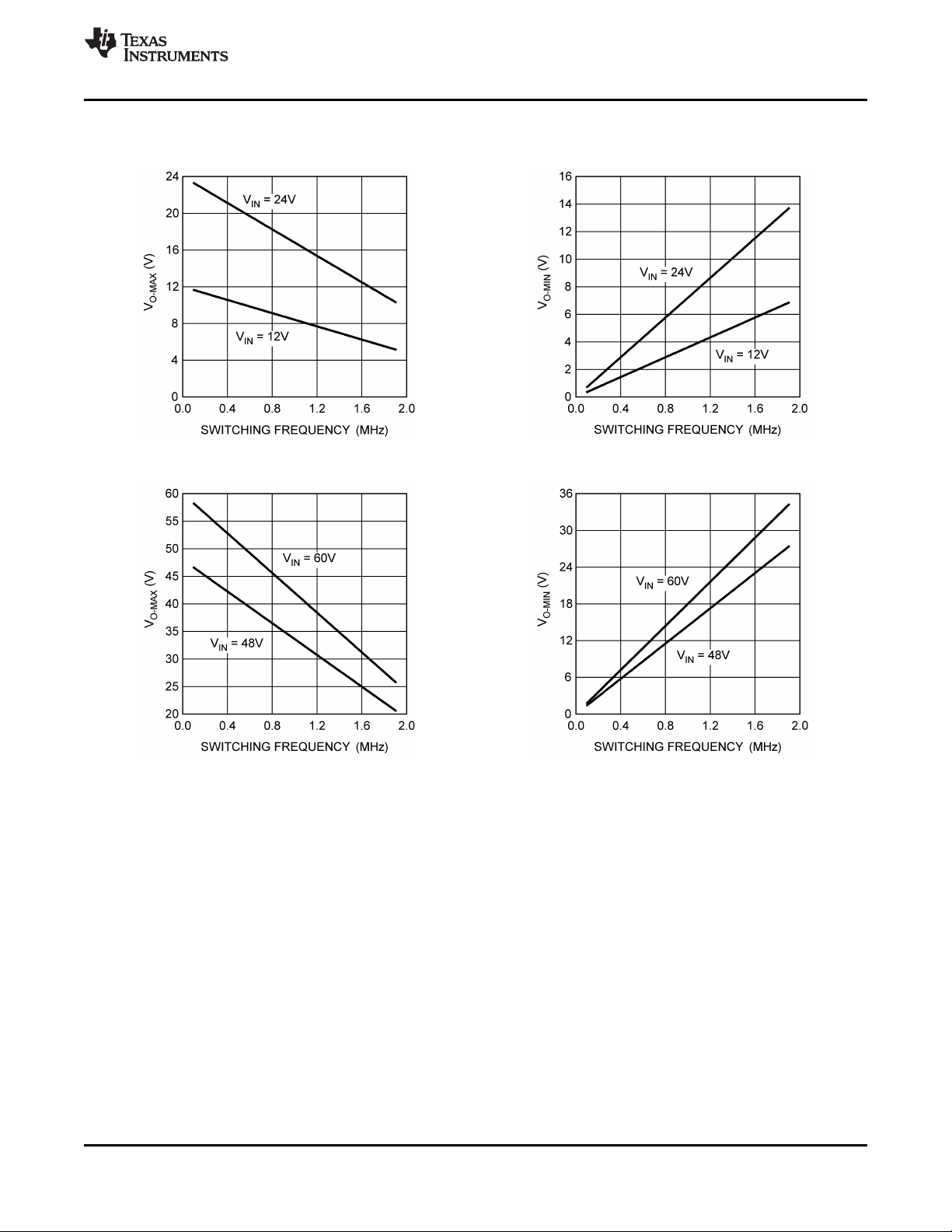

Page 9

LM3404, LM3404HV

www.ti.com

spacer

TYPICAL PERFORMANCE CHARACTERISTICS (continued)

V

vs fSW, LM3404 (TA= 25°C) V

O-MAX

Figure 15. Figure 16.

V

vs fSW, LM3404HV (TA= 25°C) V

O-MAX

SNVS465F –OCTOBER 2006–REVISED MAY 2013

vs fSW, LM3404 (TA= 25°C)

O-MIN

vs fSW, LM3404HV (TA= 25°C)

O-MIN

Figure 17. Figure 18.

Copyright © 2006–2013, Texas Instruments Incorporated Submit Documentation Feedback 9

Product Folder Links: LM3404 LM3404HV

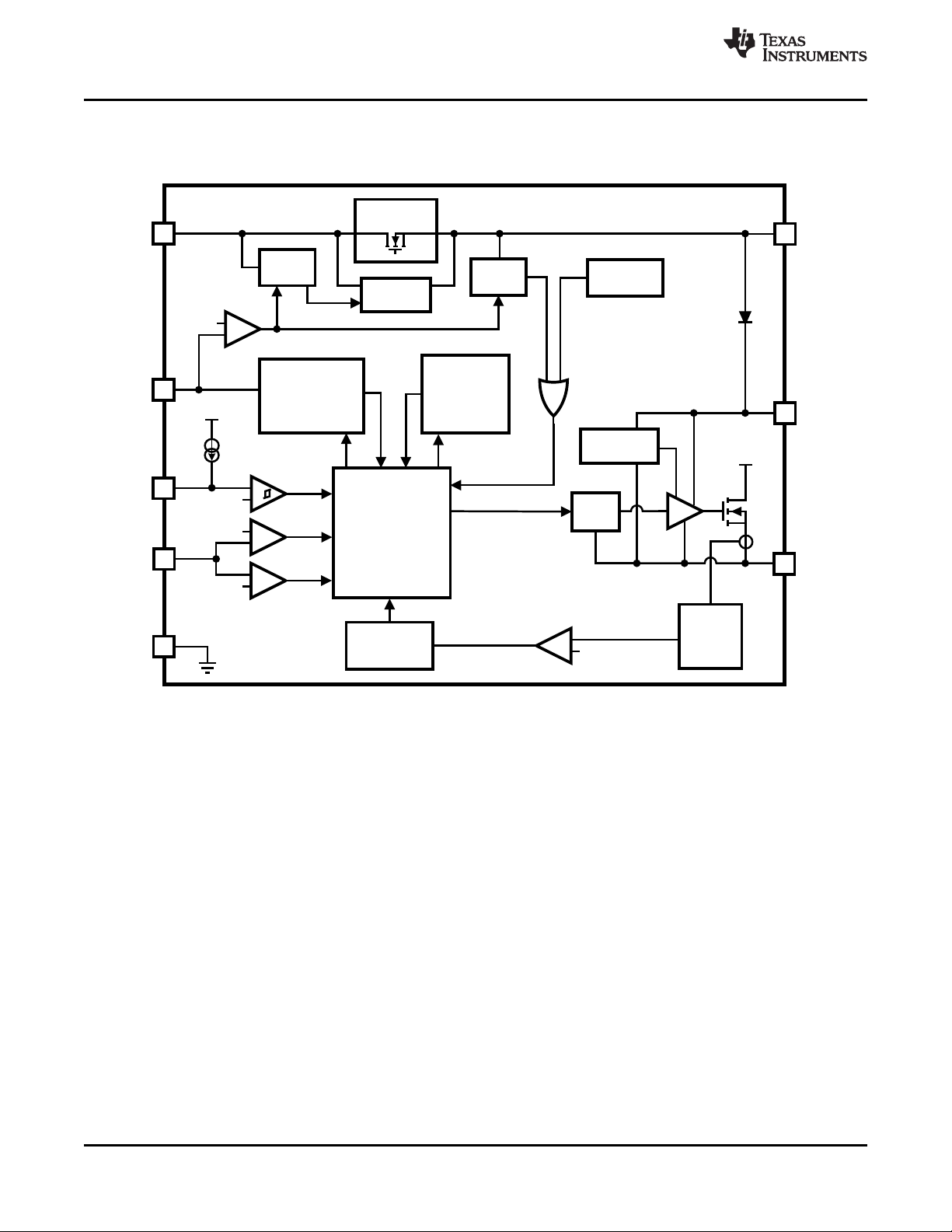

Page 10

BOOT

VCC

VIN

SW

CS

DIM

GND

VIN

SENSE

7V BIAS

REGULATOR

BYPASS

SWITCH

VCC

UVLO

THERMAL

SHUTDOWN

ON TIMER

R

ON

Complete

Start

+

-

300 ns MIN

OFF TIMER

Complete

Start

LOGIC

+

-

+

-

+

-

CURRENT

LIMIT OFF

TIMER

BUCK

SWITCH

CURRENT

SENSE

LEVEL

SHIFT

GATE DRIVE

UVLO

VIN

+

-

1.5A

0.7V

0.2V

0.3V

1.5V

5V

75 PA

SD

LM3404, LM3404HV

SNVS465F –OCTOBER 2006–REVISED MAY 2013

BLOCK DIAGRAM

www.ti.com

10 Submit Documentation Feedback Copyright © 2006–2013, Texas Instruments Incorporated

Product Folder Links: LM3404 LM3404HV

Page 11

f

SW

=

V

O

1.34 x 10

-10

x R

ON

VO = n x VF + 200 mV

LM3404/04HV

CS

R

SNS

One-shot

CS

Comparator

V

O

V

F

I

F

LED 1

LED n

+

-

-

+

I

F

V

SNS

V

REF

t

ON

= 1.34 x 10

-10

x

R

ON

V

LM3404, LM3404HV

www.ti.com

SNVS465F –OCTOBER 2006–REVISED MAY 2013

APPLICATION INFORMATION

THEORY OF OPERATION

The LM3404 and LM3404HV are buck regulators with a wide input voltage range, low voltage reference, and a

fast output enable/disable function. These features combine to make them ideal for use as a constant current

source for LEDs with forward currents as high as 1.2A. The controlled on-time (COT) architecture is a

combination of hysteretic mode control and a one-shot on-timer that varies inversely with input voltage.

Hysteretic operation eliminates the need for small-signal control loop compensation. When the converter runs in

continuous conduction mode (CCM) the controlled on-time maintains a constant switching frequency over the

range of input voltage. Fast transient response, PWM dimming, a low power shutdown mode, and simple output

overvoltage protection round out the functions of the LM3404/04HV.

CONTROLLED ON-TIME OVERVIEW

Figure 19 shows the feedback system used to control the current through an array of LEDs. A voltage signal,

V

, is created as the LED current flows through the current setting resistor, R

SNS

to the CS pin, where it is compared against a 200 mV reference, V

MOSFET when V

falls below V

SNS

. The power MOSFET conducts for a controlled on-time, tON, set by an

REF

. The on-comparator turns on the power

REF

external resistor, RON, and by the input voltage, VIN. On-time is governed by the following equation:

At the conclusion of tONthe power MOSFET turns off for a minimum off-time, t

complete the CS comparator compares V

SNS

and V

again, waiting to begin the next cycle.

REF

, to ground. V

SNS

, of 300 ns. Once t

OFF-MIN

is fed back

SNS

OFF-MIN

(1)

is

The LM3404/04HV regulators should be operated in continuous conduction mode (CCM), where inductor current

stays positive throughout the switching cycle. During steady-state CCM operation, the converter maintains a

constant switching frequency that can be selected using the following equation:

Copyright © 2006–2013, Texas Instruments Incorporated Submit Documentation Feedback 11

Figure 19. Comparator and One-Shot

• VF= forward voltage of each LED

• n = number of LEDs in series (2)

Product Folder Links: LM3404 LM3404HV

Page 12

T

SW

300 ns

V

O(MIN)

= VIN x

T

SW

TSW - 300 ns

V

O(MAX)

= VIN x

TSW = 1/f

SW

n

MAX

=

V

F(MAX)

V

O(max)

- 200 mV

D

MAX

=

t

ON

t

ON

+ t

OFF-MIN

V

O(max)

= D

MAX

x V

IN

I

L-MIN

=

0.2

R

SNS

L

-

VO x t

SNS

LM3404, LM3404HV

SNVS465F –OCTOBER 2006–REVISED MAY 2013

www.ti.com

AVERAGE LED CURRENT ACCURACY

The COT architecture regulates the valley of ΔV

current (which is also the average inductor current) the valley inductor current is calculated using the following

expression:

In this equation t

average inductor/LED current is equal to I

IF= IL= I

L-MIN

represents the propagation delay of the CS comparator, and is approximately 220 ns. The

SNS

+ ΔiL/ 2 (4)

plus one-half of the inductor current ripple, ΔiL:

L-MIN

Detailed information for the calculation of ΔiLis given in the Design Considerations section.

, the AC portion of V

SNS

. To determine the average LED

SNS

(3)

MAXIMUM OUTPUT VOLTAGE

The 300 ns minimum off-time limits the maximum duty cycle of the converter, D

output voltage, V

The maximum number of LEDs, n

maximum forward voltage of the LEDs used, V

, determined by the following equations:

O(MAX)

, that can be placed in a single series string is governed by V

MAX

F(MAX)

, using the expression:

, and in turn the maximum

MAX

O(MAX)

(5)

and the

(6)

At low switching frequency the maximum duty cycle and output voltage are higher, allowing the LM3404/04HV to

regulate output voltages that are nearly equal to input voltage. The following equation relates switching frequency

to maximum output voltage, and is also shown graphically in the Typical Performance Characteristics section:

(7)

MINIMUM OUTPUT VOLTAGE

The minimum recommended on-time for the LM3404/04HV is 300 ns. This lower limit for tONdetermines the

minimum duty cycle and output voltage that can be regulated based on input voltage and switching frequency.

The relationship is determined by the following equation, shown on the same graphs as maximum output voltage

in the Typical Performance Characteristics section:

(8)

HIGH VOLTAGE BIAS REGULATOR

The LM3404/04HV contains an internal linear regulator with a 7V output, connected between the VIN and the

VCC pins. The VCC pin should be bypassed to the GND pin with a 0.1 µF ceramic capacitor connected as close

as possible to the pins of the IC. VCC tracks VIN until VIN reaches 8.8V (typical) and then regulates at 7V as

VIN increases. Operation begins when VCC crosses 5.25V.

12 Submit Documentation Feedback Copyright © 2006–2013, Texas Instruments Incorporated

Product Folder Links: LM3404 LM3404HV

Page 13

LM3404, LM3404HV

www.ti.com

SNVS465F –OCTOBER 2006–REVISED MAY 2013

INTERNAL MOSFET AND DRIVER

The LM3404/04HV features an internal power MOSFET as well as a floating driver connected from the SW pin to

the BOOT pin. Both rise time and fall time are 20 ns each (typical) and the approximate gate charge is 6 nC. The

high-side rail for the driver circuitry uses a bootstrap circuit consisting of an internal high-voltage diode and an

external 10 nF capacitor, CB. VCCcharges CBthrough the internal diode while the power MOSFET is off. When

the MOSFET turns on, the internal diode reverse biases. This creates a floating supply equal to the VCCvoltage

minus the diode drop to drive the MOSFET when its source voltage is equal to VIN.

FAST SHUTDOWN FOR PWM DIMMING

The DIM pin of the LM3404/04HV is a TTL compatible input for low frequency PWM dimming of the LED. A logic

low (below 0.8V) at DIM will disable the internal MOSFET and shut off the current flow to the LED array. While

the DIM pin is in a logic low state the support circuitry (driver, bandgap, VCC) remains active in order to minimize

the time needed to turn the LED array back on when the DIM pin sees a logic high (above 2.2V). A 75 µA

(typical) pull-up current ensures that the LM3404/04HV is on when DIM pin is open circuited, eliminating the

need for a pull-up resistor. Dimming frequency, f

, and duty cycle, D

DIM

, are limited by the LED current rise time

DIM

and fall time and the delay from activation of the DIM pin to the response of the internal power MOSFET. In

general, f

should be at least one order of magnitude lower than the steady state switching frequency in order

DIM

to prevent aliasing.

PEAK CURRENT LIMIT

The current limit comparator of the LM3404/04HV will engage whenever the power MOSFET current (equal to

the inductor current while the MOSFET is on) exceeds 1.5A (typical). The power MOSFET is disabled for a cooldown time that is approximately 75x the steady-state on-time. At the conclusion of this cool-down time the

system re-starts. If the current limit condition persists the cycle of cool-down time and restarting will continue,

creating a low-power hiccup mode, minimizing thermal stress on the LM3404/04HV and the external circuit

components.

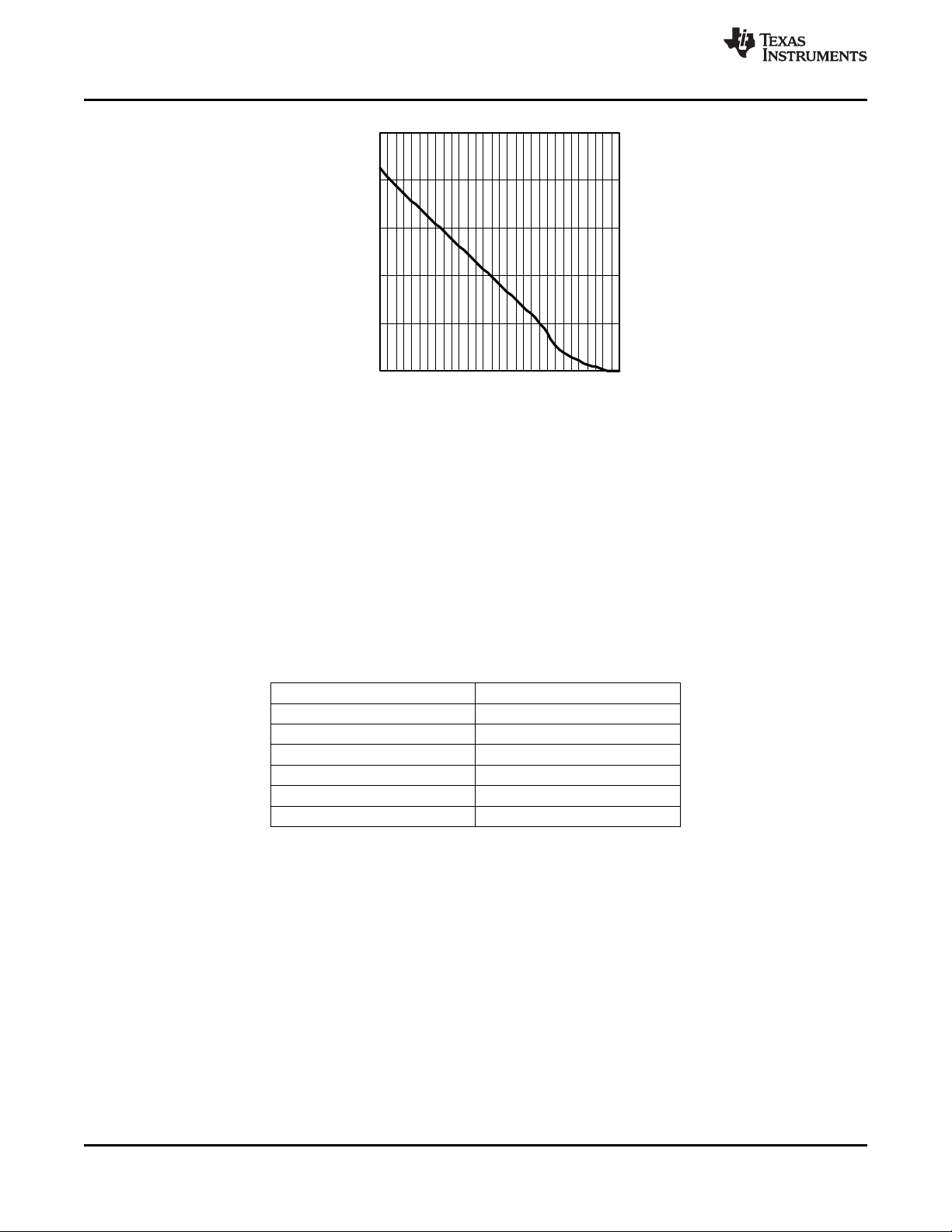

OVER-VOLTAGE/OVER-CURRENT COMPARATOR

The CS pin includes an output over-voltage/over-current comparator that will disable the power MOSFET

whenever V

overshoot is limited to 300 mV / R

The OVP/OCP comparator can also be used to prevent the output voltage from rising to V

an output open-circuit. This is the most common failure mode for LEDs, due to breaking of the bond wires. In a

current regulator an output open circuit causes V

shows a method using a zener diode, Z1, and zener limiting resistor, RZ, to limit output voltage to the reverse

breakdown voltage of Z1 plus 200 mV. The zener diode reverse breakdown voltage, VZ, must be greater than the

maximum combined VFof all LEDs in the array. The maximum recommended value for RZis 1 kΩ.

As discussed in the Maximum Output Voltage section, there is a limit to how high VOcan rise during an output

open-circuit that is always less than VIN. If no output capacitor is used, the output stage of the LM3404/04HV is

capable of withstanding V

and can go above VINor below 0V. A small (typically 10 nF) capacitor across the LED array dampens this

oscillation. For circuits that use an output capacitor, the system can still withstand V

COis rated to handle VIN. The high current paths are blocked in output open-circuit and the risk of thermal stress

is minimal, hence the user may opt to allow the output voltage to rise in the case of an open-circuit LED failure.

exceeds 300 mV. This threshold provides a hard limit for the output current. Output current

SNS

O(MAX)

by this comparator during transients.

SNS

in the event of

O(MAX)

to fall to zero, commanding maximum duty cycle. Figure 20

SNS

indefinitely, however the voltage at the output end of the inductor will oscillate

indefinitely as long as

O(MAX)

Copyright © 2006–2013, Texas Instruments Incorporated Submit Documentation Feedback 13

Product Folder Links: LM3404 LM3404HV

Page 14

ON/OFF

Q1

2N7000 or

equivalent

GND

DIM

BOOT SW

CS

RON

LM3404/04HV

VIN

D1

L1

C

B

R

SNS

C

F

R

ON

C

IN

V

IN

I

F

VCC

GND

DIM

BOOT SW

CS

RON

LM3404/04HV

VIN

D1

L1

C

B

R

SNS

C

F

R

ON

C

IN

V

IN

VCC

R

Z

Z1

LM3404, LM3404HV

SNVS465F –OCTOBER 2006–REVISED MAY 2013

www.ti.com

Figure 20. Output Open Circuit Protection

LOW POWER SHUTDOWN

The LM3404/04HV can be placed into a low power state (I

level MOSFET as shown in Figure 21. Low power MOSFETs like the 2N7000, 2N3904, or equivalent are

recommended devices for putting the LM3404/04HV into low power shutdown. Logic gates can also be used to

shut down the LM3404/04HV as long as the logic low voltage is below the over temperature minimum threshold

of 0.3V. Noise filter circuitry on the RON pin can cause a few pulses with longer on-times than normal after RON

is grounded or released. In these cases the OVP/OCP comparator will ensure that the peak inductor or LED

current does not exceed 300 mV / R

SNS

.

= 90 µA) by grounding the RON pin with a signal-

IN-SD

Figure 21. Low Power Shutdown

THERMAL SHUTDOWN

Internal thermal shutdown circuitry is provided to protect the IC in the event that the maximum junction

temperature is exceeded. The threshold for thermal shutdown is 165°C with a 25°C hysteresis (both values

typical). During thermal shutdown the MOSFET and driver are disabled.

14 Submit Documentation Feedback Copyright © 2006–2013, Texas Instruments Incorporated

Product Folder Links: LM3404 LM3404HV

Page 15

L

VIN - V

O

'iL = 'iF =

t

ON

LM3404, LM3404HV

www.ti.com

SNVS465F –OCTOBER 2006–REVISED MAY 2013

DESIGN CONSIDERATIONS

SWITCHING FREQUENCY

Switching frequency is selected based on the trade-offs between efficiency (better at low frequency), solution

size/cost (smaller at high frequency), and the range of output voltage that can be regulated (wider at lower

frequency.) Many applications place limits on switching frequency due to EMI sensitivity. The on-time of the

LM3404/04HV can be programmed for switching frequencies ranging from the 10’s of kHz to over 1 MHz. The

maximum switching frequency is limited only by the minimum on-time and minimum off-time requirements.

LED RIPPLE CURRENT

Selection of the ripple current, ΔiF, through the LED array is analogous to the selection of output ripple voltage in

a standard voltage regulator. Where the output ripple in a voltage regulator is commonly ±1% to ±5% of the DC

output voltage, LED manufacturers generally recommend values for ΔiFranging from ±5% to ±20% of IF. Higher

LED ripple current allows the use of smaller inductors, smaller output capacitors, or no output capacitors at all.

The advantages of higher ripple current are reduction in the solution size and cost. Lower ripple current requires

more output inductance, higher switching frequency, or additional output capacitance. The advantages of lower

ripple current are a reduction in heating in the LED itself and greater tolerance in the average LED current before

the current limit of the LED or the driving circuitry is reached.

BUCK CONVERTERS WITHOUT OUTPUT CAPACITORS

The buck converter is unique among non-isolated topologies because of the direct connection of the inductor to

the load during the entire switching cycle. By definition an inductor will control the rate of change of current that

flows through it, and this control over current ripple forms the basis for component selection in both voltage

regulators and current regulators. A current regulator such as the LED driver for which the LM3404/04HV was

designed focuses on the control of the current through the load, not the voltage across it. A constant current

regulator is free of load current transients, and has no need of output capacitance to supply the load and

maintain output voltage. Referring to the Typical Application circuit on the front page of this datasheet, the

inductor and LED can form a single series chain, sharing the same current. When no output capacitor is used,

the same equations that govern inductor ripple current, ΔiL, also apply to the LED ripple current, ΔiF. For a

controlled on-time converter such as LM3404/04HV the ripple current is described by the following expression:

A minimum ripple voltage of 25 mV is recommended at the CS pin to provide good signal to noise ratio (SNR).

The CS pin ripple voltage, Δv

BUCK CONVERTERS WITH OUTPUT CAPACITORS

A capacitor placed in parallel with the LED or array of LEDs can be used to reduce the LED current ripple while

keeping the same average current through both the inductor and the LED array. This technique is demonstrated

in Design Examples 1 and 2. With this topology the output inductance can be lowered, making the magnetics

smaller and less expensive. Alternatively, the circuit could be run at lower frequency but keep the same inductor

value, improving the efficiency and expanding the range of output voltage that can be regulated. Both the peak

current limit and the OVP/OCP comparator still monitor peak inductor current, placing a limit on how large Δi

can be even if ΔiFis made very small. A parallel output capacitor is also useful in applications where the inductor

or input voltage tolerance is poor. Adding a capacitor that reduces ΔiFto well below the target provides

headroom for changes in inductance or VINthat might otherwise push the peak LED ripple current too high.

Figure 22 shows the equivalent impedances presented to the inductor current ripple when an output capacitor,

CO, and its equivalent series resistance (ESR) are placed in parallel with the LED array. The entire inductor

ripple current flows through R

comparator.

Copyright © 2006–2013, Texas Instruments Incorporated Submit Documentation Feedback 15

Δv

SNS

= ΔiFx R

SNS

, is described by the following:

SNS

to provide the required 25 mV of ripple voltage for proper operation of the CS

SNS

Product Folder Links: LM3404 LM3404HV

(9)

(10)

L

Page 16

C

IN (MIN)

=

'V

IN (MAX)

IF x t

ON

'iF =

Z

C

= ESR +

'i

L

r

D

1 +

Z

C

1

2Sx f

SW

x C

O

'i

L

ESR

r

D

R

SNS

'i

C

'

i

F

'i

L

C

O

LM3404, LM3404HV

SNVS465F –OCTOBER 2006–REVISED MAY 2013

www.ti.com

Figure 22. LED and CORipple Current

To calculate the respective ripple currents the LED array is represented as a dynamic resistance, rD. LED

dynamic resistance is not always specified on the manufacturer’s datasheet, but it can be calculated as the

inverse slope of the LED’s VFvs. IFcurve. Note that dividing VFby IFwill give an incorrect value that is 5x to 10x

too high. Total dynamic resistance for a string of n LEDs connected in series can be calculated as the rDof one

device multiplied by n. Inductor ripple current is still calculated with the expression from Buck Regulators without

Output Capacitors. The following equations can then be used to estimate ΔiFwhen using a parallel capacitor:

(11)

The calculation for ZCassumes that the shape of the inductor ripple current is approximately sinusoidal.

Small values of COthat do not significantly reduce ΔiFcan also be used to control EMI generated by the

switching action of the LM3404/04HV. EMI reduction becomes more important as the length of the connections

between the LED and the rest of the circuit increase.

INPUT CAPACITORS

Input capacitors at the VIN pin of the LM3404/04HV are selected using requirements for minimum capacitance

and rms ripple current. The input capacitors supply pulses of current approximately equal to IFwhile the power

MOSFET is on, and are charged up by the input voltage while the power MOSFET is off. Switching converters

such as the LM3404/04HV have a negative input impedance due to the decrease in input current as input

voltage increases. This inverse proportionality of input current to input voltage can cause oscillations (sometimes

called ‘power supply interaction’) if the magnitude of the negative input impedance is greater the the input filter

impedance. Minimum capacitance can be selected by comparing the input impedance to the converter’s negative

resistance; however this requires accurate calculation of the input voltage source inductance and resistance,

quantities which can be difficult to determine. An alternative method to select the minimum input capacitance,

C

the change in voltage across CINduring the converter on-time, when CINsupplies the load current. C

be selected with the following:

16 Submit Documentation Feedback Copyright © 2006–2013, Texas Instruments Incorporated

, is to select the maximum input voltage ripple which can be tolerated. This value, Δv

IN(MIN)

Product Folder Links: LM3404 LM3404HV

IN(MAX)

, is equal to

can

IN(MIN)

(12)

Page 17

I

IN(rms)

= IF x

D(1 - D)

LM3404, LM3404HV

www.ti.com

SNVS465F –OCTOBER 2006–REVISED MAY 2013

A good starting point for selection of CINis to use an input voltage ripple of 5% to 10% of VIN. A minimum input

capacitance of 2x the C

value is recommended for all LM3404/04HV circuits. To determine the rms current

IN(MIN)

rating, the following formula can be used:

(13)

Ceramic capacitors are the best choice for the input to the LM3404/04HV due to their high ripple current rating,

low ESR, low cost, and small size compared to other types. When selecting a ceramic capacitor, special

attention must be paid to the operating conditions of the application. Ceramic capacitors can lose one-half or

more of their capacitance at their rated DC voltage bias and also lose capacitance with extremes in temperature.

A DC voltage rating equal to twice the expected maximum input voltage is recommended. In addition, the

minimum quality dielectric which is suitable for switching power supply inputs is X5R, while X7R or better is

preferred.

RECIRCULATING DIODE

The LM3404/04HV is a non-synchronous buck regulator that requires a recirculating diode D1 (see the Typical

Application circuit) to carrying the inductor current during the MOSFET off-time. The most efficient choice for D1

is a Schottky diode due to low forward drop and near-zero reverse recovery time. D1 must be rated to handle the

maximum input voltage plus any switching node ringing when the MOSFET is on. In practice all switching

converters have some ringing at the switching node due to the diode parasitic capacitance and the lead

inductance. D1 must also be rated to handle the average current, ID, calculated as:

ID= (1 – D) x I

F

This calculation should be done at the maximum expected input voltage. The overall converter efficiency

becomes more dependent on the selection of D1 at low duty cycles, where the recirculating diode carries the

load current for an increasing percentage of the time. This power dissipation can be calculating by checking the

typical diode forward voltage, VD, from the I-V curve on the product datasheet and then multiplying it by ID. Diode

datasheets will also provide a typical junction-to-ambient thermal resistance, θJA, which can be used to estimate

the operating die temperature of the device. Multiplying the power dissipation (PD= IDx VD) by θJAgives the

temperature rise. The diode case size can then be selected to maintain the Schottky diode temperature below

the operational maximum.

(14)

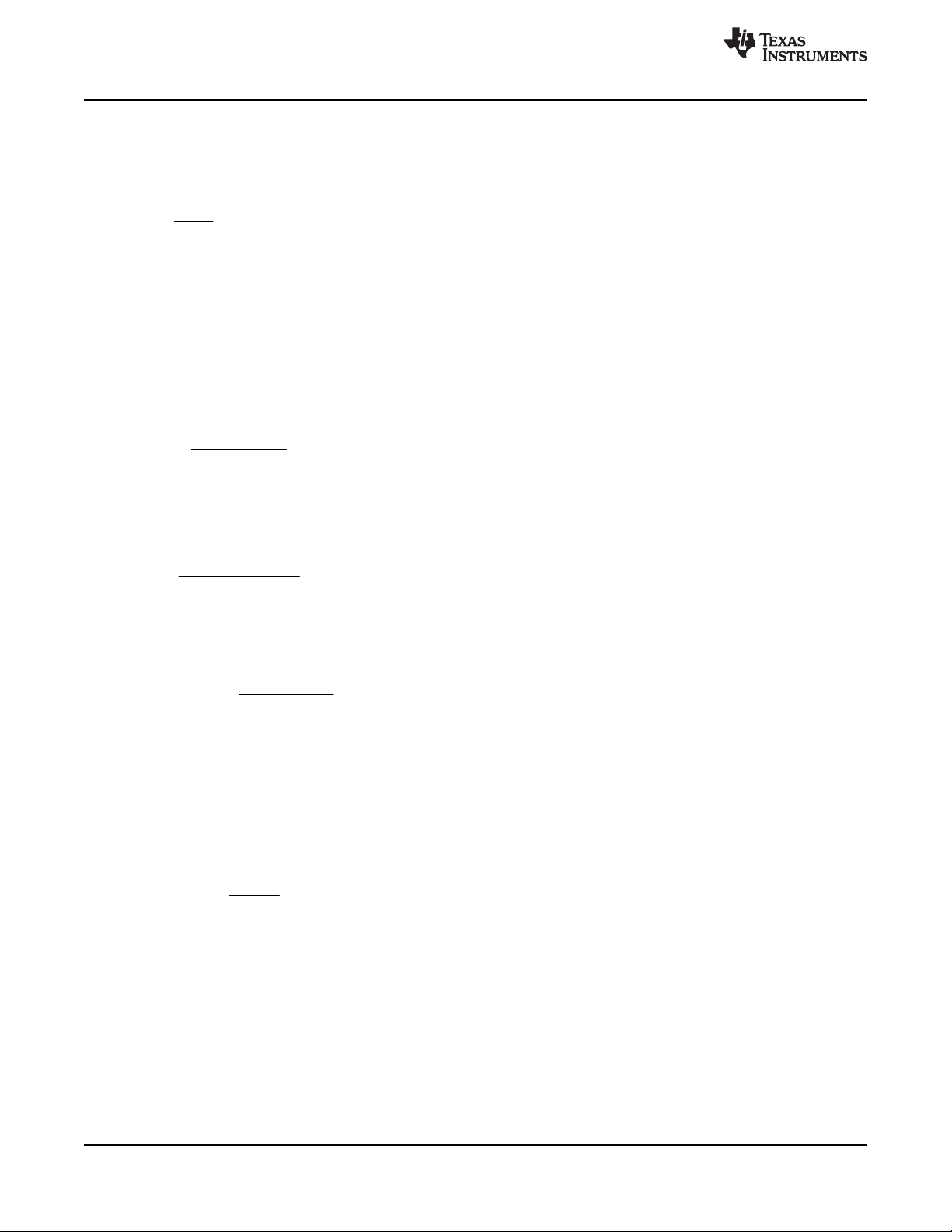

LED CURRENT DURING DIM MODE

The LM3402 contains high speed MOSFET gate drive circuitry that switches the main internal power MOSFET

between “on” and “off” states. This circuitry uses current derived from the VCC regulator to charge the MOSFET

during turn-on, then dumps current from the MOSFET gate to the source (the SW pin) during turn-off. As shown

in the block diagram, the MOSFET drive circuitry contains a gate drive under-voltage lockout (UVLO) circuit that

ensures the MOSFET remains off when there is inadequate VCC voltage for proper operation of the driver. This

watchdog circuitry is always running including during DIM and shutdown modes, and supplies a small amount of

current from VCC to SW. Because the SW pin is connected directly to the LEDs through the buck inductor, this

current returns to ground through the LEDs. The amount of current sourced is a function of the SW voltage, as

shown in Figure 23.

Copyright © 2006–2013, Texas Instruments Incorporated Submit Documentation Feedback 17

Product Folder Links: LM3404 LM3404HV

Page 18

0

5

10

15

20

25

0 1 2 3 4 5 6

SW VOLTAGE (V)

SW CURRENT (PA)

LM3404, LM3404HV

SNVS465F –OCTOBER 2006–REVISED MAY 2013

www.ti.com

Figure 23. LED Current From SW Pin

Though most power LEDs are designed to run at several hundred milliamps, some can be seen to glow with a

faint light at extremely low current levels, as low as a couple microamps in some instances. In lab testing, the

forward voltage was found to be approximately 2V for LEDs that exhibited visible light at these low current levels.

For LEDs that did not show light emission at very low current levels, the forward voltage was found to be around

900mV. It is important to remember that the forward voltage is also temperature dependent, decreasing at higher

temperatures. Consequently, with a maximum Vcc voltage of 7.4V, current will be observed in the LEDs if the

total stack voltage is less than about 6V at a forward current of several microamps. No current is observed if the

stack voltage is above 6V, as shown in Figure 23. The need for absolute darkness during DIM mode is also

application dependent. It will not affect regular PWM dimming operation.

The fix for this issue is extremely simple. Place a resistor from the SW pin to ground according to the chart

below.

The luminaire designer should ensure that the suggested resistor is effective in eliminating the off-state light

output. A combination of calculations based on LED manufacturer data and lab measurements over temperature

will ensure the best design.

TRANSIENT PROTECTION CONSIDERATIONS

Considerations need to be made when external sources, loads or connections are made to the switching

converter circuit due to the possibility of Electrostatic Discharge (ESD) or Electric Over Stress (EOS) events

occurring and damaging the integrated circuit (IC) device. All IC device pins contain zener based clamping

structures that are meant to clamp ESD. ESD events are very low energy events, typically less than 5µJ

(microjoules). Any event that transfers more energy than this may damage the ESD structure. Damage is

typically represented as a short from the pin to ground as the extreme localized heat of the ESD / EOS event

causes the aluminum metal on the chip to melt, causing the short. This situation is common to all integrated

circuits and not just unique to the LM340X device.

18 Submit Documentation Feedback Copyright © 2006–2013, Texas Instruments Incorporated

Number of LEDs Resistor Value (kΩ)

1 20

2 50

3 90

4 150

5 200

>5 300

Product Folder Links: LM3404 LM3404HV

Page 19

SW

LM3404

GND

CS

8V

V

TRANSIENT

~ 0.675

Module

Connector

Module

Connector

LM3404, LM3404HV

www.ti.com

SNVS465F –OCTOBER 2006–REVISED MAY 2013

CS PIN PROTECTION

When hot swapping in a load (e.g. test points, load boards, LED stack), any residual charge on the load will be

immediately transferred through the output capacitor to the CS pin, which is then damaged as shown in

Figure 24 below. The EOS event due to the residual charge from the load is represented as V

TRANSIENT

.

From measurements, we know that the 8V ESD structure on the CS pin can typically withstand 25mA of direct

current (DC). Adding a 1kΩ resistor in series with the CS pin, shown in Figure 25, results in the majority of the

transient energy to pass through the discrete sense resistor rather than the device. The series resistor limits the

peak current that can flow during a transient event, thus protecting the CS pin. With the 1kΩ resistor shown, a

33V, 49A transient on the LED return connector terminal could be absorbed as calculated by:

V = 25mA * 1kΩ + 8V = 33V (15)

I = 33V / 0.67Ω = 49A (16)

This is an extremely high energy event, so the protection measures previously described should be adequate to

solve this issue.

Figure 24. CS Pin, Transient Path

Copyright © 2006–2013, Texas Instruments Incorporated Submit Documentation Feedback 19

Product Folder Links: LM3404 LM3404HV

Page 20

SW

LM3404

GND

CS

8V

V

TRANSIENT

~ 0.675

Module

Connector

Module

Connector

1 k5

LM3404, LM3404HV

SNVS465F –OCTOBER 2006–REVISED MAY 2013

www.ti.com

Figure 25. CS Pin, Transient Path with Protection

Adding a resistor in series with the CS pin causes the observed output LED current to shift very slightly. The

reason for this is twofold: (1) the CS pin has about 20pF of inherent capacitance inside it which causes a slight

delay (20ns for a 1kΩ series resistor), and (2) the comparator that is watching the voltage at the CS pin uses a

pnp bipolar transistor at its input. The base current of this pnp transistor is approximately 100nA which will cause

a 0.1mV change in the 200mV threshold. These are both very minor changes and are well understood. The shift

in current can either be neglected or taken into consideration by changing the current sense resistance slightly.

CS PIN PROTECTION WITH OVP

When designing output overvoltage protection into the switching converter circuit using a zener diode, transient

protection on the CS pin requires additional consideration. As shown in Figure 26, adding a zener diode from the

output to the CS pin (with the series resistor) for output overvoltage protection will now again allow the transient

energy to be passed

Adding an additional series resistor to the CS pin as shown in Figure 27 will result in the majority of the transient

energy to pass through the sense resistor thereby protecting the LM340X device.

20 Submit Documentation Feedback Copyright © 2006–2013, Texas Instruments Incorporated

Product Folder Links: LM3404 LM3404HV

Page 21

SW

LM3404

GND

CS

8V

V

TRANSIENT

~ 0.675

Module

Connector

Module

Connector

50051 k5

SW

LM3404

GND

CS

8V

V

TRANSIENT

~ 0.675

Module

Connector

Module

Connector

1 k5

LM3404, LM3404HV

www.ti.com

SNVS465F –OCTOBER 2006–REVISED MAY 2013

Figure 26. CS Pin with OVP, Transient Path

Figure 27. CS Pin with OVP, Transient Path with Protection

Copyright © 2006–2013, Texas Instruments Incorporated Submit Documentation Feedback 21

Product Folder Links: LM3404 LM3404HV

Page 22

VIN

LM3404

GND

80V

V

IN

Module

Connector

Module

Connector

TVS

C

IN

Board Trace

Inductance

LM3404, LM3404HV

SNVS465F –OCTOBER 2006–REVISED MAY 2013

www.ti.com

VIN PIN PROTECTION

The VIN pin also has an ESD structure from the pin to GND with a breakdown voltage of approximately 80V. Any

transient that exceeds this voltage may damage the device. Although transient absorption is usually present at

the front end of a switching converter circuit, damage to the VIN pin can still occur.

When VINis hot swapped in, the current that rushes in to charge CINup to the VINvalue also charges (energizes)

the circuit board trace inductance as shown in Figure 28. The excited trace inductance then resonates with the

input capacitance (similar to an under-damped LC tank circuit) and causes voltages at the VIN pin to rise well in

excess of both VINand the voltage at the module input connector as clamped by the input TVS. If the resonating

voltage at the VIN pin exceeds the 80V breakdown voltage of the ESD structure, the ESD structure will activate

and then “snap-back” to a lower voltage due to its inherent design. If this lower snap-back voltage is less than

the applied nominal VINvoltage, then significant current will flow through the ESD structure resulting in the IC

being damaged.

An additional TVS or small zener diode should be placed as close as possible to the VIN pins of each IC on the

board, in parallel with the input capacitor as shown in Figure 29. A minor amount of series resistance in the input

line would also help, but would lower overall conversion efficiency. For this reason, NTC resistors are often used

as inrush limiters instead.

22 Submit Documentation Feedback Copyright © 2006–2013, Texas Instruments Incorporated

Figure 28. VIN Pin with Typical Input Protection

Product Folder Links: LM3404 LM3404HV

Page 23

VIN

LM3404

GND

80V

V

IN

Module

Connector

Module

Connector

TVS

C

IN

Board Trace

Inductance

TVS or

smaller

zener diode

LM3404, LM3404HV

www.ti.com

SNVS465F –OCTOBER 2006–REVISED MAY 2013

Figure 29. VIN Pin with Additional Input Protection

GENERAL COMMENTS REGARDING OTHER PINS

Any pin that goes “off-board” through a connector should have series resistance of at least 1kΩ to 10kΩ in series

with it to protect it from ESD or other transients. These series resistors limit the peak current that can flow (or

cause a voltage drop) during a transient event, thus protecting the pin and the device. Pins that are not used

should not be left floating. They should instead be tied to GND or to an appropriate voltage through resistance.

Design Example 1: LM3404

The first example circuit will guide the user through component selection for an architectural accent lighting

application. A regulated DC voltage input of 24V ±10% will power a 5.4W "warm white" LED module that consists

of four LEDs in a 2 x 2 series-parallel configuration. The module will be treated as a two-terminal element and

driven with a forward current of 700 mA ±5%. The typical forward voltage of the LED module in thermal steady

state is 6.9V, hence the average output voltage will be 7.1V. The objective of this application is to place the

complete current regulator and LED module in a compact space formerly occupied by a halogen light source.

(The LED will be on a separate metal-core PCB and heatsink.) Switching frequency will be 400 kHz to keep

switching loss low, as the confined space with no air-flow requires a maximum temperature rise of 50°C in each

circuit component. A small solution size is also important, as the regulator must fit on a circular PCB with a 1.5"

diameter. A complete bill of materials can be found in Table 1 at the end of this datasheet.

Copyright © 2006–2013, Texas Instruments Incorporated Submit Documentation Feedback 23

Product Folder Links: LM3404 LM3404HV

Page 24

L

MIN

=

VIN - V

O

'i

L

x t

ON

R

ON

=

V

O

1.34 x 10

-10

x f

SW

GND

DIM

BOOT SW

CS

RON

LM3404

VIN

D1

L1

C

B

R

SNS

C

F

R

ON

C

IN

VIN = 24V

IF = 700 mA

VCC

C

O

LED1

LM3404, LM3404HV

SNVS465F –OCTOBER 2006–REVISED MAY 2013

www.ti.com

Figure 30. Schematic for Design Example 1

RONand t

ON

A moderate switching frequency is needed in this application to balance the requirements of magnetics size and

efficiency. RONis selected from the equation for switching frequency as follows:

RON= 7.1 / (1.34 x 10

-10

x 4 x 105) = 132.5 kΩ (18)

The closest 1% tolerance resistor is 133 kΩ. The switching frequency and on-time of the circuit can then be

found using the equations relating RONand tONto fSW:

fSW= 7.1 / (1.33 x 105x 1.34 x 10

tON= (1.34 x 10

-10

x 1.33 x 105) / 24 = 743 ns (20)

-10

) = 398 kHz (19)

OUTPUT INDUCTOR

Since an output capacitor will be used to filter some of the AC ripple current, the inductor ripple current can be

set higher than the LED ripple current. A value of 40%

ΔiL= 0.4 x 0.7 = 0.28A (21)

is typical in many buck converters:

P-P

With the target ripple current determined the inductance can be chosen:

L

= [(24 – 7.1) x 7.43 x 10-7] / (0.28) = 44.8 µH (23)

MIN

The closest standard inductor value is 47 µH. The average current rating should be greater than 700 mA to

prevent overheating in the inductor. Separation between the LM3404 drivers and the LED arrays means that heat

from the inductor will not threaten the lifetime of the LEDs, but an overheated inductor could still cause the

LM3404 to enter thermal shutdown.

The inductance of the standard part chosen is ±20%. With this tolerance the typical, minimum, and maximum

inductor current ripples can be calculated:

Δi

= [(24 - 7.1) x 7.43 x 10-7] / 47 x 10-6= 266 mA

L(TYP)

Δi

= [(24 - 7.1) x 7.43 x 10-7] / 56 x 10-6= 223 mA

L(MIN)

Δi

= [(24 - 7.1) x 7.43 x 10-7] / 38 x 10-6= 330 mA

L(MAX)

P-P

P-P

P-P

(17)

(22)

(24)

(25)

(26)

24 Submit Documentation Feedback Copyright © 2006–2013, Texas Instruments Incorporated

Product Folder Links: LM3404 LM3404HV

Page 25

R

SNS

=

2

VIN - V

O

0.2 x L

IF x L + VO x t

SNS

-

x t

ON

'i

F

x r

D

'iL - 'i

F

ZC =

LM3404, LM3404HV

www.ti.com

SNVS465F –OCTOBER 2006–REVISED MAY 2013

The peak LED/inductor current is then estimated:

I

= IL+ 0.5 x Δi

L(PEAK)

I

= 0.7 + 0.5 x 0.330 = 866 mA (28)

L(PEAK)

L(MAX)

(27)

In the case of a short circuit across the LED array, the LM3404 will continue to deliver rated current through the

short but will reduce the output voltage to equal the CS pin voltage of 200 mV. The inductor ripple current and

peak current in this condition would be equal to:

Δi

L(LED-SHORT)

I

L(PEAK)

= [(24 – 0.2) x 7.43 x 10-7] / 38 x 10-6= 465 mA

P-P

(29)

= 0.7 + 0.5 x 0.465 = 933 mA (30)

In the case of a short at the switch node, the output, or from the CS pin to ground the short circuit current limit

will engage at a typical peak current of 1.5A. In order to prevent inductor saturation during these fault conditions

the inductor’s peak current rating must be above 1.5A. A 47 µH off-the shelf inductor rated to 1.4A (peak) and

1.5A (average) with a DCR of 0.1Ω will be used.

USING AN OUTPUT CAPACITOR

This application does not require high frequency PWM dimming, allowing the use of an output capacitor to

reduce the size and cost of the output inductor. To select the proper output capacitor the equation from Buck

Regulators with Output Capacitors is re-arranged to yield the following:

(31)

The target tolerance for LED ripple current is 100 mA

, and a typical value for rDof 1.8Ω at 700 mA can be read

P-P

from the LED datasheet. The required capacitor impedance to reduce the worst-case inductor ripple current of

333 mA

is therefore:

P-P

ZC= [0.1 / (0.333 - 0.1] x 1.8 = 0.77Ω (32)

A ceramic capacitor will be used and the required capacitance is selected based on the impedance at 400 kHz:

CO= 1/(2 x π x 0.77 x 4 x 105) = 0.51 µF (33)

This calculation assumes that impedance due to the equivalent series resistance (ESR) and equivalent series

inductance (ESL) of COis negligible. The closest 10% tolerance capacitor value is 1.0 µF. The capacitor used

should be rated to 25V or more and have an X7R dielectric. Several manufacturers produce ceramic capacitors

with these specifications in the 0805 case size. A typical value for ESR of 3 mΩ can be read from the curve of

impedance vs. frequency in the product datasheet.

R

SNS

A preliminary value for R

was determined in selecting ΔiL. This value should be re-evaluated based on the

SNS

calculations for ΔiF:

t

= 220 ns, R

SNS

= 0.33Ω (35)

SNS

Sub-1Ω resistors are available in both 1% and 5% tolerance. A 1%, 0.33Ω device is the closest value, and a

0.33W, 1206 size device will handle the power dissipation of 162 mW. With the resistance selected, the average

value of LED current is re-calculated to ensure that current is within the ±5% tolerance requirement. From the

expression for average LED current:

IF= 0.2 / 0.33 - (7.1 x 2.2 x 10-7) / 47 x 10-6+ 0.266 / 2 (36)

= 706 mA, 1% above 700 mA (37)

INPUT CAPACITOR

Following the calculations from the Input Capacitor section, Δv

IN(MAX)

will be 24V x 2%

= 480 mV. The

P-P

minimum required capacitance is:

C

= (0.7 x 7.4 x 10-7) / 0.48 = 1.1 µF (38)

IN(MIN)

Copyright © 2006–2013, Texas Instruments Incorporated Submit Documentation Feedback 25

Product Folder Links: LM3404 LM3404HV

(34)

Page 26

LM3404, LM3404HV

SNVS465F –OCTOBER 2006–REVISED MAY 2013

www.ti.com

To provide additional safety margin the a higher value of 3.3 µF ceramic capacitor rated to 50V with X7R

dielectric in an 1210 case size will be used. From the Design Considerations section, input rms current is:

I

= 0.7 x Sqrt(0.28 x 0.72) = 314 mA (39)

IN-RMS

Ripple current ratings for 1210 size ceramic capacitors are typically higher than 2A, more than enough for this

design.

RECIRCULATING DIODE

The input voltage of 24V ±5% requires Schottky diodes with a reverse voltage rating greater than 30V. The next

highest standard voltage rating is 40V. Selecting a 40V rated diode provides a large safety margin for the ringing

of the switch node and also makes cross-referencing of diodes from different vendors easier.

The next parameters to be determined are the forward current rating and case size. In this example the low duty

cycle (D = 7.1 / 24 = 28%) places a greater thermal stress on D1 than on the internal power MOSFET of the

LM3404. The estimated average diode current is:

ID= 0.706 x 0.72 = 509 mA (40)

A Schottky with a forward current rating of 1A would be adequate, however reducing the power dissipation is

critical in this example. Higher current diodes have lower forward voltages, hence a 2A-rated diode will be used.

To determine the proper case size, the dissipation and temperature rise in D1 can be calculated as shown in the

Design Considerations section. VDfor a case size such as SMB in a 40V, 2A Schottky diode at 700 mA is

approximately 0.3V and the θJAis 75°C/W. Power dissipation and temperature rise can be calculated as:

PD= 0.509 x 0.3 = 153 mW (41)

T

= 0.153 x 75 = 11.5°C (42)

RISE

CBAND C

F

The bootstrap capacitor CBshould always be a 10 nF ceramic capacitor with X7R dielectric. A 25V rating is

appropriate for all application circuits. The linear regulator filter capacitor CFshould always be a 100 nF ceramic

capacitor, also with X7R dielectric and a 25V rating.

EFFICIENCY

To estimate the electrical efficiency of this example the power dissipation in each current carrying element can

be calculated and summed. Electrical efficiency, η, should not be confused with the optical efficacy of the circuit,

which depends upon the LEDs themselves.

Total output power, PO, is calculated as:

PO= IFx VO= 0.706 x 7.1 = 5W (43)

Conduction loss, PC, in the internal MOSFET:

2

PC= (I

x R

F

) x D = (0.7062x 0.8) x 0.28 = 112 mW (44)

DSON

Gate charging and VCC loss, PG, in the gate drive and linear regulator:

PG= (I

+ fSWx QG) x VINPG= (600 x 10-6+ 4 x 105x 6 x 10-9) x 24 = 72 mW (45)

IN-OP

Switching loss, PS, in the internal MOSFET:

PS= 0.5 x VINx IFx (tR+ tF) x fSWPS= 0.5 x 24 x 0.706 x 40 x 10-9x 4 x 105= 136 mW (46)

AC rms current loss, P

P

= I

CIN

2

x ESR = 0.31720.003 = 0.3 mW (negligible) (47)

IN(rms)

, in the input capacitor:

CIN

DCR loss, PL, in the inductor

2

PL= I

x DCR = 0.7062x 0.1 = 50 mW (48)

F

Recirculating diode loss, PD= 153 mW

Current Sense Resistor Loss, P

= 164 mW

SNS

Electrical efficiency, η = PO/ (PO+ Sum of all loss terms) = 5 / (5 + 0.687) = 88%

Temperature Rise in the LM3404 IC is calculated as:

T

= (PC+ PG+ PS) x θJA= (0.112 + 0.072 + 0.136) x 155 = 49.2°C (49)

LM3404

26 Submit Documentation Feedback Copyright © 2006–2013, Texas Instruments Incorporated

Product Folder Links: LM3404 LM3404HV

Page 27

L

MIN

=

VIN - V

O

'i

L

x t

ON

R

ON

=

V

O

1.34 x 10

-10

x f

SW

GND

BOOT SW

CS

RON

LM3404HV

VIN

D1

L1

C

B

R

SNS

C

F

R

ON

C

IN

VIN = 48V ±10%

IF = 0.5A

VCC

C

O

LED1

LED10

LM3404, LM3404HV

www.ti.com

SNVS465F –OCTOBER 2006–REVISED MAY 2013

Design Example 2: LM3404HV

The second example circuit will guide the user through component selection for an outdoor general lighting

application. A regulated DC voltage input of 48V ±10% will power ten series-connected LEDs at 500 mA ±10%

with a ripple current of 50 mA

35V, hence the average output voltage will be 35.2V. A complete bill of materials can be found in Table 2 at the

end of this datasheet.

or less. The typical forward voltage of the LED module in thermal steady state is

P-P

Figure 31. Schematic for Design Example 2

RONand t

ON

A low switching frequency, 225 kHz, is needed in this application, as high efficiency and low power dissipation

take precedence over the solution size. RONis selected from the equation for switching frequency as follows:

RON= 35.2 / (1.34 x 10

-10

x 2.25 x 105) = 1.16 MΩ (51)

The next highest 1% tolerance resistor is 1.18 MΩ. The switching frequency and on-time of the circuit can then

be found using the equations relating RONand tONto fSW:

fSW= 35.2 / (1.18 x 106x 1.34 x 10

tON= (1.34 x 10

-10

x 1.18 x 106) / 48 = 3.3 µs (53)

-10

) = 223 kHz (52)

OUTPUT INDUCTOR

Since an output capacitor will be used to filter some of the AC ripple current, the inductor ripple current can be

set higher than the LED ripple current. A value of 30%

makes a good trade-off between the current ripple and

P-P

the size of the inductor:

ΔiL= 0.3 x 0.5 = 0.15A (54)

With the target ripple current determined the inductance can be chosen:

L

= [(48 – 35.2) x 3.3 x 10-6] / (0.15) = 281 µH (56)

MIN

(50)

(55)

Copyright © 2006–2013, Texas Instruments Incorporated Submit Documentation Feedback 27

Product Folder Links: LM3404 LM3404HV

Page 28

'i

F

x r

D

'iL - 'i

F

ZC =

LM3404, LM3404HV

SNVS465F –OCTOBER 2006–REVISED MAY 2013

www.ti.com

The closest standard inductor value above 281 is 330 µH. The average current rating should be greater than

0.5A to prevent overheating in the inductor. In this example the LM3404HV driver and the LED array share the

same metal-core PCB, meaning that heat from the inductor could threaten the lifetime of the LEDs. For this

reason the average current rating of the inductor used should have a de-rating of about 50%, or 1A.

The inductance of the standard part chosen is ±20%. With this tolerance the typical, minimum, and maximum

inductor current ripples can be calculated:

Δi

= [(48 - 35.2) x 3.3 x 10-6] / 330 x 10-6= 128 mA

L(TYP)

Δi

= [(48 - 35.2) x 3.3 x 10-6] / 396 x 10-6= 107 mA

L(MIN)

Δi

= [(48 - 35.2) x 3.3 x 10-6] / 264 x 10-6= 160 mA

L(MAX)

P-P

P-P

P-P

(57)

(58)

(59)

The peak inductor current is then estimated:

I

= IL+ 0.5 x Δi

L(PEAK)

I

= 0.5 + 0.5 x 0.16 = 0.58A (61)

L(PEAK)

L(MAX)

(60)

In the case of a short circuit across the LED array, the LM3404HV will continue to deliver rated current through

the short but will reduce the output voltage to equal the CS pin voltage of 200 mV. The inductor ripple current

and peak current in this condition would be equal to:

Δi

L(LED-SHORT)

I

L(PEAK)

= [(48 – 0.2) x 3.3 x 10-6] / 264 x 10-6= 0.598A

P-P

(62)

= 0.5 + 0.5 x 0.598 = 0.8A (63)

In the case of a short at the switch node, the output, or from the CS pin to ground the short circuit current limit

will engage at a typical peak current of 1.5A. In order to prevent inductor saturation during these fault conditions

the inductor’s peak current rating must be above 1.5A. A 330 µH off-the shelf inductor rated to 1.9A (peak) and

1.0A (average) with a DCR of 0.56Ω will be used.

USING AN OUTPUT CAPACITOR

This application uses sub-1 kHz frequency PWM dimming, allowing the use of a small output capacitor to reduce

the size and cost of the output inductor. To select the proper output capacitor the equation from Buck Regulators

with Output Capacitors is re-arranged to yield the following:

(64)

The target tolerance for LED ripple current is 50 mA

, and the typical value for rDis 10Ω with ten LEDs in

P-P

series. The required capacitor impedance to reduce the worst-case steady-state inductor ripple current of 160

mA

is therefore:

P-P

ZC= [0.05 / (0.16 - 0.05] x 10 = 4.5Ω (65)

A ceramic capacitor will be used and the required capacitance is selected based on the impedance at 223 kHz:

CO= 1/(2 x π x 4.5 x 2.23 x 105) = 0.16 µF (66)

This calculation assumes that impedance due to the equivalent series resistance (ESR) and equivalent series

inductance (ESL) of COis negligible. The closest 10% tolerance capacitor value is 0.15 µF. The capacitor used

should be rated to 50V or more and have an X7R dielectric. Several manufacturers produce ceramic capacitors

with these specifications in the 0805 case size. ESR values are not typically provided for such low value

capacitors, however is can be assumed to be under 100 mΩ, leaving plenty of margin to meet to LED ripple

current requirement. The low capacitance required allows the use of a 100V rated, 1206-size capacitor. The

rating of 100V ensures that the capacitance will not decrease significantly when the DC output voltage is applied

across the capacitor.

28 Submit Documentation Feedback Copyright © 2006–2013, Texas Instruments Incorporated

Product Folder Links: LM3404 LM3404HV

Page 29

R

SNS

=

2

VIN - V

O

0.2 x L

IF x L + VO x t

SNS

-

x t

ON

LM3404, LM3404HV

www.ti.com

R

SNS

A preliminary value for R

was determined in selecting ΔiL. This value should be re-evaluated based on the

SNS

SNVS465F –OCTOBER 2006–REVISED MAY 2013

calculations for ΔiF:

(67)

t

= 220 ns, R

SNS

= 0.43Ω (68)

SNS

Sub-1Ω resistors are available in both 1% and 5% tolerance. A 1%, 0.43Ω device is the closest value, and a

0.25W, 0805 size device will handle the power dissipation of 110 mW. With the resistance selected, the average

value of LED current is re-calculated to ensure that current is within the ±10% tolerance requirement. From the

expression for average LED current:

IF= 0.2 / 0.33 – (7.1 x 2.2 x 10-7) / 47 x 10-6+ 0.266 / 2 = 505 mA (69)

INPUT CAPACITOR

Following the calculations from the Input Capacitor section, Δv

IN(MAX)

will be 48V x 2%

= 960 mV. The

P-P

minimum required capacitance is:

C

= (0.5 x 3.3 x 10-6) / 0.96 = 1.7 µF (70)

IN(MIN)

To provide additional safety margin a 2.2 µF ceramic capacitor rated to 100V with X7R dielectric in an 1812 case

size will be used. From the Design Considerations section, input rms current is:

I

= 0.5 x Sqrt(0.73 x 0.27) = 222 mA (71)

IN-RMS

Ripple current ratings for 1812 size ceramic capacitors are typically higher than 2A, more than enough for this

design, and the ESR is approximately 3 mΩ.

RECIRCULATING DIODE

The input voltage of 48V requires Schottky diodes with a reverse voltage rating greater than 50V. The next

highest standard voltage rating is 60V. Selecting a 60V rated diode provides a large safety margin for the ringing

of the switch node and also makes cross-referencing of diodes from different vendors easier.

The next parameters to be determined are the forward current rating and case size. In this example the high duty

cycle (D = 35.2 / 48 = 73%) places a greater thermal stress on the internal power MOSFET than on D1. The

estimated average diode current is:

ID= 0.5 x 0.27 = 135 mA (72)

A Schottky with a forward current rating of 0.5A would be adequate, however reducing the power dissipation is

critical in this example. Higher current diodes have lower forward voltages, hence a 1A-rated diode will be used.

To determine the proper case size, the dissipation and temperature rise in D1 can be calculated as shown in the

Design Considerations section. VDfor a case size such as SMA in a 60V, 1A Schottky diode at 0.5A is

approximately 0.35V and the θJAis 75°C/W. Power dissipation and temperature rise can be calculated as:

PD= 0.135 x 0.35 = 47 mW T

CBAND C

F

= 0.047 x 75 = 3.5°C (73)

RISE

The bootstrap capacitor CBshould always be a 10 nF ceramic capacitor with X7R dielectric. A 25V rating is

appropriate for all application circuits. The linear regulator filter capacitor CFshould always be a 100 nF ceramic

capacitor, also with X7R dielectric and a 25V rating.

EFFICIENCY

To estimate the electrical efficiency of this example the power dissipation in each current carrying element can

be calculated and summed. Electrical efficiency, η, should not be confused with the optical efficacy of the circuit,

which depends upon the LEDs themselves.

Total output power, PO, is calculated as:

PO= IFx VO= 0.5 x 35.2 = 17.6W (74)

Copyright © 2006–2013, Texas Instruments Incorporated Submit Documentation Feedback 29

Product Folder Links: LM3404 LM3404HV

Page 30

+

-

LM3404, LM3404HV

SNVS465F –OCTOBER 2006–REVISED MAY 2013

www.ti.com

Conduction loss, PC, in the internal MOSFET:

2

PC= (I

x R

F

) x D = (0.52x 0.8) x 0.73 = 146 mW (75)

DSON

Gate charging and VCC loss, PG, in the gate drive and linear regulator:

PG= (I

+ fSWx QG) x VINPG= (600 x 10-6+ 2.23 x 105x 6 x 10-9) x 48 = 94 mW (76)

IN-OP

Switching loss, PS, in the internal MOSFET:

PS= 0.5 x VINx IFx (tR+ tF) x fSWPS= 0.5 x 48 x 0.5 x 40 x 10-9x 2.23 x 105= 107 mW (77)

AC rms current loss, P

P

= I

CIN

2

x ESR = 0.22220.003 = 0.1 mW (negligible) (78)

IN(rms)

, in the input capacitor:

CIN

DCR loss, PL, in the inductor

2

PL= I

x DCR = 0.52x 0.56 = 140 mW (79)

F

Recirculating diode loss, PD= 47 mW

Current Sense Resistor Loss, P

= 110 mW

SNS

Electrical efficiency, η = PO/ (PO+ Sum of all loss terms) = 17.6 / (17.6 + 0.644) = 96%

Temperature Rise in the LM3404HV IC is calculated as:

T

= (PC+ PG+ PS) x θJA= (0.146 + 0.094 + 0.107) x 155 = 54°C (80)

LM3404

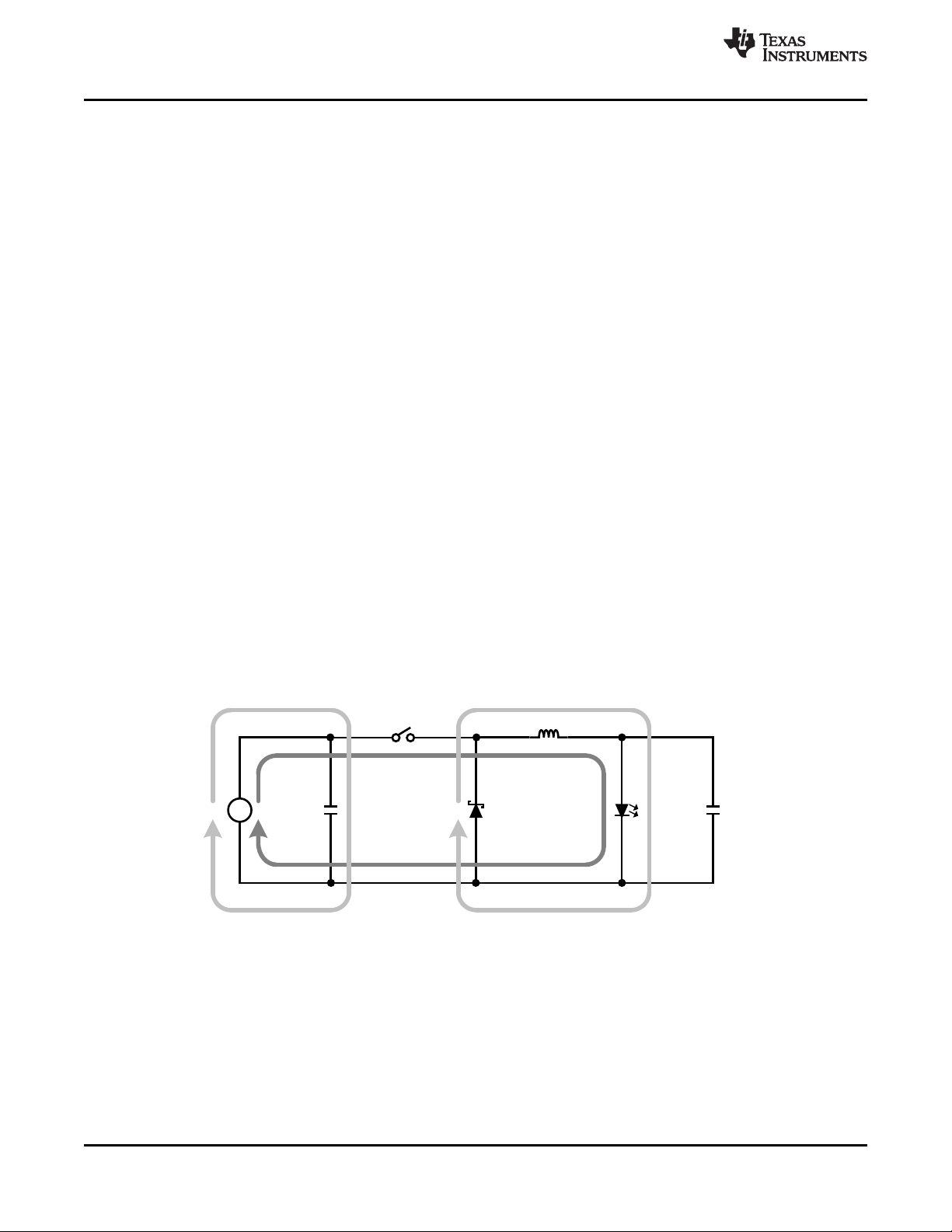

Layout Considerations

The performance of any switching converter depends as much upon the layout of the PCB as the component

selection. The following guidelines will help the user design a circuit with maximum rejection of outside EMI and

minimum generation of unwanted EMI.

COMPACT LAYOUT

Parasitic inductance can be reduced by keeping the power path components close together and keeping the

area of the loops that high currents travel small. Short, thick traces or copper pours (shapes) are best. In

particular, the switch node (where L1, D1, and the SW pin connect) should be just large enough to connect all

three components without excessive heating from the current it carries. The LM3404/04HV operates in two

distinct cycles whose high current paths are shown in Figure 32:

Figure 32. Buck Converter Current Loops

The dark grey, inner loop represents the high current path during the MOSFET on-time. The light grey, outer loop

represents the high current path during the off-time.

GROUND PLANE AND SHAPE ROUTING

The diagram of Figure 32 is also useful for analyzing the flow of continuous current vs. the flow of pulsating

currents. The circuit paths with current flow during both the on-time and off-time are considered to be continuous

current, while those that carry current during the on-time or off-time only are pulsating currents. Preference in

routing should be given to the pulsating current paths, as these are the portions of the circuit most likely to emit

EMI. The ground plane of a PCB is a conductor and return path, and it is susceptible to noise injection just as

30 Submit Documentation Feedback Copyright © 2006–2013, Texas Instruments Incorporated

Product Folder Links: LM3404 LM3404HV

Page 31

LM3404, LM3404HV

www.ti.com

SNVS465F –OCTOBER 2006–REVISED MAY 2013

any other circuit path. The continuous current paths on the ground net can be routed on the system ground plane

with less risk of injecting noise into other circuits. The path between the input source and the input capacitor and

the path between the recirculating diode and the LEDs/current sense resistor are examples of continuous current

paths. In contrast, the path between the recirculating diode and the input capacitor carries a large pulsating

current. This path should be routed with a short, thick shape, preferably on the component side of the PCB.

Multiple vias in parallel should be used right at the pad of the input capacitor to connect the component side

shapes to the ground plane. A second pulsating current loop that is often ignored is the gate drive loop formed

by the SW and BOOT pins and capacitor CB. To minimize this loop at the EMI it generates, keep CBclose to the

SW and BOOT pins.

CURRENT SENSING

The CS pin is a high-impedance input, and the loop created by R

be made as small as possible to maximize noise rejection. R

SNS

, RZ(if used), the CS pin and ground should

SNS

should therefore be placed as close as possible

to the CS and GND pins of the IC.

REMOTE LED ARRAYS

In some applications the LED or LED array can be far away (several inches or more) from the LM3404/04HV, or

on a separate PCB connected by a wiring harness. When an output capacitor is used and the LED array is large

or separated from the rest of the converter, the output capacitor should be placed close to the LEDs to reduce

the effects of parasitic inductance on the AC impedance of the capacitor. The current sense resistor should

remain on the same PCB, close to the LM3404/04HV.

Table 1. BOM for Design Example 1

ID Part Number Type Size Parameters Qty Vendor

U1 LM3404 LED Driver SOIC-8 42V, 1.2A 1 TI

L1 SLF10145T-470M1R4 Inductor 10 x 10 x 4.5mm 47µH, 1.4A, 120 mΩ 1 TDK

D1 CMSH2-40 Schottky Diode SMB 40V, 2A 1 Central Semi

Cf VJ0805Y104KXXAT Capacitor 0805 100 nF 10% 1 Vishay

Cb VJ0805Y103KXXAT Capacitor 0805 10 nF 10% 1 Vishay

Cin C3225X7R1H335M Capacitor 1210 3.3 µF, 50V 1 TDK

Co C2012X7R1E105M Capacitor 0805 1.0 µF, 25V 1 TDK

Rsns ERJ8BQFR33V Resistor 1206 0.33Ω 1% 1 Panasonic

Ron CRCW08051333F Resistor 0805 133 kΩ 1% 1 Vishay

Table 2. BOM for Design Example 2

ID Part Number Type Size Parameters Qty Vendor

U1 LM3404HV LED Driver SOIC-8 75V, 1.2A 1 TI

L1 DO5022P-334 Inductor 18.5 x 15.4 x 7.1mm 330 µH, 1.9A, 0.56Ω 1 Coilcraft

D1 CMSH1-60M Schottky Diode SMA 60V, 1A 1 Central Semi

Cf VJ0805Y104KXXAT Capacitor 0805 100 nF 10% 1 Vishay

Cb VJ0805Y103KXXAT Capacitor 0805 10 nF 10% 1 Vishay

Cin C4532X7R2A225M Capacitor 1812 2.2 µF, 100V 1 TDK

Co C3216X7R2A154M Capacitor 1206 0.15 µF, 100V 1 TDK

Rsns ERJ6BQFR43V Resistor 0805 0.43Ω 1% 1 Panasonic

Ron CRCW08051184F Resistor 0805 1.18 MΩ 1% 1 Vishay

Copyright © 2006–2013, Texas Instruments Incorporated Submit Documentation Feedback 31

Product Folder Links: LM3404 LM3404HV

Page 32

LM3404, LM3404HV

SNVS465F –OCTOBER 2006–REVISED MAY 2013

www.ti.com

REVISION HISTORY

Changes from Revision E (May 2013) to Revision F Page

• Changed layout of National Data Sheet to TI format .......................................................................................................... 31

32 Submit Documentation Feedback Copyright © 2006–2013, Texas Instruments Incorporated

Product Folder Links: LM3404 LM3404HV

Page 33

PACKAGE OPTION ADDENDUM

www.ti.com

PACKAGING INFORMATION

Orderable Device Status

LM3404HVMA/NOPB ACTIVE SOIC D 8 95 Green (RoHS

LM3404HVMAX/NOPB ACTIVE SOIC D 8 2500 Green (RoHS

LM3404HVMR/NOPB ACTIVE SO PowerPAD DDA 8 95 Green (RoHS

LM3404HVMRX/NOPB ACTIVE SO PowerPAD DDA 8 2500 Green (RoHS

LM3404MA/NOPB ACTIVE SOIC D 8 95 Green (RoHS

LM3404MAX/NOPB ACTIVE SOIC D 8 2500 Green (RoHS

LM3404MR/NOPB ACTIVE SO PowerPAD DDA 8 95 Green (RoHS

LM3404MRX/NOPB ACTIVE SO PowerPAD DDA 8 2500 Green (RoHS

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.